Abstract

Timber–concrete composite (TCC) floors are gaining popularity in sustainable construction due to their enhanced stiffness and structural efficiency. However, excessive vibrations, particularly those induced by human activity, pose significant challenges to occupant comfort and structural integrity. This study investigates the application of Tuned Mass Dampers (TMDs) to mitigate vibrations in TCC floors, with a focus on enhancing damping performance through the incorporation of pre-strained Shape Memory Alloys (SMAs) (Kellogg’s Research Labs, New Boston, NH, USA). A novel pre-strained SMA–TMD system was designed and experimentally tested to evaluate its effectiveness in vibration control under various loading conditions. The results demonstrate that pre-straining significantly increases the damping ratio of the SMA–TMD, improving its vibration mitigation capability. Compared to non-pre-strained SMA–TMD, the pre-strained SMA–TMD system exhibited superior adaptability and robustness in reducing floor vibrations, achieving a peak acceleration reduction of up to 49.91%. These findings provide valuable knowledge into the development of advanced damping solutions for timber floors, contributing to the broader application of vibration control strategies in sustainable and high-performance building systems.

1. Introduction

With the continuous deepening of the global concept of green development, green buildings, as an important area promoting sustainable development, are receiving widespread attention. Among them, the renewability, low-carbon footprint, and aesthetic practicality of timber structures are becoming key components of green buildings. However, in practical use, timber structures, particularly timber floors, face significant challenges in terms of comfort. Vibration issues not only affect comfort but may also have adverse effects on the habitability and safety of buildings. Vibration control technology, as a critical safeguard for the safety and comfort of engineering structures, has received significant attention in recent years across fields such as civil engineering, mechanical manufacturing, and aerospace. Energy dissipation devices have been widely studied, for instance, Nyabongo and Li [1] developed energy-early-dissipated braces based on the web buckling of I-beams. Traditional vibration control methods primarily include passive control, active control, and semi-active control. Among these, passive control is widely adopted due to its advantages of requiring no external energy input, simple structure, and low maintenance costs. The Tuned Mass Damper (TMD), a classic passive control device, achieves energy dissipation by attaching a substructure tuned to the vibration frequency of the primary structure. It has demonstrated remarkable effectiveness in vibration mitigation for high-rise buildings, bridges, and vehicles. However, traditional TMD designs still face limitations, such as high dependence on parameter tuning, insufficient environmental adaptability, and reduced efficiency in multi-modal vibration control. The introduction of novel materials and composite devices has recently opened new research directions for vibration control technology. For example, in the design of a diesel engine torsional shock absorber, the lumped parameter method is used to simplify the engine crankshaft model into a multi-mass system. In the free vibration analysis, after installing the damper, the frequency of the first- and second-order modes is reduced by 13.2% and 19.1%, respectively [2]. Based on particle damping technology, a dynamic vibration absorber (DVA) was proposed to suppress the vertical vibration of rolling rolls from the perspective of energy transfer and dissipation [3]. Yang [4] proposed a new type of shear-bending metal damper with a two-phase yield mechanism, which demonstrated excellent energy dissipation capacity. A novel damper with an external valve is designed and analyzed taking into account the multistage cyclic flow pattern and the vertical-specific distribution of the magnetic field through the circumferential channel [5]. Khalfi [6] established a vibration model of simply supported laminated plates with local viscoelastic constraint damping layers and applied it under impact loads. This study proposes a TMD vibration mitigation method based on a pre-strained Shape Memory Alloy-integrated Tuned Mass Damper (SMA–TMD). By leveraging the high damping characteristics of pre-strained SMA, this approach aims to reduce the sensitivity of traditional TMDs to mass, stiffness, and damping coefficient tuning while enhancing adaptability to environmental variations. The study seeks to provide innovative insights into the design and optimization of vibration control systems, advancing the application of smart materials in engineering vibration mitigation.

1.1. Overview of Research in Timber Floor Vibration

Timber is a widely used structural material, particularly for residential and low-rise commercial applications. The vibration of floor slabs is closely related to their inherent properties. Increasing the stiffness of timber floors can significantly improve their vibration behavior. By adding a concrete layer on top of the original timber floor, the stiffness of the floor increases, resulting in a noticeable improvement in its natural frequency. The natural frequency of timber floors was studied by Jarnerö et al. [7] through the in situ test of the vibration of timber floors, it was found that the natural frequency of the floor slab is highly dependent on the boundary conditions and the damping characteristics of the supports. The damping ratio ζ can be used to quantify damping. Eurocode 5 (CEN 2004) [8] states that for floor slabs, unless other values are proven to be more suitable, the modal damping ratio should be taken as g = 0.01 (which is 1.00%). For example, Hu et al. [9] reported that for timber floors, the ζ value ranges from 1.00% to 4.00%, with typical values between 2.50% and 40.00%, which may be related to the laying method, test observations indicate that the duration of the free vibration response of timber floors is shorter than that of lightweight floors, reflecting a larger ζ value. Ebadi et al. [10] experimentally verified that the presence of people and furniture on the floor increases damping, thereby affecting the effective ζ value. Both humans and furniture have the ability to absorb vibrational kinetic energy. The results showed that the presence of people can increase the modal damping ratio several times, and the degree of this effect depends on the person’s position on the floor and the considered vibration mode. Saidi et al. [11] summarized the factors that affected floor vibration such as lightweight floor slabs, floors with lower stiffness that are close to the dominant natural frequency and are easily excited, and floors with low damping. They identified low damping as one of the main reasons for excessive floor vibration.

The boundary conditions of floor slabs (provided by supports such as walls, beams, or other connectors) are considered important factors affecting the vibration performance of the slabs [12,13,14,15]. The factors affecting the boundary conditions of timber floors can be divided into beam-to-slab connections, wall-to-slab connections, slab-to-slab connections, beam size, spacing, etc. For beam-to-slab connections, Shi et al. [16] and others proposed tests for glued-laminated timber–concrete composite beam connectors, which showed that compared to pure glued-laminated timber beams, the bending capacity and bending stiffness of timber–concrete composite beams were improved by 31.20% and 182.50%, respectively. Ljuggren and Agren [17,18] simulated the gradual change in natural frequency during construction by altering support conditions and adding different levels of line loads to the surface of the floor. Jarnerö et al. [19] concluded that the in situ conditions had a significant effect on the dynamic characteristics of the base floor. The influence on the damping ratio was greater than its effect on the natural frequency but it also had a noticeable impact on the mode shapes. Due to the superior structural and building physical properties, new timber floors typically feature an upper concrete layer to form TCC floors. The composite system based on concrete and timber represents a successful engineering solution in the optimization of construction processes. The history of TCC materials dates back to the early 20th century. In 1960, the “Zum guten Hirten” hotel became the first project to use the TCC system, where concrete was poured over existing timber floors to enhance their performance [20]. However, it was only been widely used in the last 30 years [21], during which it has been proven to be an excellent solution for the renovation of existing timber floors due to current regulations on load-bearing capacity, deformability, vibration, fire resistance, earthquake resistance, and sound insulation [22]. Additionally, because it accommodates large spans without the need for walls (column–slab or frame–slab systems) and the structural floor requires rigid partitions, it has become an indispensable solution in the design of tall timber structures [23,24,25,26,27,28]. Ghafar et al. [29] conducted a series of dynamic tests to study the dynamic performance of LVL–concrete composite beams using their natural frequencies and modal characteristics. They found that beam span is the most important parameter affecting the natural frequency and critical damping. AbdGhafar et al. [30] further investigated the dynamic performance of the TCC floor system through experiments and finite element models. The study examined the natural frequency, vibration mode, and effective damping of the floor system. Fragiacomo and Lukaszewska [31] assessed the vibration performance of TCC floor systems, where concrete slabs were prefabricated off-site using connectors and then connected to on-site timber beams based on the natural frequency and damping ratio of the floor system. Compared to traditional floor systems, the advantages of TCC in the construction industry stem from the high compressive strength of concrete and the high tensile strength of timber. Due to the increasing use of larger spans, research on the applicability of TCC floors is advancing, particularly regarding vibration performance [32]. The impact of cracks in the concrete slab and the deflection of support beams are also recognised as significant factors. Currently, much of the research focuses on the dynamic characteristics of TCC floor systems, including natural frequency, damping ratio, and mode shapes. Further research has been conducted on this topic [33,34,35,36,37,38,39,40,41,42,43].

In summary, TCC floor slabs are favoured in engineering applications due to their advantages, including high load-bearing capacity, minimal deformation, and effective vibration and sound insulation. However, with their widespread use, issues such as their significant self-weight, substantial creep, high cast-in-place costs, additional deflection caused by differential shrinkage between concrete and wood, and joint problems at connections have gradually emerged. In these situations, the TCC floors’ vibration behaviours could be excessive and have not been determined. Additionally, because the TCC floor is lightweight and usually designed for long spans, the vibration behaviours could be problematic and should be investigated more for robust solutions.

