Abstract

The construction sector, facing a persistent productivity gap compared to other industries, is hindered by fragmented value streams, inconsistent performance metrics, and the limited scalability of process improvements. We introduce a pioneering, four-tiered hierarchical productivity framework to respond to these challenges. This innovative approach integrates operational, tactical, strategic, and normative layers. At its core, the framework applies standardised, repeatable process steps—mapped using Value Stream Mapping (VSM)—to capture key indicators such as input efficiency, output effectiveness, and First-Time Quality (FTQ). These are then aggregated through takt time compliance, schedule reliability, and workload balance to evaluate trade synchronisation and flow stability. Higher-level metrics—flow efficiency, multi-resource utilisation, and ESG-linked performance—are integrated into an Overall Productivity Index (OPI). Building on a modular production model, the proposed framework supports real-time sensing, AI-driven monitoring, and intelligent process control, as demonstrated through an empirical case study of continuous process monitoring for Kelly drilling operations. This validation illustrates how sensor-equipped machinery and machine learning algorithms can automate data capture, map observed activities to standardised process steps, and detect productivity deviations in situ. This paper contributes to a multi-scalar measurement architecture that links micro-level execution with macro-level decision-making. It provides a foundation for real-time monitoring, performance-based coordination, and data-driven innovation. The framework is applicable across modular construction, digital twins, and platform-based delivery models, offering benefits beyond specialised foundation work to all construction trades. Grounded in over a century of productivity research, the approach demonstrates how emerging technologies can deliver measurable and scalable improvements. Framing productivity as an integrative, actionable metric enables sector-wide performance gains. The framework supports construction firms, technology providers, and policymakers in advancing robust, outcome-oriented innovation strategies.

1. Introduction

1.1. Current Status of the Construction Sector

The construction sector is one of the largest and most consequential industries globally, essential for delivering infrastructure, housing, and economic stimuli. Despite its societal relevance and significant technological potential, construction remains burdened by persistent inefficiencies, fragmented value chains, and chronic underinvestment in innovation and digitalisation [1].

Productivity growth in the construction sector has consistently underperformed compared to other economic sectors. Over the past two decades, construction productivity has increased by only 10%, while overall global economic productivity has risen by more than 50% [2]. On average, annual labour productivity growth in construction has remained below 1%, significantly lagging behind the 2.8% yearly growth in the overall world economy and the 3.6% observed in manufacturing [2,3]. In the United States, construction productivity—measured through labour and total factor productivity (TFP)—initially exceeded national averages in the mid-20th century but began a sustained decline in the 1970s, continuing downward for over 50 years [4].

This underperformance is not only an economic concern but also a structural one. As the McKinsey Global Institute emphasised in its landmark report, the construction sector’s productivity problems are deeply rooted in its operational model: high levels of informality, weak process standardisation, poor data integration, and a project-based delivery culture that impedes learning and replication across projects [2].

In addition to economic stagnation, the sector faces escalating external pressures. Skilled labour shortages, exacerbated by demographic shifts and declining vocational training uptake, limit capacity across regions [5]. Urbanisation and population growth are driving construction demand to unprecedented levels—global construction output is expected to reach USD 22 trillion annually by 2040 [5]. Simultaneously, the industry is being called upon to decarbonise rapidly, adopt circular economy practices, and align with global climate goals such as the Paris Agreement and the UN Sustainable Development Goals [6,7,8].

These converging pressures underscore the urgent need for systemic transformation. Without a fundamental shift in how performance is measured, managed, and improved, the construction sector risks falling further behind in both economic and sustainability terms [9].

1.2. The Productivity Gap and Its Root Causes

The productivity gap in construction is not the result of isolated inefficiencies or localised management failures. Rather, it reflects deeply embedded structural characteristics of the industry that limit learning, scalability, and systemic improvement. Most construction projects are delivered by ad hoc, multi-organisational consortia that disband after completion. This temporary and fragmented project logic—often called the “one-off factory” paradigm [10,11]—prevents knowledge transfer, hinders the replication of best practices, and fosters a chronic lack of continuity in processes, technologies, and metrics.

One of the most persistent obstacles to productivity improvement is the absence of standardised measurement practices. Key performance data are rarely captured in a uniform or comparable format across firms or projects. Even when data are collected—often manually and retrospectively—they remain siloed, inconsistent, and poorly integrated into feedback loops. As a result, productivity insights are frequently limited to the local level and cannot scale across organisations, regions, or time.

Critically, the construction industry lacks a coherent measurement ontology (see Appendix A) that connects micro-level activities (e.g., process steps or trade tasks) with macro-level indicators (e.g., project profitability, carbon performance, and ESG compliance). This structural blind spot makes it exceedingly challenging to track productivity improvements, assess trade-offs, or support data-driven decisions across the value chain. Consequently, most improvement efforts remain fragmented and reactive rather than strategic and scalable.

These systemic limitations are especially concerning given the scale of the challenge ahead. Construction activity is projected to exceed USD 22 trillion annually by 2040, driven by urbanisation, infrastructure renewal, and housing demand [5]. Yet the sector remains ill-equipped to meet this demand efficiently. A global shortage of skilled labour continues to deepen, making it increasingly challenging to source qualified workers for routine construction tasks [12,13]. This shortage negatively impacts project schedules, cost certainty, and quality assurance.

Moreover, safety concerns persist, with high accident rates undermining workforce stability and project outcomes [14]. As highlighted by Elbashbishy and El-Adaway [15], labour shortages have directly contributed to project delays, cost overruns, and quality defects over the past several decades. Simultaneously, the industry faces growing pressure to align with climate goals by reducing its environmental footprint, adopting circular economy principles, and improving carbon performance [6,7].

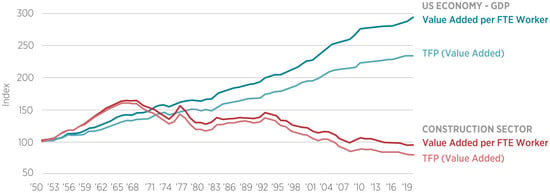

The cumulative result of these forces—economic, technological, demographic, and ecological—is a sector increasingly constrained in its ability to deliver reliable, affordable, and sustainable outcomes. This reality is illustrated in Figure 1, which compares labour productivity and total factor productivity (TFP) in the U.S. construction sector with those of the broader economy over the past 70 years. While productivity in the overall economy continued to rise, construction stagnated or declined, underscoring the persistent and widening performance gap [4,16].

Figure 1.

In red, indices of U.S. construction-sector labour productivity (value added per full-time-equivalent, FTE) and total factor productivity (TFP), 1950–2020. The same index for the overall U.S. economy is plotted in blue for comparison. During the 1950s and 1960s, construction productivity outpaced the overall economy. By 1970, labour productivity and TFP in construction began to decline, and this downturn has continued for over five decades [4]. (Data: U.S. Bureau of Economic Analysis, BEA). Reprinted/adapted with permission from Ref. [4]. 2023, Goolsbee and Syverson.

1.3. Productivity Measurement: Existing Approaches and Their Limitations

Over the past century, various methodologies have been developed to measure and enhance productivity in the construction industry. Traditional tools such as time-and-motion studies [17,18], Gantt charts [19,20], and Earned Value Management (EVM) [21] have provided foundational project planning and control frameworks. EVM, for instance, integrates scope, time, and cost parameters to assess project performance objectively. However, these methods often fall short in dynamic construction environments due to their reliance on retrospective data and limited adaptability to real-time changes.

The emergence of Lean Construction introduced principles [22,23,24,25,26] aimed at reducing waste and improving workflow efficiency. Techniques like the Last Planner System (LPS) [24,27] and takt time planning [28] have been instrumental in promoting collaborative planning and continuous improvement. LPS emphasises reliable workflow and commitment-based planning, while takt time planning aligns production pace with customer demand to ensure steady progress. Despite their benefits, these approaches often operate in silos and lack integration of real-time data analytics, limiting their effectiveness in rapidly changing project conditions [29,30].

