Investigation into the Static Mechanical Properties of Ultra-High-Performance Geopolymer Concrete Incorporating Steel Slag, Ground Granulated Blast-Furnace Slag, and Fly Ash

Abstract

1. Introduction

2. Experimental Program

2.1. Raw Materials

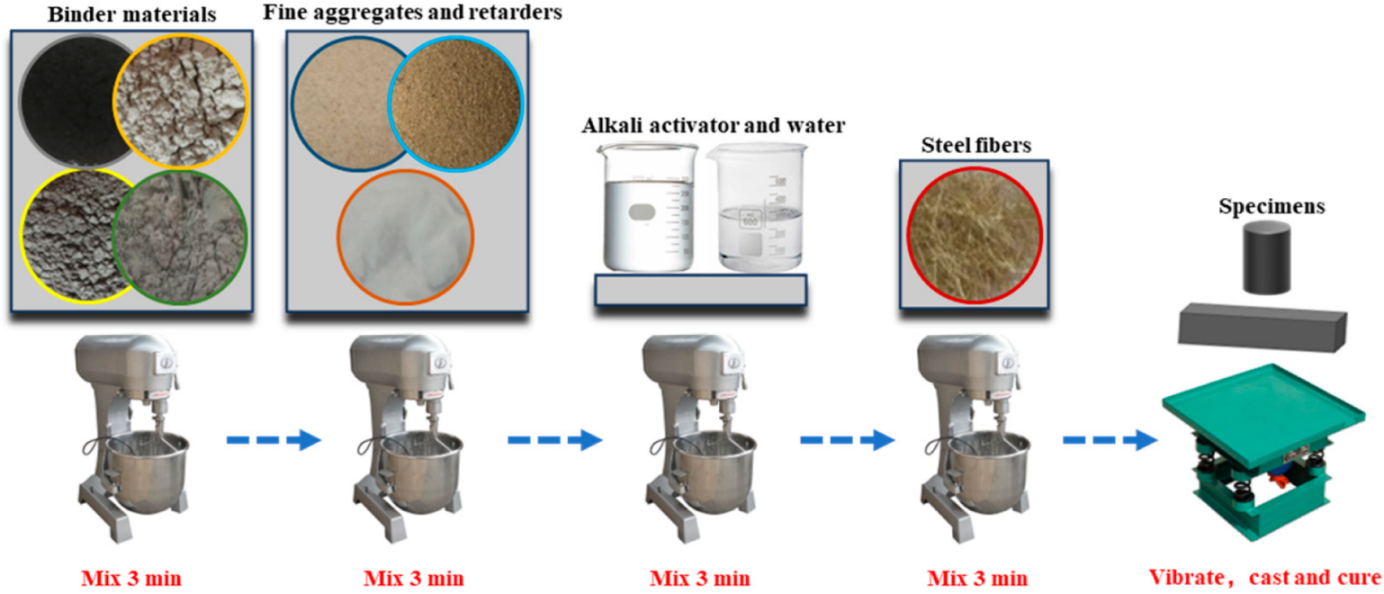

2.2. Mix Proportions and Specimen Preparation

2.3. Test Setup and Loading

2.3.1. Flowability Test

2.3.2. Axial Compression Performance Test

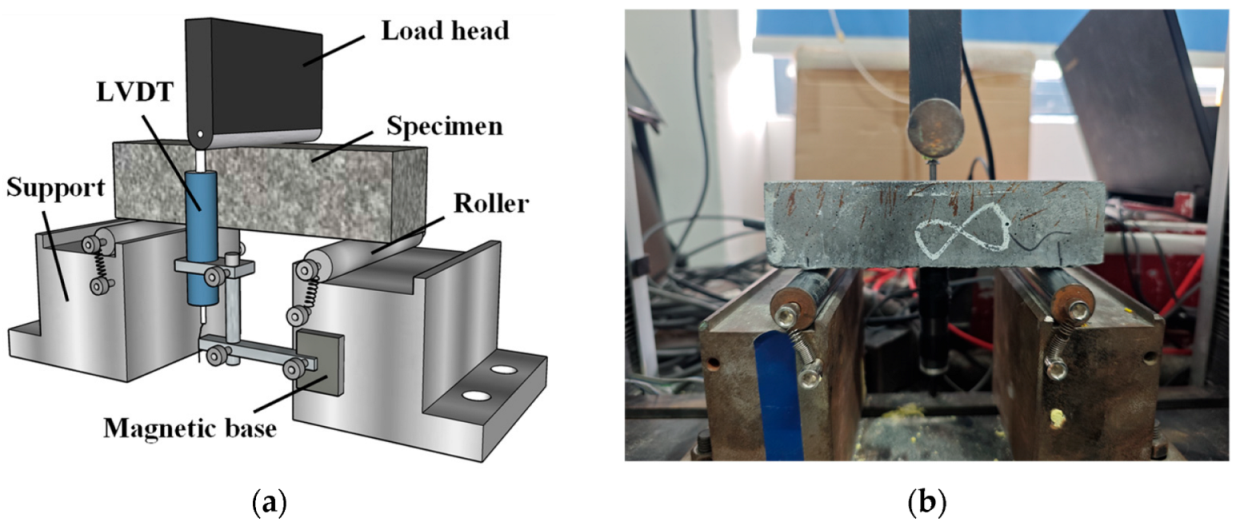

2.3.3. Third-Point Flexural Performance Test

3. Results and Discussion

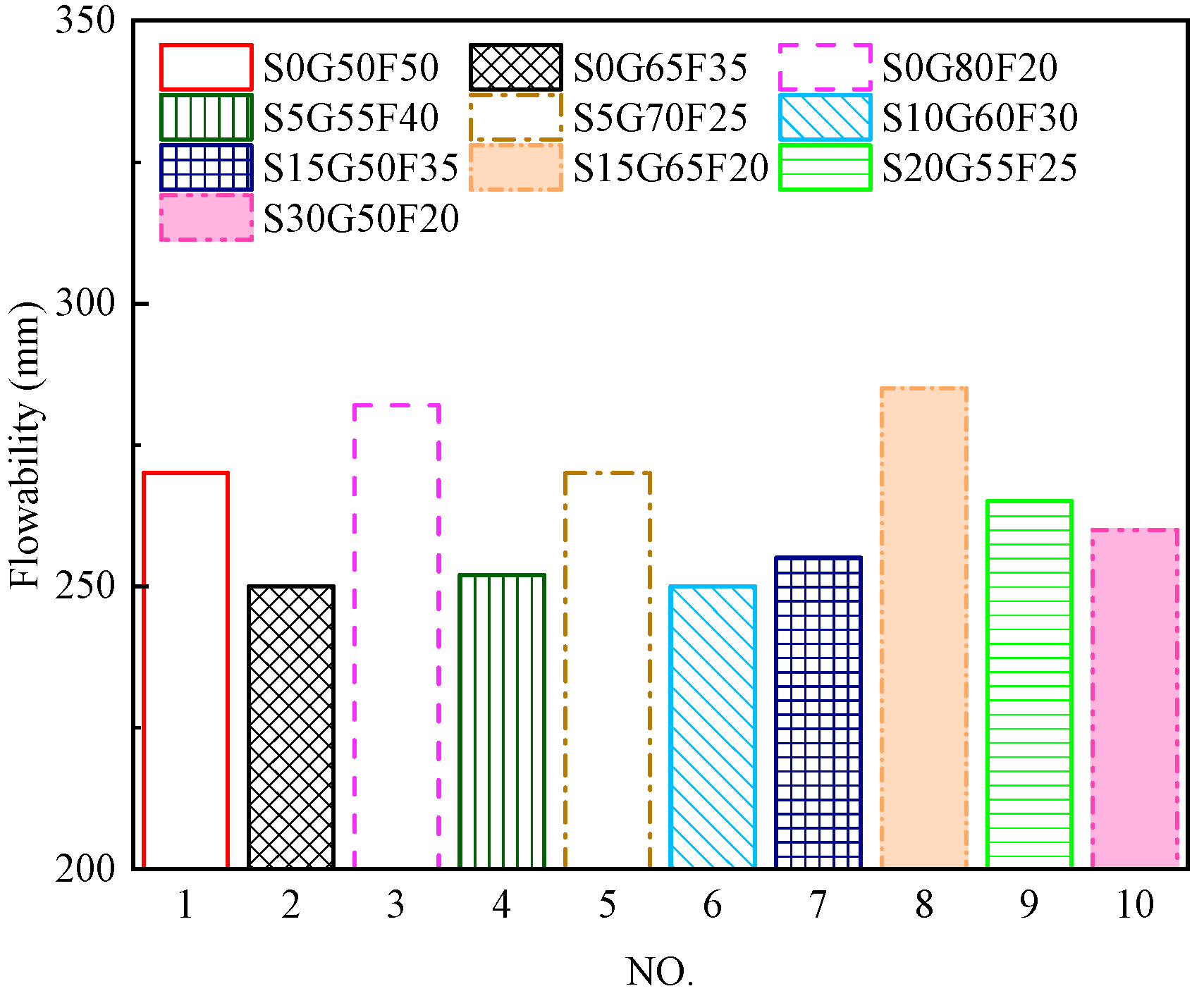

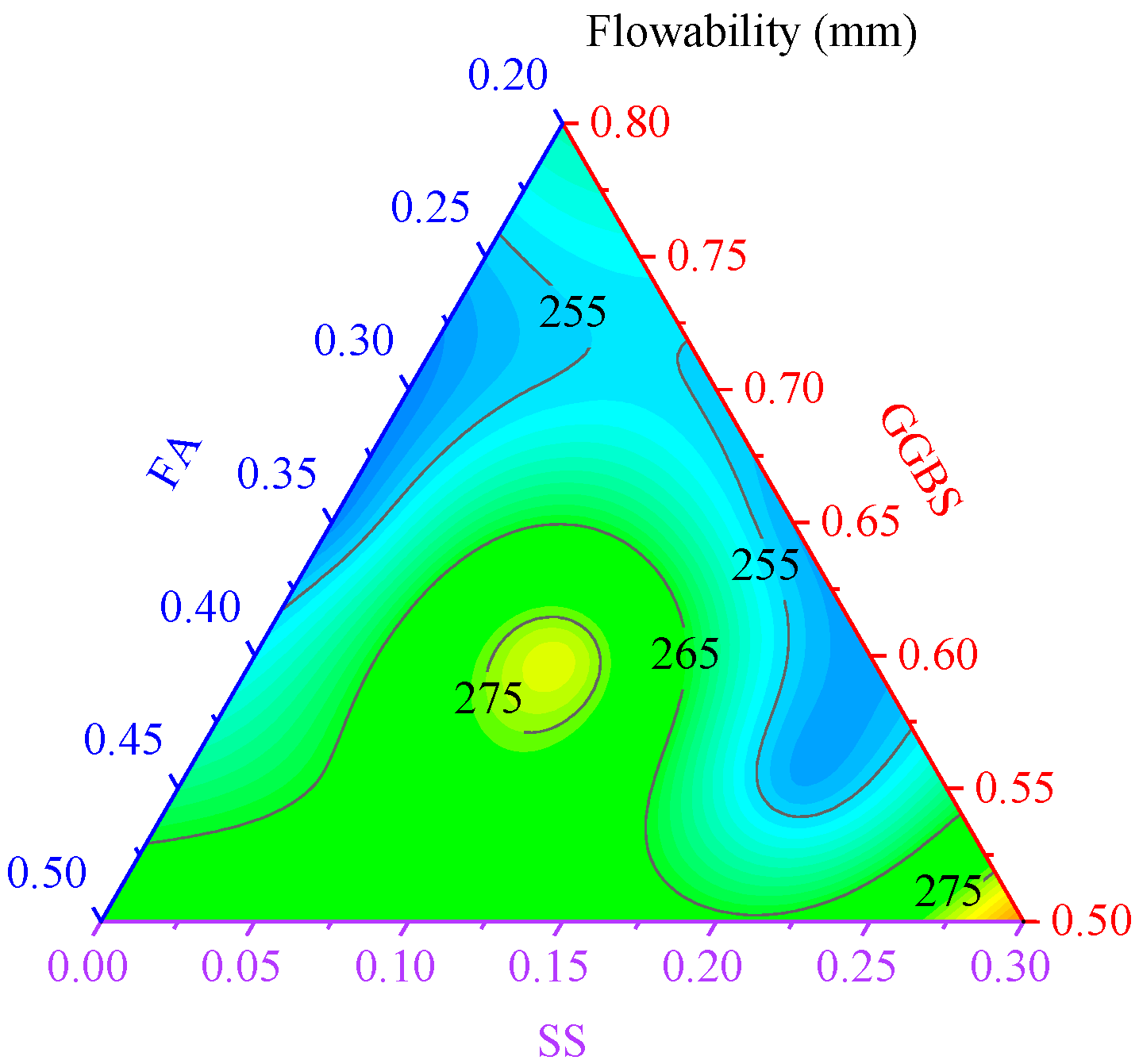

3.1. Flowability

3.2. Compressive Behaviors

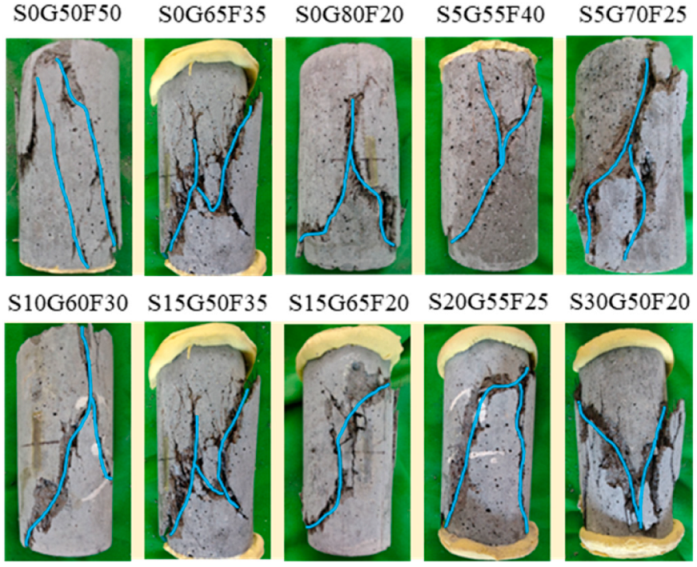

3.2.1. Failure Mode

3.2.2. Stress–Strain Curves and Compressive Parameters

3.3. Flexural Behaviors

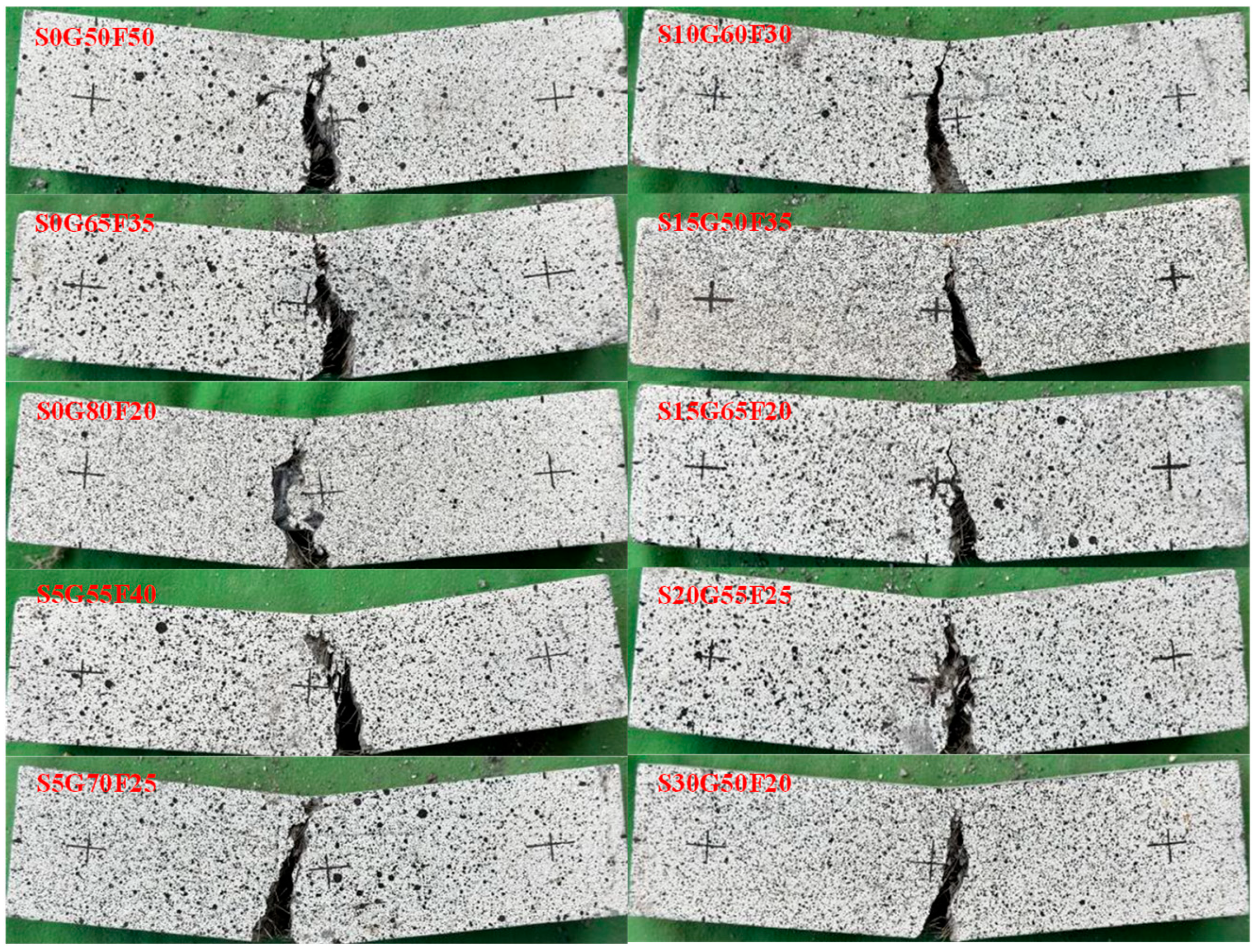

3.3.1. Failure Mode

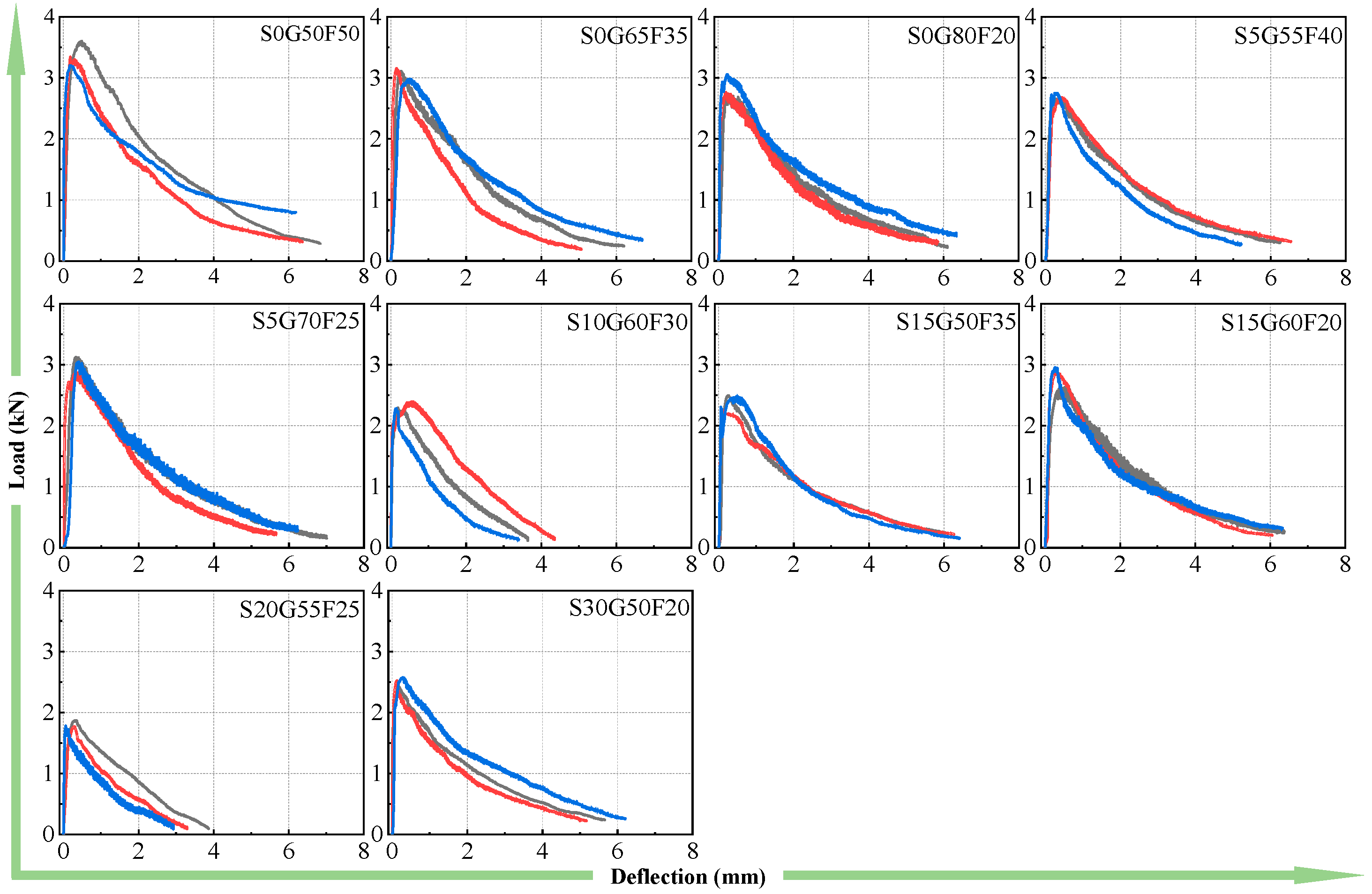

3.3.2. Load–Deflection Curves and Flexural Parameters

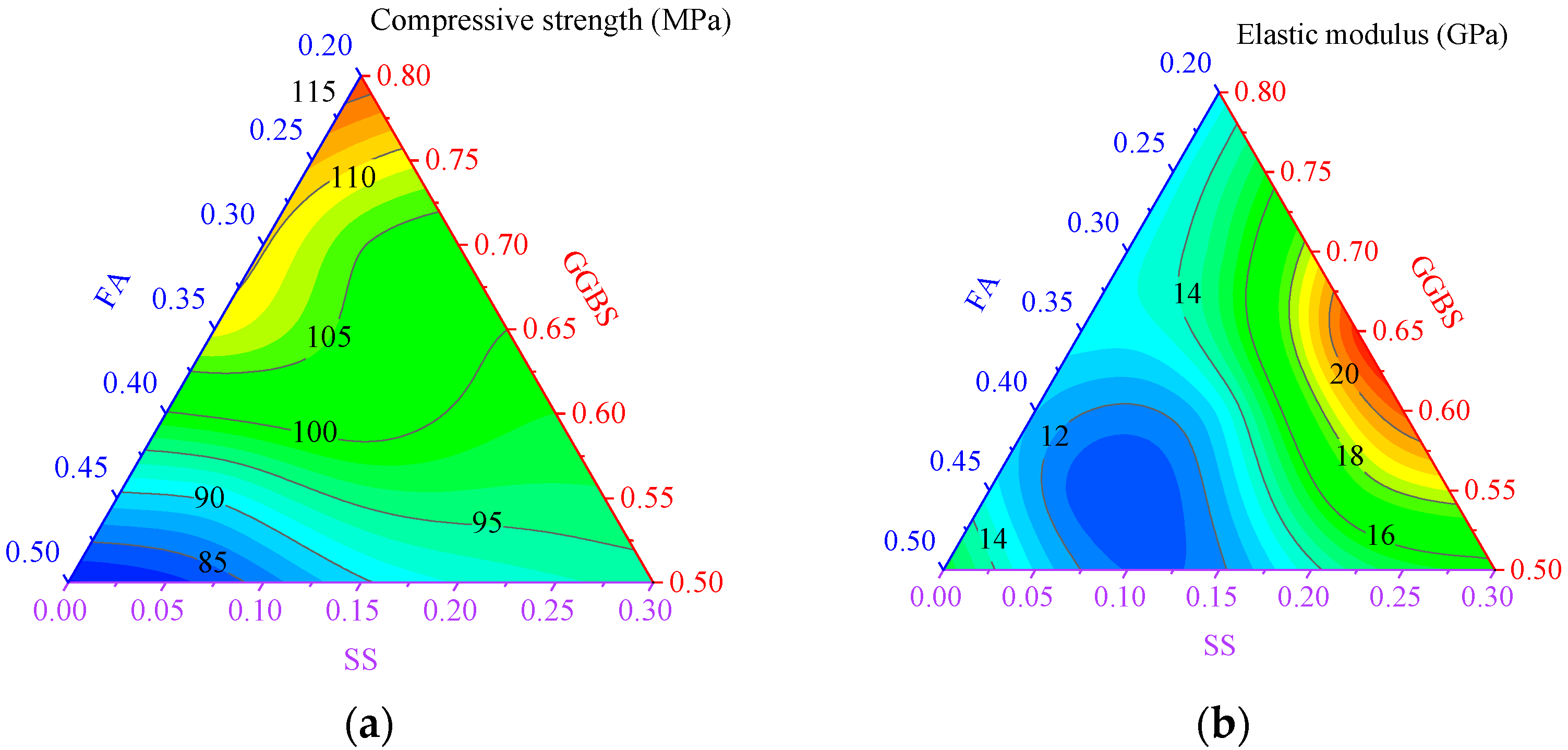

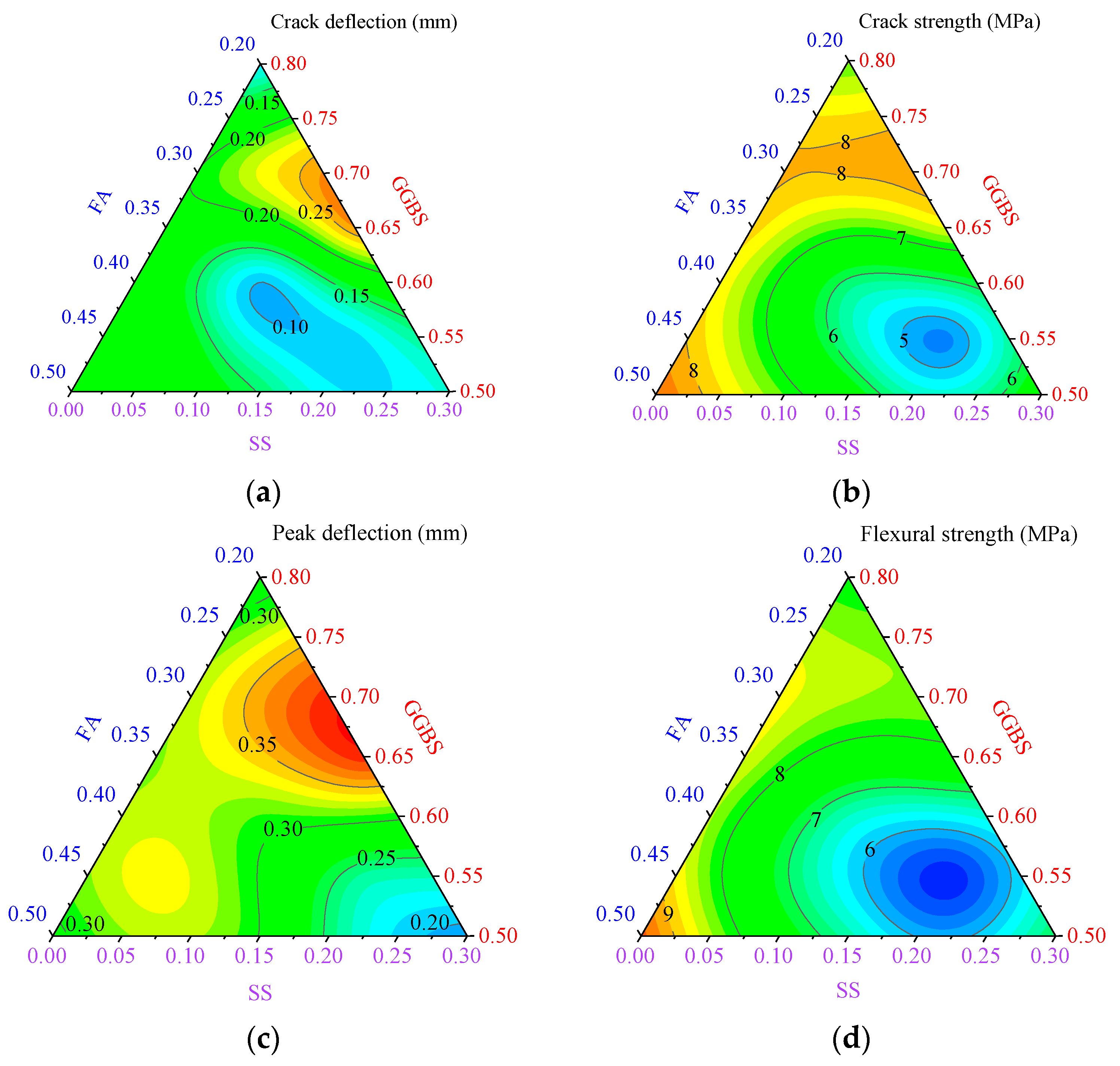

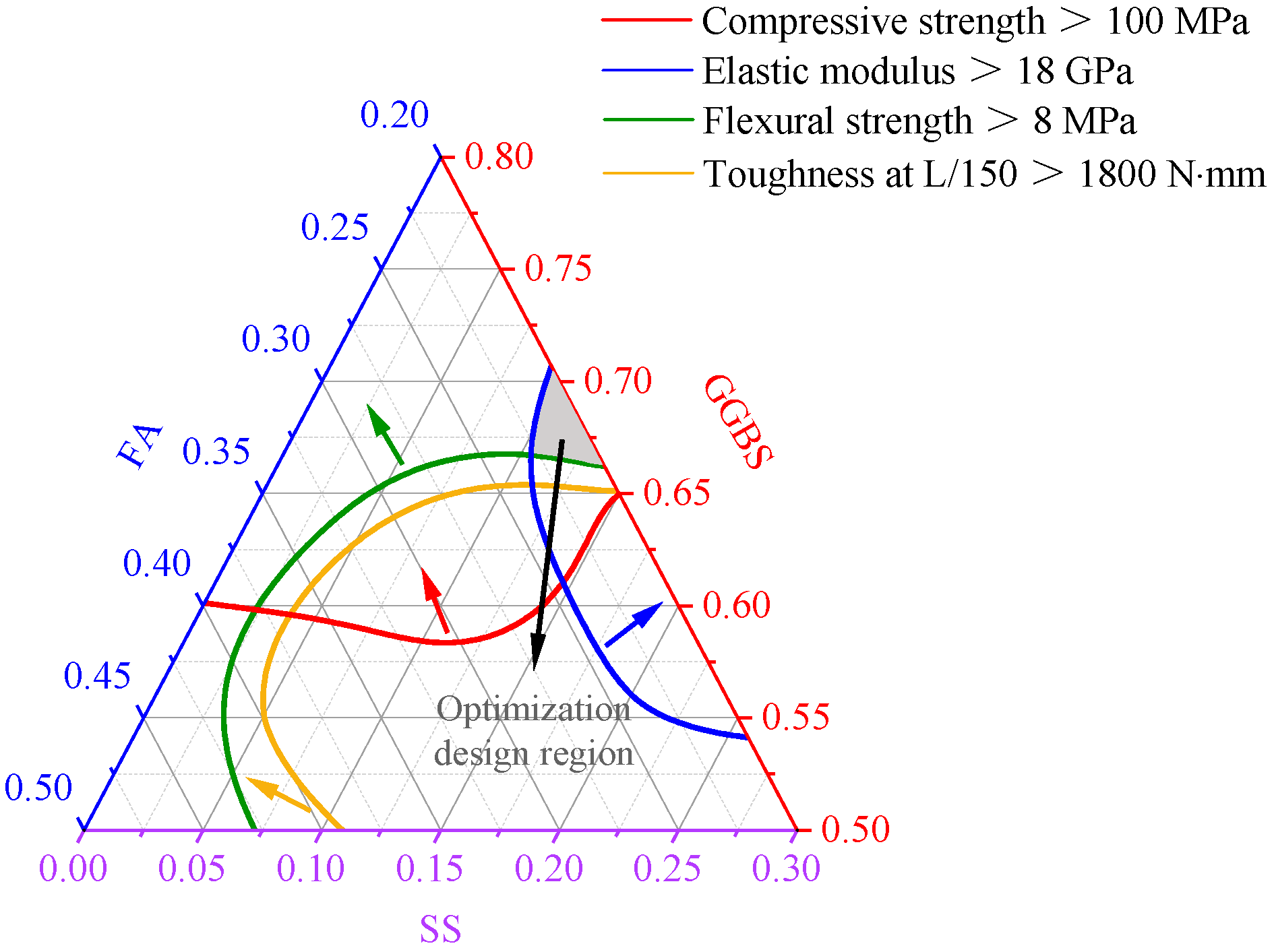

3.4. Design of Ternary Cementitious System UHPGC

4. Conclusions

- All groups of freshly mixed UHPGC pastes exhibited good workability, with flow diameters exceeding 250 mm. An appropriate proportioning of the ternary composite binder system can mitigate the negative impact of steel slag on the flowability of UHPGC paste.

