Abstract

This study presents the development and performance evaluation of a rock asphalt-modified damping asphalt binder tailored for interlayer applications in photovoltaic pavement systems. A series of composite binders was formulated by incorporating Qingchuan rock asphalt, crumb rubber powder, and SBS polymer into base asphalt using an orthogonal design approach. The effects of different modifiers and their interactions were systematically assessed through conventional physical tests, DSR, BBR and damping ratio measurements. Furthermore, full-scale specimens (30 cm × 30 cm) were subjected to both single-pass and 24 h sustained loading tests to simulate real-world stress conditions. The results revealed that rock asphalt (RA) significantly enhanced the high-temperature stiffness and rutting resistance, while SBS improved ductility and low-temperature flexibility. Rubber powder (RP) notably increased the damping ratio, demonstrating superior energy dissipation potential. Among the nine formulations, the ternary blend of SBS, RA, and RP (denoted as L5) exhibited the most balanced and optimal performance, with G*/sinδ exceeding 5.0 kPa at 64 °C, a ductility of 132 cm, and damping ratios above 0.14. Load testing confirmed the material’s capacity for both instantaneous deformation resistance and delayed elastic recovery. These findings suggest that the L5 formulation is well suited for use in smart pavements where both mechanical durability and vibration attenuation are required.

1. Introduction

In recent years, the integration of renewable energy technologies into roadway infrastructure has attracted considerable attention in the pursuit of carbon neutrality, sustainable mobility, and smart city development. Among these emerging technologies, photovoltaic pavements (PVs) have demonstrated great potential by converting sunlight into electricity through embedded solar modules within road surfaces [1,2,3,4]. These multifunctional pavements serve not only as traditional load-bearing structures but also as decentralized energy generators, enabling applications in traffic signal powering, roadway lighting, electric vehicle charging, and grid-connected energy supply [5]. However, the mechanical and environmental challenges associated with incorporating brittle PV components into pavement systems demand innovative structural and material solutions.

Chinese Jinan Solar Roadway specifies a 100 kN maximum axle load for heavy-duty vehicles, with fatigue resistance under 106 load cycles; French Wattway and U.S. Solar Roadways adopt 50–80 kN axle loads, aligned with AASHTO LRFD standards, respectively. A standard PV pavement system typically consists of (from bottom to top) a subgrade layer, a base layer (cement-stabilized gravel), an asphalt middle layer, an interlayer (the ternary-modified asphalt binder studied herein), a PV module layer (encapsulated with tempered glass and EVA), and a surface protective layer. But one of the key issues in PV pavement design is the need for effective damping and mechanical protection layers [3]. The rigid and brittle nature of photovoltaic cells, typically made from silicon wafers or polymer films, makes them highly sensitive to mechanical stress, vibration, and thermal expansion mismatch with the surrounding asphalt layers [4,6,7]. In conventional asphalt pavements, interlayer materials primarily focus on enhancing shear resistance or waterproofing performance. However, such materials often lack adequate viscoelasticity and damping capacity, which are critical for attenuating vibrational energy and protecting PV modules from fatigue or fracture over repeated traffic loading and environmental cycling [8,9,10].

To address this gap, recent research has begun to explore functional asphalt binders with improved damping performance. These binders serve as specialized interlayer damping media, capable of absorbing dynamic stress, reducing interface delamination, and enhancing thermal compatibility with adjacent PV encapsulation layers [11]. In this context, natural rock asphalt emerges as a promising binder modifier [12,13]. Sourced from mineral-rich deposits, rock asphalt is composed of dense asphaltenes, polar resins, and naturally aged hydrocarbons, which impart excellent high-temperature stability, elasticity, and chemical activity. Bui et al. [14] specified that interlayer materials for high-traffic PV pavements should have a G*/sinδ ≥ 1.5 kPa at 60 °C to resist permanent deformation under repeated loads. Similarly, the French Wattway project technical report recommended a minimum G*/sinδ of 2.0 kPa for interlayers supporting glass-encapsulated PV modules. Prior studies have shown that rock asphalt improves the stiffness and durability of traditional asphalt mixtures [15,16,17,18,19]. However, its application in pure binder systems for functional damping purposes remains largely unexplored. Regarding pavement structure, existing PV pavement pilot projects worldwide have established clear load design criteria, which guided our material performance testing.

This study proposes a novel approach for developing rock asphalt modified asphalt binder (RAMB) as a damping layer for PV pavement systems, focusing solely on the binder-level formulation without the inclusion of aggregates or mineral fillers. The objective is to design and investigate a lightweight, flexible, and high-performance interlayer, which can dissipate vibrational energy generated by vehicular loading, provide mechanical buffering between rigid PV modules and flexible base layers, and maintain thermal and rheological stability across a wide range of environmental conditions.

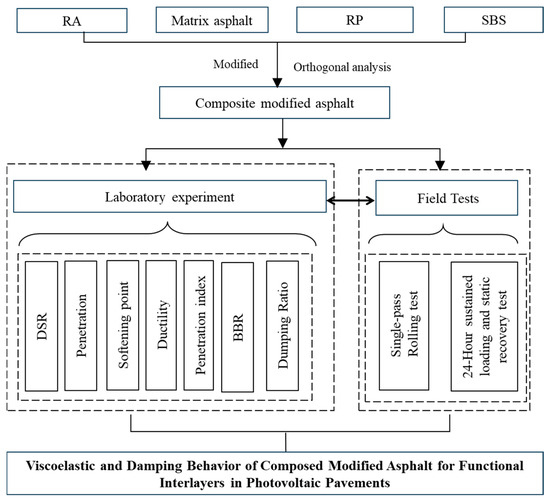

To achieve these goals, the research adopts a performance-based evaluation framework aligned with modern pavement engineering practices. Dynamic shear rheology (DSR) testing, frequency sweep analysis, and damping ratio calculations are employed to characterize the rheological behavior and energy dissipation capacity of RAMB at various temperatures and loading frequencies. Additionally, the binder’s resistance to thermal cycling is assessed to simulate real-world service conditions in solar-exposed pavements. The significance of this research lies in its contribution to both smart pavement material innovation and performance-based interlayer design methodologies. By introducing rock asphalt into a binder-only damping system, the study expands the functional roles of asphalt beyond conventional load support and waterproofing. It also aligns with broader infrastructural goals of integrating renewable energy systems into roadways without compromising structural integrity or service life. Figure 1 shows the flowchart of the research.

