Abstract

The application of glass fiber reinforced polymer (GFRP) bars offers a promising solution for enhancing the durability of reinforced concrete structures, potentially reducing maintenance costs and associated socioeconomic impacts. However, concerns persist regarding the durability of GFRP bars in the highly alkaline environment of concrete, which can lead to physical, chemical, and mechanical degradation. This study evaluates the durability of GFRP bars composed of isophthalic polyester, vinyl ester, and epoxy matrices (6.0 mm diameter) under accelerated aging conditions. The bars were exposed to non-carbonated concrete (with and without silica fume) and carbonated concrete at temperatures of 23 °C, 40 °C, and 60 °C for durations of 500, 1000, and 3000 h. Interlaminar shear strength (ISS) was measured before and after aging. SEM and FTIR analyses confirmed degradation in the polymer matrix and fiber–matrix interface. Results indicated that silica fume significantly mitigated alkalinity effects, limiting ISS loss to 11.3%. Similarly, carbonation reduced the concrete’s pH, thereby decreasing ISS degradation to 10.7% after 3000 h. Among the tested materials, GFRP bars with vinyl ester matrix exhibited superior durability, followed by those with epoxy and polyester matrices. These findings emphasize the critical role of matrix selection and concrete mix design in improving GFRP durability.

1. Introduction

The high cost of maintenance or even demolition of reinforced concrete structures due to steel bar corrosion [1], triggered by aggressive agents such as chloride ions and carbon dioxide, has intensified the search for alternatives to enhance the durability and service life of such structures. To mitigate corrosion, two principal strategies are typically employed: improving concrete durability or enhancing the corrosion resistance of reinforcing bars. Concrete-based measures include the use of corrosion-inhibiting admixtures and techniques to reduce permeability, thereby limiting the ingress of chlorides and/or CO2 [2,3]. Alternatives to conventional steel reinforcement include galvanized, epoxy-coated, stainless steel, and fiber-reinforced polymer (FRP) bars [3].

Among these, glass fiber reinforced polymer (GFRP) bars have attracted considerable attention due to their immunity to chloride-induced corrosion [4] and superior strength-to-weight ratio [5]. Nevertheless, GFRP bars remain susceptible to degradation when exposed to the alkaline environment of concrete. The primary degradation mechanism involves chemical attack by hydroxyl ions (OH−) present in the pore solution, originating from cement hydration products [6]. This alkaline attack can lead to deterioration of the polymer matrix, damage to the glass fibers, and debonding at the fiber–matrix interface, ultimately compromising the tensile strength, interlaminar shear strength, and overall durability of the composite material [7].

Several factors influence the durability of GFRP bars in concrete, including manufacturing parameters, such as the type, amount, and quality of the glass fibers and polymer matrix, as well as the characteristics of the fiber–matrix interface (e.g., sizing) [8]. In addition, concrete-related parameters—such as water-to-cement (w/c) ratio, internal relative humidity, cement type, and the use of supplementary cementitious materials—affect both the pH and the concentration of free hydroxyl ions in the pore solution, thereby influencing the degradation process [9].

The effect of the concrete cover layer on the durability of GFRP bars has been evaluated by several authors, Manalo et al. [10], Shakiba et al. [11], Bazli et al. [12], and Benmokrane et al. [13], with durability typically assessed by measuring the variation in mechanical strength before and after the reinforced concrete is exposed to aggressive environments. In addition to conventional concrete, other types such as self-compacting concrete, fiber-reinforced concrete, lightweight concrete, and high-strength concrete have also been investigated.

The results indicate that GFRP bars embedded in concrete exhibit greater durability compared to those directly exposed to aggressive environments. Regarding the type of concrete, higher compressive strength appears to offer better protection to the bars [12]. However, the use of fiber-reinforced concrete resulted in lower bond strength between the bar and the concrete than that observed with conventional concrete, after exposure to 150 days of seawater wet–dry cycles [11]. It is noteworthy, however, that in the studies reviewed, the types of concrete assessed did not involve significant changes in their constituent materials. Consequently, the alkalinity of the pore solution in contact with the bars remained similar across all cases. The chemical environment within hardened concrete is dynamic and influenced by several factors. Typically, the pH of concrete pore solutions ranges from 12.5 to 13.6, depending on the cement composition. However, in carbonated environments, the pH can decrease significantly—reaching values as low as 8.5—which reduces the alkaline reserve and can potentially alter the degradation kinetics of the embedded GFRP bars [14,15,16].

The type of resin used in the production of GFRP bars is another key factor influencing their durability. Bars manufactured with polyester resin have shown lower mechanical strength after hydrothermal aging compared to those with a vinyl ester matrix. This behavior has been attributed to the higher water and aggressive agent absorption capacity of the former resin type [6]. On the other hand, exposure of GFRP bars to an aggressive environment for three months resulted in mechanical strength reductions of approximately 40%, 51%, and 59% for bars made with polyester, epoxy, and vinyl ester resins, respectively [17].

In a study on the durability of FRP bars made with different fiber and resin types, Benmokrane et al. [18] found that resistance to alkaline environments depends on the combination of components used. Vinyl ester resin was shown to be more compatible with glass fibers than with basalt or carbon fibers. Furthermore, it was observed that epoxy resin tends to produce CFRP bars with greater durability than those made with vinyl ester resin. In this study, GFRP bars made with three different resin types will be evaluated to assess the compatibility between the resin type and the concrete matrix surrounding the GFRP bars.

