Anti-Overturning Performance of Prefabricated Foundations for Distribution Line Poles

Abstract

1. Introduction

2. Prototype Test

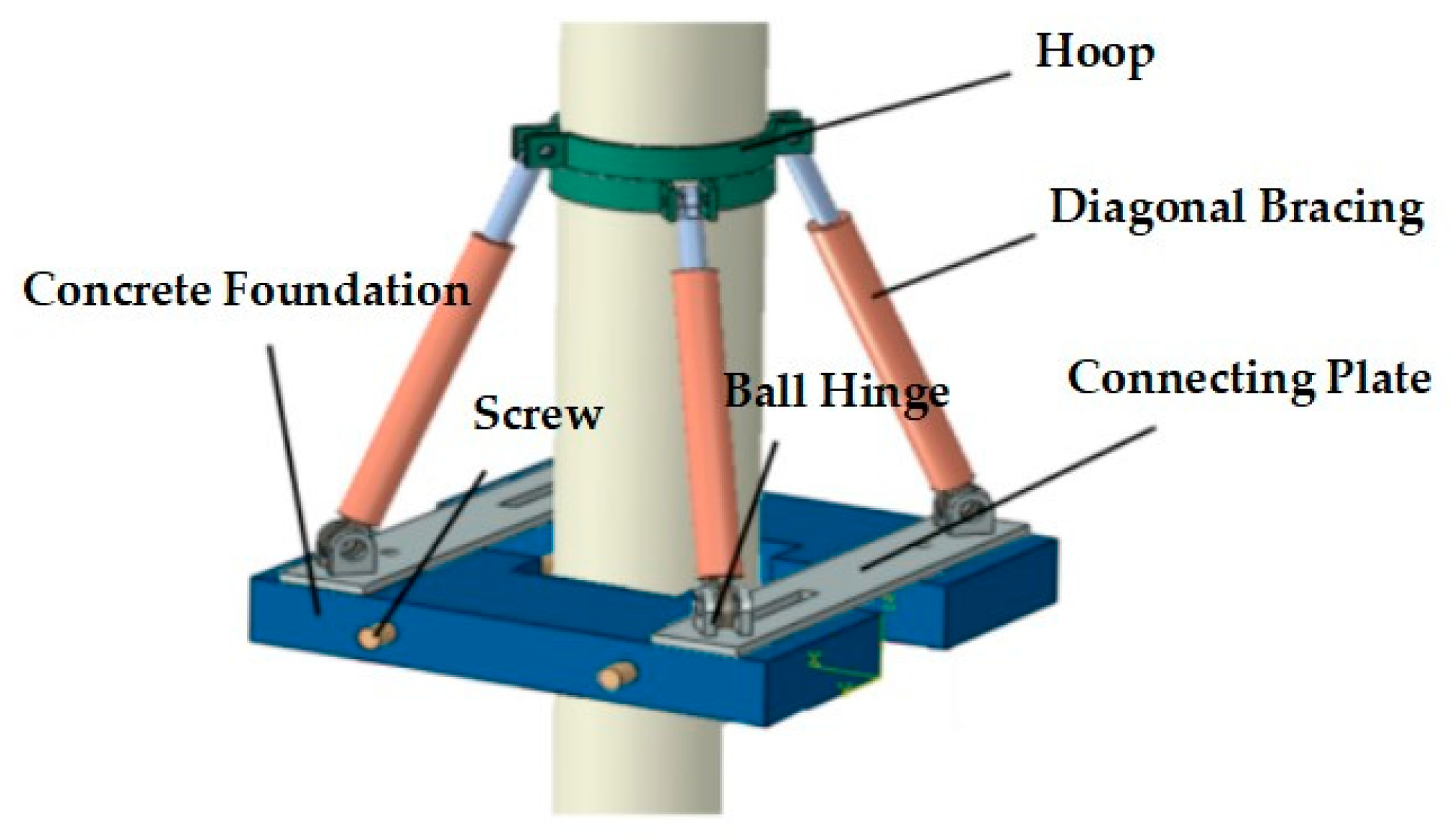

2.1. Prefabricated Foundation Composition

2.2. Experimental Design

2.3. Test Loading Device and Measurement Method

2.4. Test Observations

2.5. Test Results and Analysis

2.5.1. Overturning Moment–Rotation Angle

2.5.2. Base Reaction of Fabricated Foundation

2.5.3. Pole-Side Soil Pressure

3. Finite Element Analysis of Load-Bearing Capacity of Prefabricated Foundation

3.1. Numerical Model

3.2. Model Verification

3.3. Analysis of Influence Parameters of Anti-Overturning Capacity

3.3.1. Foundation Position

3.3.2. Depth of Pole Buried

3.3.3. Soil Parameter and Type

4. Calculation Method of Anti-Overturning Capacity

4.1. Pole Stress

4.2. Prefabricated Foundation Loading

4.3. Calculation Formula

5. Formula Verification

6. Conclusions

- (1)

