Experimental Study on Engineering Properties of Guilin Red Clay Improved by PASS Composite LBG

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Sample Preparation

2.3. Experimental Methods

2.3.1. Triaxial Compression Test

2.3.2. Variable Head Penetration Test

2.3.3. SEM Test

3. Analysis of Experimental Results

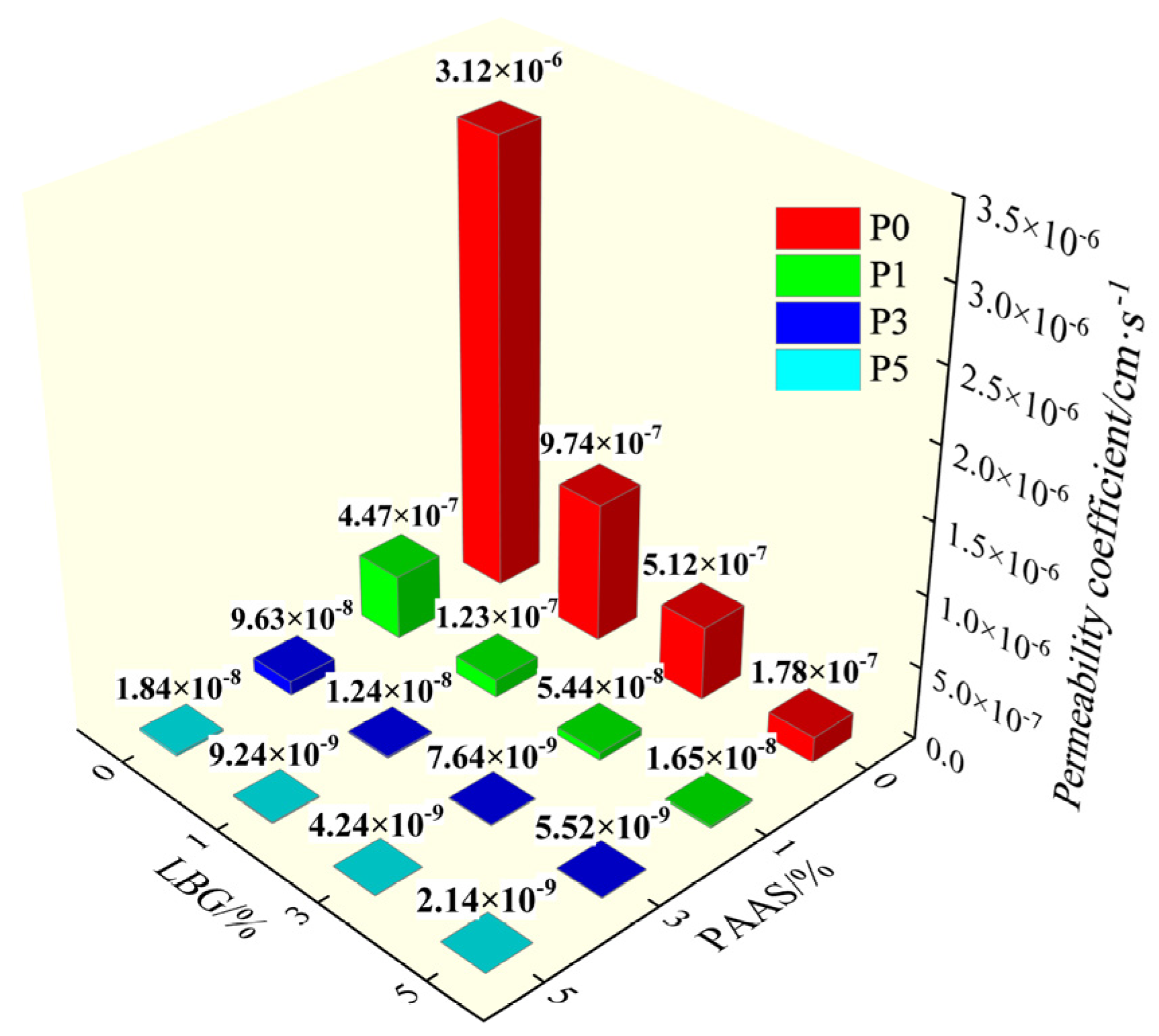