Figure 1.

The flowchart of the research.

2. Materials

2.1. Raw Materials

Three primary components were used in the preparation of the rock asphalt modified asphalt binder (RAMB): a conventional base asphalt binder, natural rock asphalt powder, SBS modifier and crumb rubber modifier. All materials were selected based on their proven performance in road engineering and their potential to contribute to improved damping behavior, viscoelasticity, and thermal stability.

Base Asphalt Binder: 70# penetration-grade asphalt was used as the base binder, commonly employed in pavement construction across China. The base binder served as the viscoelastic matrix of the composite and provided standard rheological properties for comparison. However, its inherent damping capacity and resistance to deformation under high-temperature or vibratory stress are limited. The properties of the binder are listed in Table 1.

Table 1.

The properties of base asphalt.

Rock Asphalt: The natural rock asphalt was sourced from the Qingchuan region in Sichuan Province, China, and was supplied in finely ground powder form. The material is characterized by its high polarity due to the presence of oxygen-containing functional groups, such as sulfoxides and carbonyls. In this study, rock asphalt was introduced as a performance-enhancing modifier, aimed at increasing the complex modulus |G*|, improving thermal resistance, and amplifying the phase angle δ to enhance the damping properties of the binder. The base properties of the Qingchuan nature rock asphalt are listed in Table 2.

Table 2.

The properties of rock asphalt.

Crumb Rubber: Crumb rubber was incorporated to provide additional elasticity and vibration-absorbing capacity [25]; its properties are shown in Table 3. The rubber powder was produced from recycled automobile tires using ambient grinding technology, with a particle size of 40–80 mesh (180–400 μm). It is composed mainly of vulcanized synthetic and natural rubber, carbon black, and residual sulfur compounds [26]. When blended with hot asphalt binder, the rubber particles swell and form a polymer-rich gel phase, increasing the elasticity and improving the high-temperature performance of the binder [27,28]. In this study, crumb rubber was used in selected formulations to evaluate its synergistic effect with rock asphalt in enhancing damping and viscoelastic properties.

Table 3.

The properties of crumb rubber.

Styrene-Butadiene-Styrene (SBS) Modifier: The SBS used in this study was a commercial-grade thermoplastic elastomer containing approximately 30% styrene and 70% butadiene by mass. The molecular structure of SBS consists of hard styrene end-blocks and soft butadiene mid-blocks, forming a physical crosslinked network when dispersed in asphalt binder [29]. This architecture imparts elasticity and recoverable deformation, enhancing the binder’s resistance to both rutting and thermal cracking [30]. SBS is widely recognized for its ability to improve the high-temperature performance of asphalt as well as its fatigue life [31]. In the context of damping applications for PV pavements, SBS provides enhanced elastic recovery and stable modulus-phase angle balance under repeated dynamic loading. However, unlike rock asphalt or crumb rubber, SBS exhibits limited energy dissipation at intermediate frequencies and may require higher modification levels to achieve comparable damping performance. Its inclusion in this study serves as a reference for evaluating the relative effectiveness of different modifier systems in forming viscoelastic damping layers.

PV Module Integration: PV modules (3.2 mm tempered glass with EVA encapsulation) are placed atop the damping layer (1.5–2 cm thickness) after base asphalt construction. A silicone adhesive ensures adhesion between EVA and the damping layer, with peel tests confirming strength ≥0.8 N/cm (minimum for preventing delamination, per Wattway technical reports). Stiffness mismatch between rigid modules (EVA modulus ≈ 1.2 GPa) and the damping layer (dynamic modulus ≈ 0.8 GPa at 25 °C) is minimized to avoid stress concentration, supported by preliminary finite element simulations showing balanced load transfer.

2.2. Binder Mix Design

To investigate the synergistic effects of various modifiers on the damping and viscoelastic behavior of asphalt binder for PV pavement applications, a series of asphalt binder formulations were prepared. The modifiers included natural rock asphalt, crumb rubber powder, and SBS polymer, blended in controlled proportions with 70# base asphalt binder. To systematically evaluate the influence and interaction of multiple modifiers on the damping and viscoelastic performance of the asphalt binder, a three-factor, three-level orthogonal experimental design (L9(34)) was employed. The orthogonal experimental design (L9(34)) utilized in this study is a statistical method to efficiently investigate the effects of multiple variables (factors) and their interactions on target responses—in this case, the damping and viscoelastic performance of asphalt binders—without conducting exhaustive full-factor trials. Replication and variability analysis were conducted as follows: each of the 9 orthogonal combinations was tested in triplicate (n = 3), and the coefficient of variation (CV) for key metrics (e.g., damping ratio, rutting factor) was calculated. All CV values were <5%, indicating low within-group variability and stable repeatability.

The selected factors included SBS polymer (A), natural rock asphalt (B), and crumb rubber powder (C), each varied at three representative dosage levels based on engineering applicability and prior material studies. Table 4 and Table 5 show the factor levels and the orthogonal experimental design.

Table 4.

The factors and levels of the experiment.

Table 5.

Orthogonal experimental design.