Emerging technologies offer promising pathways to overcome these limitations. Integrating Internet of Things (IoT) devices [31] enables real-time monitoring of equipment and environmental conditions on construction sites. LiDAR (Light Detection And Ranging) technology provides precise spatial measurements, facilitating accurate progress tracking [32,33]. Computer vision systems [34,35,36,37,38] can automate the detection and analysis of construction activities, enhancing quality control and safety monitoring. Machine learning algorithms further contribute by predicting project outcomes and optimising resource allocation based on historical and real-time data [39,40,41,42].

However, the absence of a unified data framework often hinders the effective deployment of these technologies. Without standardised data collection, interpretation, and integration protocols, the insights generated by these advanced tools remain fragmented and underutilised [43,44]. This fragmentation hinders the development of comprehensive performance metrics that can inform decision-making across all levels of a construction project. In light of these challenges, there is a pressing need for a cohesive productivity measurement framework that bridges traditional methodologies with modern technological capabilities [37,45]. Such a framework should facilitate the seamless integration of real-time data analytics into construction workflows, enabling stakeholders to make informed decisions that enhance efficiency, reduce waste and carbon emissions, and improve project outcomes [46,47].

1.4. Research Contribution: A Hierarchical Framework for Construction Productivity

To address the structural limitations of existing productivity metrics in construction, this article introduces a novel hierarchical productivity measurement framework that establishes a physically consistent, multi-level ontology spanning from task execution to strategic and normative decision-making.

Unlike conventional metrics that operate in isolation—e.g., labour productivity and earned value—the proposed framework integrates four distinct levels of productivity analysis into a modular and scalable architecture:

- Operational Level: Standardised process steps are recorded through Value Stream Mapping (VSM, see Appendix A) and analysed via input efficiency, output effectiveness, and First-Time Quality (FTQ). This granular data foundation enables high-resolution performance diagnostics while preserving traceability across tasks and trades.

- Tactical Level: Takt time compliance, schedule reliability, and workload balance (expressed through the Coefficient of Variation) are used to assess trade synchronisation and production flow stability. These KPIs are synthesised across process clusters and work packages.

- Strategic Level: Broader performance indicators—including flow efficiency and multi-resource utilisation—capture the coordination of trades, disciplines, and modules across spatial and temporal interfaces within the project environment.

- Normative Level: The framework culminates in a composite Overall Productivity Index (OPI), combining quality, efficiency, and effectiveness metrics with sustainability and ESG considerations to inform organisational learning and capital allocation. Relevant ESG indicators—embodied carbon, on-site energy consumption, and social employment metrics—can be integrated into the Overall Productivity Index (OPI) layer. These allow aligning productivity tracking with regulatory and sustainability goals.

This multi-scalar approach bridges the gap between micro-level task performance and macro-level governance. It supports horizontal comparability across projects and vertical integration from the jobsite to the enterprise layer.

The novelty of the framework lies in its ability to provide a bottom-up aggregation pathway, enabling real-time productivity control, cross-project benchmarking, and digital twin integration. By aligning measurement logic with production ontology (process step → component → module → project), the system is natively compatible with automation and AI integration.

It establishes the data infrastructure required for intelligent construction systems:

- IoT-based real-time sensing;

- Computer vision-enabled activity tracking;

- Agentic AI systems (see Appendix A) capable of autonomous workflow re-sequencing and predictive bottleneck elimination.

Grounded in systems theory and Lean Production logic, this framework contributes a conceptual foundation and a practical roadmap for scaling productivity solutions in industrialised and digitised construction settings. It supports evidence-based investment decisions, empirically testable hypotheses, and technology-enabled transformation across project delivery models.

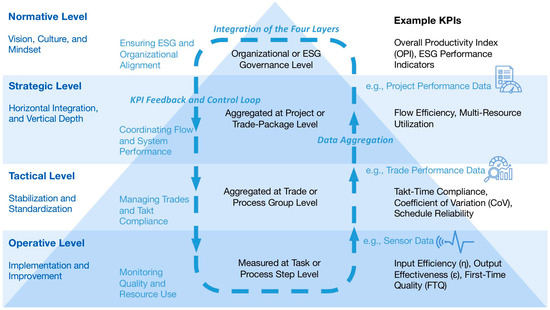

The modular and scalable system architecture, illustrated in Figure 2, depicts the logical structure, data flows, and feedback mechanisms across the four abstraction levels. Real-time indicators such as input efficiency and First-Time Quality are captured at the operational layer and aggregated through takt time performance and flow stability at the tactical and strategic levels. These metrics ultimately inform a normative layer synthesising project-wide productivity and ESG compliance into an Overall Productivity Index (OPI). Feedback loops enable top-down alignment, allowing normative goals to recalibrate tactical priorities and operational execution. The system architecture provides a scalable foundation for AI integration, sensor-driven monitoring, and platform-based process control.

Figure 2.

System architecture of the hierarchical productivity framework. The framework integrates operational, tactical, strategic, and normative layers associated with specific performance metrics. Data flow upward through the aggregation of efficiency and quality metrics and downward via feedback loops that align ESG and productivity targets with frontline process control. The architecture supports integration of real-time sensing, takt planning, AI-based monitoring, and modular construction systems.

The remainder of the article is structured as follows: (I) Section 2 reviews the historical evolution of productivity measurement in construction, from early time-and-motion studies through Lean practices; (II) Section 3 critically examines current productivity metrics and frameworks, highlighting key conceptual and data-integration challenges; (III) Section 4 introduces our four-level hierarchical framework, detailing its operational, tactical, strategic, and normative levels and illustrating how metrics roll up through a unified building ontology; (IV) Section 5 discusses implications for practice, opportunities for AI-driven validation, and the next steps for empirical testing; and concludes with reflections on the framework’s contributions, limitations, and a vision for future research and industry adoption.

2. Historical Context and Current State of the Research Field: Traditional Methods of Productivity Measurement over the Past 100 Years

2.1. Early Scientific Management and Time–Motion Studies (1900s–1920s)

Modern productivity analysis in construction traces back to early 20th-century scientific management. Pioneers like Frederick W. Taylor and Frank and Lillian Gilbreth introduced time-and-motion studies in 1921 to optimise labour-intensive tasks [48]. In a well-known bricklaying study, Frank Gilbreth reduced motions per brick from 18 to as few as 2, tripling output from 120 to 350 bricks per hour [49]. These early studies showed the value of systematic observation and standardisation in improving work efficiency. They introduced concepts such as work sampling and method engineering, which allowed managers to establish task baselines and train workers more effectively. However, these studies were labour-intensive and often met with resistance from workers wary of imposed changes. Despite this, time-and-motion analysis laid the foundation for modern engineering methods and remains a key influence on construction productivity thinking today.

2.2. Gantt Charts and Project Scheduling (1910s–1950s)

Early productivity efforts in construction paired time–motion studies with project management tools, most notably Henry L. Gantt’s bar chart around 1910 [50,51]. By mapping tasks against time, Gantt charts let managers plan, sequence work, and compare planned and actual progress. Though hand-drawn and slow to update, they provided a clear project overview and, by the mid-20th century, evolved into CPM and PERT networks for resource allocation and duration estimation. Reliant on supervisors’ manual site checks, these schedules often failed to satisfy real conditions, yet they established the enduring framework for project-level productivity monitoring.

2.3. On-Site Observational Methods—Work Sampling and Time Tracking (1940s–1980s)

As construction projects grew in scale and complexity, the industry turned to “work sampling.” Here, randomly selected teams were observed at specific intervals to quantify the time spent on direct work, supporting activities, and idle time. For example, laying bricks is better than waiting for materials. Thousands of observations were compiled to calculate labour utilisation. For example, a crew might be found to spend 50% of their time on direct work, 30% on support tasks, and 20% idle.

