Effects of Aggregate-to-Binder Ratio on Mechanical Performance of Engineered Geopolymer Composites with Recycled Rubber Aggregates

Abstract

1. Introduction

2. Experimental Program

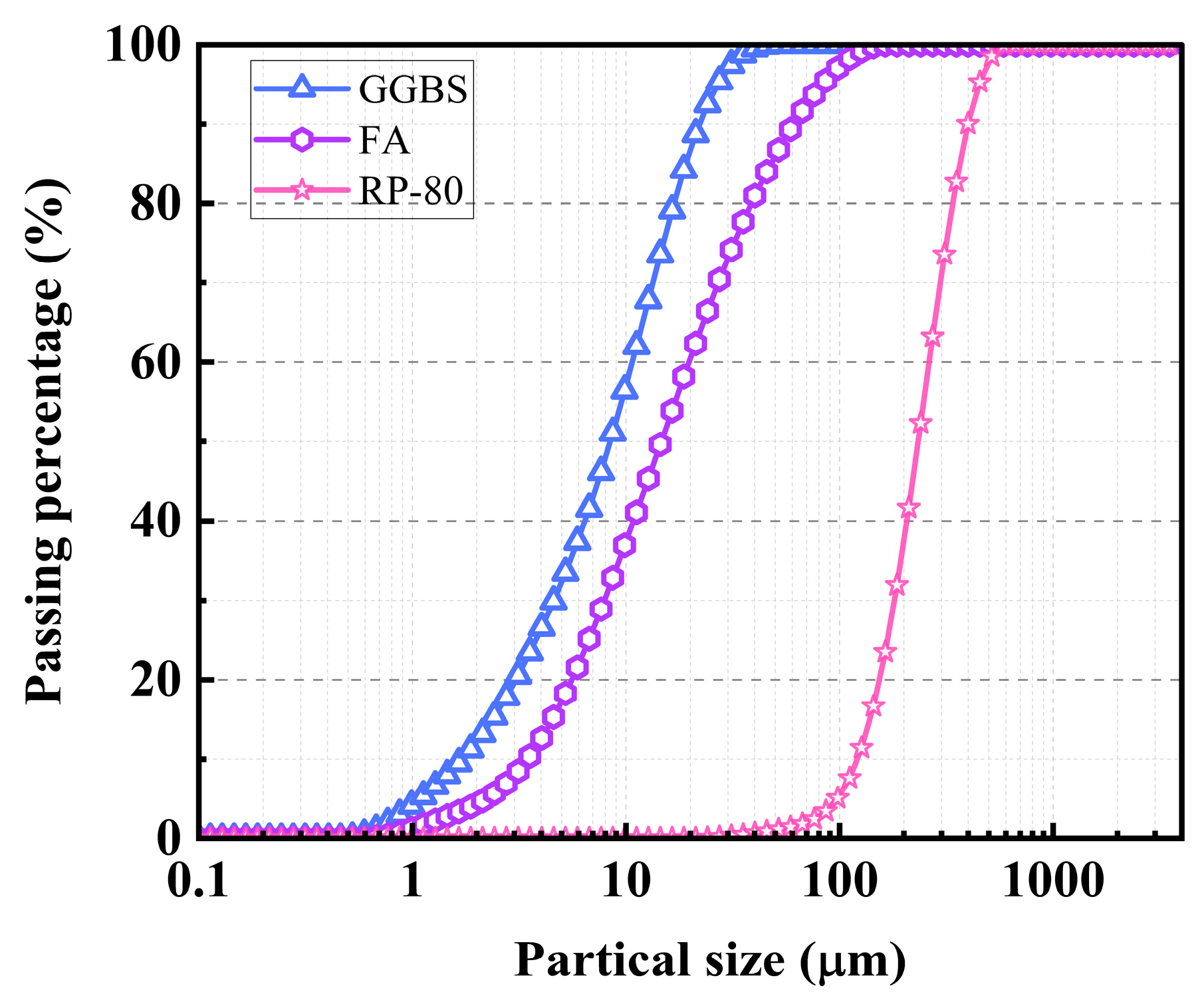

2.1. Materials and Mix Proportions

2.2. Mix Proportions

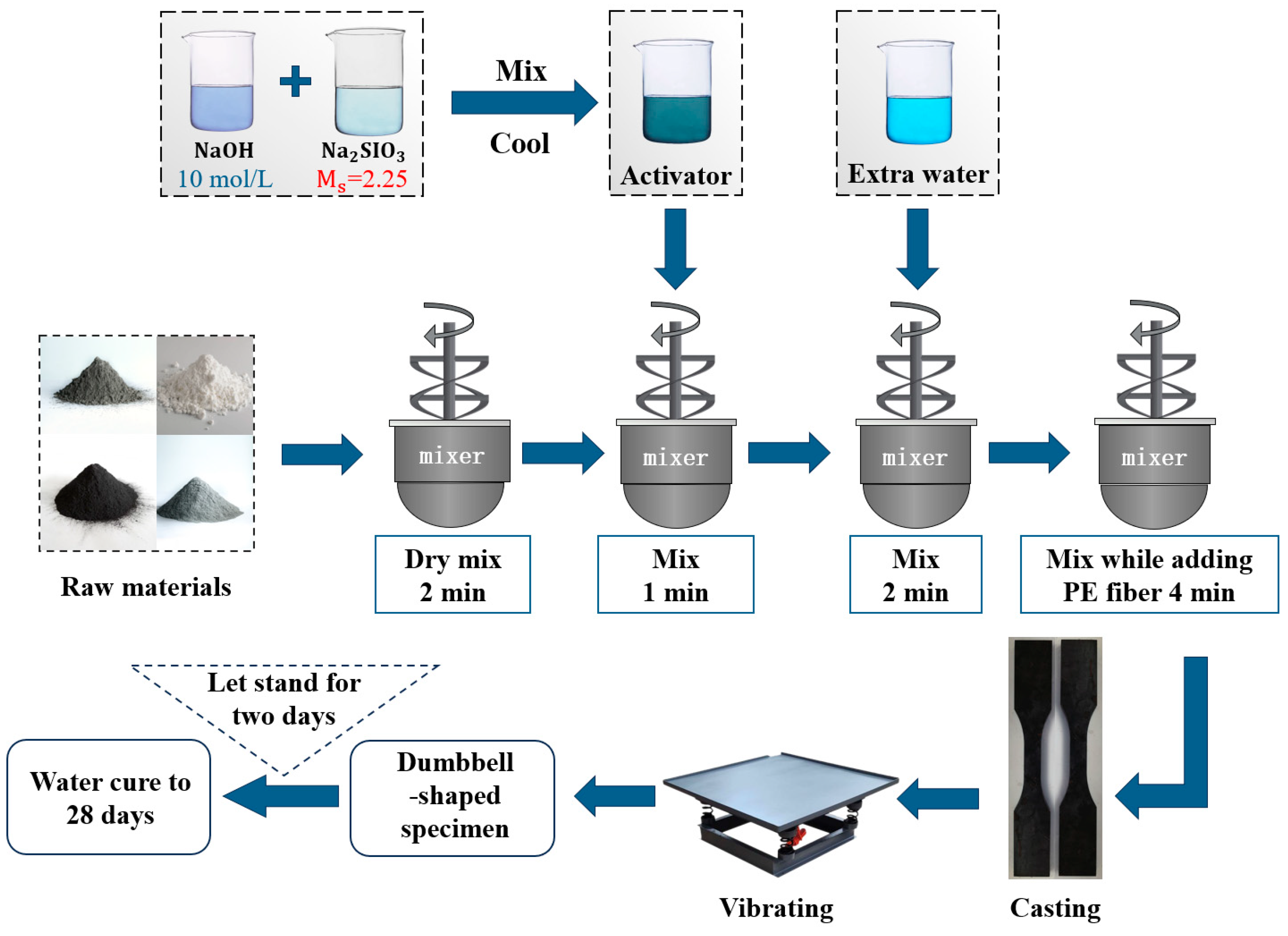

2.3. Preparation Process of R-EGC Specimens

