Abstract

To address the engineering challenges associated with Guilin red clay, such as its potentially low strength and unfavorable mechanical behavior, this study investigated the effectiveness of lignin and lime as modifiers. Consolidation undrained triaxial tests and scanning electron microscopy (SEM) were employed to evaluate the strength characteristics and microstructural changes in modified clay specimens with varying dosages. The results demonstrate distinct strengthening mechanisms: Lignin exhibits an optimal dosage (6%), significantly increasing cohesion and internal friction angle through physical reinforcement (“soil fiber” formation), but higher dosages (8%) lead to particle separation and strength reduction. In contrast, lime provides continuous and substantial strength enhancement with increasing dosage (up to 8%), primarily through chemical reactions producing cementitious compounds (e.g., C-S-H, C-A-H) that densify the structure. Consequently, lime-modified clay shows significantly higher cohesion and internal friction angle compared to lignin-modified clay at equivalent or higher dosages, with corresponding stress–strain curves shifting from enhanced (strain-hardening) to softening behavior. These findings provide practical insights into red clay improvement in geotechnical engineering applications.

1. Introduction

Red clay, as a soil type with significant regional characteristics, is mainly distributed in the southern area of China, especially in Yunnan, Guizhou, and Guangxi provinces. This soil is formed under specific geological and climatic conditions through the chemical weathering of carbonate rocks. This soil typically exhibits high water content, high porosity, and high plasticity [1,2,3]. When red clay is used as filling material, the compacted filling layer softens when exposed to water, and its structural strength decreases, posing a great hidden danger to engineering safety [4]. In view of the adverse characteristics of red clay, it is very important to propose a series of solutions to improve the adverse engineering characteristics of red clay.

Currently, both domestic and international researchers are conducting more and more in-depth and extensive research on various properties of red clay. To study the influence of depth structure on red clay, Lyu and Gu et al. [5,6] employed consolidated undrained triaxial tests, X-ray diffraction, and one-dimensional compression tests to investigate compressibility, strength, stress paths, and their variations with depth. Zeng et al. [7] studied the changes in the tensile properties of red clay through direct tensile test and Brazilian splitting test, concluding that its tensile strength is approximately 1.566 times the splitting strength. Zhang et al. [8] compared the mechanical behavior and microstructure of the original and reshaped red clay through unconfined compressive strength and SEM tests. The results showed that the original red clay had higher shear strength and smaller pore characteristics than the reshaped red clay. Mu et al. [9] studied the influence of water content on natural red clay through CU triaxial testing and found a linear relationship: internal friction angle increased while cohesion decreased with rising water content. To evaluate the effect of cracking on shear strength, Yang et al. [10] conducted indoor dry–wet cycle tests and direct shear tests on red clay, finding that the crack ratio and fractal dimension correlate well with shear strength and can be used as predictive indicators. Xiao et al. [11], using direct shear tests, found that red clay subjected to overburden pressure demonstrated higher cohesion and internal friction angle compared to samples without overburden, under otherwise identical conditions.

Due to the special engineering properties of red clay, it is difficult to grasp in engineering applications, which can easily cause engineering diseases such as uneven deformation of the foundation. Therefore, how to modify the strength characteristics of red clay is extremely important. At present, there are three ways to modify special soils at home and abroad: physical modification, chemical modification, and soil replacement. Common modifications include cement-modified soil [12,13] lime-modified soil [14,15], and curing-agent-modified soil [16,17]. Physically modified materials include fly ash, crushed stone, fiber, etc.; chemically modified materials include cement, lime, and various curing agents and stabilizers. In the study of the strength characteristics of modified red clay, Liu et al. [18,19] studied the effect of cement incorporation on the mechanical properties of red clay and observed that both cohesion and unconfined compressive strength increased with higher cement content and longer curing time. Wang et al. [20] selected Bacillus pasteurianus and iron bacteria to solidify soil, used activated carbon as a carrier, and prepared two microbial soil samples according to the optimal microbial curing conditions. When studying the basic physical and mechanical properties of microbial soil samples, they found that the density of red clay modified by microorganisms increased, the porosity decreased, the shear strength and unconfined compressive strength increased, and the physical and mechanical properties were greatly improved.

