Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction

Abstract

1. Introduction

2. Experimental Program

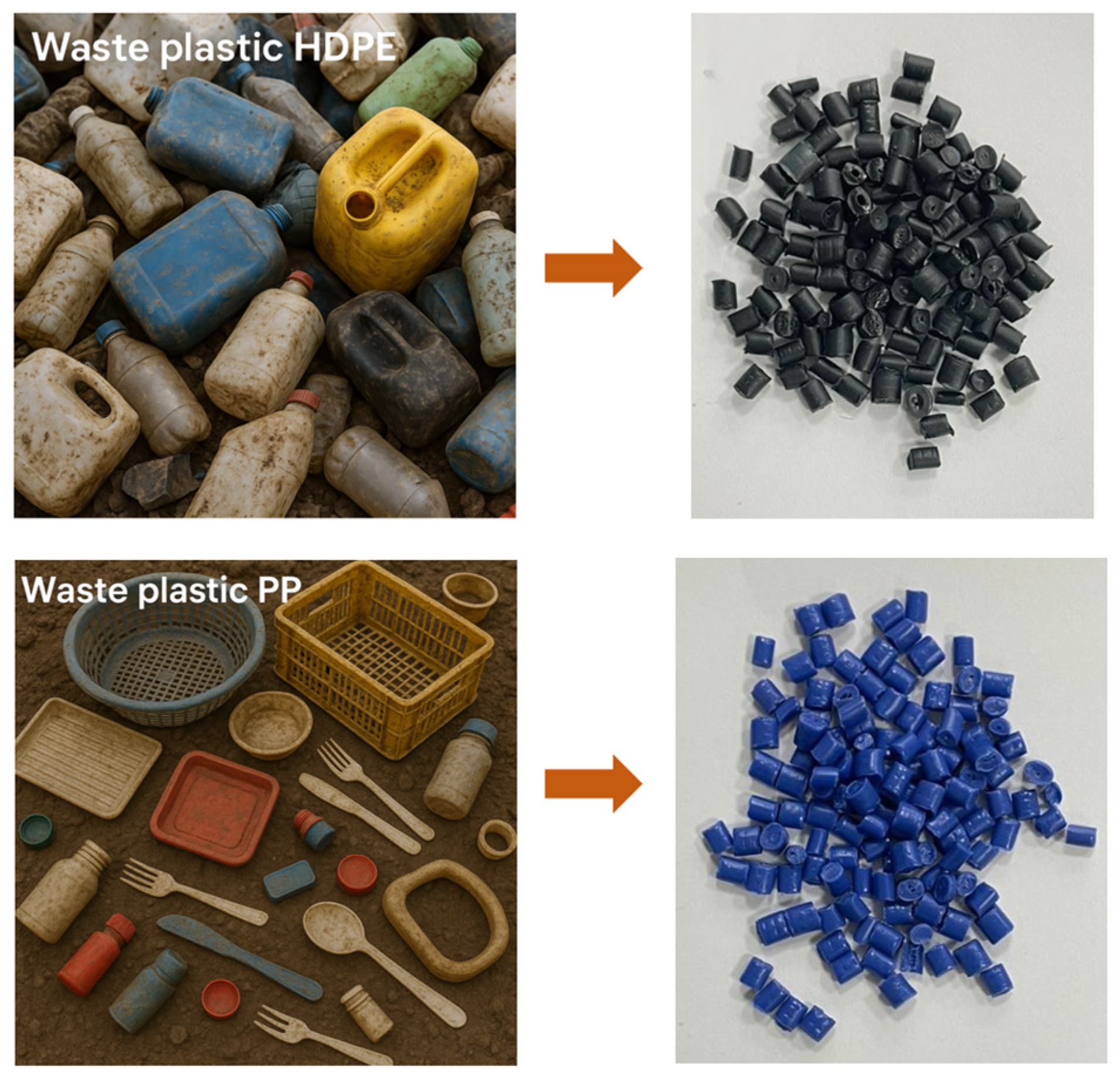

2.1. Raw Materials

2.2. Preparation of Samples

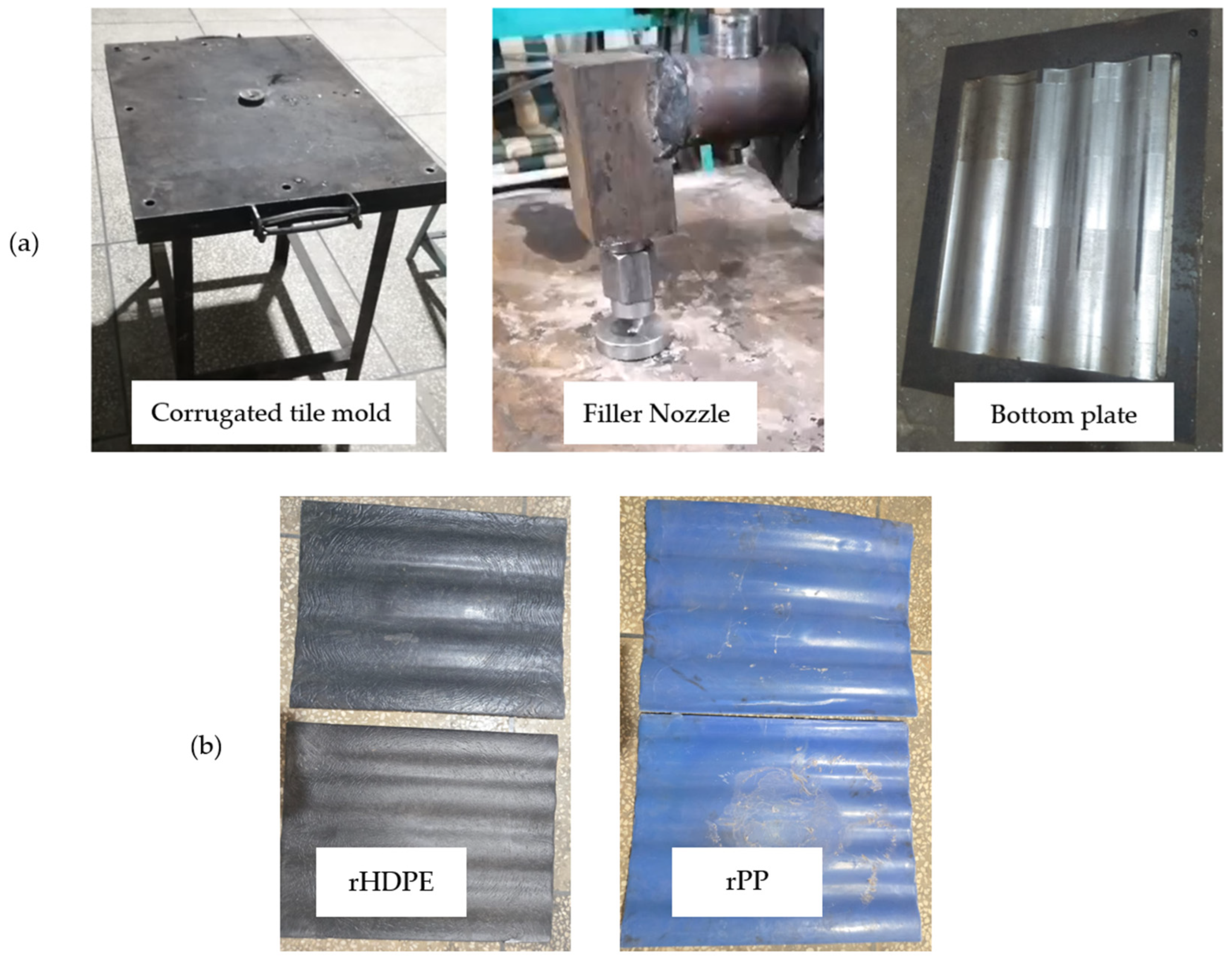

2.2.1. Preparation of Corrugated Panels

2.2.2. Preparation of Prototype Slab

2.3. Corrugated Panels Test Procedure

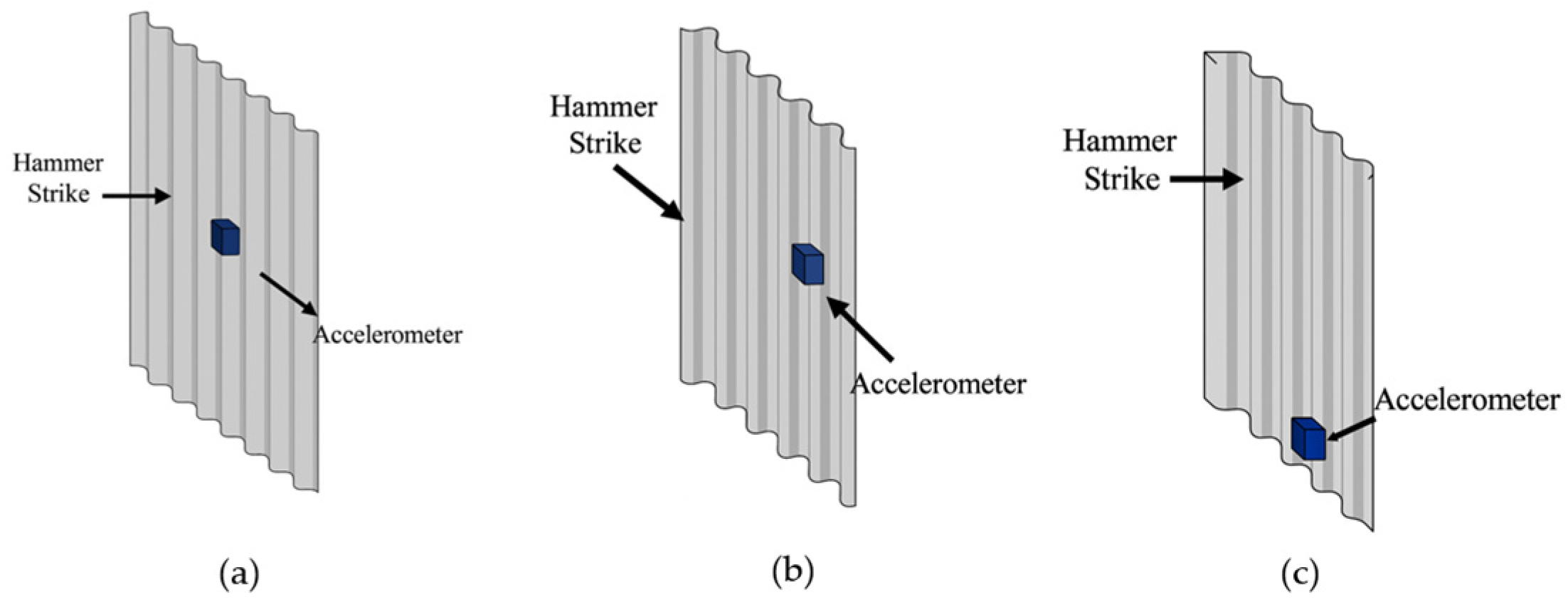

2.3.1. Dynamic Elastic Property Evaluation Procedure for Corrugated Panels

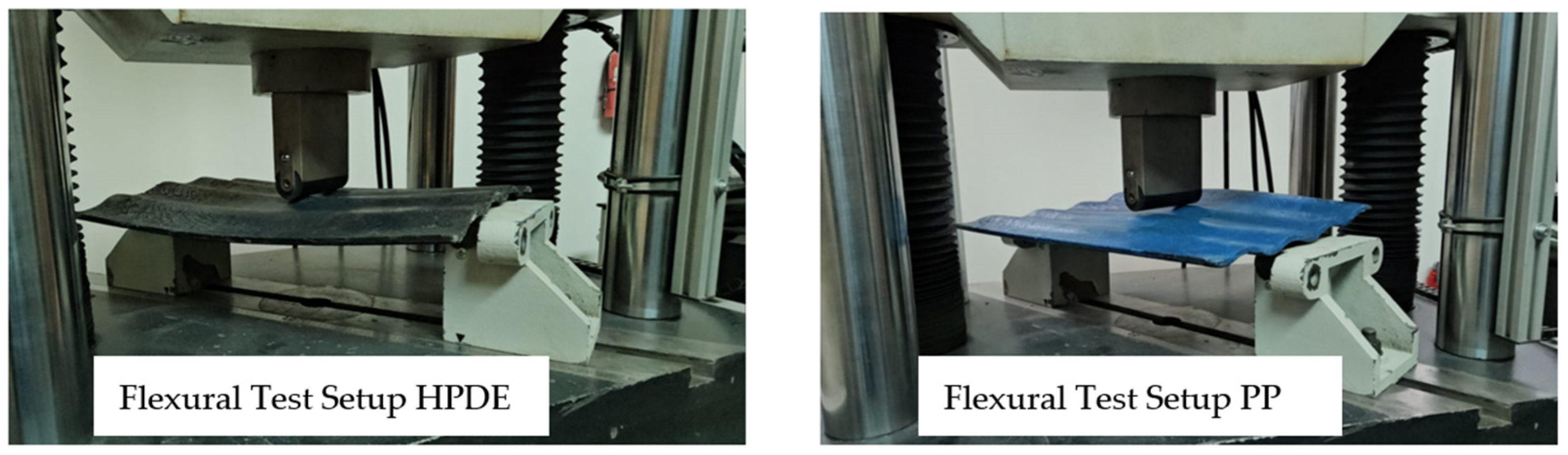

2.3.2. Flexural Test Procedure

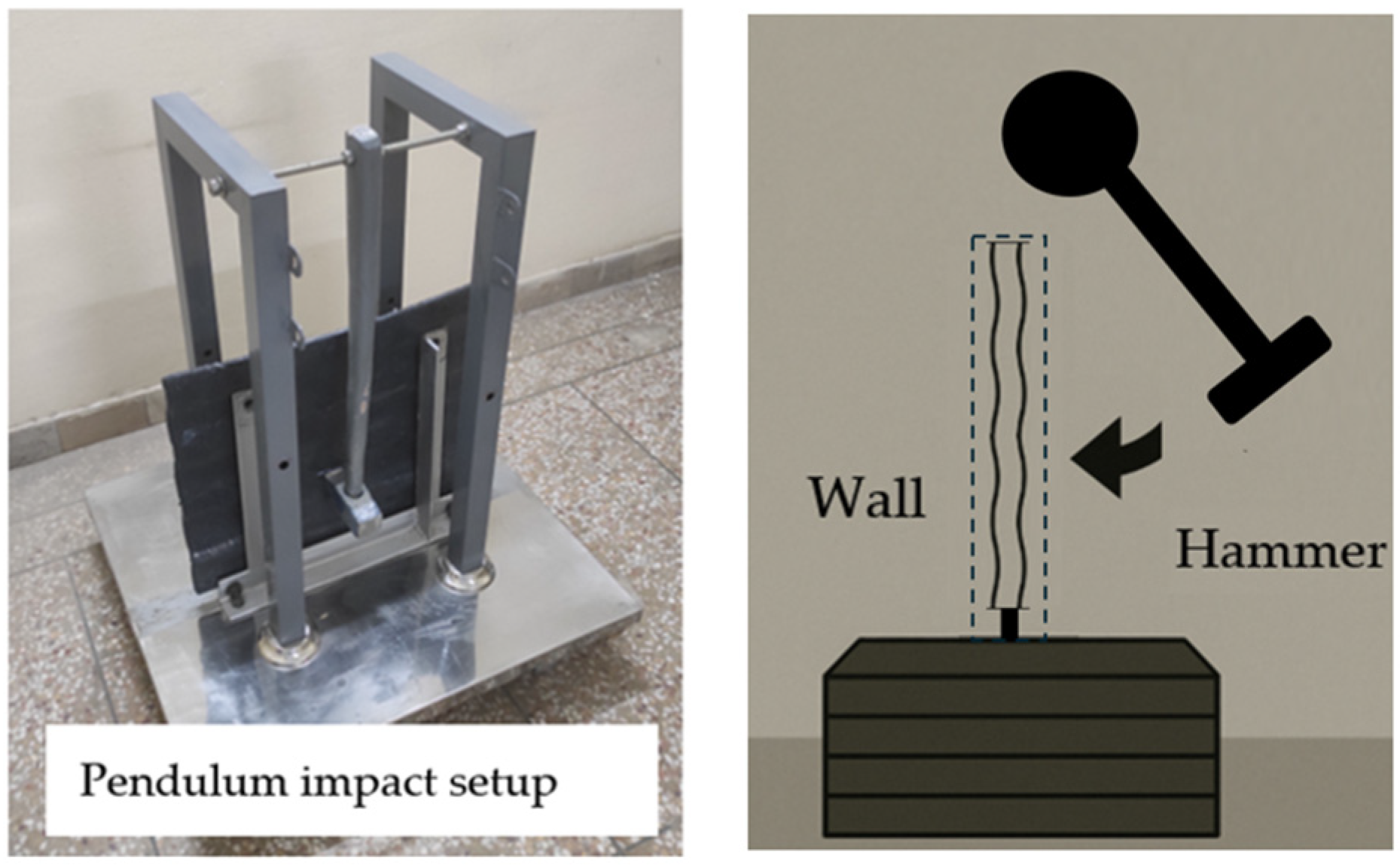

2.3.3. Vertical Panel Test Procedure—Modified Pendulum Impact Test

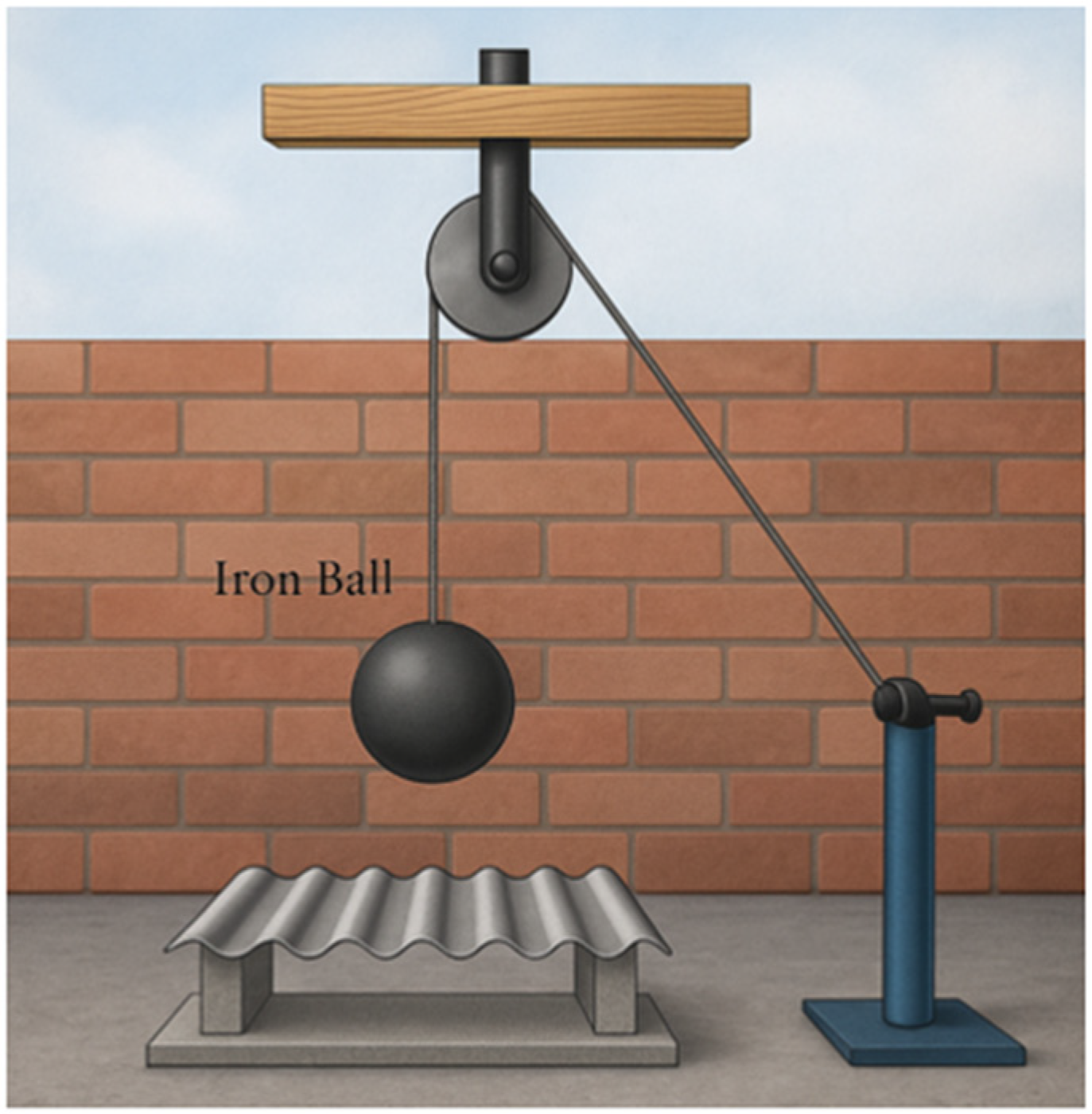

2.3.4. Horizontal Panel Test Procedure—Modified Drop Impact Test

2.3.5. Characterization and Microstructural Assessment

XRD Analysis Procedure

SEM and EDS Analysis Procedure

2.4. Prototype Slab Test Procedure

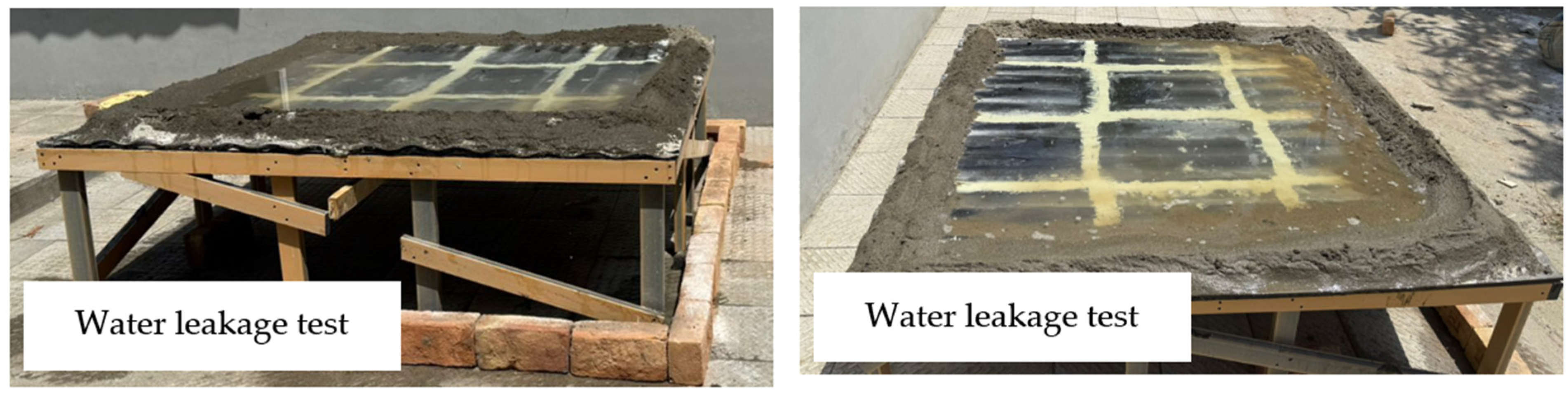

