Abstract

The interlayer bonding strength between a cement-stabilized macadam (CSM) base and an asphalt surface layer significantly influences asphalt pavement performance. This study analyzes the calculation method for the interlayer bonding coefficient, investigates its impact on pavement structural response, and proposes a threshold value. Pavement mechanics software was first employed to analyze horizontal displacement at the CSM-asphalt interface, leading to a proposed method for calculating the bonding coefficient using initial stress and displacement derived from interlayer shear tests. Subsequently, the bonding coefficient was evaluated under three interface conditions: untreated, emulsified asphalt-treated, and SBS-modified hot asphalt-treated. Results reveal substantial inherent bonding strength even in untreated interfaces. SBS-modified hot asphalt increased bonding strength by 40–50% compared to untreated interfaces and by 15–20% relative to emulsified asphalt-treated interfaces. Analysis of varying bonding coefficients demonstrates that insufficient CSM-asphalt bonding readily induces asphalt layer fatigue cracking, with bonding strength exerting the dominant influence on fatigue life. Pavements with SBS-modified hot asphalt interlayers exhibited approximately 70% longer fatigue life than untreated interfaces and 30% longer than emulsified asphalt-treated interfaces. Crucially, an interlayer bonding coefficient exceeding 5000 MPa/cm is required for layers to be considered fully bonded.

1. Introduction

Interlayer bonding performance critically influences the service life of asphalt pavements. Poor bonding conditions readily induce fatigue cracking, interlayer displacement, rutting, and other distress [1,2,3]. As illustrated in Figure 1, deficient interlayer bonding at curved sections has caused severe pavement slippage under vehicular lateral forces. Effective interlayer bonding distributes surface loads throughout the pavement structure, whereas weak bonding confines stresses to upper layers, accelerating deterioration [4,5].

Figure 1.

Examples of typical damage caused by interlayer failure.

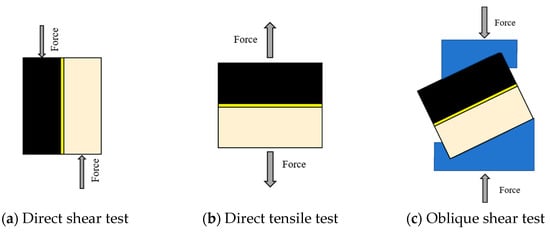

Extensive studies [6,7,8] have investigated interlayer bonding in asphalt pavements, focusing on two primary aspects: evaluation methodologies and influencing factors. Standard test methods include direct shear, tensile, and oblique shear tests (as shown in Figure 2), with direct and oblique shear being most widely adopted. Raab [9] employed model materials (steel balls simulating ideal aggregates in 10/20 permeable asphalt) to demonstrate gradation’s impact on interlayer shear strength via direct shear testing. Raposeiras [10,11] analyzed effects of mixture surface macrotexture, tack coat application rate, and loading rate using similar methods. Isailovic [12] revealed through monotonic and cyclic shear tests that monotonic results provide limited long-term performance insight, whereas cyclic testing accurately characterizes interface fatigue failure. The testing methods for interlayer bonding strength are relatively complete, and there are also many related studies. Due to the fact that interlayer bonding materials are generally asphalt-based materials, their performance is affected by factors such as temperature, loading speed, and material types. Liu [13] identified the temperature and humidity sensitivity of water-based epoxy resin adhesives (recommended for use in rigid bridge decks and high-temperature environments). Ai [14,15,16] analyzed the interlayer roughness performance using 3D laser scanning and quantified its correlation with interlayer bonding strength. Wang [5,17] developed a shear fatigue model and life prediction equation for the bonding layer. Overall, these studies indicate that the bond strength is influenced by aggregate properties, surface texture, characteristics of the bonding layer (material type, application rate), and service conditions (loading rate, temperature, humidity, confining pressure). While this research provides fundamental insights into evaluation protocols and material behavior, the investigations are primarily directed toward the interlayer bonding strength of pavement layers or studies of bonding materials. It remains unclear how the application of tack coat materials affects pavement structures, nor is it established what magnitude of interlayer bonding strength ensures complete interfacial bonding.

Figure 2.

Common test methods for evaluating interlayer bonding performance.