This method was introduced in the mid-20th century and revealed hidden delays (e.g., waiting for materials and needless travel) without continuous timing. The “Method Productivity Delay Model (MPDM)” by Adrian and Boyer (1976) later formalised this approach by measuring “tool time” versus delays [52]. Simpler methods—such as daily logs and delay surveys—also gained traction. Though requiring minimal technology, these techniques demanded statistical rigour and observer training. Although time-intensive, work sampling became a standard tool for analysing site productivity and guiding improvements, especially in larger projects.

2.4. Unit Rate Tracking and Early Productivity Standards (1960s–1980s)

Construction also adopted unit rates—hours per output (e.g., cubic meters of concrete per crew-day)—and built rate databases to benchmark performance [18]. In the 1960s, U.S. agencies added “Earned Value Management (EVM)”, using the “Cost and Schedule Performance Index (CPI, SPI)” to flag underperformance early [21]. EVM compares planned work, actual progress, and cost. A CPI or SPI below 1.0 indicates reduced productivity or delay. Although the U.S. Department of Defence formalised EVM in 1967, its success depended on timely, accurate data. A 1977 study by CICE (U.S. Construction Industry Cost Effectiveness) identified inconsistencies in productivity definitions and metrics, prompting the Construction Industry Institute (CII) to standardize measurement guidelines based on “work-hours per unit” [18]. Despite these advances, many contractors applied unit rates and EVM only sporadically, limiting their utility for real-time control.

2.5. Evolution into Industry Standards and Lean Practices (1990s–2000s)

By the late 20th century, time–motion studies, work sampling, unit rates, and EVM had become the core of construction project controls. The 1990s saw the application of Lean Construction, inspired by Toyota’s production system. While Lean is primarily a management philosophy, it introduced planning tools like the Last Planner System® and takt time planning, along with performance metrics such as Percent Plan Complete (PPC) to track planning reliability. Lean practices helped reduce idle time and improve coordination, boosting labour productivity through better workflow.

In parallel, digital tools began replacing pen and paper. By the 2000s, handheld devices and spreadsheet macros had helped supervisors capture site data, while scheduling had been migrated to software such as Microsoft Project or Primavera. These digital tools streamlined updates and reduced errors but remained largely manual and retrospective.

Most productivity data—labour hours, quantities installed, and delays—were still compiled at day’s end or weekly, creating time lags between detection and response. When a crew’s underperformance was recognised, the project had already slipped. As one industry expert observed, it was not uncommon for issues to go unnoticed for 4–8 weeks. While these traditional methods marked significant progress over unmanaged workflows, they struggled to keep pace with the dynamic complexity of large projects. This recognition has driven the industry toward real-time, technology-enabled productivity monitoring.

2.6. Summary of Advantages and Limitations

Traditional productivity measurement methods gave construction managers essential tools to plan, monitor, and improve performance. Key advantages included the following:

- Clear expectations via standard time studies and unit rates;

- Structured planning through Gantt charts and CPM;

- Identification of inefficiencies using work sampling and delay analysis;

- High-level tracking through earned value metrics.

Many of these approaches became formalised standards and contributed to meaningful productivity gains, particularly when combined with Lean and workflow optimisation.

However, key limitations remained. Data collection was manual and infrequent, often leading to delayed feedback. Information was fragmented across systems—schedules, costs, and daily logs—limiting real-time visibility. Observations relied heavily on human judgment, introducing bias, and productivity definitions varied widely across firms and regions, hindering benchmarking [18]. By the early 21st century, construction faced inconsistent performance and slow productivity growth. These limitations created a strong incentive for innovation and laid the foundation for the current shift toward real-time, integrated, and technology-enhanced productivity measurement.

3. Review of Existing Productivity Metrics and Frameworks

While Section 1 outlined the systemic roots and practical consequences of the construction productivity gap, this section reviews the current landscape of academic and applied research on productivity measurement in the built environment. The aim is to identify conceptual blind spots, methodological fragmentation, and operational constraints that continue to limit the sector’s ability to quantify, compare, and systematically improve productivity performance.

Understanding this persistent gap requires a multi-decade review of how productivity has been defined, operationalised, and interpreted across disciplines. Classical indicators such as labour productivity and total factor productivity (TFP) [53] remain dominant, particularly in macroeconomic and institutional benchmarking. However, these aggregate metrics often fail to capture the complexity and heterogeneity of construction projects, which vary widely in duration, scope, location, and delivery method.

Recent developments have introduced flow-based performance models [23,24,26,54], digital measurement systems [35,38], and efforts to integrate automation and AI into real-time productivity tracking [47,55,56,57]. These innovations offer new possibilities but also raise critical questions. How scalable are flow-based metrics across fragmented project environments? How can automation and robotics be leveraged to improve productivity in both off-site manufacturing and on-site construction activities? And what degree of standardisation using production systems is achievable in a sector still dominated by one-off project delivery? This section critically reviews the evolution of productivity measurement in construction, draws on key publications across multiple decades, and highlights areas of contention, including the suitability of TFP in heterogeneous project environments [58], the debated impact of automation and robotics on labour dynamics [59,60], and differing perspectives on the scalability and standardisation potential of modular construction [61]. By comparing converging and diverging hypotheses, we aim to provide a balanced synthesis that lays the groundwork for the hierarchical productivity framework proposed in this article. This section synthesises the evolution of productivity frameworks in construction by placing foundational theories alongside emerging digital practices. We highlight tensions and trade-offs between precision and scalability, system-level KPIs and process-level observations, and industry aspirations for automation and the reality of deeply entrenched delivery models. Through this critical synthesis, we aim to establish the epistemic and practical gaps our proposed hierarchical productivity framework—presented in Section 4 of this paper—is designed to address. The review serves not only to position our contribution to existing scholarship but also to outline why a new, multi-scalar, and ontology-driven approach to productivity measurement is both timely and necessary.

3.1. Productivity in Construction: Perceptions, Metrics, and Conceptual Foundations

Productivity in construction remains one of the most contested and complex phenomena in academic and industry discourse. While the term is widely used, its definitions, measurement units, and interpretation vary considerably across contexts. In general terms, productivity refers to the relationship between output and input, but its operationalisation in construction must account for the sector’s inherent fragmentation, variability, and project-based delivery logic.

From a macroeconomic perspective, the dominant productivity metrics include the following:

- Labour productivity, typically expressed as output (e.g., value added) per labour hour;

- Capital productivity, which considers the return on equipment and infrastructure investment;

- Total factor productivity (TFP), which attempts to capture multifactor efficiency gains beyond mere input accumulation [58,62].

While these indicators offer high-level benchmarking capabilities, their application in construction is problematic. Heterogeneity in project size, scope, contract type, geography, and work organisation undermines the comparability of aggregate productivity data. Moreover, conventional definitions often fail to differentiate between process efficiency (“doing things right”) and output effectiveness (“doing the right things”), both of which are critical to construction performance but not always aligned.

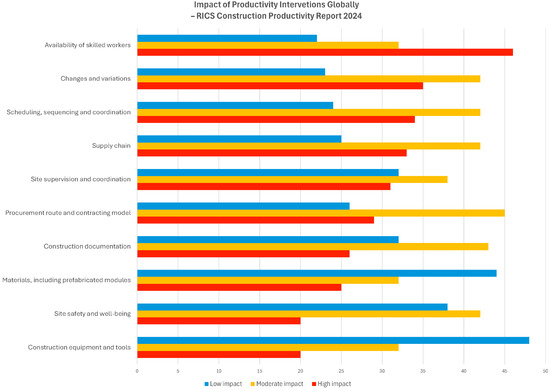

Figure 3 summarises the results of a recent industry-wide survey conducted by the Royal Institution of Chartered Surveyors (RICS) [63] to further explore how productivity is perceived at the project level. The figure shows how practitioners assess the relative impact of various factors on productivity outcomes. Notably, skilled labour availability is overwhelmingly rated as the most critical productivity driver. In contrast, interventions such as construction equipment, tools, and even off-site prefabrication are often perceived as having only moderate or low impact.

Figure 3.

