Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete

Abstract

1. Introduction

2. Experimental Process and Method

2.1. Material Preparation

- Cement: the same grade of P.C 42.5R [50] Red Lion Composite Silicate Cement (Hongshi Group Co., Ltd., Zhejiang province, China) is used to ensure the test results.

- Water: ordinary tap water for daily use was used.

- SSF: SSF used in this test came from the lathe machining trimmings of a company in Chengdu, China. The original form of SSF, which was picked to select the more neatly spiraled steel fibers (Figure 1b), is shown in Figure 1a. The surface of the selected SSF was clean and tidy, free from rust, oil, and impurities, and its mechanical properties are shown in Table 1.

- Aggregates: coarse aggregates used ordinary crushed stone with a grain size of 5–20 mm; fine aggregates adopted medium sand with a fineness modulus of 1.85 and a moisture content of 0.5% or less produced locally in Sichuan.

- Rubber: rubber particles with a particle size of 1–3 mm were obtained by shredding waste rubber tires (Figure 2).

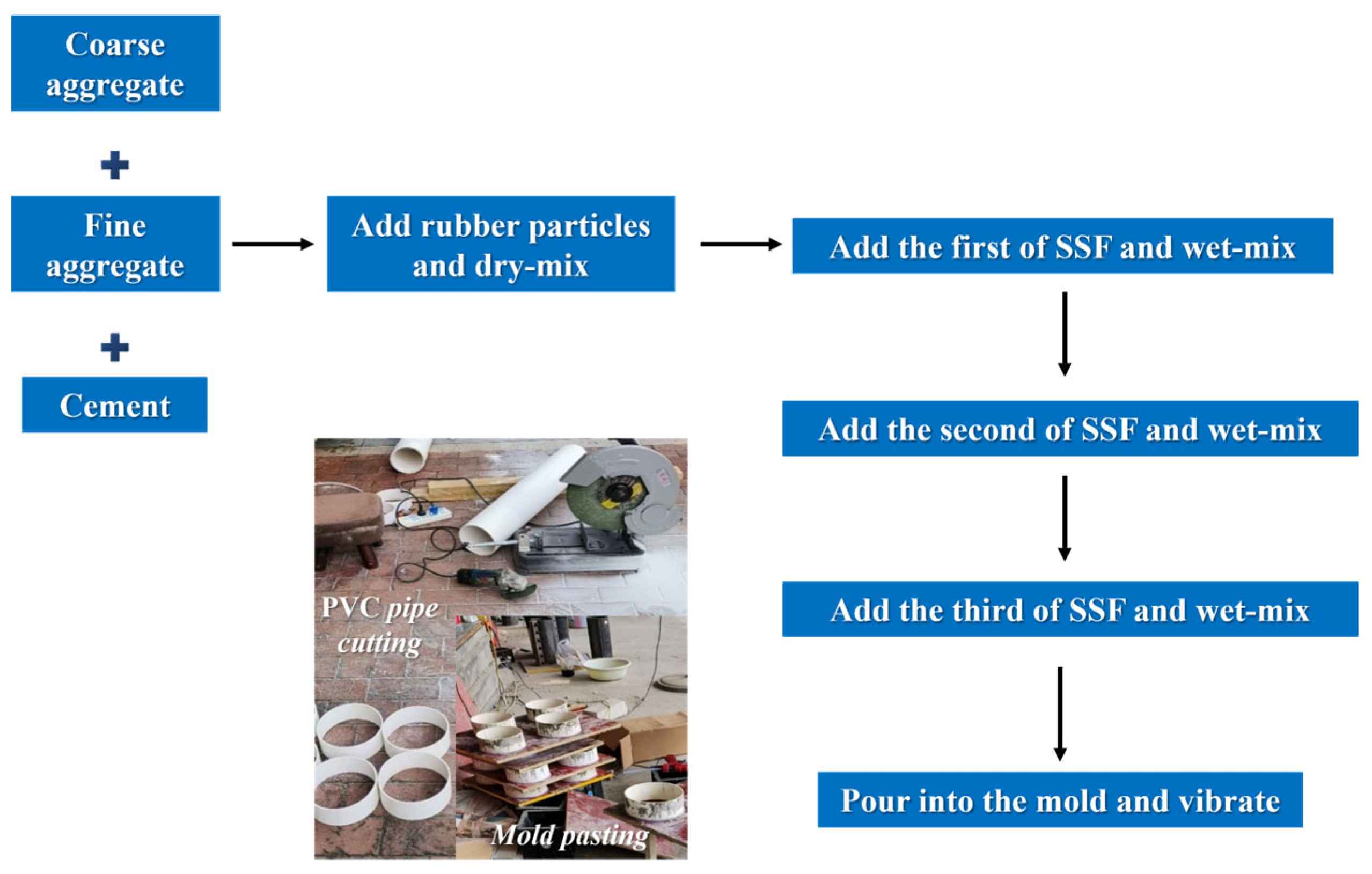

2.2. Specimens’ Manufacture and Maintenance

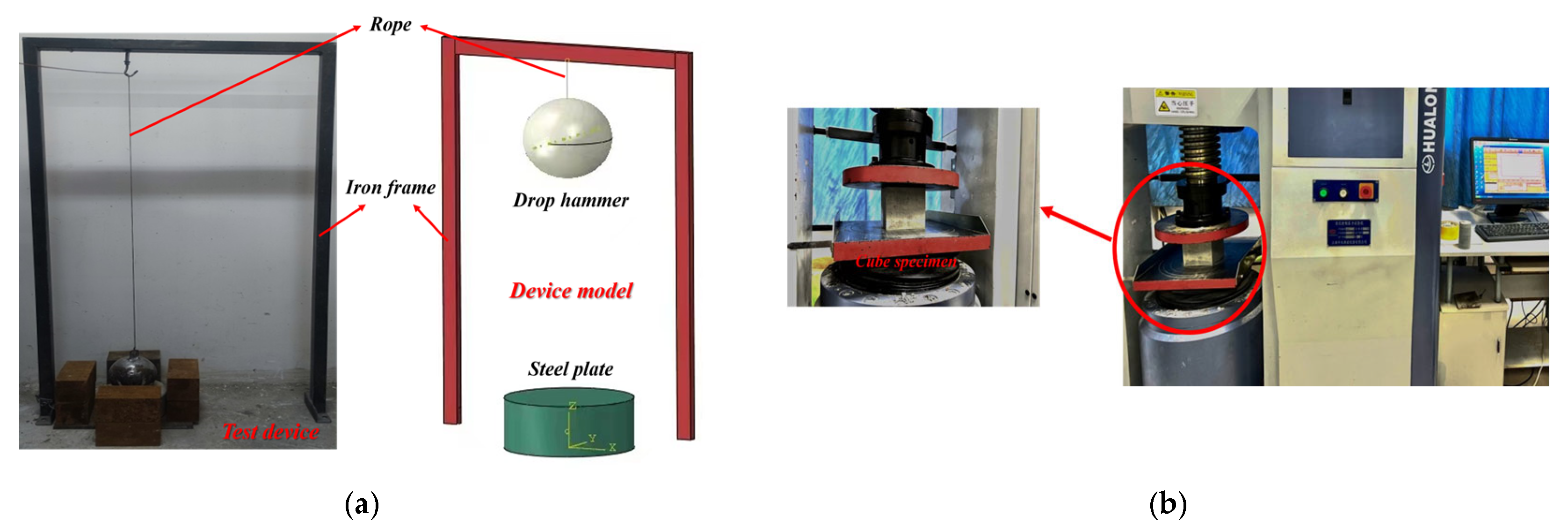

2.3. Test Device

3. Results and Discussion

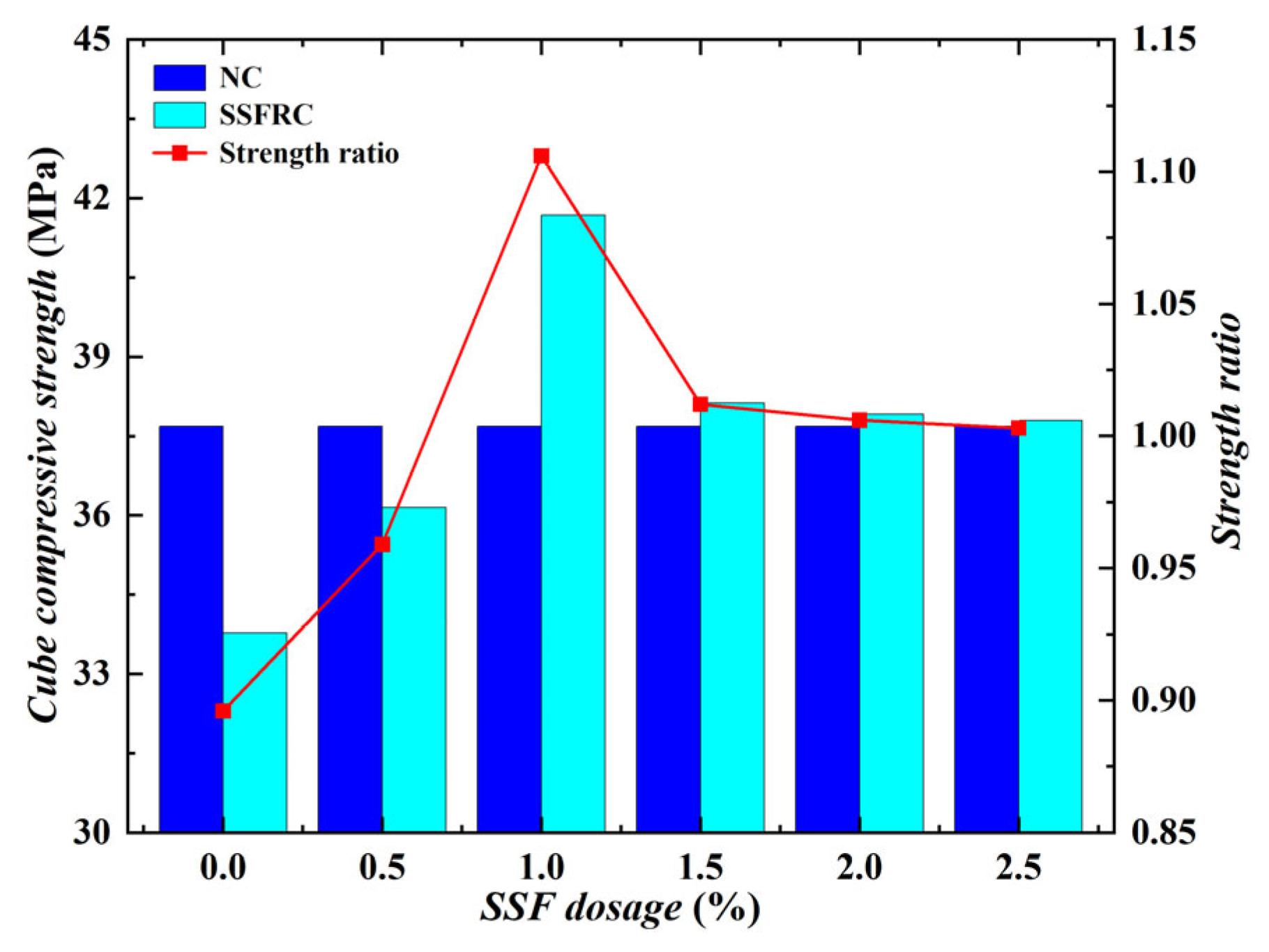

3.1. Cube Compression Test

3.1.1. Test Results and Analyses

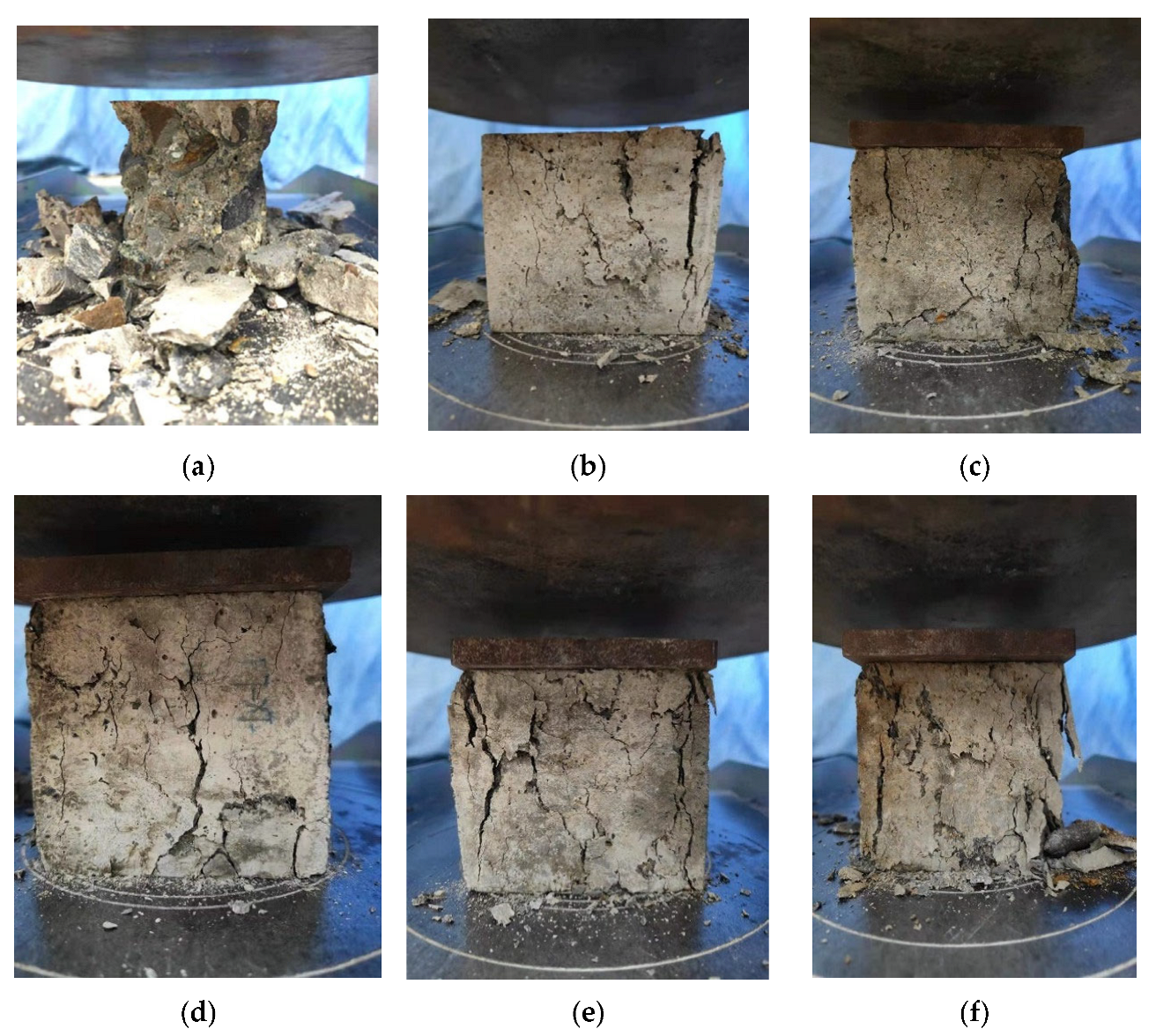

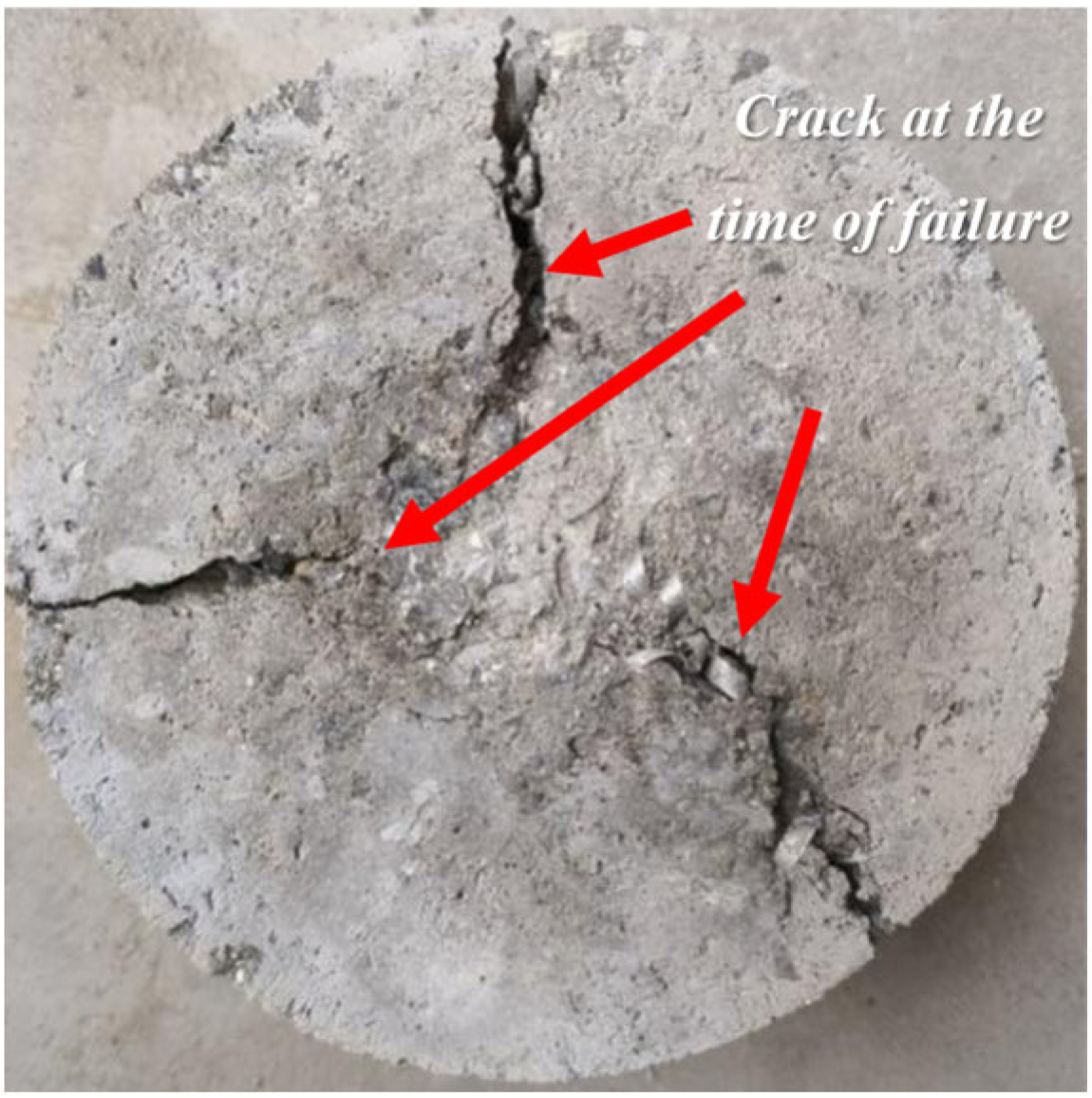

3.1.2. Failure Modes

- Under compressive loads, uniformly distributed 1% dosage of fibers can play a role through axial stress-sharing and lateral constrained deformation: the high tensile strength of the fibers themselves can bear part of the compressive stress transmission, and at the same time, their helical structure exerts radial constraints on the matrix, reducing the lateral expansion and micro-crack initiation of concrete under compression, which is consistent with [25].