2.4.1. Water Leakage Test Procedure

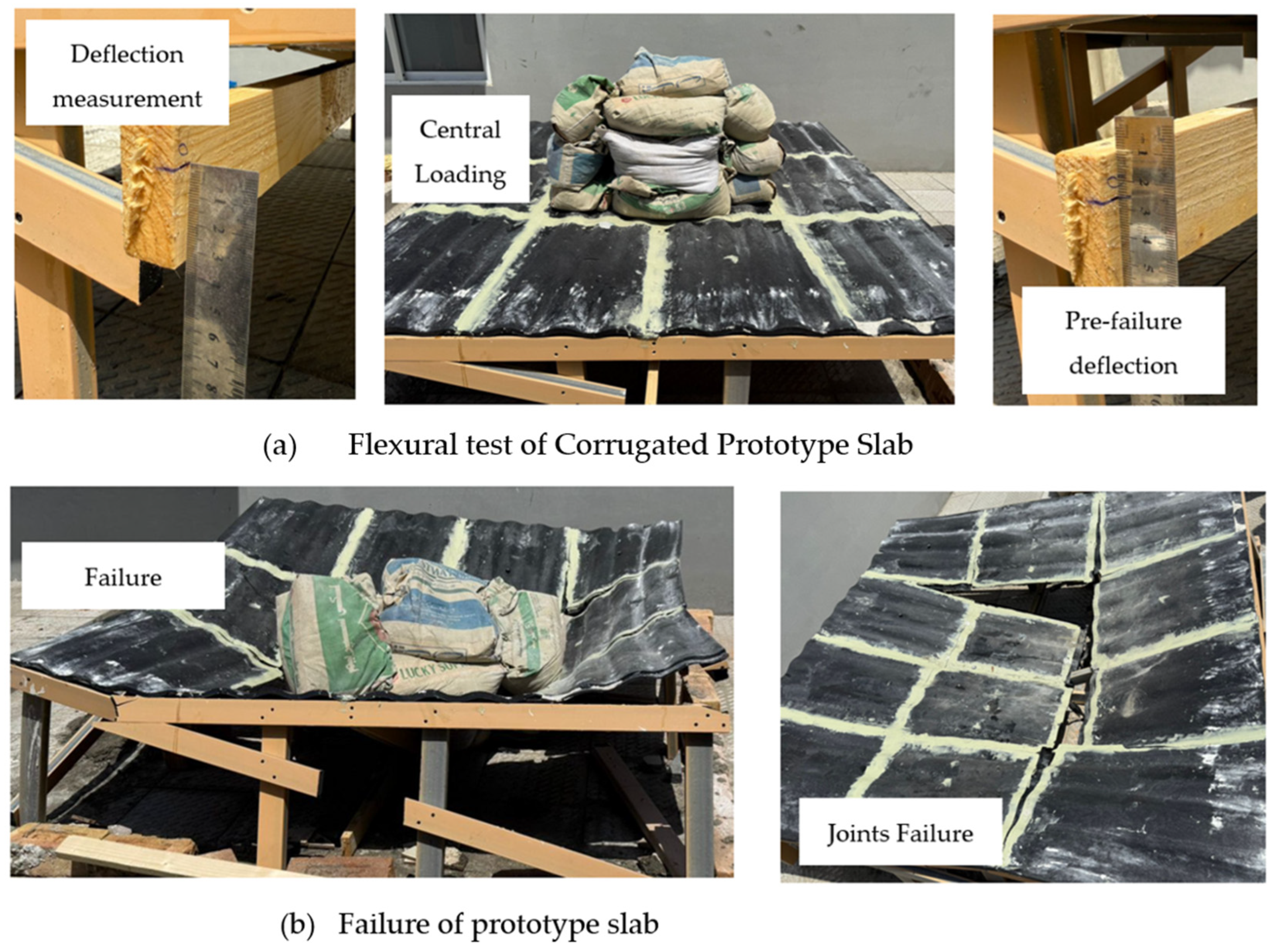

2.4.2. Flexural Capacity Test Procedure

2.5. Empirical Relationship Procedure Between Impact and Flexural Strength of Panel

3. Results

3.1. Behavior of Corrugated Panel

3.1.1. Fundamental Frequency and Damping Behavior

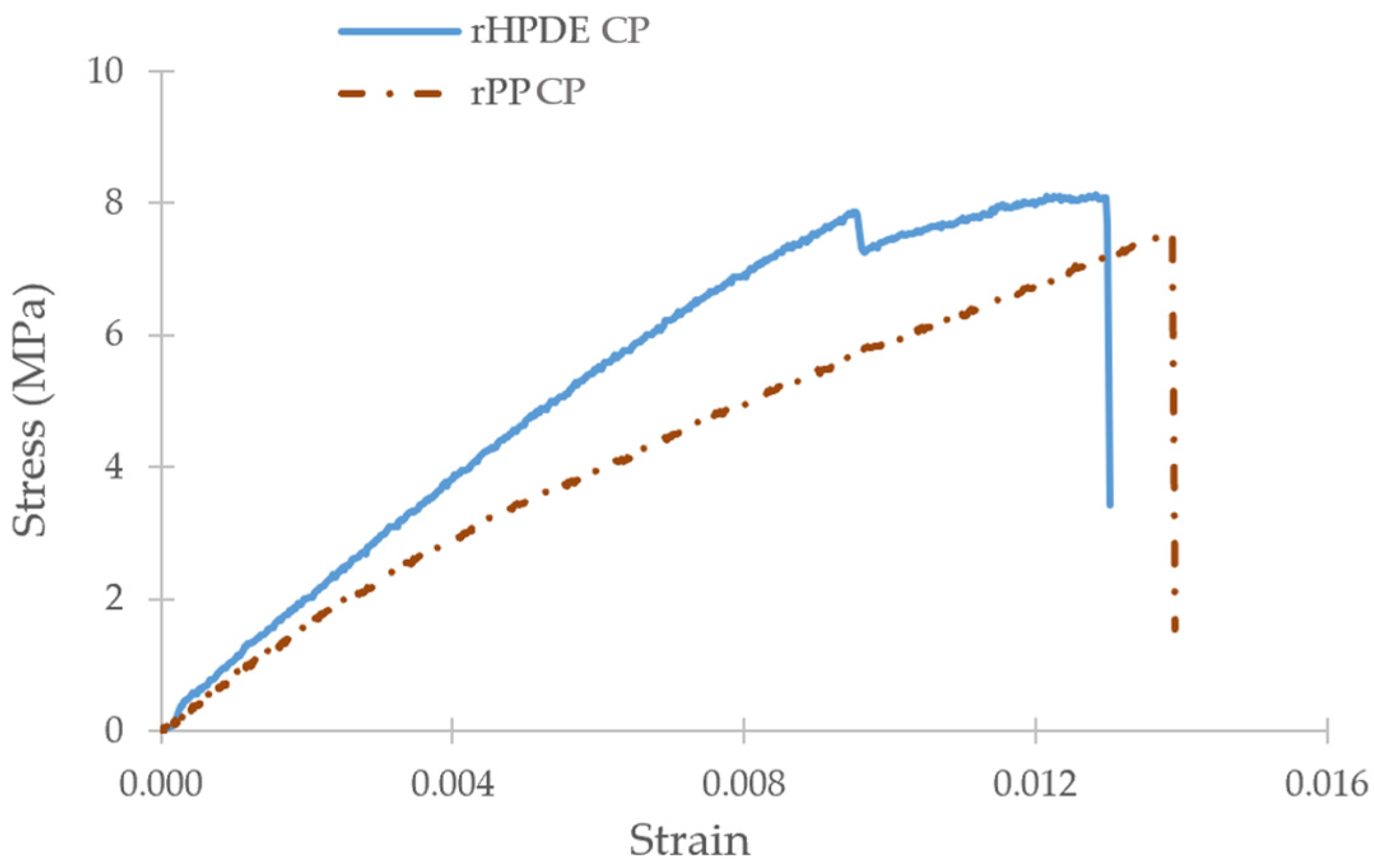

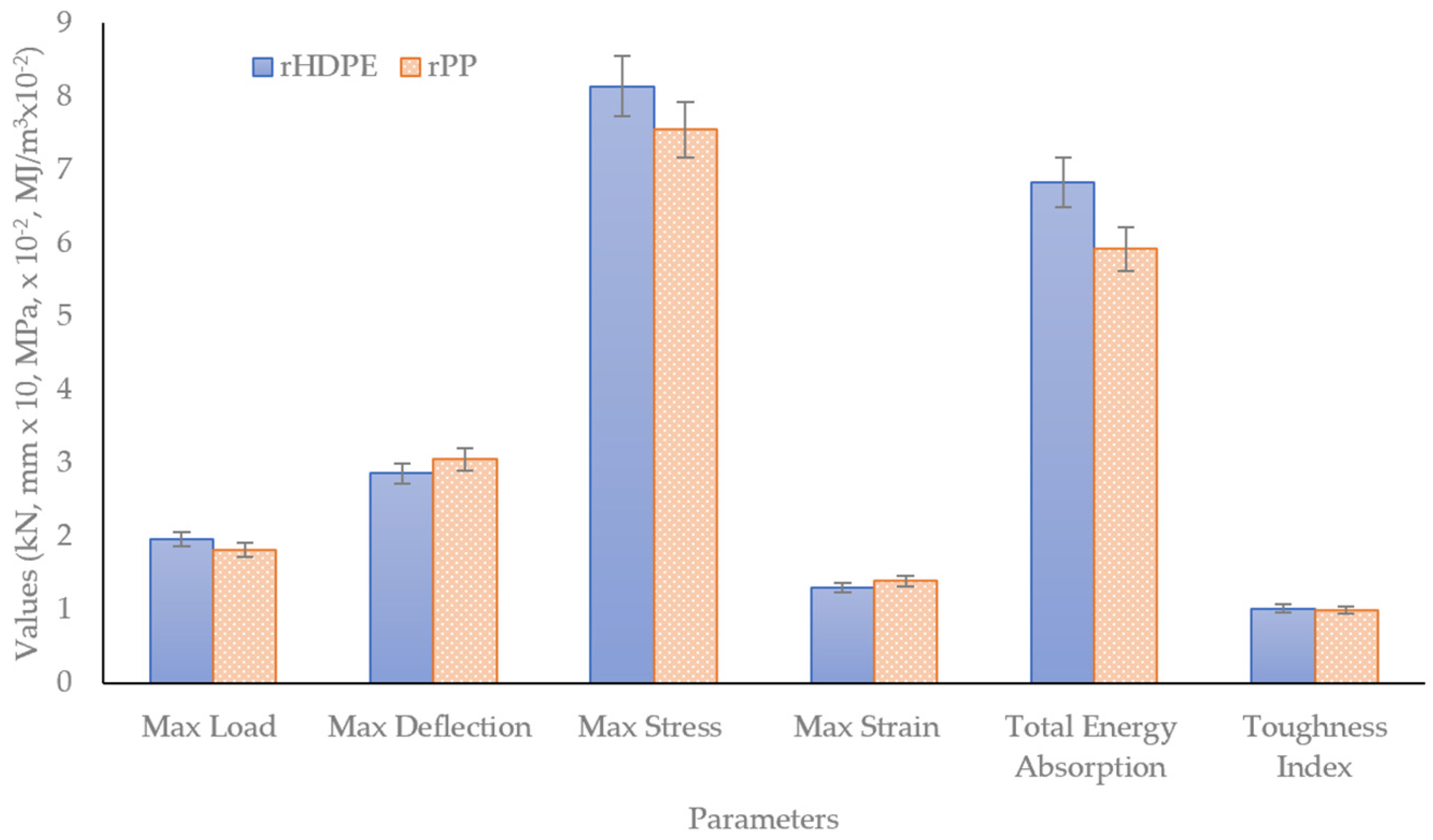

3.1.2. Flexural Performance of Recycled Corrugated Panels

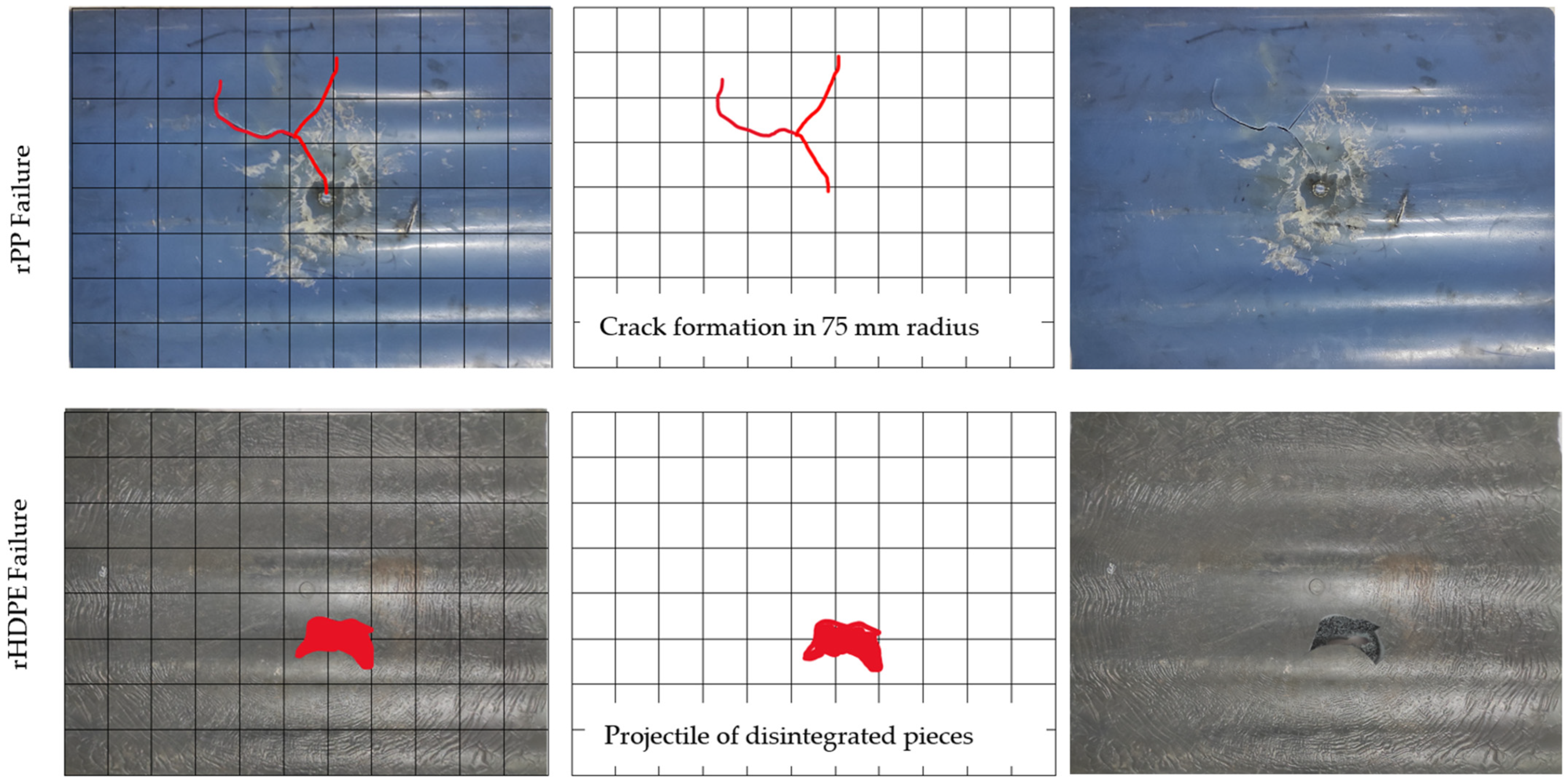

3.1.3. Behavior of Vertical Panel Under Pendulum Impact

3.1.4. Behavior of Horizontal Panel Under Drop Impact

3.1.5. Microstructural Behavior

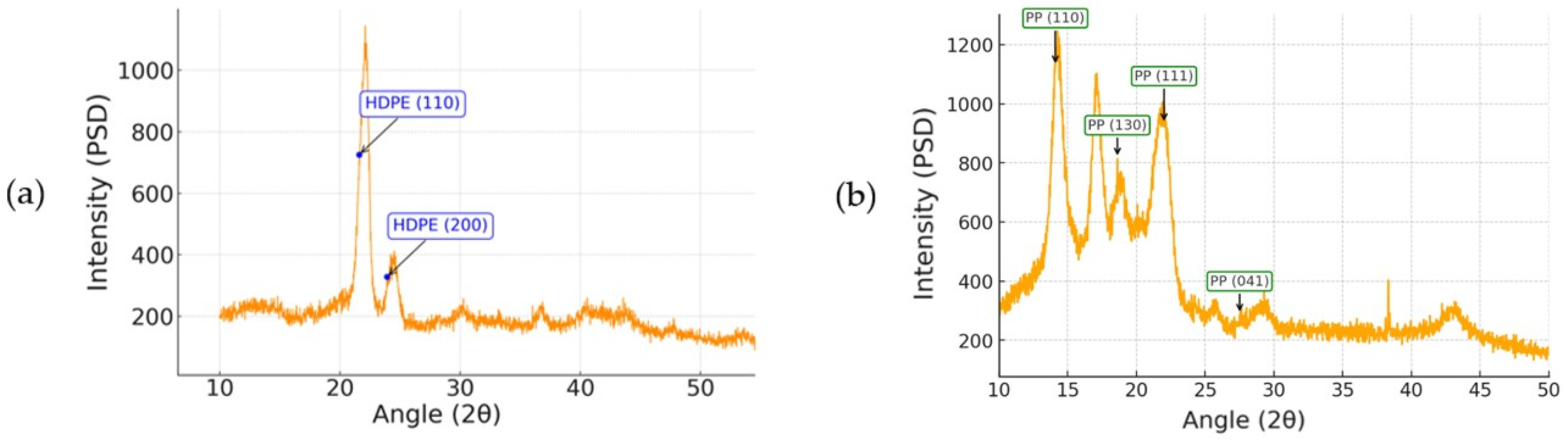

XRD Analysis

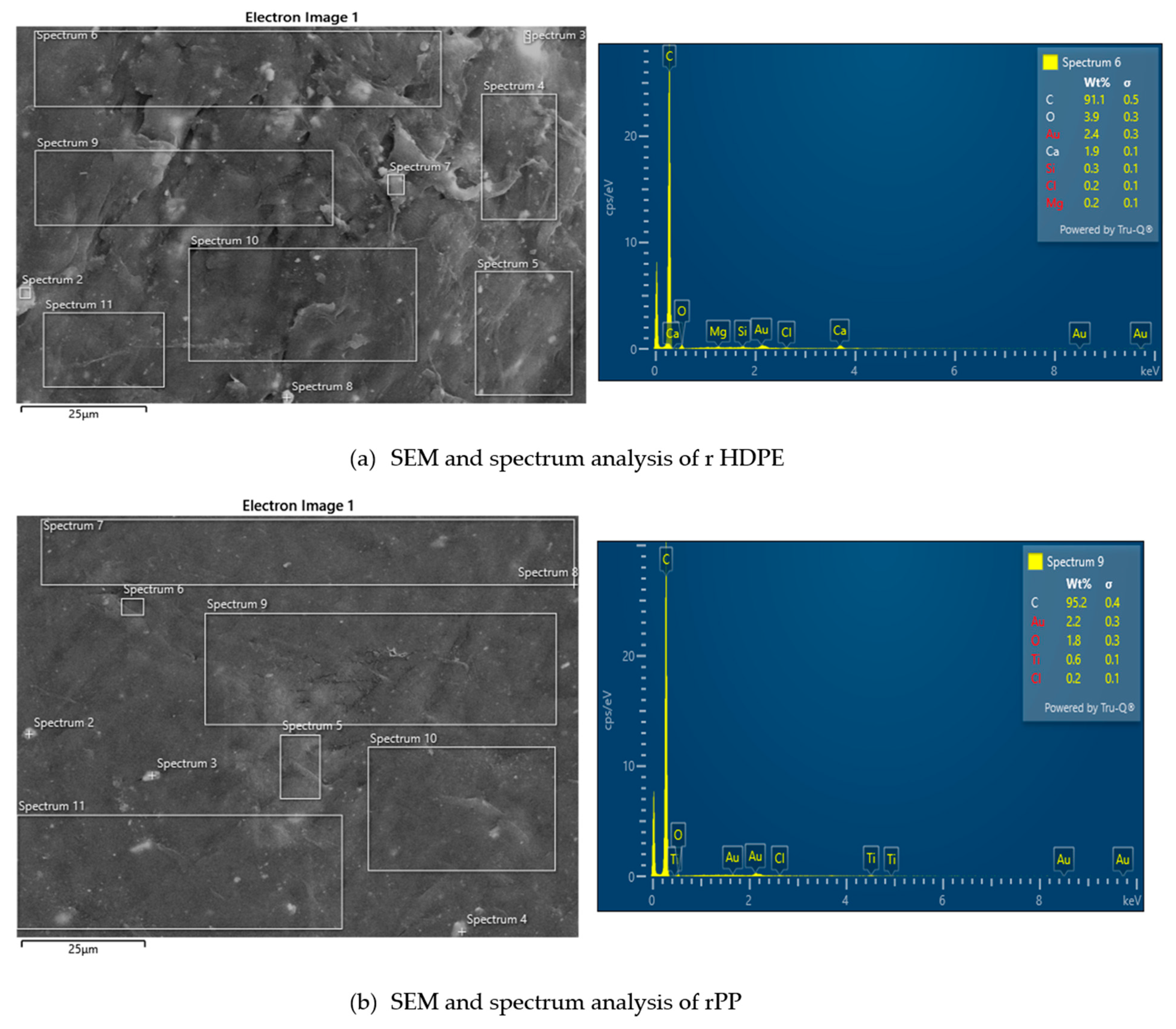

SEM and EDS Analysis

3.2. Behavior of Prototype Slab

3.2.1. Water Leakage Behavior of Prototype Slab

3.2.2. Recycled Plastic Prototype Slab (RPPS) Flexural Capacity

3.3. Empirical Relationship of Flexural Strength to Impact Strength of Recycled Panels