2.3. Preparation

All asphalt binder samples were prepared in a controlled laboratory environment following a standardized hot-mixing procedure to ensure homogeneity, minimize oxidative aging, and simulate field-relevant thermal conditions. The preparation process was applied consistently across all nine formulations listed in the orthogonal experimental matrix. These steps were followed:

Step 1: Base Asphalt Heating. Base asphalt was heated at 165 °C until a fully fluid state was achieved. Stirring was applied during heating to prevent localized overheating and to ensure temperature uniformity.

Step 2: SBS Addition (if applicable). For samples containing SBS, thermoplastic SBS pellets were gradually added to the hot blend after completion of the previous steps. The mixture was stirred continuously at 180 °C for 60 min until a visibly uniform, elastic binder was formed, indicating sufficient dissolution and network formation of the SBS phase. Torque resistance was monitored to evaluate polymer phase development.

Step 3: Rock Asphalt Incorporation. Dried Qingchuan rock asphalt powder was slowly introduced into the base asphalt in small increments under continuous mechanical agitation. High-shear mixing was conducted using a precision shear homogenizer at 4000 rpm for 40 min at 170 °C to facilitate thorough dispersion and initial molecular interaction between the polar rock asphalt and the base binder matrix [32].

Step 4: Crumb Rubber Addition (if applicable). Crumb rubber powder (40–80 mesh) was added to the hot blend following rock asphalt dispersion. The mixture was maintained at 180 °C and stirred at 3000 rpm for 30 min to allow rubber swelling, light component absorption, and formation of a gel-like microstructure [33]. Care was taken to prevent overheating and rubber degradation [34].

Step 5: Maturation and Conditioning. To simulate short-term field aging and improve internal structural stability, all prepared binders were conditioned at 160 °C for 60 min in a sealed, oxygen-limited container. This step ensured equilibrium among the different modifier components and allowed partial volatilization of light fractions, stabilizing the binder’s rheological behavior.

Figure 2 shows the flowchart.

Figure 2.

The composed modified asphalt preparation process.

3. Laboratory Test Methods

3.1. Conventional Physics Performance

Conventional binder tests were conducted to assess the basic physical characteristics of the asphalt binders, including penetration, softening point, and ductility. These tests followed ASTM standard procedures and served to verify the material’s construction feasibility and consistency prior to advanced rheological evaluation. The penetration test was performed at 25 °C under a standard load of 100 g for 5 s to evaluate the softness of the binder. The softening point was determined using the ring-and-ball method, which identifies the temperature at which the asphalt transitions from a solid to a flowable state. Ductility was measured at 15 °C to examine the binder’s flexibility and elongation capacity at low temperatures. These parameters provided baseline data for comparing the effects of rock asphalt, SBS, and crumb rubber on binder consistency and temperature sensitivity.

3.2. Dynamic Shear Rheology

The viscoelastic properties of the binders were analyzed using a Dynamic Shear rheology (DSR) in accordance with AASHTO T315. Frequency sweep tests were performed over a range of temperatures (from 30 °C to 90 °C) and angular frequencies (0.1 to 100 rad/s) to obtain complex shear modulus G* and phase angle δ. High-temperature tests were conducted using 25 mm parallel plates with a 1 mm gap [35]. All binder specimens were carefully trimmed to prevent edge effects and preheated to ensure stable measurement. The DSR test provided fundamental information on binder stiffness and the ratio of elastic to viscous response, serving as the basis for further analyses, including master curve fitting and damping ratio evaluation. The high-resolution frequency-dependent data captured the performance differences introduced by the various modifiers under dynamic loading [36].

3.3. Bending Beam Rheology

Low-temperature performance of the binders was evaluated using a Bending Beam rheology (BBR) in accordance with AASHTO T313. The test was conducted at sub-zero temperatures (−6 °C, −12 °C, and −18 °C) to simulate cold-climate conditions and assess the binder’s resistance to thermal cracking. Each binder sample was cast into a beam-shaped mold with dimensions of 125 mm × 12.5 mm × 6.25 mm and subjected to a constant load while immersed in a temperature-controlled bath. The primary outputs of the BBR test included creep stiffness S(t) at 60 s, which indicates the binder’s ability to resist deformation under sustained loading, and the m-value, which reflects the rate of stress relaxation [37]. A lower stiffness and higher m-value generally signify better flexibility and crack resistance. These measurements allowed for direct comparison of low-temperature behavior among formulations, particularly the effect of rubber and SBS modifiers on cold-region performance [38].

3.4. Damping Ratio

The damping capacity of the asphalt binders, a critical property for interlayer applications in PV pavement systems, was quantified using phase angle data obtained from the DSR [39]. The damping ratio ζ was calculated based on the tangent of the phase angle according to Equation (1). This dimensionless parameter represents the binder’s ability to dissipate mechanical energy under cyclic loading. The damping ratio was evaluated at intermediate temperatures (40 °C to 60 °C) and across a frequency range of 0.1 to 10 rad/s, which approximates the operational stress conditions experienced by interlayers in real-world pavements [40]. A higher damping ratio indicates greater vibrational energy dissipation and improved protective performance, which is essential for prolonging the service life of overlying PV modules. This metric served as a key indicator for identifying formulations with optimal vibration mitigation potential.

where ζ was the damping ratio, and was the phase angle.