- When the dosage of SSF continues to increase, the agglomerated fibers will cause a sharp increase in the interface area between them and the matrix. However, the cement paste cannot fully wet the surface of each fiber, resulting in the directional growth of calcium hydroxide crystals in the interface transition zone and a loose structure [23]. When under pressure, these weak interfaces are the first to be damaged, and the cracks rapidly expand along the edges of the aggregates, resulting in the overall compressive strength being unable to continue to increase and even slightly decreasing.

- The elastic deformation characteristics of rubber particles may exacerbate structural instability at high fiber content: when under pressure, the local deformation of rubber particles will exert additional shear force on the surrounding agglomerated fibers, causing the fiber–matrix interface to peel off earlier and further weakening the compressive performance [17].

3.2. NC Impact Resistance Analysis

3.3. SSFRC Impact Resistance Analysis

- The compressive performance mainly depends on the compactness of the material, the integrity of the matrix, and the synergistic load-bearing capacity of the fibers and the matrix. When the dosage is 1.5%, the increase in the number of fibers leads to a higher probability of local agglomeration, forming tiny voids and weak areas. Under static pressure, these voids cannot be filled by the dynamic energy dissipation of the fibers, and the stress is concentrated in the weak areas, resulting in a decrease in compressive strength.

- Impact performance is more dependent on the energy dissipation capacity of the material, and dynamic impact energy needs to be consumed through fiber bridging, rubber elastic buffering, and crack propagation inhibition. The number of fibers with a 1.5% dosage is greater than that of those with a 1% dosage, and the network formed by the three-dimensional helical structure is denser. Under impact loads, new cracks are more likely to be “captured” by fibers—fibers bear tensile stress through their bonding force with the matrix, preventing rapid crack propagation. Meanwhile, the process of fibers being pulled out or broken consumes a large amount of impact energy.

