Influence on Existing Underlying Metro Tunnel Deformation from Small Clear-Distance Rectangular Box Jacking: Monitoring and Simulation

Abstract

1. Introduction

2. Field Experiment

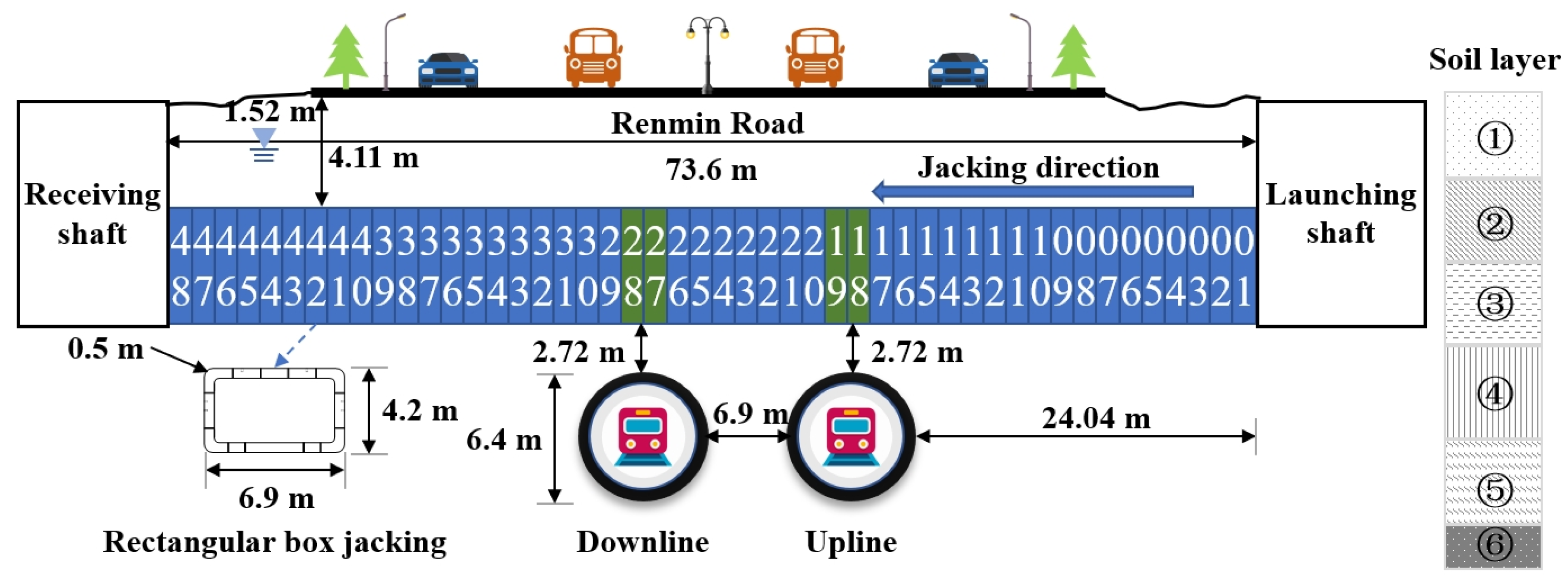

2.1. Project Overview

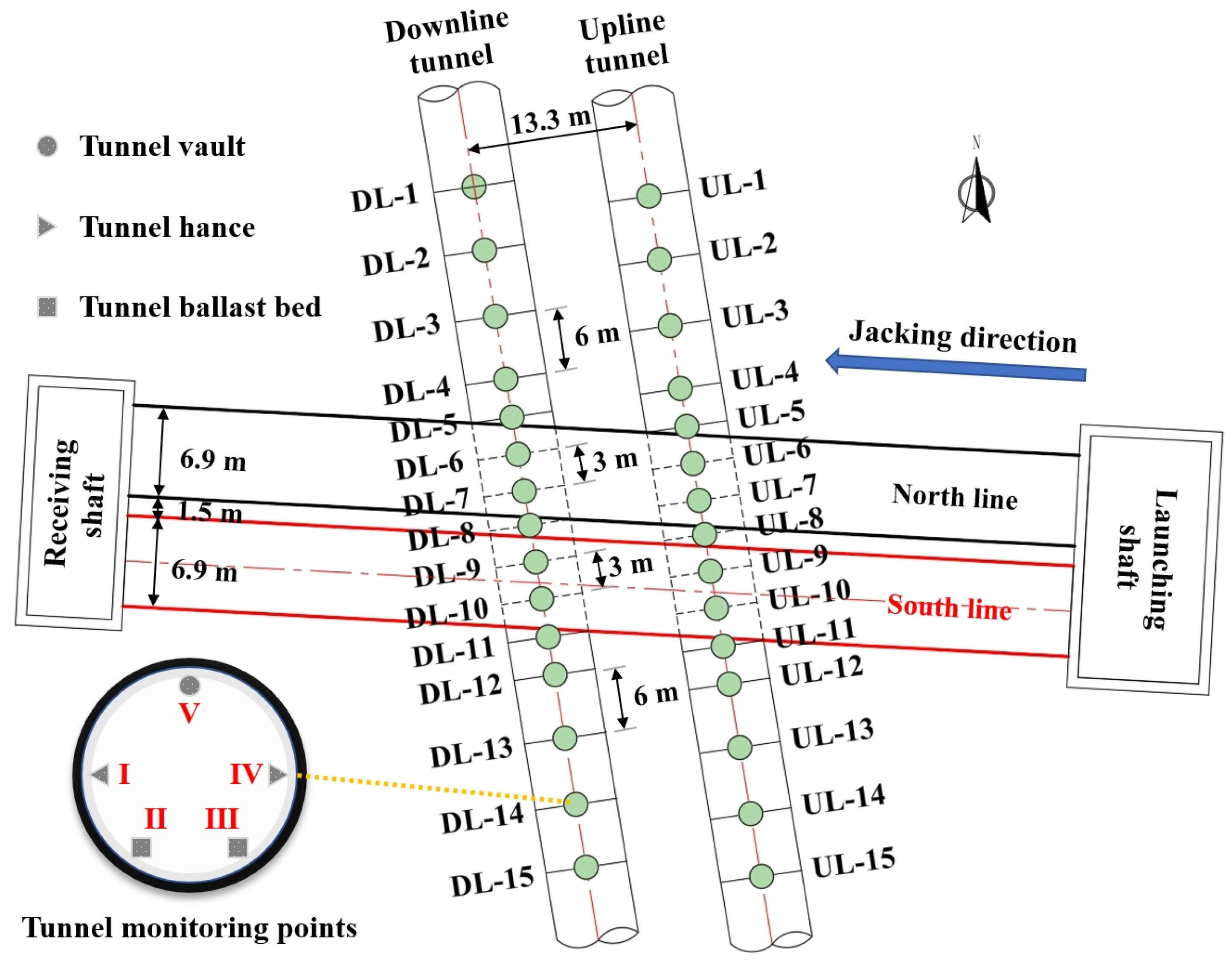

2.2. Monitoring Scheme

2.3. Experimental Program

3. Experimental Results and Analysis

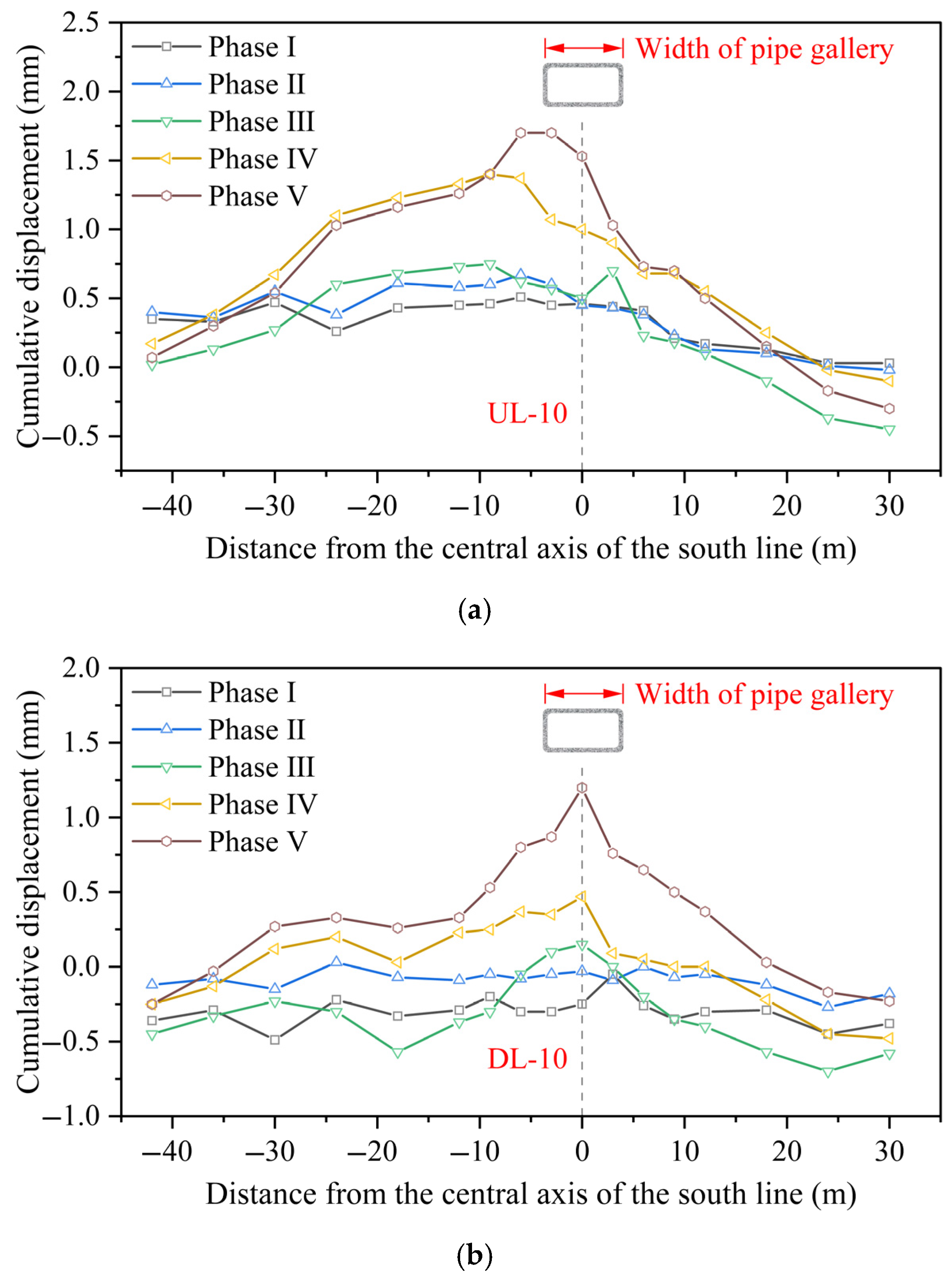

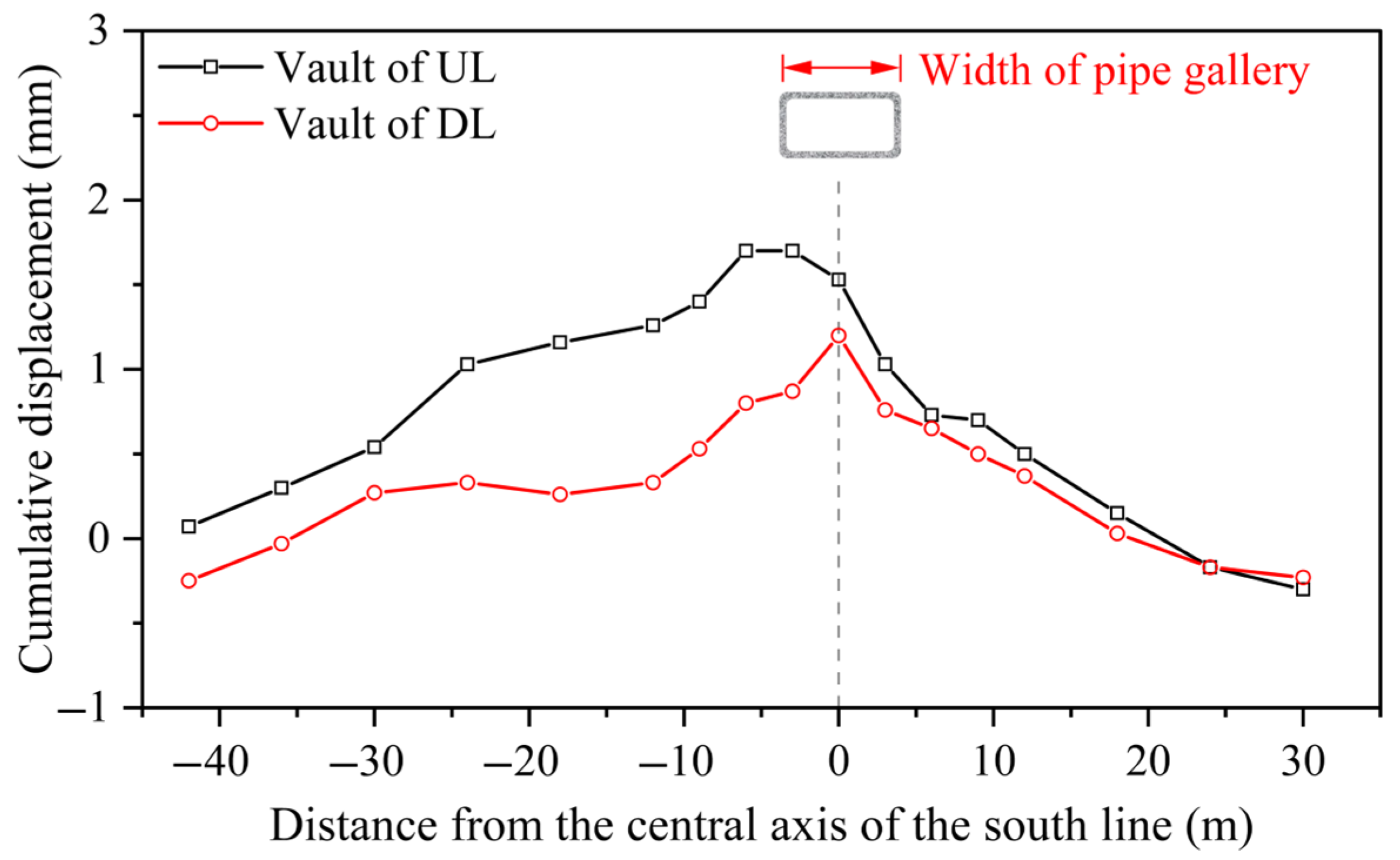

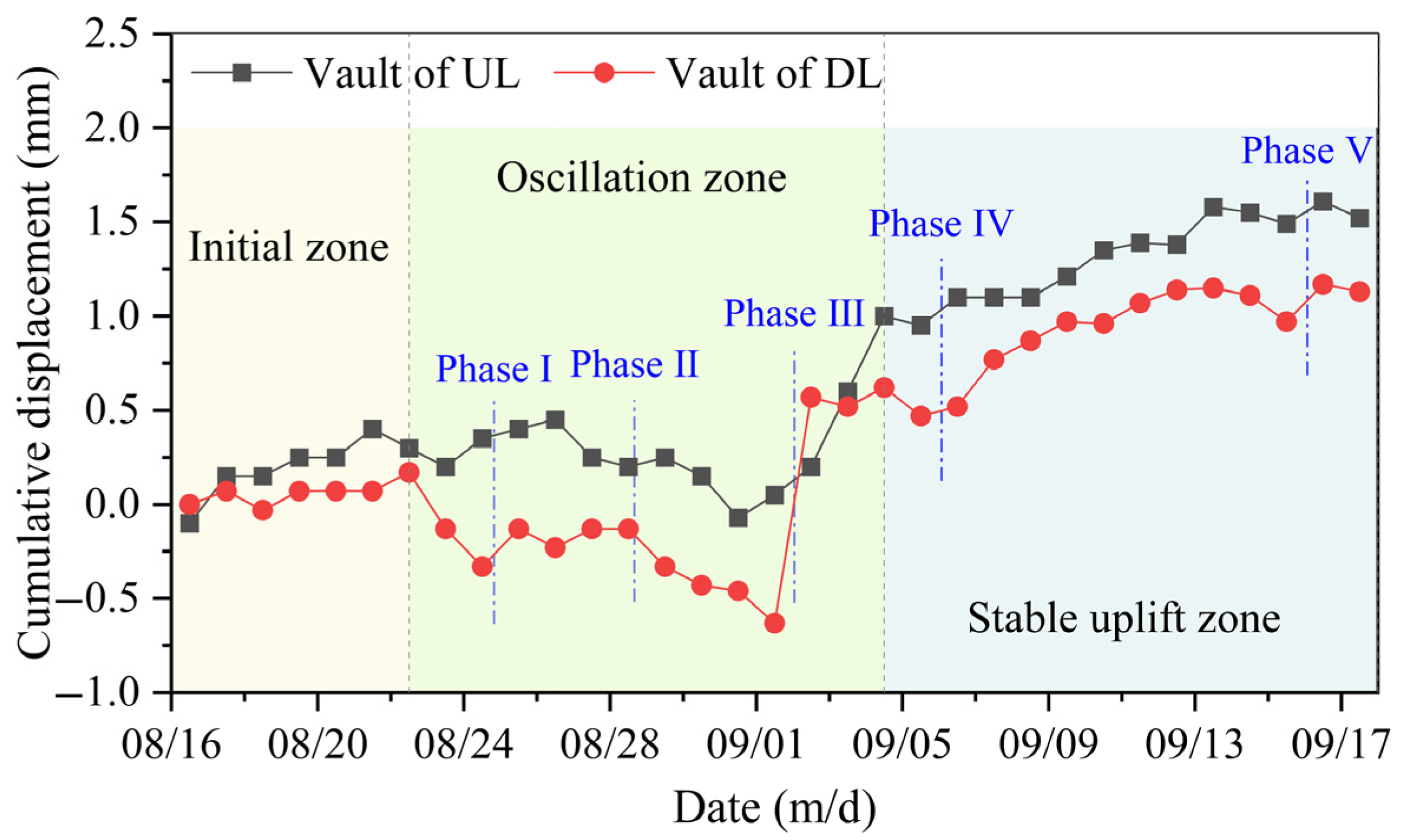

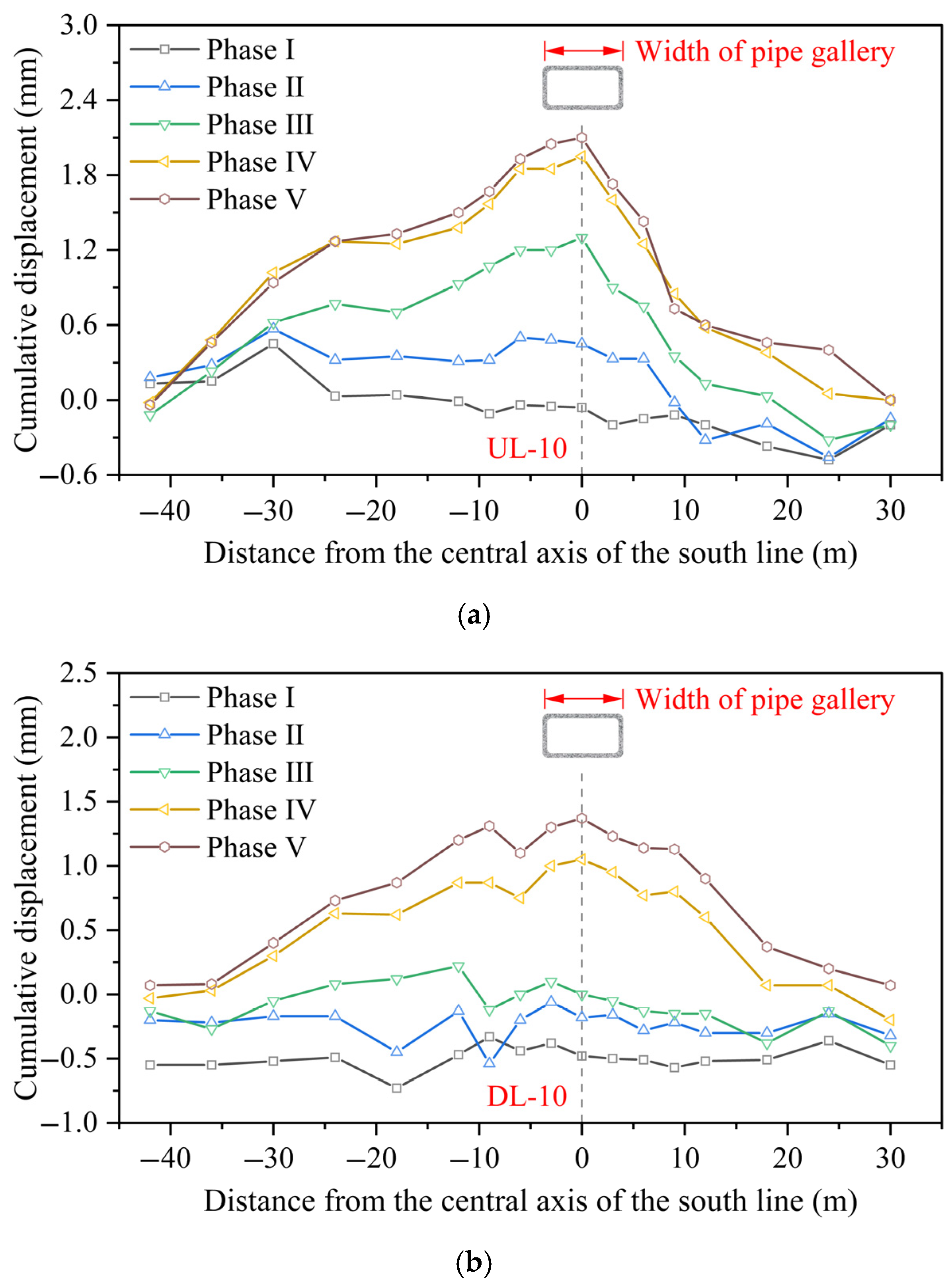

3.1. Vertical Displacement of Metro Tunnel

3.1.1. Tunnel Vault

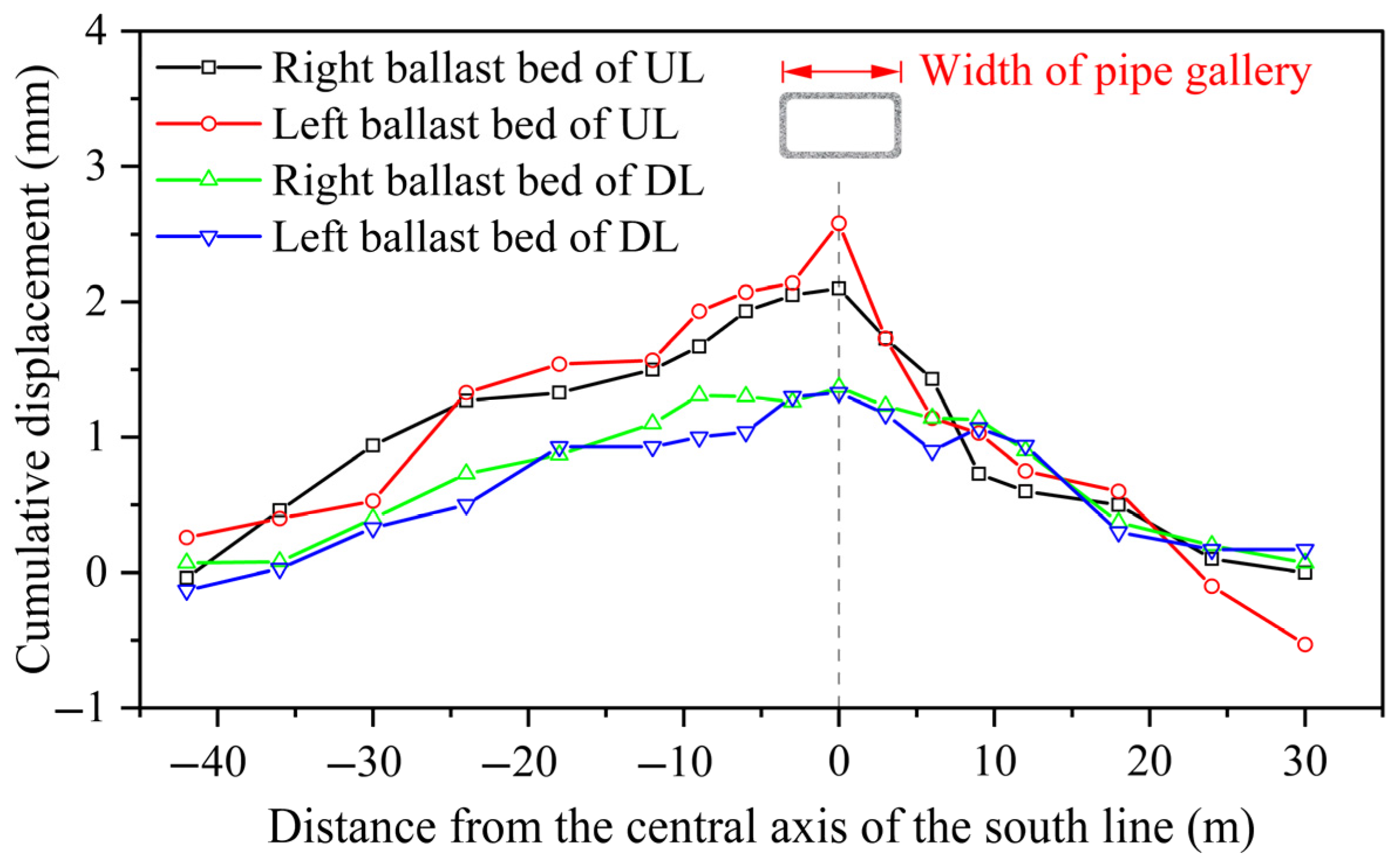

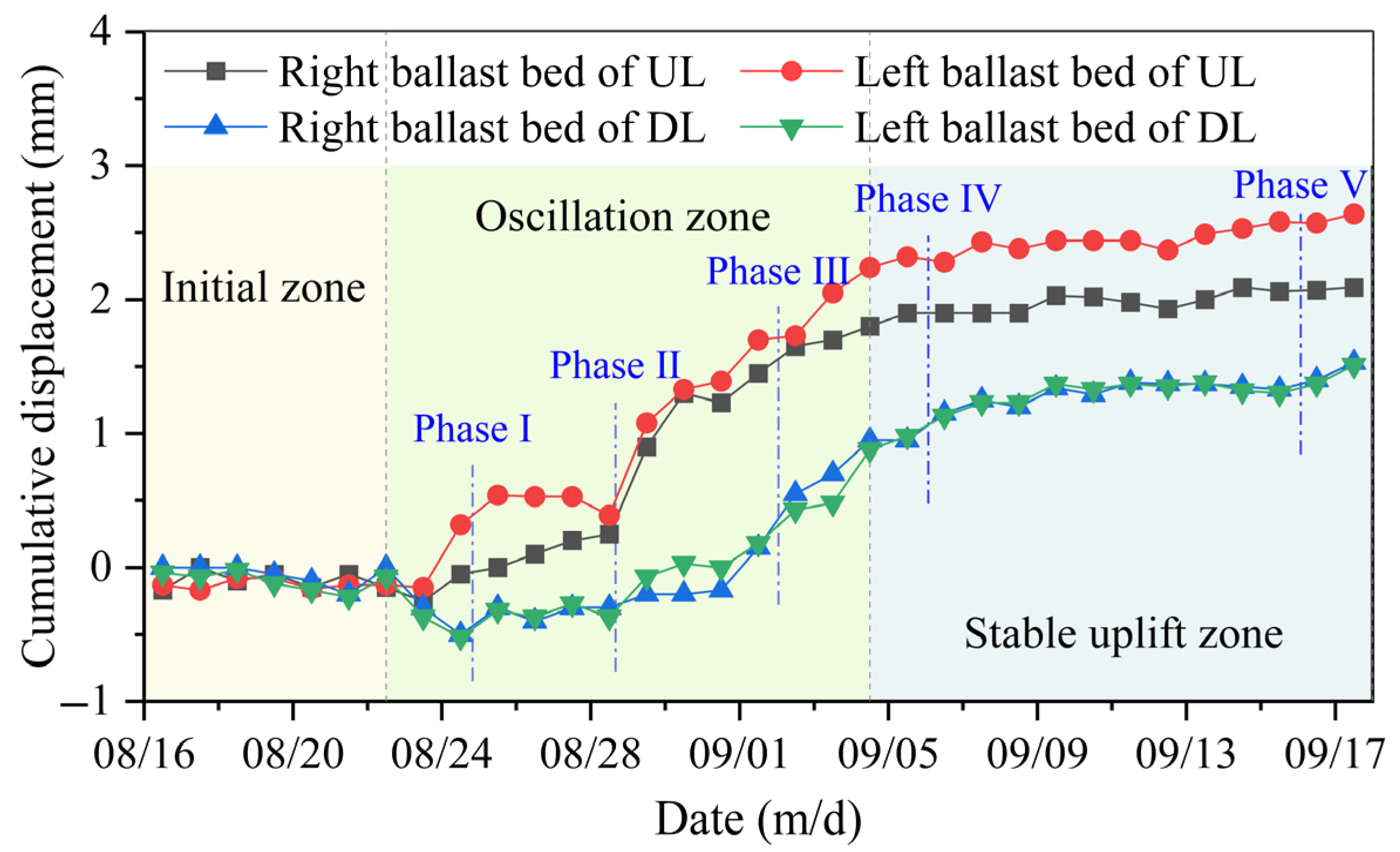

3.1.2. Tunnel Ballast Bed

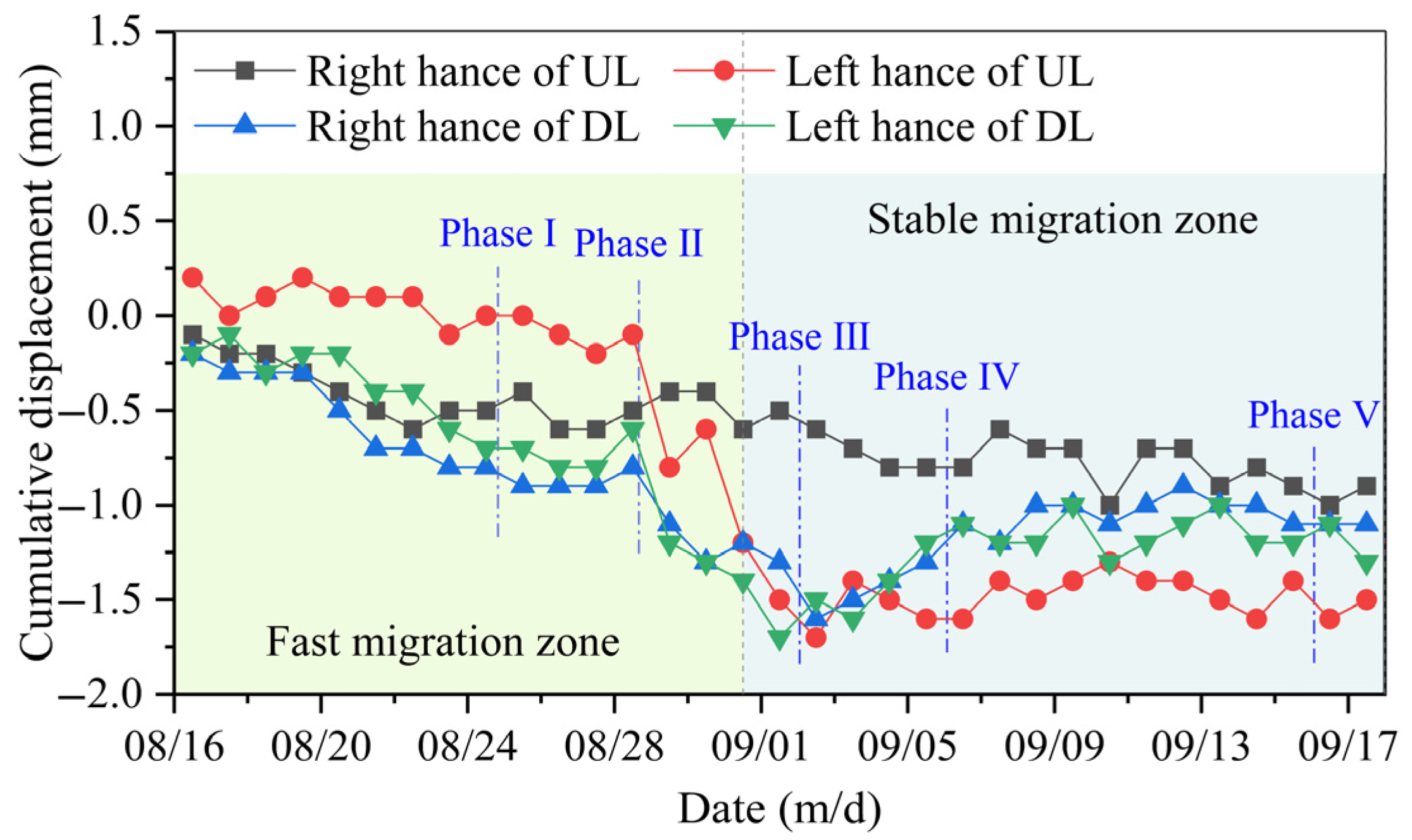

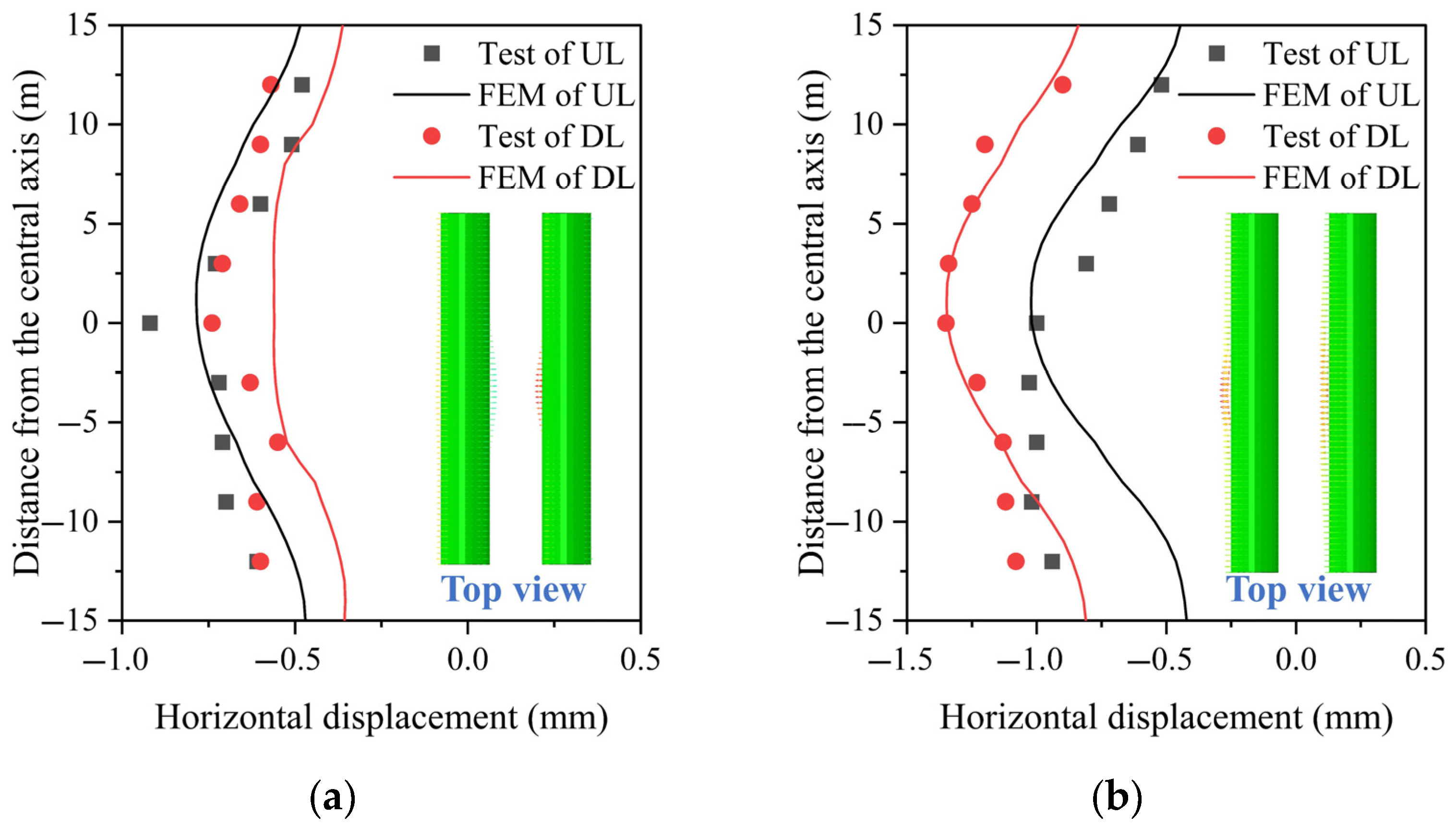

3.2. Horizontal Displacement of Metro Tunnel

4. Numerical Simulation and Discussion

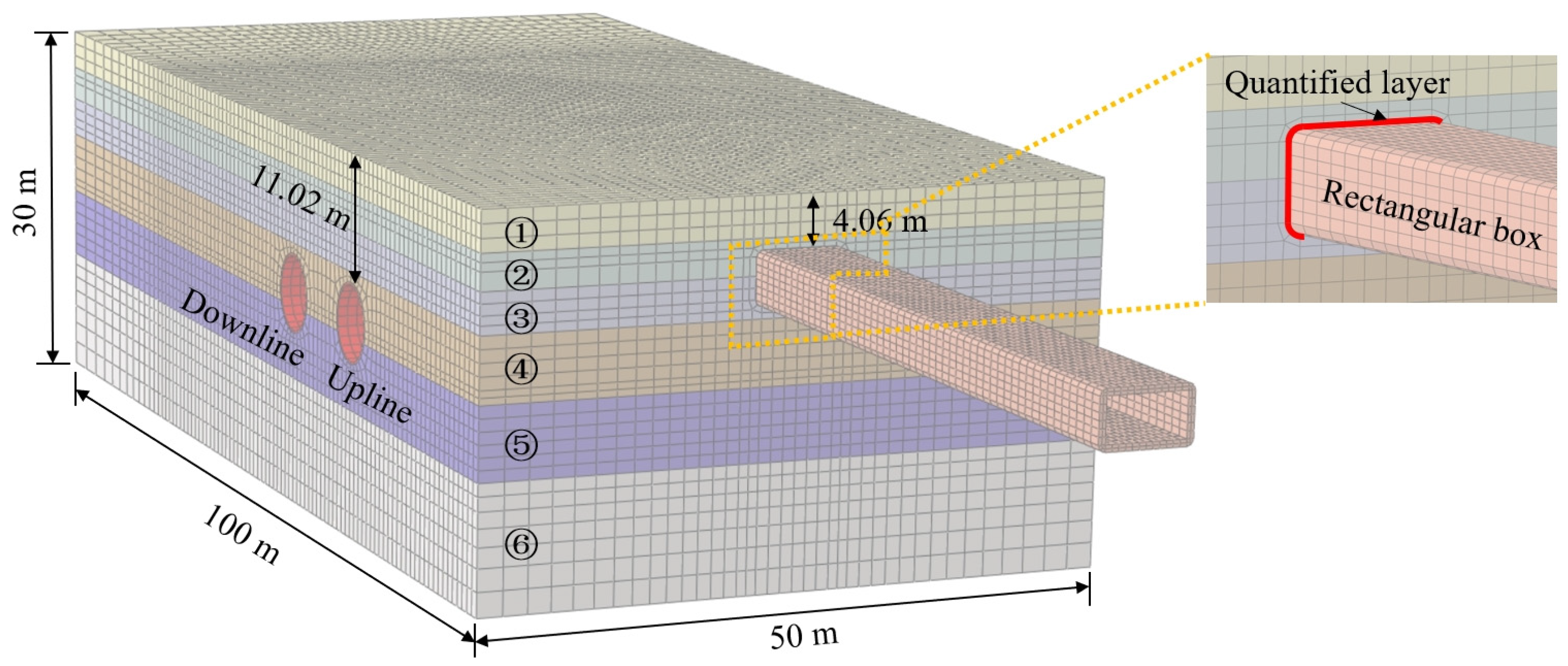

4.1. Finite Element Model

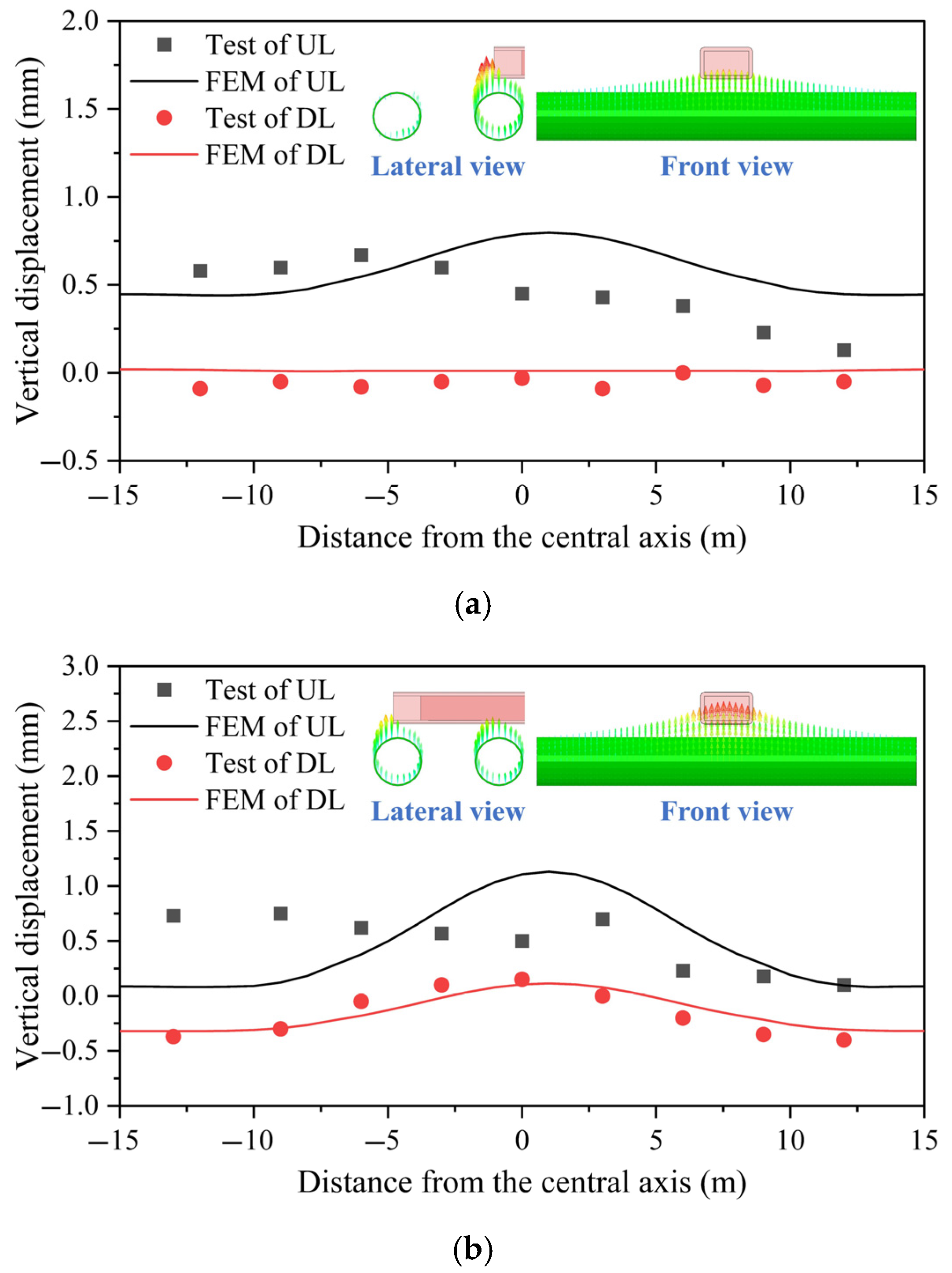

4.2. Model Validation