Therefore, the bond strength between pavement layers under different tack coat oils is tested, the influence of different tack coat oils on pavement structure mechanics and its application in pavement structure design are analyzed, and the critical bond strength of the asphalt pavement interlayer when it is completely continuous is proposed to guide the selection of tack coat oil. The research is divided into three parts: (1) By analyzing the interlayer displacement through the mechanics of layered elastic systems, a calculation method for interlayer bonding strength is proposed, and the interlayer bonding strength and coefficient of different bonding layer materials are tested. (2) Using interlayer adhesion coefficient and layered elastic system mechanics, the influence of different adhesive layer materials on the service life of pavement is analyzed. (3) Using the influence law of interlayer bonding strength on service life, the critical strength that satisfies complete interlayer bonding is proposed.

2. Materials and Test Methods

2.1. Raw Materials and Mixture Ratio Design

- (1)

- Asphalt mixtures

Three asphalt mixtures—SMA-13, AC-16, and AC-20—were prepared for laboratory evaluation using distinct aggregate gradations (Table 1) and two asphalt binders (Table 2). SMA-13 incorporated SBS-modified asphalt (70 # base asphalt with 4.5% SBS content), while AC-16 and AC-20 utilized unmodified No. 70 asphalt. Marshall testing determined optimum asphalt contents of 6.0%, 4.5%, and 4.2% for SMA-13, AC-16, and AC-20, respectively. Properties of the emulsified asphalt used in the study are provided in Table 3.

Table 1.

Aggregate gradation of asphalt mixtures.

Table 2.

General characteristics of SBS asphalt.

Table 3.

General characteristics of emulsified asphalt.

- (2)

- Cement Stabilized Macadam

Cement-stabilized macadam (CSM), widely used as a base material for asphalt pavements in China due to its high load-bearing capacity, was prepared using Ordinary Portland cement 32.5 (properties in Table 4) and aggregates (gradation in Table 5 and Table 6).

Table 4.

Basic properties of cement.

Table 5.

Cement mortar strength test.

Table 6.

Aggregate gradation of cement Stabilized Macadam.

- (3)

- Preparation of interlayer shear specimen

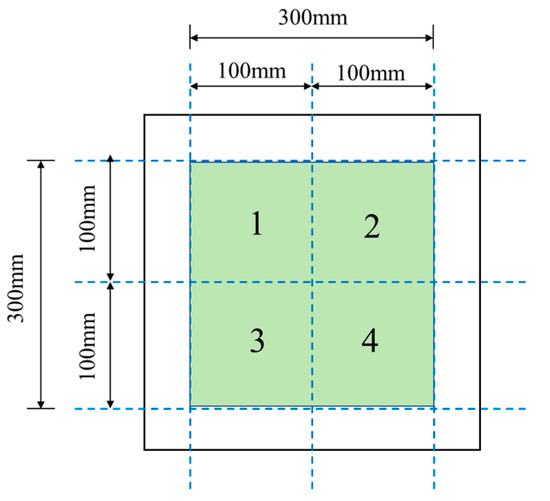

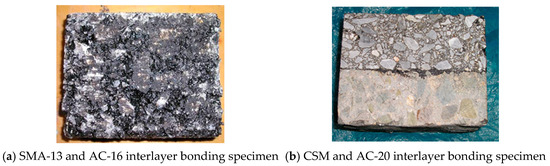

The interlayer shear specimen production process closely simulated actual pavement construction. A 30 cm × 30 cm × 5 cm lower slab was fabricated, followed by uniform application of a tack coat (1.0 kg/m2 design rate) to its surface. The upper layer was immediately compacted onto the tack-coated surface to form a composite slab, from which 10 cm × 10 cm × 10 cm shear specimens (5 cm per layer) were sectioned using a masonry saw (Figure 3). Representative specimens are shown in Figure 4. Three tack coat conditions were evaluated: untreated (no tack coat), emulsified asphalt, and SBS-modified asphalt.

Figure 3.

Preparation of shear test samples.

Figure 4.

Interlayer shear specimen.

2.2. Interlayer Shear Test

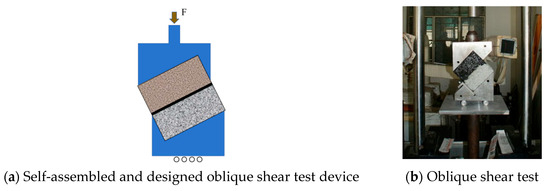

The oblique shear test employed an MTS mechanical testing system integrated with a custom shear fixture (Figure 5), applying a loading rate of 2 mm/min determined through preliminary trials to prevent premature specimen failure. Testing was conducted at 20 °C, 35 °C, and 50 °C with continuous load-displacement monitoring. Interlayer shear strength (τ) was calculated using Equation (1) [18], while bonding strength was determined via Equation (2).

where is shear strength of the bonding layer, P is the load, A is the shear area of the specimen, is inclination angle of the specimen, 45°.

where is the relative displacement between layers.

