A Sustainable Hybrid Approach to Improve Footing Bearing Capacity Using EICP and Inclined Micropiles

Abstract

1. Introduction

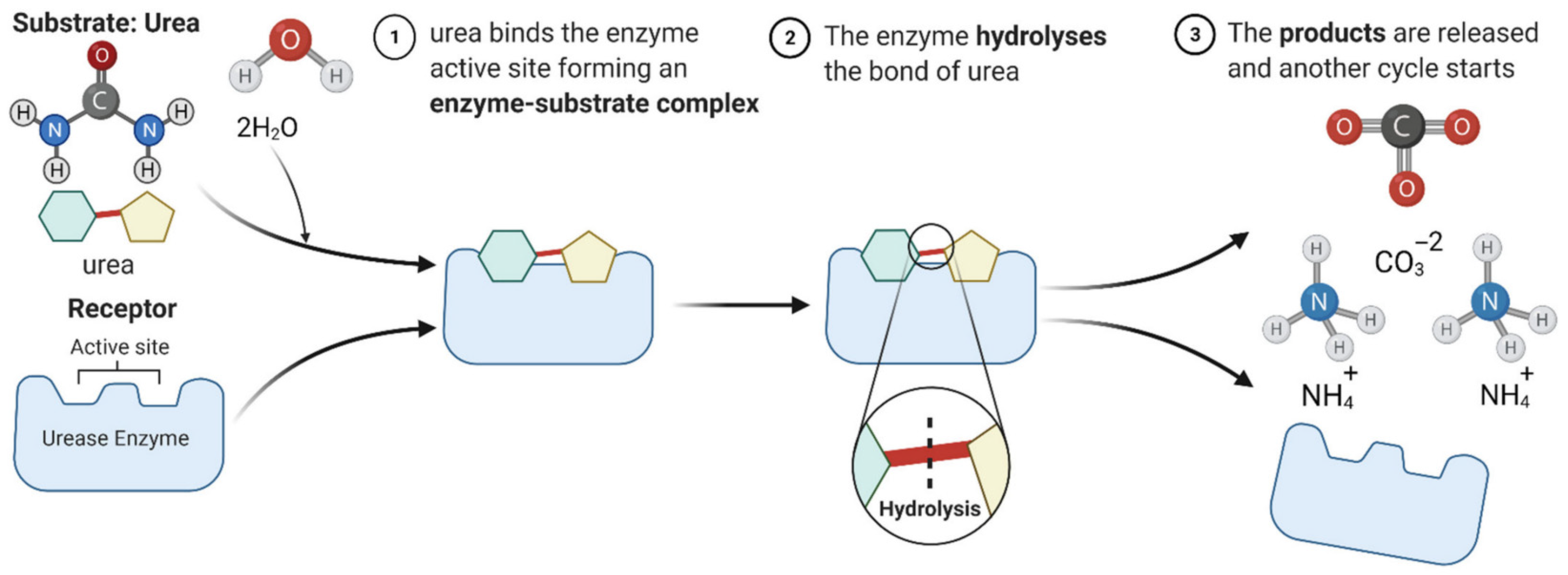

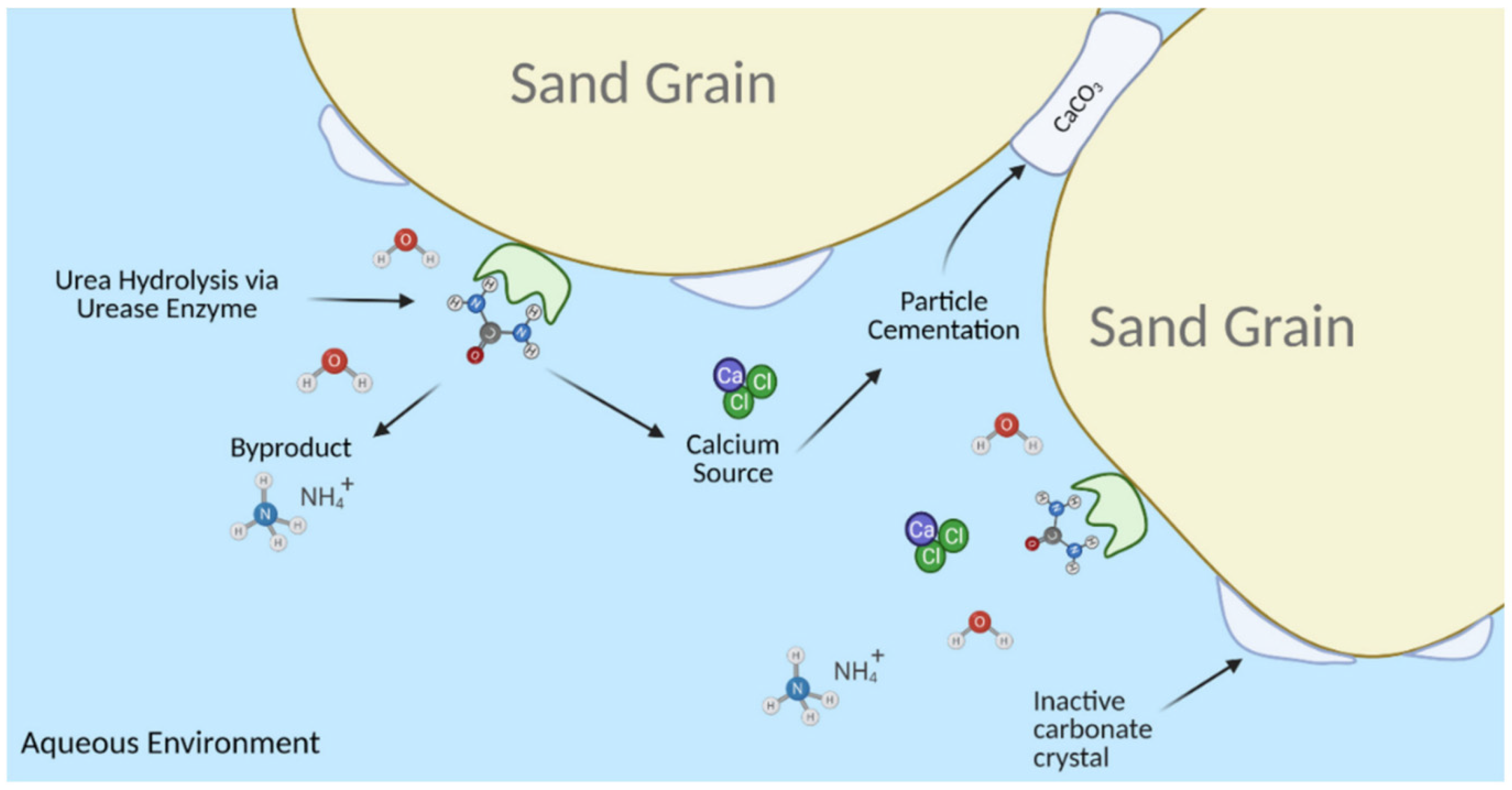

2. EICP: Theoretical Framework

3. Materials