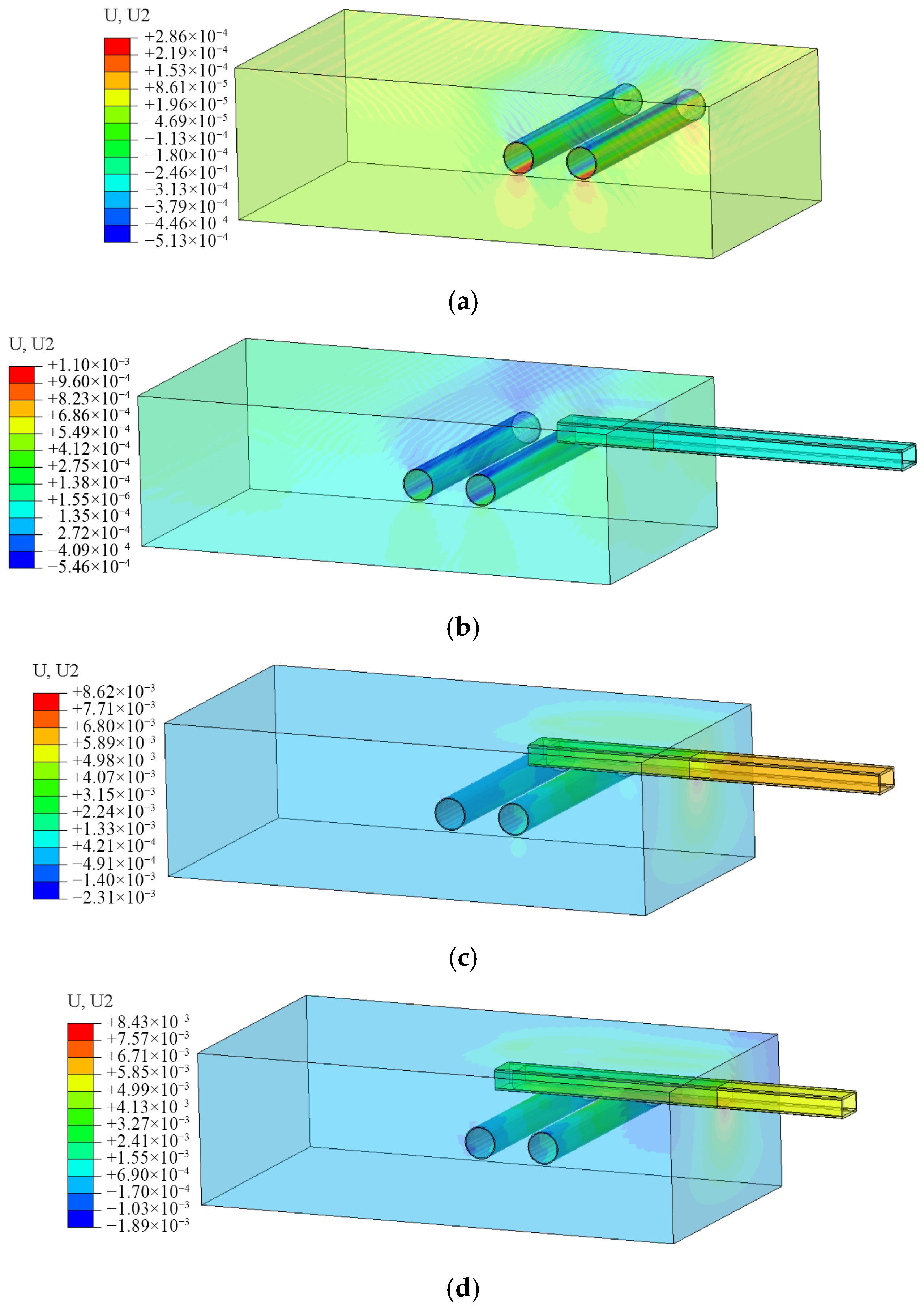

4.3. Influence of Construction Parameters

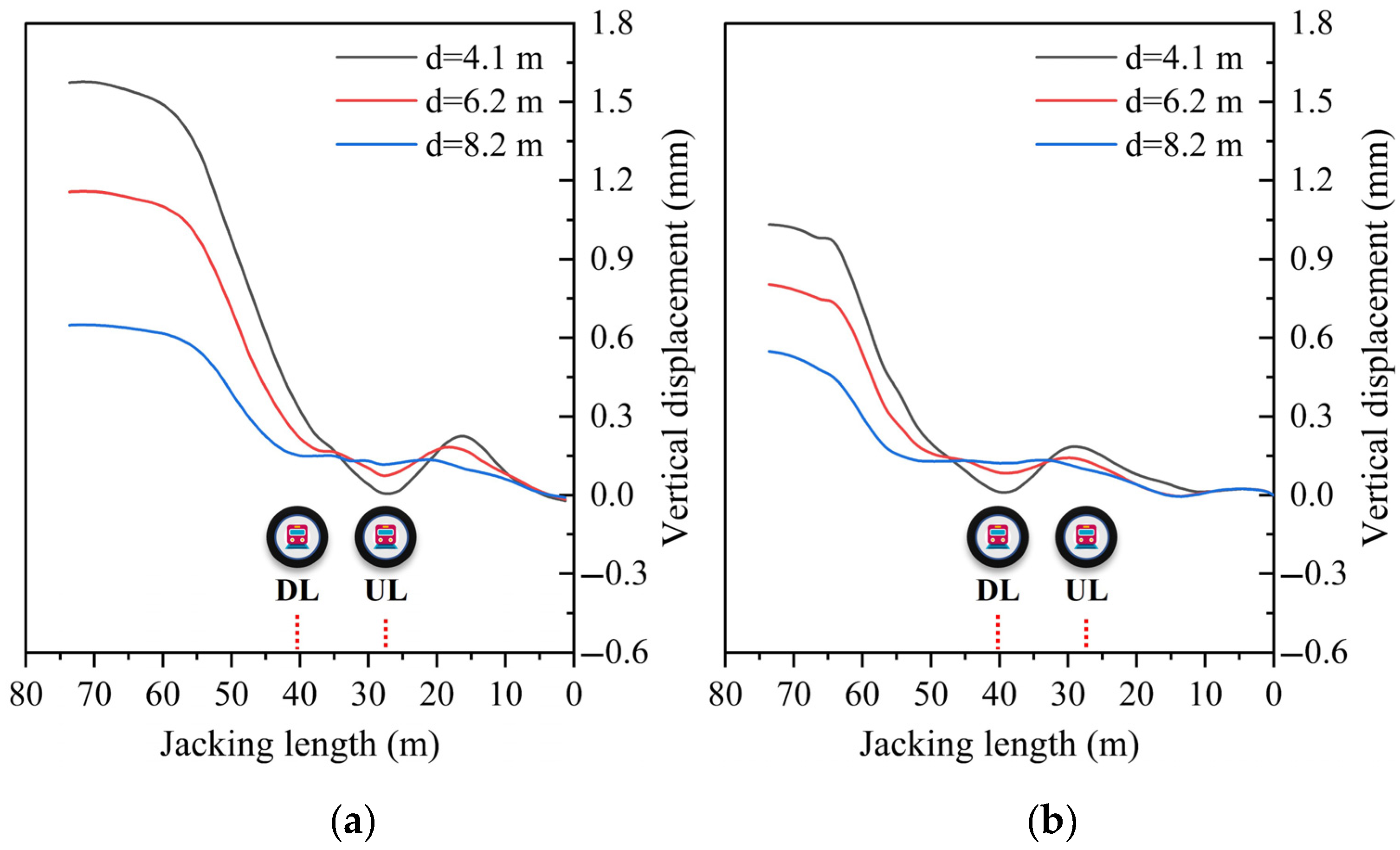

4.3.1. Pipe–Tunnel Clear Distance

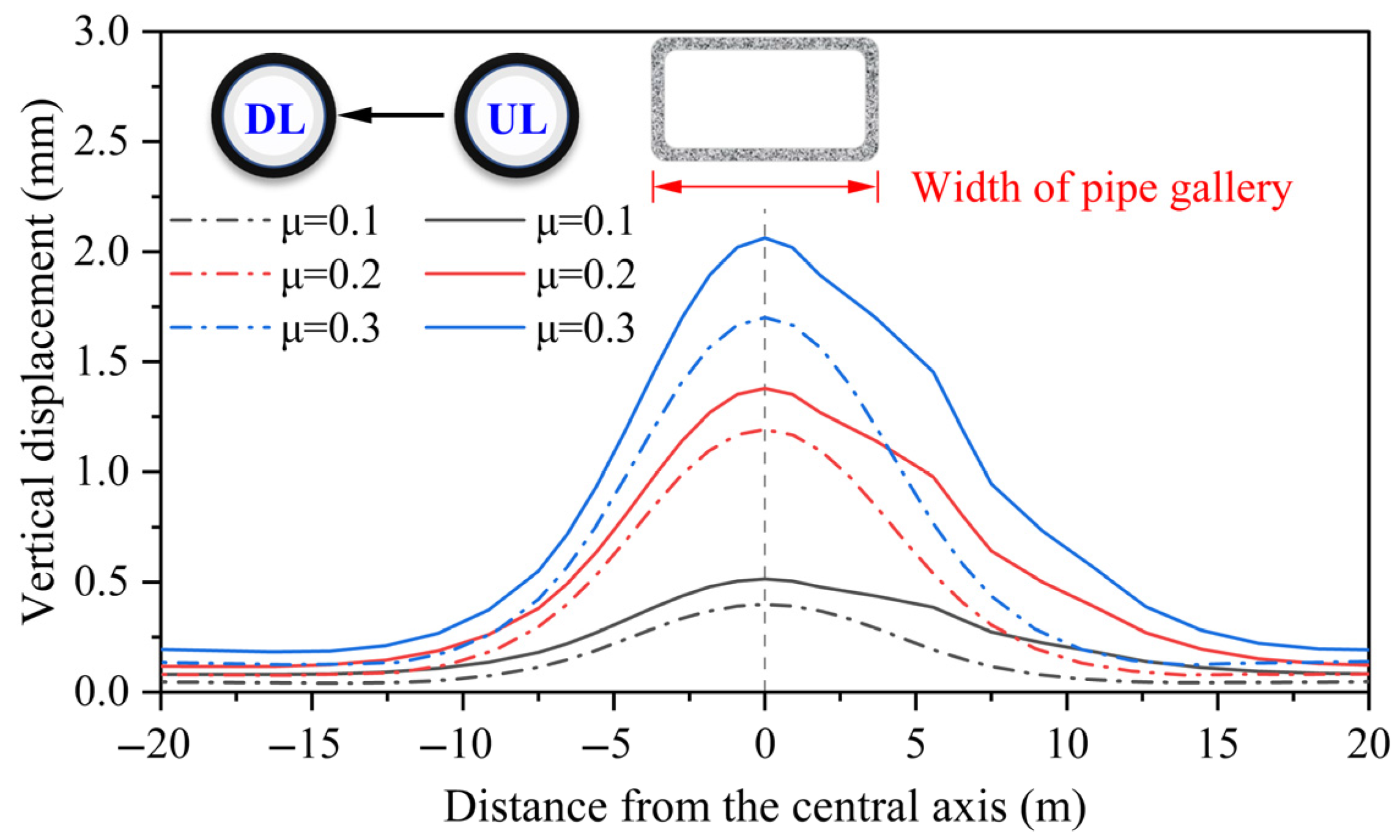

4.3.2. Pipe–Slurry Friction Coefficient

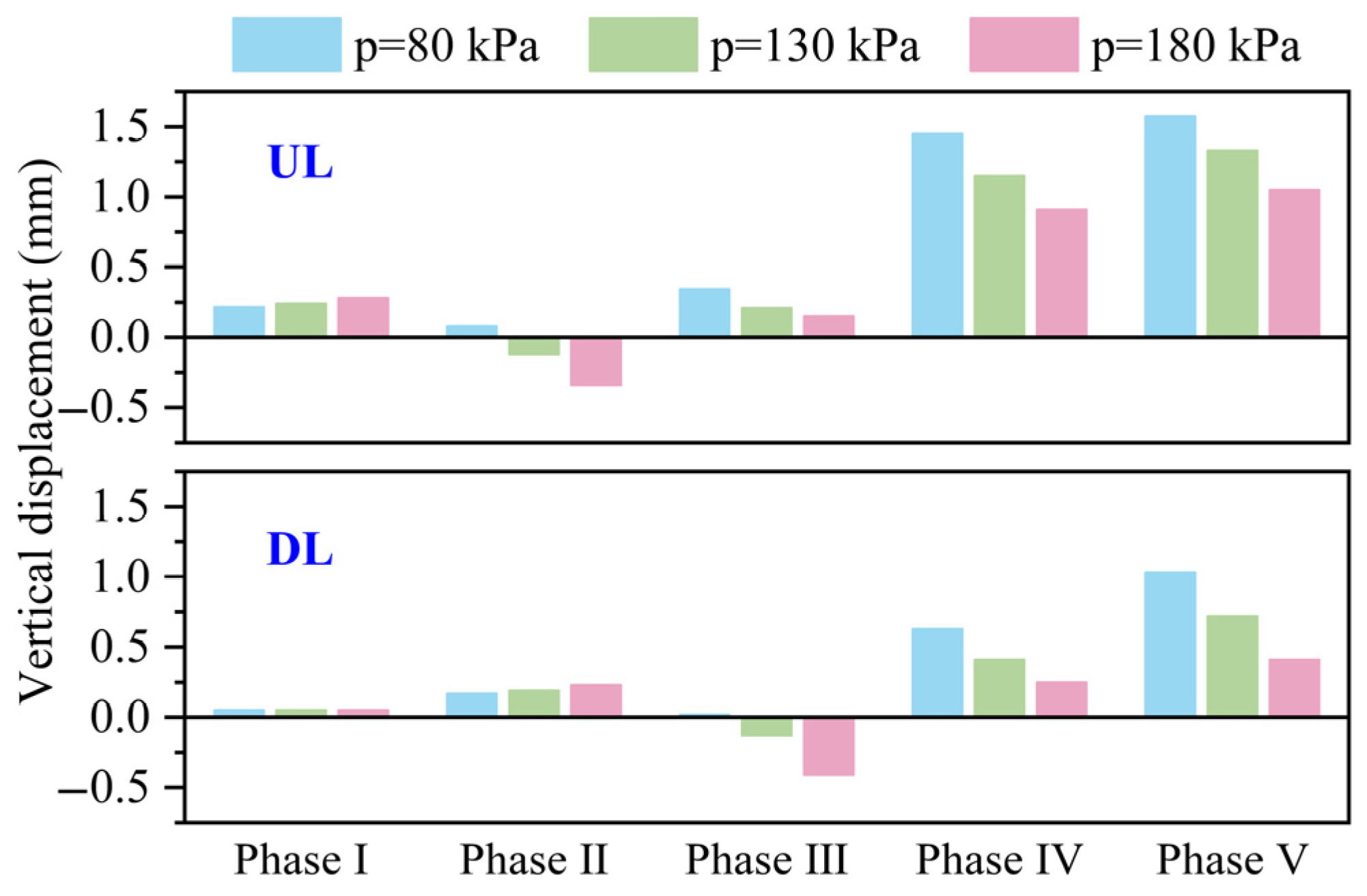

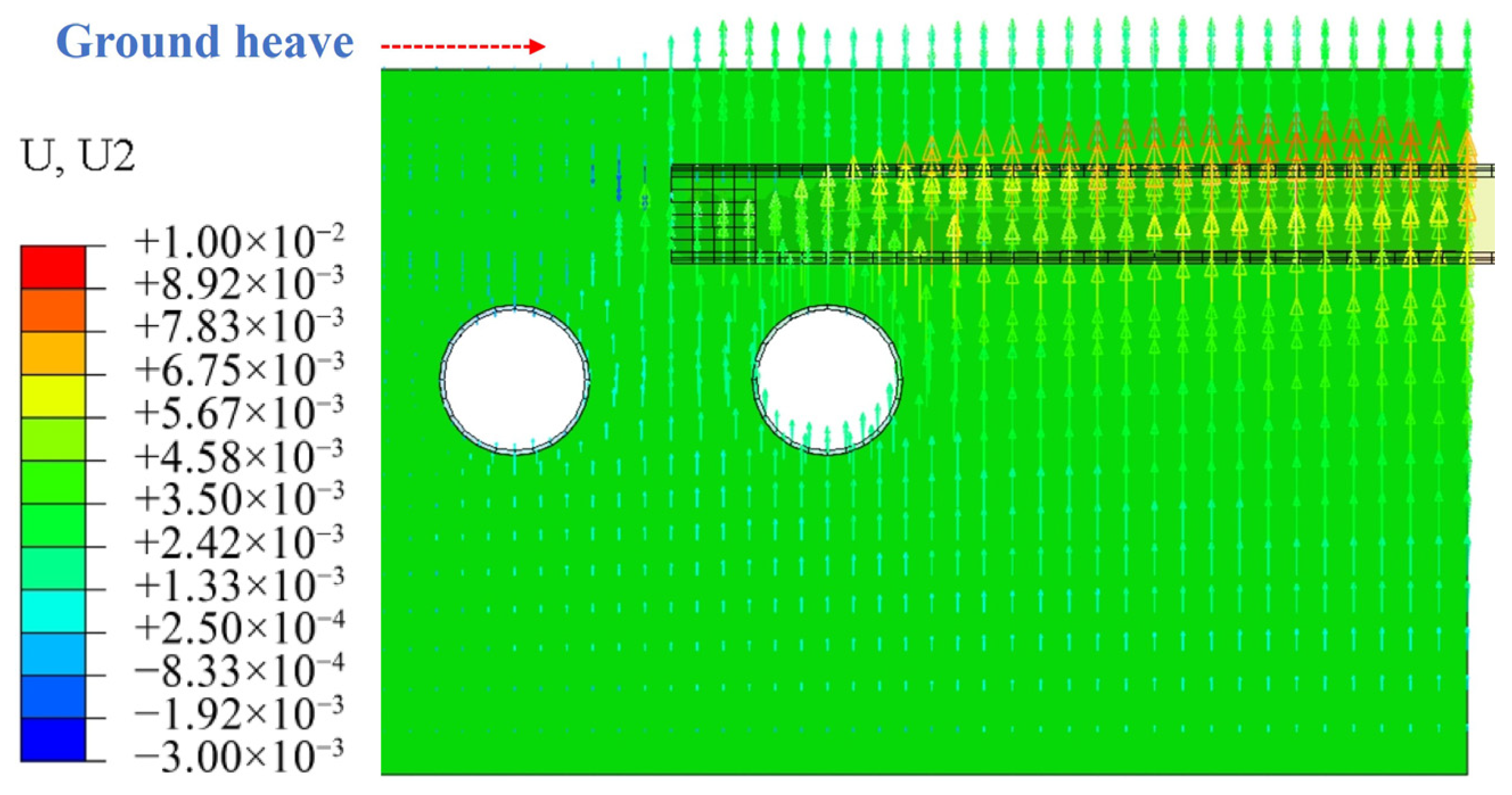

4.3.3. Grouting Pressure

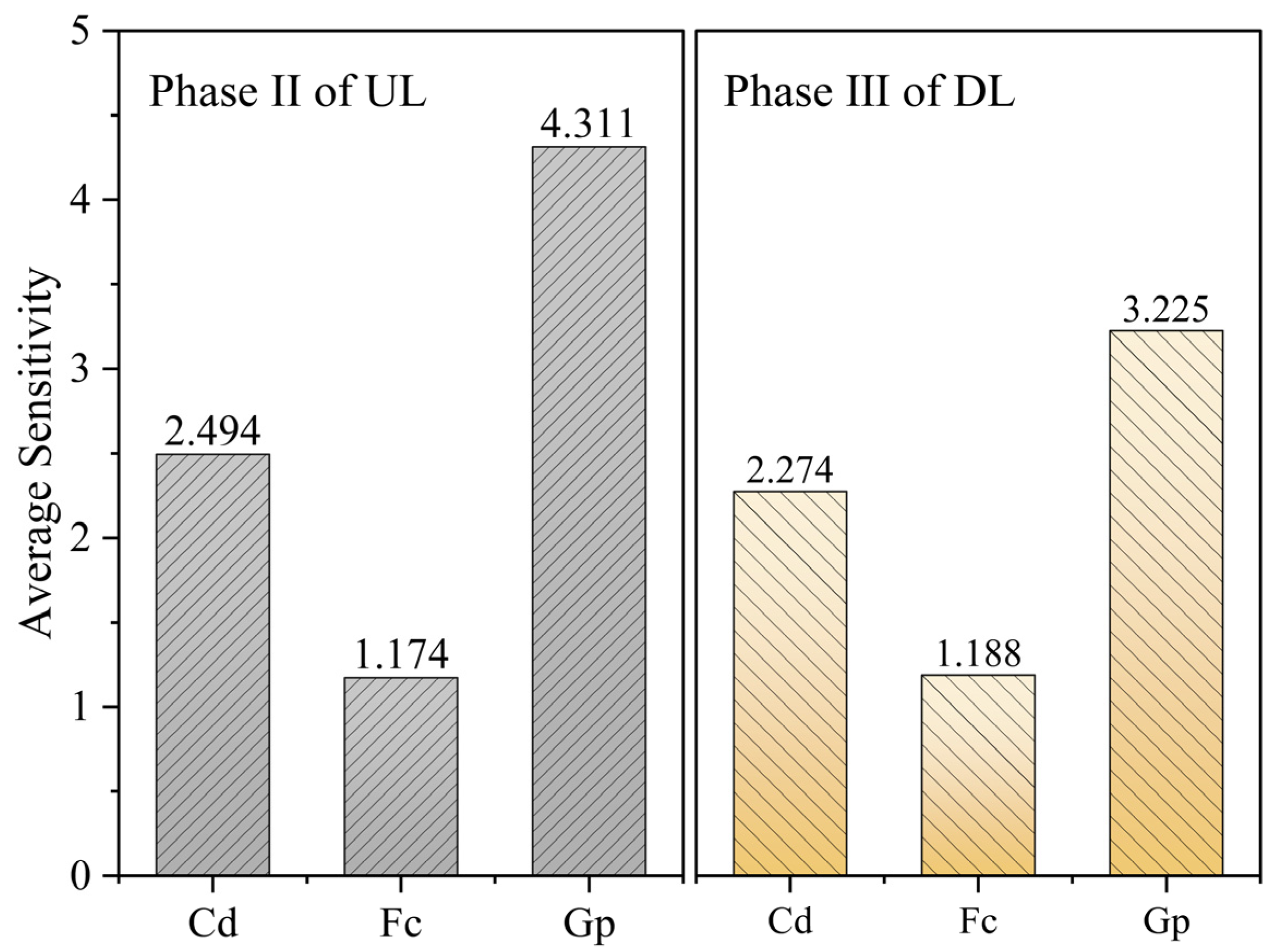

4.3.4. Parameter Sensitivity Analysis

5. Conclusions

- (1)

- During the rectangular box jacking process, the maximum deformation of the metro tunnel primarily occurs directly beneath the jacking axis. The displacement amplitude is generally controlled within 2 mm, exhibiting a symmetrical distribution pattern centered along the axis, and the influence zone of deformation extends approximately 20 m from the edge of the pipe gallery. The tunnel vault and ballast bed mainly float upward, while the tunnel hance tends to shift horizontally toward the receiving shaft. As the surrounding soil gradually consolidates during the later stages of construction, the horizontal displacement of the tunnel hance decreases, although the overall deformation trend remains stable.