2.4. Test Setup

2.4.1. Flowability Test

2.4.2. Axial Compressive Test

2.4.3. Axial Tensile Test

3. Results and Discussion

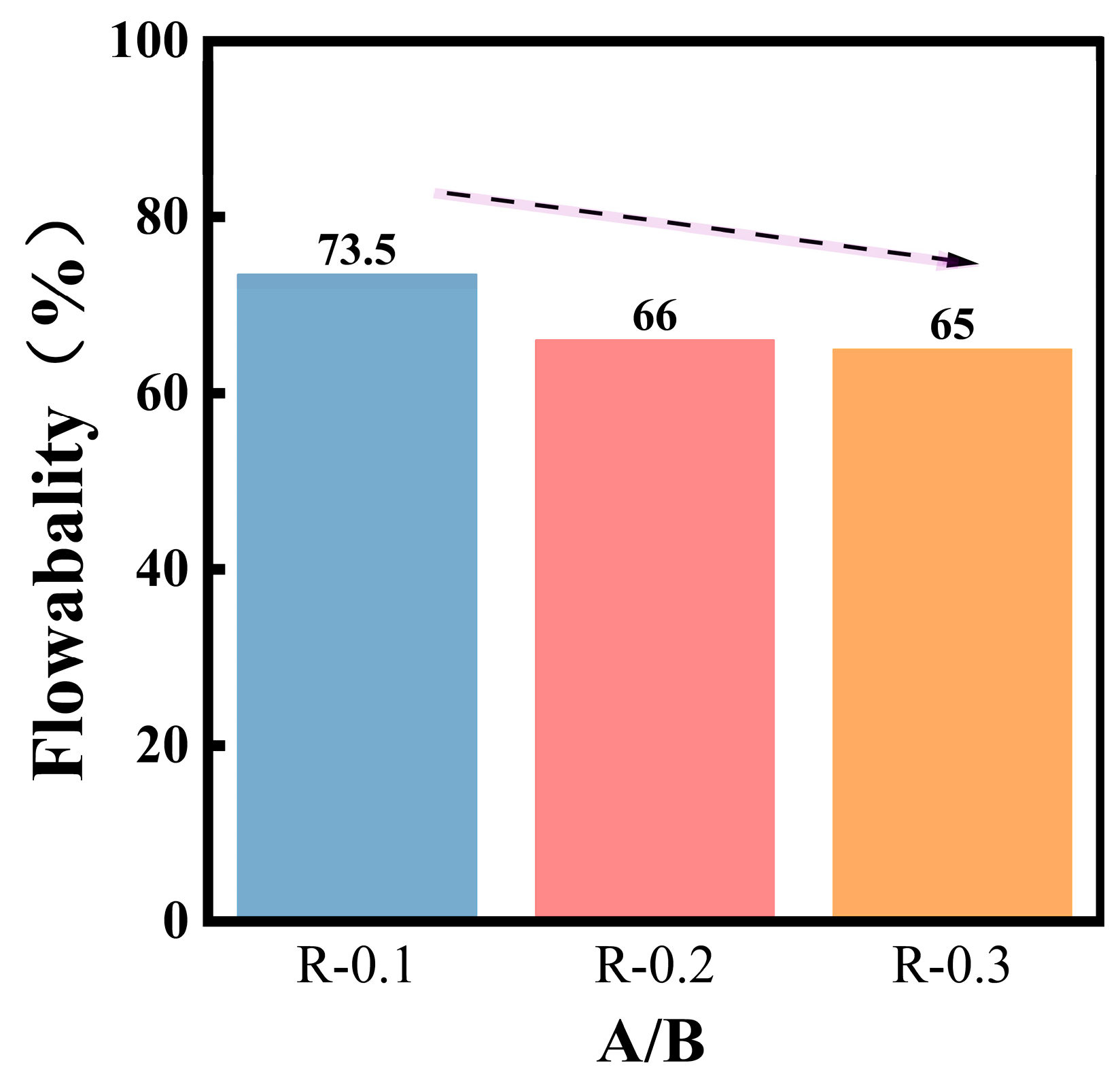

3.1. Flowability of the R-EGC Paste

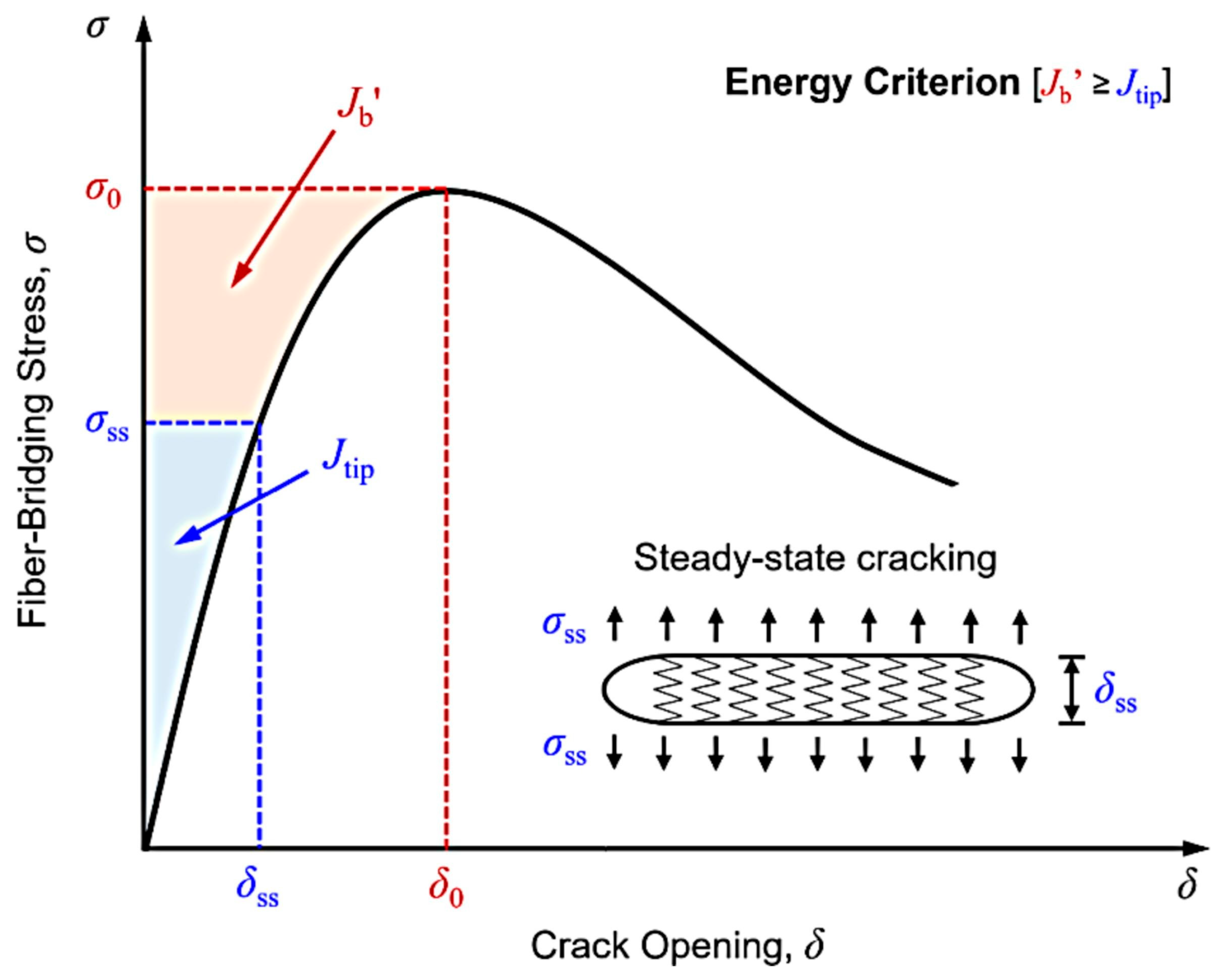

3.2. Micromechanical Design Principles of EGCs

3.3. Effect of A/B Ratio on Compression Behavior

