Abstract

The construction sector makes a major contribution to global greenhouse gas emissions, in which cement alone produces approximately 7–8% of global CO2 emissions. To abate environmental impact and promote sustainable construction, alternative low-carbon cementitious materials are gaining attention. Biochar (BC), a carbon-rich material obtained from biomass sources through the process of pyrolysis, has surfaced as a capable supplementary cementitious material due to its carbon capture capabilities and positive impact on the characteristics of cement composites. This review investigates the role of BC in cement composites, including its effects on hydration kinetics, microstructural development, fresh-state properties, and its optimal utilisation. The study also highlights the internal curing capabilities of BC when used in cement composites, its role in promoting hydration product formation, and its dual function in enhancing mechanical performance while facilitating carbon capture. Despite the benefits, there are some challenges such as variable BC properties, optimal dosage, and scalability. The review highlights the need for standardisation and further research to fully harness BC’s potential as a sustainable component in low-carbon construction technologies.

1. Introduction

The construction sector is a key source of greenhouse gas (GHG) emissions, and it is continuously growing due to an increase in population, urbanisation, and industrialisation [1]. Production of cement is the primary component of the construction industry and is responsible for about 8% of the total carbon dioxide (CO2) emissions of the globe [2]. With the rising demand for cement composites and increasing environmental concerns, the need for sustainable alternative materials has become critical. Green cement composites address this issue by incorporating supplementary materials that either replace or enhance traditional cement. This approach not only adds value to the final composite but also helps reduce the burden on landfills. Additionally, the use of waste material utilisation as supplementary materials reduces the load on sanitary landfills and helps in the preservation of natural resources [3]. Some of the alternative materials studied by the researchers are silica fume, slag, fly ash, gypsum, marble powder, glass powder, recycled fine powders, and BC [4,5,6,7,8,9,10,11,12] to produce environmentally friendly cement composites with improved characteristics. Among these alternative materials, BC has obtained substantial attention as a green supplementary cementitious material due to its carbon sequestration characteristics and capability to enhance the performance of the cement composites when added 1–2% in the cement-based composites [13].

BC is a carbon-rich, green material yielded from a biomass source through thermal treatment. The largely used technique to produce BC is pyrolysis, a thermochemical combustion process with no or limited oxygen supply [14], with a temperature range of 400 °C to 600 °C [15]. The conversion of biomass sources into BC through pyrolysis can reduce CO2 emissions up to 67% compared to burning [16]. To achieve stable carbon content in the BC, controlled temperature, rate of heating, and specific residence time are required, which can be achieved in the process of pyrolysis [17]. The BC has promising characteristics, including its stability, functional groups, high cation exchange, high porosity, and high surface area, which offer scope for researchers to explore its full potential in the construction industry for various applications [18]. The literature reflects various applications of BC, including chemical retrieval [19], effluent treatment [20], agriculture [21], anaerobic digestion [22], and carbon capture [23]. Current research states that BC has the potential for cement replacement in developing sustainable cement composites [24,25,26].

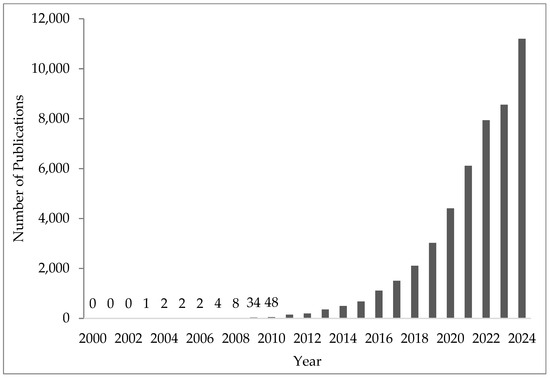

Bibliographic analysis can visualise the current surge in research on BC and its utilisation during the past two decades, aligning the direction of scientific research. Figure 1 shows the Science Direct database of research and review papers published from 2000 to 2024 for the keyword “BC.” The publication trend in Figure 1 clearly indicates that, until 2010, BC had not been explored for its potential in various applications and was largely regarded as waste. Currently, BC is being utilized across a wide range of fields, including agriculture, environmental remediation, energy production, climate change mitigation, and industrial manufacturing [27,28,29,30]. The research on BC started to increase after 2010, with a gradual increase till 2018. After 2018, a high volume of publications can be seen. Similarly, in 2024, there is a huge increase in the research, which is about a 30% increase compared to 2023. Additionally, in the last 5 years, the research focus has been observed in the “Engineering” and “Energy” fields. Despite the increase in research in these areas, there is much scope to explore the full potential of BC [31].

Figure 1.

Research publications on BC from ScienceDirect database (2000–2024).

In recent years, the incorporation of BC into cement-based composites has gained increasing attention due to its potential to enhance hydration kinetics, mechanical performance, and sustainability. However, despite a growing body of research on this topic, there is a need for studies that specifically focus on how BC influences the hydration performance of cement-based composites. Understanding the impact of BC on hydration kinetics is crucial for optimizing mix designs and predicting performance outcomes in practical applications. This review aims to fill this gap by analyzing current findings on the role of BC in modifying hydration kinetics, while also identifying research trends, challenges, and opportunities for future study. The review also highlights emerging trends in the use of BC for carbon-negative construction technologies, underscoring its potential contribution to global sustainability goals. The insights presented here are intended to support the development of more sustainable and high-performance construction materials.