- (2)

- The vertical displacement trends of both the vault and the ballast bed in the double-line tunnel exhibit similar patterns; however, the uplift magnitude of the ballast bed is generally greater than that of the vault. The evolution of displacement can be categorized into three distinct stages: the initial deformation zone, the deformation oscillation zone, and the stable uplift zone, with the self-gravity of the pipe jacking machine serving as the primary influencing factor. The horizontal displacement at the tunnel hance predominantly undergoes two stages: the fast migration zone and the stable migration zone, and the demarcation point roughly corresponds to the period when the pipe jacking machine crosses the upline and downline.

- (3)

- Throughout the entire jacking process, the deformation amplitude of the upline tunnel structure is generally greater than that of the downline, with the deformation of the right side hance and ballast bed exhibiting significantly higher values than that of the left side. This phenomenon indicates that stratum disturbances exhibit temporal and spatial effects, wherein structural components initially impacted by pipe jacking endure greater cumulative deformation during the whole construction process.

- (4)

- The finite element simulation results align well with the monitoring data. When the clear distance is increased to two times the original clear distance, the vertical displacement of the upline and downline tunnel vaults is reduced by 58.87% and 51.95%, respectively. As the friction coefficient is 0.1, 0.2, and 0.3, the deformation difference of the double-line tunnel vault is 0.12 mm, 0.19 mm, and 0.36 mm, respectively. Insufficient grouting pressure results in uneven tunnel deformation, whereas a moderate increase can effectively suppress tunnel float. However, excessive grouting pressure may trigger secondary risks, such as ground heave above shallow-buried jacked pipes. When the jacking