- The 10 UHPGC mixtures designed by the augmented simplex centroid method maintained good integrity during uniaxial compressive testing. Variation in the proportions of steel slag, GGBS, and fly ash in the ternary binder system altered the failure modes of the UHPGC. High-calcium systems tend to exhibit vertical splitting failure, whereas low-calcium systems are more prone to diagonal shear failure. Increasing the GGBS content within the ternary binder system helped maintain high levels of compressive strength and elastic modulus.

- In the three-point bending tests, UHPGC specimens with different ternary binder ratios consistently exhibited a certain degree of ductility after failure. Replacing GGBS with steel slag as a binder component led to a reduction in the flexural performance of the UHPGC.

- Utilizing the augmented simplex centroid design method and considering multiple mechanical performance indicators, an optimal mix proportion range was established. When the proportions of steel slag, GGBS, and fly ash were controlled within 9.3–13.8%, 66.2–70.7%, and 20.0–22.9%, respectively, the UHPGC met the key performance criteria of a uniaxial compressive strength > 100 MPa, elastic modulus > 18 GPa, flexural strength > 8 MPa, and toughness at L/150 > 1800 N·mm simultaneously.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Ren, Y.; Li, Q.; Shi, C. Influence of steel fiber hybridization on the static mechanical performance of ultra-high performance geopolymer concrete (UHPGC). Cem. Concr. Compos. 2025, 160, 106064. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Zhu, Y.; Dai, J.-G.; Xu, Q.; Liu, K.; Hao, F.; Sun, D. Manufacturing ultra-high performance geopolymer concrete (UHPGC) with activated coal gangue for both binder and aggregate. Compos. Part B Eng. 2024, 284, 111723. [Google Scholar] [CrossRef]

- Regalla, S.S.; N, S.K. The enhancing role of nanomaterials in revolutionizing ultra-high-performance concrete (UHPC): A journey from atomic precision to structural prominence. Case Stud. Constr. Mater. 2025, 22, e04608. [Google Scholar] [CrossRef]

- Tong, T.; Li, X.; Wang, T.; Liu, Z. An experimental-numerical study of tensile behavior of reinforced-UHPC members subject to uniaxial tension. Structures 2025, 75, 108626. [Google Scholar] [CrossRef]

- Lin, J.-X.; Luo, R.-H.; Su, J.-Y.; Guo, Y.-C.; Chen, W.-S. Coarse synthetic fibers (PP and POM) as a replacement to steel fibers in UHPC: Tensile behavior, environmental and economic assessment. Constr. Build. Mater. 2024, 412, 134654. [Google Scholar] [CrossRef]

- Qin, J.; Dai, F.; Ma, H.; Dai, X.; Li, Z.; Jia, X.; Qian, J. Development and characterization of magnesium phosphate cement based ultra-high performance concrete. Compos. Part B Eng. 2022, 234, 109694. [Google Scholar] [CrossRef]

