Detonation Dynamics and Damage Behavior of Segmented Tunnel Charges with Shaped Liners

Abstract

1. Introduction

2. Mechanism of Shaped Charge Jet Impact-Induced Explosive Detonation

3. Methods

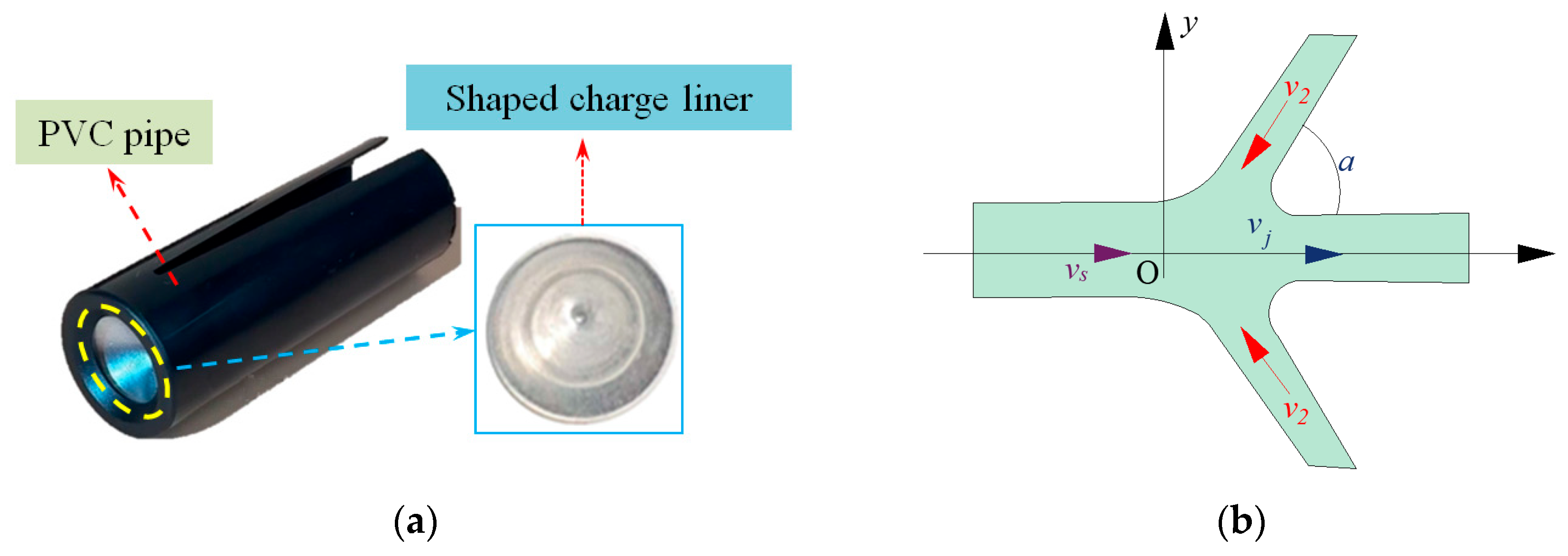

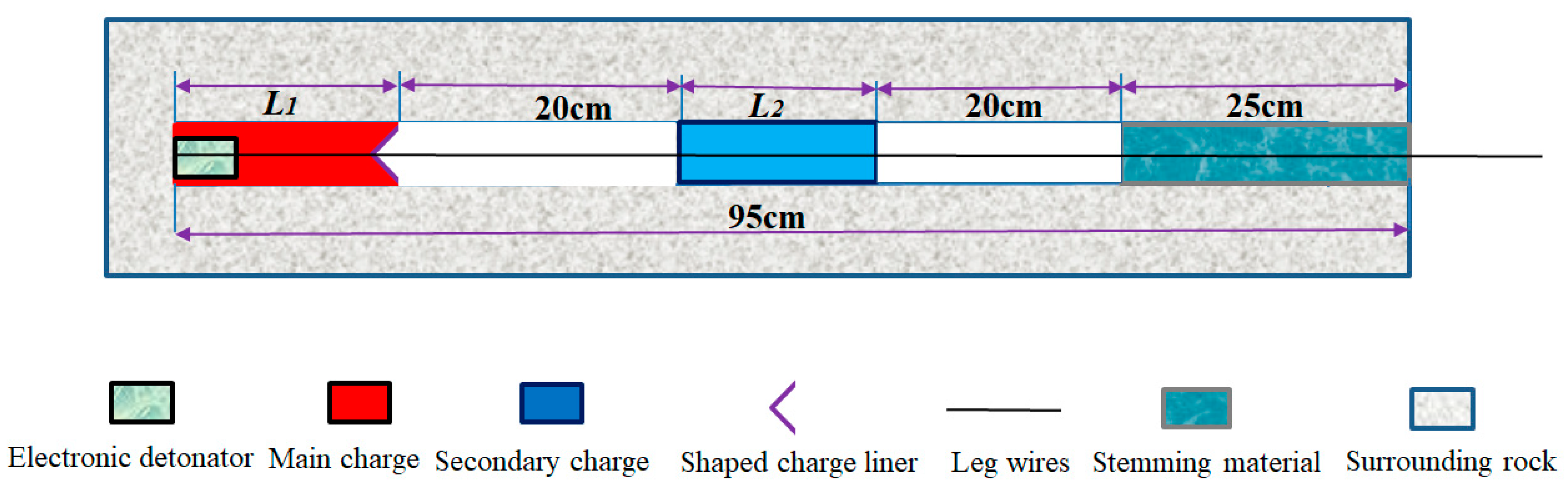

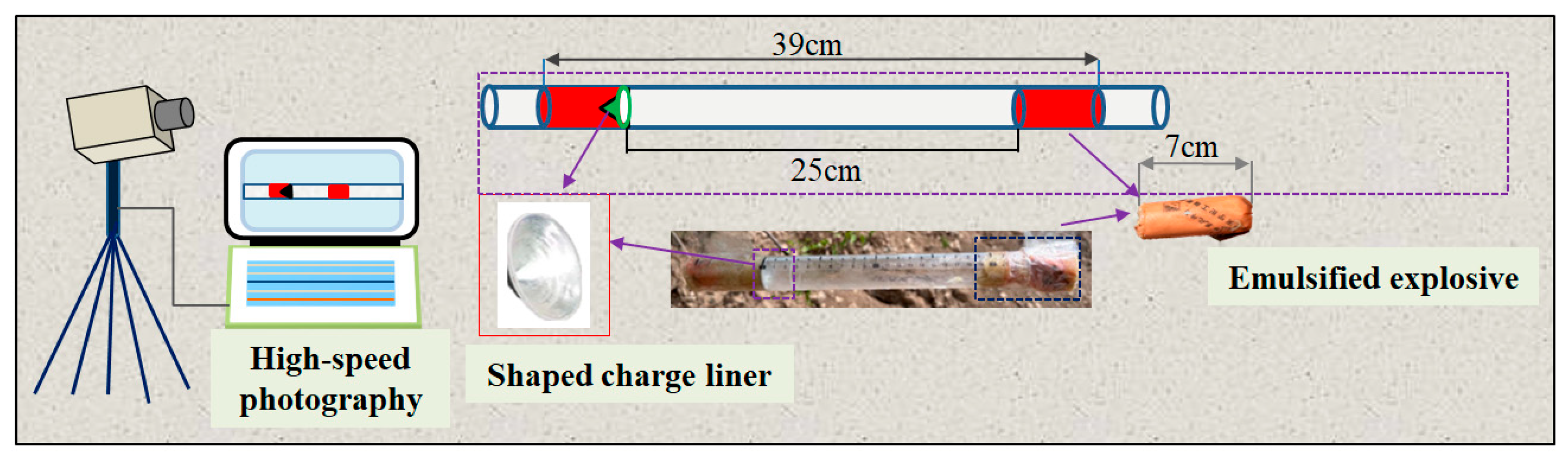

3.1. Experimental Scheme Design