machine is positioned directly above the tunnel, the sensitivity of grouting pressure is higher than that of the other two parameters, indicating its dominant role in influencing structural responses during this critical stage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Broere, W. Urban Underground Space: Solving the problems of today’s cities. Tunn. Undergr. Space Technol. 2016, 55, 245–248. [Google Scholar] [CrossRef]

- Cui, J.; Broere, W.; Lin, D. Underground Space utilisation for urban renewal. Tunn. Undergr. Space Technol. 2021, 108, 103726. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, S.; Zhang, P.; Ma, B.; Ma, P.; Feng, X. Prediction of jacking force using PSO-BPNN and PSO-SVR algorithm in curved pipe roof. Tunn. Undergr. Space Technol. 2023, 138, 105159. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Shi, J.; Hong, Y. Three-dimensional centrifuge modelling of basement excavation effects on an existing tunnel in dry sand. Can. Geotech. J. 2013, 50, 874–888. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Han, Y.; Wang, Z.; Zhang, R.; Wang, S. Analytical solution for the response of an existing tunnel induced by above-crossing shield tunneling. Comput. Geotech. 2020, 124, 103624. [Google Scholar] [CrossRef]

- Ayasrah, M. Response of Existing Pile Groups Due to Twin Tunneling: A Numerical Study. Eng. Technol. Appl. Sci. Res. 2025, 15, 23309–23316. [Google Scholar] [CrossRef]

- Ma, B.; Najafi, M. Development and applications of trenchless technology in China. Tunn. Undergr. Space Technol. 2008, 23, 476–480. [Google Scholar] [CrossRef]

- Ji, X.; Ni, P.; Barla, M.; Zhao, W.; Mei, G. Earth pressure on shield excavation face for pipe jacking considering arching effect. Tunn. Undergr. Space Technol. 2018, 72, 17–27. [Google Scholar] [CrossRef]

- Zhang, P.; Behbahani, S.S.; Ma, B.; Iseley, T.; Tan, L. A jacking force study of curved steel pipe roof in Gongbei tunnel: Calculation review and monitoring data analysis. Tunn. Undergr. Space Technol. 2018, 72, 305–322. [Google Scholar] [CrossRef]

