Research Progress on CO2 Transcritical Cycle Technology for Building Heating and Cooling Applications

Abstract

1. Introduction

2. CO2 Refrigerant

3. CO2 Transcritical Heat Pump Cycle System

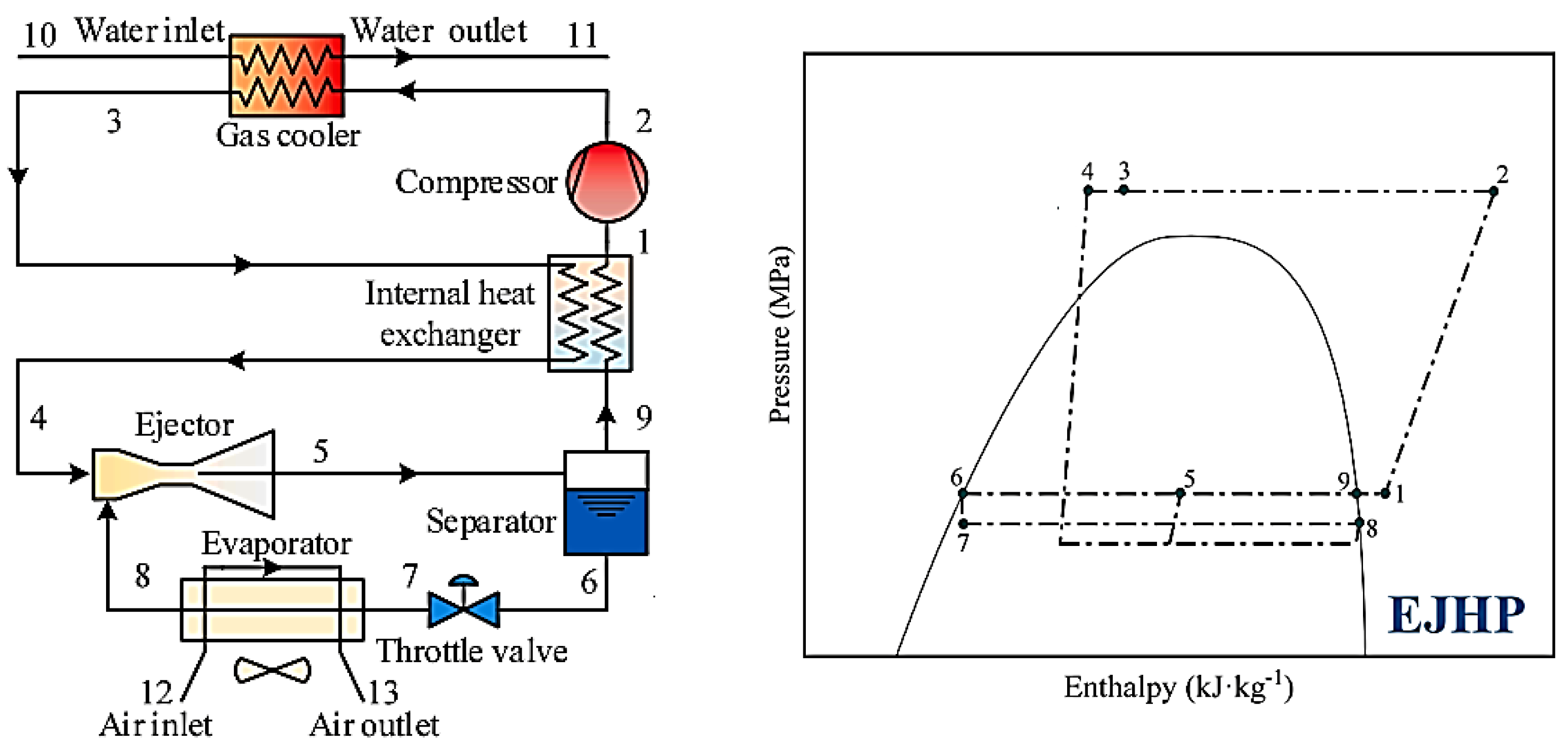

3.1. Heating-Focused Optimization

3.2. Cooling-Focused Optimization

3.3. Cross-Cutting Innovations

4. Research Status of CO2 Transcritical Cycle System for Combined Heating and Cooling Supply

5. Challenges, Limitations, and Future Works

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COP | Coefficient of Performance |

| ODP | Ozone Depletion Potential |

| GWP | Global Warming Potential |

| HFCs | Hydrofluorocarbons |

| CFD | Computational Fluid Dynamics |

| PID | Proportional-Integral-Derivative |

References

- Pan, L.; Guo, Y.; Yan, Q.; Shi, W. Modelling of regional heating and cooling load in the context of carbon neutrality. J. Build. Eng. 2024, 85, 108724. [Google Scholar] [CrossRef]

- Goetzler, W.; Young, J.; Umland, M.; Butrico, M.; Torrado, C. Cool refrigerant developments for a warming world: Low-GWP HVAC refrigerant regulations and technologies in US and global markets. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA, USA, 4–9 August 2024; pp. 1–14. [Google Scholar]

- Rosenow, J.; Gibb, D.; Nowak, T.; Lowes, R. Heating up the global heat pump market. Nat. Energy 2022, 7, 901–904. [Google Scholar] [CrossRef]