- When the foundation size is increased from 0.8 m to 0.9 m, the ultimate bearing capacity is increased by 8%; when the loading direction is changed from 0° to 45°, the ultimate carrying capacity is increased by 14%. In engineering practice, the installation orientation of prefabricated foundations can be designed according to the prevailing wind direction in the local area.

- (2)

- The ultimate bearing capacity of the prefabricated pole foundation increases with the increase in embedment depth of the pole. When the embedment depth of the pole is changed from 1.8 m to 2.0 m, the bearing capacity of the prefabricated foundation of the pole is increased by 33%; when the embedment depth of the pole is changed from 2 m to 2.5 m, the bearing capacity of the prefabricated foundation of the pole is increased by 93%; and when the embedment depth of the pole is changed from 2.5 m to 3.0 m, the bearing capacity of the prefabricated foundation of the pole is increased by 99%. When the foundation position is 1.0 m compared with the ground position, the ultimate load overturning moment of the pole prefabricated foundation is increased by 10%. Additionally, the bearing capacity of pole prefabricated foundation increases gradually with the increase in the internal friction angle, cohesion, and elastic modulus of soil; compared with silt, the bearing capacity of the pole assembly foundation in silty clay is increased by 63%.

- (3)

- In the ultimate bearing state, the prefabricated foundation is partially separated from the soil on the other side of the loading, and the reaction force distribution of the foundation is approximately triangular. The soil pressure on the front side of the pole presents the shape of a quadratic parabola with the change in depth, and the increment gradually increases and then decreases with the increase in depth. The increment in soil pressure on the front side increases first and then decreases with the increase in depth. The increment in soil pressure on the two ends of the front side is small, and the increment in soil pressure in the middle position is the largest. The soil pressure increment at the rotating point changes, and the lower the rotating point position, the greater the ultimate bearing capacity and the better the ultimate bearing capacity of the pole.

- (4)

- The foundation bearing capacity of the pole prefabricated foundation showed a positive correlation with the soil internal friction angle, cohesion, and modulus of elasticity, and the soil properties have an extremely significant effect on the pole bearing capacity. When the angle of internal friction is changed from 16° to 35°, the ultimate load capacity of the pole prefabricated foundation is increased by 33%; when cohesion is changed from 12 kPa to 25 kPa, the ultimate load capacity of the pole prefabricated foundation is increased by 75%; and when the modulus of elasticity is changed from 6 MPa to 22 MPa, the ultimate load capacity of the pole prefabricated foundation is increased by 51%.

- (5)

- The formulas for calculating the ultimate bearing capacity and ultimate overturning moment of the prefabricated foundation of the electric pole are developed by means of the limit equilibrium theory.

- (1)

- This study only conducted ultimate bearing performance tests at an actual site in Fujian Province. Prototype tests on the ultimate bearing performance of a pole’s prefabricated foundation in other regions with different geological and climatic conditions require further research.

- (2)

- Although this study analyzed the anti-overturning bearing capacity of the pole assembly foundation under different influencing factors through a combination of experiments and simulations, the impact of parameter combinations and sensitivity analysis have not been fully discussed.

