1. Introduction

Cast-in-place anchors function as anchorage systems widely utilized in both structural and non-structural components of civil engineering projects to transfer external loads to concrete elements—for example, securing steel structures to concrete foundations or facilitating load transfer in concrete column–beam connections. Headed anchors are a type of cast-in-place anchor with a specific geometry that can act as suitable alternatives to hook anchors in order to decrease steel crowding in specially designed sections [

1,

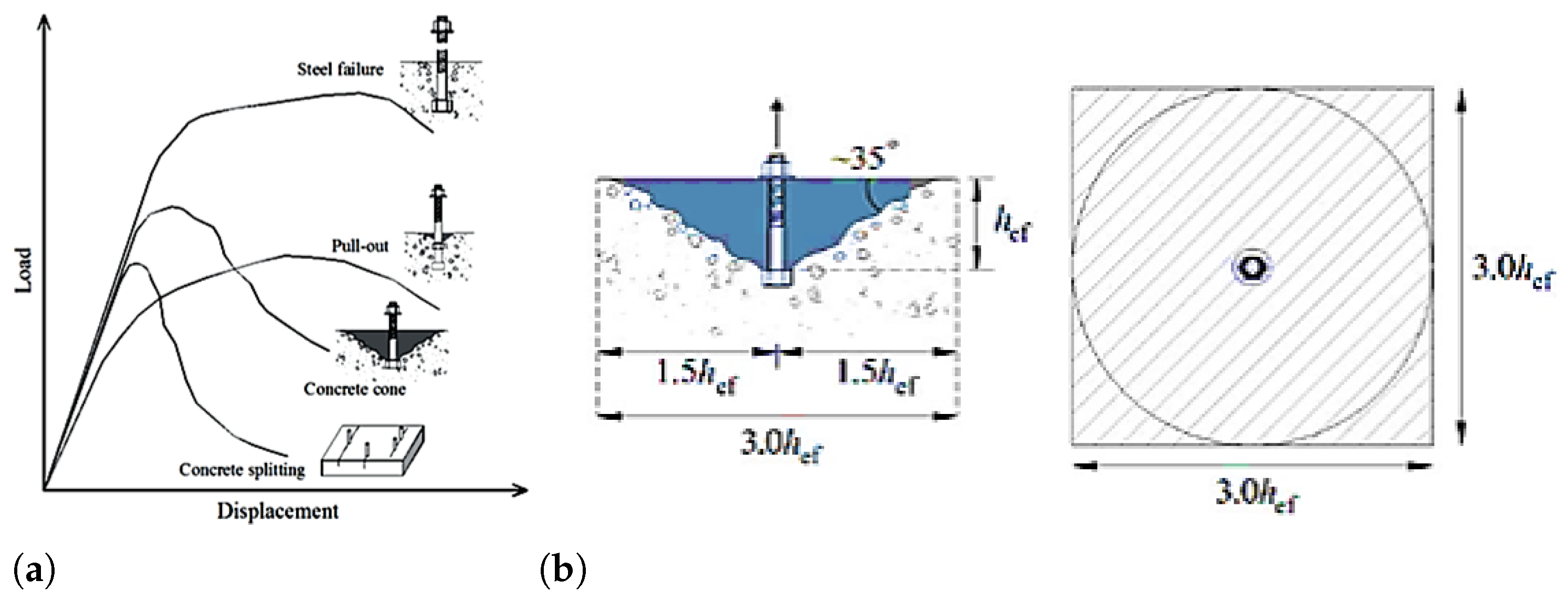

2]. Previous theoretical and experimental studies have demonstrated that when a single cast-in-place headed anchor experiences tensile loads, it exhibits two types of failure behavior: ductile and brittle failure modes, as depicted in

Figure 1a. In the load–displacement curves, both steel failure and pullout display the greatest displacement under peak loading, reflecting behavior typical of ductile failure. In cases of steel failure, the strength of a headed anchor is primarily governed by the cross-sectional area of the anchor head and the mechanical properties of the steel. Additionally, pullout failure depends on the embedment depth and cross-section. Brittle failure is observed in cases of concrete cone and concrete splitting. These failure modes demonstrate rapid declines at peak load due to the rapid and unstable propagation of concrete cracks. Cracking in the anchoring zone results from brittle failure, which arises directly from mobilizing the maximum tensile strength of the concrete. In general conditions, one of the parameters to achieve the required yield strength of concrete elements is ensuring an effective development length.

Under ideal conditions, a cast-in-place headed anchor subjected to tensile loading is expected to undergo maximum deformation at peak load at the point of failure. However, initially, the anchor should fail before the concrete loses its serviceability [

3,

4]. In recent decades, numerous experimental and numerical investigations have been conducted to develop accurate models for estimating the anchorage strength and identifying the failure modes of anchor bolts embedded in concrete structural elements. However, two main reference principles have been assumed for predicting and calculating the failure mechanism mode and strength of headed anchors. The first theoretical model, the concrete cone model, assumes a projected circular area and an inclination of 45-degree angle to the concrete surface, which was mentioned in ACI 349 [

5]. The second model, known as the Concrete Capacity Design (CCD) approach, was proposed [

3] to evaluate the tensile load-carrying capacity related to concrete cone fracture. The CCD method considers the formation of a concrete failure cone inclined at 35 degrees relative to the surface. This idealized failure region spans an approximate area of

across the concrete face, as illustrated in

Figure 1b.