- Xu, P.; Yang, Y.; Liu, X.; Wang, D.; Wang, G.; Xiang, S. Experimental investigation of a transcritical CO2 system for simultaneous heating and cooling performance. Appl. Therm. Eng. 2021, 187, 116592. [Google Scholar] [CrossRef]

- Mei, S.; Liu, Z.; Liu, X. Research progress and applications of transcritical carbon dioxide heat pumps: A review. Clean Energy Sci. Technol. 2023, 1, 118. [Google Scholar] [CrossRef]

- Bodinus, W.S. The rise and fall of carbon dioxide systems. Ashrae J. 1999, 41, 37–42. [Google Scholar]

- Calm, J.M. Comparative efficiencies and implications for greenhouse gas emissions of chiller refrigerants. Int. J. Refrig. 2006, 29, 833–841. [Google Scholar] [CrossRef]

- Rony, R.U.; Yang, H.; Krishnan, S.; Song, J. Recent advances in transcritical CO2 (R744) heat pump system: A review. Energies 2019, 12, 457. [Google Scholar] [CrossRef]

- Baek, C.; Heo, J.; Jung, J.; Cho, H.; Kim, Y. Optimal control of the gas-cooler pressure of a CO2 heat pump using EEV opening and outdoor fan speed in the cooling mode. Int. J. Refrig. 2013, 36, 1276–1284. [Google Scholar] [CrossRef]

- Yokoyama, R.; Wakui, T.; Kamakari, J.; Takemura, K. Performance analysis of a CO2 heat pump water heating system under a daily change in a standardized demand. Energy 2010, 35, 718–728. [Google Scholar] [CrossRef]

- Cao, F.; Song, Y.; Li, M. Review on development of air source transcritical CO2 heat pump systems using direct-heated type and recirculating-heated type. Int. J. Refrig. 2019, 104, 455–475. [Google Scholar] [CrossRef]

- Cao, F.; Cui, C.; Wei, X.; Xiang, Y.; Li, M.; Wang, X. The experimental investigation on a novel transcritical CO2 heat pump combined system for space heating. Int. J. Refrig. 2019, 106, 539–548. [Google Scholar] [CrossRef]

- Wu, F.M.; Li, S.Q.; Li, J.F.; Tian, J.Y.; He, S.H.; Song, W.J.; Feng, Z.P. Optimization technology for CO2 transcritical cycle heat pump in severe cold conditions. Adv. New Energy 2023, 11, 255–263. [Google Scholar]

- Keller, J.U.; Göbel, M.U. Die thermodrossel: Eine anlage zur entspannung komprimierter flüssigkeiten unter wärmeabgabe. Ki Luft-Und Kältetechnik 1997, 33, 57–60. [Google Scholar]

- Yao, L.; Li, M.; Hu, Y.; Wang, Q.; Liu, X. Comparative study of upgraded CO2 transcritical air source heat pump systems with different heat sinks. Appl. Therm. Eng. 2021, 184, 1359–4311. [Google Scholar] [CrossRef]

- Elbel, S.; Hrnjak, P. Experimental validation of a prototype ejector designed to reduce throttling losses encountered in transcritical R744 system operation. Int. J. Refrig. 2008, 31, 411–422. [Google Scholar] [CrossRef]

- Sánchez, D.; Aranguren, P.; Casi, A.; Llopis, R.; Cabello, R.; Astrain, D. Experimental enhancement of a CO2 transcritical refrigerating plant including thermoelectric subcooling. Int. J. Refrig. 2020, 120, 178–187. [Google Scholar] [CrossRef]

- Palacz, M.; Smolka, J.; Nowak, A.J.; Banasiak, K.; Hafner, A. Shape optimisation of a two-phase ejector for CO2 refrigeration systems. Int. J. Refrig. 2017, 74, 212–223. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, P. Theoretical model of transcritical CO2 ejector with non-equilibrium phase change correlation. Int. J. Refrig. 2018, 86, 218–227. [Google Scholar] [CrossRef]

- Yang, J.L.; Ma, Y.T.; Liu, S.C. Performance investigation of transcritical carbon dioxide two-stage compression cycle with expander. Energy 2007, 32, 237–245. [Google Scholar] [CrossRef]

- Nebot-Andrés, L.; Duca, M.G.D.; Aprea, C.; Žerovnik, A.; Tušek, J.; Llopis, R.; Maiorino, A. Improving efficiency of transcritical CO2 cycles through a magnetic refrigeration subcooling system. Energy Convers. Manag. 2022, 265, 115766. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, C.Y. Research on transcritical CO2 two-stage compression refrigeration cycle with expander and internal heat exchanger. Energy Conserv. 2023, 42, 40–44. [Google Scholar]

- Li, M.X.; Li, L.X.; Su, W.C.; Ma, Y.T. Experimental study of CO2 transcritical cycle with an expander heat pump system. J. Eng. Thermophys. 2004, 25, 929–931. [Google Scholar]

- Lü, Y.Y.; Ma, G.Y.; Wang, L. Novel distributed compression cycle for carbon dioxide transcritical refrigeration system. J. Refrig. 2024, 45, 94–100. [Google Scholar]

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 2014, 135, 274–285. [Google Scholar] [CrossRef]