3.4. Analysis of Factors Affecting the Impact Resistance Results of SSFRC

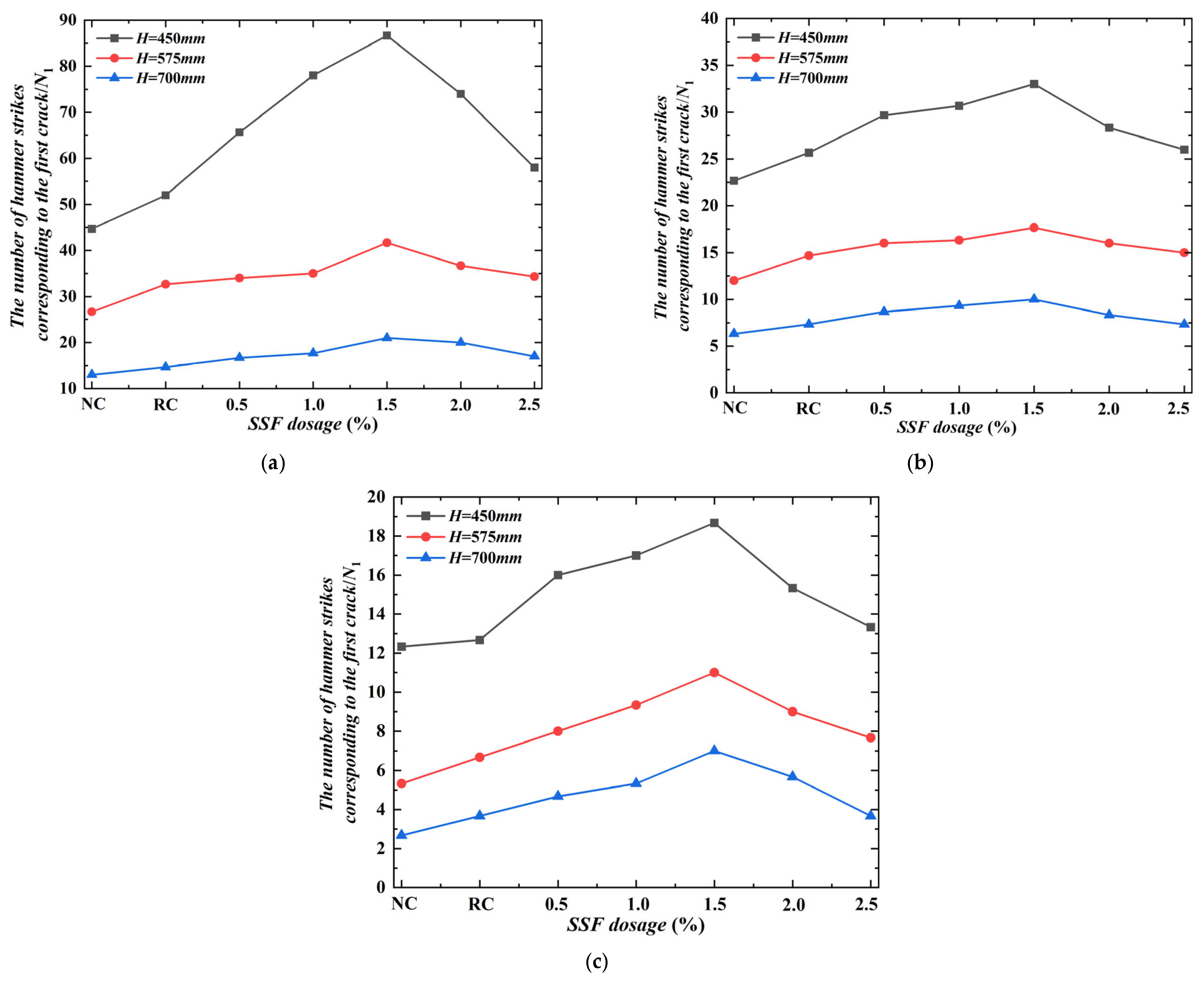

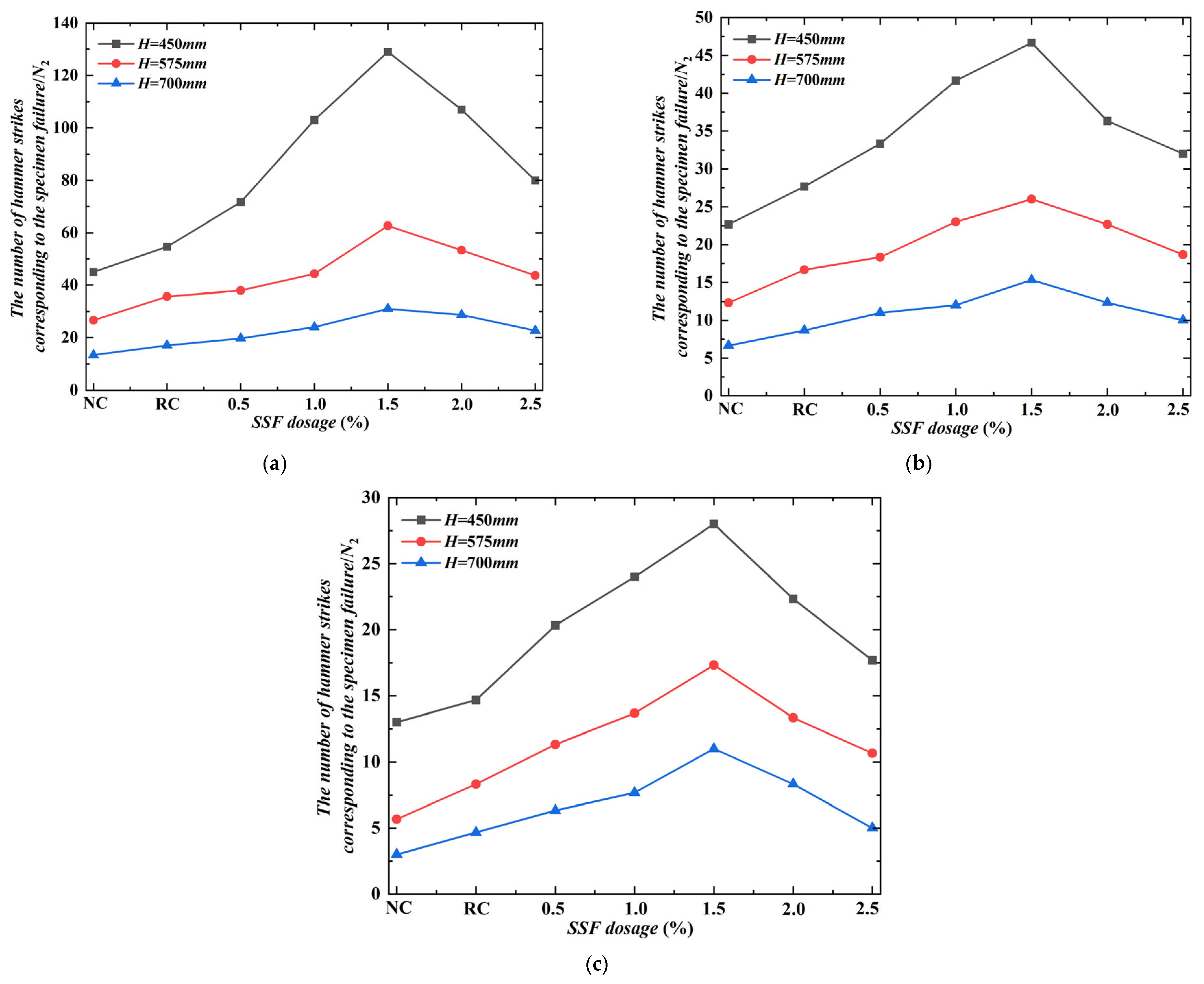

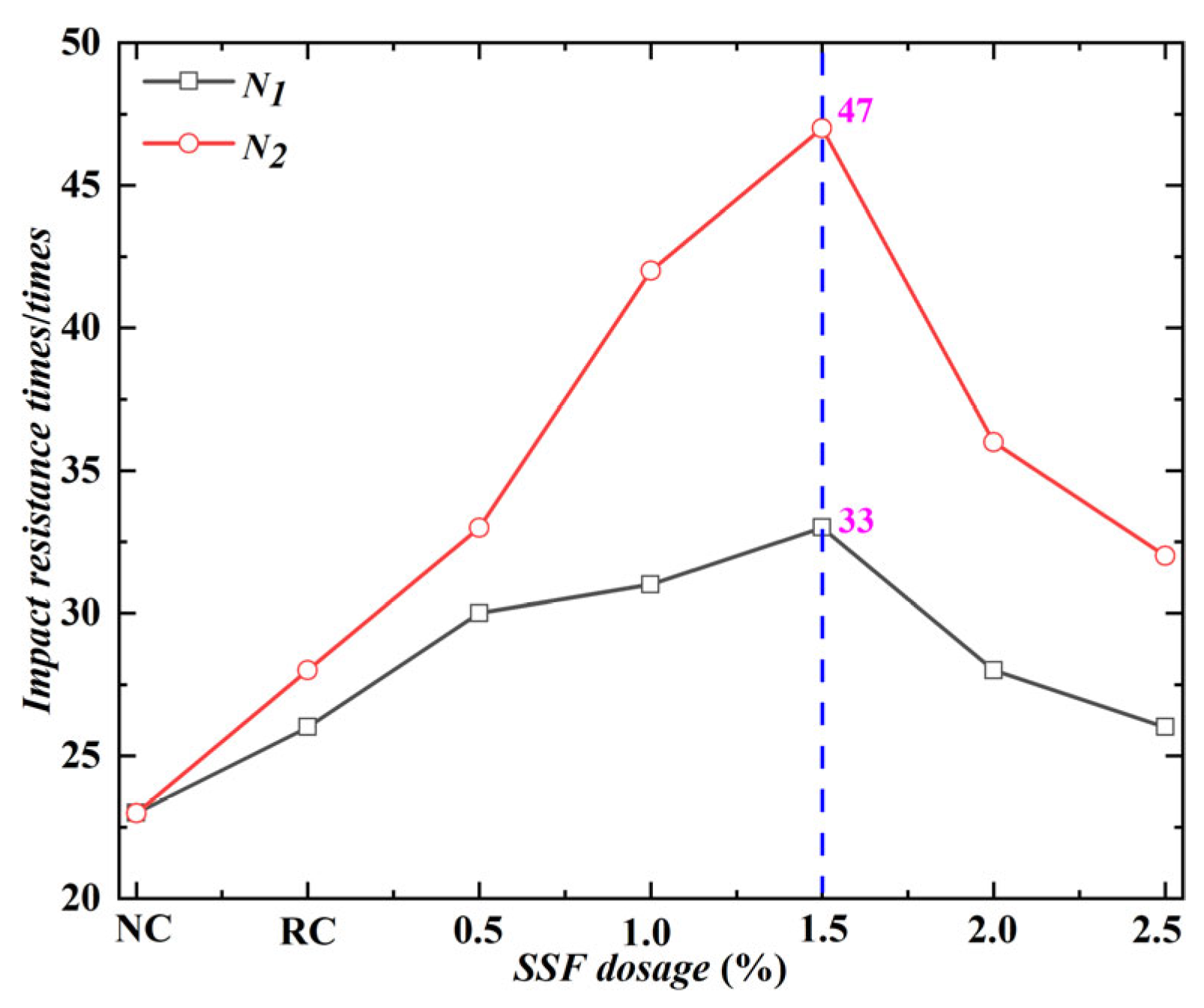

3.4.1. Effect of the Number of Hammer Strikes on the First Crack and the Specimen Failure

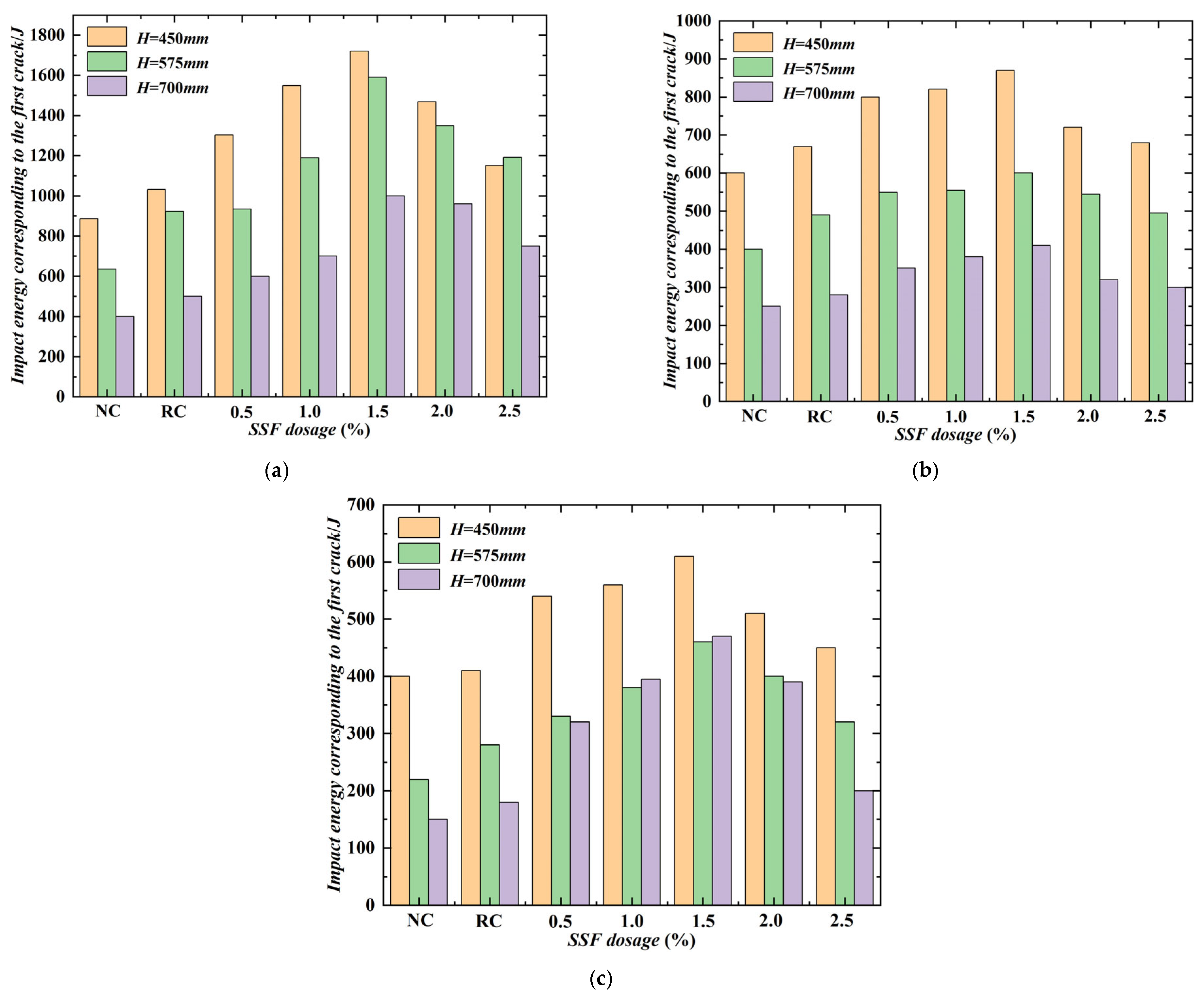

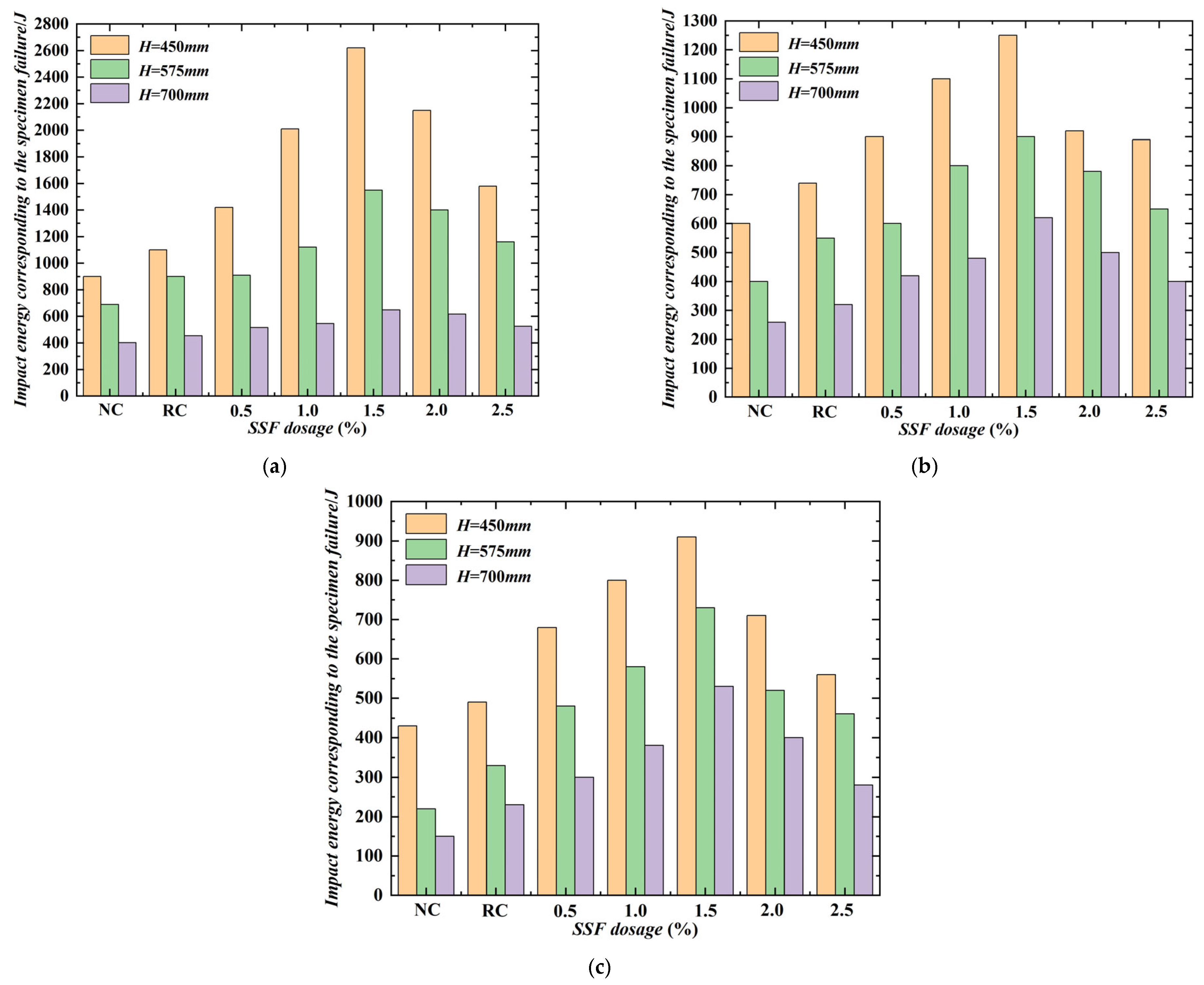

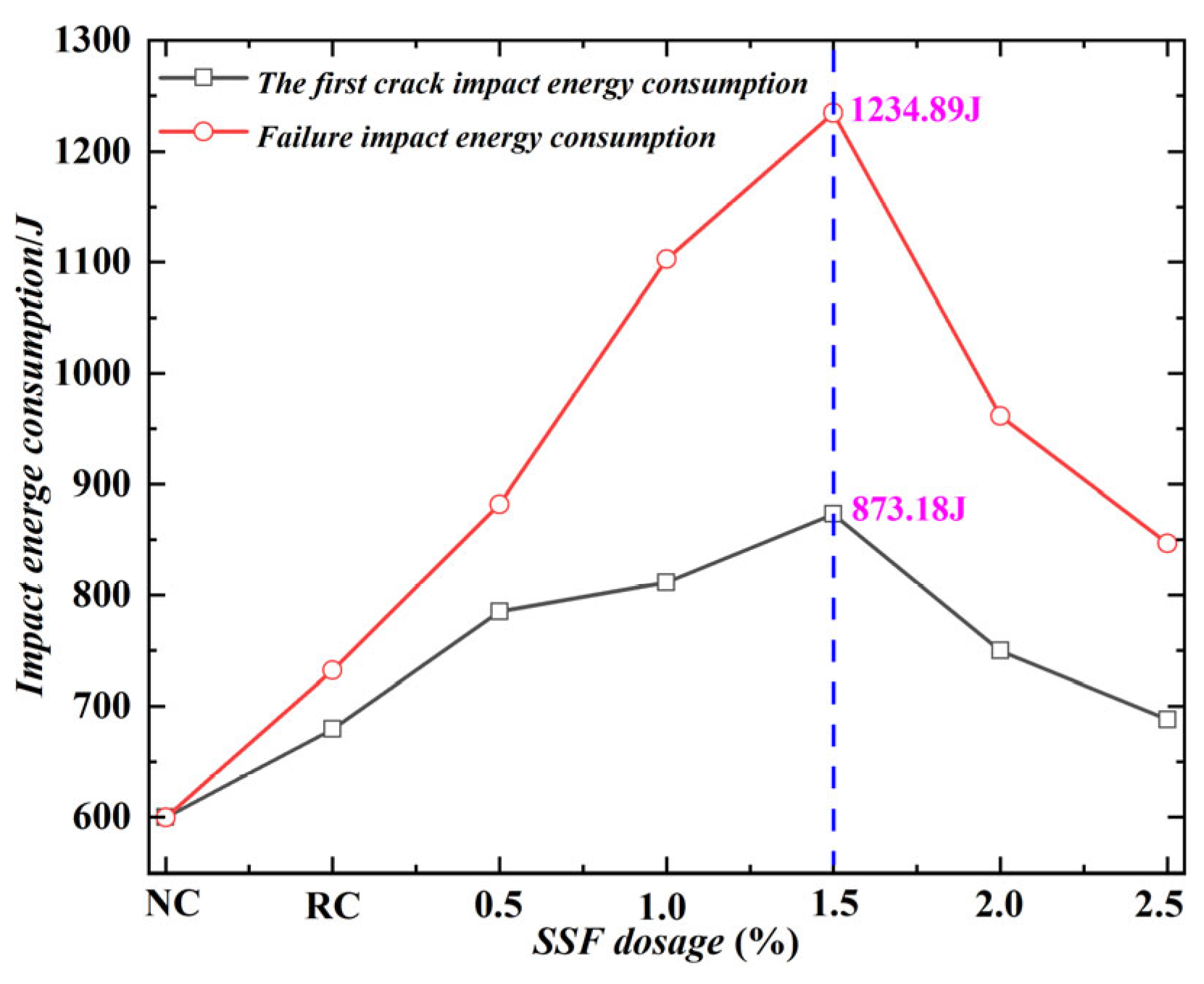

3.4.2. Effect of Drop Height on Impact Energy

3.4.3. Effect of SSF Dosage on Impact Resistance Times and Energy Consumption

3.5. Quantitative Analysis of Performance of SSFRC

4. Numerical Simulation and Analysis

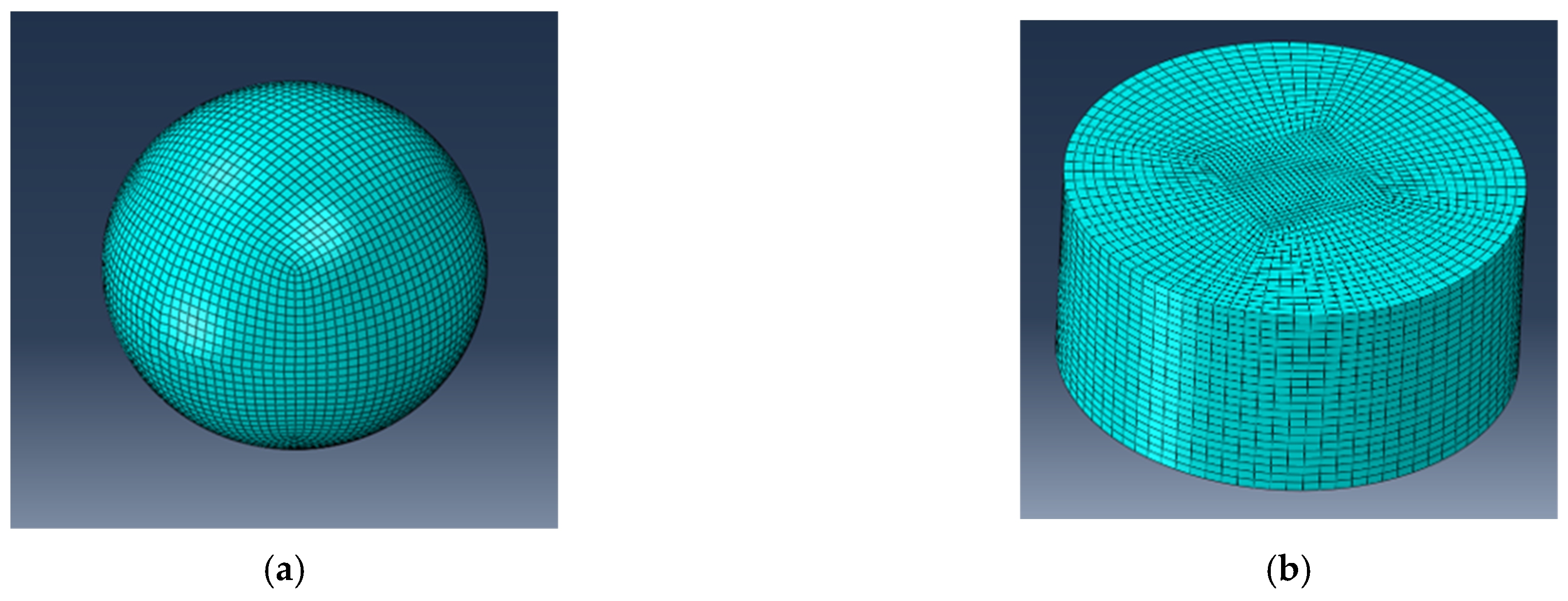

4.1. Finite Element Model

4.2. Numerical Simulation Results and Comparative Analysis

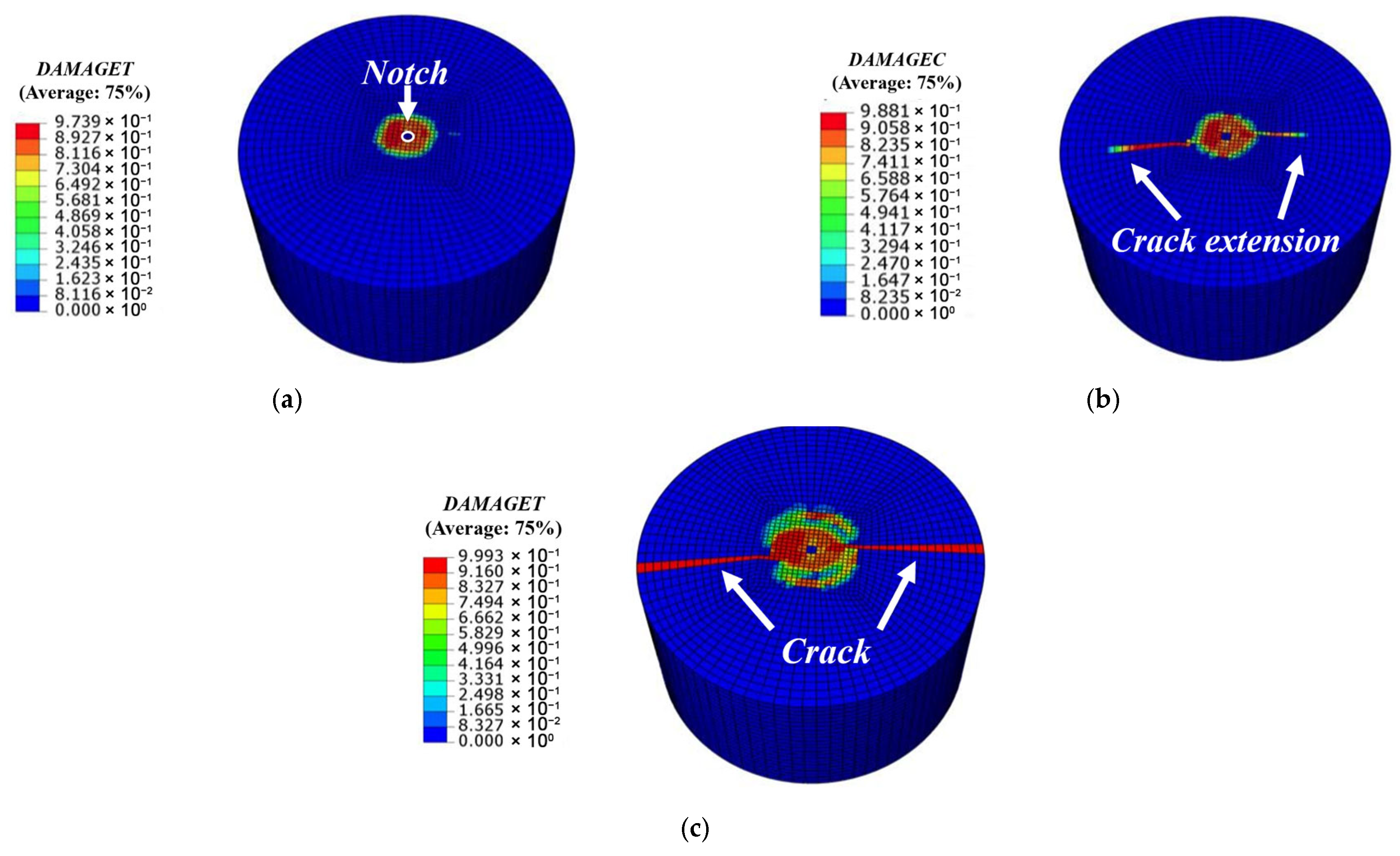

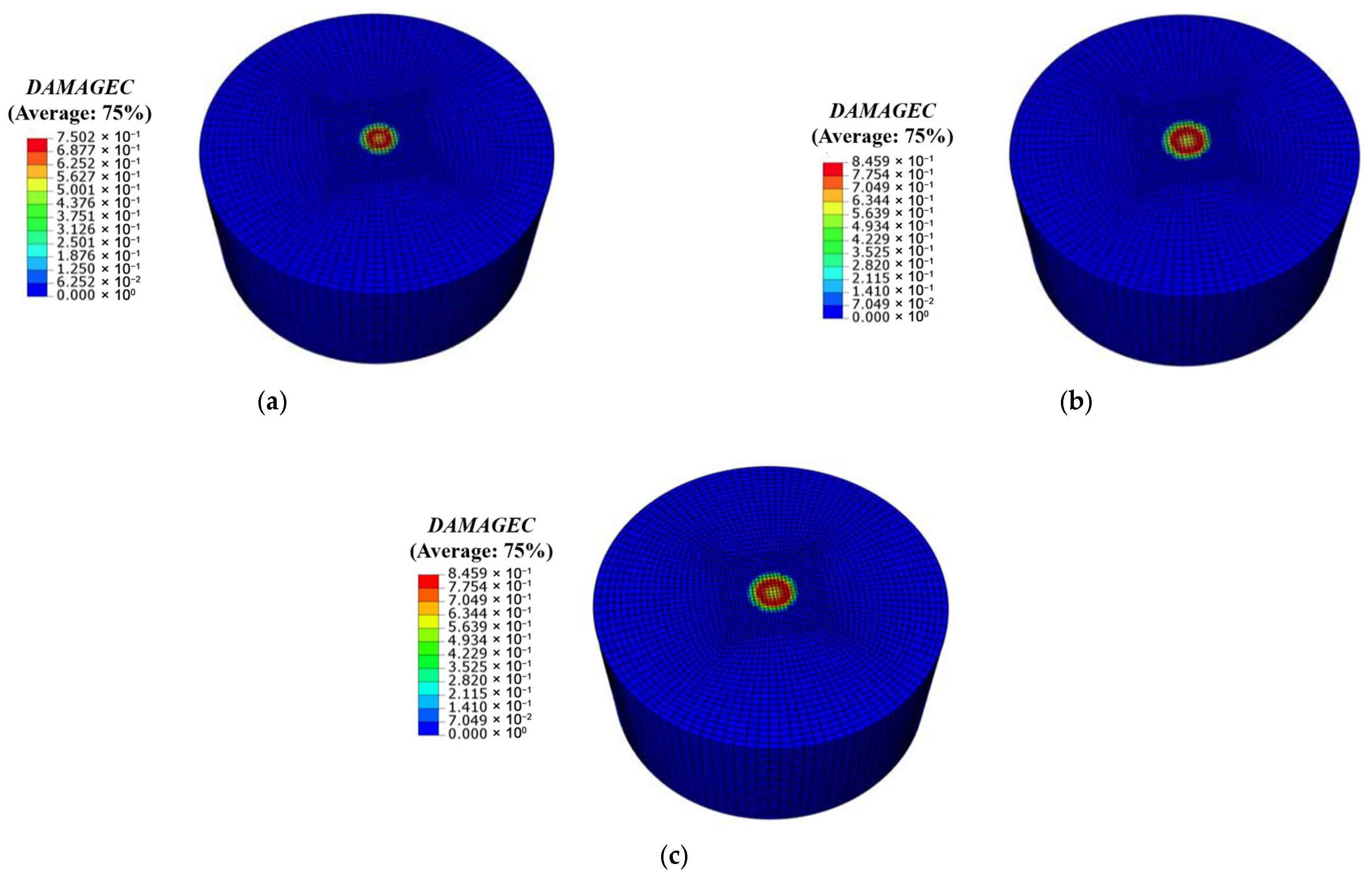

4.2.1. NC Simulation Results Compared with Experimental Results

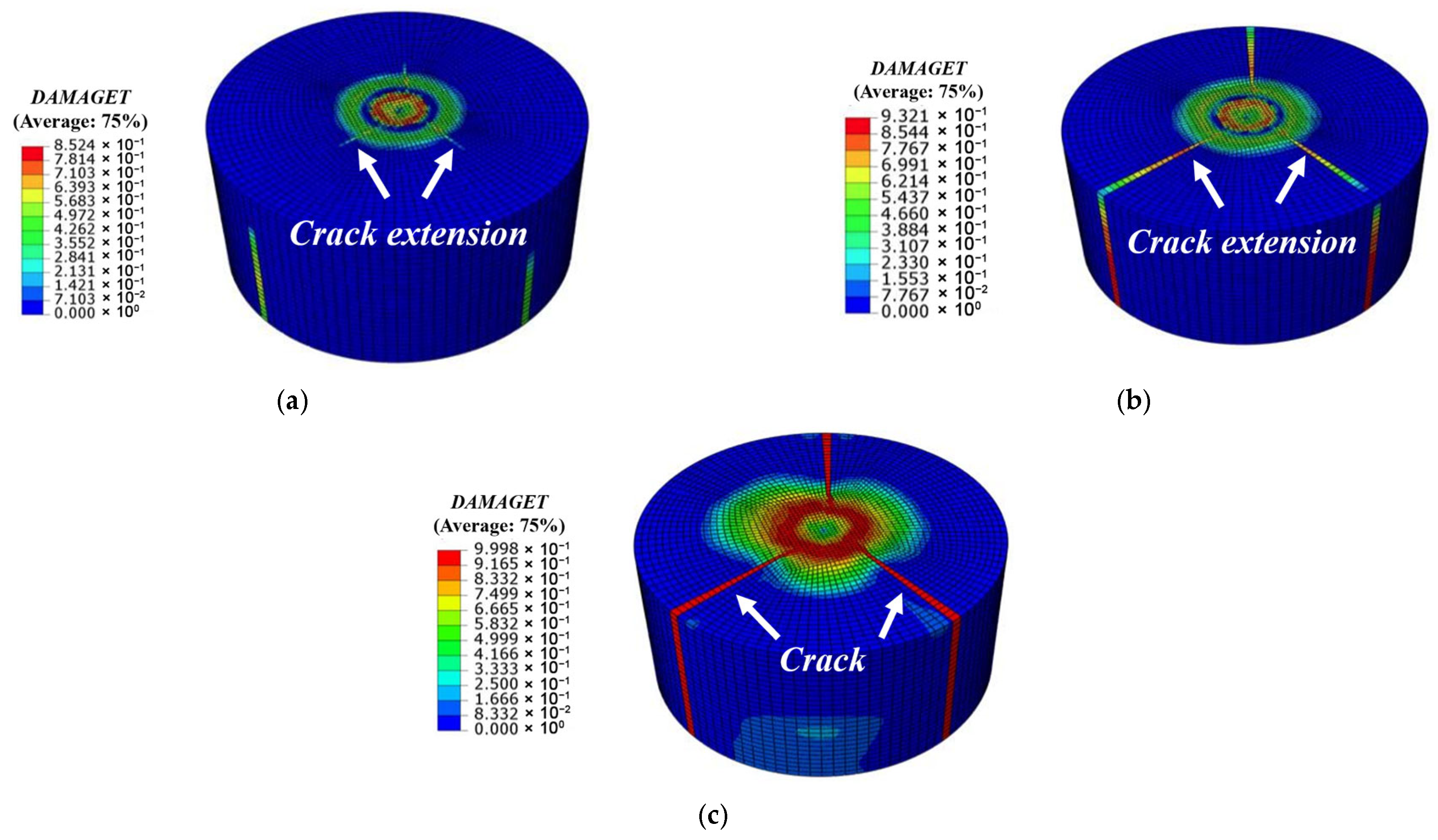

4.2.2. SSFRC Simulation Results Compared with Experimental Results

4.3. Error Analysis

5. Conclusions

- After the incorporation of SSF, the failure mode of SSFRC in the cube compression test and the drop hammer impact test exhibited the characteristics of “cracking but not scattering, breaking but not shattering”. Meanwhile, its failure process is plastic failure with good integrity. The results show that the impact resistance of SSFRC has been greatly improved due to the incorporation of SSF.

- In the cube compressive test, the optimal dosage of SSF in SSFRC is 1.0%, at which point its compressive strength reaches the maximum value, with a growth rate of 10.6% compared to NC. The growth rate reached 23.4% compared with RC. In terms of compressive strength, due to the addition of SSF, the compressive capacity of SSFRC has a better improvement effect than that of RC, indicating that SSF offsets the adverse effect of rubber particles on the strength of concrete.

