Advances in Solidification Technologies of Lunar Regolith-Based Building Materials Under Extreme Lunar Environments

Abstract

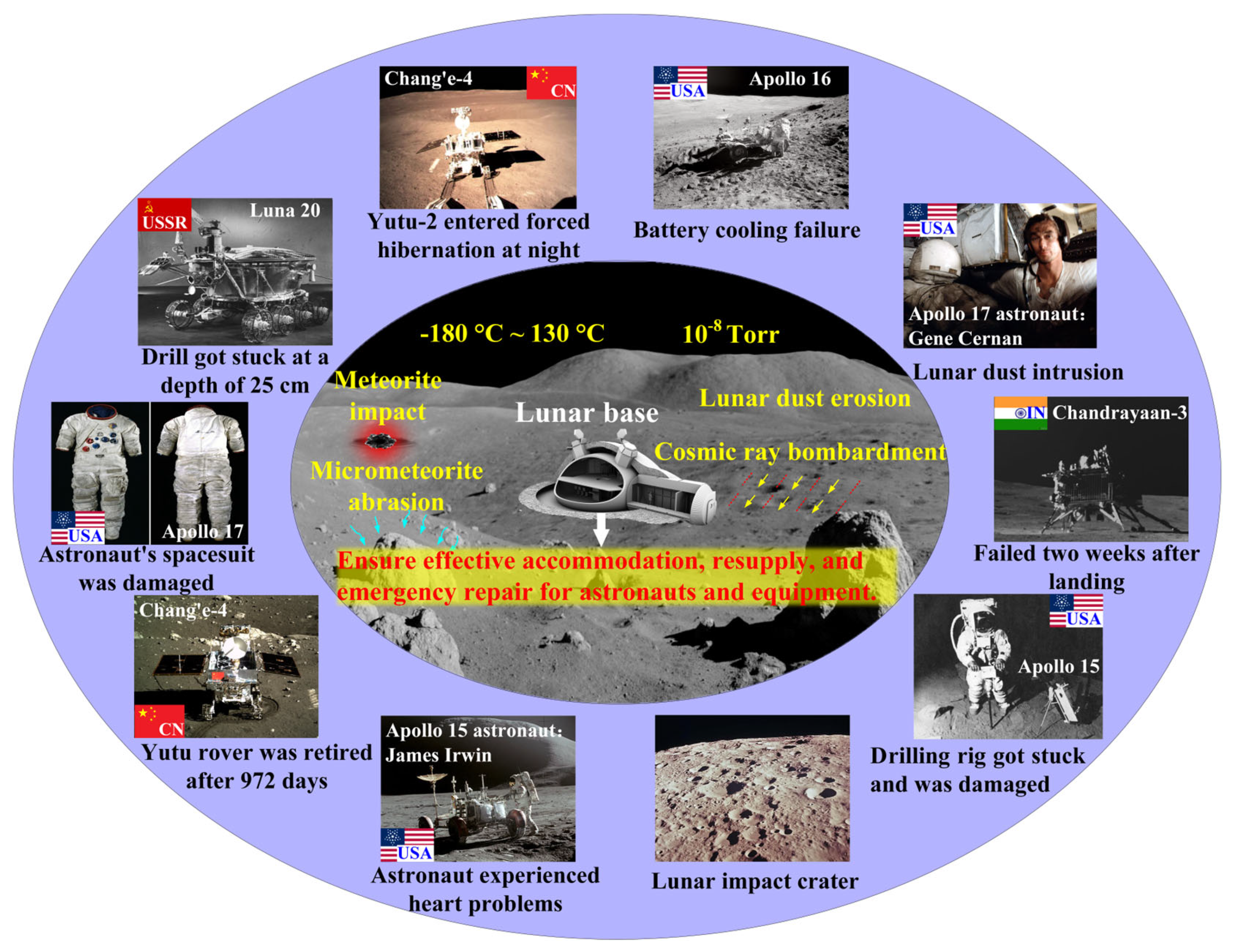

1. Introduction

2. Solidification Technologies of Lunar Regolith-Based Building Materials

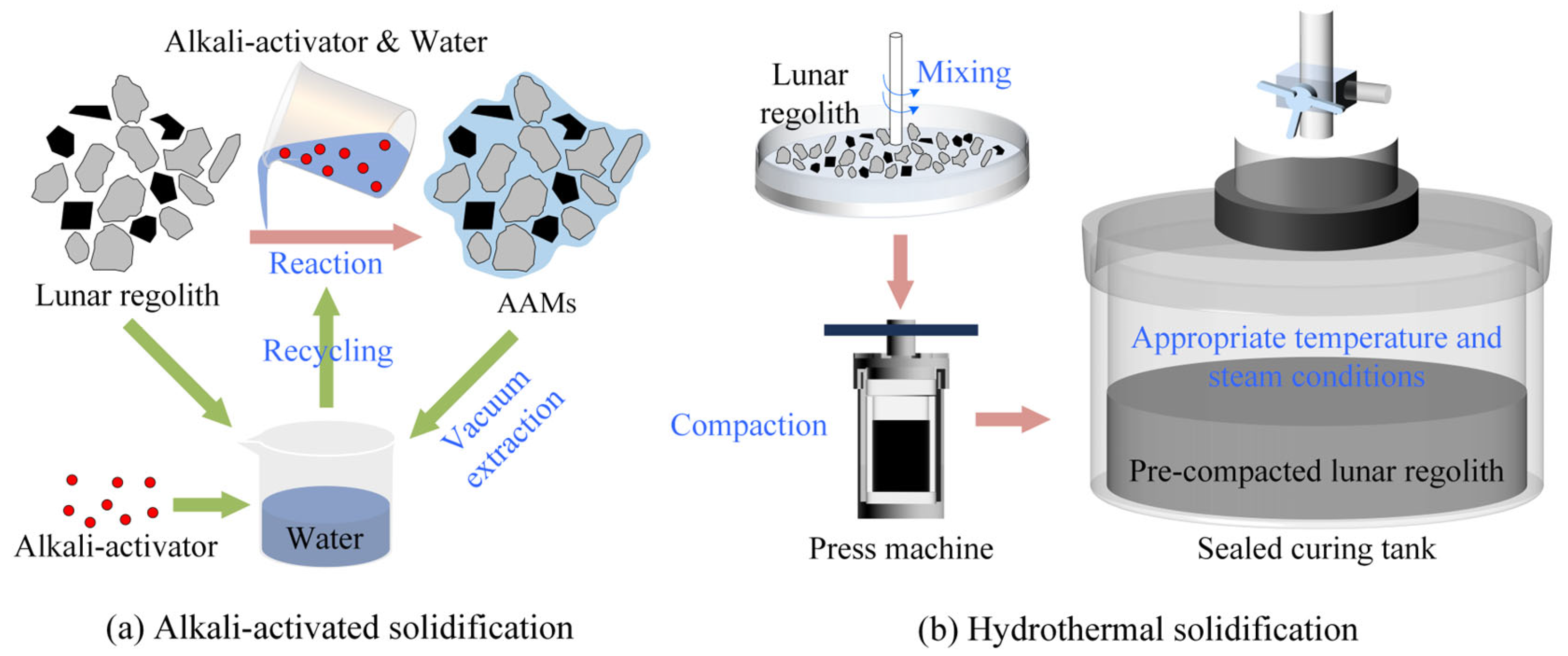

2.1. Reaction Solidification

2.1.1. Alkali-Activated Solidification

2.1.2. Hydrothermal Solidification

2.2. Sintering/Melting Solidification

2.3. Bonding Solidification

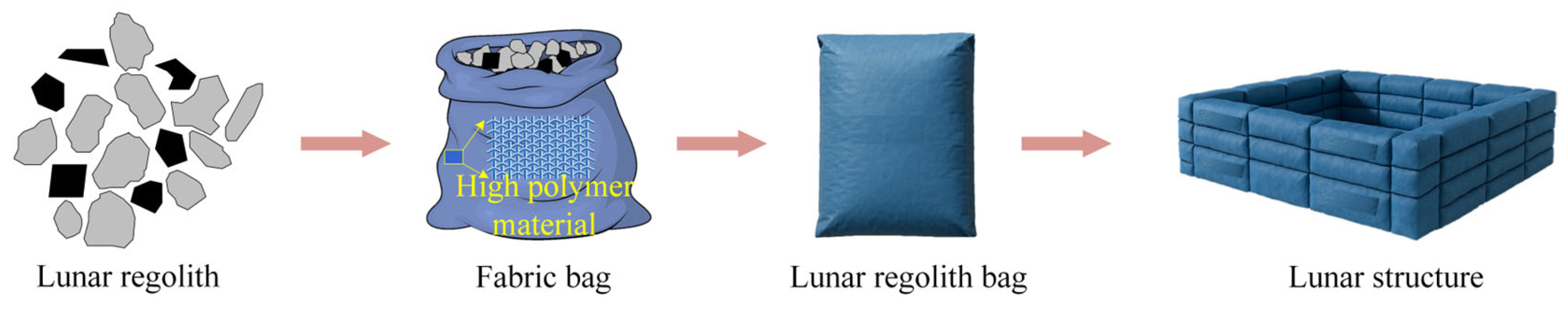

2.4. Confinement Formation

2.5. Discussion of Solidification Technologies

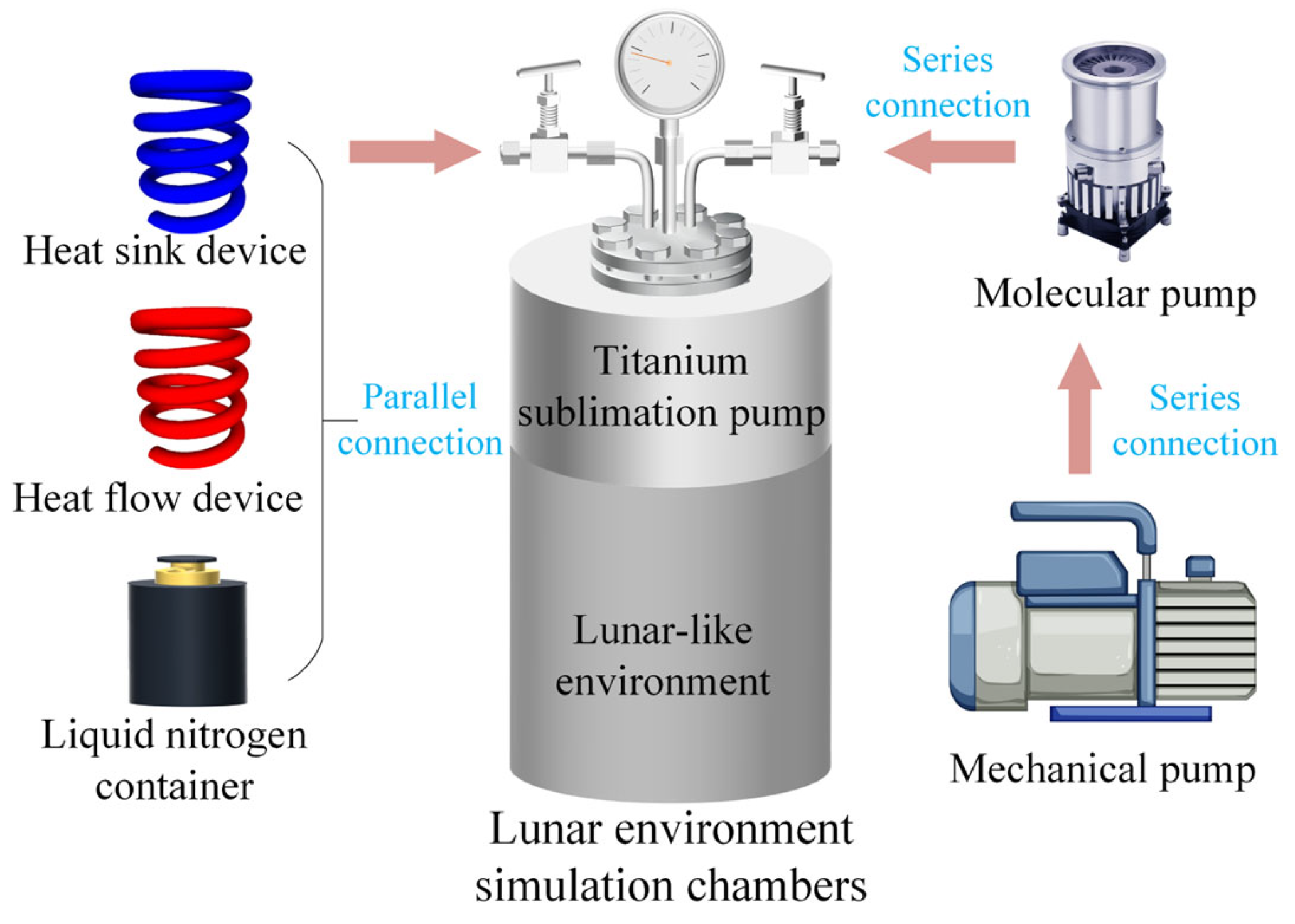

3. Lunar Environment Simulation Technologies

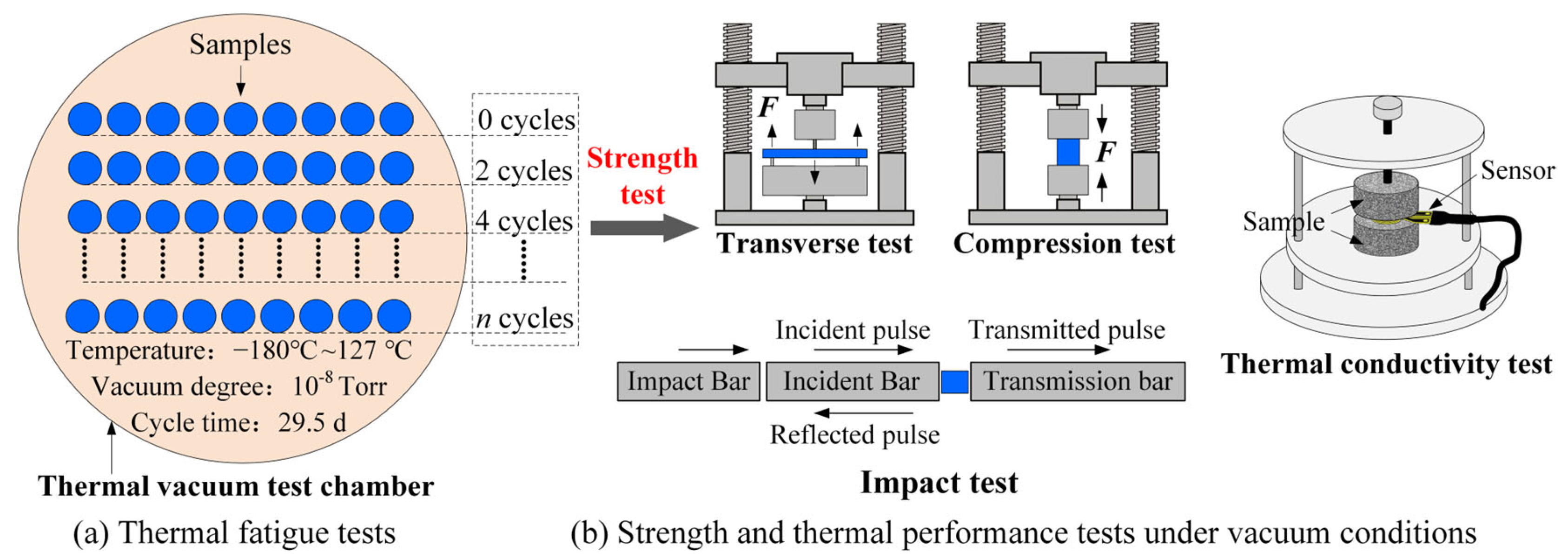

3.1. Thermal Vacuum Simulation Technology

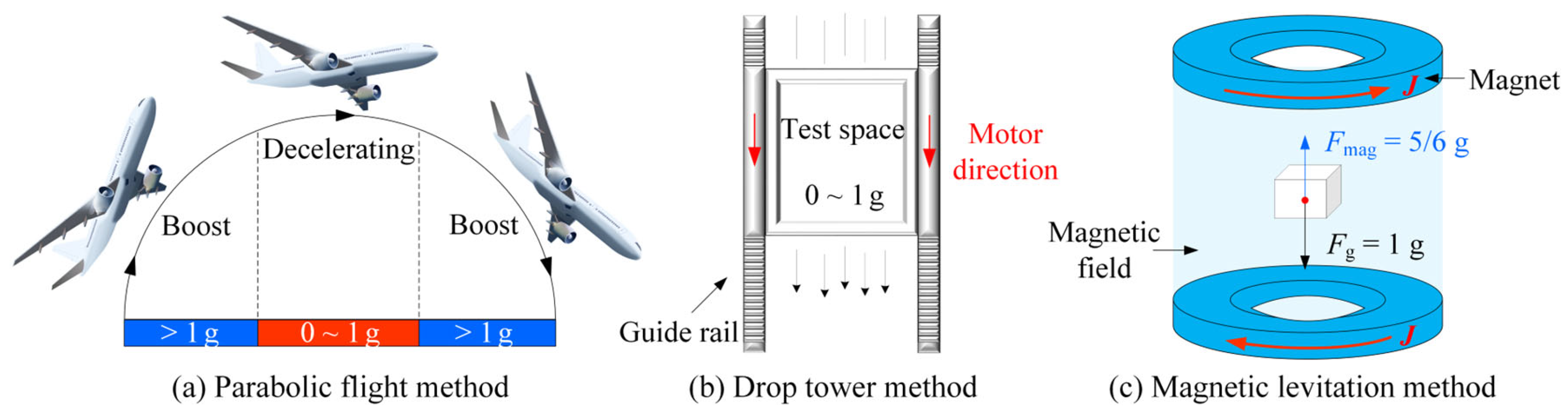

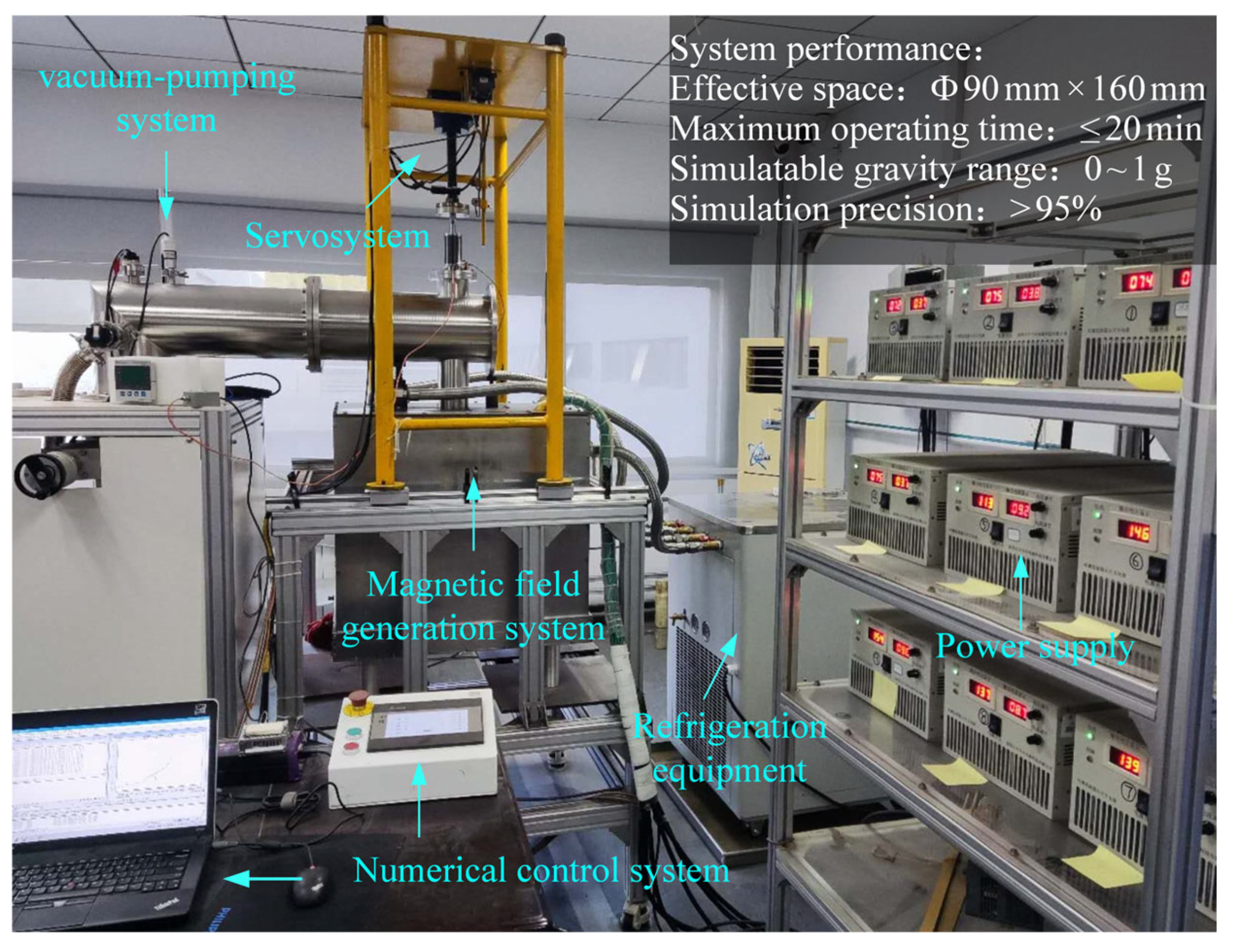

3.2. 1/6 g Gravity Simulation Technology

3.3. Discussion of Lunar Environment Simulation Technologies

4. Comprehensive Lunar Environment Simulation System

4.1. System Development Overview

4.2. System Performance

4.3. Future Application Plans

5. Conclusions

- Reaction solidification offers the advantage of rapid curing; however, it requires substantial additives, depends on specific temperature and pressure conditions during curing, and the durability of the newly formed chemical bonds under the extreme lunar environment may face significant challenges.