1.2. Application of TMD to Floor Systems

The Tuned Mass Damper (TMD) was a vibration absorber invented by Frahm in 1909 [44]. It has the advantages of being cost-effective and convenient, and significantly reduces narrow-band vibrations. Initially, this device was designed to reduce the dynamic response of ships, but it was gradually applied to civil engineering, particularly in building construction, to reduce vibrations caused by wind, earthquakes, and human-induced forces.

Timber floors exhibit a broad range of natural frequencies. When dense walker traffic passes over timber floors, especially when most of the footstep frequencies are close to the floor’s natural frequencies, the floor may experience undesirable vibration responses that exceed the comfort threshold for walkers. Passive TMD, being a cost-effective vibration control device, can effectively reduce resonant responses at controlled modes without significantly affecting the dynamic properties of the timber floor. Xu and Igusa [45] used TMDs to suppress resonance in a single-degree-of-freedom system due to broad-band random excitation. Later, Yamaguchi and Harnpornchai [46] summarized the basic characteristics of TMDs for controlling resonance excitation, including the frequency range covered by TMDs, damping ratios, and quantities, and provided design recommendations for such vibration control devices. Subsequent studies by several scholars have explored the effectiveness of TMDs in controlling bridge wind-induced vibrations [47] and vehicle–bridge coupling vibrations [48,49]. These studies concluded that Multi-Tuned Mass Dampers (MTMD) are more efficient and reliable than single TMDs. Rainer and Swallow [50] were among the first to attempt to use TMD to reduce excessive vibrations in gymnasium floors caused by rhythmic human movements. Webster et al. [51] demonstrated that TMD could reduce the peak acceleration of concrete floors under human-induced excitation by approximately 60% for vertical vibrations and 40% for lateral vibrations, respectively. Setareh and Hanson [52] developed a finite element model for floor systems, refining it through actual floor response measurements to ensure consistency with the dynamic characteristics of the floor. Then, the model was used to extract the dynamic properties of each mode of the floor, and an optimization method based on single-degree-of-freedom TMDs was applied to determine design parameters for each potentially resonant mode. Setareh and Hanson [52] used a partial modal combination method to calculate the vibration response of the floor–TMD system, optimizing the TMD design parameters with the combined response as the objective function. They found that TMD systems designed using this method, compared to traditional single-degree-of-freedom systems based on floor resonance modes, showed better vibration reduction efficiency when the floor’s modal distribution was dense. Theoretical and measured results confirmed that the MTMD system could effectively control vertical vibrations of large-span floor systems. While a single TMD is more sensitive to frequency fluctuations, MTMDs, due to their coverage of a broader frequency range, are less sensitive to such fluctuations, offering better effectiveness and reliability [48]. Chen et al. [53] designed an eddy current TMD system to effectively control human-induced vibration responses in large-span steel–concrete composite floors. The use of a low damping ratio significantly increased the operational stroke of the TMD at its resonant frequency, enhancing its stability with minimal adverse impact on vibration reduction performance. Huang et al. [54] conducted semi-active vibration control research on CLT floors using SMA-based TMD systems. Their findings showed that adjusting the stiffness of SMA via temperature control could reduce the acceleration amplitude by 26% within a specific frequency range [54].

TMD is now widely used in civil engineering and other fields due to its convenience, cost-effectiveness, and high efficiency in suppressing narrow-band vibrations. In recent years, it has gradually been adopted for vibration suppression in lightweight floor slabs. Within the frequency range of pedestrian-induced vibrations, TMD can effectively control modal resonance responses with minimal impact on the floor’s characteristics. However, traditional narrow-band TMDs perform poorly when the natural frequency of the floor changes due to variations in surface mass (furniture, decorations, etc.). Additionally, the diverse and complex designs of TMDs currently in widespread use are not well-suited for civil engineering applications. Nowadays, vibration issues in timber floor slabs are prominent, but related vibration control methods mainly focus on optimizing floor structures and adding damping materials. Research into the application of TMD as a vibration control measure remains relatively limited.

1.3. Research on SMA–TMD

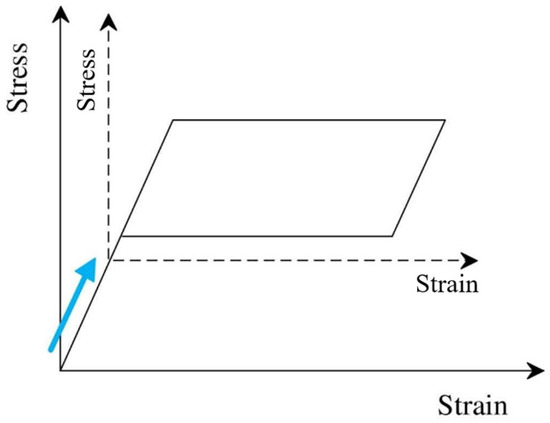

A limitation of TMD systems is that, over time, changes in their own or the structure’s dynamic properties can lead to detuning effects, causing a sharp reduction in vibration control efficiency [48]. To address this issue, TMDs can adjust their dynamic properties to match the target structure’s vibration frequencies, thereby effectively absorbing and dissipating vibration energy. Huang et al. [54] optimized the adjustable mass damper to reduce excessive vibrations in timber floors. The temperature of the SMA was controlled to re-adjust the natural frequency of the structural system since the structure’s mass or stiffness can change due to the application of loads or long-term effects. Numerical simulations showed that vibration amplitudes could be reduced by as much as 26%. Furthermore, Huang et al. [55] developed an SMA-based MTMD system to reduce human-induced vibrations in CLT floors. The results showed that these devices effectively reduced human-induced vibrations. However, the SMA–TMD system faced issues with insufficient damping ratios, leading to poor vibration reduction because superelasticity results in a small hysteresis loop area, and super elasticity and damping cannot coexist effectively. The application of pre-straining to SMA can solve this problem. As shown in Figure 1, after pre-strain the SMA bar, the stress–strain curve shifts towards the upper right region of the coordinate system. This displacement phenomenon indicates that the material skips the conventional elastic deformation phase when loaded and goes directly into the region of phase transition from austenite to martensite. Through this pre-strain treatment, SMA materials can effectively avoid the initial elastic stage and achieve more significant energy dissipation through crystal structure transformation during the phase transition. This property allows pre-strained SMA material to exhibit enhanced damping properties and energy absorption.

Figure 1.

Conceptual idea of the effect of pre-strain on SMA stress–strain hysteresis [56].

Building on the previous study on dampers [54,57,58,59], this paper aims to enhance the damping capacity by applying pre-strain to the SMA, thereby improving the damping performance across a wide frequency range. Firstly, the pre-strained SMA–TMD is designed through a theoretical model and parameter optimization. Then, experimental testing of the designed device is conducted to evaluate its effectiveness in enhancing the damping ratio and broadband frequency performance. Finally, the application of SMA–TMD in vibration control is tested on an existing TCC floor, and the impact of adjusting the damping ratio of the SMA–TMD on vibration reduction in TCC floors is evaluated.

2. Development and Tests of the Pre-Strained SMA–TMD

Applying pre-strain to SMA alters its damping, enabling the SMA–TMD to adapt to a wider range of excitation frequencies. The objective of this test is to evaluate the vibration reduction effect of the pre-strained SMA–TMD by assessing the control capability of the vibration response of timber floors under different pre-strain conditions and comparing the performance differences between traditional TMD systems and SMA–TMD systems.

2.1. Pre-Strained SMA–TMD Design

The SMA–TMD for timber floors, as shown in Figure 2, was previously investigated in our previous research [59] and experimentally tested on a full-scale CLT floor. While that configuration enhanced the robustness of the SMA–TMD to some extent, its performance under high-frequency excitation remained limited due to its low damping capacity. Moreover, the dynamic characteristics of CLT floors often change during use, for example, due to variations in usage or floor loading. The previous SMA–TMD design could not accommodate such changes, as its damping level was fixed during manufacturing. In this study, we build upon the original design [59] by introducing pre-strain to increase the damping capacity of the SMA. Most importantly, the proposed SMA–TMD is able to adjust its damping to an optimal level in response to the actual dynamic characteristics of the CLT floor.

Figure 2.

Previously designed SMA–TMD.

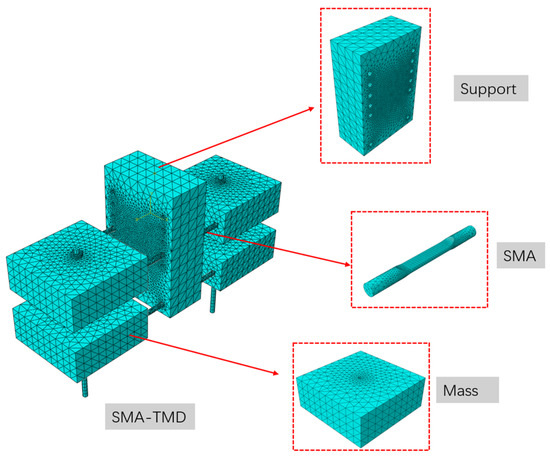

The model size was determined by modal analysis using the finite element method. In this finite element method, each component was composed of the homogeneous continuum, and the three-dimensional solid unit C3D8R was used to simulate each component in the model. The connection of each component is simulated by “surface-to-surface contact”. Material nonlinearity and contact nonlinearity are involved in the finite element simulation analysis, so the large deformation option of solution control is turned on during the analysis operation. The implicit solution method is used, and the improved Newmark method is adopted. Model grid division is shown in Figure 3.