Figure 1.

Response of tension-loaded headed anchors and idealized projected area in CCD method. (

a) Pullout response of anchors [

6]. (

b) Concrete cone area in CCD method [

3].

Figure 1.

Response of tension-loaded headed anchors and idealized projected area in CCD method. (

a) Pullout response of anchors [

6]. (

b) Concrete cone area in CCD method [

3].

To determine the nominal strength associated with the concrete cone failure of a cast-in-place single anchor subjected to tensile loading, the CCD method provides a predictive framework based on geometric and material parameters, as shown in Equation (

1).

In this context,

represents the mean nominal concrete cone strength factor, used to estimate the average breakout capacity of a headed anchor embedded in intact concrete, with a value of 16.8. The term

denotes the effective anchorage depth of the anchor, measured in millimeters. According to ACI 318-19 [

7], the coefficient k used in calculating the ultimate tensile strength of a cast-in-place single anchor is 10, whereas for a post-installed anchor, it is 7. Considering the shallow (

mm) and deep anchorage depths of the anchor, which are determined by the relationship between anchorage depth and the distance to the nearest concrete surface, tests have shown that the shallow anchorage depth is characterized by cone failure, while the deep anchorage depth is associated with side blow-out failure [

8]. According to Eligehausen et al. [

6], an increase in anchorage depth leads to a steeper crack inclination within the failure cone. Moreover, the anchorage capacity of a headed anchor is enhanced when the surrounding concrete section is confined by parallel reinforcement. In contrast, longitudinal reinforcement has been shown to have no significant impact on anchorage capacity [

9]. Observations regarding the effects of anchor head size and member thickness indicate that the ultimate tensile strength of the concrete cone increases with larger anchor head dimensions and greater concrete member thickness [

4]. The CCD method has been observed to yield non-conservative predictions of tensile breakout capacity for short-headed anchors (

mm). Conversely, for deep anchors (

mm), it provides overly conservative estimates [

4]. Investigations into the effects of concrete compressive strength and anchor anchorage depth within the CCD framework have further revealed that seismic tensile strength is lower than the nominal values prescribed by current design codes. As a result, the revised

k-value has been proposed to improve the accuracy of seismic strength predictions [

10]. Finally, the anchorage strength provisions for headed anchors outlined in Chapter 17 of ACI 318-14 [

11] were found to be excessively conservative, so new provisions were recommended and proposed for ACI 318-19 [

7,

12,

13,

14,

15].

Recent investigations have confirmed the predictive accuracy of the CCD method in estimating the ultimate tensile capacity of cast-in-place anchors embedded in plain concrete, thereby reinforcing its validity for design applications. The primary contribution of this study is the development of a pullout model for cast-in-place headed anchors, grounded in the CCD methodology, to evaluate the ultimate tensile strength of anchor bolts embedded in plain concrete. The accuracy of the proposed model is critically examined, and its applicability is assessed through a series of tensile pullout analyses. Three parameters, namely the compressive strength of concrete, embedded depth, and the yield stress of steel, have been selected as key factors to measure the tensile anchorage strength.

Section 1 outlines the key parameters affecting the anchorage behavior of headed anchors.

Section 2 details the validation process of both the experimental pullout tests and the numerical model. In

Section 3, the pullout behavior of cast-in-place headed anchors is examined, including the evaluation of ultimate anchor strength and the prediction of effective anchorage depth. Finally,

Section 4 provides a summary of the key findings derived from the study.

3. Parametric Study

Accurately defining the true load-carrying capacity and ensuring adequate ductility of a cast-in-place headed anchor under tensile loading are critical for achieving optimal structural performance. Additionally, the ACI 318-19 [

7] standard mentioned regulations to control the effective length and ultimate strength of anchorage, as well as the necessary protocols during implementation. The loading protocol adopted in this study was executed in phases using a monotonic displacement-controlled approach, continuing up to the point of failure displacement. This displacement-control approach was based on a motion set in the

z-direction in LS-DYNA. The parameters considered in this study for the analysis are presented in

Table 2,

Table 3 and

Table 4, consisting of various anchor diameters (

, compressive concrete strength for the plain slab

, embedded depth

, and the yield strength of the steel

. The interior and exterior diameter of the ring support

depend on the embedded depth of each model. The height of the plain slab

was chosen to be twice the embedded depth. Additionally, the nominal strength, calculated using Equation (

1), is reported to support subsequent discussions. Cross-sectional dimensions of the headed anchor, as selected by chapter 25 of ACI 318-19 [

7], states that it should be four times the anchor diameter.