- Braveru, C.S.; Zhou, W. Experimental study of the axial compressive behavior of square cross-section UHPC-encased composite concrete columns. J. Build. Eng. 2025, 106, 112606. [Google Scholar] [CrossRef]

- Hung, C.-C.; Agrawal, S.; Hsiao, H.-J. Rehabilitation of seismically-damaged RC beam-column joints with UHPC and high-strength steel mesh reinforcement. J. Build. Eng. 2024, 84, 108667. [Google Scholar] [CrossRef]

- Anunike, G.S.; Tarabin, M.; Hisseine, O.A. Ultra-high-performance concrete for nuclear applications: A review of raw materials and mix design approaches. Constr. Build. Mater. 2024, 438, 136938. [Google Scholar] [CrossRef]

- Fan, D.Q.; Yu, R.; Shui, Z.H.; Wu, C.F.; Song, Q.L.; Liu, Z.J.; Sun, Y.; Gao, X.; He, Y.J. A new design approach of steel fibre reinforced ultra-high performance concrete composites: Experiments and modeling. Cem. Concr. Compos. 2020, 110, 103597. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elrahman, M.A.; Abadel, A.A.; Wasim, M.; Tahwia, A. Ultra-high performance concrete versus ultra-high performance geopolymer concrete: Mechanical performance, microstructure, and ecological assessment. J. Build. Eng. 2023, 79, 107835. [Google Scholar] [CrossRef]