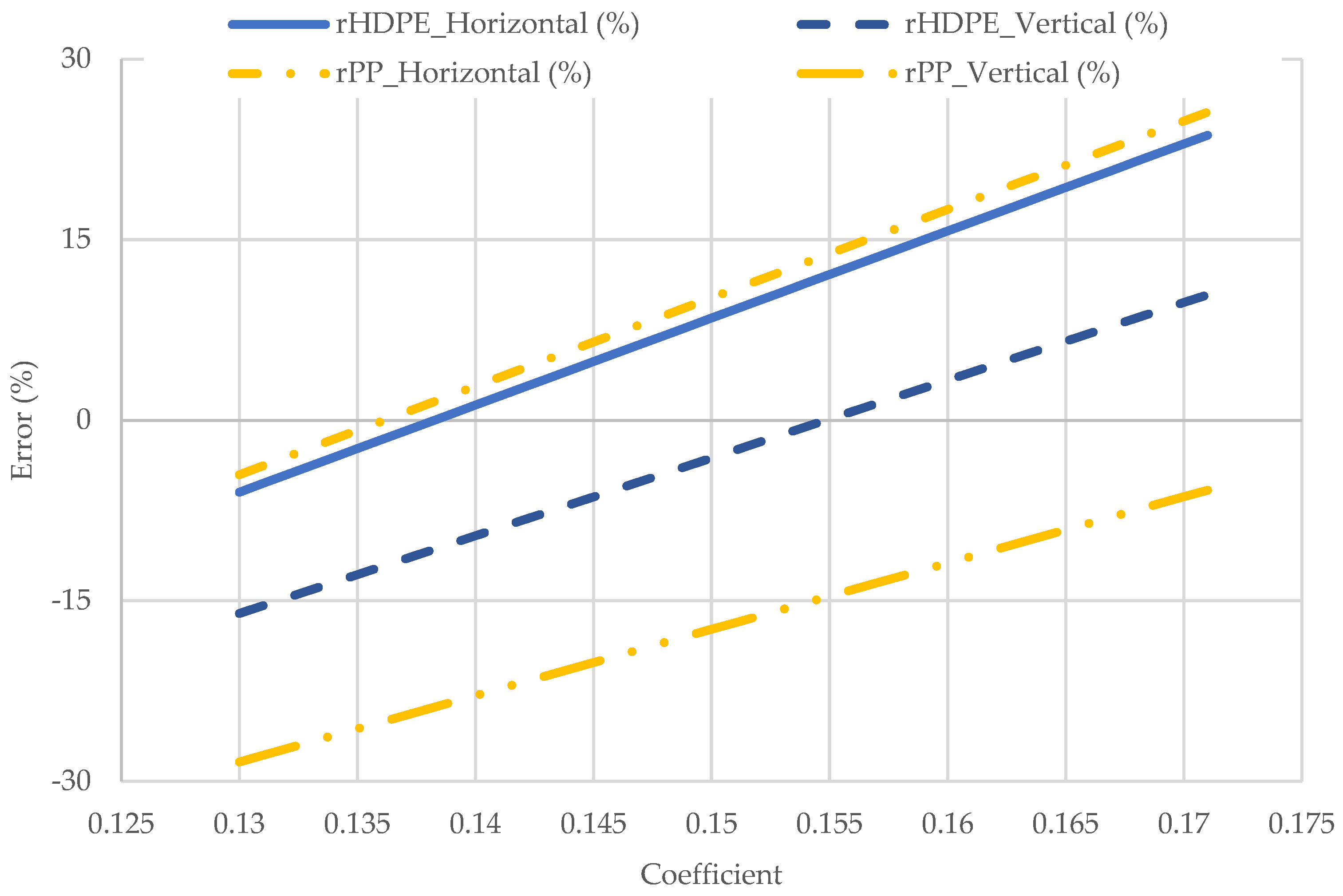

4. Challenges in Practical Applications and Their Solutions

5. Conclusions

- The following conclusions are drawn from the evaluation of the corrugated panels.

- ○

- rPP exhibited higher out-of-plane flexural stiffness (2.17 ± 0.33 GPa) and lower damping (ξF(OOP) = 4.2 ± 0.2%), suggesting improved rigidity under vibration-sensitive applications. Conversely, rHDPE showed greater damping capacity (ξF(OOP) = 8.2 ± 0.1%) but lower stiffness (2.04 ± 1.07 GPa), indicating superior vibration attenuation. This divergence supports material-specific usage based on required mechanical responses.

- ○

- rHDPE demonstrated higher flexural strength (8.136 ± 0.407 MPa) and energy absorption (6.826 ± 0.341 MJ/m3), while rPP showed superior strain capacity (1.391 ± 0.070 × 10−2), making it more ductile. Thus, rHDPE is preferred for rigid load-bearing applications, whereas rPP is optimal for flexible elements.