- Melting solidification directly utilizes lunar soil as a construction material without the need for additional Earth-supplied materials, leading to low preparation costs and high durability. Its major drawback lies in the challenges of thermal management in the ultra-high vacuum environment.

- Bonding solidification provides an efficient and controllable curing process, yet it suffers from relatively low solidification strength and limited durability of bonding agents, particularly organic adhesives, under harsh lunar surface conditions.

- Confinement formation achieves the fastest curing and allows for efficient reconfiguration. However, this method faces challenges in realizing complex architectural forms, and the durability of regolith bags is limited by micrometeorite abrasion and damage from cosmic radiation.

- It is important to note that these conclusions are primarily drawn from existing ground-based or thermal vacuum experiments. The performance and applicability of these four methods under lunar gravity conditions remain inadequately validated. The absence of reliable and stable low-gravity simulation technologies represents a critical bottleneck for further in situ assessment and development of these solidification techniques.

Author Contributions

Funding

Conflicts of Interest

References

- Heiken, G.; Vaniman, D.; French, B.M. Lunar Sourcebook: A User’s Guide to the Moon; Cambridge University Press: Cambridge, UK, 1991. [Google Scholar]

- Anand, M.; Crawford, I.A.; Balat-Pichelin, M.; Abanades, S.; Van Westrenen, W.; Péraudeau, G.; Jaumann, R.; Seboldt, W. A brief review of chemical and mineralogical resources on the Moon and likely initial in situ resource utilization (ISRU) applications. Planet. Space Sci. 2012, 74, 42–48. [Google Scholar] [CrossRef]

- Schrunk, D.G.; Sharpe, B.L.; Cooper, B.L.; Thangavelu, M. The Moon: Resources, Future Development, and Settlement; Praxis: New York, NY, USA, 2007. [Google Scholar]

- Crawford, I.A. Lunar Resources: A Review. Prog. Phys. Geogr. 2015, 39, 137–167. [Google Scholar] [CrossRef]

- Li, S.; Lucey, P.G.; Milliken, R.E.; Hayne, P.O.; Fisher, E.; Williams, J.P.; Hurley, D.M.; Elphic, R.C. Direct evidence of surface exposed water ice in the lunar polar regions. Proc. Natl. Acad. Sci. USA 2018, 115, 8907–8912. [Google Scholar] [CrossRef]

- Feldman, W.C.; Maurice, S.; Lawrence, D.J.; Little, R.C.; Lawson, S.L.; Gasnault, O.; Wiens, R.C.; Barraclough, B.L.; Elphic, R.C.; Prettyman, T.H.; et al. Evidence for Water Ice near the Lunar Poles. J. Geophys. Res. Planets 2001, 106, 23231–23251. [Google Scholar] [CrossRef]