3.1. Strength Measure

The concrete cone strength calculated using the ACI method

, the concrete cone strength from the CCD method

, the

-factor which resulted from the numerical analysis, and the LS-DYNA results

are presented in

Table 5,

Table 6 and

Table 7. Additionally,

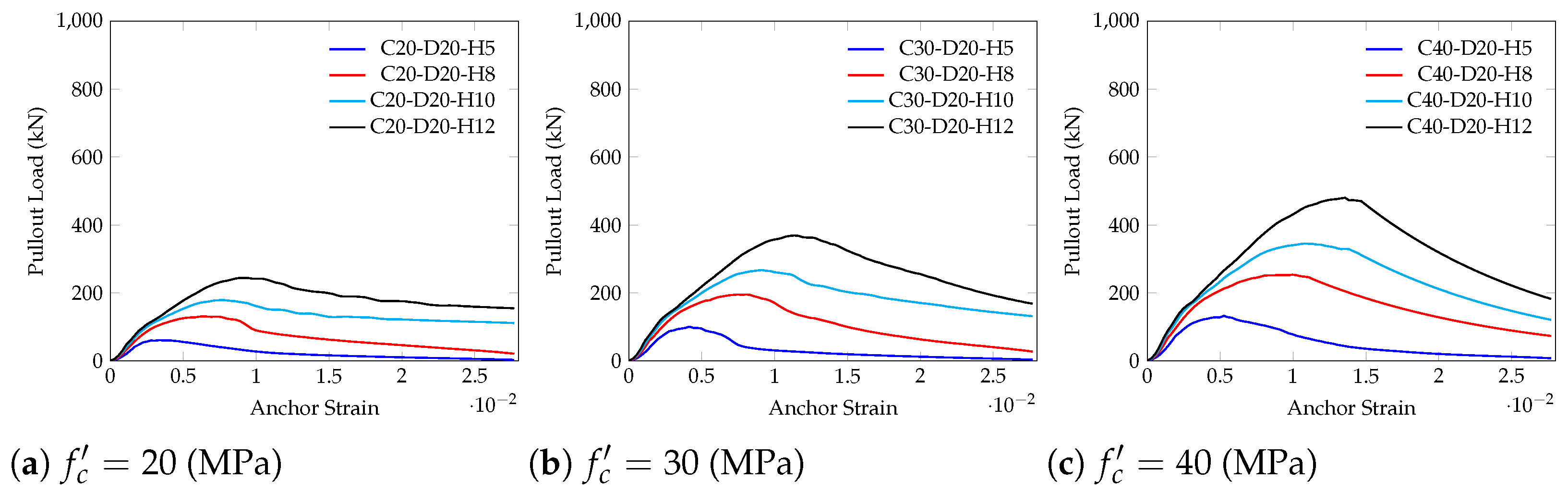

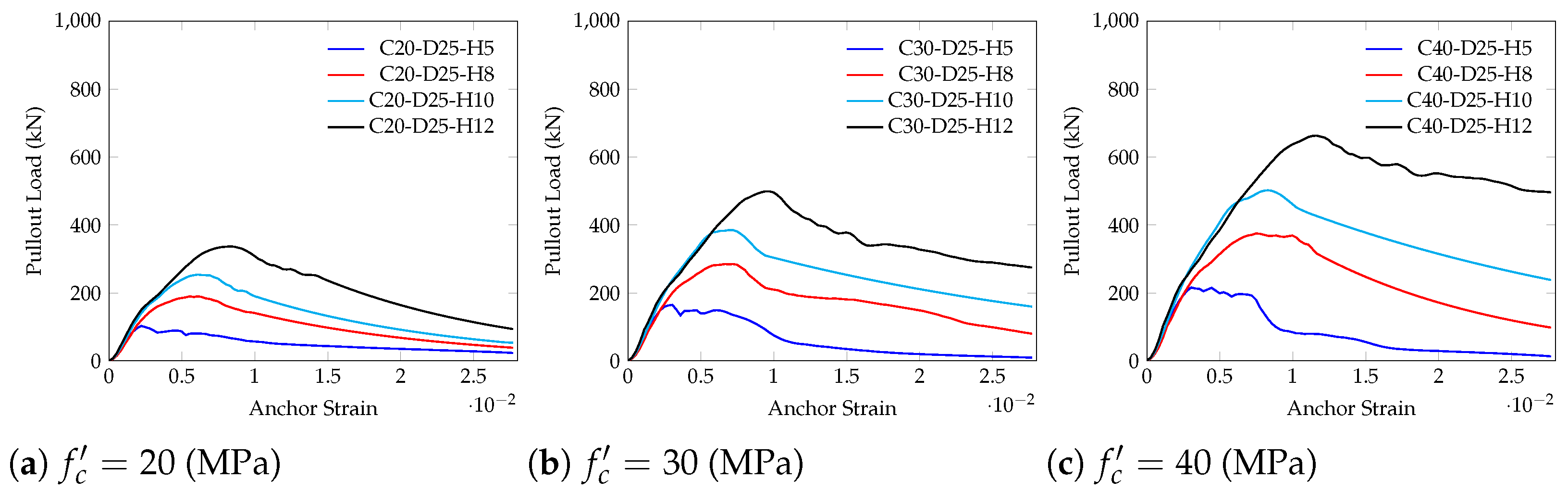

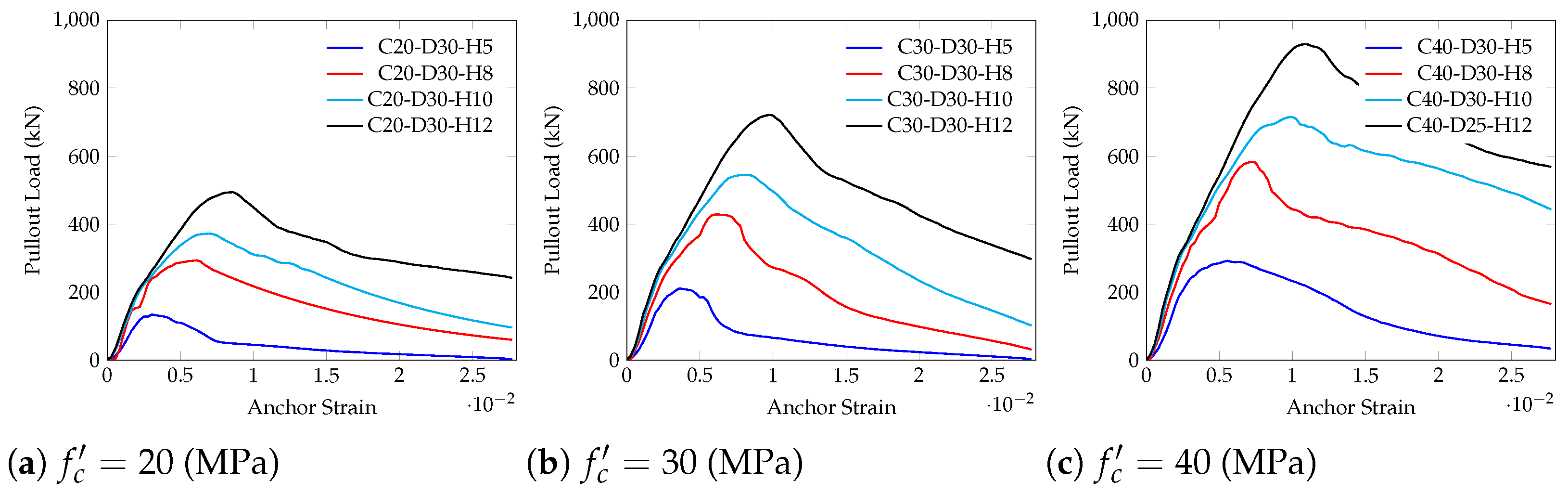

Figure 6,

Figure 7 and

Figure 8 illustrate the strength versus displacement curves from the pullout analyses conducted within the defined parametric space.

Upon reviewing the observations, the Concrete Capacity Design (CCD) method (Equation (

1)) underestimates the concrete breakout capacity of anchor bolts embedded in plain concrete slabs with compressive strengths of 35 MPa and 45 MPa, while it overestimates the capacity for the concrete slab with a compressive strength of 20 MPa. According to the results for headed anchors, which demonstrate both overestimation and underestimation, there is no consistent trend observed in comparison to the CCD (Concrete Capacity Design) method. For headed anchor bolts embedded in plain concrete slabs with low embedment depth, a trend was shown where the pullout strength increased significantly as the embedment depth decreased in concrete slabs with 30 MPa and 40 MPa concrete strength. Remarkably, the anchor bolts with a size of 30 mm exhibited the most substantial difference. Actually, the manner of change and accuracy of convergence varied for each anchor size, according to the assumed parameters. Based on three different concrete compressive strength values, namely 20 MPa, 30 MPa, and 40 MPa, an average value of the

-factor is proposed for practical use, with

,

, and

, respectively.