From the existing research, there are many related studies on the strength characteristics of modified red clay, but they still need to be improved. Based on the existing research results, this paper adds two modifiers, lignin and lime, into red clay at different dosages to prepare reshaped red clay samples. The strength index and stress–strain relationship of red clay under different modifier dosages are compared and analyzed through the consolidation undrained triaxial test. The aim is to expand the research depth of typical red clay improvement technology in the region and provide an experimental basis and theoretical support for the selection and optimization of modification schemes in red clay areas.

2. Test Overview

2.1. Test Materials

The red clay employed in this study was obtained from a red soil slope in Guilin City. Following sampling, the material was air-dried, manually crushed, passed through a 2 mm sieve, and subsequently sealed for storage. According to the “Standard for Geotechnical Test Methods” (GB/T 50123-2019) [21], the red clay was subjected to an indoor basic physical parameter test. Its basic physical parameters are measured, as shown in Table 1. The modifiers adopted in this study include lignin and lime, with their respective material properties listed in Table 2. The test material is shown in Figure 1.

Table 1.

Fundamental physical properties of red clay.

Table 2.

Basic description of modifier materials.

Figure 1.

Pictures of test materials: (a) red clay; (b) lignin; (c) lime.

2.2. Test Scheme

2.2.1. Triaxial Compression Test

In this test, the moisture content of the sample was 27.5%, and the compaction degree was controlled at 90%. The unmodified soil was used as the control group. In order to better compare the strengthening effects of lignin and lime on red clay, based on the prior literature and pre-tests, lignin and lime were added to the red clay at mass fractions of 2%, 4%, 6%, and 8%, respectively. According to the Standard for Geotechnical Test Methods (GB/T 50123-2019) [21], triaxial specimens of remolded soil with a height of 80 mm and a diameter of 39.1 mm were prepared. The prepared specimens were placed in a curing box for 7 days (humidity = 95%, temperature = 25 °C). After the curing, the specimens were vacuum saturated for 48 h. After saturation, the specimens were placed in a fully automatic triaxial instrument produced by Nanjing Soil Instrument Factory Co., Ltd., Nanjing, China, for a consolidated undrained (CU) triaxial compression test, as shown in Figure 2. Confining pressures of 100, 200, and 300 kPa were applied, with a shear rate of 0.08 mm/min. The peak deviatoric stress from the stress–strain curve was regarded as the failure strength. In cases where no peak was observed, the deviatoric stress at 15% axial strain was considered the failure stress. Testing was terminated once the axial strain reached 20%.

Figure 2.

Fully automatic triaxial instrument.

2.2.2. SEM Test

This test uses a tungsten filament scanning electron microscope instrument as shown in Figure 3. The modified soil samples after the triaxial compression test were freeze-dried. Then the samples were broken with a small mallet, and representative test blocks were selected for gold spraying. Then they were placed in the instrument for scanning and observation, and representative SEM images were selected for shooting. The magnification selected for this test was 500 times.

Figure 3.

Tungsten filament scanning electron microscope instrument.

3. Analysis of Test Results

3.1. Effect of Modifiers on the Failure Morphology of Red Clay

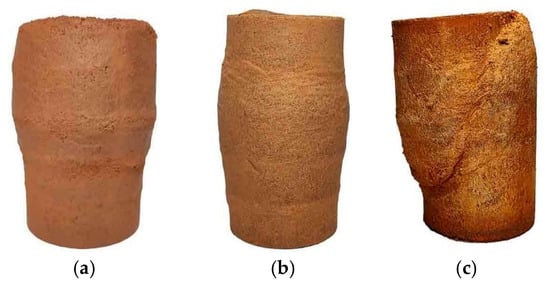

In order to explore the effect of modifiers on the failure morphology of red clay, some samples after triaxial compression tests at 100 kPa were taken for observation. The failure morphology of modified red clay is shown in Figure 4. As shown in Figure 4, the red clay samples and lignin-modified soil samples (taking the sample with 6% lignin content as an example) mainly show swelling failure, and the lime-modified soil samples (taking the sample with 8% lime content as an example) mainly show shear failure. It can be seen that lime transforms the failure morphology of red clay from plastic failure to brittle failure, and the soil strength is improved.

Figure 4.

Failure morphology of modified red clay: (a) red clay; (b) lignin-modified soil; (c) lime-modified soil.