- (3)

- While this study conducted in-depth research on the pole’s prefabricated foundation and proposed formulas for the ultimate bearing capacity of distribution line pole prefabricated foundations, further research and exploration are needed for the optimal design of such foundations. Specifically, beyond designing foundation structures with better bearing performance, more suitable designs for distribution line poles require additional investigation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dend, X.S. Simulation and Security Assessment of Continuous Pole Fall in Distribution Networks Under Typhoon Action; Harbin Institute of Technology: Harbin, China, 2022. [Google Scholar]

- Li, H.; Wang, X.P. Research status of prefabricated basic research in Electric Power Industry. World Build. Mater. 2020, 41, 53–57. [Google Scholar]

- Zhang, Z.G.; Yang, R.; Gao, W.; Dou, Y.F.; Zhu, D. Analysis of the progress of prefabricated basic research. Anhui Archit. 2023, 30, 84–86. [Google Scholar]

- Rasmussen, T.V.Ø. Integrated Strip Foundation Systems for Small Residential Buildings. Open Constr. Build. Technol. J. 2010, 4, 39–53. [Google Scholar] [CrossRef]

- Brown, F. Tower Foundation. U.S. Patent 7827748B2, 9 November 2010. [Google Scholar]

- Zhu, C.H. Calculation method of soil pressure in large cylinder with limit state. Chin. J. Geotech. Eng. 2002, 3, 313–318. [Google Scholar]

- Haldar, A.; Prasad, Y.V.; Chari, T.R. Full-scale field tests on directly embedded steel pole foundations. Can. Geotech 2000, 37, 414–437. [Google Scholar] [CrossRef]

- McNames, C.; Gajan, S. Transmission pole foundation: Alternate design methods for direct-embedded round, wood transmission poles. Electr. Transm. Substation Struct. 2009, 5, 1–14. [Google Scholar]

- Li, X.Y.; Hao, H.G.; Wang, H.J.; Zhang, L.; Guo, Y.; Lian, J.; Du, Y.; Wang, X.; Zeng, C. Design and analysis of a new prefabricated foundation for onshore wind turbines. Buildings 2024, 14, 193. [Google Scholar] [CrossRef]

- Batali, L.; Drăguşin, A.; Popa, H. Numerical modelling by finite elements for a pile foundation under lateral cyclic action. Ce Pap. 2018, 2, 579–584. [Google Scholar] [CrossRef]

- Li, G.H.; Liu, R.; Dai, X.; Wang, S.; Du, D.; Wang, L. Design of prefabricated foundation for 66kV tower assembly and simulation of mechanical properties and grounding current density distribution. J. Phys. Conf. Ser. 2022, 2296, 012023. [Google Scholar] [CrossRef]

- Ghalesari, T.; Choobbasti, J.A. Numerical analysis of settlement and bearing behaviour of piled raft in Babol clay. Eur. J. Environ. Civ. Eng. 2018, 22, 978–1003. [Google Scholar] [CrossRef]

- Wang, X.F.; Tian, Y.F.; Li, S.X.; Li, J. Exploring the bearing characteristics of suction bucket foundations in Offshore wind turbines: A comprehensive analysis of tensile and compressive behavior. Ocean Eng. 2024, 298, 117234. [Google Scholar] [CrossRef]

- Wang, S.C. Calculation method considering the favorable influence of lateral soil pressure on short column foundation. Sichuan Build. Sci. Res. 1992, 4, 25–28. [Google Scholar]

- De Almeida, J.A.M.N. Self-Stable Prefabricated Foundation for Towers. Portugal Patent 05704670, 2 November 2006. [Google Scholar]

- Zhou, X.; Shao, G.J.; Hu, F. Ultimate Bearing capacity based on unified strength theory. Appl. Mech. Mater. 2013, 368–370, 1838–1842. [Google Scholar] [CrossRef]

- Mo, Y.; Liu, X.C.; Guo, Z.H.; Teng, B.; Zou, Z.Y.; Zhu, Z.Y. Slip-Line Field Theory’s Application in Soil Subgrade. Appl. Mech. Mater. 2012, 170–173, 283–288. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Wang, Y.H.; Zhang, J.Q.; Liu, Z.; Gao, W.H. A new gradation equation for coarse-grained subgrade fillers and its applicability based on the fractal theory. Geomech. Geophys. Geo Energy Geo Resour. 2025, 11, 20. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Zhou, G.M. Investigating the compaction and the mechanical behaviors of coal gangue as subgrade filler and constructing highway subgrade in practice. Sci. Rep. 2024, 14, 26272. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Gao, W.H. Effect of different test methods on the disintegration behaviour of soft rock and the evolution model of disintegration breakage under cyclic wetting and drying. Eng. Geol. 2020, 279, 105888. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.C.; Zhang, L.; Zhang, Y.X. Fire resistance and thermal performance of hybrid fibre-reinforced magnesium oxychloride cement-based composites. Constr. Build. Mater. 2025, 472, 140867. [Google Scholar] [CrossRef]