Figure 5.

Oblique shear test device.

2.3. Layered Linear Elasticity Considering Interlayer Bonding

Multilayered elastic theory (MLET), assuming isotropic materials and fully bonded interlayer continuity, serves as the foundational mechanical model for pavement structural design. While modern computational mechanics enables consideration of partial interlayer bonding [19,20,21], establishing a physically accurate interlayer mathematical model remains critical for precise mechanical response analysis. This MLET theory assumes each layer is homogeneous, isotropic, and linearly elastic, with body forces in the structural layers neglected, while all stresses and displacements vanish at points sufficiently far from the load. The widely adopted shear-elastic compliance model proposed by De Jong [19] addresses this need by representing the interface as an infinitely thin layer where shear stress (τ) induces relative horizontal displacement (u) proportional to τ through the relationship Equation (3), with ks denoting the shear elastic stiffness modulus. This approach has been successfully implemented in layered elastic systems by Maina [22] and Kazemi [23], demonstrating its efficacy in characterizing interface behavior beyond idealized full bonding.

where AK is the standard shear elastic compliance, and F is the interface horizontal force.

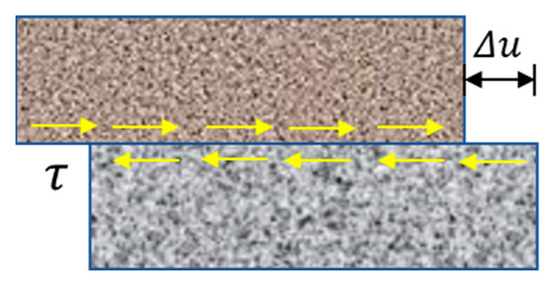

The Goodman model [24] provides a more accurate representation of actual pavement interlayer behavior by establishing direct proportionality between interlayer shear stress (τ) and relative displacement (u), expressed as Equation (4) and Figure 6. This relationship, where k denotes the interlayer shear stiffness modulus, better approximates real interface mechanics compared to idealized full-bond assumptions. This interlayer bonding model is applied to the mechanics of layered elastic systems, and the mechanical response of asphalt pavement structures is solved through the coefficient recurrence method. And the accuracy of the pavement mechanical response calculation program has been verified [2].

where K is the interface bond coefficient (N/mm3), is the shear stress (MPa).

Figure 6.

Interface mechanical model.

2.4. Analysis of the Influence of Interlayer Bonding on Pavement Structure

Four key damage indicators from China’s asphalt pavement design specifications [25]—asphalt layer fatigue, permanent deformation (rutting) in the asphalt layer, roadbed permanent deformation, and base fatigue—were analyzed to quantify interlayer bonding effects on pavement mechanical response. This analysis established critical thresholds differentiating fully bonded and fully debonded (sliding) interlayer states.

The fatigue life equation for the asphalt layer is expressed as Equation (5), in which VFA (asphalt saturation) and Ea (dynamic modulus) of the asphalt mixture are experimentally measured parameters, εa (strain) is computed via the mechanical analysis of MLET, while other parameters are selected in accordance with relevant specifications.

where is fatigue cracking life of the asphalt layer. is the target reliability index, = 1.65. is adjustment coefficient for seasonally frozen soil areas, = 1. is fatigue loading mode coefficient, = 0.87. is the temperature adjustment coefficient, = 0.6394. is asphalt saturation of the asphalt mixture (%). Ea is dynamic compressive modulus of the asphalt mixture at 20 °C.

The fatigue life equation for the semi-rigid base course is given by Equation (6), where Rs (flexural-tensile strength) of the base material is experimentally determined, σt (stress) is computed through the mechanical analysis of MLET, and other parameters are selected based on relevant specifications.

where is fatigue cracking of semi-rigid base, is the temperature adjustment coefficient, = 0.896. is bending and tensile strength of semi semi-rigid base material.

The permanent deformation calculation equation for the asphalt layer is expressed as Equation (7), where R0i (rut depth) of the asphalt mixture is experimentally determined through rutting tests, and pi (vertical stress at the top surface of sublayer i) is computed via mechanical analysis of MLET.

where is permanent deformation of the asphalt mixture layer. is permanent deformation of the i-th layer (mm). n is number of layers. is the equivalent temperature of permanent deformation of asphalt mixture layer (°C). Ne3 is accumulated number of equivalent design axle loads acting on the designed lane within the service life. hi is the thickness of the i-th layer(mm). is the permanent deformation during the rutting test (mm), when the i-th layer of asphalt mixture is tested at a temperature of 60 °C, a pressure of 0.7 MPa, and 2520 times of loading. is vertical compressive stress on the top surface of the i-th layer of the asphalt mixture layer (MPa).

