A Study on the Driving Factors of Resilience in the Carbon Footprint Knowledge System of Construction Companies

Abstract

1. Introduction and Theory

1.1. Introduction

1.2. Theory

1.2.1. Overview of Theory

Theory of Constraints (TOC) Overview

Resilience of the Carbon Footprint Knowledge System

1.2.2. Motivating Elements for Resilience Construction of Carbon Footprint Knowledge System Based on TOC

Management Capacity

Construction Capacity

Forecasting Ability

Carbon Emission Capability

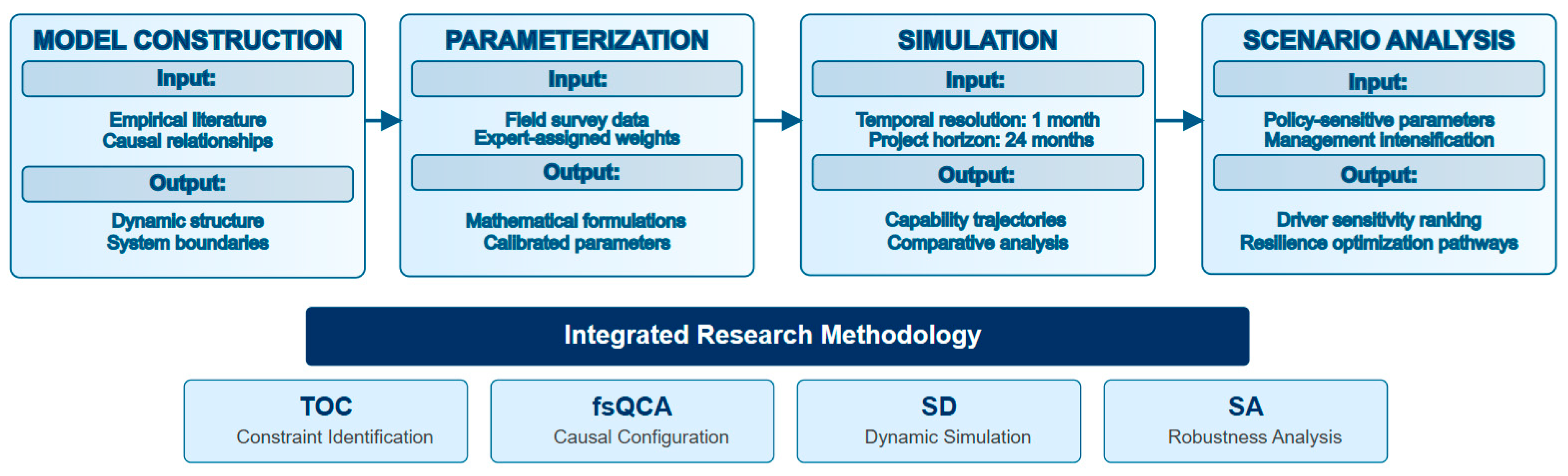

2. Methods and Materials

2.1. Selection of Research Subjects and Data Collection

Reliability and Validity Test

2.2. fsQCA Research Method

2.2.1. Data Calibration

2.2.2. Necessity Analysis

2.2.3. Carbon Footprint Calculation Strategy

2.3. System Dynamics Research Method

2.3.1. System Boundary Definition

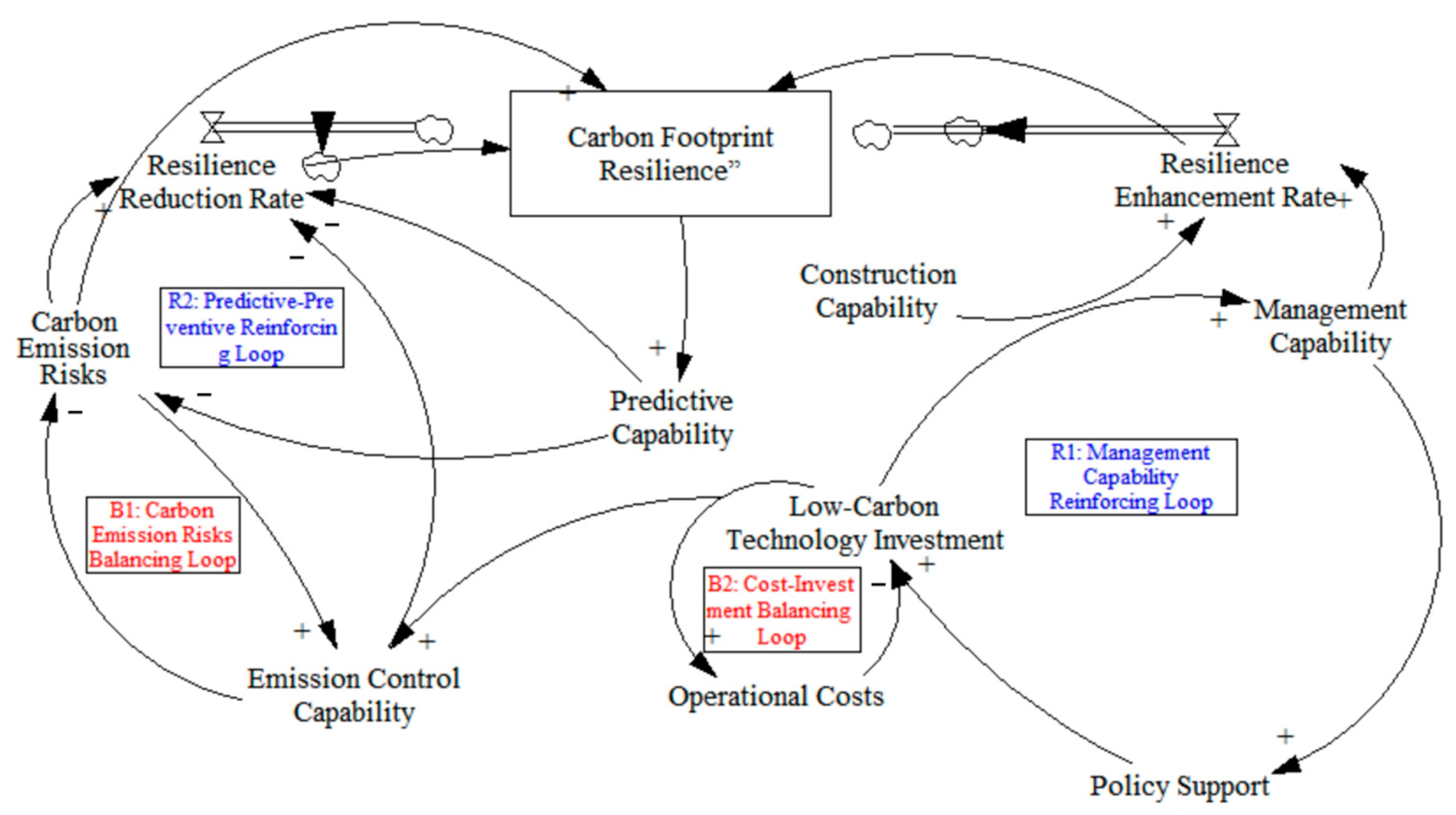

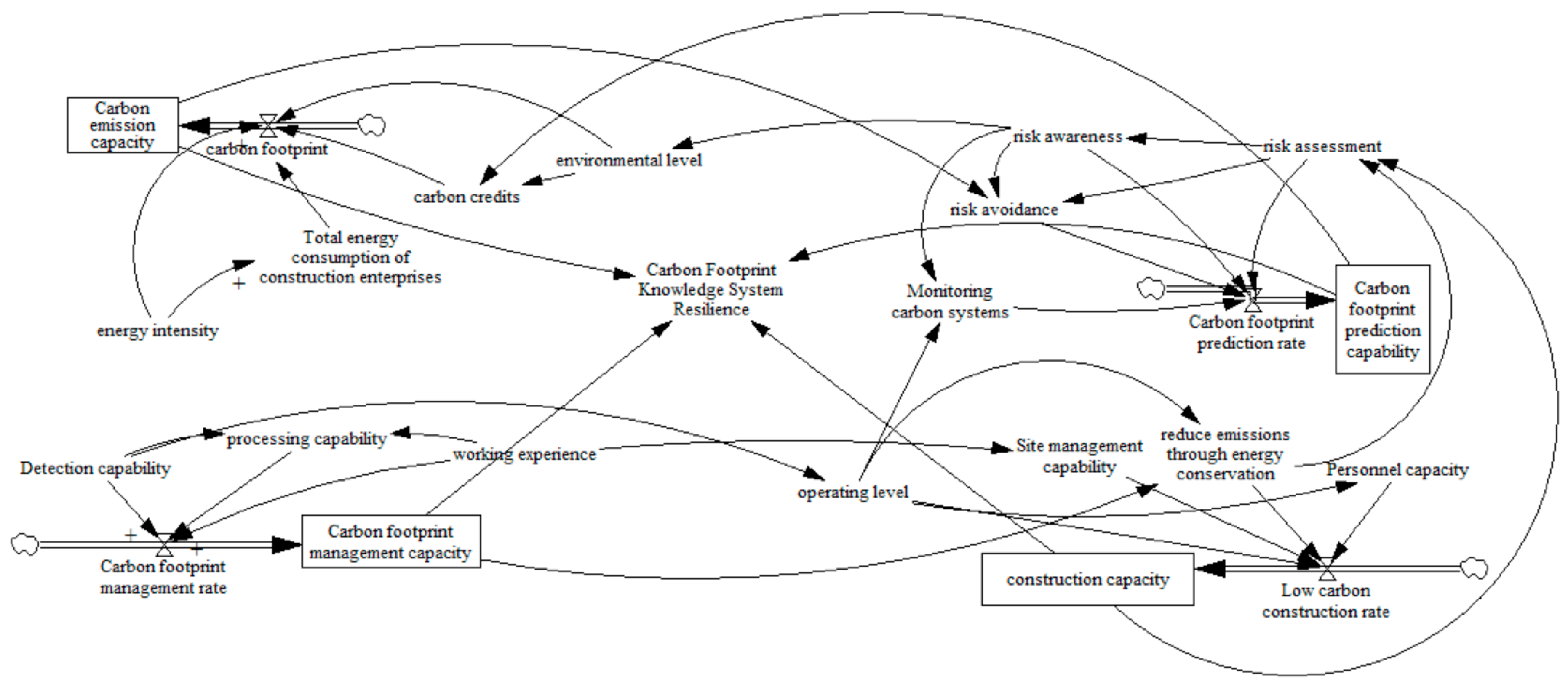

2.3.2. System Causality Map

2.3.3. Stock Flow Diagram

2.3.4. Model Variable Equation Establishment

- (1)

- Determine the ordinal relationship.

- (2)

- Determine the ratio of relative importance.

- (3)

