Study on the Bearing Performance of Pole-Assembled Inclined Pile Foundation Under Downward Pressure-Horizontal Loads

Abstract

1. Introduction

2. Numerical Simulation

2.1. Model Overview

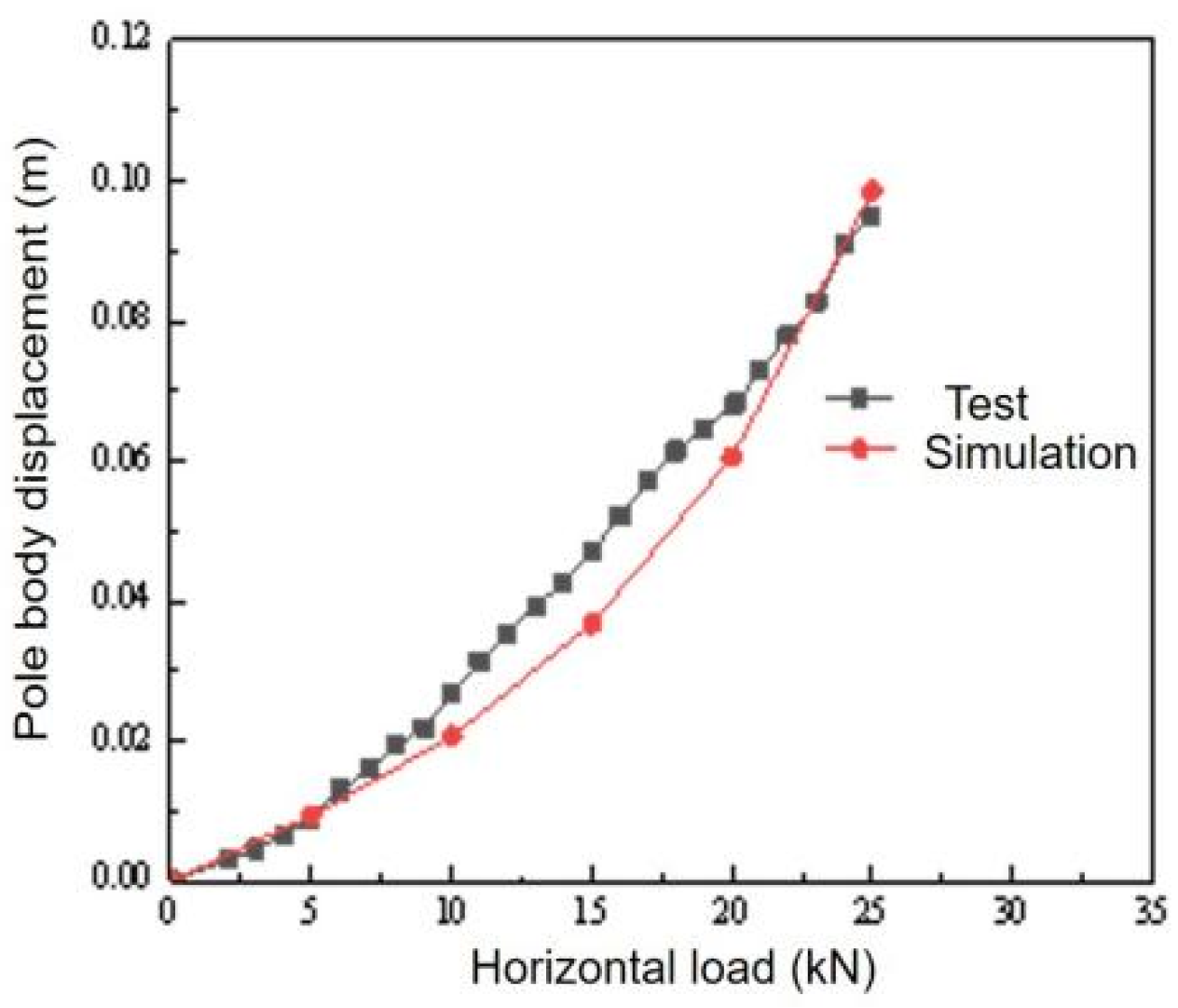

2.2. Model Validation

3. Influence of Foundation Dimensions on Load-Bearing Performance

3.1. Overview

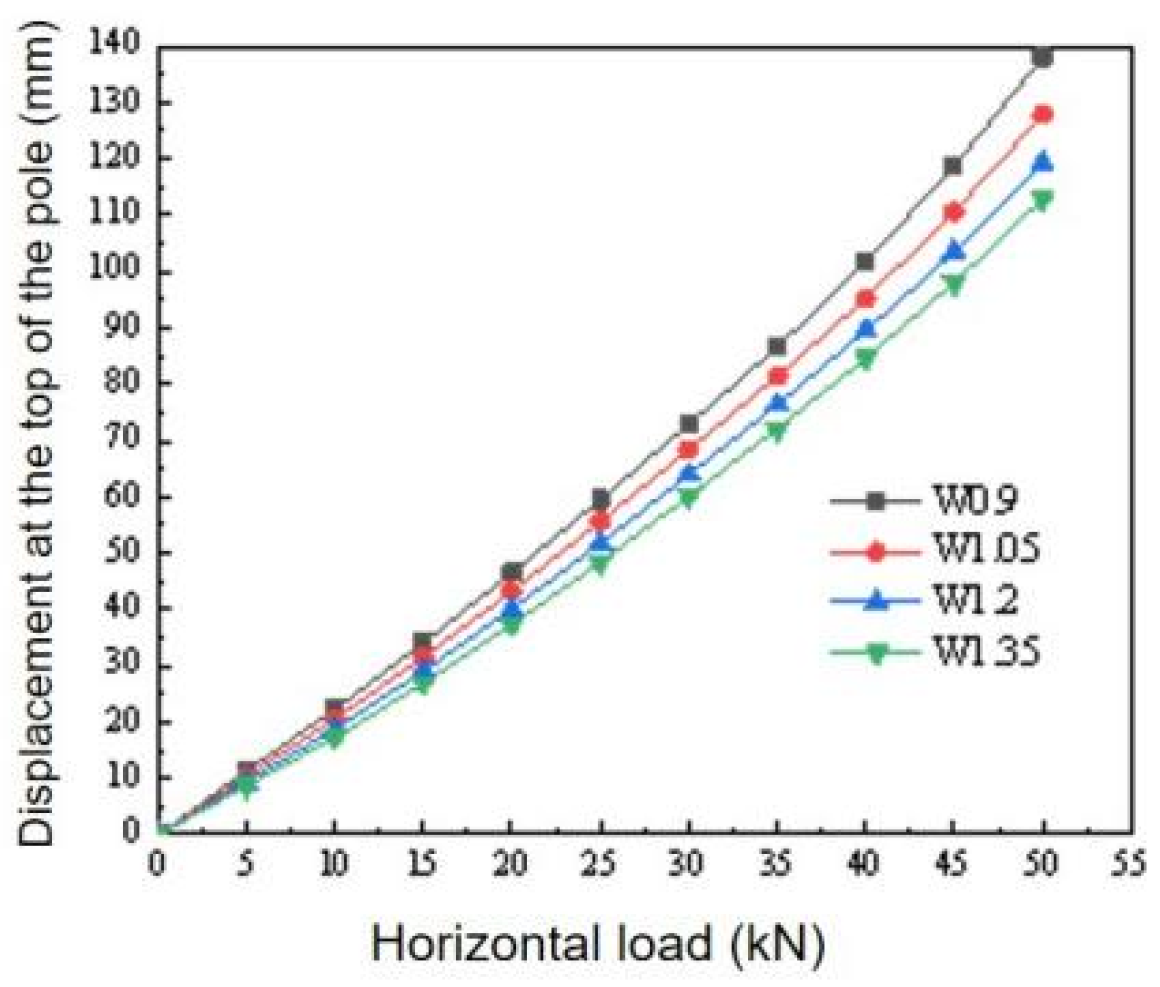

3.2. Lateral Load–Deflection Curve at the Pole Top

3.3. The Lateral Load–Movement Curve of Pile Top Under Different Foundation Dimensions

