Abstract

This study addresses the challenge of optimizing envelope retrofit strategies for aged residential buildings across China’s five distinct climate zones. A simulation-based frame work is proposed, applying a standardized Taguchi L27 experimental design to ensure direct comparability across climates. Analysis of variance (ANOVA) and effect size (partial eta squared, η2) are used to identify and quantitatively rank the sensitivity of each retrofit parameter, while interaction analysis reveals the independence or synergy between measures. Technical results are linked with discounted payback period (DPP) analysis to evaluate economic feasibility. The findings show that insulation thickness is most influential in cold climates (η2 > 0.95), whereas glazing system upgrades are dominant in warmer regions (η2 > 0.97), with parameter interactions generally insignificant. The resulting climate-responsive retrofit priority matrix offers practical guidance for region-specific design and investment decisions. This scalable and replicable method enables policymakers and practitioners to tailor low-carbon, cost-effective retrofit solutions to diverse building and climate contexts, bridging the gap between technical performance and financial viability.

1. Introduction

Buildings are widely acknowledged as significant contributors to global energy consumption and carbon emissions [1]. According to the International Energy Agency, buildings account for approximately 34% of global final energy use and 37% of energy-related CO2 emissions when considering both operational and embodied phases [2]. In China, the building sector plays an even more prominent role. Between 2015 and 2022, building energy consumption increased at an average annual rate of 3.4%, while related carbon emissions rose by 2.8% per year [3]. By 2022, buildings represented 44.8% of the nation’s total energy use, with urban residential buildings alone contributing approximately 25.7% [4,5]. These figures underscore the urgent need to improve building energy performance, particularly in the residential sector.

A substantial portion of this energy demand stems from existing buildings constructed before national energy efficiency standards were introduced [6]. China’s first official energy code, Design standard for energy efficiency of residential buildings in severe cold and cold zones (JGJ 26-86), was issued in 1986 but applied only to the northern regions and was poorly enforced [7]. A more comprehensive regulatory framework did not emerge until the release of Design standard for energy efficiency of residential buildings in hot summer and cold winter zones (JGJ 134-2001), which addressed the Hot-Summer-and-Cold-Winter zones [8]. Consequently, many buildings constructed prior to 2001 lack basic thermal performance features such as envelope insulation, airtight construction, and energy-efficient glazing [9]. These deficiencies result in excessive heating and cooling loads, as well as degraded indoor environmental quality—particularly in regions with extreme climates [10]. In this context, retrofitting existing buildings presents a scalable and cost-effective solution to reduce energy consumption, enhance indoor comfort, and support China’s carbon reduction targets [11].

Although China has implemented national retrofit programs, these tend to follow standardized frameworks that often fail to account for the country’s substantial climatic diversity [12]. According to Thermal design code for civil building (GB 50176-2016), China is divided into five primary climate zones: Severe Cold, Cold, Hot Summer and Cold Winter, Hot Summer and Warm Winter, and Mild [13]. Each zone has distinct thermal requirements. For instance, Harbin, located in the Severe Cold zone, experiences over 5000 heating degree-days annually, while Guangzhou, in the Hot-Summer-and-Warm-Winter zone, has minimal heating needs but sustained cooling demand [14]. Applying uniform retrofit strategies across such diverse regions often leads to inefficiencies—either resulting in overdesign and unnecessary cost in milder climates or in underperformance in extreme ones [15]. Therefore, retrofit solutions must be climate-sensitive to maximize both performance and cost-effectiveness.

Improving the building envelope remains one of the most effective passive strategies for reducing energy demand, as it directly influences heat transfer, solar gain, and air infiltration [16]. Numerous studies have demonstrated that envelope upgrades—such as increasing insulation thickness, applying low-emissivity glazing, and enhancing airtightness—can significantly reduce energy consumption [17,18]. For example, thermal insulation that complies with green-building standards has been shown to reduce heating loads by 43–83%, depending on climate zone, building type, and envelope thermal transmittance (U-value), which represents the rate of heat transfer through a building element [19]. In hot or arid regions, optimizing the glazing system, insulation material, and window-to-wall ratio also offers substantial cooling energy savings [20]. In China, solar gain control through glazing optimization is particularly effective in hot-summer zones, while improving thermal envelope performance can reduce heating demand by up to 20%, with additional construction costs remaining below CNY 8000 [21]. These findings collectively demonstrate that climate-responsive envelope retrofits are a technically and economically promising pathway for improving energy performance in both existing and new buildings.

Despite growing interest in building envelope retrofitting, current research remains fragmented and lacks systemic breadth. Most studies tend to isolate individual parameters—such as insulation thickness or glazing type—and are typically confined to specific climate zones or cities, limiting the generalizability of their findings [22,23,24,25]. These reductionist approaches often fail to consider the combined or interactive effects of multiple envelope components and rarely evaluate how these interactions perform under varied climatic conditions [26]. To address such multidimensional design challenges while controlling computational loads, researchers have increasingly adopted design of experiment (DOE) methods. The Taguchi method is an efficient experimental design approach that employs orthogonal arrays to systematically evaluate the influence of multiple variables while minimizing the number of required simulations [27]. However, its applications remain largely limited to single-building or single-climate studies, Wu et al. [27] applied Taguchi+MOO to rural houses in northern Henan, while Alafzadeh et al. [28] focused on an office building in one location—making cross-regional generalization difficult. Moreover, while Taguchi design identifies optimal levels, most studies rely solely on range analysis or S/N ratios, overlooking ANOVA-derived η2 values and interaction effects critical to understanding factor influence [10,29]. Consequently, researchers have yet to establish cross-climate hierarchies of dominant parameters or quantify interaction strength. In addition, economic interpretation remains fragmented: Tsang et al. [30] explored life-cycle cost and scenario-based energy–cost curves but failed to link statistical sensitivity with investment indicators. This results in a methodological gap between technical priority and economic viability. Finally, future climate uncertainties are rarely embedded into economic return models—although Shi and Chen [31] accounted for climate-adaptive comfort, their framework excluded financial payback. Collectively, these limitations underscore the need for a unified, climate-spanning Taguchi framework that integrates statistical rigor, interaction analysis, and techno-economic coupling to guide scalable retrofit decisions.

To address these limitations, this study develops a climate-responsive, simulation-based framework for optimizing envelope retrofits in aged residential buildings across China’s five official climate zones. The methodology includes five key stages: (1) selecting five representative cities based on national thermal zoning; (2) constructing a standardized residential building model for pre-code buildings; (3) applying a Taguchi L27 orthogonal design to simulate 27 envelope configurations; (4) performing EnergyPlus simulations to estimate heating, cooling, and total energy demand; and (5) analyzing the results using analysis of variance (ANOVA), partial eta squared (η2), and economic feasibility via discounted payback period (DPP) calculations. The main outcome is a retrofit priority matrix tailored to each climate zone, providing practical guidance for scalable, cost-effective envelope retrofitting decisions in China’s diverse urban settings.

2. Materials and Methods

2.1. Research Framework

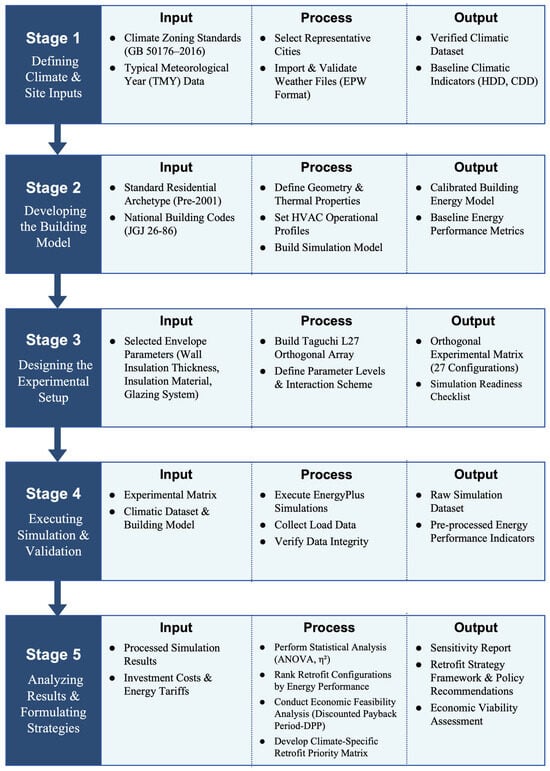

This study proposes a simulation-based framework to evaluate climate-adaptive energy retrofit strategies for aged residential buildings across China’s five climate zones. The framework consists of five sequential stages to ensure methodological rigor and replicability.

As illustrated in Figure 1, Stage 1 defines climatic and geographic inputs. Five representative cities—Harbin, Beijing, Shanghai, Guangzhou, and Kunming—were selected based on the GB 50176-2016 [13]. Typical meteorological year (TMY) datasets in EPW format were employed to represent local weather conditions, capturing heating and cooling degree days and other relevant climate variables.

Figure 1.

Simulation framework for evaluating climate-adaptive building envelope retrofits.

Stage 2 develops a standardized building archetype representing pre-2001 urban residential buildings in China. The model incorporates geometric features, thermal properties, and heating, ventilation, and air conditioning (HVAC) operational profiles in accordance with the General code for building energy efficiency and renewable energy utilization (GB 55015-2021) [32]. A calibrated building energy simulation software (EnergyPlus v24.1 (U.S. Department of Energy, Washington, DC, USA)) model was constructed as the baseline for retrofit evaluation.

Stage 3 the retrofit parameter space using a Taguchi L27 (33) orthogonal array, which systematically organizes the combinations of three envelope parameters—insulation thickness, insulation material, and glazing system—each at three levels. This approach results in 27 distinct, statistically balanced retrofit configurations, enabling clear and structured analysis of individual and interactive parameter effects within a unified experimental framework.

Stage 4 involves 135 EnergyPlus simulations—each configuration tested across five cities. Simulations reported annual heating, cooling, and total energy demand. Standardized assumptions ensured consistency across all cases.

Stage 5 integrates statistical and economic analyses. ANOVAs were used to quantify parameter sensitivity across climate zones. A discounted payback period (DPP) model was applied to assess the economic viability of optimal retrofit solutions, considering material costs and local electricity tariffs.

