Integrated Mechanical and Eco-Economical Assessments of Fly Ash-Based Geopolymer Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Program

2.2. Materials

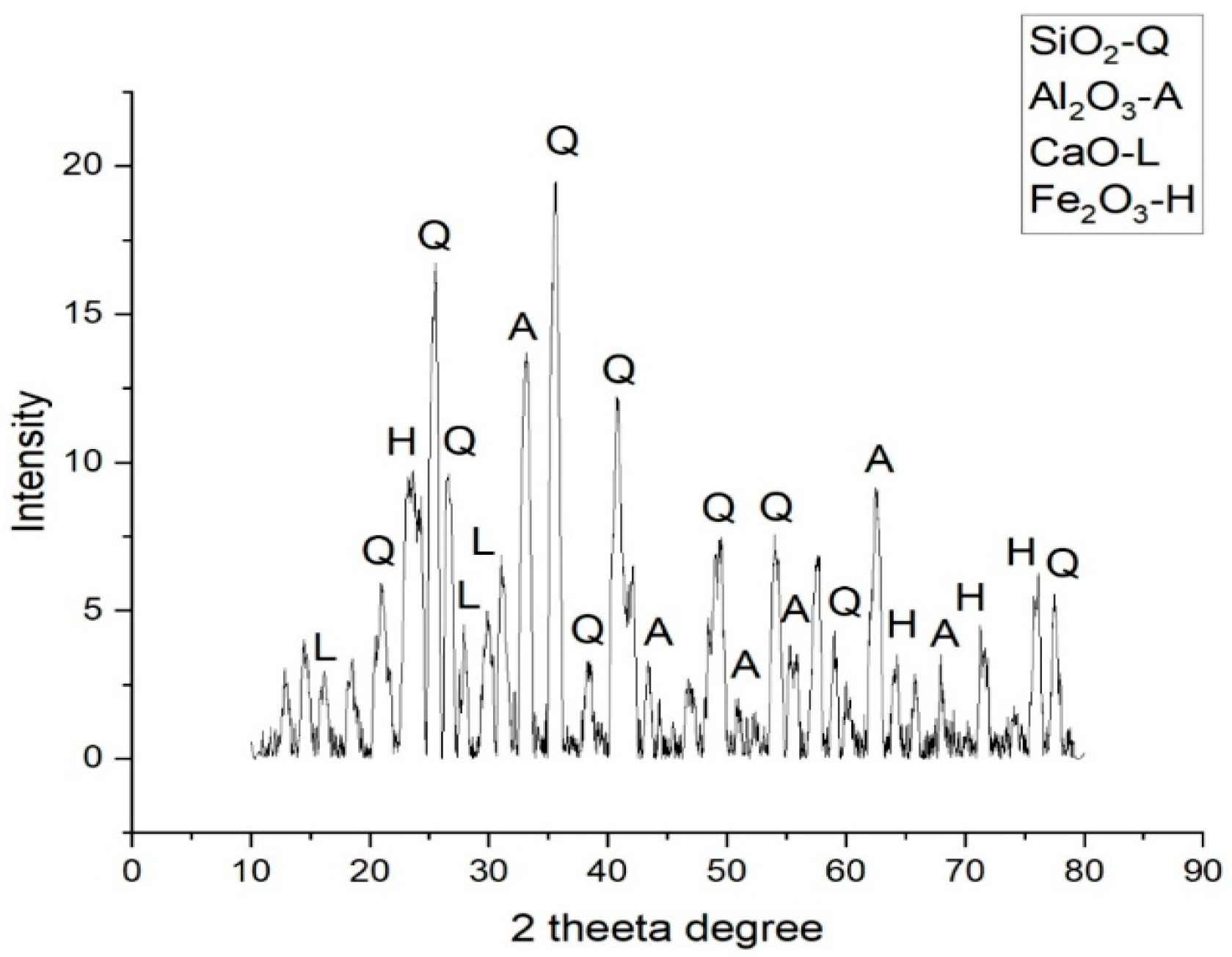

2.2.1. Fly Ash

2.2.2. Aggregates

2.2.3. Alkaline Activator Solution

2.3. Mix Designs

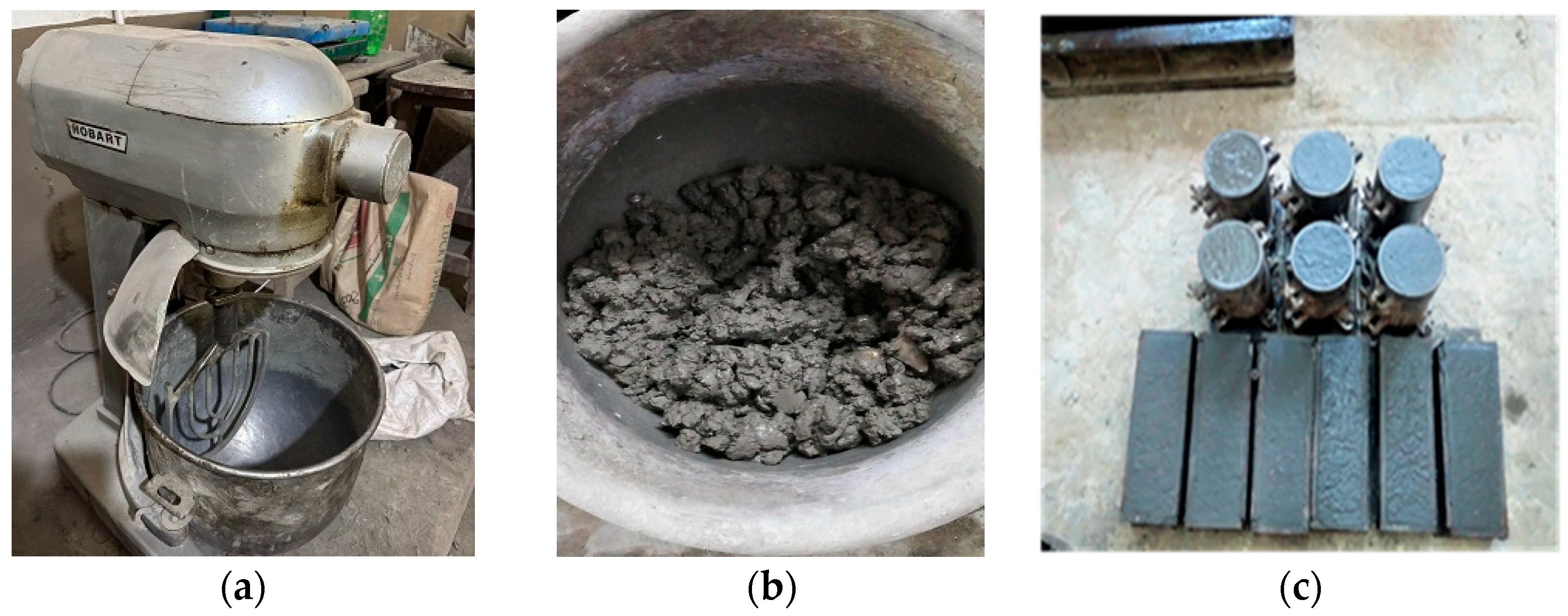

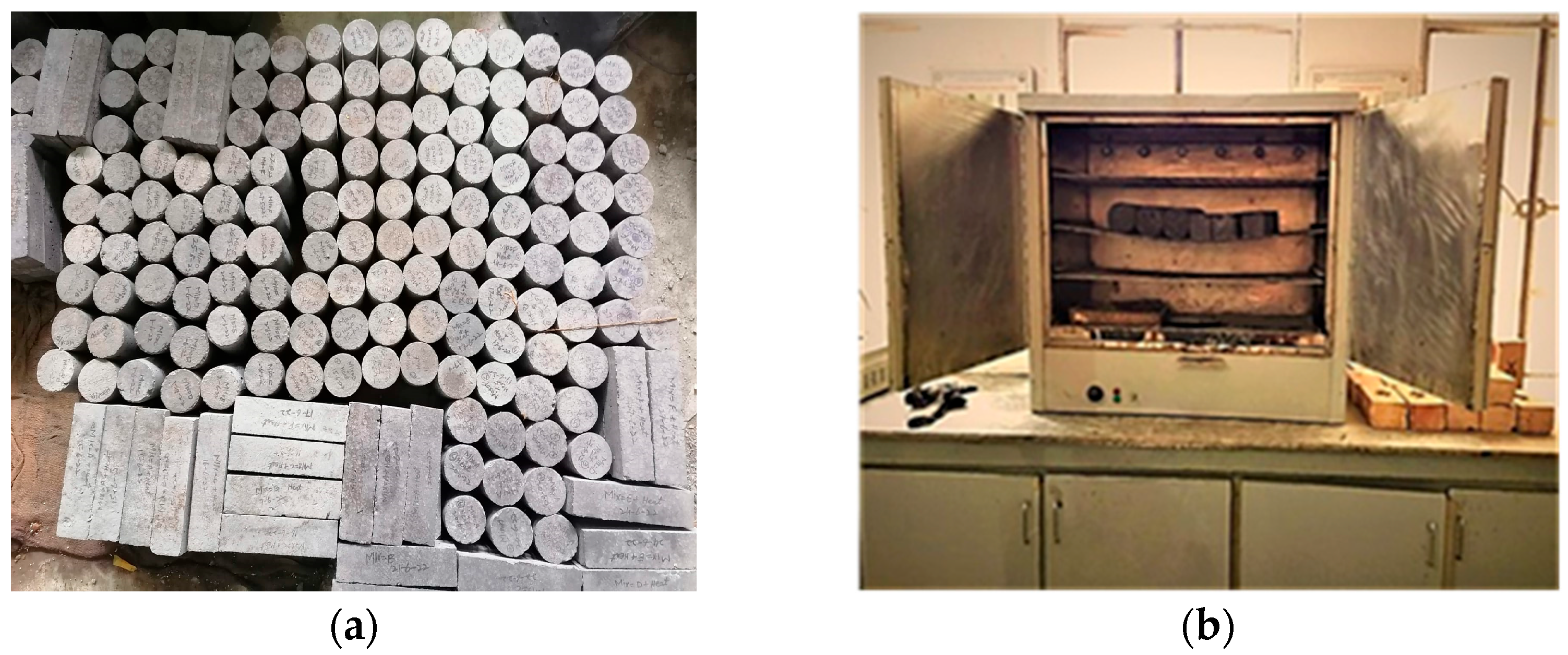

2.3.1. Preparation of Test Samples

2.3.2. Curing

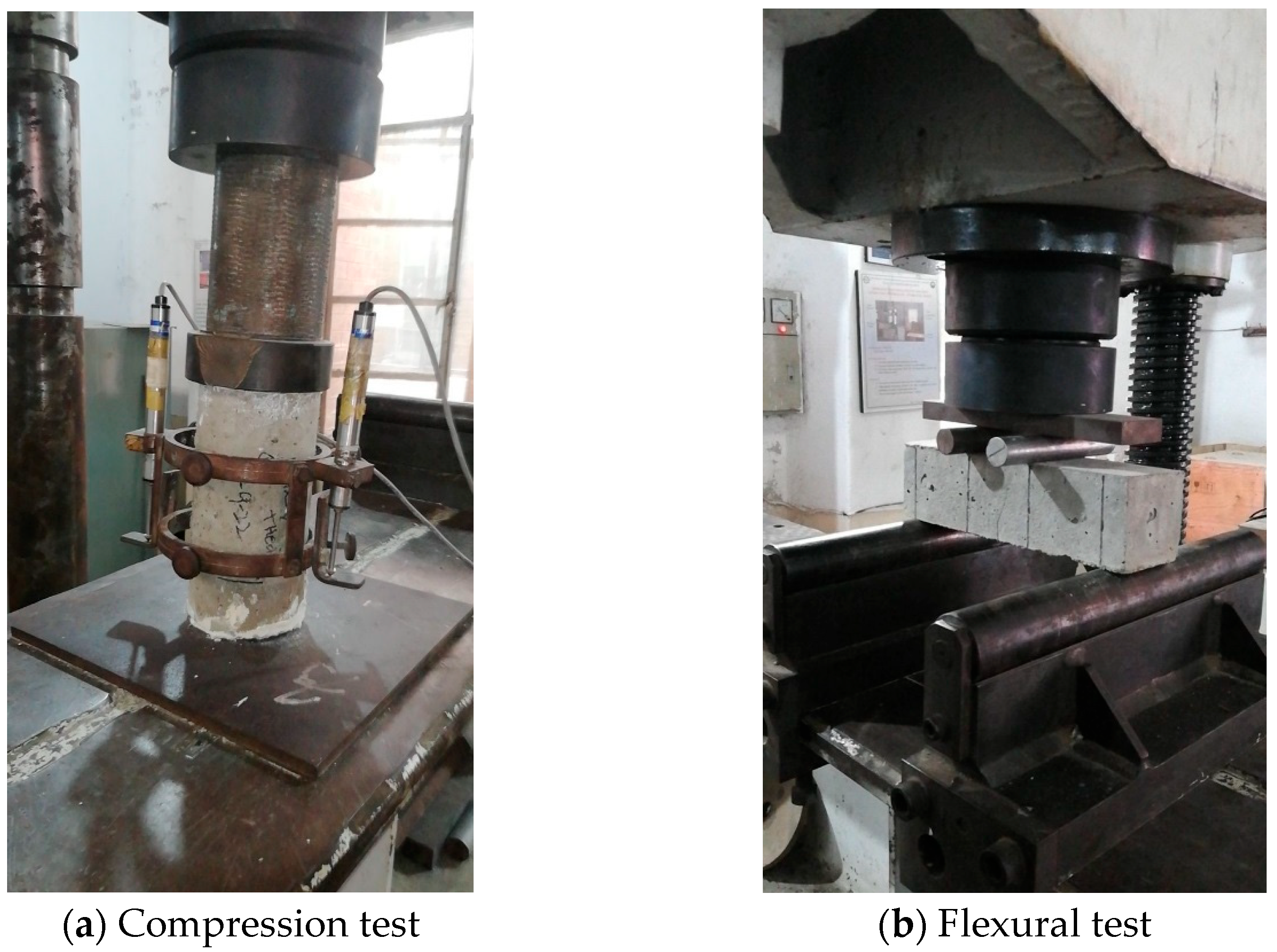

2.4. Instrumentation and Testing Procedures

3. Results and Discussions

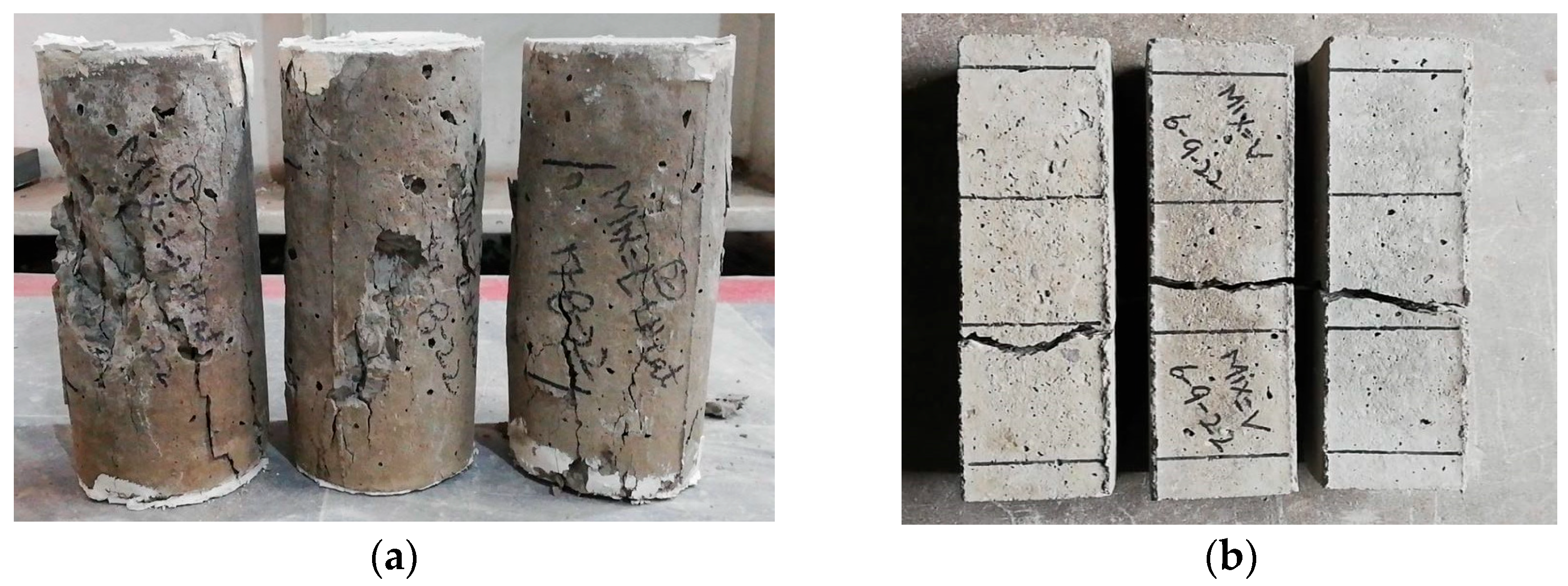

3.1. Failure of Tested GPC Specimens

3.2. Wet and Dry Densities of Ambient-Cured (A/C) and Heat-Cured (H/C) GPC

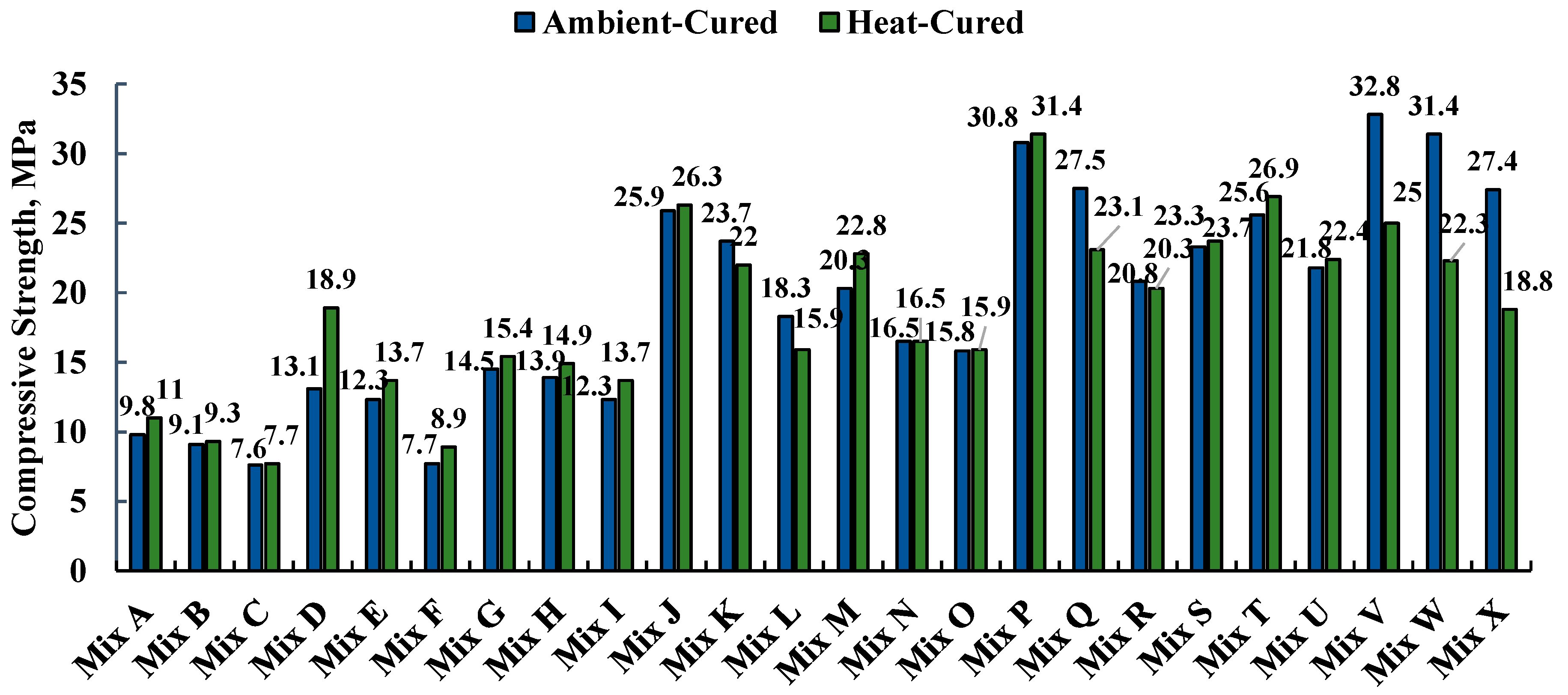

3.3. Compressive Strength (CS)

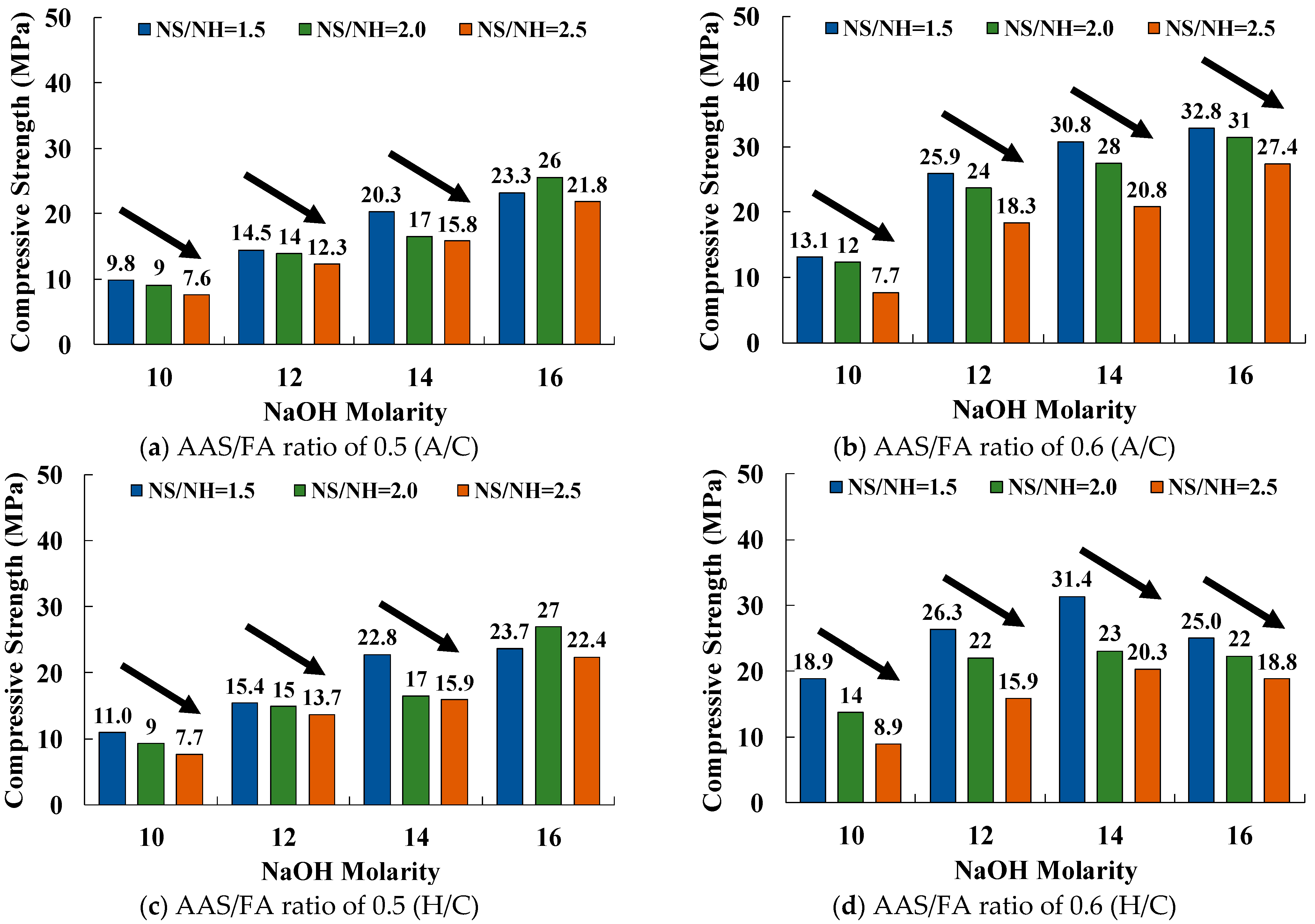

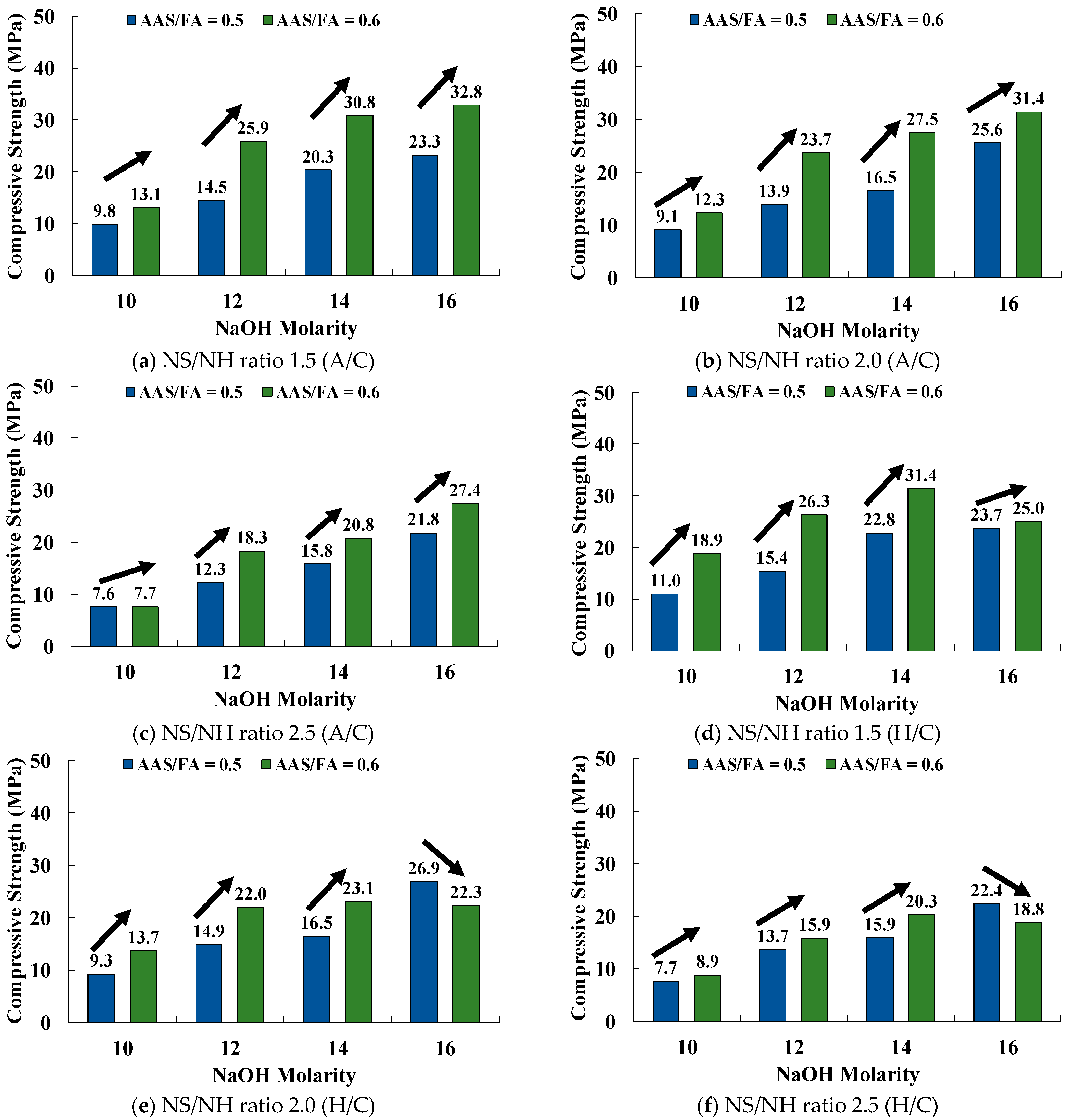

3.3.1. Influence of NS/NH Ratios

3.3.2. Influence of NaOH (NH) Molarities

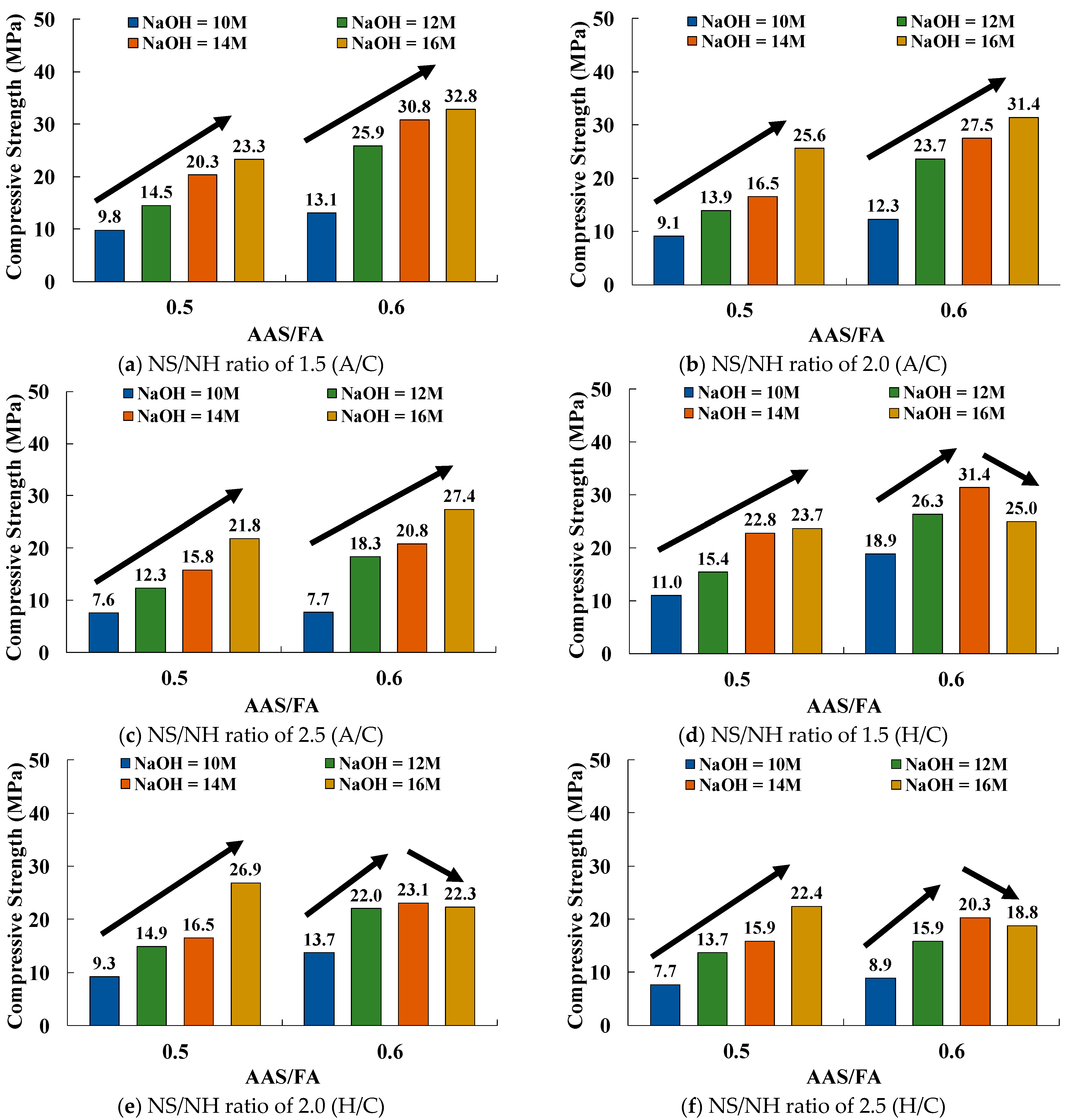

3.3.3. Influence of AAS/FA Ratios

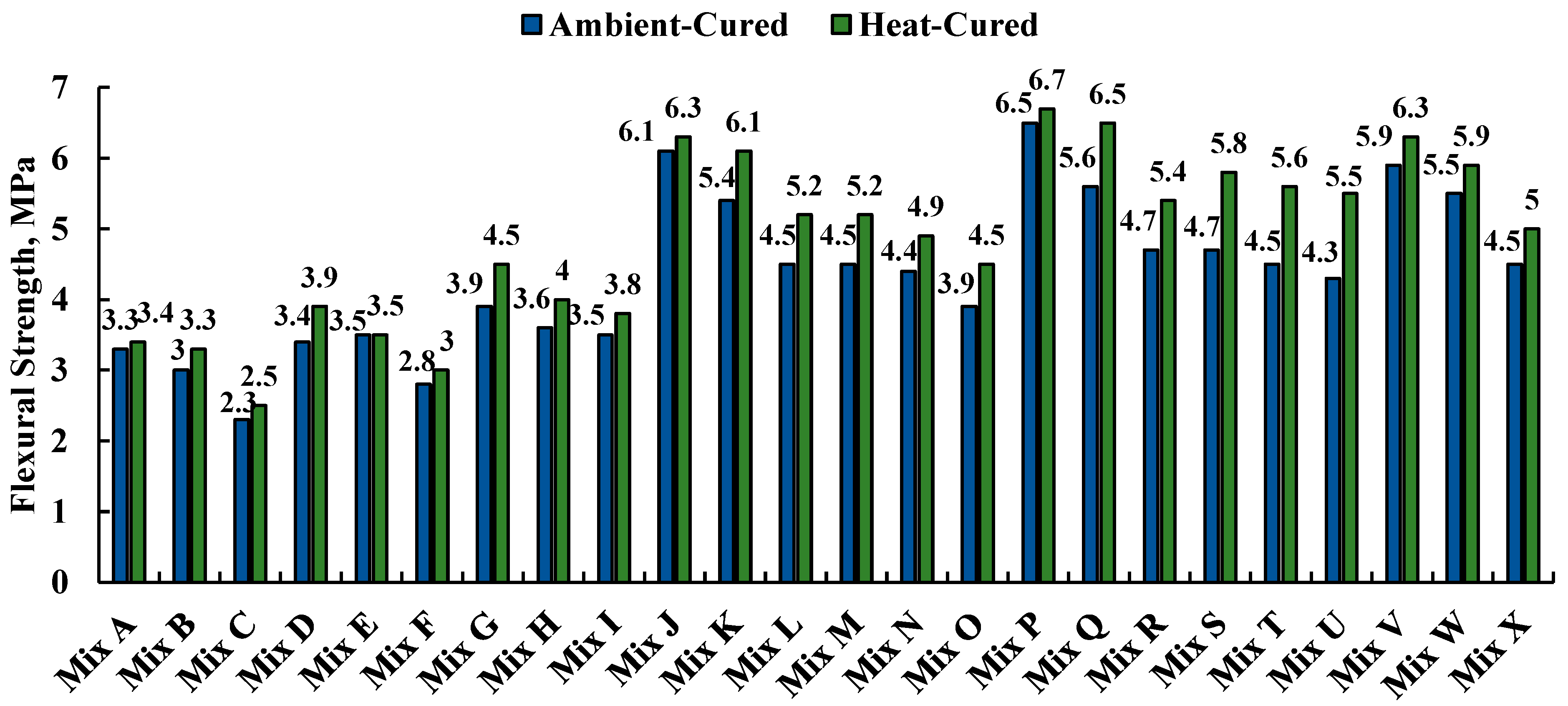

3.4. Flexural Strength

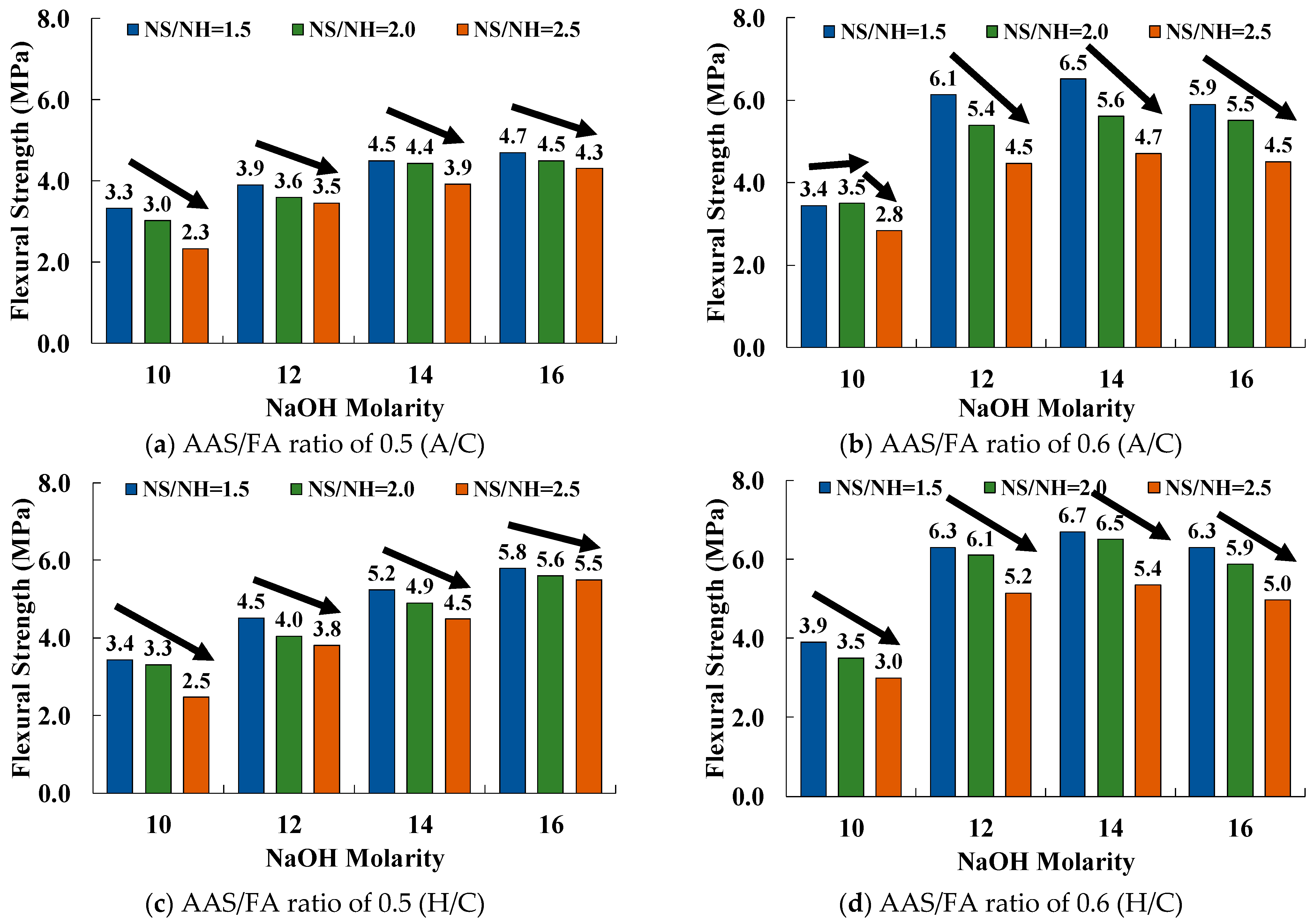

3.4.1. Influence of NS/NH Ratios