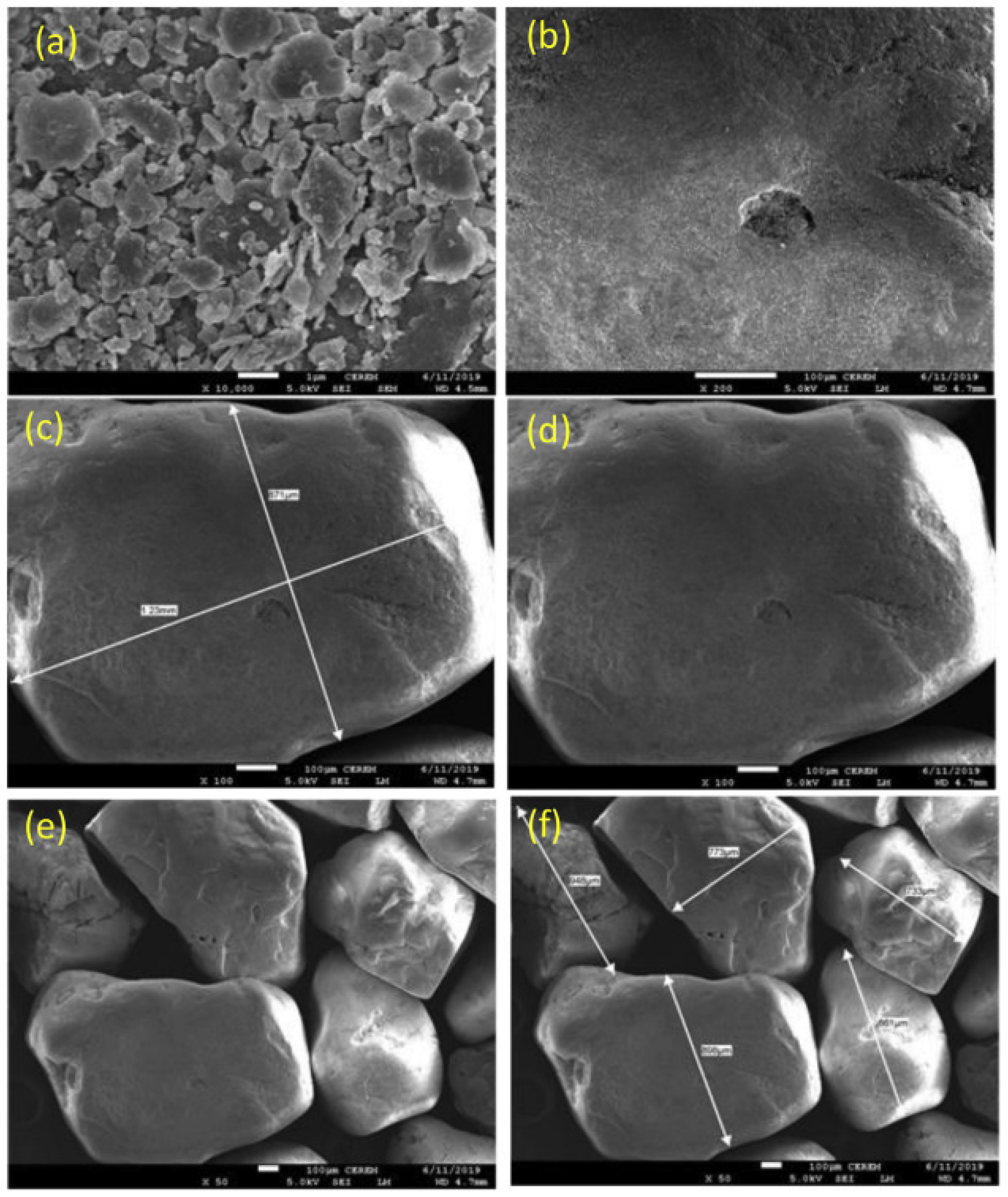

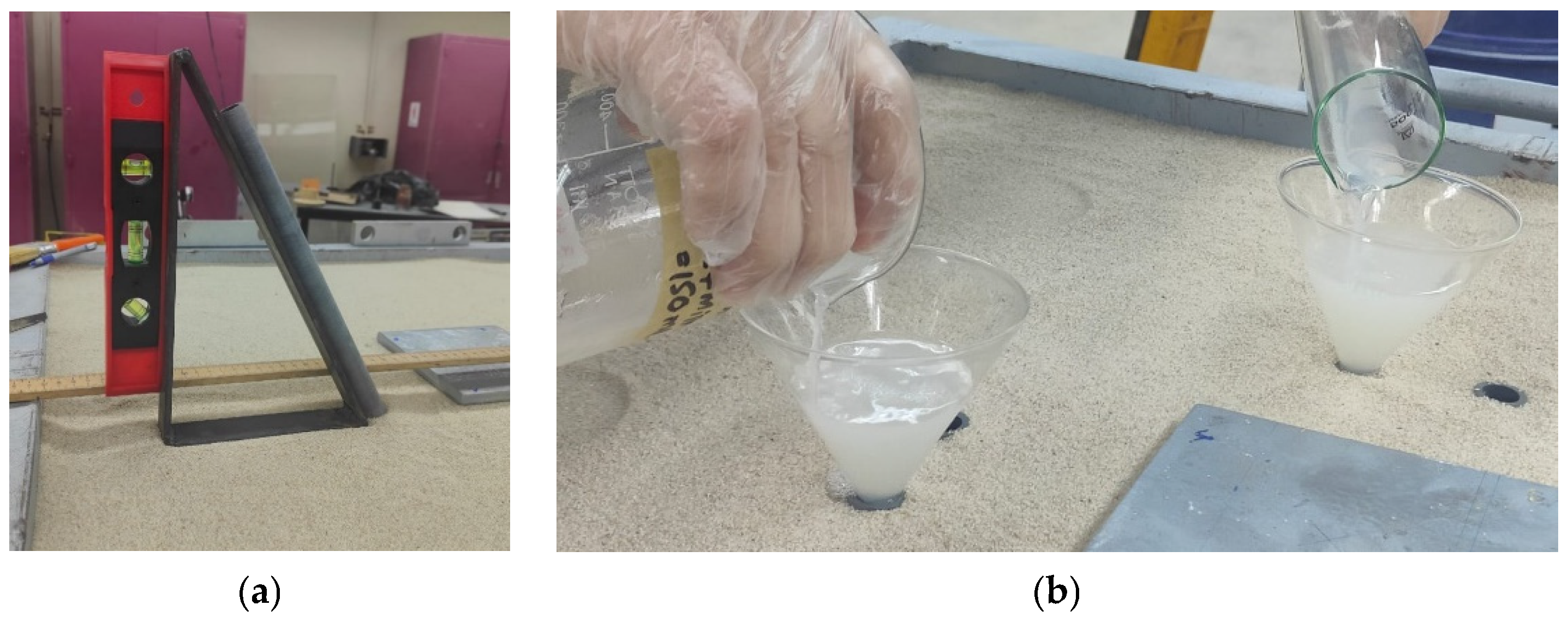

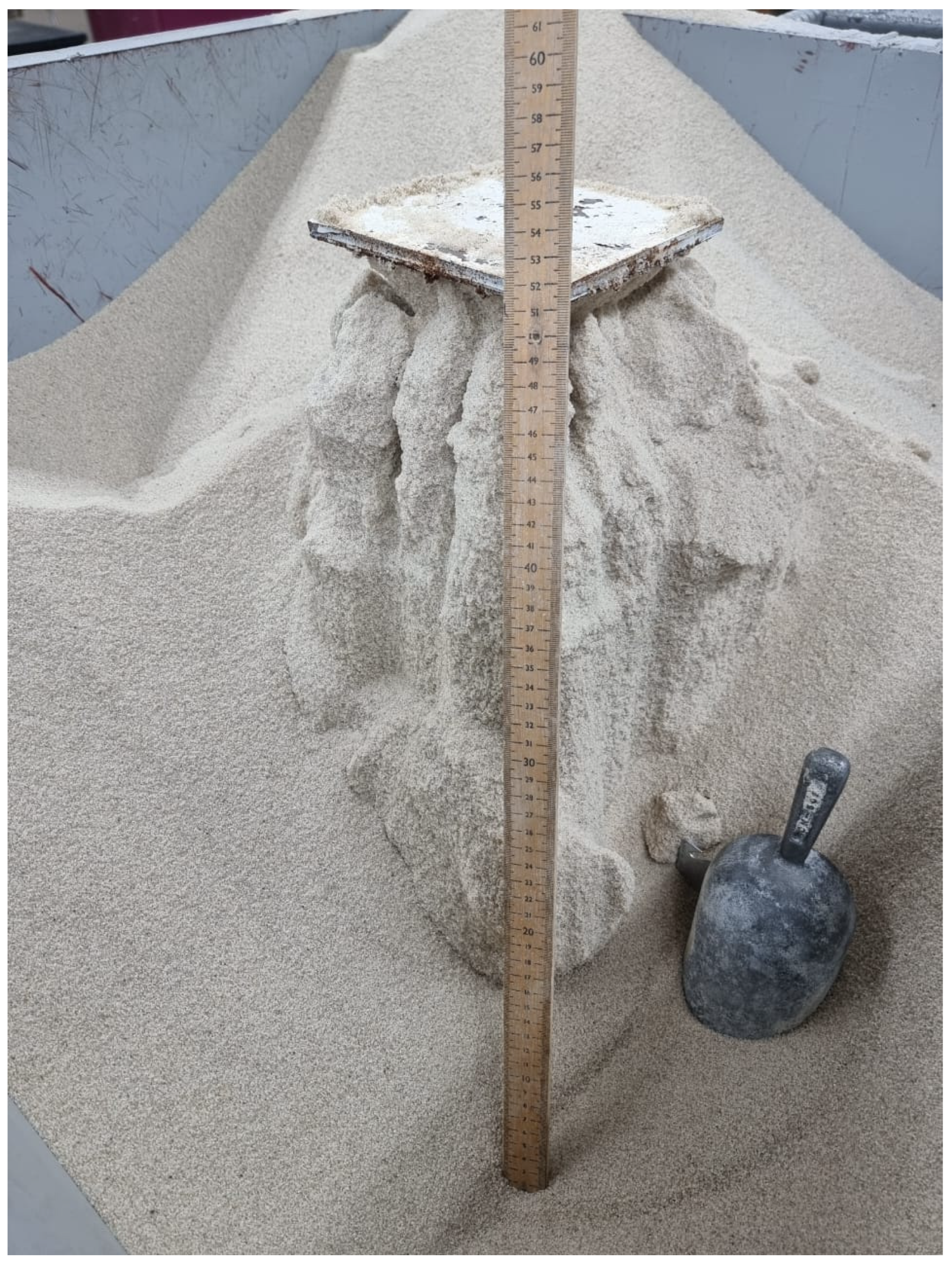

3.1. Sand

3.2. EICP Solution Preparation

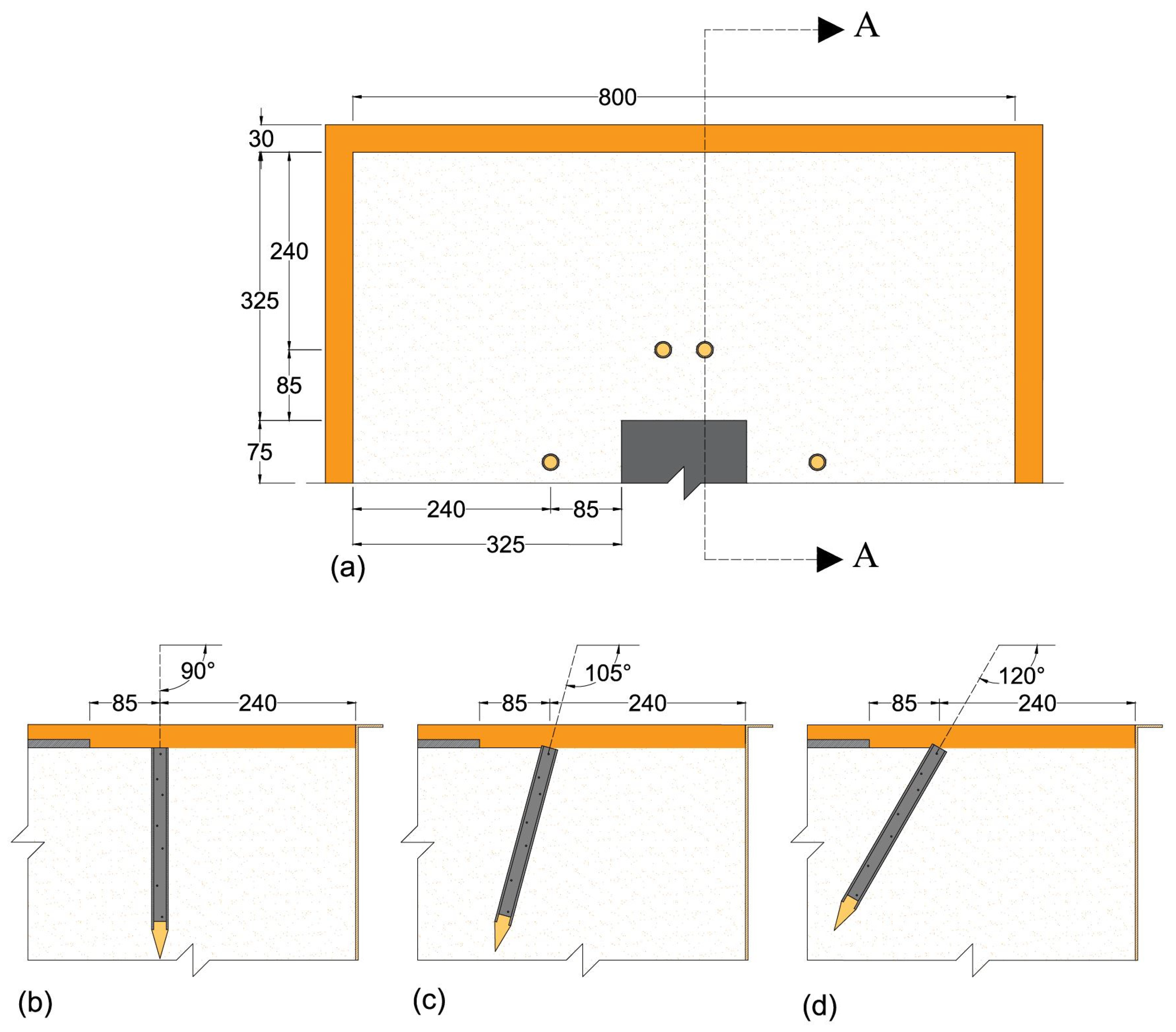

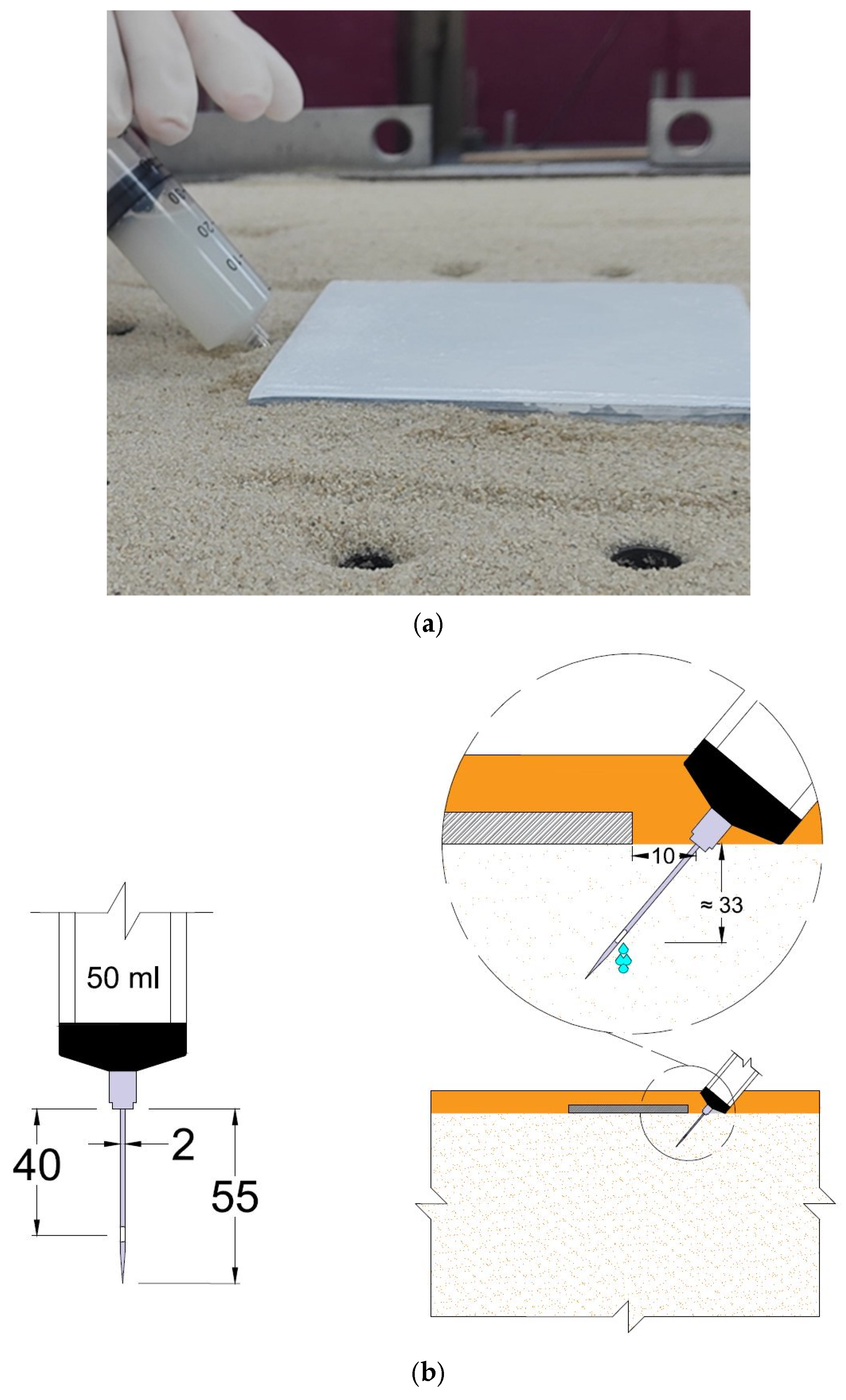