- Anand, M. Lunar Water: A Brief Review. Earth Moon Planets 2010, 107, 65–73. [Google Scholar] [CrossRef]

- Borowitz, M.; Noonan, A.; El Ghazal, R. US Strategic Interest in the Moon: An Assessment of Economic, National Security, and Geopolitical Drivers. Space Policy 2024, 69, 101548. [Google Scholar] [CrossRef]

- Li, C.; Wang, C.; Wei, Y.; Lin, Y. China’s Present and Future Lunar Exploration Program. Science 2019, 365, 238–239. [Google Scholar] [CrossRef]

- Messina, P.; Vennemann, D. The European Space Exploration Programme: Current Status of ESA’s Plans for Moon and Mars Exploration. Acta Astronaut. 2005, 57, 156–160. [Google Scholar] [CrossRef]

- Harvey, B.; Zakutnyaya, O. Russian Space Probes: Scientific Discoveries and Future Missions; Springer: New York, NY, USA, 2011; pp. 301–374. [Google Scholar]

- Hashimoto, T.; Hoshino, T.; Tanaka, S.; Otake, H.; Otsuki, M.; Wakabayashi, S.; Morimoto, H.; Masuda, K. Introduction to Japanese Exploration Study to the Moon. Acta Astronaut. 2014, 104, 545–551. [Google Scholar] [CrossRef]

- Davies, P.; Phipps, A.; Taylor, M.; da Silva Curiel, A.; Baker, A.; Gao, Y.; Sweeting, M.; Parker, D.; Crawford, I.A.; Ball, A.J.; et al. UK Lunar Science Missions: Moonlite & Moonraker. In Proceedings of the 3rd International Conference on Recent Advances in Space Technologies, Istanbul, Türkiye, 14–16 June 2007; pp. 774–779. [Google Scholar]

