High Temperature

Geopolymer concrete undergoes substantial physical and chemical changes when subjected to 200, 400, 600, and 800 °C temperatures. At these temperatures, the geopolymer experiences thermal deterioration, microcracking, dehydration, and phase changes which affect its mechanical qualities and durability. Substituting natural sand with other materials, or adjusting its percentage, modifies the aggregate-matrix contact, influencing geopolymer concrete’s thermal stability and mechanical properties. The substitution of sand can affect thermal conductivity, expansion characteristics, and the composite’s overall resistance to thermal degradation. Advanced characterization techniques, including X-ray diffraction (XRD), scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and thermal gravimetric analysis (TGA), are crucial for examining these alterations. These approaches facilitate the identification of phase transitions, microstructural changes, differences in chemical bonding, and weight loss resulting from heat degradation. Exposure to elevated temperatures can induce alterations in aluminosilicate phases within the geopolymer matrix, resulting in either crystallization or amorphization, contingent upon temperature and composition. The phase transitions correspond with observable mechanical qualities and durability alterations, which may be measured and comprehended by the previously indicated characterization techniques. The performance of geopolymer mortar specimens exposed to elevated temperatures was evaluated and compared with specimens cured at room temperature for 28 days. Durability was assessed using mechanical strength, ultrasonic pulse velocity (UPV), and weight loss tests before and after exposure to elevated temperatures of 200 °C, 400 °C, 600 °C, and 800 °C [