3.1. Permeability Characteristics

3.2. Mechanical Properties

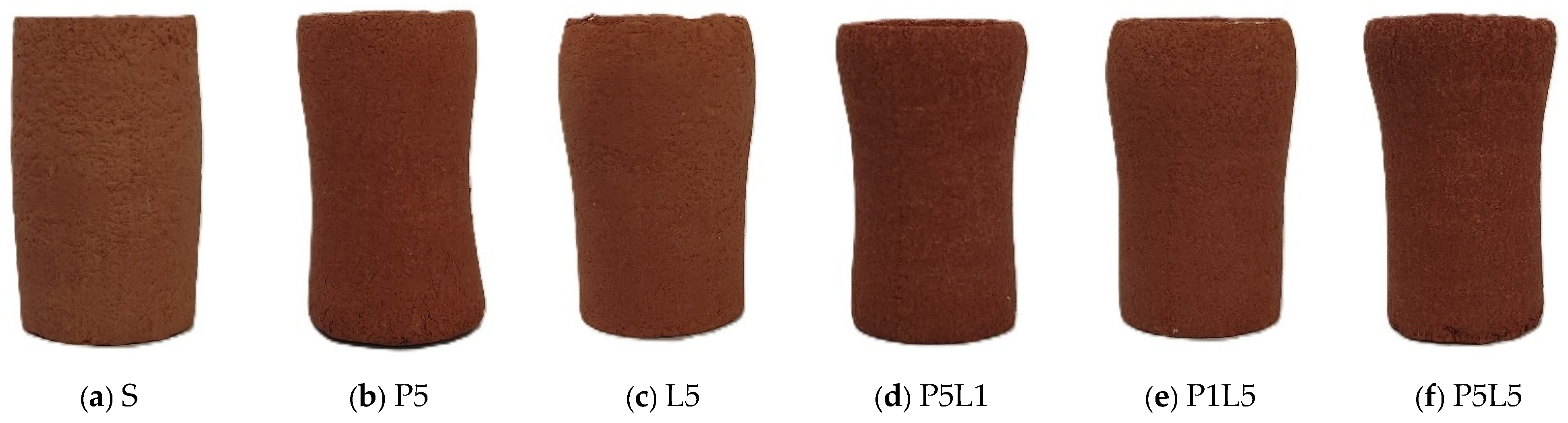

3.2.1. Failure Morphology

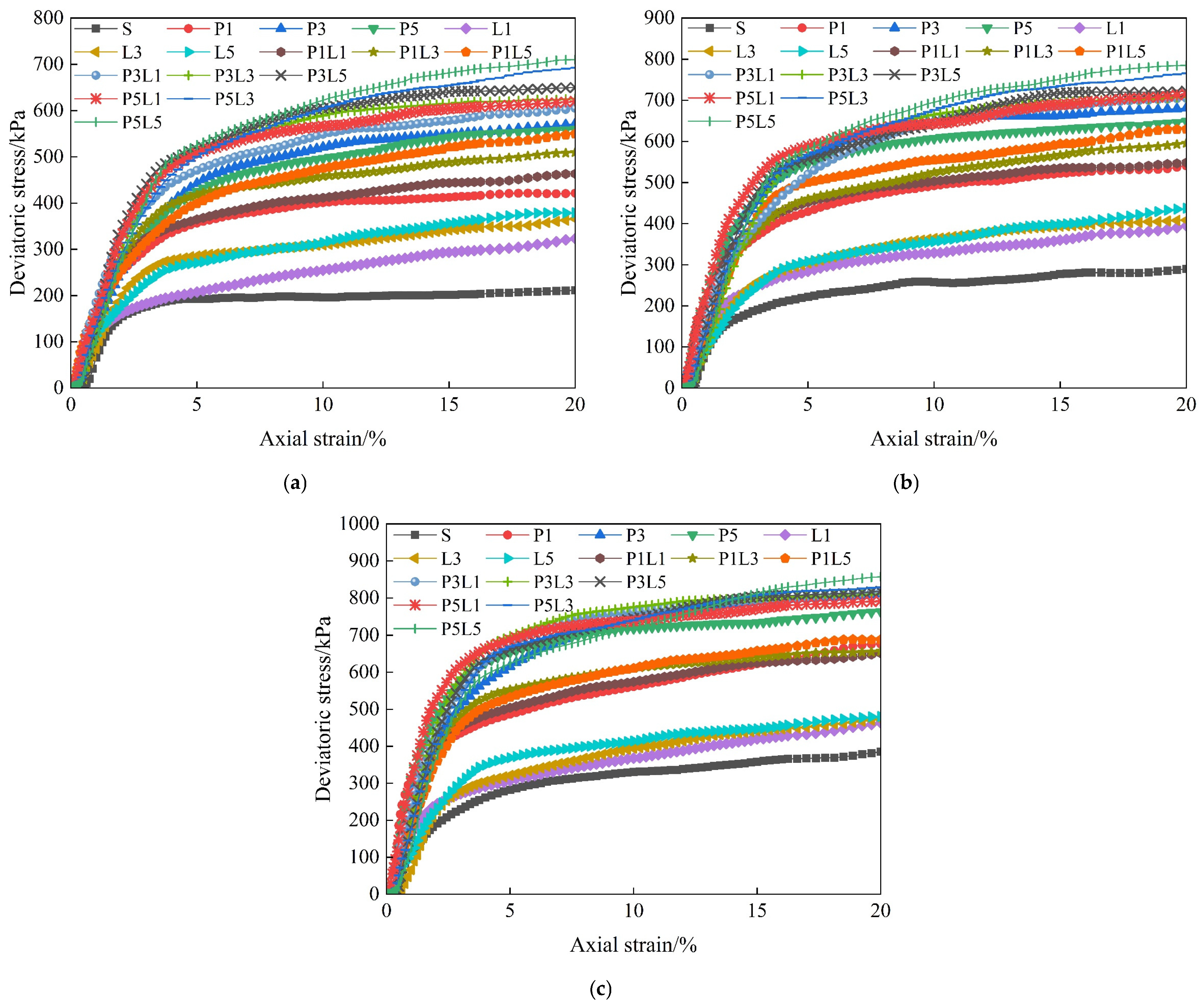

3.2.2. Stress–Strain Curve

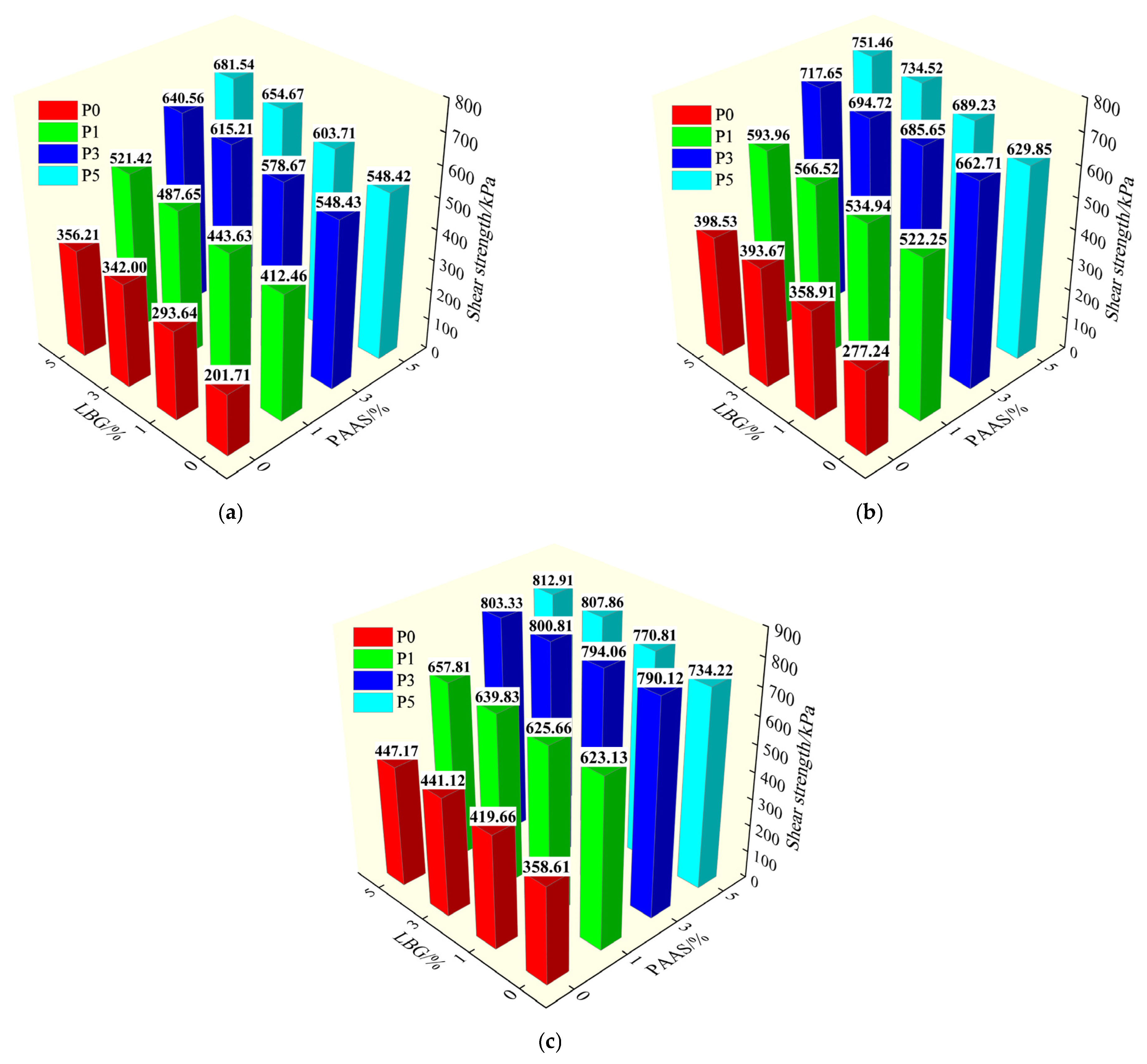

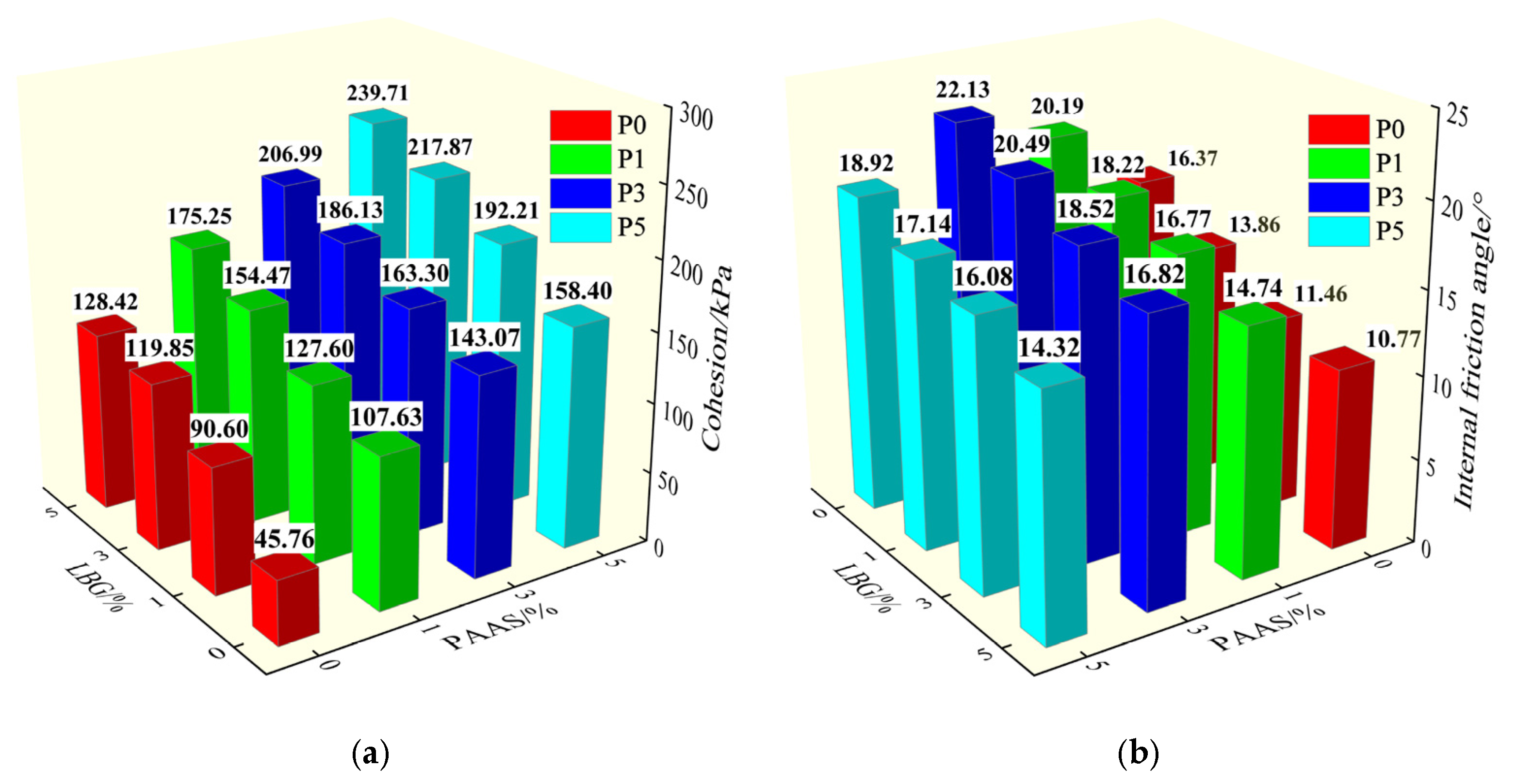

3.2.3. Shear Strength