- Calculation of evaluation indicator weight coefficients

2.4. Findings and Results

2.4.1. fsQCA Configuration Results Analysis

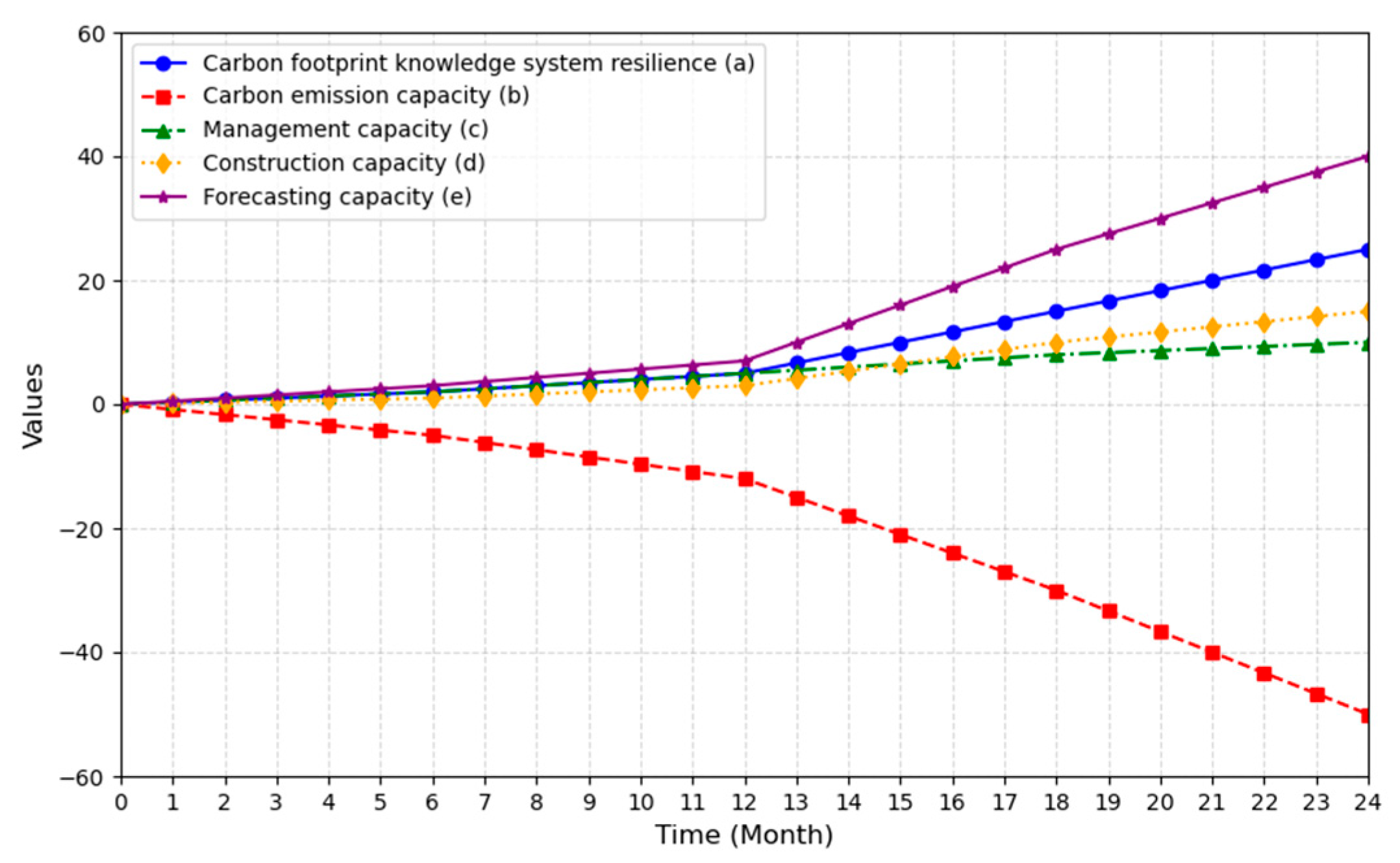