The durability of GFRP bars subjected to accelerated aging has been indirectly assessed through changes in tensile strength [6], bond strength between the bar and concrete [12], or interlaminar shear strength (ISS) [10]. The interlaminar shear strength (ISS) test has emerged as a key indicator of durability, particularly in assessing the integrity of the fiber–matrix interface, which is especially vulnerable to chemical degradation caused by the alkaline pore solution in concrete. Unlike tensile tests, which primarily reflect the load-bearing capacity of the fiber–matrix composite, ISS testing is more sensitive to interfacial deterioration mechanisms such as debonding and delamination. Manalo et al. [10] demonstrated that GFRP bars subjected to simulated pore solutions exhibited significant reductions in ISS, indicating severe damage at the interface even before observable fiber or matrix degradation. Similar findings were reported by Yu et al. [14], who noted that ISS loss was more substantial than tensile strength loss during aging, suggesting that interface weakening is an early and critical sign of overall composite degradation. In agreement with these results, Pan and Yan [15] observed pronounced ISS reductions in both GFRP and hybrid carbon/glass FRP bars after exposure to alkaline environments. These studies emphasize the importance of ISS testing as a reliable and sensitive method for assessing the durability of GFRP bars under chemically aggressive conditions typical of concrete structures.

The present work aims to investigate the influence of concrete alkalinity on the durability of embedded GFRP bars with different resin types. The investigation considers bars embedded in non-carbonated concrete—both with and without mineral admixtures—as well as in carbonated concrete. The mechanical performance, durability, and expected service life of three types of GFRP bars, fabricated with polyester, vinyl ester, and epoxy matrices, are evaluated following accelerated aging at varying temperatures (23 °C, 40 °C, and 60 °C) and exposure durations (500 h, 1000 h, and 3000 h).

2. Materials and Methods

2.1. Materials

In this study, GFRP bars with three distinct polymer matrices were used: isophthalic polyester (P), vinyl ester (V), and epoxy (E). All bars had a nominal diameter of 6 mm and featured a helical ribbed surface. The bars were manufactured by pultrusion and reinforced with continuous unidirectional glass fiber filaments (rovings). Specifically, the GFRP-P and GFRP-V bars were reinforced with E-type glass fibers, while GFRP-E bars were reinforced with ECR-type glass fibers. The corresponding properties are summarized in Table 1.

Table 1.

Summary of properties and geometric characteristics of GFPR bars tested.

The materials used for concrete production included natural quartz sand, coarse aggregate of granite origin, Portland cement (CP V ARI), and silica fume. Portland cement (CP V ARI) was selected due to the absence of pozzolans in its composition. The silica fume used in this study had a specific gravity of 2.32 g/cm3, determined using a helium gas pycnometer (Micromeritics Accupyc 1340, Norcross, GA, USA). Its specific surface area was 15.2 m2/g, measured by the BET method using a Gemini VII analyzer (Micromeritics, Norcross, GA, USA), and its equivalent particle diameter (D50), determined by laser granulometry (CILAS 1180 particle-size analyzer, Orleans, France), was 43.0 µm.

The specific mass of the cement was 3.13 g/cm3, a BET surface area of 1.4 m2/g, and an average equivalent diameter (D50) of 15.0 µm. Fine aggregate, with a specific mass of 2.65 g/cm3 and equivalent diameter (D50) of 0.4 mm, and coarse aggregate, with a specific mass of 2.77 g/cm3 and equivalent diameter (D50) of 7.1 mm, were used. The aggregates were characterized according to NBR 7211 [22], NBR NM 52 [23], NBR NM 53 [24], NBR NM 45 [25], and NBR NM 248 [26].

The mix proportions by mass were defined as 1:2.50:2.40:0.65 (binder:fine aggregate:coarse aggregate:water), with a binder content of 425.8 kg/m3. In this study, in addition to the reference concrete produced exclusively with Portland cement (REF concrete), a second mix with reduced alkalinity was prepared by replacing 10% of the Portland cement with silica fume (SA concrete). The incorporation of silica fume is well known for its pozzolanic activity, which reacts with free calcium hydroxide in the hydrated cement paste, thereby reducing the pH of the concrete [27]. This behavior was confirmed through thermogravimetric analysis (TGA), which indicated a decrease in calcium hydroxide content in the modified paste. Moreover, compressive strength tests revealed an improvement in mechanical performance, with strength increasing from 32.7 MPa to 38.0 MPa.

2.2. Reinforced Concrete Aging

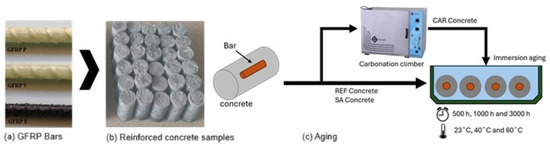

The durability of GFRP bars (Figure 1a) in reinforced concrete was assessed by immersing concrete specimens (Figure 1b) in water under different temperature conditions and exposure durations, as illustrated in Figure 1c, using a climatic chamber (FEUTRON 200, Langenwetzendorf, Germany). Cylindrical concrete specimens, measuring 100 mm in length and 56.3 mm in diameter, were internally reinforced with three types of bars (length 25.2 mm), with a concrete cover was 25 mm. To ensure that aging occurred predominantly through the lateral surfaces, the ends of the specimens were sealed with an epoxy adhesive. Specimens produced with both the reference concrete (REF concrete) and the silica-modified concrete (SA concrete) were subjected to the aging process after 28 days of curing.

