Discrete Modeling of Aging Creep in Concrete

Abstract

1. Introduction

2. Numerical Modeling

2.1. Mechanical Model

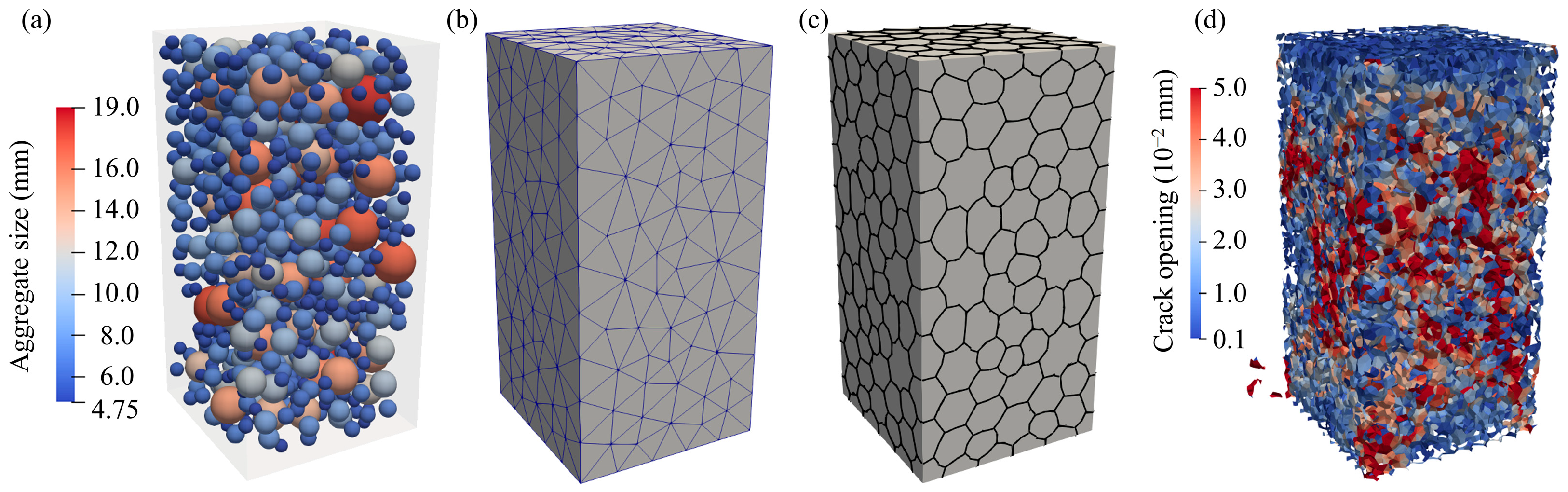

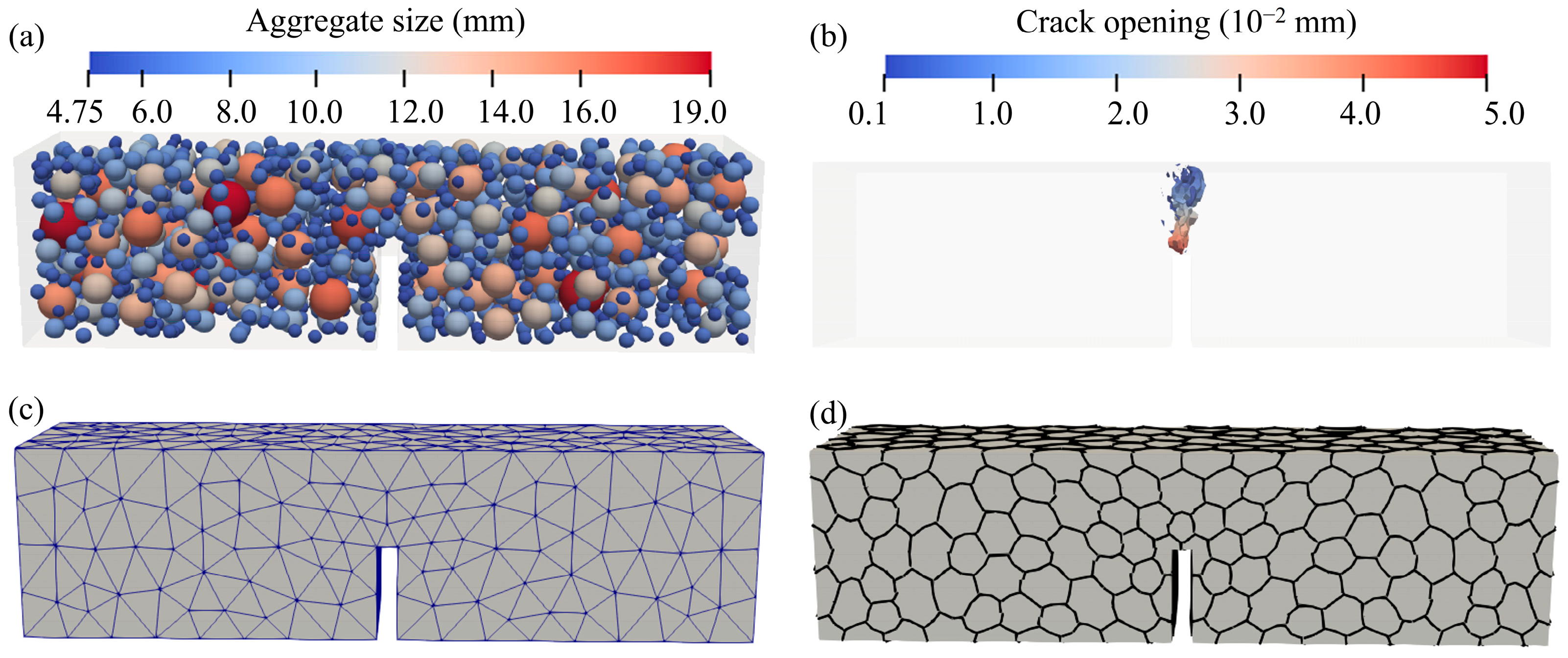

2.1.1. Mesostructure

2.1.2. Constitutive Equations