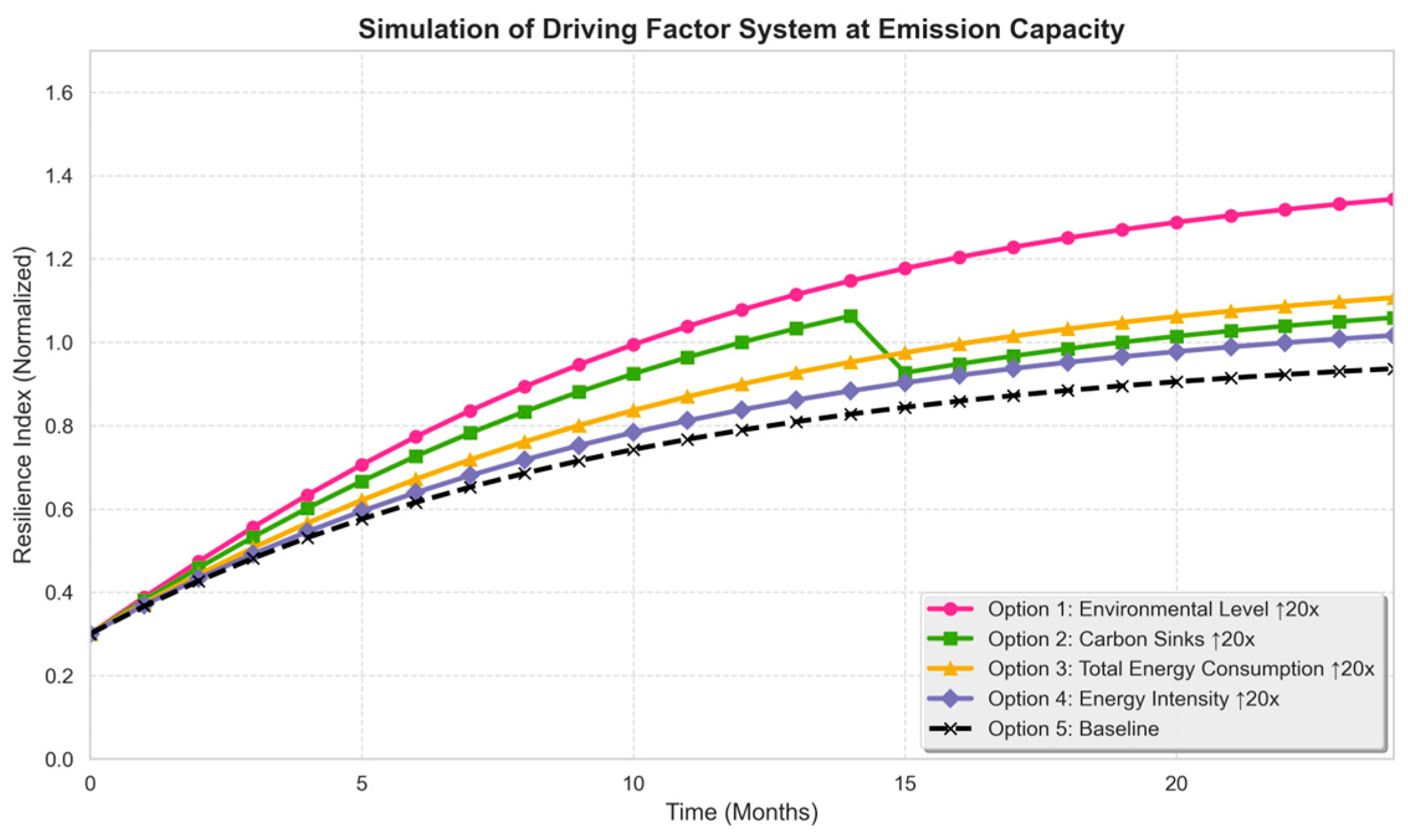

2.4.2. System Dynamics Model Simulation Result Analysis

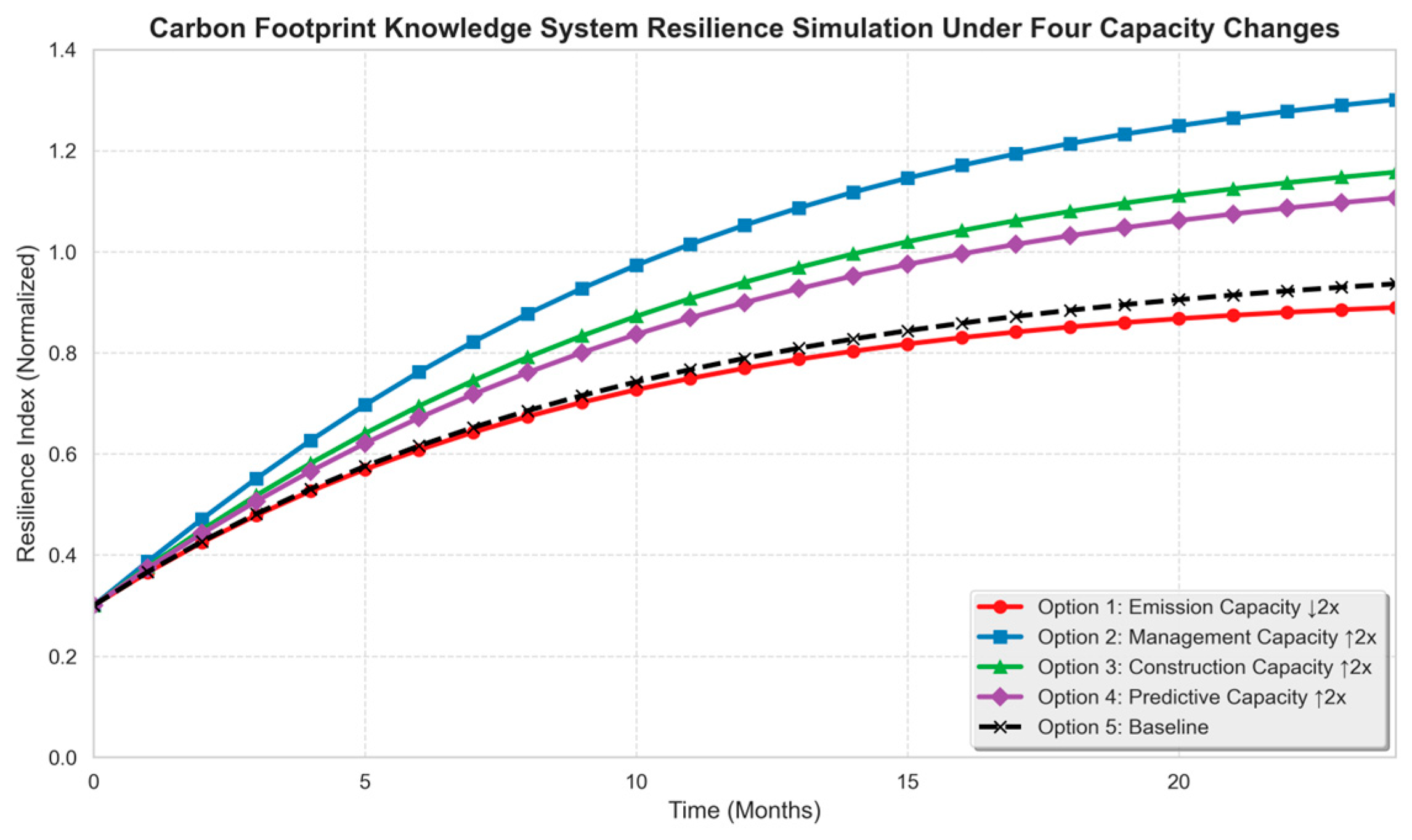

- (1)