Figure 3.

Finite element model.

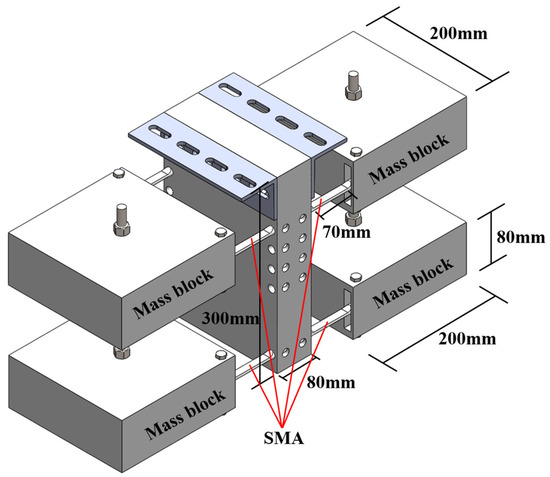

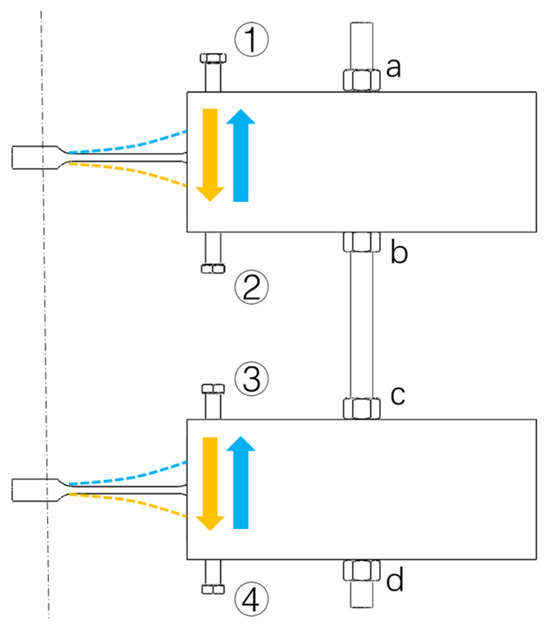

This study conducted designs for the integration of pre-strained SMA into TMD, as shown in Figure 4. The SMA was provided by Kellogg’s Research Labs, New Boston, USA. The SMA–TMD system in this study is composed of eight SMA rods connected to four cantilevered mass blocks. Specifically, two SMA rods are used per mass block to form a symmetrical configuration that enhances system performance in several ways: it prevents rotational instability by generating counteracting moments during asymmetric loading; it ensures uniform martensitic phase transformation across the SMA elements, which improves energy dissipation consistency. The nut spacing mechanism is designed to precisely control the level of mechanical pre-strain applied to the SMA rods, while also compensating for potential thermal drift that may affect the SMA’s stiffness over time. On each side, there are two mass blocks connected by a screw and four nuts. Adjusting the nuts’ spacing enables precise control of pre-strain levels (0%~3%) in the SMA rods. The adjustment of screw and nuts is illustrated as shown in Figure 5 where the yellow and blue dashed lines represent the bending of SMA rods.

Figure 4.

SMA–TMD design in this study.

Figure 5.

Adjustment schematic diagram (a, b, c and d are the nut numbers, and ①, ②, ③ and ④ are the bolt numbers).

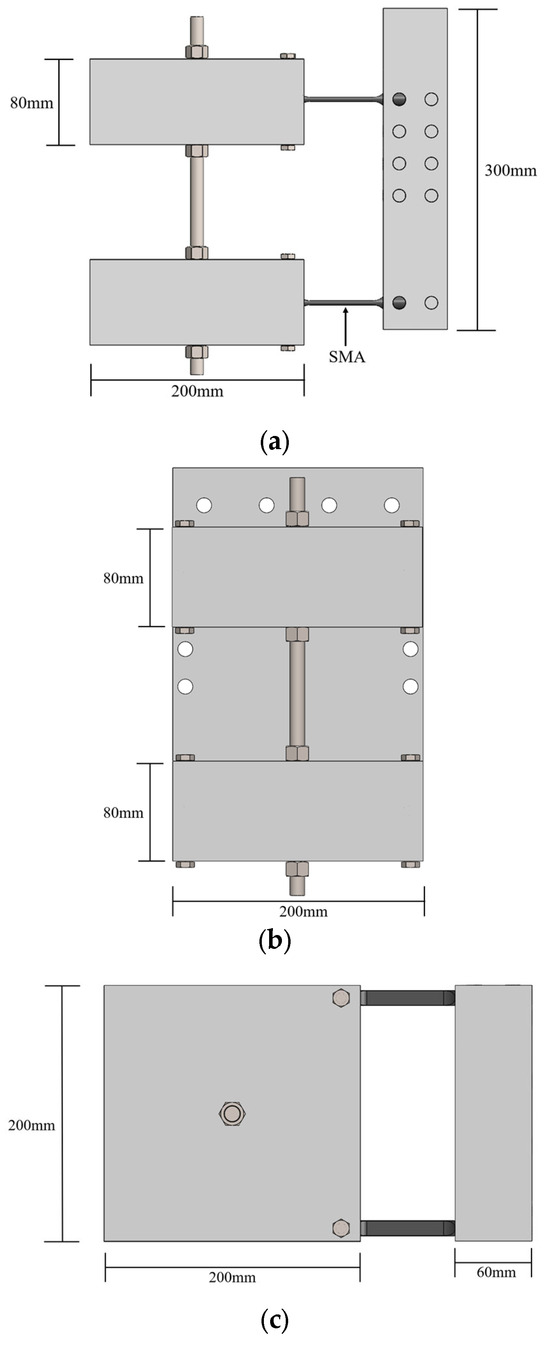

Figure 5 illustrates the adjustable pre-strain mechanism used in the SMA–TMD system. The SMA rods are connected to mass blocks via threaded rods, nuts, and bolts. By adjusting the spacing between the nuts on either side of the mass block, a bending deformation is introduced into the SMA rods, effectively applying mechanical pre-strain. The yellow and blue dashed lines in the figure represent the bent shape of the SMA rods under different levels of pre-strain. This mechanism allows for precise control of the pre-strain level without altering the overall geometry of the device, ensuring consistent and repeatable tuning of the SMA–TMD’s stiffness and damping properties. When the SMA rods are bent, the rods undergo deformation under pre-strain, promoting the phase transformation from austenite to martensite, thereby achieving greater damping performance as shown in Figure 1. The SMA–TMD can be mounted on the controlled structure using angle steel and screws. The mass, SMA bars, and connections of the SMA–TMD designed in this study are fully symmetrical. The mass frequency, stiffness, and damping properties are identical on both sides. To reduce testing costs and improve efficiency, only half of the SMA–TMD system was tested, as shown in Figure 6. This half-model provided representative frequency and damping data for the entire system and supported the next phase of timber floor vibration control research by helping to define the required vibration reduction parameters. The SMA–TMD for this test consists of five components: a fixed support, an SMA rod, angle steel and connecting bolt sets. Among them, SMA comes from Kellogg’s Research Labs. In this design, the fixed support is a rectangular steel block measuring 300 mm × 60 mm × 200 mm. Each mass block is a rectangular steel block designed with dimensions of 200 mm × 200 mm × 80 mm and a mass of 6.23 kg.

Figure 6.

Tested SMA–TMD in half: (a) front view; (b) side view; (c) top view.

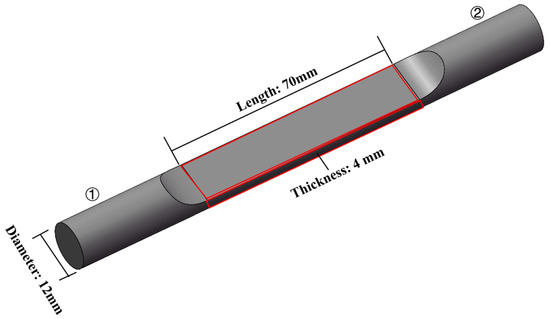

The NiTi SMA selected has a Ni content of 55.95% and a Ti content of 44.05%. The SMA rod is machined into a rectangular cross-section with dimensions of 12 mm × 4 mm to facilitate the one-way bending, and the effective length in the middle is 70 mm, as shown in Figure 7. In the application of pre-straining in SMA–TMD, a bending moment is applied to increase the strain of the SMA rod. The main deformation region is the area within the red box in Figure 7 thus it is called the effective length. During bending, End 1 is fixed in the support, while End 2 is connected to the mass block using a bolt.

Figure 7.

SMA size in the SMA–TMD (effective length in red box, ① and ② are the end numbers of SMA rods).