8]. The results are summarized in

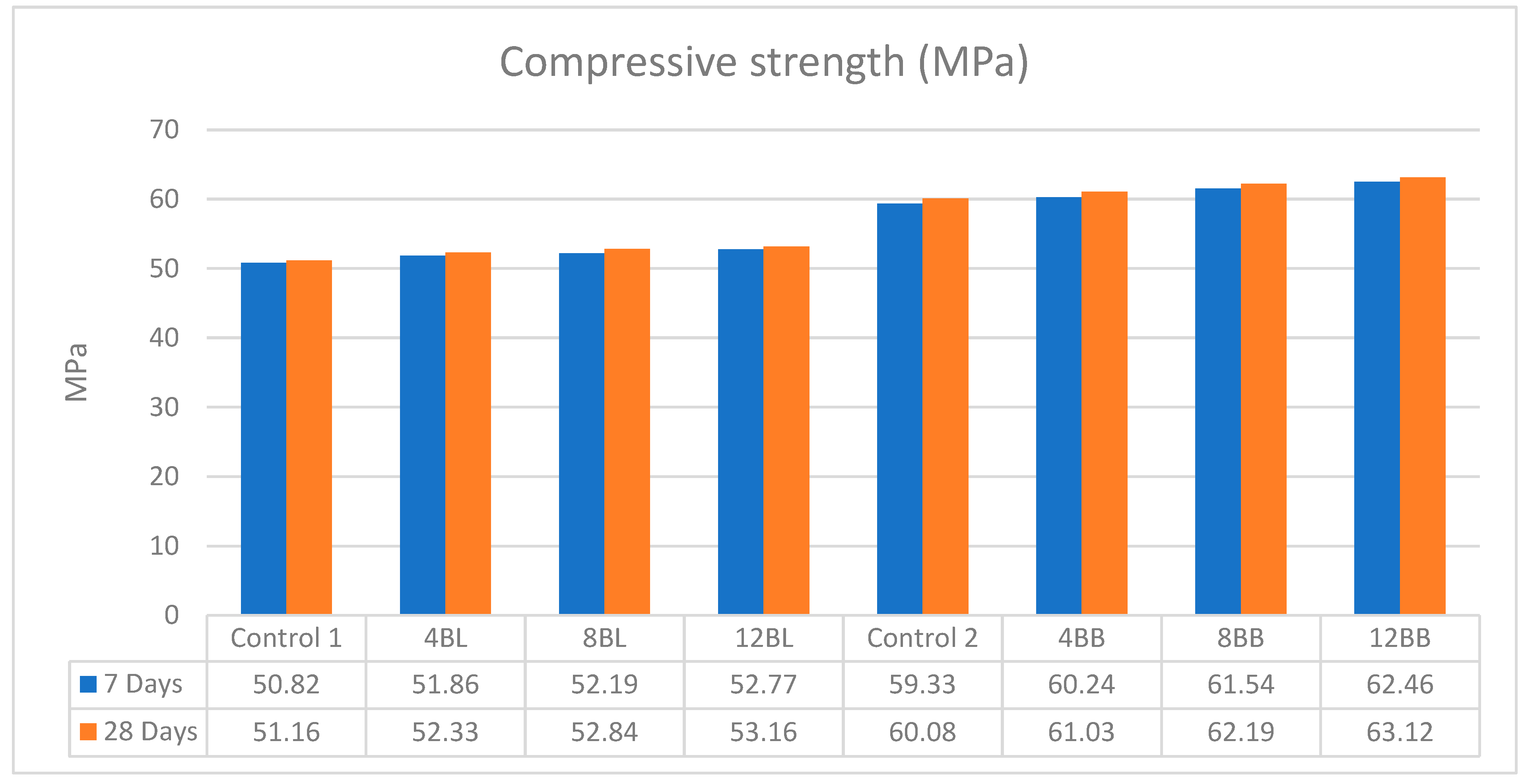

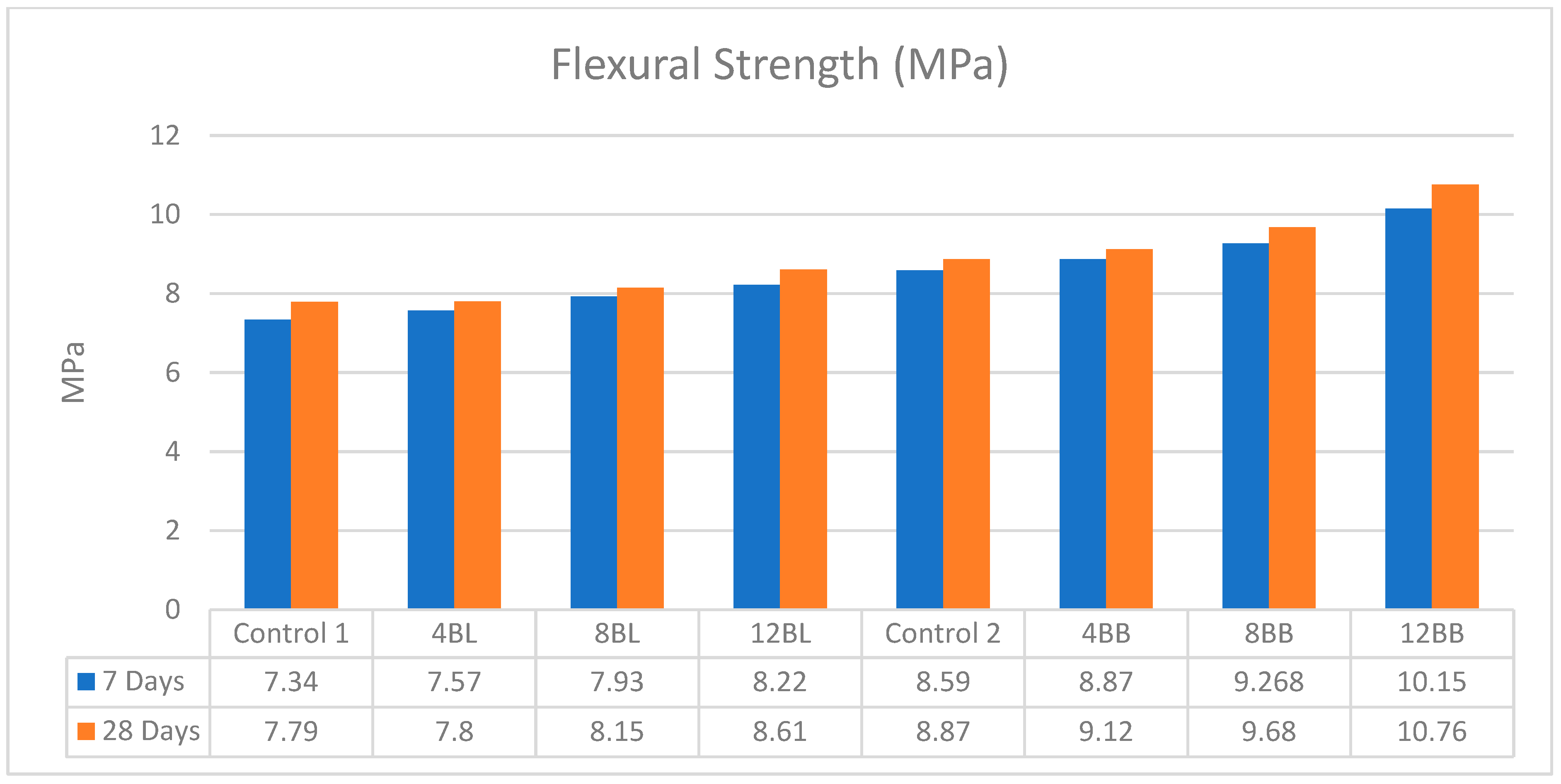

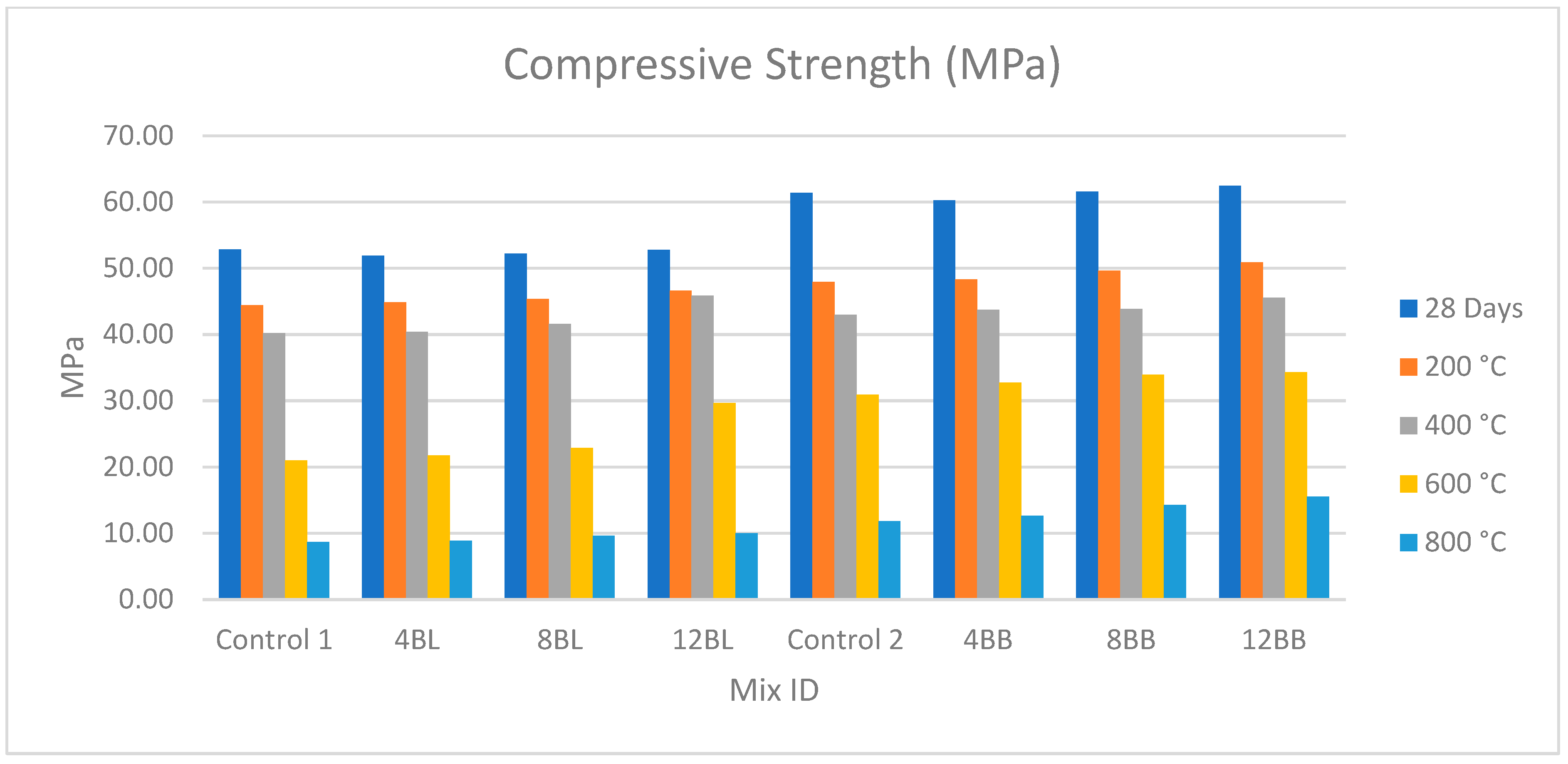

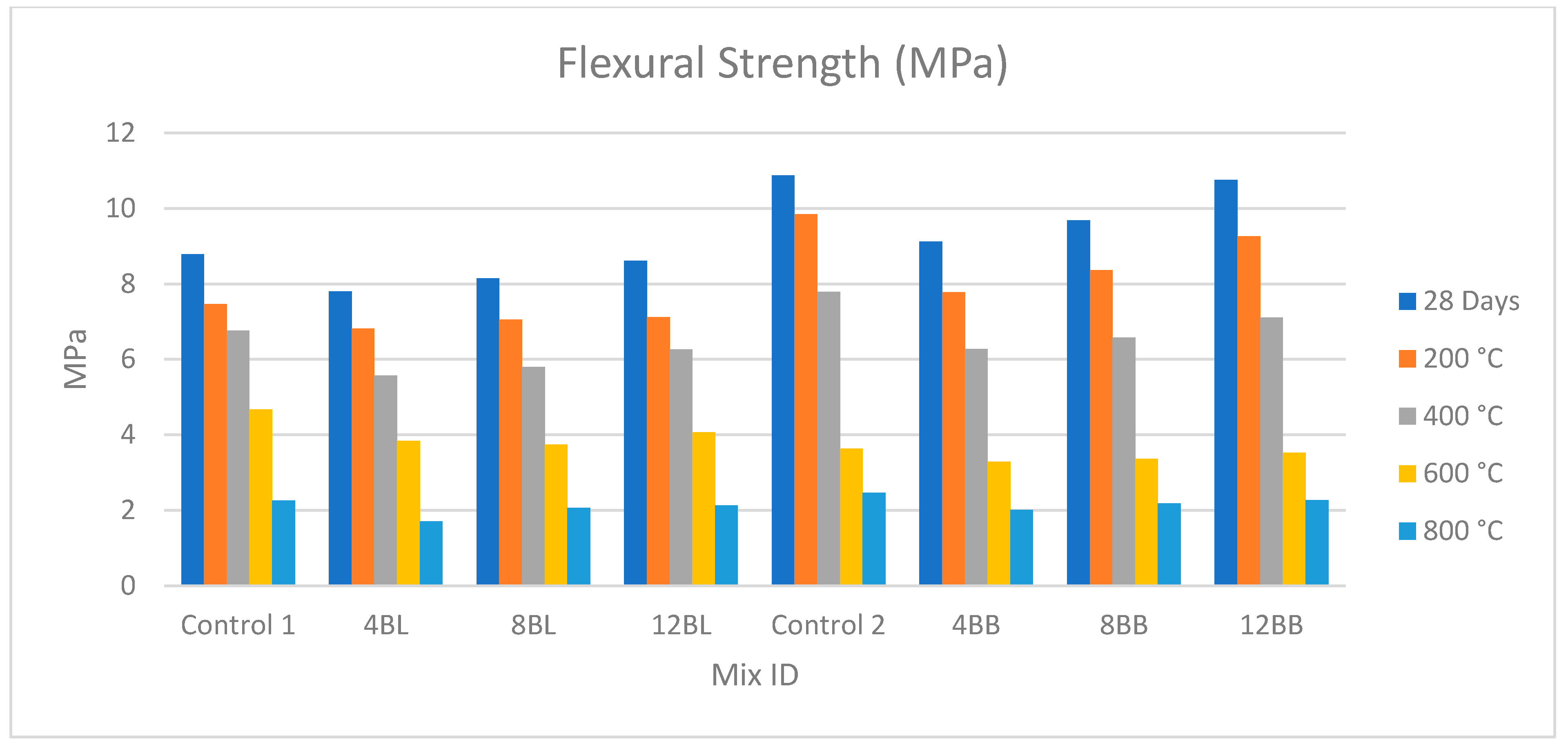

Table 6. Mechanical Strength After High-Temperature Exposure: The experimental results demonstrate a pronounced reduction in compressive and flexural strengths of geopolymer mortar specimens with increasing exposure temperature, corroborating previous investigations [

35,

36]. The highest mechanical performance (

Figure 7) was observed in the 12BB samples, while the lowest belonged to the 4BL series. For specimens exposed to 800 °C, compressive strengths for 4BB, 8BB, and 12BB were 12.64 MPa, 14.27 MPa, and 15.53 MPa, respectively. Corresponding flexural strengths were 2.01 MPa, 2.18 MPa, and 2.27 MPa. The mechanical strength reduction became more evident from 400 °C due to endothermic dehydration and water vaporization. However, our data show a slightly improved strength retention compared to these prior results, which can be linked to the reinforcing effect of basalt fibers. Basalt fibers enhance matrix cohesion and effectively bridge microcracks, delaying the onset of failure—a phenomenon also observed by K Yu et al. (2024) and Uysal et al. [

37,

38]. These thermal effects caused internal vapor pressure, which led to the formation of microcracks and thermo-chemical degradation of the geopolymer matrix (

Figure 8). Crystallization stresses and pore expansion from evaporating water further contributed to strength loss [