4. Test Setup and Procedures

4.1. Test Matrix

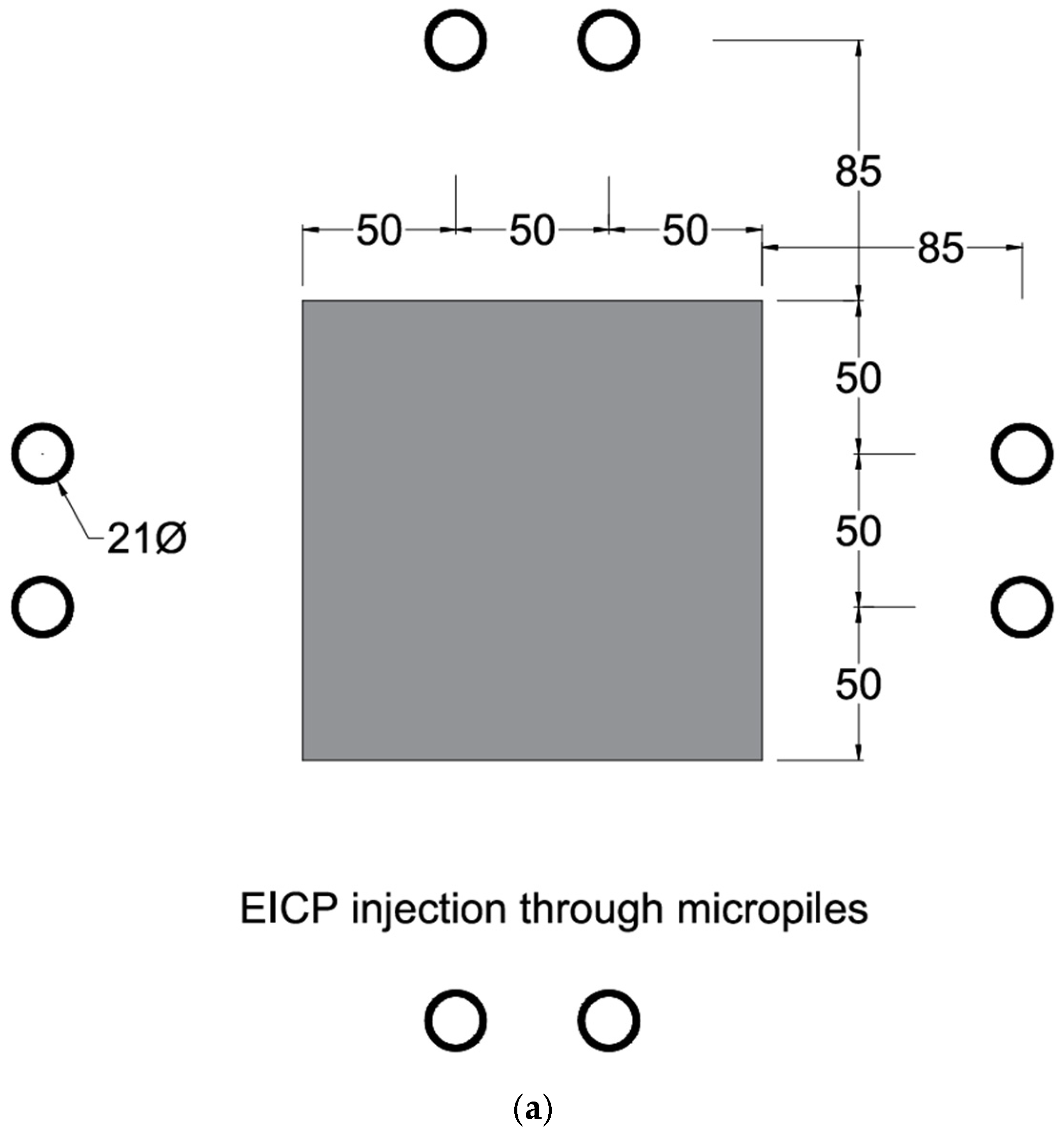

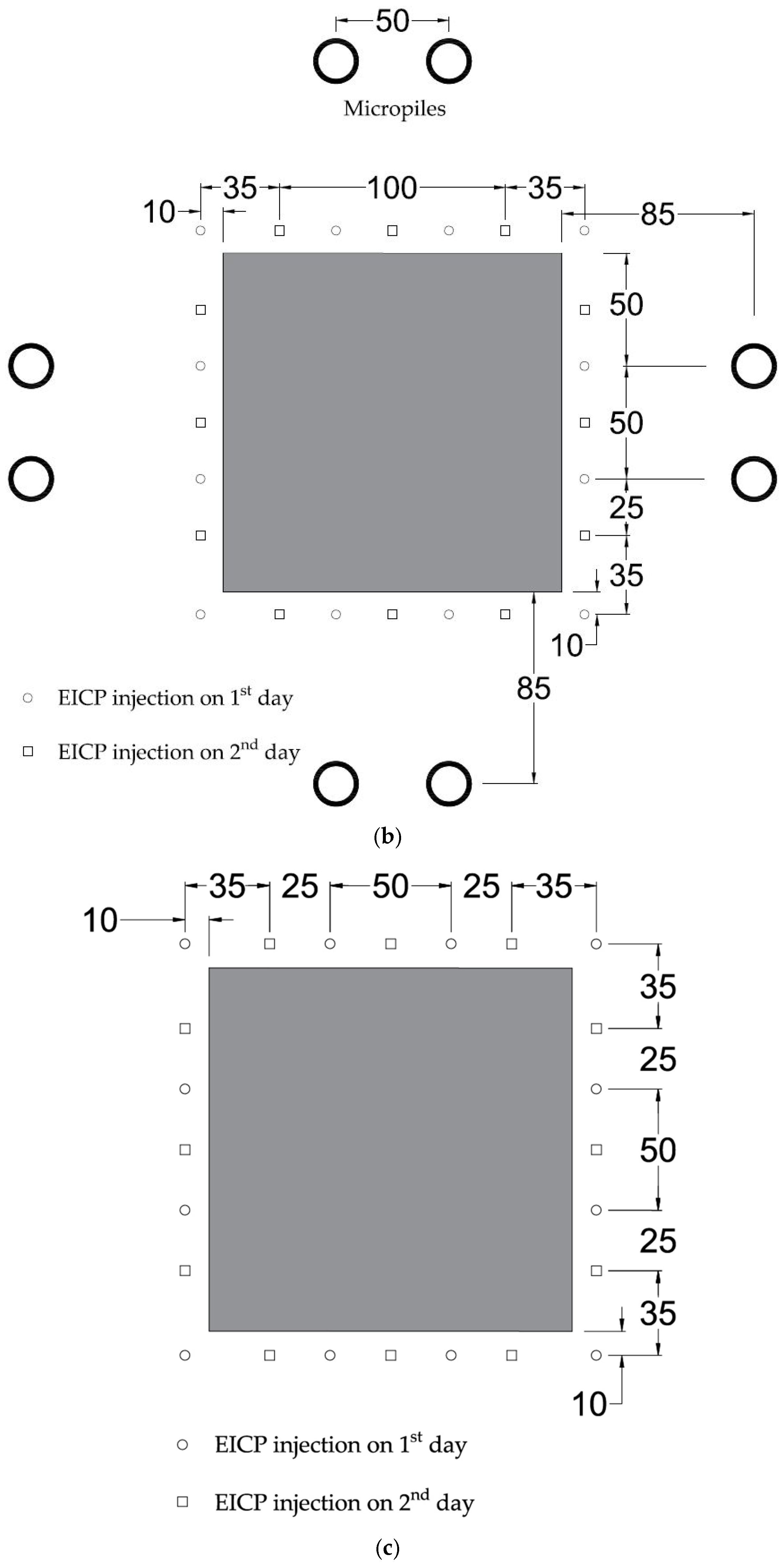

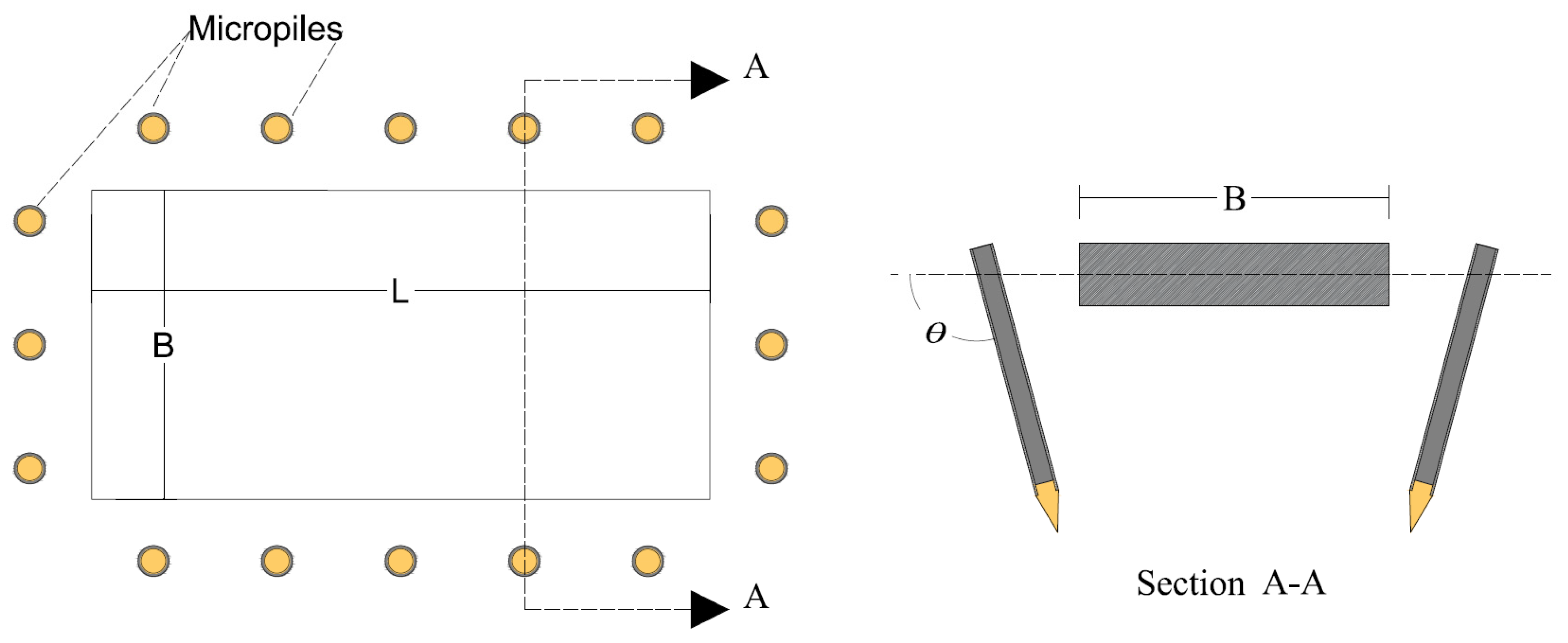

4.2. Micropile Details

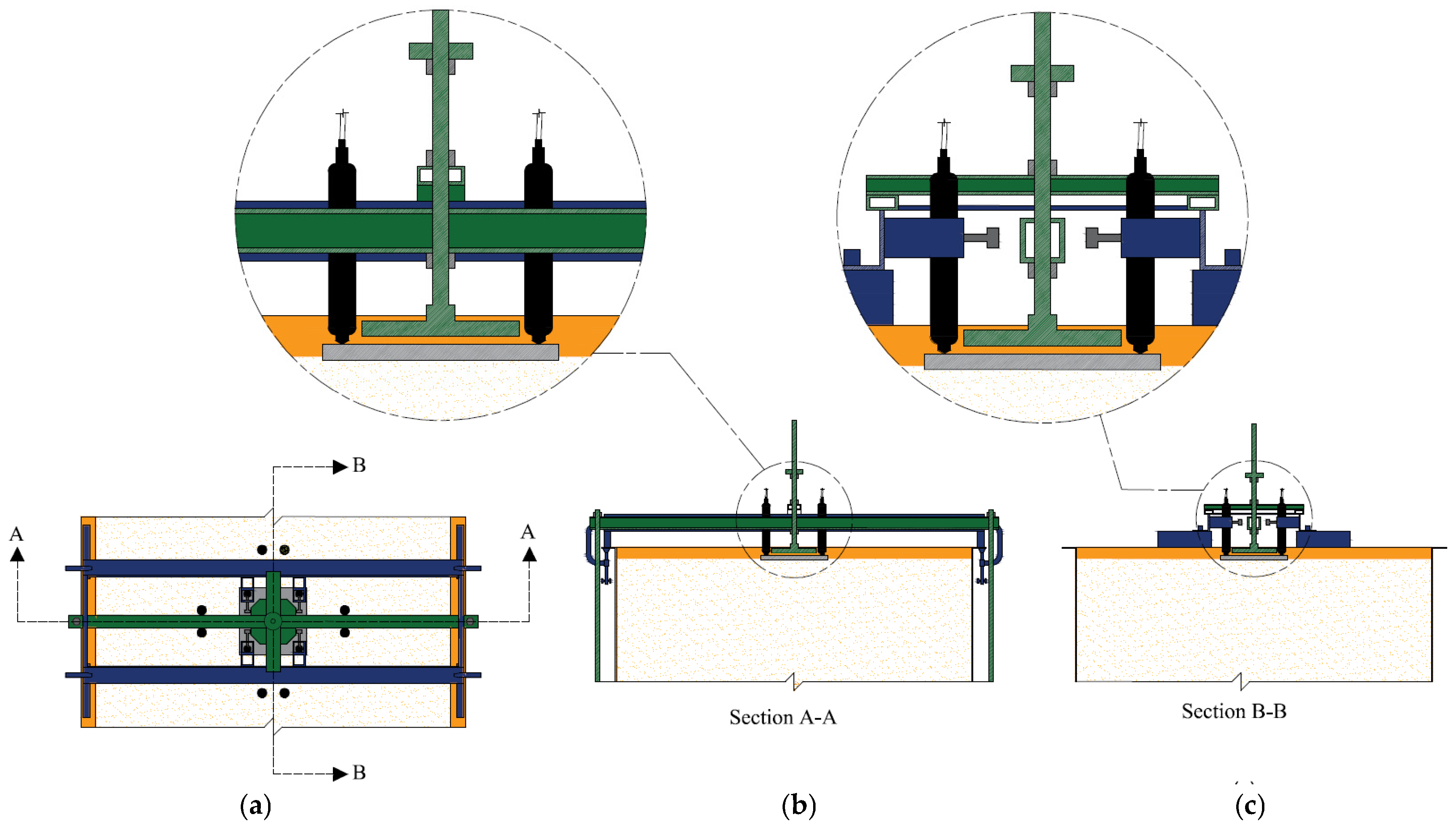

4.3. Test Setup