2.2. Aging Law of Strength Proporties

2.2.1. Hydration Evolution

2.2.2. Aging Law

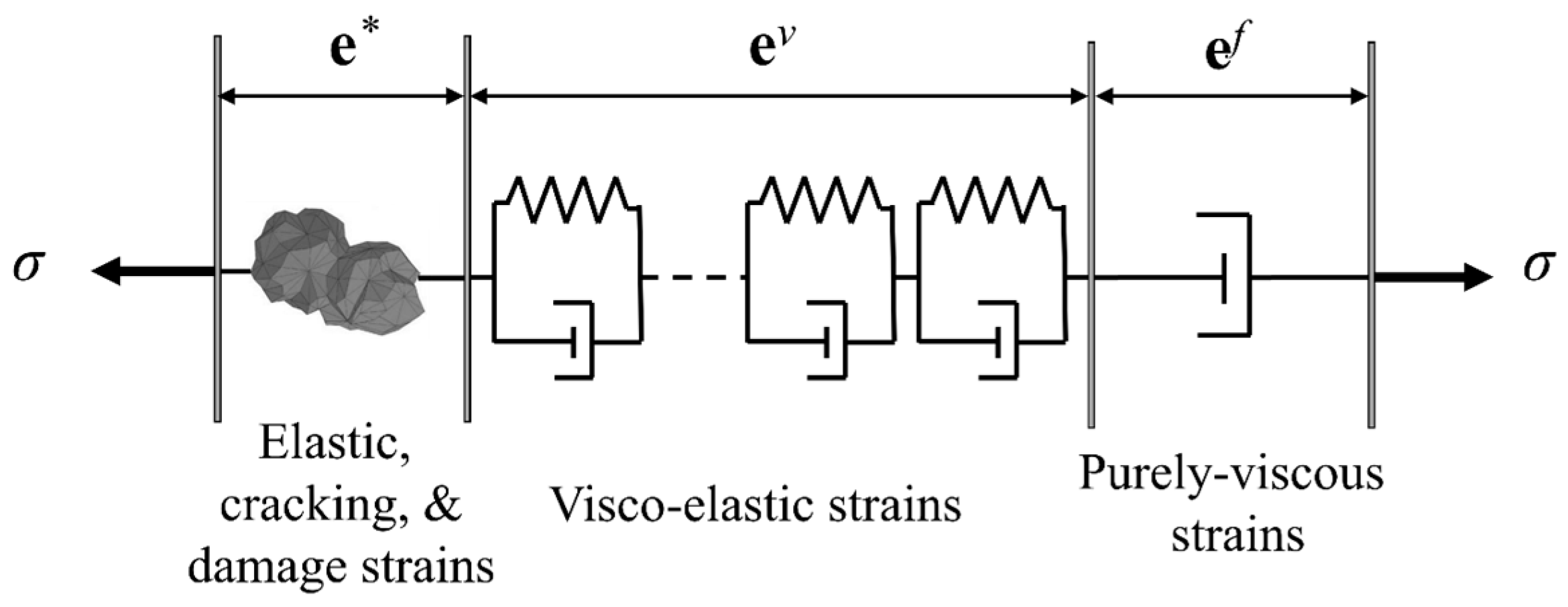

2.3. Creep Model

2.3.1. Visco-Elastic Strains

2.3.2. Purely Viscous Strains

3. Results and Discussions

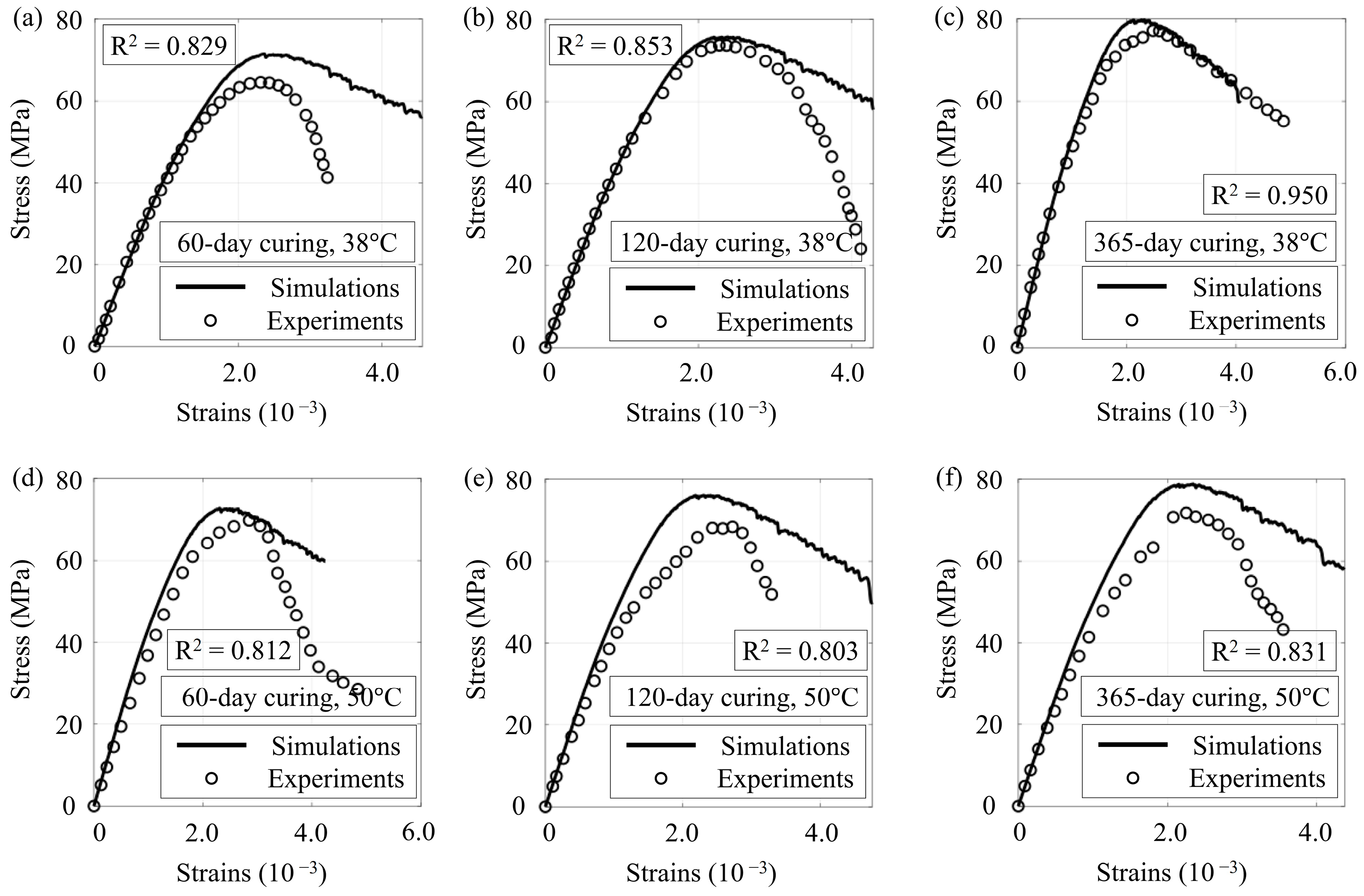

3.1. Compression Tests

