Integrated Hydrogen in Buildings: Energy Performance Comparisons of Green Hydrogen Solutions in the Built Environment

Abstract

1. Introduction

1.1. Background and Motivations

1.2. Theoretical Frameworks

- The demand for heating in a house. The amount of heat to keep the temperature at the required level;

- The efficiency of the system. This represents the energy losses that occur between the demand side (the amount of heat required in a room) and the generating side of the distribution system;

- Building construction material including the heat transport mechanism; insulation material, heat transport through conduction, radiation, and convection. Solar gain and infiltration.

1.3. Basic Hydrogen Properties and Hydrogen Pilot Projects

1.3.1. Basic Hydrogen Properties

1.3.2. Hydrogen Pilot Projects

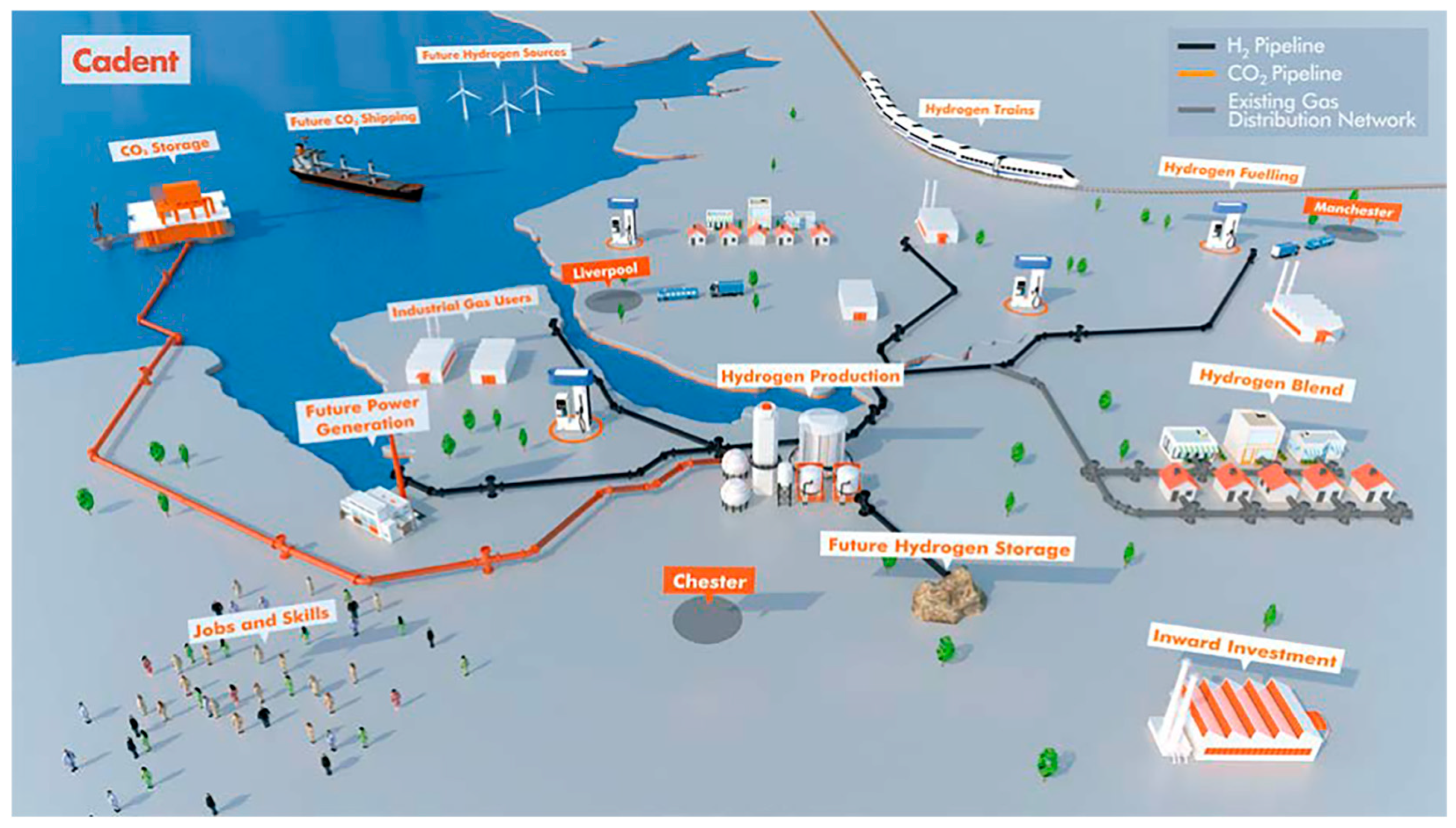

- HyNet UK

- 2.

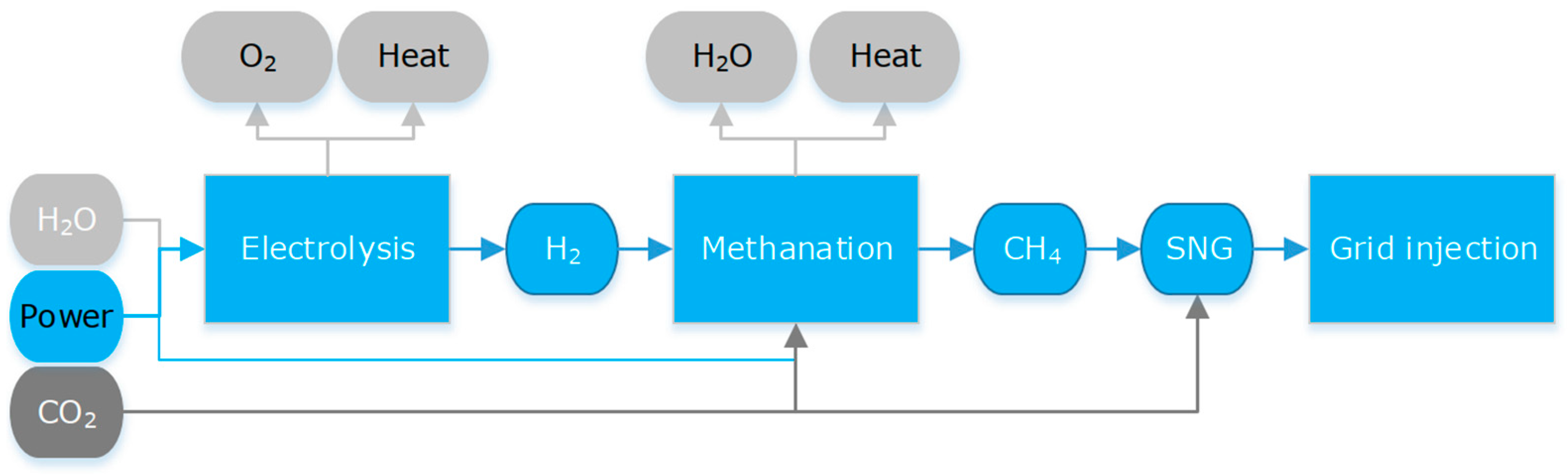

- Power-to-Gas Project Rozenburg Rotterdam, The Netherlands

- 3.

- Hy4Heat UK

| Hydrogen Distribution and Pipelines (HyNet UK) | Hydrogen Blend (Rozenburg, Rotterdam) | Hydrogen Grid (Hy4Heat UK) | Hydrogen Electricity (24/7 Green Village) | |

|---|---|---|---|---|

| Ref. | [26] | [25] | [27] | [28] |

| Hydrogen EnergySource | Solar Generator and Wind (Green Hydrogen) | Methane (Grey Hydrogen) | Not defined | Green Hydrogen |

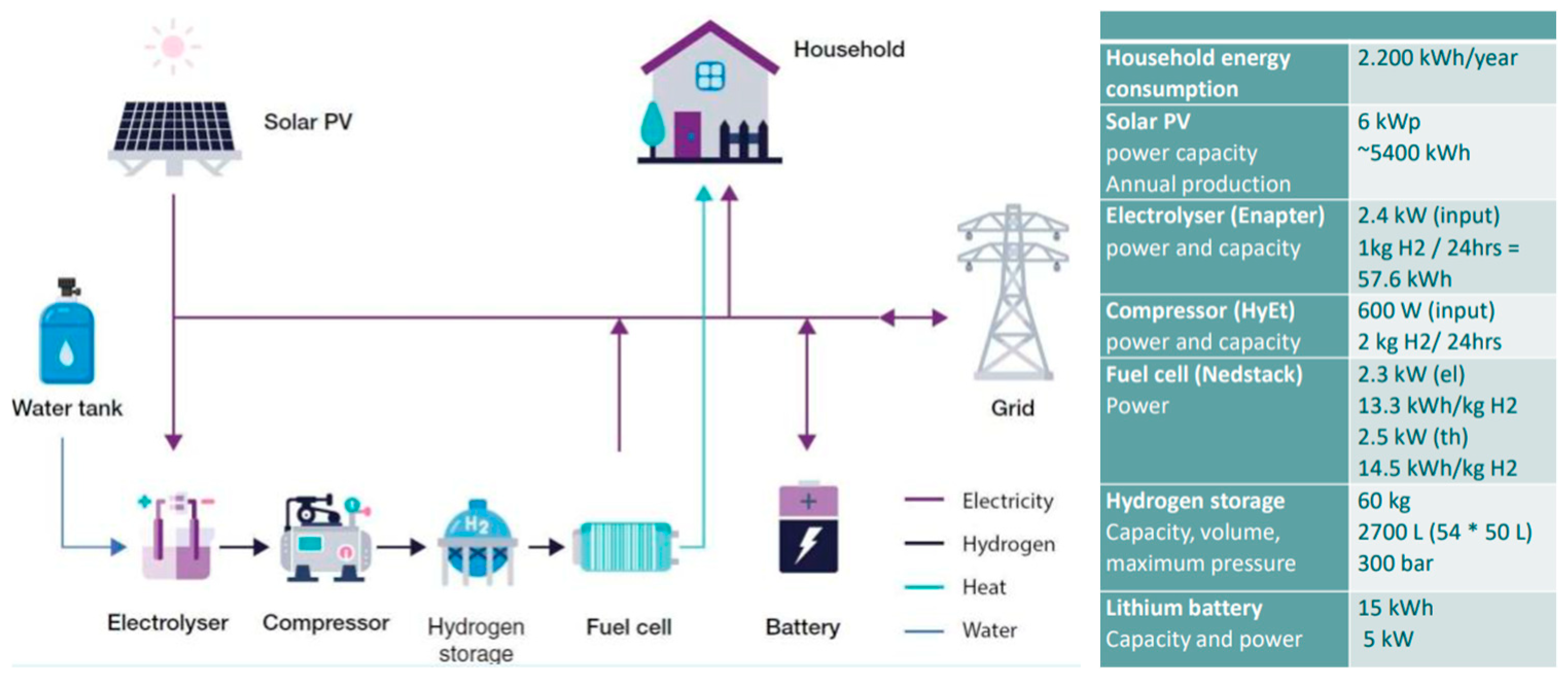

| Design System | Desalination Seawater → Power Plant (Electrolyzer) → Pipelines Distribution | Electricity Supply → Electrolysis → Methanation → Gas grid Injection | Hydrogen pipelines distribution → Hydrogen boilers → Hydrogen appliances → Heating | Hydrogen Pipelines Distribution → Electrolyser → Compressor → Hydrogen Storage → Fuel Cell → Battery → Households |

| Energy Conversion Efficiency | Not Defined | 35% (Total System Efficiency) | 90–95% (boiler efficiency) | 60% (fuel cell efficiency) |

| Suitability | Cluster and City | Apartment and old grid pipelines | Deprived neighborhoods | Independent housings or neighborhoods |

| Advantages |

|

|

|

|

| Disadvantages |

|

|

|

|

- 4.