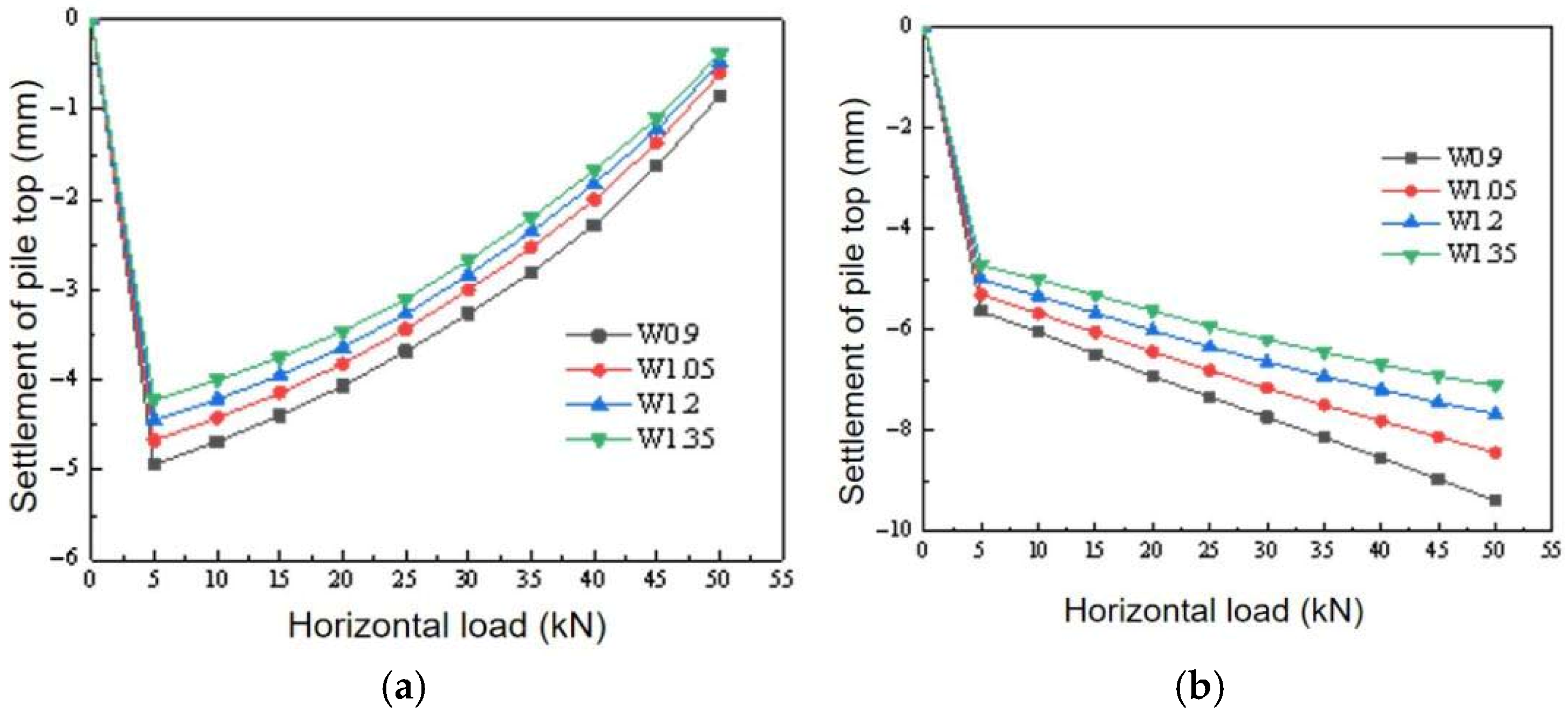

3.4. Settlement Curve of Pile Top Under Different Foundation Dimensions

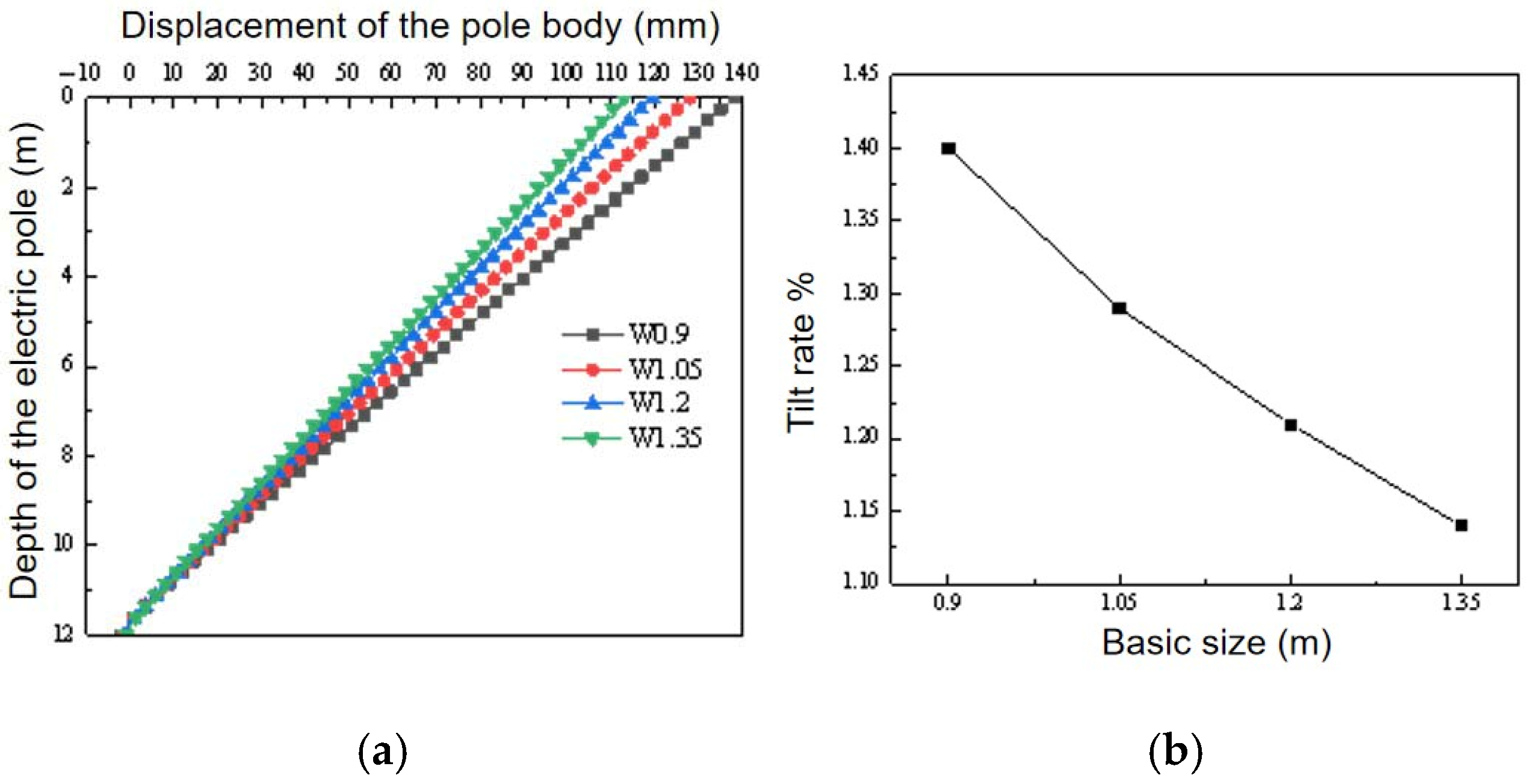

3.5. Displacement and Inclination Rate of the Electric Pole Body

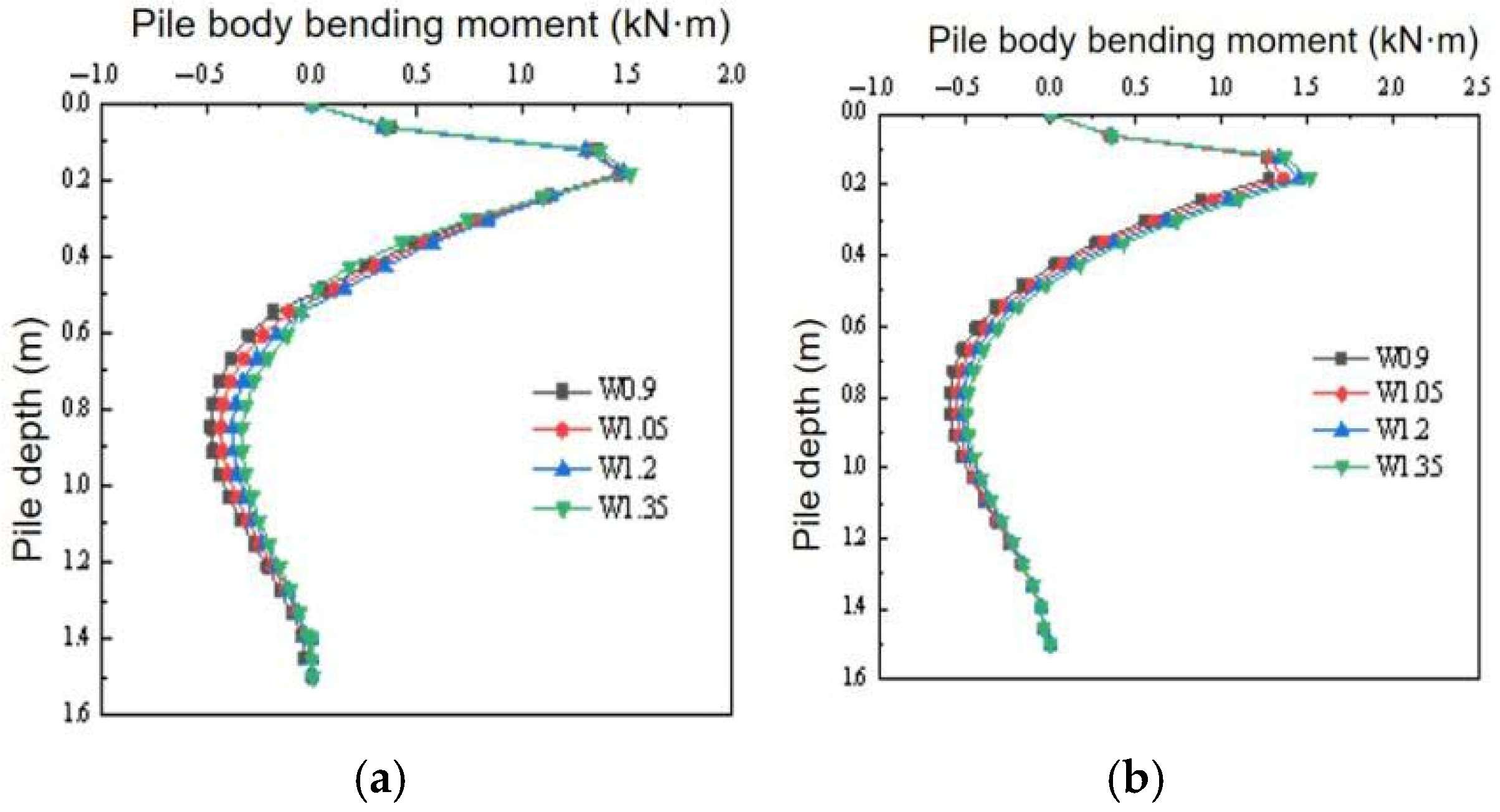

3.6. Pile Body Bending Moment Curve Under Different Foundation Dimensions

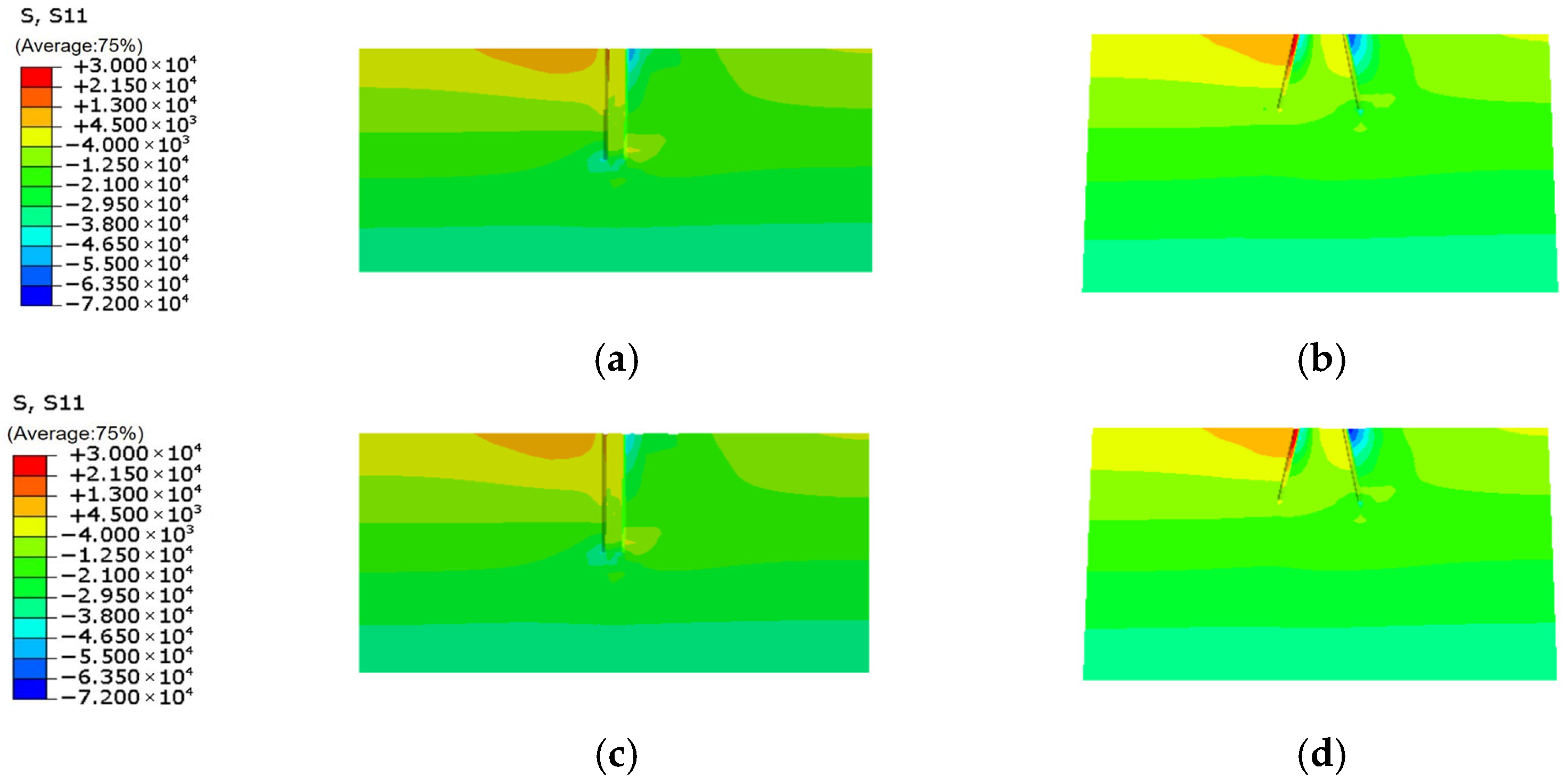

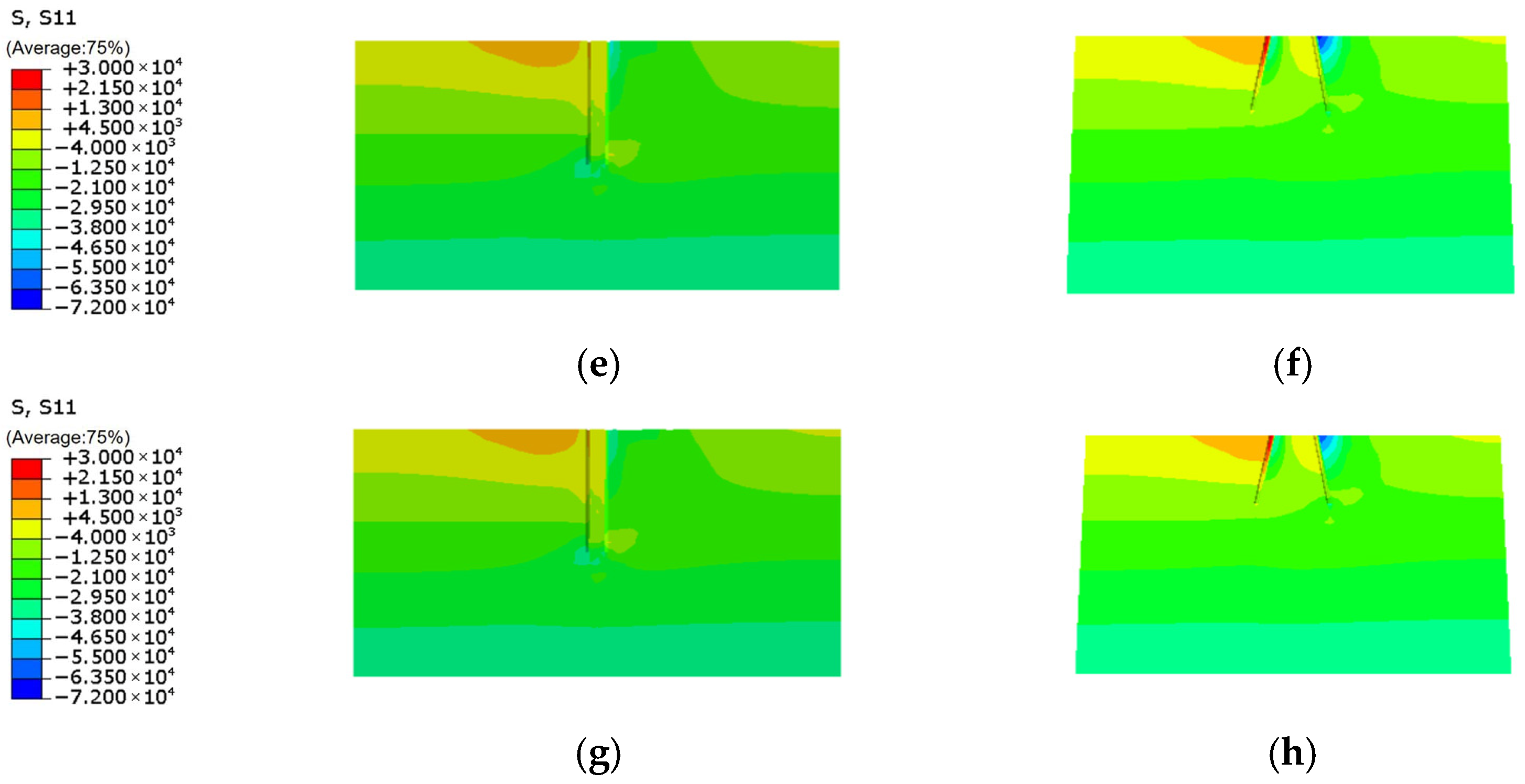

3.7. Analysis of Horizontal Stress Changes in the Soil Around the Foundation

4. Impact of Foundation Pile Tilt on Bearing Performance