- Mane, S. Chandrayaan-2: India’s Lunar Exploration Mission to the Moon. Int. J. All Res. Educ. Sci. Methods 2023, 11, 1116–1123. [Google Scholar]

- Gibney, E. First Private Moon Lander Sparks New Lunar Space Race. Nature 2019, 566, 434–436. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.; Craig, D.; Herrmann, N.; Mahoney, E.; Krezel, J.; McIntyre, N.; Goodliff, K. The Artemis Program: An Overview of NASA’s Activities to Return Humans to the Moon. In Proceedings of the 2020 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2020; pp. 1–10. [Google Scholar]

- Xu, L.; Li, H.; Pei, Z.; Zou, Y.; Wang, C. A Brief Introduction to the International Lunar Research Station Program and the Interstellar Express Mission. Chin. J. Space Sci. 2022, 42, 511–513. [Google Scholar] [CrossRef]

- Vaniman, D.; Reedy, R.; Heiken, G.; Olhoeft, G.; Mendell, W. The Lunar Environment. In Lunar Sourcebook; Heiken, G.H., Vaniman, D.T., French, B.M., Eds.; Cambridge University Press: Cambridge, UK, 1991; Volume 1, pp. 27–60. [Google Scholar]

- Benaroya, H. Lunar Habitats: A Brief Overview of Issues and Concepts. REACH 2017, 7, 14–33. [Google Scholar] [CrossRef]

- Rowe, W.J. Extraordinary Hypertension after a Lunar Mission. Am. J. Med. 2009, 122, e1. [Google Scholar] [CrossRef]

- Delp, M.D.; Charvat, J.M.; Limoli, C.L.; Globus, R.K.; Ghosh, P. Apollo Lunar Astronauts Show Higher Cardiovascular Disease Mortality: Possible Deep Space Radiation Effects on the Vascular Endothelium. Sci. Rep. 2016, 6, 29901. [Google Scholar] [CrossRef]

- Anttila, M. Concept Evaluation of Mars Drilling and Sampling Instrument. Master’s Thesis, Helsinki University of Technology, Espoo, Finland, 2005. [Google Scholar]

- Gaier, J.R. The Effects of Lunar Dust on EVA Systems During the Apollo Missions; NASA/TM-2005-213610/REV1; NASA: Greenbelt, MD, USA, 2007. [Google Scholar]

- Cain, J.R. Lunar Dust: The Hazard and Astronaut Exposure Risks. Earth Moon Planets 2010, 107, 107–125. [Google Scholar] [CrossRef]

- Gao, M.; Wang, X.; Zhang, G.; Li, M.; Liu, T.; Hao, H.; Zhang, Z.; Xie, H. The Novel Idea and Technical Progress of Lunar In-Situ Condition Preserved Coring. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 46. [Google Scholar] [CrossRef]

- Benaroya, H.; Bernold, L.; Chua, K.M. Engineering, Design and Construction of Lunar Bases. J. Aerosp. Eng. 2002, 15, 33–45. [Google Scholar] [CrossRef]

- Benaroya, H.; Bernold, L. Engineering of Lunar Bases. Acta Astronaut. 2008, 62, 277–299. [Google Scholar] [CrossRef]

- Gibney, E. How to Build a Moon Base. Nature 2018, 562, 474–478. [Google Scholar] [CrossRef]

- Sherwood, B. Principles for a Practical Moon Base. Acta Astronaut. 2019, 160, 116–124. [Google Scholar] [CrossRef]

- Marov, M.Y.; Slyuta, E.N. Early Steps toward the Lunar Base Deployment: Some Prospects. Acta Astronaut. 2021, 181, 28–39. [Google Scholar] [CrossRef]

- Isachenkov, M.; Chugunov, S.; Akhatov, I.; Shishkovsky, I. Regolith-Based Additive Manufacturing for Sustainable Development of Lunar Infrastructure-An Overview. Acta Astronaut. 2021, 180, 650–678. [Google Scholar] [CrossRef]

- Bao, C.; Zhang, D.; Wang, Q.; Cui, Y.; Feng, P. Lunar In Situ Large-Scale Construction: Quantitative Evaluation of Regolith Solidification Techniques. Engineering 2024, 39, 204–221. [Google Scholar] [CrossRef]

- Li, C.; Hu, H.; Yang, M.F.; Pei, Z.Y.; Zhou, Q.; Ren, X.; Liu, B.; Liu, D.; Zeng, X.; Zhang, G.; et al. Characteristics of the Lunar Samples Returned by the Chang’E-5 Mission. Natl. Sci. Rev. 2022, 9, nwab188. [Google Scholar] [CrossRef]

- Zhou, S.; Lu, C.; Zhu, X.; Li, F. Preparation and Characterization of High-Strength Geopolymer Based on BH-1 Lunar Soil Simulant with Low Alkali Content. Engineering 2021, 7, 1631–1645. [Google Scholar] [CrossRef]

- Li, R.; Zhou, G.; Yan, K.; Chen, J.; Chen, D.; Cai, S.; Mo, P.Q. Preparation and characterization of a specialized lunar regolith simulant for use in lunar low gravity simulation. Int. J. Min. Sci. Technol. 2022, 32, 1–15. [Google Scholar] [CrossRef]

- Alexiadis, A.; Alberini, F.; Meyer, M.E. Geopolymers from Lunar and Martian Soil Simulants. Adv. Space Res. 2017, 59, 490–495. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, L.; Pan, H.; She, W.; Zhou, C.; Zhou, H.; Yu, Z.; Xu, Z. In-Situ Solidification of Alkali-Activated Lunar Regolith: Insights into the Chemical and Physical Origins. J. Clean. Prod. 2023, 391, 136147. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, Y.; Fu, S.; He, P.; Sun, C.; Duan, X.; Zhang, X.; Zhou, Y. 3D-Printed Lunar Regolith Simulant-Based Geopolymer Composites with Bio-Inspired Sandwich Architectures. J. Adv. Ceram. 2023, 12, 510–525. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, Z.; Zhang, R.; Zhu, X.; Li, F. Preparation and Evaluation of Geopolymer Based on BH-2 Lunar Regolith Simulant under Lunar Surface Temperature and Vacuum Condition. Acta Astronaut. 2021, 189, 90–98. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, S.; Li, F. Preparation of Geopolymer Based on Lunar Regolith Simulant at In-Situ Lunar Temperature and Its Durability under Lunar High and Cryogenic Temperature. Constr. Build. Mater. 2022, 318, 126033. [Google Scholar] [CrossRef]