- Nasir, A.; Butt, F.; Ahmad, F. Enhanced mechanical and axial resilience of recycled plastic aggregate concrete reinforced with silica fume and fibers. Innov. Infrastruct. Solut. 2025, 10, 4. [Google Scholar] [CrossRef]

- Rawat, S.; Saliba, P.; Estephan, P.C.; Ahmad, F.; Zhang, Y. Mechanical performance of Hybrid Fibre Reinforced Magnesium Oxychloride Cement-based composites at ambient and elevated temperature. Buildings 2024, 14, 270. [Google Scholar] [CrossRef]

- Raza, M.U.; Butt, F.; Ahmad, F.; Waqas, R.M. Seismic safety assessment of buildings and perceptions of earthquake risk among communities in Mingora, Swat, Pakistan. Innov. Infrastruct. Solut. 2025, 10, 1–18. [Google Scholar] [CrossRef]

- Ju, Y.; Zhang, H.; Wang, D.; Kong, X.; Ma, Y.; Zhang, X.; Bai, J. Effect of mineral admixtures on the resistance to sulfate attack of reactive powder concrete. J. Clean. Prod. 2024, 440, 140769. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high-performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- GB 50061; Design Criteria for Overhead Power Lines of 66kV and Below. Standardization Administration of China: Beijing, China, 2010.

- Feng, C.P.; Chi, Y.D. Influence analysis of new Load Code on Wind Load Calculation of Steel structure single pipe communication tower. Spec. Struct. 2013, 30, 5–7. [Google Scholar]

- DL/T741; Regulations for the Operation of Overhead Transmission Lines. National Energy Administration: Beijing, China, 2019.

- DL/T 5219; Code for Design of Foundation of Overhead Transmission Lines. National Energy Administration: Beijing, China, 2023.

- Jia, S.P.; Chen, W.Z.; Yang, J.P.; Chen, P. Elastoplastic Constitutive Model Based on Modified Mohr-Coulomb Criterion and its numerical implementation. Rock Soil Mech. 2010, 31, 2051–2058. [Google Scholar]

- Chen, J. Research on the Bearing Characteristics of Super-Large Diameter Manual Bored Piles; Guangxi University: Nanning, China, 2018. [Google Scholar]

- Wang, Z.Y. Research on Anti-Overturning Performance of Prefabricated Tower and Mast Structural Foundation; China University of Mining and Technology: Xuzhou, China, 2014. [Google Scholar]

- Dong, J.Y. Main content of Technical Regulations for the Design of Steel Pipe Towers for Overhead Transmission Lines. Electr. Power Surv. Des. 2013, 6, 50–54+59. [Google Scholar]

- JGJ94; Technical Code for Building Pile Foundation. Ministry of Housing and Urban-Rural Development: Beijing, China, 2008.

| Time | Point | Event |

|---|---|---|

| 2016 | Fujian, China | Typhoon Moranti hit Fujian Province, downing 5640 power poles. |

| 2021 | Zhengzhou, Henan Province, China | Extremely rare torrential rain hit Zhengzhou, causing 10,596 poles to fall or break. |

| 2024 | Hainan, China | Super Typhoon Yagi made landfall in Hainan. A total of 68 main grid towers of 110 kilovolts and above and 61,487 distribution grid towers of 35 kilovolts and below were damaged throughout the province. The damage was mainly concentrated in the distribution network. |

| Test Number | Load Direction | Foundation Size | Hoop Position |

|---|---|---|---|

| SJ-1 | 0° | 800 mm × 800 mm | 3.3 m |

| SJ-2 | 45° | 800 mm × 800 mm | 3.3 m |

| SJ-3 | 45° | 900 mm × 900 mm | 3.3 m |

| SJ-4 | 0° | 800 mm × 800 mm | 2.8 m |

| SJ-5 | 45° | 800 mm × 800 mm | 2.8 m |

| Density ρ/kg/m3 | Elastic Modulus/MPa | Cohesion /kPa | The Angle of Internal Friction/° | Poisson’s Ratio v | |

|---|---|---|---|---|---|

| Soil body | 1810 | 14 | 22 | 30 | 0.3 |

| Loading Phase | Test Observations |

|---|---|

| 1.38 kN | When the initial load is applied, the terminal displacement of the pole loading point is 0.85 mm. There is no loosening between the pole and the soil; no slip occurs at the connection between the pole and hoop. |

