The Application and Effects of Aerogel in Ultra-Lightweight Mineralised Foams

Abstract

1. Introduction

2. Materials and Methods

2.1. Design of Experiments

- (1)

- In the first phase, the study focused on the addition method of aerogel particles in mineralised foams. By adding aerogel particles in different steps of the mineral foam preparation, the properties of mineralised foams were investigated and the workflow for mineral foam preparation was confirmed.

- (2)

- In the second phase, the water/cement ratio (w/c ratio) of the cement slurry was varied, the number of aerogel particles added was adjusted, and the aerogel particles were pre-ground to obtain powdered aerogels, and then the properties of the obtained mineralised foam specimens were tested.

- (3)

- In the third phase, cement slurry with the addition of aerogel was prepared by partially replacing OPC with CSA cement, and then mineralised foam specimens were produced and tested.

2.2. Materials

2.2.1. Cement

2.2.2. Foaming Agent

2.2.3. Calcium Sulphoaluminate Cement

2.2.4. Aerogel Particle

2.3. Specimen Preparation Process

- (i)

- Firstly, the required substances (depending on the experimental phase) were added to the F80 forced action mixer manufactured by Baron A/S and stirred at 60 rpm/min for about 3 min to ensure that the substances were homogeneously mixed. Note that in the first experimental phase, when testing the aerogel addition method, the aerogel particles were either pre-mixed or added separately during the mixing step between slurry and foam.

- (ii)

- The dry mixture was added to water and stirred for 2 min at a speed of 1800 rpm in the CIM 30 E colloidal mixer manufactured by GERTEC Maschinen-und Anlagenbau GmbH, Sulzberg, Germany to obtain a homogeneous slurry. At the same time, foam was produced using a foaming machine SBM 8 manufactured by the same company. In order to achieve the target dry density, the foam density was selected to be around 45 ± 5 kg/m3, which could be controlled by adjusting the parameters of the water and air flow rates of the foaming machine.

- (iii)

- Finally, the prepared slurry and foam were placed in the F80 forced action mixer again and stirred for 4 min at a speed of 60 rpm to produce the mineral foam.