- Manjili, F.E.; Cheraghi, M. Performance of a new two-stage transcritical CO2 refrigeration cycle with two ejectors. Appl. Therm. Eng. 2019, 156, 402–409. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Hao, J.W.; Xu, Y.F.; Yang, M.Y.; Chang, L. Thermodynamic performance of transcritical CO2 refrigeration cycle with turbo expander. Fluid Mach. 2022, 50, 40–46. [Google Scholar]

- Casi, A.; Aranguren, P.; Araiz, M.; Sanchez, D.; Cabello, R.; Astrain, D. Experimental evaluation of a transcritical CO2 refrigeration facility working with an internal heat exchanger and a thermoelectric subcooler: Performance assessment and comparative. Int. J. Refrig. 2022, 141, 66–75. [Google Scholar] [CrossRef]

- Li, H.; Huang, Q.; Yu, J. Thermodynamic analysis of a modified two-stage transcritical CO2 refrigeration cycle with an ejector and a subcooler. Int. J. Refrig. 2024, 168, 492–505. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, Q.; Zhang, W.; Zhao, Y.; Liu, G.; Li, L. Thermodynamic analysis and comparison of mechanical subcooling transcritical CO2 refrigeration system with expander and throttling valve. Case Stud. Therm. Eng. 2025, 65, 105625. [Google Scholar] [CrossRef]

- Liu, S.C.; Liu, K.; Wang, J.H.; Dai, B.M.; Yang, X.; Zhang, P. Thermodynamic analysis of transcritical CO2 booster refrigeration system with an internal heat exchanger. Fluid Mach. 2022, 50, 64–70. [Google Scholar]

- Cui, C.; Zong, S.; Song, Y.; Yin, X.; Cao, F. Experimental investigation of the extreme seeking control on a transcritical CO2 heat pump water heater. Int. J. Refrig. 2022, 133, 111–122. [Google Scholar] [CrossRef]

- Shi, W.X.; Ji, X.Y.; Pan, L.S.; Lv, Y.F.; Wei, X.L. Analysis of high-temperature approaches for CO2 transcritical heat pump systems. Acta Energ. Sol. Sin. 2022, 43, 104–111. [Google Scholar]

- Chen, Y. Optimal heat rejection pressure of CO2 heat pump water heaters based on pinch point analysis. Int. J. Refrig. 2019, 106, 592–603. [Google Scholar] [CrossRef]

- Yang, J.L.; Zhang, X.; Du, Y.F.; Han, Y.F.; Wang, L.X. Experimental and simulation study on transcritical CO2 water-to-water heat pump system. Acta Energiae Solaris Sin. 2024, 45, 265–272. [Google Scholar]

- Bai, T.; Shi, R.; Yu, J. Thermodynamic performance evaluation of an ejector-enhanced transcritical CO2 parallel compression refrigeration cycle. Int. J. Refrig. 2023, 149, 49–61. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Xie, J. Performance Optimizations of the Transcritical CO2 Two-Stage Compression Refrigeration System and Influences of the Auxiliary Gas Cooler. Energies 2021, 14, 5578. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, L.X. Experiment and simulation study of CO2 transcritical heat pump system with thermoelectric subcooling. Chem. Eng. 2023, 51, 76–81. [Google Scholar]

- Nie, J.; Ma, G.; Wang, L. Optimal Intermediate Pressure Investigation in a CO2 Transcritical Distributed Compression Refrigeration Cycle. Int. J. Refrig. 2025, 169, 405–417. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Ma, G. Theoretical investigation of a novel distributed compression cycle for CO2 trans-critical system. Energy Build. 2024, 304, 113853. [Google Scholar] [CrossRef]

- Fu, R.; Wang, J.; Zheng, M.; Yu, K.; Liu, X.; Li, X. Thermodynamic analysis of transcritical CO2 ejector expansion refrigeration cycle with dedicated mechanical subcooling. Entropy 2019, 21, 874. [Google Scholar] [CrossRef]

- Sun, Z.L.; Ma, Y.T. Thermodynamic analysis of one kind of single-stage with expender and four kinds of two-stage transcritical carbon dioxide refrigeration cycle. J. Refrig. 2016, 37, 53–59. [Google Scholar]