2.2. Climatic Zoning and Representative Cities

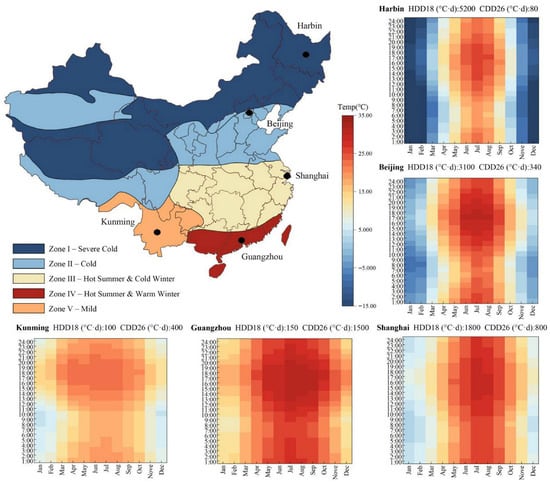

China exhibits substantial climatic diversity due to its vast geographic extent, spanning from subarctic latitudes in the northeast to tropical zones in the south. To adequately capture this range of environmental conditions in building energy analysis, the present study adopts the thermal zoning framework defined in the GB 50176-2016 [13].

This standard divides the country into five distinct thermal zones: Severe Cold, Cold, Hot Summer and Cold Winter, Hot Summer and Warm Winter, and Mild. These zones exhibit considerable variation in heating and cooling requirements due to differences in seasonal temperature, humidity, and solar radiation. As such, climate-responsive envelope retrofit strategies are essential, particularly for older buildings that were constructed without modern thermal design standards.

To represent each zone, one city was selected based on three criteria: climatic representativeness, availability of validated meteorological data, and practical relevance to residential retrofitting at the urban scale. The five cities chosen—Harbin, Beijing, Shanghai, Guangzhou, and Kunming—are widely recognized as benchmark locations for each thermal zone classification.

Hourly meteorological data were sourced from the EnergyPlus weather database in typical meteorological year (TMY) format (.epw), which represents a composite year of hourly weather data statistically selected to reflect average long-term climatic conditions for a specific location, including parameters such as dry-bulb temperature, relative humidity, solar radiation (direct and diffuse), and wind speed. To ensure consistency with national standards, the datasets used follow the Chinese Standard Weather Data (CSWD) format, compiled by the China Meteorological Administration and commonly adopted in building energy simulation across China. CSWD provides hourly meteorological records representative of the typical climatic conditions in major Chinese cities, facilitating standardized energy performance analysis [33].

An overview of the representative cities and their corresponding climate zones is shown in Figure 2. By simulating identical building configurations across these locations, this study enables robust cross-comparison of retrofit performance and supports both zone-specific design strategies and broader applicability.

Figure 2.

Climatic characteristics and thermal zone classification of selected representative cities.

2.3. Building Model Setup

The simulation model was created using SketchUp 2024 (Trimble Inc., Westminster, CO, USA) with the OpenStudio Plugin v1.8 (National Renewable Energy Laboratory, Golden, CO, USA) and simulated in EnergyPlus v24.1.

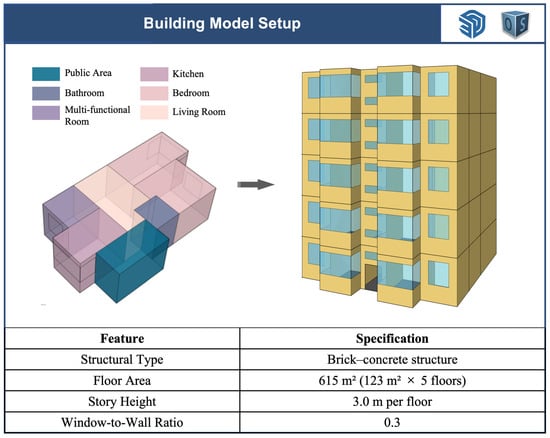

A single building archetype was chosen for simulation to ensure a consistent basis for cross-regional comparison and to reflect the most prevalent form of pre-2001 residential construction in Chinese cities. The year 2001 was chosen as a cutoff because before this date, most residential buildings in China were constructed without mandatory energy efficiency standards. Regional energy codes were only introduced in the late 1990s and early 2000s, making pre-2001 buildings a key target for retrofit due to their low thermal performance. This archetype—three to six stories, brick–concrete structure, no elevator, and no insulation—is the most prevalent form of urban residential building constructed between 1980 and 2001 [34]. These buildings have low thermal performance due to the absence of insulation and outdated glazing systems and continue to dominate a large share of the existing building stock in Chinese cities [34].

Each floor contains two residential units, resulting in a total of ten dwelling units. Every unit is subdivided into five functional thermal zones: living room, bedroom, kitchen, bathroom, and multi-functional room and public area. This leads to a total of 55 thermal zones in the building. The spatial division closely mirrors real-world residential layouts and enables differentiated modeling of occupancy, internal heat gains, and envelope exposure across functional spaces.

The external envelope is based on construction practices common before 2001. Exterior walls consist of 240 mm solid clay brick, finished with internal plaster and external cement mortar, with no insulation in the base case. Roof and ground floor structures are modeled as uninsulated reinforced concrete slabs. Windows in each dwelling have a uniform window-to-wall ratio (WWR) of 0.3, reflecting typical daylighting design and fenestration proportions in legacy buildings.

Thermal properties of all construction materials—including thermal conductivity and standard U-values—are derived from GB 50176-2016 [13]. This national standard provides normative data for common building materials and assemblies, ensuring consistency with domestic design and simulation conventions.

A summary of the building configuration and thermal zones is shown in Figure 3, and the construction materials of envelope components are provided in Table 1 and Table 2.

Figure 3.

Building configuration and thermal zones.

Table 1.

Wall, floor, and roof construction materials of sample building.

Table 2.

Window construction material of sample building.

2.4. Envelope Parameterization and L27 Design

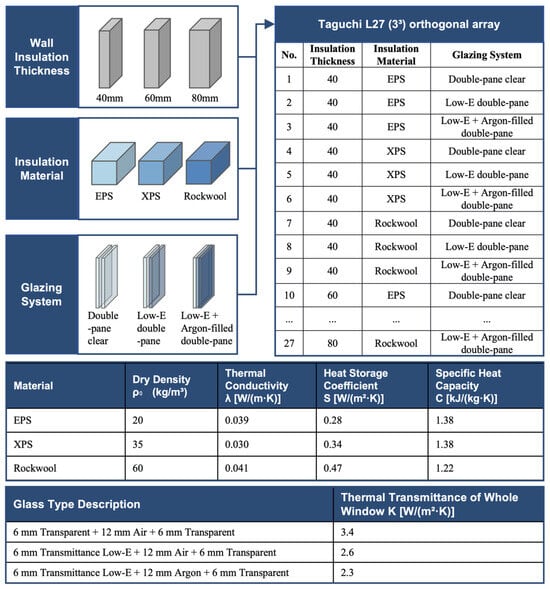

To systematically assess the influence of envelope upgrades on building energy performance, three key parameters were selected: wall insulation thickness, insulation material type, and glazing system. These variables were identified based on their demonstrated impact on thermal resistance, solar heat gain, and practical retrofit feasibility, as supported by prior studies and construction practice in China [35,36,37].

Each parameter was assigned three discrete levels, representing common retrofit options. Insulation thickness values were set at 40 mm, 60 mm, and 80 mm, corresponding to light, moderate, and intensive interventions. The insulation materials selected included expanded polystyrene (EPS), extruded polystyrene (XPS), and rockwool, offering a range of thermal conductivities and installation characteristics. Glazing systems consisted of standard double-pane clear glass, Low-E coated double-pane glass, and Low-E double-pane glass filled with argon gas, with performance defined by variations in thermal transmittance of the whole window.

To systematically evaluate the combined effects of key envelope parameters, this study employs a Taguchi L27 orthogonal array. This approach generates 27 retrofit configurations that are statistically balanced and mutually orthogonal, ensuring that each parameter’s effect can be independently assessed [38].

The application of the Taguchi method in this context is a key methodological innovation of this study. While Taguchi designs have been widely used in manufacturing and engineering optimization, their integration into climate-responsive building energy retrofit research remains limited [39,40,41]. The structured nature of the Taguchi L27 array enables clear identification and ranking of the influence of insulation thickness, insulation material, and glazing system within a unified experimental framework. By applying the same parameter matrix across five different climate zones, the method ensures the consistency and comparability of results, supporting robust cross-regional analysis. This design also provides a solid statistical foundation for ANOVA-based sensitivity analysis, making it possible to quantify the relative importance of each parameter in different climatic contexts. The Taguchi L27 framework further offers methodological scalability, as it can be readily adapted for future studies that might consider additional variables or expanded parameter levels.

An overview of the parameter levels and the structure of the experimental design is illustrated in Figure 4. This method can conduct a strict evaluation of the transformation strategy under different climatic conditions.

Figure 4.

Retrofit parameter levels and Taguchi L27 experimental design.

2.5. Simulation Setup

Energy simulations were conducted to evaluate the annual heating load, cooling load, and total energy demand associated with each retrofit configuration across five representative climate zones in China. A standardized simulation protocol was implemented to ensure methodological consistency and cross-scenario comparability. This allowed for a focused assessment of envelope parameter impacts while minimizing confounding influences from operational or behavioral variations [42].

All simulations were conducted using EnergyPlus v24.1 with standardized assumptions following GB 55015-2021 [32]. Weather data for five representative cities were sourced from official TMY .epw files. Indoor conditions were modeled using the Ideal Air Loads system, with a 15 min time step to capture short-term load variations. Temperature setpoints were fixed at 18 °C (heating) and 26 °C (cooling). Outputs included annual heating, cooling, and total energy demand. A summary of the simulation assumptions is provided in Table 3.

Table 3.

A summary of the simulation assumptions.