- 24/7 Energy Lab, Green Village, TU Delft, The Netherlands

2. Materials and Methods

2.1. Materials Development

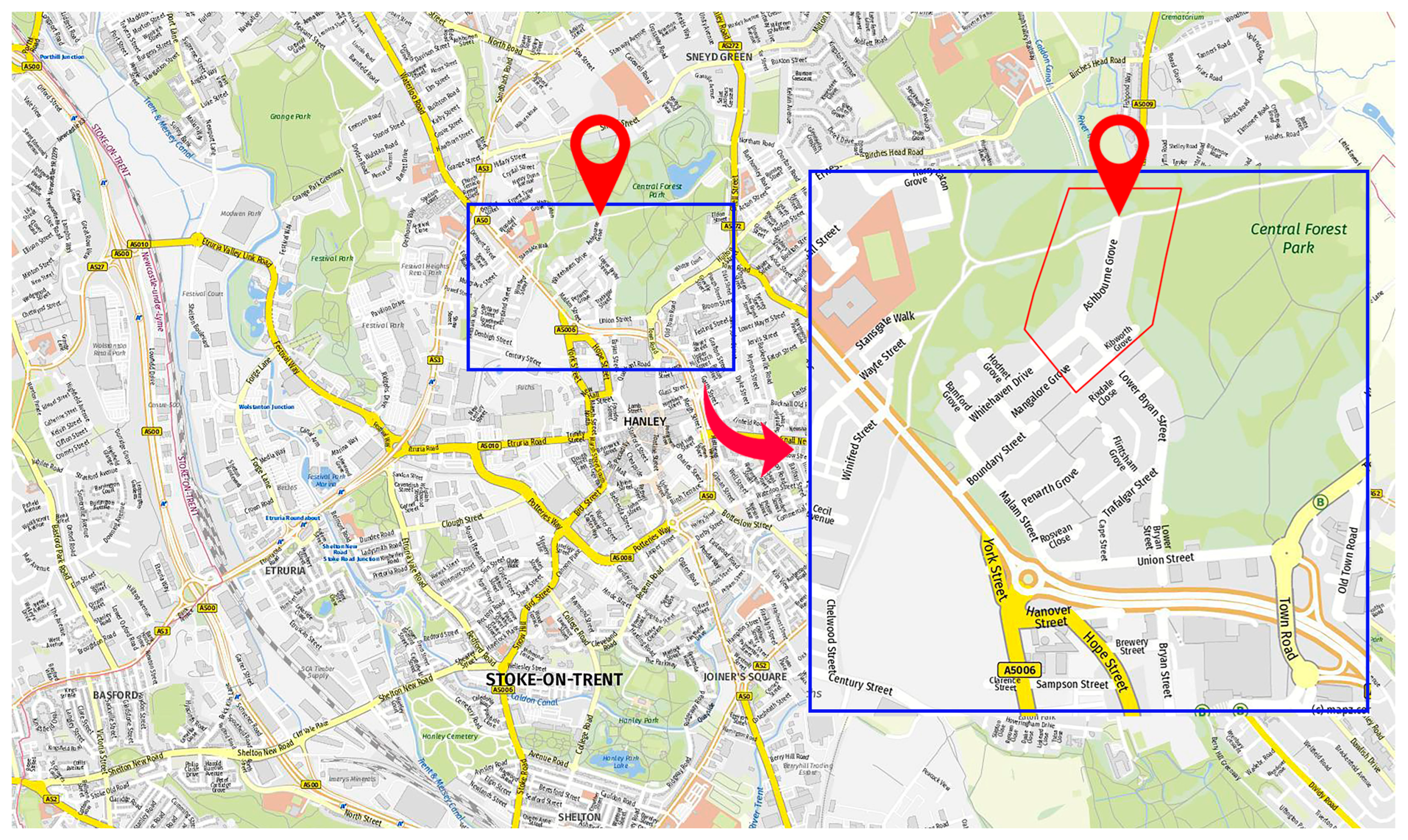

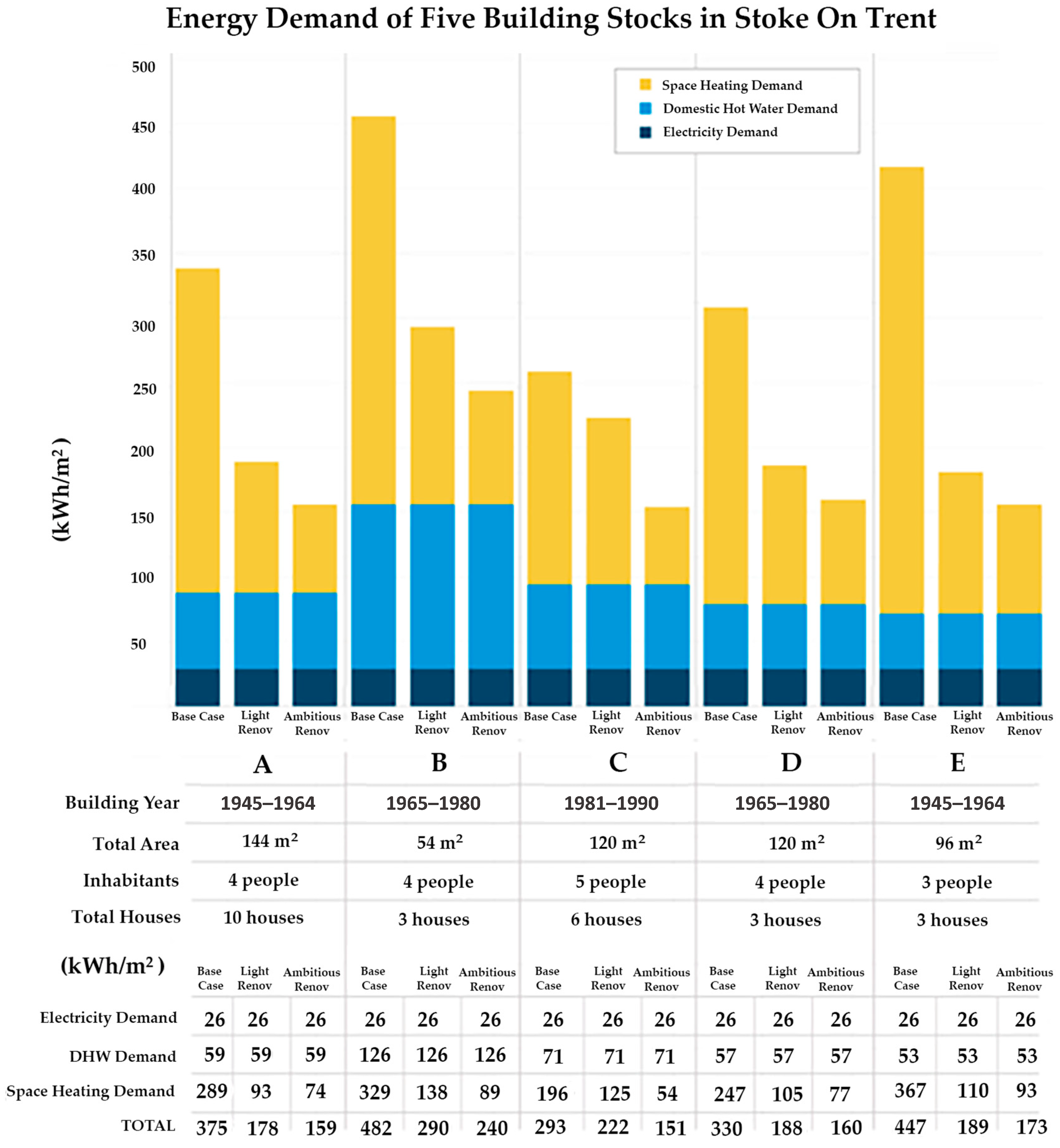

2.2. Case Study and Building Typology

2.3. Renovation Recommendation

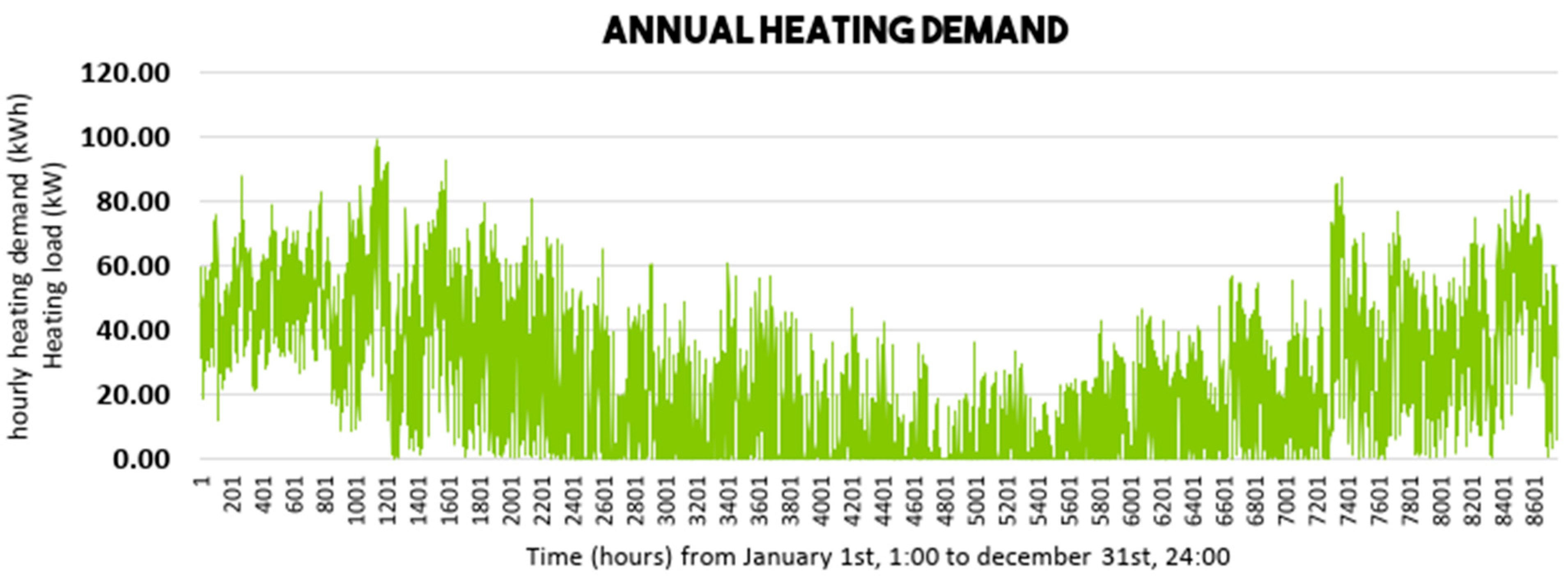

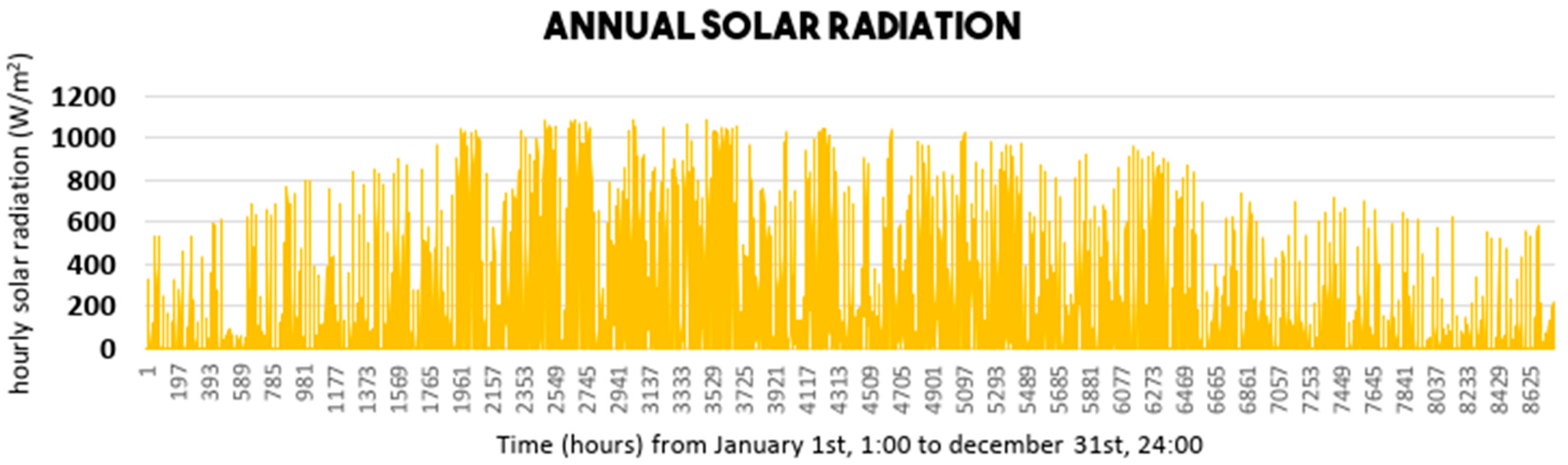

2.4. Energy Demand Modeling

2.5. Hydrogen Production System

3. Results

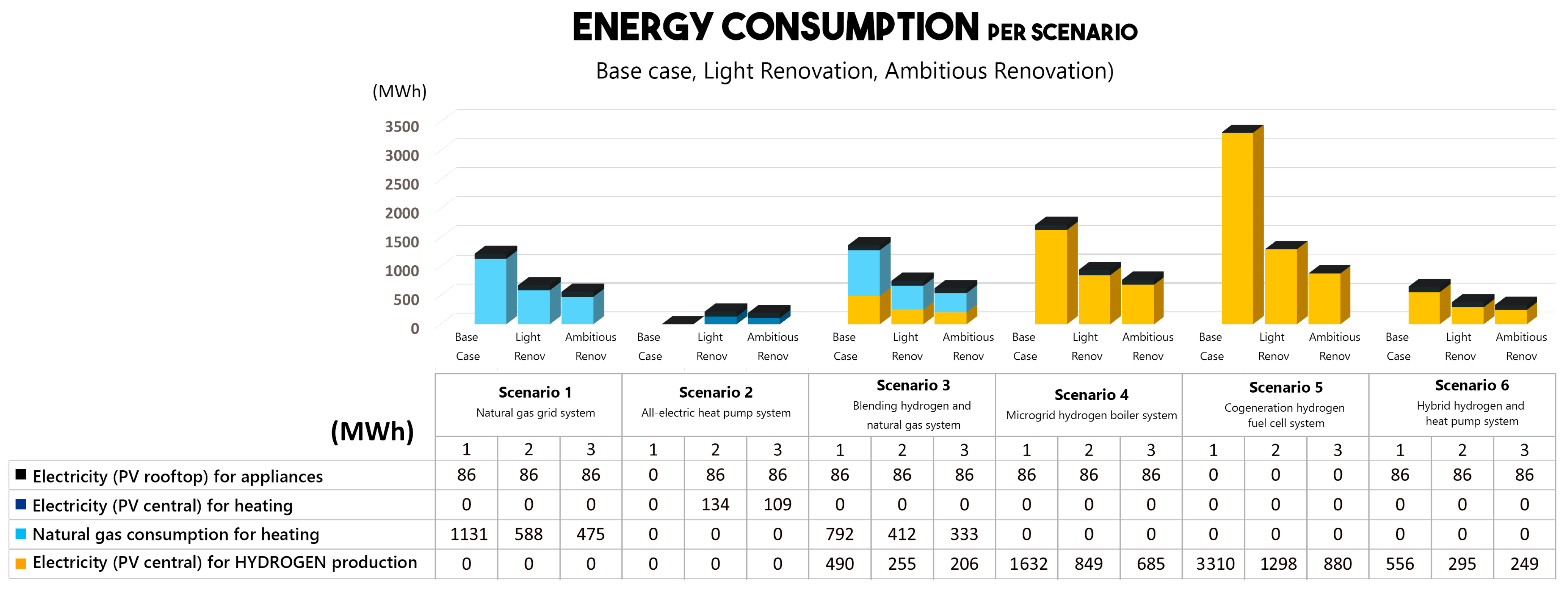

Energy Efficiency Comparison

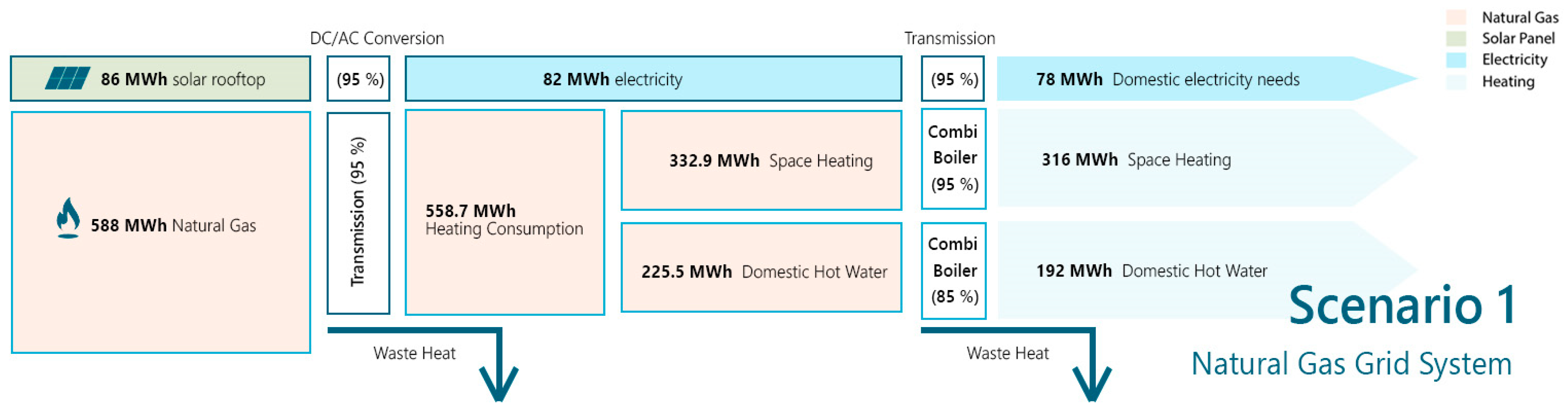