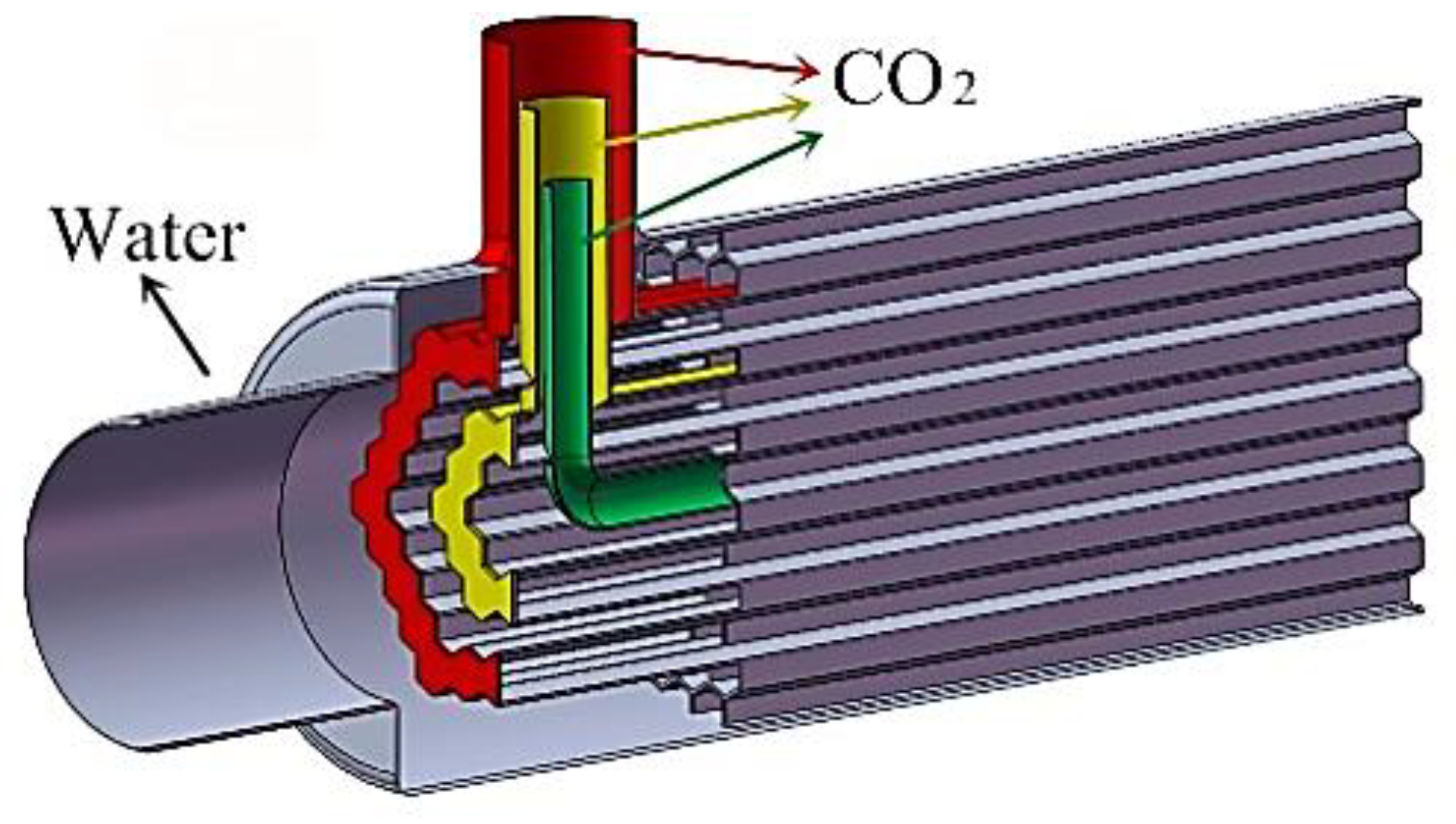

- Huang, R.; Hu, B.; Eikevik, T.M.; Wang, R.Z.; Ge, T.S. High-temperature CO2 transcritical heat pump with optimized tube-in-tube heat exchanger. J. Refrig. 2023, 44, 93–101. [Google Scholar] [CrossRef]

- Jiang, J.; Liang, S.; Xu, X.; Chen, B.; Shen, Z.; Guo, C.; Yu, L.; Qin, S. Experimental Research on a New Mini-Channel Transcritical CO2 Heat Pump Gas Cooler. Micromachines 2023, 14, 1094. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Zhang, P.; Jiang, X.; Wang, F.; Huan, C.; Ma, Z. Exergy Analysis of Transcritical CO2 Air-Source Heat Pump with Honeycomb Gas Cooler. Buildings 2023, 13, 2147. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Y.; Cao, F. Comprehensive evaluation of the transcritical CO2 ejector- expansion heat pump water heater. Int. J. Refrig. 2023, 145, 276–289. [Google Scholar] [CrossRef]

- Zhu, Y.; Huang, Y.; Li, C.; Zhang, F.; Jiang, P. Experimental investigation on the performance of transcritical CO2 ejector–expansion heat pump water heater system. Energy Convers. Manag. 2018, 167, 147–155. [Google Scholar] [CrossRef]

- Pan, L.; Yao, Z.; Yao, W.; Wei, X. Multi-objective optimization on bionic fractal structure for heat exchanging of two fluids by genetic algorithm. Int. J. Heat Mass Transf. 2023, 212, 124298. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Ituna-Yudonago, J.F.; Elizalde-Blancas, F.; Serrano-Arellano, J.; Morales-Fuentes, A. Comparative analysis of a concentric straight and a U-bend gas cooler configurations in CO2 refrigeration system. Int. J. Heat Mass Transf. 2017, 106, 756–766. [Google Scholar] [CrossRef]

- Wu, Z.; Bi, F.; Fei, J.; Zheng, Z.; Song, Y.; Cao, F. The Collaborative Optimization of the Discharge Pressure and Heat Recovery Rate in a Transcritical CO2 Heat Pump Used in Extremely Low Temperature Environment. Energies 2023, 16, 2059. [Google Scholar] [CrossRef]

- Dai, B.M.; Liu, S.C.; Sun, Z.L.; Qi, H.F.; Chen, Q.; Wang, X.M.; Ma, Y.T. Theoretical performance analysis of CO2 transcritical refrigeration cycle with mechanical subcooling. J. Refrig. 2018, 39, 13–19. [Google Scholar]

- Yang, J.L.; Bai, Y. Performance analysis for mechanical subcooling cycle of CO2 transcritical two-stage compression. Fluid Mach. 2021, 49, 59–65. [Google Scholar]

