Enhancing Mechanical Properties of Three-Dimensional Cementitious Composites Through 3 mm Short Fibre Systems: Single and Hybrid Types

Abstract

1. Introduction

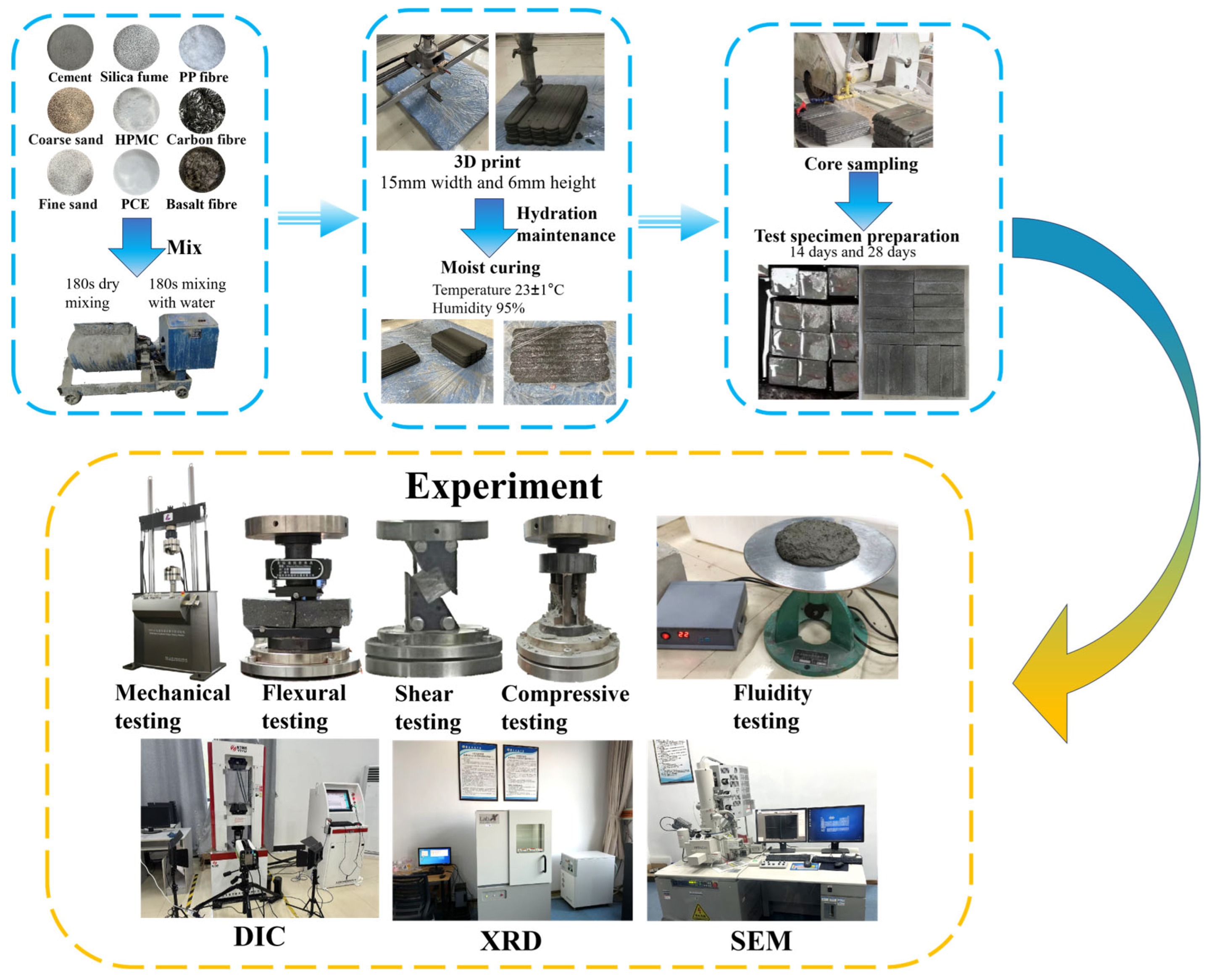

2. Experimental Program

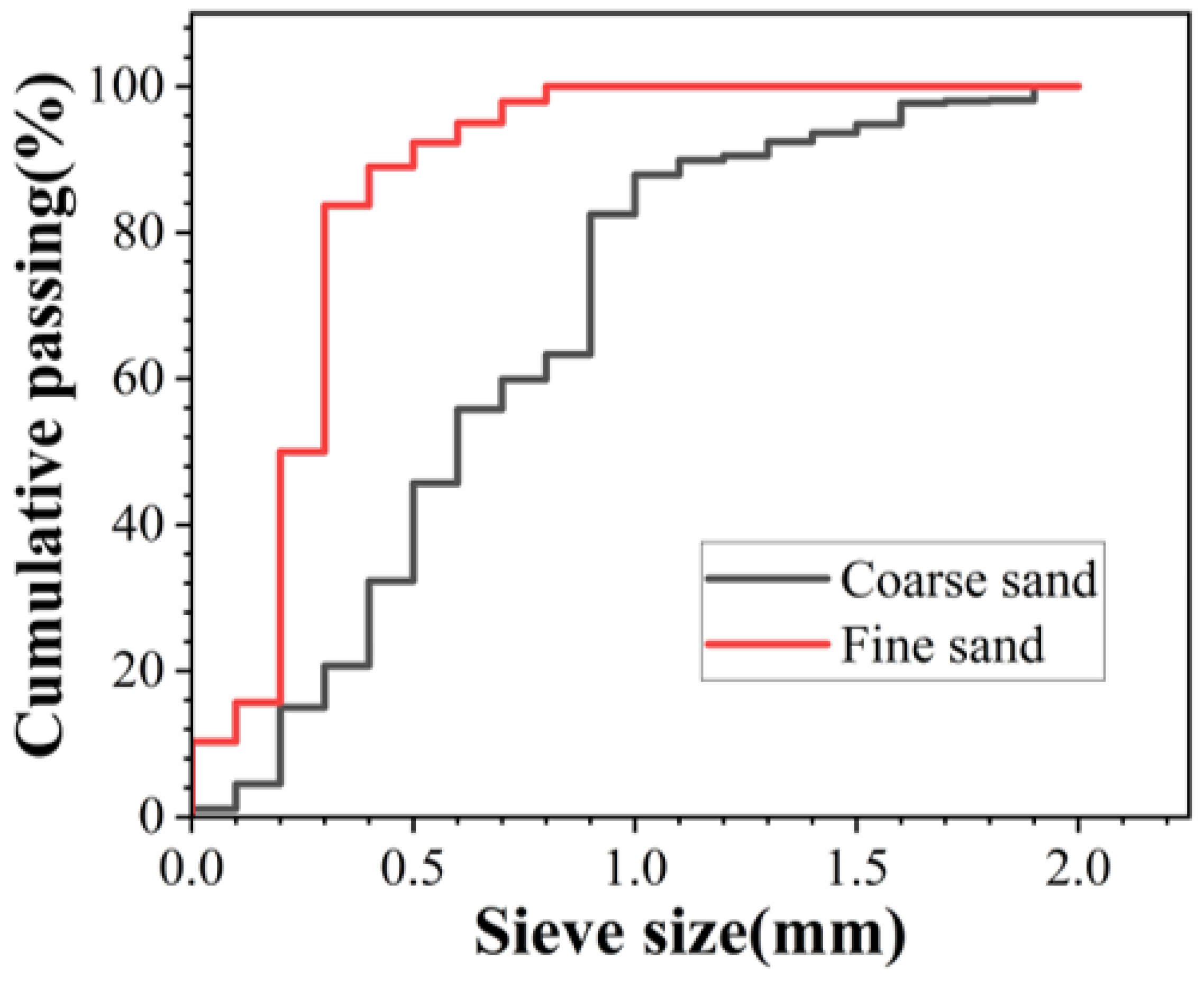

2.1. Materials

2.2. Mixture Design

2.3. Fluidity

2.4. Mechanical Strength Test

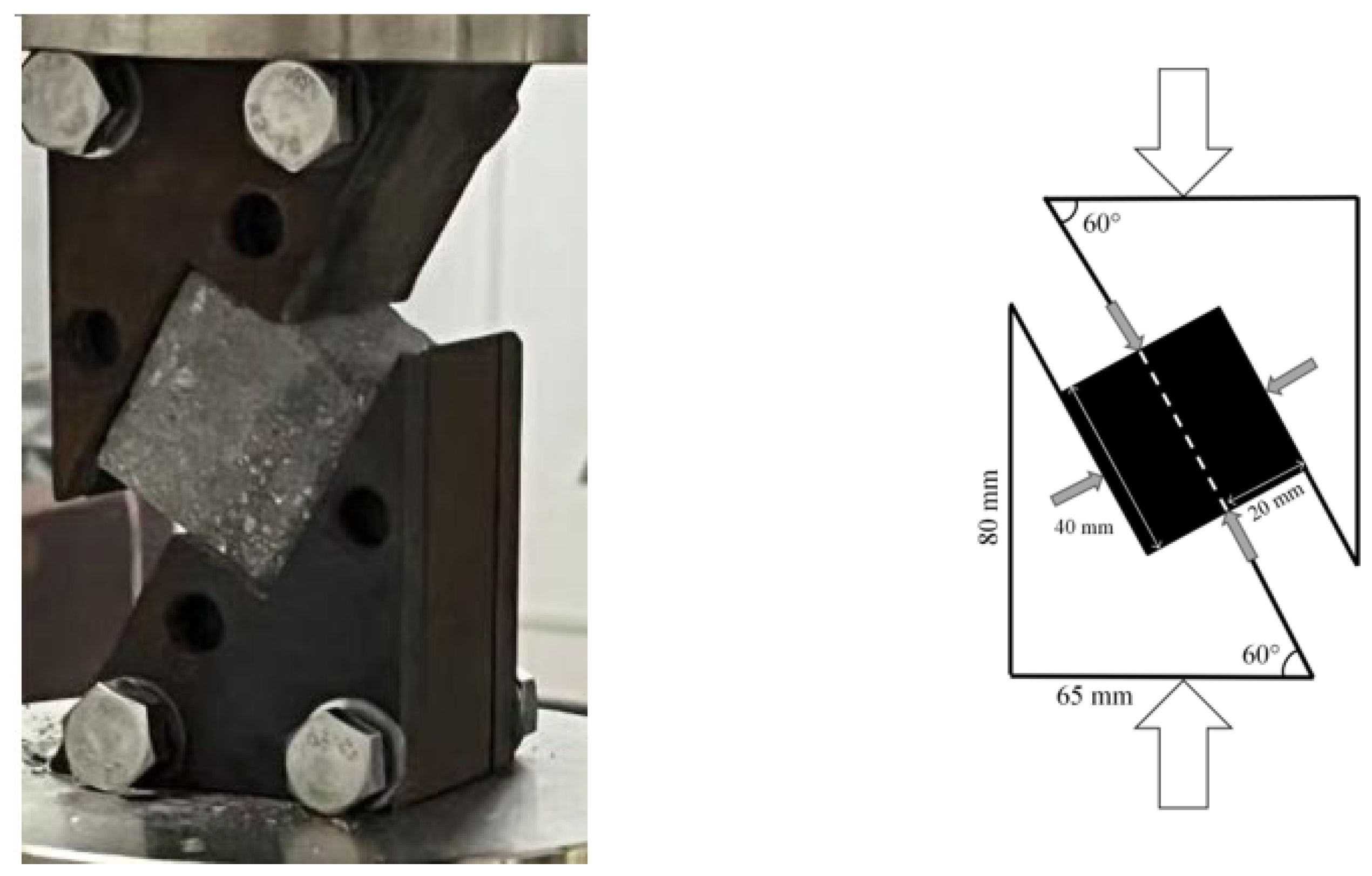

2.5. Interlayer Bond Strength Test

2.6. Digital Image Correlation (DIC)

2.7. X-Ray Powder Diffraction (XRD)

2.8. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Fresh Properties

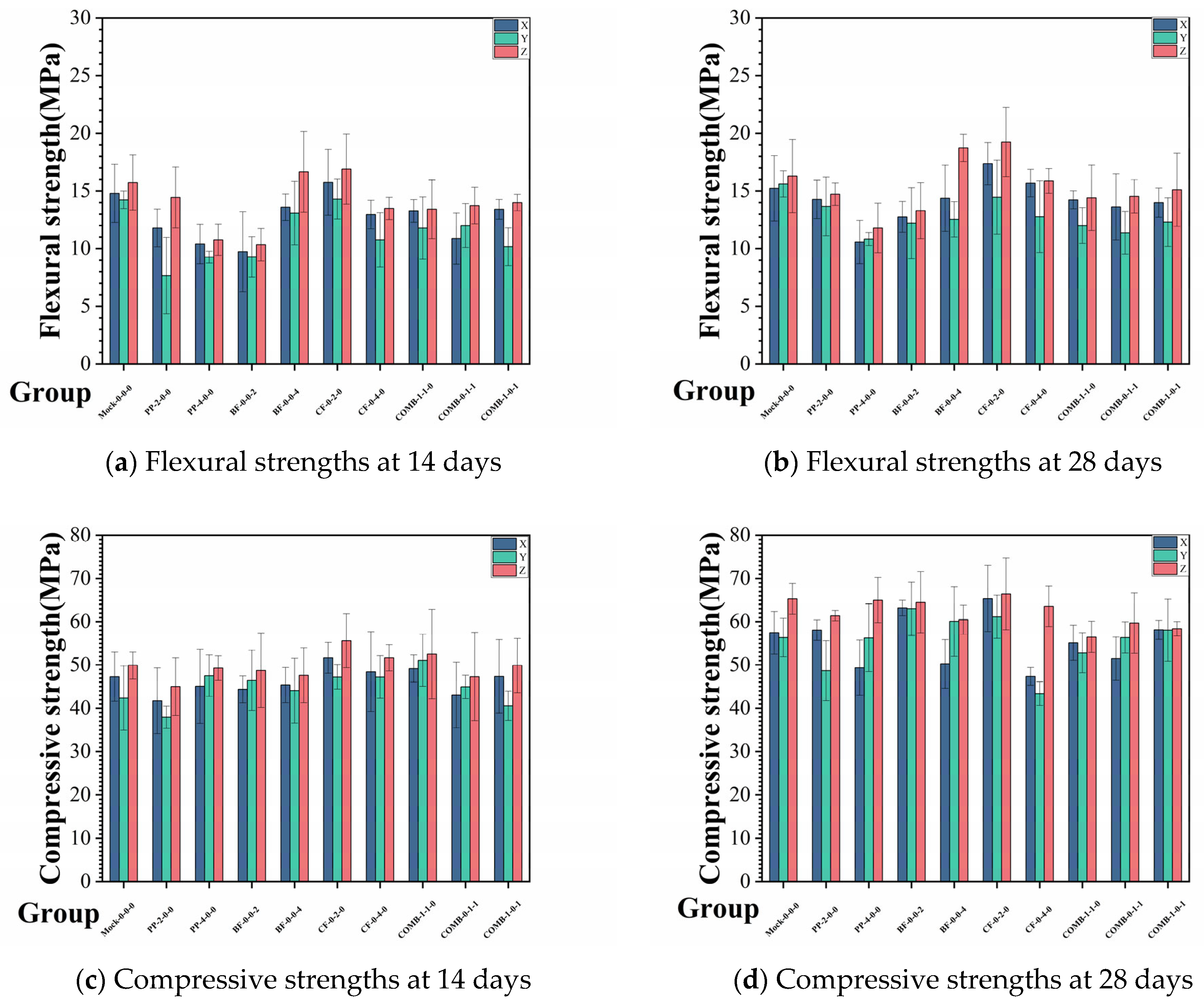

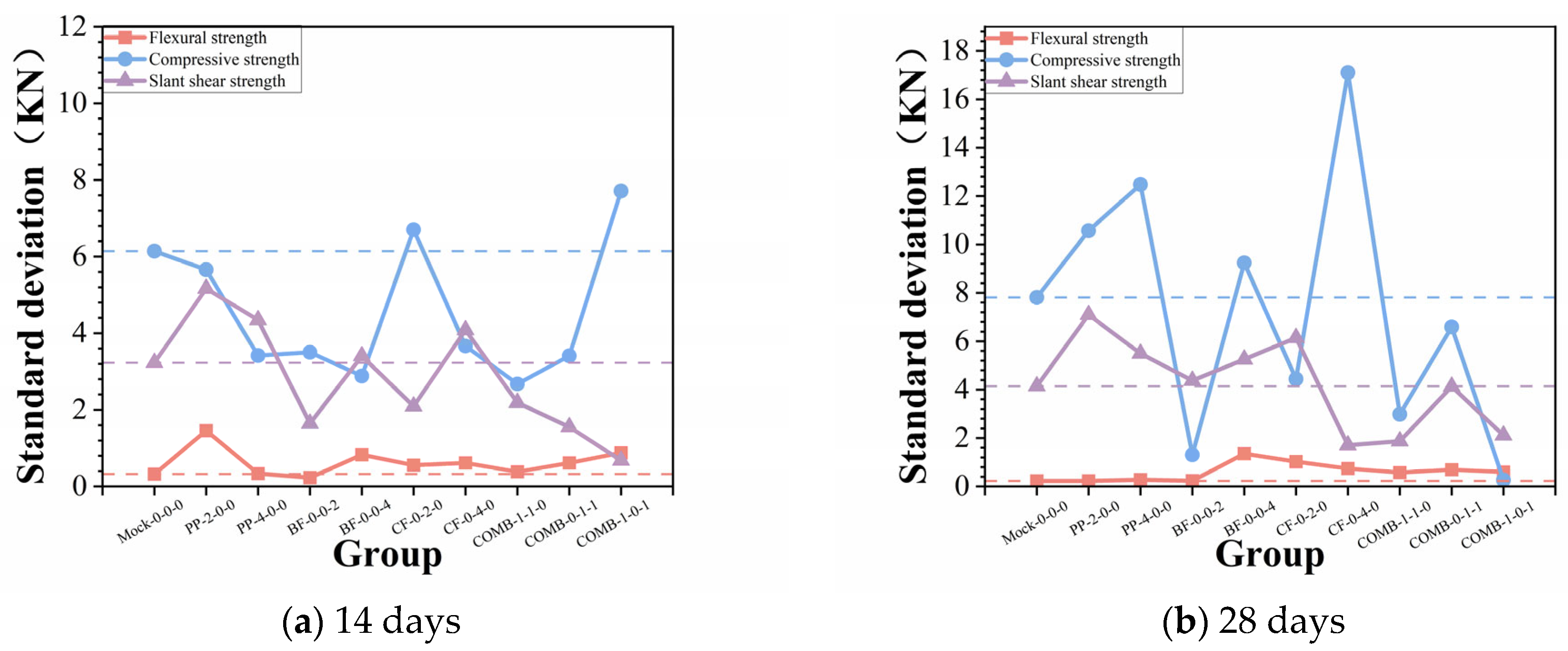

3.2. Mechanical Properties

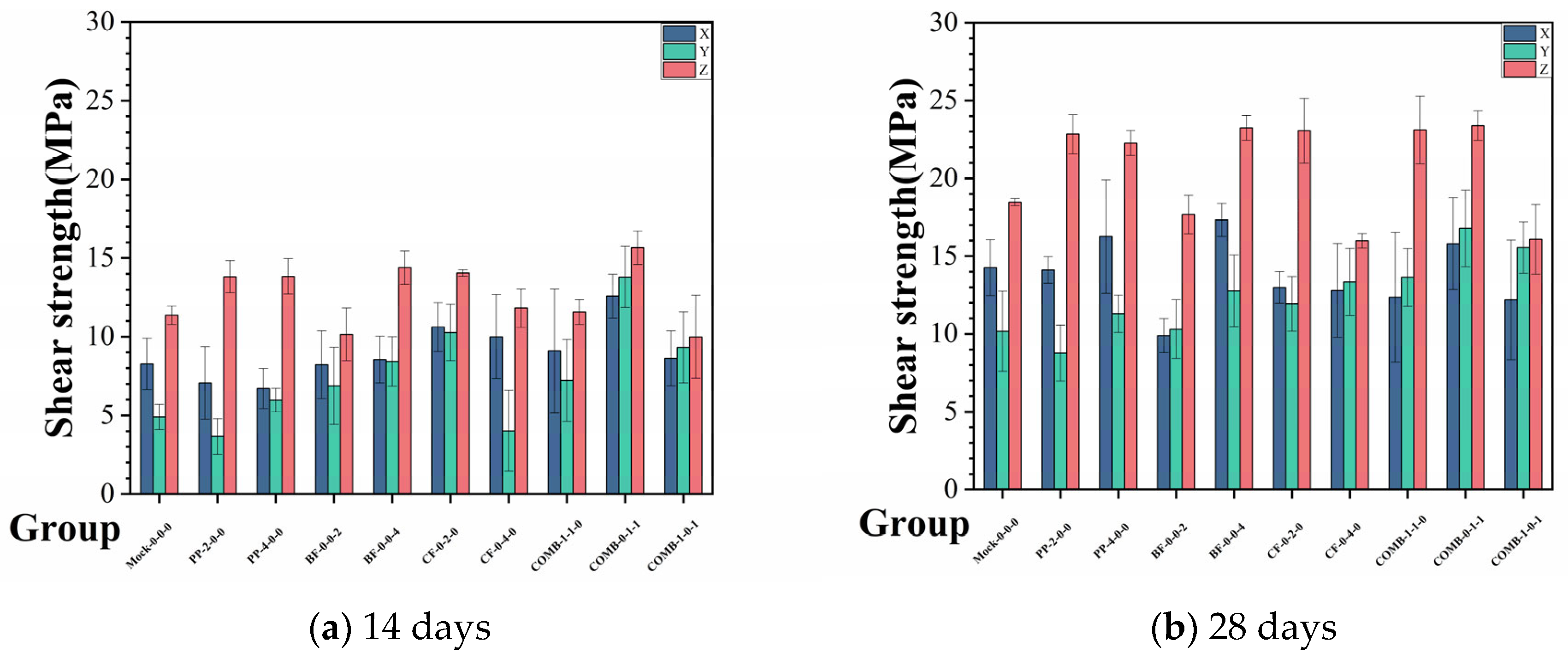

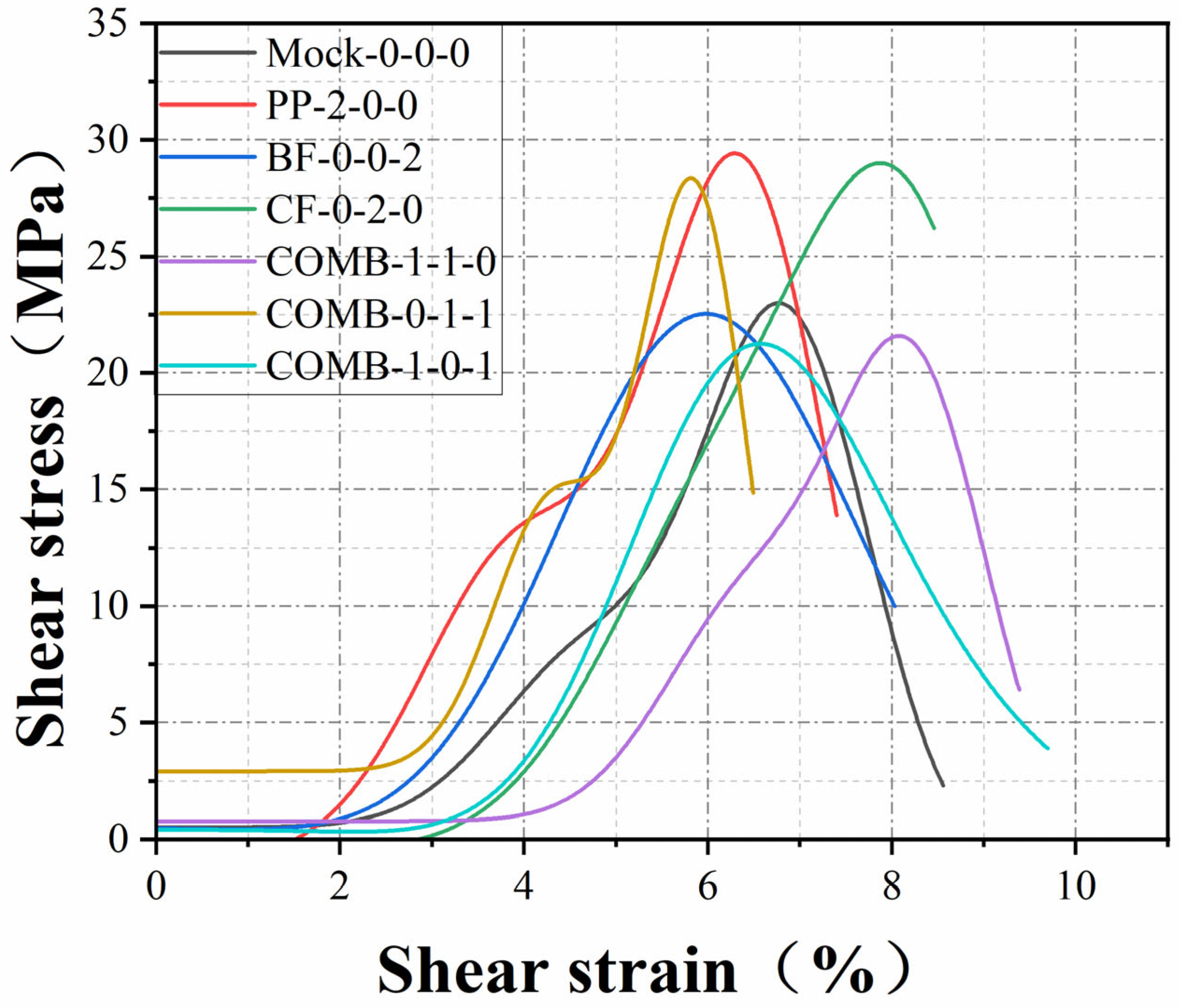

3.3. Interlayer Bond Strength

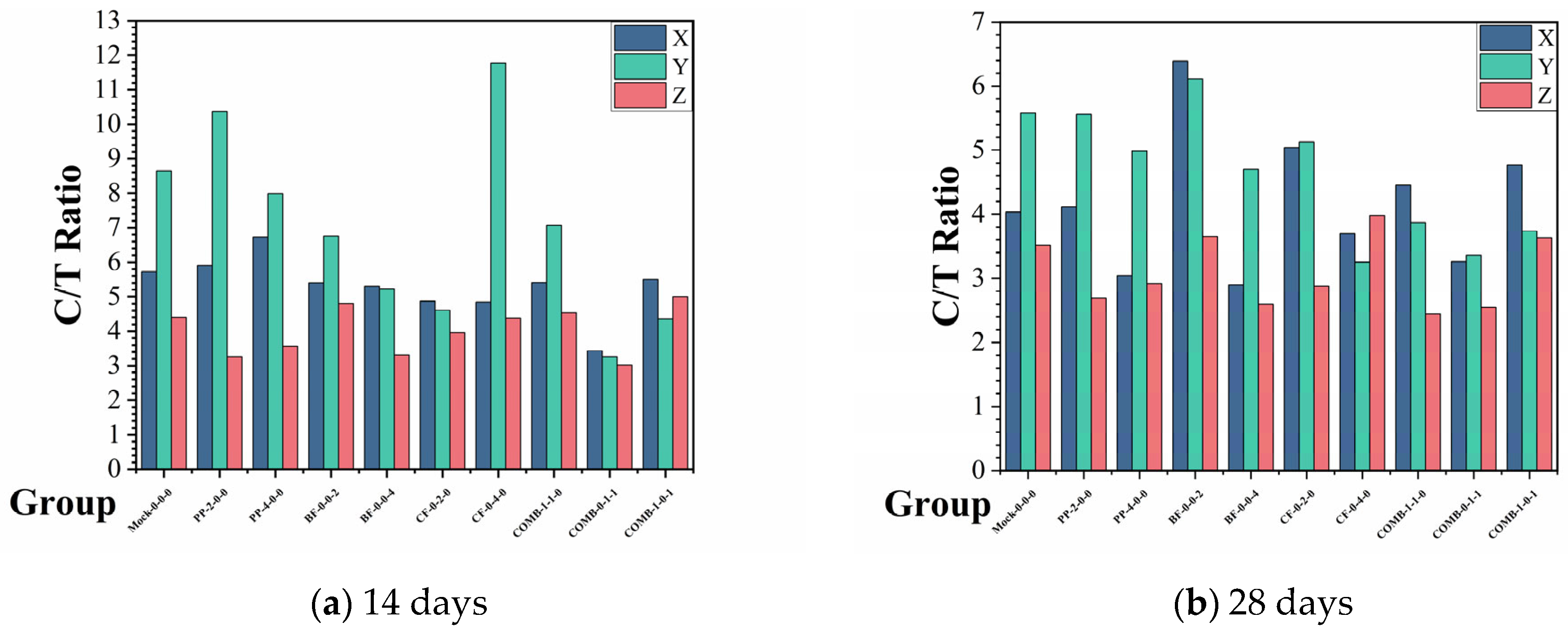

3.4. Anisotropic Behaviour

3.5. Effect of Fibre Dosage

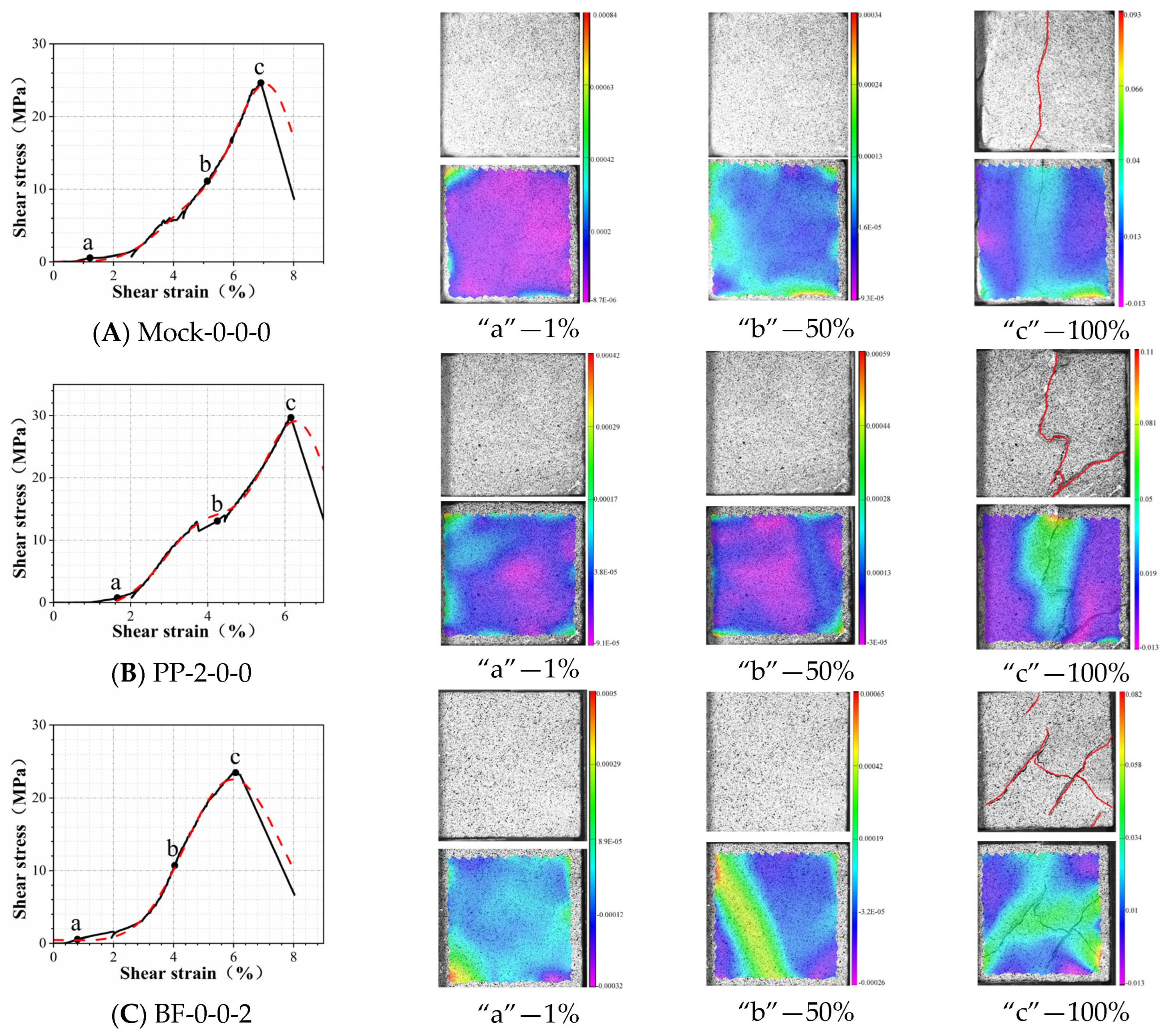