- Space Heating: Gas boiler

- Domestic Hot Water: Gas boiler

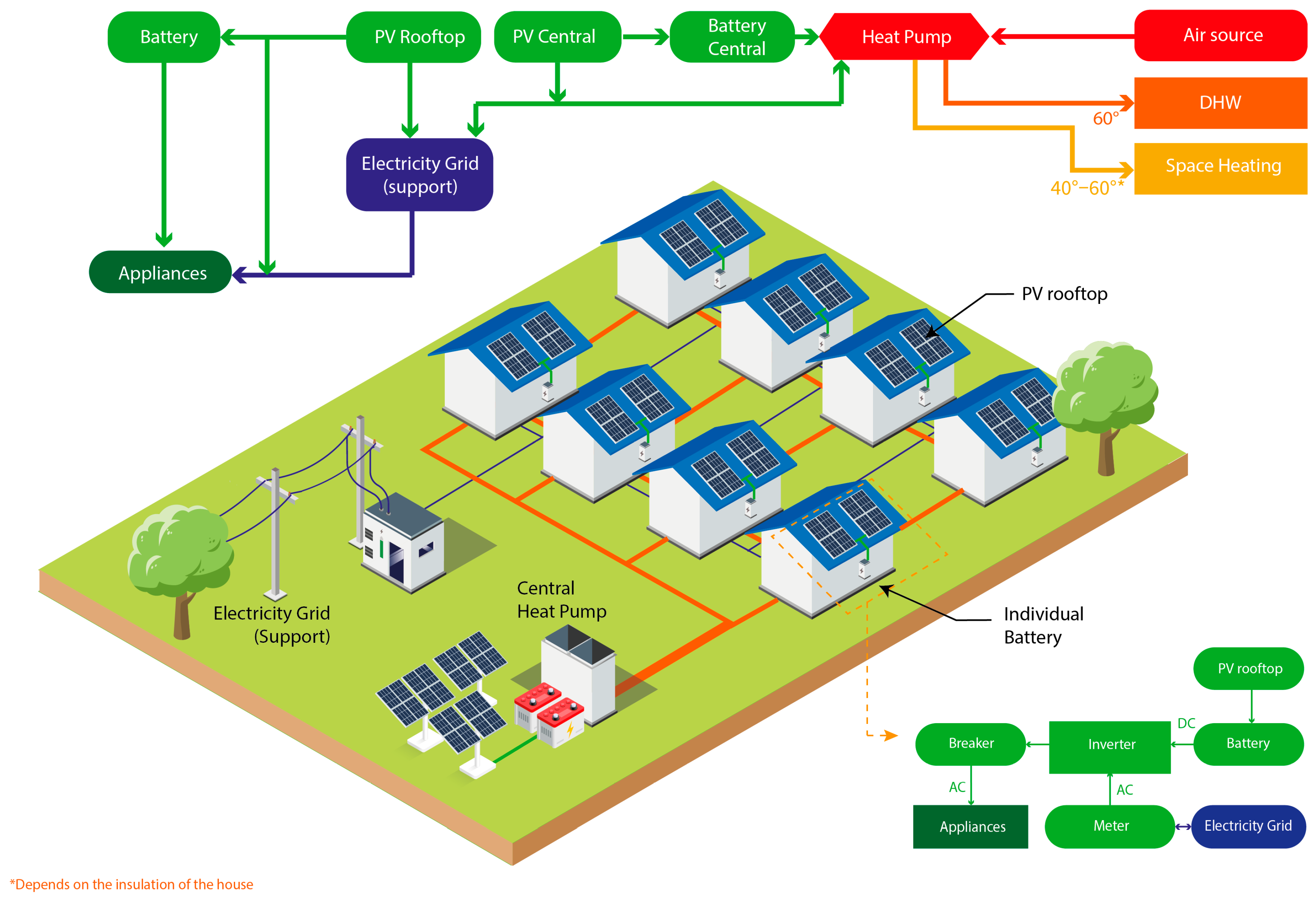

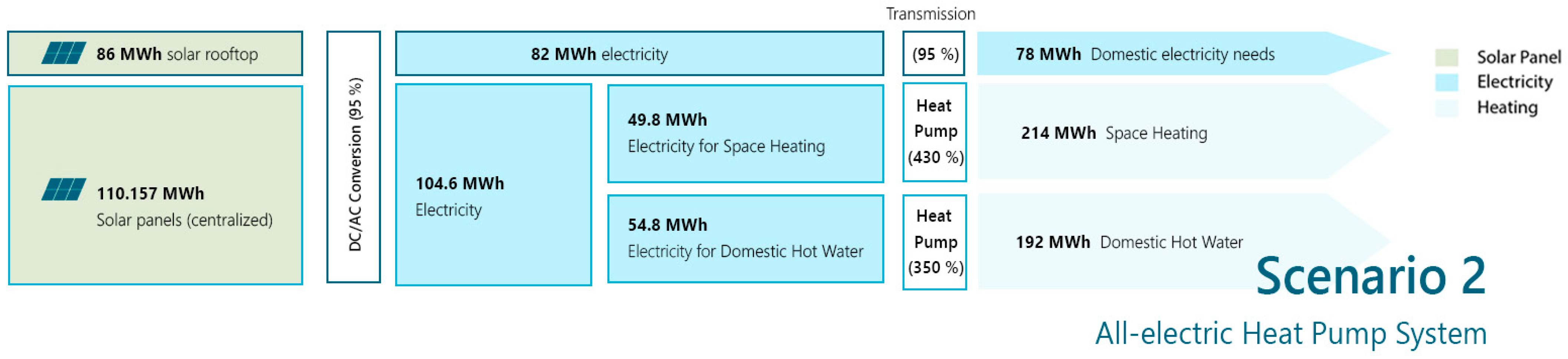

- Space Heating: Heat pump

- Domestic Hot Water: Heat pump

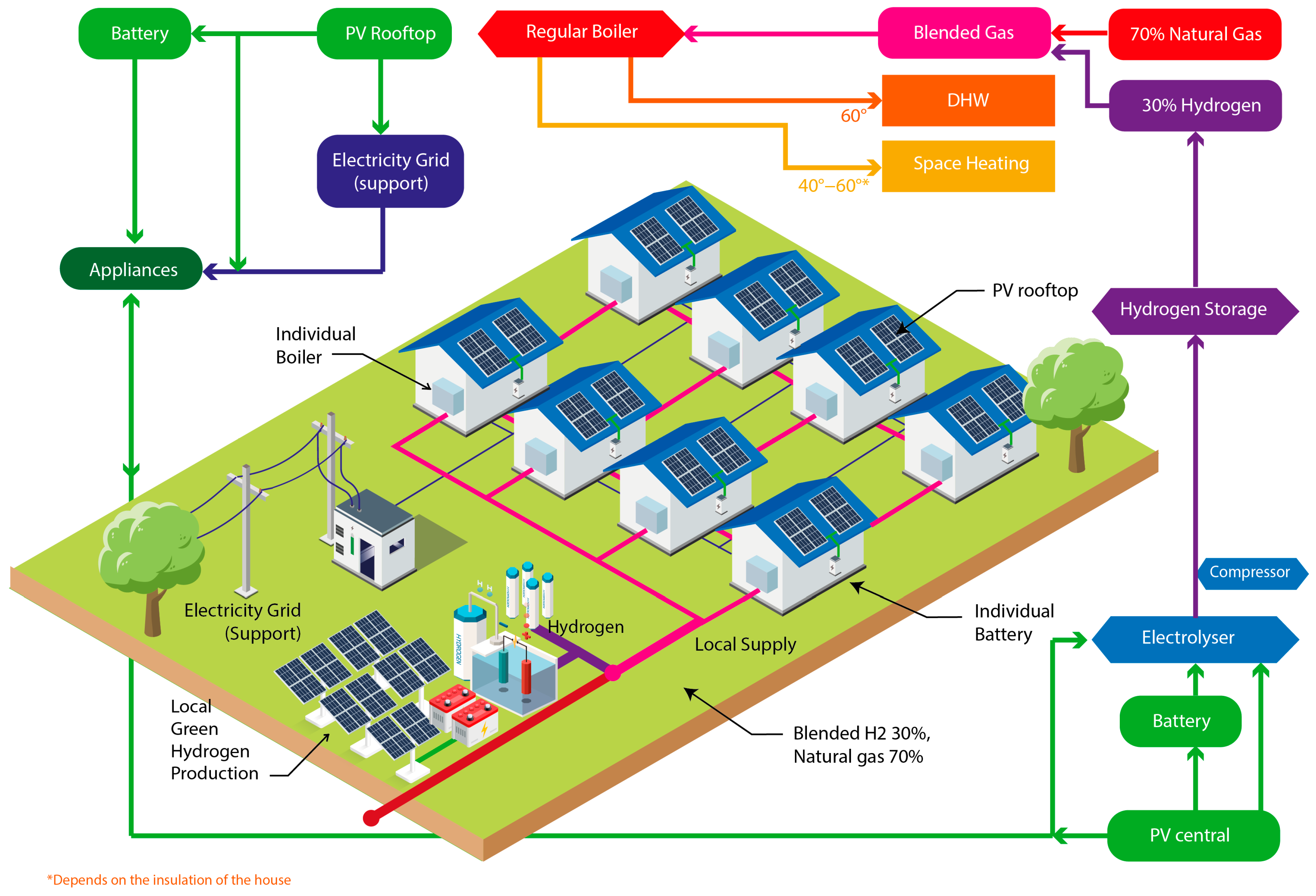

- Space heating: Regular boiler

- Domestic hot water: Regular boiler

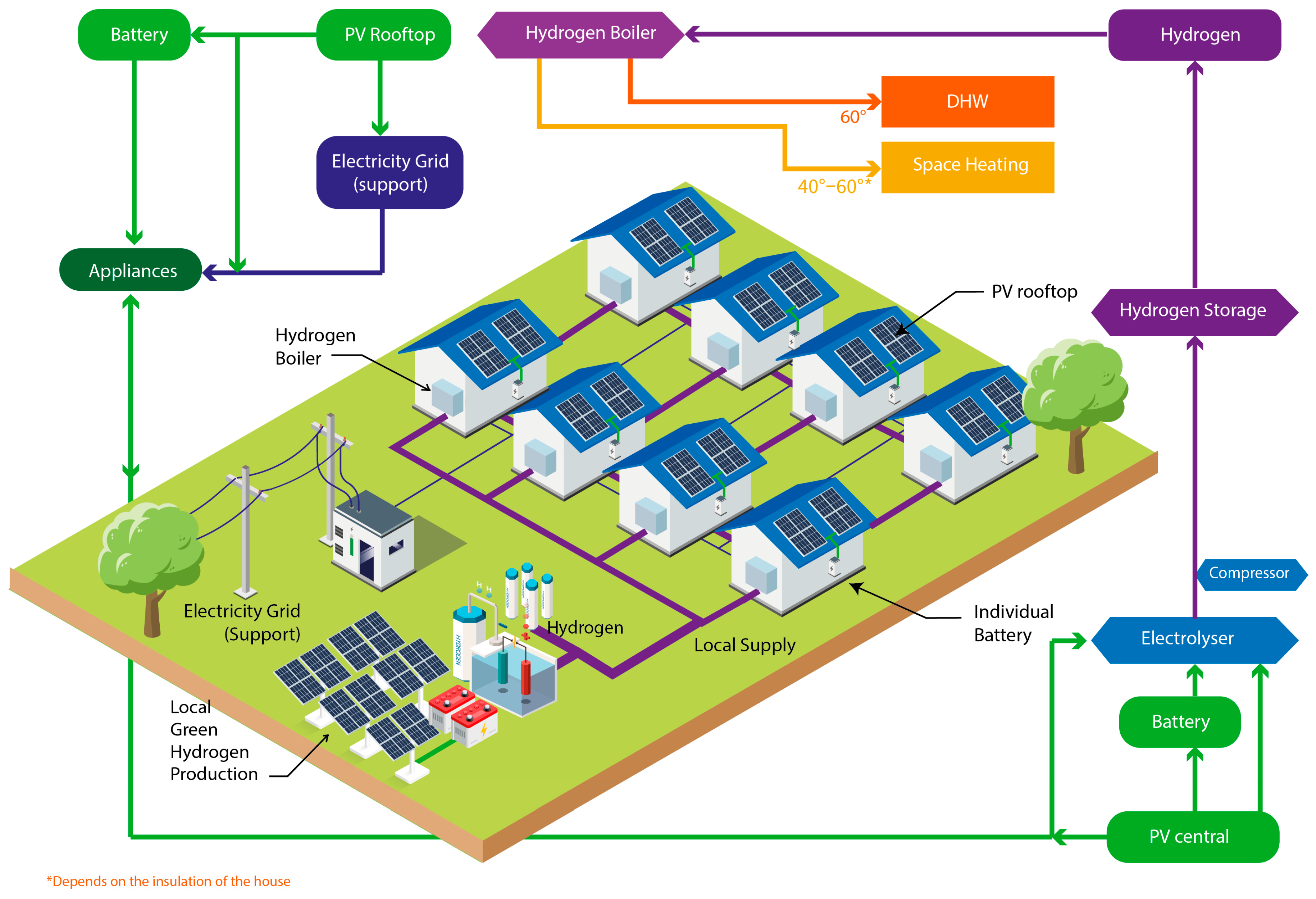

- Space Heating: Hydrogen boiler

- Domestic Hot Water: Hydrogen boiler

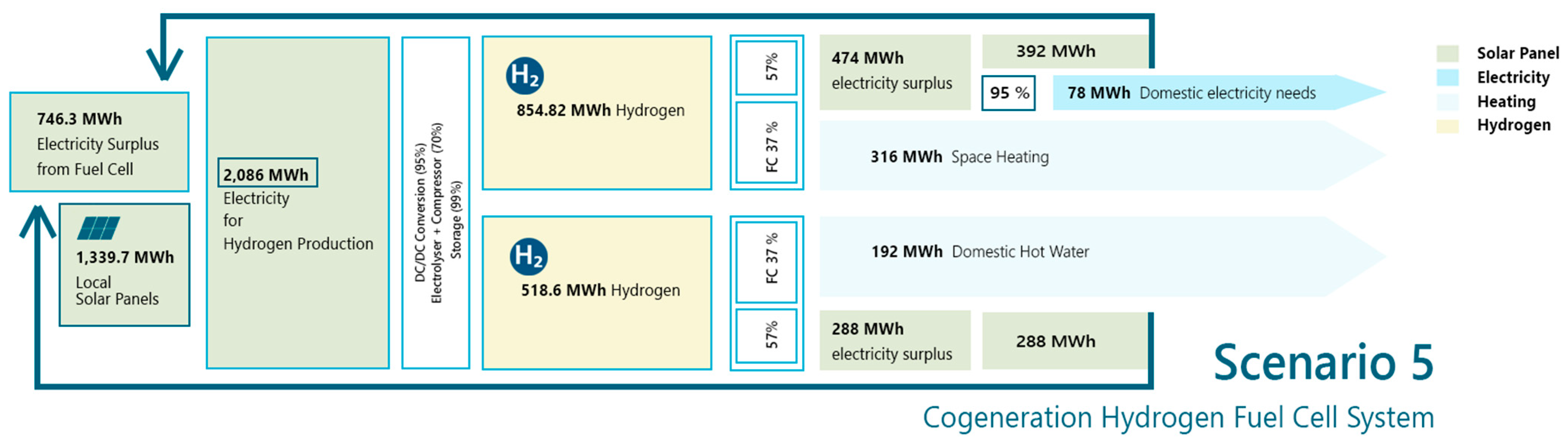

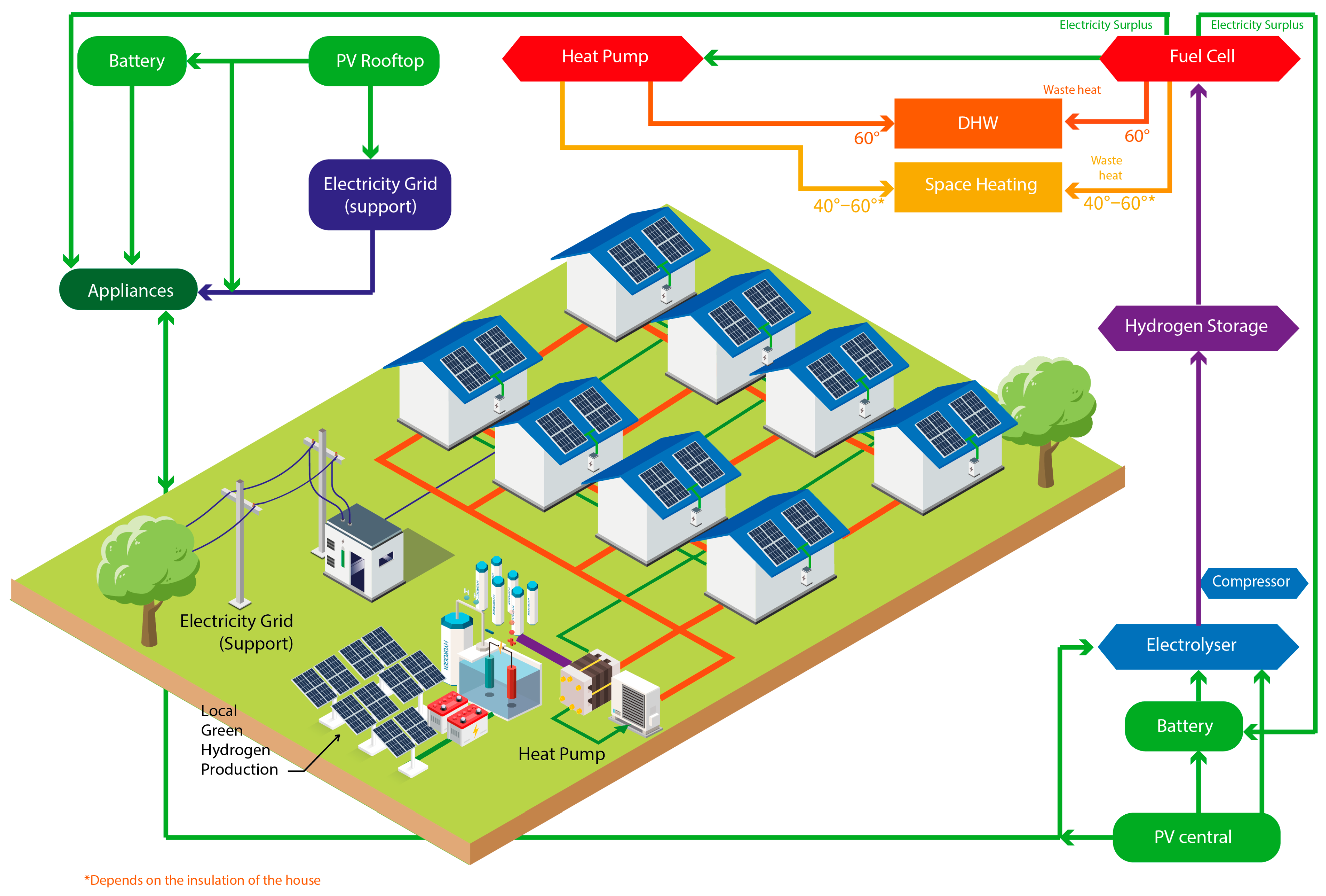

- Space Heating: Waste heat from fuel cells

