1. Introduction

Amidst escalating depletion of conventional energy resources and mounting environmental challenges, nuclear power has emerged as a pivotal clean energy solution, experiencing substantial advancement within China’s energy sector in recent years. Ensuring the safe and reliable operation of nuclear power plants (NPPs) critically depends on their supporting maritime infrastructure. This encompasses essential facilities such as circulating cooling water systems and protective coastal/offshore structures, which constitute vital safeguards for plant integrity. The pumping station structures are widely employed to supply circulating cooling water systems in nuclear power plants (NPPs) throughout China. Damage to the pumping station structure during an earthquake will impact the circulating cooling water system and may even result in a nuclear accident [

1]. Consequently, pumping station structures warrant classification as nuclear safety-related facilities. Seismic resilience of critical NPP infrastructure has remained a primary research focus over the past decade, particularly intensified following the Fukushima Daiichi accident [

2,

3,

4]. Existing seismic assessment methodologies predominantly address reactor containment structures [

5,

6], nuclear-grade piping systems [

7], seismically isolated safety facilities [

8], intake structures protecting pumping stations [

9], and concrete drainage culverts [

10]. In contrast, published research specifically addressing the seismic performance of NPP pumping station structures under complex site conditions and coupled loadings during seismic events remains notably limited.

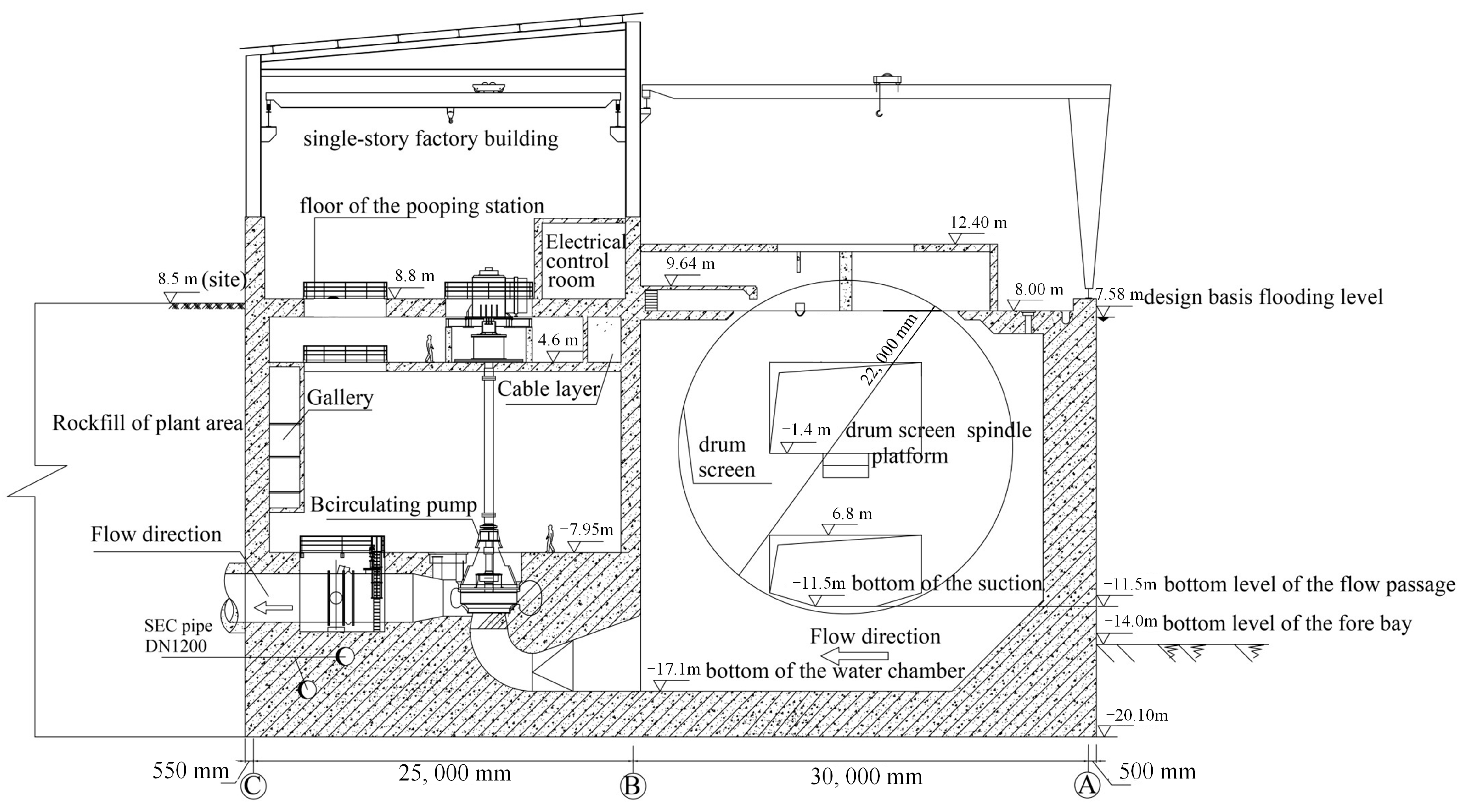

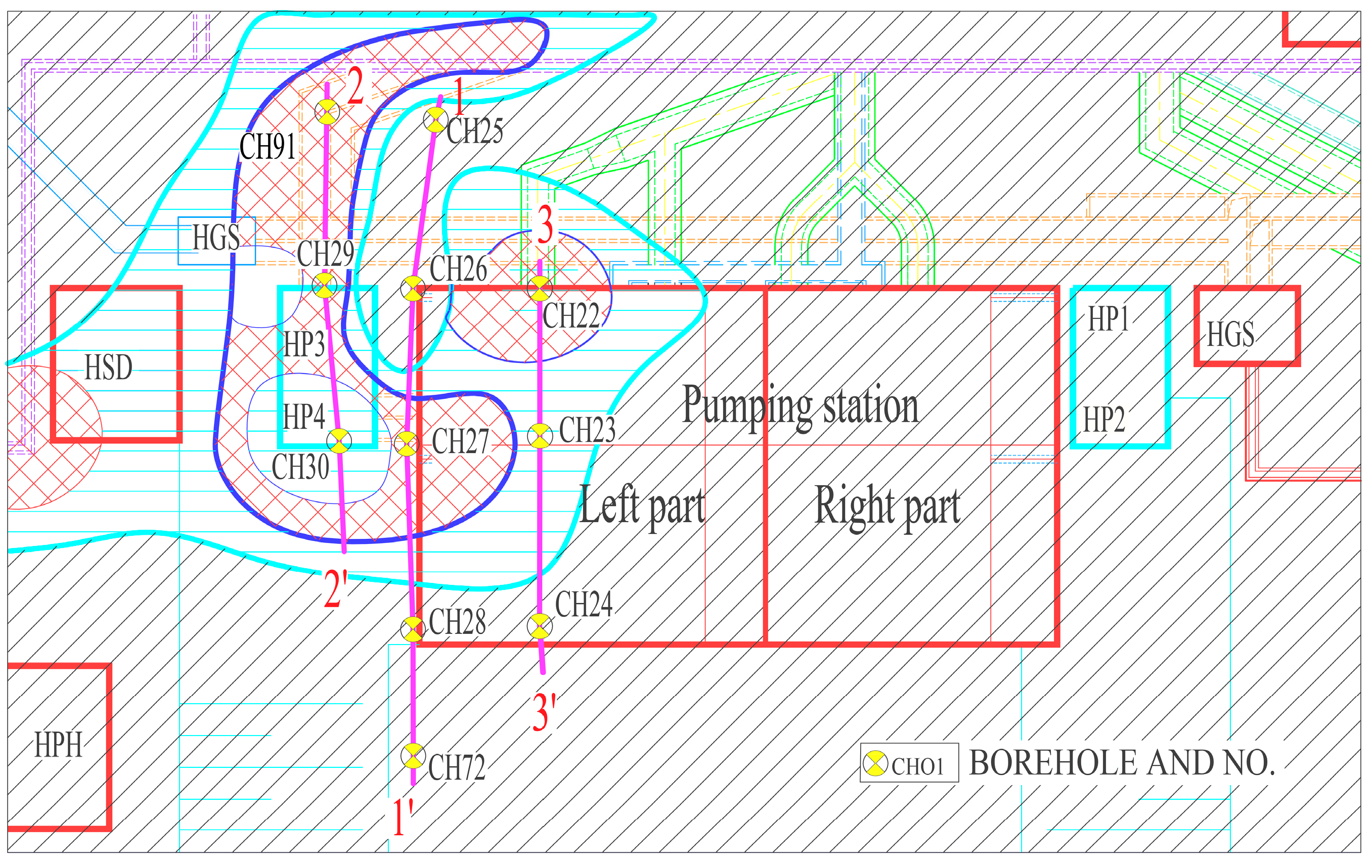

The pumping station structure in NPPs always consists of a single-story factory building above ground and an underground reinforced concrete box-foundation, of which the underground part has one side facing the fore bay, as shown in

Figure 1. Consequently, it experiences coupled static–dynamic loading during earthquakes. The finite element (FE) method stands as a cornerstone methodology in civil engineering for simulating structural and geotechnical mechanics. Its unparalleled versatility enables the modeling of complex geometries, heterogeneous materials, coupled multi-physics loadings, and intricate nonlinear material responses. A fundamental limitation arises, however, when applying the FE method to unbounded domains, such as soil foundations. Accurately capturing wave propagation phenomena, particularly radiation damping, necessitates an impractically large soil mesh, leading to prohibitive computational demands [

11]. To retain the inherent strengths of FE analysis while circumventing this critical constraint for seismic structure–soil interaction problems, researchers have developed specialized techniques. These include hybrid simulation approaches, the Damping Solvent Stepwise Extraction (DSSE) method, and advanced absorbing/side boundary models.

Hybrid simulation methodologies achieve enhanced accuracy by strategically partitioning the problem domain: the FE method resolves the localized domain encompassing the structure and adjacent near-field irregularities, while unbounded media are modeled via either the boundary element (BE) method [

12] for direct wave propagation analysis or the Scaled Boundary Finite Element (SBFE) method [