3.6. Digital Image Correlation Analysis

3.7. XRD Results

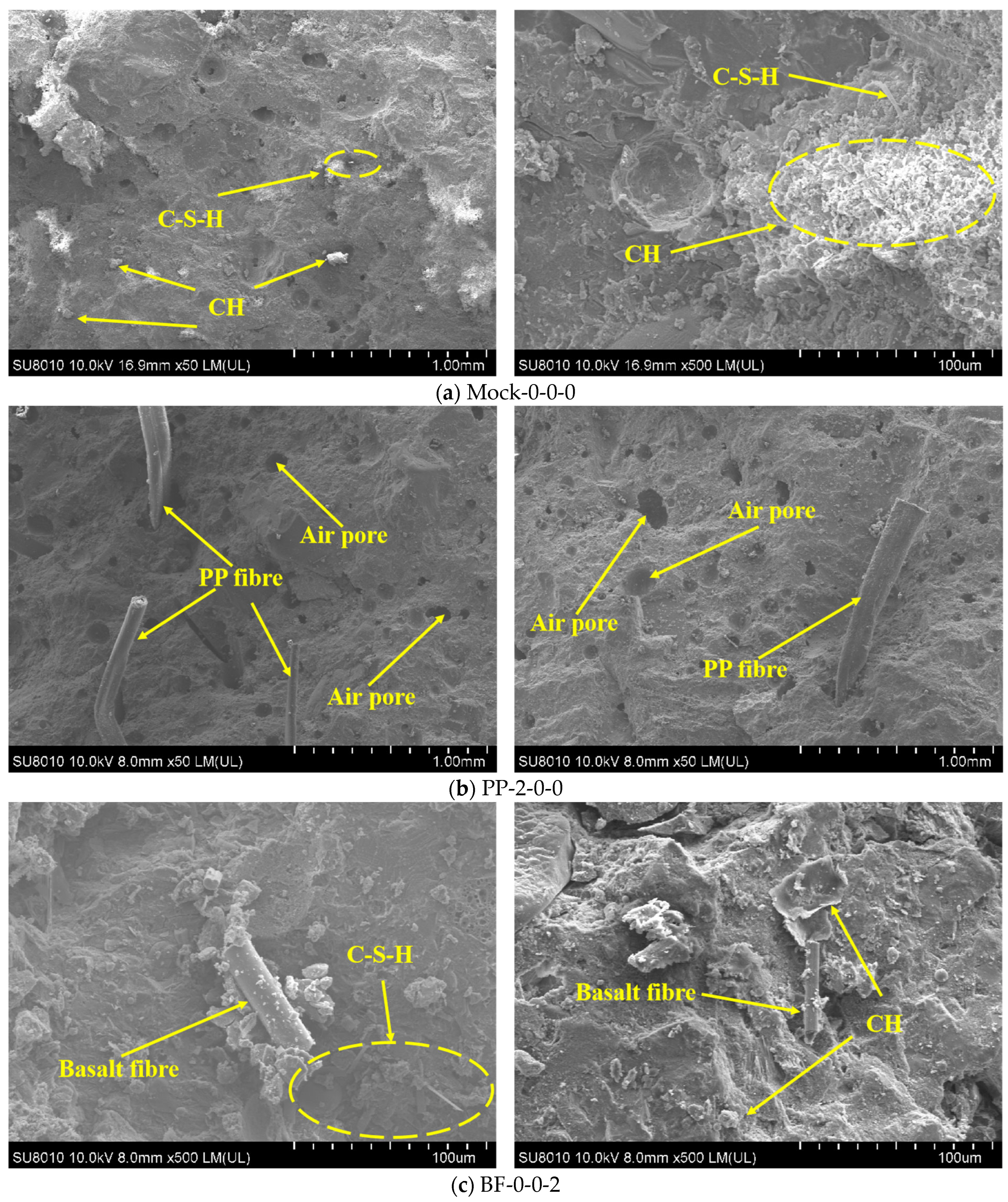

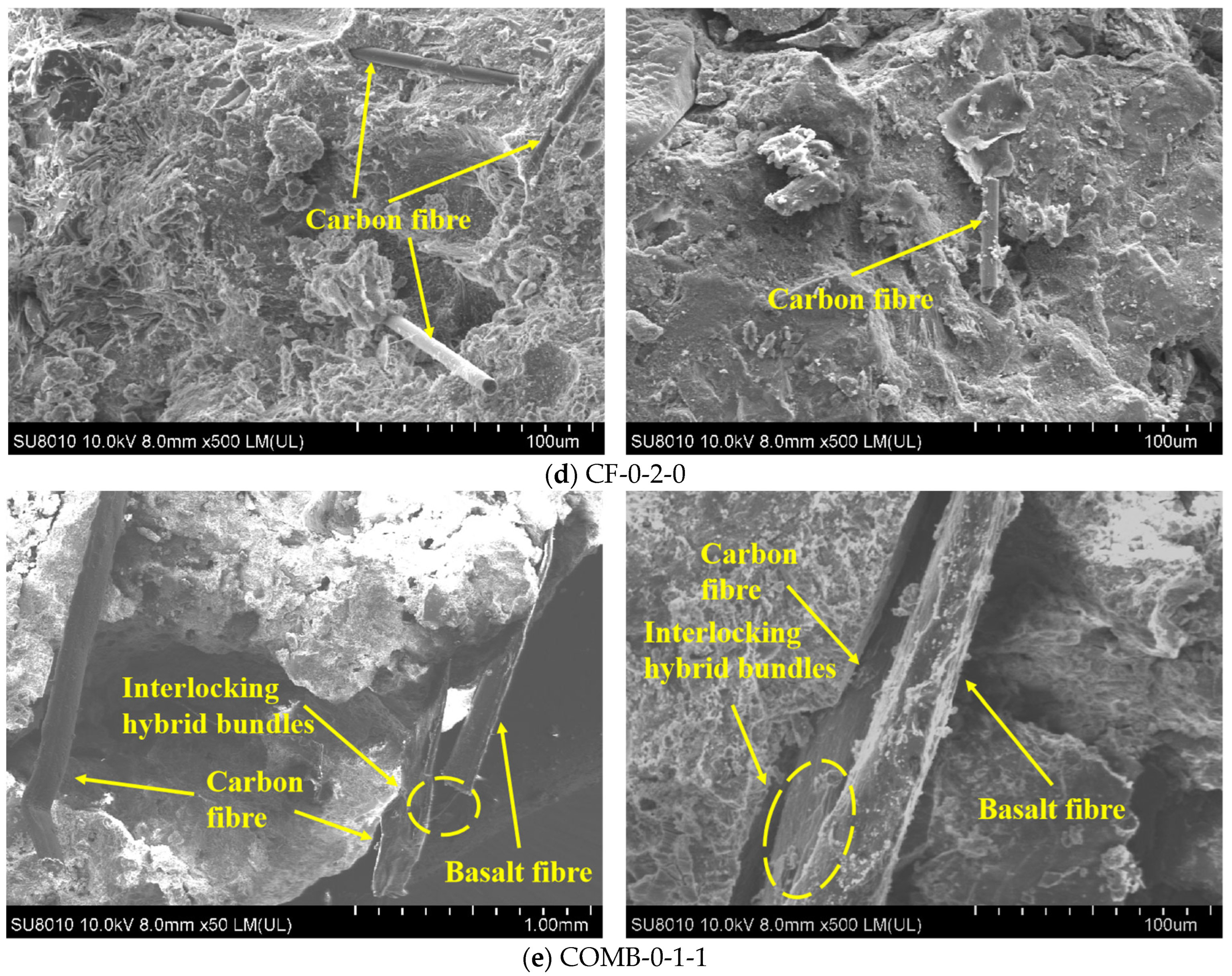

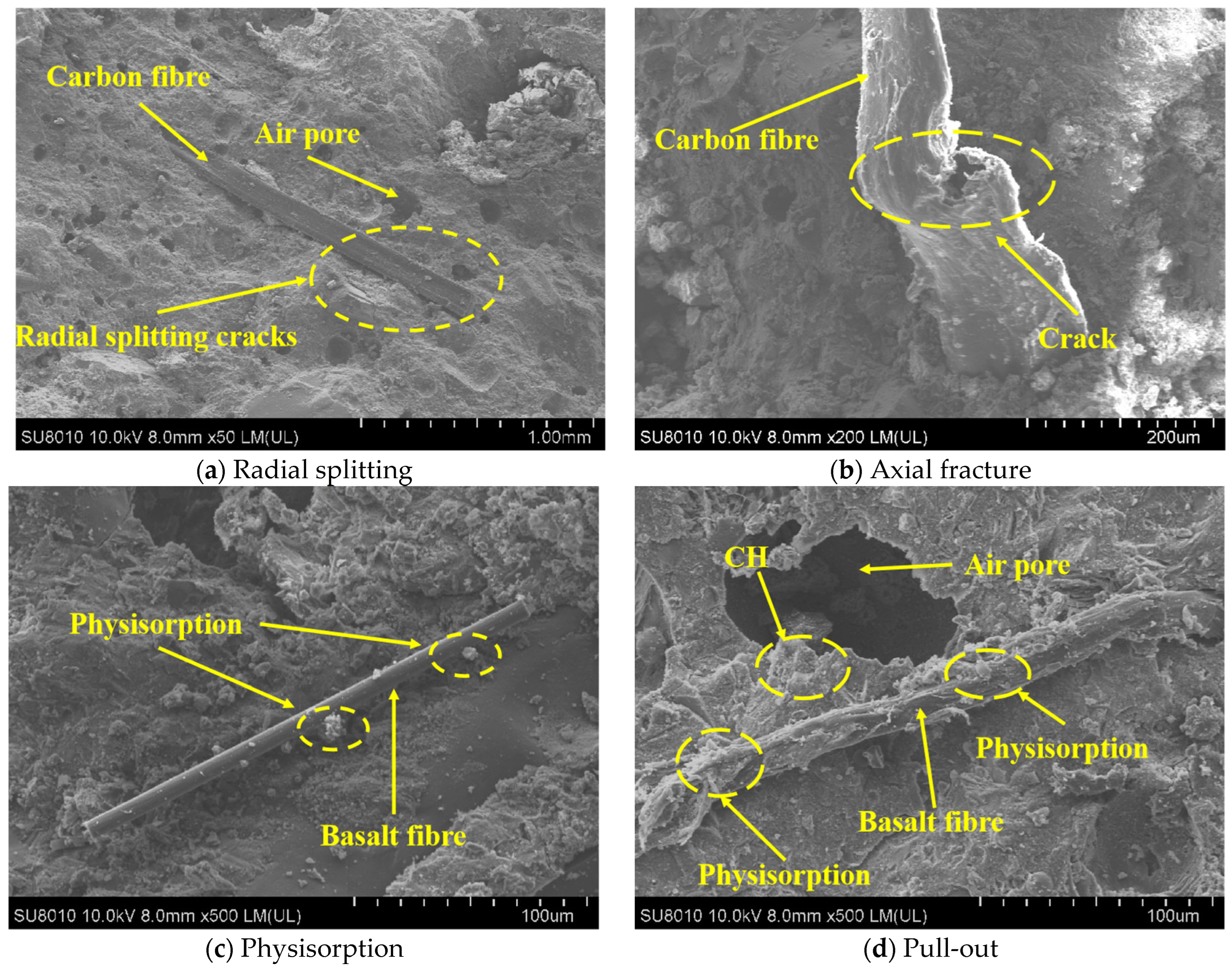

3.8. SEM Analysis

4. Conclusions

- Fibre addition increased the cohesion and viscosity of the concrete, resulting in reduced flowability. Nevertheless, all mixtures exhibited flowability in the range of 160–173 mm, which were suitable for 3D printing. Adequate fluidity ensured that all specimens could be successfully printed and reliably evaluated for mechanical and microstructural properties.

- SFR3DPC exhibited mechanical anisotropy across different loading directions. The highest strength was consistently observed in the Z direction. Fibre incorporation further intensified the anisotropy in flexural strengths. However, the hybrid fibre systems also perform well in reducing the anisotropy of SFR3DPC, making up for the shortcomings in different directions. This provides guidance for the stress surface and failure surface of engineering construction, thereby improving engineering safety.