- Comparative simulation analysis of four capabilities

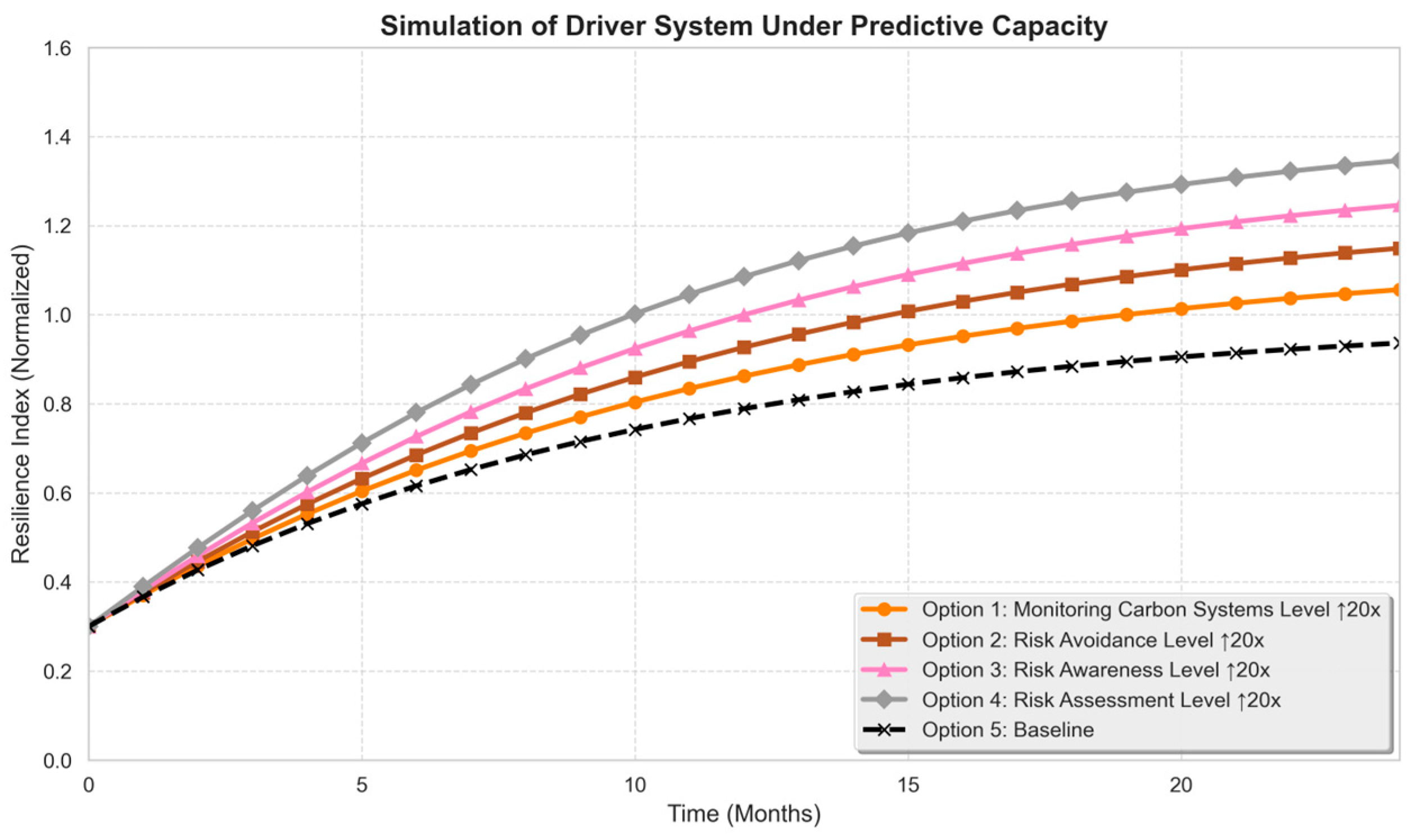

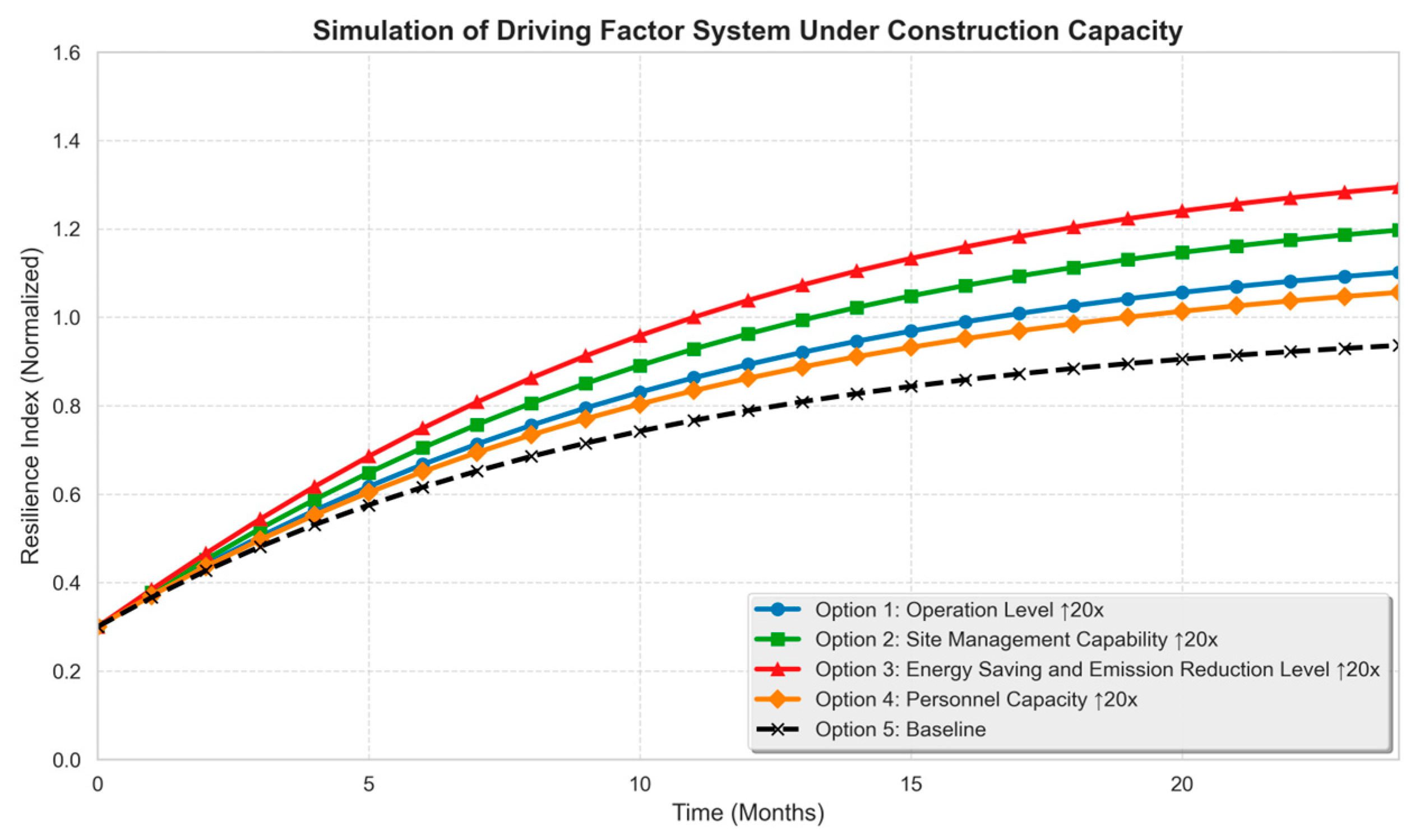

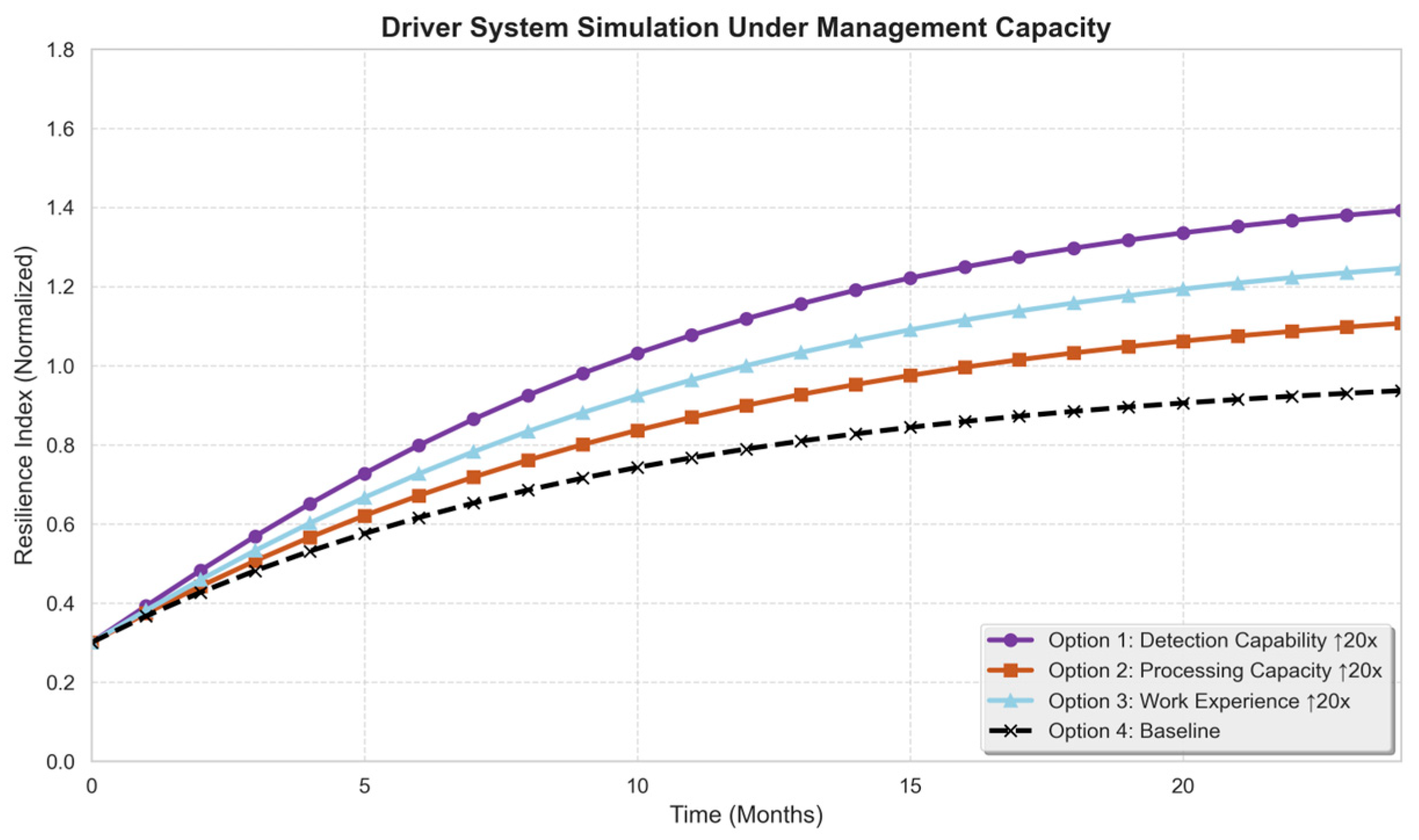

- (2)