| 4.17 kN | The end displacement of the pole loading point is 4.16 mm; there is no obvious gap between the pole and the soil. No slip occurs at the connection between the pole and hoop. |

| 6.76 kN | The terminal displacement of pole loading point is 15.15 mm; the displacement of the top loading point of the pole increases linearly with the increase in the load, and the length of the crack increases. No slip occurs at the connection between the pole and hoop. |

| 7.98 kN | The terminal displacement of pole loading point is 23.95 mm; the displacement of the loading point increases rapidly, and radial cracks appear on four sides around the diagonal brace. No slip occurs at the connection between the pole and hoop. |

| 9.29 kN | The pole loading point endpoint displacement is 34.82 mm; the soil behind the pole is uplifted, and the angle of the pole reaches 1/2 of the specified value. |

| 14.21 kN | When the load is applied to the ultimate load, the terminal position of the loading point of the electric pole is shifted to 71.43 mm; the angle of the pole increases rapidly, and when the angle of the pole reaches 0.015 rad, the pole loses its load-bearing capacity, and the radial cracks around the diagonal brace are penetrated. No slip occurs at the connection between the pole and hoop. |

| Density ρ/kg/m3 | Elastic Modulus/ MPa | Poisson’s Ratio ν | |

|---|---|---|---|

| Concrete pole | 2500 | 34,500 | 0.23 |

| Fabricated foundation | 2420 | 34,500 | 0.20 |

| Density ρ/kg/m3 | Elastic Modulus/MPa | Cohesion /kPa | The Angle of Internal Friction/° | Poisson’s Ratio ν | |

|---|---|---|---|---|---|

| Soil body | 1810 | 14 | 22 | 30 | 0.3 |

| Data Number | Overturning Moment/(kN·m) | Relative Percentage Error |

|---|---|---|

| SJ-1 | 30.15 | 1.66% |

| Simulation of SJ-1 | 29.65 | |

| SJ-2 | 34.37 | 4% |

| Simulation of SJ-2 | 32.98 | |

| SJ-3 | 37.05 | 2% |

| Simulation of SJ-3 | 36.30 |

| Influencing Factor | Category | Overturning Moment/kN·m |

|---|---|---|

| Soil type | Silt | 22.75 |

| Silty clay | 37.05 | |

| Angle of internal friction/° | 16 | 23.85 |

| 20 | 26.35 | |

| 26 | 28.85 | |

| 30 | 30.15 | |

| 35 | 31.65 | |

| Cohesion/kPa | 12 | 19.05 |

| 15 | 22.80 | |

| 18 | 27.00 | |

| 22 | 30.15 | |

| 25 | 33.25 | |

| Modulus of elasticity/MPa | 6 | 23.65 |

| 10 | 26.95 | |

| 14 | 30.15 | |

| 18 | 33.20 | |

| 22 | 35.85 |

| Test Number | Test Ultimate Load Overturning Moment Value/(kN·m) | Formula Calculation Result/(kN·m) |

|---|---|---|

| SJ-1 | 30.15 | 31.05 |

| SJ-2 | 34.37 | 34.23 |

| SJ-3 | 37.05 | 37.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Chen, C.; Yang, Y.; Niu, K.; Xu, W.; Wang, D. Anti-Overturning Performance of Prefabricated Foundations for Distribution Line Poles. Buildings 2025, 15, 2717. https://doi.org/10.3390/buildings15152717

Zhang L, Chen C, Yang Y, Niu K, Xu W, Wang D. Anti-Overturning Performance of Prefabricated Foundations for Distribution Line Poles. Buildings. 2025; 15(15):2717. https://doi.org/10.3390/buildings15152717

Chicago/Turabian StyleZhang, Liang, Chen Chen, Yan Yang, Kai Niu, Weihao Xu, and Dehong Wang. 2025. "Anti-Overturning Performance of Prefabricated Foundations for Distribution Line Poles" Buildings 15, no. 15: 2717. https://doi.org/10.3390/buildings15152717

APA StyleZhang, L., Chen, C., Yang, Y., Niu, K., Xu, W., & Wang, D. (2025). Anti-Overturning Performance of Prefabricated Foundations for Distribution Line Poles. Buildings, 15(15), 2717. https://doi.org/10.3390/buildings15152717