2. Biochar Production

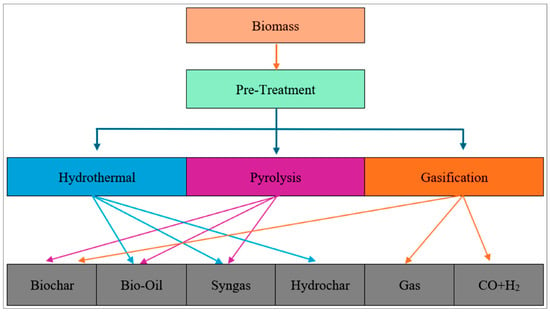

BC is a carbon-rich material produced from biomass through thermochemical processes, widely explored for its potential in sustainable cementitious applications. Figure 2 shows the thermochemical conversions of biomass sources into BC [13]. The common method used to produce BC is pyrolysis, which uses anaerobic or low-oxygen conditions during heating between 400 and 600 °C [14,15]. Pyrolysis can reduce CO2 emissions by approximately 67% compared to open burning [16]. The characteristics of BC mainly depend on the source of biomass and production conditions (including residence time, heating rate, and temperature) [32,33,34]. These parameters influence the physicochemical attributes of BC, such as particle size, porosity, and surface area (50–400 m2/g) [35], bulk density (0.3–0.5 g/cm3), and pH (7–10) [36,37], which governs its use in specific applications. Chemically, BC varies in composition based on the biomass source, showing wide ranges in elements such as CaO (0.19–63.57%) [38,39], SiO2 (4.66–78.4%) [40,41], and carbon (19.67–76.60%) [42]. BC with high silica content is particularly advantageous for cement materials due to the potential calcium silicate hydrate (C-S-H) formation [43,44]. Overall, the integration of BC with optimised production and application methods offers promising potential for environmental sustainability and material innovation.

Figure 2.

Thermochemical conversion methods to produce BC [13].

3. Role of BC in Cement Composites

BC, produced through pyrolysis or gasification from biomass sources, offers several advantages when used in cementitious systems as filler, cement, or aggregate replacement [40,45]. BC contributes to the hydration process by having water retention characteristics, acting as micro water storage tanks that help in the continued hydration and internal curing of the composite [46,47]. Various studies have studied its capabilities for improving the mechanical properties, including compressive strength and flexural strength of cement systems, due to its improved hydration product formation, which is credited to the ability of BC to offer nucleation sites for the formation of hydration products, which in turn improves the microstructural characteristics of the composites [48,49]. Table 1 summarises the relationship between various BC properties and the corresponding effects they have on the performance characteristics of cement-based composites, as adapted from [13].

Table 1.

Correlation between biochar properties and cement composite performance.

Furthermore, BC promotes waste valorisation in the construction industry. It reduces the environmental footprint of raw material extraction by being used as a sustainable alternative material in cement composites [50]. Using byproducts in the construction industry, like BC, reduces the dependency on the natural resources required for the making of conventional materials, which is a way forward towards a circular economy and sustainable construction practices [51]. BC can improve the strength and durability properties of cement composites and has the potential as a low-carbon or even carbon-negative alternative material [52]. A study reported that BC exhibits versatile properties by not only improving the characteristics of the cement composites but also playing its role in making the construction industry greener [53]. Additionally, the carbon capture capacity of BC cement composites makes them a beneficial tool in the construction industry, helping to fight climate change and achieve climate mitigation goals.

4. Hydration Kinetics of BC-Modified Cement Systems

Using BC as a partial replacement of cement affects hydration kinetics, microstructural, mechanical, and durability properties of the cement composites. Using BC with medium incorporation can enhance hydration and other characteristics. In contrast, excessive amounts of BC incorporation may negatively affect the composite due to increased porosity and reduced development of the hydration products. It is important to optimise BC dosage, fineness, and other properties for its maximum benefits while mitigating its potential weaknesses.

4.1. Water Retention and Release

The primary chemical reaction in cement composites responsible for the development of strength products is hydration. For the maturity of cement hydration and the prevention of self-desiccation of cement, proper regulation of the required water in the cement composite matrix is of key importance. BC is a highly porous material that absorbs and stores water, gradually releasing it during the hydration process of the cement composite. This behaviour allows it to act as a built-in self-curing agent, maintaining a stable moisture environment within the composite [46,53]. This mechanism complements the ongoing hydration of previously unreacted cement particles, thereby extending the hydration process and resulting in the formation of larger amounts of C-S-H in the cement composites [50]. The internal curing of BC decreases the early-age shrinkage and prevents cracking, which is a problem in cement composites with rapid moisture loss. The slow release of water by BC within the cement composite helps mitigate internal stresses and structural weaknesses caused by moisture gradients, thereby enhancing the overall performance of the cement composites [49]. Various studies reported minimal improvement in compressive strength, whereas significantly improved durability and microstructural density were observed after adding BC in the cement composites [54,55]. BC particles also improve the localized water-to-cement ratio by functioning as dispersed micro water reservoirs that help regulate moisture distribution throughout the cement composite. The uniform hydration makes the structure of the cement composites denser and cohesive, imparting strength to the composite and making it resistant to environmental degradation [56]. Moreover, the particle size and dose of BC in the cement composites have a significant effect on the cement hydration process. Various studies have reported that BC incorporated at low to moderate levels can enhance hydration and thus improve mechanical properties. However, excessive amounts of BC can reduce adhesion between cement hydration products and increase internal porosity of the cement composites [48,57]. For instance, using BC at higher percentages as a replacement for cement decreases the overall concentration of C-S-H, reducing the mechanical characteristics and durability aspects of the cement pastes [57]. This phenomenon highlights the importance of optimising BC content and particle size to balance its valuable effects with potential weaknesses.