- Among all the groups, the hybrid incorporation of 0.1 wt.% carbon fibre and 0.1 wt.% basalt fibre resulted in the greatest improvement in interlayer bond strength, reaching 23.38 MPa at 28 days, a 26.7% increase compared to the control group. This shows the advantages of hybrid fibre systems. Combined with the DIC images, it can be observed that the improvement in the interlayer bond strength of the hybrid fibre systems is also reflected in crack refinement. The fact that cracks are less likely to penetrate the structure is also instructive in terms of safety in engineering applications.

- The addition of fibres transformed the failure mode from typical brittle fracture to quasi-brittle behaviour. XRD and SEM analyses revealed that fibre reinforcement occurred primarily through physical adhesion rather than chemical bonding. The incorporation of fibres will not affect the hydration process of SFR3DPC and maintain the internal stability of the composite. While the mechanical enhancement of hybrid fibre systems was not always superior, the synergistic interaction among different fibre types facilitated crack deflection and bridging, contributing to a more desirable fracture pattern.

- Higher fibre dosages tended to cause fibre agglomeration and uneven dispersion, increasing internal porosity and reducing reinforcement efficiency. In contrast, the 0.2 wt.% dosage provided an optimal balance between dispersion and performance enhancement. Also, due to the high cost of carbon fibres, the hybrid fibre systems (COMB-0-1-1) are also advantageous in terms of cost effectiveness. This study also has profound implications in material savings and cost savings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Zhang, Z.; Zhang, X.; Chen, Z. 3D printing concrete structures: State of the art, challenges, and opportunities. Constr. Build. Mater. 