- Zhou, S.; Zhu, X.; Lu, C.; Li, F. Synthesis and Characterization of Geopolymer from Lunar Regolith Simulant Based on Natural Volcanic Scoria. Chin. J. Aeronaut. 2022, 35, 144–159. [Google Scholar] [CrossRef]

- Gu, J.; Ma, Q. Experimental Study on Geopolymerization of Lunar Soil Simulant under Dry Curing and Sealed Curing. Materials 2024, 17, 1413. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C.; Liu, H.; Chen, X.; Li, X.; Wang, T.; Wang, Y.; Zhang, W.; Wu, Y. Multiscale Study of Microstructural Evolution in Alkali-Activated Lunar Regolith Simulant under In-Situ Lunar Temperatures: Insight into the Reaction Mechanism. J. Build. Eng. 2025, 103, 112209. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C.; Zhang, W.; Liu, H.; Wang, T.; Wu, Y.; Li, X.; Chen, X. Influence of Vacuum and High-Temperature on the Evolution of Mechanical Strength and Microstructure of Alkali-Activated Lunar Regolith Simulant. J. Build. Eng. 2024, 97, 110709. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C.; Zhang, W.; Liu, H.; Zhu, C. Influence of In-Situ Lunar Temperature on the Pore Structure and Solid Phases of Alkali-Activated Lunar Regolith Simulant. J. Build. Eng. 2024, 98, 111162. [Google Scholar] [CrossRef]

- Khalifa, A.Z.; Cizer, Ö.; Pontikes, Y.; Heath, A.; Patureau, P.; Bernal, S.A.; Marsh, A.T. Advances in Alkali-Activation of Clay Minerals. Cem. Concr. Res. 2020, 132, 106050. [Google Scholar] [CrossRef]

- Jing, Y.; Zhang, Y.; Zhang, L.; Wang, Q. The Design of a Novel Alkali-Activated Binder for Solidifying Silty Soft Clay and the Study of Its Solidification Mechanism. Materials 2024, 17, 2177. [Google Scholar] [CrossRef]

- Obenaus-Emler, R.; Falah, M.; Illikainen, M. Assessment of Mine Tailings as Precursors for Alkali-Activated Materials for On-Site Applications. Constr. Build. Mater. 2020, 246, 118470. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, M.; Chen, C.; Yuan, Z.; Geng, X.; Yang, S. Solidification of Uranium Tailings Using Alkali-Activated Slag Mixed with Natural Zeolite. Nucl. Eng. Technol. 2023, 55, 523–529. [Google Scholar] [CrossRef]

- Zhao, S.; Muhammad, F.; Yu, L.; Xia, M.; Huang, X.; Jiao, B.; Li, D. Solidification/Stabilization of Municipal Solid Waste Incineration Fly Ash Using Uncalcined Coal Gangue-Based Alkali-Activated Cementitious Materials. Environ. Sci. Pollut. Res. 2019, 26, 25609–25620. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Wu, Z.; Wang, B.; Zheng, W. Solidification of Municipal Solid Waste Incineration Fly Ash with Alkali-Activated Technology. J. Environ. Manag. 2023, 348, 119404. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.T.; Lemougna, P.N.; Tang, Q.; Li, W.; Cui, X.M. Lunar Regolith Can Allow the Synthesis of Cement Materials with Near-Zero Water Consumption. Gondwana Res. 2017, 44, 1–6. [Google Scholar] [CrossRef]

- Pakulski, D.M.; Knox, K.J. Steam Injection System for Lunar Concrete. In Proceedings of the Engineering, Construction, and Operations in Space III, Denver, CO, USA, 31 May–4 June 1992; Volume 2, pp. 1347–1358. [Google Scholar]

- Lin, T.D.; Su, N. Concrete Construction on the Moon. In Proceedings of the Engineering, Construction, and Operations in Space III, Denver, CO, USA, 31 May–4 June 1992; Volume 2, pp. 1359–1369. [Google Scholar]

- Lin, T.D.; Tseng, L.; Chou, S. Lunar Concrete Made with the Dry-Mix/Steam-Injection Method. In Proceedings of the Engineering, Construction, and Operations in Space V, Albuquerque, NM, USA, 1–6 June 1996; Volume 5, pp. 592–599. [Google Scholar]

- Su, N.; Peng, Y.N. The Characteristics and Engineering Properties of Dry-Mix/Steam-Injection Concrete. Cem. Concr. Res. 2001, 31, 609–619. [Google Scholar] [CrossRef]

- Cai, L.; Ding, L.; Luo, H.; Yi, X. Preparation of Autoclave Concrete from Basaltic Lunar Regolith Simulant: Effect of Mixture and Manufacture Process. Constr. Build. Mater. 2019, 207, 373–386. [Google Scholar] [CrossRef]

- Wilhelm, S.; Curbach, M. Manufacturing of lunar concrete by steam. In Proceedings of the Earth and Space 2014, St. Louis, MO, USA, 27–29 October 2014; pp. 274–282. [Google Scholar]

- Altemir, D.A. Cold press sintering of simulated lunar basalt. In Proceedings of the Twenty-Fourth Lunar and Planetary Science Conference, Lunar and Planetary Institute, Houston, TX, USA, 15–19 March 1993; pp. 23–24. [Google Scholar]

- Indyk, S.J.; Benaroya, H. A structural assessment of unrefined sintered lunar regolith simulant. Acta Astronaut. 2017, 140, 517–536. [Google Scholar] [CrossRef]

- Han, W.; Ding, L.; Cai, L.; Zhu, J.; Luo, H.; Tang, T. Sintering of HUST-1 lunar regolith simulant. Constr. Build. Mater. 2022, 324, 126655. [Google Scholar] [CrossRef]

- Kim, Y.J.; Ryu, B.H.; Woo Jin, H.; Lee, J.; Shin, H.S. Microwave sintering of lunar regolith simulant for manufacturing building elements. In Proceedings of the Earth and Space 2021, Orlando, FL, USA, 29 March–1 April 2021; pp. 985–991. [Google Scholar]

- Liu, Z.; Li, J.; Yang, X.; Ding, Y.; Meng, S. Sintering of lunar regolith simulants using a domestic microwave: A rapid and energy-efficient strategy for construction material fabrication. J. Eur. Ceram. Soc. 2025, 45, 117047. [Google Scholar] [CrossRef]

- Balla, V.K.; Roberson, L.B.; O’Connor, G.W.; Trigwell, S.; Bose, S.; Bandyopadhyay, A. First Demonstration on Direct Laser Fabrication of Lunar Regolith Parts. Rapid Prototyp. J. 2012, 18, 451–457. [Google Scholar] [CrossRef]

- Fateri, M.; Gebhardt, A. Process Parameters Development of Selective Laser Melting of Lunar Regolith for On-Site Manufacturing Applications. Int. J. Appl. Ceram. Technol. 2015, 12, 46–52. [Google Scholar] [CrossRef]