In summary, the ability of BC to store and release water makes it a valuable tool for enhancing cement hydration and the performance of cement composites. By considering its physicochemical characteristics and proper mix design, researchers can unlock its full potential as an alternative sustainable material.

4.2. Hydration Kinetics

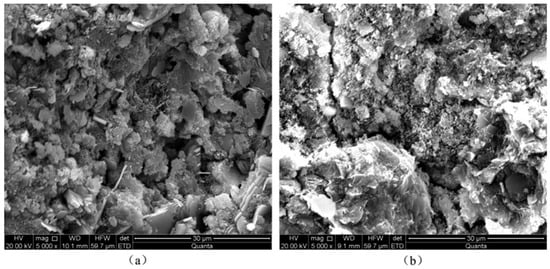

The interaction of BC with cement hydrates is a versatile process that significantly influences hydration kinetics, mechanical properties, and the overall performance of cementitious materials. Properties of BC include high surface area, high porosity, and the ability to absorb and retain moisture, which contribute to its effectiveness as an additive in cement composites [46,58]. Studies have shown that using BC can improve the development of added hydrates, contributing to the strength development of cement composites. The incorporation of BC leads to growth in the formation of brucite and other amorphous phases, which are beneficial for the mechanical properties of the cement composite [50,53]. Various studies reported the improvement of hydration by using BC in cement composites [39,59,60]. From the SEM image showing the microstructure of the control sample, Figure 3a, and the 2% BC-modified cement composite, Figure 3b, it can be observed that the sample with BC has a denser structure, attributable to the prolonged cement hydration, which itself can be attributed to the promoted growth of added hydrates [61].

Figure 3.

SEM images of cement composite (a) and 2% BC-modified cement composite (b) (license no. 6023280792234).

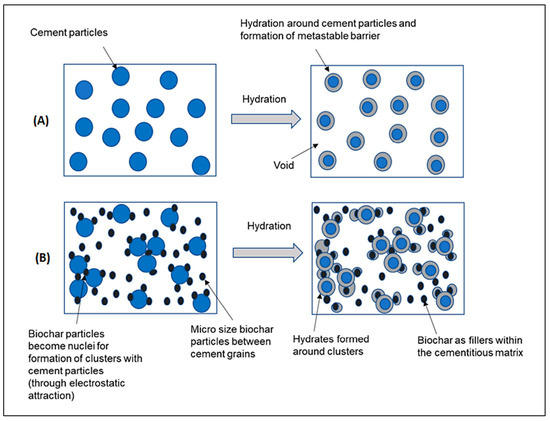

Conversely, excessive BC content can lead to a reduction in the overall volume of cement hydration products due to deficient adhesion and increased internal porosity of the composite [48,62]. Although BC does not possess self-cementing properties and does not react with water itself, the release of stored water in its porous structure supports prolonged cement hydration, during which C-S-H nucleates in the pores of BC [58]. A study reported a slight increase in the rate of hydration and about a 30 min decrease in the dormant period, which is credited to the nucleation effect of the BC by providing an additional space for the formation of added hydrates [63]. Figure 4 shows the mechanism by which adding BC modifies the hydration kinetics in the cement system. Figure 4A represents the hydration mechanism of the composite containing cement only, which shows that when the hydration starts, the initial phase is the development of hydration products around tri-calcium silicate (C3S), which can be seen by grey circles around the cement particles. After a certain amount, the hydration kinetics slow down and the full hydration capacity of the cement particle is underutilized; the blue colour shows unhydrated cement. By introducing BC in the cement system, as shown in Figure 4B, it invites positively charged particles of cement hydrates due to the presence of the -OH group. The kinetics of the hydration process are improved by the nucleation sites [64]. Using BC can enhance the hydration process, due to which additional hydrates are accumulated near the cement particles. The microstructural assessment of BC-modified cement composites reveals substantial changes in pore structure and distribution, which enhance fracture resistance [47]. Techniques such as SEM and MIP have been employed to characterise these changes, showing that BC can efficiently alter the microstructure of the cement matrix [54]. The particle size of BC influences the hydration kinetics of the composite, and various studies have reported the acceleration in the hydration process when fine particles are used [65,66].

Figure 4.

(A) Composite containing cement only. (B) Composite containing cement and BC (license no. 6023290819768).

4.3. Effect of Carbonation on Cement Hydrates

BC also affects the carbonation behaviour of cement composites by modifying the microstructure and assisting CO2 diffusion within the cement composites. Carbonation is a process in which a hydrated product of cement, called calcium hydroxide, reacts with CO2, resulting in the development of calcium carbonate, which alters pore structure and contributes to continued microstructural development. As such, carbonation acts as a secondary hydration-related process with implications for both kinetics and long-term cement matrix evolution. Carbonation reaction in the cement compounds is given in Equation (1). BC improves this process due to its porous structure and high surface area, which promotes easy CO2 ingress, accelerating both carbonation and hydration, mainly when fine BC particles are used [67,68,69,70]. Moreover, BC content can induce in situ precipitation of calcite (CaCO3) within its internal pores, thereby contributing to long-term carbon sequestration [35]. The formation of CaCO3 due to BC addition in the cement composites enhances the durability characteristics of the composite by filling microcracks and pores, leading to a more refined and denser microstructure [27,28,29,30]. This reduces permeability, limits the ingress of harmful substances such as chlorides and sulphates, and improves resistance to freeze–thaw cycles [42]. As a result, the overall mechanical stability and long-term performance of the cement composites are significantly improved.