Figure 1.

The aging process of reinforced concrete.

A third group of specimens (CAR concrete), produced with reference concrete, was subjected to an accelerated carbonation process prior to aging, in order to assess the durability of GFRP bars previously exposed to a simulated environmental condition. The carbonation procedure was carried out in accordance with ISO 1920 [28], using a carbonation chamber (Quimis Q316C1, Diadema, SP, Brazil) for a period of 70 days. The process was conducted under controlled conditions: CO2 concentration of 3.0% ± 0.5%, temperature of 27 °C ± 2 °C, and relative humidity of 65% ± 5%. After the aging period, the GFRP bars were manually extracted from the concrete specimens to evaluate their properties. The measured carbonation depths were 6.5 mm, 8.8 mm, and 10.7 mm after 56, 63, and 70 days of accelerated carbonation, respectively.

2.3. Interlaminar Shear Strength Test

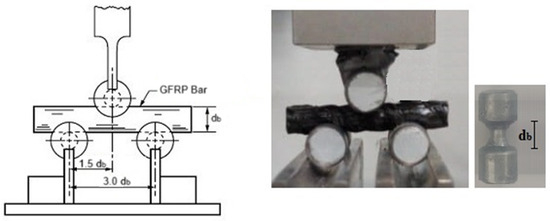

The interlaminar shear strength (ISS) test was conducted to assess the mechanical performance of GFRP bars aged under the protection of different types of concrete. The test was performed using an universal testing machine (INSTRON 2310, Pindamonhangaba, SP, Brazil) equipped with a 5 kN load cell and a displacement rate of 1.2 mm/min. The specimens were simply supported and loaded at the center, in accordance with ASTM D4475 [29], as illustrated in Figure 2.

Figure 2.

Interlaminar shear strength test setup.

The apparent interlaminar shear strength (ISS) was calculated using Equation (1):

where P is the failure load and db is the diameter of the GFRP bar.

ISS = 0.849 P/db2

2.4. Scanning Electron Microscope (SEM)

The microstructure of the GFRP bars was examined before and after accelerated aging in alkaline medium using a scanning electron microscope (JEOL JSM 6390LV, Peabody, MA, USA) equipped with a secondary electron detector (SE), operating at an accelerating voltage of 15 kV with a tungsten filament. Specimens measuring 10 mm in length were cut transversely to their axis, polished, and then coated with a thin layer of gold via vacuum deposition. The resulting micrographs were analyzed to identify potential changes in the polymer matrix, glass fibers, and the fiber-matrix interface caused by exposure to the alkaline environment.

2.5. Fourier Transform Infrared Spectroscopy (FTIR)

FTIR analysis was conducted to identify changes in the chemical structure of the polymer matrix before and after aging. A spectrometer equipped (Perkin Elmer Spectrum 400, Shelton, CT, USA) with an attenuated total reflection (ATR) accessory was used. Three specimens, each 10 mm in length, were prepared for analysis. The infrared spectra were collected over a wavelength range of 4000 to 650 cm−1 with a resolution of 4 cm−1.

3. Results

3.1. Fourier Transform Infrared Spectroscopy

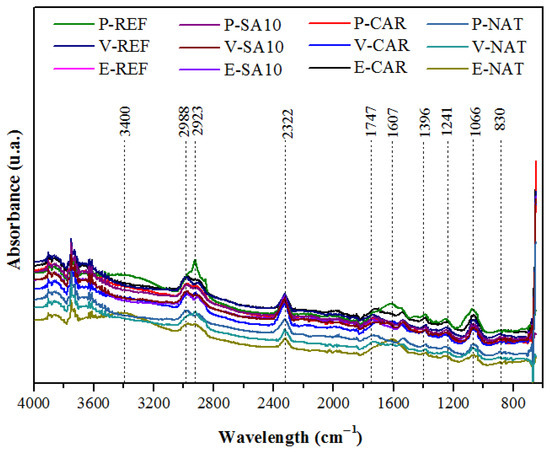

Figure 3 shows the FTIR spectra for samples of GFRP bars with polyester resin (P), vinyl ester (V), and epoxy (E), embedded in concrete, before (NAT) and after exposure for 3000 h at 60 °C. The main bands observed in the spectra were identified by [30], as follows: 3500–3400 cm−1 (O–H stretching), 3100–3000 cm−1 (=C–H stretching of the benzene ring and vinyl groups), 3000–2800 cm−1 (aliphatic C–H stretching of CH, CH2, and CH3 groups), 1750–1720 cm−1 (C=O stretching), 1507 cm−1 (aromatic C–H in the benzene ring), 1232 cm−1 (C–O stretching in esters), approximately 1180 cm−1 (C–O–C stretching), and approximately 830 cm−1 (epoxy ring deformation).

Figure 3.

FTIR spectra of GFRP bars embedded in concrete and aged for 3000 h in concrete at 60 °C.

The IR spectra of GFRP bars extracted from concrete after aging in alkaline solution showed an increase in the intensity of the peaks associated with the main functional groups present in their resins, compared to the spectra of samples analyzed prior to exposure (NAT). Although no new characteristic peaks were observed, the changes in peak intensity indicate alterations in the chemical structure of the polymer matrices in the GFRP bars. The spectra revealed a change in the band at 3400 cm−1, indicating an increase in hydroxyl (OH−) concentration. This can be attributed to the hydrolysis of ester groups, resulting in chain scission and degradation of the polymeric matrix [31,32], particularly in the GFRP bars embedded in the REF concrete specimens.