Perceived impact of productivity interventions according to construction practitioners (adapted from the RICS Construction Productivity Report 2024 [63] based on 3285 global company responses). Reprinted/adapted with permission from Ref. [63]. 2025, Aarni Heiskanen/AEC Business.

This ranking reflects a persistent belief in the primacy of human labour as the dominant performance factor—an assumption that has long shaped managerial priorities in the industry. However, it also reveals a possible misalignment between practitioner perceptions and emerging evidence on the transformative potential of automation, robotics, and AI-based coordination systems. Recent studies suggest that technological interventions can yield significant performance gains, particularly when integrated with modular, data-driven workflows and standardised measurement architectures [35,46,47,54].

Thus, while industry perceptions provide valuable insights into existing mental models and investment preferences, they must be empirically validated against measurable performance outcomes. Understanding this perceptual–empirical gap is crucial for designing productivity frameworks grounded in practice and informed by systemic evidence.

The figure illustrates that practitioners overwhelmingly identify the availability of skilled labour as the primary driver of productivity. In contrast, automation, robotics, and technological innovations—such as construction equipment, tools, and prefabricated components—are frequently perceived as having limited impact. This perception may underestimate the long-term productivity potential of such technologies, especially when they are strategically implemented. Given the opinion-based nature of these results, further empirical research is required to assess whether current practitioner perceptions align with measurable productivity outcomes, particularly in light of advances in automation and AI-enabled construction workflows.

3.2. Measurement Levels and Multi-Scale Productivity Perspectives

Productivity—defined broadly as the ratio of outputs to inputs—is a cornerstone of construction performance analysis [64]. Yet, unlike in manufacturing, its measurement in construction is characterised by heterogeneity in units, levels of observation, and conceptual clarity. Productivity is commonly quantified as labour productivity, typically expressed in output per worker- or labour-hour. This can refer to physical quantities (e.g., square meters of wall built per worker-hour) or financial metrics (e.g., value added per labour-hour) [65]. The practical appeal of such metrics lies in the relative accessibility of labour and output data on construction sites.

Complementary to labour-based metrics is capital productivity, which relates outputs to investments in equipment, machinery, and plant; however, labour and capital productivity capture only partial aspects of construction performance. To provide a more comprehensive picture, researchers increasingly refer to total factor productivity (TFP), which compares total outputs with a weighted aggregate of all primary inputs, including labour, capital, materials, and energy [65]. TFP is particularly valuable for assessing efficiency improvements where outputs increase without proportional increases in total input, such as process innovation or automation.

Significantly, construction productivity operates across multiple levels of granularity:

- At the task or trade level, metrics focus on specific activities (e.g., cubic meters of concrete poured per crew-hour).

- At the project level, broader indices combine labour and cost metrics to reflect overall efficiency (e.g., square meters delivered per euro or person-day).

- At the industry level, productivity is typically reported through national statistics or macroeconomic surveys based on value added, capital stock, and labour data.

These metrics differ not only in scale but also in the type of insight they provide. While task-level metrics offer detailed process diagnostics, project-level indices link productivity to management and coordination quality. Industry-level indicators support policy benchmarking but are often disconnected from field-level realities.

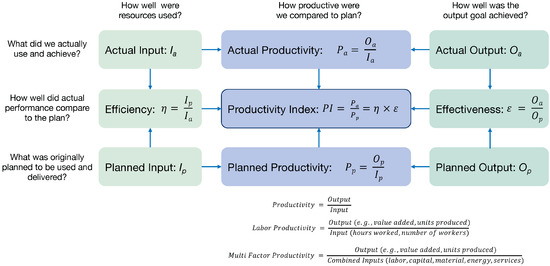

Moreover, standard productivity metrics frequently conflate planned and actual performance or mix units inconsistently, leading to limited comparability and interpretability. To address these issues, Figure 4 introduces a conceptually rigorous and physically coherent productivity model that differentiates between:

Figure 4.

Overview of key productivity performance metrics in construction. The diagram illustrates the relationships between planned and actual input and output, defining actual productivity, planned productivity, efficiency (η), effectiveness (ε), and the Productivity Index (PI). Efficiency measures resource utilisation by comparing planned to actual input, while effectiveness assesses output goal achievement by comparing actual to planned output. The PI integrates both dimensions—overall performance relative to the plan. Guiding questions alongside each metric provide practical orientation for performance evaluation. This conceptual framework has not been adapted from the existing literature and was created by the authors for this study.

- Planned Productivity (PP): The expected output per planned input;

- Actual Productivity (AP): The realised output per actual input;

- Efficiency (η): The ratio of planned input to actual input, indicating resource use;

- Effectiveness (ε): The ratio of actual output to planned output, indicating goal fulfilment;

- Productivity Index (PI): A composite metric defined as η × ε, integrating both dimensions. Unlike Earned Value Management, which aggregates cost and schedule performance retrospectively, the proposed η × ε framework focuses on real-time process-level efficiency and trade synchronisation.

This multi-dimensional framework avoids the unit inconsistencies of traditional approaches and provides a logically structured, modular foundation for productivity measurement at multiple levels. It is designed to support theoretical interpretation and field-level application, serving as a key building block for the hierarchical productivity framework presented in Section 4.

3.3. Challenges in Standardisation and Data Coherence

A persistent obstacle in construction productivity research lies in the lack of standardised, consistent measurement systems that are practically implementable and theoretically robust. Unlike manufacturing—where outputs are repetitive, measurable, and typically uniform—construction delivers heterogeneous, project-specific results. Roads, bridges, hospitals, and residential buildings vary in scope, complexity, and delivery model. Even within similar project types, site conditions, materials, and labour practices introduce variability that undermines benchmark comparability [65].

This diversity creates a fundamental challenge: no standard unit of output in construction exists. While a manufacturer can count cars produced, a contractor might quantify outputs in square meters, cubic meters, linear meters, or not at all. Attempts to compare productivity across projects become meaningless without coherent normalisation or context-specific reference points. As recent industry studies (e.g., the Singapore Construction Productivity Framework) have noted, current metrics are often described as “patchy”, fragmented, and inconsistently applied [65].

The recent literature [4,66] highlights four structural barriers to productivity standardisation:

- (1)

- Overreliance on Single-Factor Indicators: Labour productivity remains the most frequently cited metric in research and practice, yet it captures only one dimension of performance. A crew may appear more productive in labour terms by increasing equipment usage or material throughput, while total resource efficiency may decline. Hence, labour productivity can be misleading if viewed in isolation, especially in capital- or technology-intensive environments [64].

- (2)

- Activity-Level Myopia and Lack of System View: Productivity metrics often focus on individual trades or isolated tasks (e.g., cubic meters of concrete placed per hour). However, construction outcomes result from interdependent workflows. Gains in one area (e.g., faster rebar placement) can disrupt others (e.g., inspection delays or follow-on trades). This lack of systemic perspective undermines the validity of task-level metrics as proxies for overall project performance [64].

- (3)

- Macro–Micro Disconnect: A well-documented disjunction exists between project-level data and macroeconomic indicators. National or industry-wide productivity reports may show stagnation or decline. In contrast, individual projects report local gains—often due to methodological mismatches in data aggregation, output definitions, or sector-level adjustments [64]. This misalignment hampers policy relevance and undermines trust in reported figures.

- (4)

- Absence of Harmonised Data Infrastructure: Unlike manufacturing, construction lacks centralised reporting platforms for performance data. Measurement practices are typically firm-specific, undocumented, and manually conducted. This lack of structured, interoperable datasets impedes benchmarking, comparison across firms or regions, and broader research on best practices [64].

Researchers have proposed more composite and multi-level productivity models in response to these challenges. For example, Ayele and Fayek [58] introduced a Total Productivity Framework for construction, incorporating labour, materials, equipment, and energy at multiple observation levels. Their approach enables more nuanced, resource-agnostic productivity assessment across projects and firms [65]. Similarly, Sacks et al. [67,68] advocate for system-oriented productivity models grounded in Lean Construction and BIM-enabled workflows [69,70], which capture process reliability, coordination, and lifecycle performance, rather than just output–input ratios.