4.4. Effect of BC on the Fresh State Properties of Cement Composites

BC tends to lower the workability of cement composites due to its more specific surface area and porous structure, but at the same time, it acts as an internal curing tank by storing the water in its pores [66,71,72,73]. Higher dosage of BC could result in a notable reduction in flow characteristics, mainly due to the porosity of BC and the dilution [73]. A study stated a drop of about 10% in the workability of the cement composite added with 5 wt% rice husk BC as a partial replacement of cement [72]. Some studies reported a decrease in workability of cement composites by 10% to 30% when added with BC [66,71]. To maintain a workable mix and ensure ease of handling, compaction, finishing, and its application for the intended purpose, proper admixtures could be used to obtain the required consistency [74]. However, some of the studies reported improvement up to 13% in the workability of cement composites modified with BC [65,75].

The addition of BC affects the free moisture content of the cement composite matrix, preceding to reduced setting time [76,77]. Various studies have reported that initial setting time and final setting time of cement composites are reduced when incorporated with BC, which is credited to the improved early hydration of cement due to stored water in the pores of BC [33,78,79]. A study showed an 11% and 16% decrease in the initial and final setting time of the cement composite added with 3% BC, respectively [80]. Cement composite modified with 2% rice husk BC experienced a reduction in initial and final setting times of the cement composite by 26% and 14%, respectively [81]. Inclusion of BC above 5% to 10% cement replacement exhibits a delay in the setting time due to reduced hydration rate because of the dilution effect and enhanced water demand [50]. Similarly, carbon-rich and less reactive BC experiences extended setting times, whereas alkaline BC with higher ash content reduces setting times [33,65,77]. However, it is not common, but BC with sugar products could increase the setting times of the cement composites [80]. Achieving optimal fresh-state properties of cement composites added with BC requires a proper assessment of the BC’s type, specific surface area, morphology, and porosity. In the design considerations of cement composites, the amount of BC and the appropriate use of plasticisers can also play a significant role.

5. Challenges and Opportunities

Using BC in cement composites is a sustainable approach as an alternative construction material. However, it has challenges that hold back the broader application and understanding. The porosity, surface area, and chemical composition variability greatly depend on biomass source, pyrolysis temperature and particle size. Due to this, it becomes challenging to standardise the performance of the BC-based cement composites reflected in the research. Furthermore, the implementation of BC usage on an industrial scale is a challenging task because it is a comparatively new material. The availability of BC on such a large scale at this moment itself is a challenge. Similarly, maintaining the required quality, including particle size, surface area, carbon content, residence time, temperature, and heating rate, is a challenge which needs uniformity for its optimal implementation in the cement composites. Additionally, due to limited research in the construction field, BC still requires proper validation of its economic feasibility, long-term mechanical and durability assessment, and development of codes of practice for its usage. Addressing these challenges needs research, implementation of standardised testing frameworks, and collaboration with the industry to validate and optimise BC integration in real-world cementitious systems.

6. Conclusions

This review summarizes the current understanding of the BC on the hydration kinetics of cement composites. Key focus areas include BC’s role in hydration reaction, internal curing, setting time, workability, carbonation, and durability performance. The review also addresses challenges related to variability in BC characteristics and outlines the potential for BC to contribute to carbon sequestration and sustainable construction. Following are the key conclusions from the review. The key conclusions drawn from this review are summarized below:

- BC is suitable for use as a partial cement replacement in cement composites. Particularly, finer BC particles contribute more effectively due to their higher specific surface area, which enhances the filler effect and promotes hydration reactions. Their porous structure also allows water retention, supporting the hydration process and improving the microstructure of the composite.

- BC addition significantly reduces the initial and final setting times of cement composites. The presence of functional groups on BC surfaces and their catalytic activity accelerate hydration, resulting in a faster setting time. The reported reductions in setting times range from 11% to 26%.

- The porous nature BC enables it to act as an internal curing agent, enhancing hydration kinetics by improving moisture availability and reducing autogenous shrinkage. This dual mechanism not only boosts early-age strength by up to 12–18% at 2–3 wt% replacement levels but also reduces early-age shrinkage by up to 30%. These effects contribute to improved dimensional stability and durability, particularly in high-performance or low water-to-cement ratio mixes.

- Incorporation of BC contributes to carbon sequestration through in situ carbonation within its pore structure. The formation of calcium carbonate (CaCO3) inside BC pores during the hydration process facilitates long-term CO2 capture, positioning BC-modified cement composites as a potential pathway toward carbon-negative construction materials.

- Workability of fresh cement composites decreases with increasing BC content, particularly above 3 wt%. Due to its water demand and high surface area, BC absorbs a portion of the mix water, resulting in slump reductions of 10–30% unless compensated by superplasticizers. This effect necessitates careful mix design to maintain workability while achieving desired mechanical properties.

- High dosages of BC above 5 wt% may negatively affect the cement composite. Excess BC can lead to increased porosity, insufficient cementitious binder content, and reduced compressive strength, thus offsetting the benefits seen at lower replacement levels. Therefore, optimal BC content must be carefully calibrated depending on the application.