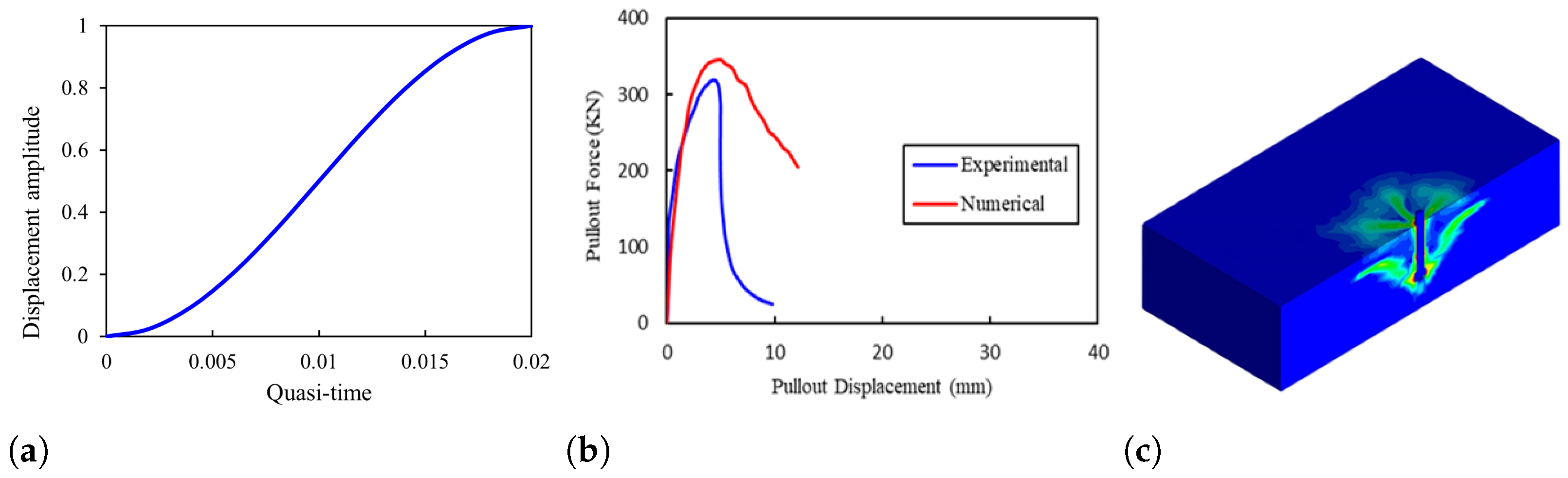

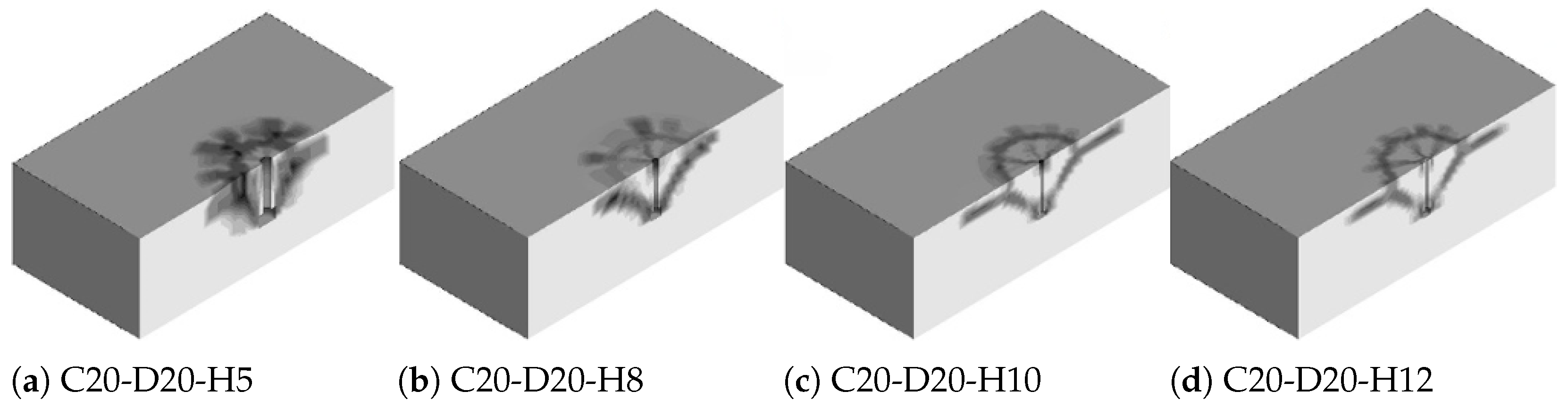

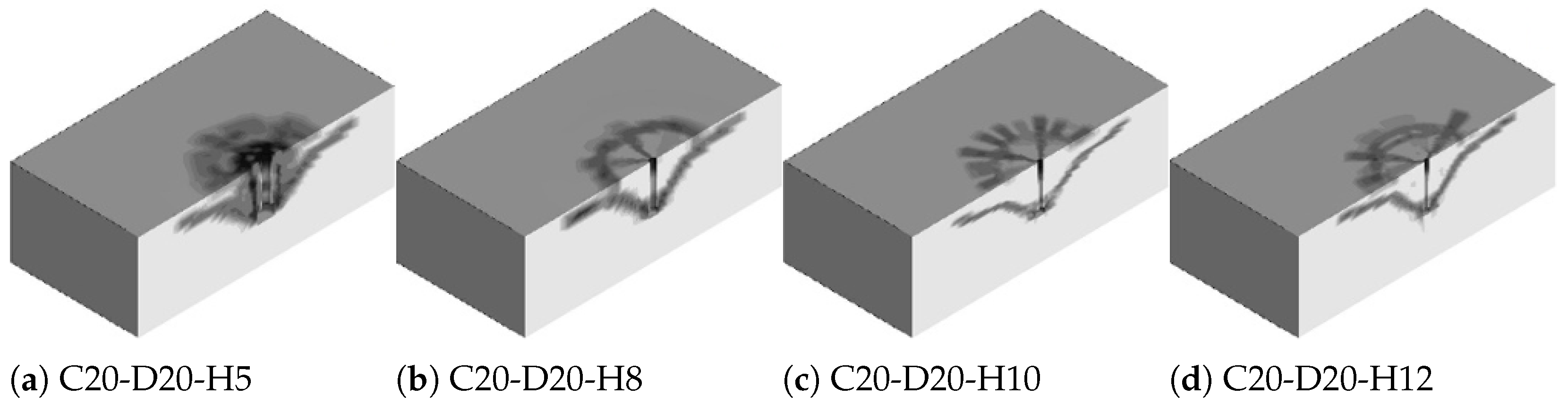

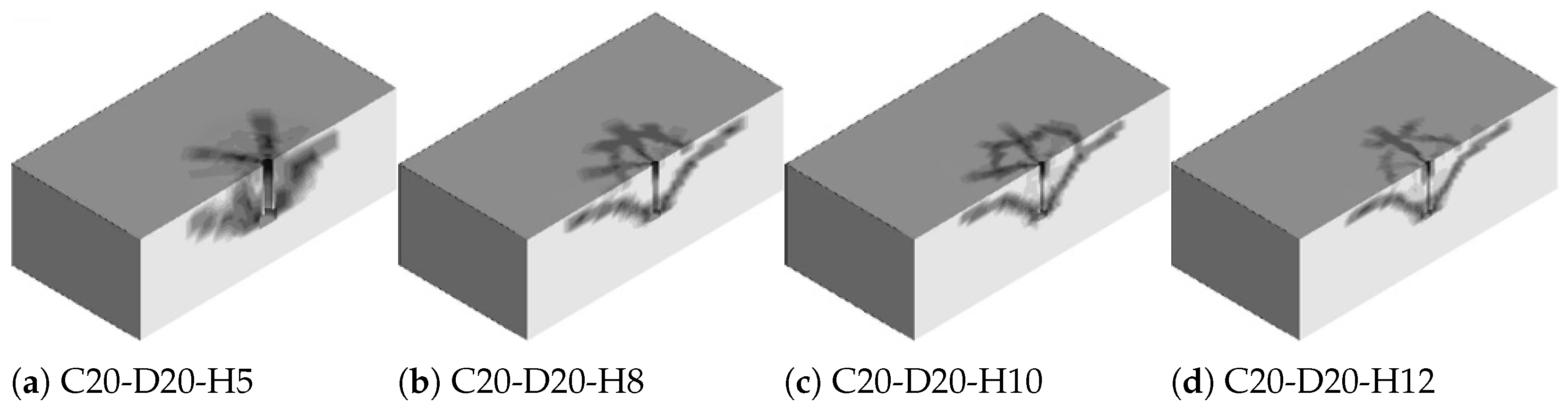

3.2. Crack Patterns

The cracking patterns observed in the modeled cast-in-place anchor bolts embedded within plain concrete slabs are illustrated in

Figure 9,

Figure 10 and

Figure 11. According to the observations, the cracking process initiates at the anchor head region and subsequently progresses toward the concrete surface at an inclination angle of

–

. The failure rate of the concrete and the associated failure pattern, as the effective depth increases, were effectively controlled, and a ductile behavior was noted. Furthermore, the observed failure pattern correlates with the pattern derived from the CCD method.