2.2. Experimental Testing Methods for the SMA–TMD

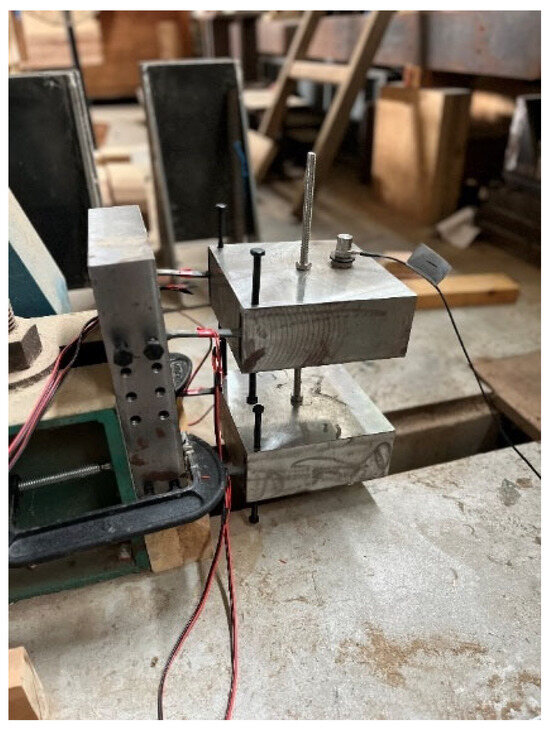

The experimental setup is shown in Figure 8. During the test, the SMA–TMD was mounted to the rigid reaction frame in the structural engineering laboratory. The frame’s high rigidity and minimal vibration ensure that its influence on the test results can be neglected. Vibration acceleration is measured by an accelerometer attached to the mass block. The accelerometer has a sampling frequency of 1000 Hz, a sensitivity of 2048.6 mV/g, and a data collection time of 10 s. The vibration of the SMA–TMD is free vibration, and the free vibration is initiated by applying and releasing a 5 mm initial displacement at the midpoint of the mass block.

Figure 8.

SMA–TMD test setup.

In this study, pre-strain is applied by changing the nuts’ spacing as shown in Figure 5. During the test, a calliper is used to precisely measure the movement of the bolts. The calliper has a measurement range of 0–150 mm, a resolution of 0.01 mm, and an accuracy of ±0.03 mm. The nuts were moved upward and downward by 0, 1, 2, 3, 4, 5, and 6 mm in total. A displacement of 0 mm indicates that no pre-strain has been applied. The pre-strain level is measured using strain gauges attached to the surface of the SMA rods. The corresponding strain values for the displacements aforementioned are 0%, 0.32%, 1.33%, 1.67%, 1.95%, 2.56%, and 2.92%. Each pre-strain test condition was repeated 10 times to ensure the reliability of the data.

2.3. Results and Analysis

Dynamic characteristics such as the natural frequency and damping ratio were analysed from the measured free vibration accelerations. The methods for analysing the natural frequency and damping ratio are based on the Singular Value Decomposition Matrix Pencil (SVD-MP) linear prediction method, which is detailed in the works of Zielinski and Duda [60]. SVD improves the quality of signals by decomposing the signal matrix to separate the main components of the signal from the noise components. Specifically, time-domain signal samples are organized into a Hankel-type matrix, and SVD decomposition is performed on the constructed matrix. The singular values are sorted by size. Large singular values typically correspond to the main components of the signal, while small singular values mainly come from noise. By using the selected principal components, the denoised signal matrix is reconstructed through the inverse process. By removing the components of the noise subspace, the influence of random noise is significantly reduced, thereby more clearly retaining the signal features. Additionally, SVD can be used for data compression, which is useful for storing and transmitting large amounts of vibration data. The MP method is designed to handle approximations of complex exponentials in the signal. The observed signal is modelled as follows in Equations (1) and (2):

represents the contaminated signal source, where is the amplitude, is the sampling period, is the duration, and is the noise is the number of complex exponential estimates. In Equation (2), and represent the damping factor and angular frequency, respectively. The SVD-MP computational code [60] was compiled using MATLAB 2022b. The computational process begins by forming a Hankel matrix from the measured time-domain vibration signal. SVD is then performed to separate the dominant signal subspace from noise. After truncating small singular values, the denoised matrix is used to construct two shifted submatrices for the MP method. A generalized eigenvalue problem is then solved to extract the complex eigenvalues, from which the natural frequencies and damping ratios are computed. This process allows for robust and efficient identification of modal parameters, even in the presence of noise.

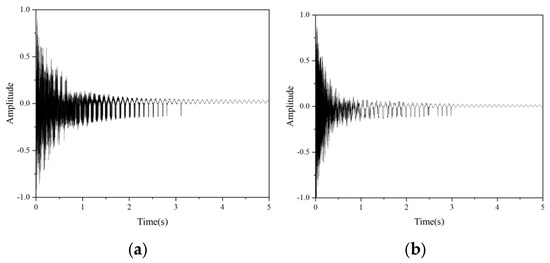

Table 1 shows SMA–TMD’s tested natural frequencies and damping ratios at different strain levels. In Table 1, the boundary condition of the SMA in the test is shown in Figure 8. In the experimental setup, each SMA rod is fixed at one end to the support frame (a clamped condition), while the other end is connected to the mass block (a free end), forming a classic cantilever boundary condition. According to Table 1, as the pre-strain level increases from 0.00% to 2.92%, the damping ratio increases from 0.8621% to 1.6949%. These results highlight the effectiveness of adjusting the pre-strain level in regulating the damping ratio of TMDs. Figure 9 shows the time history of the free vibration at two selected pre-strain levels of 0.00% and 2.92%, where the pre-strain levels are normalized and compared. It can be observed that at 2.92%, the acceleration diminishes more rapidly, and it presents that the damping ratio significantly increases compared to the former. When the pre-strain level increases from 0.00% to 2.92%, the natural frequency increases from 9.96 Hz to 12.43 Hz. In conclusion, adjusting the pre-strain level of SMA is an effective method to improve the damping ratio of the SMA–TMD.

Table 1.

SMA–TMD’s tested natural frequencies and damping ratios at different strain levels.

Figure 9.

Free vibration time history: (a) pre−strain level of 0%; (b) pre−strain level of 2.92%.

While traditional TMDs exhibit a linear force–displacement response with limited damping from material hysteresis or friction, the SMA–TMD introduces a nonlinear hysteretic behavior due to phase transformation in the SMA. This results in significantly higher energy dissipation, especially when pre-strain is applied. The pre-strain shifts the SMA response into the martensitic transformation region, broadening the hysteresis loop and enhancing damping capacity. Furthermore, the SMA–TMD demonstrates improved adaptability to frequency variations, offering greater robustness against detuning compared to conventional TMDs.

3. Application of the SMA–TMD to the TCC Floor

3.1. The Tested TCC Floor

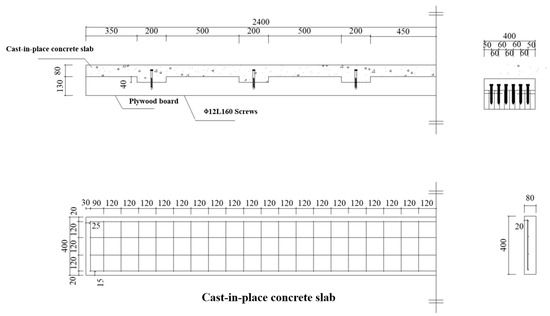

In the design of the SMA–TMD, the dynamic performance of the floor, such as its natural frequency and damping ratio, should be tested. The controlled object selected for this test is a TCC floor. The span of the TCC floor is 4.8 m, and its width is 0.4 m. It is composed of a 130 mm grooved glued-laminated timber floor and an 80 mm cast-in-place concrete slab, connected by screws. The details of the specimen can be seen in Figure 10.

Figure 10.

Schematic diagram of the TCC floor.

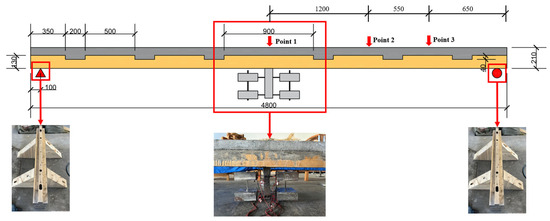

Since the test considers the height requirement for the SMA–TMD, a timber floor support is designed as shown in Figure 11. The boundary condition is set as simply supported at both ends. The support simulated a timber wall with dimensions of 370 mm × 120 mm × 1200 mm. Four triangle supports at both ends prevent the lateral overturning of the measured side. The dimensions of the triangular supports are 300 mm × 300 mm × 120 mm.

Figure 11.

TCC floor boundary conditions and damper position.