- ○

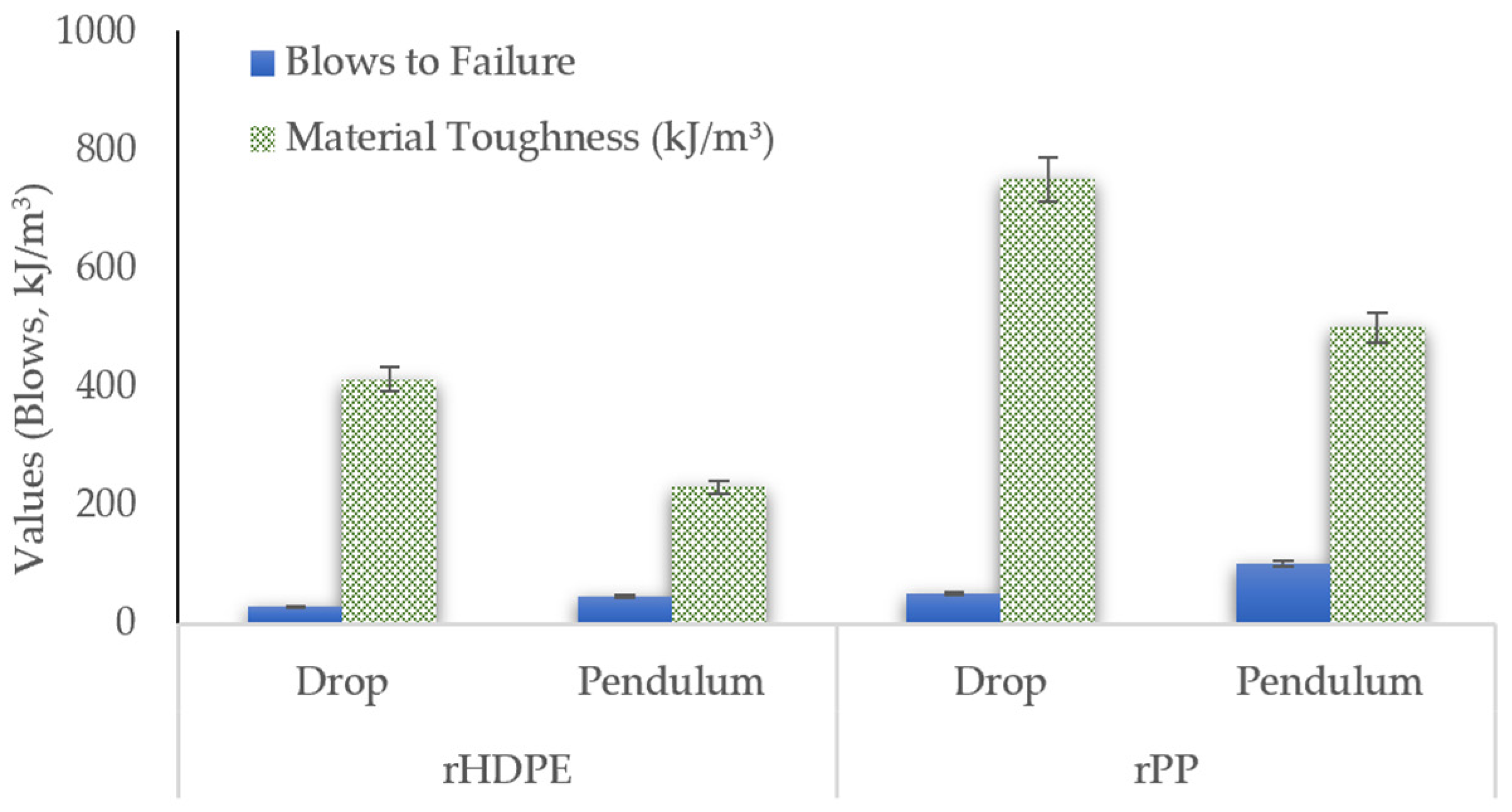

- Impact response analysis revealed rPP’s superior ductility, with radial cracks and higher energy absorption, while rHDPE displayed brittle failure with minimal crack propagation. Toughness analysis corroborated rPP’s resilience under dynamic loading.

- ○

- Drop-weight and pendulum impact testing confirmed rPP’s greater toughness (750.15 ± 58.84 kJ/m3) and total energy absorption (2.65 ± 0.20 kJ). In contrast, rHDPE showed brittle fragmentation, validating rPP for impact-prone systems.

- ○

- Microstructural analysis via XRD showed retained semi-crystalline structure for both polymers. rPP displayed higher crystallinity than rHDPE. SEM-EDS revealed more homogenous and cleaner morphology for rPP, suggesting superior recycling consistency.

- The following conclusions are drawn from the evaluation of the recycled plastic corrugated prototype slabs.

- ○