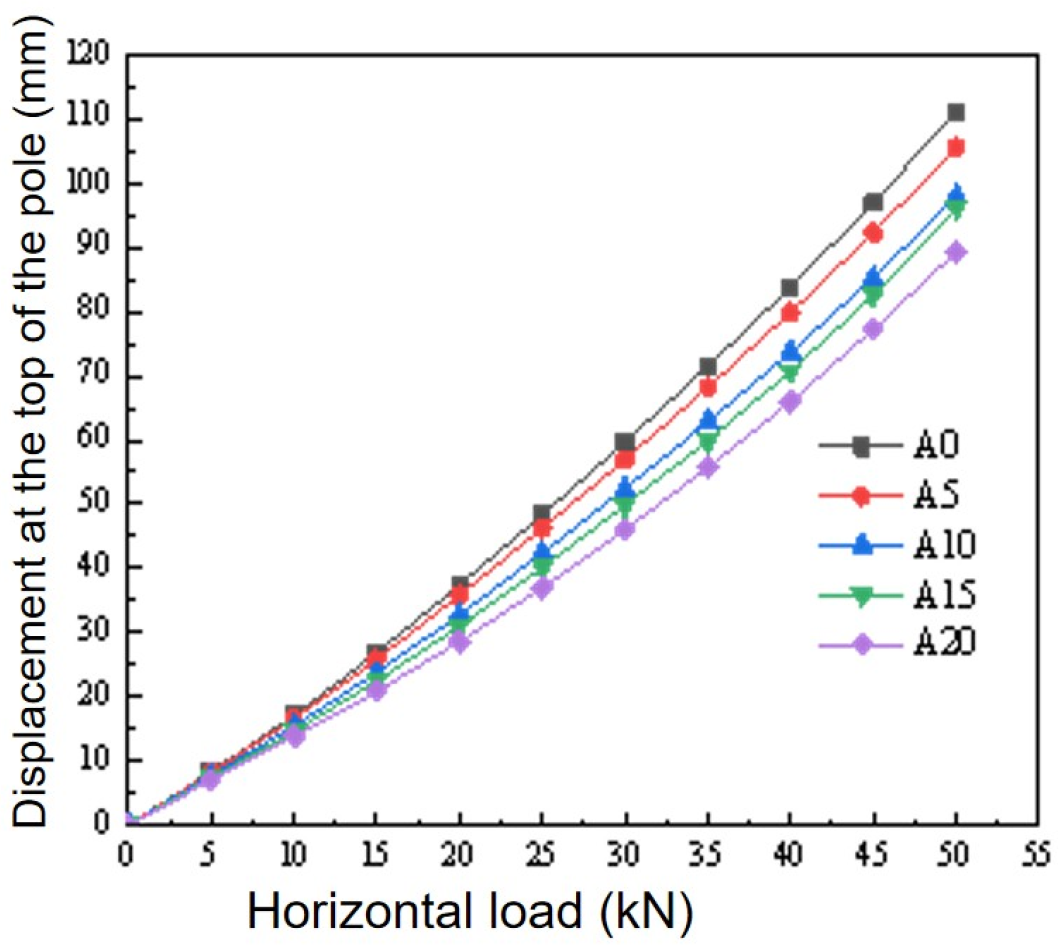

4.1. Horizontal Load–Displacement Graph at the Peak of Electric Pole

4.2. The Lateral Load–Movement Curve of Pile Top Under Different Pile Inclination Angles

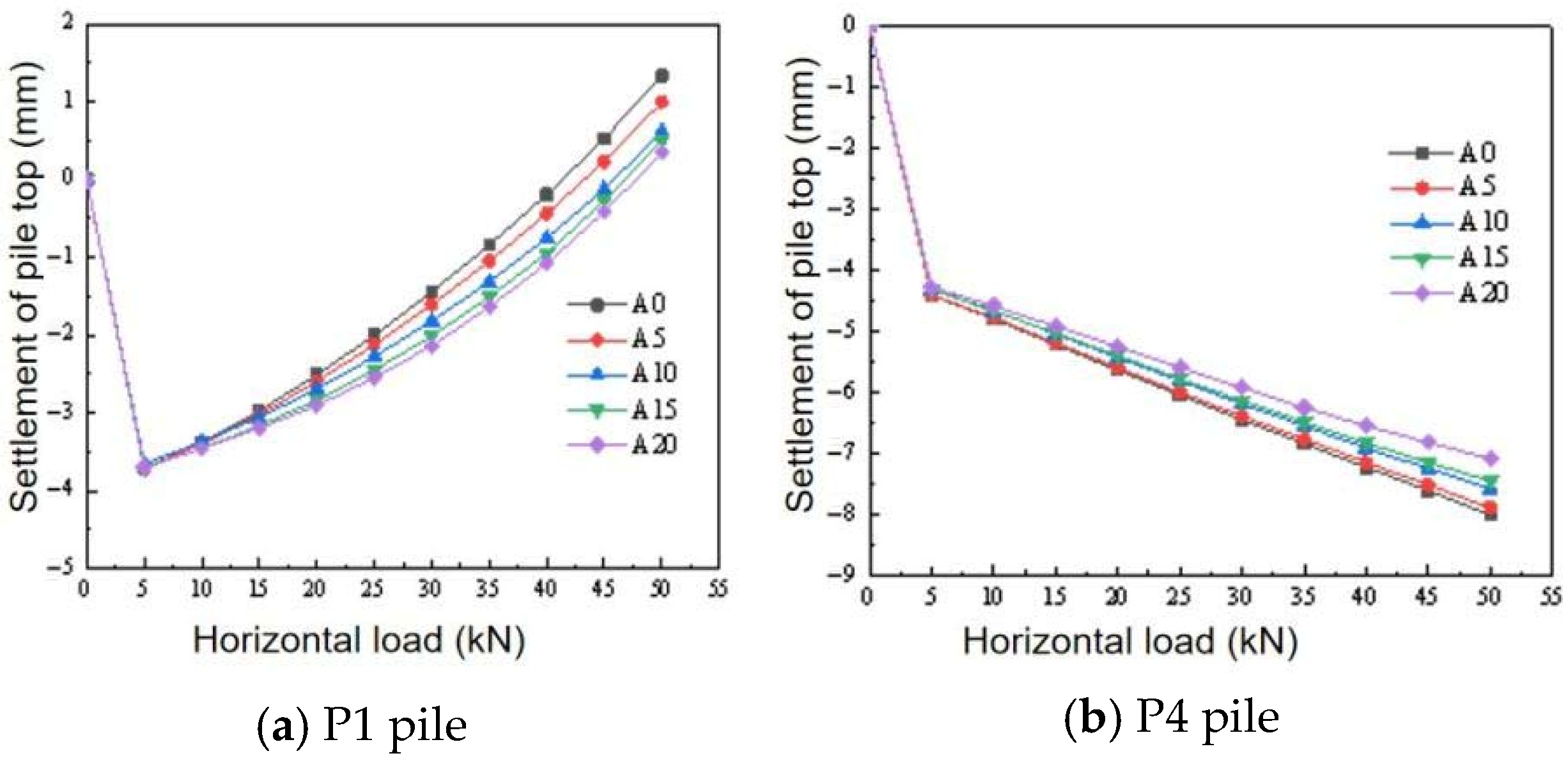

4.3. Settlement Curve of Pile Top Under Different Pile Inclination Angles

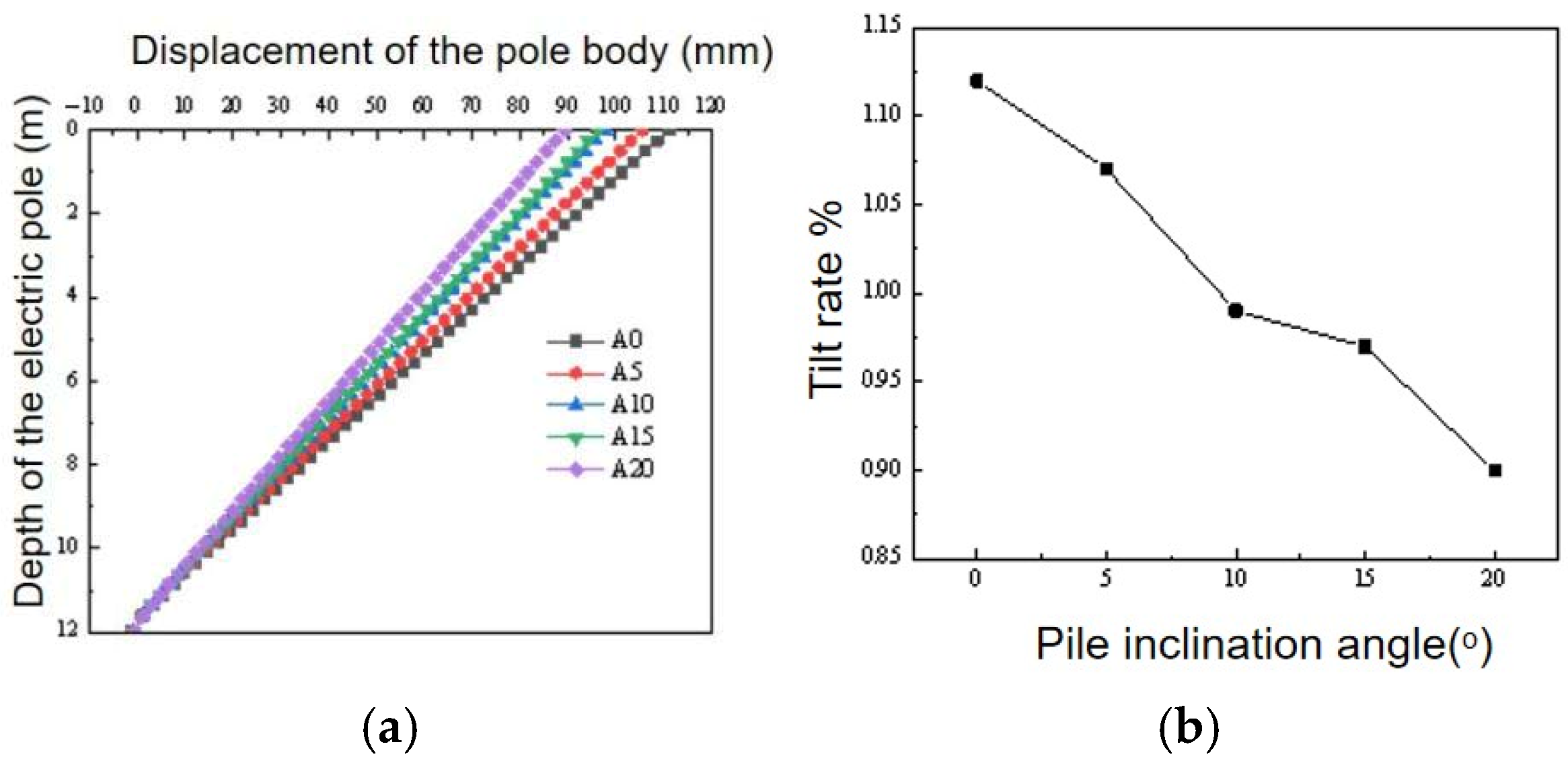

4.4. The Displacement Curve and Inclination Rate of the Electric Pole Body

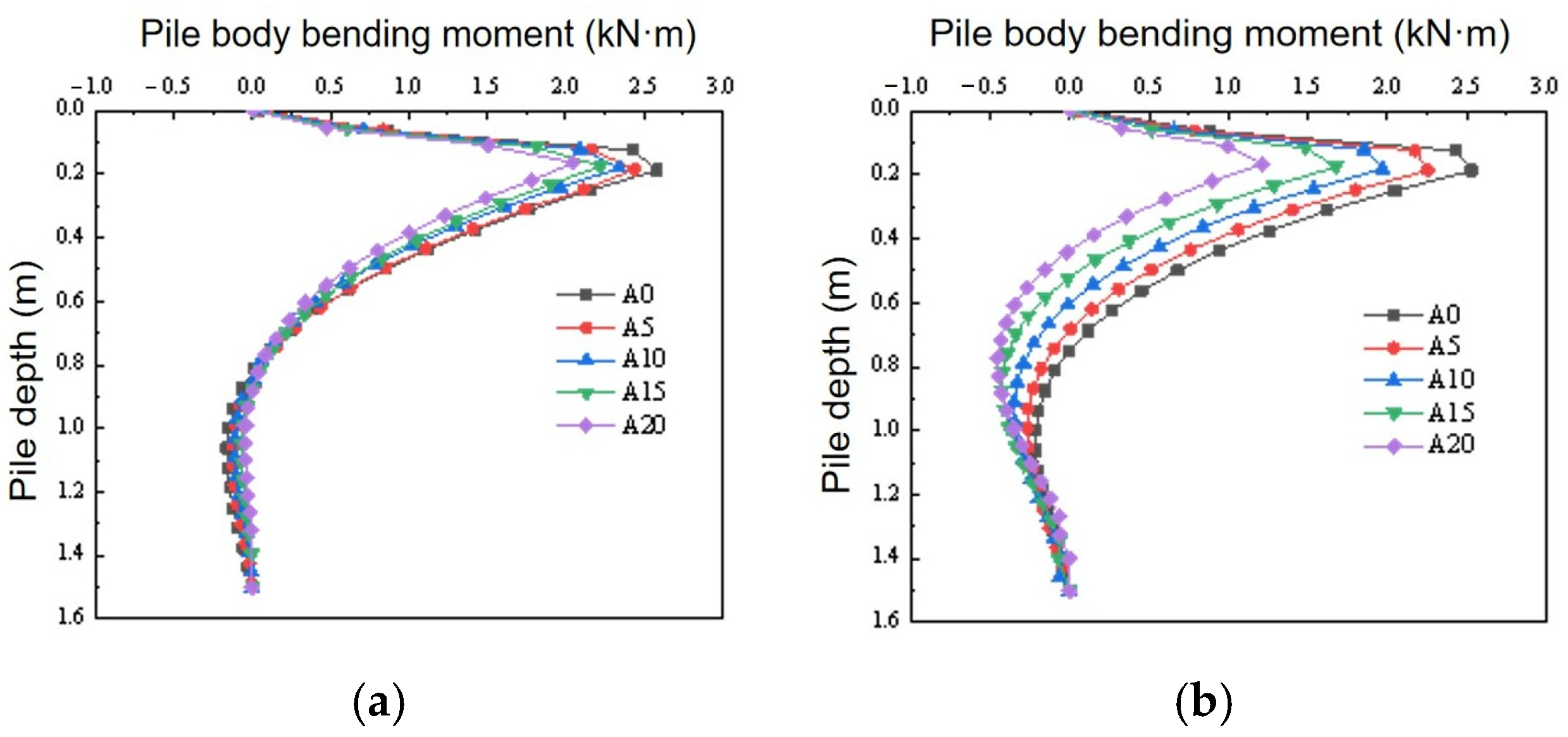