5. Test Results and Discussion

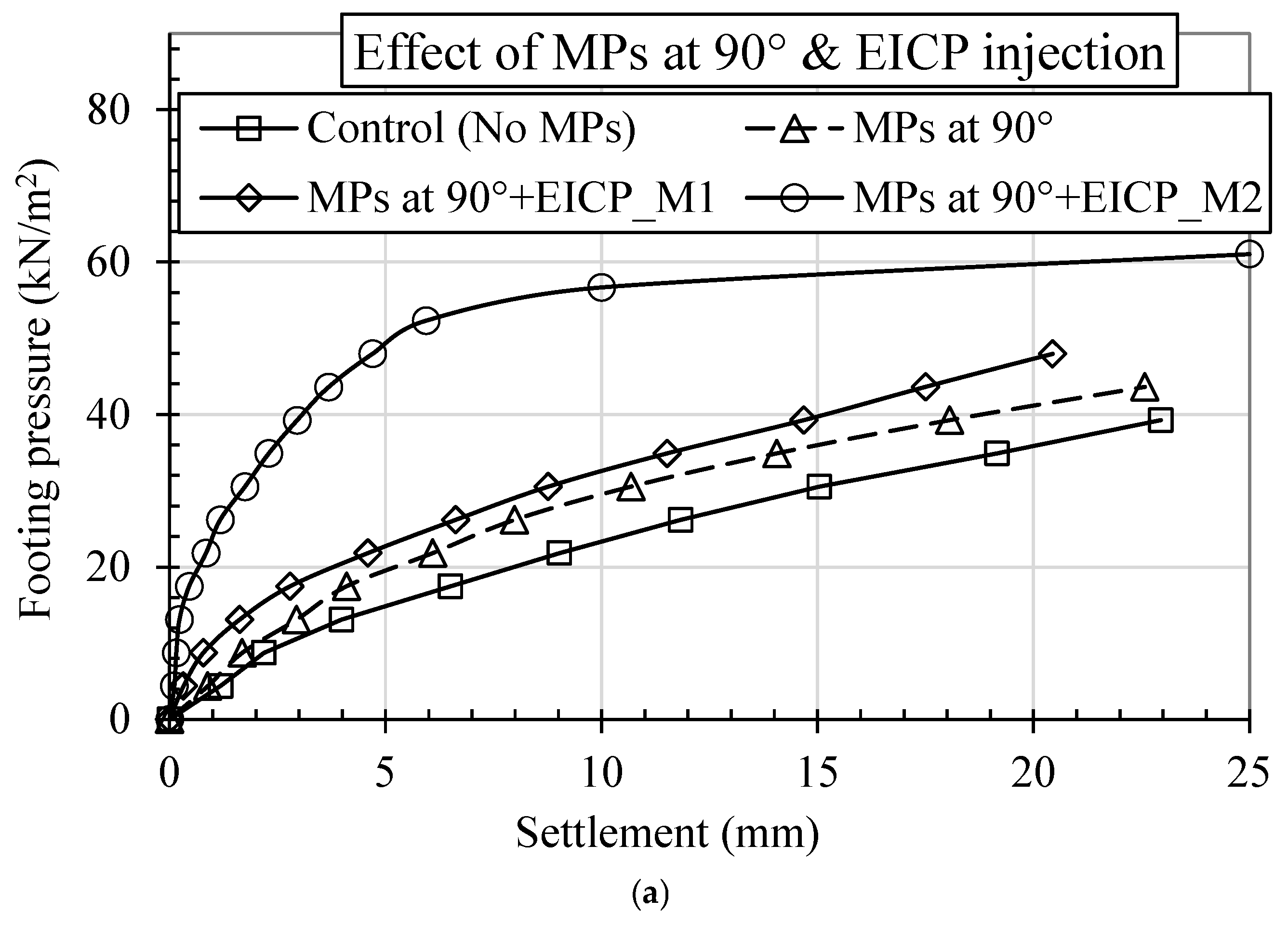

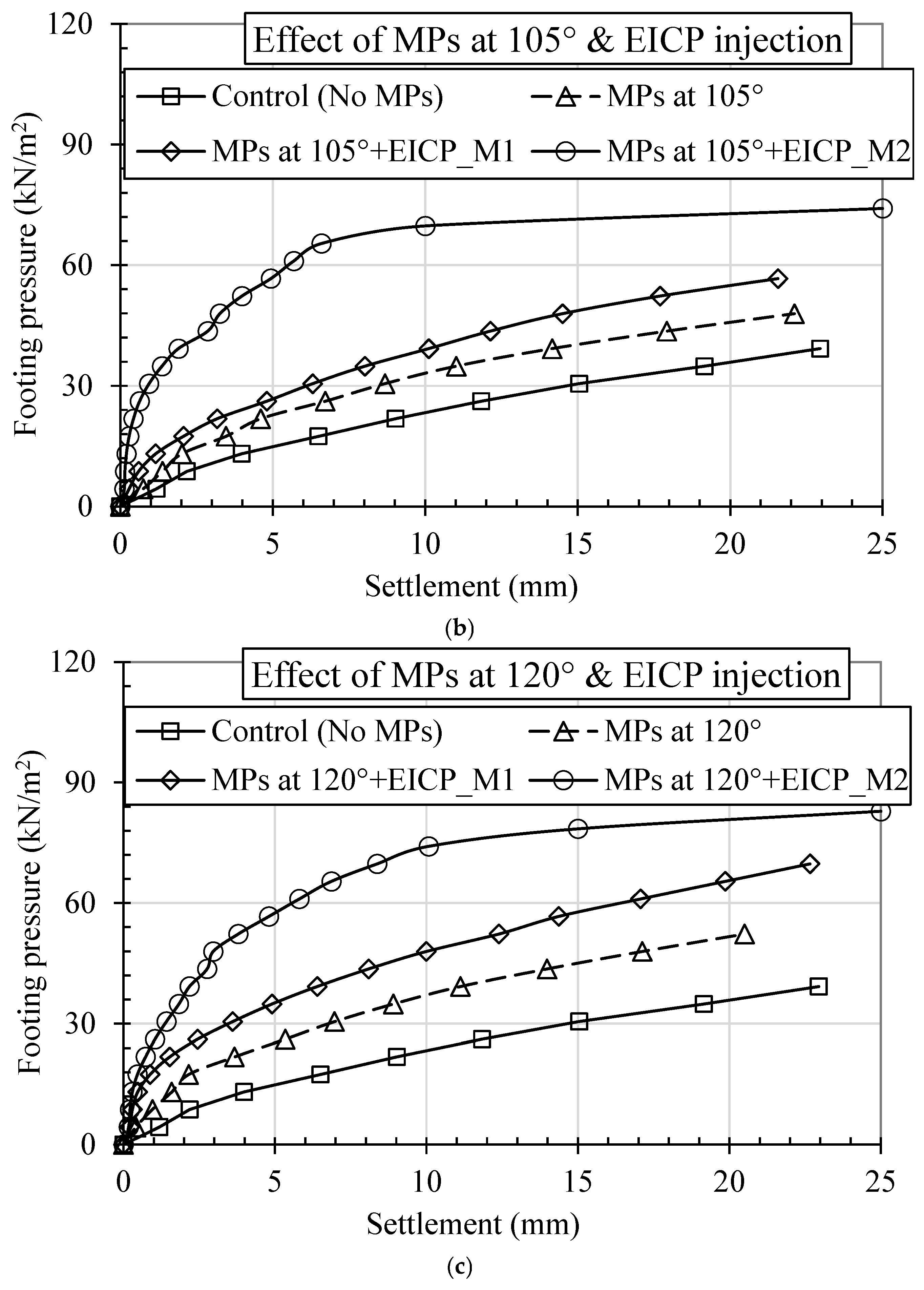

- Irrespective of the micropiles’ inclination, the pattern of footing pressure variation with settlement is similar for both EICP injection methods.