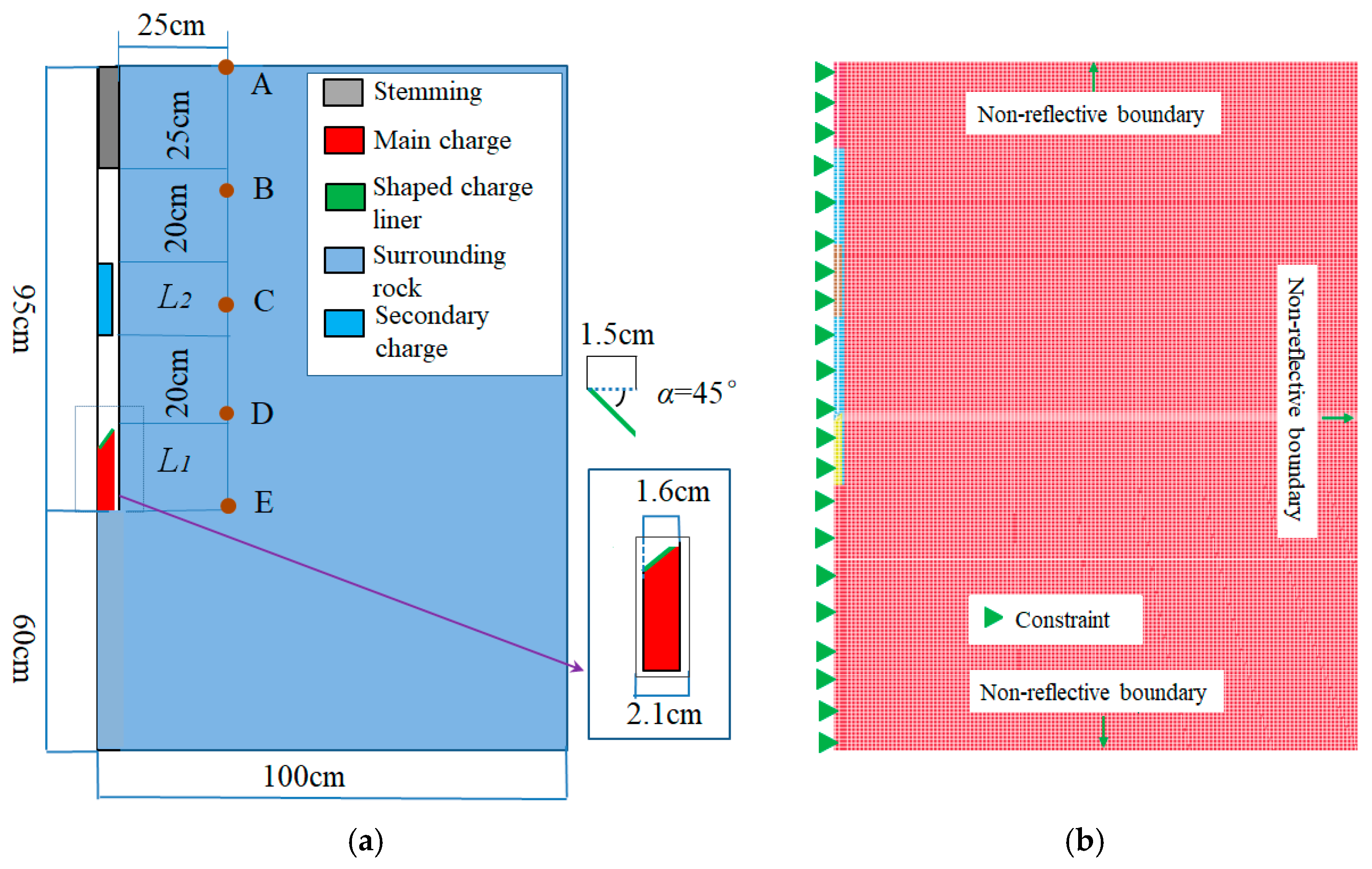

3.2. Numerical Model Establishment

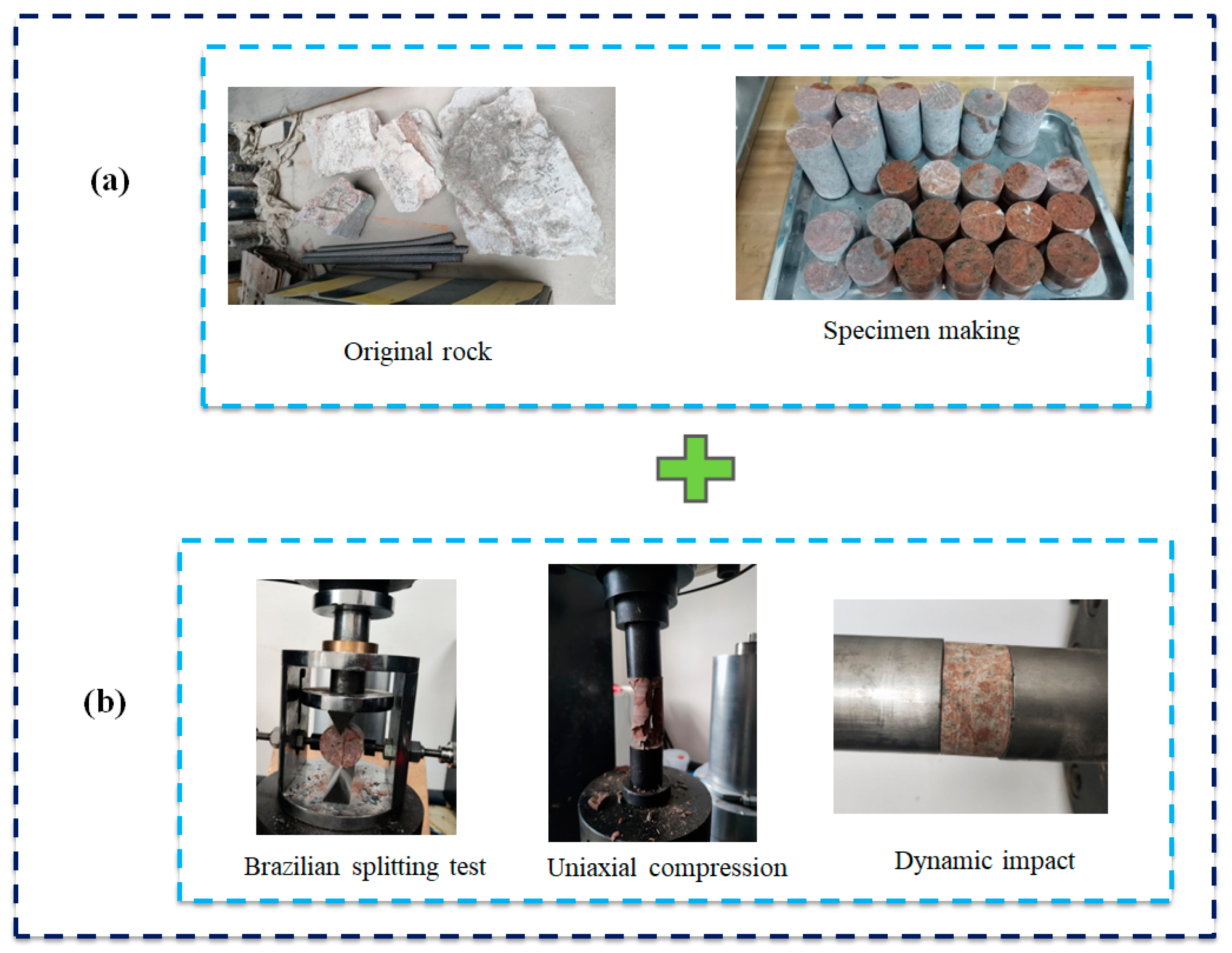

3.3. Numerical Model Parameter Determination

3.3.1. Rock Mass Parameters

3.3.2. Liner Parameters

3.3.3. Air Material Parameters

3.3.4. Explosive Equation of State and Parameters

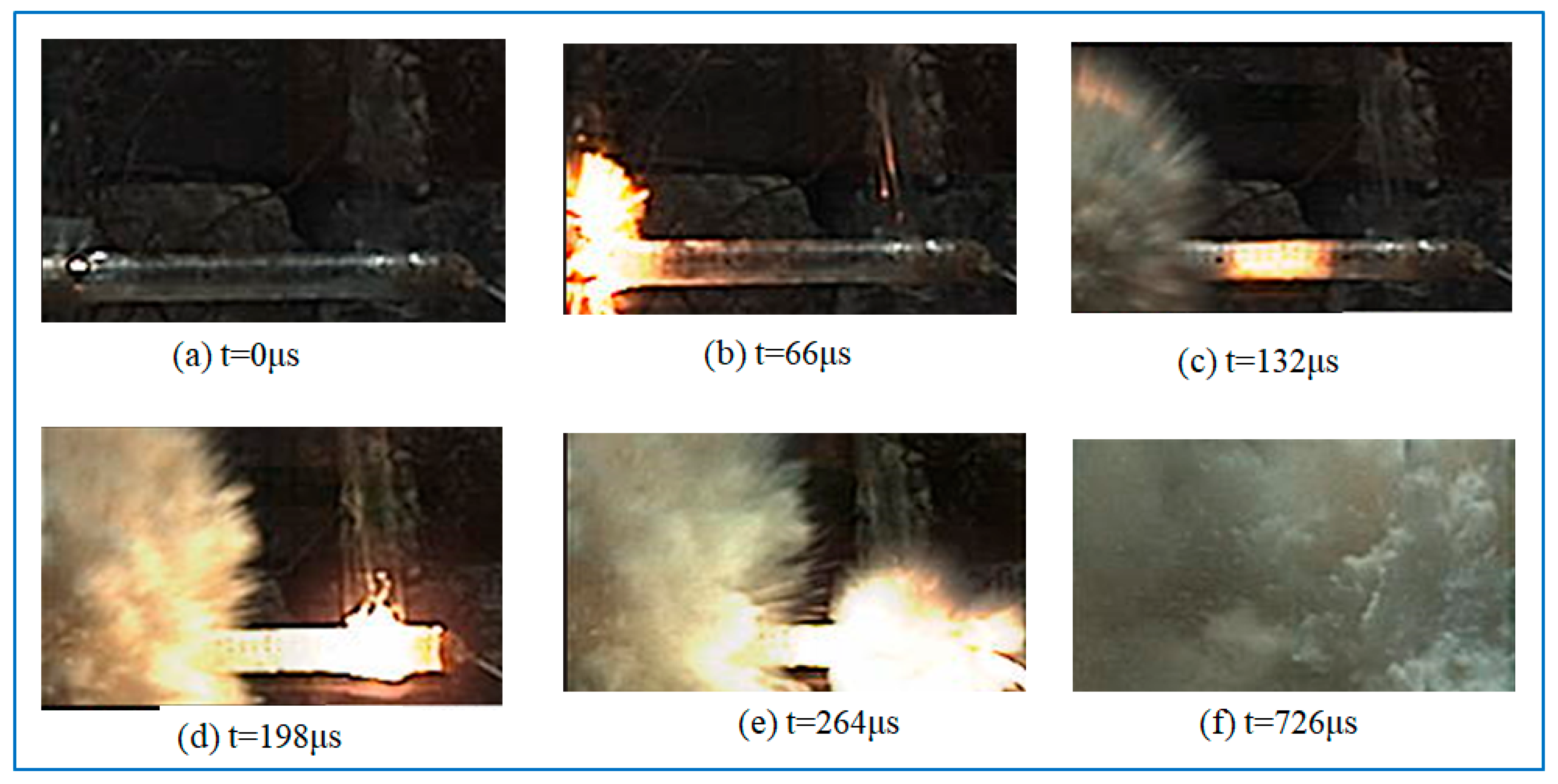

3.4. Validation of Simulation Method