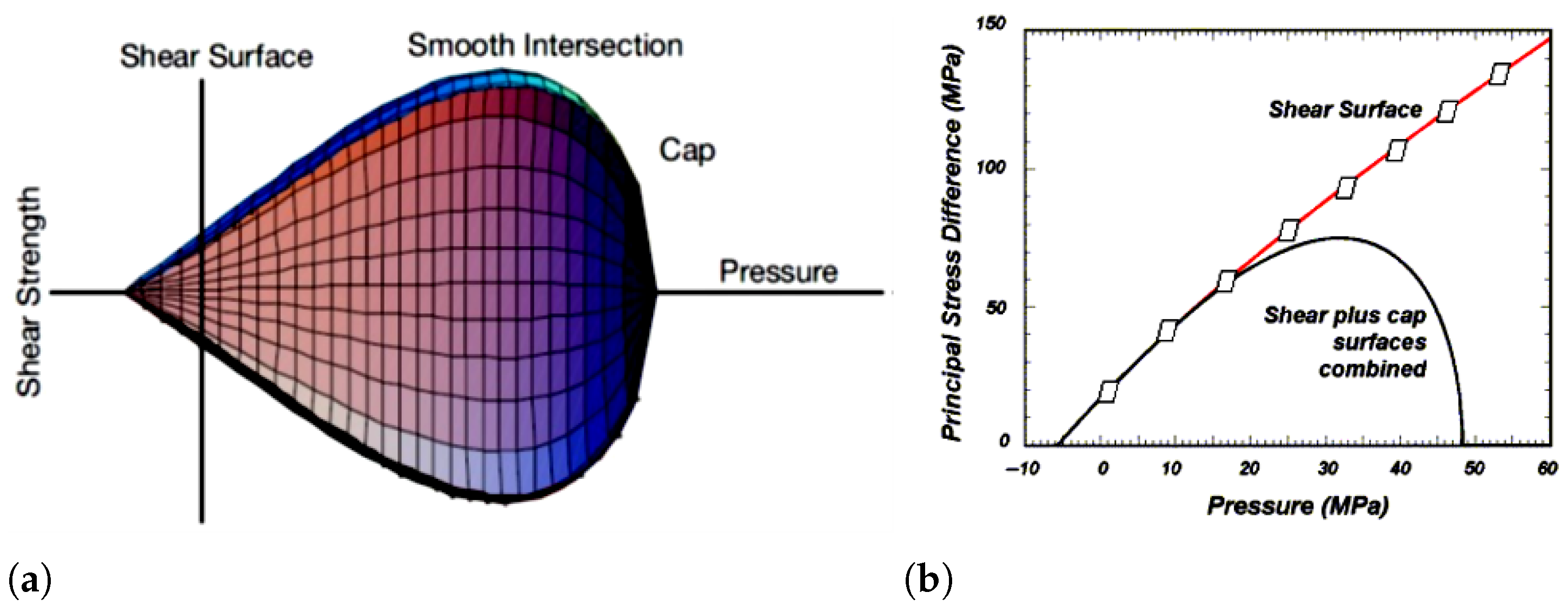

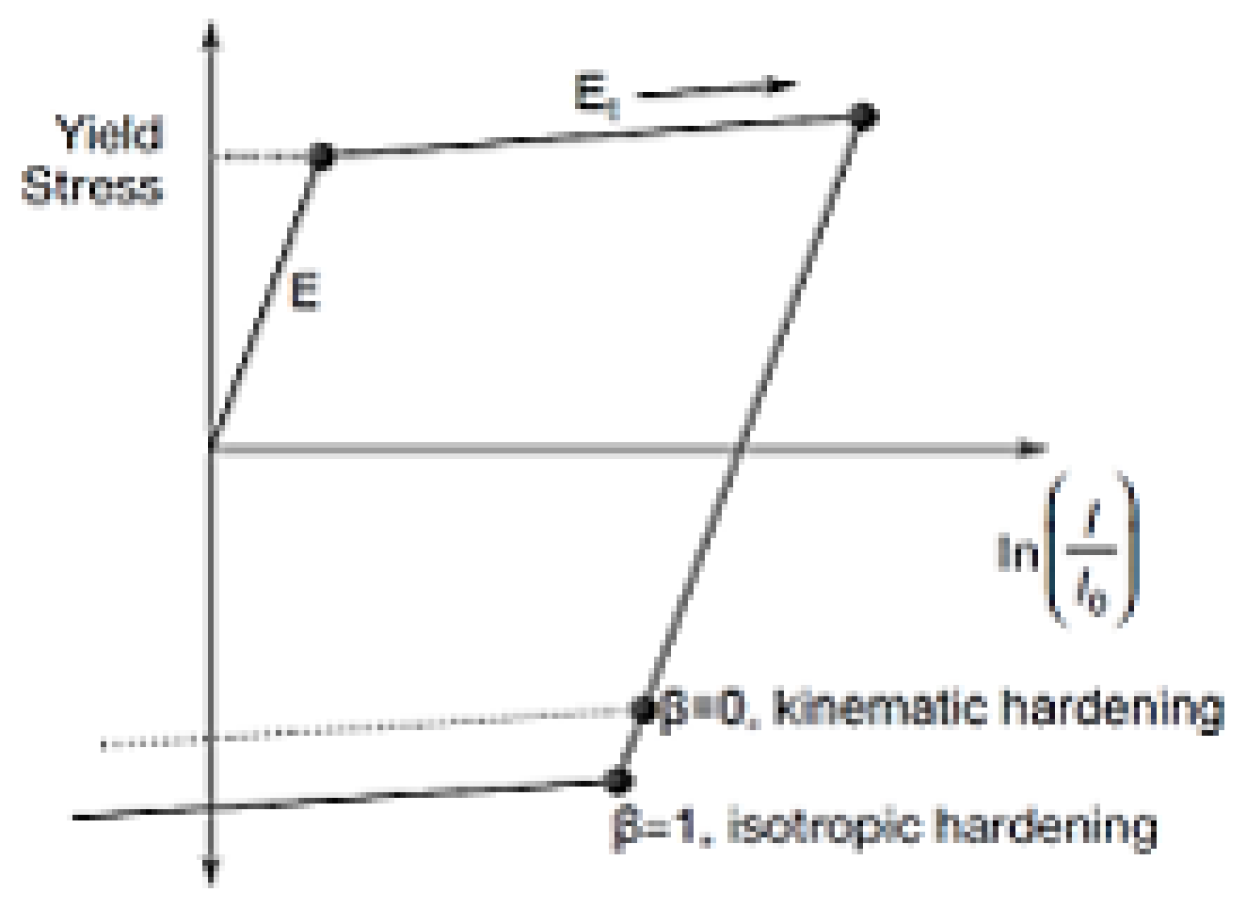

Based on observations, initially the damage initiates directly around the head of the anchor. Stress concentrations due to tensile forces cause local crushing and micro-cracking in the surrounding concrete. The cap plasticity model captures the onset of damage where compressive and tensile failure mechanisms interact at the anchor–concrete interface. Furthermore, as tensile load increases, cracks begin to propagate radially from the anchor head toward the concrete surface, forming the early shape of a breakout cone. The radial pattern indicates the formation of tensile cracks driven by the anchor’s uplift force. The cap yield surface adapts to the evolving stress state, simulating the coalescence of multiple cracks under mixed-mode failure. The breakout cone is now fully developed, characterized by a wide radial crack pattern reaching the free surface. The damage zone is distributed along a conical surface typical of concrete breakout failures. The propagation follows a roughly – angle from the anchor axis, consistent with empirical observations and analytical models like CCD.