13] for computationally efficient semi-analytical solutions. Unfortunately, the BE method poses certain limitations in solving complicated practical engineering problems owing to its reliance on the fundamental solution for many cases [

14,

15]. When the hybrid FE-SBFE method is applied to a time-domain analysis, its inherently global spatiotemporal solution formulation imposes significant practical constraints. Geometric configuration and material homogeneity requirements stemming from scaling center selection restrict application to complex real-world systems [

16,

17]. To circumvent these limitations, Yin et al. [

18] pioneered a three-dimensional Damping Solvent Stepwise Extraction (DSSE) framework capable of modeling large-scale structural systems founded upon unbounded viscous-spring soil domains with full nonlinear seismic response capabilities. However, the stepwise extraction approximation inevitably accumulates errors with each incremental extraction, causing the dynamic stiffness to eventually deviate from the true infinite ground dynamic stiffness. Side boundary models trace their origins to the late 1960s, approximating radiation damping by emulating wave propagation theory through differential operators engineered to suppress spurious wave reflections at truncated domain interfaces.

Regulatory frameworks for seismic design of nuclear power plants (NPPs) in China [

19] mandate the implementation of wave-absorbing boundaries—including viscous [

20], viscoelastic [

21], and transmitting [

22] boundaries—for safety analysis of nuclear structures. However, contemporary seismic assessment of pumping station infrastructure demands unprecedented analytical sophistication to address advanced constitutive modeling of nonlinear material behaviors, complex multi-excitation scenarios, and high-fidelity structure–soil interaction. Compounding these challenges, the diminishing availability of ideal sites necessitates deployment on heterogeneous geological strata, substantially increasing computational complexity. Consequently, developing an integrated computational methodology enabling efficient yet rigorous static–dynamic coupled analysis has become critically imperative for reliable safety evaluation.

This research presents an integrated computational methodology for static–dynamic coupled analysis of nuclear pumping station structures, incorporating a novel viscous-spring boundary within ANSYS. The approach develops a Compact Viscous-Spring (CVs) element to model radiation damping in unbounded domains, while establishing a time-domain solution framework through synthesis of the Maximum Initial Time-step (MIT) method with the implicit Newmark integration scheme. Implementation leverages ANSYS User Programmable Features (UPFs) to embed the methodology’s computational kernel, creating an extensible simulation platform. Validation via two case studies precedes application to a pumping station under actual site seismic conditions, demonstrating the framework’s efficacy in resolving complex soil–structure interaction phenomena critical for nuclear safety assessment.

2. The Compact Viscous-Spring Boundary Based on MIT Method

This section establishes a time-domain computational framework for static–dynamic coupled systems through integration of the Maximum Initial Time-step (MIT) method with a novel Compact Viscous-Spring (CVs) boundary model.