3.4.2. Influence of NaOH (NH) Molarities

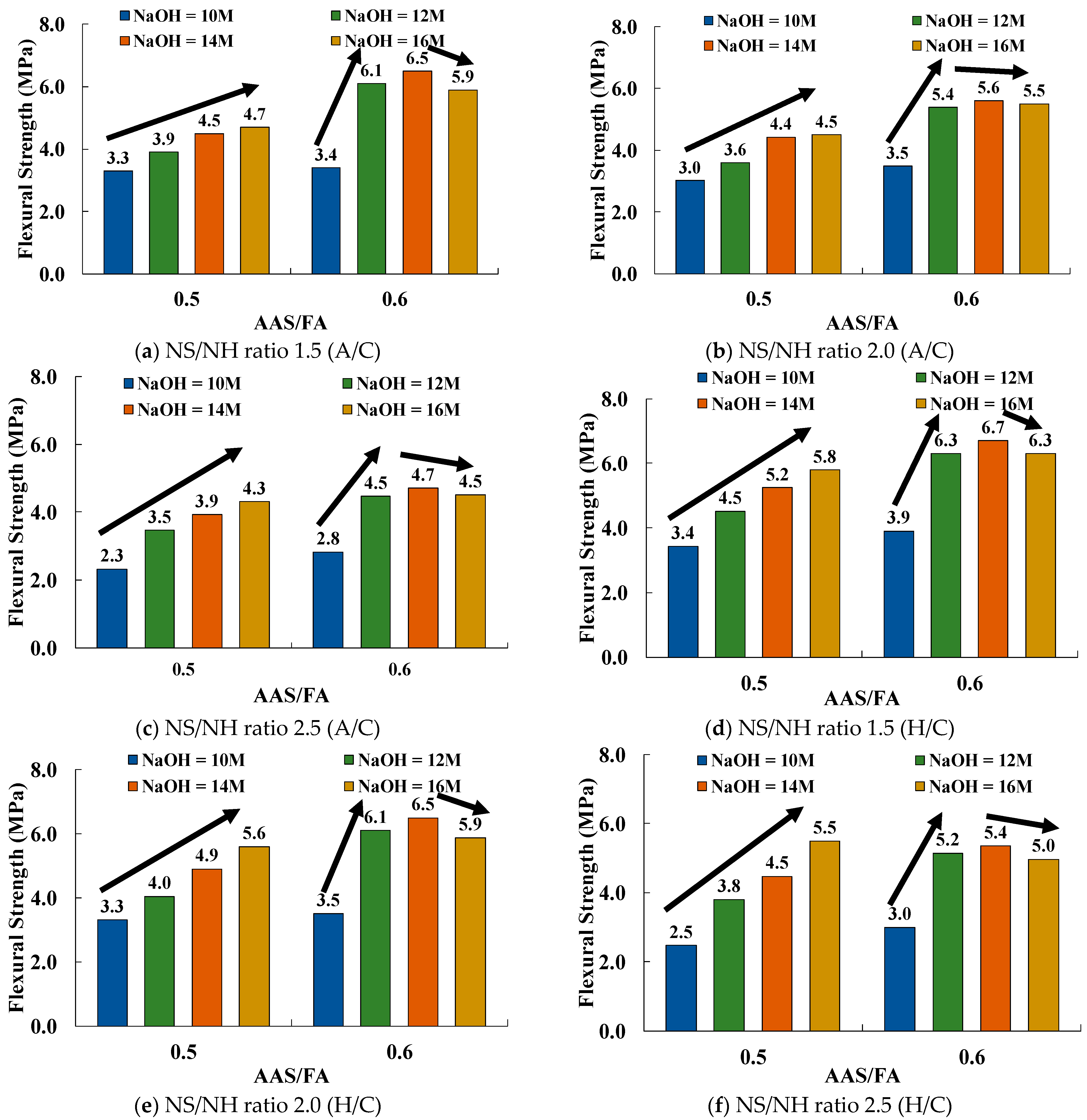

3.4.3. Influence of AAS/FA Ratios

3.5. Comparison of Ambient Versus Heat Curing

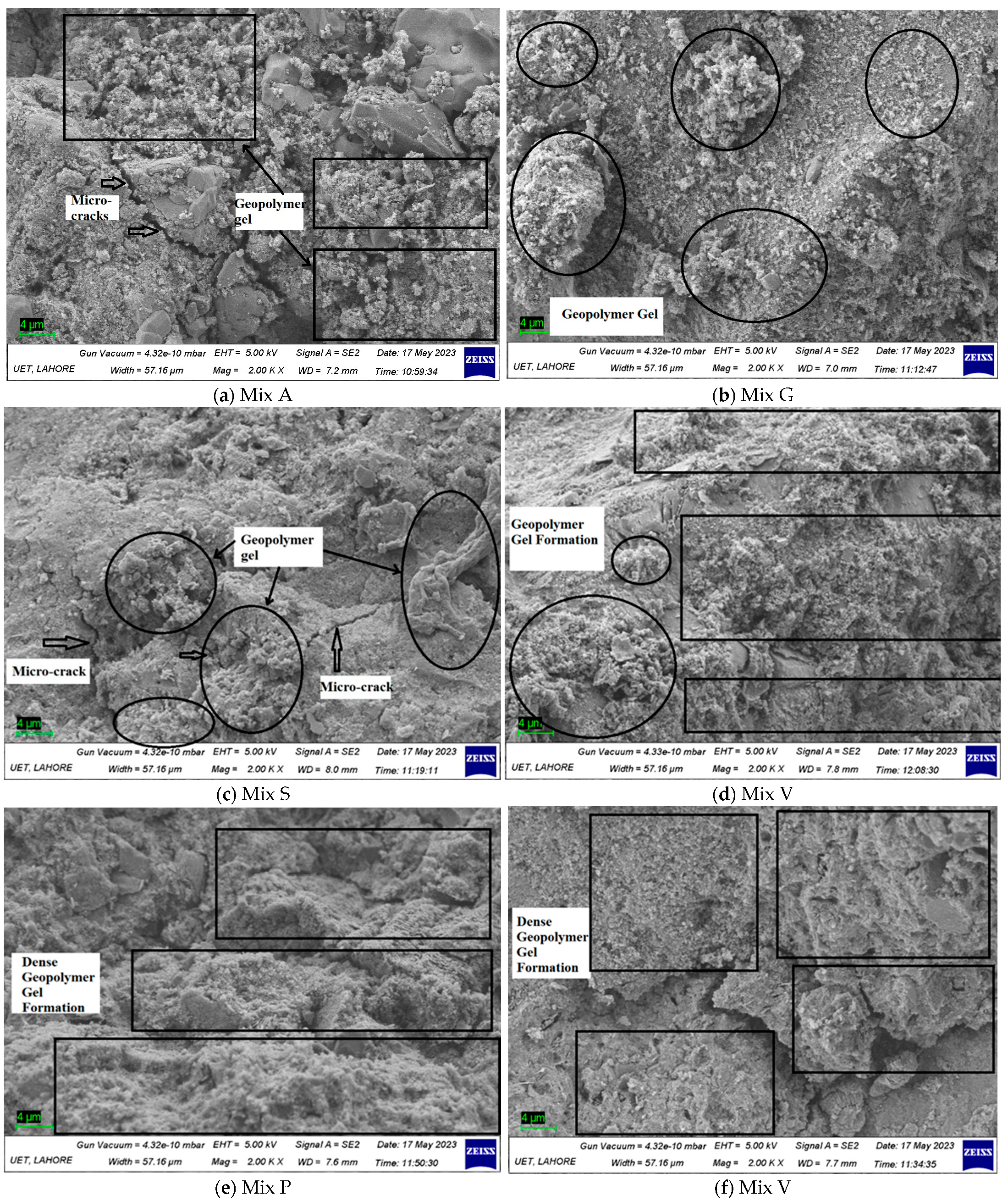

3.6. Scanning Electron Microscopy (SEM) Analysis of GPC

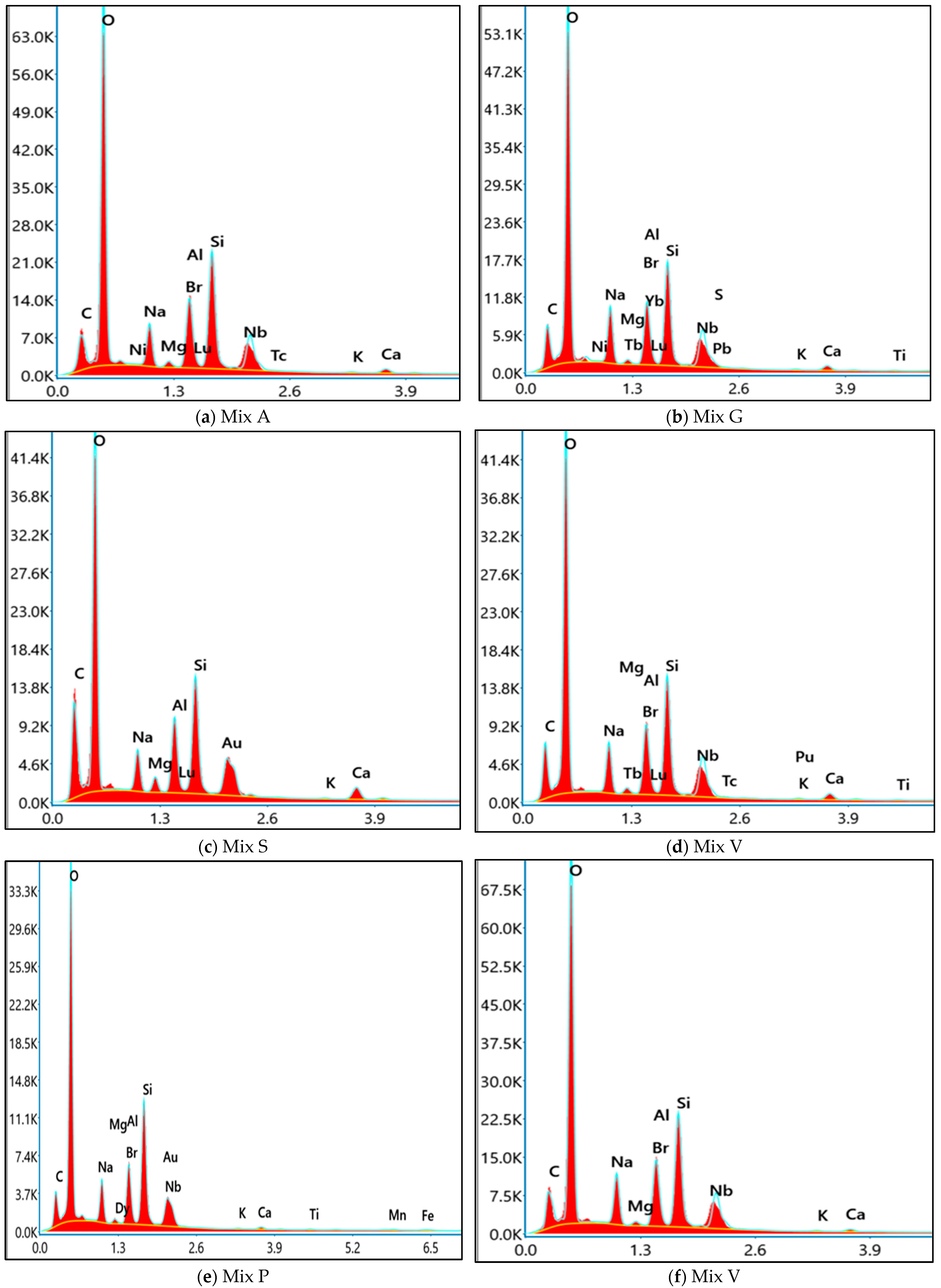

3.7. Energy-Dispersive X-Ray Spectroscopy (EDX) Analysis of GPC

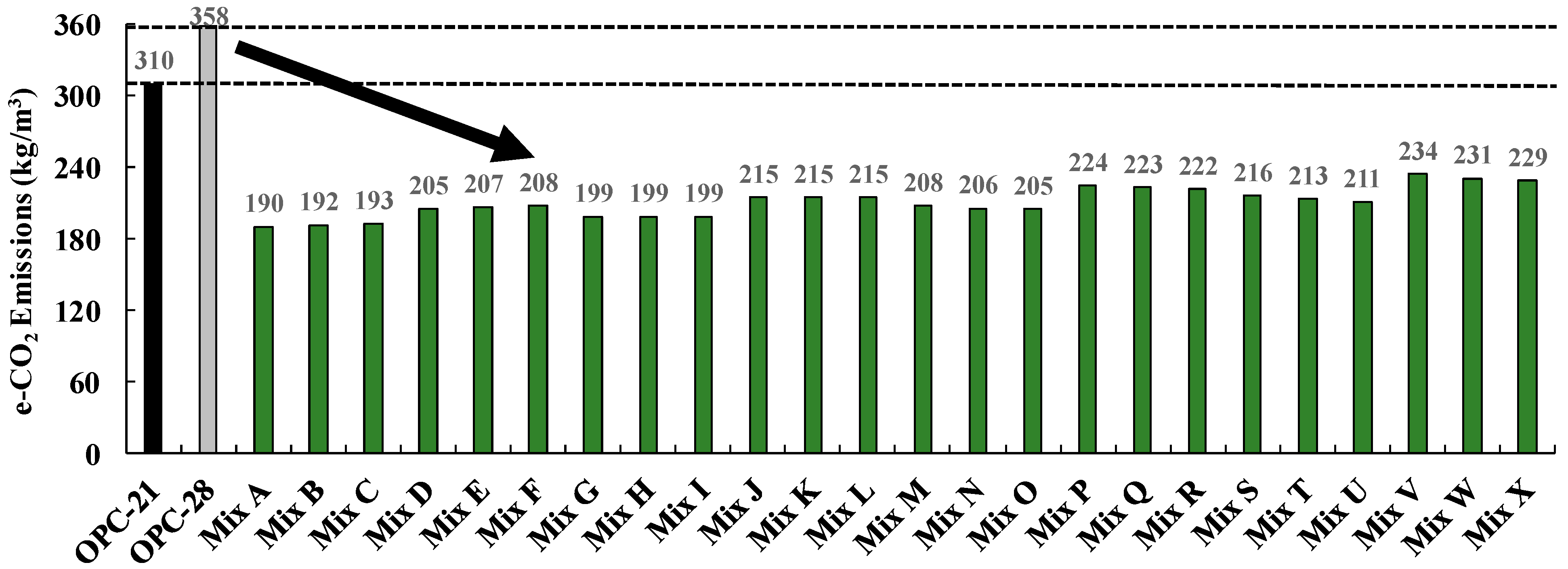

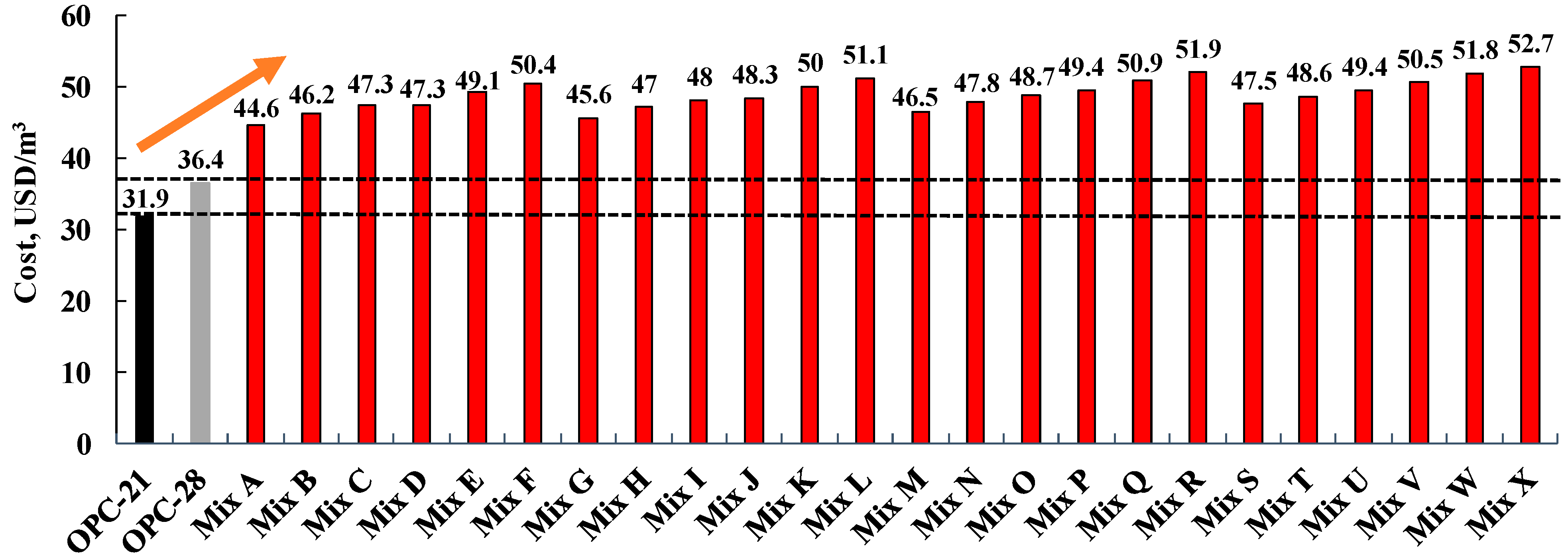

3.8. Environmental Assessment and Cost Analysis

4. Conclusions

- Effect of NaOH molarity: for A/C GPC, increasing NH molarity from 10-M to 16-M enhanced CS. by 145%, with the maximum CS. of 32.8 MPa achieved at 16-M NaOH. The FS. also increased by 90% with increasing NH molarity raised from 10-M to 14-M, reaching an optimal FS of 6.5 MPa at 14 M.

- Influence of NS/NH ratio: increasing the NS/NH ratios from 1.5 to 2.5 decreased the CS. of A/C GPC mixes by 12.5% and the FS. by 9.1%. The maximum CS. of 32.8 MPa and FS. of 6.5 MPa were obtained at a NS/NH ratio of 1.5.