3.2. Effect of Modifier on Shear Strength Index of Red Clay

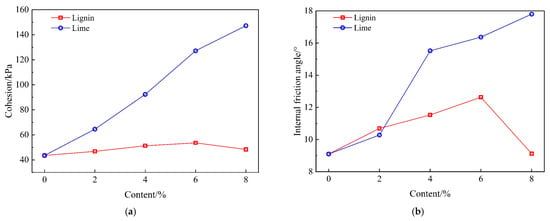

Figure 5 presents the variation in the shear strength parameters of red clay with different lignin contents. As the lignin dosage increases, both cohesion and internal friction angle exhibit an initial rise followed by a subsequent decline. Specifically, as the lignin content increases from 0% to 6%, the cohesion rises from 43.50 kPa to 53.57 kPa, representing an increase of 23.14%, while the internal friction angle increases from 9.1° to 12.63°, representing an increase of 38.79%. However, when the lignin content further increases to 8%, the cohesion decreases to 48.37 kPa, and the internal friction angle drops sharply to 9.12°. With the increase in the amount of lignin added, the bite force and friction between lignin and soil particles increase, and the strengthening effect of lignin gradually emerges, thereby improving the shear strength index of the soil. However, when the amount of lignin added continues to increase to a certain extent, too much fiber may cause uneven distribution or agglomeration in the soil, which, in turn, reduces the overall interaction effect between the fiber and the soil particles, resulting in a decrease in cohesion and internal friction angle. In addition, the addition of excessive fiber will increase the distance between soil particles, resulting in a weakening of the attraction between particles, and ultimately causing a decrease in the cohesion and internal friction angle of the soil. Therefore, with the increase in the amount of lignin added, the shear strength of the soil will increase to a certain peak value and then will show a downward trend with the increase in the amount of lignin added.

Figure 5.

Change curve of shear strength index with modifier content: (a) cohesion; (b) internal friction angle.

With increasing lime content, both the cohesion and internal friction angle of red clay exhibit a sustained and progressive enhancement. As the lime dosage increases from 0% to 8%, the cohesion rises markedly from 43.54 kPa to 147.2 kPa, reflecting a growth of 338.08%, while the internal friction angle increases from 9.1° to 17.8°, reflecting an increase of 95.65%. These results demonstrate that lime has a substantial strengthening effect on the shear strength index of red clay. The main compounds in lime include CaO, MgO, and SiO2. When lime comes into contact with water, these compounds react chemically with water, resulting in the production of free Ca2+ and Mg2+ in the soil. Na+ and H+ are adsorbed on the surfaces of clay particles through cation exchange processes. Due to the large cohesive force of calcium ions and magnesium ions, they will undergo ion exchange with soil particles, thereby changing the ion concentration in the soil. At the same time, this ion exchange causes soil particles to approach each other under the action of gravity, forming a flocculated structure. Under the action of ion exchange and flocculation, the pores in the spatial structure of the soil gradually become smaller, the mutual attraction between atoms increases accordingly, and the contact between particles becomes closer, thereby enhancing the cohesion and internal friction angle of the soil, and significantly enhancing the strength and stability of the soil. Therefore, with the increase in the amount of lime added, the shear strength of the soil gradually increases.

Comparative analysis of Figure 5a,b shows that at high modifier addition, the cohesion and internal friction angle of red clay after lime addition are greater than those after lignin addition. This shows that the effect of lime on the shear strength index of red clay is greater than that of lignin on the shear strength index of red clay.