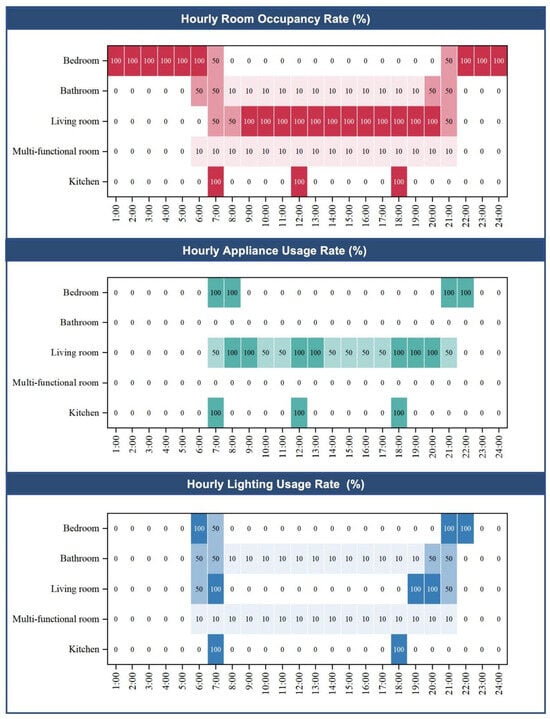

The internal gain schedules were modeled with hourly resolution, distinguishing between room functions and diurnal patterns. Figure 5 illustrates the typical hourly distributions of room occupancy rate, appliance usage rate, and lighting usage rate, which were applied uniformly to all zones within each residential unit. All internal load settings were specified based on the national standard GB 55015-2021 [32].

Figure 5.

Typical hourly distributions of room occupancy rate, appliance usage rate, and lighting usage rate.

This uniform simulation framework ensures that any observed performance differences across configurations and climate zones are directly attributable to variations in envelope design, thus supporting valid cross-comparative analysis and robust interpretation.

2.6. Performance and Economic Analysis Methods

2.6.1. Statistical Analysis

Statistical analysis was conducted using IBM SPSS Statistics 27 to evaluate the influence of envelope retrofit parameters on building energy performance across five climate zones. The analysis included four steps:

First, descriptive statistics summarized energy consumption patterns for heating, cooling, and total energy loads across all retrofit levels. Second, one-way analysis of variance (ANOVA) was used to test whether each parameter—insulation thickness, insulation material, and glazing system—had a statistically significant impact, with p < 0.05 indicating significance. Third, partial eta squared (η2) values, which represent the proportion of total variance attributable to a specific factor in ANOVA, were calculated to quantify effect sizes and rank the relative sensitivity of each parameter. Fourth, a two-way factorial ANOVA was performed to detect interaction effects among the three retrofit variables. This step enabled the identification of two-way and three-way interactions, revealing whether the influence of one parameter was dependent on the level of another. This extended analysis improves understanding of combined retrofit effects and informs more realistic multi-measure planning.

This structured approach enabled the identification and prioritization of key retrofit parameters with respect to heating, cooling, and total energy loads. The statistical methods and corresponding output metrics are summarized in Table 4.

Table 4.

Overview of statistical analysis methods.

2.6.2. Economic Analysis

To assess the economic viability of the optimal envelope retrofit strategies, this study adopts the discounted payback period (DPP) method, accounting for the time value of money. The DPP measures the number of years required for the present value of cumulative energy cost savings to equal or exceed the initial retrofit investment, using a constant annual discount rate.

where

= Annual energy cost savings in year t, assumed constant;

= Annual discount rate, set at 5%;

= Total upfront investment;

= Number of years required for cumulative discounted savings to match or exceed the investment.

The 5% discount rate is selected based on government-endorsed guidance for public sector energy efficiency projects in China. Specifically, the guidance recommends using a 5% real discount rate for retrofit feasibility evaluations under stable inflation conditions.

The analysis considered two cost components: external wall insulation and glazing system upgrades. Investment costs were based on 2024 Chinese market prices, with unit prices of 120 CNY/m2 for 80 mm extruded polystyrene (XPS) insulation, 75 CNY/m2 for 40 mm expanded polystyrene (EPS), and 250 CNY/m2 for Low-E argon-filled double-pane glazing (including frames and installation). The assumed retrofit areas were 687 m2 for external walls and 187 m2 for windows, reflecting typical mid-rise residential buildings constructed before national energy codes.

Annual energy cost savings were derived from the simulated annual energy savings in each city, multiplied by local tier-1 residential electricity tariffs: Harbin (0.5250 CNY/kWh), Beijing (0.4883), Shanghai (0.6170), Guangzhou (0.5890), and Kunming (0.3600) [43,44,45,46,47]. The DPP was calculated for the optimal retrofit configuration in each city.

3. Results

3.1. Statistical Description of Energy Performance

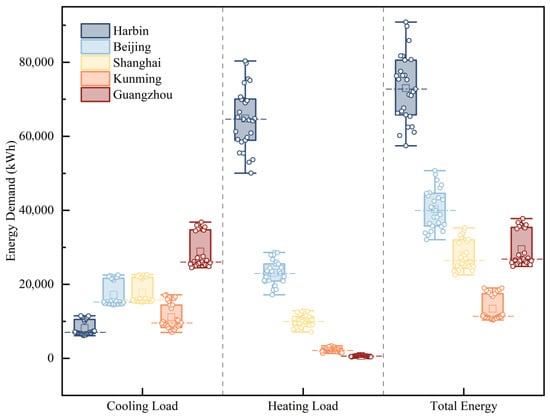

Figure 6 illustrates the distribution of total annual energy demand across 27 retrofit configurations in five cities, constructed via the Taguchi L27 orthogonal matrix. Harbin records the highest baseline energy demand at 185,365 kWh, followed by Beijing (93,396 kWh), Shanghai (58,703 kWh), Guangzhou (48,497 kWh), and Kunming (17,928 kWh). The interquartile ranges in Figure 6 indicate considerable dispersion in colder climates: Harbin’s demand spans a 33,435 kWh gap between maximum and minimum values, and its standard deviation exceeds 10,500 kWh—the highest among all cities.

Figure 6.

Descriptive statistics of annual energy demand across five cities.

This variation reflects climate-driven retrofit sensitivity. In severe cold zones like Harbin and Beijing, envelope retrofits—especially thick insulation and high-performance glazing—substantially mitigate heating loads, leading to larger variance across retrofit cases. Shanghai, representing a transitional climate, shows moderate variability (standard deviation: 4457 kWh), reflecting dual sensitivity to heating and cooling loads. Guangzhou and Kunming show lower dispersion (SD: 3598 and 2336 kWh, respectively), as their energy use is dominated by cooling or remains low overall.

These results suggest that thermal climate severity governs both the potential impact and variability of retrofit strategies. In colder regions, retrofit decisions significantly influence energy outcomes, justifying more aggressive or layered upgrades. In milder zones, performance gains are smaller, indicating a need for more selective, cost-conscious strategies. This performance landscape provides a quantitative foundation for optimal design selection, discussed next. Detailed energy performance data for all configurations are provided in the Table A1, Table A2, Table A3, Table A4 and Table A5.

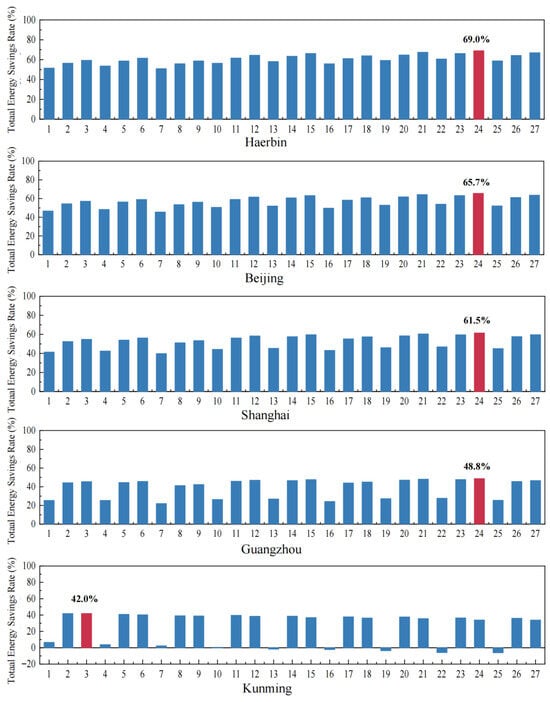

3.2. Comparison of Optimal Retrofit Configurations

Figure 7 compares the optimal configuration—defined as the lowest energy demand scenario from the L27 matrix—for each city. For Harbin, Beijing, Shanghai, and Guangzhou, the same configuration (No. 24) was most effective, yielding energy demands of 57,441, 32,067, 22,577, and 24,852 kWh, respectively. Compared to their baselines, these values represent relative savings of 69.0%, 65.7%, 61.5%, and 48.8%. Kunming, in contrast, achieved its lowest energy use (10,396 kWh) using Configuration No. 3, a lighter intervention, saving 42.0%.

Figure 7.

Total energy saving rate across five cities.

The shared success of Configuration No. 24—combining 80 mm XPS insulation with argon-filled Low-E double glazing—demonstrates the effectiveness of high-resistance, low-transmittance systems in both heating- and cooling-dominated climates. The fact that this design consistently outperforms others across disparate climates highlights its thermal and optical adaptability. Kunming’s deviation underscores the principle of diminishing returns in mild zones, where modest insulation (40 mm EPS) suffices and further envelope enhancements yield negligible gains.

While a high-performance retrofit shows cross-climate robustness, the Kunming case validates the need for climate-calibrated configurations. Over-specifying retrofits in mild zones may reduce cost-efficiency and user acceptance. Thus, universal retrofit strategies must be tempered with region-specific tailoring, particularly when policy and budget constraints are considered.

3.3. Statistical Analysis of Envelope Parameters

3.3.1. One-Way ANOVA Results

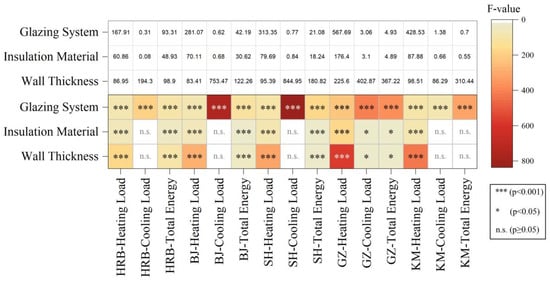

To statistically evaluate the impact of various envelope parameters on energy performance, one-way ANOVA tests were performed for each city, assessing the effects of wall insulation thickness, insulation material, and glazing system on annual heating load, cooling load, and total energy consumption. Figure 8 summarizes the resulting F-values, p-values, and statistical significance across all cases.

Figure 8.