- Water leakage testing confirmed the watertight performance of edge-modified slabs with overlapping joints under a continuous 6 h test, validating their roofing application.

- ○

- Flexural slab evaluation showed ductile deformation with a peak load of 1.86 kN and 27 mm maximum deflection. Energy absorption of 26.8 N-m indicates structural adequacy for lightweight structural systems.

- An empirical model relating flexural and impact strengths showed that rPP retained over 50% of its flexural strength post-impact, versus 27.65% for rHDPE. A coefficient of 0.155 provided a consistent predictive value across all datasets.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DEML | Longitudinal Dynamic Elastic Modulus |

| DEMF(IP) | In-plane Flexural Dynamic Elastic Modulus |

| DEMF(OOP) | Out-of-plane Flexural Dynamic Elastic Modulus |

| rHDPE | Recycled High-Density Polyethylene |

| rPP | Recycled Polypropylene |

| RFL | Longitudinal Resonance Frequency |

| RFF(IP) | In-plane Flexural Resonance Frequency |

| RFF(OOP) | Out-of-plane Flexural Resonance Frequency |

| ξL | Longitudinal Damping |

| ξF(IP) | In-plane Flexural Damping |

| ξF(OOP) | Out-of-plane Flexural Damping |

References

- Thomson, N.; Banfill, P. Corrugated-Iron Buildings: An Endangered Resource within the Built Heritage. J. Archit. Conserv. 2005, 11, 71–87. [Google Scholar] [CrossRef]

- Delvasto, S.; Toro, E.F.; Perdomo, F.; De Gutiérrez, R.M. An Appropriate Vacuum Technology for Manufacture of Corrugated Fique Fiber Reinforced Cementitious Sheets. Constr. Build. Mater. 2010, 24, 187–192. [Google Scholar] [CrossRef]

- Haba, B.; Djellali, S.; Abdelouahed, Y.; Boudjelida, S.; Faleschini, F.; Carraro, M. Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction. Polymers 2025, 17, 881. [Google Scholar] [CrossRef]

- Besir, A.B.; Cuce, E. Green Roofs and Facades: A Comprehensive Review. Renew. Sustain. Energy Rev. 2018, 82, 915–939. [Google Scholar] [CrossRef]