2.4. Variables and Tests

3. Results and Discussion

3.1. Effect of Addition Method

3.1.1. Effect of Aerogel Particles on Foam

3.1.2. Effect of the Addition Method of Aerogel Particles on Mineralised Foam

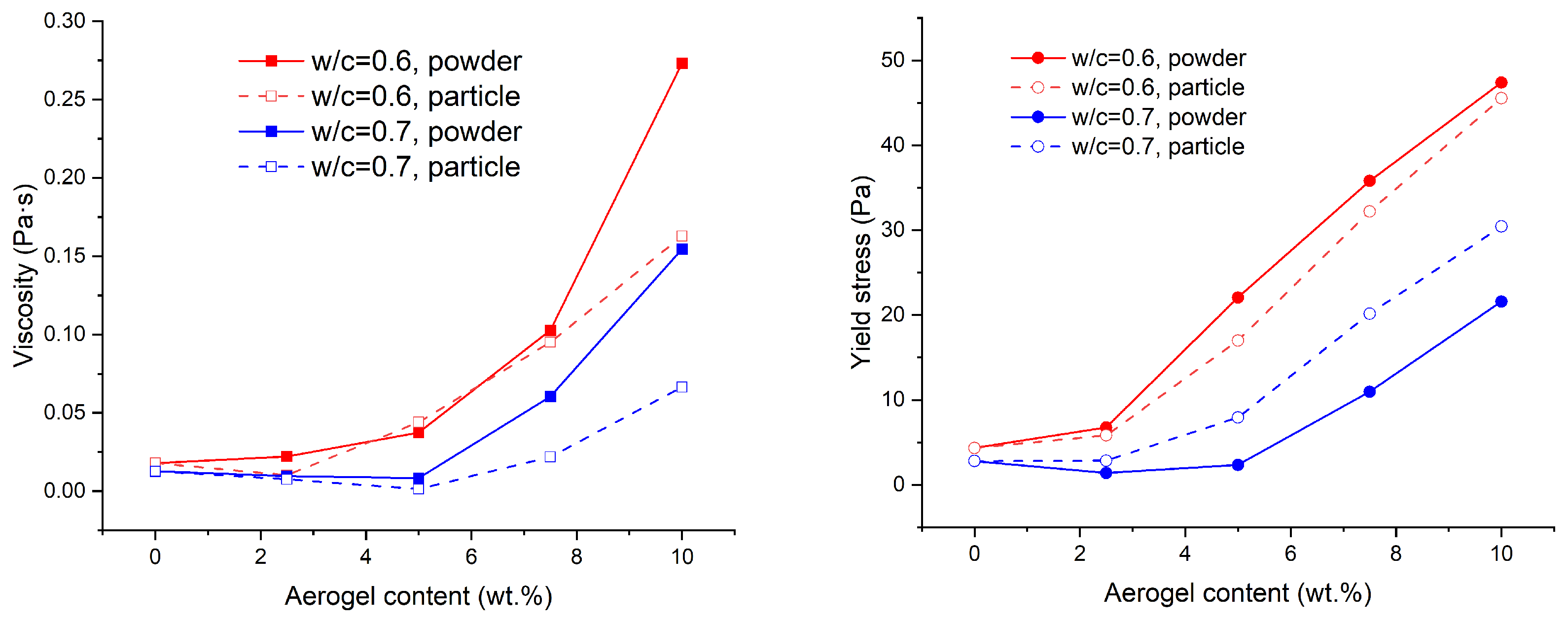

3.2. Effect of Pre-Ground/Unground Aerogel Particle Content on Mineralised Foams at Different Water/Cement Ratios

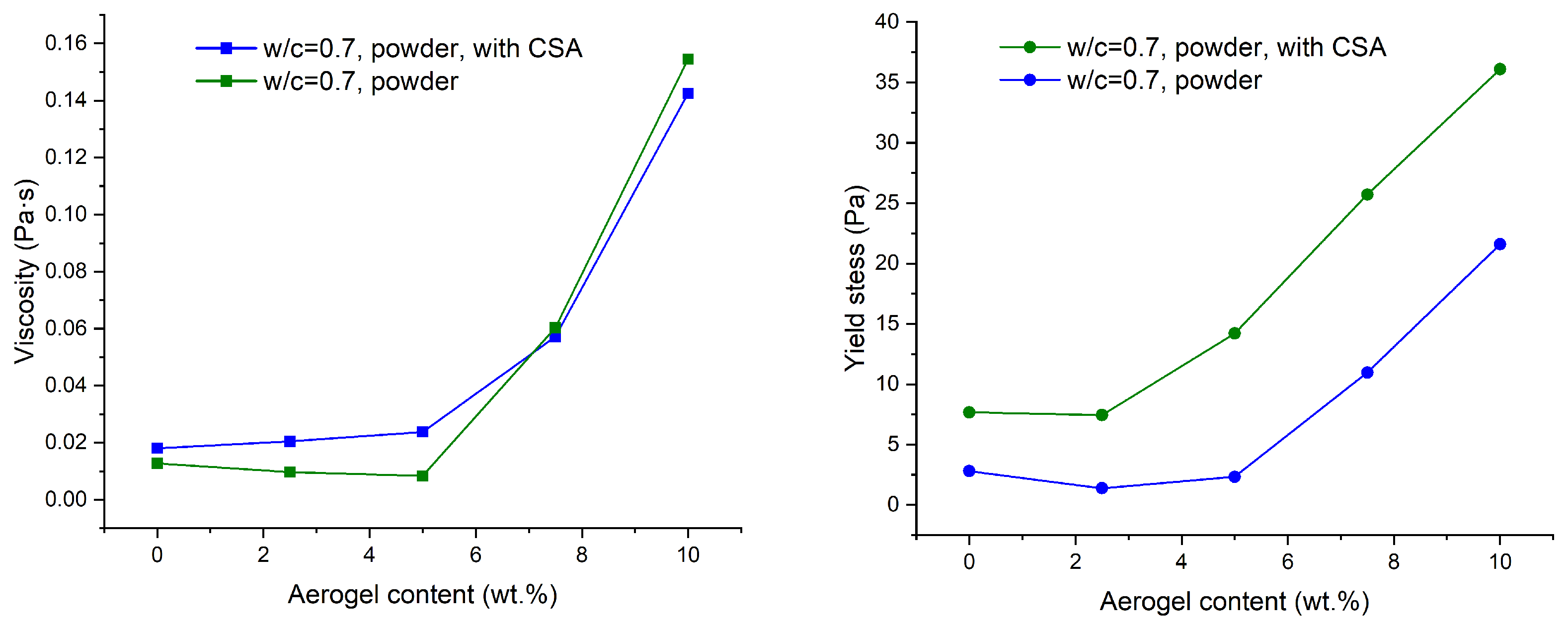

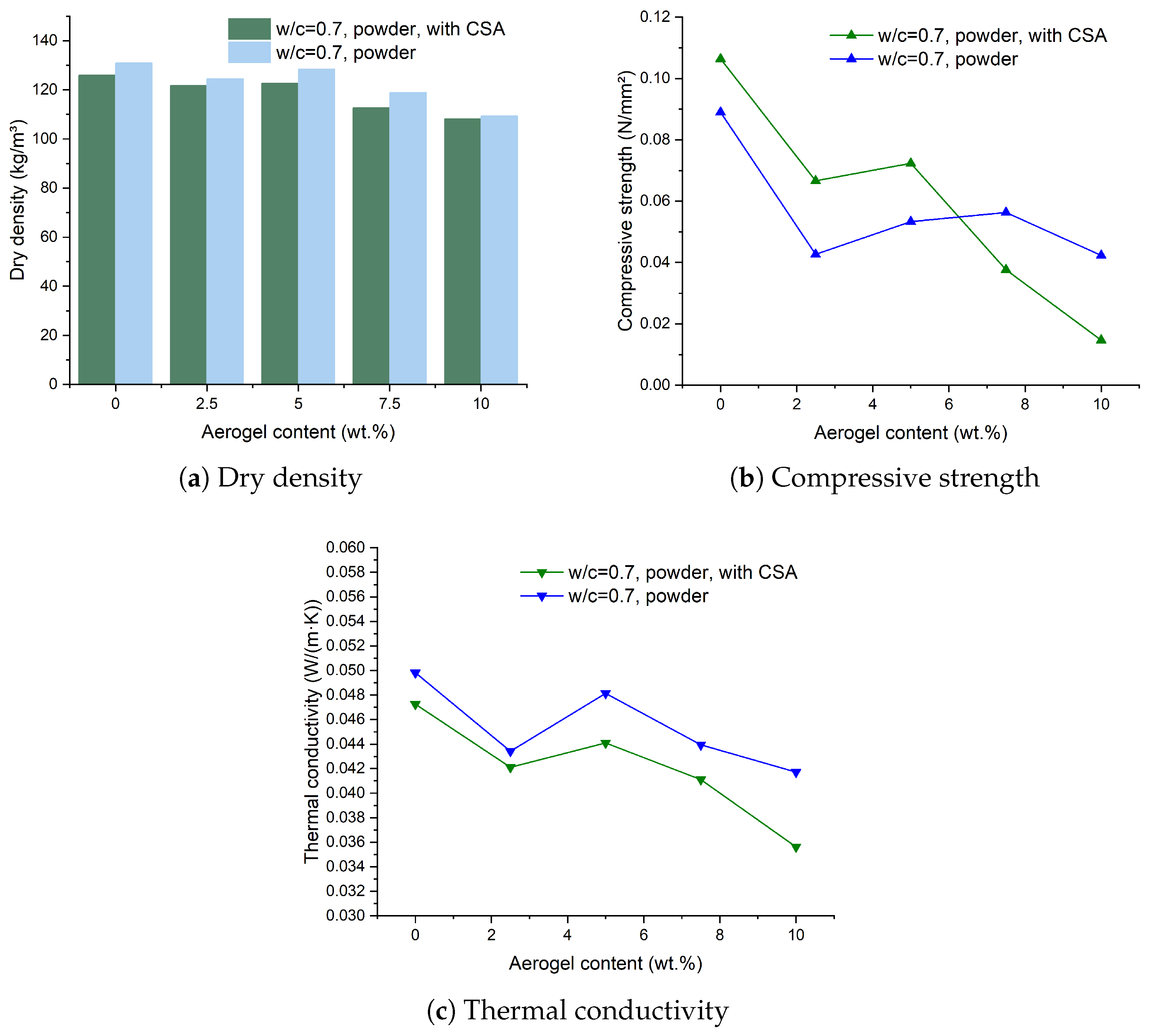

3.3. Aerogel-Containing Mineralised Foams Prepared Using OPC/CSA Mixed Cement Bases

4. Conclusions

- (1)

- In the extremely-low-density range, aerogels had a slightly different effect on mineralised foams than they did on dense material systems. Depending on the mixing method used, aerogels could seriously affect the stability of the foam during the mixing phase, leading instead to an increase in the density of the material and a change in the corresponding properties.

- (2)

- By mixing the aerogel with the cement slurry in advance, it was possible to limit the defoaming effect of the aerogel to a certain extent and to achieve the production of mineralised foams containing aerogel within an ultra-low-density range.

- (3)

- In this study, the high-energy mixer likely caused the differently shaped aerogels to become uniform during mixing with cement slurry. Although this method ensured a homogeneous mixture of aerogel and cement slurry, it also prevented the evaluation of the effect of aerogel shape on the mineralised foam performance.

- (4)

- By adding aerogel to the mineralised foam, the thermal conductivity of the material was effectively reduced to achieve better thermal insulation without significantly changing its dry density. At w/c ratio of 0.6 for the slurry used, the thermal conductivity of the material reached its lowest point as the aerogel content rose to 10 wt% of the cement, with an average measurement of 0.036 W/(m·K), which was in a comparable range to plastic foams reported in the literature.

- (5)