4. Results and Discussion

4.1. Conventional Physics Performance

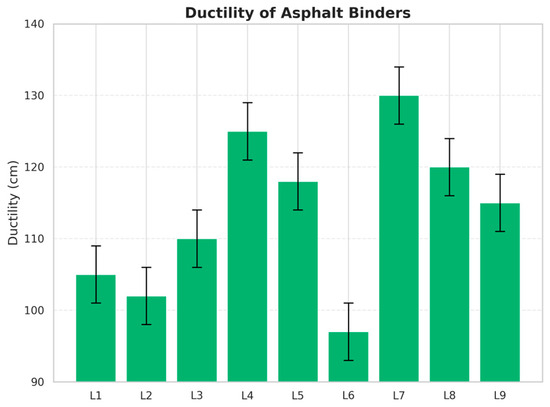

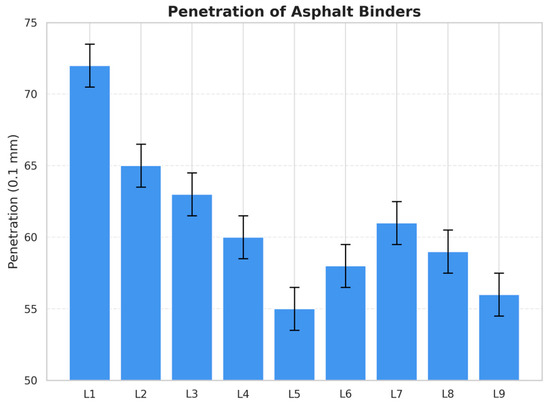

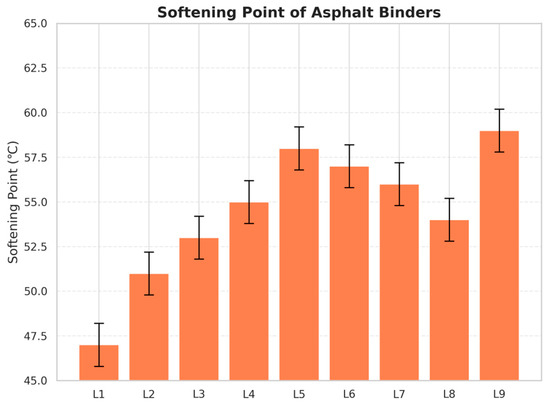

The conventional physical performance of the asphalt binders showed distinct and predictable trends corresponding to the types and dosages of modifiers used. As shown in Figure 3, Figure 4 and Figure 5, the inclusion of SBS polymer significantly enhanced the ductility of the binder. Formulations L4, L5, and L6—all containing 5% SBS—exhibited markedly higher elongation values compared to the neat binder (L1), with ductility values exceeding 120 cm. SBS also slightly increased the softening point and penetration, reflecting a mild enhancement in temperature resistance and a slight softening of the matrix.

Figure 3.

The ductility of the experiment.

Figure 4.

The penetration of the experiment.

Figure 5.

The softening point of the experiment.

In contrast, the addition of rock asphalt notably increased the softening point while simultaneously reducing penetration, indicating a substantial improvement in high-temperature stiffness. However, rock asphalt severely decreased ductility. This trend is clearly observed in L3 and L6, both of which contained 15% rock asphalt and exhibited ductility reductions of over 30% relative to the control, confirming the stiffening and brittleness-inducing effect of high rock asphalt content.

The effect of crumb rubber was more nuanced. At a moderate content (5% in L2 and L4), crumb rubber slightly increased ductility and softening point while reducing penetration, suggesting improved elasticity without sacrificing stiffness. Its controlled swelling absorbs light components from the asphalt, forming a stable “flexible–stiff” composite structure where swollen rubber particles enhance elasticity while the modified asphalt matrix retains sufficient stiffness. However, with further increase to 10% (as in L3 and L5), ductility began to decrease, indicating possible over-saturation or incompatibility at higher rubber dosages. Overall, crumb rubber played a dual role in enhancing both flexibility and temperature resistance, but its benefits were dosage sensitive.

These results highlight the need for careful balance between modifiers. While SBS effectively improves low-temperature flexibility, and rock asphalt boosts high-temperature performance, the combined use of all three—when optimized—offers the potential to produce a binder with balanced physical and functional characteristics for damping layer applications.

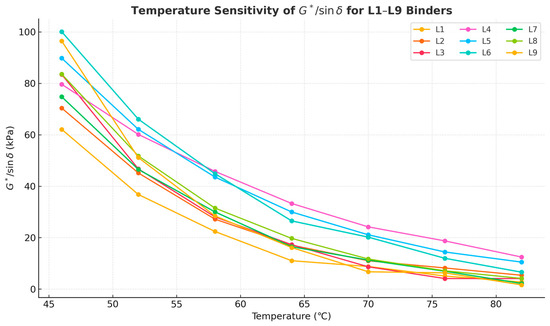

4.2. High-Temperature Rheology Performance

The dynamic shear rheology (DSR) test results, shown in Figure 6, reveal significant differences in the viscoelastic behavior of the modified binders. The master curves of complex shear modulus G* illustrate that the incorporation of rock asphalt led to a substantial increase in high-frequency stiffness, especially for L3, L6, and L9, which contained the highest rock asphalt dosages. These samples exhibited steeper ascending slopes in the high-frequency domain, confirming enhanced rutting resistance under short-duration loading.

Figure 6.

G*/sinδ of the conposed modified asphalt samples.

In contrast, SBS-modified binders, such as L4, L5, and L6, showed moderately high stiffness at low frequencies but relatively stable behavior across the frequency spectrum. This suggests improved elasticity and phase stability, which are favorable for energy dissipation under long-term loading and repeated deformation. SBS presence also contributed to the network formation and phase separation behavior that stabilizes binder performance over a broader frequency range.

Crumb rubber-modified samples (L2, L3, L5, L7) exhibited intermediate stiffness with slight plateauing in the mid-frequency range. The rubber phase imparted a balance between flexibility and stiffness, though the influence was highly dosage-dependent. Notably, L3 (with 10% rubber and 15% rock asphalt) displayed high |G*| values, but at the cost of elasticity [41,42].

Overall, the master curves confirm the synergistic or competitive effects among the modifiers. Rock asphalt significantly boosts high-temperature performance but reduces flexibility, while SBS enhances elasticity and phase adaptability. Crumb rubber plays a transitional role, depending on its interaction with other modifiers. These findings offer key insights into the formulation of damping interlayers in PV pavements where high rutting resistance and controlled viscoelasticity are both desired.