- Impact of AAS/FA ratio: both A/C and H/C GPC showed increased CS. with increasing AAS/FA ratios from 0.5 to 0.6. The average CS. of A/C GPC improved by 42.3%, reaching a maximum CS. of 32.8 MPa at an AAS/FA ratio of 0.6. For FS., increases of 3% to 56.4% were observed across various NH molarities, with the maximum FS. of 6.5 MPa achieved at the same ratio.

- Results for heat-cured GPC: CS. of H/C GPC rose by 66% with NH molarity increased from 10-M to 14-M, achieving the maximum CS. of 31.4 MPa at 14-M, NS/NH ratio of 1.5, and AAS/FA ratio of 0.6. FS. also improved by 47.2%, reaching an optimum FS. of 6.7 MPa under these conditions.

- Microstructural observations: The SEM analysis showed that a higher NH molarity (16-M) resulted in increased AA solution availability, facilitating greater leaching and dissolution of silica and alumina ions from FA, thereby enhancing N-A-S-H gel formation.

- Environmental and cost assessment: GPC mixes demonstrated e-CO2 emissions that were 35–40% lower than those of OPC concrete, although GPC costs were approximately 30–35% higher due to the expense of AA components (NH and NS solutions).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GPC | Geopolymer Concrete |

| FAGPC | Fly Ash-based Geopolymer Concrete |

| CS | Compressive Strength |

| FS | Flexural Strength |

| NH | Sodium Hydroxide |

| AAS | Alkaline Activator Solution |

| NS/NH | Sodium silicate to sodium hydroxide |

References

- Kanwal, S.; Khan, Q.S.; Sheikh, M.N.; Qazi, A.U.; Hadi, M.N.S. Axial Compressive Behaviour of GPC Filled FRP Tubes: Experimental and Analytical Investigations. Structures 2023, 55, 650–663. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adeyemi, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Dai, J.G.; Kazmi, S.M.S.; Munir, M.J. Evolutionary artificial intelligence approach for performance prediction of bio-composites. Constr. Build. Mater. 2021, 290, 123245. [Google Scholar] [CrossRef]

- Khan, Q.S.; Mumtaz, T.; Qazi, A.U.; Pham, T.M. Influence of alkaline activators on mechanical properties of environmentally friendly geopolymer concrete under different curing regimes. Environ. Sci. Pollut. Res. 2024, 31, 60619–60639. [Google Scholar] [CrossRef] [PubMed]