- Niu, Q.Y.; Guan, X.; Qin, T.; Song, Z.Y. Performance analysis of trans-critical CO2 heat pump system with ejector. Fluid Mach. 2022, 50, 93–100. [Google Scholar]

- Song, Y.; Cui, C.; Li, M.; Cao, F. Investigation on the effects of the optimal medium-temperature on the system performance in a transcritical CO2 system with a dedicated transcritical CO2 subcooler. Appl. Therm. Eng. 2020, 168, 114846. [Google Scholar] [CrossRef]

- Dai, B.M.; Zhao, R.R.; Liu, S.C.; Qian, J.B.; Xu, T.Y.H.; Liu, C.; Yang, P.F. Performance analysis of CO2 combined cooling and heating system integrated with ejector and mechanical subcooling. J. Refrig. 2023, 44, 69–76, 109. [Google Scholar]

- Wang, L.; Zhang, X.R. Performance of transcritical CO2 combined cooling and heating system with split flow cooling. Chem. Ind. Eng. Prog. 2022, 41, 60–66. [Google Scholar]

- Wang, J.; Belusko, M.; Liu, M.; Semsarilar, H.; Liddle, R.; Alemu, A.; Evans, M.; Zhao, C.; Hudson, J.; Bruno, F. A comprehensive study on a novel transcritical CO2 heat pump for simultaneous space heating and cooling-Concepts and initial performance. Energy Convers. Manag. 2021, 243, 114397. [Google Scholar] [CrossRef]

- Guo, D.Q.; Liu, C.; Lü, Y.F.; Pan, L.S. Performance analysis of the CO2 transcritical combined cooling and heating cycle. J. Therm. Power Eng. 2022, 37, 35–40, 59. [Google Scholar]

- Liu, Y.F.; Lu, C.Y.; Zhang, H.; Luo, Y.H.; Liu, S. Experimental study on performance of CO2 transcritical cycle combined cooling and heating unit. Chem. Eng. 2023, 51, 47–52. [Google Scholar]

- Maddah, S.; Safaei, M.R. Determination of the optimal discharge pressure of the transcritical CO2 heat pump cycles for heating and cooling performances based on new correlation. J. Therm. Anal. Calorim. 2021, 145, 1537–1546. [Google Scholar] [CrossRef]

| Substance | Molar Mass (kg/kmol) | Tb (°C) | Tc (°C) | Pc (MPa) | TLV-TWA (PPM) | Atmospheric Life (yr) | ODP | GWP (100 yr) |

|---|---|---|---|---|---|---|---|---|

| HFC245fa | 134.05 | 15.1 | 154.0 | 3.65 | 300 | 7.6 | 0.00 | 1030 |

| HC600 | 58.12 | −0.5 | 152.0 | 3.63 | 600 | 0.018 | 0.00 | 20 |

| HC600a | 58.12 | −11.7 | 134.7 | 3.63 | 600 | 0.019 | 0.00 | 20 |

| HFC245ca | 134.05 | −1.4 | 124.9 | 3.20 | 1000 | 240.0 | 0.00 | 9810 |

| HFC134a | 102.03 | −26.1 | 101.1 | 4.06 | 1000 | 14.0 | 0.00 | 1430 |

| HFC152a | 66.05 | −24.0 | 111.3 | 4.52 | 1000 | 1.4 | 0.00 | 124 |

| HFC227ea | 170.05 | −16.4 | 102.8 | 3.00 | 1000 | 42.0 | 0.00 | 3220 |

| HFC236ea | 152.04 | −6.2 | 139.1 | 3.06 | 1000 | 8.0 | 0.00 | 710 |

| HFC236fa | 152.04 | −9.5 | 153.2 | 4.05 | 1000 | 240.0 | 0.00 | 3220 |

| HCFC123 | 152.93 | −27.8 | 183.7 | 4.03 | 50 | 1.3 | 0.02 | 77 |

| HCFC124 | 136.48 | −12.0 | 122.3 | 4.21 | 1000 | 5.8 | 0.02 | 609 |

| HCFC141b | 116.95 | −32.0 | 204.4 | 4.21 | 500 | 9.3 | 0.12 | 725 |

| HCFC142b | 100.50 | −21.5 | 150.0 | 4.06 | 1000 | 17.9 | 0.00 | 2310 |

| HC600/HFC245fa | 129.27 | 153.9 | 7.12 | 3.66 | 319 | 7.12 | 0.00 | 966 |

| Carbon Dioxide | |||

|---|---|---|---|

| Refrigerant name | R744 | Chemical formula | CO2 |

| Relative molecular mass | 44.01g/mol | Standard boiling point | −78.4 °C |

| Critical temperature | 31.1 °C | Critical pressure | 7.38 MPa |

| Ozone depletion Potential (ODP) | 0 | Global warming potential (GWP) | 1 |

| Toxic | Non-toxic | Flammable | Nonflammable |

| Authors (Year) | Key Innovation | Application | Performance Improvement | Major Advantage |