3.2. Three-Point Bending Tests

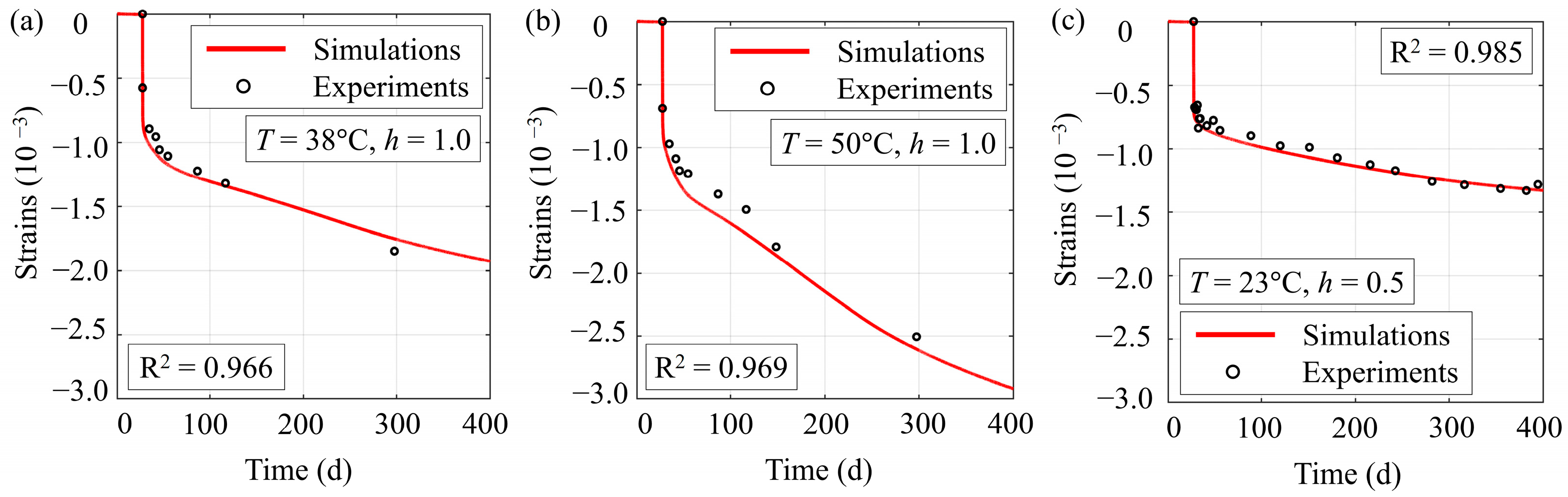

3.3. Creep Tests

3.4. Discussion

4. Conclusions

- (1)

- The numerical framework consists of the aging formulation of the LDPM to formulate the mechanical behavior, and the creep formulation based on MPS theory to formulate the time-dependent creep deformation. The elastic, cracking and damage strains, visco-elastic strains, and purely viscous strains are formulated in the constitutive equations based on the classical assumption of strain additivity.