- As the angle of inclination of the micropiles increases, the rate of footing pressure increase with settlement also rises. Additionally, EICP injection significantly amplified this rate, with method M2 of EICP injection showing a much higher increase in footing pressure as settlement progresses. Furthermore, as the footing pressure increases, the rate of increase in settlement increases. This increase in settlement at higher loads is more pronounced with method M2 of EICP injection, likely due to the sudden collapse of the solidified sand clumps (Figure 10 and Figure 11).

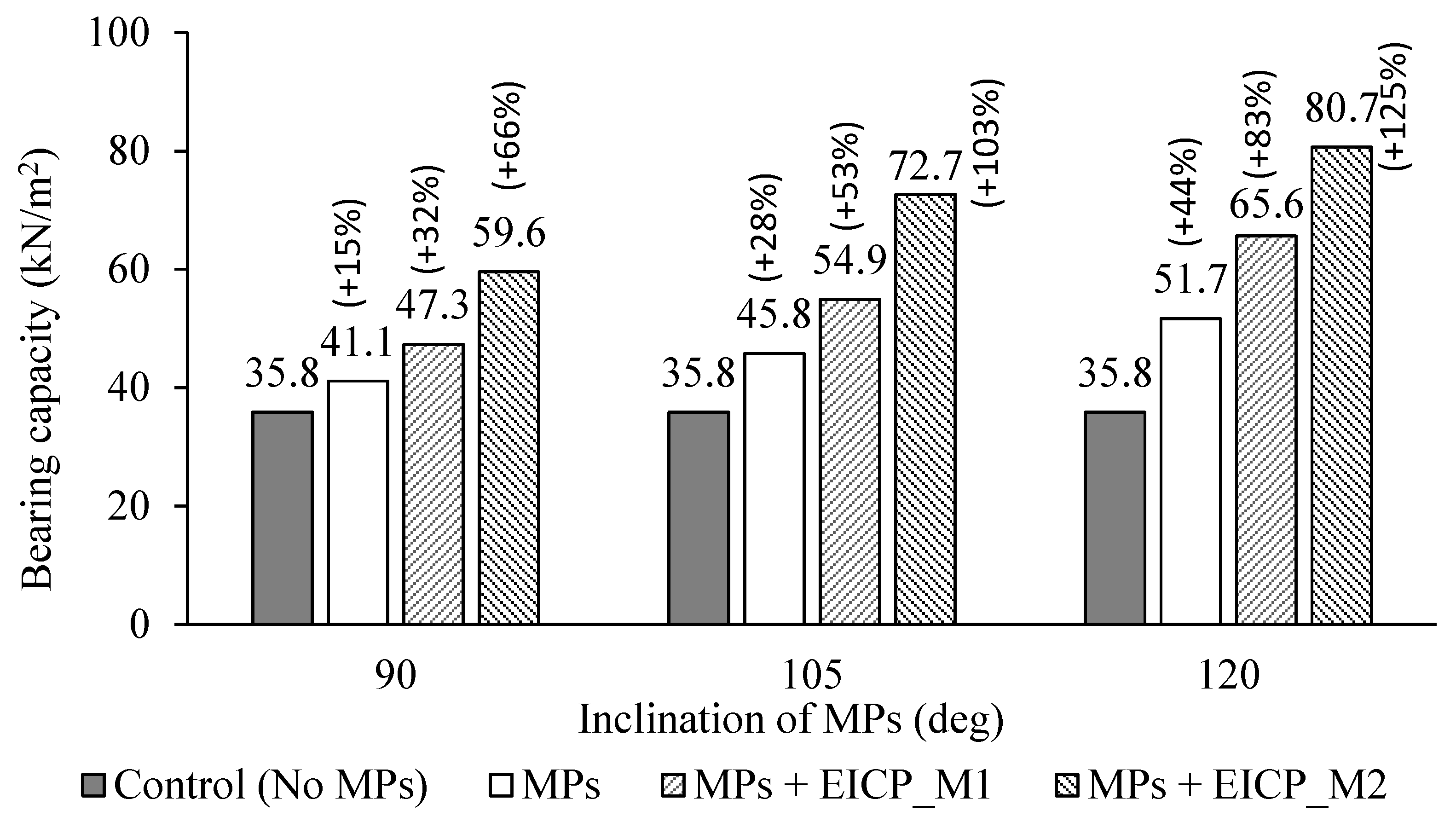

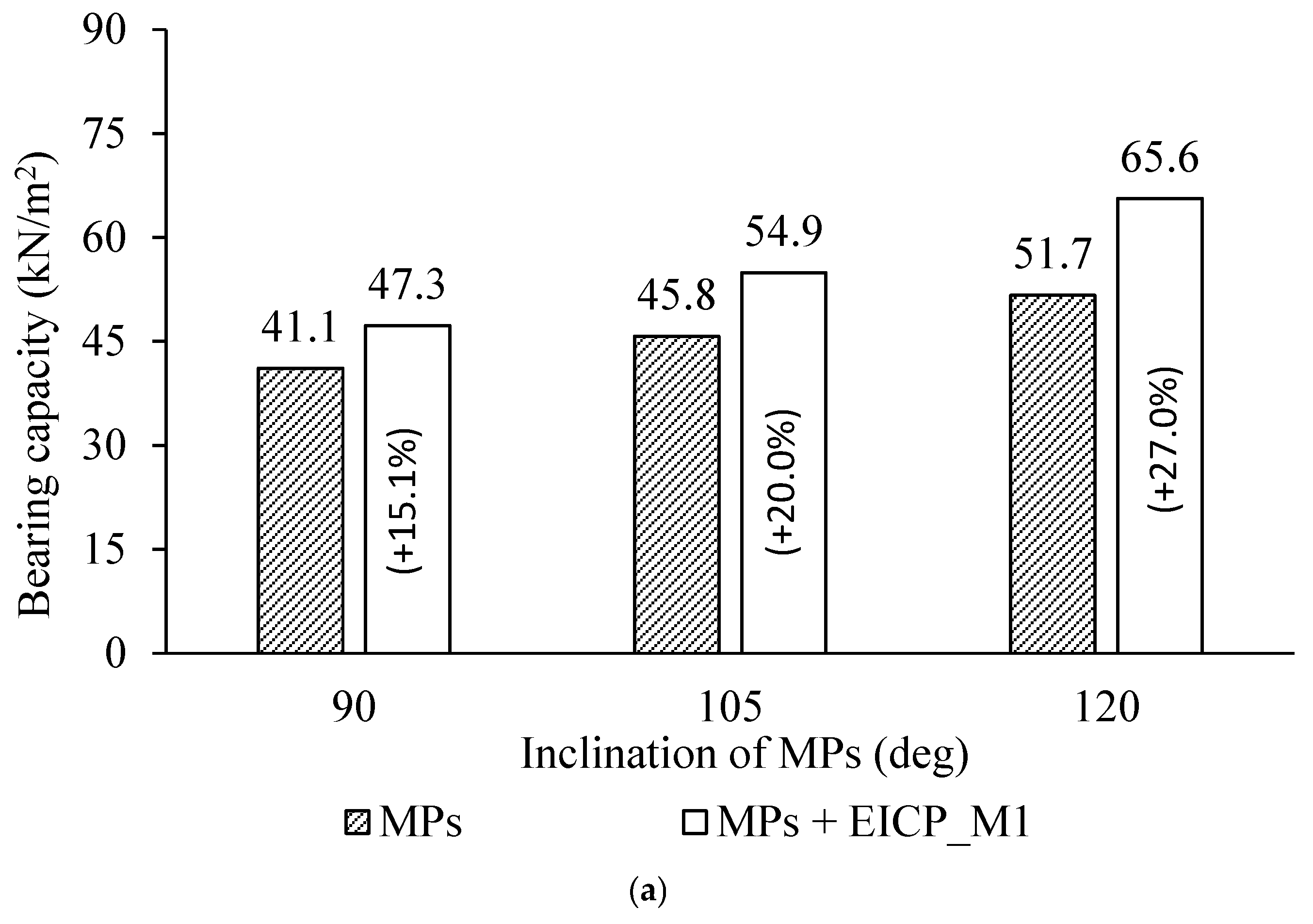

- The incorporation of EICP through micropiles (method M1) significantly enhanced the load-bearing capacity of the footing, with a notable increase observed as the inclination angle of the micropiles increased. Compared to the control, the bearing capacity improvements for footings confined by EICP-injected micropiles at inclinations of 90°, 105°, and 120° were 32%, 53%, and 83%, respectively (Figure 12). In contrast, without EICP injection, the increases were only 15%, 28%, and 44% at the same inclination angles, as seen from Figure 12 [38]. It is evident that the load-bearing capacity enhancement achieved by combining EICP (injected through micropiles) with micropiles is significantly higher compared to the incorporation of micropiles alone. The EICP injection of soil through micropiles (method M1) caused 15%, 20%, and 27% increases in the bearing capacity of footings (compared to the footing with micropiles alone) for inclinations of 90°, 105°, and 120°, respectively (Figure 13a). The substantial enhancements observed for EICP-injected micropiles are credited to the combined effect of soil confinement by the micropiles (which enhances with the enhancement in micropile’s angle of inclination) and the calcification process, which intensifies with increasing pile inclination. Notably, the EICP solution incorporated with micropiles at 120° exhibited a much higher effect compared to the EICP solution incorporated at 90°. This can be attributed to the closer or beneath-the-footing sand cementation that occurs at a 120° inclination, whereas the cementation at a 90° inclination is not as close. The use of EICP offers a low-carbon, bio-mediated alternative to traditional cement-based ground improvement, contributing to environmental sustainability.