- Meurisse, A.; Makaya, A.; Willsch, C.; Sperl, M. Solar 3D printing of lunar regolith. Acta Astronaut. 2018, 152, 800–810. [Google Scholar] [CrossRef]

- Fateri, M.; Meurisse, A.; Sperl, M.; Urbina, D.; Madakashira, H.K.; Govindaraj, S.; Gancet, J.; Imhof, B.; Hoheneder, W.; Waclavicek, R.; et al. Solar sintering for lunar additive manufacturing. J. Aerosp. Eng. 2019, 32, 04019101. [Google Scholar] [CrossRef]

- Ghosh, A.; Favier, J.J.; Harper, M.C. Solar sintering on lunar regolith simulant (JSC-1) for 3D printing. Proc. Int. Astronaut. Congr. (IAC) 2016, 2, 1195–1203. [Google Scholar]

- Imhof, B.; Urbina, D.; Weiss, P.; Sperl, M.; Hoheneder, W.; Waclavicek, R.; Madakashira, H.; Salini, J.; Govindaraj, S.; Gancet, J.; et al. Advancing solar sintering for building a base on the Moon. In Proceedings of the 69th International Astronautical Congress (IAC), Adelaide, Australia, 25–29 September 2017; pp. 25–29. [Google Scholar]

- Meurisse, A.; Beltzung, J.C.; Kolbe, M.; Cowley, A.; Sperl, M. Influence of Mineral Composition on Sintering Lunar Regolith. J. Aerosp. Eng. 2017, 30, 04017014. [Google Scholar] [CrossRef]

- Song, L.; Xu, J.; Fan, S.; Tang, H.; Li, X.; Liu, J.; Duan, X. Vacuum Sintered Lunar Regolith Simulant: Pore-Forming and Thermal Conductivity. Ceram. Int. 2019, 45, 3627–3633. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Bodiford, M.P.; Burks, K.H.; Ethridge, E.; Tucker, D.; Kim, W.; Toutanji, H.; Fiske, M.R. Lunar Contour Crafting: A Novel Technique for ISRU-Based Habitat Development. In Proceedings of the AIAA 43rd Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. AIAA Paper 2005-2424. [Google Scholar]

- Toutanji, H.A.; Evans, S.; Grugel, R.N. Performance of lunar sulfur concrete in lunar environments. Constr. Build. Mater. 2012, 29, 444–448. [Google Scholar] [CrossRef]

- Edmunson, J.; Fiske, M.R.; Mueller, R.P.; Alkhateb, H.S.; Akhnoukh, A.K.; Morris, H.C.; Townsend, I.I.; Fikes, J.C.; Johnston, M.M. Additive Construction with Mobile Emplacement: Multifaceted Planetary Construction Materials Development. In Proceedings of the 16th Biennial International Conference on Engineering, Science, Construction, and Operations in Challenging Environment, Cleveland, OH, USA, 9–12 April 2018; pp. 782–792. [Google Scholar]

- Roedel, H.; Lepech, M.D.; Loftus, D.J. Protein-Regolith Composites for Space Construction. In Proceedings of the Earth and Space 2014, St. Louis, MO, USA, 27–29 October 2014; pp. 291–300. [Google Scholar]

- Lee, T.S.; Lee, J.; Ann, K.Y. Manufacture of polymeric concrete on the Moon. Acta Astronaut. 2015, 114, 60–64. [Google Scholar] [CrossRef]

- Rosa, I.; Lepech, M.D.; Loftus, D.J. Multiscale Modeling and Testing of Protein-Bound Regolith and Soils. In Proceedings of the 16th Biennial International Conference on Engineering, Science, Construction, and Operations in Challenging Environments, Cleveland, OH, USA, 9–12 April 2018; pp. 580–590. [Google Scholar]

- Brown, S.; Lundberg, K.; McGarity, G.; Silverman, P. Lunar Regolith Bagging System; Report No. TEX-4312/ME-4182; NASA: Greenbelt, MD, USA, 1990. [Google Scholar]

- Smithers, G.A.; Nehls, M.K.; Hovater, M.A.; Evans, S.W.; Miller, J.S.; Broughton, R.M., Jr.; Beale, D.; Kilinc-Balci, F. A One-Piece Lunar Regolith Bag Garage Prototype; No. NASA/TM-2007-215073; NASA: Greenbelt, MD, USA, 2007. [Google Scholar]

- Ruess, F.; Zacny, K.; Braun, B. Lunar in-situ resource utilization: Regolith bags automated filling technology. In Proceedings of the AIAA SPACE 2008 Conference and Exposition, San Diego, CA, USA, 9–11 September 2008; p. 7678. [Google Scholar]

- Gosau, J.M. Regolith Stabilization and Building Materials for the Lunar Surface. In Earth and Space 2012: Engineering, Science, Construction, and Operations in Challenging Environments; American Society of Civil Engineers: New York, NY, USA, 2012; pp. 243–249. [Google Scholar]

- Bao, C.; Feng, P.; Zhang, D.; Wang, Q.; Yang, S. Conceptual design and experimental investigation of regolith bag structures for lunar in situ construction. J. Build. Eng. 2024, 95, 110245. [Google Scholar] [CrossRef]

- Pilehvar, S.; Arnhof, M.; Erichsen, A.; Valentini, L.; Kjøniksen, A.L. Investigation of severe lunar environmental conditions on the physical and mechanical properties of lunar regolith geopolymers. J. Mater. Res. Technol. 2021, 11, 1506–1516. [Google Scholar] [CrossRef]

- Kaufmann, E.; Kömle, N.I.; Kargl, G. Laboratory simulation experiments on the solid-state greenhouse effect in planetary ices. Icarus 2006, 185, 274–286. [Google Scholar] [CrossRef]

- Mateo-Martí, E.; Prieto-Ballesteros, O.; Sobrado, J.M.; Gómez-Elvira, J.; Martín-Gago, J.A. A chamber for studying planetary environments and its applications to astrobiology. Meas. Sci. Technol. 2006, 17, 2274. [Google Scholar] [CrossRef]

- Craven, P.; Vaughn, J.; Schneider, T.; Norwood, J.; Abbas, M.; Alexander, R. MSFC lunar environments test system (LETS) system development. In Proceedings of the Third Lunar Regolith Simulant Workshop, Huntsville, AL, USA, 17–20 March 2009. No. M09-0391. [Google Scholar]

- Kleiman, J.; Horodetsky, S.; Issoupov, V. A planetary environmental simulator/test facility. In Protection of Materials and Structures from the Space Environment; Springer: Berlin/Heidelberg, Germany, 2013; pp. 355–370. [Google Scholar]