- Domestic Hot Water: Waste heat from fuel cells

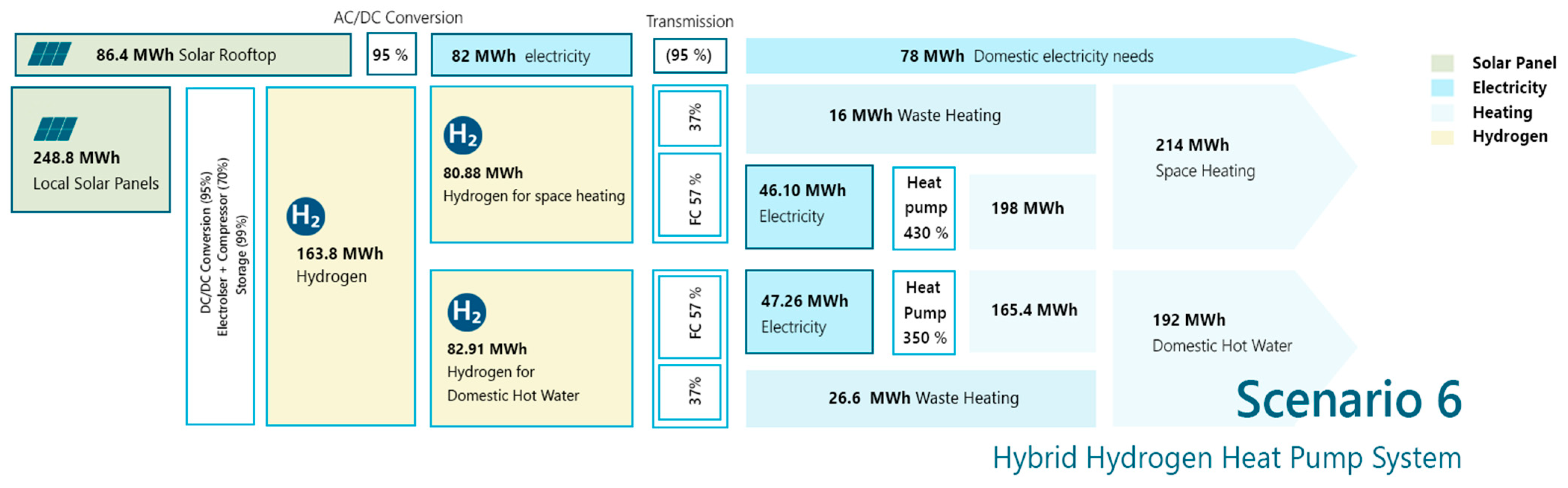

- Space Heating: Heat Pump, Fuel Cell

- Domestic Hot Water: Hydrogen gas grid with hydrogen boiler

4. Discussion

4.1. Long-Term Heating Strategies and Hydrogen Forecast in 2030

4.2. Safety Considerations in Hydrogen Integration for Buildings

- In Scenario 1 (Natural Gas Grid) and Scenario 2 (All-Electric Heat Pump),hydrogen is not used directly; therefore, safety concerns are limited to conventional gas and electrical standards.