- Ghafoor, M.T.; Khan, Q.S.; Qazi, A.U.; Sheikh, M.N.; Hadi, M.N.S. Influence of Alkaline Activators on the Mechanical Properties of Fly Ash Based Geopolymer Concrete Cured at Ambient Temperature. Constr. Build. Mater. 2021, 273, 121752. [Google Scholar] [CrossRef]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly Ash Application as Supplementary Cementitious Material: A Review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.R.; Chen, B.; Haque, M.A.; Kazmi, S.M.S.; Munir, M.J. Development of plant-concrete composites containing pretreated corn stalk bio-aggregates and different type of binders. Cem. Concr. Compos. 2021, 121, 104054. [Google Scholar] [CrossRef]

- Alnahhal, A.M.; Alengaram, U.J.; Yusoff, S.; Darvish, P.; Srinivas, K.; Sumesh, M. Engineering Performance of Sustainable Geopolymer Foamed and Non-Foamed Concretes. Constr. Build. Mater. 2022, 316, 125601. [Google Scholar] [CrossRef]

- Numan, M.; Khan, Q.S.; Qazi, A.U.; Kazmi, S.M.S.; Munir, M.J. Development of cement-less recycled aggregated concrete mixes: A step towards sustainable construction. Sustainability 2025, 17, 2371. [Google Scholar] [CrossRef]

- Tauqir, M.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S. Shear Behavior of Geopolymer Concrete Slender Beams. Buildings 2023, 13, 1191. [Google Scholar] [CrossRef]

- Trusilewicz, L.; Fernandez-Martinez, F.; Rahhal, V.; Talero, R. TEM and SAED characterization of metakaolin. Pozzolanic Activity. J. Am. Ceram. Soc. 2012, 95, 2989–2996. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Torse, A.G.D.; Palomo, A.; Lopez-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkaline activation of fly ash. Part II. Degree of Reaction. Fuel 2006, 85, 1960–1969. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Palomo, A.; Sabrados, Z.; Sanz, J. The role played by the reactive alumina content in the alkaline activation of fly ashes. Microporous Mesoporous Mater. 2006, 91, 111–119. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.E.; Anay, R.; Ziehl, P. Sustainable Concrete: Building a Greener Future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Raj, R.S.; Arulraj, G.P.; Anand, N.; Kanagaraj, B.; Lubloy, E. Influence of Nano-Fly Ash on Mechanical Properties, Microstructure Characteristics and Sustainability Analysis of Alkali Activated Concrete. Dev. Built Environ. 2024, 17, 100352. [Google Scholar] [CrossRef]