Nonetheless, achieving industry-wide standardisation remains a formidable challenge. Productivity metrics must balance simplicity for site-level applications with comprehensiveness for strategic decision-making. Too much abstraction undermines adoption; too much granularity impedes scalability. Navigating this tension between practicality and precision remains one of the core methodological dilemmas in construction productivity research [64].

3.4. Fragmentation, Silo Thinking, and the One-Off Nature of Projects

A defining characteristic of the construction industry that profoundly affects productivity is its high degree of fragmentation across organisational structures, knowledge domains, and process interfaces. Unlike manufacturing, where integrated firms operate stable, repetitive workflows within vertically coordinated supply chains, construction projects are typically delivered by temporary, project-specific coalitions of independent actors. These include clients, architects, engineers, general contractors, subcontractors, and suppliers, each with their own incentives, information systems, and operational routines [71].

This project-based delivery model, often described as the “one-off factory” paradigm [72], implies that each construction site functions as a bespoke production system, with unique participants, processes, and constraints. After project completion, teams dissolve, knowledge dissipates, and organisational learning is lost. The lack of continuity prevents cumulative innovation, as successful practices from one project are rarely systematically transferred to subsequent ones. Organisationally, this leads to siloed responsibility and limited collaboration. Traditional procurement methods such as Design–Bid–Build (DBB) reinforce the separation between disciplines and phases. In DBB, the design team is contractually isolated from the construction team, and both may be disconnected from facility operators and users. This transactional fragmentation fosters mistrust, adversarial dynamics, and inefficiencies at the interfaces between design, procurement, and execution [73].

Process-wise, data flows are non-integrated, with information often recreated, lost, or reinterpreted at each handover. As a result, productivity-related insights (e.g., output rates, cost efficiencies, and error rates) are rarely captured in reusable formats. Moreover, subcontracting arrangements typically lack transparency and shared KPIs, making system-wide performance monitoring difficult. Epistemically, fragmentation manifests in divergent definitions of productivity across trades and stakeholders. A subcontractor may define success as maximising crew utilisation; a general contractor may focus on schedule adherence; the client may prioritise cost per square meter. Without aligned metrics and shared frameworks, productivity analysis becomes subjective and non-comparable [74,75].

The consequence is a sector structurally resistant to continuous improvement. Innovations such as Lean Construction [22,23,24,54,76,77,78], Integrated Project Delivery (IPD) [79,80,81,82], and Building Information Modelling (BIM) [44,46,59,70,83] have been proposed to overcome these silos, yet adoption remains inconsistent and context-dependent. Without mechanisms for longitudinal knowledge retention and organisational learning, the sector remains trapped in a cycle of repetition without accumulation—rebuilding not just projects but also their inefficiencies. Construction’s endemic fragmentation—organisational, procedural, and cognitive—creates conditions under which productivity cannot be reliably measured, improved, or scaled. Overcoming this requires technical solutions and reconfiguring roles, responsibilities, and information structures across the project lifecycle.

3.5. External Variability and Systemic Dependencies

In addition to internal fragmentation and siloed processes, the construction sector is uniquely exposed to various external variables and systemic interdependencies that can significantly distort productivity measurements and impair performance management. Unlike manufacturing, which operates under tightly controlled conditions, construction unfolds in dynamic, often unpredictable environments, where operating conditions vary daily, seasonally, and across locations [84].

One of the most prominent external influences is the weather. Rain, snow, extreme heat, and wind can delay or suspend site activities, particularly those performed outdoors or at height. These weather-induced delays are largely uncontrollable and do not reflect the underlying efficiency of work crews or management. Nonetheless, they reduce output per labour-hour, thereby depressing measured productivity without indicating process-level failure [65,85].

Beyond meteorological factors, construction depends on interconnected and often fragile supply chains. Projects require the timely delivery of diverse materials, components, and equipment, much of which is sourced globally. Disruptions in transportation, customs, or supplier logistics (e.g., due to strikes, port congestion, or raw-material shortages) can create downstream bottlenecks that limit on-site resources. In such cases, productivity loss is not a result of local inefficiency but systemic vulnerability to supply-side interruptions [86,87].

Site location and logistics further amplify variability. Urban construction projects face access restrictions, delivery windows, and spatial constraints that reduce operational efficiency. In contrast, remote or rural projects may suffer from poor infrastructure and longer workforce or material mobilisation lead times. These geographical conditions directly affect task pacing, buffer times, and crew sequencing, thus distorting productivity baselines across contexts [65].

Regulatory compliance is another often-overlooked factor. Construction must adhere to numerous legal and administrative requirements, including permitting, inspections, environmental controls, and safety regulations. While essential, these procedures frequently introduce non-productive time, waiting periods, and iterative rework, particularly when regulatory frameworks are misaligned or inconsistently enforced across jurisdictions [88].

Finally, the industry’s continued dependence on skilled labour creates exposure to labour market volatility. Shortages of qualified workers, regional wage pressure, and turnover risk can reduce task performance or lead to reliance on less-experienced substitutes. Extended overtime, while often used to mitigate schedule delays, can further reduce productivity due to fatigue and error propagation [15,74,75].

Together, these external influences create a high degree of contextual variability that complicates the measurement and management of productivity. Macro-level indicators smooth over these local fluctuations, while micro-level metrics often fail to distinguish between endogenous inefficiencies and exogenous constraints. This misalignment results in a macro–micro disconnect: a project may be executed efficiently under challenging conditions yet appear unproductive statistically. Addressing this problem requires context-sensitive productivity models that can account for variable baselines, normalise performance against exogenous factors, and distinguish controllable from uncontrollable causes of inefficiency. Without such differentiation, attempts at standardisation or benchmarking risk penalising well-managed projects simply because they operate in more demanding environments [64].

3.6. Lessons from Manufacturing: Flow, Modularity, and Standardisation

While the construction sector grapples with stagnant productivity, the manufacturing industry has achieved decades of consistent performance gains. Rather than emphasising why construction lags, this section distils transferable principles from manufacturing that can inform productivity strategies in the built environment without neglecting the fundamental differences between the two sectors.

Manufacturing success is primarily rooted in four interconnected principles [89]:

- Process standardisation to reduce variability and ensure repeatability;

- Modularisation and prefabrication to enable efficient assembly and reduce on-site complexity;

- Automation and robotics to increase throughput and minimise human error;

- Integrated supply chains synchronise material, information, and process flows.

Each of these principles has analogues in construction, but they are applied unevenly due to the project-based, non-repetitive, and geographically dispersed nature of construction delivery systems [89].

Still, modularisation and off-site manufacturing offer particularly promising pathways for adaptation. Prefabricated building components, such as volumetric modules, curtain wall systems, and multi-trade assemblies, allow for relocating value-adding activities into controlled factory settings, where process improvements can be codified and scaled. This not only reduces rework and weather-related delays but also facilitates the use of automated tools such as robotic welding, CNC-based timber fabrication, and AI-driven quality control [90,91].

Yet the goal is not to mimic manufacturing’s wholesale model but to implement context-aware hybridisation. For example, while mass production in the automotive sector favours low variability and high volume, construction must remain flexible to accommodate client-specific design, site conditions, and regulatory constraints. Concepts such as mass customisation, digital twins, and Lean-driven takt planning allow for adaptable standardisation, offering both efficiency and contextual responsiveness [92].

Furthermore, manufacturing teaches the value of systemic integration: when upstream design, procurement, and production are aligned through digital platforms and shared KPIs, waste is reduced and predictability increases. Such integration is possible in construction via BIM-enabled coordination, early contractor involvement, and platform-based industrialisation models, in which standard interfaces and modular logic govern otherwise custom outcomes [93,94].

Importantly, successful transfer requires more than technology. It demands organisational change, cultural openness, and capability development across firms and project teams. Without this adaptive infrastructure, even advanced tools remain isolated experiments. Construction can draw valuable lessons from manufacturing, particularly regarding the power of flow-centric thinking, standardised modularity, and digitally integrated systems. These insights lay the conceptual foundation for the hierarchical productivity framework proposed in Section 4. The framework seeks to reconcile the granularity and variability of construction with the control logic and scalability of industrial systems [5].