- In Scenario 3 (Natural Gas and Hydrogen Blend),hydrogen is introduced into the existing gas network up to safe limits (typically <20% by volume). While this approach reduces carbon emissions with minimal infrastructure change, it still necessitates upgraded sensors, pressure regulators, and blend control systems.

- In Scenario 4 (Hydrogen Microgrid Boiler) and Scenario 5 (Hydrogen Fuel Cell System),hydrogen is used at higher concentrations or in pure form. These systems require upgraded pipe materials resistant to hydrogen embrittlement, the integration of flame arrestors, and continuous leak monitoring with automatic shut-off mechanisms.

- In Scenario 6 (Hybrid Hydrogen Heat Pump),operational complexity is introduced, but it allows for modular risk control, using hydrogen only during peak demand and reducing the need for constant high-pressure storage.To mitigate these risks, a combination of technical measures, building design adaptations, and regulatory frameworks is required [37,38]. Recent pilot programs based on standardization, such as Hy4Heat and HyDeploy in the UK, have demonstrated that domestic hydrogen systems can be operated safely with the following:

- Advanced hydrogen leak detectors;

- Proper ventilation design;

- Use of explosion-proof materials and fittings;

- Safety shut-off valves integrated into smart control systems;

- Updated appliances certified for hydrogen operation (e.g., hydrogen-ready boilers).

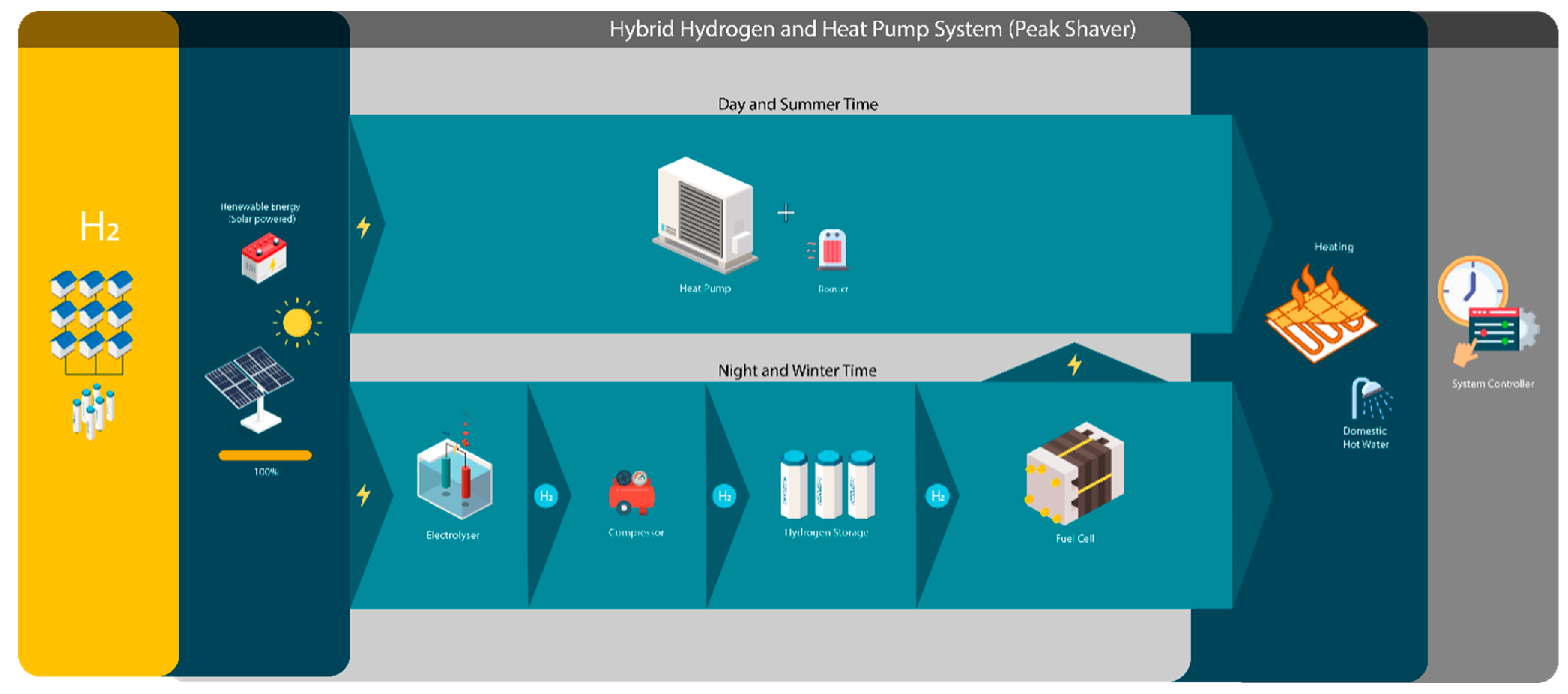

4.3. Hydrogen as a Peak Shaver (System Optimized in Hybrid Hydrogen and Heat Pump)

- Decreased peak demand for electricity. This can help to reduce the need for new power plants or solar panels and decrease the capital costs of the system.

- Increased system efficiency. The heat pump can operate more efficiently when the demand is lower.

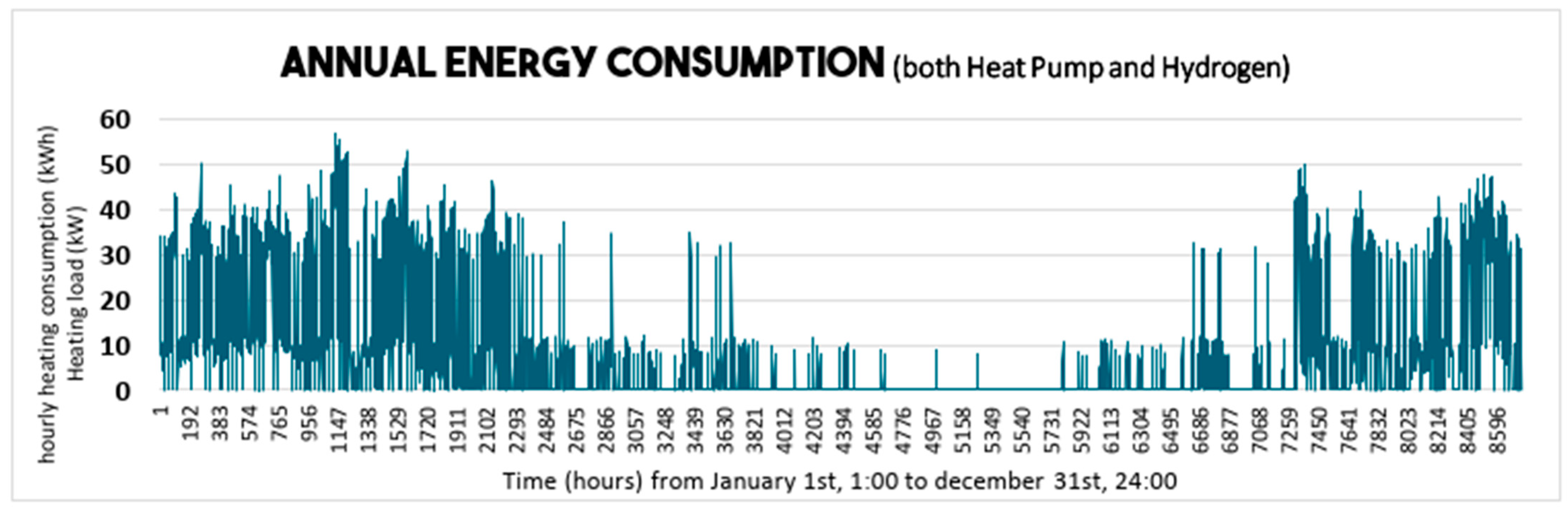

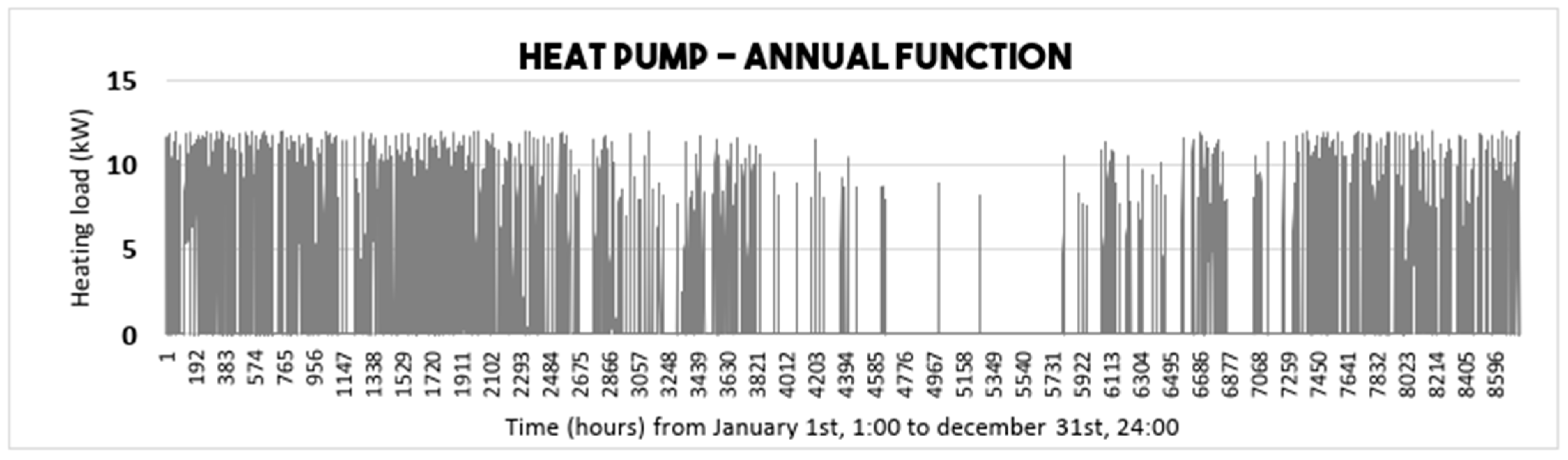

4.4. Annual Set up of Hybrid Hydrogen and Heat Pump System

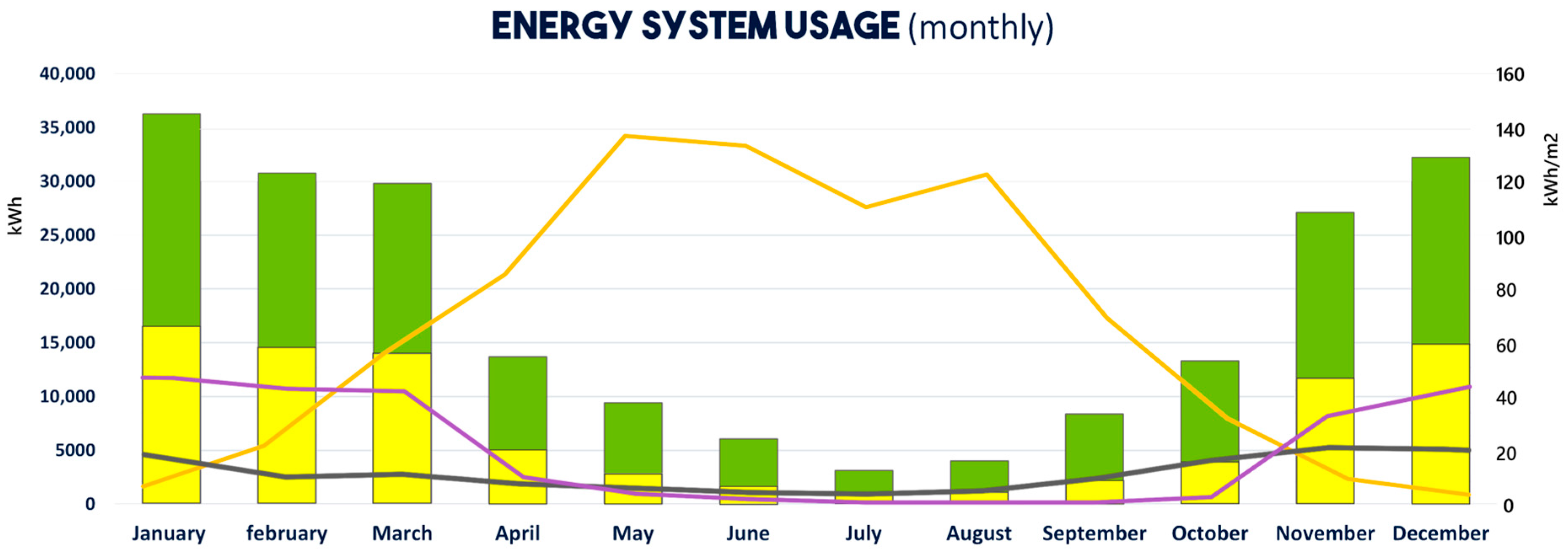

4.5. Monthly Set up of Hybrid Hydrogen and Heat Pump System

- High Temperature. Firstly, when the temperature falls within the range of 18–28. 22 degrees Celsius or exceeds this range, the system ensures that the heating is completely turned off. This prevents unnecessary heating when the temperature is completely excessively hot. However, an advanced dynamic control, when the temperature exceeds this range, can also be switched to a cooling system.