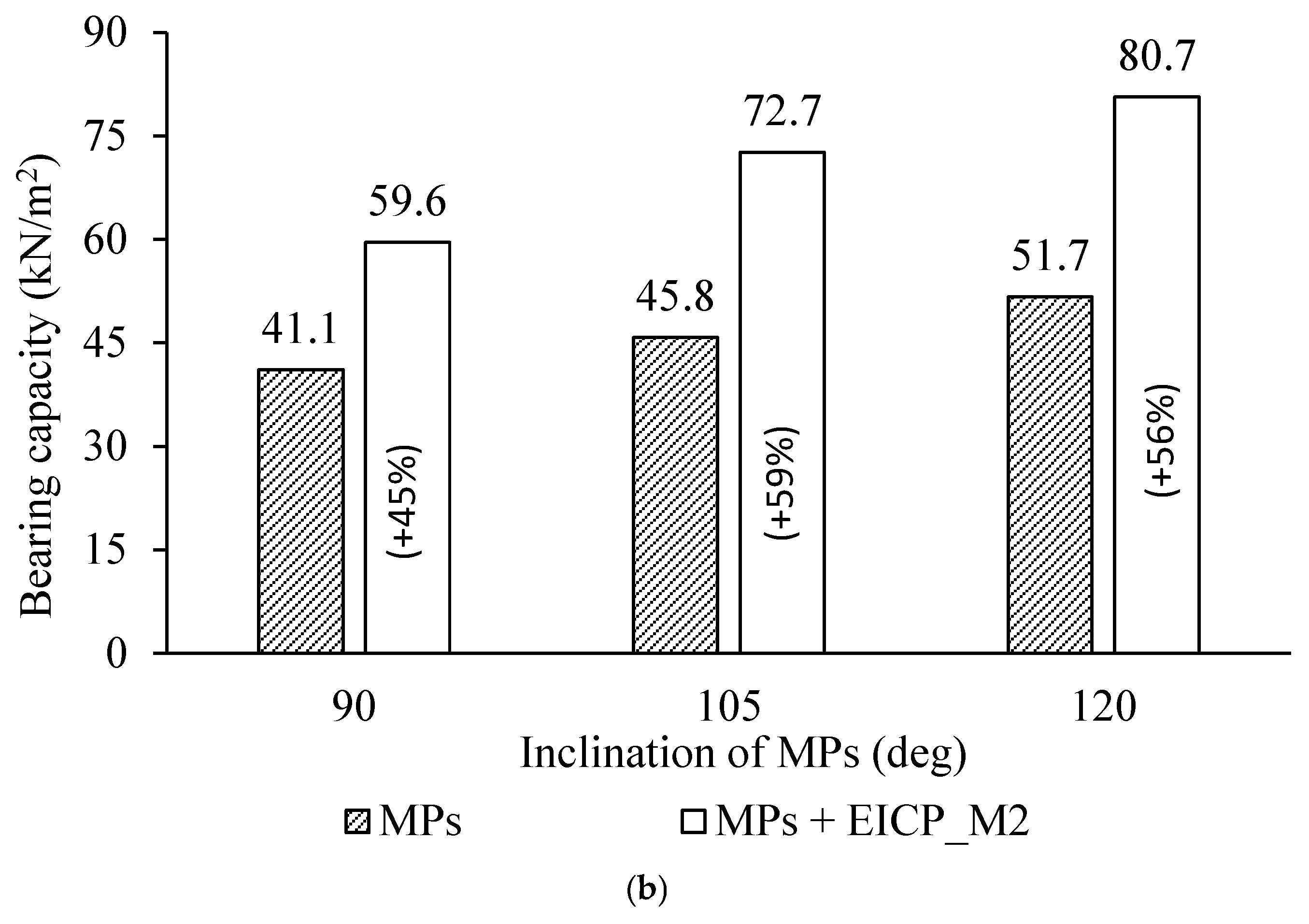

- A similar trend (similar to method M1) is observed for EICP injected around the footing (method M2), but the enhancement in bearing capacity of the footing is much higher as compared to method M1. Compared to the control, the bearing capacity improvements for footings confined by EICP treatment using method M2 for micropile inclinations of 90°, 105°, and 120° were 66%, 103%, and 125%, respectively (Figure 12). In contrast, for EICP treatment using method M1, the increases were only 32%, 53%, and 83% at the same inclination angles (Figure 12). It is evident that the load-bearing capacity enhancement achieved by combining EICP treatment using method M2 with micropiles is significantly higher compared to the incorporation of micropiles alone. The EICP injection of soil (method M2) caused 45%, 59%, and 56% increases in the bearing capacity of footings (compared to the footing with the micropiles alone) for inclinations of 90°, 105°, and 120°, respectively (Figure 13b). The substantial enhancements observed for EICP-injected micropiles are attributed to the combined effect of soil confinement provided by the micropiles and the calcification process, which is not related to the pile inclination, as the injection is directly into the soil surrounding the footing.

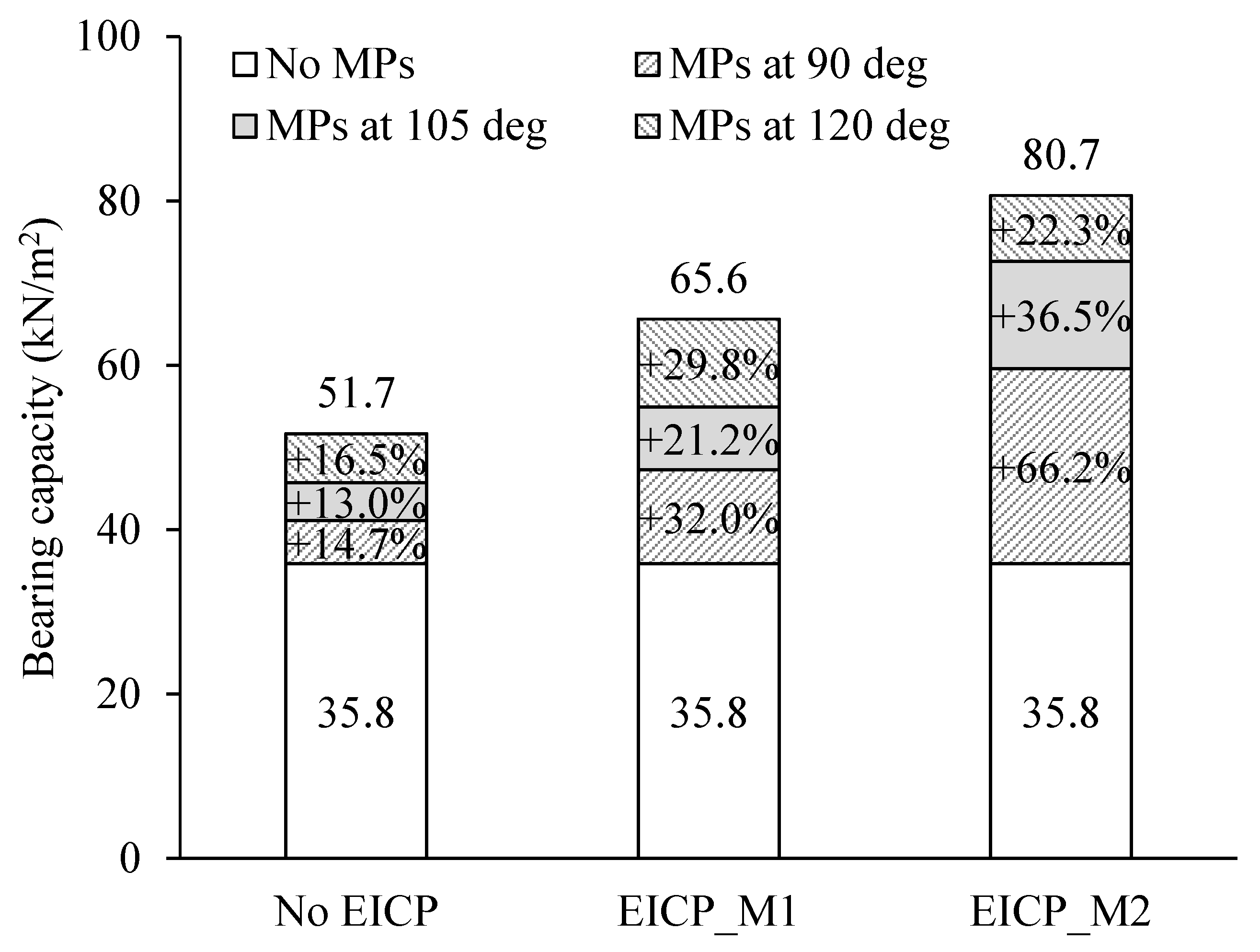

- It is observed from Figure 14 that, for micropiles alone (without EICP), the bearing capacity increased by 14.7%, 13.0%, and 16.5% for micropile inclinations of 90°, 105°, and 120°, respectively. When EICP treatment was applied using method M1, the bearing capacity increases were 32.0%, 21.2%, and 29.8% for the same inclination angles (Figure 14). For EICP treatment using method M2, the bearing capacity increases were 66.2%, 36.5%, and 22.3% for 90°, 105°, and 120° micropile inclinations, respectively (Figure 14).

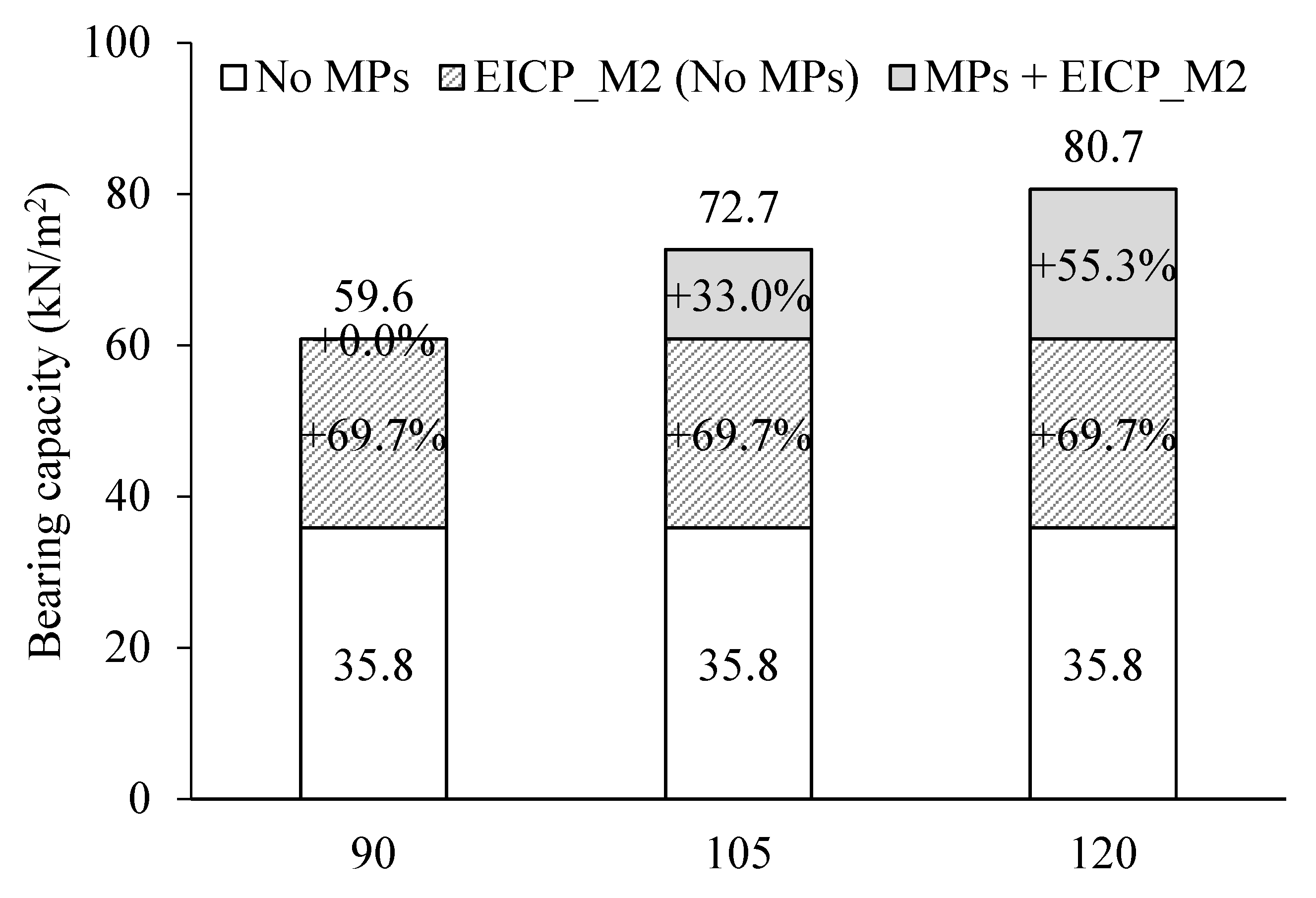

- The bearing capacity enhancement due to EICP treatment using method M2 was quite significant at 69.7%, as it increased the bearing capacity to 60.8 kN/m2. However, when combined with vertical micropiles, the bearing capacity slightly decreased to 59.6 kN/m2. Although this represents a marginal reduction of 1.2 kN/m2, the plotted increase beyond EICP treatment M2 is shown as 0% in Figure 15 due to the negligible difference and the value indicated on the plot corresponds to the EICP treatment combined with vertical micropiles (59.6 kN/m2) rather than EICP treatment M2 alone (60.8 kN/m2). The similarity in BC values between the EICP treatment method M2 and its combination with vertical micropiles suggests that the micropiles had almost no additional effect on improving the bearing capacity. This is likely because the failure mechanism was dominated by the sudden collapse of the calcified sand columns formed by EICP, possibly due to shear band formation or the brittle nature of the calcified columns. The micropiles, being positioned away from the footing, did not provide confinement initially due to little expansion of the surrounding soil due to calcification. Moreover, at failure, the sudden soil expansion due to the collapse of calcified sand columns could not be prevented by the vertical micropiles. This highlights the need for placing vertical micropiles closer to the footing or alternative confinement strategies to enhance the performance of EICP-treated soils in similar scenarios for sustainable solutions to ensure both efficiency and reliability. Nevertheless, the provision of micropiles to EICP-treated sand caused 33.0% and 55.3% enhancement for micropile inclinations of 105° and 120°, respectively (Figure 15).