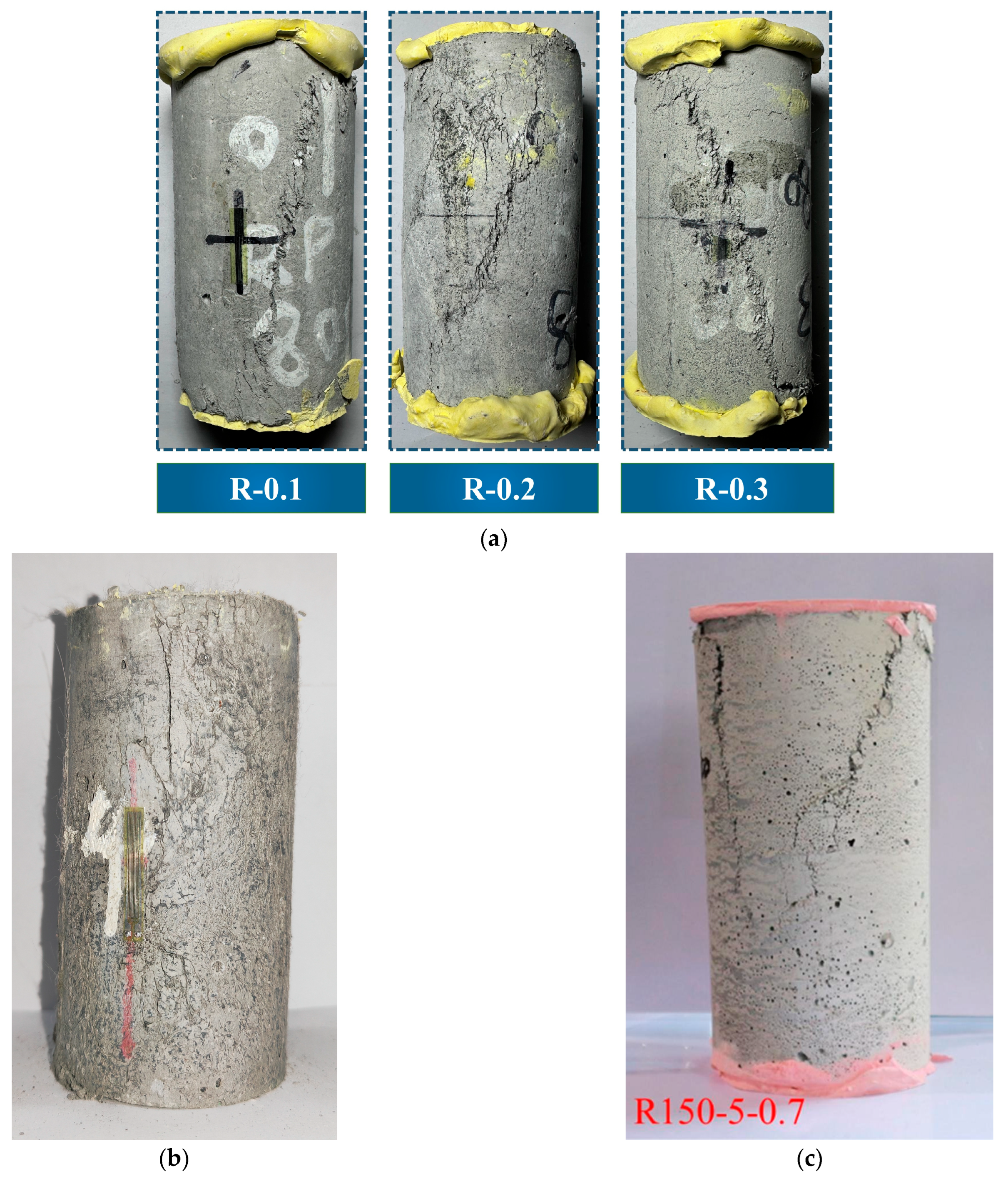

3.3.1. Failure Mode

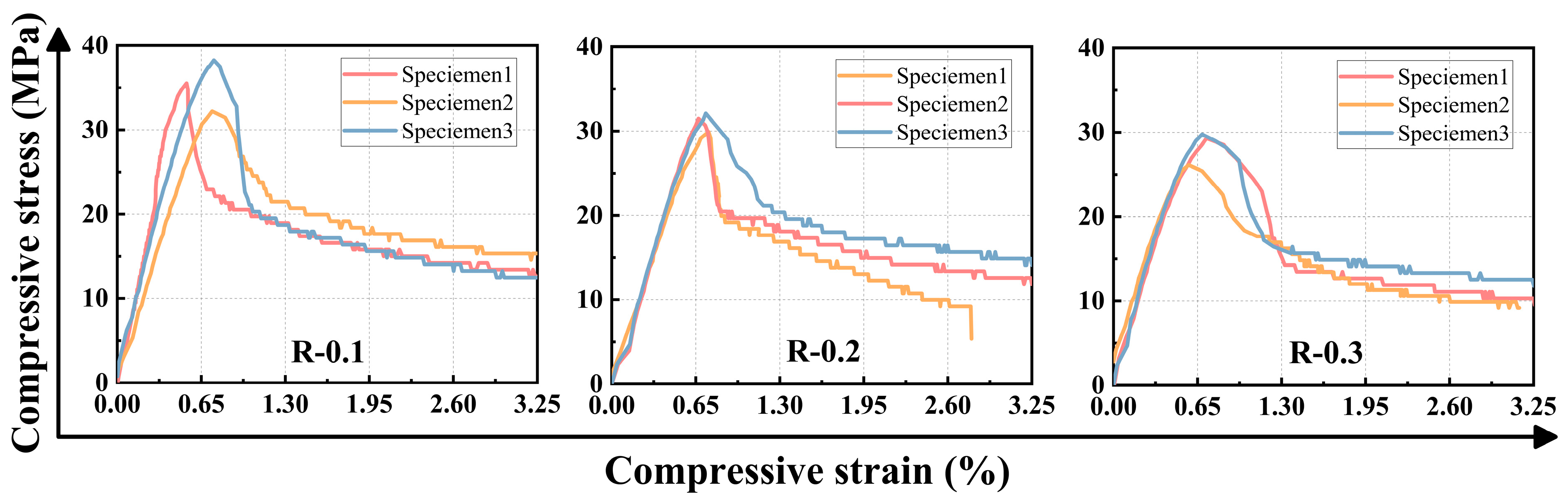

3.3.2. Effect of A/B Ratio on Stress–Strain Curves

3.3.3. Compressive Strength, Peak Strain, and Modulus of Elasticity

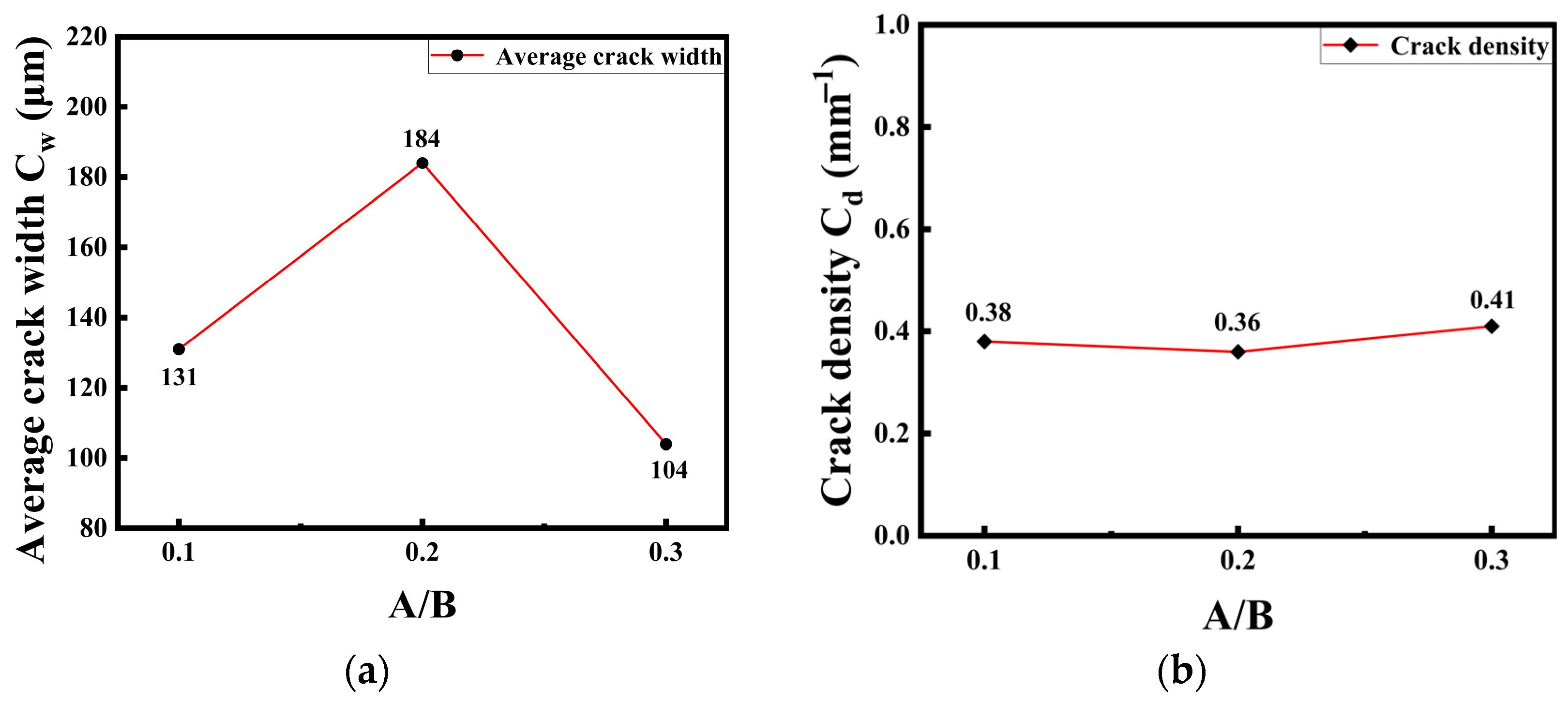

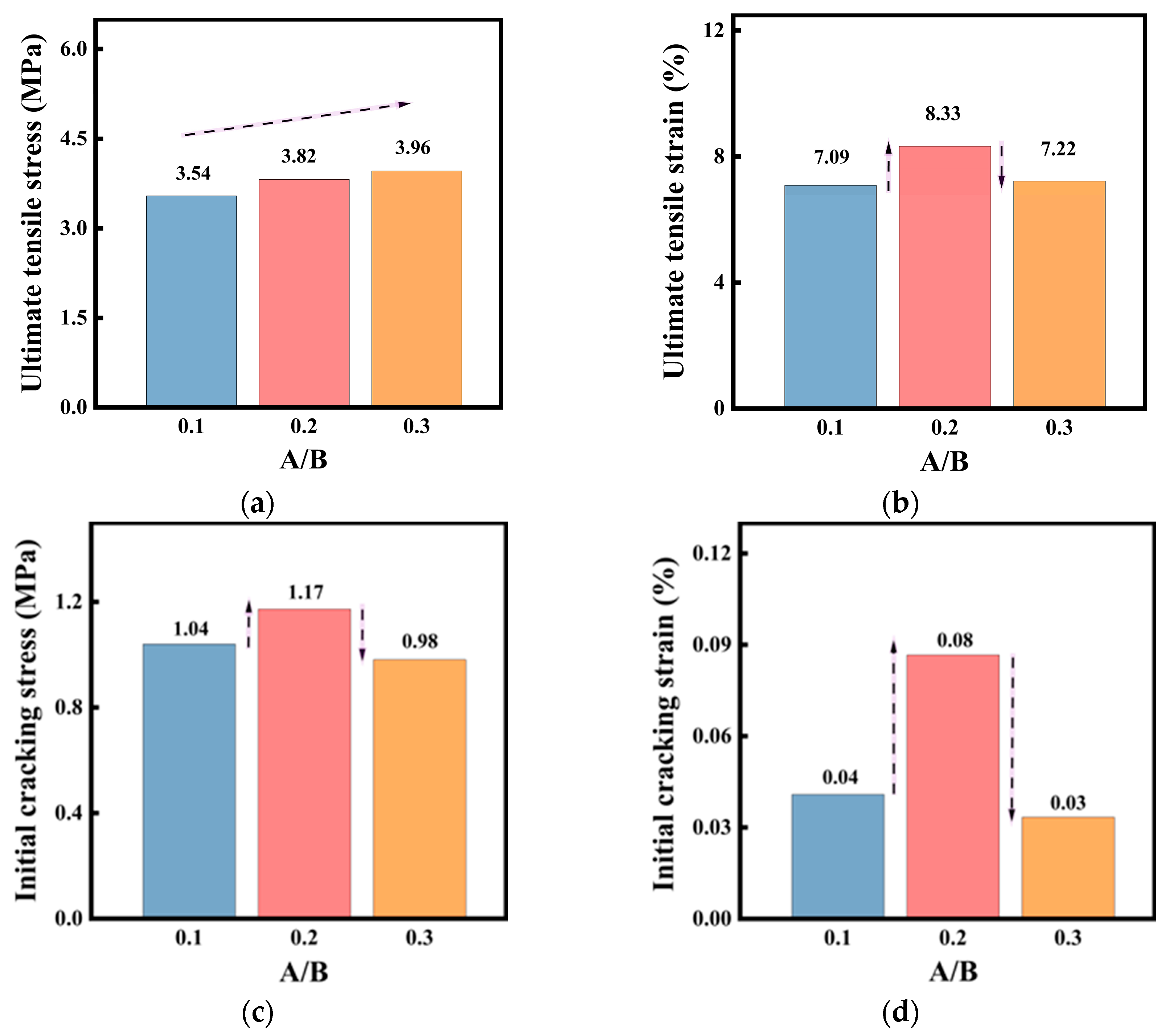

3.4. Effect of A/B Ratio on Uniaxial Tensile Behavior