- Low-Temperature solar heating. In conditions where there is sunlight, but the temperature is relatively low, the system activates the heat pump to provide heating, along with solar energy with availability to be stored as hydrogen. This ensures energy efficiency by harnessing solar energy directly when maintaining comfort.

- Lowest Temperature. Additionally, when there is sunlight, but the temperature is at its lowest, the system prioritizes heating via hydrogen. This method utilizes a hydrogen source to provide effective heating during extremely cold conditions.

- Low to Average Capacity. When the heating demand ranges from zero to average heating capacity, the heat pump is activated to generate the required heating.

- Average to Maximum Capacity. In cases where the heating demand exceeds the average capacity but remains within the maximum capacity, the system activates the hydrogen source.

- Excess Capacity. If the energy demand exceeds the maximum average heating capacity of the system, it automatically switches to hydrogen to meet the increased demand. This prevents overloading the heat pump.

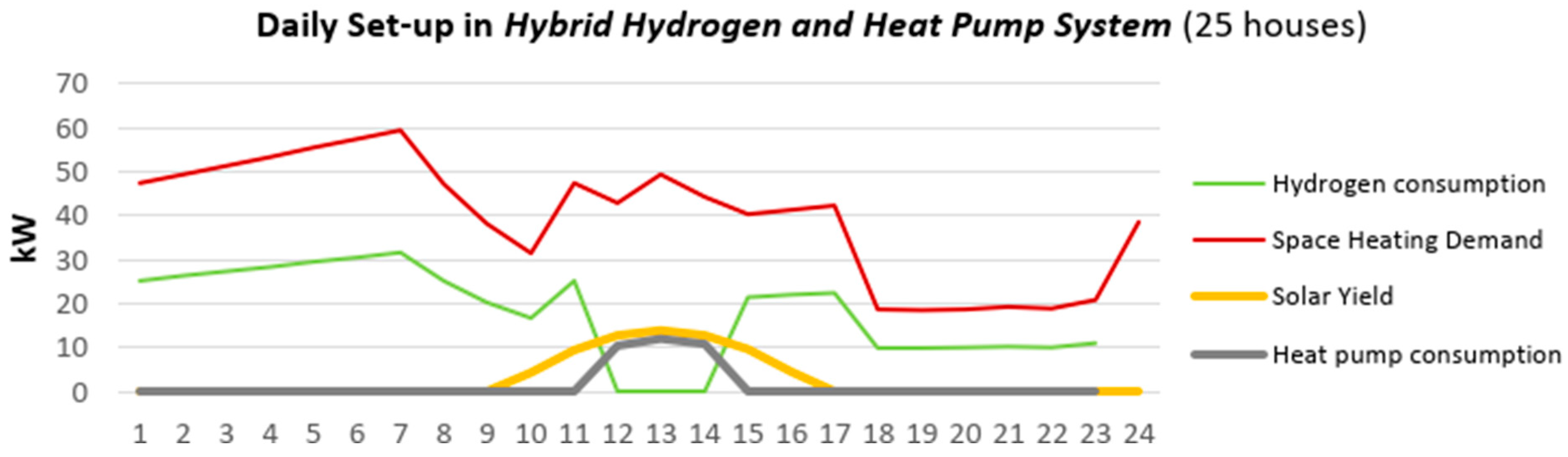

4.6. Daily Set up of Hybrid Hydrogen and Heat Pump System

- Hours 0–6: Hydrogen is fully utilized as there is no solar yield during this period.

- Hours 7–12: Increased activity during these hours results in higher hydrogen consumption, which subsequently decreases as solar radiation begins to rise.

- Hours 13–18: Solar yield reaches its peak during this timeframe, allowing the heat pump to take the lead. Consequently, hydrogen consumption is minimized.

- Hours 19–24: As solar yield diminishes, hydrogen is reactivated to meet the demand.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Secretary of State for Business, Energy, and Industrial Strategy; UK’s Nationally Determined Contribution (NDC), ICTU. 2022. Available online: https://unfccc.int/sites/default/files/NDC/2022-09/UK%20NDC%20ICTU%202022.pdf (accessed on 3 November 2022).

- Holland, L. Fuel of the Future? Inside the UK’s First Hydrogen-Powered Homes. 2022. Available online: https://news.sky.com/story/fuel-of-the-future-inside-the-uks-first-hydrogen-powered-homes-12287892 (accessed on 7 December 2022).

- Department for Energy Security and Net Zero, HM Government. UK Hydrogen Strategy. 2021. Available online: https://assets.publishing.service.gov.uk/media/64c7e8bad8b1a70011b05e38/UK-Hydrogen-Strategy_web.pdf (accessed on 9 December 2022).

- Environmental and Energy Study Institute. EESI. Fossil Fuels. 2022. Available online: https://www.eesi.org/topics/fossil-fuels/description (accessed on 3 January 2023).

- Rongé, J.; François, I. Use of Hydrogen in Buildings; BatHyBuild Study; WaterstofNet: Turnhout, Belgium, 2021. [Google Scholar]

- IEA. The Future of Heat Pumps; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/the-future-of-heat-pumps (accessed on 9 December 2022).

- Gerhardt, N.; Bard, J.; Schmitz, R.; Beil, M.; Pfennig, M.; Kneiske, T. Hydrogen in the Energy System of the Future: Focus on Heat in Buildings; Technical Report; Fraunhofer Institute for Energy Economics and Energy System Technology (IEE): Hannover, Germany, 2020. [Google Scholar]

- Cebon, D. Hydrogen for Heating. 2020. Available online: https://www.csrf.ac.uk/blog/hydrogen-for-heating/ (accessed on 18 December 2022).

- IEA. The Future of Hydrogen; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 19 December 2022).

- Northern Gas Network. 2017. Available online: https://www.northerngasnetworks.co.uk/wp-content/uploads/2017/04/H21-Executive-Summary-Interactive-PDF-July-2016-V2.pdf (accessed on 20 January 2023).

- Winter, C.-J. Hydrogen energy—Abundant, efficient, clean: A debate over the energy-system-of-change. Int. J. Hydrogen Energy 2009, 34, S1–S52. [Google Scholar] [CrossRef]

- Rosenow, J. Is heating homes with hydrogen all but a pipe dream? An evidence review. Joule 2022, 6, 2225–2228. [Google Scholar] [CrossRef]

- Dodd, N.; Donatello, S.; Cordella, M. Level(s) Indicator 1.1: Use Stage Energy Performance. 2021. Available online: https://susproc.jrc.ec.europa.eu/product-bureau//sites/default/files/2021-01/UM3_Indicator_1.1_v1.1_25pp.pdf (accessed on 23 January 2023).

- Van Gaalen, I.M.K.; Van der Linden, A.C. Building Physics, 2nd ed.; ThiemeMeulenhoff: Amersfoort, The Netherlands, 2018. [Google Scholar]

- Bokel, R. Building Physics Energy 01. 2021. Available online: https://www.studeersnel.nl/nl/document/technische-universiteit-delft/bucky-lab-seminars-building-physics/building-physics-lecture-notes-01-april-2016/1002329 (accessed on 25 January 2023).

- ARUP. Five Minutes Guide Hydrogen. Available online: https://www.arup.com/globalassets/downloads/insights/five-minute-guide-to-hydrogen.pdf (accessed on 8 March 2023).

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engine. Prog. Energy Combust. Sci. 2009, 25, 490–527. [Google Scholar] [CrossRef]

- Mazloomi, K.; Gomes, C. Hydrogen as an energy carrier, prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033. [Google Scholar] [CrossRef]

- Shell Global Solutions International BV. Integrated Design for Efficient Advanced Liquefaction of Hydrogen (Idealhy). 2013. Available online: https://idealhy.eu/ (accessed on 9 June 2023).

- Vick, B.D. Adding concentrated solar power plants to wind farms to achieve a good quality electrical load match. Sol. Energy 2013, 92, 298–312. [Google Scholar] [CrossRef]

- Ananthachar, V.; Duffy, J. Efficiencies of hydrogen storage systems onboard fuel cell vehicle. Solar Energy 2005, 78, 687–694. [Google Scholar] [CrossRef]

- Zhou, L. Progress and problems in hydrogen storage methods. Renew. Sustain. Energy Rev. 2005, 9, 395–408. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Hydrogen Review. 2021. Available online: https://www.iea.org/reports/global-hydrogen-review-2021 (accessed on 10 June 2023).

- Roben, F.; Kicherer, L.; Jurgens, S.; Decher, H.; Schafers, H.; Von Dusterlho, J.E. Decarbonization of the heating sector in hamburg grid constraints, efficiency, and costs of green hydrogen vs heat pump. In Proceedings of the International Conference on the European Energy Market, EEM, IEEE Computer Society, Ljubljana, Slovenia, 13–15 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Vlap, H.; Van der Steen, A. DNV GL Oil and Gas. Power-to-Gas project in Rozenburg, The Netherlands. 2015. Available online: https://projecten.topsectorenergie.nl/storage/app/uploads/public/5b7/54a/624/5b754a624582f744864490.pdf (accessed on 12 June 2023).

- HyNet. Cadent UK. HyNet North West Infrastructure and Technology. Available online: https://hynet.co.uk/ (accessed on 12 June 2023).

- Hy4heatUK. Department for Business, Energy and Industrial Strategy, BEIS. 2021. Available online: https://www.hy4heat.info/reports (accessed on 12 June 2023).

- 24/7 Energy Hub. TU Delft 2023. Available online: https://www.thegreenvillage.org/24-7-energy-hub/ (accessed on 12 June 2023).

- Stoke-on-Trent city council. Energy Master Planning Report. Energy Strategy 2023–2033. Available online: https://www.stoke.gov.uk/download/downloads/id/2440/energy_strategy_202333.pdf (accessed on 13 June 2023).

- Wai, C.W.; Mohammed, A.H.; Ting, L.S. Energy Management Key Practices: A proposed list for Malaysian Universities. Int. J. Energy Environ. 2011, 2, 749–760. [Google Scholar]

- Parameshwaran, R.; Kalaiselvam, S.; Harikrishnan, S.; Elayaperumal, A. Sustainable thermal energy storage technologies for buildings: A review. Renew. Sustain. Energy 2012, 16, 2394–2433. [Google Scholar] [CrossRef]

- International Energy Agency, IEA. Hydrogen. Available online: https://www.iea.org/energy-system/low-emission-fuels/hydrogen. (accessed on 2 August 2023).

- Energystar. Energy Star Building Manual, Heating and Cooling System Upgrades; Energy Star: Washington, DC, USA, 2001; p. 32.

- Hall, A.J. Domestic Heating by Gas: Boiler System Guidance for Installers and Specifiers; Energy Saving Trust: London, UK, 2008. [Google Scholar]

- Ferreira, A.P.R.A.; Oliveira, R.C.P.; Mateus, M.M.; Santos, D.M.F. A Review of the Use of Electrolytic Cells for Energy and Environmental Applications. Energies 2023, 16, 1593. [Google Scholar] [CrossRef]

- Department for Energy Security and Net Zero, HM Government. GHG Conversion Factors for Company Reporting. 2023. Available online: https://www.gov.uk/government/collections/government-conversion-factors-for-company-reporting (accessed on 3 August 2023).

- ISO/TR 15916:2015; Basic Considerations for the Safety of Hydrogen Systems. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:tr:15916:ed-2:v1:en (accessed on 2 May 2025).