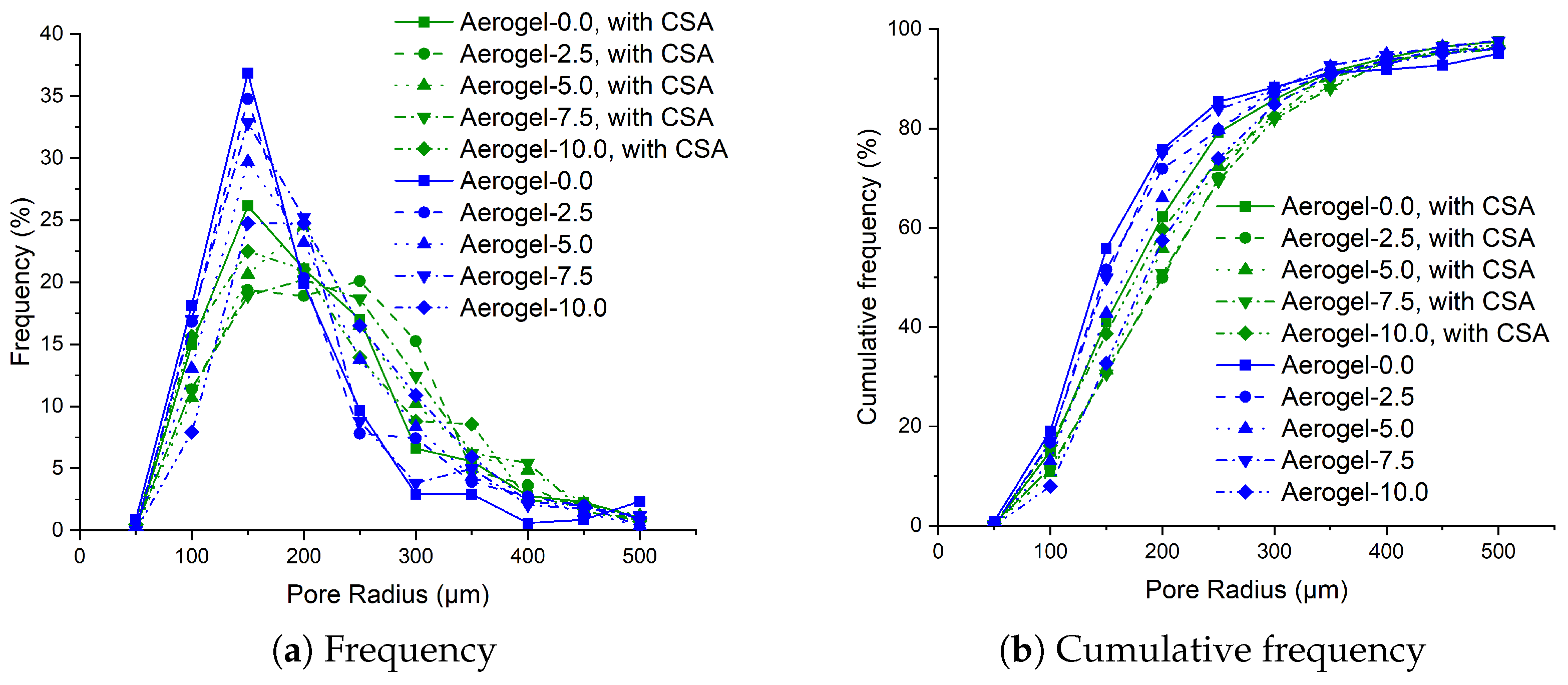

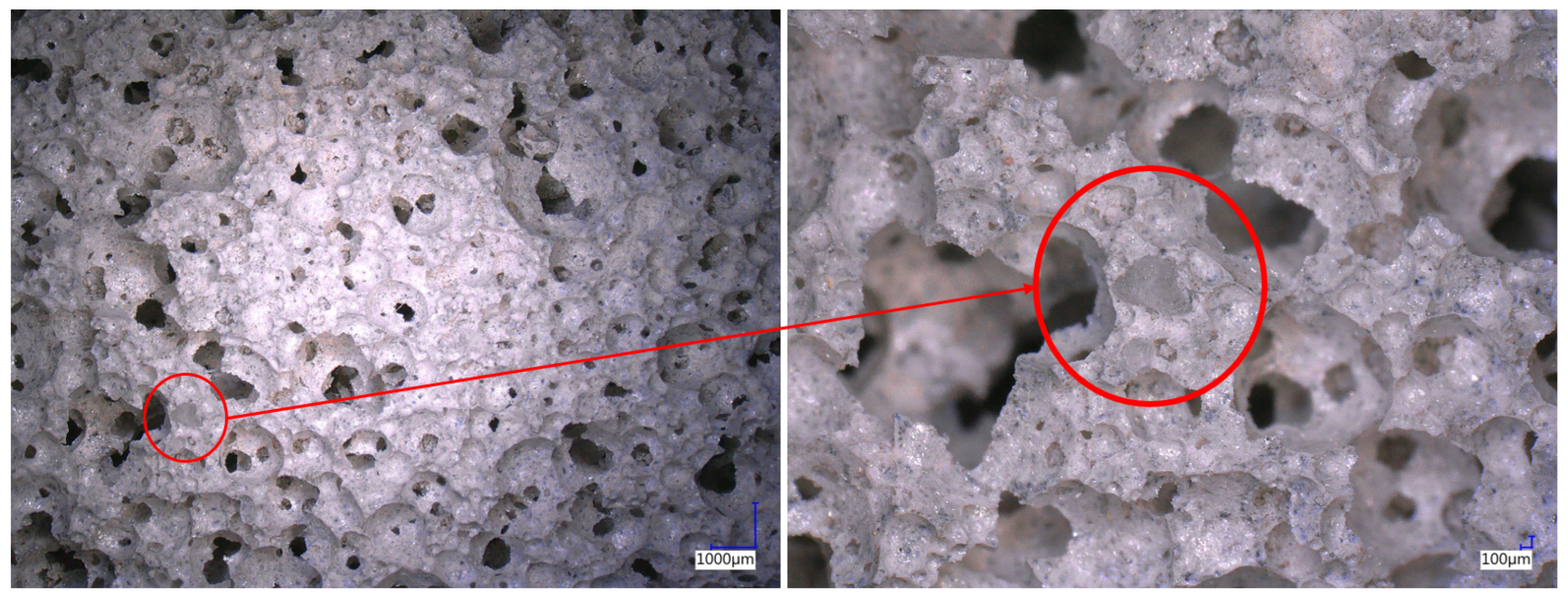

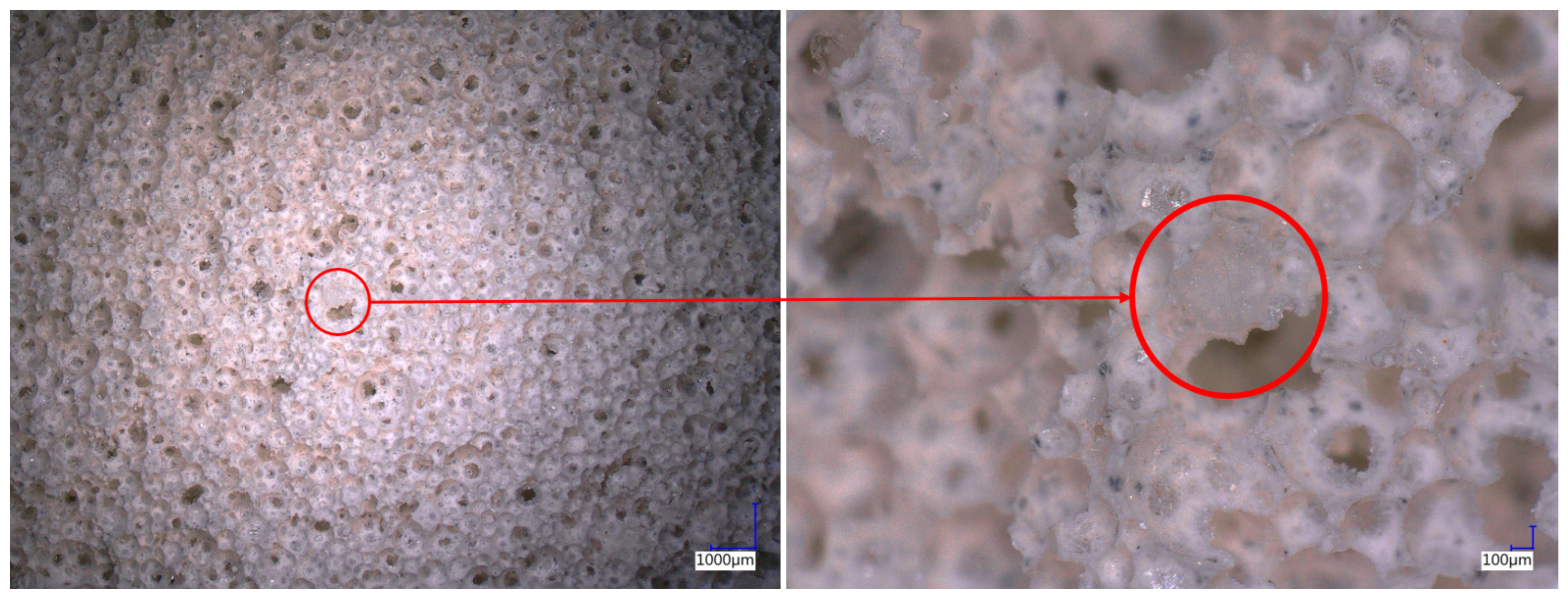

- By partially replacing the Ordinary Portland Cement with a suitable CSA cement, the pore structure of the mineralised foam was improved. The formation of irregular cavities, cracks, and connections between pores was suppressed, allowing most pores to retain a near-ideal circular (spherical) shape. In addition, the distribution of pore radius became more uniform, and the overall increase in pore size caused by high aerogel content was inhibited. The observations also indicated that the pore radius distribution alone was not sufficient to represent the pore structure of mineralised foams within this density range. It was recommended that future work include the influence of irregularly shaped pores and cavities in the structural analysis, as they also had a significant impact on the material’s overall performance.

- (6)

- The combined use of CSA cement and aerogel for optimising the performance of mineralised foam was feasible to a certain extent. In terms of thermal conductivity, the combination showed a clear synergistic reduction effect, with specimens prepared using OPC/CSA cement generally showing lower thermal conductivity at the same aerogel content. However, for compressive strength, the synergistic enhancement effect only appeared at low aerogel content (smaller than 5 wt.