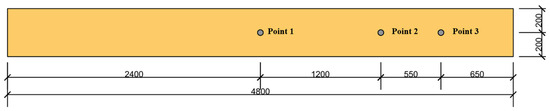

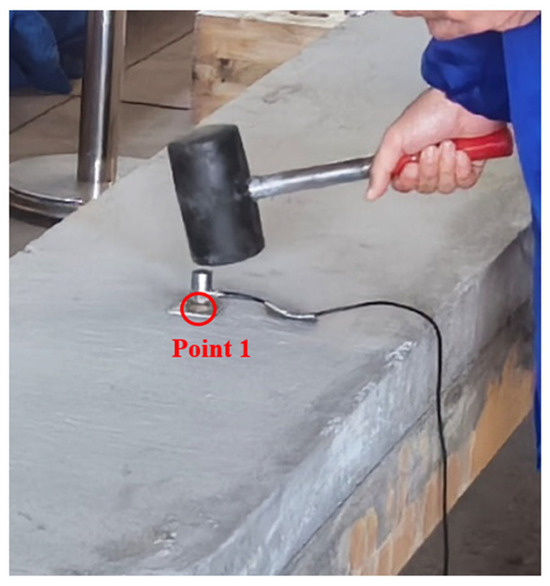

Three measurement points (Point 1, Point 2 and Point 3) were placed as shown in Figure 11 and Figure 12. Accelerometers were installed at the measurement points, with a sampling frequency of 1000 Hz, meeting the minimum sampling rate requirement of 500 Hz as specified in BS EN 16929:2018 [61]. The free vibration method was used to determine the dynamic characteristics of the TCC floor. The excitation device used for this purpose is an impact hammer. As shown in Figure 13, using an impact hammer to strike the free vibration caused by the span, when the hammer head touches the test point of the beam, a brief and localised force occurs, which triggers the free vibration. The impact excites the natural vibration frequencies of the beam, which correspond to the inherent modes of the structure. In the first mode shape of the beam, the amplitude of the mid-span position is the largest, so choosing the mid-span position as the impact point can effectively excite the first bending mode.

Figure 12.

Measuring points (unit: mm).

Figure 13.

Hammering method.

The tests were conducted under different additional loads on the floor. Table 2 presents the testing procedure. Each test was conducted using the hammering method for 60 s of free vibration, and the test was repeated 10 times. The results were analysed using the SVD-MP. The dynamic characteristics of the TCC floor under different loads are presented in Table 2 as well, which shows that the natural frequency decreases with the increase in floor mass. The damping ratios tested are in a range from 1.4845% to 2.4133%. When the increase in floor mass leads to a decrease in the damping phenomenon, it can be understood from the damping ratio formula in structural dynamics, which is Equation (3) [62]. When the floor mass increases while and remain constant, the denominator increases, resulting in less damping than .

Table 2.

Tested natural frequencies and damping ratios of the TCC floor with different additional masses.

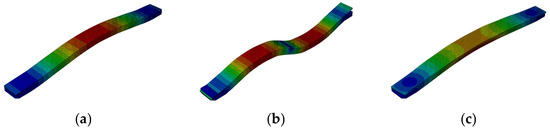

Due to the insufficient number of accelerometers in the test, it was difficult to perform an accurate modal analysis. However, simulations can effectively compensate for this limitation. In this study, modal analysis of the TCC floor with a mass of 660 kg (Test No. C1) was carried out using the frequency analysis in the ABAQUS 2021. Figure 14 shows the numerical estimation of the vibration modes of the TCC floor in Test No. C1. Based on the modal analysis results from the numerical simulation, the first three natural frequencies of the floor are listed in Table 3. Figure 14 shows the first three mode shapes of the TCC floor unit. The first mode corresponds to the bending mode (Figure 14a), the second mode corresponds to the transverse bending mode (Figure 14b), and the third mode corresponds to the torsional mode (Figure 14c).

Figure 14.

Mode shapes of the TCC floor from the numerical simulations((a) first mode; (b) second mode; (c) third mode).

Table 3.

First three natural frequencies of the TCC floor from the numerical simulations.

3.2. Timber Floor Vibration Evaluation Standards

This research focuses on the study of walking load impacts on timber floor vibration and comfort. Thus, this study uses the Vibration Dose Value (VDV) and the Response Factor (RF) as two indicators to evaluate the comfort level of the TCC floor. The RF has long been used as a design criterion for floor continuous vibration and is included in design codes such as BS-6472-1:2008 [63] and ISO 10137:2007 [64]. The RF calculation method is shown in Equation (4):

In the formula:

means RF.

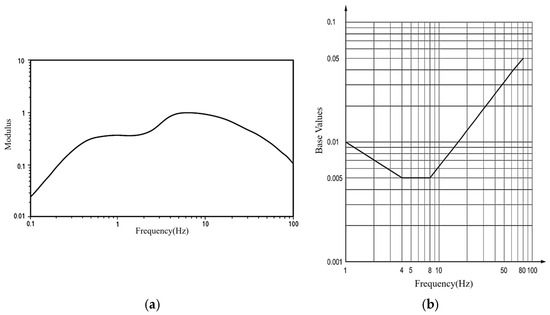

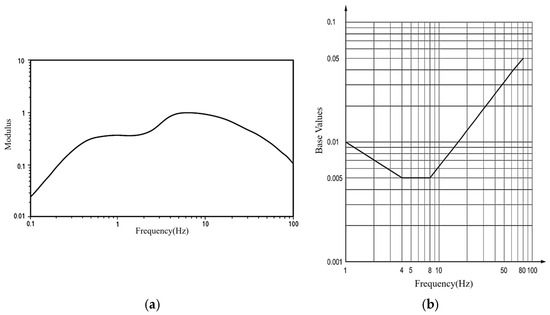

is the weighted root mean square acceleration, which can be frequency-weighted according to the curves proposed in BS 6472-1:2008 as shown in Figure 15a.

is the reference impact value, which can be determined using Figure 15b.

According to BS-6472-1:2008, when the calculated RF does not exceed the limit values appropriate for the environment, the vibration response to continuous vibrations can be considered satisfactory. The specific limit values are listed in Table 4.

Table 4.

Recommended multiplying factors based on single-person excitation [63].

The VDV method is mainly used to evaluate the intermittent vibration response of floor slabs. The VDV was included in the testing standards of BS 6472-1:2008 and ISO 10137:2007. The vibration dose can be calculated by the time history response of floor acceleration weighted by frequency in Equation (5):

In the formula, is the weighted acceleration, and frequency weighting can be performed according to the curve proposed by BS 6472-1:2008 (as shown in Figure 15). is the total time for the floor to be stimulated. Ranges of VDV probabilities leading to various negative comments are shown in Table 5.

Figure 15.

(a) Vertical vibration frequency weighted curve in BS 6472-1:2008; (b) basic vibration perception curve in ISO 10137:2007.

Table 5.

Vibration dose value ranges might result in various probabilities of adverse comments within residential buildings [63].

3.3. Testing the Effectiveness of the SMA–TMD on TCC Floor Vibration Reduction

The effectiveness of SMA–TMD was tested using human-induced timber floor vibrations. The new damper designed in this paper uses a screw to connect the mass block, which can apply a pre-strain to the connecting rod SMA. Figure 16 shows the position and size of the damper. The SMA–TMD was installed in the central point of the TCC floor. Pre-strained SMA–TMD and non-pre-strained SMA–TMD were compared. Different additional masses on the floor were tested to test the robustness of the SMA–TMD. The strain amplitudes used were 0 and 2.92%, and the additional masses were 0, 80 kg, 140 kg, and 260 kg. The results were analyzed using VDV and RF for evaluation. The accelerations were collected for both single-person slow and fast walking, with Test Nos. S1–S9 as slow walking and Test Nos. F1–F9 as fast walking. The testing plan is shown in Table 6.

Figure 16.

SMA–TMD’s installation.

Table 6.

Test plan for testing the effectiveness of SMA–TMD.

Walker with a mass of 70 kg walked as shown in Figure 17. In the test, a metronome was used to play the slow-walking beat, so that the walker on the floor could walk with the sound of the metronome and ensure the accuracy of the walking speed. The slow-walking frequency is 1.7 Hz, while the fast-walking frequency is 3.6 Hz.

Figure 17.

TCC floor-walking test.

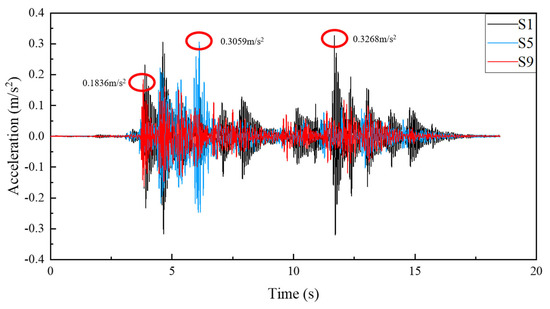

Table 7 and Table 8 show the vibration performance of TCC floors in Test Nos. S1, S5, S9, F1, F5, F9, which compare no TMD, non-pre-strained SMA–TMD and pre-strained SMA–TMD. It should be noted that the natural frequencies of the SMA–TMD in Test Nos. S5 and F5 are a little bit lower than the floor’s natural frequency and could cause off-tuning. The reason is that pre-strain can increase the SMA’s stiffness thus non-pre-strain has lower stiffness. Overall, the TCC floor response under human-induced vibration can be reduced by applying the SMA–TMD system. As shown in Table 7, compared to Test No. S1 without the TMD control system, the addition of SMA–TMD in Test No. S5 can reduce the VDV by about 15.40%, the peak acceleration by 6.40%, and the RF by 22.91%. Then, in Test No. S9 where pre-strain is applied to the SMA–TMD, all test indicators show significant improvement, with VDV reduced by 44.47%, peak acceleration reduced by 43.82%, and RF reduced by 40.82%. It is evident that the vibration control performance of the SMA–TMD with pre-strain has significantly improved. As shown in Table 8, Test Nos. F1, F5 and F9 were tested under fast-walking conditions, with vibration variation trends similar to those observed in the slow-walking test group. Comparatively, Test No. F9 exhibited a 31.87% reduction in peak acceleration relative to F1, whereas F5 showed a 14.81% decrease. Notably, when pre-strained SMA–TMD was applied (F9) under fast walking, there was less attenuation of RF and VDV values compared to the non-pre-strained case (F5). Figure 18 shows the vibration time history data. It can be seen that pre-strained SMA–TMD (Test No. S9) has a significant effect on reducing the TCC floor vibration. The reasons for the observed phenomenon are as follows: Fast walking induces vibrations over a broad frequency range, particularly at higher frequencies. Since only a single TMD is employed, its effective frequency bandwidth is limited. As a result, the performance of the SMA–TMD system under fast walking is less effective compared to that under slow walking. To enhance its performance across a wider frequency range, future work will explore the application of multiple TMDs.