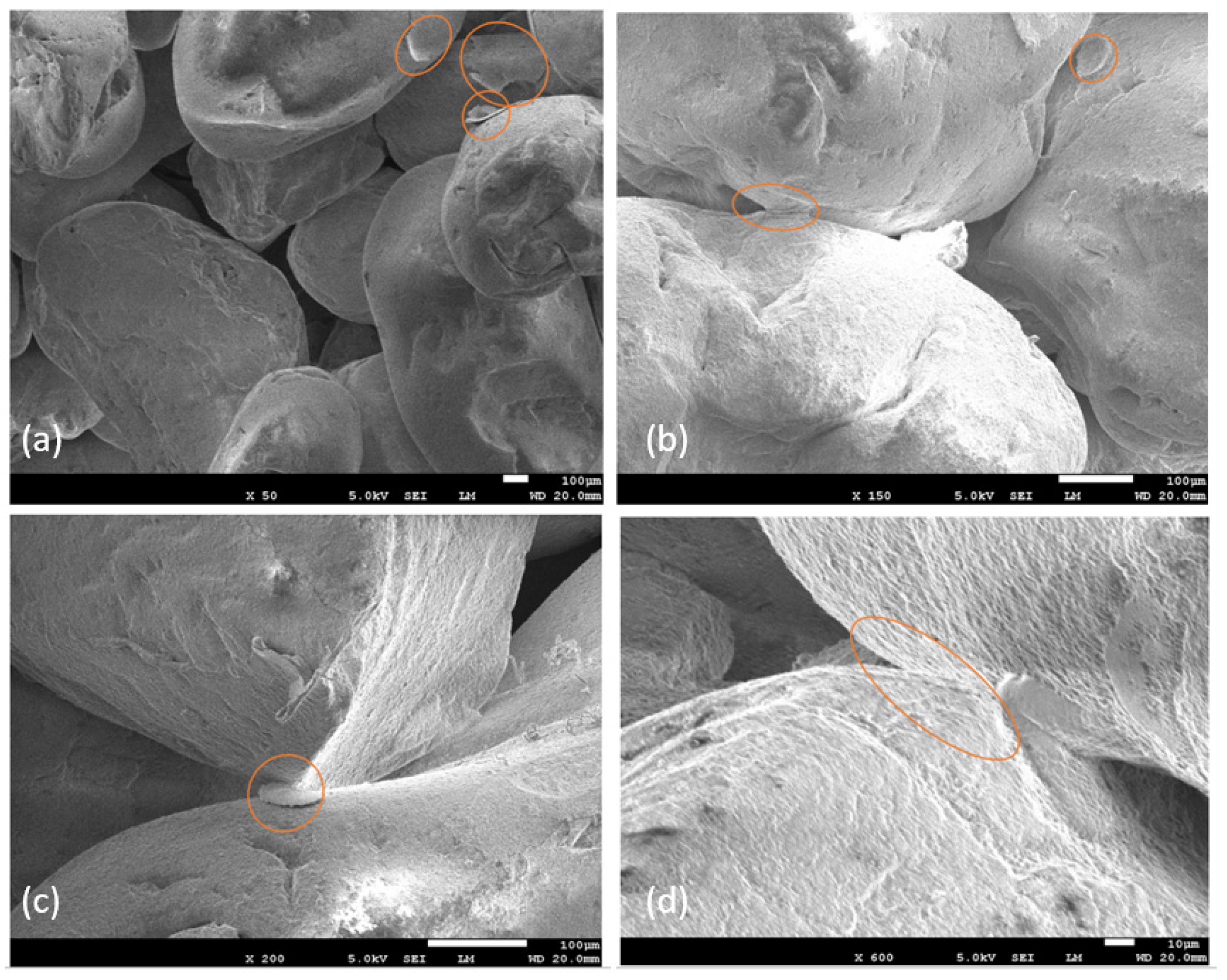

6. SEM Analysis

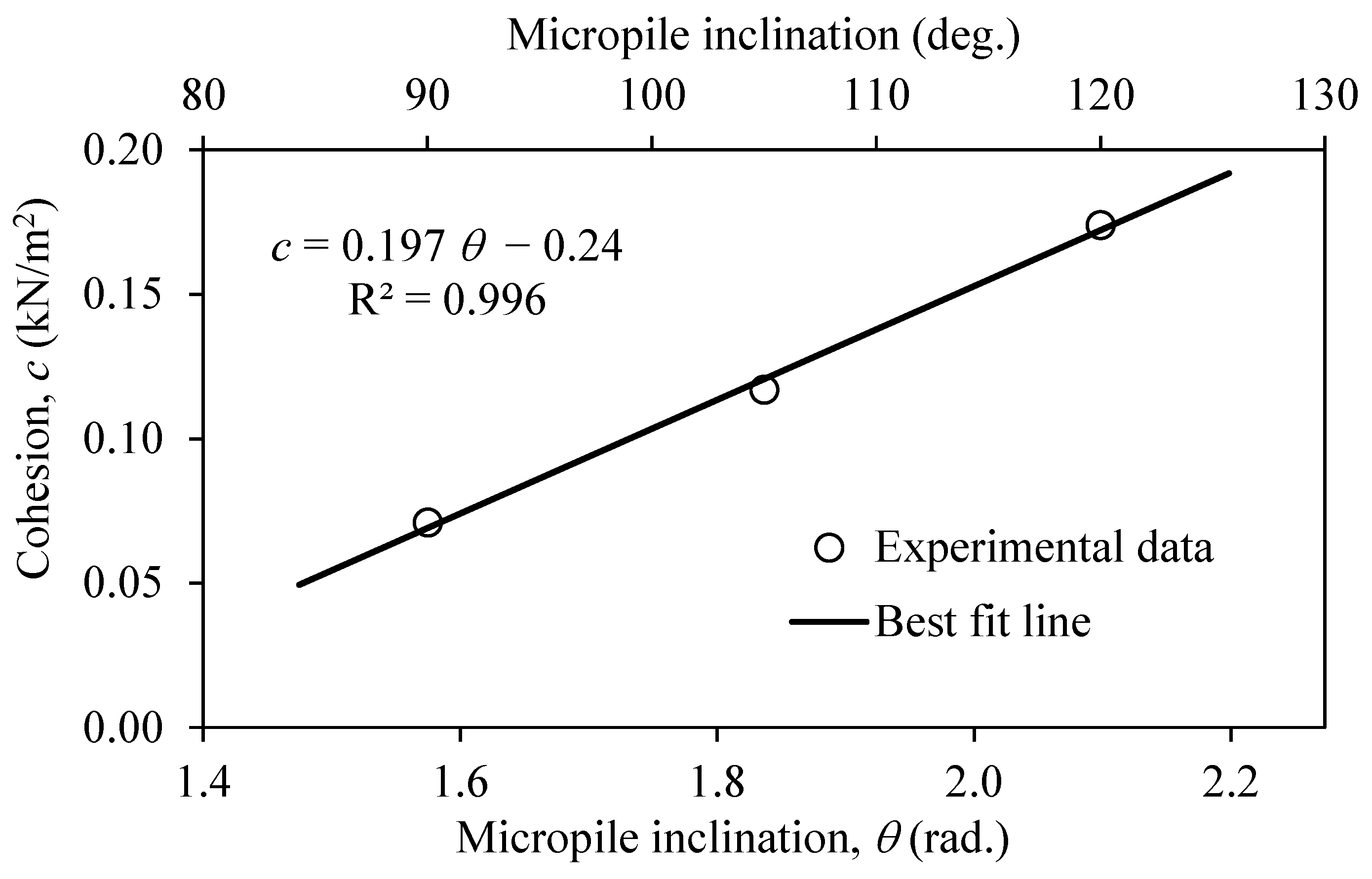

7. Bearing Capacity Prediction of Footings

8. Conclusions

- Regardless of micropile inclination, both EICP injection methods (M1 and M2) were observed to exhibit similar patterns of footing pressure variation with settlement, indicating that the basic load–settlement behavior remains consistent across treatment approaches.

- An increase in micropile inclination was found to lead to a higher rate of footing pressure increase with settlement. EICP treatment significantly amplifies this effect, with method M2 demonstrating a steeper rise in footing pressure as settlement increases.

- Incorporating EICP through micropiles (method M1) was found to significantly improve the load-bearing capacity of footings, with higher gains observed at increased micropile inclinations. The single tests showed bearing capacity increases of 32%, 53%, and 83% for micropile inclinations of 90°, 105°, and 120°, respectively, compared to the control. This enhancement is attributed to a combination of soil confinement from micropiles and intensified calcification at higher inclinations. The use of EICP offers a low-carbon, bio-mediated alternative to traditional cement-based ground improvement, contributing to environmental sustainability.

- EICP treatment method M2 provided greater bearing capacity improvements compared to method M1, with increases of 66%, 103%, and 125% for micropile inclinations of 90°, 105°, and 120°, respectively. These gains result from a combination of micropile confinement and uniform calcification around the footing, which appeared to be unaffected by micropile inclination due to direct injection into the surrounding soil. This method, requiring fewer materials and less energy-intensive processes, reinforces the potential of sustainable biogeotechnical solutions.

- EICP treatment method M2 with vertical micropiles indicated no improvement in bearing capacity. This is because the failure mechanism is dominated by the sudden collapse of calcified sand columns formed by EICP treatment, and the vertical micropiles, located farther from the footing, fail to provide confinement. The lack of initial soil expansion due to calcification also prevents them from providing confinement. This highlights the need for closer vertical micropile placement or alternative confinement strategies in such cases for sustainable solutions to ensure both efficiency and reliability.

- Although method M2 showed superior performance in improving bearing capacity for small footings and loose sand, its limited penetration depth may reduce its effectiveness for larger footings and denser sands. In such cases, method M1’s ability to reinforce deeper soil layers offers a more efficient solution for enhancing load-bearing capacity. Tailoring sustainable treatment strategies based on site conditions is essential for maximizing both environmental and structural benefits.

- SEM images of EICP-injected sand indicate calcite cementation at particle contact points, which acted as a binder between particles, explaining the bearing capacity enhancement due to the treated sand. The post-test photographs of the cementation of EICP-treated sand around the micropiles and footing further verify the calcification of sand.

- The predicted bearing capacities, based on modified reduction factors and shear strength parameters, showed good agreement with experimental results. The prediction error falls within a narrow range of −1.8% to +3.9%, demonstrating the potential reliability of the proposed models. Further validation with a larger dataset would be required to confirm the model’s reliability for practical adoption of sustainable soil reinforcement strategies with confidence.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arab, M.G.; Alsodi, R.; Almajed, A.; Yasuhara, H.; Zeiada, W.; Shahin, M.A. State-of-the-art review of enzyme-induced calcite precipitation (EICP) for ground improvement: Applications and prospects. Geosciences 2021, 11, 492. [Google Scholar] [CrossRef]

- Wani, K.S.; Mir, B.A. Effect of microbial stabilization on the unconfined compressive strength and bearing capacity of weak soils. Transp. Infrastruct. Geotechnol. 2021, 8, 59–87. [Google Scholar] [CrossRef]

- Hadi, S.; Abbas, H.; Almajed, A.; Binyahya, A.; Al-Salloum, Y. Biocementation by Sporosarcina pasteurii ATCC6453 under simulated conditions in sand columns. J. Mater. Res. Technol. 2022, 18, 4375–4384. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Australia, 2004. [Google Scholar]

- Omoregie, A.I.; Wong, C.S.; Rajasekar, A.; Ling, J.H.; Laiche, A.B.; Basri, H.F.; Ouahbi, T. Bio-based solutions for concrete infrastructure: A review of microbial-induced carbonate precipitation in crack healing. Buildings 2025, 15, 1052. [Google Scholar] [CrossRef]

- Feng, D.; Yu, Y.; Wang, J.; Fang, C.; Liang, S. Experimental study on shear and disintegration resistance of MICP-treated residual granite soil. Environ. Earth Sci. 2024, 83, 179. [Google Scholar] [CrossRef]

- Hamed Khodadadi, T.; Kavazanjian, E.; van Paassen, L.; DeJong, J. Bio-Grout Materials: A Review. In Grouting 2017; American Society of Civil Engineers: Reston, VA, USA, 2017; pp. 1–12. [Google Scholar] [CrossRef]

- Valencia-Galindo, M.; Sáez, E.; Ovalle, C.; Ruz, F. Evaluation of the effectiveness of a soil treatment using calcium carbonate precipitation from cultivated and Lyophilized bacteria in soil’s compaction water. Buildings 2021, 11, 545. [Google Scholar] [CrossRef]