- Kumaraswamy, J.; Vijay Praveen, P.M.; Alzahrani, H.A.H.; Sharma, S.; Shetty, V.; Shabari Shedthi, B. Experimental Investigation of Heat Transfer Rate for Building Roof with Corrugated Sheets Using Phase Change Material (PCM). Case Stud. Therm. Eng. 2024, 59, 104508. [Google Scholar] [CrossRef]

- Almodóvar-Melendo, J.-M.; La Roche, P. Thermal Evaluation of a Water-to-Air Heat Exchanger Combined with Different Roof Configurations for Passive Cooling. Buildings 2025, 15, 1098. [Google Scholar] [CrossRef]

- Mohammed, H.; Kennedy, J.B. Fatigue Resistance of Corrugated Steel Sheets Bolted Lap Joints under Flexture. Pract. Period. Struct. Des. Constr. 2009, 14, 242–245. [Google Scholar] [CrossRef]

- Malek, S.; Williams, C. The Equilibrium of Corrugated Plates and Shells. Nexus Netw. J. 2017, 19, 619–627. [Google Scholar] [CrossRef]

- Yang, M.; Gao, C.; Pang, J.; Li, S.; Hu, D.; Li, X.; Zhang, Z. High-Cycle Fatigue Behavior and Fatigue Strength Prediction of Differently Heat-Treated 35CrMo Steels. Metals 2022, 12, 688. [Google Scholar] [CrossRef]

- Henderson, D.J.; Ginger, J.D. Response of Pierced Fixed Corrugated Steel Roofing Systems Subjected to Wind Loads. Eng. Struct. 2011, 33, 3290–3298. [Google Scholar] [CrossRef]

- Brochu, M.; Verreman, Y.; Ajersch, F.; Bouchard, D. High Cycle Fatigue Strength of Permanent Mold and Rheocast Aluminum 357 Alloy. Int. J. Fatigue 2010, 32, 1233–1242. [Google Scholar] [CrossRef]

- Thakre, G.; Kaushal, V.; Najafi, M. A Comparative Impact Assessment of Hail Damage to Tile and Built-Up Roofing Systems: Technical Review and Field Study. Preprints 2024. [Google Scholar] [CrossRef]

- Da Silva, T.R.; De Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Setyanto, D. Design and FE Modeling of UPVC Corrugated Hollow Roofing Sheet. MATEC Web Conf. 2019, 258, 01017. [Google Scholar] [CrossRef]

- De Mello Innocentini, M.D.; Vieira De Faria, M.A.; Rosseto Crespi, M.; Batista Andrade, V.H. Air Permeability Assessment of Corrugated Fiber-Cement Roofing Sheets. Cem. Concr. Compos. 2019, 97, 259–267. [Google Scholar] [CrossRef]

- Soto, F.R.C.; Bueno, J.D.J.P.; Mendoza López, M.L.; Chavela, M.H.; Ramos, M.E.P.; Manzano-Ramírez, A. Hydrothermal Evaluation of Vernacular Housing: Comparing Case Studies of Waste PET Bottles, Stone, and Adobe Houses. Buildings 2022, 12, 1162. [Google Scholar] [CrossRef]

- Lin, M.-C.; Lin, J.-H.; Lin, J.-Y.; Lin, T.A.; Lou, C.-W. Fabrication, Properties, and Failure of Composite Sandwiches Made with Sheet Extrusion Method. J. Sandw. Struct. Mater. 2020, 22, 689–701. [Google Scholar] [CrossRef]

- Talib, R.; Boyd, D.; Hayhow, S.; Ahmad, A.G.; Sulieman, M. Investigating Effective Waterproofing Materials in Preventing Roof Leaking; Initial Comparative Study: Malaysia, U.K. Procedia Manuf. 2015, 2, 419–427. [Google Scholar] [CrossRef][Green Version]

- Okamoto, S. Water Leak Testing of Japanese Tiled Roofs under Vibration and Scattering. IERI Procedia 2012, 1, 47–52. [Google Scholar] [CrossRef][Green Version]

- Afizah Asman, N.S.; Dullah, S.; Ayog, J.L.; Mirasa, A.K.; Djamila, H. The Hydrological Performance of Lightweight Green Roofs Made From Recycled Waste Materials As the Drainage Layer. MATEC Web Conf. 2017, 103, 04011. [Google Scholar] [CrossRef]

- Cascone, S. Green Roof Design: State of the Art on Technology and Materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef]

- Saba, M.; Coronado-Hernández, O.E.; Gil, L.K.T. Energy Efficiency in Subtropical Homes: Replacing Asbestos–Cement Roofs with Sustainable Alternatives. Buildings 2024, 14, 4082. [Google Scholar] [CrossRef]

- Gaggino, R.; Kreiker, J.; Filippín, C.; Sánchez Amono, M.P.; González Laría, J.; Peisino, L.E. The Comprehensive Comparison of Thermal and Physical-Mechanical Properties of the Recycled Rubber and Plastic Roofing Tiles versus Roofing Tiles Made with Different Traditional Materials. Adv. Civ. Eng. 2018, 2018, 7361798. [Google Scholar] [CrossRef]

- Kittisak, B.; Prayoon, S. Properties of Corrugated Roofing Sheet Material from Sugarcane Bagasse Fibers. J. Phys. Conf. Ser. 2021, 1860, 012007. [Google Scholar] [CrossRef]

- Jara-Vinueza, O.; Pavon, W.; Remache, A.; Arroyo, F.; Gutiérrez, M.; Mora Figueroa, E. Evaluation of Mechanical Behavior and Application Potential of Totora (Schoenoplectus Californicus)-and-Recycled Low-Density Polyethylene–Aluminum (LDPE–Al) Hybrid Panels. Buildings 2025, 15, 2212. [Google Scholar] [CrossRef]

- Yoshino, Y.; Kimura, Y. Strength and Stiffness of Corrugated Plates Subjected to Bending. Buildings 2025, 15, 469. [Google Scholar] [CrossRef]

- Xia, Y.; Friswell, M.I.; Flores, E.I.S. Equivalent Models of Corrugated Panels. Int. J. Solids Struct. 2012, 49, 1453–1462. [Google Scholar] [CrossRef]

- Abd El-Latif, M.Y.; Yossef, M.; Chen, A.; Elsayad, M. Behavior of Stressed Skin Corrugated Sheet under Hydrostatic Loads. Case Stud. Constr. Mater. 2024, 20, e03343. [Google Scholar] [CrossRef]

- Das, A.J.; Ali, M. Sustainable Development and Assessment of Low-Strength/High-Toughness Recycled Plastic Rebars for Structural Elements Under Light Loads. Sustainability 2025, 17, 4997. [Google Scholar] [CrossRef]

- Karedla, A.B.; Schuster, J.; Shaik, Y.P. Possibility of Making Plastic Roof Tiles from Waste Plastic, Sand, and Fly Ash. Constr. Mater. 2024, 4, 597–610. [Google Scholar] [CrossRef]

- Das, A.J.; Ali, M. Prospective Use and Assessment of Recycled Plastic in Construction Industry. Recycling 2025, 10, 41. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Fitas, R.; Schaffrath, H.J.; Schabel, S. A Review of Optimization for Corrugated Boards. Sustainability 2023, 15, 15588. [Google Scholar] [CrossRef]

- ASTM E1876-15; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2015.

- Ahmed, S.; Ali, M. Use of Agriculture Waste as Short Discrete Fibers and Glass-Fiber-Reinforced-Polymer Rebars in Concrete Walls for Enhancing Impact Resistance. J. Clean. Prod. 2020, 268, 122211. [Google Scholar] [CrossRef]

- Hussain, T.; Ali, M. Improving the Impact Resistance and Dynamic Properties of Jute Fiber Reinforced Concrete for Rebars Design by Considering Tension Zone of FRC. Constr. Build. Mater. 2019, 213, 592–607. [Google Scholar] [CrossRef]

- Li, D.; Zhou, L.; Wang, X.; He, L.; Yang, X. Effect of Crystallinity of Polyethylene with Different Densities on Breakdown Strength and Conductance Property. Materials 2019, 12, 1746. [Google Scholar] [CrossRef]

- Sutar, H.; Sahoo, P.C.; Sahu, P.S.; Sahoo, S.; Murmu, R.; Swain, S.; Mishra, S.C. Mechanical, Thermal and Crystallization Properties of Polypropylene (PP) Reinforced Composites with High Density Polyethylene (HDPE) as Matrix. Mater. Sci. Appl. 2018, 09, 502–515. [Google Scholar] [CrossRef]

- ASTM E661-15; Standard Test Method for Performance of Panel-Type Wall Constructions. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E2140-22; Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors and Curtain Walls by Uniform Static Air Pressure Difference. ASTM International: West Conshohocken, PA, USA, 2022.