Table 7.

Floor vibration performance at slow walking.

Table 8.

Floor vibration performance at fast walking.

Figure 18.

Time history of floor vibration acceleration of Test Nos. S1, S5 and S9.

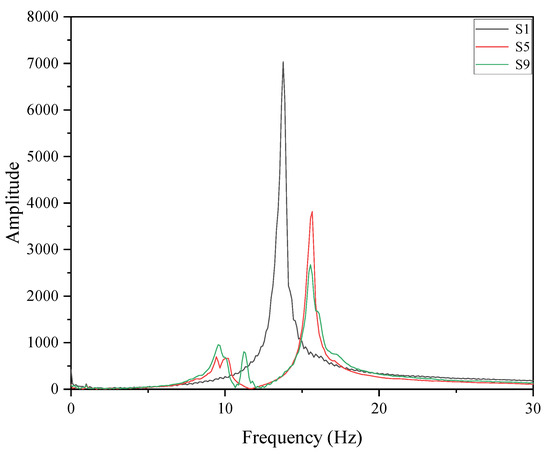

The results above can be explained by analysing the data in the frequency domain. Figure 19 shows the FFT analysis of the free vibration response of the TCC floor in Test No. S1, Test No. S5, and Test No. S9. It can be seen from the figure that when using SMA–TMD, the first peak in the frequency domain is split into two smaller peaks, and the amplitude decreases. This indicates that in the absence of TMD, the vibration of the TCC floor is primarily dominated by a single mode in the range of 13.78 Hz. When TMD is applied, according to Den Hartog’s theoretical model, TMD distributes the energy of the single mode across two modes, thereby attenuating the amplitude in that mode. As the pre-strain increases, the damping ratio increases, and the amplitude further decreases, enhancing the vibration control performance. It can also be noted that Test No. S9 applied closer natural frequencies between the TMD and the floor, which is beneficial to adjusting the two peaks to be both low. Due to the frequency ratio not being optimally applied in Test No. S5, the amplitude around 15–18 Hz remains relatively large. In the future design of SMA–TMD systems for reducing vibration in timber floors, the TMD frequency and its damping ratio should be optimally designed. Also, the effect of the SMA pre-strain on the TMD stiffness increase should be considered.

Figure 19.

FFT analysis of TCC floor responses.

3.4. Evaluating the Robustness of the SMA–TMD

In the real world, the timber floor may face various loads and excitation conditions, so it is necessary to evaluate the robustness of the SMA–TMD system under different floor loading scenarios. It is important to note that the floor loading variation can change the floor natural frequencies and thus change the tuning conditions of the TMD. By adding different masses to the floor, it is possible to simulate the actual operating conditions of the floor under various loads. Figure 20 shows how the additional mass was added to the TCC floor.

Figure 20.

Adding additional mass to the TCC floor.

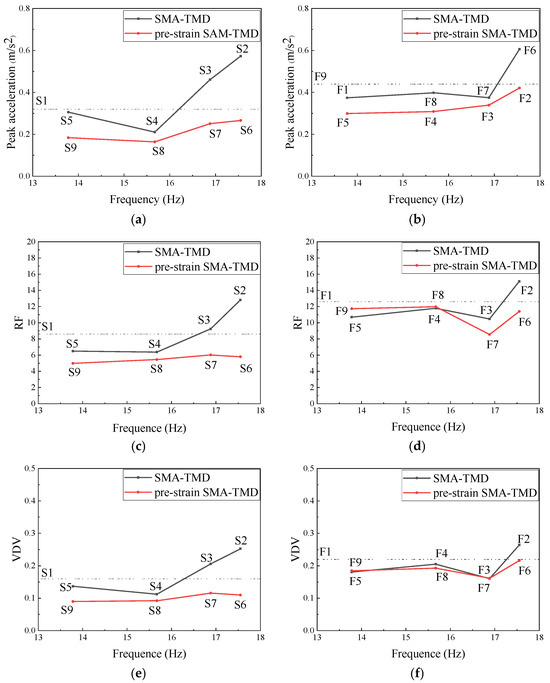

The testing plan is shown in Table 6. The robustness of the pre-strained SMA–TMD in controlling floor vibrations was tested under varying conditions of additional mass on the floor. Table 9 and Table 10 present the comparative results of peak acceleration, RF, and VDV measured in Test Nos. S1–S9 and F1–F9, respectively. The vibration tests conducted under various additional mass conditions revealed that both the SMA–TMD and the pre-strained SMA–TMD effectively controlled floor vibrations.

Table 9.

Floor vibration performance under different additional mass at slow walking.

Table 10.

Floor vibration performance under different additional mass at fast walking.

Based on previous studies [65], TMD always demonstrates the best vibration control performance near its optimal tuning frequency. In this study, Test Nos. S9, F9, S5 and F5 were set as optimal tuning frequency test groups, where the natural frequency of the SMA–TMD is closer to that of the TCC floor (natural frequencies in Test Nos. S5 and F5 were not optimally tuned but were closest to the optimal ones in non-pre-strain groups). To ensure a fair comparison between cases with and without the SMA–TMD system, the reference test without TMD (Test No. S1) was also conducted under the same loading condition with 260 kg of additional mass. It can be observed that the vibration reduction effect in Test Nos. S9 and F9 is obviously superior among all groups. For example, RF and VDV in Test Nos. S9 were reduced by 40.82% and 44.47%, respectively. From Table 9 and Table 10, it was observed that the floor’s natural frequency changes with variations in the mass on the floor. Consequently, when the floor’s frequency does not match the initial set frequency of the SMA–TMD, an off-tuning phenomenon occurs, as seen in Test Nos. S2, S3, S4, F2, F3 and F4. Figure 21 presents the variations of peak acceleration, RF, and VDV of all tests. It can be seen that, in off-tuning testing conditions, the vibration response is intended to increase, especially in Test Nos, S2, F2, S6 and F6. In other words, from S5 to S2, from S9 to S6, from F5 to F2, and from F9 to F6, the vibration responses generally increase. The most important finding is that compared to non-pre-strained SMA–TMD, the pre-strained version exhibited greater stability without significant fluctuations, as demonstrated in Figure 21. The reason can be explained that the higher damping because of pre-strain can increase the frequency bandwidth, thus attenuating the vibration broadly even though the main structural frequency is changing. This is similar to the previous MTMD timber floor vibration tests [59]. Therefore, even when the floor’s frequency changes, the pre-strained SMA–TMD maintains its effective control capabilities. However, under high-frequency excitations caused by fast walking, the stability and effectiveness of vibration control from the pre-strained SMA–TMD diminish. The bandwidth of the pre-strained SMA–TMD may not be wide enough to cover the high-frequency excitations. This shortage should be addressed in the future by implementing higher damping technologies such as SMA cooling or adding MTMD [59]. The external cooling system can perform dynamic temperature management on the SMA element to maintain the SMA temperature below the end temperature of the martensitic phase transformation. Changing the phase transformation temperature can effectively adjust the TMD’s stiffness and damping ratio to the optimal [66]. In addition, the MTMD composed of multiple mass-spring units can be tuned to different frequencies, forming a hybrid configuration of the main TMD to control the low-frequency vibration and the sub-TMD for the high-frequency vibration, so as to achieve more efficient expansion of the vibration attenuation bandwidth [59]. In summary, the pre-strained SMA–TMD was proven to exhibit high robustness across various loading conditions.

Figure 21.

Robustness evaluation: (a) peak acceleration under slow walking; (b) peak acceleration under fast walking; (c) RF under slow walking; (d) RF under fast walking; (e) VDV under slow walking; (f) VDV under fast walking.