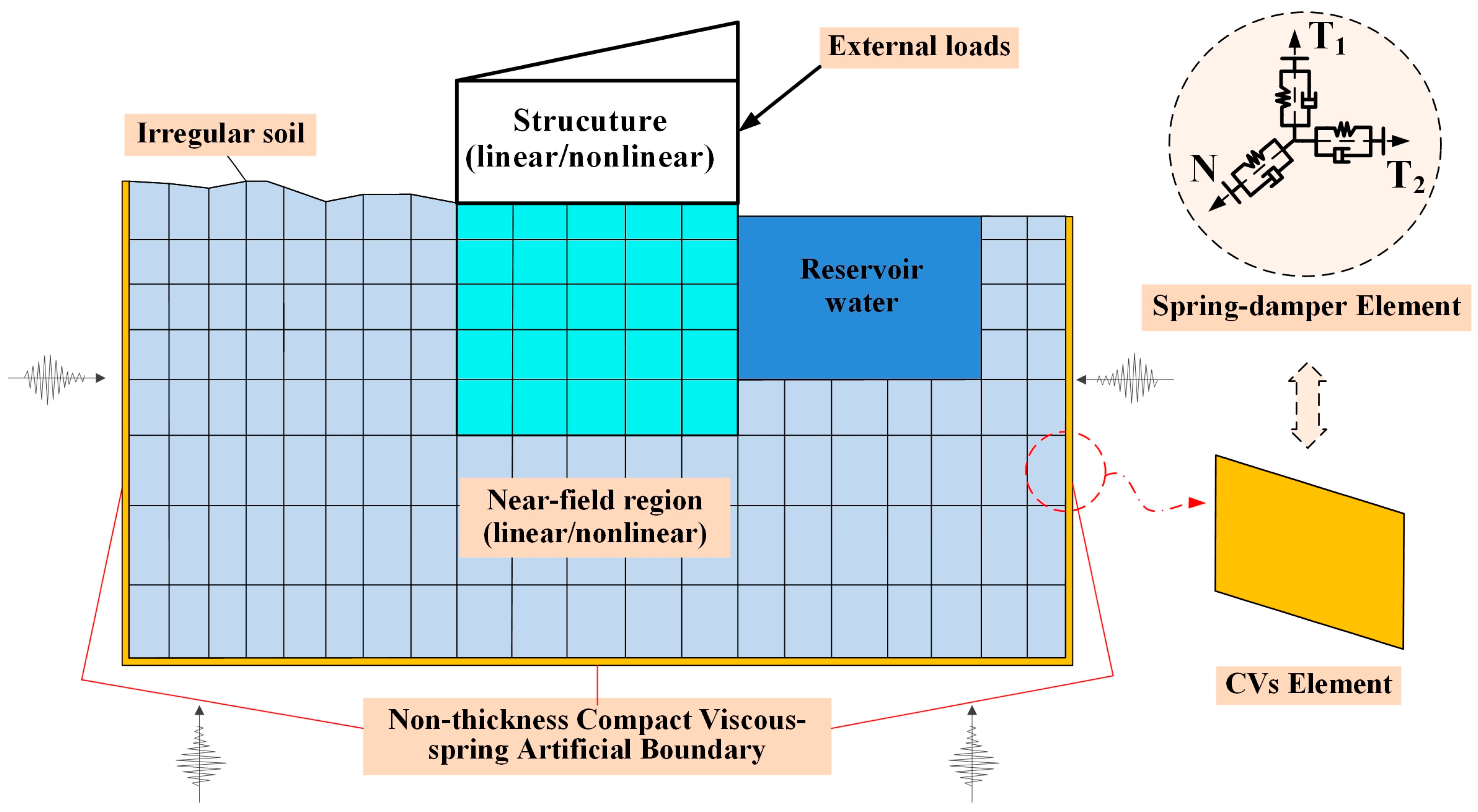

Figure 2 schematically depicts the static–dynamic coupled analysis framework employing the viscous-spring boundary methodology. This configuration utilizes solid elements to discretize near-field domains with geological complexity, while nonlinear structural systems exhibiting constitutive complexity and geometric irregularity are characterized through specialized finite elements. And the entire system is also excited by the static loads from rockfill or reservoir water and the seismic motion from the far field. As mentioned above, the viscous-spring artificial boundary condition consists of introducing the viscous dashpots and springs at the outer boundary to attenuate both outgoing and reflected waves based on the theory of wave propagation, resulting in negligible amplitudes when reaching the outer boundary. Consequently, wave energy attenuation within this formulation yields near-field motions equivalent to an unbounded domain’s free-field response. The methodology delivers enhanced solution fidelity and broadband frequency stability in modeling radiation damping mechanisms—attributes enabling seismic performance assessment for critical infrastructure.

Conventional viscous-spring artificial boundary necessitates a discrete spring-damper element at each boundary node, as schematically illustrated within the dashed enclosure in

Figure 2. The parameters of the physical items on the nodes can be obtained from Equation (1).

where

K and

C are the stiffness and damping of the physical items, respectively. The subscripts

N and

T denote the normal and tangential, respectively. These parameters derive from fundamental properties: shear modulus

G, mass density

ρ, and seismic wave propagation velocities (

cp: P-wave,

cs: S-wave). Geometric considerations include

R (radial distance from boundary node to wave source) and

Ai (area associated with node

i, where subscript

i indexes the number of areas around the node).

αN and

αT are the modified coefficients, respectively. Through parameter analysis and some example tests, the numerical solution only slightly varies with the change in the modified parameters around the recommended value:

αN = 1.33 and

αT = 0.67 [

21].

Considering the soil–structure dynamic interaction model as a complete system only under the seismic excitation, the dynamic equilibrium is governed by the following:

where [

K], [

C], and [

M] represent the stiffness matrix, damping matrix, and mass matrix, respectively.

,

and {

u} represent acceleration, velocity, and displacement, respectively. The subscript

s denotes nodes inside bounded soil, and

b denotes the nodes on the outer boundary; {

Fb} is the equivalent nodal load vector, that is,

, where

quantifies the interaction load arising from free-field excitation when physical components achieve complete dissipation of scattered wave energy.

Although the conventional model can simulate the dynamic characteristics of the pumping station structure, disastrous results will be obtained from multi-load excitation. This is due to several significant limitations of the viscous-spring boundary in finite element analysis. For example, it fails to adequately account for static–dynamic coupling effects, particularly in nonlinear scenarios involving material nonlinearity, geometric nonlinearity, or contact nonlinearity. Secondly, the determination of spring-damping coefficients becomes significantly challenging when dealing with complex heterogeneous materials characterized by spatial variations in material properties and anisotropic behavior. Furthermore, the implementation of spring elements proves to be computationally cumbersome and time-consuming. Most critically, this approach demands substantial computational resources, with the spring elements occupying extensive memory storage and requiring prolonged computation time during matrix operations. These inherent constraints collectively restrict the scope of practical implementation and computational efficiency, particularly when analyzing large-scale engineering structures or conducting sophisticated dynamic simulations. Based on this, the authors develop the Compact Viscous-Spring (CVs) boundary model based on the MIT method for static–dynamic coupled analysis.