3.3. Effect of Modifiers on Stress–Strain Curve of Red Clay

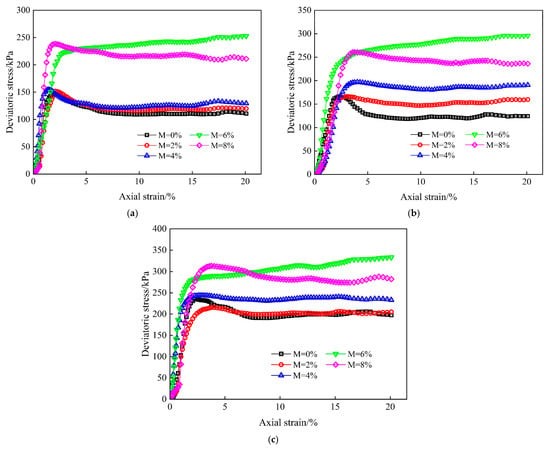

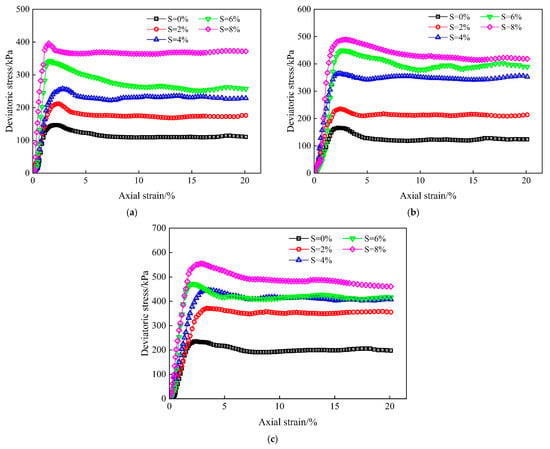

Figure 6 presents the stress–strain responses of red clay corresponding to varying lignin contents, where M denotes the lignin dosage. As shown in Figure 6, at confining pressures of 100 kPa and 200 kPa, with the increase in axial strain, when the lignin addition is 6%, the peak deviator stress of the sample is the largest, followed by the samples with lignin additions of 2%, 4%, and 8%, and the peak deviator stress of the plain soil is the smallest. Under a confining pressure of 300 kPa, with the increase in axial strain, when the lignin addition is 6%, the deviator stress of the sample is the largest, followed by the samples with lignin additions of 4%, 8% and the plain soil, and the deviator stress of the plain soil is the smallest. Across all confining pressures, when the lignin addition is 2%, 4%, and 8%, with the increase in axial strain, the deviator stress of the sample peaks at the axial strain of 4%, and its stress–strain curves all show a softening type. In contrast, the sample with 6% lignin shows a distinct strain-hardening behavior: the rate of increase in deviatoric stress begins to decrease at approximately 3% axial strain, then gradually levels off without a sharp drop, indicating a continuous resistance to deformation. Under a confining pressure of 100 kPa, the lignin in the samples with lignin contents of 2% and 4% does not play a role, causing their stress–strain curves to show similar trends. Through analysis, it can be seen that no matter the confining pressure, red clay with a lignin addition of 6% shows hardening, while the red clay with other lignin addition amounts shows softening. It can be seen that when lignin is used as a modifier to modify red clay, the filling effect of lignin with an addition amount of 6% on the soil is the best. At this time, a good bond is formed between lignin and clay particles. This bonding effect makes the interface between lignin and clay firmer and less likely to be damaged. During the loading process, lignin and soil bear external forces together, and the reinforcing effect of fiber is fully exerted, so that the stress–strain curve of the sample shows a hardening type. However, too much lignin added to the sample will make it difficult for lignin to be evenly dispersed in the sample, forming agglomerations or voids, which will reduce the mechanical properties of the sample and cause the stress–strain curve of the sample to transform into a strain softening type.

Figure 6.

Stress–strain curves of red clay with different lignin contents: (a) 100 kpa; (b) 200 kpa; (c) 300 kpa.

Figure 7 presents the stress–strain responses of red clay corresponding to varying lime contents, where S denotes the lime dosage. As shown in Figure 7, across all confining pressures, when the lime addition amount is 8%, the peak deviator stress of the sample is the largest, followed by the samples with lime addition amounts of 2%, 4%, and 6%, and the peak deviator stress of the plain soil is the smallest. With the increase in the amount of lime added, the deviator stress growth acceleration of the sample is faster in the elastic stage. Under different lime addition amounts, the deviator stress of the sample peaks at 2–3% axial strain, and its stress–strain curve shows a softening type. Through analysis, it can be seen that with the gradual increase in the lime addition amount, the peak stress of the sample shows a trend of gradual increase. As a reaction accelerator, lime reacts chemically with the substances in the soil to generate cementing substances. These cementing substances can effectively fill the pores between soil particles, enhance the density of the soil, and the bonding force between particles. With the increase in lime addition amount, the amount of cementing substances generated also increases accordingly, making the structure of the soil more compact, thereby increasing the peak stress of the sample. As the reaction continues, the amount of cementing material increases, further improving the strength of the soil. In the elastic stage of sample compression and shearing, the formation and distribution of cementing material significantly improve the strength of the soil, and the sample stiffness is relatively large. Therefore, in the elastic stage of sample compression and shearing, the higher the amount of lime added, the faster the strength of the sample increases. It can be seen that the increase in the amount of lime added can effectively improve the shear strength of red clay.