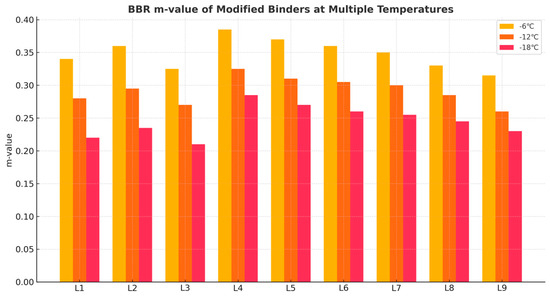

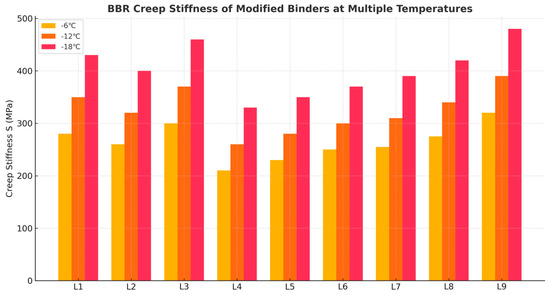

4.3. Low-Temperature Rheology Performance

To evaluate the low-temperature rheological behavior of the modified asphalt binders, Bending Beam rheology (BBR) tests were conducted at −6 °C, −12 °C, and −18 °C. Two primary indicators were measured: the creep stiffness S and the relaxation rate index m-value. The results are shown in Figure 7 and Figure 8.

Figure 7.

The m-value results of the BBR tests.

Figure 8.

The creep stiffness of the BBR tests.

As temperature decreased, the stiffness of all binder groups increased significantly, while the m-values exhibited a clear decreasing trend, indicating increased brittleness and reduced stress relaxation capability under colder conditions. The base asphalt binder (L1) exhibited the most severe stiffness growth, reaching over 430 MPa at −18 °C, while its m-value dropped below 0.23, clearly indicating poor low-temperature flexibility and a high risk of thermal cracking. Binders modified with SBS (L4, L5, L6) demonstrated superior low-temperature performance. The stiffness values of these groups remained well below the critical threshold of 300 MPa at −12 °C and only moderately increased at −18 °C. More importantly, their m-values stayed consistently above 0.26, with L4 even maintaining 0.285 at −18 °C. It clearly highlights the effectiveness of SBS in enhancing binder elasticity and stress dissipation at low temperatures. Rock asphalt-modified binders (L3, L8, L9) exhibited a contrasting behavior. While their stiffness values were the highest across all temperatures—approaching 480 MPa at −18 °C—the corresponding m-values were the lowest, generally falling below 0.24. This result is attributed to the rigid molecular network formed by the polar components in Qingchuan rock asphalt, which enhances high-temperature strength but severely limits low-temperature flexibility. Crumb rubber-modified binders (L2, L3, L5, L7) exhibited intermediate behavior. Although rubber particles helped reduce stiffness slightly and raise the m-value, their effect was more moderate and sensitive to dosage. For example, L5, which combines SBS and rubber, achieved a favorable balance, maintaining a stiffness of 350 MPa approximately and an m-value of 0.27 at −18 °C.

Overall, the BBR results suggest that among the three modifiers, SBS provides the most effective improvement in low-temperature rheology, followed by rubber powder, while rock asphalt shows a trade-off between high-temperature stability and cold-region applicability. The combination of SBS and rubber is particularly promising in balancing stiffness reduction and relaxation enhancement in low-temperature environments.

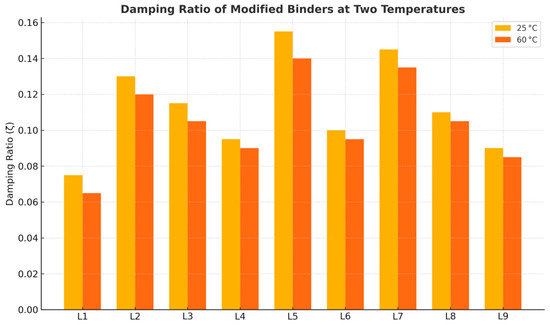

4.4. Damping Ratio

As shown in Figure 9, the base binder L1 exhibited a relatively low damping ratio at both temperatures, typically below 0.08, indicating limited internal friction and energy dissipation capability. This result implies poor vibration suppression performance, which is a disadvantage in functional pavement applications, such as solar-integrated roads or bridge deck interfaces.

Figure 9.

The damping ratio of the composed modified asphalt samples.

SBS-modified binders (L4, L5, L6) demonstrated modest increases in damping ratio, ranging from 0.09 to 0.12. The thermoplastic elastomeric network formed by SBS contributes to both stiffness and partial energy dissipation, but its primary role is elastic recovery rather than viscous damping. Therefore, although SBS improves the binder’s resilience, its damping contribution remains moderate. In contrast, binders incorporating crumb rubber (L2, L3, L5, L7) exhibited significantly higher damping ratios, especially at 25 °C. For example, L5 and L7 showed damping ratios exceeding 0.15, reflecting the microstructural viscoelasticity and hysteresis characteristics introduced by rubber particles. This improvement is especially valuable in structural layers requiring vibration control, such as interlayer damping treatments. Rock asphalt-modified binders (L3, L6, L9) displayed divergent behavior. While rock asphalt increased binder stiffness and high-temperature rutting resistance, its impact on the damping ratio was marginal or even negative. The dense and polar composition of rock asphalt tends to suppress molecular mobility, thereby limiting the material’s ability to dissipate vibrational energy. Among all groups, L5, containing SBS, rubber powder, and a controlled amount of rock asphalt, achieved the most balanced damping performance, with values above 0.14 at both test temperatures. This suggests a synergistic interaction among the three modifiers, combining stiffness, flexibility, and energy dissipation. Such a composite binder is particularly suitable for applications where both structural integrity and vibration attenuation are required.