- (2)

- The model provides accurate representations of the time-dependent mechanical properties of concrete under compression and three-point bending. The typical failure modes and crack pattern in compression and three-point bending tests were well reproduced.

- (3)

- The material strength and creep deformations of concrete increase with the increase in environmental temperature. The proposed model can simulate the temperature dependence of strength evolution and creep behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shah, S.P.; Swartz, S.E.; Ouyang, C. Fracture Mechanics of Concrete: Applications of Fracture Mechanics to Concrete, Rock and Other Quasi-Brittle Materials; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- Wu, L.; Huang, D. Peridynamic modeling and simulations on concrete dynamic failure and penetration subjected to impact loadings. Eng. Fract. Mech. 2022, 259, 108135. [Google Scholar] [CrossRef]

- Yang, L.; Li, K.; Hu, X.; Peng, Z.; Liu, Q.F.; Shi, C. Mesoscopic discrete modeling of compression and fracture behavior of concrete: Effects of aggregate size distribution and interface transition zone. Cem. Concr. Compos. 2024, 147, 105411. [Google Scholar] [CrossRef]

- Vandamme, M.; Ulm, F.J. Nanogranular origin of concrete creep. Proc. Natl. Acad. Sci. USA 2009, 106, 10552–10557. [Google Scholar] [CrossRef] [PubMed]

- Rahimi-Aghdam, S.; Bažant, Z.P.; Cusatis, G. Extended microprestress-solidification theory for long-term creep with diffusion size effect in concrete at variable environment. J. Eng. Mech. 2019, 145, 04018131. [Google Scholar] [CrossRef]

- Abdellatef, M.; Boumakis, I.; Wan-Wendner, R.; Alnaggar, M. Lattice Discrete Particle Modeling of concrete coupled creep and shrinkage behavior: A comprehensive calibration and validation study. Constr. Build. Mater. 2019, 211, 629–645. [Google Scholar] [CrossRef]

- Bolander, J.E.; Eliáš, J.; Cusatis, G.; Nagai, K. Discrete mechanical models of concrete fracture. Eng. Fract. Mech. 2021, 257, 108030. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Jivkov, A.; Das, B.B. A review of multi-scale modelling of concrete deterioration: Fundamentals, techniques and perspectives. Constr. Build. Mater. 2023, 406, 133472. [Google Scholar] [CrossRef]

- Ulm, F.J.; Coussy, O. Couplings in early-age concrete: From material modeling to structural design. Int. J. Solids Struct. 1998, 35, 4295–4311. [Google Scholar] [CrossRef]

- Jendele, L.; Šmilauer, V.; Červenka, J. Multiscale hydro-thermo-mechanical model for early-age and mature concrete structures. Adv. Eng. Softw. 2014, 72, 134–146. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, F.; Maekawa, K. Multi-scale and multi-chemo-physics lifecycle evaluation of structural concrete under environmental and mechanical impacts. J. Intell. Constr. 2023, 1, 1–18. [Google Scholar] [CrossRef]

- Thomas, J.J.; Biernacki, J.J.; Bullard, J.W.; Bishnoi, S.; Dolado, J.S.; Scherer, G.W.; Luttge, A. Modeling and simulation of cement hydration kinetics and microstructure development. Cem. Concr. Res. 2011, 41, 1257–1278. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Gan, Y.; Chang, Z.; Schlangen, E.; Šavija, B. Microstructure informed micromechanical modelling of hydrated cement paste: Techniques and challenges. Constr. Build. Mater. 2020, 251, 118983. [Google Scholar] [CrossRef]

- Lootens, D.; Bentz, D.P. On the relation of setting and early-age strength development to porosity and hydration in cement-based materials. Cem. Concr. Compos. 2016, 68, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Koenders, E.A.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, Z.; Shen, L.; Sheng, D. Development of sustainable concrete incorporating seawater: A critical review on cement hydration, microstructure and mechanical strength. Cem. Concr. Compos. 2021, 121, 104100. [Google Scholar] [CrossRef]