2.1. The CVs Element

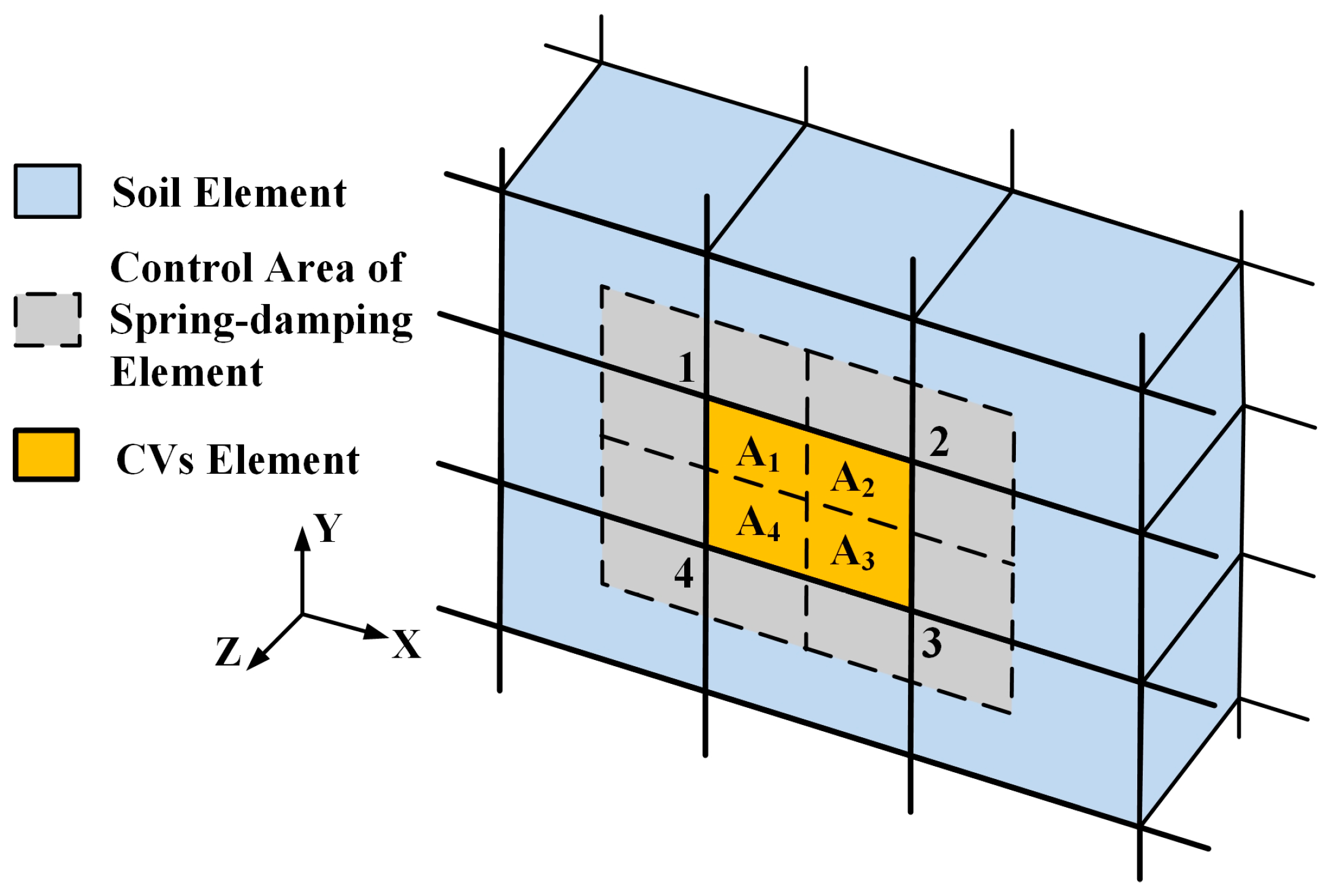

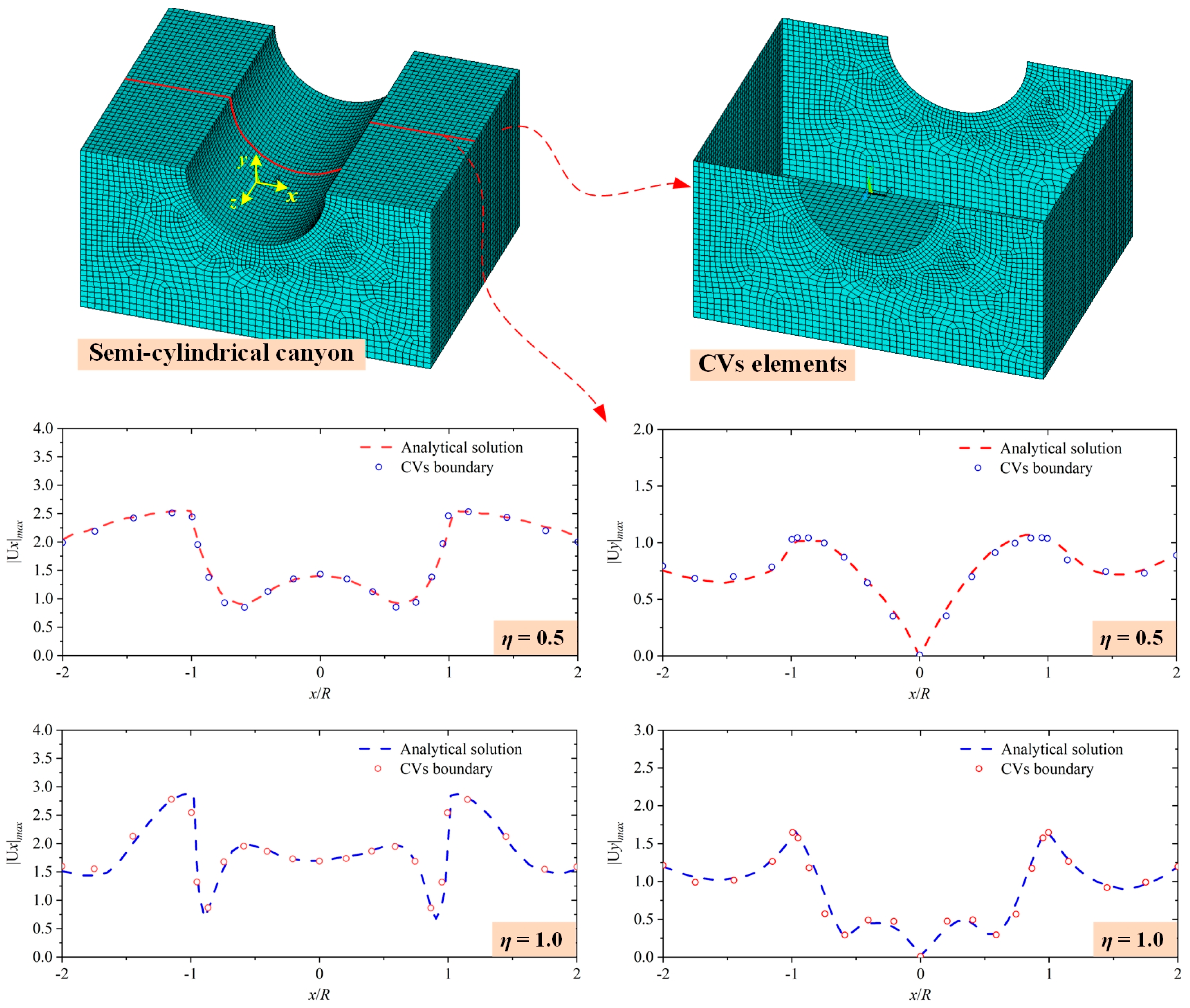

Figure 3 illustrates the enhanced implementation viscous boundary formulation featuring a non-thickness Compact Viscous-Spring (CVs) interface element for soil–structure systems. This boundary element directly interfaces with the existing nodal topology at soil–structure interfaces and lateral boundaries. Near-field domains are discretized using solid elements capturing complex geostratigraphic configurations, while the complete assembly is subjected to simultaneous static geostatic pressures and far-field seismic excitation.

Figure 3 presents the geometric configuration of a non-thickness CVs interface element featuring a quadrilateral topology with four nodes. According to theoretical deduction, a viscous-spring artificial boundary is a simulation of external boundary stress conditions, so the established CVs element is only a correction of the total stiffness matrix and damping matrix, and the element itself has no displacement function and elastic stiffness matrix. Consequently, stiffness and damping contributions from adjacent domains are accumulated at corresponding nodes, yielding a diagonal element matrix. This formulation maintains structural analogy to conventional finite element stiffness and damping matrices, permitting direct assembly into the global system matrix.

The element matrix for the CVs element is defined as follows:

with

Adopting the fundamental postulate of perfect scattered wave energy dissipation within CVs elements, the resultant wavefield superposition manifests as equivalent nodal forces applied at boundary nodes, thereby simulating seismic excitation input. This equivalence yields the CVs element’s nodal load formulation:

where the superscript “

e” denotes the physical parameter of CVs element.

2.2. The MIT Method

Figure 2 depicts the static–dynamic coupled analysis system undergoing simultaneous seismic ground motions and sustained static loading regimes. Thus, Equation (1) of motion can be rewritten as follows.

where {

Fa} represents the static loads vector. After the coupled loads are applied, the Newmark implicit integration [

23] can be introduced to solve the time-domain recursively. The basic assumptions of the node velocity and displacement at any time step Δt are as follows:

where

α and

β are the constants of Newmark implicit integration, respectively.

By substituting Equations (8) and (9) into the equation provided by Equation (7), an expression containing only the terms at the end of the time step

t + Δ

t can be obtained, with similar terms appropriately merged. The expression is expressed as follows:

with

where

.