- Impact resistance tests were conducted on SSFRC to study the effects of drop weight, drop height, and SSF dosage. The results showed that compared with NC, the addition of SSF increased N1 and N2, and both N1 and N2 increased with the increase of SSF dosage. The maximum is reached when the steel fiber dosage is 1.5%. When the drop height is fixed, the greater the weight of the drop hammer, the smaller N1 and N2 will be. When the weight of the drop hammer is fixed, the greater the drop height, the smaller N1 and N2 will be.

- By comparing the failure modes of NC cylindrical specimens and SSFRC cylindrical specimens with the numerical simulation results, it was found that the overall failure trend and failure state were consistent, which confirmed that the numerical simulation had high accuracy. The damage degree and area of SSFRC are significantly higher than those of NC, which indicates that SSFRC has a higher impact load-bearing capacity. Although there are certain differences between the experimental data of N1 and N2 and the simulated data, such differences are still within an acceptable range.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereiro, B.; Lenz, E.; Torres, B.; Estevan, L. Mechanical properties of recycled aggregate concrete reinforced with conventional and recycled steel fibers and exposed to high temperatures. Constr. Build. Mater. 2024, 452, 138976. [Google Scholar] [CrossRef]

- Zhao, X.H.; Jiang, G.; Yang, L.; Jia, Y.S.; Fang, H.Y.; Sun, J.S.; Zhao, H.N. Experimental study on the damage characteristics of steel fiber reinforced concrete slabs attacked by chloride ion under contact explosion. Appl. Ocean Res. 2024, 153, 104270. [Google Scholar] [CrossRef]

- Palacio, A.J.; Raggiotti, B.B.; Rougier, V.C. Development and experimental verification of a design method for steel fibre-reinforced high strength lightweight self-compacting concrete. Constr. Build. Mater. 2024, 453, 139012. [Google Scholar] [CrossRef]