35]. Notably, flexural strength decreased less than compressive strength, indicating higher thermal resilience in tensile response [

39]. The vapor action highlighted reduced flexural and compressive strength with increasing temperature [

29]. Weight loss analysis revealed that specimens with higher basalt fiber content had significantly better resistance to mass reduction under high temperatures. As shown in

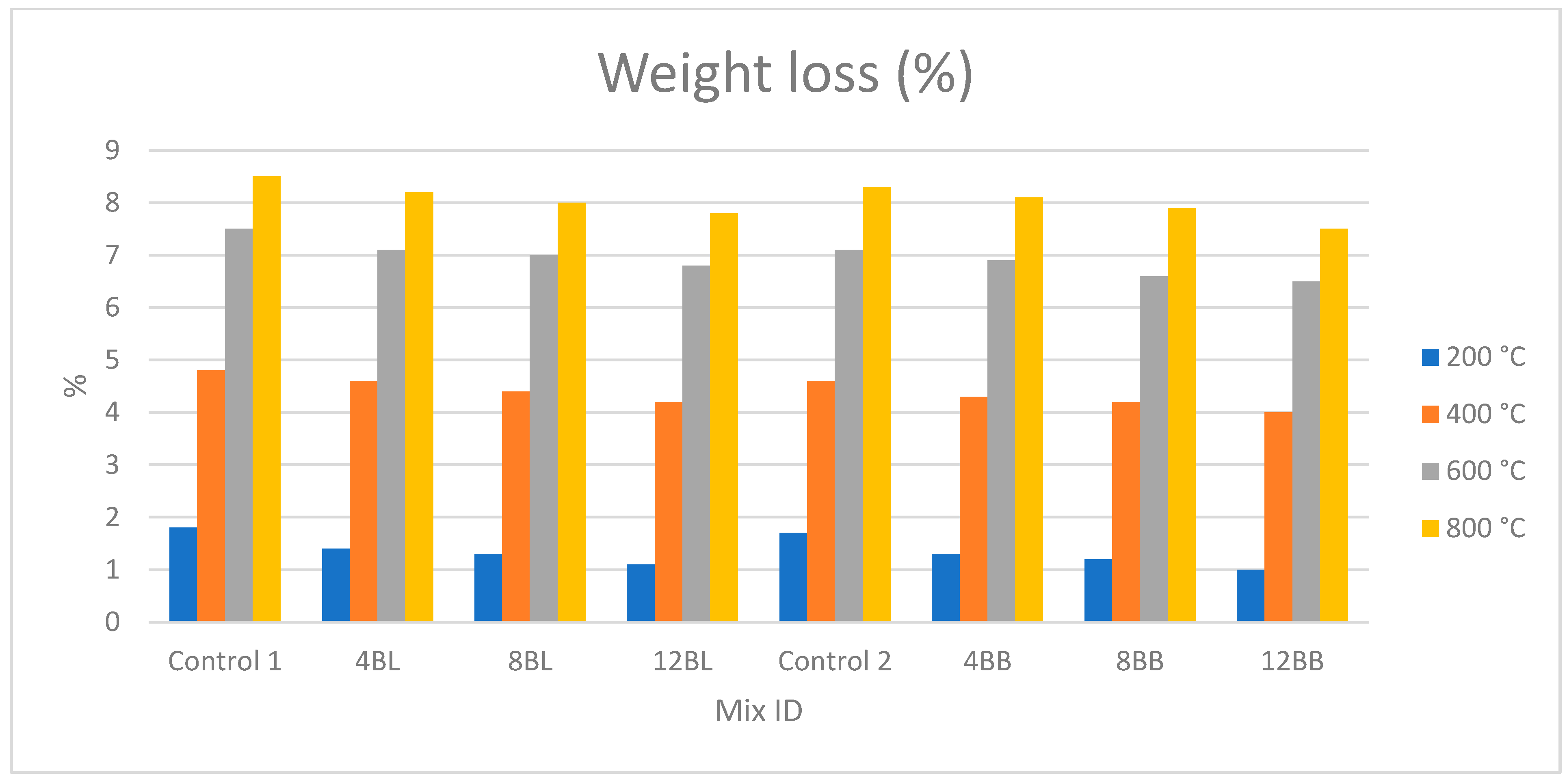

Figure 9, the control sample exhibited the highest weight loss, while 12BB had the least. This improvement was attributed to BF’s ability to limit thermal cracking, thereby reducing volatile escape pathways and structural deterioration [

40]. The weight loss increased sharply after 400 °C (

Table 7), reinforcing the mechanical findings. The basalt fibers helped stabilize the matrix and maintain structural integrity under thermal stress, contributing to lower porosity and improved durability [