4.5. Pile Body Bending Moment Curve Under Different Pile Inclination Angles

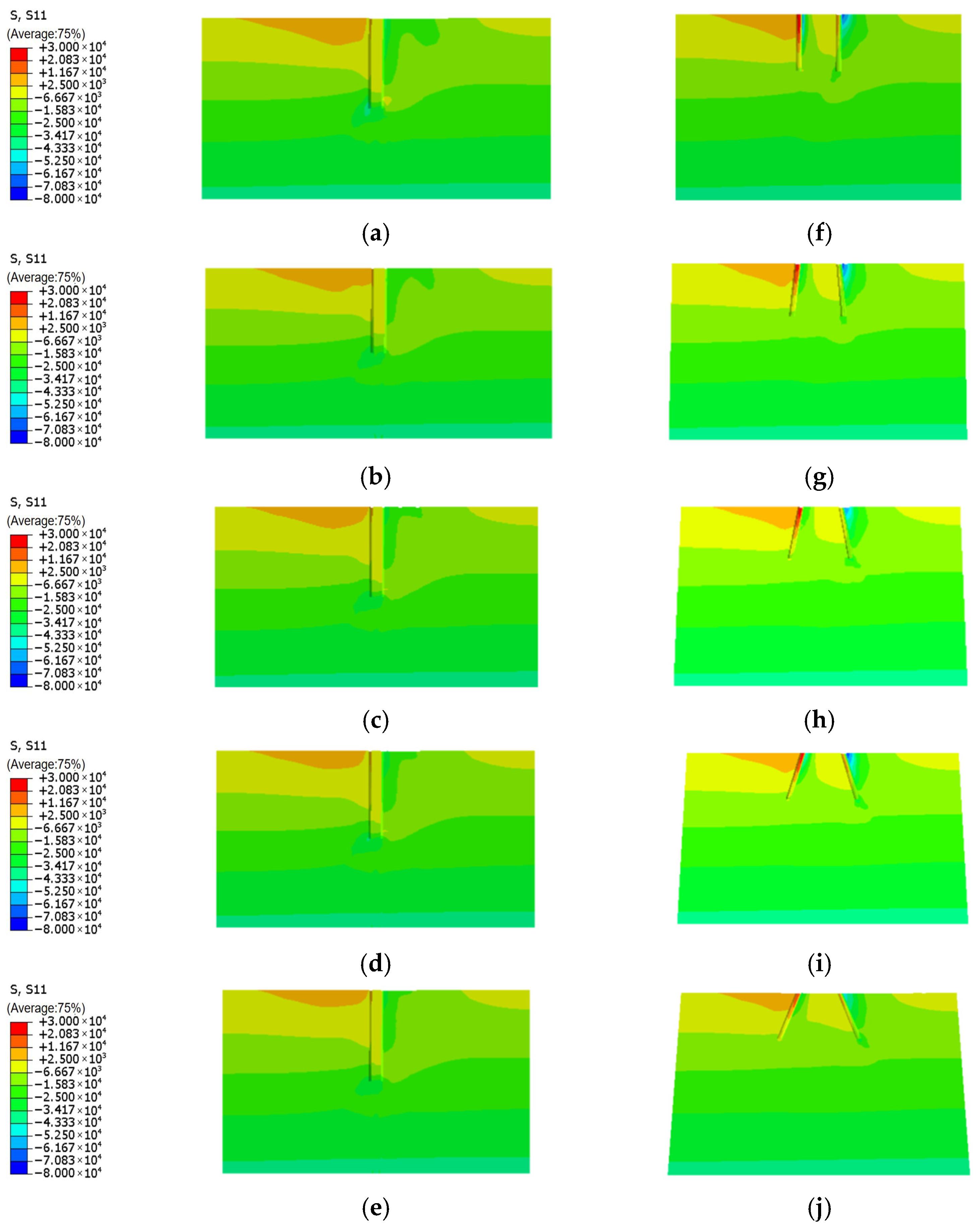

4.6. Analysis of Horizontal Soil Stress Around the Foundation

5. Conclusions

- (1)

- The larger the foundation size is, the greater the anti-overturning bearing ability and vertical bearing ability of the prefabricated foundation will be. The ultimate anti-overturning bearing capacities of the foundation sizes of 1.05 m, 1.2 m and 1.35 m increased by 5.32%, 10.90% and 15.77%, respectively, compared with those of the size of 0.9 