In GFRP bars with vinyl ester resin, a slight variation in the shape of the bands in the 1440–1350 cm−1 region was observed after exposure, which may indicate minor changes in the chemical structure of the aged samples compared to the unexposed ones. For bars with epoxy resin, changes were detected in the band at 1062 cm−1, associated with C–O bond deformation. These findings are consistent with the results reported by Vemuganti et al. [30] and Sawpan et al. [33].

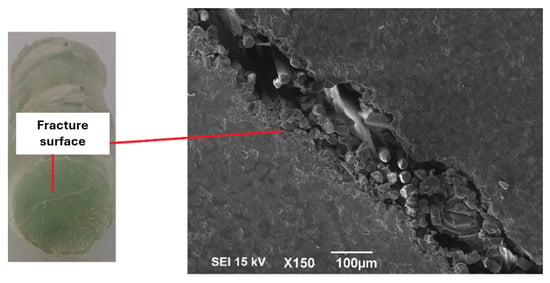

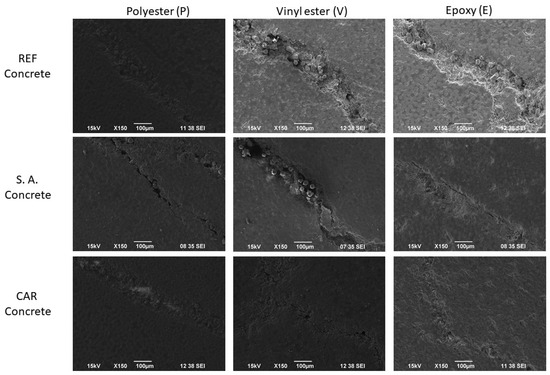

3.2. Fracture Surface Analysis

It was observed that the failure of the bars after the interlaminar shear test is characterized by the formation of horizontal cracks along the mid-plane, just below the load application point, propagating toward the ends of the specimen (shear failure), as shown in Figure 4. This allows for the investigation of the effects of aging on the strength of the polymer matrix and the fiber–matrix interface through analysis of the fracture surface.

Figure 4.

Fracture surface after interlaminar shear test in samples unaged.

Figure 5 shows micrographs obtained by scanning electron microscopy of the fracture surface of GFRP bars exposed to the most severe accelerated aging condition: a temperature of 60 °C for 3000 h.

Figure 5.

SEM images of the fracture surface of GFRP bars aged for 3000 h at 60 °C.

For the GFRP bars embedded in the reference concrete, the primary mode of failure was rupture at the matrix–glass fiber interface. Fragments of the polymer matrix remained adhered to the fractured fiber surfaces, indicating strong fiber–matrix adhesion. Bars embedded in concrete containing silica fume exhibited a similar failure pattern. In contrast, samples aged in carbonated concrete showed signs of glass fiber damage and debonding at the fiber–matrix interface.

Hydroxyl ions penetrate the GFRP bar, first interacting with the polymeric matrix and eventually reaching the glass fibers. This leads to chemical alterations in the matrix structure (as shown by FTIR analysis) and weakens the bond between the matrix and fibers. Consequently, the interlaminar shear strength decreases, and once the hydroxyl ions contact the glass fibers, fiber rupture occurs. These results emphasize the polymeric matrix’s critical role as a protective barrier against alkaline degradation.

The fracture surface analysis of GFRP bars subjected to aging was conducted by Zhu et al. [34], who attributed the matrix damage and fiber–matrix debonding to resin hydrolysis. Therefore, the authors observed that debonding can lead to an uneven distribution of stress under loading, ultimately resulting in the rupture of the glass fibers.

3.3. Interlaminar Shear Strength (ISS)

Table 2 presents the experimental results of the interlaminar shear strength (ISS) tests conducted on GFRP bars with polyester, vinyl ester, and epoxy matrices, embedded in concrete specimens and exposed to temperatures of 23 °C, 40 °C, and 60 °C for durations of 500 h, 1000 h, and 3000 h. In addition, GFRP bars were also tested in the as-received condition from the manufacturer to serve as a control.

Table 2.

Interlaminar shear strength of unaged and aged bars.