%). As the aerogel proportion increased, the use of CSA cement continued to improve the pore structure by preventing irregular cavities and connected pores, but the compressive strength of the material was weakened. It was recommended that future studies consider the relationship between the aerogel particle size and the thickness of the pore walls.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OPC | Ordinary Portland Cement |

| CSA | Calcium sulphoaluminate |

References

- Agency, I.E. World Energy Outlook 2023—Analysis; Technical Report; International Energy Agency: Paris, France, 2023. [Google Scholar]

- Paraschiv, S.; Paraschiv, L.S.; Serban, A. Increasing the Energy Efficiency of a Building by Thermal Insulation to Reduce the Thermal Load of the Micro-Combined Cooling, Heating and Power System. Energy Rep. 2021, 7, 286–298. [Google Scholar] [CrossRef]

- Bentoumi, L.; Touba, B.; Bessaïh, R.; Bouttout, A. Impact of Thermal Insulation on Energy Consumption in Buildings. J. Therm. Eng. 2024, 10, 924–935. [Google Scholar] [CrossRef]

- Kosny, J.; Yarbrough, D. Thermal Efficiency of Insulation in Building Structures—The Impact of Thermal Bridging. In Thermal Insulation and Radiation Control Technologies for Buildings; Springer Nature: Cham, Switzerland, 2022; pp. 443–486. [Google Scholar] [CrossRef]

- Othuman Mydin, M.A.; Wang, Y.C. Structural Performance of Lightweight Steel-Foamed Concrete–Steel Composite Walling System under Compression. Thin-Walled Struct. 2011, 49, 66–76. [Google Scholar] [CrossRef]