- National Fire Protection Association. NFPA 2: Hydrogen Technologies Code; NFPA: Quincy, MA, USA, 2023; Available online: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=2 (accessed on 5 May 2025).

| Form | Storage Condition | Gravimetric Energy Density | Volumetric Energy Density | Typical Storage Pressure |

|---|---|---|---|---|

| Compressed Gas (CGH2) | Room temperature, high pressure | 120 MJ/kg | 1.5–2.0 kWh/L | 350–700 bar |

| Liquid Hydrogen (LH2) | Cyrigenic liquid at −253 °C | 120 MJ/kg | 2.8 kWh/L | 1 atm |

| Atmospheric H2 | Ambient temperature and pressure | 120 MJ/kg | 0.01 kWh/L | 1 atm |

| Metal Hydrides | Absorbed in solid material | 1.5–10 MJ/kg (varies) | 1–1.5 kWh/L | 10–1000 bar |

| Material | Energy per kg | Energy per Liter | Energy per m3 | ||

|---|---|---|---|---|---|

| (MJ/kg) | (kWh/kg) | (MJ/L) | (kWh/L) | (kWh/Nm3) | |

| Hydrogen (liquid) | 143 | 33.3 | 10.1 | 2.8 | 2800 |

| Hydrogen (compressed, 700 bar) | 143 | 33.3 | 5.6 | 1.5 | 1500 |

| Hydrogen (atm. pressure) | 143 | 33.3 | 0.0107 | 0.003 | 3 |

| Methane (atm. pressure) | 55.6 | 10.6–13.1 | 0.0378 | 0.0105 | 10.6 |

| Natural gas (liquid) | 53.6 | 10.6–13.1 | 22.2 | 6.16 | 6160 |

| Natural gas (compressed 250 bar) | 53.6 | 10.6–13.1 | 9 | 2.5 | 2500 |

| Natural gas (atm. pressure) | 53.6 | 10.6–13.1 | 0.0364 | 0.0101 | 10.1 |

| Pilot Projects | Appliances | System | Scale | Name of the System |

|---|---|---|---|---|

| Basic energy system (Base case) | Natural gas boiler system | |||

| Frequently used alternative | All-electric heat pump system | |||

| PurifHy Projects | (Methanation) | Hydrogen blend | Apartment | Natural gas and hydrogen blended system |

| (Rozenburg, Rotterdam) | Power-to-Gas | |||

| HyNet UK | Boilers | Hydrogen grid | City or | Microgrid hydrogen boiler system |

| Hy4Heat UK | Boilers | Neighborhood | ||

| 24/7 Energy Lab | Fuel cell + Heat pump | Hydrogen hybrid | Building | Hybrid hydrogen heat pump system |

| Cogeneration hydrogen fuel cell system; to understand the basic fuel cell production system without any intervention with other heating system (waste-heat deployment) | Cogeneration hydrogen fuel cell system | |||

| Building Models in Real-life (Stoke-on-Trent) | |||||

|---|---|---|---|---|---|

|  |  |  |  | |

| Building Models in Tabula (English Houses Database) | |||||

|  |  |  |  | |

| Type | A | B | C | D | E |

| Built year | 1945–1964 | 1965–1980 | 1981–1990 | 1965–1980 | 1945–1964 |

| Occupants | 4 people | 4 people | 5 people | 4 people | 3 people |

| Total Floor | 2 floors | 1 floors | 2 floors | 2 floors | 1 floors |

| Total unit | 10 units | 3 units | 6 units | 3 units | 3 units |

| Window area | 26.9 m2 | 6.7 m2 | 9.0 m2 | 22.4 m2 | 9.0 m2 |

| Total house | 25 houses|1 block | ||||

| Refurbishment Measure | Type A | Type B | Type C | Type D | Type E | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Insulation | U-Value | Insulation | U-Value | Insulation | U-Value | Insulation | U-Value | Insulation | U-Value | |

| Light Renovation (W/m2 K) | ||||||||||

| Window change | Yes | 2.2 | No | 4.8 | No | 3.1 | No | 3.1 | No | 2.2 |

| Wall insulation | Yes | 0.6 | Yes | 0.6 | Yes | 0.6 | Yes | 0.6 | Yes | 0.6 |

| Roof insulation | Yes | 0.13 | Yes | 0.13 | No | 0.4 | Yes | 0.13 | Yes | 0.13 |

| Floor insulation | No | 0.59 | No | 0.72 | No | 0.5 | No | 0.59 | Yes | 0.72 |

| Ambitious Renovation (W/m2 K) | ||||||||||

| Window change | Yes | 1.6 | Yes | 1.6 | Yes | 1.6 | Yes | 1.6 | Yes | 1.6 |

| Wall insulation | No | 0.6 | No | 0.6 | No | 0.6 | No | 0.6 | No | 0.6 |

| Roof insulation | No | 0.13 | No | 0.13 | No | 0.13 | No | 0.13 | No | 0.13 |

| Floor insulation | No | 0.59 | No | 0.59 | No | 0.59 | No | 0.59 | No | 0.72 |

| Building Input Parameters | Type A | Type B | Type C | Type D | Type E |

|---|---|---|---|---|---|

| Dimension | |||||

| Width | 6 m | 6 m | 7.5 m | 6 m | 8 m |

| Length | 9.5 m | 9 m | 8 m | 10 m | 12 m |

| Floor height | 3 m | 3 m | 3 m | 3 m | 3 m |

| Total floors | 2 | 1 | 2 | 2 | 1 |

| Total facade area (incl. glass) North | 33.6 m2 | 25.2 m2 | 42 m2 | 33.6 m2 | 33.6 m2 |

| Total facade area (incl. glass) East | 67.2 m2 | 16.8 m2 | 22.4 m2 | 56 m2 | 22.4 m2 |

| Total facade area (incl. glass) South | 33.6 m2 | 25.2 m2 | 21.0 m2 | 33.6 m2 | 33.6 m2 |

| Total facade area (incl. glass) West | 67.2 m2 | 16.8 m2 | 22.40 m2 | 56 m2 | 22.4 m2 |

| Total roof area (incl. glass) | 72 m2 | 54 m2 | 60 m2 | 60 m2 | 96 m2 |

| Total ground floor area | 72 m2 | 54 m2 | 60 m2 | 60 m2 | 96 m2 |

| Total floor surface area | 114 m2 | 54 m2 | 120 m2 | 120 m2 | 96 m2 |

| Transmissions | |||||

| Rc window | 0.45 m2 K/W | 0.45 m2 K/W | 0.45 m2 K/W | 0.45 m2 K/W | 0.45 m2 K/W |

| Rc facade walls | 1.49 m2 K/W | 1.49 m2 K/W | 1.49 m2 K/W | 1.49 m2 K/W | 1.49 m2 K/W |

| Rc roof | 7.52 m2 K/W | 7.52 m2 K/W | 2.33 m2 K/W | 7.52 m2 K/W | 7.52 m2 K/W |

| Rc floor | 1.52 m2 K/W | 1.22 m2 K/W | 1.83 m2 K/W | 1.52 m2 K/W | 1.22 m2 K/W |

| U-value window | 1.6 W/m2 K | 1.6 W/m2 K | 1.6 W/m2 K | 1.6 W/m2 K | 1.6 W/m2 K |

| U-value facade wall | 0.6 W/m2 K | 0.6 W/m2 K | 0.6 W/m2 K | 0.6 W/m2 K | 0.6 W/m2 K |

| U-value roof | 0.13 W/m2 K | 0.13 W/m2 K | 0.4 W/m2 K | 0.13 W/m2 K | 0.13 W/m2 K |

| U-value floor | 0.59 W/m2 K | 0.72 W/m2 K | 0.5 W/m2 K | 0.59 W/m2 K | 0.72 W/m2 K |

| Infiltration | |||||

| Air Change Hour (ACH) | 0.50/h | 0.50/h | 0.50/h | 0.50/h | 0.50/h |

| Flow rate infiltration | 171 m3/h | 81 m3/h | 81 m3/h | 168 m3/h | 134.4 m3/h |

| Ventilation | |||||

| Heat Recovery Efficiency | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Ventilation Flow Rate per person | 25 m3/h/person | 25 m3/h/person | 25 m3/h/person | 25 m3/h/person | 25 m3/h/person |

| Total Surface of Windows | |||||

| Window area (East) | 20.16 m2 | 5.04 m2 | 6.72 m2 | 16.8 m2 | 6.72 m2 |

| Window area (West) | 6.72 m2 | 1.68 m2 | 2.24 m2 | 5.6 m2 | 2.24 m2 |

| Internal heat gain | |||||

| Heat gain per person | 117 W/person | 117 W/person | 117 W/person | 117 W/person | 117 W/person |

| Light power per square meter | 3 W/m2 | 3 W/m2 | 3 W/m2 | 3 W/m2 | 3 W/m2 |

| Appliances per power per m2 | 3 W/m2 | 3 W/m2 | 3 W/m2 | 3 W/m2 | 3 W/m2 |

| Description | Formula | Values |

|---|---|---|

| Transmission | 2323.7 Wh | |

| Infiltration | 829.9 Wh | |

| Ventilation | 41.2 Wh | |

| Solar Gain | 229.8 Wh | |

| Internal Gain | 1332.0 Wh | |

| Total Heat Demand | 1633.0 Wh |

| Square Meter (m2) | Total Houses | A (Base Case) | B (Light Renovation) | C (Ambitious Renovation) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TABULA | Calculation/Modeling | TABULA | Calculation/Modeling | TABULA | Calculation/Modeling | ||||||||

| Space heating (kWh) | Space heating (kWh) | DHW (kWh) | Electricity (kWh) | Space heating (kWh) | Space heating (kWh) | DHW (kWh) | Electricity (kWh) | Space heating (kWh) | Space heating (kWh) | DHW (kWh) | Electricity (kWh) | ||

| A (144 m2) | 10 | 40,493 kWh | 41,687 kWh | 8490 kWh | 3781 kWh | 15,538 kWh | 13,412 kWh | 8490 kWh | 3781 kWh | 13,810 kWh | 10,642 kWh | 8490 kWh | 3781 kWh |

| B (54 m2) | 3 | 12,312 kWh | 17,791 kWh | 6792 kWh | 1418 kWh | 7479 kWh | 7450 kWh | 6792 kWh | 1418 kWh | 5060 kWh | 4736 kWh | 6792 kWh | 1418 kWh |

| C (120 m2) | 6 | - | 23,557 kWh | 8790 kWh | 3151 kWh | 12,432 kWh | 15,052 kWh | 8490 kWh | 3151 kWh | 9948 kWh | 6792 kWh | 8490 kWh | 3151 kWh |

| D (120 m2) | 3 | 24,941 kWh | 29,609 kWh | 6792 kWh | 3150 kWh | 13,740 kWh | 12,596 kWh | 6792 kWh | 2521 kWh | 11,280 kWh | 9275 kWh | 6792 kWh | 3150 kWh |

| E (96 m2) | 3 | 24,941 kWh | 35,261 kWh | 5094 kWh | 2521 kWh | 9888 kWh | 10,572 kWh | 5094 kWh | 2521 kWh | 8832 kWh | 8954 kWh | 5094 kWh | 2521 kWh |

| Annual Energy Demand for One Block (25 Houses) | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|

| Space heating demand | 806.19 MWh | 316.28 MWh | 214.25 MWh |

| Domestic hot water demand | 191.88 MWh | 191.88 MWh | 191.88 MWh |

| Electricity demand | 77.98 MWh | 77.98 MWh | 77.98 MWh |

| Total energy demand | 1075.05 MWh | 586.14 MWh | 484.11 MWh |

| Energy Consumption | Unit | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|---|

| Space heating demand | MWh | 806.19 | 316.28 | 214.25 |

| Efficiency (40–60 °C) of boiler | % | 95 | 95 | 95 |

| Energy consumption for boiler | MWh | 848.82 | 332.93 | 225.53 |

| Efficiency of grid transmission | % | 95 | 95 | 95 |

| Total natural gas for space heating | MWh | 893.29 | 350.45 | 237.40 |

| Domestic Hot Water (DHW) demand | MWh | 191.88 | 191.88 | 191.88 |

| Efficiency (≥60 °C) of boiler n | % | 85 | 85 | 85 |

| Energy consumption for boiler | MWh | 225.74 | 225.74 | 225.74 |

| Efficiency grid transmission | % | 95 | 95 | 95 |

| Total natural gas for DHW | MWh | 237.62 | 237.62 | 237.62 |

| Electricity demand for appliances | MWh | 77.98 | 77.98 | 77.98 |

| Efficiency of local grid transmission | % | 95 | 95 | 95 |

| Energy consumption for grid transmission | MWh | 82.08 | 82.08 | 82.08 |

| Efficiency of DC/AC conversion | % | 95 | 95 | 95 |

| Total electricity (PV rooftop) for appliances | MWh | 86.40 | 86.40 | 86.40 |

| Total natural gas consumption (space heating + DHW) | MWh MWh | 893.29 +237.62 1130.91 | 350.45 + 237.62 588.07 | 237.40 + 237.62 475.02 |

| Energy Consumption | Unit | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|---|

| Space heating demand | MWh | - | 316.28 | 214.25 |

| Efficiency (40–60 °C) of heat pump | % | - | 430 | 430 |

| Energy consumption for heat pump | MWh | - | 73.55 | 49.83 |

| Efficiency of grid transmission | % | - | 95 | 95 |

| Total natural gas for space heating | MWh | - | 77.42 | 52.45 |

| Domestic Hot Water (DHW) demand | MWh | - | 191.88 | 191.88 |

| Efficiency (≥60 °C) of heat pump | % | - | 350 | 350 |

| Energy consumption for heat pump | MWh | - | 54.82 | 54.82 |

| Efficiency grid transmission | % | - | 95 | 95 |

| Total natural gas for DHW | MWh | - | 57.70 | 57.70 |

| Electricity demand for appliances | MWh | - | 77.98 | 77.98 |

| Efficiency of DC/AC conversion | % | - | 95 | 95 |

| Energy consumption for grid transmission | MWh | - | 82.08 | 82.08 |

| Efficiency of local grid transmission | % | - | 95 | 95 |

| Total electricity (PV rooftop) for appliances | MWh | - | 86.40 | 86.40 |

| Total electricity (PV central) for heating | MWh MWh | - - | 77.42 + 57.70 135.134 | 52.45 + 57.70 110.157 |

| Energy Consumption | Unit | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|---|