- Comparative simulation analysis of the drivers under the four capabilities

2.5. Sensitivity Analysis

3. Conclusions

3.1. Main Outcomes

3.2. Limitations

3.3. Future Recommendations

4. Discussion and Countermeasures

4.1. Discussion

4.2. Countermeasures

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

Appendix A

Appendix A.1. Questionnaire

- Dear Participant

| No. | Survey Content | Options |

|---|---|---|

| I. Basic Information | Enterprise type: | □ State—owned □ Private □ Joint venture □ Other (Please specify: ______) |

| Annual turnover: | □ <1 million □ 1–5 million □ 5.1–10 million □ >10 million | |

| Years in operation: | □ <5 years □ 5–10 years □ 11–20 years □ >20 years | |

| II. Management Capability | The enterprise has established a dedicated carbon footprint management team. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| The carbon footprint management system is clearly defined and effectively implemented. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| Managers regularly receive training on carbon emission policies. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| III. Construction Capability | Construction workers have mastered low-carbon construction techniques. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| The enterprise uses energy-saving construction equipment. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| Construction waste is effectively recycled and reused. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| IV. Predictive Capability | The enterprise can predict carbon emission risks in advance. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| Historical carbon footprint data are completely recorded and analyzed. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| There is a system for real-time monitoring of abnormal carbon emissions. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| V. Emission Control Capability | The enterprise has adopted carbon reduction technologies (such as carbon capture). | 1 □ 2 □ 3 □ 4 □ 5 □ |

| Carbon emission targets are completed on schedule every year. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| Green materials with a low carbon footprint are prioritised in procurement. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| VI. Employee Awareness | Employees have a high awareness of carbon footprint reduction. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| Employees actively participate in carbon footprint reduction activities within the enterprise. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| VII. Supplier Collaboration | The enterprise collaborates closely with suppliers on carbon footprint reduction. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| Suppliers are required to meet certain carbon footprint standards. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| VIII. R & D Investment in Low—Carbon Technologies | The enterprise invests a sufficient amount in research and development of low-carbon technologies. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| There are clear R&D plans for low-carbon technologies in the enterprise. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| IX. Communication and Promotion of Carbon Footprint Reduction | The enterprise actively communicates and promotes carbon footprint reduction within the organization. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| The enterprise conducts external communication and promotion on its carbon footprint reduction achievements. | 1 □ 2 □ 3 □ 4 □ 5 □ | |

| X. Adaptability to Carbon—related Policies | The enterprise can quickly adapt to new carbon-related policies. | 1 □ 2 □ 3 □ 4 □ 5 □ |

| The enterprise has contingency plans for potential changes in carbon-related policies. | 1 □ 2 □ 3 □ 4 □ 5 □ |

Appendix A.2. Causal Loop Diagram

Appendix A.3. Variable Expressions and Parameter Values

| Nature of the Variable | Variable Name | Variable Equation Expression |

|---|---|---|

| state variable (A) | Management capacity a1 | Carbon footprint management capacity = INTEG (carbon footprint management rate, a1) |

| Construction capacity a2 | Low-carbon construction capacity = INTEG (low-carbon construction rate, a2) | |

| Carbon emission capacity a3 | Carbon emission capacity = INTEG (carbon emission rate, a3) | |

| Carbon footprint predictive capacity a4 | Carbon footprint predictive capacity = INTEG (carbon footprint predictive rate, a4) | |

| flow rate variable (B) | Carbon footprint management rate b1 | Carbon footprint management rate = detection capability × degree to which detection capability influences the carbon footprint management rate b11 + working experience × degree to which working experience influences the carbon footprint management rate b12 + processing capacity × Processing capacity degree of influence of carbon footprint management rate b13 |

| Low-carbon construction rate b2 | Low-carbon construction rate = site management capacity x the extent to which site management capacity affects the low-carbon construction rate b21 + personnel capacity x the extent to which personnel capacity affects the low-carbon construction rate b22 + operation level x the extent to which operation level affects the low-carbon construction rate b23 + energy savings and emission reduction x the extent to which energy saving and emission reduction affects the low-carbon construction rate b24 | |

| Carbon emission rate b3 | Carbon emission rate = level of environmental protection × degree of influence of level of environmental protection on carbon emission rate b31 + carbon sinks × degree of influence of carbon sinks on carbon emission rate b32 + energy intensity × degree of influence of energy intensity on carbon emission rate b33 + total energy consumption of construction enterprises × degree of influence of total energy consumption of construction enterprises on carbon emission rate b34 | |

| Carbon footprint prediction rate b4 | Carbon footprint prediction rate = risk assessment x the extent to which risk assessment influences carbon footprint prediction rate b41 + risk awareness x the extent to which risk awareness influences carbon footprint prediction rate b42 + detecting carbon systems x the extent to which detecting carbon systems influences carbon footprint prediction rate b43 + risk avoidance x the extent to which risk avoidance influences carbon footprint prediction rate b44. | |

| auxiliary variable (C) | Processing capability c1 | Processing capacity = testing capacity x the extent to which testing capacity affects processing capacity c11 + working experience x the extent to which working experience affects processing capacity c12 |

| On-site management capacity c2 | Site management competence = working experience × degree of influence of working experience on site management competence c21 | |

| Personnel capacity c3 | Personnel capacity = level of operation x degree of influence of level of operation on personnel capacity c31 | |

| Reduce emissions through energy conservation c4 | Energy savings and emission reduction = operational capacity x the extent to which operational capacity affects energy saving and emission reduction c41 + management capacity x the extent to which management capacity affects energy saving and emission reduction c42 | |

| Environmental level c5 | Level of environmental protection = risk awareness x the extent to which risk awareness influences the level of environmental protection c51 | |

| Carbon credits c6 | Carbon sinks = level of environmental protection x degree of impact of level of environmental protection on carbon sinks c61 + carbon footprint forecasting capacity x degree of impact of carbon footprint forecasting capacity on carbon sinks c62 | |

| Total energy consumption of construction enterprises c7 | Total energy consumption of construction firms = energy intensity × degree of influence of energy intensity on total energy consumption of construction firms c71 | |

| Risk awareness c8 | Risk awareness = risk assessment x the extent to which the risk assessment influences risk awareness c81 | |

| Monitoring carbon systems c9 | Monitoring carbon systems = risk awareness x the extent to which risk awareness influences monitoring carbon systems c91 + operational capacity x the extent to which operational capacity influences monitoring carbon systems c92 | |

| Risk avoidance c10 | Risk aversion = risk awareness x the extent to which risk awareness influences risk aversion c101 + risk assessment x the extent to which risk assessment influences risk aversion c102 + emission capacity x the extent to which emission capacity influences risk aversion c103 | |

| Operating ability c11 | Operational capability = detection capability x the extent to which detection capability affects operational capability c111 | |

| Risk assessment c12 | Risk assessment = energy savings x extent of impact of energy savings on risk assessment c121 + construction capacity x extent of impact of construction capacity on risk assessment c122 | |

| Carbon footprint knowledge system resilience c13 | Carbon footprint knowledge system resilience = management capability x degree to which management capability influences carbon footprint knowledge system resilience c131 + construction capability x degree to which construction capability influences carbon footprint knowledge system resilience c132 + forecasting capability x degree to which forecasting capability influences carbon footprint knowledge system resilience c133 + carbon emission capability x degree to which carbon emission capability influences resilience carbon footprint knowledge system resilience c134 | |

| Constant (D) | Detection capability d1 | Detection capability = d1 |

| Working experience d2 | Working experience = d2 | |

| Energy intensity d3 | Energy intensity = d3 |

- (1)

- Resilience Initial Value Equation

- (2)

- Management Capability Evolution Equation

- (3)

- Construction Capability Impact Equation

- (4)

- Predictive Capability Calculation Equation

- (5)

- Emission Capability Correlation Equation

- (6)