|---|---|---|---|---|

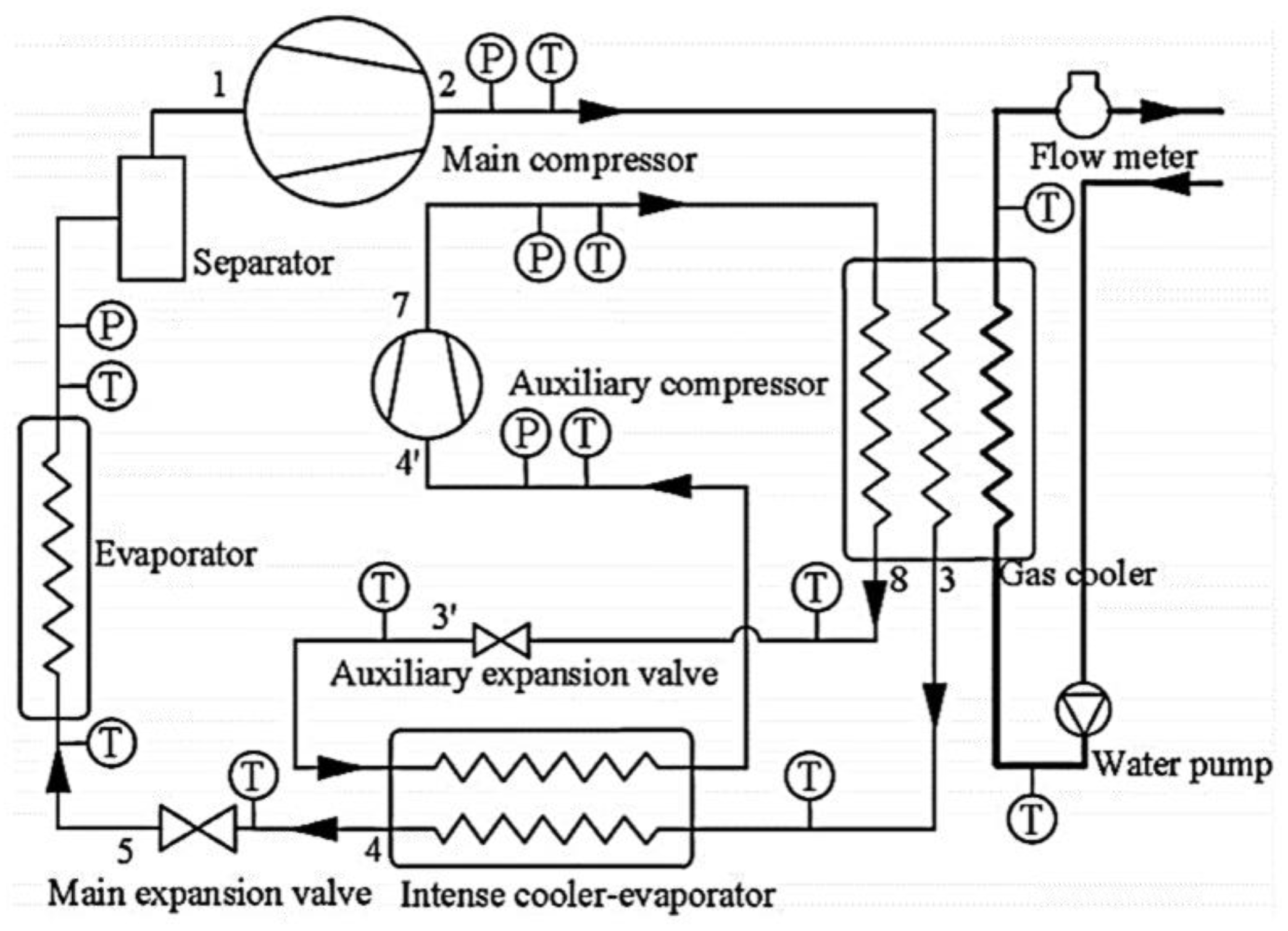

| Cao et al. (2019) [12] | Primary + auxiliary CO2 cycles; graded heat sink utilization | Building heating | COP ↑15.3%; optimal discharge pressure ↓39% | Stable high-temp output (70 °C) in −20 °C to 0 °C environments; compressor frequency synergy |

| Wu et al. (2023) [13] | Work recovery via vortex tube expansion | Severe cold heating | COP ↑18.2% vs. single-stage | Steady 45 °C heat supply at −15 °C; superior COP under high compression ratios |

| Keller & Göbel (1997) [14] | Vortex tube replaces throttling valve | Room heating | COP ↑25% | Reduces throttling losses; optimizes heat transfer irreversibility |