Uniaxial Tensile Failure Mode

3.5. Economic Evaluation of R-EGC

4. Microscopic Analysis

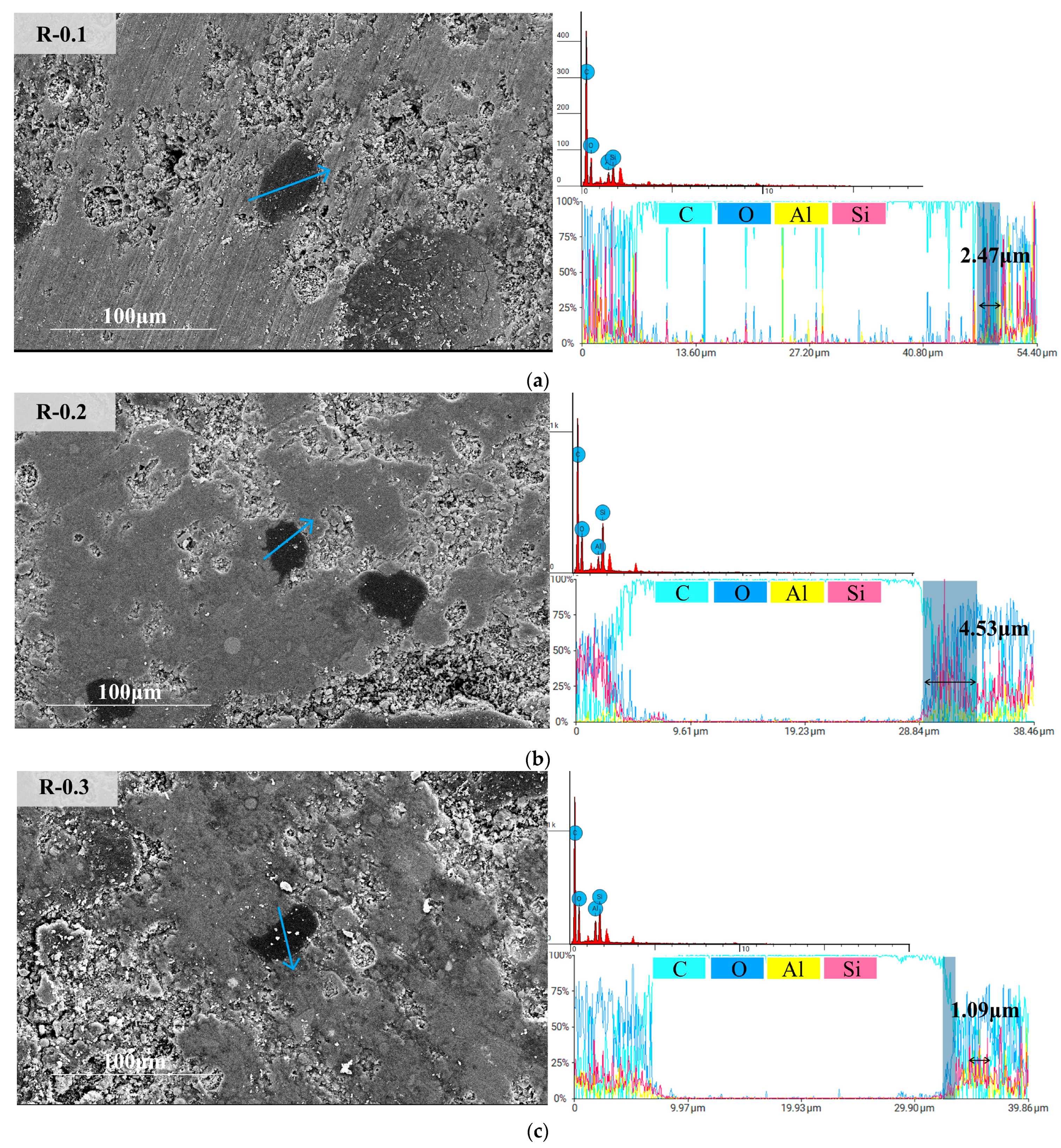

Interfacial Transition Zone (ITZ)

5. Conclusions

- (1)

- A lower A/B ratio improves the workability of the fresh mix and the dispersion of fibers, while an increase in the A/B ratio leads to reduced flowability.

- (2)

- At A/B = 0.3, the material exhibits optimal crack-control performance under tensile loading. R-0.3 shows the narrowest average crack width of 104 μm and the highest crack density of 0.41 mm−1, making it suitable for engineering applications requiring high durability, such as port terminals, subterranean utility tunnels, and traffic tunnels.