4. Numerical Simulation Result Analysis

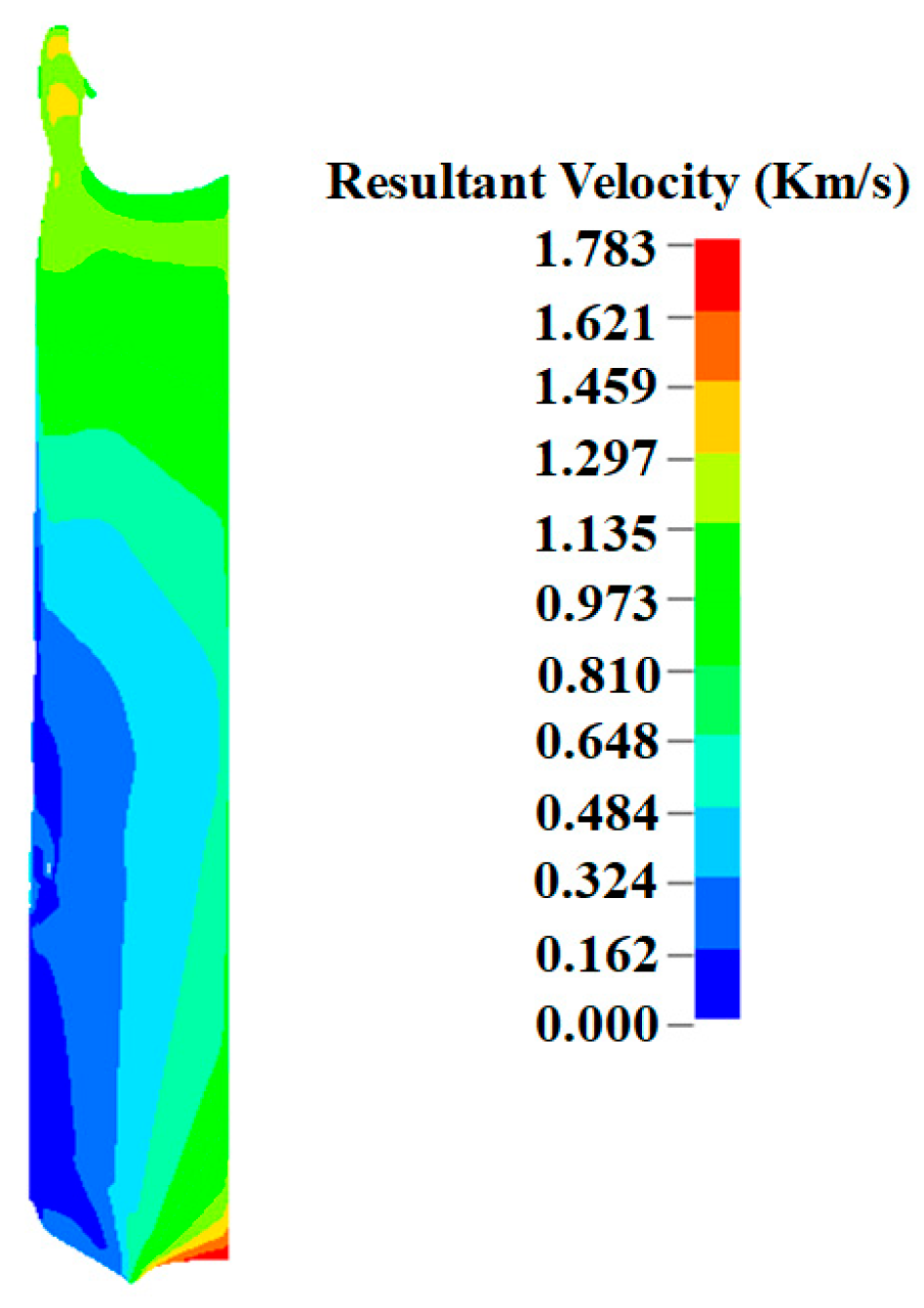

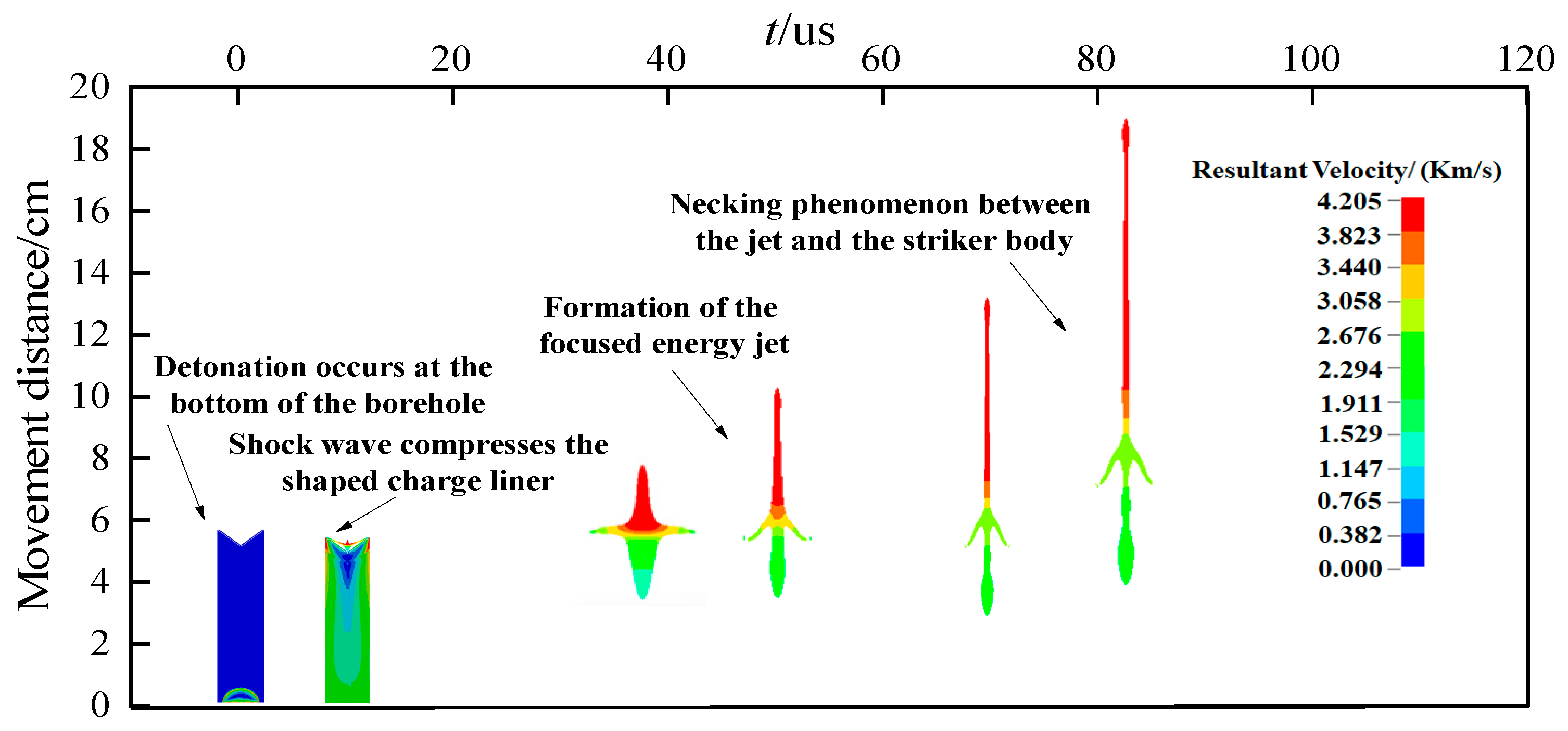

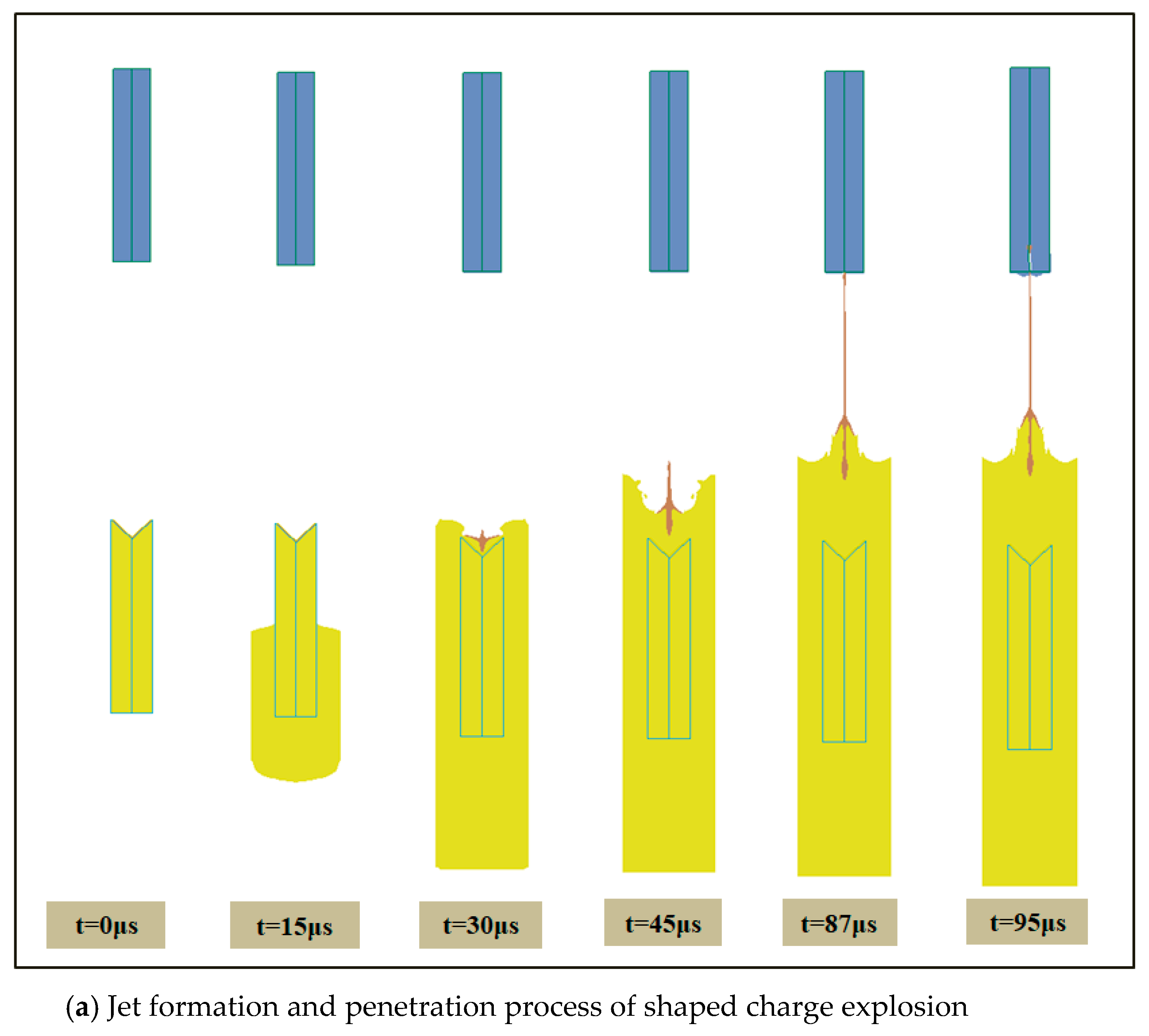

4.1. Formation and Motion Regularity of Shaped Charge Jet

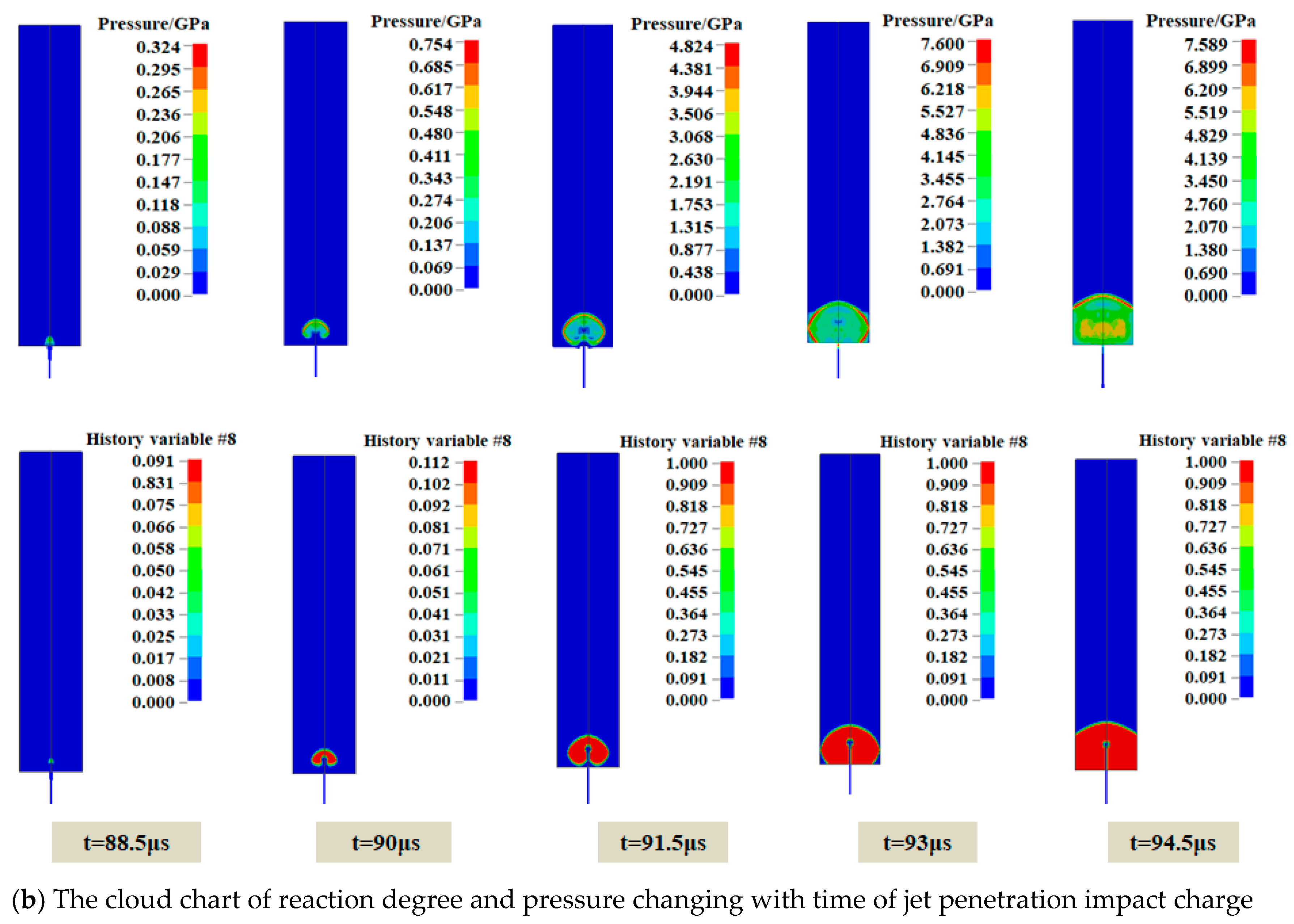

4.2. Numerical Results of Emulsion Explosive Shock Initiation