- The variability in BC properties poses challenges for standardization and large-scale application. Properties such as particle size, surface chemistry, and porosity vary significantly depending on the type of biomass and pyrolysis conditions. This inconsistency complicates performance prediction and underscores the need for standardized BC production and characterization protocols.

Author Contributions

Conceptualization, S.R.; methodology, S.R. and A.B.-J.; software, S.R.; validation, A.B.-J.; formal analysis, S.R.; investigation, S.R.; writing—original draft preparation, S.R.; writing—review and editing, S.R. and A.B.-J.; visualization, S.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental Impact of Cement Production and Solutions: A Review. Mater. Today Proc. 2021, 48, 741–746. [Google Scholar] [CrossRef]

- Yin, M.; Li, J.; Zheng, H.; Chen, L.; Li, H.; Wang, H.; Ma, Z.; Xu, X.; Gao, C. A genome recoding method enables scalable multiplex base editing. Nat. Commun. 2025, 16, 6201. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, X.; Zhang, Z.; Wei, C.; Xu, C. Synergistic utilization of blast furnace slag with other industrial solid wastes in cement and concrete industry: Synergistic mechanisms, applications, and challenges. Green. Energy Resour. 2023, 1, 100012. [Google Scholar] [CrossRef]

- Noor Azline, M.N.; Nabilah, A.B.; Nor Azizi, S.; Ernaleza, M.; Farah Nora Aznieta, A.A. Enhanced Autogeneous Self-Healing of MgO Blended Composites Incorporating with Silica Fume. Clean. Eng. Technol. 2023, 16, 100670. [Google Scholar] [CrossRef]

- Li, X.; Mehdizadeh, H.; Ling, T.C. Environmental, Economic and Engineering Performances of Aqueous Carbonated Steel Slag Powders as Alternative Material in Cement Pastes: Influence of Particle Size. Sci. Total Environ. 2023, 903, 166210. [Google Scholar] [CrossRef] [PubMed]

- da Silva Magalhães, M.; Cezar, B.F.; Lustosa, P.R. Influence of Brazilian Fly Ash Fineness on the Cementing Efficiency Factor, Compressive Strength and Young’s Modulus of Concrete. Dev. Built Environ. 2023, 14, 100147. [Google Scholar] [CrossRef]

- Alyousef, R.; Abbass, W.; Aslam, F.; Shah, M.I. Potential of Waste Woven Polypropylene Fiber and Textile Mesh for Production of Gypsum-Based Composite. Case Stud. Constr. Mater. 2023, 18, e02099. [Google Scholar] [CrossRef]

- Iqbal, S.; Zaheer, M.; Room, S. Mechanical & Microstructural Properties of Self-Compacting Concrete by Partial Replacement of Cement with Marble Powder and Sand with Rice Husk Ash. Sciencetech 2023, 4, 82–99. [Google Scholar]

- Nassar, R.U.D.; Saeed, D.; Ghebrab, T.; Room, S.; Deifalla, A.; Al Amara, K. Heat of Hydration, Water Sorption and Microstructural Characteristics of Paste and Mortar Mixtures Produced with Powder Waste Glass. Cogent Eng. 2024, 11, 2297466. [Google Scholar] [CrossRef]

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable Transition towards Biomass-Based Cement Industry: A Review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- Dai, T.; Fang, C.; Liu, T.; Zheng, S.; Lei, G.; Jiang, G. Waste Glass Powder as a High Temperature Stabilizer in Blended Oil Well Cement Pastes: Hydration, Microstructure and Mechanical Properties. Constr. Build. Mater. 2024, 439, 137359. [Google Scholar] [CrossRef]

- Wei, M.; Chen, L.; Lei, N.; Li, H.; Huang, L. Mechanical Properties and Microstructures of Thermally Activated Ultrafine Recycled Fine Powder Cementitious Materials. Constr. Build. Mater. 2025, 475, 141195. [Google Scholar] [CrossRef]

- Room, S.; Bahadori-Jahromi, A. Biochar-Enhanced Carbon-Negative and Sustainable Cement Composites: A Scientometric Review. Sustainability 2024, 16, 10162. [Google Scholar] [CrossRef]

- Kant Bhatia, S.; Palai, A.K.; Kumar, A.; Kant Bhatia, R.; Kumar Patel, A.; Kumar Thakur, V.; Yang, Y.H. Trends in Renewable Energy Production Employing Biomass-Based Biochar. Bioresour. Technol. 2021, 340, 158. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kua, H.W. Effect of Water Entrainment by Pre-Soaked Biochar Particles on Strength and Permeability of Cement Mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Hu, J.; Guo, H.; Wang, X.; Gao, M.T.; Yao, G.; Tsang, Y.F.; Li, J.; Yan, J.; Zhang, S. Utilization of the Saccharification Residue of Rice Straw in the Preparation of Biochar Is a Novel Strategy for Reducing CO2 Emissions. Sci. Total Environ. 2019, 650, 1141–1148. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiya, S.; Bhusan Das, B.; Kanavaris, F. Biochar-Concrete: A Comprehensive Review of Properties, Production and Sustainability. Case Stud. Constr. Mater. 2024, 20, e02859. [Google Scholar] [CrossRef]