- (3)

- At A/B = 0.2, the material demonstrates the best tensile ductility. R-0.2 achieves a tensile strength of 3.82 MPa and an ultimate tensile strain of up to 8.33%, making it applicable for engineering projects with high-tensile-ductility requirements, such as high-rise buildings, anchorage zones of bridge expansion joints, and airport runways.

- (4)

- Microscopic analysis indicates that the A/B ratio affects the width of the ITZ and the size of initial defects in the R-EGC. R-0.2 has the widest ITZ at 4.53 μm, suggesting that a moderate A/B ratio helps enhance tensile ductility, while R-0.3 has the narrowest ITZ at 1.09 μm, indicating that a higher A/B ratio improves the material’s crack-control capability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khalil, W.; Obeidy, N. Some properties of sustainable concrete containing two environmental wastes. MATEC Web Conf. 2018, 162, 02029. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, W.; Su, Y.; Jia, F.; Long, X. Plastic damage prediction of concrete under compression based on deep learning. Acta Mech. 2024, 235, 255–266. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; Tayeh, B.A.; Sivalingam, S.; Rosli, M.F.B.; Haruna, S.; Khan, M.I. Mechanical and deformation properties of rubberized engineered cementitious composite (ECC). Case Stud. Constr. Mater. 2020, 13, e00385. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, T.; Lu, D.; Han, X.; Sun, H.; Huang, J.; Ye, X.; Zhang, C.; Chen, Z.; Yang, Y. Dynamic tensile properties of steel fiber reinforced polyethylene fiber-engineered/strain-hardening cementitious composites (PE-ECC/SHCC) at high strain rate. Cem. Concr. Compos. 2023, 143, 105234. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.; Weng, J.; Yang, E.-H. Micromechanics of engineered cementitious composites (ECC): A critical review and new insights. Constr. Build. Mater. 2023, 362, 129765. [Google Scholar] [CrossRef]

- Lin, J.-X.; Song, Y.; Xie, Z.-H.; Guo, Y.-C.; Yuan, B.; Zeng, J.-J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Jiang, Z.-X.; Su, J.-Y.; Ruan, G.-W.; Lv, J.-H.; Yang, Z.-M.; Lai, H.-M.; Lin, J.-X. Tensile behavior of rubberized high strength-high ductile concrete under elevated temperature. Constr. Build. Mater. 2024, 446, 138036. [Google Scholar] [CrossRef]

- Xu, S.-L.; Xu, H.-L.; Huang, B.-T.; Li, Q.-H.; Yu, K.-Q.; Yu, J.-T. Development of ultrahigh-strength ultrahigh-toughness cementitious composites (UHS-UHTCC) using polyethylene and steel fibers. Compos. Commun. 2022, 29, 100992. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, J.-T.; Yu, K.-Q.; Xu, S.-L. Basic mechanical properties of ultra-high ductility cementitious composites: From 40 MPa to 120 MPa. Compos. Struct. 2018, 185, 634–645. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar] [CrossRef] [PubMed]

- Elmesalami, N.; Celik, K. A critical review of engineered geopolymer composite: A low-carbon ultra-high-performance concrete. Constr. Build. Mater. 2022, 346, 128491. [Google Scholar] [CrossRef]

- Celik, K.; Hay, R.; Hargis, C.W.; Moon, J. Effect of volcanic ash pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 2019, 197, 803–812. [Google Scholar] [CrossRef]

- Chen, Y.; Sha, A.; Jiang, W.; Lu, Q.; Du, P.; Hu, K.; Li, C. Eco-friendly bismuth vanadate/iron oxide yellow composite heat-reflective coating for sustainable pavement: Urban heat island mitigation. Constr. Build. Mater. 2025, 470, 140645. [Google Scholar] [CrossRef]

- Xu, L.-Y.; Lao, J.-C.; Qian, L.-P.; Shi, D.-D.; Lan, J.; Xie, T.-Y.; Hou, D.; Huang, B.-T. Upcycling red mud into high-strength high-ductility Engineered Geopolymer Composites (EGC): Toward superior performance and sustainability. Compos. Part B Eng. 2025, 305, 112713. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Engineered geopolymer composites: A state-of-the-art review. Cem. Concr. Compos. 2023, 135, 104850. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Lương, Q.-H.; Choi, J.-I.; Ranade, R.; Li, V.C.; Lee, B.Y. Ultra-ductile behavior of fly ash-based engineered geopolymer composites with a tensile strain capacity up to 13.7%. Cem. Concr. Compos. 2021, 122, 104133. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Dinkha, Y.Z.; Haido, J.H.; Ali, M.H.; Tayeh, B.A. Engineering properties of sustainable green concrete incorporating eco-friendly aggregate of crumb rubber: A review. J. Clean. Prod. 2021, 324, 129251. [Google Scholar] [CrossRef]

- Gao, X.; Yang, J.; Shao, J.; Zhu, H.; Xu, J.; Haruna, S.I. Regulation of carbon nanotubes on internal humidity of concrete with recycled tire rubber: Mechanism analysis and modeling. J. Build. Eng. 2024, 82, 108253. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Barluenga, G.; Bollati, M.; Witoszek, B. Static and dynamic behaviour of recycled tyre rubber-filled concrete. Cem. Concr. Res. 2002, 32, 1587–1596. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, B.S.; Awang, A.B.; Wong, S.S.; Nhavene, C.P. Properties of nano silica modified rubbercrete. J. Clean. Prod. 2016, 119, 66–75. [Google Scholar] [CrossRef]

- Hisbani, N.; Shafiq, N.; Shams, M.A.; Farhan, S.A.; Zahid, M. Properties of concrete containing crumb rubber as partial replacement of fine Aggregate—A review. Hybrid Adv. 2025, 10, 100481. [Google Scholar] [CrossRef]

- Etli, S. Mechanical Properties of Self-Compacting Mortars Containing Rubber Waste Particles as Fine Aggregate in Freeze–Thaw Cycles. J. Mater. Civ. Eng. 2024, 36, 04024246. [Google Scholar] [CrossRef]

- Adebayo, I.W.; Long, G.; Tang, Z.; Ghone, M.O.; Zaland, S.; Garba, M.J.; Yang, K.; Akhunzada, K.; Oluwasina, U.A. Effect of crumb rubber and polyethylene fiber on the strength and toughness of fly ash/slag-based geopolymer concrete. Constr. Build. Mater. 2024, 455, 139133. [Google Scholar] [CrossRef]

- Chen, G.; Zhuo, K.-X.; Luo, R.-H.; Lai, H.-M.; Cai, Y.-J.; Xie, B.-X.; Lin, J.-X. Fracture behavior of environmentally friendly high-strength concrete using recycled rubber powder and steel fibers: Experiment and modeling. Case Stud. Constr. Mater. 2024, 21, e03501. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Huseien, G.F.; Abidin, A.R.Z.; Ismail, M. Long-term mechanical and durable properties of waste tires rubber crumbs replaced GBFS modified concretes. Constr. Build. Mater. 2020, 256, 119505. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, S. Experimental and analytical study on the mechanical properties of rubberized self-compacting concrete. Constr. Build. Mater. 2022, 329, 127177. [Google Scholar] [CrossRef]