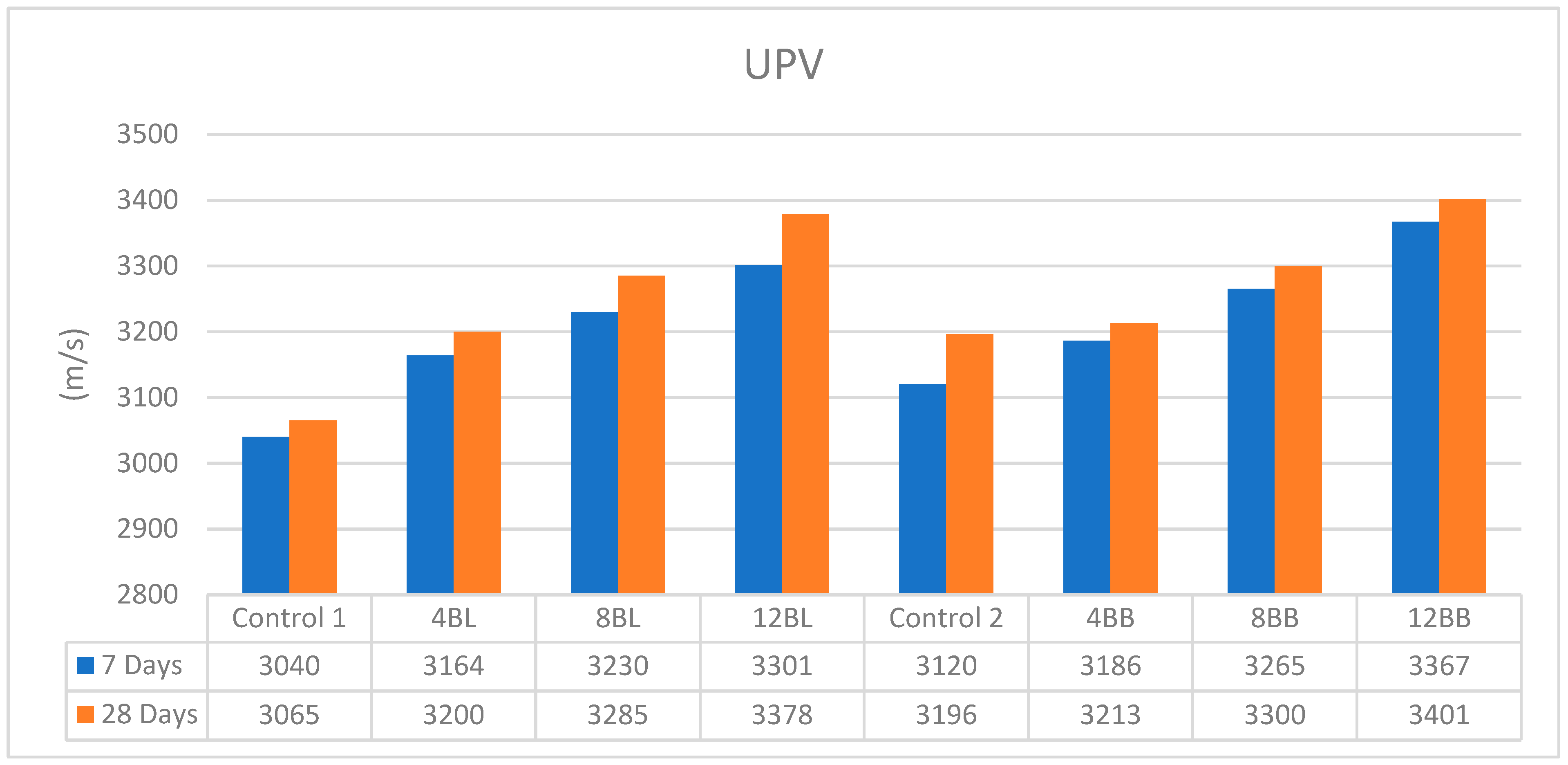

41]. The internal pressure increased gradually as the temperature soared over 100 °C. UPV and Damage Degree Assessment: To quantify internal degradation, UPV tests were conducted on all samples before and after high-temperature exposure. The results are shown in