- Naenudon, S.; Wongsa, A.; Ekprasert, J.; Sata, V.; Chindaprasirt, P. Enhancing the Properties of Fly Ash-Based Geopolymer Concrete Using Recycled Aggregate from Waste Ceramic Electrical Insulator. J. Build. Eng. 2023, 68, 106132. [Google Scholar] [CrossRef]

- Amin, M.; Elsakhawy, Y.; Abu el-hassan, K.; Abdelsalam, B.A. Behavior Evaluation of Sustainable High Strength Geopolymer Concrete Based on Fly Ash, Metakaolin, and Slag. Case Stud. Constr. Mater. 2022, 16, e00976. [Google Scholar] [CrossRef]

- Rajmohan, B.; Nayaka, R.R.; Rajesh Kumar, K.; Kaleemuddin, K. Mechanical and Durability Performance Evaluation of Heat Cured Low Calcium Fly Ash Based Sustainable Geopolymer Concrete. Mater. Today Proc. 2022, 58, 1337–1343. [Google Scholar] [CrossRef]

- Gill, P.; Parveen. Development of Detailed Mix Design Methodology for Low Calcium Fly Ash Based Geopolymer Concrete Incorporating OPC and Crumb Rubber. Infrastructures 2022, 7, 149. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the Mechanical Properties and Environmental Impacts of Pervious Concrete Containing Fly Ash Based on the Cement-Aggregate Ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Abd Elmoaty, A.E.M.; Elshaboury, A.M. Setting Time and 7-Day Strength of Geopolymer Mortar with Various Binders. Constr. Build. Mater. 2018, 187, 974–983. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of Low-Calcium Fly and Bottom Ash-Based Geopolymer Concrete Cured at Ambient Temperature. Ceramics. Int. 2015, 41, 5945–5958. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and Mechanical Properties of Alkali-Activated Fly Ash-Slag Concrete Cured at Ambient Temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Yazid, M.H.; Faris, M.A.; Abdullah, M.M.A.B.; Ibrahim, M.S.I.; Razak, R.A.; Burduhos Nergis, D.D.; Burduhos Nergis, D.P.; Benjeddou, O.; Nguyen, K.S. Mechanical Properties of Fly Ash-Based Geopolymer Concrete Incorporation Nylon66 Fiber. Materials 2022, 15, 9050. [Google Scholar] [CrossRef] [PubMed]

- Abdulrahman, H.; Muhamad, R.; Visintin, P.; Azim Shukri, A. Mechanical Properties and Bond Stress-Slip Behaviour of Fly Ash Geopolymer Concrete. Constr. Build. Mater. 2022, 327, 126909. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Al-Azzawi, M.; Yu, T. Effects of Fly Ash Characteristics and Alkaline Activator Components on Compressive Strength of Fly Ash-Based Geopolymer Mortar. Constr. Build. Mater. 2018, 175, 41–54. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The Effects of Ground Granulated Blast-Furnace Slag Blending with Fly Ash and Activator Content on the Workability and Strength Properties of Geopolymer Concrete Cured at Ambient Temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of Water Addition, Plasticizer and Alkaline Solution Constitution on Fly Ash Based Geopolymer Concrete Performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Sajan, P.; Jiang, T.; Lau, C.K.; Tan, G.; Ng, K. Combined Effect of Curing Temperature, Curing Period and Alkaline Concentration on the Mechanical Properties of Fly Ash-Based Geopolymer. Clean. Mater. 2021, 1, 100002. [Google Scholar] [CrossRef]

- Yifei, C.; Gao, K.; Zhang, P. Experimental and statistical study on mechanical characteristics of geopolymer concrete. Materials 2020, 13, 1651. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wan, X.; Qian, Y.; Qiao, J.; Jia, J.; Mo, L.; Gao, M.; Cui, H.; Liu, Y.; Min, F. The Effect on the Compressive Strength of Fly Ash Based Geopolymer Concrete with the Generation of Hydroxy Sodalite. Constr. Build. Mater. 2021, 309, 125174. [Google Scholar] [CrossRef]

- Chithambaram, S.J.; Kumar, S.; Prasad, M.M. Thermo-mechanical characteristics of geopolymer mortar. Constr. Build. Mater. 2020, 213, 100–108. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Torse, A.G.D.; Palomo, A.; Lopez-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkaline activation of fly ash. Part I. Potential Ash Reactivity. Fuel 2006, 85, 625–634. [Google Scholar] [CrossRef]

- ASTM C-114-23; Standard Test Methods for the Chemical Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C-618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Matsunaga, T.; Kim, J.K.; Hardcastle, S.; Rohatgi, P.K. Crystallinity and selected properties of fly ash particles. Mater. Sci. Eng. A 2002, 325, 333–343. [Google Scholar] [CrossRef]

- BS 812-110; 1990 Testing Aggregates-Part 110: Methods for Determination of Aggregate Crushing Value (ACV). British Standard: London, UK, 1990.

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C 295-19; Standard Guide for Petrographic Examination of Aggregates for Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C136 ASTM C136/C136M; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C138/C138M-23; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric). ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C39/C39M Astm C39/C39M-2020; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C78-22; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- Poloju, K.K.; Rollakanti, C.R.; Manchiryal, R.K. A Study on Effect of Alkaline Activator on Strength Properties of Geopolymer Concrete. Int. J. Eng. Res. Manag. 2020, 1–2. [Google Scholar]

- Pavithra, P.; Srinivasula Reddy, M.; Dinakar, P.; Hanumantha Rao, B.; Satpathy, B.K.; Mohanty, A.N. Effect of the Na2SiO3 /NaOH Ratio and NaOH Molarity on the Synthesis of Fly Ash-Based Geopolymer Mortar. In Proceedings of the Geo-Chicago 2016, Chicago, IL, USA, 14–18 August 2016; pp. 336–344. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on Setting, Workability and Early Strength Properties of Fly Ash Geopolymer Concrete Cured in Ambient Condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of Engineering Properties of Normal and High Strength Fly Ash Based Geopolymer and Alkali-Activated Slag Concrete Compared to Ordinary Portland Cement Concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive Strength and Microstructure Analysis of Geopolymer Paste Using Waste Glass Powder and Fly Ash. J. Clean. Prod. 2018, 172, 2892–2898. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon Dioxide Equivalent (CO2-e) Emissions: A Comparison between Geopolymer and OPC Cement Concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Abdullah, M.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S. Experimental and analytical investigations on shear performance of ambient-cured reinforced geopolymer concrete beams. Buildings 2023, 14, 204. [Google Scholar] [CrossRef]

- Khan, Q.S.; Akbar, H.; Qazi, A.U.; Kazmi, S.M.J.; Munir, M.J. Bond stress behavior of a steel reinforcing bar embedded in geopolymer concrete incorporating natural and recycled aggregates. Infrastructures 2024, 9, 93. [Google Scholar] [CrossRef]

- Yaseri, S.; Jafarinoor, A.; Mahdikhani, M. production of sustainable self-consolidating mortar with low environmental impact. Environ. Sci. Pollut. Res. 2023, 30, 31035–31059. [Google Scholar] [CrossRef] [PubMed]

| Name | Mix ID | FA (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | NaOH Sol. (kg/m3) | Na2SiO3 Sol. (kg/m3) |

|---|---|---|---|---|---|---|

| Mix A | GPC-10-1.5-0.5 | 368 | 1294 | 554 | 73.6 | 110.4 |

| Mix B | GPC-10-2.0-0.5 | 61.3 | 122.6 | |||

| Mix C | GPC-10-2.5-0.5 | 52.5 | 131.4 | |||

| Mix D | GPC-10-1.5-0.6 | 345 | 1294 | 554 | 82.8 | 124.2 |

| Mix E | GPC-10-2.0-0.6 | 69 | 138 | |||

| Mix F | GPC-10-2.5-0.6 | 59.1 | 147.8 | |||

| Mix G | GPC-12-1.5-0.5 | 368 | 1294 | 554 | 73.6 | 110.4 |

| Mix H | GPC-12-2.0-0.5 | 61.3 | 122.6 | |||

| Mix I | GPC-12-2.5-0.5 | 52.5 | 131.4 | |||

| Mix J | GPC-12-1.5-0.6 | 345 | 1294 | 554 | 82.8 | 124.2 |

| Mix K | GPC-12-2.0-0.6 | 69 | 138 | |||

| Mix L | GPC-12-2.5-0.6 | 59.1 | 147.8 | |||

| Mix M | GPC-14-1.5-0.5 | 368 | 1294 | 554 | 73.6 | 110.4 |

| Mix N | GPC-14-2.0-0.5 | 61.3 | 122.6 | |||

| Mix O | GPC-14-2.5-0.5 | 52.5 | 131.4 | |||

| Mix P | GPC-14-1.5-0.6 | 345 | 1294 | 554 | 82.8 | 124.2 |

| Mix Q | GPC-14-2.0-0.6 | 69 | 138 | |||

| Mix R | GPC-14-2.5-0.6 | 59.1 | 147.8 | |||

| Mix S | GPC-16-1.5-0.5 | 368 | 1294 | 554 | 73.6 | 110.4 |

| Mix T | GPC-16-2.0-0.5 | 61.3 | 122.6 | |||

| Mix U | GPC-16-2.5-0.5 | 52.5 | 131.4 | |||

| Mix V | GPC-16-1.5-0.6 | 345 | 1294 | 554 | 82.8 | 124.2 |

| Mix W | GPC-16-2.0-0.6 | 69 | 138 | |||

| Mix X | GPC-16-2.5-0.6 | 59.1 | 147.8 |

| Element | CaO (%) | MgO (%) | SiO2 (%) | SO3 (%) | Al2O3 (%) | Fe2O3 (%) | L.O.I (%) |

|---|---|---|---|---|---|---|---|

| Fly Ash | 5.1 | 1.05 | 71.2 | 1.9 | 8.1 | 4.85 | 5.8 |

| Name | Mix ID | Wet Density (kg/m3) | Dry Density (kg/m3) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| A/C | H/C | A/C | H/C | A/C | H/C | A/C | H/C | ||