- Ong, D.E.L.; Choo, C.S. Assessment of non-linear rock strength parameters for the estimation of pipe-jacking forces. Part 1. Direct shear testing and backanalysis. Eng. Geol. 2018, 244, 159–172. [Google Scholar] [CrossRef]

- Xu, X.; Tong, L.; Li, Z.; Liu, X.; Hu, Q.; Yao, H.; Li, J. Influence of extreme shallow jacked box tunnelling on underlying metro tunnels: A case study. Undergr. Space 2023, 12, 234–250. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, B.; Qin, Y. Construction of a large-section long pedestrian underpass using pipe jacking in muddy silty clay: A case study. Tunn. Undergr. Space Technol. 2016, 60, 151–164. [Google Scholar] [CrossRef]

- Choi, J.-I.; Lee, S.-W. Influence of existing tunnel on mechanical behavior of new tunnel. KSCE J. Civ. Eng. 2010, 14, 773–783. [Google Scholar] [CrossRef]

- Li, P.; Du, S.-J.; Ma, X.-F.; Yin, Z.-Y.; Shen, S.-L. Centrifuge investigation into the effect of new shield tunnelling on an existing underlying large-diameter tunnel. Tunn. Undergr. Space Technol. 2014, 42, 59–66. [Google Scholar] [CrossRef]