- Hesami, S.; Salehi Hikouei, I.; Emadi, S.A.A. Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 2016, 133, 228–234. [Google Scholar] [CrossRef]

- El Marzak, M.; Karim Serroukh, H.; Benaicha, M.; Jalbaud, O.; Hafidi Alaoui, A.; Burtschell, Y. Rheological and mechanical analysis of self-compacting concrete incorporating rubber aggregates. Case Stud. Constr. Mater. 2025, 22, e04564. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete—A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, Z.; Shen, D.; An, J.; Sun, Y.; Li, N. Microstructure evolution and impact resistance of crumb rubber concrete after elevated temperatures. Constr. Build. Mater. 2023, 384, 131340. [Google Scholar] [CrossRef]

- Najim, K.B.; Hall, M.R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Constr. Build. Mater. 2012, 27, 521–530. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, H.; Qian, S. Investigation on Properties of ECC Incorporating Crumb Rubber of Different Sizes. J. Adv. Concr. Technol. 2015, 13, 241–251. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, J.; Zhang, P.; Guo, J.; Hu, S. Enhanced effect and mechanism of colloidal nano-SiO2 modified rubber concrete. Constr. Build. Mater. 2023, 378, 131203. [Google Scholar] [CrossRef]

- Yang, Z.-M.; Pan, H.-S.; Jiang, Z.-X.; Lv, J.-H.; Ruan, G.-W.; Lai, H.-M.; Lin, J.-X. Pseudo strain-hardening alkali-activated composites with up to 100% rubber aggregate: Static mechanical properties analysis and constitutive model development. Constr. Build. Mater. 2024, 439, 137338. [Google Scholar] [CrossRef]

- Hou, M.; Zhang, D.; Li, V.C. Crack width control and mechanical properties of low carbon engineered cementitious composites (ECC). Constr. Build. Mater. 2022, 348, 128692. [Google Scholar] [CrossRef]

- Zhao, S.; Yu, Q.; Qiao, F.; Huang, J.; Yin, S.; Wen, Z.; Gu, G. Setting and strength characteristics of alkali-activated carbonatite cementitious materials with ground slag replacement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2006, 21, 125–128. [Google Scholar] [CrossRef]

- Lin, J.-X.; Chen, G.; Pan, H.-S.; Wang, Y.-C.; Guo, Y.-C.; Jiang, Z.-X. Analysis of stress-strain behavior in engineered geopolymer composites reinforced with hybrid PE-PP fibers: A focus on cracking characteristics. Compos. Struct. 2023, 323, 117437. [Google Scholar] [CrossRef]

- Peng, Y.-Q.; Zheng, D.-P.; Pan, H.-S.; Yang, J.-L.; Lin, J.-X.; Lai, H.-M.; Wu, P.-Z.; Zhu, H.-Y. Strain hardening geopolymer composites with hybrid POM and UHMWPE fibers: Analysis of static mechanical properties, economic benefits, and environmental impact. J. Build. Eng. 2023, 76, 107315. [Google Scholar] [CrossRef]

- Pan, H.; Xie, Z.; Chen, G.; Su, J.; Zhuo, K.; Chen, Z.; Lin, J.; Feng, C.; Guo, Y. Dynamic compressive behavior of high-strength engineered geopolymer composites. J. Build. Eng. 2023, 80, 108036. [Google Scholar] [CrossRef]

- Su, J.-Y.; Chen, G.; Pan, H.-S.; Lin, J.-X.; Zhang, J.; Zhuo, K.-X.; Chen, Z.-B.; Guo, Y.-C. Rubber modified high strength-high ductility concrete: Effect of rubber replacement ratio and fiber length. Constr. Build. Mater. 2023, 404, 133243. [Google Scholar] [CrossRef]

- Chen, S.-J.; Liu, R.-A.; Huang, X.-Y.; Yang, Z.-M.; Lin, J.-X. PET particles modify strain hardening cementitious composites: An approach to introduce defects to enhance deformation capacity. Constr. Build. Mater. 2024, 447, 138064. [Google Scholar] [CrossRef]

- Chen, Z.-B.; Su, J.-Y.; Luo, R.-H.; Lin, J.-X.; Chen, X.-F.; Huang, P.-Y.; Guo, Y.-C. Experimental investigation on fracture behavior of rubberized engineered cementitious composites under thermo-mechanical loadings. Eng. Fract. Mech. 2025, 315, 110838. [Google Scholar] [CrossRef]

- Lin, J.-X.; He, G.-J.; Wu, J.-S.; Deng, W.-B.; Zhou, Z.-Y.; Guo, G.-S.; Sheng, C.; Xie, B.-X.; Guo, Y.-C. Mechanical performance of steel-PE hybrid fiber-reinforced SHAAC: A comparative study of two distinct hybridization approaches. J. Mater. Res. Technol. 2025, 35, 5637–5650. [Google Scholar] [CrossRef]

- MIIT. Standard Test Method for the Mechanical Properties of Ductile Fiber Reinforced Cementitious Composites; Building Materials Industry Press: Beijing, China, 2018. [Google Scholar]

- ASTM-C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM-C469/C469M; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2020.

- Yokota, H.; Rokugo, K.; Sakata, N. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composite with Multiple Fine Cracks; Springer: Tokyo, Japan, 2007. [Google Scholar]

- Li, Z.; Zhou, J.; Leung, C.K.Y. Fiber distribution in strain-hardening cementitious composites (SHCC): Experimental investigation and its correlation with matrix flowability and tensile strength. Cem. Concr. Compos. 2025, 160, 106068. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Quéneudec, M. Transport of fluids in cement–rubber composites. Cem. Concr. Compos. 2004, 26, 21–29. [Google Scholar] [CrossRef]

- Abaza Osama, A.; Hussein Zaids, S. Flexural Behavior of Steel Fiber-Reinforced Rubberized Concrete. J. Mater. Civ. Eng. 2016, 28, 04015076. [Google Scholar] [CrossRef]

- Li Victor, C.; Leung Christopher, K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Synthesis of heat and ambient cured one-part geopolymer mixes with different grades of sodium silicate. Ceram. Int. 2015, 41, 5696–5704. [Google Scholar] [CrossRef]

- Ohno, M. Green and Durable Geopolymer Composites for Sustainable Civil Infrastructure. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2017. [Google Scholar]

- Nematollahi, B.; Qiu, J.; Yang, E.-H.; Sanjayan, J. Micromechanics constitutive modelling and optimization of strain hardening geopolymer composite. Ceram. Int. 2017, 43, 5999–6007. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Khan, S.U.; Ayub, T. PET Fiber–Reinforced Engineered Geopolymer and Cementitious Composites. J. Mater. Civ. Eng. 2022, 34, 15. [Google Scholar] [CrossRef]

- Zhong, H.; Poon, E.W.; Chen, K.; Zhang, M. Engineering properties of crumb rubber alkali-activated mortar reinforced with recycled steel fibres. J. Clean. Prod. 2019, 238, 117950. [Google Scholar] [CrossRef]