4.3. Analysis of Stress Propagation Process and Damage Characteristics of Surrounding Rock

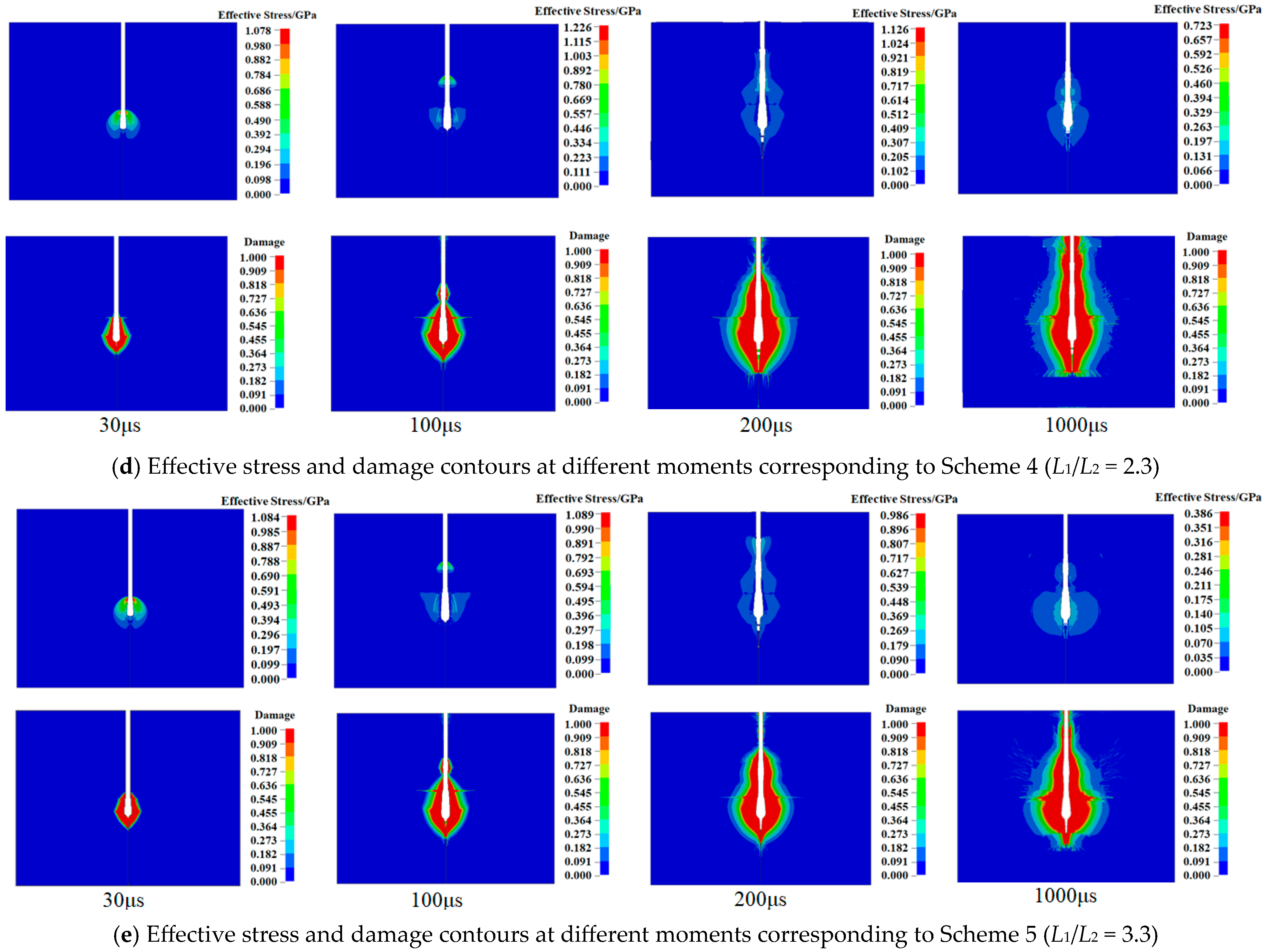

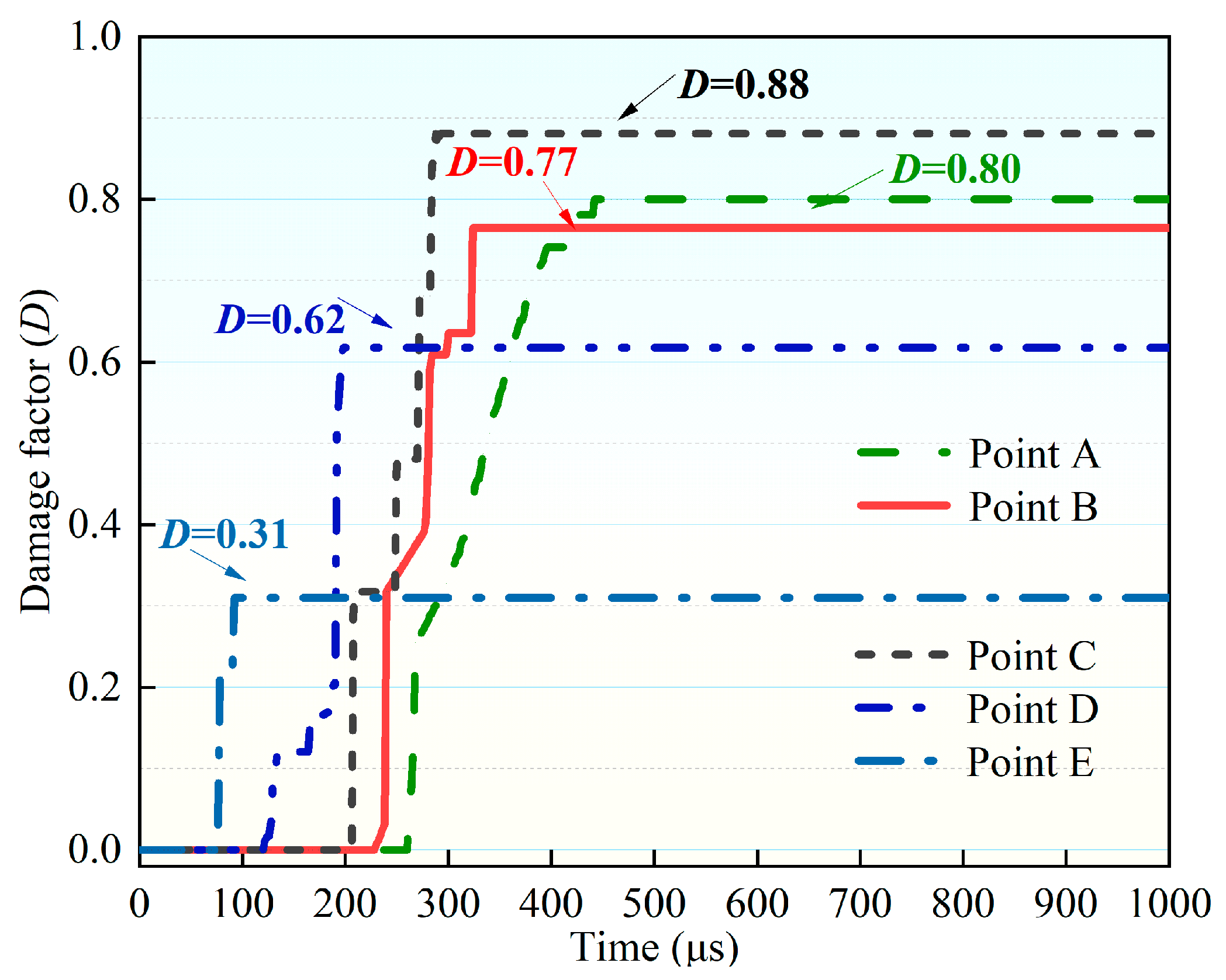

4.3.1. Stress Propagation and Damage Evolution Process of Surrounding Rock

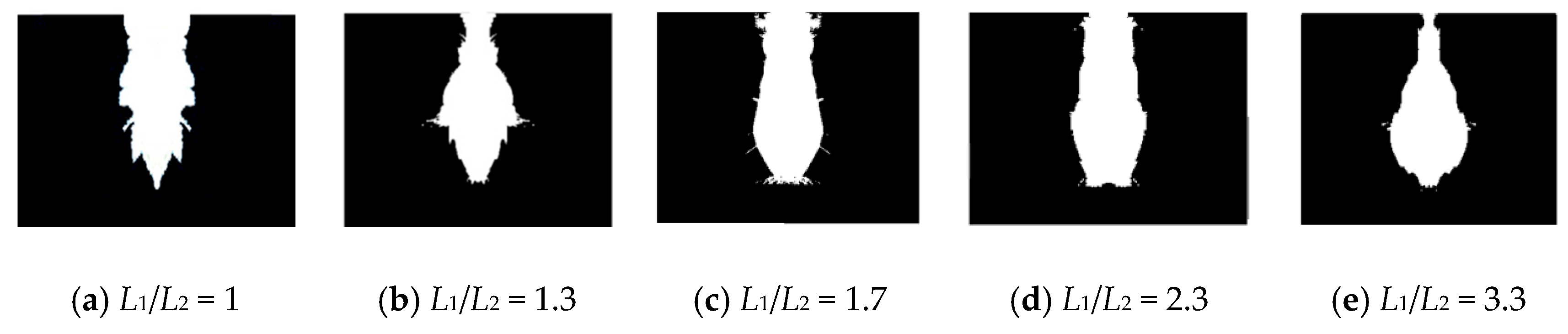

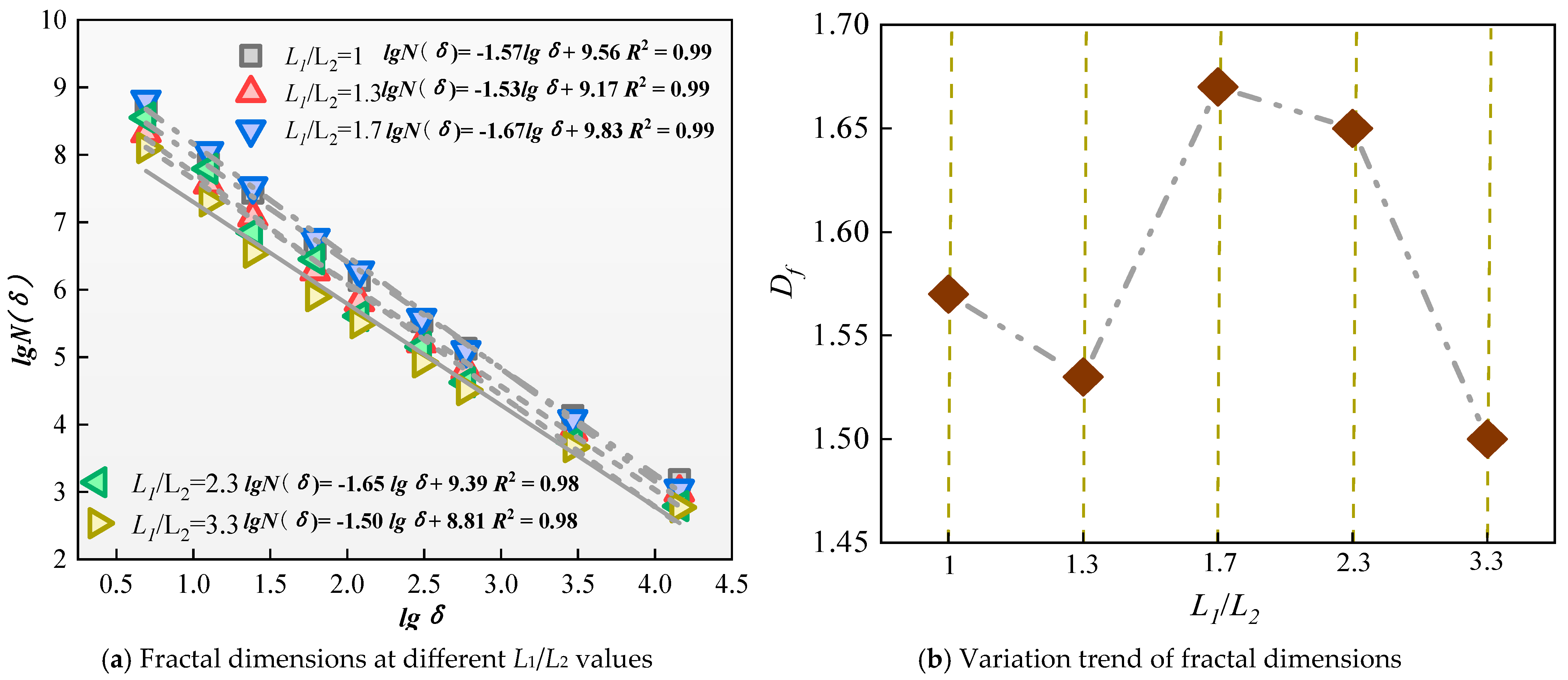

4.3.2. The Change Rule of Fractal Dimensions