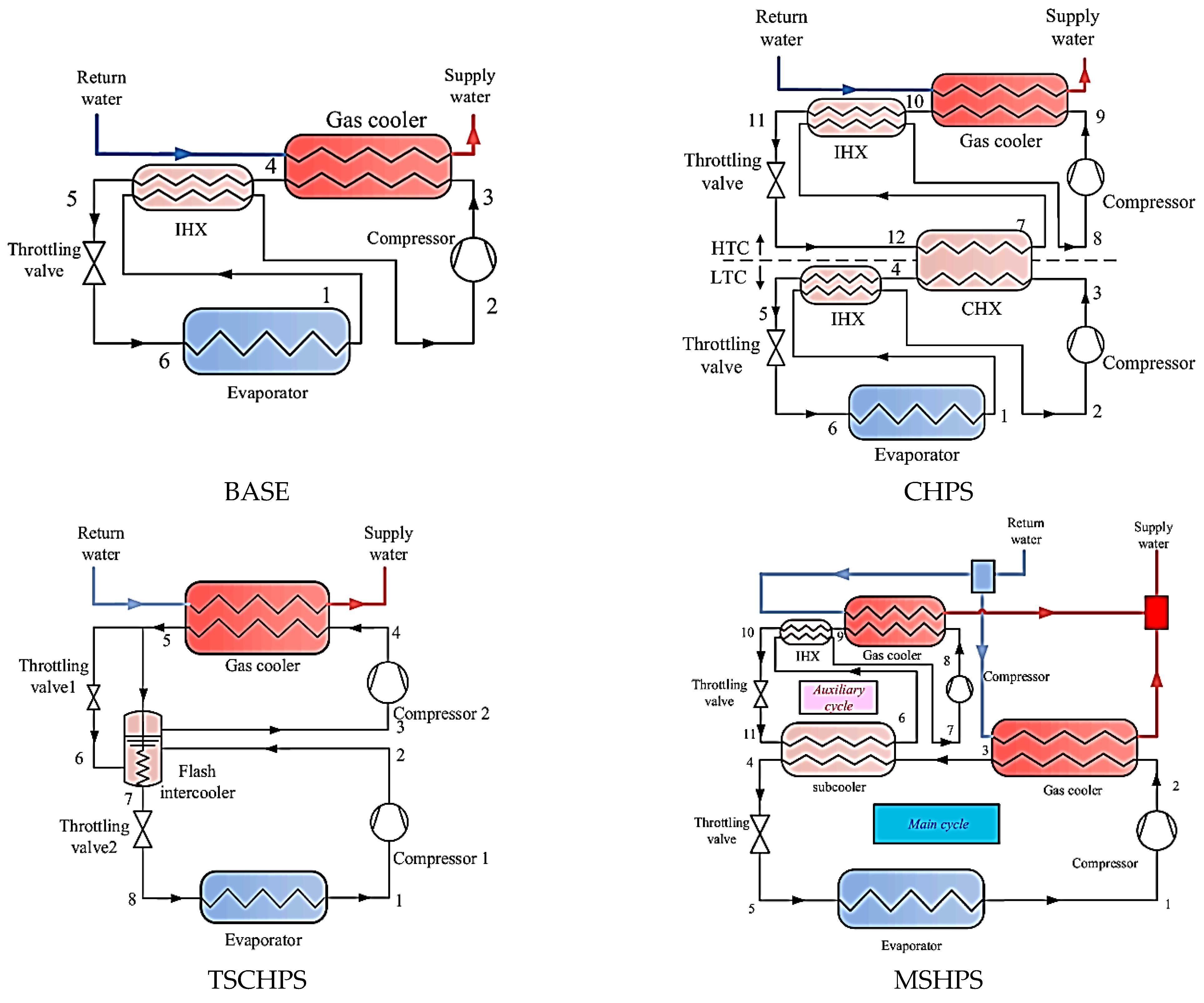

| Yao et al. (2021) [15] | Cascade/secondary compression integration | Floor radiation heating | COP ↑10–46.96% | Enhanced efficiency for small/medium buildings |

| Lü et al. (2024) [24] | Secondary supercritical CO2 pressurization | Commercial cooling | Cooling capacity ↑26.5%; COP ↑10.76% at 35 °C | Minimizes throttling dryness; compression process optimization |

| Chesi et al. (2014) [25] | Parallel compression cycle (with flash tank configuration) | R744 refrigeration cycle | Best COP ↑10%, cooling capacity increased by over 25% | Significantly enhanced system performance by reducing throttling losses and optimizing flash tank separation efficiency |

| Manjili & Cheraghi (2019) [26] | Expansion work recovery for compressor power reduction | Tropical cooling (>40 °C) | COP ↑20–80% | Adaptability to high-ambient temps; reduces external power input |

| Zhang et al. (2022) [27] | Converts expansion work into useful feedback | General cooling | COP ↑38.4–45.1% | Minimizes throttling energy loss; high exergy efficiency |

| Casi et al. (2022) [28] | Peltier-effect subcooling at gas cooler outlet | Cooling at 35 °C | COP ↑16.2%; cooling capacity ↑20.8% | Enhances refrigerant enthalpy difference; no moving parts |