- Li, M.; Wen, K.; Li, Y.; Zhu, L. Impact of oxygen availability on microbially induced calcite precipitation (MICP) treatment. Geomicrobiol. J. 2018, 35, 15–22. [Google Scholar] [CrossRef]

- Al-Thawadi, S. High Strength in-Situ Biocementation of Soil by Calcite Precipitating Locally Isolated Ureolytic Bacteria. Ph.D. Thesis, Murdoch University, Perth, Australia, 2008. [Google Scholar]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio/Technol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Nemati, M.; Voordouw, G. Modification of porous media permeability, using calcium carbonate produced enzymatically in situ. Enzym. Microb. Technol. 2003, 33, 635–642. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Ikuma, K.; Choi, S.G. Sand and silty-sand soil stabilization using bacterial enzyme–induced calcite precipitation (BEICP). Can. Geotech. J. 2019, 56, 808–822. [Google Scholar] [CrossRef]

- Yuan, L.; Li, G.; Liu, J.; Wang, P.; Liu, C.; Zhang, J. Study on Mechanical Properties of Sandy Soil Solidified by Enzyme-Induced Calcium Carbonate Precipitation (EICP). Buildings 2024, 14, 1977. [Google Scholar] [CrossRef]

- Wen, C. Laboratory Investigations on the Effectiveness of Bio-Enzyme on the Strength of Cement or Lime Treated High Liquid Limit Soil. Int. J. Geosynth. Ground Eng. 2024, 10, 96. [Google Scholar] [CrossRef]

- Zhao, Z.; Hamdan, N.; Shen, L.; Nan, H.; Almajed, A.; Kavazanjian, E.; He, X. Biomimetic hydrogel composites for soil stabilization and contaminant mitigation. Environ. Sci. Technol. 2016, 50, 12401–12410. [Google Scholar] [CrossRef]

- Graddy, C.M.R.; Gomez, M.G.; Kline, L.M.; Morrill, S.R.; DeJong, J.T.; Nelson, D.C. Diversity of sporosarcina-like bacterial strains obtained from meter-scale augmented and stimulated biocementation experiments. Environ. Sci. Technol. 2018, 52, 3997–4005. [Google Scholar] [CrossRef]

- Ghasemi, P.; Montoya, B.M. Effect of treatment solution chemistry and soil engineering properties due to microbially induced carbonate precipitation treatments on vegetation health and growth. ACS EST Eng. 2022, 2, 2196–2205. [Google Scholar] [CrossRef]

- Zhang, Q.; Ye, W.; Liu, Z.; Wang, Q.; Chen, Y. Influence of injection methods on calcareous sand cementation by EICP technique. Constr. Build. Mater. 2023, 363, 129724. [Google Scholar] [CrossRef]

- Xue, Y.; Arulrajah, A.; Chu, J.; Horpibulsuk, S. Soybean urease-based EICP stabilization of washed recycled sands derived from demolition wastes cured at low temperatures. Constr. Build. Mater. 2024, 434, 136735. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Liu, Y.; Li, Z.; Wang, S. Evaluation of wind erosion resistance of EICP solidified desert sand based on response surface methodology. Constr. Build. Mater. 2024, 447, 138119. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Zhang, Y.; Cheng, Y. Application of chitosan in EICP treatment for stabilization of red mud against wind erosion. Constr. Build. Mater. 2025, 465, 140164. [Google Scholar] [CrossRef]

- Raymond, A.J.; Purdy, C.; Fox, T.; Kendall, A.; DeJong, J.T.; Kavazanjian, E., Jr.; Martin, K. Life cycle sustainability assessment of enzyme-induced carbonate precipitation (EICP) for fugitive dust control. Acad. J. Civ. Eng. 2019, 37, 600–607. [Google Scholar] [CrossRef]

- Alotaibi, E.; Arab, M.G.; Abdallah, M.; Nassif, N.; Omar, M. Life cycle assessment of biocemented sands using enzyme induced carbonate precipitation (EICP) for soil stabilization applications. Sci. Rep. 2022, 12, 6032. [Google Scholar] [CrossRef]

- Sabatini, P.J.; Armour, T.; Groneck, P.; Keeley, J.W.; Tanyu, B. Micropile Design and Construction (Reference Manual for NHI Course 132078) (No. FHWA-NHI-05-039). United States. Department of Transportation. Federal Highway Administration. Available online: https://rosap.ntl.bts.gov/view/dot/50231/dot_50231_DS1.pdf (accessed on 15 July 2025).

- Juran, I.; Bruce, D.A.; Dimillio, A.; Benslimane, A. Micropiles: The state of practice. Part II: Design of single micropiles and groups and networks of micropiles. Proc. Inst. Civ. Eng.-Ground Improv. 1999, 3, 89–110. [Google Scholar] [CrossRef]

- Sadek, M.; Shahrour, I. Influence of the head and tip connection on the seismic performance of micropiles. Soil Dyn. Earthq. Eng. 2006, 26, 461–468. [Google Scholar] [CrossRef]

- Babu, G.L.S.; Murthy, B.S.; Murthy, D.S.N.; Nataraj, M.S. Bearing capacity improvement using micropiles: A case study. In GeoSupport 2004: Drilled Shafts, Micropiling, Deep Mixing, Remedial Methods, and Specialty Foundation Systems; American Society of Civil Engineers: Orlando, FL, USA, 2004; pp. 692–699. [Google Scholar] [CrossRef]

- Han, J.; Ye, S.-L. A field study on the behavior of a foundation underpinned by micropiles. Can. Geotech. J. 2006, 43, 30–42. [Google Scholar] [CrossRef]

- Salari, M.; Lezgy-Nazargah, M.; Shafaie, V.; Rad, M.M. Numerical study of the ultimate bearing capacity of two adjacent rough strip footings on granular soil: Effects of rotational and horizontal constraints of footings. Buildings 2024, 14, 1653. [Google Scholar] [CrossRef]

- Thyman, M.; Johansson, B. Strengthening of Buildings for Storey Extension. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2013. [Google Scholar]

- Motlagh, P.A.; Pak, A. Comparison of Seismic Retrofitting Methods for Existing Foundations in Seismological Active Regions. Int. J. Struct. Constr. Eng. 2014, 8, 536–541. [Google Scholar]

- Bruce, D.A.; Cadden, A.W.; Sabatini, P.J. Practical advice for foundation design–micropiles for structural support. In Contemporary Issues in Foundation Engineering; American Society of Civil Engineers: Austin, TX, USA, 2005; pp. 1–25. [Google Scholar] [CrossRef]

- Zimmer, M. Molecular mechanics evaluation of the proposed mechanisms for the degradation of urea by urease. J. Biomol. Struct. Dyn. 2000, 17, 787–797. [Google Scholar] [CrossRef]

- Krajewska, B. Urease-aided calcium carbonate mineralization for engineering applications: A review. J. Adv. Res. 2018, 13, 59–67. [Google Scholar] [CrossRef]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based methods for ecofriendly stabilization of different types of natural sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Almajed, A.; Khodadadi Tirkolaei, H.; Kavazanjian, E., Jr. Baseline investigation on enzyme-induced calcium carbonate precipitation. J. Geotech. Geoenviron. Eng. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Abbas, H.; Almajed, A.; Kotwal, E.; Al-Salloum, Y. Bearing capacity enhancement of footings using confining inclined micropiles: Experimental and analytical investigation. Case Stud. Constr. Mater. 2025, 22, e04184. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wu, L. Applicability and theoretical calculation of enzymatic calcium carbonate precipitation for sand improvement. Geomicrobiol. J. 2020, 37, 389–399. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J. An experimental study on enzymatic-induced carbonate precipitation using yellow soybeans for soil stabilization. KSCE J. Civ. Eng. 2020, 24, 2026–2037. [Google Scholar] [CrossRef]

- Vesić, A.S. Analysis of ultimate loads of shallow foundations. J. Soil Mech. Found. Div. 1973, 99, 45–73. [Google Scholar] [CrossRef]

- Tsukada, Y.; Miura, K.; Tsubokawa, Y.; Otani, Y.; You, G.-L. Mechanism of bearing capacity of spread footings reinforced with micropiles. Soils Found. 2006, 46, 367–376. [Google Scholar] [CrossRef]

| Test ID | Procedure of Enhancing Bearing Capacity | Angle of Micropiles with Horizontal, in Deg (Radians) | EICP Injection Method 1 | Curing Time (Days) |

|---|---|---|---|---|

| T1 | Unreinforced (Control) | 0° (0) | - | - |

| T2 | Micropiles | 90° (π/2) | - | - |

| T3 | Micropiles | 105° (7π/12) | - | - |

| T4 | Micropiles | 120° (2π/3) | - | - |

| T5 | Micropiles + EICP | 90° (π/2) | M1 | 21 |

| T6 | Micropiles + EICP | 105° (7π/12) | M1 | 21 |

| T7 | Micropiles + EICP | 120° (2π/3) | M1 | 21 |

| T8 | Micropiles + EICP | 90° (π/2) | M2 | 21 |

| T9 | Micropiles + EICP | 105° (7π/12) | M2 | 21 |

| T10 | Micropiles + EICP | 120° (2π/3) | M2 | 21 |

| T11 | EICP | - | M2 | 21 |

| Test ID (EICP Treatment Method) | Angle of MPs with Horizontal, in Deg (Radians) | RD Modification Factor, | Modified RD of Sand, | Estimated Shear Strength Parameters | Bearing Capacity (kN/m2) | Error in Prediction | ||

|---|---|---|---|---|---|---|---|---|

| c (kN/m2) | (deg) | Exp. | Pred. | |||||

| Equation (9) | Equation (11) | Equation (10) | Equation (8) | |||||

| T1 (-) | - | 1.00 | 0.51 * | 0.00 | 35.35 | 35.8 | 36.4 | +1.5% |

| T5 (M1) | 90° (π/2) | 1.17 | 0.60 | 0.00 | 36.09 | 47.3 | 47.1 | −0.4% |

| T6 (M1) | 105° (7π/12) | 1.28 | 0.65 | 0.00 | 36.52 | 54.9 | 55.3 | +0.7% |

| T7 (M1) | 120° (2π/3) | 1.41 | 0.72 | 0.00 | 37.10 | 65.6 | 65.5 | −0.2% |

| T11 (M2) | - | 1.00 | 0.51 | 0.31 | 35.35 | 60.8 | 61.9 | +1.8% |

| T8 (M2) | 90° (π/2) | 1.17 | 0.60 | 0.31 | 36.09 | 59.6 | 61.9 ** | +3.9% |

| T9 (M2) | 105° (7π/12) | 1.28 | 0.65 | 0.31 | 36.52 | 72.7 | 72.9 | +0.3% |

| T10 (M2) | 120° (2π/3) | 1.41 | 0.72 | 0.31 | 37.10 | 80.7 | 79.2 | −1.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almajed, A.; Kotwal, E.; Al-Salloum, Y.; Abbas, H. A Sustainable Hybrid Approach to Improve Footing Bearing Capacity Using EICP and Inclined Micropiles. Buildings 2025, 15, 2915. https://doi.org/10.3390/buildings15162915

Almajed A, Kotwal E, Al-Salloum Y, Abbas H. A Sustainable Hybrid Approach to Improve Footing Bearing Capacity Using EICP and Inclined Micropiles. Buildings. 2025; 15(16):2915. https://doi.org/10.3390/buildings15162915

Chicago/Turabian StyleAlmajed, Abdullah, Esmatullah Kotwal, Yousef Al-Salloum, and Husain Abbas. 2025. "A Sustainable Hybrid Approach to Improve Footing Bearing Capacity Using EICP and Inclined Micropiles" Buildings 15, no. 16: 2915. https://doi.org/10.3390/buildings15162915

APA StyleAlmajed, A., Kotwal, E., Al-Salloum, Y., & Abbas, H. (2025). A Sustainable Hybrid Approach to Improve Footing Bearing Capacity Using EICP and Inclined Micropiles. Buildings, 15(16), 2915. https://doi.org/10.3390/buildings15162915