- de Souza, T.B.; Medeiros, M.H.F.; Araújo, F.W.C.; de Melo Neto, A.A. The Influence of Expanded Polystyrene Granules on the Properties of Foam Concrete. Mater. Struct. 2023, 56, 19. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and Applications of Foamed Concrete; a Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, J.; Yu, Z.; Ye, Y.; Sun, X.; Zhang, Y.; Zhu, P.; Jiang, F. Air Drying Scalable Production of Hydrophobic, Mechanically Stable, and Thermally Insulating Lignocellulosic Foam. Chem. Eng. J. 2022, 450, 138300. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A Mini-Review on Building Insulation Materials from Perspective of Plastic Pollution: Current Issues and Natural Fibres as a Possible Solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.; Deng, X.; Beiyuan, J.; Chen, X.; Liu, D.; Lv, D.; Duan, C.; Lin, L.; Cha, R.; Xie, W.; et al. Review of Synthetic Polymer-Based Thermal Insulation Materials in Construction and Building. J. Build. Eng. 2024, 97, 110846. [Google Scholar] [CrossRef]

- Michalak, J. External Thermal Insulation Composite Systems (ETICS) from Industry and Academia Perspective. Sustainability 2021, 13, 13705. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Hekimoğlu, G.; Ustaoğlu, A.; Sarı, A.; Kaplan, G.; Bayraktar, O.Y.; Sutcu, M.; Ozbakkaloglu, T. Foam Concrete Produced with Recycled Concrete Powder and Phase Change Materials. Sustainability 2022, 14, 7458. [Google Scholar] [CrossRef]

- Şimşek, O.; Ünal, M.T.; Gökçe, H.S. Performance of Foam Concrete Developed from Construction and Demolition Waste. Mater. Today Sustain. 2024, 27, 100822. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Zou, S.; Duan, Z.; Ma, Y. Developing Recycled Foamed Concrete for Engineered Material Arresting System. J. Build. Eng. 2022, 53, 104555. [Google Scholar] [CrossRef]

- Lalrinmawii, E.; Sahu, S.; Sarkar, P.; Davis, R. Feasible Use of Recycled Foam Concrete in Cement Mortar. IOP Conf. Ser. Mater. Sci. Eng. 2020, 936, 012011. [Google Scholar] [CrossRef]

- Klemczak, B.; Gołaszewski, J.; Cygan, G.; Gołaszewska, M.; Jonkers, H.; Zhilyaev, D.; Koenders, E.A.B. Utilization of Waste Foam Concrete with MPCM as a Substitution Material for Cement in Mortars. J. Build. Eng. 2024, 90, 109284. [Google Scholar] [CrossRef]

- Decký, M.; Drusa, M.; Zgútová, K.; Blaško, M.; Hájek, M.; Scherfel, W. Foam Concrete as New Material in Road Constructions. Procedia Eng. 2016, 161, 428–433. [Google Scholar] [CrossRef]

- Serpilli, M.; Clementi, F.; Lenci, S. An Experimental and Numerical Study on the In-Plane Axial and Shear Behavior of Sprayed in-Situ Concrete Sandwich Panels. Eng. Struct. 2021, 232, 111814. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.; Amin, M.N.; Ahmed, B.; Khan, K.; Arifeen, S.U.; Althoey, F. Foam Concrete for Lightweight Construction Applications: A Comprehensive Review of the Research Development and Material Characteristics. Rev. Adv. Mater. Sci. 2024, 63. [Google Scholar] [CrossRef]

- Sulik, P.; Kukfisz, B.; Dowbysz, A.; Oszczak-Nowińska, A. Fire Resistance of Foamed Concrete for Discontinuous Partition Filling. Materials 2024, 17, 1315. [Google Scholar] [CrossRef]

- Awoyera, P.; Onoja, E.; Adesina, A. Fire Resistance and Thermal Insulation Properties of Foamed Concrete Incorporating Pulverized Ceramics and Mineral Admixtures. Asian J. Civ. Eng. 2020, 21, 147–156. [Google Scholar] [CrossRef]

- Schiavoni, S.; D´Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Neugebauer, A.; Chen, K.; Tang, A.; Allgeier, A.; Glicksman, L.R.; Gibson, L.J. Thermal Conductivity and Characterization of Compacted, Granular Silica Aerogel. Energy Build. 2014, 79, 47–57. [Google Scholar] [CrossRef]

- Fickler, S.; Milow, B.; Ratke, L.; Schnellenbach-Held, M.; Welsch, T. Development of High Performance Aerogel Concrete. Energy Procedia 2015, 78, 406–411. [Google Scholar] [CrossRef]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and Optimization of Ultra-Light and Thermal Insulative Aerogel Foam Concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Lu, L.; Wang, H.; Yun, S.; Hu, J.; Wang, M. A State-of-the-Art Review of Novel Aerogel Insulation Materials for Building Exterior Walls. Energy Sources Part A Recover. Util. Environ. Eff. 2024, 46, 16231–16252. [Google Scholar] [CrossRef]

- Li, Z.; Yao, S.; Wang, G.; Deng, X.; Zhou, F.; Wu, X.; Liu, Q. Enhancing Water Resistance in Foam Cement through MTES-Based Aerogel Impregnation. Gels 2024, 10, 118. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Yiqiang, C.; Yunsheng, Z.; Jones, M.R. Characterization and Simulation of Microstructure and Thermal Properties of Foamed Concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar] [CrossRef]