- Resilience Dynamic Evolution Equation

| Nature of the Variable | Variable Name | Variational Equation Expressions |

|---|---|---|

| state variable (A) | Management capacity a1 | Carbon footprint management capacity = INTEG (carbon footprint management rate, 0.189) |

| Construction capacity a2 | Low-carbon construction capacity = INTEG (low carbon construction rate, 0.238) | |

| Carbon emission capacity a3 | Carbon emission capacity = INTEG (carbon emission rate, −0.206) | |

| Carbon footprint prediction capability a4 | Carbon footprint prediction capacity = INTEG (carbon footprint prediction rate, 0.367) | |

| flow rate variable (B) | Carbon footprint management rate b1 | Carbon footprint management rate = detection capacity x 0.361 + work experience x 0.258 + processing capacity x 0.433 |

| Low-carbon construction rate b2 | Low-carbon construction rate = site management capability x 0.357 + operation level x 0.255 + personnel capability x 0.212 + energy saving and emission reduction x 0.177 | |

| Carbon footprint b3 | Carbon emission rate = −carbon sink x 0.306 + energy intensity x 0.191 + total energy consumption of building enterprises x 0.367 − environmental protection level x 0.137 | |

| Carbon footprint prediction rate b4 | Carbon footprint prediction rate = risk assessment x 0.251 + risk awareness x 0.377 + detecting carbon systems x 0.211 + risk avoidance x 0.161 | |

| auxiliary variable (C) | Processing capability c1 | Handling capacity = inspection capacity x 0.565 + work experience x 0.435 |

| On-site management capacity c2 | Site management skills = work experience x 0.5 | |

| Personnel capacity c3 | Personnel capacity = operating level x 0.3 | |

| Reduce emissions through energy conservation c4 | Energy saving and emission reduction = operation level x 0.417 + management capacity x 0.583 | |

| Environmental level c5 | Level of environmental protection = risk awareness x 0.4 | |

| Carbon credits c6 | Carbon sink = environmental protection level x 0.615 + carbon footprint prediction capacity x 0.385 | |

| Total energy consumption of construction enterprises c7 | Total energy consumption of construction enterprises = energy intensity × 0.7 | |

| Risk awareness c8 | Risk awareness = risk assessment x 0.6 | |

| Monitoring carbon systems c9 | Monitoring carbon systems = risk awareness x 0.4 + operational capacity x 0.6 | |

| Risk avoidance c10 | Risk avoidance = risk awareness x 0.292 + risk assessment x 0.322 + emission capacity x 0.386 | |

| Operating level c11 | Operating level = detection capability x 0.7 | |

| Risk assessment c12 | Risk assessment = energy efficiency x 0.417 + construction capacity x 0.583 | |

| Carbon footprint knowledge system resilience c13 | Carbon Footprint Knowledge System Toughness = Management Capability x 0.355 + Construction Capability x 0.273 + Forecasting Capability x 0.195 − Carbon Emission Capability x 0.177 | |

| Constant (D) | Detection capability d1 | Detection capacity = 0.364 |

| Working experience d2 | Work experience = 0.324 | |

| Energy intensity d3 | Energy intensity = 0.226 |

References

- Li, S.; Han, G.; Du, B. Carbon emissions assessment of ultra-high performance concrete in construction industry: Calculation method and case study. Energy Build. 2025, 329, 115260. [Google Scholar] [CrossRef]

- Mugula, J.; Nakayenga, J.; GuhaRay, A.; Hata, T. Use of lignocellulose-degrading enzyme bio-cemented soils in the construction industry. Environ. Geotech. 2025, 12, 353–369. [Google Scholar] [CrossRef]

- Li, J.; Liu, S. Research on carbon footprint evaluation of assembled concrete building at the stage of building construction. Constr. Econ. 2021, 101–105. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Q.; Shi, Z.W. Analysis of carbon emission influencing factors in the stage of assembled building construction. Technol. Ind. 2023, 23, 144–151. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzhpL7ANCO31BBTNbTo_kCIHC6jZtd55EVKg73fiwtXYFRiHGCjShVo-g8DsfneL8539jHNS3frK9bO_4xuY-nxnCwZIf6IEGeOGIacnjBIyJQnzZXPVhGV2e7DQ1-wDwiq9HmhC4RdERj0LYdrRlqXvYhdHCeSnZ6gZ8WN6lk_6Yw==&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Ling, J.P. Research on TOC-based production planning and control methods for complex moulds. Mod. Inf. Technol. 2021, 5, 173–176. [Google Scholar]

- Zhang, J.; Fang, Y.; Wei, J.D.; Lin, J.T.; Chen, P.B.; Zhu, C.Z. Spatial and temporal differences of carbon sources/sinks in farmland ecosystems in Anhui Province based on carbon footprint. Fujian J. Agric. 2021, 78–90. [Google Scholar] [CrossRef]

- Fu, W.; Luo, M.C.; Chen, J.C. Progress and Prospect of Research on Carbon Footprint and Its Influencing Factors. For. Econ. 2021, 43, 39–49. [Google Scholar]

- Ke, S.F. Research on Influencing Factors of Carbon Footprint, Reduction Potential and Low-Carbon Development Strategy of Beijing Municipality; People’s Daily Press: Beijing, China, 2015. [Google Scholar]

- Kahn, C.B.; Reinschmidt, K.; Teufel-Shone, N.I.; Oré, C.E.; Henson, M.; Attakai, A. American Indian Elders’ resilience: Sources of strength for building a healthy future for youth. Am. Indian Alsk. Nativ. Ment. Health Res. (Online) 2016, 23, 117–133. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Torabi, S.A.; Mansouri, S.A. Building organisational resilience in the face of multiple disruptions. Int. J. Prod. Econ. 2018, 197, 63–83. [Google Scholar] [CrossRef]

- Ma, Z.; Xiao, L.; Yin, J. Toward a dynamic model of organisational resilience. Nankai Bus. Rev. Int. 2018, 9, 246–263. [Google Scholar] [CrossRef]

- Tomasz, I.; Monika, W.; Karel, H. Organisational resilience as a response to the energy crisis: Systematic literature review. Energies 2023, 16, 702. [Google Scholar]

- Burnard, K.J.; Bhamra, R. Challenges for organisational resilience. Contin. Resil. Rev. 2019, 1, 17–25. [Google Scholar] [CrossRef]

- Chen, H.Y.; Chang, R.P.; Meng, W.N. Exploration of low carbon management mode of enterprise innovation. Shandong Soc. Sci. 2015, S2, 124–126. [Google Scholar] [CrossRef]

- Zhao, X. Optimal Management Method of Carbon Footprint of Manufacturing Enterprises Based on TOC Constraint Theory. Master’s Thesis, Hefei University of Technology, Hefei, China, 2015. [Google Scholar]

- Zhou, J.L. Research on Influencing Factors and Role Mechanisms of Contractors’ Low-Carbon Construction Behaviour. Master’s Thesis, Tianjin University, Tianjin, China, 2016. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzh490LQiTUlcd8uT3uHzpfZFPH9kgWPu1mrxYE8JPFEP0x048-qFqxX7e0ssxyeskA9bKdVnN73Hc4ByAnicMFlqyasYWq8foTN77xu_ptYOkgKRQXg0zvWq3Z3Y7w3tX6Us_nMSb6S8OL4JC1IpiXWjGzfbcYg9XoBjBFtTe8INuUa11lJ6s-A&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Zhou, H.B. Research on influencing factors and control measures of low carbon construction. Constr. Econ. 2011, 2, 5–8. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, X.; Cui, Q. Effectiveness and equity implications of carbon policies in the United States construction industry. Build. Environ. 2012, 49, 259–269. [Google Scholar] [CrossRef]

- Qian, M.M. Research on the Influencing Factors of Robustness of Construction Supply Chain Under EPC Mode. Master’s Thesis, Tianjin University of Technology, Tianjin, China, 2015. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzgqPh1GW-vYGdgJfFLYFC7i_etp1pwL1_MMe1NEumVmnIF-yDGujaXPd6S_BT2GzR4rR60-jySykiJHc38OwrFDQdPJkfgS91jutaj8Xlz-goxwszhOtZbrzUYefBgPmPddO5I5mXB2dm9XkjhXHRVU_zZ6hTwzao47iYEj_PevO6y1Qzo7PmR0&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Wang, J.Y. Research on Influencing Factors and Enhancement Strategies of Assembly Building Supply Chain Toughness under the Perspective of Dynamic Capability. Master’s Thesis, North University of Technology, Beijing, China, 2023. Available online: https://link.cnki.net/doi/10.26926/d.cnki.gbfgu.2023.000705 (accessed on 7 August 2025).