- Rosa, R.E.M.; Bhibho, T.; Dőnmez, A.A.; Cusatis, G.; Bažant, Z.P. The shard test and nanoporomechanics reverse classical paradigm of cement hydration being contractive. Proc. Natl. Acad. Sci. USA 2024, 121, e2418448121. [Google Scholar] [CrossRef]

- Sun, W.; Fish, J.; Leng, Z.; Ni, P. PD-FEM chemo-thermo-mechanical coupled model for simulation of early-age cracks in cement-based materials. Comput. Methods Appl. Mech. Eng. 2023, 412, 116078. [Google Scholar] [CrossRef]

- Gamnitzer, P.; Brugger, A.; Drexel, M.; Hofstetter, G. Modelling of coupled shrinkage and creep in multiphase formulations for hardening concrete. Materials 2019, 12, 1745. [Google Scholar] [CrossRef]

- Bažant, Z.P.; L’Hermite, R. Mathematical Modeling of Creep and Shrinkage of Concrete; John Wiley & Sons: Hoboken, NJ, USA, 1988. [Google Scholar]

- Tošić, N.; Aidarov, S.; de la Fuente, A. Systematic review on the creep of fiber-reinforced concrete. Materials 2020, 13, 5098. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Chern, J.C. Concrete creep at variable humidity: Constitutive law and mechanism. Mater. Struct. 1985, 18, 1–20. [Google Scholar] [CrossRef]

- Ulm, F.J.; Coussy, O. Modeling of thermochemomechanical couplings of concrete at early ages. J. Eng. Mech. 1995, 121, 785–794. [Google Scholar] [CrossRef]

- Bažant, Z.P. Prediction of concrete creep effects using age-adjusted effective modulus method. ACI J. 1972, 69, 212–217. [Google Scholar]

- Jennings, H.M. Colloid model of C-S-H and implications to the problem of creep and shrinkage. Mater. Struct. 2004, 37, 59–70. [Google Scholar] [CrossRef]

- Pichler, C.; Lackner, R. A multiscale creep model as basis for simulation of early-age concrete behavior. Comput. Concr. 2008, 5, 295–328. [Google Scholar] [CrossRef][Green Version]

- Scheiner, S.; Hellmich, C. Continuum microviscoelasticity model for aging basic creep of early-age concrete. J. Eng. Mech. 2009, 135, 307–323. [Google Scholar] [CrossRef]

- Jirásek, M.; Havlásek, P. Accurate approximations of concrete creep compliance functions based on continuous retardation spectra. Comput. Struct. 2014, 135, 155–168. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S.; Ulm, F.J. Microprestress-solidification theory for concrete creep. I: Aging and drying effects. J. Eng. Mech. 1997, 123, 1188–1194. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Prasannan, S. Solidification theory for concrete creep. I: Formulation. J. Eng. Mech. 1989, 115, 1691–1703. [Google Scholar] [CrossRef]

- Jirásek, M.; Havlásek, P. Microprestress–solidification theory of concrete creep: Reformulation and improvement. Cem. Concr. Res. 2014, 60, 51–62. [Google Scholar] [CrossRef]

- Di Luzio, G.; Cusatis, G. Solidification–microprestress–microplane (SMM) theory for concrete at early age: Theory, validation and application. Int. J. Solids Struct. 2013, 50, 957–975. [Google Scholar] [CrossRef]

- Liang, M.; Luzio, G.D.; Schlangen, E.; Šavija, B. Experimentally informed modeling of the early-age stress evolution in cementitious materials using exponential conversion from creep to relaxation. Comput.-Aided Civ. Infrastruct. Eng. 2024, 39, 3507–3530. [Google Scholar] [CrossRef]

- Cusatis, G.; Pelessone, D.; Mencarelli, A. Lattice discrete particle model (LDPM) for failure behavior of concrete. I: Theory. Cem. Concr. Compos. 2011, 33, 881–890. [Google Scholar] [CrossRef]