4. A Unified Hierarchical Framework for Productivity Measurement in Construction

This section introduces the authors’ original contribution: a hierarchical productivity measurement and control framework developed from first principles through conceptual synthesis. Our framework advances the current state of the art in construction productivity research. While prior studies have focused either on micro-level task productivity or macroeconomic indicators at the national or industry level, a cohesive model that structurally integrates these layers has been missing. Our framework addresses this critical gap by systematically linking operational, tactical, strategic, and normative levels through a unified performance ontology.

Whereas conventional productivity models often treat activities in isolation—differentiating between primary and secondary value creation—our framework is grounded in flow-based logic. It rejects this binary distinction and instead conceptualises all functions as interdependent elements of a continuous production stream. Each layer of the hierarchy contributes to value creation, not through its classification as “core” or “supporting”, but through its role in ensuring flow, quality, and systemic alignment.

The framework further recognises that productivity manifests differently across scales: at the operational level, efficiency—“doing things right”—is paramount, whereas at the strategic and normative levels, effectiveness—“doing the right things”—becomes the primary driver. Our model unifies these dimensions by embedding them within a scalable, modular structure, making productivity observable, measurable, and controllable across projects, firms, and ecosystems.

This contribution builds on, but extends beyond, existing approaches by explicitly integrating Lean Construction principles, flow optimisation metrics, and hierarchical KPI structures into one consistent system. It forms the core theoretical foundation for the control framework and empirical validation strategies discussed in the following sections. In short, this section marks the transition from conceptual critique to architectural proposition: from identifying the productivity gap to formally structuring how it can be closed.

4.1. Empirical Validation of Kelly Drilling Using Geiger et al.’s Modular Production Model

To demonstrate the applicability of the proposed hierarchical productivity model, a pilot implementation was carried out on a large-scale residential construction site involving repetitive Kelly drilling operations by Geiger et al. 2025 [95]. Using a combination of IoT sensors, manual observations, and takt-based scheduling data, flow efficiency and input efficiency were tracked over three weeks, in which construction processes were decomposed into standardised, repeatable process steps linked to fixed time metrics. This work demonstrates a concrete use case by applying the modular production model to continuous process monitoring for Kelly drilling operations on an active foundation site. In this empirical study, sensors of drilling rigs capture real-time data streams—such as spindle torque, penetration depth, and feed rate—and relay them to an AI-driven monitoring system. Machine learning algorithms map these raw signals to the predefined process-step classification (e.g., “align casing”, “initiate drilling”, “extract spoil”, and “flush casing”), automatically segmenting the operation into its constituent steps and measuring actual durations against the established reference times.

By comparing the sensed data with the modular toolkit’s standard times, the system identifies deviations in situ, pinpointing, for example, excessive idle periods during spoil removal or suboptimal feed rates under varying soil conditions. These insights validate the model’s ability to link micro-level execution metrics to higher-level flow diagnostics, enabling frontline supervisors to intervene immediately when productivity drifts from the benchmark.

Through this Kelly drilling case study, we confirm that combining Geiger et al. ’s [95] ontological production model with AI-supported sensing and pattern recognition not only automates data capture but also grounds our hierarchical productivity framework in practical, site-based evidence. The analysis revealed significant cycle-time variations traced back to inconsistent crew deployment and equipment readiness. After introducing visual management and minor takt optimisations, the Coefficient of Variation (CV) decreased by 18% and output per crew hour increased by 12%. This initial test underscores the practical value of real-time productivity KPIs and validates the framework’s applicability on-site. This validation lays the groundwork for scaling the approach to other trades, ensuring robust, real-time productivity control via AI-driven process monitoring across the entire construction phase. Further deployments are planned to extend the empirical foundation across multiple trade types.

4.2. Operational Level

The starting point for productivity measurement and optimisation in construction lies at the operational or shop-floor level. This is where physical value creation occurs—materials, labour, and equipment converge to execute planned construction tasks.

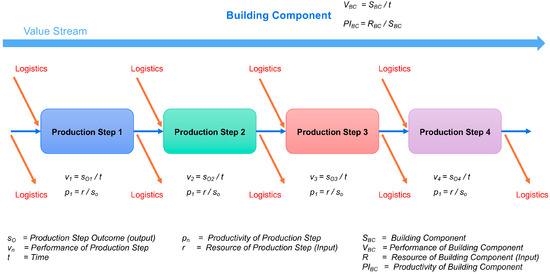

Building on a modular-construction toolkit [95], the process-step level—the individual tasks on the shop floor—becomes the anchor point for meaningful productivity measurement. Every on-site activity is broken down into discrete, standardised process steps, such as “position rebar cage”, “place formwork panel”, or “pour concrete”. These steps are repeatable units: they occur similarly, regardless of project size, building type, or site peculiarities. Because they are constant, they provide a common standard for comparison across projects and companies (Figure 5). Standardising at the process-step level does not impose uniformity on the finished building but establishes a universal production vocabulary. Each step is given a precise definition, an expected sequence, and a reference time, derived from empirical observations, time-and-motion studies, or parametric estimates.

Figure 5.

Modular decomposition of a building component into standardised, repeatable production steps, forming the basis of a construction-specific value stream developed by the authors. Each process step is defined by its measurable output (soi), performance (vi = soi/t), and productivity (pi = ri/si), with logistics transitions linking steps. The aggregated performance and productivity of the entire building component (VBC and PIBC) derive from the sum of standardised outputs and resource inputs. This representation offers a physically consistent, granular model for value stream analysis at the operational level, enabling benchmarking, automation, and real-time performance monitoring based on process-step logic.

Using Value Stream Mapping (VSM) at this level of detail, each shop-floor process is laid out as a continuous flow of interconnected production steps (see Figure 4). In a construction context, VSM is applied to visualise the production of an individual building component—the smallest repeatable unit we track for productivity. A building component is a subset of a broader construction module, such as one bored pile in a bored pile wall or a single room on a complete floor. Although modules and their constituent components vary from project to project, each element can still be represented as a standardised sequence of value-adding process steps [95].

From a production flow perspective, therefore, the manufacture of any building component can be decomposed into its value stream—a step-wise, left-to-right representation that shows how materials, information, and resources move through drilling, reinforcing, concreting, and so on.

Shingo’s distinction between process and operation is a pillar of Lean manufacturing [96,97,98]. In his original model, the process runs horizontally (X-axis) as the value stream, while the operations—the discrete work steps at each station—run vertically (Y-axis). When this concept is transposed to construction, a station can be associated with a production step, as illustrated in Figure 5. However, in construction, it is not the product that flows from station to station but the production that flows through the product:

On a construction site, the vertically oriented operation axes represent the sequence of sub-steps that constitute a complete production step (e.g., the drilling process for a bored pile or drywall construction in a single room). In contrast, the process axis represents the flow of production steps that create a building component.

By treating these standardised activities as modular process steps, teams gain a powerful toolkit for systematising performance analysis and continuous improvement. Each process step is defined consistently and is repeatable, enabling direct comparability across projects, teams, and contexts. This modularity unlocks several core capabilities:

- Benchmarking performance: Actual task durations and resource usage can be compared against standard benchmarks derived from the Value Stream Map (VSM) of a given building component. These benchmarks represent the sum of expected durations for standardised process steps plus idealised logistics times (assumed to be zero in a just-in-time setup). This enables the calculation of performance deviations at the level of individual construction elements.

- Benchmarking productivity: Similarly, productivity can be evaluated as the ratio of the resource input (e.g., labour hours) to the actual output (e.g., installed area or component volume), allowing for quantifiable comparisons of work efficiency across different crews, shifts, or sites.

- Waste identification: Discrepancies between standard and actual sequences (e.g., idle time, rework, and excessive motion) become visible within the process-step model, highlighting bottlenecks and non-value-adding activities for elimination.