3. Analysis of Calculation Methods for Interlayer Adhesion Coefficient

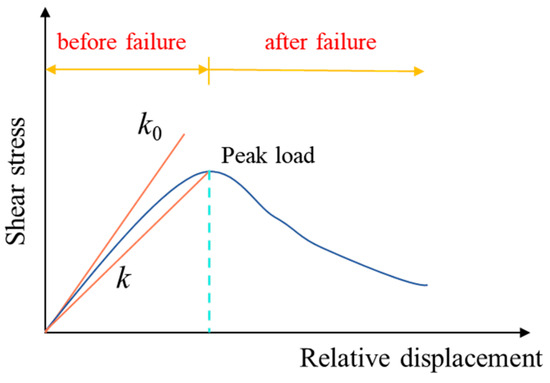

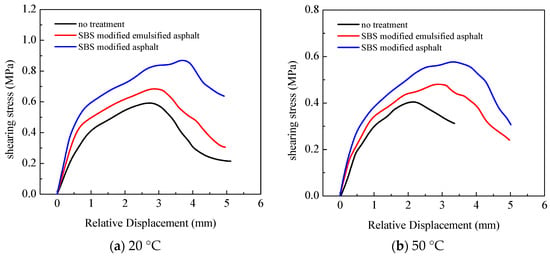

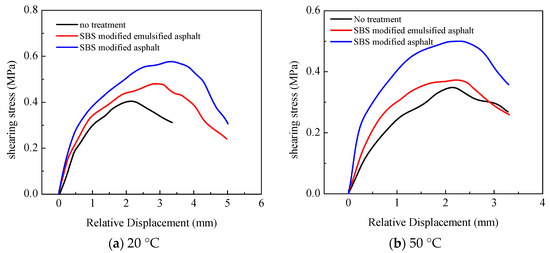

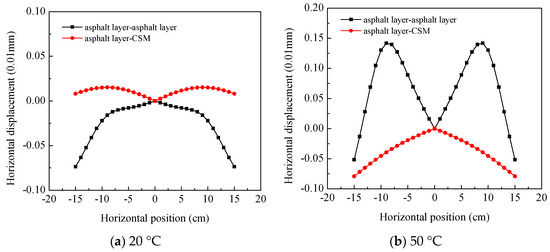

The shear stress versus relative displacement curve [26] of interlayer bonding is shown in Figure 7. It can be seen from Figure 7 that the interlayer shear stress changes synchronously with the increase of the relative displacement value before failure. It is not until the relative displacement increases to a certain critical value that the shear stress reaches its maximum value. Due to the presence of residual stress, shear stress does not decrease sharply. The slope corresponding to each displacement point represents the interface bond coefficient K. The K value is a variable value until the interface adhesion completely fails. Therefore, it is feasible to use the interlayer tangential modulus to evaluate the interlayer bonding performance. Due to the different values of the interlayer bonding coefficient at each position, it is an important issue to use the interlayer bonding coefficient at which point as the analysis index. At present, most studies use the load and relative displacement at the peak load to calculate the interlayer bonding coefficient. The calculation method of the interlayer adhesion coefficient needs to be discussed [27,28,29]. When the interlayer shear strength reaches its peak, the interlayer is already at the edge of failure. The variation curves of shear stress with relative displacement between the asphalt layer–asphalt layer and asphalt layer–CSM are shown in Figure 8 and Figure 9 at 20 °C and 50 °C, respectively. It can be vividly seen from Figure 8 and Figure 9 that the shear stress of interlayer bonding reaches its peak when the relative displacement reaches 2–4 mm. The horizontal displacement distribution of the upper-middle layers and asphalt layer–CSM layer of a 6-layer asphalt pavement structure, which is calculated by the layered elastic system mechanics program in Section 2.3, and was shown in Figure 10. It can be clearly seen from Figure 10 that the horizontal displacement between layers is less than 0.002 mm, and the maximum horizontal displacement is only 0.0015 mm at 50 °C. Therefore, it is not appropriate to use the peak value of interlayer shear stress to calculate the interlayer adhesion coefficient and the actual stress on the pavement structure. The ratio of shear stress to displacement at the initial moment should be used as the interlayer bonding coefficient, i.e., K0 in Figure 7.