m. Additionally, the lateral movement and inclination rate of the pole body decreased.

- (2)

- The bigger the pile inclination angle, the more excellent the anti-overturning bearing capacity and prefabricated foundation vertical bearing ability. The ultimate anti-overturning bearing ability at pile body inclinations of 5°, 10°, 15° and 20° increased by 4.0%, 11.0%, 13.5% and 19.2%, respectively, compared with 0°, and the lateral movement and pole inclination rate decreased. As the pile inclination angle increases, the foundation pile body’s maximum bending moment shows a decline. The largest moment arises at position 0.2 m of the pile shaft. Although increasing the pile inclination angle can enhance the bearing capacity of the foundation, an excessively large inclination angle is not conducive to the control of construction quality. It is recommended that the pile body inclination angle be controlled within 10° in engineering design.

- (1)

- In actual engineering, the geological conditions are complex. We only select a single set of soil parameters, and the bearing performance of the prefabricated inclined pile foundation analyzed is also carried out under the soil parameters selected in this study. Therefore, it is suggested to analyze the bearing ability of prefabricated inclined pile foundations under different geological conditions.

- (2)

- This study only analyzes the bearing ability of the foundation under downward pressure-horizontal conditions and does not analyze the bearing performance of the foundation under upward pull-horizontal conditions.