2023, 405, 133364. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani-Aghabaglou, A. Assessment of materials, design parameters and some properties of 3D printing concrete mixtures; a state-of-the-art review. Constr. Build. Mater. 2022, 316, 125865. [Google Scholar] [CrossRef]

- Huang, X.; Yang, W.; Song, F.; Zou, J. Study on the mechanical properties of 3D printing concrete layers and the mechanism of influence of printing parameters. Constr. Build. Mater. 2022, 335, 127496. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749. [Google Scholar] [CrossRef]

- Khan, M.; Mcnally, C. Recent developments on low carbon 3D printing concrete: Revolutionizing construction through innovative technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, C.; Liu, Z.; Wang, H.; Ren, Q. Mechanical anisotropy of ultra-high performance fibre-reinforced concrete for 3D printing. Cem. Concr. Compos. 2022, 125, 104310. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía De Gutiérrez, R.; Villaquirán-Caicedo, M.A.; Delvasto Arjona, S. 3D printing with cementitious materials: Challenges and opportunities for the construction sector. Autom. Constr. 2023, 146, 104693. [Google Scholar] [CrossRef]

- Yan, K.; Li, L.; Ye, J.; Bazarov, D.; Deng, B.; Yu, K. Anisotropic size effect of 3D printed LC3-based engineered cementitious composites (LC3-ECC). J. Build. Eng. 2024, 92, 109668. [Google Scholar] [CrossRef]

- Shen, D.; Liu, X.; Zeng, X.; Zhao, X.; Jiang, G. Effect of polypropylene plastic fibers length on cracking resistance of high performance concrete at early age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Cao, J.; Shengzhao, E.; Yang, Y.; Shi, Y.; Chai, J.; Xu, Z. A strategy for the improvement of the bonding performance of 3D-printed concrete interlayer interfaces. J. Build. Eng. 2024, 97, 110675. [Google Scholar] [CrossRef]