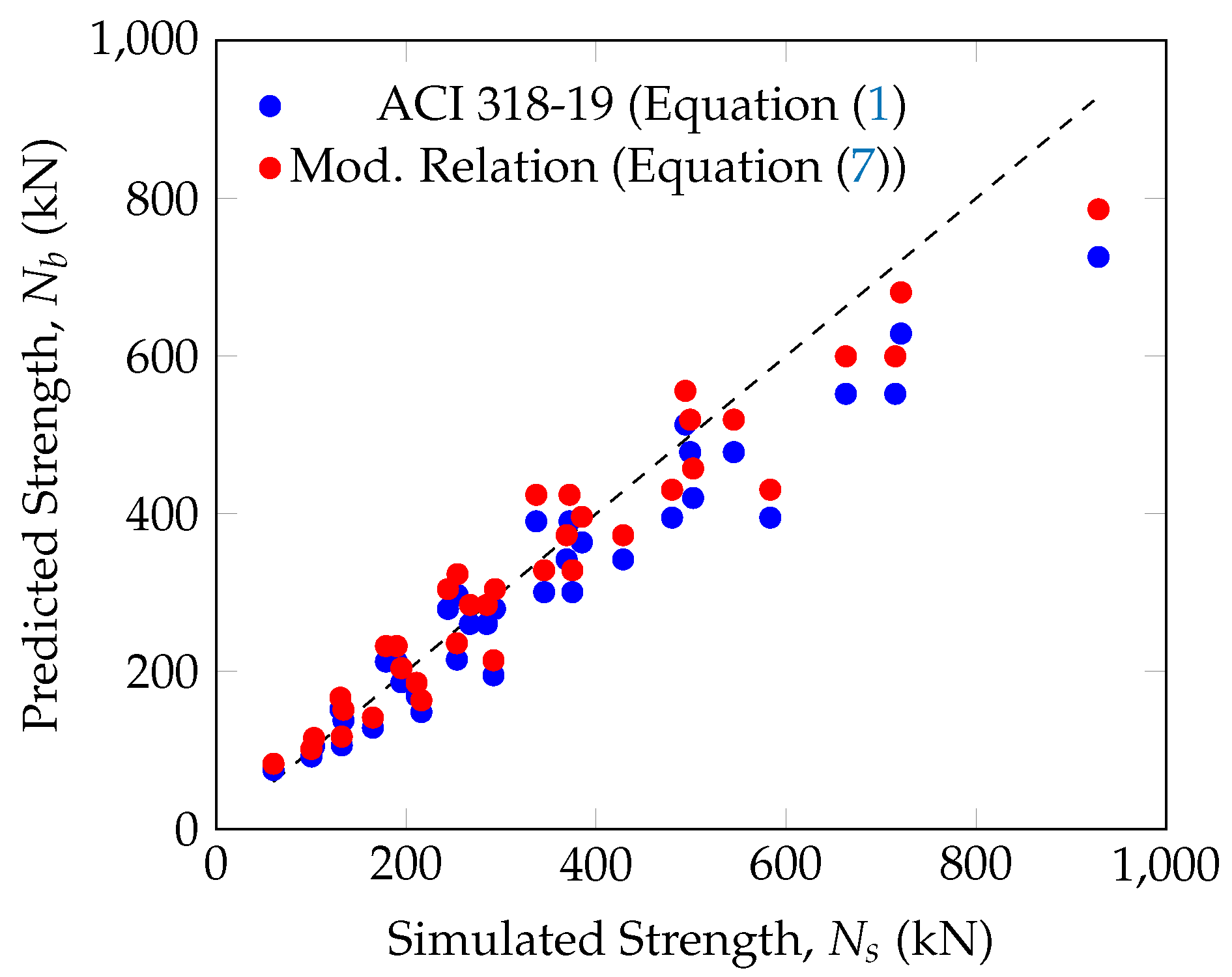

3.3. Modified Strength Prediction

Based on the obtained numerical results, a modified pullout strength prediction,

, is presented as Equation (

7) according to logarithmic nonlinear regression and is compared with ACI 318-19 [

7]

as

Figure 12. Regarding the trend of modified pullout strength

, its scatter with respect to simulated strength

is significantly lower than the code-based strength. The

initially shows greater convergence with the CCD method up to an anchorage depth. However, for deeper anchorage depths, the modified strength trend becomes upward.

Additionally, the smallest disparity between the results obtained from the Concrete Capacity Design (CCD) method and the LS-DYNA results is observed when the

and the concrete compressive strength is 30 MPa. In the case of cast-in-place headed anchors with large size and concrete slabs with low strength (anchor size of 30 mm and

MPa) under tensile loads, both overestimation and underestimation situations prevail, which needs review and more experimental studies for determine the final anchorage strength capacity. However, the headed anchor size of 25 mm with a concrete compressive strength of 30 MPa has the highest convergence to all assumed modes. The results confirm a notable loss and gain in strength, so in this way, modified strength prediction according to Equation (

7) is recommended in design codes governing the tensile capacity of cast-in-place headed anchor bolts.