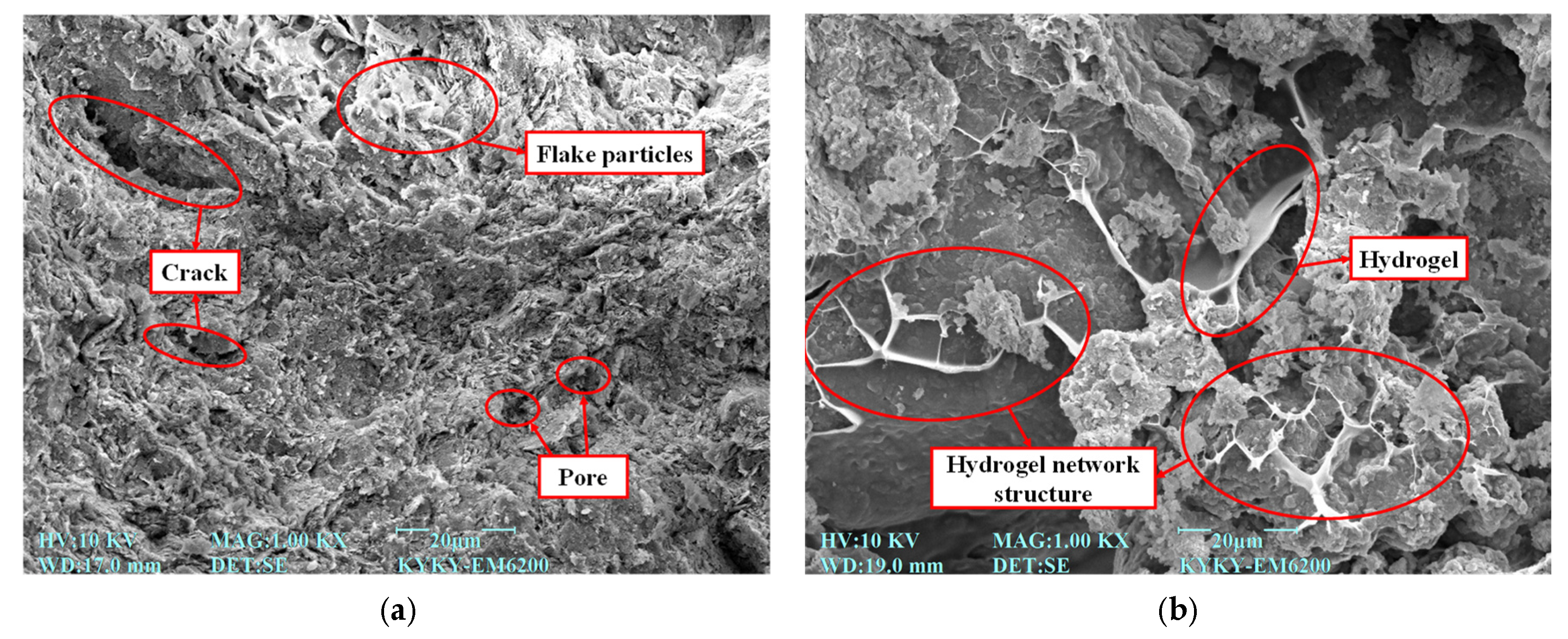

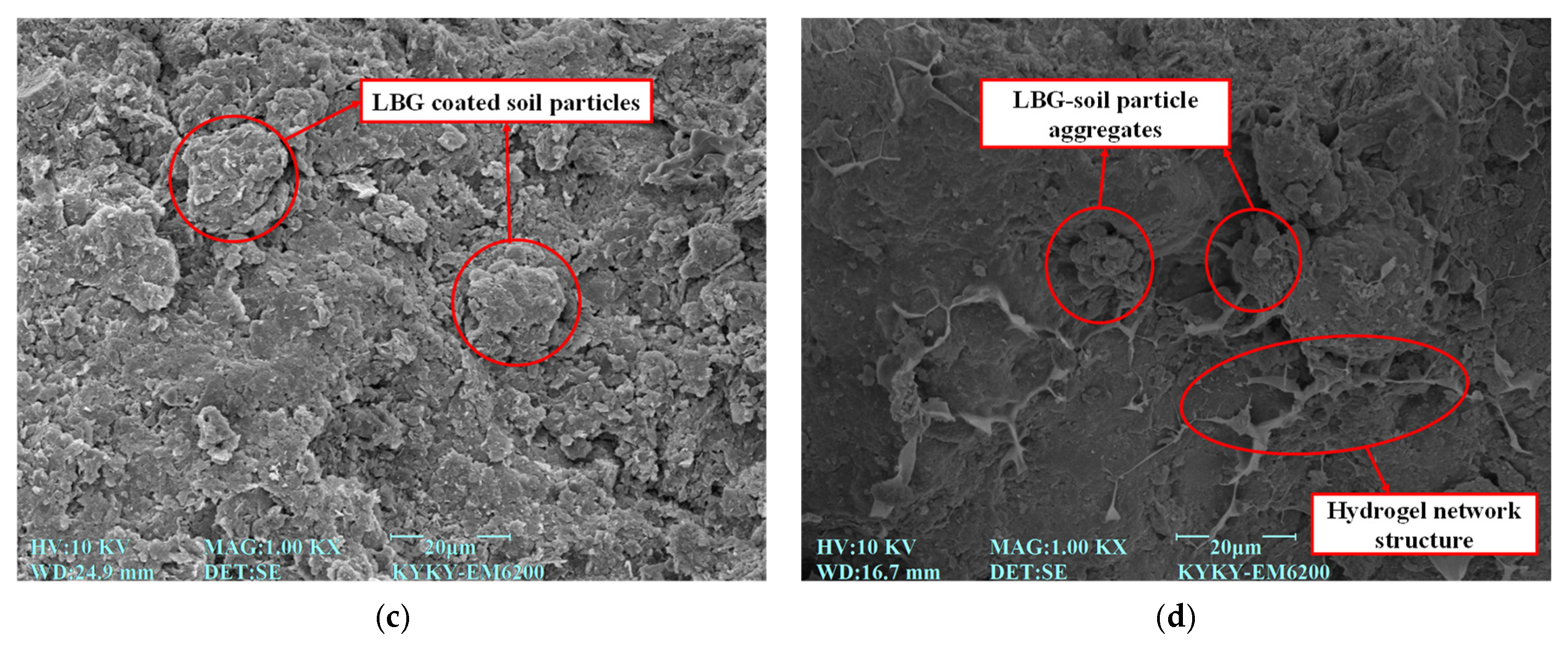

3.3. Microstructural Characteristics

4. Discussion

5. Conclusions

- (1)

- The addition of either PAAS or LBG alone effectively improved the impermeability of red clay, with PAAS having a more pronounced effect. The combined addition of PAAS and LBG to red clay exhibited a significant synergistic effect, significantly reducing the permeability of the soil structure by filling multi-scale pores and blocking seepage channels. This effect was superior to the addition of a single modifier;

- (2)

- After adding different modifiers, the failure mode of red clay is swelling failure, and the stress–strain curve shows a strain hardening type. The addition of modifiers significantly improved the shear strength of the red clay. Compared with single modifiers, PAAS improved shear strength more effectively than LBG. The combined modification of PAAS and LBG further enhanced the shear strength improvement, demonstrating even better mechanical properties;

- (3)