Since the response of strong earthquake excitation at the initial time has not yet begun, that is,

=

=

=

=

=

= 0. Therefore, the right term in Equation (12) is only the static load term is not 0. By substituting Equations (11) and (12) into Equation (10), one obtains the structure motion expression as

At the same time, it is assumed that the initial time step Δ

t is maximized, that is, tends to infinity.

Then, Equation (13), which introduces the effect of the maximum initial time-step, can be rewritten as follows.

Generally, the linear static equilibrium equation is shown as follows:

It can be seen that Equation (16) and the linear static equilibrium Equation (17) are consistent except for some differences in boundary stiffness. The rigid constraint is often used in static analysis, while the CVs artificial boundary is employed in dynamic analysis. In general, the Saint-Venant principle governs static loading scenarios, confining structural influence to near-field foundation regions. When the range of the foundation is large, the above static–dynamic coupled algorithm is similar to the static analysis results. Therefore, assuming the maximum value of the initial time step in the dynamic analysis, the initial step can be equivalent to the static analysis under the coupling of static and dynamic loads, so that coupling analysis of static and dynamic calculations can be realized, which is defined as the MIT method. Furthermore, the stress state induced by static loading provides the initial condition for subsequent dynamic analysis, ensuring solution stability throughout transient response simulation.

It is worth noting that the algorithm is also suitable for nonlinear static and dynamic coupled analysis and is easy to implement in various types of implicit finite element software (e.g., ANSYS), which can avoid the need for traditional load case operations and simplify the post-processing process. It has high operability and is suitable for engineering applications.

2.3. ANSYS Implementation for Static–Dynamic Coupled Analysis

To improve the operability of the CVs boundary based on the MIT method for static–dynamic coupled analysis, it is necessary to implement embedding in commercial FE software ANSYS, which is widely used in the nuclear power engineering field.

This implementation integrates User Programmable Features (UPFs), script-driven ANSYS Parametric Design Language (APDL), and the Graphical User Interface (GUI) to establish a comprehensive static–dynamic coupled analysis toolkit. The CVs element is embedded via UPF’s user-defined element API (UserElem), while the MIT method is operationalized through APDL scripting. Analysis workflow control is achieved through a parameterized APDL input file that automates finite element modeling and solution sequencing. Post-processing utilizes either APDL or GUI to interpret seismic analysis results stored in binary .rst files.

Implementation requires initial development of core computational subroutines using UPF’s C/FORTRAN API. These custom routines must be compiled and linked to the ANSYS executable prior to execution—platform-specific compilation procedures are documented in the official literature [

24].

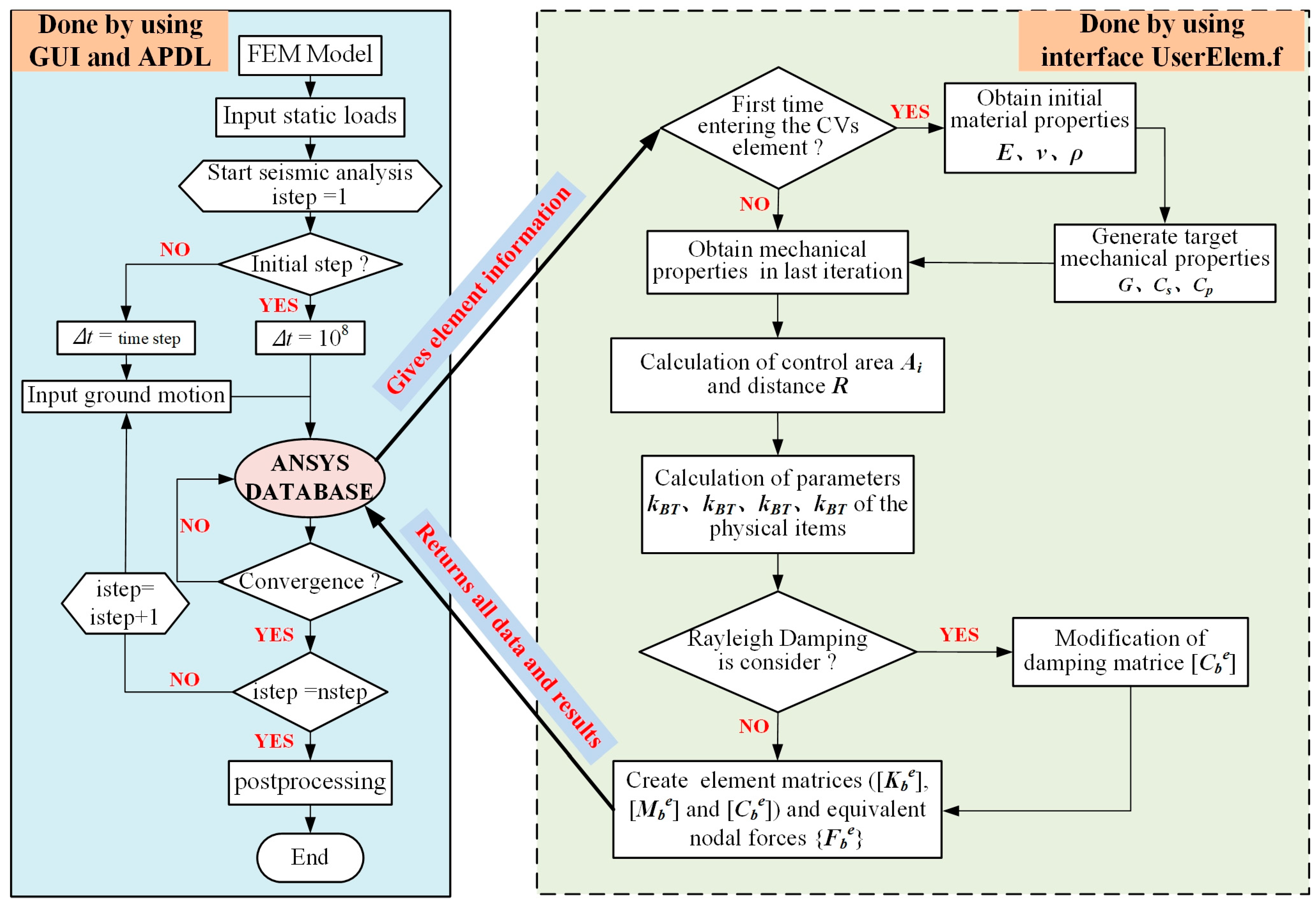

Figure 4 presents the computational workflow, with UPF-dependent processes delineated within dashed boundaries. Key implementation stages are subsequently elaborated:

(1) Pre-processing. The FE model is established using the ANSYS Preprocessor. The CVs element can be first established by the standard element with the same topology as the user element to be discretized. Then the EMODIF command is used to replace the standard element with the user element.

(2) Solution. After entering the solution phase of the static–dynamic coupled analysis, the static load vector is applied to the structures. Then, the initial time-step is set to 108, which is obtained through sensitivity analysis, and any larger value has little effect on the result. And the ANSYS database provides all the information of the CVs element into the interface subprogram UserElem.f, and performs the following steps:

a. Check whether the CVs element subroutine is entered for the first time. If “Yes”, use the material parameters to generate the final element material mechanical parameters. Then enter step “b”; if “No”, the material mechanics parameters of the previous iteration will be directly obtained and enter step “b”.

b. Determine

Ai for node

i within the CVs elements and compute the distance

R from the boundary node to the scattered wave source. Then, equivalent coefficients

kBN,

kBT,

cBN, and

cBT are obtained by Equation (5), and then judge whether Rayleigh damping is generally considered that structural damping is

α and

β represent Rayleigh damping proportionality coefficients. Per ANSYS documentation, defining these parameters (ALPHA/BETA commands) introduces supplemental damping in user-defined elements. Therefore, the CVs element damping matrices are exclusively calculated using Equation (18). If “No”, it means that the element has not considered damping and enters step “

c”; if “Yes”, minor modifications are needed as follows:

c. Compute and assemble the element-level matrices (stiffness, damping, mass) and equivalent nodal load vector. Subsequently, return all generated data to update the superordinate database.