| Mix A | GPC-10-1.5-0.5 | 2397 | 2395 | 2357 | 2376 | 9.8 | 11 | 3.3 | 3.4 |

| Mix B | GPC-10-2.0-0.5 | 2414 | 2446 | 2389 | 2420 | 9.1 | 9.3 | 3 | 3.3 |

| Mix C | GPC-10-2.5-0.5 | 2433 | 2401 | 2408 | 2357 | 7.6 | 7.7 | 2.3 | 2.5 |

| Mix D | GPC-10-1.5-0.6 | 2408 | 2433 | 2369 | 2382 | 13.1 | 18.9 | 3.4 | 3.9 |

| Mix E | GPC-10-2.0-0.6 | 2433 | 2401 | 2382 | 2350 | 12.3 | 13.7 | 3.5 | 3.5 |

| Mix F | GPC-10-2.5-0.6 | 2408 | 2414 | 2395 | 2362 | 7.7 | 8.9 | 2.8 | 3 |

| Mix G | GPC-12-1.5-0.5 | 2412 | 2408 | 2363 | 2376 | 14.5 | 15.4 | 3.9 | 4.5 |

| Mix H | GPC-12-2.0-0.5 | 2420 | 2414 | 2395 | 2382 | 13.9 | 14.9 | 3.6 | 4 |

| Mix I | GPC-12-2.5-0.5 | 2414 | 2476 | 2376 | 2427 | 12.3 | 13.7 | 3.5 | 3.8 |

| Mix J | GPC-12-1.5-0.6 | 2427 | 2433 | 2427 | 2414 | 25.9 | 26.3 | 6.1 | 6.3 |

| Mix K | GPC-12-2.0-0.6 | 2433 | 2452 | 2395 | 2433 | 23.7 | 22 | 5.4 | 6.1 |

| Mix L | GPC-12-2.5-0.6 | 2420 | 2439 | 2369 | 2414 | 18.3 | 15.9 | 4.5 | 5.2 |

| Mix M | GPC-14-1.5-0.5 | 2414 | 2427 | 2382 | 2401 | 20.3 | 22.8 | 4.5 | 5.2 |

| Mix N | GPC-14-2.0-0.5 | 2439 | 2439 | 2414 | 2389 | 16.5 | 16.5 | 4.4 | 4.9 |

| Mix O | GPC-14-2.5-0.5 | 2433 | 2433 | 2389 | 2409 | 15.8 | 15.9 | 3.9 | 4.5 |

| Mix P | GPC-14-1.5-0.6 | 2471 | 2427 | 2427 | 2414 | 30.8 | 31.4 | 6.5 | 6.7 |

| Mix Q | GPC-14-2.0-0.6 | 2465 | 2439 | 2446 | 2401 | 27.5 | 23.1 | 5.6 | 6.5 |

| Mix R | GPC-14-2.5-0.6 | 2439 | 2420 | 2395 | 2395 | 20.8 | 20.3 | 4.7 | 5.4 |

| Mix S | GPC-16-1.5-0.5 | 2452 | 2439 | 2412 | 2433 | 23.3 | 23.7 | 4.7 | 5.8 |

| Mix T | GPC-16-2.0-0.5 | 2433 | 2452 | 2414 | 2439 | 25.6 | 26.9 | 4.5 | 5.6 |

| Mix U | GPC-16-2.5-0.5 | 2433 | 2429 | 2420 | 2401 | 21.8 | 22.4 | 4.3 | 5.5 |

| Mix V | GPC-16-1.5-0.6 | 2477 | 2452 | 2435 | 2433 | 32.8 | 25 | 5.9 | 6.3 |

| Mix W | GPC-16-2.0-0.6 | 2459 | 2408 | 2427 | 2389 | 31.4 | 22.3 | 5.5 | 5.9 |

| Mix X | GPC-16-2.5-0.6 | 2443 | 2437 | 2414 | 2389 | 27.4 | 18.8 | 4.5 | 5.0 |

| Elements | O | Si | Al | Na | Mg | K | Ca | Si/Al |

|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | ||

| Mix A | 63.42 | 4.93 | 2.45 | 4.97 | 0.38 | 0.04 | 0.23 | 2.01 |

| Mix G | 61.73 | 4.23 | 2.63 | 6.43 | 0.3 | 0.04 | 0.25 | 1.61 |

| Mix S | 53.61 | 3.44 | 2.65 | 3.47 | 0.73 | 0.03 | 0.47 | 1.30 |

| Mix V | 63.4 | 5.83 | 2.25 | 5.5 | 0.32 | 0.04 | 0.14 | 2.59 |

| Mix P (heat-cured) | 60.45 | 4.33 | 1.78 | 5.16 | 0.32 | 0.03 | 0.29 | 2.43 |

| Mix V (heat-cured) | 62.56 | 4.58 | 2.12 | 5.71 | 0.24 | 0.04 | 0.12 | 2.16 |

| Materials | FA | CA | FA | NS Sol. | NaOH Solution | Water | OPC | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-M | 12-M | 14-M | 16-M | |||||||

| e-CO2 (kg/kg) | 0.009 | 0.0459 | 0.0139 | 0.6964 | 0.5841 | 0.7009 | 0.8187 | 0.9355 | 0.0003 | 0.8300 |

| Name | Mix ID | e-CO2 (kg/m3) | Total e-CO2 | Cost | ||||

|---|---|---|---|---|---|---|---|---|

| FA | Aggregates | NaOH | Na2SiO3 | Water | kg/m3 | $/m3 | ||

| Mix A | GPC-10-1.5-0.5 | 3.31 | 67.09 | 42.99 | 76.88 | 0.015 | 190.3 | 44.6 |

| Mix B | GPC-10-2.0-0.5 | 35.80 | 85.44 | 0.013 | 191.6 | 46.2 | ||

| Mix C | GPC-10-2.5-0.5 | 30.72 | 91.50 | 0.011 | 192.6 | 47.3 | ||

| Mix D | GPC-10-1.5-0.6 | 3.10 | 67.09 | 48.36 | 86.49 | 0.017 | 205.1 | 47.3 |

| Mix E | GPC-10-2.0-0.6 | 40.30 | 96.10 | 0.014 | 206.6 | 49.1 | ||

| Mix F | GPC-10-2.5-0.6 | 34.52 | 102.99 | 0.012 | 207.7 | 50.4 | ||

| Mix G | GPC-12-1.5-0.5 | 3.31 | 67.09 | 51.58 | 76.88 | 0.014 | 198.9 | 45.6 |

| Mix H | GPC-12-2.0-0.5 | 42.96 | 85.44 | 0.012 | 198.8 | 47 | ||

| Mix I | GPC-12-2.5-0.5 | 36.86 | 91.50 | 0.010 | 198.7 | 48 | ||

| Mix J | GPC-12-1.5-0.6 | 3.10 | 67.09 | 58.03 | 86.49 | 0.016 | 214.7 | 48.3 |

| Mix K | GPC-12-2.0-0.6 | 48.36 | 96.10 | 0.013 | 214.6 | 50 | ||

| Mix L | GPC-12-2.5-0.6 | 41.42 | 102.99 | 0.011 | 214.6 | 51.1 | ||

| Mix M | GPC.-14-1.5-0.5 | 3.31 | 67.09 | 60.25 | 76.88 | 0.013 | 207.5 | 46.5 |

| Mix N | GPC.-14-2.0-0.5 | 50.18 | 85.44 | 0.011 | 206 | 47.8 | ||

| Mix O | GPC.-14-2.5-0.5 | 43.06 | 91.50 | 0.009 | 204.9 | 48.7 | ||

| Mix P | GPC.-14-1.5-0.6 | 3.10 | 67.09 | 67.78 | 86.49 | 0.014 | 224.4 | 49.4 |

| Mix Q | GPC.-14-2.0-0.6 | 56.49 | 96.10 | 0.012 | 222.8 | 50.9 | ||

| Mix R | GPC.-14-2.5-0.6 | 48.38 | 102.99 | 0.010 | 221.6 | 51.9 | ||

| Mix S | GPC-16-1.5-0.5 | 3.31 | 67.09 | 68.85 | 76.88 | 0.011 | 216.1 | 47.5 |

| Mix T | GPC-16-2.0-0.5 | 57.34 | 85.44 | 0.009 | 213.2 | 48.6 | ||

| Mix U | GPC-16-2.5-0.5 | 49.20 | 91.50 | 0.008 | 211.1 | 49.4 | ||

| Mix V | GPC-16-1.5-0.6 | 3.10 | 67.09 | 77.45 | 86.49 | 0.013 | 234.1 | 50.5 |

| Mix W | GPC-16-2.0-0.6 | 64.50 | 96.10 | 0.011 | 230.8 | 51.8 | ||

| Mix X | GPC-16-2.5-0.6 | 55.28 | 102.99 | 0.009 | 228.5 | 52.7 | ||

| Concrete | Cement | Coarse Aggregates | Fine Aggregates | Water | e-CO2 | Cost |

|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | $/m3 | |

| OPC (21 MPa) | 303 | 1028 | 830 | 205 | 310 | 31.9 |

| OPC (28 MPa) | 361 | 1028 | 817 | 205 | 358 | 36.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, Q.S.; Ahmad, R.H.; Qazi, A.U.; Kazmi, S.M.S.; Munir, M.J.; Javed, M.H. Integrated Mechanical and Eco-Economical Assessments of Fly Ash-Based Geopolymer Concrete. Buildings 2025, 15, 2555. https://doi.org/10.3390/buildings15142555

Khan QS, Ahmad RH, Qazi AU, Kazmi SMS, Munir MJ, Javed MH. Integrated Mechanical and Eco-Economical Assessments of Fly Ash-Based Geopolymer Concrete. Buildings. 2025; 15(14):2555. https://doi.org/10.3390/buildings15142555

Chicago/Turabian StyleKhan, Qasim Shaukat, Raja Hilal Ahmad, Asad Ullah Qazi, Syed Minhaj Saleem Kazmi, Muhammad Junaid Munir, and Muhammad Hassan Javed. 2025. "Integrated Mechanical and Eco-Economical Assessments of Fly Ash-Based Geopolymer Concrete" Buildings 15, no. 14: 2555. https://doi.org/10.3390/buildings15142555

APA StyleKhan, Q. S., Ahmad, R. H., Qazi, A. U., Kazmi, S. M. S., Munir, M. J., & Javed, M. H. (2025). Integrated Mechanical and Eco-Economical Assessments of Fly Ash-Based Geopolymer Concrete. Buildings, 15(14), 2555. https://doi.org/10.3390/buildings15142555