- Mehmandari, T.A.; Shokouhian, M.; Josheghan, M.Z.; Mirjafari, S.A.; Fahimifar, A.; Armaghani, D.J.; Tee, K.F. Flexural properties of fiber-reinforced concrete using hybrid recycled steel fibers and manufactured steel fibers. J. Build. Eng. 2024, 98, 111069. [Google Scholar] [CrossRef]

- Esmailzade, M.; Eskandarinia, M.; Aslani, F. Effect of impurities of steel fibers extracted from shredded tires on the behavior of fiber-reinforced concrete. Structures 2024, 45, 1175–1188. [Google Scholar] [CrossRef]

- Archibong, F.N.; Sanusi, O.M.; Médéric, P.; Hocine, N.A. An overview on the recycling of waste ground tyre rubbers in thermoplastic matrices: Effect of added fillers. Resour. Conserv. Recycl. 2021, 175, 105894. [Google Scholar] [CrossRef]

- Bi, R.S.; Zhang, Y.; Jiang, X.; Yang, H.X. Simulation and techno-economical analysis on the pyrolysis process of waste tire. Energy 2022, 260, 125039. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Lopez, G.; Artetxe, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Waste tyre valorization by catalytic pyrolysis—A review. Renew. Sustain. Energy Rev. 2020, 129, 109932. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber Concrete: Mechanical and dynamical properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, G.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, G.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Astrauskas, T.; Januševičius, T.; Kizinievič, O.; Kizinievič, V. Potential applications of rubber buffing dust and recovered crumb rubber in cement concrete. Results Eng. 2024, 24, 103266. [Google Scholar] [CrossRef]

- Ji, Y.C.; Qasem, M.J.S.; Xu, T.D.; Mohammed, A.O.Y. Mechanical properties investigation on recycled rubber desert sand concrete. J. CO2 Util. 2024, 88, 102939. [Google Scholar] [CrossRef]