- Avgerinos, V.; Potts, D.M.; Standing, J.R. Numerical investigation of the effects of tunnelling on existing tunnels. Géotechnique 2017, 67, 808–822. [Google Scholar] [CrossRef]

- Zheng, Z.; Xue, X.; Su, D.; Chen, J.; Qiu, T.; Chen, P.; Xie, D.; Su, L.; Chen, W.; Huang, S.; et al. Instability mechanism and reinforcement measures for segments of Ultra-Large diameter shield tunnels when constructing cross passages by mechanical methods. Tunn. Undergr. Space Technol. 2024, 154, 106125. [Google Scholar] [CrossRef]

- Liang, R.; Wu, W.; Yu, F.; Jiang, G.; Liu, J. Simplified method for evaluating shield tunnel deformation due to adjacent excavation. Tunn. Undergr. Space Technol. 2018, 71, 94–105. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, Y.; Liu, Z.; Miao, L. Theoretical prediction model for deformations caused by construction of new tunnels undercrossing existing tunnels based on the equivalent layered method. Comput. Geotech. 2020, 123, 103565. [Google Scholar] [CrossRef]

- Wu, H.-N.; Shen, S.-L.; Liao, S.-M.; Yin, Z.-Y. Longitudinal structural modelling of shield tunnels considering shearing dislocation between segmental rings. Tunn. Undergr. Space Technol. 2015, 50, 317–323. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, R.; Li, Z.; Kang, C.; El Naggar, M.H.; Xiao, M.; Wu, W. Analytical solution for longitudinal deformation of shield tunnel induced by overcrossing tunnelling considering circumferential joints. J. Rock Mech. Geotech. Eng. 2023, 15, 2355–2374. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Z.; Zhang, C.; Han, X.; Liu, T.; Zhang, X. Analysis of longitudinal deformation of existing rectangular pipe jacking tunnel caused by shield tunnel undercrossing. Tunn. Undergr. Space Technol. 2025, 161, 106532. [Google Scholar] [CrossRef]

- He, H.; Wang, S.; Shen, W.; Zhang, W. The influence of pipe-jacking tunneling on deformation of existing tunnels in soft soils and the effectiveness of protection measures. Transp. Geotech. 2023, 42, 101061. [Google Scholar] [CrossRef]

- Ma, L.; Xue, C.; Yang, Q.; Chen, D.; Wang, B. A simplified method for evaluating the carrying-soil phenomenon in large cross-section rectangular pipe jacking. Eng. Fail. Anal. 2024, 165, 108750. [Google Scholar] [CrossRef]

- Ye, P.; Lan, B.; Zhang, P.; Zeng, C.; Xu, T.; Xu, Y.; Wu, R. Numerical Simulation Study on Evolution Process of Carrying-Soil Effect of Rectangular Pipe Jacking. Buildings 2024, 14, 3057. [Google Scholar] [CrossRef]

- Ma, P.; Shimada, H.; Sasaoka, T.; Moses, D.N.; Matsumoto, F.; Chen, X. Investigation on the engineering effects of the geometrical configuration of the jacking rectangular pipe. Tunn. Undergr. Space Technol. 2022, 119, 104239. [Google Scholar] [CrossRef]

- Chen, X.; Ma, B.; Najafi, M.; Zhang, P. Long rectangular box jacking project: A case study. Undergr. Space 2021, 6, 101–125. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Lun, K.; Xie, J.; Ma, P. A Prediction Method for Frictional Resistance in Long-Distance Rectangular Pipe Jacking Considering Complex Contact States. Buildings 2025, 15, 1904. [Google Scholar] [CrossRef]

- Liu, W.; Wu, Y.; Zhao, H.; Xu, X.; Miao, L. Deformations of Subway Tunnels Induced by the Overcrossing Jacked Box Tunnels. Symmetry 2021, 13, 1800. [Google Scholar] [CrossRef]

- Luo, L.; Zhe, Q.; Liu, W.; Fang, Y.; Wang, F. Research on the Longitudinal Deformation of Segments Induced by Pipe-Jacking Tunneling over Existing Shield Tunnels. Buildings 2025, 15, 1394. [Google Scholar] [CrossRef]

- Lin, C.; Zheng, J.; Ye, Y.; Nadim, F.; Liu, Z.; Zhao, C.; Chen, Y.; Ding, Z. Analytical solution for tunnelling-induced response of an overlying pipeline considering gap formation. Undergr. Space 2024, 15, 298–311. [Google Scholar] [CrossRef]

- Ma, P.; Shimada, H.; Sasaoka, T.; Hamanaka, A.; Moses, D.N.; Dintwe, T.K.M.; Matsumoto, F.; Ma, B.; Huang, S. A new method for predicting the friction resistance in rectangular pipe-jacking. Tunn. Undergr. Space Technol. 2022, 123, 104338. [Google Scholar] [CrossRef]

- Wang, F.; Shi, J.; Huang, H.; Zhang, D. Modified analytical solution of shield tunnel lining considering nonlinear bending stiffness of longitudinal joint. Tunn. Undergr. Space Technol. 2020, 106, 103625. [Google Scholar] [CrossRef]

- Shou, K.; Yen, J.; Liu, M. On the frictional property of lubricants and its impact on jacking force and soil–pipe interaction of pipe-jacking. Tunn. Undergr. Space Technol. 2010, 25, 469–477. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, S.; Ma, B.; Zhang, H.; Tan, X.; Zhao, Y.; Ma, P.; Su, X.; Wei, Y. Full-scale test study on the mechanical response of ultra-large section jacking prestressed concrete cylinder pipe (JPCCP) under axial jacking force. Tunn. Undergr. Space Technol. 2025, 155, 106194. [Google Scholar] [CrossRef]

| No. | City/Country | Project Name | Construction Method | Object | Minimum Clear Distance (m) |

|---|---|---|---|---|---|

| 1 | Guangzhou, China | Liede Drainage Project | Rectangular pipe jacking | Metro station pile foundations and structures | 2.3 |

| 2 | Nanjing, China | Underground Passage Construction | Rectangular pipe jacking | Metro lines | <4.5 |

| 3 | Singapore | Deep Tunnel Sewerage System (DTSS) Phase II | Pipe jacking | Metro lines and substructures | 2.5 |

| 4 | Singapore | Thomson–East Coast Line (TEL) | Pipe jacking, Shield tunnelling | Metro lines and pile foundations | <2.5 |

| 5 | London, UK | Crossrail Project | Microtunnelling, Shield tunnelling | Metro lines | 2–3 |

| 6 | Paris, France | Grand Paris Express | Pipe jacking, Shield tunnelling | Dense urban infrastructure | <3 |

| Soil Layer | Thickness (m) | Density (kg·m−3) | Compression Modulus (MPa) | Poisson Ratio | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|

| ① Artificial fill | 3.2 | 1850 | 23.8 | 0.33 | 23 | 12.1 |

| ② Clay | 2.8 | 1890 | 30.8 | 0.3 | 22 | 15.2 |

| ③ Silty clay | 3.2 | 1870 | 27.6 | 0.32 | 26 | 13.6 |

| ④ Silty clay mixed with silt | 5.1 | 1840 | 42.5 | 0.23 | 7 | 24.1 |

| ⑤ Sand clay | 5.7 | 1870 | 53 | 0.22 | 3 | 29.3 |

| ⑥ Silty clay | 10.6 | 1920 | 36.2 | 0.35 | 37 | 16.5 |

| Phase | Time | Location of the Machine | Distance (m) | Relative Position Diagram |

|---|---|---|---|---|

| 16 August 10:00 | Start jacking | 0 | - | |

| I | 25 August 09:50 | Entering the affect zone of UL | 16.90 |  |

| II | 29 August 08:55 | Entering the above of UL | 27.21 |  |

| III | 2 September 07:35 | Entering the above of DL | 40.52 |  |

| IV | 6 September 16:20 | Leaving the affect zone of DL | 58.09 |  |

| V | 9 September 07:35 | End of jacking | 73.60 | - |

| Item | Upline | Downline | |||

|---|---|---|---|---|---|

| Maximum | Minimum | Maximum | Minimum | ||

| Vault | Monitoring section | UL-8 | UL-15 | DL-9 | DL-1 |

| Measuring point | I | I | I | I | |

| Value (mm) | 1.70 | −0.29 | 1.21 | −0.25 | |

| Ballast bed | Monitoring section | UL-9 | UL-15 | DL-9 | DL-1 |

| Measuring point | II | II | III | II | |

| Value (mm) | 2.58 | −0.53 | 1.37 | −0.13 | |

| Thickness (m) | Density (kg·m−3) | Elastic Modulus (MPa) | Poisson Ratio | Remark | |

|---|---|---|---|---|---|

| Tunnel lining | 0.50 | 2400 | 27,600 * | 0.2 | 80% reduction |

| Jacked pipe | 0.45 | 2400 | 34,500 | 0.2 | |

| Quantified layer | 0.03 | 1050 | 1 | 0.38 |

| Parameters | Symbol | Value | ||

|---|---|---|---|---|

| Pipe–tunnel clear distance (m) | d | 4.1 | 6.2 | 8.2 |

| Pipe–slurry friction coefficient | μ | 0.1 | 0.2 | 0.3 |

| Grouting pressure (kPa) | p | 80.0 | 130.0 | 180.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Zhou, H.; Ma, B. Influence on Existing Underlying Metro Tunnel Deformation from Small Clear-Distance Rectangular Box Jacking: Monitoring and Simulation. Buildings 2025, 15, 2547. https://doi.org/10.3390/buildings15142547

Ma C, Zhou H, Ma B. Influence on Existing Underlying Metro Tunnel Deformation from Small Clear-Distance Rectangular Box Jacking: Monitoring and Simulation. Buildings. 2025; 15(14):2547. https://doi.org/10.3390/buildings15142547

Chicago/Turabian StyleMa, Chong, Hao Zhou, and Baosong Ma. 2025. "Influence on Existing Underlying Metro Tunnel Deformation from Small Clear-Distance Rectangular Box Jacking: Monitoring and Simulation" Buildings 15, no. 14: 2547. https://doi.org/10.3390/buildings15142547

APA StyleMa, C., Zhou, H., & Ma, B. (2025). Influence on Existing Underlying Metro Tunnel Deformation from Small Clear-Distance Rectangular Box Jacking: Monitoring and Simulation. Buildings, 15(14), 2547. https://doi.org/10.3390/buildings15142547