- Cusatis, G.; Mencarelli, A.; Pelessone, D.; Baylot, J. Lattice discrete particle model (LDPM) for failure behavior of concrete. II: Calibration and validation. Cem. Concr. Compos. 2011, 33, 891–905. [Google Scholar] [CrossRef]

- Jia, D.; Brigham, J.C.; Fascetti, A. An efficient static solver for the lattice discrete particle model. Comput.-Aided Civ. Infrastruct. Eng. 2024, 39, 3531–3551. [Google Scholar] [CrossRef]

- Troemner, M.; Lale, E.; Cusatis, G. Lattice discrete particle model simulations of energetic size effect and its implications for shear design specifications of reinforced concrete squat walls. Eng. Struct. 2025, 322, 119085. [Google Scholar] [CrossRef]

- Zhu, Z.; Troemner, M.; Wang, W.; Cusatis, G.; Zhou, Y. Lattice discrete particle modeling of the cycling behavior of strain-hardening cementitious composites with and without fiber reinforced polymer grid reinforcement. Compos. Struct. 2023, 322, 117346. [Google Scholar] [CrossRef]

- Yang, L.; Troemner, M.; Cusatis, G.; Su, H. A novel analytical model of particle size distributions in granular materials. Eng. Comput. 2025, 41, 645–665. [Google Scholar] [CrossRef]

- Yang, L.; Pathirage, M.; Su, H.; Alnaggar, M.; Di Luzio, G.; Cusatis, G. Computational modeling of expansion and deterioration due to alkali–silica reaction: Effects of size range, size distribution, and content of reactive aggregate. Int. J. Solids Struct. 2022, 234, 111220. [Google Scholar] [CrossRef]

- Yin, H.; Troemner, M.; Li, W.; Lale, E.; Yang, L.; Shen, L.; Cusatis, G. An interprocess communication-based two-way coupling approach for implicit–explicit multiphysics lattice discrete particle model simulations. Eng. Fract. Mech. 2024, 310, 110515. [Google Scholar] [CrossRef]

- Zhu, Y.; Jia, D.; Brigham, J.C.; Fascetti, A. Coupled lattice discrete particle model for the simulation of water and chloride transport in cracked concrete members. Comput.-Aided Civ. Infrastruct. Eng. 2025, 40, 982–1003. [Google Scholar] [CrossRef]

- Li, W.; Zhou, X.; Carey, J.W.; Frash, L.P.; Cusatis, G. Multiphysics lattice discrete particle modeling (M-LDPM) for the simulation of shale fracture permeability. Rock Mech. Rock Eng. 2018, 51, 3963–3981. [Google Scholar] [CrossRef]

- Pathirage, M.; Bentz, D.P.; Di Luzio, G.; Masoero, E.; Cusatis, G. The ONIX model: A parameter-free multiscale framework for the prediction of self-desiccation in concrete. Cem. Concr. Compos. 2019, 103, 36–48. [Google Scholar] [CrossRef]

- Yang, L.; Pathirage, M.; Su, H.; Alnaggar, M.; Di Luzio, G.; Cusatis, G. Computational modeling of temperature and relative humidity effects on concrete expansion due to alkali–silica reaction. Cem. Concr. Compos. 2021, 124, 104237. [Google Scholar] [CrossRef]

- Di Luzio, G.; Cusatis, G. Hygro-thermo-chemical modeling of high performance concrete. I: Theory. Cem. Concr. Compos. 2009, 31, 301–308. [Google Scholar] [CrossRef]

- Wan-Wendner, L.; Wan-Wendner, R.; Cusatis, G. Age-dependent size effect and fracture characteristics of ultra-high performance concrete. Cem. Concr. Compos. 2018, 85, 67–82. [Google Scholar] [CrossRef]

- Wan, L.; Wendner, R.; Liang, B.; Cusatis, G. Analysis of the behavior of ultra high performance concrete at early age. Cem. Concr. Compos. 2016, 74, 120–135. [Google Scholar] [CrossRef]