Figure 7.

Stress–strain curves of red clay with different lime contents: (a) 100 kpa; (b) 200 kpa; (c) 300 kpa.

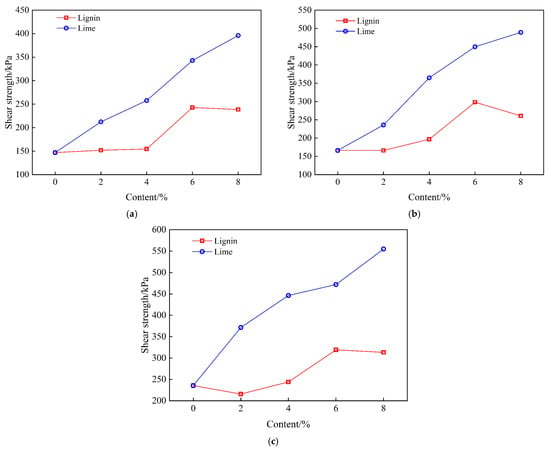

3.4. Effect of Modifiers on the Shear Strength of Red Clay

In order to evaluate how lignin and lime influence the shear strength of red clay, the peak deviator stress from the stress–strain curve was selected as the indicator of shear strength. Figure 8 illustrates the impact of these additives on red clay’s shear strength under varying confining pressures. As shown in Figure 8, when the addition amount is 2% and 4%, the effect of lignin on the shear strength of red clay is small, and when the addition amount is 6% and 8%, the effect is large. When the modifier is lignin, the shear strength of red clay with an addition amount of 6% is the largest. In contrast, lime modification exhibits a more consistent and significant improvement in shear strength across all addition levels. For a given confining pressure and modifier content, lime-modified red clay consistently demonstrates higher shear strength compared to lignin-modified red clay. This shows that lime has a more substantial strengthening effect on red clay than lignin under equivalent conditions.

Figure 8.

Effect of modifiers on the shear strength of red clay under different confining pressures: (a) 100 kpa; (b) 200 kpa; (c) 300 kpa.

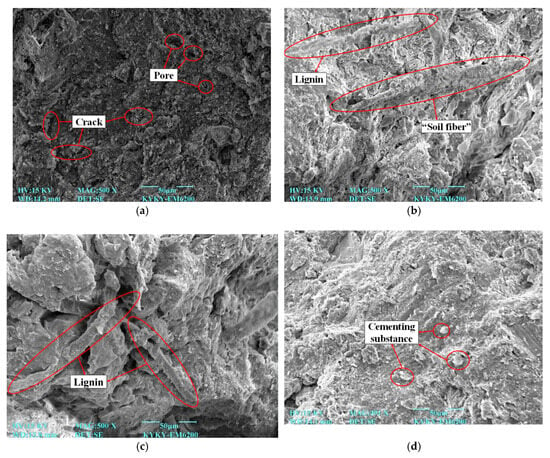

3.5. Effect of Modifiers on the Microstructure of Red Clay

Figure 9 shows the SEM images of modified soil. Figure 9a shows the SEM image of red clay. As can be seen from the figure, the microstructure of red clay is honeycomb-like, the soil particles are of different sizes, overlapped and scattered, the soil structure is relatively loose, and there are large and small pores and cracks. Figure 9b shows the SEM image of 6% lignin-modified red clay. It can be observed that lignin appears as thin strips that are closely bonded to the soil particles, forming “soil fibers” characterized by strong toughness and adhesion [22]. These “soil fibers” effectively reinforce the soil, resulting in a denser microstructure and improved strength. Figure 9c shows the SEM image of 8% lignin-modified red clay. As can be seen from the figure, part of the lignin is not bonded to the soil particles and does not fully play its reinforcement role, resulting in a large spacing between soil particles and a looser soil structure. This is one of the reasons why the shear strength of 8% lignin-modified red clay is lower than that of 6% lignin-modified red clay. Figure 9d is an SEM image of 8% lime-modified red clay. It can be seen from the figure that the CaO in the lime reacts with water to generate Ca(OH)2, which then reacts with SiO2 and Al2O3 in the red clay to generate cementing substances such as C-S-H and C-A-H. These reaction products effectively fill the pores and cracks within the soil and cement the particles together, thereby enhancing particle bonding and significantly improving the soil’s structural integrity and strength.