- Zaid, O.; Alsharari, F.; Ahmed, M. Utilization of Engineered Biochar as a Binder in Carbon Negative Cement-Based Composites: A Review. Constr. Build. Mater. 2024, 417, 135246. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, S.; Sun, Y.; Tsang, D.C.W.; Cheng, K.; Ok, Y.S. Assembling Biochar with Various Layered Double Hydroxides for Enhancement of Phosphorus Recovery. J. Hazard Mater 2019, 365, 665–673. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Gao, Y.; Bolan, N.; Shaheen, S.M.; Xu, S.; Wu, X.; Xu, X.; Hu, H.; Lin, J.; Zhang, F.; et al. Conversion of Biological Solid Waste to Graphene-Containing Biochar for Water Remediation: A Critical Review. Chem. Eng. J. 2020, 390, 124611. [Google Scholar] [CrossRef]

- Sahoo, S.S.; Vijay, V.K.; Chandra, R.; Kumar, H. Production and Characterization of Biochar Produced from Slow Pyrolysis of Pigeon Pea Stalk and Bamboo. Clean. Eng. Technol. 2021, 3, 100101. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, H.; He, S.; Zhao, Q.; Wei, L. A Review of Biochar in Anaerobic Digestion to Improve Biogas Production: Performances, Mechanisms and Economic Assessments. Bioresour. Technol. 2021, 341, 125797. [Google Scholar] [CrossRef] [PubMed]

- Dissanayake, P.D.; You, S.; Igalavithana, A.D.; Xia, Y.; Bhatnagar, A.; Gupta, S.; Kua, H.W.; Kim, S.; Kwon, J.H.; Tsang, D.C.W.; et al. Biochar-Based Adsorbents for Carbon Dioxide Capture: A Critical Review. Renew. Sustain. Energy Rev. 2020, 119, 109582. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as Green Additives in Cement-Based Composites with Carbon Dioxide Curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Asadi Zeidabadi, Z.; Bakhtiari, S.; Abbaslou, H.; Ghanizadeh, A.R. Synthesis, Characterization and Evaluation of Biochar from Agricultural Waste Biomass for Use in Building Materials. Constr. Build. Mater. 2018, 181, 301–308. [Google Scholar] [CrossRef]

- Osman, A.I.; Farghali, M.; Dong, Y.; Kong, J.; Yousry, M.; Rashwan, A.K.; Chen, Z.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.S. Reducing the Carbon Footprint of Buildings Using Biochar-Based Bricks and Insulating Materials: A Review. Environ. Chem. Lett. 2024, 22, 71–104. [Google Scholar] [CrossRef]

- Yang, C.; Yao, Q.; Li, L.; Xiao, X.; Lu, L.; Liu, C.; Zhu, C.; Zhan, S.; Yuan, H. The Isolated Ca-Nx Sites in Biochar Boosting Fe Catalyzed Fenton-like Oxidation of Tris(2-Chloroethyl) Phosphate: Properties, Mechanisms, and Applications. Appl. Catal. B Environ. Energy 2025, 366, 125056. [Google Scholar] [CrossRef]

- Qiu, Z.; Chen, F.; Yu, Y.; Gu, Y.; Wang, X.; Wang, Y. Effects of Water-Cement Ratio and Particle Diameter on the Mechanical Properties of Cement Paste Particles. Opt. Lasers Eng. 2025, 187, 108874. [Google Scholar] [CrossRef]

- Yang, H.; Wang, X.; Wang, J.; Liu, H.; Jin, H.; Zhang, J.; Li, G.; Tang, Y.; Ye, C. High-Value Utilization of Agricultural Waste: A Study on the Catalytic Performance and Deactivation Characteristics of Iron-Nickel Supported Biochar-Based Catalysts in the Catalytic Cracking of Toluene. Energy 2025, 323, 135806. [Google Scholar] [CrossRef]

- Zhao, M.; Zou, G.; Li, Y.; Pan, B.; Wang, X.; Zhang, J.; Xu, L.; Li, C.; Chen, Y. Biodegradable Microplastics Coupled with Biochar Enhance Cd Chelation and Reduce Cd Accumulation in Chinese Cabbage. Biochar 2025, 7, 31. [Google Scholar] [CrossRef]

- Ahmed, A.S.F.; Vanga, S.; Raghavan, V. Global Bibliometric Analysis of the Research in Biochar. J. Agric. Food Inf. 2018, 19, 228–236. [Google Scholar] [CrossRef]

- Ghorbani, M.; Neugschwandtner, R.W.; Soja, G.; Konvalina, P.; Kopecký, M. Carbon Fixation and Soil Aggregation Affected by Biochar Oxidized with Hydrogen Peroxide: Considering the Efficiency of Pyrolysis Temperature. Sustainability 2023, 15, 7158. [Google Scholar] [CrossRef]

- Liu, J.; Liu, G.; Zhang, W.; Li, Z.; Xing, F.; Tang, L. Application Potential Analysis of Biochar as a Carbon Capture Material in Cementitious Composites: A Review. Constr. Build. Mater. 2022, 350, 128715. [Google Scholar] [CrossRef]

- Yek, P.N.Y.; Cheng, Y.W.; Liew, R.K.; Wan Mahari, W.A.; Ong, H.C.; Chen, W.H.; Peng, W.; Park, Y.K.; Sonne, C.; Kong, S.H.; et al. Progress in the Torrefaction Technology for Upgrading Oil Palm Wastes to Energy-Dense Biochar: A Review. Renew. Sustain. Energy Rev. 2021, 151, 111645. [Google Scholar] [CrossRef]