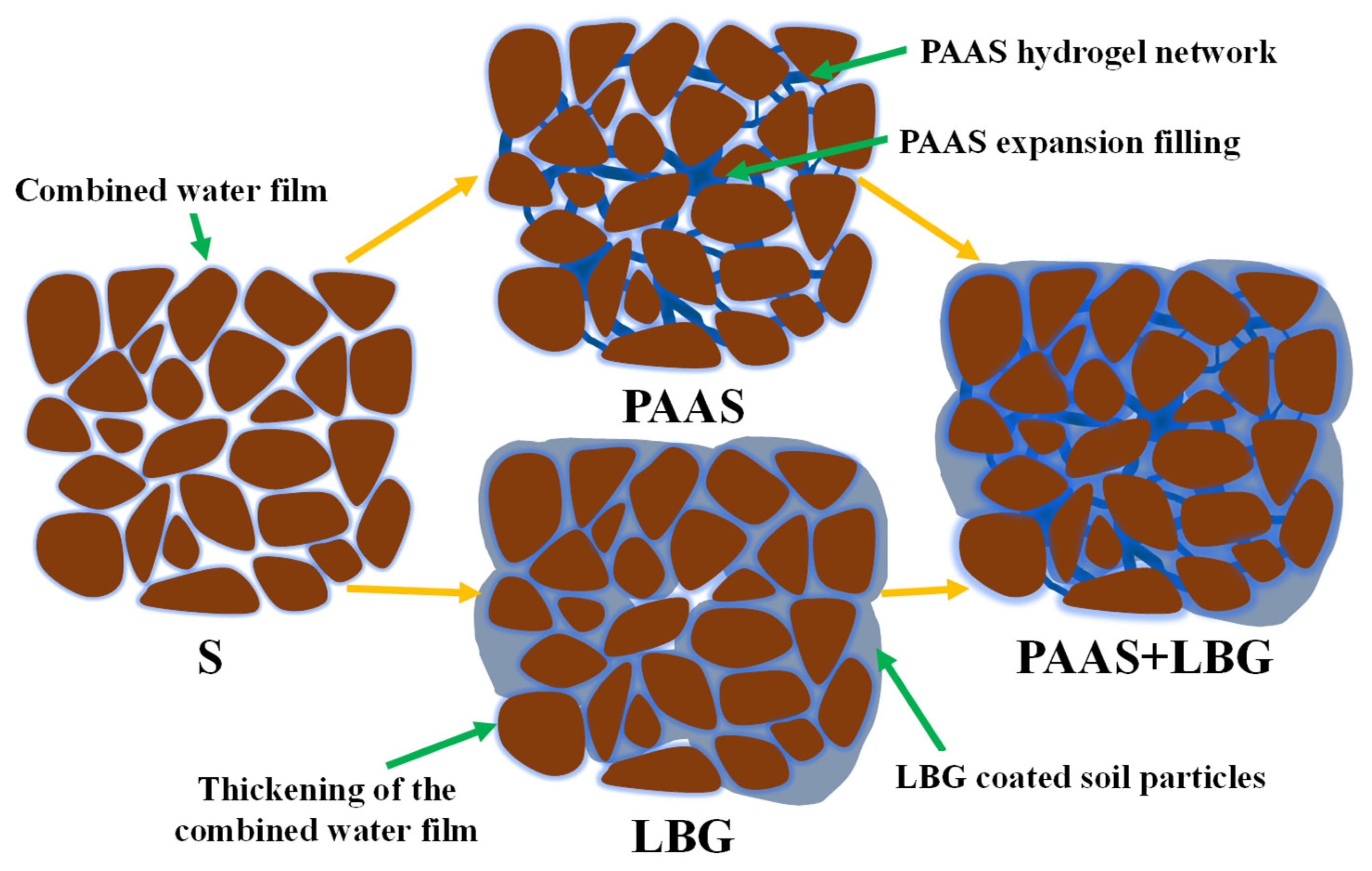

- PAAS relies primarily on its hydrogel network formed by water swelling and ionic bonding between -COO− groups and clay particle cations to enhance inter-particle cohesion and overall structural stability. LBG, on the other hand, primarily enhances adhesion through hydrogen bonding and the formation of LBG-soil particle aggregates with clay particles. However, its hydrophilicity reduces particle surface roughness, thereby decreasing the internal friction angle;

- (4)

- Under the combined modification conditions of PAAS and LBG, PAAS leads the formation of a continuous hydrogel network, providing high structural stability and cohesion. LBG helps improve density and integrity by filling pores and enhancing interparticle contact area. The synergistic effect of the two significantly optimizes the microstructure of the red clay, comprehensively enhancing its shear strength and impermeability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wesley, L.D. Cluster Hypothesis and the Shear Strength of a Tropical Red Clay. Geotechnique 1973, 23, 109–113. [Google Scholar] [CrossRef]

- Lyu, H.; Gu, J.; Li, W.; Liu, F.B. Analysis of Compressibility and Mechanical Behavior of Red Clay Considering Structural Strength. Arab. J. Geosci. 2020, 13, 411. [Google Scholar] [CrossRef]

- Gu, J.; Lyu, H.; Fan, L. Influence of Structural Strength on Geotechnical Properties of Intact Red Clay. Arab. J. Geosci. 2021, 14, 1921. [Google Scholar] [CrossRef]