Figure 9.

SEM image of modified soil: (a) red clay; (b) 6% lignin; (c) 8% lignin; (d) 8% lime.

4. Discussion

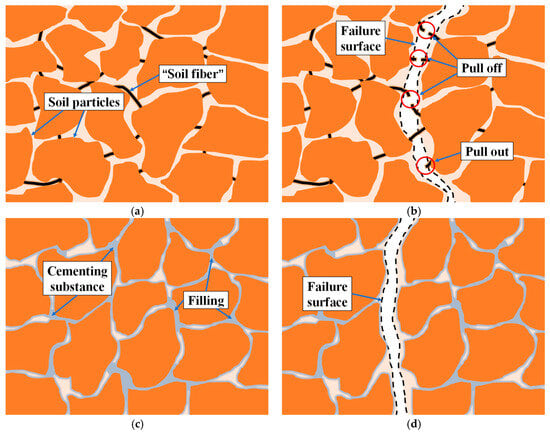

4.1. Improvement Mechanism of Red Clay by Modifier

Figure 10 is a diagram of the mechanism of modified soil. When lignin is used as a modifier, it is distributed in the soil in a fibrous or ribbon-like form, forming a “soil–fiber” complex with soil particles. It strengthens the overall structure of the soil through bite force and friction and improves its mechanical properties, as shown in Figure 10a. Under load, lignin can share part of the stress, inhibit crack expansion, and delay soil damage. When the soil is damaged, lignin will be pulled off or pulled out of the soil, as shown in Figure 10b. When lime is used as a modifier, it reacts with the water in the soil to generate Ca(OH)2 and further reacts with SiO2 and Al2O3, rich in red clay, to generate volcanic ash and produce cementing substances. These cementing substances fill the pores and cracks in the soil, wrap the soil particles, and firmly bond them together, significantly enhancing the strength of the soil, as shown in Figure 10c. Because the generated cementing substances make the soil form a more rigid cementing structure, the ductility of the soil decreases. When the soil is damaged, the cementing material is damaged first, causing the soil structure to fail brittlely, as shown in Figure 10d.

Figure 10.

Mechanism diagram of modified soil: (a) model diagram of lignin-modified soil; (b) damage diagram of lignin-modified soil; (c) model diagram of lime-modified soil; (d) damage diagram of lime-modified soil.

4.2. Comparison of Test Results

Red clay is a commonly used filling material in engineering construction. Its unfavorable engineering properties often cause engineering diseases. Therefore, exploring the optimal solution for modifying red clay has always been a research hotspot. This paper studies the influence of two modifiers, lignin and lime, on the strength characteristics of red clay through consolidation undrained triaxial tests. According to the test results, when lignin is used to modify the strength characteristics of red clay, the optimal addition amount is 6%. Zhao et al. [23] and Dong et al. [24] also studied the strength characteristics of lignin-modified red clay, and the optimal addition amounts were 9% and 2%, respectively. The inconsistency with the previous research results may be caused by factors such as the different regions where red clay is used and the different types of lignin used. When lime is used to modify red clay, the strength of red clay continues to increase with the increase in lime addition. This is consistent with the results of previous studies [25,26].

This study systematically compared the reinforcement effects of two typical modified materials, lignin and lime, on red clay in the same region. The differences and influencing mechanisms were analyzed in combination with the strength test results, providing comparable data support for the selection of red clay modifiers. It also provides a practical reference for the material selection and ratio optimization for regional clay soil engineering property improvement.

5. Conclusions

This study investigates the strength characteristics of red clay from Guilin, modified with different dosages of lignin and lime, through consolidated undrained triaxial tests. The effects of these modifiers on the shear strength index and stress–strain behavior of red clay were systematically analyzed. Furthermore, scanning electron microscopy (SEM) was employed to examine the microstructural changes induced by the modifiers, providing insight into both physical and chemical modification mechanisms. The main conclusions are as follows:

(1) When lignin is added to red clay as a modifier, the failure morphology of red clay is mainly bulging failure. As the lignin content increases, both cohesion and internal friction angle initially increase and then decrease. The optimal performance is observed at a 6% lignin content, where cohesion and internal friction angle reach their maximum values of 53.57 kPa and 12.63°, respectively. The shear strength is the largest, and its stress–strain curve shows a strengthening type. When the lignin addition is 2%, 4%, and 8%, the stress–strain curves of red clay all show a softening type.