- Rabbow, E.; Parpart, A.; Reitz, G. The planetary and space simulation facilities at DLR Cologne. Microgravity Sci. Technol. 2016, 28, 215–229. [Google Scholar] [CrossRef]

- Prasad, K.D.; Murty, S.V.S. Development of a chamber to simulate lunar surface environment. Planet. Space Sci. 2020, 191, 105038. [Google Scholar] [CrossRef]

- Johnson, S.W.; Lee, D.J.; Pyrz, A.P.; Thompson, J.E. Simulating the effects of gravitational field and atmosphere on behavior of granular media. J. Spacecr. Rocket. 1970, 7, 1311–1317. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Ding, X.; Xu, K.; Guan, Y. Thermal vacuum regolith environment simulator for China’s deep lunar drilling exploration. Appl. Therm. Eng. 2018, 144, 779–787. [Google Scholar] [CrossRef]

- Haber, F.R.; Haber, H.E. Possible methods of producing the gravity-free state for medical research. J. Aviat. Med. 1950, 21, 395–400. [Google Scholar]

- Comstock, D.; Petro, A. Reduced Gravity Technology Demonstration Results from NASA’s FAST Program and Future Plans. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 188. [Google Scholar]

- Hrvatin, E. Biomechanics in weightlessness. PAJ J. Perform. Art 2002, 24, 102–107. [Google Scholar] [CrossRef]

- Kirkpatrick, A.W.; Keaney, M.A.; Bentz, K.; Groleau, M.; Tyssen, M.; Keyte, J.; Broderick, T.J. The use of the National Research Council of Canada’s Falcon 20 Research Aircraft as a Terrestrial Analogue Space Environment (TASE) for space surgery research: Challenges and suggested solutions. Planet. Space Sci. 2010, 58, 717–723. [Google Scholar] [CrossRef]

- Liu, T.Y.; Wu, Q.P.; Sun, B.Q.; Han, F.T. Microgravity level measurement of the Beijing drop tower using a sensitive accelerometer. Sci. Rep. 2016, 6, 31632. [Google Scholar] [CrossRef]

- Marchese, A.J.; Dryer, F.L.; Colantonio, R.O.; Nayagam, V. Microgravity combustion of methanol and methanol/water droplets: Drop tower experiments and model predictions. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1996; Volume 26, pp. 1209–1217. [Google Scholar]

- Selig, H.; Dittus, H.; Lämmerzahl, C. Drop tower microgravity improvement towards the nano-g level for the MICROSCOPE payload tests. Microgravity Sci. Technol. 2010, 22, 539–549. [Google Scholar] [CrossRef]

- Takamasa, T. Research on gas-liquid two-phase flow using the JAMIC drop shaft. J. Jpn. Soc. Microgravity Appl. 2000, 17, 121. [Google Scholar]

- Li, R.; Zhou, G.; Chen, G.; Hall, M.R.; Zhao, X. Geotechnical magnetic-similitude-gravity model testing method. Int. J. Phys. Model. Geotech. 2019, 19, 181–199. [Google Scholar] [CrossRef]

- Sanavandi, H.; Guo, W. A magnetic levitation based low-gravity simulator with an unprecedented large functional volume. npj Microgravity 2021, 7, 40. [Google Scholar] [CrossRef] [PubMed]

- Geim, A. Everyone’s magnetism: Though it seems counterintuitive, today’s research magnets can easily levitate seemingly nonmagnetic objects, thereby opening an Earthbound door to microgravity conditions. Phys. Today 1998, 51, 36–39. [Google Scholar] [CrossRef]

- Mo, P.Q.; Gao, F.; Zhou, G.; Li, R.; Yan, K.; Chen, J. An Experimental Study on Triaxial Compression Tests and Cone Penetration Tests in Planetary Regolith Simulant under Low Gravity Fields. J. Test. Eval. 2019, 47, 1677–1700. [Google Scholar] [CrossRef]

- Li, R.; Chen, J.; Zhang, J.; Chen, D.; Zhao, X.; Mo, P.Q.; Zhou, G. Cone penetration resistance of CUMT-1 lunar regolith simulant under magnetic-similitude lunar gravity condition. Acta Geotech. 2023, 18, 6725–6744. [Google Scholar] [CrossRef]

| Oxide | Apollo12 | Apollo14 | Apollo15 | Apollo16 | Chang’e-5 | JSC-1 | CUMT-1 | BH-1 |

|---|---|---|---|---|---|---|---|---|

| SiO2 | 42.20 | 46.30 | 48.10 | 46.80 | 42.20 | 47.71 | 42.68 | 43.3 |

| TiO2 | 7.80 | 3.00 | 1.70 | 1.20 | 5.00 | 1.59 | 1.31 | 2.90 |

| Al2O3 | 13.60 | 12.90 | 17.40 | 14.60 | 10.80 | 15.02 | 15.20 | 16.50 |

| FeO | 15.30 | 15.10 | 10.40 | 14.30 | 22.50 | 10.79 | 26.76 | 16.70 |

| MnO | 0.20 | 0.22 | 0.14 | 0.19 | 0.28 | 0.18 | 0.11 | 0.30 |

| MgO | 7.80 | 9.30 | 9.40 | 11.50 | 6.48 | 9.01 | 3.44 | 3.00 |

| CaO | 11.90 | 10.70 | 10.70 | 10.80 | 11.00 | 10.42 | 5.62 | 8.80 |

| Na2O | 0.47 | 0.54 | 0.70 | 0.39 | 0.26 | 2.70 | 3.23 | 3.80 |

| K2O | 0.16 | 0.31 | 0.55 | 0.21 | 0.19 | 0.82 | 0.00 | 3.30 |

| P2O5 | 0.05 | 0.40 | 0.51 | 0.18 | 0.23 | 0.66 | 0.13 | 0.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, R. Advances in Solidification Technologies of Lunar Regolith-Based Building Materials Under Extreme Lunar Environments. Buildings 2025, 15, 2543. https://doi.org/10.3390/buildings15142543

Chen J, Li R. Advances in Solidification Technologies of Lunar Regolith-Based Building Materials Under Extreme Lunar Environments. Buildings. 2025; 15(14):2543. https://doi.org/10.3390/buildings15142543

Chicago/Turabian StyleChen, Jun, and Ruilin Li. 2025. "Advances in Solidification Technologies of Lunar Regolith-Based Building Materials Under Extreme Lunar Environments" Buildings 15, no. 14: 2543. https://doi.org/10.3390/buildings15142543

APA StyleChen, J., & Li, R. (2025). Advances in Solidification Technologies of Lunar Regolith-Based Building Materials Under Extreme Lunar Environments. Buildings, 15(14), 2543. https://doi.org/10.3390/buildings15142543