Figure 7.

Interlayer shear stress versus relative displacement.

Figure 8.

Relationship between shear stress and relative displacement (asphalt layer—asphalt layer).

Figure 9.

Relationship between shear stress and relative displacement (asphalt layer—CSM).

Figure 10.

Horizontal displacement distribution of asphalt structure at different temperatures.

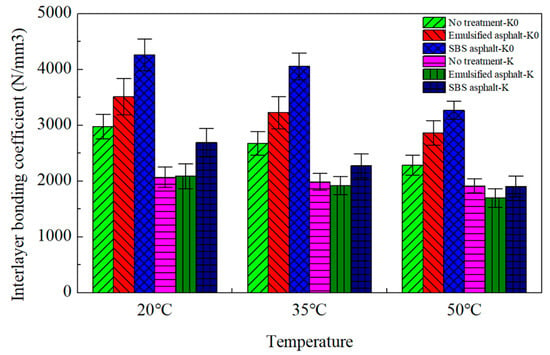

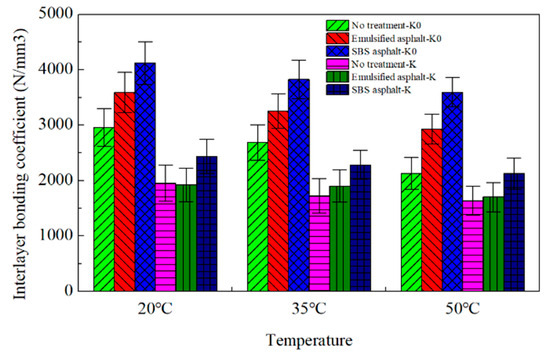

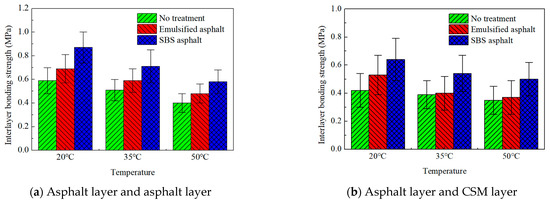

4. Analysis of Interlayer Bonding Performance

Table 7 and Table 8 and Figure 11, Figure 12 and Figure 13 present interlayer bonding coefficients and bonding strengths across treatment methods and temperatures. The data demonstrate that peak-based bonding coefficients (K) are consistently lower than initial coefficients (K0), confirming K0 as a more rational characterization parameter. Both K0 and bonding strength exhibit progressive reduction with rising temperatures, regardless of treatment method. Notably, inherent bonding persists even without interlayer treatment (though inferior to tack-coated interfaces), while SBS-modified asphalt yields superior coefficients and strength versus emulsified asphalt or untreated interfaces at all temperatures. Crucially, the material discontinuity between cement-stabilized macadam (CSM) and asphalt layers results in lower bonding parameters compared to asphalt–asphalt interfaces.

Table 7.

Bonding performance between asphalt layers at different temperatures.

Table 8.

Bonding performance between asphalt layer and CSM layer at different temperatures.

Figure 11.

Interlayer bonding coefficient between asphalt layer and asphalt layer.

Figure 12.

Interlayer bonding coefficient between asphalt layer and CSM layer.

Figure 13.

Interlayer bonding strength between different materials.

5. Analysis of the Mechanical Response of Interlayer Bonding to Pavement

To evaluate the influence of bonding conditions at asphalt–asphalt and asphalt–CSM interfaces on pavement mechanical response, interlayer bonding coefficients at 20 °C (Table 8) were analyzed alongside complete sliding and fully bonded scenarios. Using the Table 9 pavement structure, key responses—including structural stresses, asphalt layer fatigue life, permanent deformation, subgrade compressive strain, and base fatigue life—were computed via the interlayer-sensitive PADS program [2]. Subsequent application of Section 2.4 methodologies generated quantitative damage metrics (Table 10, Table 11, Table 12 and Table 13), revealing that interlayer bonding significantly governs all damage mechanisms. Critically, insufficient CSM–asphalt layer bonding substantially promotes asphalt layer fatigue cracking, with the CSM–surface interface exerting greater influence than asphalt–asphalt interfaces. Furthermore, the results indicate that none of the three evaluated interlayer treatment methods achieves complete adhesion between layers.

Table 9.

Structural forms of asphalt pavement.

Table 10.

Effect of interlayer bonding performance on fatigue life of asphalt layer.

Table 11.