(2) When lime is added to red clay as a modifier, the failure morphology of red clay is mainly shear failure. With increasing lime content, both cohesion and internal friction angle consistently rise, resulting in a progressive enhancement of shear strength. Unlike lignin-modified clay, all lime-modified samples display a softening type regardless of the lime content.

(3) Through comparative analysis, it is found that after lime is added to red clay, the shear strength index of red clay is significantly increased. With the increase in lime addition, the shear strength of red clay becomes stronger and stronger. Lignin added to red clay can also enhance the shear strength of red clay, but the enhancement effect is far less than the shear strength of lime-modified red clay.

(4) SEM analysis shows that the original structure of red clay is loose and porous, exhibiting poor strength. After adding lignin, the “soil–fiber” formed in the soil structure achieves physical reinforcement. The strength of the soil is significantly enhanced. However, adding too much lignin will cause ineffective bonding in some areas, resulting in increased particle spacing, loose structure, and reduced strength. Lime generates cementing substances such as C-S-H and C-A-H through chemical reactions, filling the pores and cracks in the soil and cementing the particles to form a dense structure, which significantly enhances the strength of the soil.

Author Contributions

Conceptualization, B.Y. and M.H.; methodology, W.C. and J.C.; software, Z.X.; validation, W.C. and B.Y.; formal analysis, H.Z. and X.W.; investigation, Z.X.; resources, X.W. and M.H.; data curation, W.C. and J.C.; writing—original draft preparation, Z.X.; writing—review and editing, W.C. and H.Z.; visualization, B.Y.; supervision, W.C.; project administration, W.C. and B.Y.; funding acquisition, B.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangxi Natural Science Foundation (grant number 2024GXNSFBA010011).

Data Availability Statement

Data are contained within the paper.

Conflicts of Interest

Author Xiaobo Wang was employed by the company Sichuan Road & Bridge Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wesley, L.D. Cluster Hypothesis and the Shear Strength of a Tropical Red Clay. Geotechnique 1973, 23, 109–113. [Google Scholar] [CrossRef]

- Kang, Q. Shear Test Mechanical Characterization of Red Clay on Slope Field in Hunan Province Under Hot-Humid-Acid Conditions. Master’s Thesis, Xiangtan University, Xiangtan, China, 2018. [Google Scholar]

- Gong, Y.; Chen, H.F. Description on Research Status of Red Clay. Subgrade Eng. 2019, 202, 47–53. [Google Scholar]

- Tang, Y.Z.; Kong, L.W.; Guo, A.G.; Wang, Z. Experimental Study on Wetting Deformation of Compacted Laterite. Chin. J. Geotech. Eng. 2011, 33, 483–489. [Google Scholar]

- Lyu, H.; Gu, J.; Li, W.; Liu, F.B. Analysis of Compressibility and Mechanical Behavior of Red Clay Considering Structural Strength. Arab. J. Geosci. 2020, 13, 411. [Google Scholar] [CrossRef]

- Gu, J.; Lyu, H.; Fan, L. Influence of Structural Strength on Geotechnical Properties of Intact Red Clay. Arab. J. Geosci. 2021, 14, 1921. [Google Scholar] [CrossRef]

- Zeng, L.; Yu, H.C.; Gao, Q.F.; Liu, J.; Liu, Z.H. Evolution of Tensile Properties of Compacted Red Clay under Wet and Dry Cycles. KSCE J. Civ. Eng. 2022, 26, 606–618. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Pu, S.Y.; Li, R.Y.M.; Zhang, J. Microscopic and Mechanical Properties of Undisturbed and Remoulded Red Clay from Guiyang, China. Sci. Rep. 2020, 10, 18003. [Google Scholar] [CrossRef] [PubMed]

- Mu, R.; Huang, Z.H.; Guo, J.Q.; Pu, S.Y.; Mu, L.S.; Ren, X.B. Experimental Study on CU Triaxial Test of Undisturbed Red Clay with Different Water Content Ratio in Guiyang. Water Resour. Hydropower Eng. 2019, 50, 189–194. [Google Scholar]