- Mydin, M. Influence of Density, Porosity and Void Size on Thermal Conductivity of Green Lightweight Foamed Concrete. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 92, 25–35. [Google Scholar] [CrossRef]

- Ge, Z.; Yuan, H.; Sun, R.; Zhang, H.; Wang, W.; Qi, H. Use of Green Calcium Sulphoaluminate Cement to Prepare Foamed Concrete for Road Embankment: A Feasibility Study. Constr. Build. Mater. 2020, 237, 117791. [Google Scholar] [CrossRef]

- García-Maté, M.; De la Torre, A.G.; León-Reina, L.; Losilla, E.R.; Aranda, M.A.G.; Santacruz, I. Effect of Calcium Sulfate Source on the Hydration of Calcium Sulfoaluminate Eco-Cement. Cem. Concr. Compos. 2015, 55, 53–61. [Google Scholar] [CrossRef]

- Li, T.; Huang, F.; Li, L.; Zhu, J.; Jiang, X.; Huang, Y. Preparation and Properties of Sulphoaluminate Cement-Based Foamed Concrete with High Performance. Constr. Build. Mater. 2020, 263, 120945. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Klemczak, B.; Smolana, A.; Gołaszewska, M.; Cygan, G.; Mankel, C.; Peralta, I.; Röser, F.; Koenders, E.A.B. Effect of Foaming Agent, Binder and Density on the Compressive Strength and Thermal Conductivity of Ultra-Light Foam Concrete. Buildings 2022, 12, 1176. [Google Scholar] [CrossRef]

- Ndiaye, K.; Samson, G.; Ginestet, S.; Rouviere, Y.; Cyr, M. Foamed Calcium Sulfoaluminate Cement with Controlled Porous Network for Daily or Seasonal Heat Storage in Ettringite. J. Build. Eng. 2024, 98, 111284. [Google Scholar] [CrossRef]

- DIN EN 13302:2018-08; Bitumen Und Bitumenhaltige Bindemittel– Bestimmung der Dynamischen Viskosität von Bitumenhaltigem Bindemittel Mit Einem Viskosimeter Mit Rotierender Spindel. German Institute for Standardization: Berlin, Germany, 2018. [CrossRef]

- Yousuf, N.; Olayiwola, O.; Guo, B.; Liu, N. A Comprehensive Review on the Loss of Wellbore Integrity Due to Cement Failure and Available Remedial Methods. J. Pet. Sci. Eng. 2021, 207, 109123. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, M.; Liu, R.; Li, X.; Liu, Y.; Jiang, P.; Yan, J.; Zhu, Z.; Chen, M. Rheological Properties of Cement-Based Slurry and Evaluation of Rheological Model: Influence of Particle Size and Shape. Constr. Build. Mater. 2023, 406, 133498. [Google Scholar] [CrossRef]

- DIN EN 12390-3:2019-10; Prüfung von Festbeton—Teil_3: Druckfestigkeit von Probekörpern. German Institute for Standardization: Berlin, Germany, 2018. [CrossRef]

- Falliano, D.; Parmigiani, S.; Suarez-Riera, D.; Ferro, G.A.; Restuccia, L. Stability, Flexural Behavior and Compressive Strength of Ultra-Lightweight Fiber-Reinforced Foamed Concrete with Dry Density Lower than 100 Kg/M3. J. Build. Eng. 2022, 51, 104329. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of Fly Ash and Silica Fume on Hardened Properties of Foam Concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Wei, J.; Wang, T.; Zhong, Y.; Zhang, Y.; Leung, C.K.Y. Performance Evaluation of Foamed Concrete with Lightweight Aggregate: Strength, Shrinkage, and Thermal Conductivity. Materials 2024, 17, 3869. [Google Scholar] [CrossRef] [PubMed]

- DIN EN 480-11:2005-12; Zusatzmittel Für Beton, Mörtel Und Einpressmörtel—Prüfverfahren—Teil_11: Bestimmung von Luftporenkennwerten in Festbeton. German Institute for Standardization: Berlin, Germany, 2018. [CrossRef]

- Li, Z.; Wang, G.; Deng, X.; Liu, Q.; Shulga, Y.M.; Chen, Z.; Wu, X. Preparation and Characterization of Silica Aerogel Foam Concrete: Effects of Particle Size and Content. J. Build. Eng. 2024, 82, 108243. [Google Scholar] [CrossRef]

- Wang, G.; Pelton, R.; Hrymak, A.; Shawafaty, N.; Heng, Y.M. On the Role of Hydrophobic Particles and Surfactants in Defoaming. Langmuir 1999, 15, 2202–2208. [Google Scholar] [CrossRef]

- Pott, J.U. Entwicklungsstrategien Für zementgebundene Schäume. Ph.D. Thesis, Leibniz Universität Hannover, Hannover, Germany, 2006. [Google Scholar]

- Xu, T.; Garrecht, H. Effects of Mixing Techniques and Material Compositions on the Compressive Strength and Thermal Conductivity of Ultra-Lightweight Foam Concrete. Materials 2024, 17, 2640. [Google Scholar] [CrossRef]

- Strzałkowski, J.; Garbalińska, H. The Dynamic Thermal Properties of Aerogel-Incorporated Concretes. Constr. Build. Mater. 2022, 340, 127706. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Gustavsen, A.; Jacobsen, S. Aerogel-Incorporated Concrete: An Experimental Study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