ANOVA results for envelope parameters by city and energy type.

The results indicate strong and consistent significance patterns for heating load across all climate zones. In Harbin, Beijing, and Shanghai—cities characterized by dominant heating demand—all three envelope parameters showed statistically significant effects (p < 0.001) on heating load. Wall insulation thickness, in particular, yielded exceptionally high F-values, such as 313.35 in Shanghai and 428.53 in Kunming, underscoring its pivotal role in enhancing thermal resistance.

In contrast, cooling load exhibited a more selective sensitivity to envelope retrofit parameters. Across all five cities, the glazing system was highly significant (p < 0.001), especially in climates with substantial cooling demand. Notably, the F-values for glazing exceeded 750 in Beijing, 844.95 in Shanghai, and 402.87 in Guangzhou, confirming its dominant contribution to cooling energy reduction. By comparison, wall insulation thickness and insulation material had no statistically significant effect on cooling load in Harbin, Beijing, Shanghai, or Kunming (p > 0.05). Only in Guangzhou—where cooling demand prevails year-round—did both insulation-related variables reach marginal significance (p ≈ 0.045–0.047), though their F-values remained low (<5).

Total energy demand reflected the integrated effects of both heating and cooling loads. In colder cities such as Harbin and Beijing, all three parameters significantly influenced total energy use (p < 0.001). Shanghai exhibited a similar pattern, with the glazing system again showing a substantial impact (F = 180.82). In Guangzhou, all parameters were statistically significant (p < 0.01), although the glazing system remained the most influential (F = 367.22). Interestingly, in Kunming, only the glazing system showed a significant effect on total energy (F = 310.44, p < 0.001), while wall insulation thickness and insulation material were not significant (p > 0.5). This indicates that in temperate climates, solar gain control via glazing systems is the dominant factor influencing energy efficiency.

These findings reinforce the climatic dependency of retrofit effectiveness. wall insulation thickness plays a critical role in heating-dominated regions, while glazing systems are universally significant—particularly for cooling performance and total energy reduction. Insulation material demonstrates moderate but consistent significance in colder climates, with diminishing impact in milder or hot humid environments.

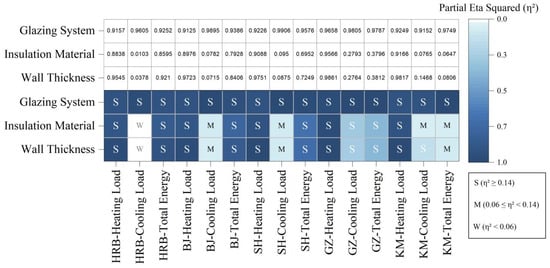

3.3.2. Sensitivity Based on Effect Size (η2)

To complement the significance testing results, a sensitivity analysis using partial eta squared (η2) was conducted to quantify the proportion of variance in energy performance attributable to each envelope parameter. This approach enables a direct comparison of effect sizes, clarifying which retrofit measures exert the strongest influence in various climatic contexts [48].

As shown in Figure 9, in severely cold climates such as Harbin and Beijing, all three envelope parameters demonstrated strong sensitivity (η2 > 0.85) with respect to both heating load and total energy demand. Wall insulation thickness had the greatest effect in these regions (η2 = 0.9545 for Harbin and 0.9723 for Beijing), highlighting its critical role in minimizing heat loss during prolonged winters. Insulation material and glazing systems also yielded η2 values above 0.88, reflecting their strong and comparable influence on heating energy performance.

Figure 9.

Effect size (η2) of envelope parameters across cities and energy types.

Regarding cooling load, insulation-related parameters had limited influence. In Harbin and Shanghai, wall insulation thickness and insulation material exhibited weak or moderate η2 values (typically < 0.10). However, exceptions were noted in Guangzhou and Kunming, where cooling demand is more prominent. In Guangzhou, all three parameters showed strong sensitivity to cooling load (η2 > 0.27), while in Kunming, wall insulation thickness achieved a strong effect (η2 = 0.1468) and insulation material a moderate one (η2 = 0.0765).

The glazing system, by contrast, emerged as the most consistently impactful variable across all cities and energy indicators. It produced strong effect sizes for both cooling load and total energy demand in nearly every climate zone. In Shanghai, Guangzhou, and Kunming, the η2 values for glazing on cooling load exceeded 0.90, confirming the central role of solar heat gain control in warm climates. Even in heating-dominated cities like Beijing, the η2 values for glazing reached 0.9895 for cooling load and 0.9386 for total energy, reinforcing its year-round influence.

In temperate climates such as Kunming, while heating load remained highly sensitive to all parameters (η2 > 0.91), total energy demand displayed only moderate sensitivity to wall insulation thickness (η2 = 0.0806) and insulation material (η2 = 0.0647), suggesting that thermal mass and glazing-related solar gain management are more decisive in such settings.

In summary, the results of the η2-based sensitivity analysis underscore the critical role of wall insulation thickness in heating-dominated climates, where it exerts the strongest influence on both heating load and total energy demand. Meanwhile, glazing systems emerge as the most consistently impactful parameter across all climate zones, particularly for reducing cooling loads and overall energy use. Although insulation material demonstrates a secondary level of influence, its effect remains significant in colder regions and gradually diminishes in temperate and cooling-dominated environments.

These insights further emphasize the importance of climate-specific retrofit prioritization. In cold regions, insulation-focused measures are essential, whereas in hot or transitional climates, improving glazing performance should take precedence to maximize energy efficiency.

3.3.3. Two-Way Interaction Effects

To further investigate whether combinations of envelope retrofit parameters exert synergistic or antagonistic effects on building energy performance, a series of two-way factorial ANOVAs were conducted. Specifically, the interaction effects between insulation thickness and insulation material, insulation thickness and glazing system, and insulation material and glazing system were tested for each of the five representative climate zones. For each interaction pair, the dependent variables included annual heating load, cooling load, and total energy demand.

In Table A6, the results show that for Harbin, Beijing, Shanghai, and Guangzhou, none of the interaction terms were statistically significant (p ≥ 0.05). This indicates that the impact of each parameter on energy performance is additive and independent in these cities, with no evidence of synergistic or offsetting effects when parameters are combined. In practical terms, this finding implies that building envelope retrofits in most Chinese climate zones can be optimized on a per-parameter basis, simplifying both technical evaluation and implementation planning. Retrofit strategies can be prioritized based on individual parameter sensitivity without requiring elaborate coordination between insulation and glazing upgrades.

An exception was observed in Kunming, a city with a mild, transitional climate. Here, the interaction between insulation thickness and glazing system showed marginal statistical significance for total energy demand (F = 3.55, p = 0.0266). This suggests that in such climates, combined effects of envelope parameters may be more pronounced due to a balance of both heating and cooling needs. Nevertheless, this isolated result does not substantially alter the broader conclusion that retrofit parameters largely operate independently across China’s diverse climatic regions.

Overall, the absence of strong interaction effects supports a modular and scalable approach to retrofit decision-making, in which insulation and glazing improvements can be assessed and deployed independently according to context-specific priorities and constraints.

3.4. Economic Feasibility Assessment

To assess the economic feasibility of optimal building envelope retrofitting strategies across various climate zones, a discounted payback period (DPP) analysis was performed using simulated annual energy savings and 2024 market prices in China. The assessment was based on a typical residential building with 687 m2 of external wall area and 187 m2 of window area.

The investment costs comprised two primary components: external wall insulation and glazing system upgrades. For insulation, the unit costs (materials plus installation) were set at 120 CNY/m2 for 80 mm extruded polystyrene (XPS) and 75 CNY/m2 for 40 mm expanded polystyrene (EPS). High-performance glazing (Low-E, argon-filled double-pane) was priced at 250 CNY/m2, including frames and installation [49]. Annual energy cost savings were estimated based on 2024 tier-1 residential electricity tariffs specific to each city: Harbin (0.5250 CNY/kWh), Beijing (0.4883), Shanghai (0.6170), Guangzhou (0.5890), and Kunming (0.3600). Table 5 summarizes annual energy savings, retrofit costs, cost savings, and resulting DPP values for each city.

Table 5.

Economic feasibility of optimal retrofit configurations.

The analysis reveals that envelope retrofits in colder climates offer clear economic advantages when evaluated using the discounted payback period (DPP). In Harbin, the DPP is just 2.07 years, owing to substantial heating demand and high annual energy savings. Beijing also demonstrates favorable results, with a DPP of 4.98 years, while Shanghai’s DPP of 7.01 years remains acceptable given its balanced profile of heating and cooling loads. In contrast, Guangzhou—where cooling demand dominates—shows a notably longer DPP of 12.77 years, indicating lower economic returns on investment. Kunming, which features a mild climate and minimal baseline energy demand, exhibits a DPP greater than 50 years, suggesting that comprehensive envelope retrofits are not financially viable in such regions.

These findings highlight the necessity of climate-adaptive investment strategies. In severe cold and cold zones, large-scale envelope retrofitting is both energy-efficient and economically justified. However, in milder climates, retrofit efforts should focus on cost-effective or comfort-oriented measures, unless additional benefits—such as government incentives, carbon reduction, or improved occupant health—justify more extensive implementation.

4. Discussion

4.1. Explanation of Climatic Differences

Simulation results across the five representative cities—Harbin, Beijing, Shanghai, Guangzhou, and Kunming—demonstrate pronounced variation in total annual energy demand and retrofit parameter sensitivity, shaped by distinct climatic conditions. In Harbin, heating loads exceed 80,000 kWh annually, with wall insulation showing the strongest effect on heating demand (η2 = 0.9545) and total energy use (η2 = 0.921), followed closely by glazing (η2 = 0.9252). Conversely, Guangzhou, located in a hot humid zone, is dominated by cooling loads, where glazing upgrades contribute the most significant savings (η2 > 0.98), while insulation exhibits limited impact (η2 = 0.3812).

These differences are primarily governed by the thermal gradient intensity and seasonal load dominance. In severely cold climates like Harbin, extended heating periods intensify conductive losses through opaque envelope components, making thicker insulation essential. Nighttime radiative losses also elevate the value of low-emissivity glazing. In Beijing, although current heating patterns are similar, future projections suggest a transition toward cooling-dominated energy profiles, with the proportion of cooling demand in residential buildings expected to rise from 14% to 20% by 2060 [50]. This elevates the importance of dual-season strategies, combining insulation with solar gain control.