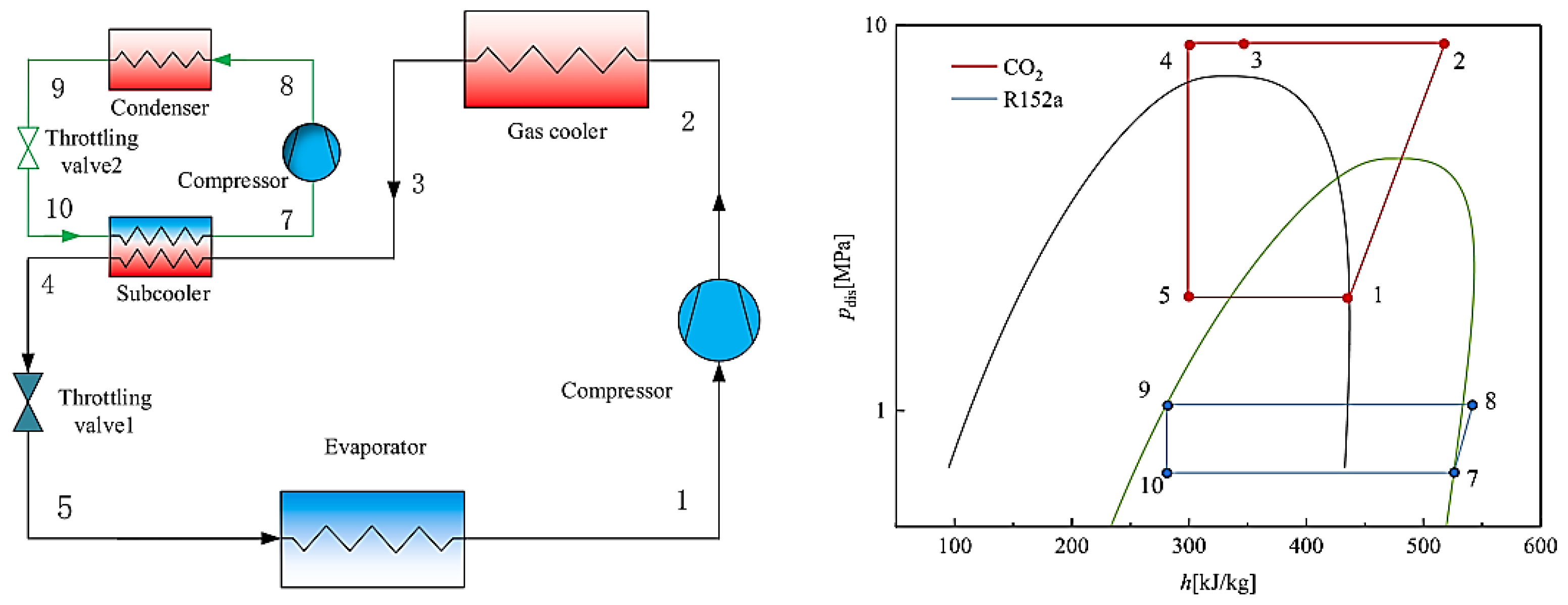

| Li et al. (2024) [29] | Two-stage cycle with internal heat distribution | Combined cooling/heating | COP ↑14.2% | Optimizes energy efficiency; reduces waste in heat exchange |

| Sun et al. (2016) [42] | Expander efficiency > 60% | Cooling | Outperforms two-stage cycles in COP | Simplifies system structure while maintaining efficiency |

| Ambient Temperature Range | Baseline Single-Stage Cycle (COP) | Ejector-Enhanced Cycle (COP) | Expander-Integrated Cycle (COP) | Subcooler-Equipped Cycle (COP) | Distributed Compression Cycle (COP) | Dual-Ejector Two-Stage Cycle (COP) | Optimal Configuration |

|---|---|---|---|---|---|---|---|

| −20 °C to −10 °C | 1.5–1.8 [12,13] | 1.6–1.9 [27] | 2.0–2.3 [13,35] | 1.7–2.0 [20] | N/A (not optimized for low temps) | N/A | Expander-Integrated |

| −10 °C to 0 °C | 1.8–2.2 [12] | 1.9–2.4 [28] | 2.3–2.6 [35,38] | 2.0–2.3 [43] | N/A | N/A | Expander-Integrated |

| 0 °C to 10 °C | 2.2–2.5 [15] | 2.4–2.7 [27] | 2.5–2.8 [35] | 2.3–2.6 [20] | 2.4–2.7 [54] | N/A | Expander/Ejector (tie) |

| 10 °C to 30 °C | 2.0–2.3 [21] | 2.3–2.6 [28] | 2.4–2.7 [35] | 2.5–2.8 [20,43] | 2.5–2.9 [16,54] | N/A | Subcooler-Equipped |

| 30 °C to 40 °C | 1.7–2.0 [18,21] | 2.0–2.3 [30] | 1.9–2.2 [35] | 2.1–2.4 [20] | 2.2–2.5 [16,54] | 2.0–2.6 [18] | Distributed Compression |

| >40 °C | 1.5–1.7 [18] | 1.8–2.0 [30] | 1.7–1.9 [35] | 1.9–2.1 [20] | 2.0–2.2 [54] | 2.3–3.1 [18] | Dual-Ejector Two-Stage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Chang, H.; Zhou, J.; Mu, B.; Quan, S.; Pan, L. Research Progress on CO2 Transcritical Cycle Technology for Building Heating and Cooling Applications. Buildings 2025, 15, 2952. https://doi.org/10.3390/buildings15162952

Shi W, Chang H, Zhou J, Mu B, Quan S, Pan L. Research Progress on CO2 Transcritical Cycle Technology for Building Heating and Cooling Applications. Buildings. 2025; 15(16):2952. https://doi.org/10.3390/buildings15162952

Chicago/Turabian StyleShi, Weixiu, Haiyu Chang, Junwei Zhou, Bai Mu, Shuang Quan, and Lisheng Pan. 2025. "Research Progress on CO2 Transcritical Cycle Technology for Building Heating and Cooling Applications" Buildings 15, no. 16: 2952. https://doi.org/10.3390/buildings15162952

APA StyleShi, W., Chang, H., Zhou, J., Mu, B., Quan, S., & Pan, L. (2025). Research Progress on CO2 Transcritical Cycle Technology for Building Heating and Cooling Applications. Buildings, 15(16), 2952. https://doi.org/10.3390/buildings15162952