- Soliman, N.; Omran, A.; Aghaee, K.; Ozbulut, O.; Tagnit-Hamou, A. Synergistic effect of nano-to-macro waste glass of various particle sizes on ultra-high-performance concrete: Tradeoff between mix design parameters and performance through a statistical design approach. J. Build. Eng. 2024, 95, 110129. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Lao, J.-C.; Ma, R.-Y.; Xu, L.-Y.; Li, Y.; Shen, Y.-N.; Yao, J.; Wang, Y.-S.; Xie, T.-Y.; Huang, B.-T. Fly ash-dominated High-Strength Engineered/Strain-Hardening Geopolymer Composites (HS-EGC/SHGC): Influence of alkalinity and environmental assessment. J. Clean. Prod. 2024, 447, 141182. [Google Scholar] [CrossRef]

- Xu, D.; Cui, Y.; Li, H.; Yang, K.; Xu, W.; Chen, Y. On the future of Chinese cement industry. Cem. Concr. Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material design of economical ultra-high performance concrete (UHPC) and evaluation of their properties. Cem. Concr. Compos. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Lao, J.-C.; Xu, L.-Y.; Huang, B.-T.; Dai, J.-G.; Shah, S.P. Strain-hardening Ultra-High-Performance Geopolymer Concrete (UHPGC): Matrix design and effect of steel fibers. Compos. Commun. 2022, 30, 101081. [Google Scholar] [CrossRef]

- Wetzel, A.; Middendorf, B. Influence of silica fume on properties of fresh and hardened ultra-high performance concrete based on alkali-activated slag. Cem. Concr. Compos. 2019, 100, 53–59. [Google Scholar] [CrossRef]