Effect of interlayer bonding performance on fatigue life of semi-rigid base.

Table 12.

Effect of interlayer bonding performance on permanent deformation of subgrade.

Table 13.

Effect of interlayer bonding performance on permanent deformation of asphalt layer (mm).

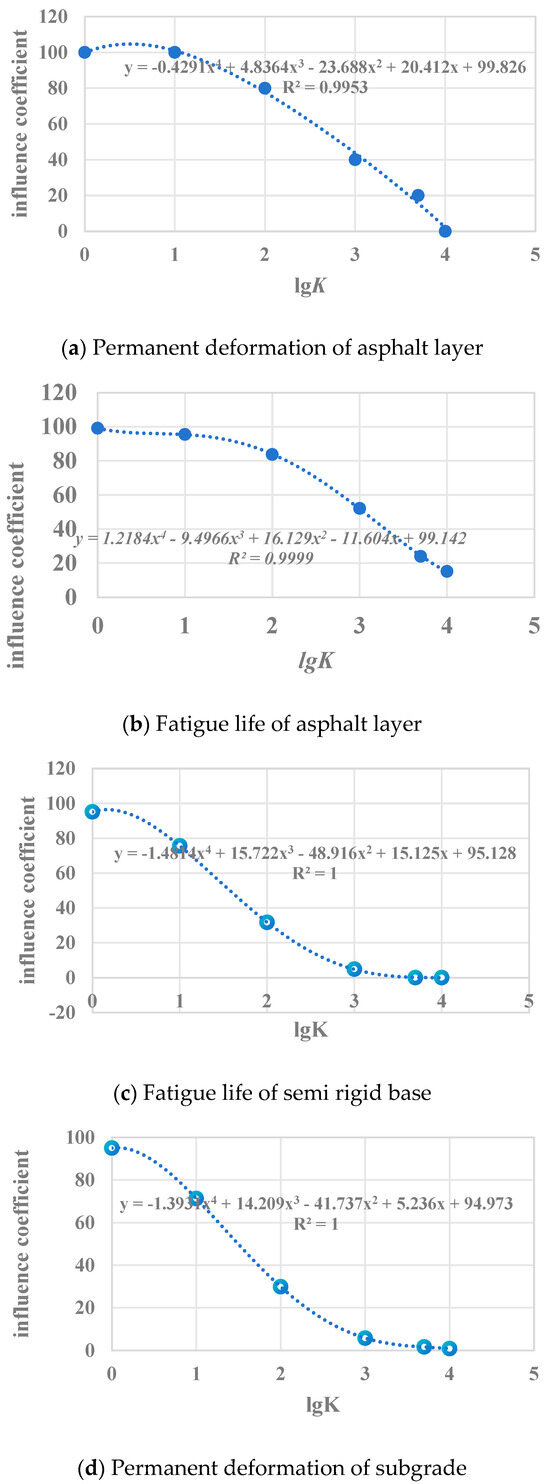

6. Analysis of Critical Values of Interlayer Bonding Coefficient

Analysis in Section 5 reveals the significant influence of the interlayer bonding performance on asphalt pavement performance. Given the absence of established standards for interlayer adhesion coefficients, critical values were determined by evaluating the impact of the bonding coefficient between the semi-rigid base and asphalt layer on structural performance. A representative 7-layer highway pavement structure (properties in Table 9) was analyzed using adhesion coefficients between the CSM and asphalt layer ranging from complete sliding to complete bonding (1, 10, 100, 1000, 5000, 10,000 MPa/cm). As shown in Table 14, this bonding condition minimally affects asphalt layer permanent deformation, moderately influences semi-rigid base fatigue life and subgrade permanent deformation, and most significantly impacts CSM fatigue life. Influence coefficients calculated via Equation (8) (Figure 14, Table 15) yielded the control values in Table 16 using a 10% influence threshold. Notably, asphalt layer permanent deformation—being substantially below the specification limit of 10 mm—was excluded from this control criterion. The results demonstrate that interlayer bonding coefficients exceeding 5000 MPa/cm effectively represent complete bonding between the CSM and asphalt layers.

where IC is the influence coefficient, Rk is the mechanical response when the interfacial adhesion coefficient is K, and Rfb is the mechanical response when the interfacial adhesion coefficient is fully bonded.

Table 14.

Performance of pavement under different interlayer bonding conditions.

Figure 14.

Influence coefficient of pavement performance under different interlayer bonding conditions.

Table 15.

Influence coefficient under different interlayer bonding conditions.

Table 16.