4.3.3. Analysis of Blasting Effective Stress and Damage Effect

5. Field Verification and Application

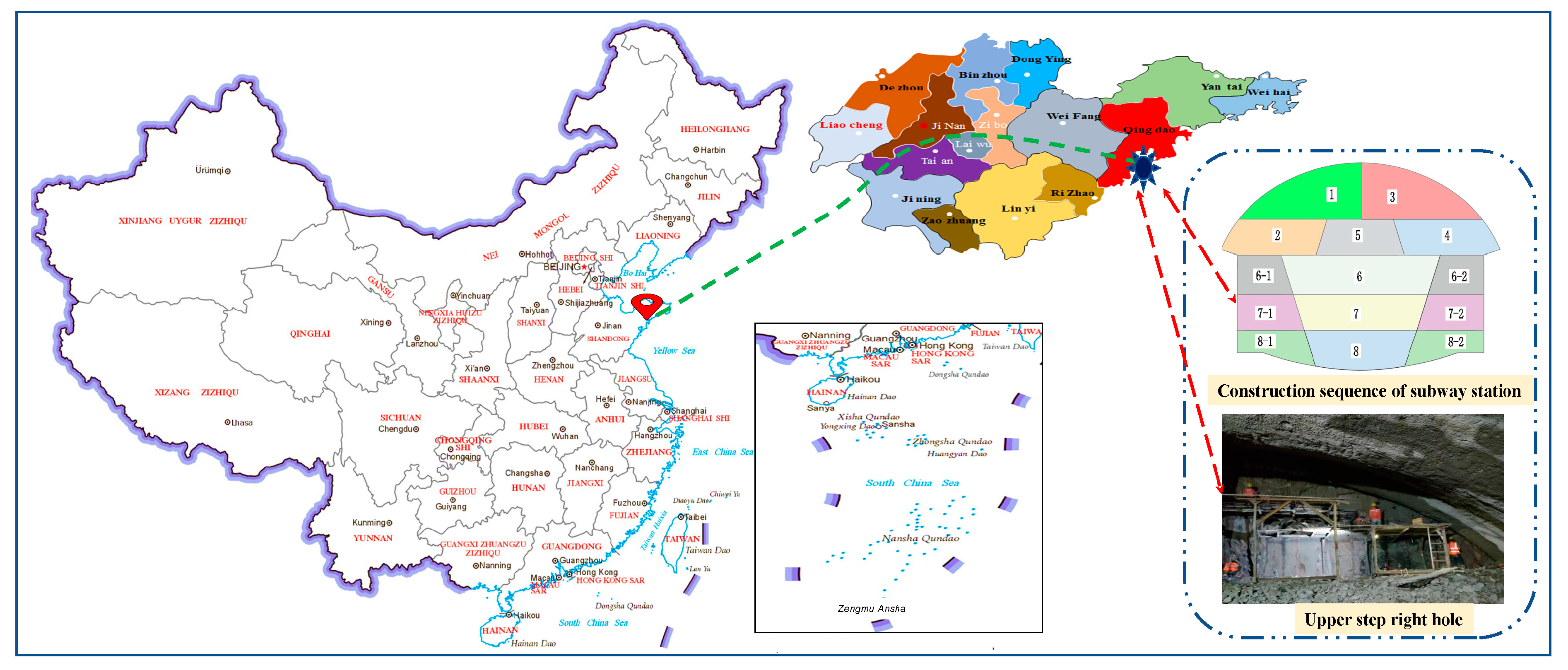

5.1. Site Overview and Blasting Scheme

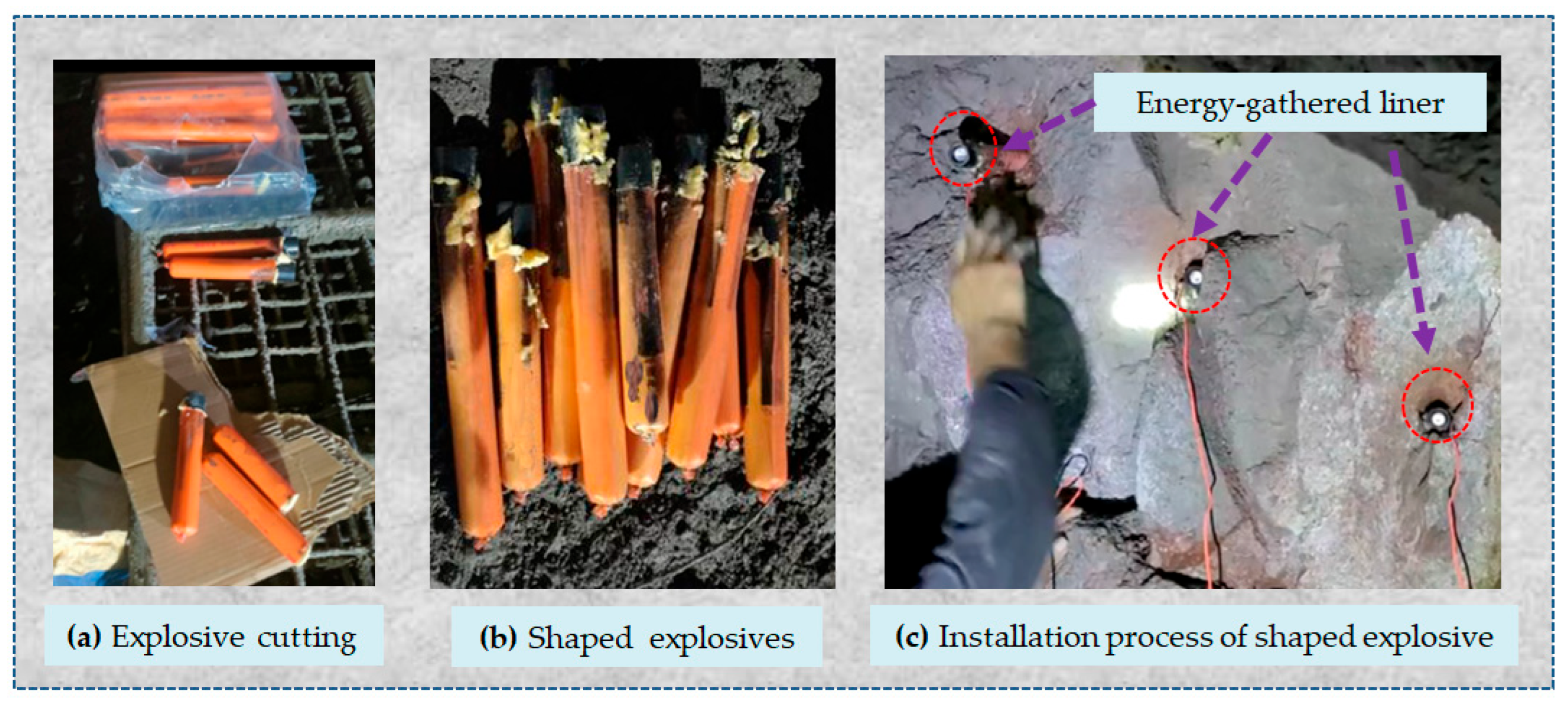

5.2. Test Preparation

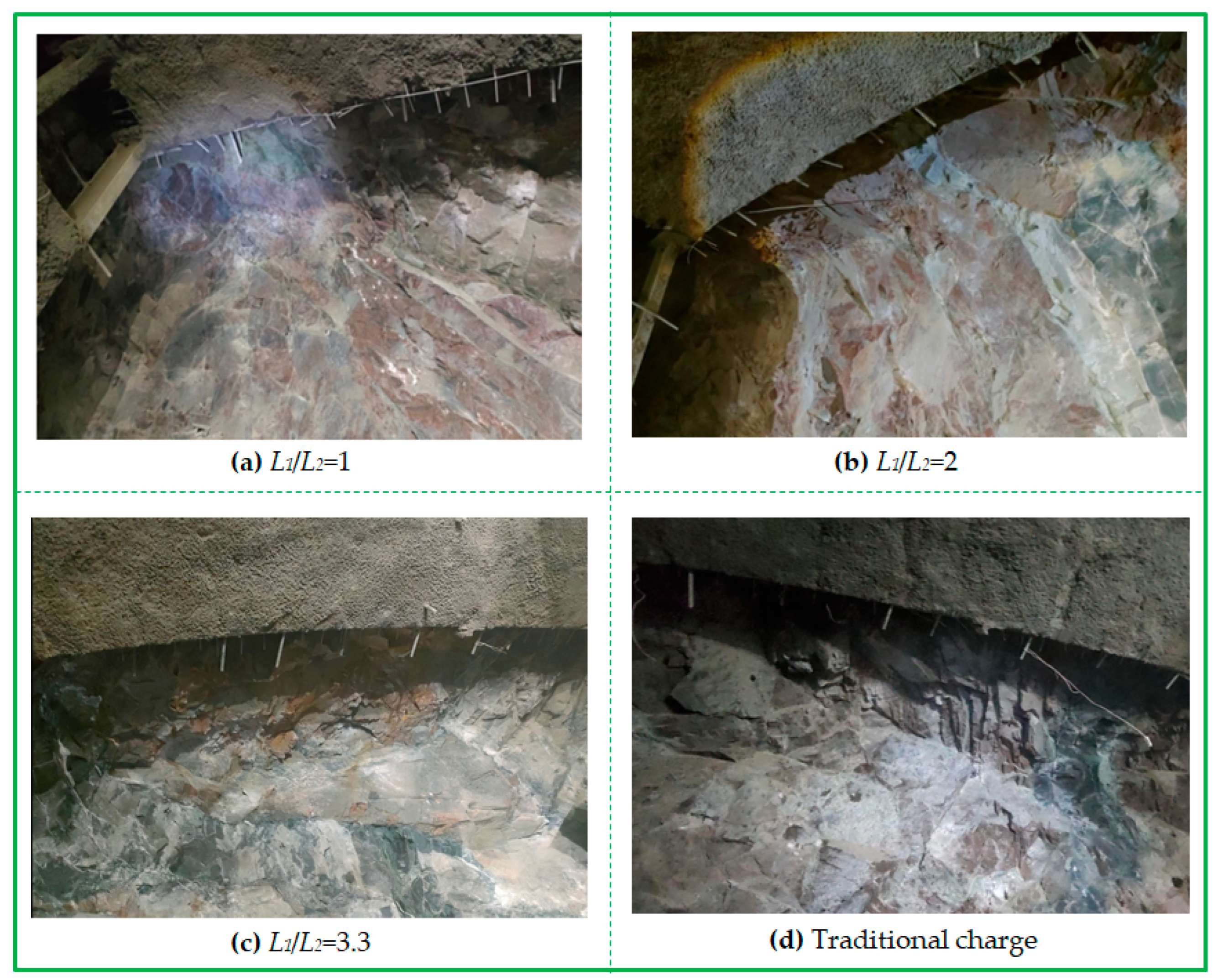

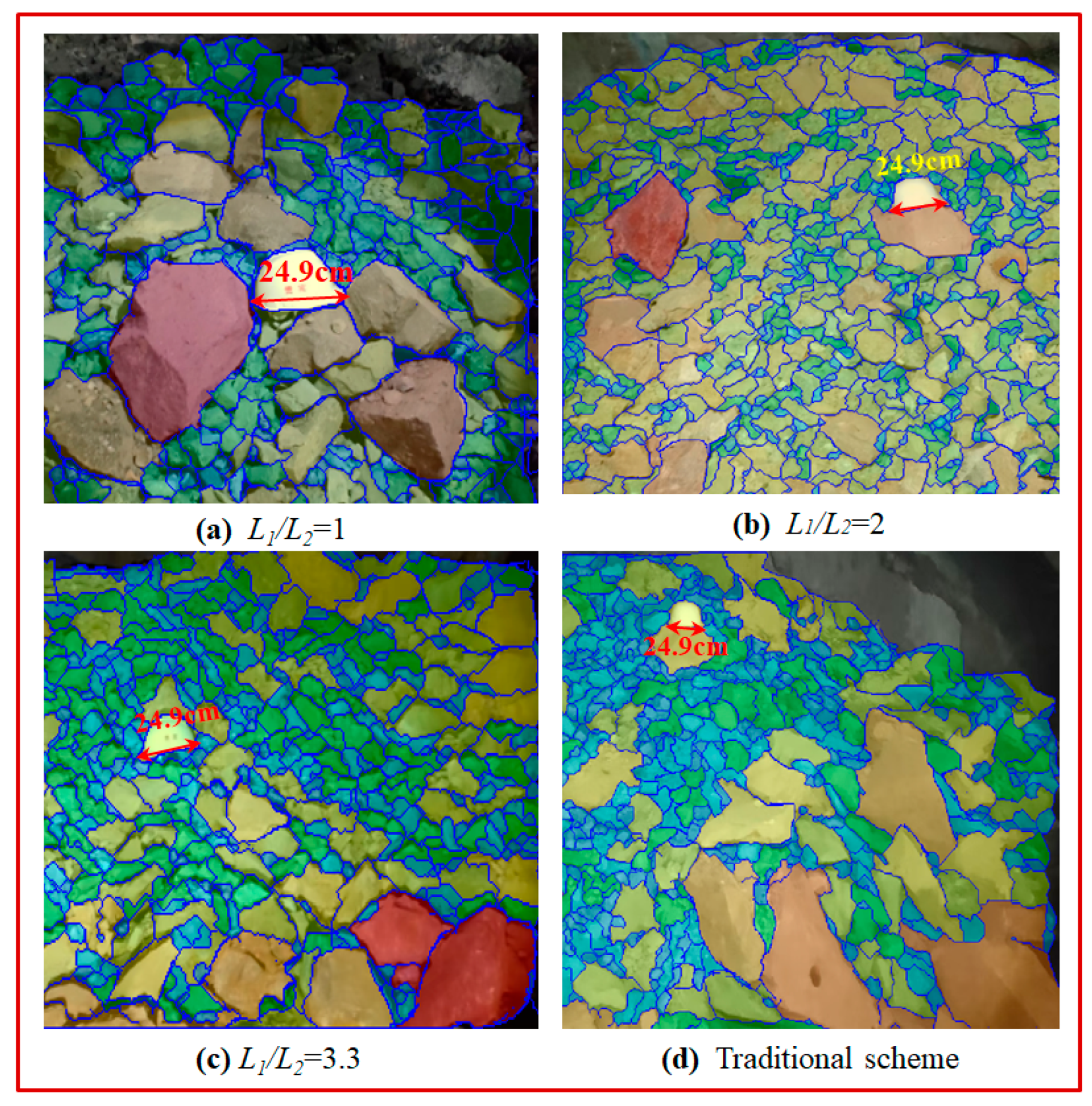

5.3. Field Test Results

6. Conclusions

- (1)

- The model tests and numerical simulation results indicate that the ALE method can clearly reproduce the formation and movement of a shaped charge jet in a borehole, the shock initiation of the exposed emulsified explosives, and the evolution of dynamic rock damage. Compared with high-speed photography observations, the error is controlled within 6.4%.