- Winters, D.; Boakye, K.; Simske, S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability 2022, 14, 4633. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; McGrouther, K.; Huang, H.; Lu, K.; Guo, X.; He, L.; Lin, X.; Che, L.; Ye, Z.; et al. Effect of Biochar on the Extractability of Heavy Metals (Cd, Cu, Pb, and Zn) and Enzyme Activity in Soil. Environ. Sci. Pollut. Res. 2016, 23, 974–984. [Google Scholar] [CrossRef] [PubMed]

- Alkhasha, A.; Al-Omran, A.; Louki, I. Impact of Deficit Irrigation and Addition of Biochar and Polymer on Soil Salinity and Tomato Productivity. Can. J. Soil Sci. 2019, 99, 380–394. [Google Scholar] [CrossRef]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of Pervious Concrete Performance with Pulverized Biochar as Cement Replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Gupta, S.; Muthukrishnan, S.; Kua, H.W. Comparing Influence of Inert Biochar and Silica Rich Biochar on Cement Mortar–Hydration Kinetics and Durability under Chloride and Sulfate Environment. Constr. Build. Mater. 2021, 268, 121142. [Google Scholar] [CrossRef]

- Chen, T.; Zhao, L.; Gao, X.; Li, L.; Qin, L. Modification of Carbonation-Cured Cement Mortar Using Biochar and Its Environmental Evaluation. Cem. Concr. Compos. 2022, 134, 104764. [Google Scholar] [CrossRef]

- Khan, M.I.; Abdy Sayyed, M.A.; Ali, M.M.A. Examination of Cement Concrete Containing Micro Silica and Sugarcane Bagasse Ash Subjected to Sulphate and Chloride Attack. Mater. Today Proc. 2021, 39, 558–562. [Google Scholar] [CrossRef]

- Murali, G.; Wong, L.S. A Comprehensive Review of Biochar-Modified Concrete: Mechanical Performance and Microstructural Insights. Constr. Build. Mater. 2024, 425, 135986. [Google Scholar] [CrossRef]

- Nguyen, M.N. Potential Use of Silica-Rich Biochar for the Formulation of Adaptively Controlled Release Fertilizers: A Mini Review. J. Clean. Prod. 2021, 307, 127188. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, B.; Chen, Z.; Zhu, L.; Schnoor, J.L. Insight into Multiple and Multilevel Structures of Biochars and Their Potential Environmental Applications: A Critical Review. Environ. Sci. Technol. 2018, 52, 5027–5047. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Maierdan, Y.; Guo, T.; Chen, B.; Fang, S.; Zhao, L. Biochar as Carbon Sequestration Material Combines with Sewage Sludge Incineration Ash to Prepare Lightweight Concrete. Constr. Build. Mater. 2022, 343, 128116. [Google Scholar] [CrossRef]

- Lv, C.; Shen, Z.; Cheng, Q.; Tang, C.S.; Wang, Y.; Gu, K. Effects of Biochar and Polypropylene Fibre on Mechanical Behaviour of Cement-Solidified Sludge. Soil Use Manag. 2022, 38, 1667–1678. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Falliano, D.; Carvajal, J.F.; Celi, A.C.B.; Ferro, G.A.; Tulliani, J.M.; Lavagna, L.; Restuccia, L. The Effect of Different Biochar on the Mechanical Properties of Cement-Pastes and Mortars. Buildings 2023, 13, 2900. [Google Scholar] [CrossRef]

- Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials 2023, 16, 2809. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, Y.; Labianca, C.; Wang, L.; Ruan, S.; Poon, C.S.; Ok, Y.S.; Tsang, D.C.W. Carbon-Negative Cement-Bonded Biochar Particleboards. Biochar 2022, 4, 58. [Google Scholar] [CrossRef]

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, S.M.J.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A Review on Mechanical, Thermal, and Environmental Properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Ruscica, G.; Peinetti, F.; Natali Sora, I.; Savi, P. Analysis of Electromagnetic Shielding Properties of Cement-Based Composites with Biochar and PVC as Fillers. C-J. Carbon Res. 2024, 10, 21. [Google Scholar] [CrossRef]

- Nahuat-Sansores, J.R.; Cruz-Argüello, J.C.; Gurrola, M.P.; Trejo-Arroyo, D.L. Suitability of Biochar as Supplementary Cementitious Material (SCM) or Filler: Waste Revalorization, a Critical Review. Rev. Ing. Civ. 2022, 6, 12. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Poon, C.S.; Wang, C.H.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C.W. Roles of Biochar and CO2 Curing in Sustainable Magnesia Cement-Based Composites. ACS Sustain. Chem. Eng. 2021, 9, 8603–8610. [Google Scholar] [CrossRef]

- Mrad, R.; Chehab, G. Mechanical and Microstructure Properties of Biochar-Based Mortar: An Internal Curing Agent for PCC. Sustainability 2019, 11, 2491. [Google Scholar] [CrossRef]

- Aman, A.M.N.; Selvarajoo, A.; Lau, T.L.; Chen, W.H. Biochar as Cement Replacement to Enhance Concrete Composite Properties: A Review. Energies 2022, 15, 7662. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A.; Mahmood, A.H.; Han, T. Carbon Sequestration in Cementitious Composites Using Biochar and Fly Ash –Effect on Mechanical and Durability Properties. Constr. Build. Mater. 2021, 291, 123363. [Google Scholar] [CrossRef]