- Transfer of best practices: Because a process step such as “pour concrete” is identically defined across projects, successful strategies and learned optimisations from one site can be directly transferred to another, reinforcing organisational learning.

Thus, the process-step level is the industry’s ground truth for standardisation and continuous improvement, converting diverse construction workflows into comparable, measurable, and optimisable units. Integrated metrics such as input efficiency, output effectiveness, and First-Time Quality percentages are applied at the process-step level, enabling granular performance tracking. These metrics feed into a composite Productivity Index (PI), which quantifies how efficiently resources are being transformed into value-added outputs, which are the building components.

Moreover, this flow-based structure, broken down into standardised process steps, supports real-time performance and productivity monitoring, especially in process domains where sensor-equipped machinery is used (e.g., special civil engineering tasks like Kelly drilling). In such cases, data collection can be automated and linked directly to process steps through AI-based pattern recognition, as outlined [95].

Even in conventional building construction, where automation is significantly lower than in specialised civil engineering, there remains substantial potential for implementing effective productivity tracking mechanisms. Artificial intelligence (AI) advancements are creating new opportunities for enhancing data accuracy and reducing the burden of manual observation. AI technologies, particularly computer vision, machine learning, and pattern recognition, can be trained to identify and classify recurring construction activities from images, video footage, or sensor data. These systems can map observed actions to specific, predefined process steps within the modular construction toolkit, enabling automated process recognition even in environments not initially designed for full automation.

Ultimately, the operational level—enriched through modular standardisation, systematic measurement, and data-driven analysis—becomes a critical enabler of continuous productivity optimisation. It transforms construction sites from reactive environments into proactive, intelligently managed systems, capable of learning and evolving through each project cycle.

It bears repeating that effective performance and productivity measurement hinges on the built asset’s hierarchical structural model—an ontology. Any building is decomposed into construction modules, subdivided into construction elements. A value stream composed of standardised process steps can be defined for every aspect. This production-oriented ontology is a generic concept that can be applied to any built asset.

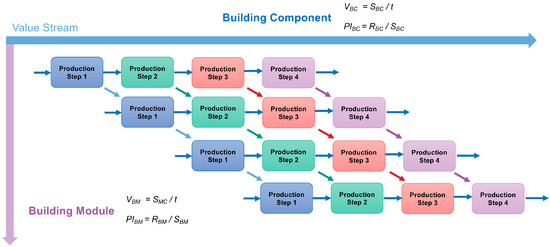

4.3. Tactical Level (or Trade Level)

The operational level focuses on the repeatable process steps that turn materials into a single building component; the tactical level governs how those steps are sequenced, balanced, and handed off among multiple trades working on the same construction module. At the trade level, the focus shifts to variability control, schedule adherence, and coordination of multiple trades and subcontractors. To quantify performance at this stage, we propose using the Coefficient of Variation (CV) to capture workload balance, complemented by takt time compliance and schedule adherence metrics. These indicators reflect the ability of planning teams to stabilise production rhythms and control process variability, which is essential for preventing disruptions that propagate into higher-level risks.

In Figure 6, a sequencing model is sketched. Adapting Shingo’s two-axis model, we treat each trade crew (e.g., production step concrete, drywall, etc.) as a “station” that executes a column of sub-steps. The horizontal axis, as above, represents the flow of production steps from one production step to the next or from one trade to the next, while the vertical axis lists the repetitive production step, flowing vertically from one building component to the next building component. Optimising only the vertical column—say, reducing the cycle time of drywall installation—may yield local gains yet leave downstream crews waiting for materials or inspection. Conversely, redesigning the horizontal flow without stabilising the underlying tasks pushes variability to the next station. Productivity emerges when efficient operations (task-level cycle time and quality) are nested inside a well-balanced, waste-free process flow (trade sequence and takt rhythm) [96,97,98].

Figure 6.

The authors developed a dual-axis sequencing model for trade-level productivity optimisation, adapted from Shingo’s process-operation framework [96]. The vertical axis represents standardised production steps performed repeatedly across multiple building components. In contrast, the horizontal axis captures the hand-off sequence between trades or production steps within a construction module. This structure enables concurrent tracking of vertical (task-level) efficiency and horizontal (flow-level) coordination, highlighting the interplay between takt time stability, workload balance, and First-Time Quality in multi-trade construction environments.

Aligning the two axes of the trade-level model with our core definitions of performance and productivity highlights that every productivity indicator is tied to a specific level of abstraction:

- Horizontal productivity is calculated along the process axis. It aggregates the cycle times and First-Time Quality scores of the standardised process steps that form a single building component (e.g., one bored pile or one drywall partition).

- Vertical productivity is measured along the operational axis. It sums the performance of all construction elements produced by one trade within a defined zone or takt window, yielding the overall productivity of a construction module (e.g., an entire bored-pile wall or a completed apartment floor).

Because the metric hierarchy is anchored in the building ontology introduced earlier—process step → building component → construction module—KPIs roll up structurally from the shop floor to the project dashboard without losing fidelity. In other words, the KPI system is inseparable from the ontology of the built asset: (I) horizontal metrics benchmark value creation within one building component; (II) vertical metrics benchmark the cumulative output of those components. This ensures a coherent, bottom-up line of sight from task efficiency to construction module-level performance.

Simply running several production steps in parallel does not, by itself, increase productivity. Because productivity is defined as output divided by input, adding more crews or equipment boosts both sides of the ratio proportionally; the headline index, therefore, remains flat.

Genuine improvement appears only when parallelisation is combined with repetitive work sequences and a takt rhythm. As a production crew performs the same standardised task—pile after pile, room after room—learning-curve effects shorten cycle times, hand-off delays shrink, and material flows stabilise. Under this disciplined cadence, the additional resources devoted to parallel crews yield disproportionately higher output, tipping the input–output ratio in favour of actual productivity gain. In short, it is not parallel work per se that drives improvement, but the repetitive, takt-paced execution that unlocks the efficiencies inherent in standardised process steps.

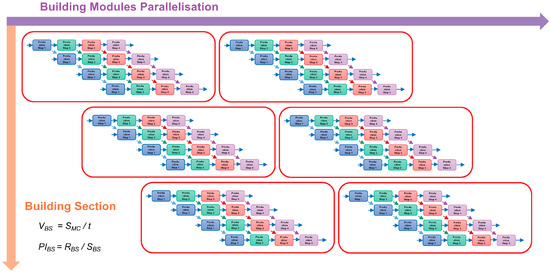

4.4. Strategic Level (or Building Section or Building)

As individual process steps aggregate into building components and such components into construction modules, multiple construction modules can be combined to represent an entire building section, such as civil works, shell construction, façade works, and interior fitting. We can calculate section-level productivity and section-level performance by summing the standardised input and output data for all construction modules within that section (Figure 7).

Figure 7.

Aggregation of standardised productivity metrics from construction modules to building sections developed by the authors. The model illustrates how planned versus actual productivity and performance can be tracked at the strategic level in real time by summing process data from the operational and tactical layers. This structure enables transparent performance benchmarking and supports incentive mechanisms—such as performance-based contracts and real-time bonus pools—that reward collaborative gains in takt time reliability, flow stability, and First-Time Quality across multiple trades and building zones. This conceptual framework has not been adapted from the existing literature and was created by the authors for this study.

Project teams begin their work with a rigorously defined baseline because planned productivity and performance for each building section can be assembled from the same bottom-up ontology—step by step from process to component, component to module, and module to section. Summing the standard task durations, resource hours, and takt counts produces a section-level target that is directly comparable to live field data. The resulting percentage deviation, calculated as (actual minus planned) divided by planned, and expressed in real time, immediately reveals whether productivity is slipping or improving. Crucially, this variance is traceable down to the individual process step so that managers can pinpoint the root cause of an overrun or an outperformance within minutes rather than weeks.