4. Conclusions

In this study, a pre-strained SMA–TMD vibration control system was designed and tested. By mechanically adjusting the pre-strain level of SMAs, the research investigated how SMA pre-strain enhances the vibration reduction of the TCC floor system under different floor loading conditions. Based on the research findings, the following conclusions can be drawn:

- The damping ratio of the SMA–TMD increases with the increase in pre-strain level. Specifically, without any pre-strain, the damping ratio of the SMA–TMD is 0.8621%. As the pre-strain increases, the damping ratio continues to rise, reaching 1.6949% when the pre-strain is 2.92%. Additionally, as the pre-strain increases, the natural frequency slightly increases.

- The pre-strained SMA–TMD significantly reduces the vibration response of the TCC floor, with the highest reduction of peak acceleration by 49.91%, RF (Response Factor) by 40.82% and VDV (Vibration Dose Value) by 44.47%. Compared with the SMA–TMD system without pre-strain, there is an improvement in vibration reduction.

- The pre-strained SMA–TMD has stronger robustness and better adaptability to floor mass changes. Specifically, compared with non-pre-strained SMA–TMD, the pre-strained SMA–TMD showed more consistent performance, retaining its vibration control capability even after changes in the floor frequency.

The findings above provide new insights for vibration control technologies in timber floor systems, emphasizing the potential of pre-strained SMA–TMD systems to enhance performance. The ability to adjust the pre-strain level of the SMA allows for a more responsive system, offering higher efficiency in vibration mitigation compared to traditional methods. Moreover, the increased robustness and adaptability of the pre-strained SMA–TMD system suggest its practical applicability across a wider range of structural configurations and loading conditions. Future research should focus on further improving damping performance by integrating additional energy dissipation mechanisms, such as viscoelastic layers or hybrid damping systems, alongside the pre-strained SMA–TMD. Simplifying the structural design of the SMA–TMD to reduce installation complexity and cost will support broader adoption in real-world projects. Full-scale experimental testing on practical TCC floor systems under both short-term dynamic loads and long-term service conditions is recommended to evaluate durability, tuning stability, and creep effects. Moreover, incorporating artificial intelligence and machine learning techniques to monitor floor responses and actively adjust TMD parameters in real time could significantly enhance adaptability and vibration mitigation across a wider range of user and environmental conditions. These efforts will contribute to more robust, scalable, and intelligent vibration control strategies in sustainable timber construction.

Author Contributions

Conceptualization, H.H.; Methodology, H.Y., X.L. and H.H.; Software, H.S.; Validation, X.L., H.S., Y.P. and Y.L.; Formal analysis, H.S., B.S. and H.H.; Investigation, H.Y., X.L., H.S. and H.H.; Resources, H.Y., B.S. and H.H.; Data curation, X.L.; Writing—original draft, X.L.; Writing—review & editing, H.Y., Y.P., B.S., Y.L. and H.H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to express gratitude to National Natural Science Foundation of China (52478179), Newcastle University’s Start-Up Funding and Northern Accelerator for their financial support.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nyabongo, E.; Li, X. Development of energy-early-dissipated braces based on web buckling of low-yield I-section steel. J. Constr. Steel Res. 2024, 217, 108672. [Google Scholar] [CrossRef]

- Qiu, Z.; Chen, R.; Gan, X.; Wu, C. Torsional damper design for diesel engine: Theory and application. Phys. Scr. 2024, 99, 125214. [Google Scholar] [CrossRef]

- He, D.; Xu, H.; Wang, M.; Wang, T. Transmission and Dissipation of Vibration in a Dynamic Vibration Absorber-Roller System Based on Particle Damping Technology. Chin. J. Mech. Eng. 2024, 37, 108. [Google Scholar] [CrossRef]

- Yang, J.; Liang, S.; Zhu, X.; Dang, L.; Shen, T.; Zhou, S. Experimental and theoretical research on a shear-bending-metallic-damper with a double-phased yield mechanism. J. Constr. Steel Res. 2023, 203, 107839. [Google Scholar] [CrossRef]

- Yuan, X.; Qiu, T.; Tian, T. Design and modelling methodology for a new magnetorheological damper featuring a multi-stage circumferential flow mode. Int. J. Mech. Mater. Des. 2022, 18, 785–806. [Google Scholar] [CrossRef]

- Khalfi, B.; Ross, A. Transient response of a plate with partial constrained viscoelastic layer damping. Int. J. Mech. Sci. 2013, 68, 304–312. [Google Scholar] [CrossRef]

- Jarnerö, K.; Brandt, A.; Olsson, A. In Situ Testing of Timber Floor Vibration Properties. In Proceedings of the 11th World Conference on Timber Engineering (WCTE 2010), Trentino, Italy, 20–24 June 2010. [Google Scholar]

- British Standards Institution. UK National Annex to Eurocode 5: Design of Timber Structures In Part 1-1: General, Common Rules and Rules for Buildings London; British Standards Institution: London, UK, 2004. [Google Scholar]

- Hu, L.; Chui, Y. Development of a Design Method to Control Vibrations Induced by Normal Walking Action in Wood-Based Floors. In Proceedings of the 8th World Conference on Timber Engineering, Oslo, Norway, 19–22 June 2023. [Google Scholar]

- Ebadi, M.M.; Doudak, G.; Smith, I. Evaluation of floor vibration caused by human walking in a large glulam beam and deck floor. Eng. Struct. 2019, 196, 109349. [Google Scholar] [CrossRef]

- Saidi, I.; Haritos, N.; Gad, E.F.; Wilson, J.L. Floor vibrations due to human excitation—Damping perspective. In Earthquake Engineering in Australia; Australian Earthquake Engineering Society: Canberra, Australia, 2006. [Google Scholar]

- Racic, V.; Pavic, A.; Brownjohn, J.M.W. Experimental identification and analytical modelling of human walking forces: Literature review. J. Sound Vib. 2009, 326, 1–49. [Google Scholar] [CrossRef]

- Pavic, A.; Reynolds, P. Vibration serviceability of long-span concrete building floors. Part 1: Review of background information. Shock Vib. Dig. 2002, 34, 191–211. [Google Scholar]

- Bernard, E.S. Dynamic Serviceability in Lightweight Engineered Timber Floors. J. Struct. Eng. 2008, 134, 258–268. [Google Scholar] [CrossRef]

- Weckendorf, J.; Ussher, E.; Smith, I. Dynamic response of CLT plate systems in the context of timber and hybrid construction. Compos. Struct. 2016, 157, 412–423. [Google Scholar] [CrossRef]

- Shi, B.; Liu, W.; Yang, H. Experimental investigation on the long-term behaviour of prefabricated timber-concrete composite beams with steel plate connections. Constr. Build. Mater. 2021, 266, 120892. [Google Scholar] [CrossRef] [PubMed]

- Ljunggren, F. In Floor Vibration—Dynamic Properties and Subjective Perception. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2006. [Google Scholar]

- Ljunggren, F.; Ågren, A. Dynamic and Subjective Analysis of a Lightweight/Semi-Heavyweight Floor in a Laboratory. Build. Acoust. 2006, 13, 255–272. [Google Scholar] [CrossRef]

- Jarnerö, K.; Brandt, A.; Olsson, A. Vibration properties of a timber floor assessed in laboratory and during construction. Eng. Struct. 2015, 82, 44–54. [Google Scholar] [CrossRef]

- Rijal, R.; Samali, B.; Shrestha, R.; Crews, K. Experimental and analytical study on dynamic performance of timber-concrete composite beams. Constr. Build. Mater. 2015, 75, 46–53. [Google Scholar] [CrossRef]

- Yeoh, D.; Fragiacomo, M.; De Franceschi, M.; Heng Boon, K. State of the art on timber-concrete composite structures: Literature review. J. Struct. Eng. 2011, 137, 1085–1095. [Google Scholar] [CrossRef]

- Klotz, S.; Holschemacher, K.; Köhler, S. Wirtschaftlichkeit von Holz-Beton-Verbunddecken. In Proceedings of the Innovationen im Bauwesen-Holz-Beton-Verbund, Leipzig, Germany, 18–19 March 2004; pp. 269–279. [Google Scholar]

- Newcombe, M.P.; Van Beerschoten, W.A.; Carradine, D.; Pampanin, S.; Buchanan, A.H. In-plane experimental testing of timber-concrete composite floor diaphragms. J. Struct. Eng. 2010, 136, 1461–1468. [Google Scholar] [CrossRef]

- Smith, I.; Frangi, A. Use of Timber in Tall Multi-Storey Buildings; International Association for Bridge and Structural Engineering: Zurich, Switzerland, 2014. [Google Scholar]

- Movaffaghi, H.; Pyykkö, J.; Yitmen, I. Value-driven design approach for optimal long-span timber-concrete composite floor in multi-storey wooden residential buildings. Civ. Eng. Environ. Syst. 2020, 37, 100–116. [Google Scholar] [CrossRef]

- Stepinac, M.; Šušteršič, I.; Gavrić, I.; Rajčić, V. Seismic design of timber buildings: Highlighted challenges and future trends. Appl. Sci. 2020, 10, 1380. [Google Scholar] [CrossRef]