- Hub, A.; Zimmermann, G.; Knippers, J. Leichtbeton mit Aerogelen als Konstruktionswerkstoff. Beton Stahlbetonbau 2013, 108, 654–661. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Vashchuk, A.; Klapiszewski, Ł. Research Development in Silica Aerogel Incorporated Cementitious Composites—A Review. Polymers 2022, 14, 1456. [Google Scholar] [CrossRef] [PubMed]

- Welsch, T.; Vievers, Y.; Schnellenbach-Held, M.; Bialuschewski, D.; Milow, B. Comparison of Different Aerogel Granules for Use as Aggregate in Concrete. Gels 2023, 9, 406. [Google Scholar] [CrossRef]

- Fickler, S.; Heidrich, T.; Welsch, T.; Schnellenbach-Held, M. Hochleistungsaerogelbeton – Optimierung, Tragverhalten, Festigkeit. Beton Stahlbetonbau 2022, 117, 498–509. [Google Scholar] [CrossRef]

- Amani, P.; Miller, R.; Javadi, A.; Firouzi, M. Pickering Foams and Parameters Influencing Their Characteristics. Adv. Colloid Interface Sci. 2022, 301, 102606. [Google Scholar] [CrossRef]

- Moradpour, N.; Yang, J.; Tsai, P.A. Liquid Foam: Fundamentals, Rheology, and Applications of Foam Displacement in Porous Structures. Curr. Opin. Colloid Interface Sci. 2024, 74, 101845. [Google Scholar] [CrossRef]

- Hu, N.; Li, Y.; Wu, Z.; Lu, K.; Huang, D.; Liu, W. Foams Stabilization by Silica Nanoparticle with Cationic and Anionic Surfactants in Column Flotation: Effects of Particle Size. J. Taiwan Inst. Chem. Eng. 2018, 88, 62–69. [Google Scholar] [CrossRef]

- Krzan, M.; Jarek, E.; Petkova, H.; Santini, E.; Szyk-Warszynska, L.; Ravera, F.; Liggieri, L.; Mileva, E.; Warszynski, P. Hydrophobisation of Silica Nanoparticles Using Lauroyl Ethyl Arginate and Chitosan Mixtures to Induce the Foaming Process. Polymers 2022, 14, 4076. [Google Scholar] [CrossRef]

- Choi, M.; Choi, W.K.; Jung, C.H.; Kim, S.B. The Surface Modification and Characterization of SiO2 Nanoparticles for Higher Foam Stability. Sci. Rep. 2020, 10, 19399. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Kim, J.H.; Lee, J.H.; Kang, S.T. Critical Grain Size of Fine Aggregates in the View of the Rheology of Mortar. Int. J. Concr. Struct. Mater. 2017, 11, 627–635. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, H.; Zhang, G.; Liu, J.; Liu, Z.; Du, F. Study on Preparation and Performance of Advanced Aerogel Foamed Concrete with Ultra-Light Aerogel. Constr. Build. Mater. 2023, 366, 130166. [Google Scholar] [CrossRef]

| Group | Initial Height (cm) | Final Height (cm) | Height Difference (cm) |

|---|---|---|---|

| 1 | 12.25 | 11.88 | 0.38 |

| 2 | 12.00 | 11.63 | 0.38 |

| 3 | 13.50 | 2.38 | 11.13 |

| 4 | 13.13 | 0.63 | 11.50 |

| Group | Material Content (kg/m3) | Aerogel Addition | |||

|---|---|---|---|---|---|

| Cement | Water | Aerogel | Foam | ||

| 3-04-F80 | 113.14 | 45.25 | 5.66 | 39.60 | Addition in step (iii) |

| 3-04-ELBA | 113.14 | 45.25 | 5.66 | 39.60 | Addition in step (iii) |

| 1-06-F80 | 98.90 | 57.53 | 4.79 | 39.56 | Addition in step (i) |

| Group | Design Density | Fresh Density | Compressive Strength (28d) | Thermal Conductivity |

|---|---|---|---|---|

| kg/m3 | kg/m3 | N/mm2 | W/(m·K) | |

| 3-04-F80 | 203.64 | 310.48 | 0.20 | 0.055 |

| 3-04-ELBA | 203.64 | 669.03 | 2.07 | 0.090 |

| 1-06-F80 | 197.79 | 176.37 | 0.04 | 0.044 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Garrecht, H.; Jiang, C.; Lu, C. The Application and Effects of Aerogel in Ultra-Lightweight Mineralised Foams. Buildings 2025, 15, 2671. https://doi.org/10.3390/buildings15152671

Xu T, Garrecht H, Jiang C, Lu C. The Application and Effects of Aerogel in Ultra-Lightweight Mineralised Foams. Buildings. 2025; 15(15):2671. https://doi.org/10.3390/buildings15152671

Chicago/Turabian StyleXu, Tongyu, Harald Garrecht, Chao Jiang, and Chuanyuan Lu. 2025. "The Application and Effects of Aerogel in Ultra-Lightweight Mineralised Foams" Buildings 15, no. 15: 2671. https://doi.org/10.3390/buildings15152671

APA StyleXu, T., Garrecht, H., Jiang, C., & Lu, C. (2025). The Application and Effects of Aerogel in Ultra-Lightweight Mineralised Foams. Buildings, 15(15), 2671. https://doi.org/10.3390/buildings15152671