- (2)

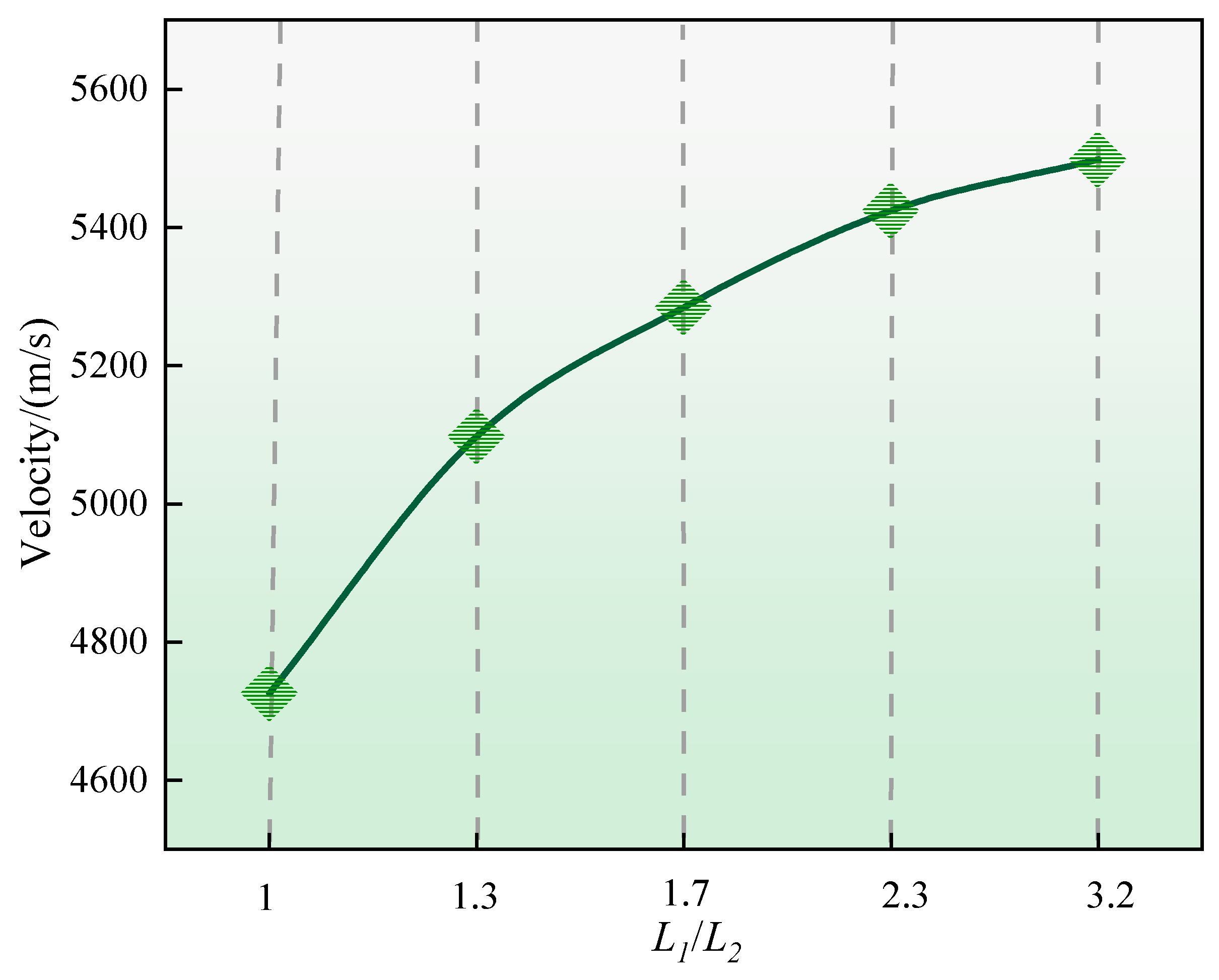

- The formation, movement, and impact-induced detonation process of the shaped jet indicate that although the jet velocity increases with the rise in the L1/L2 ratio, the rate of increase tends to diminish progressively.

- (3)

- The numerical simulation results indicate that, under the conditions of the current simulation experiment, when the gathering liner and two-stage air-segmented charge arrangement are used in the peripheral holes, the L1/L2 ratio (ranging from 1 to 3.3) significantly affects the surrounding rock damage patterns, blasting fractal dimensions, and damage uniformity. The most reasonable blasting fragmentation size and average damage degree occur when the ratio is between 1.7 and 2.3.

- (4)

- On-site tests show that, under the given working conditions, when the surrounding holes are charged with two-stage charge rolls with a spacing of 20 cm and an L1/L2 ratio of 2, the average over-excavation and undercut are controlled within 7 cm, with the maximum over-excavation controlled within 12 cm. The corresponding average fragmentation size (d50) is minimized. This suggests that this ratio reduces the fragmentation size of the smooth blasting layer while achieving better smooth blasting effects. It also indicates that the shaped charge can be effectively applied in the surrounding hole segmented charging structure.

- (5)

- The L1/L2 ratio derived in this study is only applicable to the field conditions discussed in the paper. The value is influenced by several factors, such as surrounding rock type, cycle advance rate, and the spacing between segmented explosives. In other engineering applications, this ratio requires further investigation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| L1 | Length of main charge |

| L2 | Length of secondary charge |

References

- Zhang, W.; Liu, D.; Tang, Y.; Qiu, W.; Zhang, R. Multifractal Characteristics of Smooth Blasting Overbreak in Extra-Long Hard Rock Tunnel. Fractal Fract. 2023, 7, 842. [Google Scholar] [CrossRef]

- Zhao, D.; Huang, Y.; Chen, X.; Han, K.; Chen, C.; Zhao, X.; Chen, W. Numerical Investigations on Dynamic Responses of Subway Segmental Tunnel Lining Structures under Internal Blasts. Tunn. Undergr. Space Technol. 2023, 135, 105058. [Google Scholar] [CrossRef]

- Cheng, L.; Yang, Z.; Zhao, P.; Li, F. Damage Characteristics of Blasting Surrounding Rock in Mountain Tunnel in Fault Fracture Zones Based on the Johnson—Holmquist-2 Model. Buildings 2024, 14, 3682. [Google Scholar] [CrossRef]

- Salum, A.H.; Murthy, V.M.S.R. Optimising Blast Pulls and Controlling Blast-Induced Excavation Damage Zone in Tunnelling Through Varied Rock Classes. Tunn. Undergr. Space Technol. 2019, 85, 307–318. [Google Scholar] [CrossRef]

- Zhang, W.; Mei, J.; Sun, K.; Xu, B. Fine Controlled Blasting of Subsurface Excavation for Subway Stations in Soft–Hard Mixed-Medium Rock Mass. Tunn. Undergr. Space Technol. 2025, 158, 106407. [Google Scholar] [CrossRef]

- Sumiya, F.; Kato, Y. A Study on Smooth Blasting Technique Using Detonating Cords. Sci. Technol. Energetic Mater. 2007, 68, 167–171. [Google Scholar]

- Wang, J.; Cao, A.; Liu, J.; Wang, H.; Liu, X.; Li, H.; Sun, Y.; Long, Y.; Wu, F. Numerical Simulation of Rock Mass Structure Effect on Tunnel Smooth Blasting Quality: A Case Study. Appl. Sci. 2021, 11, 10761. [Google Scholar] [CrossRef]

- Hayes, G.A. Linear Shaped-Charge (LSC) Collapse Model. J. Mater. Sci. 1984, 19, 3049–3058. [Google Scholar] [CrossRef]

- Fourney, W.L.; Barker, D.B.; Holloway, D.C. Model studies of well stimulation using propellant charges. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 91–101. [Google Scholar] [CrossRef]

- Ma, G.; An, X. Numerical Simulation of Blasting Induced Rock Fractures. Int. J. Rock Mech. Min. Sci. 2008, 45, 966–975. [Google Scholar] [CrossRef]

- Yang, R.; Cao, W.; Gao, X. Experimental Study on Explosion Effect of Slotted Cartridge with Different Structure. J. China Coal Soc. 2015, 41. 32–36+49. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Y.; Hou, T.; Liu, K.; Miao, Y.; Li, J.; Zhao, X.; Zhang, M. Research on Directional Rock Blasting Based on Different Slotted Pipe Materials of the Combined Charge Structure. Sci. Rep. 2024, 14, 7394. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, Y.; Peng, Y.; Wu, L. Experimental Research and Application of Drilling and Blasting with Directional Damage-Reduction Shaped Charge. Sci. Rep. 2024, 14, 9549. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Sun, Q.; Zou, B.; Mu, Q. Numerical Study on an Innovative Shaped Charge Approach of Rock Blasting and the Timing Sequence Effect in Microsecond Magnitude. Rock Mech. Rock Eng. 2021, 54, 4523–4542. [Google Scholar] [CrossRef]

- Song, Y.; Li, X.; Guo, D.; Shi, B. Study on the Decoupled Charge Effect in Deep-Hole Cumulative Blasting of Coal Seam. Adv. Civ. Eng. 2019, 2019, 8486198. [Google Scholar] [CrossRef]

- Yang, J.; Fu, Q.; Gao, Y.; Wu, X.; Chang, X.; Li, C. A Novel Method of Combined Deep Hole Blasting for Gob-Side Roadway Protection. Rock Mech. Rock Eng. 2023, 56, 1234–1251. [Google Scholar] [CrossRef]

- Xu, S.; Wu, B.; Zhang, H.; Qi, S.; Bian, H.; Wang, J. Directional Crack Propagation and Optimization Strategies for Multi-Hole Shaped Charge Blasting in Tunnel Construction. Structures 2025, 72, 108268. [Google Scholar] [CrossRef]

- Xu, S.; Wu, B.; Zhang, H.; Qi, S.; Wang, J.; Bian, H. Study on crack propagation mechanism and charge structure optimization of tunnel shaped charge hydraulic blasting. Case Stud. Constr. Mater. 2024, 21, e3805. [Google Scholar] [CrossRef]

- Wang, S.; Gong, M.; Wu, H.; Wu, X.; Liu, X. Optimization Study of Water Interval Charge Structure Based on the Evaluation of Rock Damage Effect in Smooth Blasting. Appl. Sci. 2024, 14, 2868. [Google Scholar] [CrossRef]

- Ding, C.; Yang, R.; Zhu, X.; Feng, C.; Zhou, J. Rock Fracture Mechanism of Air-Deck Charge Blasting Considering the Action Effect of Blasting Gas. Tunn. Undergr. Space Technol. 2023, 142, 105420. [Google Scholar] [CrossRef]

- Ma, C.; Xie, W.; Liu, Z.; Li, Q.; Xu, J.; Tan, G. A New Technology for Smooth Blasting Without Detonating Cord for Rock Tunnel Excavation. Appl. Sci. 2020, 10, 6764. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Pradhan, M.; Dhekne, P.Y. Investigating Rock Fragmentation in Distributed Spherical Air-Gap Blasting Technique. Powder Technol. 2020, 362, 101–110. [Google Scholar] [CrossRef]

- Wu, X.; Gong, M.; Wu, Y.; Luo, X.; Wu, H.; Chen, X. Experimental and Numerical Study on the Cumulative-Deck Charging Structure Based on Explosive Sympathetic Detonation in Tunnel Smooth Blasting. Alex. Eng. J. 2025, 116, 561–573. [Google Scholar] [CrossRef]

- Shi, S.; Zhou, C.; Gao, W.; Li, Z.; Zhang, X.J. Study on Reasonable Sympathetic Detonation Distance of Emulsion Explosive in Axial Shaped Charge Structure. Blasting 2025, 1–12. Available online: http://kns.cnki.net/kcms/detail/42.1164.tj.20250410.0841.002.html (accessed on 24 April 2025).