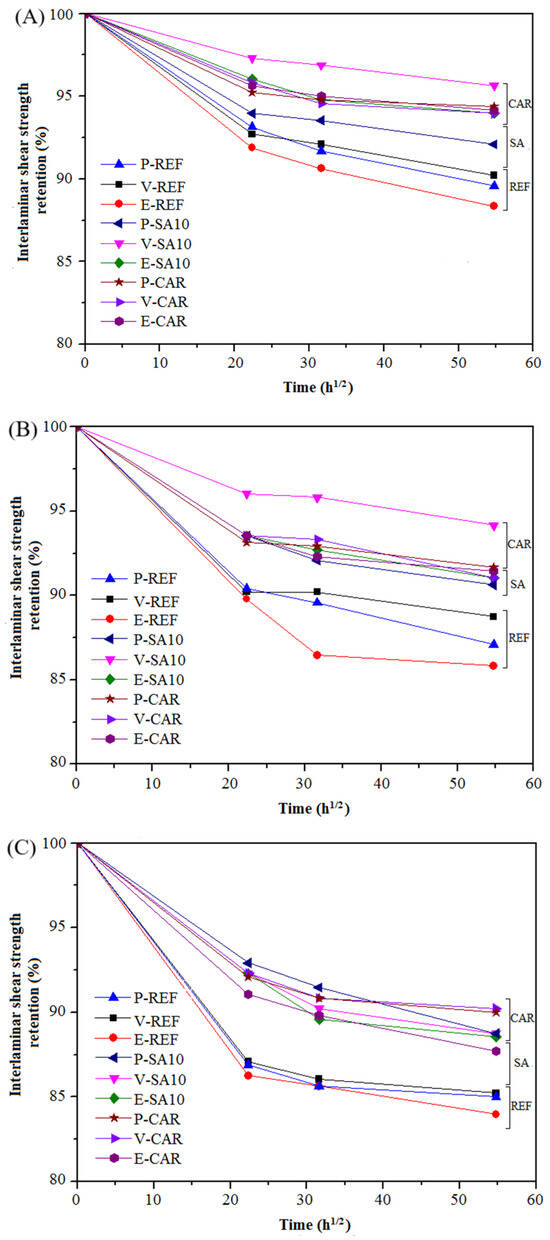

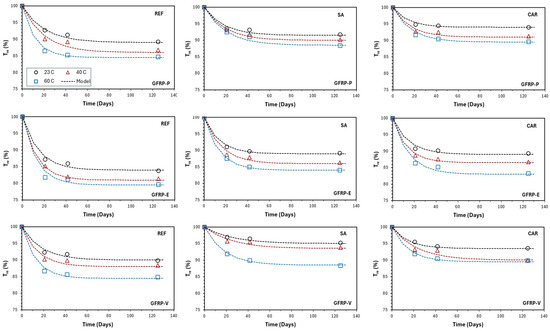

For all mixtures, a reduction in mechanical strength was observed with increasing immersion time and water temperature, demonstrating the well-known sensitivity of GFRP bars to moisture. However, because the bars were protected by different types of concrete, there was a variation in durability loss, indicating that the composition of the matrix protecting the bars affects the attack mechanisms.

In reinforced concrete samples containing GFRP bars and subjected to 23 °C, a reduction in the shear strength of the bars was observed by around 10.6%, 6.1% and 5.8%, for those containing REF, SA-10 concrete coverings, and CAR, respectively (Figure 5). It is noted that the addition of 10% silica fume (SA-10) to the concrete resulted in a cement matrix that was less aggressive to the GFRP bars and, consequently, there was a smaller reduction in their resistance to interlaminar shear, compared to the bars aged in the concrete REF. The lower aggressiveness of the SA-10 matrix was a consequence of the pozzolanic activity of the silica fume, which, by fixing calcium hydroxide Ca(OH)2 and forming additional C-S-H (Equation (2)), reduces the porosity and pH in the concrete pore solution, reducing degradation to the polymeric matrix of GFRP bars.

The average reduction in interlaminar shear strength of GFRP bars aged in carbonated concrete (CAR) was only 5.8%, lower than that observed in specimens containing REF concrete (10.1%) and quite similar to that observed in those containing SA-concrete. 10 (6.1%). Just like the pozzolanic reaction resulting from the addition of silica fume, the carbonation of concrete reduces the pH of the matrix through the reaction of CO2 with hydrated calcium-based compounds (mainly portlandite), forming calcite (CaCO3). This reduction proved to be beneficial for GFRP bars, as shown in Figure 6.

Figure 6.

Interlaminar shear strength retention of aged GFRP bars versus conditioning time of specimens at: (A) 23 °C, (B) 40 °C, and (C) 60 °C.

In reinforced concrete samples containing GFRP bars and subjected to 40 °C, shear strength was significantly affected in samples containing REF concrete covering and slightly reduced in those with SA-10 and CAR concretes, as shown in Figure 6B. After aging for 3000 h, the shear strength of GFRP bars was reduced by 12.8%, 8.1%, and 8.6% when using REF, SA-10, and CAR concrete coverings, respectively. The greater loss of resistance due to the increase in temperature occurs due to the greater ease of reaction between the polymeric resin and alkaline ions and water molecules. Despite presenting a more significant loss of resistance than bars inserted in concrete subjected to 23 °C, similar behavior was observed depending on the types of concrete.

Figure 6C shows that samples of GFRP bars aged in concrete and subjected to 60 °C for 3000 h showed average ISS reductions equal to 15.3%, 11.3% and 10.7%, respectively, maintaining the relative behavior observed in samples exposed to 40 °C and 23 °C. Thus, it is observed that the increase in temperature accelerates the degradation process of GFRP bars inserted in the concrete, regardless of the type of covering concrete and that concretes containing pozzolanic and/or carbonated additions are less aggressive to GFRP bars.

The results presented in Figure 5 indicate that the increase in temperature had an immediate impact on reducing the interlaminar shear strength, since this increase in temperature can affect the fiber-matrix interface. The water molecules that penetrate through the fiber-resin interface have a plasticizing effect and cause hydrolysis reactions, leading to interfacial fracture, according to Equation (3).

This degradation process may also have caused damage to the glass fibers, such as leaching, which weakens the bond between the fiber and the polymer matrix. These results corroborate the results presented by Yu et al. [14], that is, the most critical degradation of GFRP bars occurs in an alkaline environment with greater availability of free hydroxyl ions. Manalo et al. [10] obtained similar results, measuring higher rates of degradation of interlaminar shear strength in higher alkalinity solutions, with a 27% reduction in strength in GFRP bars (vinyl ester matrix and ECR glass fiber) immersed in an alkaline solution for 112 days and at 60 °C. In contrast, Pan and Yan [15] observed a maximum reduction in interlaminar shear strength of 57.3% in GFRP bars (epoxy matrix and E-glass fiber) immersed in alkaline solution for 140 days at 60 °C.