- Abd Allah Abd-Elaty, M.; Farouk Ghazy, M.; Hussein Khalifa, O. Mechanical and thermal properties of fibrous rubberized geopolymer mortar. Constr. Build. Mater. 2022, 354, 129192. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Alguhi, H.; Tomlinson, D. Experimental and analytical study of steel and chopped glass fibre reinforced concrete under compression. Constr. Build. Mater. 2024, 418, 135421. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Astrauskas, T.; Januševičius, T.; Kizinievič, O.; Kizinievič, V. Potential applications of rubber buffing dust and recovered crumb rubber in cement concrete. Results Eng. 2024, 24, 103266. [Google Scholar] [CrossRef]

- Xu, S.; Yuan, P.; Liu, J.; Pan, Z.; Liu, Z.; Su, Y.; Li, J.; Wu, C. Development and preliminary mix design of ultra-high-performance concrete based on geopolymer. Constr. Build. Mater. 2021, 308, 125110. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, M.; Xie, M.; Yang, Y.; Liu, T.; Zhou, T.; Cen, Q.; Liu, Z.; Li, B. From waste to energy: Comprehensive understanding of the thermal-chemical utilization techniques for waste tire recycling. Renew. Sustain. Energy Rev. 2025, 211, 115354. [Google Scholar] [CrossRef]

- Peng, Z.; Xiong, Q.-X.; Zhou, X.; Gao, X.; Zhao, X.-Y.; Meng, Z.; Liu, Q.-F. A porosity-based mechanics model for studying crack evolution from ITZ to mortar matrix in concrete. Comput. Methods Appl. Mech. Eng. 2025, 444, 118085. [Google Scholar] [CrossRef]

- Cai, Y.; Xiong, B.; Zhao, B. Evolution of the interfacial transition zone of alkali-activated concrete with aging. Constr. Build. Mater. 2025, 489, 142364. [Google Scholar] [CrossRef]

- Sun, L.; Wang, X.; Zhang, C. Three-dimensional high fidelity mesoscale rapid modelling algorithm for concrete. Structures 2024, 70, 107561. [Google Scholar] [CrossRef]

- Kishore, K.; Tomar, R. Understanding the role of interfacial transition zone in cement paste and concrete. Mater. Today Proc. 2023, 80, 877–881. [Google Scholar] [CrossRef]

- Singh, P.; Singh, D.N.; Singh, A. Interfacial transition zone in rubberized concrete: A panacea for the extreme environmental conditions. Constr. Build. Mater. 2025, 469, 140477. [Google Scholar] [CrossRef]

| Composition | FA | GGBS |

|---|---|---|

| wt% | ||

| MgO | 1.01 | 6.01 |

| SiO2 | 54 | 34.5 |

| Al2O3 | 31.2 | 17.7 |

| CaO | 4.01 | 34 |

| Fe2O3 | 4.16 | 1.03 |

| SO3 | 2.2 | 1.64 |

| TiO2 | 1.13 | / |

| other | 2.37 | 5.12 |

| Properties | FA | GGBS |

|---|---|---|

| Moisture content (%) | 0.5 | 0.45 |

| Loss on ignition (%) | 4.6 | 0.84 |

| Specific surface area (m2/kg) | 1835 | 429 |

| Density (g/cm3) | 2.3 | 3.1 |

| Fiber Type | Length (mm) | Diameter (μm) | Modulus of Elasticity (GPa) | Tensile Strength (MPa) | Density (g/cm3) | Elongation (%) |

|---|---|---|---|---|---|---|

| PE | 18 | 24 | 116 | 3000 | 0.97 | 3 |

| Group | RP | Binder | Activator | Water | BaCl2 | PE | |

|---|---|---|---|---|---|---|---|

| FA | GGBS | ||||||

| R-0.1 | 51.8 | 971.2 | 242.8 | 486.0 | 129.6 | 12.1 | 14.6 |

| R-0.2 | 103.5 | ||||||

| R-0.3 | 155.3 | ||||||

| Specimen | Compressive Strength (MPa) | Peak Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|

| R-0.1 | 35.3 (3.02) | 0.66 (0.13) | 7.52 (0.18) |

| R-0.2 | 31.2 (1.12) | 0.72 (0.04) | 5.87 (0.37) |

| R-0.3 | 28.4 (1.98) | 0.66 (0.07) | 7.09 (0.51) |

| Group | Ultimate Tensile Strength (MPa) | Ultimate Tensile Strain (%) | Initial Cracking Strength (MPa) | Initial Cracking Strain (%) |

|---|---|---|---|---|

| R-0.1 | 3.54 (0.63) | 7.09 (0.04) | 1.04 (0.29) | 0.04 (0.03) |

| R-0.2 | 3.82 (0.20) | 8.83 (0.28) | 1.17 (0.49) | 0.08 (0.13) |

| R-0.3 | 3.96 (0.52) | 7.23 (0.12) | 0.98 (0.26) | 0.03 (0.03) |

| Materials | Cost (USD/ton) |

|---|---|

| FA | 70 |

| GGBS | 77 |

| RPs | 47 |

| Water | 0.5 |

| Alkali activator | 96.2 |

| PE fibers | 30,000 |

| Group | Cost (USD/m3) |

|---|---|

| R-0.1 | 573.93 |

| R-0.2 | 576.36 |

| R-0.3 | 578.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhi, S.; Chai, R.; Zhou, Z.; He, J.; Yao, Z.; Yang, Z.; Zhong, G.; Guo, Y. Effects of Aggregate-to-Binder Ratio on Mechanical Performance of Engineered Geopolymer Composites with Recycled Rubber Aggregates. Buildings 2025, 15, 2496. https://doi.org/10.3390/buildings15142496

Li Y, Zhi S, Chai R, Zhou Z, He J, Yao Z, Yang Z, Zhong G, Guo Y. Effects of Aggregate-to-Binder Ratio on Mechanical Performance of Engineered Geopolymer Composites with Recycled Rubber Aggregates. Buildings. 2025; 15(14):2496. https://doi.org/10.3390/buildings15142496

Chicago/Turabian StyleLi, Yiwei, Shuzhuo Zhi, Ran Chai, Zhiying Zhou, Jiarui He, Zizhao Yao, Zhan Yang, Genquan Zhong, and Yongchang Guo. 2025. "Effects of Aggregate-to-Binder Ratio on Mechanical Performance of Engineered Geopolymer Composites with Recycled Rubber Aggregates" Buildings 15, no. 14: 2496. https://doi.org/10.3390/buildings15142496

APA StyleLi, Y., Zhi, S., Chai, R., Zhou, Z., He, J., Yao, Z., Yang, Z., Zhong, G., & Guo, Y. (2025). Effects of Aggregate-to-Binder Ratio on Mechanical Performance of Engineered Geopolymer Composites with Recycled Rubber Aggregates. Buildings, 15(14), 2496. https://doi.org/10.3390/buildings15142496