- Abubaker, S.A.; Chaqmaqchee, F.A.; Taha, A.H. X-Ray Fluorescence Techniques. ARO 2021, 9, 22–25. [Google Scholar] [CrossRef]

- Pang, A.L.; Husin, M.R.; Arsad, A.; Ahmadipour, M. Effect of Graphene Nanoplatelets on Structural, Morphological, Thermal, and Electrical Properties of Recycled Polypropylene/Polyaniline Nanocomposites. J. Mater. Sci. Mater. Electron. 2021, 32, 9574–9583. [Google Scholar] [CrossRef]

- Liço, E.; Rapa, V.; Drushku, S.; Chatzitheodoridis, E. Morphological and Chemical Study of Recycled Plastic Materials by Using Scanning Electron Microscopy and Energy Dispersive Analysis. Zašt. Mater. 2011, 52, 231–236. [Google Scholar]

- Hu, B.; Guo, P.; Han, S.; Chen, S. Distribution Characteristics of Microplastics in the Soil of Mangrove Restoration Wetland and the Effects of Microplastics on Soil Characteristics. Ecotoxicology 2022, 31, 1120–1136. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Kalloudis, M.; Koutsos, V. High-Density Polyethylene–Polypropylene Blends: Examining the Relationship Between Nano/Microscale Phase Separation and Thermomechanical Properties. Polymers 2025, 17, 166. [Google Scholar] [CrossRef] [PubMed]

- Kassab, R.A.; Sadeghian, P. Effects of Material Non-Linearity on the Structural Performance of Sandwich Beams Made of Recycled PET Foam Core and PET Fiber Composite Facings: Experimental and Analytical Studies. Structures 2023, 54, 1259–1277. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Yuan, H.; Guo, H.; Zhuang, W. The Plastic Behavior in the Large Deflection Response of Fiber Metal Laminate Sandwich Beams under Transverse Loading. Materials 2022, 15, 439. [Google Scholar] [CrossRef] [PubMed]

- Talukder, M.K.; Haque, M.N. Experimental investigation of flexural capacity and deflection of low strength RCC beam strengthened with flexural steels and steel shear key. Asian J. Civ. Eng. 2023, 24, 29–56. [Google Scholar] [CrossRef]

- Tesfaw, S.; Bogale, T.M.; Fatoba, O. Evaluation of Tensile and Flexural Strength Properties of Virgin and Recycled High-Density Polyethylene (HDPE) for Pipe Fitting Application. Mater. Today Proc. 2022, 62, 3103–3113. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, Z.; Deng, S.; Jiang, H.; Tian, Y.; Geng, J. Full-Scale Experimental Study on Flexural Performance of the New Precast UHPC Diaphragm Slab in Utility Tunnels. Buildings 2023, 13, 1349. [Google Scholar] [CrossRef]

- Acharya, M.; Gurung, K.; Mashal, M. Full-Scale Flexural Testing of Slabs Made of Modular Structural Concrete Insulated Panels. PCI J. 2022, 67, 55–76. [Google Scholar] [CrossRef]

- Asadoullahtabar, S.R.; Asgari, A.; Tabari, M.M.R. Assessment, Identifying, and Presenting a Plan for the Stabilization of Loessic Soils Exposed to Scouring in the Path of Gas Pipelines, Case Study: Maraveh-Tappeh City. Eng. Geol. 2024, 342, 107747. [Google Scholar] [CrossRef]

| Specimen | Test Type | Applicability | Standard/ Reference |

|---|---|---|---|

| Corrugated Panel | Flexural Test | Evaluate load-carrying capacity and comparative stiffness of rHDPE and rPP corrugated panels | [32] |

| Dynamic Resonance | Assess out-of-plane stiffness and damping behavior of rHDPE and rPP roofing sheets | [34] | |

| Vertical Impact Test | Investigate dynamic impact resistance and crack development for vertical use such as claddings, etc. | [35] | |

| Horizontal Impact | Investigate dynamic impact resistance and crack development for horizontal use such as roofing, etc. | [36] | |

| XRD Analysis | Verified post-load crystallinity retention in rHDPE and rPP corrugated samples | [37] | |

| SEM–EDS Analysis | Characterized homogeneity, dispersion, and micro-defects in recycled plastic-based panels | [38] | |

| Prototype Slab | Flexural Test | Full-scale slab (1.63 × 1.6 m, 12 mm) test for load-bearing capacity, deflection profile, and failure mode | [39] |

| Water Leakage Test | Waterproof performance using 6 h custom ponding test, aligned with metal roof static water penetration methods | [40] |

| Sample | RFL | RFF(IP) | RFF(OOP) | DEML | DEMF(IP) | DEMF(OOP) | ξL | ξF(IP) | ξF(OOP) |

|---|---|---|---|---|---|---|---|---|---|

| (Hz) | (Hz) | (Hz) | (GPa) | (GPa) | (GPa) | (%) | (%) | (%) | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

| rHDPE | 1043.1 ± 110.9 | 1065.3 ± 88.7 | 976.1 ± 43.9 | 1.53 ± 0.33 | 2.43 ± 0.40 | 2.04 ± 1.07 | 3.4 ± 0.4 | 6.9 ± 2.8 | 8.2 ± 0.1 |

| rPP | 1042.5 ± 22.5 | 1065.0 ± 0.00 | 998.6 ± 66.4 | 1.37 ± 0.14 | 1.91 ± 0.26 | 2.17 ± 0.33 | 8.6 ± 0.7 | 5.8 ± 0.5 | 4.2 ± 0.2 |

| Material | Weight (kg) | Max Load (kN) | Max Deflection (mm × 10) | Max Stress (MPa) | Max Strain (×10−2) | Total Energy Absorption (MJ/m3 × 10−2) | Toughness Index |

|---|---|---|---|---|---|---|---|

| rHDPE | 3.100 ± 0.155 | 1.958 ± 0.098 | 2.860 ± 0.143 | 8.136 ± 0.407 | 1.302 ± 0.065 | 6.826 ± 0.341 | 1.017 ± 0.051 |

| rPP | 3.200 ± 0.160 | 1.816 ± 0.091 | 3.051 ± 0.153 | 7.546 ± 0.377 | 1.391 ± 0.070 | 5.918 ± 0.296 | 1.000 ± 0.050 |

| Test Type | Sample | Impact Height (m) | Angular Distance (m) | Impact Energy (J/Blow) | Impact Strength (Blows) | Total Energy (kJ) | Impact Strength (MPa) | Material Toughness (kJ/m3) |

|---|---|---|---|---|---|---|---|---|

| Drop Weight | rHDPE | 1.8 | - | 52.06 | 28 ± 3 | 1.45 ± 0.15 | 2.25 ± 0.23 | 411.84 ± 44.12 |

| rPP | 1.8 | - | 52.06 | 51 ± 4 | 2.65 ± 0.20 | 4.11 ± 0.31 | 750.15 ± 58.83 | |

| Pendulum | rHDPE | - | 0.6 | 17.35 | 47 ± 4 | 0.81 ± 0.06 | 1.26 ± 0.09 | 230.43 ± 19.61 |

| rPP | - | 0.6 | 17.35 | 102 ± 9 | 1.77 ± 0.15 | 2.74 ± 0.23 | 500.10 ± 44.12 |

| Material | Test | Approx. Crack Lengths | Disintegration Area | Crack Orientation |

|---|---|---|---|---|

| rPP | Pendulum | ~75 mm radial cracks (2–3 emanating) | Negligible (no pieces detached) | Radial from impact (~60° apart) |

| Drop Weight | One crack ~450 mm (along panel length) | None (intact except for split) | ~0° (along corrugation/length) | |

| rHDPE | Pendulum | Minimal crack propagation (<20 mm) | ~100 mm diameter impact crater | Localized shatter at center |

| Drop Weight | Two cracks ~450 mm and ~250 mm | No small debris (broke into 3 large sections) | ~0° and ~60° (diverging paths) |

| Sample | C (wt%) | O (wt%) | Au (wt%) | Ca (wt%) | Si (wt%) | Cl (wt%) | Mg (wt%) | Ti (wt%) | Fe (wt%) |

|---|---|---|---|---|---|---|---|---|---|

| rHDPE | 91.1 ± 0.5 | 3.9 ± 0.3 | 2.4 ± 0.3 | 1.9 ± 0.1 | 0.3 ± 0.1 | 0.2 ± 0.1 | 0.2 ± 0.1 | — | — |

| rPP | 95.2 ± 0.4 | 2.2 ± 0.3 | 0.6 ± 0.3 | — | — | 0.2 ± 0.1 | — | 0.6 ± 0.1 | 0.1 ± 0.1 |

| Time Interval (h) | Water Head * (cm) | Water Leakage Observed | Water Collected Below (Liters) | Remarks |

|---|---|---|---|---|

| 0 | 7.67 | 0% | 0 | No leakage |

| 2 | 7.67 | 0% | 0 | No leakage |

| 4 | 7.67 | 0% | 0 | No leakage |

| 6 | 7.67 | 0% | 0 | No leakage |

| Max Load (kN × 10−2) | Slab Width (m) | Slab Length (m) | Slab Thickness (mm) | Max Deflection (mm × 10) | Energy Absorption (N-m) | |

|---|---|---|---|---|---|---|

| Value | 186.33 | 1.6 | 1.68 | 12.7 | 2.7 | 26.8 |

| Material | Panel | Test Type | Impact Strength Original (MPa) | Impact Strength Empirical (MPa) | Percentage Error |

|---|---|---|---|---|---|

| rHDPE | Horizontal | Drop test | 2.25 ± 0.23 | 2.52 ± 0.13 | +12.09% |

| Vertical | Pendulum Test | 1.26 ± 0.09 | 1.26 ± 0.06 | +0.08% | |

| rPP | Horizontal | Drop Test | 4.11 ± 0.31 | 4.68 ± 0.23 | +13.83% |

| Vertical | Pendulum Test | 2.74 ± 0.23 | 2.34 ± 0.12 | −14.62% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, A.J.; Ali, M. Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction. Buildings 2025, 15, 2423. https://doi.org/10.3390/buildings15142423

Das AJ, Ali M. Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction. Buildings. 2025; 15(14):2423. https://doi.org/10.3390/buildings15142423

Chicago/Turabian StyleDas, Aaroon Joshua, and Majid Ali. 2025. "Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction" Buildings 15, no. 14: 2423. https://doi.org/10.3390/buildings15142423

APA StyleDas, A. J., & Ali, M. (2025). Multiscale Evaluation of Recycled Plastic Corrugated Panels for Sustainable Construction. Buildings, 15(14), 2423. https://doi.org/10.3390/buildings15142423