| Space heating demand | MWh | 806.19 | 316.28 | 214.25 |

| Efficiency (40–60 °C) of boiler | % | 95 | 430 | 430 |

| Energy consumption for boiler | MWh | 848.62 | 73.55 | 49.83 |

| Efficiency of grid transmission | % | 95 | 95 | 95 |

| Heating demand for 70% natural gas | MWh | 594.03 | 233.05 | 157.86 |

| Efficiency of grid transmission | % | 95 | 95 | 95 |

| Total natural gas for space heating | MWh | 625.30 | 245.32 | 166.17 |

| Heating demand for 30% hydrogen | MWh | 254.59 | 99.88 | 67.66 |

| Efficiency of Hydrogen storage | % | 99 | 99 | 99 |

| Energy consumption for hydrogen storage | MWh | 257.15 | 100.89 | 68.34 |

| Efficiency of (electrolyser + compressor) ** | % | 70 | 70 | 70 |

| Energy consumption (electrolyser + compressor) | MWh | 367.37 | 144.12 | 97.63 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV Central to produce hydrogen (DHW) | MWh | 386.70 | 151.71 | 102.867 |

| Domestic Hot Water (DHW) demand | MWh | 191.88 | 191.88 | 191.88 |

| Efficiency (≥60 °C) of boiler | % | 85 | 350 | 350 |

| Energy consumption for boiler | MWh | 225.742 | 54.82 | 54.82 |

| 70% natural gas consumption | MWh | 158.02 | 158.02 | 158.02 |

| Efficiency of grid transmission | % | 95 | 95 | 95 |

| Total natural gas for DHW | MWh | 166.336 | 166.336 | 166.336 |

| 30% hydrogen | MWh | 67.72 | 67.72 | 67.72 |

| Efficiency of hydrogen storage | % | 99 | 99 | 99 |

| Energy consumption for hydrogen storage | MWh | 68.4 | 68.4 | 68.4 |

| Efficiency of (electrolyser + compressor) ** | % | 70 | 70 | 70 |

| Energy of (electrolyser + compressor) | MWh | 97.72 | 97.72 | 97.72 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV central to produce hydrogen (for DHW) | MWh | 102.867 | 102.867 | 102.867 |

| Electricity demand for appliances | MWh | 77.98 | 77.98 | 77.98 |

| Efficiency of local grid transmission | % | 95 | 95 | 95 |

| Energy consumption for grid transmission | MWh | 82.08 | 82.08 | 82.08 |

| Efficiency of DC/AC conversion | % | 95 | 95 | 95 |

| Total electricity (PV rooftop) for appliances | MWh | 86.40 | 86.40 | 86.40 |

| Total natural gas consumption (space heating + DHW) | MWh | 625.30 + 166.34 791.64 | 245.32 + 166.34 411.66 | 166.17 + 166.34 332.51 |

| Total Electricity (PV Central) for hydrogen production | MWh MWh | 386.70 + 102.87 489.57 | 151.71+102.87 254.58 | 102.77 + 102.87 205.64 |

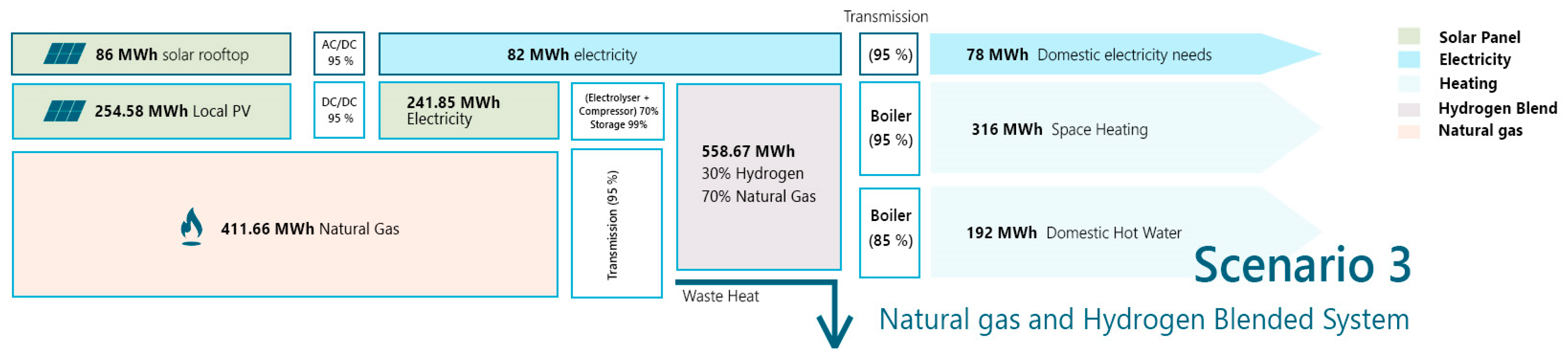

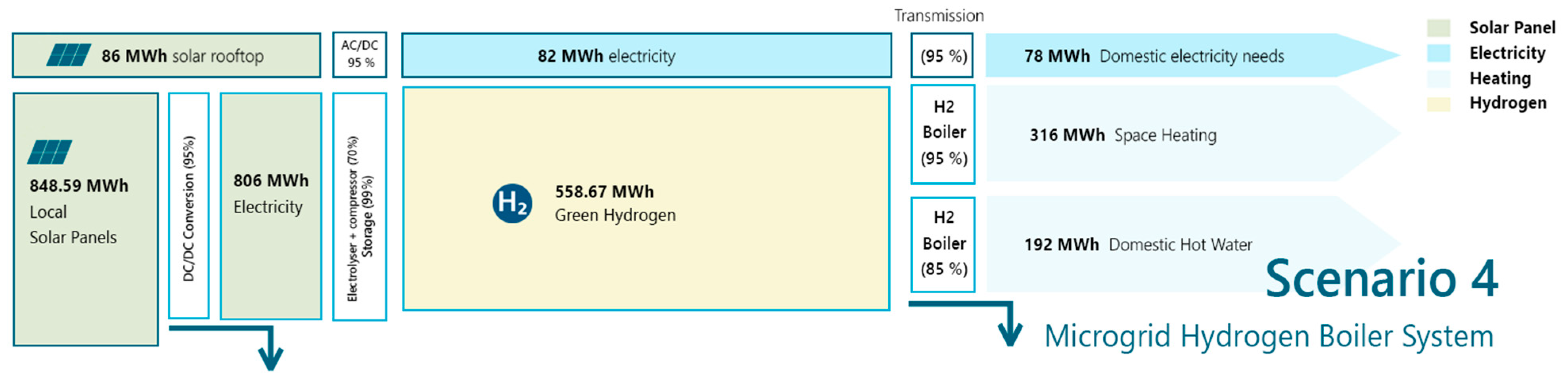

| Energy Consumption | Unit | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|---|

| Space heating demand | MWh | 806.19 | 316.28 | 214.25 |

| Efficiency (40–60 °C) of hydrogen boiler | % | 95 | 95 | 95 |

| Energy consumption for hydrogen boiler | MWh | 848.82 | 332.93 | 225.53 |

| Efficiency of hydrogen storage | % | 99 | 99 | 99 |

| Energy consumption of hydrogen storage | MWh | 857.39 | 336.29 | 227.80 |

| Efficiency of electrolyser + compressor | % | 70 | 70 | 350 |

| Energy consumption electrolyser + compressor | MWh | 1224.84 | 480.42 | 325.43 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV central to produce hydrogen (for space heating) | MWh | 1289 | 505.70 | 342.56 |

| Domestic Hot Water (DHW) demand | MWh | 191.88 | 191.88 | 191.88 |

| Efficiency (≥60 °C) of hydrogen boiler | % | 85 | 85 | 85 |

| Energy consumption for hydrogen boiler | MWh | 225.74 | 225.74 | 225.74 |

| Efficiency of hydrogen storage | % | 99 | 99 | 99 |

| Hydrogen storage consumption | MWh | 228.02 | 228.02 | 228.02 |

| Efficiency of electrolyser + compressor | % | 70 | 70 | 70 |

| Energy consumption electrolyser + compressor | MWh | 325.74 | 325.74 | 325.74 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV central to produce hydrogen (for DHW) | MWh | 342.89 | 342.89 | 342.89 |

| Electricity demand for appliances | MWh | 77.98 | 77.98 | 77.98 |

| Efficiency of local grid transmission | % | 95 | 95 | 95 |

| Energy consumption for grid transmission | MWh | 82.08 | 82.08 | 82.08 |

| Efficiency of DC/AC conversion | % | 95 | 95 | 95 |

| Total electricity (PV rooftop) for appliances | MWh | 86.40 | 86.40 | 86.40 |

| Total electricity (PV central) for hydrogen production | MWh MWh | 1289 + 342.89 1631.89 | 505.69 + 342.89 848.59 | 342.56 + 342.89 685.45 |

| Energy Consumption | Unit | Base Case | Light Renov | Ambitious Renov |

|---|---|---|---|---|

| Space heating demand | MWh | 806.19 | 316.28 | 214.25 |

| Efficiency (40–60 °C) of fuel cell | % | 37 | 37 | 37 |

| Energy consumption for fuel cell | MWh | 2178.90 | 854.82 | 579.06 |

| Efficiency of hydrogen storage | % | 99 | 99 | 99 |

| Energy consumption of hydrogen storage | MWh | 2200 | 863.45 | 548.91 |

| Efficiency of electrolyser + compressor | % | 70 | 70 | 70 |

| Energy consumption electrolyser + compressor | MWh | 3144 | 1233 | 835.58 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV central to produce hydrogen (for space heating) | MWh | 3309 | 1298 | 879.6 |

| Domestic Hot Water (DHW) demand | MWh | 191.88 | 191.88 | 191.88 |

| Efficiency (≥60 °C) of fuel cell | % | 37 | 37 | 37 |

| Energy consumption for fuel cell | MWh | 518.6 | 518.6 | 518.6 |

| Efficiency of hydrogen storage | % | 99 | 99 | 99 |

| Hydrogen storage consumption | MWh | 523.83 | 523.83 | 523.83 |

| Efficiency of electrolyser + compressor | % | 70 | 70 | 70 |

| Energy consumption electrolyser + compressor | MWh | 748.34 | 748.34 | 748.34 |

| Efficiency of DC/DC conversion | % | 95 | 95 | 95 |

| PV central to produce hydrogen (for DHW) | MWh | 787.72 | 787.72 | 787.32 |

| Electricity generated by fuel cell (Space Heating) | MWh | 2015.47 | 790.7 | 535.625 |

| Efficiency of Fuel cell (electricity) | % | 57 | 57 | 57 |

| Electricity surplus by fuel cell | MWh | 114.82 | 114.82 | 114.82 |

| Electricity generated by fuel cell (DHW) | MWh | 518.6 | 518.6 | 518.6 |

| Efficiency of Fuel cell (electricity) | % | 57 | 57 | 57 |

| Electricity surplus by fuel cell | MWh | 295.60 | 295.60 | 295.60 |

| Electricity demand for appliances | MWh | 77.98 | 77.98 | 77.98 |

| Efficiency of local grid transmission | % | 95 | 95 | 95 |

| Energy consumption for grid transmission | MWh | 82.08 | 82.08 | 82.08 |

| Total electricity surplus (deviation) | MWh | 1361.5 (+) | 664.22 (+) | 518.82 (+) |

| Total electricity (PV central) for hydrogen production | MWh MWh | 3309 + 787.72 4097.36 | 1298 + 787.72 2085.72 | 879.6 + 787.72 1667.32 |

| No. | Parameters | 1 | 2 | 3 | |||

|---|---|---|---|---|---|---|---|

| Bare Minimum | Remark | Average | Remark | Limit Max | Remark | ||

| A | Temperature | <9.84 °C | A1 | 9.84 °C (to 18 °C) | A2 | 18 °C | A3 |

| B | Solar Radiation | 0 W/m2 | B1 | 750 W/m2 | B2 | >750 W/m2 | B3 |

| C | Heat Load hour (25 household) | <48.9 kWh | C1 | 48.9 kWh (to 98.99 kWh) | C2 | >98.99 kWh (Max amount in data) | C3 |

| No. | Heating with Hydrogen source | Heating by Heat Pump | Heating turn off | ||||

| 1. | A1 | A2 | A3 | ||||

| 2. | B1, B2 | B1, B2 | B3 | ||||

| 3. | C2, C3 | C1 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurniawati, H.; Broersma, S.; Itard, L.; Mohammadi, S. Integrated Hydrogen in Buildings: Energy Performance Comparisons of Green Hydrogen Solutions in the Built Environment. Buildings 2025, 15, 3232. https://doi.org/10.3390/buildings15173232

Kurniawati H, Broersma S, Itard L, Mohammadi S. Integrated Hydrogen in Buildings: Energy Performance Comparisons of Green Hydrogen Solutions in the Built Environment. Buildings. 2025; 15(17):3232. https://doi.org/10.3390/buildings15173232

Chicago/Turabian StyleKurniawati, Hamida, Siebe Broersma, Laure Itard, and Saleh Mohammadi. 2025. "Integrated Hydrogen in Buildings: Energy Performance Comparisons of Green Hydrogen Solutions in the Built Environment" Buildings 15, no. 17: 3232. https://doi.org/10.3390/buildings15173232

APA StyleKurniawati, H., Broersma, S., Itard, L., & Mohammadi, S. (2025). Integrated Hydrogen in Buildings: Energy Performance Comparisons of Green Hydrogen Solutions in the Built Environment. Buildings, 15(17), 3232. https://doi.org/10.3390/buildings15173232