- Sebastian, W.; Webb, S.; Nagree, H.S. Orthogonal distribution and dynamic amplification characteristics of partially prefabricated timber-concrete composites. Eng. Struct. 2020, 219, 110693. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, X.; Gong, H.; Zhang, J.; Lv, Z.; Hong, W. Experimental study on the impact sound insulation of cross laminated timber and timber-concrete composite floors. Appl. Acoust. 2020, 161, 107173. [Google Scholar] [CrossRef]

- Ghafar, N.H.A. In Vibration Performance of LVL-Concrete Composite Floor Systems. In Proceedings of the World Conference on Timber Engineering (WCTE 2008), Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- AbdGhafar, H.; Deam, B.L.; Fragiacomo, M. Dynamic Measurements of LVL-Concrete Composite Floors. In Proceedings of the 13th Asia Pacific Vibration Conference, University of Canterbury, Christchurch, New Zealand, 22–25 November 2009; pp. 1–8. [Google Scholar]

- Fragiacomo, M.; Lukaszewska, E. Development of prefabricated timber–concrete composite floor systems. Proc. Inst. Civ. Eng.-Struct. Build. 2011, 164, 117–129. [Google Scholar] [CrossRef]

- Shi, B.; Zhou, X.; Tao, H.; Yang, H.; Wen, B. Long-Term Behavior of Timber–Concrete Composite Structures: A Literature Review on Experimental and Numerical Investigations. Buildings 2024, 14, 1770. [Google Scholar] [CrossRef]

- Dolan, J.; Murray, T.; Johnson, J.; Runte, D.; Shue, B. Preventing annoying wood floor vibrations. J. Struct. Eng. 1999, 125, 19–24. [Google Scholar] [CrossRef]

- Talja, A.; Toratti, T. Effect on Floating Floors on the Vibration Performance of Wood-Concrete Composite Floors. In Proceedings of the World Conference on Timber Engineering (WCTE 2000), Whistler, BC, Canada, 31 July–3 August 2000. [Google Scholar]

- Mertens, C.; Martin, Y.; Dobbels, F. Investigation of the vibration behaviour of timber-concrete composite floors as part of a performance evaluation for the Belgian building industry. Build. Acoust. 2007, 14, 25–36. [Google Scholar] [CrossRef]

- Casagrande, D.; Giongo, I.; Pederzolli, F.; Franciosi, A.; Piazza, M. Analytical, numerical and experimental assessment of vibration performance in timber floors. Eng. Struct. 2018, 168, 748–758. [Google Scholar] [CrossRef]

- Hamm, P.; Richter, A.; Winter, S. Floor Vibrations–New Results. In Proceedings of the 11th World Conference on Timber Engineerig (WCTE2010), Riva del Garda, Trentino, Italy, 20–24 June 2010. [Google Scholar]

- Rijal, R.; Samali, B.; Crews, K.; Shrestha, R. Dynamic Behaviour of Timber-Concrete Composite Flooring Systems. In Proceedings of the 11th World Conference on Timber Engineering 2010, WCTE 2010, Trentino, Italy, 20–24 June; pp. 1815–1820.

- Skinner, J.; Harris, R.; Paine, K.; Walker, P.; Bregula, J. The characterisation of Connectors for the Upgrade of Timber Floors With Thin Structural Toppings. In Proceedings of the World Conference of Timber Engineering 2012, Auckland, New Zealand, 15–19 July 2012. [Google Scholar]

- Omenzetter, P.; Kohli, V.; Desgeorges, Y. Evaluation of timber-concrete floor performance under occupant-induced vibrations using continuous monitoring. Key Eng. Mater. 2013, 569, 230–237. [Google Scholar] [CrossRef]

- Fong, L.Y.; Ghafar, N.H.A.; Abd Rahman, N.; Fragiacomo, M.; Ibrahim, Z.; Buchanan, A. Comparison Between The Vibration Performance Of Lvlconcrete Composite (Lcc) Flooring System Made Of Malaysian And New Zealand Lvl. Malays. J. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Marshall, E.J.; Granello, G.; Palermo, A. Vibration performance of timber-concrete composite floors: A case study. SESOC J. 2020, 33, 33–46. [Google Scholar]

- Mushina, J.; Abd Ghafar, N.; Yeoh, D.; Mushina, W.; Boon, K.H. Vibration Behaviour of Natural Timber and Timber Concrete Composite Deck System. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012023. [Google Scholar]

- Hermann, F. Device For Damping Vibrations of Bodies. US Patent 89958, 18 April 1911. [Google Scholar]

- Xu, K.; Igusa, T. Dynamic characteristics of multiple substructures with closely spaced frequencies. Earthq. Eng. Struct. Dyn. 1992, 21, 1059–1070. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Harnpornchai, N. Fundamental characteristics of Multiple Tuned Mass Dampers for suppressing harmonically forced oscillations. Earthq. Eng. Struct. Dyn. 1993, 22, 51–62. [Google Scholar] [CrossRef]

- Gu, M.; Chen, S.R.; Chang, C.C. Parametric study on multiple tuned mass dampers for buffeting control of Yangpu Bridge. J. Wind Eng. Ind. Aerodyn. 2001, 89, 987–1000. [Google Scholar] [CrossRef]

- Lin, C.C.; Wang, J.F.; Chen, B.L. Train-Induced Vibration Control of High-Speed Railway Bridges Equipped with Multiple Tuned Mass Dampers. J. Bridge Eng. 2005, 10, 398–414. [Google Scholar] [CrossRef]

- Chen, S.R.; Wu, J. Performance enhancement of bridge infrastructure systems: Long-span bridge, moving trucks and wind with tuned mass dampers. Eng. Struct. 2008, 30, 3316–3324. [Google Scholar] [CrossRef]

- Rainer, J.H.; Swallow, J.C. Dynamic behaviour of a gymnasium floor. Can. J. Civ. Eng. 1986, 13, 270–277. [Google Scholar] [CrossRef][Green Version]

- Webster, A.; Vaicaitis, R. Application of Tuned Mass Dampers To Control Vibrations of Composite Floor Systems. Eng. J. 1992, 29, 116–124. [Google Scholar] [CrossRef]

- Setareh, M.; Hanson, R.D. Tuned Mass Dampers for Balcony Vibration Control. J. Struct. Eng. 1992, 118, 723–740. [Google Scholar] [CrossRef]

- Chen, Z.; Feng, Z.; Chen, J.; Sun, X.; Hua, X. Hybrid control of the vortex-induced vibration of a pedestrian landscape bridge based on aerodynamic measures and pulley-type TMD. J. Vib. Shock 2024, 43, 140–148. [Google Scholar]

- Huang, H.; Chang, W.-S. Application of pre-stressed SMA-based tuned mass damper to a timber floor system. Eng. Struct. 2018, 167, 143–150. [Google Scholar] [CrossRef]

- Huang, H.; Gao, Y.; Chang, W.-S. Human-induced vibration of cross-laminated timber (CLT) floor under different boundary conditions. Eng. Struct. 2020, 204, 110016. [Google Scholar] [CrossRef]

- Jiang, Z.-Q.; Liu, L.-T.; Chang, W.-S.; Wang, W.; Wang, Y.-H.; Huang, H. Enhancing CLT floor vibration mitigation with pre-strained shape memory alloy-tuned mass dampers. Structures 2024, 67, 106980. [Google Scholar] [CrossRef]

- Huang, H.; Mosalam, K.M.; Chang, W.-S. Adaptive tuned mass damper with shape memory alloy for seismic application. Eng. Struct. 2020, 223, 111171. [Google Scholar] [CrossRef]

- Huang, H.; Zhu, Y.-Z.; Chang, W.-S. Comparison of bending fatigue of NiTi and CuAlMn shape memory alloy bars. Adv. Mater. Sci. Eng. 2020, 2020, 8024803. [Google Scholar] [CrossRef]

- Huang, H.; Wang, C.; Chang, W.-S. Reducing human-induced vibration of cross-laminated timber floor—Application of multi-tuned mass damper system. Struct. Control Health Monit. 2021, 28, e2656. [Google Scholar] [CrossRef]

- Zieliński, T.; Duda, K. Frequency and Damping Estimation Methods—An Overview. Metrol. Meas. Syst. 2011, 18, 505–528. [Google Scholar] [CrossRef]

- BS EN 16929:2018; Test Methods—Timber Floors—Determination of Vibration Properties. British Standards Institution: Brussels, Belgium, 2018.

- Clough, R.W.; Penzien, J.; Griffin, D.S. Dynamics of Structures, 3rd ed.; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- BS 6472-1:2008; Guide to Evaluation of Human Exposure to Vibration in Buildings. In Part 1: Vibration Sources Other Than Blasting. British Standards Institution: London, UK, 2008.

- ISO 10137:2007; Bases for Design of Structures—Serviceability of Buildings and Walkways Against Vibrations. International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- Hartog, D. Mechanical Vibrations. In The Aeronautical Journal; McGraw-Hill: New York, NY, USA, 1957; Volume 61, p. 139. [Google Scholar]

- Huang, H.; Chang, W.-S.; Mosalam, K.M. Feasibility of shape memory alloy in a tuneable mass damper to reduce excessive in-service vibration. Struct. Control Health Monit. 2017, 24, e1858. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).