3.4. Prediction of Interlaminar Shear Strength of GFRP Bars

GFRP bars are used in reinforcement to internally reinforce concrete, as shown by interlaminar shear strength, FTIR, and SEM results, affecting their capacity to reinforce concrete structures. Thus, due to the unfeasibility of natural (long-term) durability tests of GFRP bars inserted in concrete, the results of accelerated tests were adopted to estimate the long-term durability of GFRP bars, based on the Arrhenius model [35,36,37,38], obtaining the degradation rate (Equation (4)).

where k is the degradation rate (1/time), A is a constant related to the material and the degradation process, is the activation energy (J/mol), R is the universal gas constant ((8.3143 J/mol). mol.K), and T is the temperature (in K).

Different prediction models have been established based on the Arrhenius equation to determine the long-term strength of GFRP bars [34]. To predict the reduction in flexural strength of polymer matrix composites exposed to temperatures of 50, 80, and 100 °C, an equation was developed by Phani and Bose [39], that relates the strength at a given time t to the initial bar strength and parameters that account for the exposure temperature. Based on this equation, it is possible to determine the strength retention Tₑᵣ using Equation (5):

where is the shear strength at time t, is the shear strength of unaged bar, is the shear strength retention (%), is the shear strength retention (%) at the time infinite, t is the exposure time, and τ is a characteristic time dependent on temperature.

Figure 7 compares the fitting curves and the experimental results for the GFRP bars. The parameters adjusted using Equation (5) are listed in Table 3, Table 4 and Table 5. It can be seen that for all the bars, the R2 value was above 96%, indicating that Equation (5) shows good potential for use in predicting the service life of reinforced concrete structures, as also observed by Zhu et al. [34].

Figure 7.

Experimental results and theoretical model of shear strength retention of aged GFRP bars at 23 °C, 40 °C, and 60 °C.

Table 3.

Parameters determined for the analytical model of aged polyester bars.

Table 4.

Parameters determined for the analytical model of aged epoxy bars.

Table 5.

Parameters determined for the analytical model of aged vinyl ester bars.

It was observed that ranged from 79.5% to 95%, depending on the type of concrete used in the bar’s protective cover layer. Higher strength retention values were found in GFRP bars protected by concrete with lower alkalinity.

Based on the model presented in Equation (5), it is possible to determine the exponent from Equation (4). For this, the degradation rate k can be expressed either as the inverse of the time required for a material property to reach a given value or as the logarithm of the time needed for a material property to reach a given value. This relationship is a linear function of with a slope of [30], as shown in Equation (6).

In this way, rewriting Equation (5) in this form gives:

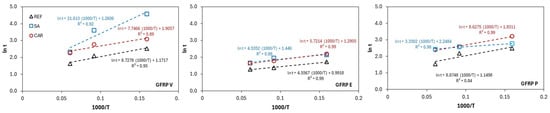

For a of 95%, the values of t and ln t for different temperatures and types of concrete cover can be calculated. Once the relationship between ln t and 1/T is determined, the value of corresponds to the slope of the line, as shown in Figure 8 and Table 6.

Figure 8.

Arrhenius graphs of aged GFRP bars in different concretes at 23 °C, 40 °C, and 60 °C for Tre = 95%.

Table 6.

Values of Ea/R of aged bars.

Zhu et al. [34] identified values on the order of 5600 for the Ea/R ratio, while the values obtained in this study ranged from 3330 to 8875. An exception was the high Ea/R value of 21,613 obtained for GFRP bar V protected by SA concrete, which is consistent with the result shown in Figure 7, demonstrating that this combination shows the lowest strength reduction under accelerated aging.

Based on Equation (8), the time shift factor (TSF) for the apparent horizontal shear strength required to reach the same value of TSF at temperatures t1 and t0 can be obtained from Arrhenius plots [34].

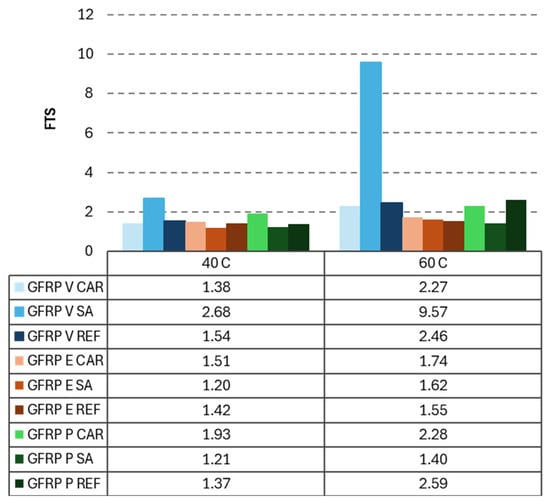

The TSF values of the three kinds of GFRP bars and different concretes at temperatures (40 °C and 60 °C) relative to the reference temperature (23 °C) were calculated as shown in Figure 9. For a temperature of 40 °C, the TSF values ranged from 1.2 to 2.68, while for a temperature of 60 °C, the values ranged from 1.40 to 9.57. These findings are consistent with the results reported by Zhu et al. [34] and Tu et al. [36].

Figure 9.

Time shift factor (TSF) of GFRP at 40 °C and 60 °C compared to 20 °C.