If calculation results do not meet the convergence conditions, enter the next equilibrium iteration step; if they meet, enter the next load step until the end of the seismic analysis.

(3) Post-processing. Conveniently, all results of the pumping station structure can be processed with standard ANSYS. Plotting results is unnecessary since the CVs elements serve as an artificial boundary. Crucially, the computed motion of the entire system represents the total amplitude.

5. Summaries and Conclusions

This study develops a novel CVs boundary based on MIT for static–dynamic coupled time-domain analysis, introducing non-thickness CVs elements to model radiation damping via viscous-spring artificial boundaries for soil–structure interaction, while formulating the MIT method through Newmark implicit integration characteristics to resolve boundary value problems in coupled systems.

Addressing practical needs for coupled FE modeling in complex engineering structures, a systematic ANSYS implementation framework for the MIT-based CVs boundary is presented, where UserElem API realizes CVs elements while APDL executes the MIT method. Validation via analytical benchmark cases confirms the solution’s reliability and effectiveness for static–dynamic coupled analyses.

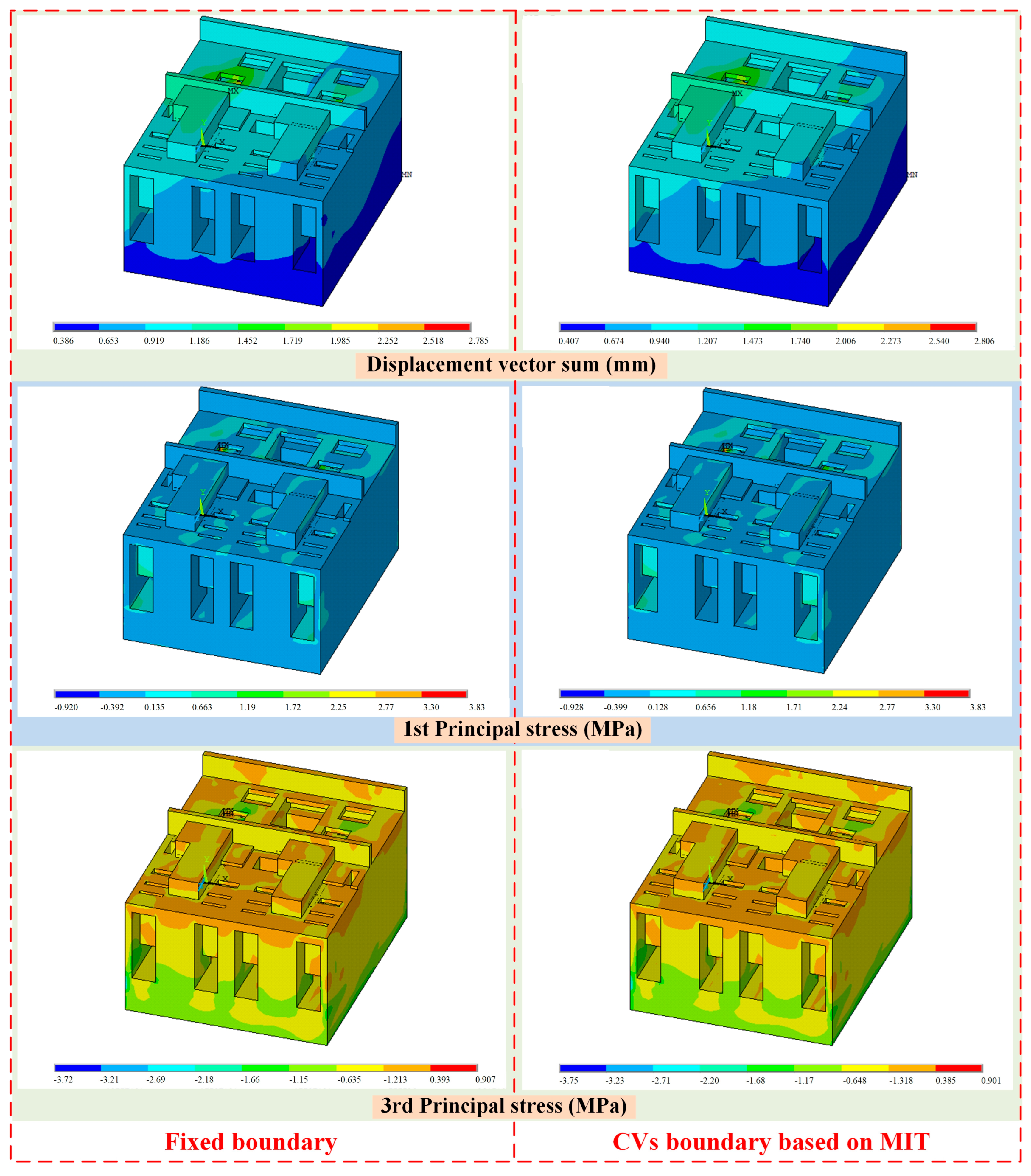

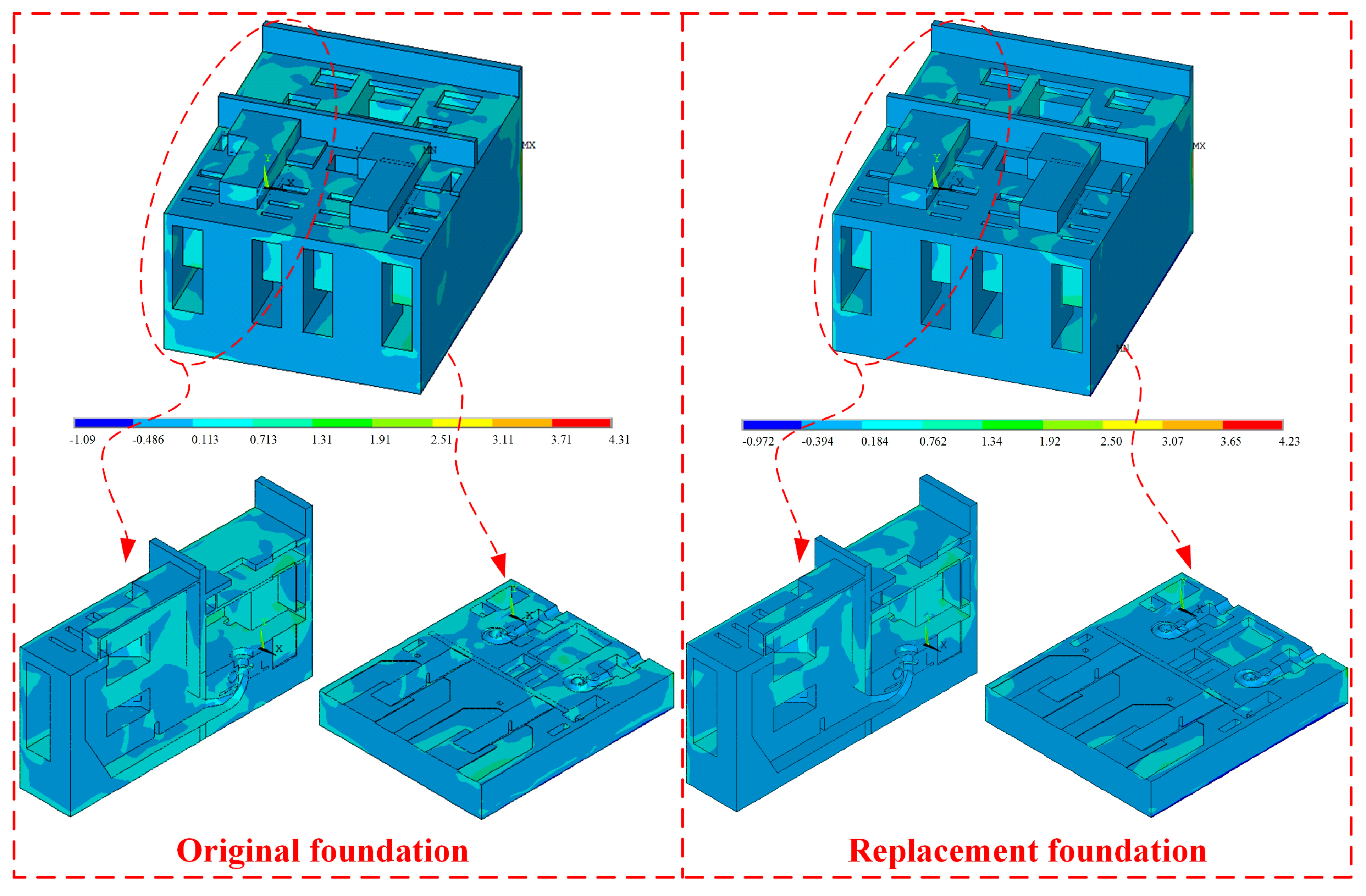

Finally, the pumping station structure subjected to multi-load excitation was comprehensively evaluated from the discussion of structural stress, response, deformation, and seismic stability, and the influence of local non-homogeneity was also revealed. The principal findings are summarized as follows:

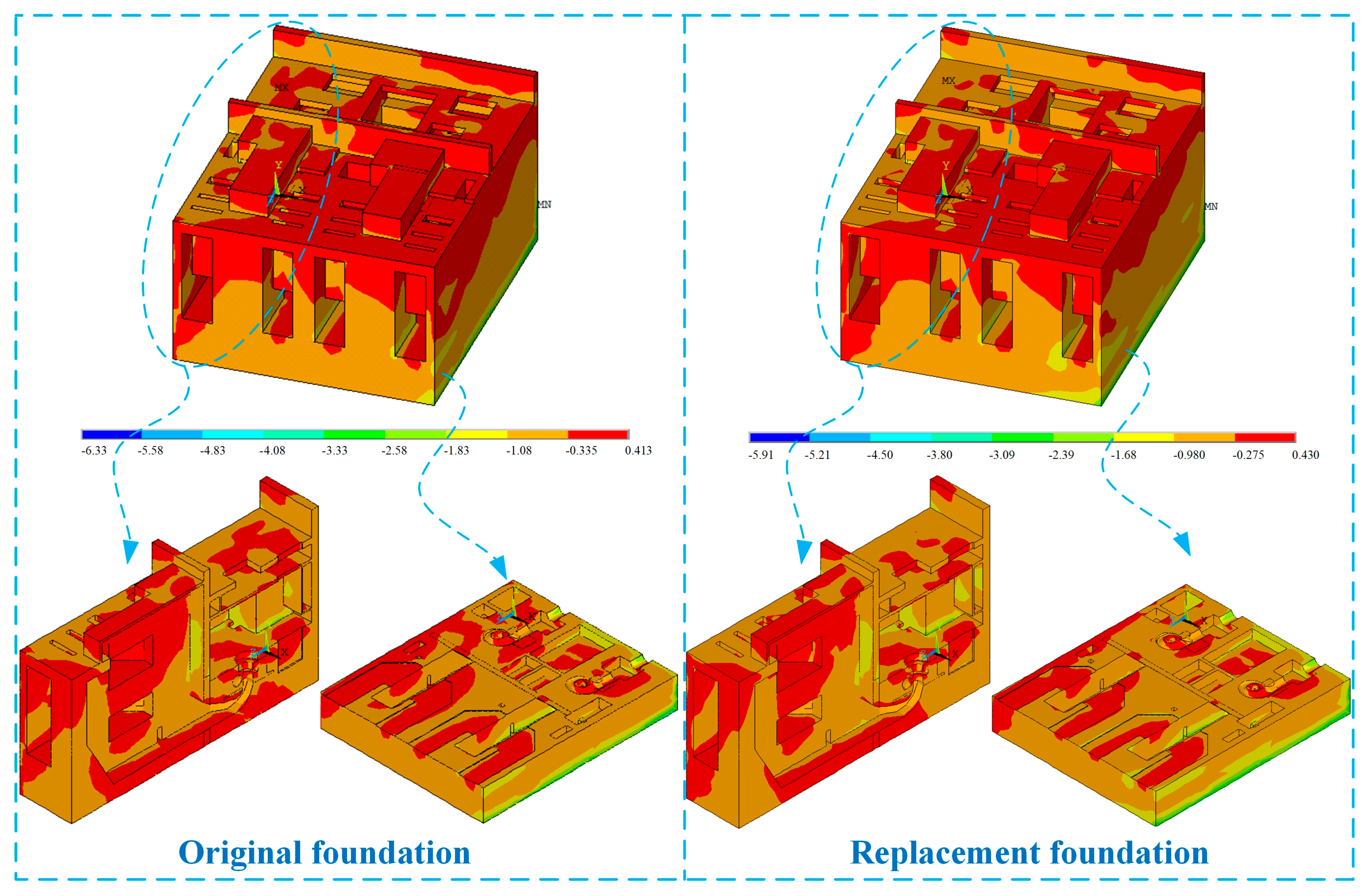

- (1)

The influence of foundation replacement on the stress value and distribution of the pump station structure is not obvious. The principal tensile stress of the bottom of the water chamber, the corner of the floor to the wall, and the contact surface between the wall and backfill are larger and need to be reinforced. In contrast, the principal compressive stress meets the strength requirements of concrete.