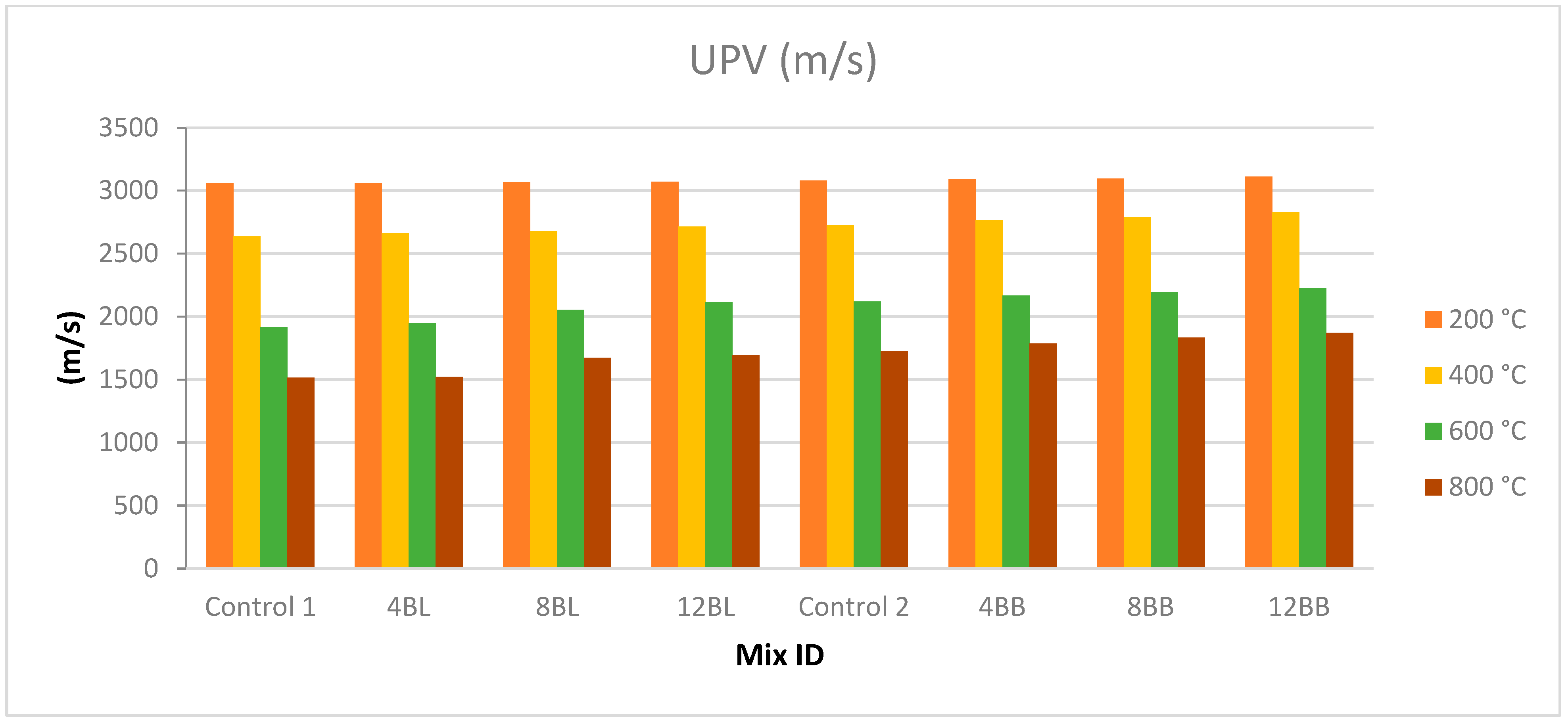

Table 8 and

Figure 10. UPV values decreased with increasing temperature due to rising pore volume and crack formation, consistent with the observed mechanical deterioration [

42]. For Control 1 samples, UPV values at 200 °C, 400 °C, 600 °C, and 800 °C were 3060 m/s, 2635 m/s, 1916 m/s, and 1516 m/s, respectively. For Control 2 samples, UPV values at 200 °C, 400 °C, 600 °C, and 800 °C were 3080 m/s, 2725 m/s, 2120 m/s, and 1723 m/s, respectively. This improved thermal resistance is further supported by ultrasonic pulse velocity (UPV) measurements, which demonstrated less internal damage and higher integrity in basalt-reinforced samples, consistent with findings from Xiao et al. (2021) [

43].

Basalt is a volcanic rock that exhibits thermal stability and is abundant in silica (SiO

2), alumina (Al

2O

3), and iron oxides. Limestone mainly consists of calcium carbonate (CaCO

3), which undergoes decomposition at high temperatures (about 700–900 °C) [

44]. Basalt maintains stability and enhances the geopolymer network under elevated temperatures owing to its high melting point (~1000–1200 °C) [

45]. Limestone experiences decarbonization (CaCO

3 → CaO + CO

2) at around 700–800 °C, resulting in mass loss, pores, fissures formation, and a matrix weakening. The mineral phases of basalt exhibit exceptional thermal stability, maintaining the integrity of the geopolymer matrix [

46].