- Liu, F.; Fan, C.; Wang, B.; Zhou, C.; Chen, Z. Comparative study of interfacial debonding mechanism of fiber pull-out in magnesium phosphate cementitious composites. J. Build. Eng. 2025, 102, 111901. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical Properties of Natural as well as Synthetic Fiber Reinforced Concrete: A Review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Kazemi, F.; Shafighfard, T.; Yoo, D. Data-Driven Modeling of Mechanical Properties of Fiber-Reinforced Concrete: A Critical Review. Arch. Comput. Methods Eng. 2024, 31, 2049–2078. [Google Scholar] [CrossRef]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- Peng, S.; Wu, B.; Du, X.; Zhao, Y.; Yu, Z. Study on dynamic splitting tensile mechanical properties and microscopic mechanism analysis of steel fiber reinforced concrete. Structures 2023, 58, 105502. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Ribeiro, R.P.; Jaramillo Nieves, L.J.; Bernardin, A.M. Effect of fiberglass waste and fly ash addition on the mechanical performance of Portland cement paste. Clean. Mater. 2023, 7, 100176. [Google Scholar] [CrossRef]

- Al-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt Fiber Reinforced Concrete: A Compressive Review on Durability Aspects. Materials 2023, 16, 429. [Google Scholar] [CrossRef] [PubMed]

- Gong, L.; Yu, X.; Liang, Y.; Gong, X.; Du, Q. Multi-scale deterioration and microstructure of polypropylene fiber concrete by salt freezing. Case Stud. Constr. Mater. 2023, 18, e1762. [Google Scholar] [CrossRef]

- Soni, A.; Kumar, S.; Majumder, B.; Dam, H.; Dutta, V.; Das, P.K. Synergy of waste plastics and natural fibers as sustainable composites for structural applications concerning circular economy. Environ. Sci. Pollut. Res. Int. 2024, 31, 38846–38865. [Google Scholar] [CrossRef] [PubMed]

- Solahuddin, B.A.; Yahaya, F.M. A narrative review on strengthening of reinforced concrete beams using carbon fibre reinforced polymer composite material through experimental investigation and numerical modelling. Structures 2023, 52, 666–710. [Google Scholar] [CrossRef]

- Muthukumarana, T.V.; Arachchi, M.A.V.H.; Somarathna, H.M.C.C.; Raman, S.N. A review on the variation of mechanical properties of carbon fibre-reinforced concrete. Constr. Build. Mater. 2023, 366, 130173. [Google Scholar] [CrossRef]

- Bakhshi, A.; Zafar, M.S.; Hojati, M. A study on achieving high tensile ductility in 3D-Printable engineered cementitious composites reinforced with 8 mm fibers. J. Build. Eng. 2025, 103, 112196. [Google Scholar] [CrossRef]

- Wang, S.; Yang, R.; Li, Y.; Yue, Z. Effects of cement content, polypropylene fiber length and dosage on fluidity and mechanical properties of fiber-toughened cemented aeolian sand backfill. Int. J. Miner. Metall. Mater. 2024, 31, 2404–2416. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Meng, Y.; Han, Z.; Jin, T. Comprehensive performance evaluation of steel fiber-reinforced asphalt mixture for induction heating. Int. J. Pavement. Eng. 2022, 23, 3838–3849. [Google Scholar] [CrossRef]

- Vairagade, V.S.; Dhale, S.A. Hybrid fibre reinforced concrete—A state of the art review. Hybrid Adv. 2023, 3, 100035. [Google Scholar] [CrossRef]

- Yousefi, M.; Khandestani, R.; Gharaei-Moghaddam, N. Flexural behavior of reinforced concrete beams made of normal and polypropylene fiber-reinforced concrete containing date palm leaf ash. Structures 2022, 37, 1053–1068. [Google Scholar] [CrossRef]

- Chen, X.; Ai, Y.; Wu, Q.; Cheng, S.; Wei, Y.; Xu, X.; Fan, T. Potential use of nano calcium carbonate in polypropylene fiber reinforced recycled aggregate concrete: Microstructures and properties evaluation. Constr. Build. Mater. 2023, 400, 132871. [Google Scholar] [CrossRef]

- Xie, H.; Yang, L.; Zhang, Q.; Huang, C.; Chen, M.; Zhao, K. Research on energy dissipation and damage evolution of dynamic splitting failure of basalt fiber reinforced concrete. Constr. Build. Mater. 2022, 330, 127292. [Google Scholar] [CrossRef]

- Zhang, X.; Lou, C.; Lyu, X. Experimental study on direct tensile fatigue performance of basalt fiber reinforced concrete. Sci. Rep. 2024, 14, 765. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, S.; Han, F.; Qin, J.; Lu, L.; Xue, Q.; Ji, Y. Mechanical relationship between compressive strength and sulfate erosion depth of basalt fiber reinforced concrete. Constr. Build. Mater. 2024, 411, 134412. [Google Scholar] [CrossRef]

- Fu, Q.; Zhou, Z.; Wang, Z.; Huang, J.; Niu, D. Insight into dynamic compressive response of carbon nanotube/carbon fiber-reinforced concrete. Cem. Concr. Compos. 2022, 129, 104471. [Google Scholar] [CrossRef]

- Wang, H.; He, X.; Zhou, M.; Wei, B.; Wu, W.; Zhou, G.; He, J. A study on the tensile fracture behavior of polypropylene fiber reinforced concrete based on a microscale model. Constr. Build. Mater. 2024, 417, 135291. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, Mechanical and Dynamic Properties of Basalt Fiber Reinforced Concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Yang, J. Experimental Study on Dynamic Splitting Characteristics of Carbon Fiber Reinforced Concrete. Materials 2021, 14, 94. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Yuan, H.; Zhang, J.; Zhang, P. Enhancing concrete performance: A comprehensive review of hybrid fiber reinforced concrete. Structures 2024, 64, 106560. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Masoud Salehi, A.; Mehraein, M.; Asadollahfardi, G. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Liu, M.; Guo, Z.; Qian, Y.; Chen, L.; Mao, X.; Zhao, J.; Yang, D. Investigation into the long-term alkali resistance of basalt fibers. J. Build. Eng. 2024, 98, 111105. [Google Scholar] [CrossRef]

- He, S.; He, J.; Guo, X.; Ueda, T.; Wang, Y. Detection of CFRP-concrete interfacial defects by using electrical measurement. Compos. Struct. 2022, 295, 115843. [Google Scholar] [CrossRef]

- Song, F.; Chen, Q.; Zheng, Q. Multifunctional ultra-high performance fibre-reinforced concrete with integrated self-sensing and repair capabilities towards in-situ structure monitoring. Compos. Struct. 2023, 321, 117240. [Google Scholar] [CrossRef]

- Piao, R.; Woo, S.Y.; Lee, D.; Jeong, C.K.; Banthia, N.; Yoo, D. Investigating the effect of carbon fiber dosage on the mechanical and thermoelectric properties of ultra-high-performance fiber-reinforced concrete. J. Sustain. Cem. Based Mater. 2025, 1–15. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, Y.; Li, Z.; Zhou, G.; Yu, X.; Xu, D.; Yong, Q.; Zhao, H.; Xie, Z. Interaction mechanisms between polycarboxylate superplasticizers and cement, and the influence of functional groups on superplasticizer performance: A review. Polym. Bull. 2024, 81, 10415–10438. [Google Scholar] [CrossRef]

- Gu, X.; Wang, S.; Liu, J.; Wang, H.; Xu, X.; Wang, Q.; Zhu, Z. Effect of hydroxypropyl methyl cellulose (HPMC) as foam stabilizer on the workability and pore structure of iron tailings sand autoclaved aerated concrete. Constr. Build. Mater. 2023, 376, 130979. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, D.; Li, H.; Sun, X.; Zhao, K.; Wang, Y. Effect of FA and GGBFS on compressive strength, rheology, and printing properties of cement-based 3D printing material. Constr. Build. Mater. 2022, 339, 127685. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard Test Methods for Physical and Mechanical Properties of Concrete. Standardization Administration of China: Beijing, China, 2019.