- Yuan, X.R. Research on the Evolution of Low Carbon Competitiveness of Manufacturing Enterprises. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2012. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzj2ESyUp0HUGotxk86mtj_bsoXaIJ-fNsRv2BjbCmRtBt0m8nO-ZgrHSVp2uFeWAEkebDgCP9OX571NMnInPOX9TCtCeZDLezY8ggRxxuW0PrlO9Ehfb9ZPFwaJY3TPhDTnDsfJHGua-iZWs_V8wsy_xJXfy2MenD9_RbM6LH8ASty0zadcsQqy&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Lou, S.M. Empirical Research on the Motivation and Behaviour of Low-Carbon Production in High-Carbon Enterprises. Master’s Thesis, Henan University of Technology, Jiaozuo, China, 2015. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzjcbOBKfkhTO5-Xx1uhFSXHr0f-TvWEbhPFNE3D8B_SGtqrM_vT_5v4ACtti71MYQGW8YFQPbUh1EwZ5JodVfFlUxz7OJnR8ml70u8HrDTjwwfJjjsJlcipDpxlRifQQfYO2uRrfErpyQGWhxbz_thHxWKEqEoONk0Uu9ukaqGGMno0BqXMkcW1&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Han, H. Research on the Relationship Between Corporate Carbon Asset Management and Competitive Advantage Mediated by Resource Advantage. Master’s Thesis, Tianjin University of Finance and Economics, Tianjin, China, 2013. Available online: https://kns.cnki.net/kcms2/article/abstract?v=si2fSHvxfzgu6ySgk9vFdXo9QkainmjpdrwSqcaMrcZjhzLVFaqTcLu1dYu9YUuBtY195xPe7Pm_D5LaqBx4isdZz_CO_zymp7uNtcrCWvvNOaGHkfT6Sm_KMV30Y5Auf3bqTN97J2yfHeYzDMOHBeQODSwzGBrILEoEUag-OmA8B8LEiiO-Z-n9oC3XDrpW&uniplatform=NZKPT&language=CHS (accessed on 7 August 2025).

- Zhang, Y.F. Study on the Impact of Digital Transformation on Carbon Neutrality in Building Construction Enterprises. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2023. Available online: https://link.cnki.net/doi/10.27623/d.cnki.gzkyu.2023.001590 (accessed on 7 August 2025).

- Zhang, F.; Luo, Y.; Song, C.X.; Pan, J.Y. High-tech enterprises’ high-quality development path based on fsQCA methodology-A case study of Shaanxi Province. J. Syst. Manag. 2023, 32, 796–811. [Google Scholar]

- Wang, X.; He, H.Y.; Cu, P.; Zhang, L. Research on Interdisciplinary Cultivation of Talents for Emerging Interdisciplinary Fields in Universities of Double First-Class Construction—An Empirical Analysis Based on Qualitative Comparative Analysis (QCA). China High. Educ. Res. 2019, 12, 21–28. [Google Scholar] [CrossRef]

- Yang, L.; Liu, D.H.; Wei, Q.F. Research on regional innovation ecosystem capacity enhancement under symbiosis theory. Sci. Res. 2023, 41, 1897–1909. [Google Scholar]

- Zhu, J.M.; Cui, X.Y. Research on the relationship between international technology merger and acquisition factor grouping and dual innovation performance. Res. Sci. 2022, 40, 1527–1536. [Google Scholar]

- Lv, R.J.; Zhang, B.B.; Zhang, Y.M. Research on the antecedent group state of cross-regional technology transfer efficiency. Res. Sci. 2018, 36, 1986–1994. [Google Scholar]

- Zhang, X.X.; Hao, X.L. Inducing and moderating employees’ digital transformation resistance in the group perspective. Sci. Res. 2023, 41, 2050–2061. [Google Scholar]

- Xiao, J.; Zeng, P.; Ren, G. How to enhance the performance of green transformation in the manufacturing industry? A group study based on TOE framework. Res. Sci. 2022, 40, 2162–2172. [Google Scholar]

- Yan, Y.; Ye, G.Y.; Liang, X.M. Institutional pressure, local government response and regional environmental performance - a qualitative comparative analysis based on data from 30 provinces. Res. Sci. 2024, 42, 300–309. [Google Scholar]

- Xiang, G.P.; Lou, S.Z.; Wang, J. Who is more favoured:A qualitative comparative analysis of the availability of financing for entrepreneurial firms. Res. Sci. 2019, 37, 1642–1650. [Google Scholar]

- Tian, J.; Xu, J.B. Research on driving factors of business model innovation of platform enterprises. Sci. Res. 2020, 38, 949–960. [Google Scholar] [CrossRef]

- Issa Zadeh, S.B.; López Gutiérrez, J.S.; Esteban, M.D.; Fernández-Sánchez, G.; Garay-Rondero, C.L. A framework for accurate carbon footprint calculation in seaports: Methodology proposal. J. Mar. Sci. Eng. 2023, 11, 1007. [Google Scholar] [CrossRef]

- Issa-Zadeh, S.B.; Esteban, M.D.; López-Gutiérrez, J.-S.; Garay-Rondero, C.L. Unveiling the Sensitivity Analysis of Port Carbon Footprint via Power Alternative Scenarios: A Deep Dive into the Valencia Port Case Study. J. Mar. Sci. Eng. 2024, 12, 1290. [Google Scholar] [CrossRef]

- Fang, G.; Tan, J.X. Research on knowledge value-added of industry-university-research collaborative innovation under the Internet environment. Sci. Res. 2020, 38, 1325–1337. [Google Scholar]

- Wang, D.D. Research on Driving Mechanism of Green Construction Based on System Dynamics. Master’s Thesis, Yangzhou University, Yangzhou, China, 2021. [Google Scholar] [CrossRef]

- Aftabi, N.; Moradi, N.; Mahroo, F.; Kianfar, F. SD-ABM-ISM: An integrated system dynamics and agent-based modeling framework for information security management in complex information systems with multi-actor threat dynamics. Expert Syst. Appl. 2025, 263, 125681. [Google Scholar] [CrossRef]

- Marcuzzo, R.; Silberg, T.R.; Uriona-Maldonado, M. Growth of residential solar energy in Brazil: A system dynamics approach. Renew. Sustain. Energy Rev. 2025, 215, 115582. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J.; Zang, Y. Financial risk identification and control in the openness context: A system dynamics approach to Renminbi Internationalization. Int. Rev. Econ. Financ. 2025, 97, 103542. [Google Scholar] [CrossRef]

- Sharafian, A.; Ali, A.; Ullah, I.; Khalifa, T.R.; Bai, X.; Qiu, L. Fuzzy adaptive control for consensus tracking in multiagent systems with incommensurate fractional-order dynamics: Application to power systems. Inf. Sci. 2025, 689, 121455. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X.; Szolnoki, A. Coevolutionary dynamics of feedback-evolving games in structured populations. Chaos Solitons Fractals 2025, 193, 116070. [Google Scholar] [CrossRef]

- Wang, S.; Wei, M.L.; Song, X.P.; Liu, W.; Song, L. Stability analysis of high-stage filling body based on improved CRITIC-G1 method combined empowerment cloud model. J. Chongqing Univ. 2022, 45, 68–80. [Google Scholar]

- Chen, S.; Fan, S.; Qiao, Z.; Wu, Z.; Lin, B.; Li, Z.; Riegler, M.A.; Wong, M.Y.H.; Opheim, A.; Korostynska, O.; et al. Transforming healthcare: Intelligent wearable sensors empowered by smart materials and artificial intelligence. Adv. Mater. 2025, 37, e2500412. [Google Scholar] [CrossRef]

- Moubarak, H.F.A.; Afthanorhan, A. Psychological empowerment of politically empowered Saudi women. Humanit. Soc. Sci. Commun. 2025, 12, 517. [Google Scholar] [CrossRef]

- Wang, X.; Niu, J.; Fang, B.; Han, G.; He, J. Empowering teachers’ professional development with LLMs: An empirical study of developing teachers’ competency for instructional design in blended learning. Teach. Teach. Educ. 2025, 165, 105091. [Google Scholar] [CrossRef]