- Wang, Q.; Wang, T.; Tian, C.; Sun, Y.; Wei, X.; Li, Z.; Wang, X.; Li, Y. Application of Interval Charge of Peripheral Hole Shaped Charge Device in Smooth Blasting. Blasting 2024, 41, 77–84. [Google Scholar]

- Liu, Z.; Wang, X.; Wang, Y.; Li, Z.; Liang, L.; Sun, Y.; Tian, C.; Wang, T.; Wang, X. Study on the Effect of Shaped Charge Device on the Detonation Distance of Emulsion Explosive under Constraint Conditions. Blasting 2024, 41, 171–178. [Google Scholar]

- Tian, J.; Zhang, C.; Li, Z.; Liao, L. Design and Engineering Application of New Energy-Gathering Tube. Blasting 2025, 42. 159–165+198. [Google Scholar]

- Liu, Z.; Yang, R.; Zuo, J.; Xu, P.; Zhao, Y.; Yang, Z. Research on the Crack Formation Mechanism of Shaped Charge Blasting and the New Dual-Shaped Charge Blasting Technology. Mech. Adv. Mater. Struct. 2025, 32, 374–390. [Google Scholar] [CrossRef]

- Huang, J. Simulation Study on Oblique Penetration of Shaped Charge Jet into Moving Body. Ph.D. Thesis, North University of China, Taiyuan, China, 2015. [Google Scholar]

- Arnold, W.; Rottenkolber, E. High Explosive Initiation Behavior by Shaped Charge Jet Impacts. Procedia Eng. 2013, 58, 184–193. [Google Scholar] [CrossRef][Green Version]

- Held, M. Critical Area for the Initiation of High Explosive Charges. Shock. Waves Condens. Matter 1984, 1983, 555–557. [Google Scholar] [CrossRef]

- Peugeot, F.; Quidot, M. Threshold Energy: A Dimensional Extension of the Critical Energy for Jet Attack Application. Propellants. Explos. Pyrotech. 1998, 23, 188–192. [Google Scholar] [CrossRef]

- James, H.R. An Extension to the Critical Energy Criterion Used to Predict Shock Initiation Thresholds. Propellants. Explos. Pyrotech. 1996, 21, 8–13. [Google Scholar] [CrossRef]

- Wu, B.; Xu, S.; Meng, G.; Cai, J.; Wei, H.; Li, H.; Zhang, J. Study on dynamic evolution law of blasting cracks in elliptical bipolar linear shaped charge blasting. Shock. Vib. 2021, 2021, 5272878. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Yin, J.; Yi, J.; Wang, H. Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target. Materials 2021, 14, 3701. [Google Scholar] [CrossRef]

- Xie, L.; Lu, W.; Zhang, Q.; Jiang, Q.; Chen, M.; Zhao, J. Analysis of Damage Mechanisms and Optimization of Cut Blasting Design under High In-Situ Stresses. Tunn. Undergr. Space Technol. 2017, 66, 19–31. [Google Scholar] [CrossRef]

- Murphy, M.Y.; Baum, D.W.; Kuklo, R.M.; Simonson, S.C. Effect of Multiple and Delayed Jet Impact and Penetration on Concrete Target Borehole Diameter. Proc. 19th Int. Symp. Ballist. 2001, 1553–1559. [Google Scholar]

- Li, Z.; Hu, Y.; Wang, G.; Zhou, M.; Hu, W.; Zhang, X.; Gao, W. Study on Cyclic Blasting Failure Characteristics and Cumulative Damage Evolution Law of Tunnel Rock Mass under Initial In-Situ Stress. Eng. Fail. Anal. 2023, 150, 107310. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, R.; Yang, Y.; Fu, T.; Tian, Y.; Yan, H.; Wang, D.; Jiao, X.; Zhou, H. Study on the Influence of Notched Empty Hole Parameters on Directional Fracture Blasting Effect. Buildings 2024, 14, 4077. [Google Scholar] [CrossRef]

- Shen, S.; Zheng, R.; Wang, W.; Ye, C. Effect of Charge Eccentric Position on the Response of Reinforced Concrete Columns Under Blast Loading. Buildings 2025, 15, 1898. [Google Scholar] [CrossRef]

- Ribeiro, J.B.; Silva, C.; Mendes, R. Estimation of the reactive flow model parameters for an ammonium nitrate–based emulsion explosive using genetic algorithms. J. Energetic Mater. 2010, 28, 180–204. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H.; Wang, J.; Tian, N. Finite Element Analyses of Constitutive Models Performance in the Simulation of Blast-Induced Rock Cracks. Comput. Geotech. 2021, 135, 104172. [Google Scholar] [CrossRef]

- Anderson, C.E., Jr.; Orphal, D.L. Analysis of the Terminal Phase of Penetration. Int. J. Impact Eng. 2003, 29, 69–80. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Fu, H.; Mu, H.; Liu, Y.; Zuo, C.; Li, Q. Study on Blasting Technology of Long and Short Straight Hole Combined Cutting in Small Section Tunnel. Blasting 2025, 42, 97. [Google Scholar]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman: New York, NY, USA, 1982. [Google Scholar]

- You, S.; Yang, R.; Ding, C.; Xiao, C.; Chen, W.; Wang, L.; Chen, J.; Shi, Y.; Miao, H.; Cao, J. Study on the Effect of Blast Delay Time Between Blastholes in Sublevel Caving. Min. Metall. Explor. 2024, 41, 1771–1791. [Google Scholar] [CrossRef]

- Ding, X.; Xiao, X.; Cui, J.; Wu, D.; Pan, Y. Damage Evolution, Fractal Dimension and a New Crushing Energy Formula for Coal with Bursting Liability. Process Saf. Environ. Prot. 2023, 169, 619–628. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, X.; Li, Z.; Gao, W.; Xu, Z.; Zhang, Y.; Zhou, J. Effects of In-Situ Stress on Damage and Fractal during Cutting Blasting Excavation. Fractal Fract. 2024, 8, 450. [Google Scholar] [CrossRef]

- You, S.; Yang, R.; Xiao, C.; Ding, C.; Li, C.; Yang, Z.; Li, J. Study on the Superposition Effect of Stress Waves and Crack Propagation Law Between Blastholes at Different Angles. Opt. Lasers Eng. 2024, 178, 108193. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, W.; Wang, H.; Bai, X.; Zhang, Y.; Fan, Y.; Lv, N.; Yang, B.; Cheng, B.; Yan, G.; et al. Influence of Angle Between Bedding Plane and Blast Hole on Smooth Blasting Effect of Tunnel. Eng. Blasting 2025, 31, 24–33. [Google Scholar] [CrossRef]

- Zhou, J. Study on the Influence of Minimum Resistance Line and Decoupling Coefficient on Explosion Energy in Bench Blasting. Ph.D. Thesis, Kunming University of Science and Technology, Kunming, China, 2020. [Google Scholar] [CrossRef]

| ρ/(kg/m3) | Pel/GPa | A2/GPa | A3/GPa | B | B0 | B1 | T1/GPa | T2/GPa |

| 2600 | 6.0 | 37.84 | 21.29 | 0.05 | 1.22 | 1.22 | 25.7 | 0.0 |

| n | a0 | N | G | Q0 | βc | βt | /ms−1 | /ms−1 |

| 1.2 | 0.1 | 0.76 | 0.04 | 1.0 | 0.026 | 0.007 | 0 | 0.007 |

| ft* | fs* | fc/MPa | A1/GPa | |||||

| 0.04 | 0.21 | 89 | 25.7 |

| Material | Ga/(GPa) | Aa/(MPa) | Ba/(MPa) | na | Ca | ma |

|---|---|---|---|---|---|---|

| Aluminum | 28 | 265 | 426 | 0.34 | 0.015 | 1.0 |

| ρa/(kg/m3) | C0 | C1 | C2 | C3 | C4 | C5 | C6 | /(GPa) | |

|---|---|---|---|---|---|---|---|---|---|

| 1.29 | 0.0 | 0.0 | 0.0 | 0.0 | 0.4 | 0.4 | 0.0 | 0.025 | 0.0 |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| a | 0.002 | y | 2.026 | e | 0.534 |

| b | 0.673 | c | 0.407 | g | 0.630 |

| x | 12.291 | d | 0.030 | z | 3.918 |

| G1 | 116.502 | G2 | 27.957 | I | 821,766 |

| L1/L2 | Average Effective Stress of Measuring Points A~E (MPa) | Standard Deviation of Stress | Average Damage Degree of Measuring Points A~E | Standard Deviation of Damage Degree |

|---|---|---|---|---|

| 1 | 85.18 | 28.85 | 0.68 | 0.15 |

| 1.3 | 86.88 | 29.62 | 0.69 | 0.11 |

| 1.7 | 97.2 | 28.68 | 0.77 | 0.09 |

| 2.3 | 94.37 | 28.33 | 0.74 | 0.08 |

| 3.3 | 84.6 | 47.31 | 0.66 | 0.35 |

| Name | Hole Number | Hole Depth (m) | Hole Length (m) | Single-Hole Charge (kg) | Total Explosives (kg) |

|---|---|---|---|---|---|

| Cutting hole | 18 | 0.95 | 1.27/1.22/1.16 | 0.65/0.6/0.55 | 9.9 |

| Auxiliary hole | 34 | 0.95 | 0.95 | 0.4 | 13.6 |

| Peripheral hole | 34 | 0.95 | 0.95 | 0.3 | 10.2 |

| Bottom hole | 12 | 0.95 | 0.95 | 0.5 | 6.0 |

| Footing | 98 | 39.7 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, X.; Zhu, Z.; Wu, Y.; Yu, H.; Gao, W.; Lv, B. Detonation Dynamics and Damage Behavior of Segmented Tunnel Charges with Shaped Liners. Buildings 2025, 15, 2815. https://doi.org/10.3390/buildings15162815

Li Z, Zhang X, Zhu Z, Wu Y, Yu H, Gao W, Lv B. Detonation Dynamics and Damage Behavior of Segmented Tunnel Charges with Shaped Liners. Buildings. 2025; 15(16):2815. https://doi.org/10.3390/buildings15162815

Chicago/Turabian StyleLi, Zhuo, Xiaojun Zhang, Zhenye Zhu, Yongbo Wu, Hongbing Yu, Wenxue Gao, and Ben Lv. 2025. "Detonation Dynamics and Damage Behavior of Segmented Tunnel Charges with Shaped Liners" Buildings 15, no. 16: 2815. https://doi.org/10.3390/buildings15162815

APA StyleLi, Z., Zhang, X., Zhu, Z., Wu, Y., Yu, H., Gao, W., & Lv, B. (2025). Detonation Dynamics and Damage Behavior of Segmented Tunnel Charges with Shaped Liners. Buildings, 15(16), 2815. https://doi.org/10.3390/buildings15162815