Complete adhesion coefficient between layers with different road performance.

7. Conclusions

This study investigates the impact of interlayer treatment methods on pavement mechanical response and establishes a theoretical framework for the bonding coefficient under fully continuous interlayer conditions. Key findings include the following:

- (1)

- Analysis of shear stress–displacement relationships reveals peak shear stress occurs at 2–4 mm displacement—orders of magnitude greater than actual structural displacements (<0.002 mm) calculated via layered elastic theory. This validates the initial shear stress–displacement ratio as the appropriate bonding coefficient metric.

- (2)

- Oblique shear testing demonstrates significant inherent bonding without treatment, while tack coats substantially enhance performance. SBS-modified asphalt consistently outperforms other methods, providing 40–50% higher bonding strength than untreated interfaces and 15–20% higher than emulsified asphalt across all temperatures (20 °C, 35 °C, 50 °C). Material incompatibility reduces asphalt–CSM bonding effectiveness by 18–25% compared to asphalt–asphalt interfaces.

- (3)

- The CSM–asphalt interface critically governs pavement performance, particularly asphalt surface fatigue life. This interface exerts 3.2× greater influence on fatigue life than on permanent deformation. A bonding coefficient threshold of >5000 MPa/cm is required to achieve mechanical equivalence to fully bonded conditions.

Author Contributions

Conceptualization, W.G. and S.C.; methodology, Z.B.; software, S.C.; validation, Q.Z. and D.T.; investigation, Q.Z. and D.T.; writing—review and editing, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

Authors Weijun Guo, Zhanjun Bai, Qunfeng Zhang, and Daizhou Tong are employed by the company Zhejiang Huhangyong Maintenance Engineering Co., Ltd. The rest author declare no conflict of interest.

References

- Yang, K.; Li, R. Characterization of bonding property in asphalt pavement interlayer: A review. J. Traffic Transp. Eng. 2021, 8, 374–387. [Google Scholar] [CrossRef]

- Chen, S.; Wang, D.; Yi, J.; Feng, D. Analytical calculations for asphalt pavement considering interlayer performance. J. Transp. Eng. Part B Pavements 2022, 148, 04022022. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Gong, M.; Huang, Q.; Ren, H. Interlayer residual stress analysis of steel bridge deck pavement during gussasphalt pavement paving. Constr. Build. Mater. 2022, 324, 126624. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, F.; Chen, Z.; Li, X.; Amirkhanian, S. Application of Tack Coat in Pavement Engineering. Constr. Build. Mater. 2017, 152, 856–871. [Google Scholar] [CrossRef]

- Wang, X.; Su, Z.; Xu, A.; Zhou, A.; Zhang, H. Shear fatigue between asphalt pavement layers and its application in design. Constr. Build. Mater. 2017, 135, 297–305. [Google Scholar] [CrossRef]

- Covey, D.; Coleri, E.; Mahmoud, A. Tack coat rheological properties and the effects on interlayer shear strength. J. Mater. Civ. Eng. 2017, 29, 04017221. [Google Scholar] [CrossRef]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Innovative composite materials as reinforcing interlayer systems for asphalt pavements: An experimental study. Road Mater. Pavement Des. 2019, 20 (Suppl. 2), S617–S631. [Google Scholar] [CrossRef]

- Ragni, D.; Takarli, M.; Petit, C.; Graziani, A.; Canestrari, F. Use of acoustic techniques to analyse interlayer shear-torque fatigue test in asphalt mixtures. Int. J. Fatigue 2020, 131, 105356. [Google Scholar] [CrossRef]

- Raab, C.; Abd El Halim, A.O.; Partl, M.N. Interlayer bond testing using a model material. Constr. Build. Mater. 2012, 26, 190–199. [Google Scholar] [CrossRef]

- Raposeiras, A.C.; Vega-Zamanillo, Á.; Calzada-Pérez, M.A.; Castro-Fresno, D. Influence of surface macro-texture and binder dosage on the adhesion between bituminous pavement layers. Constr. Build. Mater. 2012, 28, 187–192. [Google Scholar] [CrossRef]

- Raposeiras, A.C.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Rodriguez-Hernandez, J. Test methods and influential factors for analysis of bonding between bituminous pavement layers. Constr. Build. Mater. 2013, 43, 372–381. [Google Scholar] [CrossRef]

- Isailović, I.; Wistuba, M.P. Asphalt mixture layers’ interface bonding properties under monotonic and cyclic loading. Constr. Build. Mater. 2018, 168, 590–597. [Google Scholar] [CrossRef]