In transitional climates such as Shanghai, the heating–cooling balance requires optimized trade-offs. While wall insulation loses effectiveness beyond 60 mm, glazing improvements remain impactful, especially Low-E with argon fill (η2 = 0.9906 for cooling; 0.9576 for total energy). In Kunming, characterized by mild year-round temperatures, overall energy loads are low. However, glazing still provides measurable benefits (η2 > 0.97) due to solar exposure, though insulation delivers diminishing returns.

These climate-specific response patterns suggest that retrofit priorities must be calibrated to regional thermal conditions. Cold zones warrant envelope thickening; hot climates benefit more from solar control; mild regions require cost-efficient moderation. Furthermore, anticipated climatic warming—particularly in Beijing and Shanghai—calls for future-proofing retrofit strategies, ensuring that current interventions remain effective under shifting thermal demands. This points to a broader need for integrated climate forecasting within retrofit decision-making frameworks, aligning building upgrades with long-term environmental resilience.

4.2. Influence of Envelope Parameters

Statistical analysis across 27 retrofit configurations reveals distinct patterns in parameter sensitivity depending on climate zone. In Harbin and Beijing, located in cold and severe cold regions, wall insulation thickness demonstrates the highest effect size, with η2 > 0.95 for both heating and total energy demand. In contrast, its impact drops sharply in Guangzhou (η2 = 0.3812) and Kunming (η2 = 0.0806), where cooling dominates or thermal gradients are minimal. Insulation material follows similar trends: moderately influential in cold zones (η2 ≈ 0.88–0.90), but negligible in mild climates (η2 = 0.0647 in Kunming). Glazing systems show broad effectiveness, with η2 values exceeding 0.98 for cooling in Shanghai and Guangzhou, remaining above 0.91 even in colder climates.

These trends reflect how retrofit components address climate-specific thermal challenges. In heating-dominated regions, thicker insulation minimizes conductive losses during prolonged winters, explaining its leading role. Insulation material conductivity further refines this effect, though its marginal gains decrease under lower thermal stress. In contrast, glazing plays a dual role: reducing solar heat gain via low solar heat gain coefficient (SHGC) coatings in hot climates and minimizing radiant heat loss through low U-value windows in colder ones. In transitional climates like Shanghai, both mechanisms operate simultaneously, enhancing glazing’s influence. Importantly, a diminishing return threshold is observed—extending insulation beyond 60 mm delivers <5% incremental savings, suggesting a saturation point in thermal resistance benefits.

These results reinforce the need for climate-adaptive envelope strategies. In cold zones, insulation remains foundational but should be optimized around cost-effective thresholds. In hot or transitional climates, glazing becomes the dominant upgrade, offering greater flexibility and impact. Insulation material selection holds value primarily in sub-zero environments, and its influence is marginal elsewhere. Additionally, combinatory strategies—such as moderate insulation paired with advanced glazing—outperform single-measure interventions in mixed climates. Effective retrofit planning must therefore move beyond one-size-fits-all prescriptions, integrating climate-specific parameter hierarchies and interaction synergies to guide cost-efficient and thermally robust solutions.

4.3. Regional Retrofit Recommendations

Sensitivity analysis across five representative Chinese cities highlights the need for climate-adaptive retrofit strategies. Table 6 presents a retrofit priority matrix, ranking the influence of wall insulation thickness, insulation material, and glazing systems based on η2 values for heating, cooling, and total energy demands in each climate zone, as defined by GB 50176-2016. For example, in Harbin (Severe Cold zone), wall insulation thickness exhibits the highest impact (η2 = 0.9545), while in Guangzhou (Hot Summer–Warm Winter), glazing systems dominate (η2 > 0.98) and insulation has minimal effect (η2 = 0.3812). Kunming (Mild zone) shows limited thermal load sensitivity overall, with glazing as the only parameter with substantial impact (η2 = 0.9749).

Table 6.

Climate-specific retrofit priority matrix.

These variations are rooted in the interplay between regional thermal loads and retrofit component behavior. In heating-dominated climates like Harbin and Beijing, conductive heat loss through opaque envelopes dominates, making thick insulation essential. In contrast, in southern cities such as Guangzhou and Shanghai, solar heat gain through fenestration becomes the critical factor, explaining the high effectiveness of low-emissivity, low-SHGC glazing. In mild climates, where annual thermal gradients are narrow, passive systems—such as natural ventilation and external shading—offer better cost/performance ratios than intensive envelope upgrades.

As summarized in Table 5, retrofit strategies should be tailored to local climatic and operational conditions. In Harbin, ≥80 mm XPS or rockwool insulation paired with high-performance multi-pane glazing is recommended. Beijing requires dual-season measures integrating insulation and low-E glazing. Shanghai benefits most from argon-filled low-E glass, with moderate insulation (60 mm) sufficing. Guangzhou should focus on solar control and airtight window systems, while Kunming is best served by passive solutions rather than thermal envelope enhancement.

Although configuration No. 24—combining the most advanced insulation and glazing measures—consistently yields the highest energy savings in most cities, a uniform application of this solution across all climate zones is not advisable. Statistical analyses demonstrate that the marginal gains of intensive envelope retrofits diminish substantially in milder climates, as evidenced by increased payback periods and lower cost-effectiveness. In regions with mild climates such as Kunming, retrofit measures should focus on targeted, economically viable interventions, including selective glazing upgrades, external shading devices, and improvements in natural ventilation, rather than comprehensive envelope renovation. Retrofit decision-making should be informed by a holistic assessment of climatic context, economic constraints, and user requirements, as opposed to a one-size-fits-all approach.

Real-world feasibility must also be considered. In less-developed or mountainous areas like Kunming, access to high-performance materials or skilled labor may be limited, reinforcing the relevance of low-cost, low-tech alternatives. Moreover, the findings suggest a disconnect between existing codes—such as GB 55015-2021 [32] and GB 50176-2016 [13]—and actual climatic performance. These codes impose uniform envelope requirements, potentially leading to overdesign in mild zones or insufficient protection in severe climates. A zonal-responsive update to retrofit standards is therefore recommended to maximize energy and cost efficiency.

In summary, this retrofit matrix provides a quantitative, evidence-based decision framework for regional envelope upgrade strategies, integrating climatic sensitivity, retrofit effectiveness, and implementation feasibility. It can inform national policy development, local retrofit planning, and support the design of future zoning-specific building energy standards.

4.4. Implications for Design and Policy

This study offers actionable insights for envelope design and retrofit policymaking across diverse climate regions in China. By quantifying the climate-specific sensitivity of key envelope parameters, the results support a shift toward performance-oriented, regionally differentiated retrofit strategies.

From a design perspective, interventions should align with both thermal demand intensity and performance–cost efficiency. In Harbin, where heating loads are dominant, ≥80 mm of XPS or rockwool insulation combined with multi-pane Low-E glazing demonstrates significant energy savings. In Shanghai, Low-E argon-filled glazing paired with ≤60 mm insulation achieves optimal performance with economic viability. In Guangzhou, solar control glazing alone yields the highest energy savings, while wall insulation offers limited additional benefit. In Kunming, with minimal thermal loads, passive strategies such as shading devices and operable windows are preferable.

Envelope upgrades can also yield co-benefits for occupant health. By improving thermal stability and reducing solar heat gain, such strategies mitigate indoor overheating risks, especially for vulnerable populations during summer heatwaves [51].

On the policy side, the findings support differentiated technical pathways. A regionally adaptive approach to retrofitting allows for more precise alignment of thermal performance goals with real-world climatic demands. For instance, glazing subsidies in cooling-dominated areas and insulation support in heating-intensive regions can enhance the effectiveness of programs such as the Green Building Action Plan [48], ensuring equitable resource allocation and measurable impact.

Moreover, this framework can serve as a foundation for targeted retrofit incentive schemes that maximize return on investment. By linking simulation-based parameter sensitivity (e.g., η2 values) with implementation priorities, policymakers can better support projects that combine environmental benefit with technical feasibility.

4.5. Comparison with Prior Research, Innovations, and Limitations

Earlier Taguchi-based retrofit studies have been limited to one climate or a single building type [27,28], have stopped at signal-to-noise charts rather than reporting statistical effect sizes [10], or have explored cost and future weather in isolation [30]. Building on these gaps, our work (i) applies one Taguchi L27 array across five Chinese climate zones, giving a transferable “one-matrix-many-zones” approach that studies insulation thickness, material and glazing together, something missing from previous single-zone papers [29,52]; (ii) uses two-way ANOVA with partial eta squared to rank both main and interaction effects, providing the first cross-climate hierarchy of envelope parameters and addressing the absence of η2 in earlier research [15,17]; and (iii) converts those statistics into a climate-specific retrofit priority matrix that links technical influence to simple payback guidance—bridging the long-noted gap between energy modelling and investment advice [53]. In addition, constructability constraints and occupant acceptability are folded into the recommendations, moving beyond purely theoretical optimization [36].

This study still has several weaknesses. First, it relies on typical-year weather files, so it cannot capture how retrofit priorities might shift under future climate scenarios. Second, the use of an Ideal Air Loads HVAC model replaces real plant dynamics, which may lead to over- or under-estimation of cooling penalties in certain zones. Third, the economic analysis is limited to discounted payback and does not include full life-cycle costing or account for investment risk from price fluctuations [54]. Fourth, occupant behavior is represented only by standard schedules; adopting richer, stochastic behavior models could alter interaction effects and η2 values. Finally, the simulations are based on a single residential archetype. While this archetype is widely representative of pre-2001 construction, it may not fully capture the diversity of building forms, envelope details, or renovation histories present across all regions. Addressing these issues—by coupling the framework with future weather data, more detailed cost models, stochastic user patterns, and multiple building types—should be a priority for future research.

5. Conclusions

This study developed a climate-responsive simulation framework to evaluate envelope retrofit strategies for aged residential buildings across China’s five major climate zones. Based on a standardized model, 27 retrofit configurations were tested using a Taguchi L27 orthogonal array and EnergyPlus simulations. Three key envelope parameters—insulation thickness, insulation material, and glazing system—were assessed through analysis of variance (ANOVA) and partial eta squared (η2), enabling a rigorous quantification of their relative influence across climates.