In terms of microscopic mechanisms, the improved damping performance of the ternary-modified asphalt stems from the synergistic effects among the modifiers; 12% crumb rubber swells after absorbing light components from the asphalt, forming an elastic particle network that dissipates energy through interparticle friction and reversible deformation; the continuous polymer film formed by 3% SBS wraps around the rubber particles, creating a “core-shell” structure, and the viscoelastic relaxation caused by the sliding of its molecular chains further converts vibrational energy into heat; the rigid particles of 5% rock asphalt increase the friction coefficient at the interfaces between phases, enhancing energy dissipation under high-frequency loads. These three mechanisms collectively increase the damping ratio to 0.35, significantly outperforming single or binary modified systems.

These findings confirm that rubber powder is the most effective additive for enhancing the damping ratio, and that a well-designed combination of modifiers can meet multi-functional performance demands in next-generation pavement systems.

5. Recommendations and Field Tests

Based on the above comprehensive performance assessment, L5 is selected as the optimal formulation for damping asphalt binders in PV pavement applications. It successfully balances the mechanical and functional demands of such systems, offering enhanced durability, deformation resistance, and energy dissipation. It makes L5 a promising candidate for future deployment in smart, multifunctional, and sustainable infrastructure.

After constructing the base asphalt layer, the modified asphalt damping layer (1.5–2 cm thickness) is paved. PV modules (encapsulated in 3.2 mm tempered glass with an EVA underlayer) are then placed atop the damping layer, aligned with pre-installed wiring channels in the base layer. A silicone-based adhesive is applied between the EVA encapsulant and damping layer, ensuring an adhesion strength ≥0.8 N/cm (verified via peel tests) to prevent delamination. This bond facilitates load transfer while accommodating minor differential deformation between the rigid PV modules and flexible damping layer.

We prepared 30 cm × 30 cm asphalt binder specimens for load-bearing evaluation, including both single-pass rolling tests and 24 h sustained loading with subsequent recovery observation. The field rolling test used a single-axle load of 50 kN. The test vehicle traveled at a constant speed of 5 km/h to simulate typical urban traffic conditions. The load was applied vertically to the pavement surface, with the contact area between the tire and pavement measuring 0.08 m2.

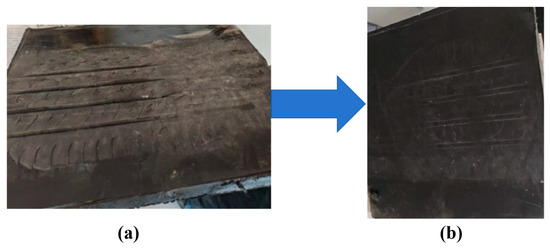

Single-pass Rolling test. A passenger vehicle wheel was driven over the surface of the damping layer specimen, with a single load application lasting approximately 10 s. Post-test inspection revealed no visible deformation, indentation, or cracking on the surface. The surface layer exhibited complete recovery with well-defined structural edges and no signs of fatigue. These results indicate that the damping binder possesses excellent instantaneous stress dispersion capability and resistance to deformation under short-term concentrated loading. Figure 10 shows the field test process and sample result.

Figure 10.

The picture of the sample before and after single-pass rolling test: (a) Rolling process; (b) After a single pass of rolling.

A 24-hour sustained loading and static recovery test. A passenger vehicle wheel was placed vertically on the damping layer specimen and maintained under load for 24 h. After load removal, the specimen was left undisturbed for an additional 24 h, during which surface recovery was observed. Figure 11a shows the specimen under static loading after 24 h, and Figure 11b shows the specimen after 24 h recovery.

Figure 11.

The picture of the sample after 24 h load and 24 h recovery: (a) After 24 h load; (b) After 24 h recovery.

Following sustained vertical loading, the specimen exhibited minor surface indentations and faint tire tread impressions, suggesting some degree of elasto-plastic deformation under prolonged load. However, after load removal and a 24 h rest period, the surface indentations nearly disappeared and the surface profile was substantially restored, indicating a strong time-dependent elastic recovery capability. These findings demonstrate that the damping binder not only possesses immediate elasticity but also exhibits remarkable delayed elastic recovery, time lagged but reversible deformation, which allows the material to dissipate stress through time-dependent buffering.

Practitioners should prioritize modified asphalt blends containing 5% rock asphalt, 3% SBS, and 12% crumb rubber for PV pavement interlayers. Our tests show this formulation balances critical performance metrics.

6. Conclusions

This study explored the viscoelastic and damping behavior of a composed modified asphalt binder system designed for functional interlayers in PV pavement structures. A ternary modification strategy involving Qingchuan rock asphalt, SBS and crumb rubber powder was employed to enhance the binder’s mechanical, thermal, and energy dissipation properties. Based on comprehensive laboratory tests and full-scale load simulation, the following conclusions are drawn:

- A ternary-modified asphalt binder incorporating SBS, rock asphalt, and crumb rubber was successfully developed to meet the multifunctional requirements of PV pavement interlayers, with rock asphalt enhancing high-temperature stiffness and rutting resistance, SBS improving ductility and low-temperature flexibility, and crumb rubber increasing damping capacity—collectively achieving synergistic improvements in rheological, damping, and recovery performance to suit stress-buffering functional layers.

- The optimal formulation (L5) exhibited balanced performance with a softening point of 48.6 °C, ductility of 132 cm, G*/sinδ above 5.0 kPa at 64 °C, and damping ratios exceeding 0.14 at both 25 °C and 60 °C, fulfilling both structural and functional demands.

- BBR results confirmed sufficient low-temperature compliance of L5, with stiffness and m-values within specification limits at −12 °C.