- Yang, B.; Qin, C.; Chen, J.H.; Chen, Y.; Wang, L.Y. Experimental Study on the Influence of Cracks to Shear Strength Attenuation of Red Clay. Geotech. Investig. Surv. 2022, 50, 1–6. [Google Scholar]

- Xiao, L.N.; Huang, Z.H.; He, F.C.; Qu, W.T. Study on the Change Law of Shear Strength of Red Clay under Overburden Load. J. Henan Polytech. Univ. (Nat. Sci.) 2021, 40, 156–162. [Google Scholar]

- Chen, W.; Hou, Y.Z.; Chen, J. Study on Physical and Mechanical Properties and Micro-mechanism of Modified Expansive Soil with Disintegrated Sandstone-cement. Water Resour. Hydropower Eng. 2021, 52, 132–140. [Google Scholar]

- Zhao, X.; Gu, T.F.; Fan, N.N. Experimental Study on Disintegration of Loess Improved by Cement. J. Northwest Univ. (Nat. Sci. Ed.) 2024, 54, 18–25. [Google Scholar]

- Bian, J.M. Water Stability of Lime-treated Expansive Soil. J. Change River Sci. Res. Inst. 2016, 33, 77–82. [Google Scholar]

- Ruan, L.L. Experimental Study on Swelling Characteristics and Influencing Factors of Lime Improved Loess. J. Highw. Transp. Res. Dev. 2023, 40, 88–93+102. [Google Scholar]

- Zhang, D.M.; Li, J.D.; Wang, X.; Zhang, Y.J.; Zhao, J.L.; Guo, Y.H. Experimental Study on Physical and Mechanical Properties of Loess Reinforced Compound curing Agent. Mater. Rep. 2024, 38, 151–156. [Google Scholar]

- Zhu, Y.Y. Experimental Study on Cement and Fly Ash Improving the Southern Red Soils. Master’s Thesis, South China Agricultural University, Guangzhou, China, 2017. [Google Scholar]

- Liu, B.C.; Li, C.J.; Pan, Z.Y.; Zhang, B.H. Laboratory Test for Mechanical Properties of Guilin Red Clay Mixed with Cement. J. Eng. Geol. 2012, 20, 633–638. [Google Scholar]

- Liu, B.C.; Tang, Q.; Li, Y.; Li, C.J. Laboratory Test Study on Mechanical Properties of Additive to Organic Cement Red Clay in Guilin region. J. Eng. Geol. 2013, 21, 554–559. [Google Scholar]

- Wang, L.R.; Chen, J.; Yang, H.; Huang, Y.; Huang, Y. Effectiveness and Mechanism of Improving Strength of Red Clay by Microorganism. J. Chang. River Sci. Res. Inst. 2022, 39, 125–131. [Google Scholar]

- GB/T 50123-2019; Geotechnical Test Method Standard. China Planning Publishing House: Beijing, China, 2019.

- Liu, B.C.; Zhou, H.F.; Wang, X.B.; Lian, G.; Yang, B. Effect of Modifiers on the Disintegration Characteristics of Red Clay. Sustainability 2024, 16, 4551. [Google Scholar] [CrossRef]

- Zhao, X.F.; Chen, K.S. Study on Shear Resistance and Dynamic Shear Properties of Lignin Modified Red Clay. J. Guangxi Univ. (Nat. Sci. Ed.) 2023, 48, 68–78. [Google Scholar]

- Dong, J.; Chen, J.; Wu, Z.H.; Yang, H.; Chen, T.X. Experimental Study on the Shear Strength and Deformation Characteristics of Lignin-fiber Red Clay. J. Geomech. 2019, 25, 421–427. [Google Scholar]

- Chen, L.J.; Chen, X.J.; Wang, H.; Huang, X.; Song, Y. Mechanical Properties and Microstructure of Lime-treated Red Clay. KSCE J. Civ. Eng. 2021, 25, 70–77. [Google Scholar] [CrossRef]

- Zhao, L.H.; Zhao, X.S.; Cheng, A.; Chen, Z.X.; Rao, J.L.; Mo, L.L. Synergistic Effects of Red Clay and Lime for Improving Phyllite Soil. Minerals 2023, 13, 1321. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).