- Golewski, G.L. Comparative measurements of fracture toughgness combined with visual analysis of cracks propagation using the DIC technique of concretes based on cement matrix with a highly diversified composition. Theor. Appl. Fract. Mech. 2022, 121, 103553. [Google Scholar] [CrossRef]

- Xu, W.; Jiang, D.; Zhao, Q.; Wang, L. Study on printability of 3D printing carbon fiber reinforced eco-friendly concrete: Characterized by fluidity and consistency. Case Stud. Constr. Mater. 2024, 21, e3589. [Google Scholar] [CrossRef]

- Rahman, M.; Rawat, S.; Yang, R.C.; Mahil, A.; Zhang, Y.X. A comprehensive review on fresh and rheological properties of 3D printable cementitious composites. J. Build. Eng. 2024, 91, 109719. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, J.; Wang, Q.; Shi, J.; Wang, H. PVA fibre reinforced high-strength cementitious composite for 3D printing: Mechanical properties and durability. Addit. Manuf. 2022, 49, 102500. [Google Scholar] [CrossRef]

- Saberian, M.; Tajaddini, A.; Li, J.; Zhang, G.; Wang, L.; Sun, D.; Maqsood, T.; Roychand, R. Mechanical properties of polypropylene fibre reinforced recycled concrete aggregate for sustainable road base and subbase applications. Constr. Build. Mater. 2023, 405, 133352. [Google Scholar] [CrossRef]

- Du, Y.; Lu, S.; Xu, J.; Xia, W.; Wang, T.; Wang, Z. Experimental study of impact mechanical and microstructural properties of modified carbon fiber reinforced concrete. Sci. Rep. 2022, 12, 12928. [Google Scholar] [CrossRef] [PubMed]

- Bai, W.; Li, Y.; Gong, Z.; And Liu, J. A new method for generating the random fiber arrangement of representative volume element for unidirectional fiber reinforced composites. Mech. Adv. Mater. Struct. 2024, 31, 6035–6043. [Google Scholar] [CrossRef]

- Sadat, H.A.; Sadeghian, P. Assessing Compressive Properties of GFRP Bars: Novel Test Fixture and Statistical Analysis. J. Compos. Constr. 2025, 29, 4025011. [Google Scholar] [CrossRef]

- Yang, C.; Xu, X.; Lei, Z.; Sun, J.; Wang, Y.; Luo, G.; Yao, H.; Mei, Y. Enhancing mechanical properties of three-dimensional concrete at elevated temperatures through recycled ceramic powder treatment methods. J. Mater. Res. Technol. 2024, 31, 434–446. [Google Scholar] [CrossRef]

- Lei, C.; Xie, Z.; Wu, K.; Fu, Q. Controlled Vertically Aligned Structures in Polymer Composites: Natural Inspiration, Structural Processing, and Functional Application. Adv. Mater. 2021, 33, 2103495. [Google Scholar] [CrossRef] [PubMed]

- Surehali, S.; Tripathi, A.; Neithalath, N. Anisotropy in Additively Manufactured Concrete Specimens under Compressive Loading—Quantification of the Effects of Layer Height and Fiber Reinforcement. Materials 2023, 16, 5488. [Google Scholar] [CrossRef] [PubMed]

- Burbano-Garcia, C.; Araya-Letelier, G.; Astroza, R.; Silva, Y.F. Adobe mixtures reinforced with fibrillated polypropylene fibers: Physical/mechanical/fracture/durability performance and its limits due to fiber clustering. Constr. Build. Mater. 2022, 343, 128102. [Google Scholar] [CrossRef]

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2022, 319, 126130. [Google Scholar] [CrossRef]

- Zaid, O.; El Ouni, M.H. Advancements in 3D printing of cementitious materials: A review of mineral additives, properties, and systematic developments. Constr. Build. Mater. 2024, 427, 136254. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, R.; Chen, Y.; Lou, C. Experimental study on the axial tensile properties of polypropylene fiber reinforced concrete. Sci. Rep. 2023, 13, 16383. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Lei, D.; She, Z.; Xi, B. Flexural performance and damage evaluation on basalt fiber reinforced polymer (BFRP) sheet reinforced concrete. Constr. Build. Mater. 2023, 395, 132321. [Google Scholar] [CrossRef]

- Liu, B.; Ye, J.; Liu, X.; Lin, W.; Deng, Z.; Liu, Q. Shear strength and failure criterion of carbon fiber reinforced coral concrete under combined compression-shear stresses. Constr. Build. Mater. 2022, 325, 126728. [Google Scholar] [CrossRef]

- Li, K.; Yang, C.; Huang, W.; Zhao, Y.; Wang, Y.; Pan, Y.; Xu, F. Effects of hybrid fibers on workability, mechanical, and time-dependent properties of high strength fiber-reinforced self-consolidating concrete. Constr. Build. Mater. 2021, 277, 122325. [Google Scholar] [CrossRef]

| Materials | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| OPC | 64.12 | 20.73 | 2.75 | 4.14 | 1.25 | 2.71 | 0.89 | 0.44 |

| SF | 0.11 | 98.12 | 0.09 | 0.41 | 0.05 | 0.47 | 0.06 | \ |

| Materials | Length (mm) | Diameter (μm) | Tensile Strength (MPa) | Density (g/cm3) | Fracture Elongation (%) | Elasticity Modulus (GPa) |

|---|---|---|---|---|---|---|

| PP | 3.0 ± 0.05 | 7.0 | \ | 0.91 | 27 | 3–4 |

| BF | 3000 | 2.64 | \ | 91–110 | ||

| CF | 4120 | 1.76 | 1.82 | 230–300 |

| Group | Cement | SF | Fine Sand | Coarse Sand | PP | CF | BF | HPMC | PCE | Water |

|---|---|---|---|---|---|---|---|---|---|---|

| Mock-0-0-0 | 1000 | 100 | 690 | 300 | 0 | 0 | 0 | 1.28 | 2 | 352 |

| PP-2-0-0 | 1000 | 100 | 690 | 300 | 2 | 0 | 0 | 1.28 | 2 | 352 |

| PP-4-0-0 | 1000 | 100 | 690 | 300 | 4 | 0 | 0 | 1.28 | 2 | 352 |

| BF-0-0-2 | 1000 | 100 | 690 | 300 | 0 | 0 | 2 | 1.28 | 2 | 352 |

| BF-0-0-4 | 1000 | 100 | 690 | 300 | 0 | 0 | 4 | 1.28 | 2 | 352 |

| CF-0-2-0 | 1000 | 100 | 690 | 300 | 0 | 2 | 0 | 1.28 | 2 | 352 |

| CF-0-4-0 | 1000 | 100 | 690 | 300 | 0 | 4 | 0 | 1.28 | 2 | 352 |

| COMB-1-1-0 | 1000 | 100 | 690 | 300 | 1 | 1 | 0 | 1.28 | 2 | 352 |

| COMB-0-1-1 | 1000 | 100 | 690 | 300 | 0 | 1 | 1 | 1.28 | 2 | 352 |

| COMB-1-0-1 | 1000 | 100 | 690 | 300 | 1 | 0 | 1 | 1.28 | 2 | 352 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, H.; Cao, Y.; Mei, Y.; Xiong, Z. Enhancing Mechanical Properties of Three-Dimensional Cementitious Composites Through 3 mm Short Fibre Systems: Single and Hybrid Types. Buildings 2025, 15, 2519. https://doi.org/10.3390/buildings15142519

Yao H, Cao Y, Mei Y, Xiong Z. Enhancing Mechanical Properties of Three-Dimensional Cementitious Composites Through 3 mm Short Fibre Systems: Single and Hybrid Types. Buildings. 2025; 15(14):2519. https://doi.org/10.3390/buildings15142519

Chicago/Turabian StyleYao, Han, Yujie Cao, Yangling Mei, and Zhixuan Xiong. 2025. "Enhancing Mechanical Properties of Three-Dimensional Cementitious Composites Through 3 mm Short Fibre Systems: Single and Hybrid Types" Buildings 15, no. 14: 2519. https://doi.org/10.3390/buildings15142519

APA StyleYao, H., Cao, Y., Mei, Y., & Xiong, Z. (2025). Enhancing Mechanical Properties of Three-Dimensional Cementitious Composites Through 3 mm Short Fibre Systems: Single and Hybrid Types. Buildings, 15(14), 2519. https://doi.org/10.3390/buildings15142519