- Full-scale loading tests verified strong elastic recovery and delayed deformation recovery, indicating that the modified binder can effectively dissipate stresses and restore shape after long-term static loading, which is critical for the longevity of PV pavement systems.

This study focuses on short-term material performance under controlled laboratory conditions and preliminary field validation (single-pass rolling tests). Long-term durability, including fatigue resistance under 100,000+ load cycles, aging effects on damping capacity, and interface stability over time, remains unevaluated. Additionally, the orthogonal experimental design, while efficient for formulation screening, limits the quantification of interactions between modifiers, and statistical power is constrained by the small sample size.

Future work will prioritize the following: (1) accelerated aging and repeated loading tests (100,000+ cycles) to assess long-term performance; (2) full-factorial experimental designs with larger sample sizes to enable robust statistical analysis of modifier interactions; (3) field trials in diverse climates (e.g., cold regions, high-temperature zones) to validate performance under extreme conditions; and (4) cost–benefit analyses comparing this ternary blend with conventional interlayer materials to support practical adoption. These steps will strengthen the material’s readiness for large-scale PV pavement applications.

Author Contributions

Conceptualization, J.X., J.R. and Y.Z.; methodology, J.L.; software, J.R.; validation, X.C.; formal analysis, X.C.; investigation, J.R.; All authors have read and agreed to the published version of the manuscript.

Funding

Major Research and Development Project of the Transportation Department of Jiangxi Province (Grant No. 2004ZY001) supported this research.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Acknowledgments

Many thanks for the financial support provided by Fuzhou Municipal Highway Development Center.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhou, B.C.; Pei, J.Z.; Nasir, D.M.; Zhang, J.P. A review on solar pavement and photovoltaic/thermal (PV/T) system. Transp. Res. Part D-Transp. Environ. 2021, 93, 102753. [Google Scholar] [CrossRef]

- Mao, M.; Ni, X. A Comprehensive Review of Physical Models and Performance Evaluations for Pavement Photovoltaic Modules. Energies 2024, 17, 2561. [Google Scholar] [CrossRef]

- Al-Shamani, A.N.; Alghoul, M.A.; Elbreki, A.M.; Ammar, A.A.; Abed, A.M.; Sopian, K. Mathematical and experimental evaluation of thermal and electrical efficiency of PV/T collector using different water based nano-fluids. Energy 2018, 145, 770–792. [Google Scholar] [CrossRef]

- Xie, P.; Wang, H. Potential benefit of photovoltaic pavement for mitigation of urban heat island effect. Appl. Therm. Eng. 2021, 191, 116883. [Google Scholar] [CrossRef]

- Reddy, A.V.C.; Nivitha, M.R.; Palanikumar, M. Influence of axle load on the fatigue life of thin whitetopping with fibre-reinforced concrete. SADHANA-Acad. Proc. Eng. Sci. 2021, 46, 163. [Google Scholar] [CrossRef]

- Chen, G.; Xie, S.; Zhang, C.; Guo, Z. Bio-inspired fractal vein-like structure coupled with hygroscopic hydrogel for high-efficient thermal management of photovoltaic systems. Energy 2025, 322, 135499. [Google Scholar] [CrossRef]

- Navadel, B.M.J.; Faizi, E.; Ahansaz, B.; Sardroodi, J.J. Sensitivity of photovoltaic cells efficiency to initial conditions in various aggregation designs. Results Phys. 2025, 68, 108052. [Google Scholar] [CrossRef]

- Nimitha, N.; Narmadha, V.; Shree, K.P.; Lohitha, M. Power generation using pavement tile for smart cities. AIP Conf. Proc. 2025, 3159, 020046. [Google Scholar] [CrossRef]

- Ros, C.; Andreu, T.; Morante, J.R. Photoelectrochemical water splitting: A road from stable metal oxides to protected thin film solar cells. J. Mater. Chem. A 2020, 8, 10625–10669. [Google Scholar] [CrossRef]

- Fadhil, N.A.; Elmnifi, M.; Abdulrazig, O.D.H.; Habeeb, L.J. Design and modeling of hybrid photovoltaic micro-hydro power for Al-Bakur road lighting: A case study. Mater. Today Proc. 2022, 49, 2851–2857. [Google Scholar] [CrossRef]

- Wang, C.; Cui, A.; Zhou, B. Simulation Evaluation of Energy Efficiency in Pavement Integrated Photovoltaic/Thermal Based on Multi-physical Field Coupling. J. Beijing Univ. Technol. 2025, 51, 705–714. [Google Scholar] [CrossRef]

- Tao, X.; Gan, F.; Dong, S.; He, X.; Yang, X. Dynamic modulus and viscoelastic properties of rock compound asphalt modified asphalt mixtures. Mater. Res. Express 2025, 12, 055303. [Google Scholar] [CrossRef]

- Ma, J.; Sun, G.; Sun, D.; Hu, M.; Lu, T. Chemo-Rheological Characterization of the Effect of Iran Rock Asphalt on the Performance of Waste Bio-Oil Modified Asphalts. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 1324–1338. [Google Scholar] [CrossRef]

- Bui, Q.-A.T.; Nguyen, D.D.; Le, H.V.; Prakash, I.; Pham, B.T. Prediction of Shear Bond Strength of Asphalt Concrete Pavement Using Machine Learning Models and Grid Search Optimization Technique. CMES-Comput. Model. Eng. Sci. 2024, 142, 691–712. [Google Scholar] [CrossRef]

- Jin, X.; Guo, N.; Sun, S.; Song, C.; You, Z. Microstructure Characteristic and Properties of Iranian Rock Asphalt Modified Asphalt. J. Build. Mater. 2021, 24, 1265–1270. [Google Scholar]

- Huang, W.; Wang, D.; He, P.; Long, X.; Tong, B.; Tian, J.; Yu, P. Rheological characteristics evaluation of bitumen composites containing rock asphalt and diatomite. Appl. Sci. 2019, 9, 1023. [Google Scholar] [CrossRef]

- Li, Y.F.; Chen, J.; Yan, J.; Guo, M. Influence of Buton Rock Asphalt on the Physical and Mechanical Properties of Asphalt Binder and Asphalt Mixture. Adv. Mater. Sci. Eng. 2018, 2018, 2107512. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zeng, Y.; Feng, Y.N.; Zhang, C.X.; Zhang, L. Carbon emissions analysis of producing modified asphalt with natural asphalt. Green Process. Synth. 2023, 12, 20228146. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Zafra-Mejía, C.A. Natural Asphalts in Pavements: Review. Sustainability 2023, 15, 2098. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2010.