Results revealed clear climate-specific trends in retrofit performance. In heating-dominated cities such as Harbin and Beijing, insulation thickness was the most influential factor (η2 > 0.95), while in cooling-dominated and transitional zones like Guangzhou and Shanghai, glazing systems—particularly Low-E argon-filled double glazing—had the highest impact (η2 > 0.97). Two-way factorial analysis of variance showed that interaction effects between envelope parameters were statistically insignificant (p ≥ 0.05) in Harbin, Beijing, Shanghai, and Guangzhou, indicating that insulation and glazing act independently in most regions and supporting modular retrofit planning. Only in Kunming, a mild transitional city, did a marginal interaction emerge, reflecting dual heating–cooling demands. The observed diminishing returns and extended payback periods for intensive retrofits in mild climates highlight the necessity for differentiated, climate-specific approaches. Economic analysis using the discounted payback period (DPP) revealed promising returns in colder zones (2.07–7.01 years), but limited economic viability in milder climates such as Guangzhou (12.77 years) and Kunming (DPP > 50 years). Consequently, the application of highly protective envelope retrofits should be prioritized in severe and cold zones, while targeted, cost-effective measures are recommended for mild regions.

In sum, this study presents a scalable and transferable framework that supports independent, performance-based envelope optimization. The findings reinforce the value of regionally adaptive retrofit strategies and provide a quantitative basis for evidence-based policy and design. Future research should incorporate life-cycle assessment, climate change projections, and field validation to enhance policy relevance and real-world applicability.

Author Contributions

Conceptualization, P.G.; methodology, P.G.; software, P.G.; validation, P.G. and M.F.I.M.N.; formal analysis, P.G.; investigation, P.G.; resources, P.G.; data curation, P.G.; writing—original draft preparation, P.G.; writing—review and editing, M.F.I.M.N.; visualization, P.G.; supervision, M.F.I.M.N.; project administration, P.G.; funding acquisition, M.F.I.M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to express their sincere gratitude to Universiti Kebangsaan Malaysia (UKM) for providing the academic environment and resources that supported the completion of this research. Special thanks are extended to the anonymous reviewers for their insightful comments and constructive suggestions, which helped improve the quality of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HRB | Harbin |

| BJ | Beijing |

| SH | Shanghai |

| GZ | Guangzhou |

| KM | Kunming |

| EPS | Expanded Polystyrene |

| XPS | Extruded Polystyrene |

| η2 | Partial Eta Squared |

| ANOVA | Analysis of Variance |

| DPP | Discounted Payback Period |

| TMY | Typical Meteorological Year |

| CSWD | Chinese Standard Weather Data |

| HVAC | Heating, Ventilation, and Air Conditioning |

| SHGC | Solar Heat Gain Coefficient |

| U-value | Thermal Transmittance (U-value) |

| GB | Guobiao (Chinese National Standard) |

Appendix A

Table A1.

Simulation results for Harbin (Severe Cold zone).

Table A1.

Simulation results for Harbin (Severe Cold zone).

| No. | A: Wall Insulation Thickness (mm) | B: Insulation Material | C: Glazing System | Heating Load (kWh) | Cooling Load (kWh) | Total Energy (kWh) |

|---|---|---|---|---|---|---|

| 0 | 0 | None | Single-pane clear | 177,960.39 | 7404.38 | 185,364.77 |

| 1 | 40 | EPS | Double-pane clear | 79,767.71 | 9975.16 | 89,742.86 |

| 2 | 40 | EPS | Low-E double-pane | 74,461.28 | 6135.87 | 80,597.14 |

| 3 | 40 | EPS | Low-E + Argon-filled double-pane | 69,020.47 | 6294.44 | 75,314.91 |

| 4 | 40 | XPS | Double-pane clear | 75,495.52 | 10,375.68 | 85,871.21 |

| 5 | 40 | XPS | Low-E double-pane | 70,083.69 | 6405.13 | 76,488.82 |

| 6 | 40 | XPS | Low-E + Argon-filled double-pane | 64,632.96 | 6596.20 | 71,229.16 |

| 7 | 40 | Rockwool | Double-pane clear | 80,356.00 | 10,519.95 | 90,875.95 |

| 8 | 40 | Rockwool | Low-E double-pane | 75,095.47 | 6582.69 | 81,678.16 |

| 9 | 40 | Rockwool | Low-E + Argon-filled double-pane | 69,667.57 | 6756.64 | 76,424.21 |

| 10 | 60 | EPS | Double-pane clear | 69,959.24 | 10,767.09 | 80,726.32 |

| 11 | 60 | EPS | Low-E double-pane | 64,405.21 | 6628.78 | 71,033.99 |

| 12 | 60 | EPS | Low-E + Argon-filled double-pane | 58,945.07 | 6863.39 | 65,808.46 |

| 13 | 60 | XPS | Double-pane clear | 66,524.88 | 11,038.48 | 77,563.35 |

| 14 | 60 | XPS | Low-E double-pane | 60,879.23 | 6793.25 | 67,672.48 |

| 15 | 60 | XPS | Low-E + Argon-filled double-pane | 55,418.74 | 7061.80 | 62,480.55 |

| 16 | 60 | Rockwool | Double-pane clear | 70,637.38 | 11,106.18 | 81,743.57 |

| 17 | 60 | Rockwool | Low-E double-pane | 65,133.47 | 6890.54 | 72,024.00 |

| 18 | 60 | Rockwool | Low-E + Argon-filled double-pane | 59,683.33 | 6890.54 | 66,815.42 |

| 19 | 80 | EPS | Double-pane clear | 64,173.12 | 11,239.31 | 75,412.43 |

| 20 | 80 | EPS | Low-E double-pane | 58,459.89 | 6914.87 | 65,374.75 |

| 21 | 80 | EPS | Low-E + Argon-filled double-pane | 53,000.92 | 7209.18 | 60,210.11 |

| 22 | 80 | XPS | Double-pane clear | 61,292.44 | 11,477.71 | 72,770.15 |

| 23 | 80 | XPS | Low-E double-pane | 55,499.15 | 7062.43 | 62,561.58 |

| 24 | 80 | XPS | Low-E + Argon-filled double-pane | 50,046.54 | 7394.28 | 57,440.82 |

| 25 | 80 | Rockwool | Double-pane clear | 64,791.16 | 11,516.62 | 76,307.78 |

| 26 | 80 | Rockwool | Low-E double-pane | 59,129.62 | 7119.54 | 66,249.16 |

| 27 | 80 | Rockwool | Low-E + Argon-filled double-pane | 53,678.86 | 7417.91 | 61,096.77 |

Table A2.

Simulation results for Beijing (Cold zone).

Table A2.

Simulation results for Beijing (Cold zone).

| No. | A: Wall Insulation Thickness (mm) | B: Insulation Material | C: Glazing System | Heating Load (kWh) | Cooling Load (kWh) | Total Energy (kWh) |

|---|---|---|---|---|---|---|

| 0 | 0 | None | Single-pane clear | 71,327.64 | 22,068.15 | 93,395.79 |

| 1 | 40 | EPS | Double-pane clear | 28,634.47 | 21,072.17 | 49,706.64 |

| 2 | 40 | EPS | Low-E double-pane | 28,009.41 | 14,469.00 | 42,478.42 |

| 3 | 40 | EPS | Low-E + Argon-filled double-pane | 25,547.99 | 14,428.52 | 39,976.51 |

| 4 | 40 | XPS | Double-pane clear | 26,737.88 | 21,440.65 | 48,178.53 |

| 5 | 40 | XPS | Low-E double-pane | 25,995.89 | 14,656.52 | 40,652.40 |

| 6 | 40 | XPS | Low-E + Argon-filled double-pane | 23,546.21 | 14,653.48 | 38,199.69 |

| 7 | 40 | Rockwool | Double-pane clear | 28,576.66 | 22,159.26 | 50,735.92 |

| 8 | 40 | Rockwool | Low-E double-pane | 27,949.48 | 15,408.61 | 43,358.09 |

| 9 | 40 | Rockwool | Low-E + Argon-filled double-pane | 25,501.46 | 15,388.65 | 40,890.11 |

| 10 | 60 | EPS | Double-pane clear | 24,399.65 | 21,653.92 | 46,053.57 |

| 11 | 60 | EPS | Low-E double-pane | 23,500.07 | 14,640.18 | 38,140.24 |

| 12 | 60 | EPS | Low-E + Argon-filled double-pane | 21,069.70 | 14,686.37 | 35,756.07 |

| 13 | 60 | XPS | Double-pane clear | 22,943.41 | 21,826.70 | 44,770.11 |

| 14 | 60 | XPS | Low-E double-pane | 21,942.27 | 14,668.30 | 36,610.57 |

| 15 | 60 | XPS | Low-E + Argon-filled double-pane | 19,528.76 | 14,752.05 | 34,280.81 |

| 16 | 60 | Rockwool | Double-pane clear | 24,514.12 | 22,350.51 | 46,864.63 |

| 17 | 60 | Rockwool | Low-E double-pane | 23,626.64 | 15,216.63 | 38,843.27 |

| 18 | 60 | Rockwool | Low-E + Argon-filled double-pane | 21,205.31 | 15,272.67 | 36,477.98 |

| 19 | 80 | EPS | Double-pane clear | 21,963.90 | 21,958.22 | 43,922.12 |

| 20 | 80 | EPS | Low-E double-pane | 20,887.35 | 14,691.71 | 35,579.06 |

| 21 | 80 | EPS | Low-E + Argon-filled double-pane | 18,470.60 | 14,804.12 | 33,274.72 |

| 22 | 80 | XPS | Double-pane clear | 20,760.65 | 22,106.82 | 42,867.46 |

| 23 | 80 | XPS | Low-E double-pane | 19,575.83 | 14,718.48 | 34,294.31 |

| 24 | 80 | XPS | Low-E + Argon-filled double-pane | 17,197.73 | 14,869.72 | 32,067.45 |

| 25 | 80 | Rockwool | Double-pane clear | 22,093.32 | 22,528.32 | 44,621.64 |

| 26 | 80 | Rockwool | Low-E double-pane | 21,034.90 | 15,149.39 | 36,184.29 |

| 27 | 80 | Rockwool | Low-E + Argon-filled double-pane | 18,625.33 | 15,268.08 | 33,893.41 |

Table A3.