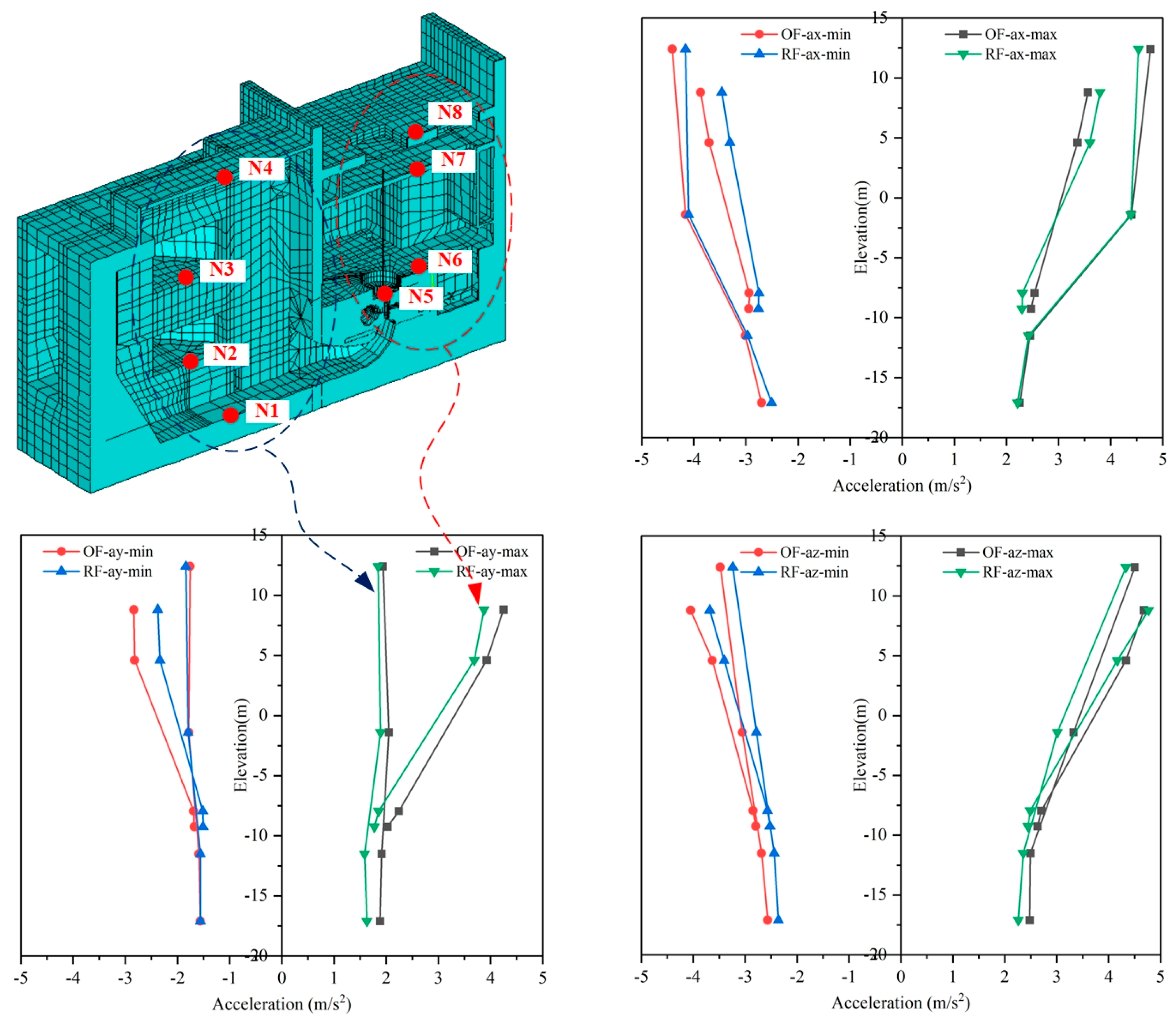

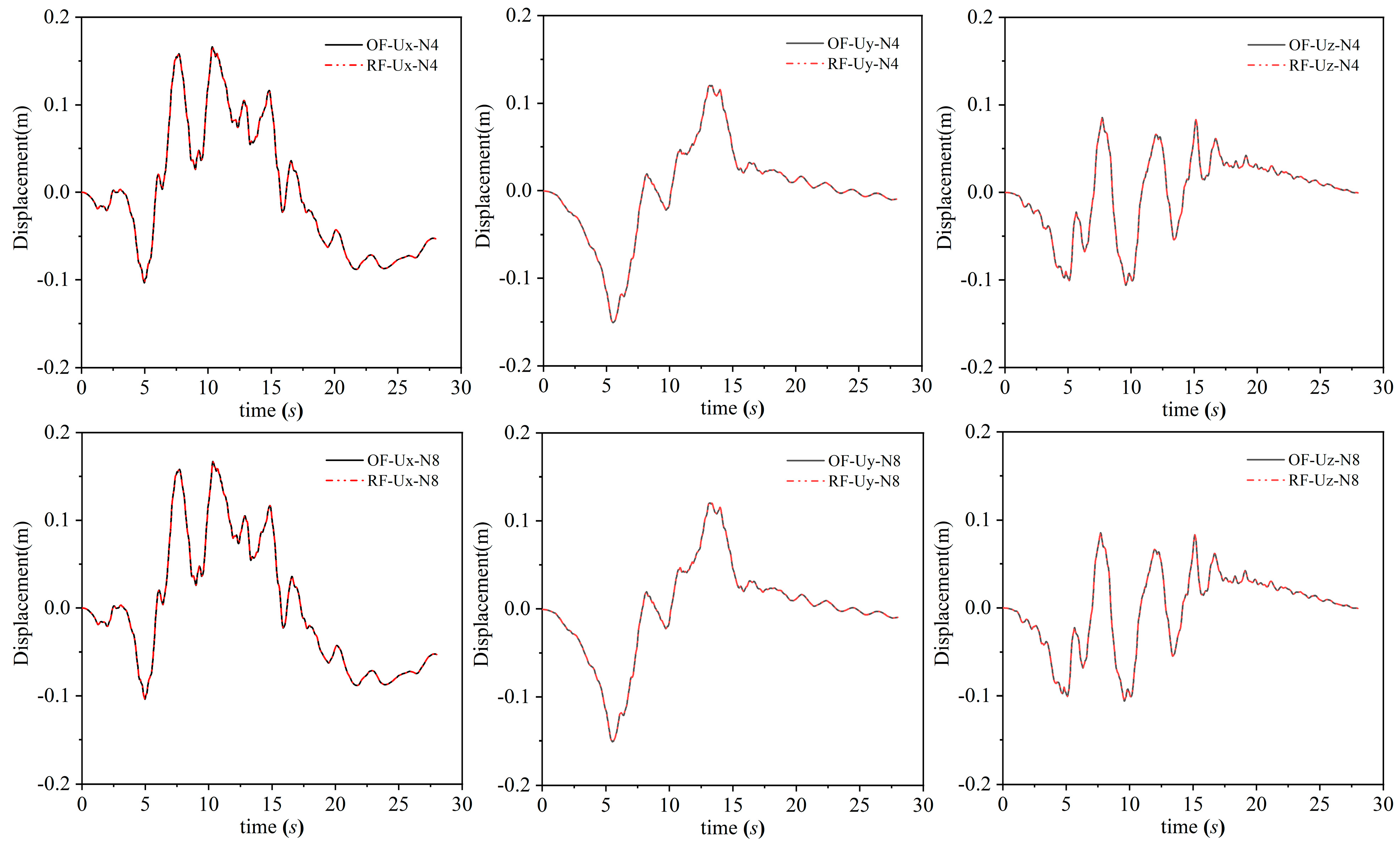

- (2)

Acceleration amplitudes increase with depth in both horizontal and vertical orientations, exhibiting consistent trends across foundation conditions. Structural acceleration variations primarily stem from pump station internal geometry and backfill interactions, while displacement amplitudes exhibit negligible variation.

- (3)

The pump station structure has good anti-sliding and anti-overturning and has enough safety guarantees under the condition of two types of foundation.

- (4)

The measured xenolith may have a slight influence on the seismic response and foundation safety of the pumping station structure.

- (5)

Leveraging ANSYS’s advanced solvers and comprehensive features, including its extensive element library and robust pre-/postprocessing capabilities, this methodology demonstrates superior computational efficiency and modeling versatility for complex engineering applications.

The proposed method for soil–structure dynamic interaction analysis shows significant potential for application in NPPs. This study focuses primarily on the seismic response analysis of pumping station structures to provide technical support for their design. Although the model is capable of nonlinear analysis, its application to beyond-design-basis seismic scenarios will be addressed in subsequent research.