- JTG E20-2011 T0620; Bitumen Dynamic Viscosity Test (Vacuum Reduced Pressure Capillary Method). Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG E20-2011 T0611; Bitumen Flash Point and Ignition Point Test (Cleveland Open Cup Method). Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Xie, Z.; Shen, J. Effect of cross-linking agent on the properties of asphalt rubber. Constr. Build. Mater. 2014, 67, 234–238. [Google Scholar] [CrossRef]

- Feng, X.; Fu, H.; Dai, Z.; Li, W. Study on performance and microscopic mechanism of hydrogen peroxide treated waste crumb rubber modified asphalt. J. Traffic Transp. Eng. (Engl. Ed.) 2025, 12, 331–343. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A review on compatibility between crumb rubber and asphalt binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Padhan, R.K.; Gupta, A.A.; Mohanta, C.S.; Badoni, R.P.; Bhatnagar, A.K. Performance improvement of a crumb rubber modified bitumen using polyoctenamer and cross linking agent. Road Mater. Pavement Des. 2017, 18, 999–1006. [Google Scholar] [CrossRef]

- Zhou, Q.; Shi, Z.; Zhang, D.; Zhao, M.; Yuan, M.; Zheng, S.; Liu, B.; Song, X.; Jiang, X.; Zhao, S.; et al. Research on the Performance and Mechanism of SBS Latex–Modified Emulsified Asphalt. J. Mater. Civ. Eng. 2025, 37, 04025035. [Google Scholar] [CrossRef]

- Zhao, Y.; Dong, R.; Zhao, J.; Wang, Y.; Guo, F.; Wei, X.; Li, B.; Huang, Y. Rheological Properties and Influence Mechanisms of Twin-Screw Activated Rubber Powder Composite SBS-Modified Asphalt. Materials 2025, 18, 2359. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.; Yang, X.; Yan, J.; Du, X.; Lin, H. Laboratory Evaluation of Asphalt Binder and Asphalt Mixture Modified Using Styrene–Butadiene–Styrene/Rock Asphalt. Processes 2025, 13, 292. [Google Scholar] [CrossRef]

- Xie, S.; Cheng, Z.; Zhou, Y.; Cao, Y.; Wang, T.; Zhang, Z.; Dai, Y.; Zhang, W. Performance of Asphalt Mixtures Modified with Desulfurized Rubber and Rock Asphalt Composites. Buildings 2024, 14, 3026. [Google Scholar] [CrossRef]

- Yan, Y.; Guo, R.; Zhang, S.; Yang, Y.; Liu, Z. Effect of crumb rubber depolymerisation degree on the properties of modified asphalt. Case Stud. Constr. Mater. 2025, 22, e04602. [Google Scholar] [CrossRef]

- White, G.; Kidd, A. Analysis of the Effects of Rubber Dosage and Digestion Time on the Mechanical Properties of Low Dosage Crumb-Rubber-Modified Asphalt Concrete Mixtures. Materials 2025, 18, 1419. [Google Scholar] [CrossRef]

- Ravichandran, M.; Castorena, C. Critical Evaluation of Dynamic Shear Rheometer (DSR)-Based Methods to Measure Asphalt Binder Diffusion. J. Test. Eval. 2021, 49, 4014–4031. [Google Scholar] [CrossRef]

- Zeng, Z.A.; Shane, U.B.; Castorena, C. Low-temperature performance grade characterisation of asphalt binder using the dynamic shear rheometer. Int. J. Pavement Eng. 2022, 23, 811–823. [Google Scholar] [CrossRef]

- Xie, C.; Ye, Q.; Fan, L.; Weng, A.; Liu, H. Study on Rheological Properties of Waste Cooking Oil and Organic Montmorillonite Composite Recycled Asphalt. Buildings 2024, 14, 3149. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, S.; Pang, J.; Chen, J.; Xuan, W.A. Effects of Aging on Rheological Properties and Microstructural Evolution of SBS Modified Asphalt and Crumb Rubber Modified Asphalt Binders. Buildings 2024, 14, 1722. [Google Scholar] [CrossRef]

- Goli, A.; Moghadas, B.; Sadeghi, P. Evaluating the effects of additives, gradation and traffic conditions on damping ratio and resonant frequency in asphalt mixtures. Int. J. Pavement Eng. 2025, 26, 2513455. [Google Scholar] [CrossRef]

- Zhong, X.G.; Zeng, X.; Rose, J.G. Shear Modulus and Damping Ratio of Rubber-modified Asphalt Mixes and Unsaturated Subgrade Soils. J. Mater. Civ. Eng. 2002, 14, 496–502. [Google Scholar] [CrossRef]

- Moghimi, S.; Shafabakhsh, G.; Divandari, H. Evaluation of Rutting, Fatigue, and Moisture Resistance of Low-Energy Asphalt Mixtures Modified by Crumb Rubber. Adv. Civ. Eng. 2023, 2023, 6668963. [Google Scholar] [CrossRef]

- Guo, Z.X.; Wang, L.; Feng, L.; Guo, Y.Y. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Constr. Build. Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).