- Zeng, L.; Yu, H.C.; Gao, Q.F.; Liu, J.; Liu, Z.H. Evolution of Tensile Properties of Compacted Red Clay under Wet and Dry Cycles. KSCE J. Civ. Eng. 2022, 26, 606–618. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Pu, S.Y.; Li, R.Y.M.; Zhang, J. Microscopic and Mechanical Properties of Undisturbed and Remoulded Red Clay from Guiyang, China. Sci. Rep. 2020, 10, 18003. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.W.; Li, K.Y.; Li, J.M.; Tang, S.B. Influence of soil particle size on the engineering properties and microstructure of a red clay. Appl. Sci. 2021, 11, 10887. [Google Scholar] [CrossRef]

- Qi, Y.L.; Bai, M.Z.; Zhou, H.; Shi, H.; Li, P.X.; He, B.H. Study on the Mechanical Properties of Red Clay under Drying-Wetting Cycles. Adv. Mater. Sci. Eng. 2021, 2021, 8665167. [Google Scholar] [CrossRef]

- Fu, J. Research on Improvement of Red Clay in a Highway Engineering. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chengdu, China, 13–15 December 2019; IOP Publishing: Bristol, UK, 2020; Volume 780, p. 042039. [Google Scholar]

- Wang, J.Q.; Liu, H.Z.; Lin, Z.N.; Tang, Y. Experimental study on engineering properties of red clay modified by sodium polyacrylate. Hydrogeol. Eng. Geol. 2024, 51, 110–117. [Google Scholar]

- Jiang, X.L.; Guo, J.H.; Yang, H.; Bao, S.F.; Wen, C.P.; Chen, J.Y. Study on Stress–Strain Relationship of Coir Fiber-Reinforced Red Clay Based on Duncan–Chang Model. Appl. Sci. 2022, 13, 556. [Google Scholar] [CrossRef]

- Chen, W.W.; Xie, Z.G.; Chen, J.G.; Hong, M.Y.; Wang, X.B.; Zhou, H.F.; Yang, B. Experimental Study on the Strength Characteristics of Modified Guilin Red Clay. Buildings 2025, 15, 2533. [Google Scholar] [CrossRef]

- Song, Y.; Chen, Y.L.; Cheng, J.C.; Liu, W.; Li, J.Q.; Zhang, J.W.; Zheng, J.J. Study on the physical properties of red clay cured by different external admixtures combined with enzyme induced carbonate precipitation technology. Carbonates Evaporites 2024, 39, 98. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Li, G.; Zhang, J.L. Investigation of the mechanical behavior of polypropylene fiber-reinforced red clay. Appl. Sci. 2021, 11, 10521. [Google Scholar] [CrossRef]

- Li, J.; Zhu, F.Q.; Wu, F.S.; Chen, Y.X.; Richards, J.; Li, T.X.; Li, P.; Shang, D.J.; Yu, J.; Viles, H.; et al. Impact of soil density on biomineralization using EICP and MICP techniques for earthen sites consolidation. J. Environ. Manag. 2024, 363, 121410. [Google Scholar] [CrossRef] [PubMed]

- Alqaissi, Z.H.; Fattah, M.Y.; Ibrahim, M.A. Enhancement of Properties of Soft Clay via Enzymatically Induced Calcite Precipitation. Prog. Eng. Sci. 2025, 2, 100110. [Google Scholar] [CrossRef]

- Zhang, J.W.; Wang, P.K.; Dong, Y.; Zheng, J.J.; Song, Y.; Liu, H.L.; Zhang, M. Investigation of desiccation cracking of earthen site soils treated by enzyme-induced calcium carbonate precipitation (EICP). Biogeotechnics 2025, in press. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Wei, Y.Q.; Cai, H.; Wang, Z.W.; Yang, T.; Wang, Q.H.; Wu, S.F. Microbial-Induced Carbonate Precipitation for Strengthening Soft Clay. Adv. Mater. Sci. Eng. 2020, 2020, 8140724. [Google Scholar] [CrossRef]

- Deng, Z.H.; Huang, H.Q.; Ye, B.L.; Xiang, P.; Li, C.Q. Mechanical performance of RAC under true-triaxial compression after high temperatures. J. Mater. Civ. Eng. 2020, 32, 04020194. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.J.; Dupla, J.C.; Canou, J. Soil-water retention behaviour of fine/coarse soil mixture with varying coarse grain contents and fine soil dry densities. Can. Geotech. J. 2022, 59, 291–299. [Google Scholar] [CrossRef]

- Zheng, Y.H.; Baudet, B.A. Pore structure response of reconstituted kaolin and illite-smectite mixed-layer rich clay to 1D compression. Appl. Clay Sci. 2025, 276, 107892. [Google Scholar] [CrossRef]

- Zheng, Y.H.; Zhu, T.F.; Chen, J.Q.; Shan, K.; Li, J.R. Relationship Between Pore-Size Distribution and 1D Compressibility of Different Reconstituted Clays Based on Fractal Theory. Fractal Fract. 2025, 9, 235. [Google Scholar] [CrossRef]