- Adebayo, I.W.; Long, G.C.; Tang, Z.; Ghone, M.O.; Zaland, S.; Garba, M.J.; Yang, K.; Akhunzada, K.; Oluwasina, U.A. Effect of crumb rubber and polyethylene fiber on the strength and toughness of fly ash/slag-based geopolymer concrete. Constr. Build. Mater. 2024, 455, 139133. [Google Scholar] [CrossRef]

- Mohseni, E.; Koushkbaghi, M. Recycling of landfill waste tyre in construction materials: Durability of concrete made with chipped rubber. Constr. Build. Mater. 2023, 409, 134114. [Google Scholar] [CrossRef]

- Shahjalal, M.; Islam, K.; Batool, F.; Tiznobaik, M.; Hossain, F.M.; Ahmed, K.S.; Alam, M.S.; Ahsan, R. Fiber-reinforced recycled aggregate concrete with crumb rubber: A state-of-the-art review. Constr. Build. Mater. 2023, 404, 133233. [Google Scholar] [CrossRef]

- Peng, M.; Gao, Y.T.; Wei, J.C.; Han, Y.; Chen, X.L.; Kou, X.J. Experimental study on mechanical properties and toughness of recycled steel fiber rubber concrete. Case Stud. Constr. Mater. 2024, 21, e03858. [Google Scholar] [CrossRef]

- Chen, L.L.; Chen, X.D.; Ren, Y.; Lu, B.Y.; Lv, Z.Y. Integrating machine learning with multi-objective optimization to maximize the ductility of macro-synthetic fiber reinforced rubber concrete. Case Stud. Constr. Mater. 2025, 22, e04647. [Google Scholar] [CrossRef]

- Alsaif, A.; Alharbi, Y.R. Strength, durability and shrinkage behaviours of steel fiber reinforced rubberized concrete. Constr. Build. Mater. 2022, 345, 128295. [Google Scholar] [CrossRef]

- Lai, D.; Demartino, C.; Xiao, Y. High-strain rate compressive behavior of fiber-reinforced rubberized concrete. Constr. Build. Mater. 2022, 319, 125739. [Google Scholar] [CrossRef]

- Dong, S.; Zhao, Q.H.; Zhu, H. Mechanical properties and constitutive model of steel fiber-reinforced rubberized concrete. Constr. Build. Mater. 2022, 327, 126720. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Peng, S.; Yu, Z.P.; Du, X.Q. Research and mechanism analysis on dynamic compressive behavior of steel fiber reinforced concrete. Constr. Build. Mater. 2023, 368, 130358. [Google Scholar] [CrossRef]