- (3)

- Field tests are the most intuitive way to evaluate the bearing performance of prefabricated foundations. Therefore, it is recommended to conduct field tests to study the bearing performance of prefabricated foundations when inclined piles are applied.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, J.-Y.; Liu, M.-H. Analysis of Overhead Optical Cable Installation Methods. Heilongjiang Sci. Technol. Inf. 2010, 16, 47+184. [Google Scholar]

- Ye, J.-B.; Wang, C.-F.; Huang, W.-P.; Zhang, J.; Zhou, X. Effect of inclination angle on the response of double-row retaining piles: Experimental and numerical investigation. Teh. Vjesn. 2020, 27, 1150–1159. [Google Scholar]

- Wang, D.; Ju, Y.-Z.; Ju, M.-S.; Song, M.; Zhao, J.; Bai, J. Uplift Bearing Capacity of Squeezed Branch Pile Group. Geotech. Geol. Eng. 2022, 41, 283–293. [Google Scholar] [CrossRef]

- Wang, D.-H.; Ju, Y.-Z.; Zhao, X.-P.; Bai, J.-F. Field test and numerical simulation on bearing capacity of squeezed branch pile in Transmission line. Mechanics 2017, 23, 762–768. [Google Scholar]

- Huang, W.-H.; Zhou, Z.-Y.; Zhang, C.-T.; Qiu, H.-S. Numerical Analysis of Bearing Behavior for Inclined-Vertical Pile Groups in Coastal Terrestrial Zones. Eng. Constr. 2021, 35, 301–306. [Google Scholar]

- Li, L.-Q.; Zhao, H.-Q. Analysis of Lateral Bearing Behavior for Inclined Pile Foundations Under Combined Loading. Eng. Sci. Technol. 2022, 54, 124–134. [Google Scholar]

- Fan, W.-F.; Xu, Y.-Q. Numerical Analysis of Bearing Behavior for Inclined Pile Foundations in Transmission Tower Bases Under Horizontal Loading. Ground Treat. 2023, 5, 492–497. [Google Scholar]

- Song, Y.-G.; Wang, J.-K. Numerical Simulation-Based Analysis of Horizontal and Vertical Bearing Behavior in Inclined Pile Groups. J. Lanzhou Univ. Technol. 2023, 49, 142–149. [Google Scholar]

- Liu, C.; Yan, C.-D.; Zheng, G.; Liu, T.; Yang, Y. Field Testing and Numerical Analysis of Supporting Performance of Oblique Piles Used in Pit Excavation. Int. J. Geomech. 2023, 23, 04023204. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, J.-T.; Wu, W.-B.; Wen, M.; Wang, K.; Faheem, R.S.M. Bearing behaviors and design method of laterally loaded batter pile groups (BPGs) in sand. Ocean Eng. 2023, 287, 115685. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, K.-H.; Wu, J.-T.; Chen, W.; Tu, Y. Investigation of the vertical responses of 2 × 2 square flexible batter pile groups in sand. Mar. Geores. Geotechnol. 2023, 41, 751–763. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, B.-J.; Miao, P.; Yan, C.-D. Model test and stress mechanism study of horizontally loaded inclined pile group. J. Tianjin Univ. (Nat. Sci. Technol.) 2023, 56, 275–288. [Google Scholar]

- Zhang, L.; Shen, J.-H.; Chen, C.; Luo, D. Lateral bearing characteristics of inclined pile-cap system installed in sandy ground. Chin. J. Geotech. 2024, 46, 120–130. [Google Scholar]

- Fan, W.-F.; Cao, W.-P. Numerical Analysis of Lateral Bearing-Deformation Behavior in Capped Inclined Single Piles. J. Chang. River Sci. Res. Inst. 2016, 33, 121–125. [Google Scholar]

- Aminfar, A.; Ahmadi, H.; Aminfar, H.M. Parametric study on the effects of pile inclination angleon the response of batter piles in offshore jacket platforms. J. Mar. Sci. Appl. 2016, 15, 193–200. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.-L.; Zhang, Z.-H.; Wei, H.-W. Field test study and numerical analysis of the horizontal bearing characteristics of pile groups. Geotech. Investig. Surv. 2023, 51, 19–28. [Google Scholar]

- Wu, K.-H. Numerical simulation study on the influence of inclined pile arrangement on the bearing capacity of micro pile groups. Fujian Constr. Sci. Technol. 2015, 2, 4–7. [Google Scholar]

- Asgari, A.; Bagheri, M.; Hadizadeh, M. Advanced seismic analysis of soil-foundation-structure interaction for shallow and pile foundations in saturated and dry deposits: Insights from 3D parallel finite element modeling. Structures 2024, 69, 107503. [Google Scholar] [CrossRef]

- Bagheri, M.; Jamkhaneh, M.E.; Samali, B. Effect of seismic soil–pile–structure interaction on mid-and high-rise steel buildings resting on a group of pile foundations. Int. J. Geomech. 2018, 18, 04018103. [Google Scholar] [CrossRef]

- Çetindemir, O. Nonlinear constitutive soil models for the soil–structure interaction modeling issues with emphasis on shallow tunnels: A review. Arab. J. Sci. Eng. 2023, 48, 12657–12691. [Google Scholar] [CrossRef]

- Ju, Y.; Zhang, H.; Wang, D.; Kong, X.; Ma, Y.; Zhang, X.; Bai, J. Effect of mineral admixtures on the resistance to sulfate attack of reactive powder concrete. J. Clean. Prod. 2024, 440, 140769. [Google Scholar] [CrossRef]

- Wang, D.; Ma, Y.; Kang, M.; Ju, Y.; Zeng, C. Durability of reactive powder concrete containing mineral admixtures in seawater erosion environment. Constr. Build. Mater. 2021, 306, 124863. [Google Scholar] [CrossRef]

- Ju, Y.-Z.; Shen, T.; Wang, D. Bonding behavior between reactive powder concrete and normal strength concrete. Constr. Build. Mater. 2020, 242, 118024. [Google Scholar] [CrossRef]

- Jian, W.-B.; Wu, Z.-X.; Liu, H.-M.; Chen, Z.; Zhang, M. Cone penetration parameters of soil in coastal areas of Fujian. Chin. J. Rock Mech. Eng. 2004, S1, 4414–4417. [Google Scholar]

| Type | Density | Elastic Modulus/(MPa) | Poisson Ratio | Angle of Friction (°) | Cohesion (kPa) |

|---|---|---|---|---|---|

| Soil layer 1 | 1830 | 3.8 | 0.3 | 21 | 12 |

| Soil layer 2 | 1950 | 7 | 0.3 | 27 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Song, W.; Hao, W.; Guo, F.; Yang, Y.; Kang, M.; Zhang, L.; Wang, Y. Study on the Bearing Performance of Pole-Assembled Inclined Pile Foundation Under Downward Pressure-Horizontal Loads. Buildings 2025, 15, 2656. https://doi.org/10.3390/buildings15152656

Zhao C, Song W, Hao W, Guo F, Yang Y, Kang M, Zhang L, Wang Y. Study on the Bearing Performance of Pole-Assembled Inclined Pile Foundation Under Downward Pressure-Horizontal Loads. Buildings. 2025; 15(15):2656. https://doi.org/10.3390/buildings15152656

Chicago/Turabian StyleZhao, Chong, Wenzhuo Song, Wenzheng Hao, Furan Guo, Yan Yang, Mengxin Kang, Liang Zhang, and Yun Wang. 2025. "Study on the Bearing Performance of Pole-Assembled Inclined Pile Foundation Under Downward Pressure-Horizontal Loads" Buildings 15, no. 15: 2656. https://doi.org/10.3390/buildings15152656

APA StyleZhao, C., Song, W., Hao, W., Guo, F., Yang, Y., Kang, M., Zhang, L., & Wang, Y. (2025). Study on the Bearing Performance of Pole-Assembled Inclined Pile Foundation Under Downward Pressure-Horizontal Loads. Buildings, 15(15), 2656. https://doi.org/10.3390/buildings15152656