- Salemi, N.; Abtahi, S.M.; Rowshanzamir, M.A.; Hejazi, S.M. Improving hydraulic performance and durability of sandwich clay liner using super-absorbent polymer. J. Sandw. Struct. Mater. 2019, 21, 1055–1071. [Google Scholar] [CrossRef]

- Özbakan, N.; Evirgen, B. An Effect of Sodium Polyacrylate on Sandy Soil Parameters and Its Use in Soil Improvement. In Proceedings of the 7th World Congress on Civil, Structural, and Environmental Engineering, Lisbon, Portugal, 10–12 April 2022. [Google Scholar]

- Özbakan, N.; Evirgen, B. The effect of sodium polyacrylate gel on the properties of liquefiable sandy soil under seismic condition. J. Eng. Res. 2023, 11, 100006. [Google Scholar] [CrossRef]

- Jeldres, M.; Robles, P.; Toledo, P.G.; Saldaña, M.; Quezada, L.; Jeldres, R.I. Improved dispersion of clay-rich tailings in seawater using sodium polyacrylate. Colloids Surf. A Physicochem. Eng. Asp. 2021, 612, 126015. [Google Scholar] [CrossRef]

- Zhang, J.L.; Hou, Y.W.; Jiang, T.; Yuan, K.K. Evaluation of the effects of Locust Bean Gum application on loess solidification and vegetation growth. Discov. Appl. Sci. 2025, 7, 557. [Google Scholar] [CrossRef]

- Shen, X.F.; Wang, L.N.; Yang, B.J.; Han, J.Y.; Zhang, L.X. Effect of locust bean gum biopolymer on mechanical properties of organic soil. Environ. Earth Sci. 2025, 84, 34. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Geotechnical Test Method Standard. China Planning Publishing House: Beijing, China, 2019.

- Zhang, J.C.; Li, Y.N.; Zhang, C.W. Pounding induced overturning resistance of FPB-isolated structures considering soil-structure-interactions. Soil Dyn. Earthq. Eng. 2024, 177, 108416. [Google Scholar] [CrossRef]

- Sakiewicz, P.; Piotrowski, K.; Rajca, M.; Cieślak, S. Post-recycling sodium polyacrylate with nanostructural halloysite additive as the basic components of the new hybrid soil modifier—The circular economy rules for sap in agriculture. Resources 2024, 13, 75. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, X.C.; Luo, L.; Tian, Y.; Zeng, S.P. Seepage characteristics of broken carbonaceous shale under cyclic loading and unloading conditions. Energy Fuels 2023, 38, 1192–1203. [Google Scholar] [CrossRef]

- Chen, X.L.; Yang, T.; Cai, X.L.; Liu, Y.; Huang, C.Y.; He, J.S.; Tian, D.; Yang, G.; Shen, F.; Zhang, Y.Z. Eco-friendly hydrogel based on locust bean gum for water retaining in sandy soil. Int. J. Biol. Macromol. 2024, 275, 133490. [Google Scholar] [CrossRef]

- Dong, Z.T.; Tian, S.S.; Xue, H.T.; Lu, S.F.; Liu, S.F.; Liu, B.; Erastova, V.; Wu, M.; Wu, R.Y. Analysis of pore types in lower cretaceous Qingshankou shale influenced by electric heating. Energy Fuels 2024, 38, 20577–20590. [Google Scholar] [CrossRef]

| Test Number | PAAS/% | LBG/% | Test Number | PAAS/% | LBG/% |

|---|---|---|---|---|---|

| S | 0 | 0 | P1L3 | 1 | 3 |

| P1 | 1 | 0 | P1L5 | 1 | 5 |

| P3 | 3 | 0 | P3L1 | 3 | 1 |

| P5 | 5 | 0 | P3L3 | 3 | 3 |

| L1 | 0 | 1 | P3L5 | 3 | 5 |

| L3 | 0 | 3 | P5L1 | 5 | 1 |

| L5 | 0 | 5 | P5L3 | 5 | 3 |

| P1L1 | 1 | 1 | P5L5 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Han, K.; Xie, Z.; Zhou, H.; Yang, B. Experimental Study on Engineering Properties of Guilin Red Clay Improved by PASS Composite LBG. Buildings 2025, 15, 3291. https://doi.org/10.3390/buildings15183291

Cui Y, Han K, Xie Z, Zhou H, Yang B. Experimental Study on Engineering Properties of Guilin Red Clay Improved by PASS Composite LBG. Buildings. 2025; 15(18):3291. https://doi.org/10.3390/buildings15183291

Chicago/Turabian StyleCui, Yanshuo, Kuiliang Han, Zhigao Xie, Haofeng Zhou, and Bai Yang. 2025. "Experimental Study on Engineering Properties of Guilin Red Clay Improved by PASS Composite LBG" Buildings 15, no. 18: 3291. https://doi.org/10.3390/buildings15183291

APA StyleCui, Y., Han, K., Xie, Z., Zhou, H., & Yang, B. (2025). Experimental Study on Engineering Properties of Guilin Red Clay Improved by PASS Composite LBG. Buildings, 15(18), 3291. https://doi.org/10.3390/buildings15183291