- Pathirage, M.; Bousikhane, F.; D’ambrosia, M.; Alnaggar, M.; Cusatis, G. Effect of alkali silica reaction on the mechanical properties of aging mortar bars: Experiments and numerical modeling. Int. J. Damage Mech. 2019, 28, 291–322. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S. Microprestress-solidification theory for concrete creep. II: Algorithm and verification. J. Eng. Mech. 1997, 123, 1195–1201. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Cusatis, G.; Cedolin, L. Temperature effect on concrete creep modeled by microprestress-solidification theory. J. Eng. Mech. 2004, 130, 691–699. [Google Scholar] [CrossRef]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling time-dependent behavior of concrete affected by alkali silica reaction in variable environmental conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef]

- Bousikhane, F. Experimental Investigation and Multi-Physics Computational Modeling for Assessment, Mitigation and Prevention of Concrete Deterioration. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 2018. [Google Scholar]

- ASTM C192; Making and Curing Concrete Test Specimens in the Laboratory. ASTM: West Conshohocken, PA, USA, 2018.

- Lothenbach, B.; Winnefeld, F.; Alder, C.; Wieland, E.; Lunk, P. Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes. Cem. Concr. Res. 2007, 37, 483–491. [Google Scholar] [CrossRef]

- Zunino, F.; Castro, J.; Lopez, M. Thermo-mechanical assessment of concrete microcracking damage due to early-age temperature rise. Constr. Build. Mater. 2015, 81, 140–153. [Google Scholar] [CrossRef]

- Yu, P.; Duan, Y.H.; Fan, Q.X.; Tang, S.W. Improved MPS model for concrete creep under variable humidity and temperature. Constr. Build. Mater. 2020, 243, 118183. [Google Scholar] [CrossRef]

| Materials | Specific Information | Quantity (kg/m3) |

|---|---|---|

| Portland cement | Holcim St. Genevieve Type 1 | 420.0 |

| Coarse aggregate | Size range: 4.75~19.0 mm | 1078.6 |

| Fine aggregate | Size range: 0.15~4.75 mm | 718.5 |

| Water | Potable | 176.2 |

| w/c | Water/Cement | 0.42 (-) |

| Superplasticizer | BASF Glenium 7500 | 3.2 |

| Size (mm) | 4.75 | 9.5 | 12.5 | 19.0 |

|---|---|---|---|---|

| Pasing | 0 | 33.3% | 66.7% | 100% |

| Parameters | Values | Parameters | Values | Parameters | Values |

|---|---|---|---|---|---|

| 0.25 | 1.460 | 96,522 MPa | |||

| 0.4 | 0.1 | 0.5 | |||

| 2.0 | 1.0 | 3.409 | |||

| 5.0 | 200.0 MPa | 0.338 | |||

| 750.0 MPa | 0.2 | 0.228 | |||

| 0.165 | 0.318 | 8.378 MPa | |||

| 76.475 mm | 7.125 × 106 1/h | 0.005 | |||

| 7.171 | 0.400 | 45.656 kJ/mol | |||

| 0.876 |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| 2.867 | 2.800 × 10−12 m2/N | ||

| 2.315 × 10−14 m2/N/s | 2.809 × 10−13 m2/N | ||

| 86.158 kJ/mol | 33.031 kJ/mol | ||

| 58.561 km/N/°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Pathirage, M. Discrete Modeling of Aging Creep in Concrete. Buildings 2025, 15, 2841. https://doi.org/10.3390/buildings15162841

Yang L, Pathirage M. Discrete Modeling of Aging Creep in Concrete. Buildings. 2025; 15(16):2841. https://doi.org/10.3390/buildings15162841

Chicago/Turabian StyleYang, Lifu, and Madura Pathirage. 2025. "Discrete Modeling of Aging Creep in Concrete" Buildings 15, no. 16: 2841. https://doi.org/10.3390/buildings15162841

APA StyleYang, L., & Pathirage, M. (2025). Discrete Modeling of Aging Creep in Concrete. Buildings, 15(16), 2841. https://doi.org/10.3390/buildings15162841