- Gao, Y.T.; Wang, B.; Liu, C.J.; Hui, D.; Xu, Q.; Zhao, Q.H.; Qin, Y.W.; Dong, W. Experimental investigation on static compressive toughness of steel fiber rubber concrete. Rev. Adv. Mater. Sci. 2022, 61, 576–586. [Google Scholar] [CrossRef]

- Zhuang, J.P.; Xu, R.X.; Pan, C.Y.; Li, H.X. Dynamic stress–strain relationship of steel fiber-reinforced rubber self-compacting concrete. Constr. Build. Mater. 2022, 344, 128197. [Google Scholar] [CrossRef]

- Noaman, A.T.; Bakar, B.H.; Akil, H. Experimental investigation on compression toughness of rubberized steel fibre concrete. Constr. Build. Mater. 2016, 115, 163–170. [Google Scholar] [CrossRef]

- Luo, T.; Zhang, C.; Sun, C. Experimental investigation on the freeze-thaw resistance of steel fibers reinforced rubber concrete. Materials. 2020, 13, 1260. [Google Scholar] [CrossRef]

- Alsaif, A.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Freeze-thaw resistance of steel fibre reinforced rubberised concrete. Constr. Build. Mater. 2019, 195, 450–458. [Google Scholar] [CrossRef]

- Noaman, A.T.; Bakar, B.H.; Akil, H.; Alani, A.H. Fracture characteristics of plain and steel fibre reinforced rubberized concrete. Constr. Build. Mater. 2017, 152, 414–423. [Google Scholar] [CrossRef]

- Zhang, X.G.; Li, Y.L.; Fan, Y.H.; Zhou, G.Q.; Huang, Y.J.; Xu, P.; Ding, Y.H. Analysis on the impact resistance of steel fiber reinforced recycled aggregate concrete. Structures 2025, 75, 108599. [Google Scholar] [CrossRef]

- Cao, Y.; Alyousef, R.; Baharom, S.; Shah, S.N.; Alaskar, A.; Alabduljabbar, H.; Mohamed, A.M.; Assilzadeh, H. Dynamic attainment of mixed aspect ratio for concrete members reinforced with steel fiber under impact loading. Mech. Adv. Mater. Struc. 2020, 29, 1986–1995. [Google Scholar] [CrossRef]

- Hao, Y.F.; Huang, X.; Hao, H. Mesoscale modelling of concrete reinforced with spiral steel fibres under dynamic splitting tension. Adv. Struct. Eng. 2018, 21, 1197–1210. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Yoon, Y.S. Influence of steel fibers and fiber-reinforced polymers on the impact resistance of one-way concrete slabs. J. Compos. Mater. 2014, 48, 695–706. [Google Scholar] [CrossRef]

- Sun, X.W.; Zhao, K.; Li, Y.C.; Huang, R.Y.; Ye, Z.B.; Zhang, Y.L.; Ma, J. A study of strain-rate effect and fiber reinforcement effect on dynamic behavior of steel fiber-reinforced concrete. Constr. Build. Mater. 2018, 158, 657–669. [Google Scholar] [CrossRef]

- Jin, L.; Hao, H.M.; Zhang, R.B.; Du, X.Y. Mesoscale simulation on the effect of elevated temperature on dynamic compressive behavior of steel fiber reinforced concrete. Fire Technol. 2020, 56, 1801–1823. [Google Scholar] [CrossRef]

- Su, Y.; Li, J.; Wu, C.Q.; Wu, P.T.; Li, Z.X. Effects of steel fibres on dynamic strength of UHPC. Constr. Build. Mater. 2016, 114, 708–718. [Google Scholar] [CrossRef]

- Zhang, X.G.; Zhu, Y.N.; Fan, Y.H.; Zhou, G.Q.; Huang, Y.J.; Li, M.B.; Shen, W.L. Experimental study on impact resistance and dynamic constitutive relation of steel fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 2024, 449, 138396. [Google Scholar] [CrossRef]

- Guo, S.Q.; Ding, Y.H.; Xu, P.; Wu, J.; Bao, J.W. Stress-strain relationship of steel fiber reinforced fully recycled coarse/fine aggregate concrete under cyclic loading. Case Stud. Constr. Mater. 2025, 22, e04139. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.H.; Hao, H.; Sarker, P.K. Experimental and numerical study of steel fibre reinforced geopolymer concrete slab under impact loading. Eng. Struct. 2025, 322, 119096. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, D.J.; Li, G.S.; Yao, Y.M.; Ou, Y.F.; Shi, C.J.; Du, Y.X. Flexural response of basalt textile reinforced concrete with pre-tension and short fibers under low-velocity impact loads. Case Stud. Constr. Mater. 2018, 169, 859–876. [Google Scholar] [CrossRef]

- Ramesh, A.; Rajeev, P.; Xu, S.Q.; Sanjayan, J.; Lu, G.X. Impact response of textile-reinforced 3D printed concrete panels. Eng. Struct. 2024, 315, 118489. [Google Scholar] [CrossRef]

- Lv, J.; Han, W.C.; Zheng, J.L.; Lin, S.A.; Yuan, S.J. Effects of basalt fibre and rubber particles on the mechanical properties and impact resistance of concrete. Structures 2024, 65, 106677. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Experimental investigation of crumb rubber concrete columns under seismic loading. Structures 2015, 3, 13–27. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, Z.Q.; Shen, D.X.; An, J.L.; Sun, Y.Y.; Li, N. Microstructure evolution and impact resistance of crumb rubber concrete after elevated temperatures. Constr. Build. Mater. 2023, 384, 131340. [Google Scholar] [CrossRef]

- Dong, J.Y.; Liu, Y.C.; Yuan, S.C.; Li, K.P.; Zhang, F.Y.; Guan, Z.W.; Chai, H.K.; Wang, Q.Y. Mechanical behavior and impact resistance of rubberized concrete enhanced by basalt fiber-epoxy resin composite. Constr. Build. Mater. 2024, 435, 136836. [Google Scholar] [CrossRef]

- Chen, J.X.; Zhuang, J.P.; Shen, S.Z.; Dong, S.Q. Experimental investigation on the impact resistance of rubber self-compacting concrete. Structures 2022, 39, 691–704. [Google Scholar] [CrossRef]

- Ofuyatan, O.M.; Muhit, I.B.; Babafemi, A.J.; Osibanjo, I. Evaluation of self-compacting rubberized concrete properties: Experimental and machine learning approach. Structures 2023, 58, 105423. [Google Scholar] [CrossRef]

- Gonen, T. Freezing-thawing and impact resistance of concretes containing waste crumb rubbers. Case Stud. Constr. Mater. 2018, 177, 436–442. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- AbdelAleem, B.H.; Ismail, M.K.; Hassan, A.A. The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete. Constr. Build. Mater. 2018, 162, 816–829. [Google Scholar] [CrossRef]

- GB 175-2023; Common Portland Cement. State Administration for Market Regulation and Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- CECS13:2009; Standard for Test Methods of Fiber-reinforced Concrete. China Engineering Construction Association Standard: Beijing, China, 2009.

- JGJ55-2011; Code for Design of Mix Proportions of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

| Length (L)/mm | Thickness (T)/mm | Average Tensile Strength (ft)/MPa | Elastic Modulus (E)/×105 MPa | External Characteristics |

|---|---|---|---|---|

| 20–40 | <0.5 | >380 | 2.05 | 3D spiral |

| Specimen Number | Concrete Strength | Dosage of SSF (%) | Material Consumption per Unit Volume (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| Concrete | Stone | Sand | Water | SSF | Rubber (10%) | |||

| NC | C30 | 0 | 339.6 | 1241.1 | 639.3 | 180 | 0 | 0 |

| SSF0.0-RC10.0 | 0 | 339.6 | 1241.1 | 639.3 | 180 | 0 | 32 | |

| SSF0.5-RC10.0 | 0.5 | 339.6 | 1241.1 | 639.3 | 180 | 39.5 | 32 | |

| SSF1.0-RC10.0 | 1.0 | 339.6 | 1241.1 | 639.3 | 180 | 79 | 32 | |

| SSF1.5-RC10.0 | 1.5 | 339.6 | 1241.1 | 639.3 | 180 | 118.5 | 32 | |

| SSF2.0-RC10.0 | 2.0 | 339.6 | 1241.1 | 639.3 | 180 | 158 | 32 | |

| SSF2.5-RC10.0 | 2.5 | 339.6 | 1241.1 | 639.3 | 180 | 197.5 | 32 | |

| Specimen Number | Specimen Specification (mm) | Cube Compression (Group × Number) | Specimen Specification (mm) | Impact Resistance (Group × Number) |

|---|---|---|---|---|

| NC | 100 × 100 × 100 | 1 × 3 | φ 150 × 65 | 9 × 3 |

| SSF0.0-RC10.0 | 1 × 3 | 9 × 3 | ||

| SSF0.5-RC10.0 | 1 × 3 | 9 × 3 | ||

| SSF1.0-RC10.0 | 1 × 3 | 9 × 3 | ||

| SSF1.5-RC10.0 | 1 × 3 | 9 × 3 | ||

| SSF2.0-RC10.0 | 1 × 3 | 9 × 3 | ||

| SSF2.5-RC10.0 | 1 × 3 | 9 × 3 | ||

| Total | 21 | 189 |

| Specimen Number | Concrete Strength | Cube Compressive Strength | Strength Ratio |

|---|---|---|---|

| NC | C30 | 37.68 | 1 |

| SSF0.0-RC10.0 | 33.77 | 0.896 | |

| SSF0.5-RC10.0 | 36.15 | 0.959 | |

| SSF1.0-RC10.0 | 41.68 | 1.106 | |

| SSF1.5-RC10.0 | 38.12 | 1.012 | |

| SSF2.0-RC10.0 | 37.91 | 1.006 | |

| SSF2.5-RC10.0 | 37.79 | 1.003 |

| Height (mm) Weight (kg) | 450 | 575 | 700 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | |

| 4.5 | 48 | 49 | 1 | 29 | 29 | 1 | 15 | 15 | 1 |

| 45 | 45 | 2 | 24 | 25 | 2 | 11 | 11 | 1 | |

| 41 | 41 | 1 | 26 | 26 | 1 | 13 | 14 | 1 | |

| Average | 44.67 | 45.00 | 1.33 | 26.33 | 26.67 | 1.33 | 13.00 | 13.33 | 1.00 |

| 6.0 | 22 | 22 | 1 | 11 | 11 | 1 | 6 | 7 | 1 |

| 25 | 25 | 2 | 13 | 13 | 1 | 7 | 7 | 1 | |

| 21 | 21 | 1 | 12 | 13 | 1 | 6 | 6 | 2 | |

| Average | 22.67 | 22.67 | 1.33 | 12.00 | 12.33 | 1.00 | 6.33 | 6.67 | 1.33 |

| 7.5 | 14 | 15 | 1 | 6 | 6 | 1 | 3 | 4 | 2 |

| 10 | 10 | 1 | 5 | 6 | 2 | 2 | 2 | 1 | |

| 13 | 14 | 2 | 5 | 5 | 1 | 3 | 3 | 1 | |

| Average | 12.33 | 13.00 | 1.33 | 5.33 | 5.67 | 1.33 | 2.67 | 3.00 | 1.33 |

| Height (mm) Dosage (%) | 450 | 575 | 700 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | |

| 0 | 55 | 58 | 3 | 32 | 34 | 2 | 17 | 19 | 3 |

| 52 | 54 | 3 | 35 | 39 | 3 | 12 | 14 | 2 | |

| 49 | 52 | 3 | 31 | 34 | 3 | 15 | 18 | 2 | |

| Average | 52.00 | 54.67 | 3.00 | 32.67 | 35.67 | 2.67 | 14.67 | 17.00 | 2.33 |

| 0.5 | 67 | 74 | 3 | 33 | 35 | 3 | 16 | 19 | 3 |

| 61 | 67 | 2 | 37 | 42 | 3 | 19 | 21 | 3 | |

| 69 | 74 | 3 | 32 | 37 | 4 | 15 | 19 | 3 | |

| Average | 65.97 | 71.67 | 2.67 | 34.00 | 38.00 | 3.33 | 16.67 | 19.67 | 3.00 |

| 1.0 | 77 | 103 | 3 | 35 | 45 | 2 | 20 | 26 | 2 |

| 86 | 99 | 4 | 39 | 47 | 4 | 16 | 21 | 4 | |

| 71 | 107 | 4 | 31 | 41 | 4 | 17 | 25 | 3 | |

| Average | 78.00 | 103.00 | 3.67 | 35.00 | 44.33 | 3.33 | 17.67 | 24.00 | 3.00 |

| 1.5 | 88 | 127 | 3 | 39 | 58 | 2 | 23 | 32 | 4 |

| 81 | 131 | 3 | 41 | 63 | 3 | 19 | 29 | 3 | |

| 91 | 129 | 4 | 45 | 67 | 4 | 21 | 32 | 5 | |

| Average | 86.67 | 129.0 | 3.33 | 41.67 | 62.67 | 3.00 | 21.00 | 31.00 | 4.00 |

| 2.0 | 69 | 105 | 2 | 35 | 52 | 3 | 22 | 29 | 3 |

| 75 | 112 | 4 | 37 | 55 | 4 | 20 | 31 | 3 | |

| 78 | 104 | 4 | 38 | 53 | 4 | 18 | 26 | 5 | |

| Average | 74.00 | 107.0 | 3.33 | 36.67 | 53.33 | 3.67 | 20.00 | 28.67 | 3.67 |

| 2.5 | 62 | 79 | 3 | 34 | 45 | 3 | 17 | 24 | 2 |

| 57 | 87 | 5 | 36 | 40 | 4 | 16 | 23 | 4 | |

| 55 | 74 | 3 | 33 | 46 | 5 | 18 | 21 | 3 | |

| Average | 58.00 | 80.00 | 3.67 | 34.33 | 43.67 | 4.00 | 17.00 | 22.67 | 3.00 |

| Height (mm) Dosage (%) | 450 | 575 | 700 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | |

| 0 | 26 | 29 | 2 | 14 | 16 | 2 | 8 | 9 | 1 |

| 27 | 28 | 2 | 17 | 18 | 1 | 7 | 9 | 3 | |

| 24 | 26 | 3 | 13 | 16 | 3 | 7 | 8 | 2 | |

| Average | 25.67 | 27.67 | 2.33 | 14.67 | 16.67 | 2.00 | 7.33 | 8.67 | 2.00 |

| 0.5 | 32 | 36 | 3 | 15 | 17 | 2 | 8 | 10 | 3 |

| 29 | 33 | 3 | 16 | 19 | 3 | 9 | 12 | 4 | |

| 28 | 31 | 2 | 17 | 19 | 4 | 9 | 11 | 3 | |

| Average | 29.67 | 33.33 | 2.67 | 16.00 | 18.33 | 3.00 | 8.67 | 11.00 | 3.00 |

| 1.0 | 31 | 42 | 2 | 17 | 24 | 4 | 9 | 11 | 2 |

| 29 | 39 | 3 | 16 | 22 | 3 | 10 | 13 | 4 | |

| 32 | 44 | 4 | 16 | 23 | 4 | 9 | 12 | 3 | |

| Average | 30.67 | 41.67 | 3.00 | 16.33 | 23.00 | 3.67 | 9.33 | 12.00 | 3.00 |

| 1.5 | 33 | 46 | 4 | 18 | 27 | 2 | 11 | 15 | 3 |

| 37 | 49 | 3 | 17 | 25 | 3 | 9 | 15 | 3 | |

| 29 | 45 | 4 | 18 | 26 | 4 | 10 | 16 | 5 | |

| Average | 33.00 | 46.67 | 3.67 | 17.67 | 26.00 | 3.00 | 10.00 | 15.33 | 3.67 |

| 2.0 | 28 | 39 | 2 | 16 | 23 | 3 | 8 | 13 | 3 |

| 25 | 37 | 3 | 15 | 24 | 5 | 9 | 12 | 2 | |

| 32 | 33 | 4 | 17 | 21 | 4 | 8 | 12 | 4 | |

| Average | 28.33 | 36.33 | 3.00 | 16.00 | 22.67 | 4.00 | 8.33 | 12.33 | 3.00 |

| 2.5 | 25 | 31 | 4 | 13 | 17 | 2 | 7 | 10 | 3 |

| 26 | 33 | 3 | 15 | 19 | 4 | 7 | 9 | 5 | |

| 27 | 32 | 3 | 17 | 20 | 3 | 8 | 11 | 3 | |

| Average | 26.00 | 32.00 | 3.33 | 15.00 | 18.67 | 3.00 | 7.33 | 10.00 | 3.67 |

| Height (mm) Dosage (%) | 450 | 575 | 700 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | N1 | N2 | Number of Cracks | |

| 0 | 13 | 15 | 3 | 6 | 8 | 3 | 3 | 4 | 2 |

| 11 | 13 | 2 | 7 | 8 | 1 | 4 | 6 | 2 | |

| 14 | 16 | 2 | 7 | 9 | 2 | 4 | 4 | 3 | |

| Average | 12.67 | 14.67 | 2.33 | 6.67 | 8.33 | 2.00 | 3.67 | 4.67 | 2.33 |

| 0.5 | 15 | 19 | 2 | 7 | 10 | 2 | 4 | 6 | 3 |

| 17 | 22 | 3 | 8 | 12 | 2 | 5 | 6 | 2 | |

| 16 | 20 | 2 | 9 | 12 | 3 | 5 | 7 | 3 | |

| Average | 16.00 | 20.33 | 2.33 | 8.00 | 11.33 | 2.33 | 4.67 | 6.33 | 2.67 |

| 1.0 | 18 | 25 | 3 | 10 | 14 | 3 | 5 | 8 | 3 |

| 16 | 23 | 3 | 11 | 15 | 3 | 5 | 7 | 4 | |

| 17 | 24 | 4 | 7 | 12 | 3 | 6 | 8 | 2 | |

| Average | 17.00 | 24.00 | 3.33 | 9.33 | 13.67 | 3.00 | 5.33 | 7.67 | 3.00 |

| 1.5 | 19 | 28 | 3 | 11 | 17 | 3 | 7 | 11 | 4 |

| 19 | 29 | 4 | 12 | 17 | 3 | 6 | 10 | 3 | |

| 18 | 27 | 4 | 10 | 18 | 4 | 8 | 12 | 4 | |

| Average | 18.67 | 28.00 | 3.67 | 11.00 | 17.33 | 3.33 | 7.00 | 11.00 | 3.67 |

| 2.0 | 15 | 23 | 4 | 8 | 13 | 3 | 6 | 8 | 4 |

| 16 | 22 | 4 | 9 | 13 | 4 | 6 | 9 | 3 | |

| 15 | 22 | 4 | 10 | 14 | 3 | 5 | 8 | 3 | |

| Average | 15.33 | 22.33 | 4.00 | 9.00 | 13.33 | 3.33 | 5.67 | 8.33 | 3.33 |

| 2.5 | 13 | 18 | 3 | 8 | 10 | 3 | 3 | 5 | 4 |

| 14 | 18 | 4 | 7 | 11 | 3 | 4 | 5 | 4 | |

| 13 | 17 | 3 | 8 | 11 | 3 | 4 | 5 | 3 | |

| Average | 13.33 | 17.67 | 3.33 | 7.67 | 10.67 | 3.00 | 3.67 | 5.00 | 3.67 |

| Performance Metrics | Optimal Dosage of SSF | Key Quantitative Data | Comparison Benchmark |

|---|---|---|---|

| Compressive property | 1.0% | The cube compressive strength reaches 41.68 MPa, and the strength ratio is 1.106. | About 23.4% higher than RC |

| Impact resistance performance N1 | 1.5% | Under a 4.5 kg drop hammer and a height of 450 mm, N1 is 87 times, and the corresponding energy is 1719.97 J. | About 230% higher than RC |

| Impact resistance performance N2 | 1.5% | Under a 4.5 kg drop hammer and a height of 450 mm, N2 is 129 times, and the corresponding energy is 2560.01 J. | About 360% higher than RC |

| Name | Symbol | Unit | Numerical Value |

|---|---|---|---|

| Young’s modulus | E | MPa | 30,000 |

| Poisson’s ratio | ν | -- | 0.2 |

| Expansion angle | φ | ° | 30 |

| Eccentricity ratio | λ | -- | 0.1 |

| fb0/fc0 | -- | -- | 1.16 |

| Projection shape parameter | K | -- | 0.6667 |

| Viscosity parameter | μ | -- | 0.0005 |

| Number | NC | SSFRC |

|---|---|---|

| t1 | 45 | 87 |

| s1 | 38 | 76 |

| t1/s1 | 1.18 | 1.14 |

| Error | 15.5% | 12.6% |

| t2 | 45 | 129 |

| s2 | 39 | 115 |

| t2/s2 | 1.15 | 1.12 |

| Error | 13.3% | 10.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Gao, Y.; Wang, C.; Li, Y.; Fan, T. Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete. Buildings 2025, 15, 2857. https://doi.org/10.3390/buildings15162857

Li M, Gao Y, Wang C, Li Y, Fan T. Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete. Buildings. 2025; 15(16):2857. https://doi.org/10.3390/buildings15162857

Chicago/Turabian StyleLi, Mingshuai, Yongtao Gao, Chengzhao Wang, Youzhi Li, and Tao Fan. 2025. "Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete" Buildings 15, no. 16: 2857. https://doi.org/10.3390/buildings15162857

APA StyleLi, M., Gao, Y., Wang, C., Li, Y., & Fan, T. (2025). Impact Resistance Test and Numerical Simulation Study of Scrap Steel Fiber Rubber Concrete. Buildings, 15(16), 2857. https://doi.org/10.3390/buildings15162857