Simulation results for Shanghai (Hot Summer and Cold Winter zone).

Table A3.

Simulation results for Shanghai (Hot Summer and Cold Winter zone).

| No. | A: Wall Insulation Thickness (mm) | B: Insulation Material | C: Glazing System | Heating Load (kWh) | Cooling Load (kWh) | Total Energy (kWh) |

|---|---|---|---|---|---|---|

| 0 | 0 | None | Single-pane clear | 35,846.28 | 22,857.00 | 58,703.28 |

| 1 | 40 | EPS | Double-pane clear | 12,882.90 | 21,464.47 | 34,347.37 |

| 2 | 40 | EPS | Low-E double-pane | 12,605.17 | 15,235.50 | 27,840.66 |

| 3 | 40 | EPS | Low-E + Argon-filled double-pane | 11,315.60 | 15,154.76 | 26,470.35 |

| 4 | 40 | XPS | Double-pane clear | 11,893.31 | 21,801.04 | 33,694.35 |

| 5 | 40 | XPS | Low-E double-pane | 11,542.43 | 15,419.80 | 26,962.23 |

| 6 | 40 | XPS | Low-E + Argon-filled double-pane | 10,269.36 | 15,371.61 | 25,640.96 |

| 7 | 40 | Rockwool | Double-pane clear | 12,772.88 | 22,497.64 | 35,270.52 |

| 8 | 40 | Rockwool | Low-E double-pane | 12,488.11 | 16,139.85 | 28,627.96 |

| 9 | 40 | Rockwool | Low-E + Argon-filled double-pane | 11,210.48 | 16,076.00 | 27,286.48 |

| 10 | 60 | EPS | Double-pane clear | 10,732.83 | 21,921.28 | 32,654.12 |

| 11 | 60 | EPS | Low-E double-pane | 10,290.27 | 15,353.84 | 25,644.11 |

| 12 | 60 | EPS | Low-E + Argon-filled double-pane | 9040.96 | 15,347.77 | 24,388.73 |

| 13 | 60 | XPS | Double-pane clear | 9992.41 | 22,036.31 | 32,028.72 |

| 14 | 60 | XPS | Low-E double-pane | 9508.40 | 15,351.72 | 24,860.12 |

| 15 | 60 | XPS | Low-E + Argon-filled double-pane | 8277.37 | 15,378.05 | 23,655.43 |

| 16 | 60 | Rockwool | Double-pane clear | 10,754.79 | 22,555.98 | 33,310.77 |

| 17 | 60 | Rockwool | Low-E double-pane | 10,318.68 | 15,881.32 | 26,200.00 |

| 18 | 60 | Rockwool | Low-E + Argon-filled double-pane | 9076.31 | 15,881.53 | 24,957.84 |

| 19 | 80 | EPS | Double-pane clear | 9512.74 | 22,120.72 | 31,633.46 |

| 20 | 80 | EPS | Low-E double-pane | 8986.61 | 15,351.30 | 24,337.92 |

| 21 | 80 | EPS | Low-E + Argon-filled double-pane | 7768.09 | 15,401.72 | 23,169.81 |

| 22 | 80 | XPS | Double-pane clear | 8924.03 | 22,210.86 | 31,134.88 |

| 23 | 80 | XPS | Low-E double-pane | 8347.17 | 15,345.21 | 23,692.38 |

| 24 | 80 | XPS | Low-E + Argon-filled double-pane | 7146.09 | 15,430.44 | 22,576.53 |

| 25 | 80 | Rockwool | Double-pane clear | 9550.74 | 22,636.06 | 32,186.80 |

| 26 | 80 | Rockwool | Low-E double-pane | 9034.65 | 15,765.04 | 24,799.70 |

| 27 | 80 | Rockwool | Low-E + Argon-filled double-pane | 7820.71 | 15,819.41 | 23,640.12 |

Table A4.

Simulation results for Guangzhou (Hot Summer and Warm Winter zone).

Table A4.

Simulation results for Guangzhou (Hot Summer and Warm Winter zone).

| No. | A: Wall Insulation Thickness (mm) | B: Insulation Material | C: Glazing System | Heating Load (kWh) | Cooling Load (kWh) | Total Energy (kWh) |

|---|---|---|---|---|---|---|

| 0 | 0 | None | Single-pane clear | 4900.99 | 43,596.27 | 48,497.26 |

| 1 | 40 | EPS | Double-pane clear | 991.17 | 35,144.28 | 36,135.45 |

| 2 | 40 | EPS | Low-E double-pane | 942.12 | 26,037.85 | 26,979.97 |

| 3 | 40 | EPS | Low-E + Argon-filled double-pane | 775.23 | 25,628.94 | 26,404.17 |

| 4 | 40 | XPS | Double-pane clear | 859.28 | 35,272.86 | 36,132.14 |

| 5 | 40 | XPS | Low-E double-pane | 802.57 | 26,039.04 | 26,841.60 |

| 6 | 40 | XPS | Low-E + Argon-filled double-pane | 645.37 | 25,650.07 | 26,295.44 |

| 7 | 40 | Rockwool | Double-pane clear | 954.96 | 36,827.95 | 37,782.91 |

| 8 | 40 | Rockwool | Low-E double-pane | 900.14 | 27,567.42 | 28,467.56 |

| 9 | 40 | Rockwool | Low-E + Argon-filled double-pane | 739.27 | 27,177.63 | 27,916.91 |

| 10 | 60 | EPS | Double-pane clear | 731.91 | 34,918.01 | 35,649.92 |

| 11 | 60 | EPS | Low-E double-pane | 663.43 | 25,534.46 | 26,197.90 |

| 12 | 60 | EPS | Low-E + Argon-filled double-pane | 517.44 | 25,163.47 | 25,680.91 |

| 13 | 60 | XPS | Double-pane clear | 653.23 | 34,750.15 | 35,403.38 |

| 14 | 60 | XPS | Low-E double-pane | 578.00 | 25,269.94 | 25,847.94 |

| 15 | 60 | XPS | Low-E + Argon-filled double-pane | 443.05 | 24,913.69 | 25,356.74 |

| 16 | 60 | Rockwool | Double-pane clear | 725.28 | 35,966.89 | 36,692.17 |

| 17 | 60 | Rockwool | Low-E double-pane | 654.82 | 26,454.92 | 27,109.74 |

| 18 | 60 | Rockwool | Low-E + Argon-filled double-pane | 511.71 | 26,091.54 | 26,603.26 |

| 19 | 80 | EPS | Double-pane clear | 607.65 | 34,621.51 | 35,229.16 |

| 20 | 80 | EPS | Low-E double-pane | 528.75 | 25,076.92 | 25,605.67 |

| 21 | 80 | EPS | Low-E + Argon-filled double-pane | 401.48 | 24,727.73 | 25,129.21 |

| 22 | 80 | XPS | Double-pane clear | 553.57 | 34,460.72 | 35,014.29 |

| 23 | 80 | XPS | Low-E double-pane | 470.19 | 24,829.67 | 25,299.86 |

| 24 | 80 | XPS | Low-E + Argon-filled double-pane | 355.73 | 24,495.77 | 24,851.50 |

| 25 | 80 | Rockwool | Double-pane clear | 604.33 | 35,476.53 | 36,080.86 |

| 26 | 80 | Rockwool | Low-E double-pane | 524.36 | 25,806.05 | 26,330.40 |

| 27 | 80 | Rockwool | Low-E + Argon-filled double-pane | 399.40 | 25,461.59 | 25,861.00 |

Table A5.

Simulation results for Kunming (Mild zone).

Table A5.

Simulation results for Kunming (Mild zone).

| No. | A: Wall Insulation Thickness (mm) | B: Insulation Material | C: Glazing System | Heating Load (kWh) | Cooling Load (kWh) | Total Energy (kWh) |

|---|---|---|---|---|---|---|

| 0 | 0 | None | Single-pane clear | 11,710.85 | 6217.44 | 17,928.29 |

| 1 | 40 | EPS | Double-pane clear | 3222.30 | 13,506.93 | 16,729.23 |

| 2 | 40 | EPS | Low-E double-pane | 3395.04 | 7019.31 | 10,414.35 |

| 3 | 40 | EPS | Low-E + Argon-filled double-pane | 2847.72 | 7548.29 | 10,396.01 |

| 4 | 40 | XPS | Double-pane clear | 2825.42 | 14,404.99 | 17,230.41 |

| 5 | 40 | XPS | Low-E double-pane | 2931.94 | 7652.03 | 10,583.97 |

| 6 | 40 | XPS | Low-E + Argon-filled double-pane | 2424.67 | 8257.33 | 10,682.00 |

| 7 | 40 | Rockwool | Double-pane clear | 3071.22 | 14,416.67 | 17,487.89 |

| 8 | 40 | Rockwool | Low-E double-pane | 3201.59 | 7694.66 | 10,896.25 |

| 9 | 40 | Rockwool | Low-E + Argon-filled double-pane | 2685.87 | 8257.85 | 10,943.72 |

| 10 | 60 | EPS | Double-pane clear | 2416.36 | 15,401.86 | 17,818.21 |

| 11 | 60 | EPS | Low-E double-pane | 2455.87 | 8336.88 | 10,792.75 |

| 12 | 60 | EPS | Low-E + Argon-filled double-pane | 1983.26 | 9032.86 | 11,016.13 |

| 13 | 60 | XPS | Double-pane clear | 2164.62 | 16,082.57 | 18,247.19 |

| 14 | 60 | XPS | Low-E double-pane | 2164.45 | 8816.97 | 10,981.41 |

| 15 | 60 | XPS | Low-E + Argon-filled double-pane | 1717.33 | 9578.63 | 11,295.96 |

| 16 | 60 | Rockwool | Double-pane clear | 2366.38 | 15,980.86 | 18,347.23 |

| 17 | 60 | Rockwool | Low-E double-pane | 2397.56 | 8741.77 | 11,139.33 |

| 18 | 60 | Rockwool | Low-E + Argon-filled double-pane | 1935.12 | 9453.63 | 11,388.75 |

| 19 | 80 | EPS | Double-pane clear | 2013.85 | 16,582.37 | 18,596.22 |

| 20 | 80 | EPS | Low-E double-pane | 1980.87 | 9170.78 | 11,151.66 |

| 21 | 80 | EPS | Low-E + Argon-filled double-pane | 1550.99 | 9974.86 | 11,525.85 |

| 22 | 80 | XPS | Double-pane clear | 1820.02 | 17,188.01 | 19,008.02 |

| 23 | 80 | XPS | Low-E double-pane | 1759.08 | 9607.76 | 11,366.84 |

| 24 | 80 | XPS | Low-E + Argon-filled double-pane | 1352.00 | 10,475.37 | 11,827.37 |

| 25 | 80 | Rockwool | Double-pane clear | 1984.54 | 17,057.30 | 19,041.84 |

| 26 | 80 | Rockwool | Low-E double-pane | 1949.39 | 9490.31 | 11,439.70 |

| 27 | 80 | Rockwool | Low-E + Argon-filled double-pane | 1526.92 | 10,309.43 | 11,836.35 |

Appendix B

Table A6.