- Wan, Y.; Chen, Z.; Liu, Y.; Chen, C.; Packianather, M. Empowering LLMs by hybrid retrieval-augmented generation for domain-centric Q&A in smart manufacturing. Adv. Eng. Inform. 2025, 65, 103212. [Google Scholar]

| Features | Form | Quantities | Percentage (%) | Features | Form | Quantities | Percentage (%) |

|---|---|---|---|---|---|---|---|

| Sex | Male | 64 | 60.4 | Office | Middle management | 83 | 78.3 |

| Female | 42 | 39.6 | Senior management | 23 | 21.7 | ||

| Age | 18–25 | 21 | 19.8 | Nature of enterprise | State-owned business | 32 | 30.2 |

| 26–35 | 38 | 35.8 | Private enterprise | 42 | 39.6 | ||

| 36–45 | 37 | 34.9 | Foreign, private, and joint ventures | 32 | 30.2 | ||

| 46 years and over | 10 | 9.4 | Type of business | Large corporation | 31 | 29.2 | |

| Educational level | High school and below | 10 | 9.4 | Medium-sized enterprise | 43 | 40.6 | |

| Technical college | 32 | 30.2 | Small and microenterprises | 32 | 30.2 | ||

| Undergraduate | 54 | 50.9 | |||||

| Master’s degree or above | 10 | 9.4 |

| Variant | Measurement Item | Subject | Cronbach’s α Coefficient | Overall Cronbach’s α |

|---|---|---|---|---|

| Management capacity | Our company’s carbon footprint managers have enough working experience. | 3 | 0.758 | 0.872 |

| Our company’s managers can detect carbon footprints. | ||||

| Our company’s managers have sufficient capacity to handle carbon footprints. | ||||

| Predictive capacity | Our company has a well-developed strategy to avoid and contain risky events. | 4 | 0.826 | |

| Risk awareness is common in our company. | ||||

| Our company has a specialised carbon monitoring system. | ||||

| Our company conducts risk assessments before construction. | ||||

| Construction capacity | Our company utilises low-carbon, energy-saving, and emission reduction technologies in the construction process and actively introduces new construction technologies. | 4 | 0.867 | |

| The enterprise strengthens the management of the construction site during the construction process and reduces the waste of materials and resources. | ||||

| Enterprises use low-energy machinery and equipment with a strong level of operation in the construction process. | ||||

| Enterprises implement low-carbon behaviour and low-carbon production in the construction process. | ||||

| Emission capacity | Enterprises improve the type and number of plants per unit area of the construction site to increase the construction carbon sink. | 4 | 0.816 | |

| Enterprises involved in the construction process provide a strong level of environmental protection and attach great importance to reducing carbon emissions in the construction process. | ||||

| The total amount of energy consumed by the enterprise in the construction process is high. | ||||

| The energy intensity of the enterprise in the construction process is high. | ||||

| Carbon footprint knowledge system resilience | Companies can observe and recognise not only actual changes and impending crises but also potential future developments. | 3 | 0.768 | |

| Companies can move quickly from normal operational mode to crisis response mode in the wake of a carbon crisis. | ||||

| Companies can redeploy personnel to fill key staffing gaps in the wake of a crisis. |

| Dimension | Subject | KMO Value | Bartlett’s Test of Sphericity | Degrees of Freedom | Significance |

|---|---|---|---|---|---|

| Management capacity | 3 | 0.682 | 82.107 | 3 | 0.000 |

| Predictive capacity | 4 | 0.796 | 149.293 | 6 | 0.000 |

| Construction capacity | 4 | 0.833 | 190.217 | 6 | 0.000 |

| Emission capacity | 4 | 0.800 | 137.107 | 6 | 0.000 |

| Carbon footprint knowledge system resilience | 4 | 0.697 | 80.080 | 3 | 0.000 |

| Variant | Location | |||

|---|---|---|---|---|

| Full Affiliation Point | Junction | Unaffiliated Point | ||

| Prerequisite variables | Management capacity | 5 | 3.6164 | 1 |

| Predictive capacity | 5 | 3.5825 | 1 | |

| Construction capacity | 5 | 3.7123 | 1 | |

| Emission capacity | 5 | 3.5212 | 1 | |

| Outcome variable | Carbon footprint knowledge system resilience | 5 | 3.7421 | 1 |

| Prerequisite | Consistency | Catch-All |

|---|---|---|

| Management capacity | 0.789039 | 0.815867 |

| ~Management capacity | 0.531056 | 0.740913 |

| Predictive capacity | 0.800476 | 0.826743 |

| ~Predictive capacity | 0.517713 | 0.723418 |

| Construction capacity | 0.810961 | 0.805459 |

| ~Construction capacity | 0.500079 | 0.738620 |

| Emission capacity | 0.777601 | 0.813663 |

| ~Emission capacity | 0.533916 | 0.733203 |

| 1 | 2 | 3 | |

|---|---|---|---|

| Management capacity | ⚫ | ⚫ | |

| Predictive capacity | ⚫ | ⚫ | |

| Construction capacity | ⚫ | ● | |

| Emission capacity | ⚫ | ⚫ | |

| Original coverage | 0.664019 | 0.620334 | 0.591263 |

| Unique coverage | 0.130103 | 0.0864177 | 0.0573472 |

| Consistency | 0.870108 | 0.881888 | 0.878452 |

| Overall coverage 0.807784 | |||

| Overall consistency 0.860843 | |||

| Configuration ID | Core Conditions | Frequency in Sample | Management Implications |

|---|---|---|---|

| 1 | Management capability, emission capability | 28 times, accounting for 23.3% of the total sample | Strengthen managers’ experience in carbon footprint disposal and conduct regular carbon emission management training. |

| 2 | Management capability, predictive Capability, construction capability | 22 times, accounting for 18.3% of the total sample | Integrate risk early-warning systems with low-carbon construction technologies and establish cross-departmental collaborative management mechanisms. |

| 3 | Predictive capability, emission capability (with construction capability as an auxiliary condition) | 18 times, accounting for 15.0% of the total sample | Optimise construction plans based on risk predictions and prioritise the use of low-carbon building materials. |

| Variable | Peak Value (Normalised) | Inflection Point (Month) | Time-to-Peak (Month) | Key Trend Description |

|---|---|---|---|---|

| Carbon Footprint Knowledge System Resilience | 1.8 (Normalised Index) | 12 | 24 | Shows steady growth over 24 months, with accelerated growth after the 12th month due to synergistic effects of capabilities. |

| Management Capability | 1.6 (Normalised Index) | 6 | 24 | Maintains a relatively fast growth trend throughout the period, with no significant slowdown; the inflection point at 6 months marks the start of stable acceleration. |

| Construction Capability | 1.5 (Normalised Index) | 12 | 24 | Grows slowly in the first 12 months, then accelerates rapidly after the 12th month, reaching a peak at the end of the period. |

| Predictive Capability | 1.4 (Normalised Index) | 12 | 15 | Exhibits slow growth in the first 12 months, followed by rapid improvement, peaking at 15 months and remaining stable thereafter. |

| Emission Capability | −0.8 (Normalised Index, Negative Correlation) | 12 | 24 | Shows a slow decreasing trend in the first 12 months, then a rapid decline after the 12th month, with the lowest value (peak reduction) at 24 months. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, M.; Lai, W.; Wu, C. A Study on the Driving Factors of Resilience in the Carbon Footprint Knowledge System of Construction Companies. Buildings 2025, 15, 2856. https://doi.org/10.3390/buildings15162856

Fan M, Lai W, Wu C. A Study on the Driving Factors of Resilience in the Carbon Footprint Knowledge System of Construction Companies. Buildings. 2025; 15(16):2856. https://doi.org/10.3390/buildings15162856

Chicago/Turabian StyleFan, Minnan, Wenzhe Lai, and Chuanjie Wu. 2025. "A Study on the Driving Factors of Resilience in the Carbon Footprint Knowledge System of Construction Companies" Buildings 15, no. 16: 2856. https://doi.org/10.3390/buildings15162856

APA StyleFan, M., Lai, W., & Wu, C. (2025). A Study on the Driving Factors of Resilience in the Carbon Footprint Knowledge System of Construction Companies. Buildings, 15(16), 2856. https://doi.org/10.3390/buildings15162856