- Sinha, S.; Pandey, A.; B, S.N.; Prasad, B. Preliminary Study of Agricultural Waste as Biochar Incorporated into Cementitious Materials. J. Archit. Environ. Struct. Eng. Res. 2023, 6, 5695. [Google Scholar] [CrossRef]

- Vafaei, B.; Ghahremaninezhad, A. Effects of Biochar as a Green Additive on the Self-Healing and Properties of Sustainable Cementitious Materials. ACS Sustain. Chem. Eng. 2024, 12, 8261–8275. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.Y. Strength and Durability Improvements of Biochar-Blended Mortar or Paste Using Accelerated Carbonation Curing. J. CO2 Util. 2021, 54, 101766. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of Silica Fume, Metakaolin & SBR Latex on Strength and Durability Performance of Pervious Concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Xue, Q.; Huang, X.; Liu, L.; Poon, C.S. Sludge Biochar as a Green Additive in Cement-Based Composites: Mechanical Properties and Hydration Kinetics. Constr. Build. Mater. 2020, 262, 120723. [Google Scholar] [CrossRef]

- Berti, D.; Biscontin, G.; Lau, J. Effect of Biochar Filler on the Hydration Products and Microstructure in Portland Cement–Stabilized Peat. J. Mater. Civ. Eng. 2021, 33, 04021263. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Carbonaceous Micro-Filler for Cement: Effect of Particle Size and Dosage of Biochar on Fresh and Hardened Properties of Cement Mortar. Sci. Total Environ. 2019, 662, 952–962. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Tulliani, J.M.; Kua, H.W. Carbonaceous Admixtures in Cementitious Building Materials: Effect of Particle Size Blending on Rheology, Packing, Early Age Properties and Processing Energy Demand. Sci. Total Environ. 2022, 807, 150884. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of Biochar from Food and Wood Waste as Green Admixture for Cement Mortar. Sci. Total Environ. 2018, 619, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kua, H.W.; Pang, S.D. Biochar-Mortar Composite: Manufacturing, Evaluation of Physical Properties and Economic Viability. Constr. Build. Mater. 2018, 167, 874–889. [Google Scholar] [CrossRef]

- Kumar, A.; Pippal, A.; Agarwal, R.; Kumar, R.; Bhanavath, S.N.; Athar, H.; Kushwah, S. Thermo-Physical Study of Biochar Mixture into The Cement Based Material for Thermal Comfort. J. Build. Des. Environ. 2023, 2, 21478. [Google Scholar] [CrossRef]

- Zhang, D.; Han, T.; Wang, J.; Sun, C.; Jiang, X.Y.; Ni, Z.; Guo, J. An Insight into the Effect of Rice Straw Biochar on Compressive Strength and Thermal Conductivity of Cement. Proc. J. Phys. Conf. Ser. 2022, 2168, 012012. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.; Wang, L.; Yan, J.; Ma, B.; Zhu, X.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C.W. Biochar as Construction Materials for Achieving Carbon Neutrality. Biochar 2022, 4, 59. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Wang, Q. Accelerated Carbonation of Regenerated Cementitious Materials from Waste Concrete for CO2 Sequestration. J. Build. Eng. 2022, 55, 104701. [Google Scholar] [CrossRef]

- Tan, K.; Pang, X.; Qin, Y.; Wang, J. Properties of Cement Mortar Containing Pulverized Biochar Pyrolyzed at Different Temperatures. Constr. Build. Mater. 2020, 263, 120616. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.Y. Hydration-Strength-Durability-Workability of Biochar-Cement Binary Blends. J. Build. Eng. 2021, 42, 103064. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical Properties of Mortar Containing Bio-Char From Pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of Biochar Addition on Long-Term Behavior of Concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Tan, K.-H.; Wang, T.-Y.; Zhou, Z.-H.; Qin, Y.-H. Biochar as a Partial Cement Replacement Material for Developing Sustainable Concrete: An Overview. J. Mater. Civ. Eng. 2021, 33, 03121001. [Google Scholar] [CrossRef]

- Chi, L.; Du, T.; Lu, S.; Li, W.; Wang, M. Electrochemical Impedance Spectroscopy Monitoring of Hydration Behaviors of Cement with Na2CO3 Accelerator. Constr. Build. Mater. 2022, 357, 129374. [Google Scholar] [CrossRef]

- Gupta, S.; Krishnan, P.; Kashani, A.; Kua, H.W. Application of Biochar from Coconut and Wood Waste to Reduce Shrinkage and Improve Physical Properties of Silica Fume-Cement Mortar. Constr. Build. Mater. 2020, 262, 120688. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Adesina, A. Recent Advancements in the Use of Biochar for Cementitious Applications: A Review. J. Build. Eng. 2020, 32, 101705. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Kua, H.W.; Yang, J.; Ok, Y.S.; Ding, S.; Hou, D.; Poon, C.S. The Roles of Biochar as Green Admixture for Sediment-Based Construction Products. Cem. Concr. Compos. 2019, 104, 103348. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A. Utilization of Biochar from Unwashed Peanut Shell in Cementitious Building Materials–Effect on Early Age Properties and Environmental Benefits. Fuel Process. Technol. 2021, 218, 106841. [Google Scholar] [CrossRef]

- Haris Javed, M.; Ali Sikandar, M.; Ahmad, W.; Tariq Bashir, M.; Alrowais, R.; Bilal Wadud, M. Effect of Various Biochars on Physical, Mechanical, and Microstructural Characteristics of Cement Pastes and Mortars. J. Build. Eng. 2022, 57, 104850. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).