- Murali, G.; Nassar, A.K.; Swaminathan, M.; Kathirvel, P.; Wong, L.S. Effect of silica fume and glass powder for enhanced impact resistance in GGBFS-based ultra high-performance geopolymer fibrous concrete: An experimental and statistical analysis. Def. Technol. 2024, 41, 59–81. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Liu, Z.; Li, J.; Xu, S.; Liu, K.; Su, Y.; Chen, G. Investigations on the response of ceramic ball aggregated and steel fibre reinforced geopolymer-based ultra-high performance concrete (G-UHPC) to projectile penetration. Compos. Struct. 2021, 255, 112983. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Z.; Zhu, H.; Duan, P.; Fang, Y.; Jiang, Z. Mechanisms of CLDH seeding on hydration kinetics of slag-based geopolymer: Towards aluminosilicate cement phase engineering. Compos. Part B Eng. 2024, 271, 111157. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Chen, G.; Liu, L.-Y.; Li, J.-F.; Lin, J.-X.; Guo, Y.-C. In-situ tensile behavior of hybrid PE/PP fibers reinforced strain-hardening alkali-activated composites (H-SHAAC) subjected to different temperatures. J. Build. Eng. 2024, 98, 111332. [Google Scholar] [CrossRef]

- Lin, J.-X.; He, G.-J.; Wu, J.-S.; Deng, W.-B.; Zhou, Z.-Y.; Guo, G.-S.; Sheng, C.; Xie, B.-X.; Guo, Y.-C. Mechanical performance of steel-PE hybrid fiber-reinforced SHAAC: A comparative study of two distinct hybridization approaches. J. Mater. Res. Technol. 2025, 35, 5637–5650. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, C.; Guo, Y.; Cui, H.; Xue, J. Improved mechanical and thermal properties of sustainable ultra-high performance geopolymer concrete with cellulose nanofibres. J. Build. Eng. 2025, 102, 112068. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Z.; Xie, J.; Hu, X.; Shi, C. Trends toward lower-carbon ultra-high performance concrete (UHPC)—A review. Constr. Build. Mater. 2024, 420, 135602. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Rostami, M.; Behfarnia, K. The effect of silica fume on durability of alkali activated slag concrete. Constr. Build. Mater. 2017, 134, 262–268. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, J.; Liu, Z.; Xu, S.; Liu, K.; Su, Y.; Fang, J.; Chen, G. Projectile impact resistance of fibre-reinforced geopolymer-based ultra-high performance concrete (G-UHPC). Constr. Build. Mater. 2021, 290, 123189. [Google Scholar] [CrossRef]

- Lin, S.; Liu, J.; Liu, C.; Liu, K.; Liu, P.; Su, Y. Triaxial compressive behaviour of ultra-high performance geopolymer concrete (UHPGC) and its applications in contact explosion and projectile impact analysis. Constr. Build. Mater. 2024, 449, 138394. [Google Scholar] [CrossRef]

- Abdellatief, M.; Al-Tam, S.M.; Elemam, W.E.; Alanazi, H.; Elgendy, G.M.; Tahwia, A.M. Development of ultra-high-performance concrete with low environmental impact integrated with metakaolin and industrial wastes. Case Stud. Constr. Mater. 2023, 18, e01724. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; AlAteah, A.H.; Mostafa, S.A. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Constr. Build. Mater. 2024, 434, 136722. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Y.; Chen, T.; Gao, X. Porous biochar-assisted aqueous carbonation of steel slag as an adsorptive crystallization modifier for value-added cement applications. Cem. Concr. Compos. 2025, 159, 106002. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, G.; Wang, Q.; Li, S.; Zhang, J.; Sun, H.; Saqib, I. Effects of the surface nano-reconstruction of steel slag on the performance of cement-based materials. Constr. Build. Mater. 2025, 475, 141172. [Google Scholar] [CrossRef]

- Liu, X.; Bao, Y.-P. Separation and extraction of iron resources from hazardous electric arc furnace (EAF) steel slag: Aggregation of Fe-rich layers, magnetic separation, powder characterization. Process Saf. Environ. Prot. 2024, 190, 420–428. [Google Scholar] [CrossRef]

- Huo, B.; Luo, Y.; Li, B.; Chen, C.; Zhang, Y. Influence of particle size on the reactivity of chemical modified steel slag powder. J. Sustain. Cem.-Based Mater. 2023, 12, 62–70. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Zhang, C.X.; Aden, N.; Li, X.P.; Shangguan, F.Q. Comparison of iron and steel production energy use and energy intensity in China and the U.S. J. Clean. Prod. 2014, 65, 108–119. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, X.; Lu, H.; Ni, T.; Li, Y. Waste energy recovery and energy efficiency improvement in China’s iron and steel industry. Appl. Energy 2017, 191, 502–520. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Mi, G. Effect of blended steel slag–GBFS mineral admixture on hydration and strength of cement. Constr. Build. Mater. 2012, 35, 8–14. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.; Li, J.; Yu, Q.; Wang, X.; Gao, D.; Wang, F.; Cai, S.; Zeng, Y. Effects from Converter Slag and Electric Arc Furnace Slag on Chlorophyll a Accumulation of Nannochloropsis sp. Appl. Sci. 2021, 11, 9127. [Google Scholar] [CrossRef]

- Jia, R.; Liu, J.; Jia, R. A study of factors that influence the hydration activity of mono-component CaO and bi-component CaO/Ca2Fe2O5 systems. Cem. Concr. Res. 2017, 91, 123–132. [Google Scholar] [CrossRef]

- Ma, H.-C.; Geng, Y.; Wang, Q.-H.; Lai, L.-H.; Li, G.-D.; Wang, Y.-Y. Autogenous shrinkage model for concrete with weathered steel slag coarse aggregate. Structures 2025, 75, 108862. [Google Scholar] [CrossRef]

- Zhang, L.; Cui, J.; Chen, Z.; Jing, X.; Liu, Y.; He, B.; Cang, D. Recycling of carbonated steel slag in building materials: Recycling pathways and recent advances. J. Build. Eng. 2025, 104, 112285. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Gu, D.-D.; Ge, Q.; Shi, X.-Y.; Zhang, H.-M.; Wang, R.; Zhang, H.; Kosiba, K. Role of laser scan strategies in defect control, microstructural evolution and mechanical properties of steel matrix composites prepared by laser additive manufacturing. Int. J. Miner. Metall. Mater. 2021, 28, 462–474. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Tao, M.-J.; Li, J.-G.; Zhang, J.-B.; Qin, S.; Liu, S.-H.; Peng, L.-J.; Zhang, X.-P.; Zhang, X.; Zeng, Y.-N. A review of use of metallurgical slag for its carbonation products: Processes, crystallization behavior, and application status. J. Iron Steel Res. Int. 2023, 30, 2341–2365. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Z.; Li, S.; Ding, Z.; Huang, H. Study on the inhibition of steel slag’s volume expansion caused by plant urease and the properties of asphalt mixture. Constr. Build. Mater. 2025, 469, 140443. [Google Scholar] [CrossRef]

- Gu, J.; Wei, C.; Wu, P.; Cao, Z.; Shao, Y.; Liu, X.; Zhang, Z. Application and mechanism analysis of steel slag in resource recovery and environmental remediation: A review. Miner. Eng. 2025, 227, 109268. [Google Scholar] [CrossRef]

- Song, Q.; Song, T.; Nie, J.; Zhou, H.; Hu, Y.; Chen, Y.; Deng, Y.; He, Q.; Cheng, F. An investigation on the use of coal gangue and coal gasification slag as reducing agent in synergistic utilization of steel slag for higher-activity supplementary cementitious materials. Constr. Build. Mater. 2025, 477, 141094. [Google Scholar] [CrossRef]

- Ren, Z.; Ding, M.; Li, D. Study on the monotonic axial compression behavior of the GFRP confined autoclaved steel slag blocks compound concrete circular column. J. Build. Eng. 2025, 105, 112397. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Q.; Zhang, X.; Cao, T.; Wu, Z. Synergistic improvement on temperature and moisture stability of asphalt mixture with steel slag aggregate coated by waterborne polyurethane. Constr. Build. Mater. 2025, 472, 140847. [Google Scholar] [CrossRef]