Two-way interaction effects results of five cities.

Table A6.

Two-way interaction effects results of five cities.

| City | Interaction Effect | Dependent Variable | F Value | p Value |

|---|---|---|---|---|

| Harbin | Wall Insulation Thickness × Insulation Material Type | Heating Load | 0.0164 | 0.9994 |

| Harbin | Wall Insulation Thickness × Insulation Material Type | Cooling Load | 0.0032 | 0.9999 |

| Harbin | Wall Insulation Thickness × Insulation Material Type | Total Energy | 0.0087 | 0.9998 |

| Harbin | Wall Insulation Thickness × Glazing System | Heating Load | 0.0078 | 0.9999 |

| Harbin | Wall Insulation Thickness × Glazing System | Cooling Load | 1.4308 | 0.2643 |

| Harbin | Wall Insulation Thickness × Glazing System | Total Energy | 0.0313 | 0.9979 |

| Harbin | Insulation Material Type × Glazing System | Heating Load | 0.0001 | 1 |

| Harbin | Insulation Material Type × Glazing System | Cooling Load | 0.0304 | 0.998 |

| Harbin | Insulation Material Type × Glazing System | Total Energy | 0.0002 | 1 |

| Beijing | Wall Insulation Thickness × Insulation Material Type | Heating Load | 0.0346 | 0.9975 |

| Beijing | Wall Insulation Thickness × Insulation Material Type | Cooling Load | 0.0032 | 0.9999 |

| Beijing | Wall Insulation Thickness × Insulation Material Type | Total Energy | 0.0045 | 0.9999 |

| Beijing | Wall Insulation Thickness × Glazing System | Heating Load | 0.0493 | 0.995 |

| Beijing | Wall Insulation Thickness × Glazing System | Cooling Load | 0.5517 | 0.7003 |

| Beijing | Wall Insulation Thickness × Glazing System | Total Energy | 0.1916 | 0.9397 |

| Beijing | Insulation Material Type × Glazing System | Heating Load | 0.0003 | 1 |

| Beijing | Insulation Material Type × Glazing System | Cooling Load | 0.1148 | 0.9756 |

| Beijing | Insulation Material Type × Glazing System | Total Energy | 0.0013 | 0.9999 |

| Shanghai | Wall Insulation Thickness × Insulation Material Type | Heating Load | 0.0452 | 0.9958 |

| Shanghai | Wall Insulation Thickness × Insulation Material Type | Cooling Load | 0.0036 | 0.99997 |

| Shanghai | Wall Insulation Thickness × Insulation Material Type | Total Energy | 0.003 | 0.99998 |

| Shanghai | Wall Insulation Thickness × Glazing System | Heating Load | 0.0512 | 0.9946 |

| Shanghai | Wall Insulation Thickness × Glazing System | Cooling Load | 0.4018 | 0.8048 |

| Shanghai | Wall Insulation Thickness × Glazing System | Total Energy | 0.2498 | 0.906 |

| Shanghai | Insulation Material Type × Glazing System | Heating Load | 0.0003 | 1 |

| Shanghai | Insulation Material Type × Glazing System | Cooling Load | 0.151 | 0.9601 |

| Shanghai | Insulation Material Type × Glazing System | Total Energy | 0.0024 | 0.99999 |

| Kunming | Wall Insulation Thickness × Insulation Material Type | Heating Load | 0.1486 | 0.9612 |

| Kunming | Wall Insulation Thickness × Insulation Material Type | Cooling Load | 0.002 | 0.99999 |

| Kunming | Wall Insulation Thickness × Insulation Material Type | Total Energy | 0.001 | 0.99999 |

| Kunming | Wall Insulation Thickness × Glazing System | Heating Load | 0.235 | 0.9149 |

| Kunming | Wall Insulation Thickness × Glazing System | Cooling Load | 1.2485 | 0.3262 |

| Kunming | Wall Insulation Thickness × Glazing System | Total Energy | 3.5457 | 0.0266 * |

| Kunming | Insulation Material Type × Glazing System | Heating Load | 0.0011 | 0.99999 |

| Kunming | Insulation Material Type × Glazing System | Cooling Load | 0.0079 | 0.9999 |

| Kunming | Insulation Material Type × Glazing System | Total Energy | 0.0383 | 0.9969 |

| Guangzhou | Wall Insulation Thickness × Insulation Material Type | Heating Load | 0.1123 | 0.9766 |

| Guangzhou | Wall Insulation Thickness × Insulation Material Type | Cooling Load | 0.0046 | 0.99995 |

| Guangzhou | Wall Insulation Thickness × Insulation Material Type | Total Energy | 0.0043 | 0.99996 |

| Guangzhou | Wall Insulation Thickness × Glazing System | Heating Load | 0.123 | 0.9724 |

| Guangzhou | Wall Insulation Thickness × Glazing System | Cooling Load | 0.0787 | 0.9879 |

| Guangzhou | Wall Insulation Thickness × Glazing System | Total Energy | 0.0795 | 0.9876 |

| Guangzhou | Insulation Material Type × Glazing System | Heating Load | 0.0008 | 1 |

| Guangzhou | Insulation Material Type × Glazing System | Cooling Load | 0.0122 | 0.9997 |

| Guangzhou | Insulation Material Type × Glazing System | Total Energy | 0.0078 | 0.9999 |

Note: “*” denotes a statistically significant interaction effect at the 0.05.

References

- Zhong, X.; Hu, M.; Deetman, S.; Steubing, B.; Lin, H.X.; Hernandez, G.A.; Behrens, P. Global greenhouse gas emissions from residential and commercial building materials and mitigation strategies to 2060. Nat. Commun. 2021, 12, 6126. [Google Scholar] [CrossRef]

- International Energy Agency. Buildings: A Source of Enormous Untapped Efficiency Potential. 2023. Available online: https://www.iea.org/energy-system/buildings (accessed on 12 May 2025).

- China Association of Building Energy Efficiency. China Building Energy Consumption and Carbon Emissions Research Report. 2023. Available online: https://qikan.cqvip.com/Qikan/Article/Detail?id=7111494196&from=Qikan_Search_Index (accessed on 12 May 2025).

- China Association of Building Energy Efficiency. 2024 China Urban and Rural Construction Sector Carbon Emissions Research Report. Economic Reference News, 22 January 2025. Available online: http://jjckb.xinhuanet.com/20250122/6548a802a87d46679ae39548791548f3/c.html (accessed on 12 May 2025).

- Ministry of Housing and Urban-Rural Development. Notice on the Issuance of the “14th Five-Year Plan” for Building Energy Conservation and Green Building Development. 2023. Available online: https://www.gov.cn/zhengce/zhengceku/2022-03/12/content_5678698.htm?utm_source=chatgpt.com (accessed on 12 May 2025).

- Liu, Z.; Yu, C.; Qian, Q.K.; Huang, R.; You, K.; Visscher, H.; Zhang, G. Incentive initiatives on energy-efficient renovation of existing buildings towards carbon–neutral blueprints in China: Advancements, challenges and prospects. Energy Build. 2023, 296, 113343. [Google Scholar] [CrossRef]

- JGJ 26-86; Design Standard for Energy Efficiency Of Residential Buildings in Severe Cold and Cold Zones. China Architecture & Building Press: Beijing, China, 1986.

- JGJ 134-2001; Design Standard for Energy Efficiency of Residential Buildings in Hot Summer And Cold Winter Zones. China Architecture & Building Press: Beijing, China, 2001.

- Lang, S. Progress in energy-efficiency standards for residential buildings in China. Energy Build. 2004, 36, 1191–1196. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, T.; Zhang, J.; Yue, C.; Lu, J.; Zhang, Y.; Fu, M. Uncertainty analysis of envelope retrofits for existing residential buildings in underdeveloped areas: A case study of Daokou, China. Energy Build. 2023, 284, 112828. [Google Scholar] [CrossRef]

- Huang, Y.; El Mankibi, M.; Cantin, R. Thermal performance characterization of supply-air double windows: A new guarded hot box protocol and numerical modelization. Energy Build. 2023, 287, 112993. [Google Scholar] [CrossRef]

- Ma, G.; Liu, T.; Shang, S. Improving the climate adaptability of building green retrofitting in different regions: A weight correction system for Chinese national standard, Sustain. Cities Soc. 2021, 69, 102843. [Google Scholar] [CrossRef]

- GB 50176-2016; Thermal Design Code for Civil Building. China Architecture & Building Press: Beijing, China, 2016.

- Bai, L.; Song, B.; Yang, L. The applicability of the current thermal climate zones for building energy-saving design of China. IOP Conf. Ser. Earth Environ. Sci. 2021, 668, 012057. [Google Scholar] [CrossRef]

- Cao, H.; Liu, X.; Feng, G.; Wang, C.; Huang, K.; Hou, X.; Chen, J. Research on the evaluation of the renovation effect of existing energy-inefficient residential buildings in a severe cold region of China. Energy Build. 2024, 312, 114184. [Google Scholar] [CrossRef]

- Dabous, S.A.; Hosny, F. A Review of Building Envelope Retrofitting Methods for Improving Energy Efficiency, Aesthetic, and Indoor Environmental Quality. Energy Nexus 2025, 18, 100407. [Google Scholar] [CrossRef]

- Nasrollahzadeh, N. Comprehensive building envelope optimization: Improving energy, daylight, and thermal comfort performance of the dwelling unit. J. Build. Eng. 2021, 44, 103418. [Google Scholar] [CrossRef]