4. Conclusions

In this study, three types of GFRP bars—manufactured with polyester, vinyl ester, and epoxy matrices—were evaluated while embedded in different concrete matrices: reference (REF), silica fume-containing (SA-10), and carbonated (CAR). Specimens were exposed to temperatures of 23 °C, 40 °C, and 60 °C. The following conclusions were drawn:

- Elevated temperatures accelerated the degradation of GFRP bars embedded in concrete, regardless concrete composition.

- FTIR analysis indicated that exposure to concrete and elevated temperatures induced structural changes in the polymer matrices.

- SEM micrographs of fractured surfaces after interlaminar shear tests demonstrated the displacement of glass fibers from the polymer matrix, indicating interfacial weakening.

- Concretes containing pozzolanic additions (e.g, silica fume) and/or carbonation exhibited lower alkalinity and were less aggressive toward GFRP bars. Replacing 10% of cement (by mass) with silica fume proved beneficial to the durability of GFRP bars, indirectly extending the service life of concrete structures reinforced with GFRP bars.

- Accelerated aging led to evident degradation, characterized by matrix deterioration and interfacial debonding between the fibers and the matrix, with more pronounced effects at 60 °C.

- Among the bars studied, GFRP bars with a vinyl ester matrix exhibited the best performance after aging in concrete environments, considering the combination of all factors.

- A prediction model for the interlaminar shear strength of GFRP was calibrated using experimental data and demonstrated suitability for long-term performance estimation.

Author Contributions

Conceptualization, R.C.d.A.M. and P.R.L.L.; methodology, P.R.L.L. and D.V.R.; software, R.C.d.A.M. and P.R.L.L.; analysis of experimental results, R.C.d.A.M. and P.R.L.L.; resources, R.C.d.A.M. and D.V.R.; writing—review and editing, R.C.d.A.M., P.R.L.L., and D.V.R.; supervision, P.R.L.L. and D.V.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

We acknowledge the following Brazilian institutions: The Foundation for Research Support of the State of Bahia (FAPESB), the National Council for Scientific and Technological Development (CNPq), the Coordination for the Improvement of Higher Education Personnel (CAPES), the Durability of Materials Laboratory (State University of Feira de Santana), the Post Graduate Program in Civil Engineering at the Federal University of Bahia, Brazil (PPEC/UFBA), Fio Cruz Foundation (FIOCRUZ), and the State University of Santa Cruz (UESC), research project (SEI nº 073.17253.2023.0034157-83).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Goyal, A.; Pouya, H.S.; Ganjian, E.; Claisse, P. A review of corrosion and protection of steel in concrete. Arab. J. Sci. Eng. 2018, 43, 5035–5055. [Google Scholar] [CrossRef]

- Daniyal, M.; Akhtar, S. Corrosion assessment and control techniques for reinforced concrete structures: A review. J. Build. Pathol. Rehabil. 2020, 5, 1. [Google Scholar] [CrossRef]

- Zhang, P.; Su, Y.; Liu, Y.; Gao, D.; Sheikh, S.A. Flexural behavior of GFRP reinforced concrete beams with CFRP grid-reinforced ECC stay-in-place formworks. Compos. Struct. 2021, 277, 114653. [Google Scholar] [CrossRef]

- Ahmed, A.; Guo, S.; Zhang, Z.; Shi, C.; Zhu, D. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete. Constr. Build. Mater. 2020, 256, 119484. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; Elsafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester polyester, and epoxy glass-FRP bars for concrete structures. Compos. Part B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef]

- Moura, R.C.A.; Ribeiro, D.V.; Lima, P.R.L. Mechanical damage assessment of GFRP rebars with different resins due to hydrothermal aging. Mater. Res. 2021, 24, 13. [Google Scholar] [CrossRef]

- Fergani, H.; Di Benedetti, M.; Oller, C.M.; Lynsdale, C.; Guadagnini, M. Durability, and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress. Constr. Build. Mater. 2018, 170, 637–648. [Google Scholar] [CrossRef]

- Morales, C.N.; Claude, G.; Alvarez, J.; Nanni, A. Evaluation of fiber content in GFRP bars image processing. Compos. Part B Eng. 2020, 200, 108307. [Google Scholar] [CrossRef]

- Benzecry, V.; Al-Khafaji, A.F.; Haluza, R.T.; Bakis, C.E.; Myers, J.J.; Nanni, A. Durability assessment of 15- to 20-year-old GFRP bars extracted from bridges in the US. I: Select bridges, bar extraction, and concrete assessment. J. Compos. Constr. 2021, 25, 04021007. [Google Scholar] [CrossRef]

- Manalo, A.; Maranan, G.; Benmokrane, B.; Cousin, P.; Alajarmeh, O.; Ferdous, W.; Liang, R.; Hota, G. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Shakiba, M.; Bazli, M.; Karamloo, M.; Mortazavi, S.M.R. Bond-slip performance of GFRP and steel reinforced beams under wet-dry and freeze-thaw cycles: The effect of concrete type. Constr. Build. Mater. 2022, 342, 127916. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments. Constr. Build. Mater. 2017, 148, 429–443. [Google Scholar] [CrossRef]

- Benmokrane, B.; Wang, P.; Ton-That, T.M.; Rahman, H.; Robert, J.F. Durability of glass fiber-reinforced polymer reinforcing bars in concrete environment. J. Compos. Constr. 2002, 6, 143–153. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, S.; Pan, Y.; Mil, X.; Liu, J. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution. Constr. Build. Mater. 2021, 299, 123995. [Google Scholar] [CrossRef]