- Xu, H.; Chen, A.; Wu, S.; Li, Y.; Li, J.; Zhu, Y.; Wu, J.; Zhou, Y.; Feng, J. Mechanism of asphalt concrete reinforced with industrially recycled steel slag from the perspectives of adhesion and skeleton. Constr. Build. Mater. 2024, 424, 135899. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Jing, H.; Jia, H.; Zhou, L.; Chen, H.; Zhang, L. Microwave self-healing characteristics of bituminous mixtures with different steel slag aggregate and waste ferrite filler. Constr. Build. Mater. 2023, 407, 133304. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, M.; Ma, G.; Sanjayan, J. An eco-friendly ultra-high-performance geopolymer concrete with quaternary binders for 3D printing. J. Clean. Prod. 2025, 487, 144614. [Google Scholar] [CrossRef]

- Shi, K.; Deng, H.; Hu, J.; Zhou, J.; Cai, X.; Liu, Z. Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials 2023, 16, 3875. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhang, J.; Zhang, J.; Deng, Q.; Xue, Z.; Huang, G.; Huang, X. Influence of steel slag and steel fiber on the mechanical properties, durability, and life cycle assessment of ultra-high performance geopolymer concrete. Constr. Build. Mater. 2024, 441, 137590. [Google Scholar] [CrossRef]

- Filazi, A.; Tortuk, S.; Pul, M. Determination of optimum blast furnace slag ash and hemp fiber ratio in cement mortars. Structures 2023, 57, 105024. [Google Scholar] [CrossRef]

- Filazi, A.; Akat, R.; Pul, M.; Tortuk, S.; Özdin, A. Physical Structural Mechanical and Thermal Insulation Properties of Hemp Fiber-Substituted Geopolymer Composites. Materials 2025, 18, 2536. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume. Cem. Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Sanyin, Z.; Qijun, Y.; Fei, Q.; Jiaqi, H.; Suhong, Y.; Ziyun, W.; Guobang, G. Setting and strength characteristics of alkali-activated carbonatite cementitious materials with ground slag replacement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2006, 21, 125–128. [Google Scholar] [CrossRef]

- Liang, G.; Yao, W.; Wei, Y. A green ultra-high performance geopolymer concrete containing recycled fine aggregate: Mechanical properties, freeze-thaw resistance and microstructure. Sci. Total Environ. 2023, 895, 165090. [Google Scholar] [CrossRef] [PubMed]

- Cornell, J.A. A Comparison between Two Ten-Point Designs for Studying Three-Component Mixture Systems. J. Qual. Technol. 1986, 18, 1–15. [Google Scholar] [CrossRef]

- ASTM-C1437; Flow of Hydraulic Cement Mortar. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM-C469/C469M; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2022.

- Chen, Z.-B.; Su, J.-Y.; Luo, R.-H.; Lin, J.-X.; Chen, X.-F.; Huang, P.-Y.; Guo, Y.-C. Experimental investigation on fracture behavior of rubberized engineered cementitious composites under thermo-mechanical loadings. Eng. Fract. Mech. 2025, 315, 110838. [Google Scholar] [CrossRef]

- ASTM C78/C78M; Standard Test Method for Determining the Flexural Strength of Concrete. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2022.

- Zhang, Y.; Zhu, Y.; Qu, S.; Kumar, A.; Shao, X. Improvement of flexural and tensile strength of layered-casting UHPC with aligned steel fibers. Constr. Build. Mater. 2020, 251, 118893. [Google Scholar] [CrossRef]

- ASTM C1609/C1609M; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2024.

- EFNARC. The European Guidelines for Self-Compacting Concrete. Specification, Production and Use; The Self Compacting European Project Group EFNARC: Farnham, UK, 2002; pp. 15–16, 25–26. [Google Scholar]

- Evcin, A. Investigation the Effects of Different Deflocculants on the Viscosity of Slips. Sci. Res. Essays 2011, 6, 2302–2305. [Google Scholar]

- Alonso, M.M.; Gismera, S.; Blanco, M.T.; Lanzón, M.; Puertas, F. Alkali-activated mortars: Workability and rheological behaviour. Constr. Build. Mater. 2017, 145, 576–587. [Google Scholar] [CrossRef]

- Huang, G.; Wang, M.; Liu, Q.; Zhao, S.; Liu, H.; Liu, F.; Feng, L.; Song, J. Simultaneous utilization of mine tailings and steel slag for producing geopolymers: Alkali-hydrothermal activation, workability, strength, and hydration mechanism. Constr. Build. Mater. 2024, 414, 135029. [Google Scholar] [CrossRef]

- Song, W.; Zhu, Z.; Pu, S.; Wan, Y.; Xu, X.; Song, S.; Zhang, J.; Yao, K.; Hu, L. Multi-technical characterization and correlations between properties of standard cured alkali-activated high-calcium FA binders with GGBS as additive. Constr. Build. Mater. 2020, 241, 117996. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Brouwers, H.J.H. Characterization of alkali activated slag–fly ash blends containing nano-silica. Constr. Build. Mater. 2015, 98, 397–406. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Zhang, Z.; Dai, J.-G.; Liu, K.; Wang, Y.; Chu, Y.; Sun, D. Hybrid fiber reinforced ultra-high performance coal gangue geopolymer concrete (UHPGC): Mechanical properties, enhancement mechanism, carbon emission and economic analysis. J. Build. Eng. 2024, 96, 110428. [Google Scholar] [CrossRef]

- Constâncio Trindade, A.C.; Liebscher, M.; Curosu, I.; de Andrade Silva, F.; Mechtcherine, V. Influence of elevated temperatures on the residual and quasi in-situ flexural strength of strain-hardening geopolymer composites (SHGC) reinforced with PVA and PE fibers. Constr. Build. Mater. 2022, 314, 125649. [Google Scholar] [CrossRef]

- Eltantawi, I.; Sheikh, M.N.; Hadi, M.N.S. Design of a novel ternary blended Self-Compacting Ultra-high-performance Geopolymer Concrete. Constr. Build. Mater. 2024, 451, 138819. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, T.; Cao, L.; Kan, L.; Wu, M. Influence of steel slag on the properties of alkali-activated fly ash and blast-furnace slag based fiber reinforced composites. Cem. Concr. Compos. 2021, 116, 103875. [Google Scholar] [CrossRef]

- Lin, J.-X.; Liu, R.-A.; Liu, L.-Y.; Zhuo, K.-Y.; Chen, Z.-B.; Guo, Y.-C. High-strength and high-toughness alkali-activated composite materials: Optimizing mechanical properties through synergistic utilization of steel slag, ground granulated blast furnace slag, and fly ash. Constr. Build. Mater. 2024, 422, 135811. [Google Scholar] [CrossRef]

- Niklioć, I.; Marković, S.; Janković-Častvan, I.; Radmilović, V.V.; Karanović, L.; Babić, B.; Radmilović, V.R. Modification of mechanical and thermal properties of fly ash-based geopolymer by the incorporation of steel slag. Mater. Lett. 2016, 176, 301–305. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, H.; Zhang, B.; Wang, Q.; Wu, P.; Yang, T.; Dong, Z. Predictive theoretical model for elastic modulus of marine geopolymer concrete: Insights into micro-mesoscopic components and alkaline content effects. Comput. Struct. 2025, 316, 107876. [Google Scholar] [CrossRef]

- Li, K.; Yang, Z.; Nicolaides, D.; Liang, M.; Briseghella, B.; Marano, G.C.; Zhang, Y. Autogenous shrinkage and sustainability assessment of alkali-activated slag incorporating steel slag. Constr. Build. Mater. 2024, 438, 137219. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Xu, S.; Yuan, P.; Liu, J.; Pan, Z.; Liu, Z.; Su, Y.; Li, J.; Wu, C. Development and preliminary mix design of ultra-high-performance concrete based on geopolymer. Constr. Build. Mater. 2021, 308, 125110. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, P.; Liu, S. Microwave pre-curing of Portland cement-steel slag powder composite for its hydration properties. Constr. Build. Mater. 2018, 189, 1093–1104. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Wang, D.; Yan, P.; Luo, L.; Zhang, H.; Zhang, H.; Gu, X. Hydration superposition effect and mechanism of steel slag powder and granulated blast furnace slag powder. Constr. Build. Mater. 2023, 366, 130101. [Google Scholar] [CrossRef]