Decarbonated limestone results in the disruption of matrix continuity, hence diminishing mechanical performance and durability. Basalt may engage more significantly in the geopolymerization reaction, providing additional reactive silica and alumina. Limestone mainly serves as a filler and does not chemically augment the geopolymer gel. The substitution of natural sand with basalt powder improves thermal stability due to its high melting point (~1000–1200 °C) and contributes additional reactive silica and alumina that participate in geopolymerization, enhancing the matrix’s chemical and mechanical stability under heat. Conversely, limestone substitution results in decarbonation at around 700–800 °C, leading to pore formation and matrix weakening, as evidenced by the larger weight loss and greater strength degradation in limestone-based samples [

42,

44]. These microstructural differences underscore the importance of filler selection for high-temperature applications.

For the 12BB samples, UPV values at 200 °C, 400 °C, 600 °C, and 800 °C were 3112 m/s, 2830 m/s, 2223 m/s, and 1869 m/s, respectively [

47]. For 12BL samples, UPV values at 200 °C, 400 °C, 600 °C, and 800 °C were 3069 m/s, 2714 m/s, 2117 m/s, and 1693 m/s, respectively. Microstructural Synergy Involving Basalt Fibers [

48]: Basalt fibers and basalt powder derive from the same source material, so they exhibit analogous thermal expansion behavior, possess comparable thermal expansion coefficients, and thus eliminate fiber-matrix discrepancies at elevated temperatures, hence decreasing thermal stress and fiber pull-out [

45]. Conversely, basalt fibers and limestone powder exhibit differential thermal expansion, resulting in debonding and microcracking [

4]. Enhanced fiber-matrix cohesion is achieved using basalt powder during thermal cycling. Research indicates that geopolymers, including basalt-based fillers, have superior compressive strength following exposure to temperatures exceeding 600 °C [

49]. Mortars containing limestone often exhibit a more significant loss of strength and integrity following heat treatment.

The reduction in compressive strength following exposure to 800 °C corresponds with the findings of [

36], who linked analogous decreases to microcracking and matrix degradation. The observed gradual strength loss in fiber-reinforced samples aligns with the findings of [

37], indicating that basalt fibers may effectively bridge cracks and postpone the onset of failure [

50,

51]. The observed trends in strength degradation following thermal exposure are likely attributable to matrix dehydration and internal microcracking, as indicated by the SEM analyses in prior studies [

52].

In contrast, the control samples recorded the lowest UPV values, indicating more significant internal damage [

5]. Damage levels were quantified using previous studies’ relative reduction in UPV values. A clear correlation was found between temperature increase and damage degree, with damage progressively increasing as temperature rose [

6]. However, samples with higher basalt fiber content showed lower damage levels, highlighting basalt fiber’s role in enhancing high-temperature resistance by reducing crack propagation and maintaining matrix integrity [

40]. This condition resulted from evaporation in the internal structure, which also caused the increase in pores and decrease in values [

53]. The values were almost consistent when comparing the UPV and the mechanical findings [

54]. In every series, a proportionate association was found between the increase in high temperatures and the damage degrees [

49]. The fracture breadth and number of metakaolin-based geopolymer samples increased as the temperatures rose [

35]. The level of damage was assessed using the UPV values. Ref. [

8] employed the UPV values in their earlier research to calculate the damage degree. The UPV test following fiber incorporation indicates enhanced microstructural integrity. Basalt fibers appear to inhibit the development of microcracks under thermal stress, a phenomenon similarly reported by [

55], who observed that fibers could create mechanical interlocks that counteract shrinkage-induced cracking. The relative damage:

caused by the UPV (ultrasonic pulse velocity) response in a geopolymer mortar is a key indicator of the material’s internal integrity and homogeneity. Unlike traditional cement mortars, geopolymer mortars may exhibit more variable UPV readings due to differences in raw material composition, curing conditions, and the formation of microcracks or voids during synthesis. Lower UPV values generally indicate potential internal defects such as pores, cracks, or incomplete polymerization, which can compromise the mechanical performance and durability of the mortar. Conversely, higher UPV values suggest a denser, more uniformly bonded matrix, reflecting better structural quality. Therefore, comparing UPV results across samples or formulations can assess the relative damage or imperfections within geopolymer mortars, helping optimize mix designs and predict long-term performance more accurately. The relative damage was calculated according to Equation (1) [

17]; the results are illustrated in

Table 9.