- Pan, Y.; Yan, D. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

- Ramanathan, S.; Benzecry, V.; Suraneni, P.; Nanni, A. Condition assessment of concrete and glass fiber reinforced polymer (GFRP) rebar after 18 years of service life. Case Stud. Constr. Mater. 2021, 14, e00494. [Google Scholar] [CrossRef]

- Zeng, J.J.; Hao, Z.H.; Liang, Q.J.; Zhuge, Y.; Liu, Y. Durability assessment of GFRP bars exposed to combined accelerated aging in alkaline solution and a constant load. Eng. Struct. 2023, 297, 116990. [Google Scholar] [CrossRef]

- Benmokrane, B.; Hassan, M.; Robert, M.; Vijay, P.V.; Manalo, A. Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars. J. Compos. Constr. 2020, 24, 04020010. [Google Scholar] [CrossRef]

- American Society for Testing and Materials D792; Standard Test Methods for Density and Specific Gravity of Plastics by Displacement. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- American Society for Testing and Materials D3171; Standard Test Methods for Constituent Content of Composite Materials. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- American Society for Testing and Materials D7205; Standard Test Methods for Tensile Properties Matrix Composite Materials. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- Brazilian Association for Technical Standards NBR 7211; Aggregates for Concrete—Specification. ABNT—Brazilian Association for Technical Standards: Rio de Janeiro, Brazil, 2009.

- Brazilian Association for Technical Standards NBR NM 52; Fine Aggregate—Determination of the Bulk Specific Gravity and Apparent Specific Gravity. ABNT—Brazilian Association for Technical Standards: Rio de Janeiro, Brazil, 2009.

- Brazilian Association for Technical Standards NBR NM 53; Coarse Aggregate—Determination of the Bulk Specific Gravity, Apparent Specific Gravity, and Water Absorption. ABNT—Brazilian Association for Technical Standards: Rio de Janeiro, Brazil, 2009.

- Brazilian Association for Technical Standards NBR NM 45; Aggregates—Determination of the Unit Weight and Air-Void Contents. ABNT—Brazilian Association for Technical Standards: Rio de Janeiro, Brazil, 2006.

- Brazilian Association for Technical Standards NBR NM 248; Aggregates—Sieve Analysis of Fine and Coarse Aggregates. ABNT—Brazilian Association for Technical Standards: Rio de Janeiro, Brazil, 2003.

- Ganapathy, V.; Muthukumaran, G.; Sudhagar, P.E.; Rashedi, A.; Norahim, M.N.F.; Ilyas, R.A.; Goh, K.L.; Jawaid, M.; Naveen, J. Mechanical properties of cellulose-based multiscale composites: A review. Polym. Compos. 2023, 44, 734–756. [Google Scholar] [CrossRef]

- International Standard 1920; Testing Concrete—Part. 12: Determination of the Carbonation Resistance of Concrete—Accelerated Carbonation Method. ISO—International Standard: Geneva, Switzerland, 2015.

- American Society for Testing and Materials D4475; Standard Test Methods for Apparent Horizontal Shear Strength of Pultruded Plastic Rods by the Short-Beam Method. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- Vemuganti, S.; Chennareddy, R.; Riad, A.; Taha, M.M.R. Pultruded GFRP reinforcing bars using nanomodified vinyl ester. Materials 2020, 13, 5710. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.G.; Leung, C.K.L.; Kim, J.K.; Liu, M.Y. Degradation of glass fiber-reinforced plastic composites containing nano clay in alkaline environment. J. Compos. Mater. 2011, 45, 2147–2156. [Google Scholar] [CrossRef]

- Arczewska, P.; Polak, M.A.; Penlidis, A. Degradation of glass fiber reinforced polymer (GFRP) bars in concrete environment. Constr. Build. Mater. 2021, 293, 123451. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Mamun, A.A.; Holdsworth, P.G. Long term durability of pultruded polymer composite rebar on concrete environment. Mater. Des. 2014, 57, 616–624. [Google Scholar] [CrossRef]

- Zhu, P.; Li, Z.; Zhu, Y.; Wu, Y.; Qu, W. Prediction of the long-term tensile strength of GFRP bars in concrete. Buildings 2023, 13, 1035. [Google Scholar] [CrossRef]

- Visco, A.M.; Brancato, V.; Campo, N. Degradation effects in polyester and vinyl ester resins induced by accelerated aging in seawater. J. Compos. Mater. 2011, 46, 2025–2040. [Google Scholar] [CrossRef]

- Tu, J.; Xie, H.; Gao, K. Prediction of the long-term performance and durability of GFRP bars under the combined effect of a sustained load and severe environments. Materials 2020, 13, 2341. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.A.G.; Fonseca, B.S.; Biscaia, H. On estimates of durability of FRP based on accelerated tests. Compos. Struct. 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Xue, W.; Li, Y.; Fu, K.; Hu, X.; Li, Y. Accelerated ageing test and durability prediction model for mechanical properties of GFRP connectors in precast concrete sandwich panels. Constr. Build. Mater. 2020, 237, 117632. [Google Scholar] [CrossRef]

- Phani, K.K.; Bose, N.R. Temperature dependence of hydrothermal ageing of CSM-laminate during water immersion. Compos. Sci. Technol. 1987, 29, 79–87. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).