- Liu, M.; Han, S.; Pan, J.; Ren, W. Study on cohesion performance of waterborne epoxy resin emulsified asphalt as interlayer materials. Constr. Build. Mater. 2018, 177, 72–82. [Google Scholar] [CrossRef]

- Huang, H.; Zhan, Y.; Tao, Y.; Ai, C.; Ren, D.; Jin, D. Three-dimensional characterization of bonding features for asphalt pavement interface using a novel interlayer isolation film. Constr. Build. Mater. 2021, 311, 125301. [Google Scholar] [CrossRef]

- Rahman, A.; Huang, H.; Ai, C.; Ding, H.; Xin, C.; Lu, Y. Fatigue performance of interface bonding between asphalt pavement layers using four-point shear test set-up. Int. J. Fatigue 2019, 121, 181–190. [Google Scholar] [CrossRef]

- Ai, C.; Rahman, A.; Song, J.; Gao, X.; Lu, Y. Characterization of interface bonding in asphalt pavement layers based on direct shear tests with vertical loading. J. Mater. Civ. Eng. 2017, 29, 04017102. [Google Scholar] [CrossRef]

- Ye, H.; Wang, X.; Fang, N.; Su, Z.; Sun, X. Interlayer Working Conditions Classification and Treatment Measures of Airport Asphalt Pavement Overlay. J. Adv. Transp. 2019, 2019, 9646091. [Google Scholar] [CrossRef]

- Li, P.; Niu, T.F.; Zhang, Y.L.; MA, K. Study on Anti-shearing Property of Asphalt Pavement for Concrete Bridge Deck Based on Oblique Shear Test. J. Wuhan Univ. Technol. Transp. Sci. Eng. 2015, 39, 1071–1075. [Google Scholar] [CrossRef]

- De Jong, D.L. Computer Program Bisar, Layered Systems under Normal and Tangential Loads; Report assumed; Koninklijke/Shell Laboratorium: Amsterdam, The Netherlands, 1979. [Google Scholar]

- You, L.; Yan, K.; Hu, Y.; Ma, W. Impact of interlayer on the anisotropic multi-layered medium overlaying viscoelastic layer under axisymmetric loading. Appl. Math. Model. 2018, 61, 726–743. [Google Scholar] [CrossRef]

- Wu, S.; Chen, H.; Zhang, J. Effects of interlayer bonding conditions between semi-rigid base layer and asphalt layer on mechanical responses of asphalt pavement structure. Int. J. Pavement Res. Technol. 2017, 10, 274–281. [Google Scholar] [CrossRef]

- Maina, J.W.; De Beer, M.; Matsui, K. Effects of layer interface slip on the response and performance of elastic multi-layered flexible airport pavement systems. In Proceedings of the 5th International Conference on Maintenance and Rehabilitation of Pavements and Technological Control, Park City, UT, USA, 8–10 August 2007; pp. 145–150. [Google Scholar]

- Kazemi, S.F.; Hand, A.J.T.; Hajj, E.Y.; Sebaaly, P.E. Modeling Interface Debonding between Asphalt Layers under Dynamic Aircraft Loading. In Proceedings of the International Conference on Highway Pavements and Airfield Technology 2017, Philadelphia, PA, USA, 27–30 August 2017; pp. 378–388. [Google Scholar]

- Goodman, R.E.; Taylor, R.L.; Brekke, T.L. A model for the mechanics of jointed rock. J. Soil Mech. Found. Div. 1968, 94, 637–659. [Google Scholar] [CrossRef]

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. China Communications Press: Beijing, China, 2017.

- Chen, J.-S.; Huang, C.-C. Effect of Surface Characteristics on Bonding Properties of Bituminous Tack Coat. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 142–149. [Google Scholar] [CrossRef]

- Al-Hosainat, A.; Nazzal, M.D.; Talha, S.A.; Kim, S.S.; Abbas, A.; Mohammad, L. A comprehensive laboratory evaluation of the factors affecting the Micro-Surfacing interlayer bond strength. Constr. Build. Mater. 2022, 323, 126538. [Google Scholar] [CrossRef]

- Yang, K.; Li, R.; Yu, Y.; Pei, J.; Liu, T. Evaluation of interlayer stability in asphalt pavements based on shear fatigue property. Constr. Build. Mater. 2020, 258, 119628. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Ahmadi, S. Laboratory investigation of modified bitumen for interlayer in rigid–flexible composite pavement. J. Thermoplast. Compos. Mater. 2022, 35, 1866–1888. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).