Turning these insights into action requires that management reward genuine productivity gains, not merely cost-cutting or schedule compliance in isolation. Performance-based contract clauses can link a share of fees or profits to closing the productivity gap, while rolling bonus pools for crews can grow as takt targets are beaten without compromising First-Time Quality. When two adjacent trades jointly reduce hand-off delays, both parties can receive an additional reward, ensuring that local optimisation never comes at the expense of overall flow. Real-time dashboards and leader boards displayed in site offices reinforce this culture by providing instantaneous, transparent feedback. Moreover, crews that document improvements and transfer them to sister projects can receive formal credits toward future bids or internal promotion, embedding continuous learning in the corporate DNA.

In this way, the hierarchical KPI structure ceases to be a passive reporting tool and becomes an active management lever. By tying financial and reputational incentives directly to productivity variance, executives ensure that every participant—from boardroom to shop floor—shares a tangible stake in narrowing the industry’s stubborn productivity gap.

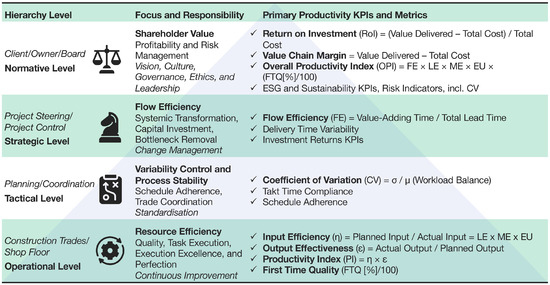

4.5. Normative Level (or Project Management or Level)

At the normative level (Figure 8), executive leadership sets the guiding principles defining how a construction enterprise creates long-term value, controls risk, and fulfils its social licence. While classic profitability metrics—Return on Investment (ROI), Operating Cash Flow, or Value-Chain Margin—remain indispensable, they are no longer sufficient. To steer a modern, data-driven organisation, management needs composite indicators that link financial outcomes to operational performance, stakeholder expectations, and sustainability goals [99]. Specifically, we propose the use of an Overall Productivity Index (OPI), calculated as the product of flow efficiency, resource efficiency factors (labour, material, and equipment), and First-Time Quality (FTQ) metrics.

Figure 8.

The authors developed the hierarchical productivity measurement framework for the construction sector, integrating normative, strategic, tactical, and operational levels. The model aligns key productivity KPIs with Lean principles at each level, prioritising systemic flow efficiency over isolated resource optimisation. It highlights how task-level performance aggregates into project, firm, and macro-level productivity, offering a structured approach to bridging micro and macro perspectives. This conceptual framework has not been adapted from the existing literature and was created by the authors for this study.

To integrate ESG dimensions into the OPI, we propose a weighted composite scoring system complementing the traditional flow and resource efficiency metrics. Environmental indicators (e.g., CO2 intensity per m3 concrete or material circularity ratio), social indicators (e.g., on-site safety scores or labour conditions), and governance metrics (e.g., compliance with procurement standards) are normalised on a 0–1 scale and incorporated via a configurable ESG multiplier. The ESG multiplier accounts for ESG compliance and can be adapted to reflect project-specific sustainability goals or regulatory requirements. This modular integration ensures that productivity gains align with global and/or regional sustainability targets.

ESG compliance and sustainability KPIs further complement the measurement framework at this level, reflecting construction firms’ broader societal and environmental responsibilities. These KPIs ensure that strategic decisions optimise economic return, environmental stewardship, and social impact—critical factors for winning public tenders, securing ESG-oriented financing, and maintaining a resilient brand.

For instance, the normative layer may incorporate EU taxonomy criteria or national reporting obligations (e.g., CO2 footprint declarations or labour standards) into platform-based workflows to ensure regulatory compliance [100].

A defining feature of the proposed hierarchical production model is its explicit emphasis on flow efficiency as the primary strategic lever for improving productivity. It sets it apart from conventional models that focus predominantly on resource optimisation. Rather than merely seeking to maximise the use of labour, equipment, or materials, this model prioritises the stability of process flow and the reduction of variability (known as Mura in Lean terminology), recognising these as critical prerequisites for achieving sustainable and meaningful performance gains.

The core of this approach lies in a structured framework based on decomposed, standardised, and repeatable process steps. These steps form the building blocks of what the authors call a “production model”, constructed using Value Stream Mapping (VSM) techniques. Through the lens of VSM, inefficiencies in the flow of work, materials, and information are made visible and measurable, allowing for targeted interventions at multiple organisational levels. This shift enables the proposed framework to be more holistic and dynamic than traditional productivity measurement approaches, such as OEE-based models in manufacturing or task-level earned value analysis in construction, especially in complex, multi-trade environments.

What truly distinguishes this hierarchical model is its systematic integration of Lean Construction principles across all tiers of decision-making. At the normative level, foundational values and long-term objectives are supported by practices such as Hansei (critical self-reflection) and Kaikaku (radical change), which enable paradigm shifts in organisational direction [101,102]. At the strategic level, tools like Value Stream Mapping and Heijunka (production levelling) ensure alignment between high-level planning and flow-efficiency goals [89,103,104]. On the tactical level, the focus shifts to implementing pull systems and reducing variability (Mura), ensuring that processes are responsive to actual demand rather than speculative scheduling [11,26]. Finally, the operational level is shaped by Kaizen (continuous improvement), Jidoka (autonomation or built-in quality), and the 5S methodology, which collectively foster clean, standardised, and quality-driven work environments [105,106].

By embedding these Lean principles into a vertically integrated control architecture, the proposed framework extends beyond traditional siloed applications, offering a novel, comprehensive productivity measurement system that reflects construction projects’ multi-stakeholder, multi-scale nature. It not only enhances operational execution and enables dynamic productivity governance across the construction value chain but also embeds a culture of reflection, responsiveness, and continuous improvement. It transforms productivity optimisation from disconnected practices into a cohesive, systemic strategy deeply rooted in flow, value, and learning principles. Furthermore, it is designed to facilitate aggregating granular operational data into higher-level strategic insights while providing actionable feedback loops at each hierarchy level.

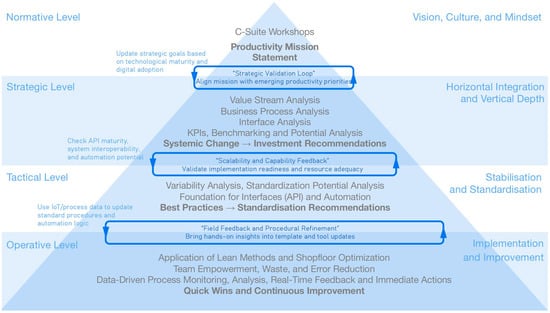

To operationalise the hierarchical productivity model, we developed an original, multi-level control architecture (Figure 9) formalising vertical and horizontal feedback loops between the normative, strategic, tactical, and operational levels, enabling continuous learning, cross-level alignment, and adaptive performance optimisation. Figure 9 illustrates how real-time operational feedback, process standardisation, and strategic recalibration can be integrated into dynamic control structures. The architecture supports responsive and data-driven productivity management across the construction value chain through digitalisation, sensor-based monitoring, and standardised KPIs.

Figure 9.

The Feedback-Driven Control Architecture developed by the authors integrates feedback loops between normative, strategic, tactical, and operative levels. The model illustrates how digitalisation, sensor-based monitoring, and standardised KPIs enable a continuous refinement of mission alignment, resource planning, and operational practices. Feedback arrows highlight how real-time field insights inform standardisation, tactical feasibility calibrates strategic investments, and strategic goals are recalibrated based on digital maturity and evolving productivity priorities. This conceptual framework has not been adapted from the existing literature and was created by the authors for this study.

5. Discussion and Future Outlook

The proposed hierarchical productivity framework introduces a structured and ontologically coherent foundation for transitioning the construction industry from fragmented, manually managed processes to an integrated, digital, and performance-driven system. The framework addresses one of the sector’s most persistent barriers: the lack of systemic coherence in data, decision-making, and performance interpretation by vertically aligning productivity metrics across operational, tactical, strategic, and normative levels and horizontally aligning them across stakeholders and process domains.