- Guo, D.; Guo, M.; Zhou, Y.; Zhu, Z. Use of nano-silica to improve the performance of LC3-UHPC: Mechanical behavior and microstructural characteristics. Constr. Build. Mater. 2024, 411, 134280. [Google Scholar] [CrossRef]

- Han, Y.; Park, K.-B.; Yang, B.; Wang, X.-Y. Optimizing and designing the effects of microwave pre-curing on the properties of ternary blended concrete with slag and fly ash using the simplex centroid method. Constr. Build. Mater. 2024, 419, 135443. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y. Mixture design of concrete using simplex centroid design method. Cem. Concr. Compos. 2018, 89, 76–88. [Google Scholar] [CrossRef]

- He, P.; Zhang, B.; Lu, J.-X.; Poon, C.S. A ternary optimization of alkali-activated cement mortars incorporating glass powder, slag and calcium aluminate cement. Constr. Build. Mater. 2020, 240, 117983. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | Fe2O3 | CaO | K2O | SO3 | MgO | Other |

|---|---|---|---|---|---|---|---|---|

| SS | 16.82 | 8.19 | 29.51 | 33.52 | 0.10 | 0.77 | 4.09 | 7.00 |

| GGBS | 34.50 | 17.70 | 1.03 | 34.00 | 0 | 1.64 | 6.01 | 5.12 |

| FA | 53.97 | 31.15 | 4.16 | 4.01 | 2.04 | 0 | 1.01 | 3.67 |

| SF | 95.45 | 0.30 | 0.11 | 1.20 | 1.14 | 0.39 | 0.66 | 0.75 |

| Shape | Length (mm) | Diameter (mm) | Tensile Strength (MPa) | Aspect Ratio (L/d) |

|---|---|---|---|---|

| Straight | 13 | 0.2 | 2600 | 65 |

| Run | Mix IDs | SS | GGBS | FA | SF | Aggregate | Activator | Water | BaCl2 | Steel Fiber | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FS | MS | NH | NS | |||||||||

| 1 | S0G50F50 1 | 0 | 430 | 430 | 45 | 272 | 634 | 68 | 361 | 78 | 9 | 157 |

| 2 | S0G65F35 | 0 | 559 | 301 | ||||||||

| 3 | S0G80F20 | 0 | 688 | 172 | ||||||||

| 4 | S5G55F40 | 43 | 473 | 344 | ||||||||

| 5 | S5G70F25 | 43 | 602 | 215 | ||||||||

| 6 | S10G60F30 | 86 | 516 | 258 | ||||||||

| 7 | S15G50F35 | 129 | 430 | 301 | ||||||||

| 8 | S15G65F20 | 129 | 559 | 172 | ||||||||

| 9 | S20G55F25 | 172 | 473 | 215 | ||||||||

| 10 | S30G50F20 | 258 | 430 | 172 | ||||||||

| Run | Mix IDs | Compressive Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| 1 | S0G50F50 | 81.38 (0.77) | 15.50 (1.60) |

| 2 | S0G65F35 | 109.54 (1.99) | 13.44 (1.20) |

| 3 | S0G80F20 | 116.76 (1.11) | 13.16 (0.44) |

| 4 | S5G55F40 | 89.67 (1.24) | 11.04 (0.15) |

| 5 | S5G70F25 | 104.54 (5.30) | 14.68 (0.61) |

| 6 | S10G60F30 | 102.41 (2.48) | 12.77 (0.38) |

| 7 | S15G50F35 | 89.75 (3.27) | 11.81 (1.24) |

| 8 | S15G65F20 | 99.77 (2.01) | 21.63 (1.43) |

| 9 | S20G55F25 | 96.11 (2.14) | 17.52 (2.37) |

| 10 | S30G50F20 | 94.05 (1.90) | 15.48 (4.02) |

| Run | Mix IDs | Crack Deflection (mm) | Crack Strength (MPa) | Peak Deflection (mm) | Flexural Strength (MPa) | Toughness at L/600 (N⋅mm) | Toughness at L/150 (N⋅mm) |

|---|---|---|---|---|---|---|---|

| 1 | S0G50F50 | 0.167 (0.047) | 8.39 (0.720) | 0.293 (0.138) | 9.51 (1.17) | 446 (77) | 2317 (82) |

| 2 | S0G65F35 | 0.195 (0.107) | 7.95 (0.70) | 0.317 (0.161) | 8.67 (0.20) | 351 (118) | 1997 (53) |

| 3 | S0G80F20 | 0.107 (0.034) | 7.18 (0.75) | 0.281 (0.085) | 7.99 (0.43) | 390 (78) | 1972 (149) |

| 4 | S5G55F40 | 0.190 (0.031) | 7.24 (0.41) | 0.340 (0.068) | 7.59 (0.11) | 291 (30) | 1787 (28) |

| 5 | S5G70F25 | 0.239 (0.073) | 8.08 (0.32) | 0.359 (0.031) | 8.46 (0.30) | 298 (132) | 1964 (115) |

| 6 | S10G60F30 | 0.082 (0.034) | 5.77 (0.49) | 0.304 (0.205) | 6.53 (0.14) | 377 (11) | 1575 (148) |

| 7 | S15G50F35 | 0.153 (0.074) | 6.59 (0.29) | 0.303 (0.140) | 6.76 (0.32) | 326 (33) | 1672 (83) |

| 8 | S15G65F20 | 0.271 (0.044) | 7.77 (0.45) | 0.393 (0.120) | 7.92 (0.37) | 292 (42) | 1823 (76) |

| 9 | S20G55F25 | 0.102 (0.039) | 4.50 (0.42) | 0.230 (0.118) | 5.07 (0.14) | 246 (40) | 1131 (87) |

| 10 | S30G50F20 | 0.123 (0.037) | 6.66 (0.48) | 0.193 (0.067) | 7.07 (0.13) | 399 (43) | 1682 (55) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.-H.; Huang, T.; Huang, B.-Y.; Hua, C.-B.; Huang, Q.; Chen, J.-W.; Liu, H.-L.; He, Z.-J.; Rouzi, N.-B.; Xie, Z.-H.; et al. Investigation into the Static Mechanical Properties of Ultra-High-Performance Geopolymer Concrete Incorporating Steel Slag, Ground Granulated Blast-Furnace Slag, and Fly Ash. Buildings 2025, 15, 2535. https://doi.org/10.3390/buildings15142535

Cai Y-H, Huang T, Huang B-Y, Hua C-B, Huang Q, Chen J-W, Liu H-L, He Z-J, Rouzi N-B, Xie Z-H, et al. Investigation into the Static Mechanical Properties of Ultra-High-Performance Geopolymer Concrete Incorporating Steel Slag, Ground Granulated Blast-Furnace Slag, and Fly Ash. Buildings. 2025; 15(14):2535. https://doi.org/10.3390/buildings15142535

Chicago/Turabian StyleCai, Yan-Hua, Tao Huang, Bo-Yuan Huang, Chuan-Bin Hua, Qiang Huang, Jing-Wen Chen, Heng-Liang Liu, Zi-Jie He, Nai-Bi Rouzi, Zhi-Hong Xie, and et al. 2025. "Investigation into the Static Mechanical Properties of Ultra-High-Performance Geopolymer Concrete Incorporating Steel Slag, Ground Granulated Blast-Furnace Slag, and Fly Ash" Buildings 15, no. 14: 2535. https://doi.org/10.3390/buildings15142535

APA StyleCai, Y.-H., Huang, T., Huang, B.-Y., Hua, C.-B., Huang, Q., Chen, J.-W., Liu, H.-L., He, Z.-J., Rouzi, N.-B., Xie, Z.-H., & Chen, G. (2025). Investigation into the Static Mechanical Properties of Ultra-High-Performance Geopolymer Concrete Incorporating Steel Slag, Ground Granulated Blast-Furnace Slag, and Fly Ash. Buildings, 15(14), 2535. https://doi.org/10.3390/buildings15142535