Investigation of the Effects of Almond Husk Ash on the Engineering Properties of Expansive Soil

Abstract

1. Introduction

- If the soil becomes liquid, structures may get damaged, so the density and hardness of the soil should be increased to prevent this situation [2].

- The soil should be improved to increase the bearing capacity and shear strength and prevent slip failure [3].

- Soil improvement is used to immobilize or stabilize contaminants in dredged soil to mitigate and preferably eliminate environmental impacts [4].

2. Materials and Methods

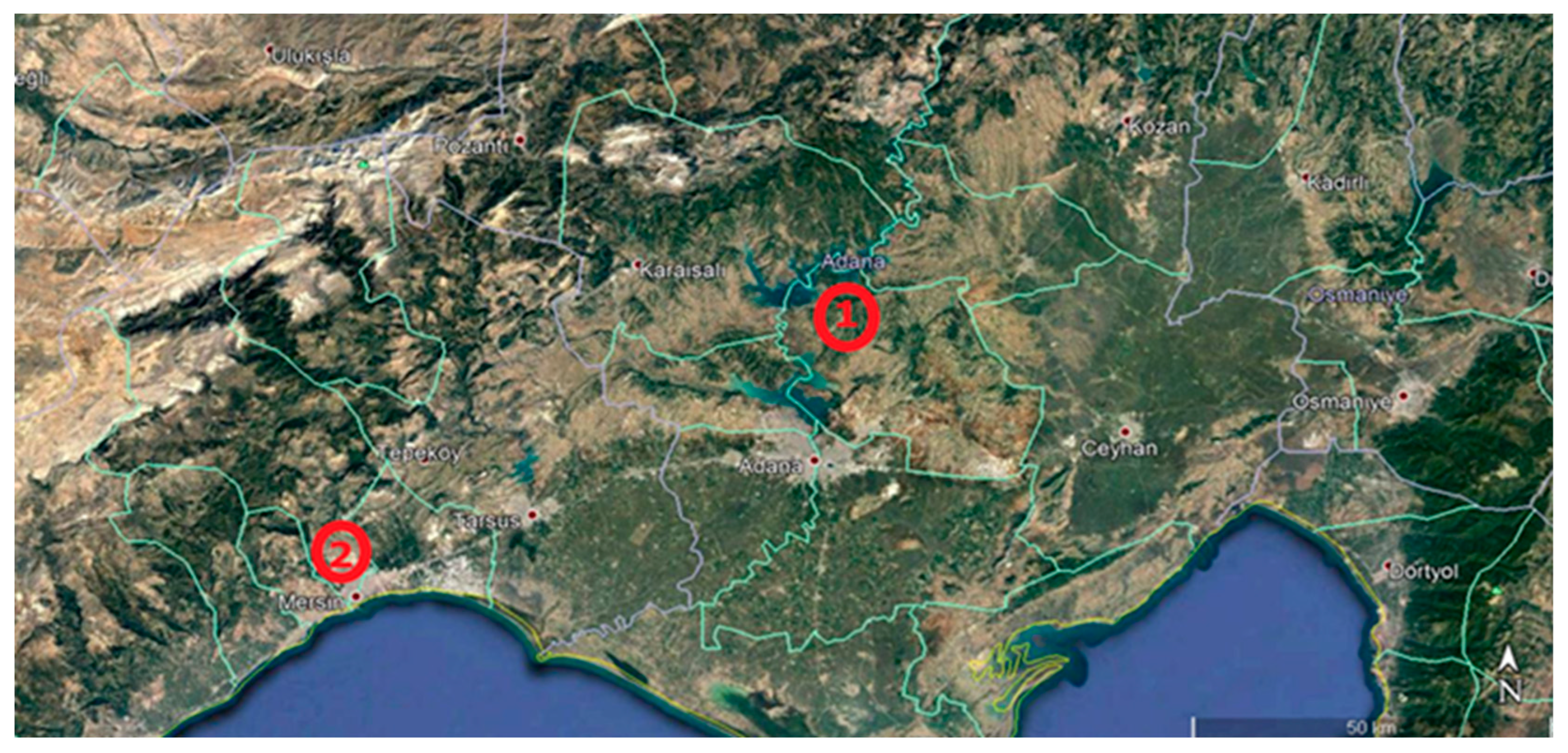

2.1. Materials

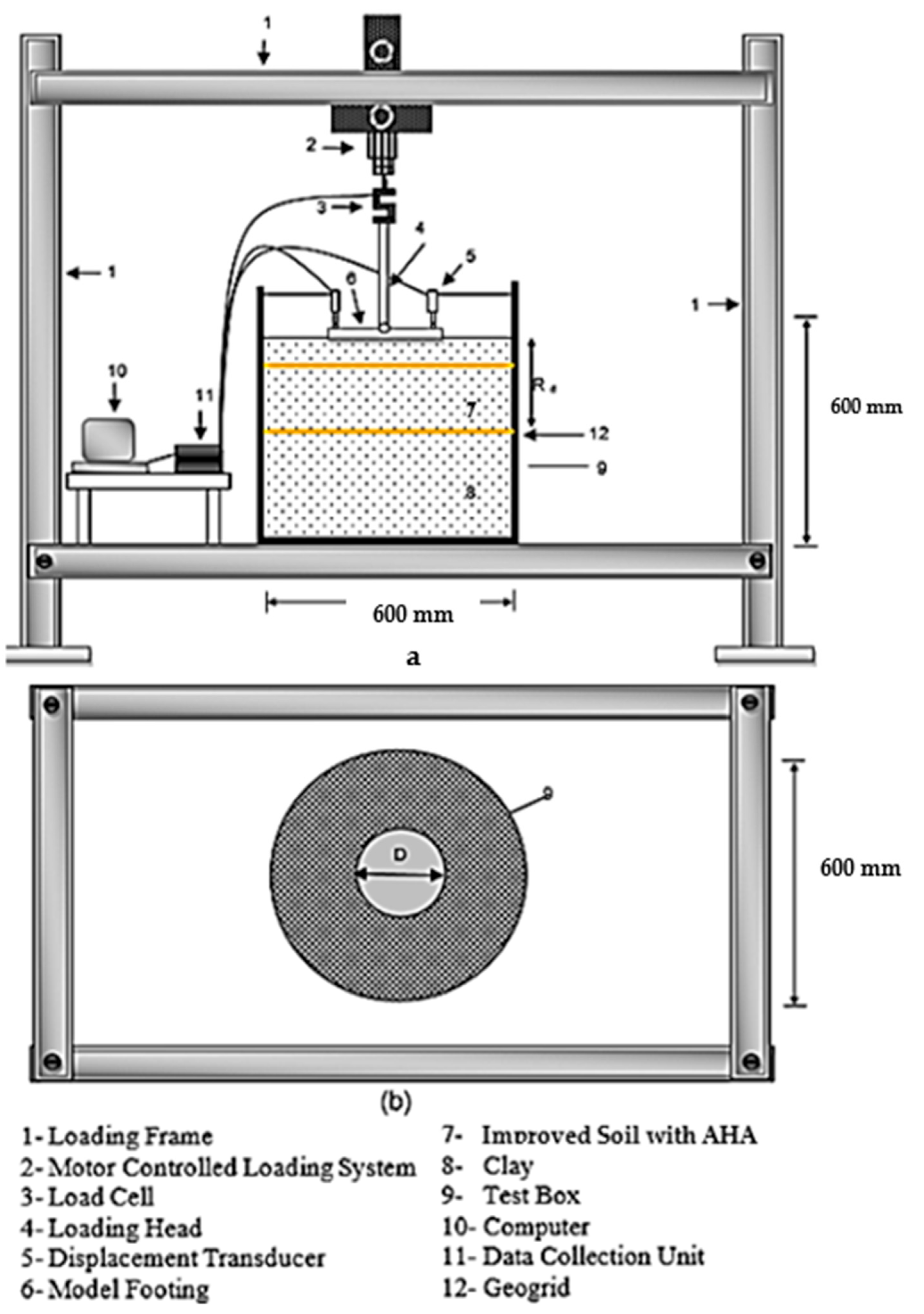

2.2. Method

3. Results

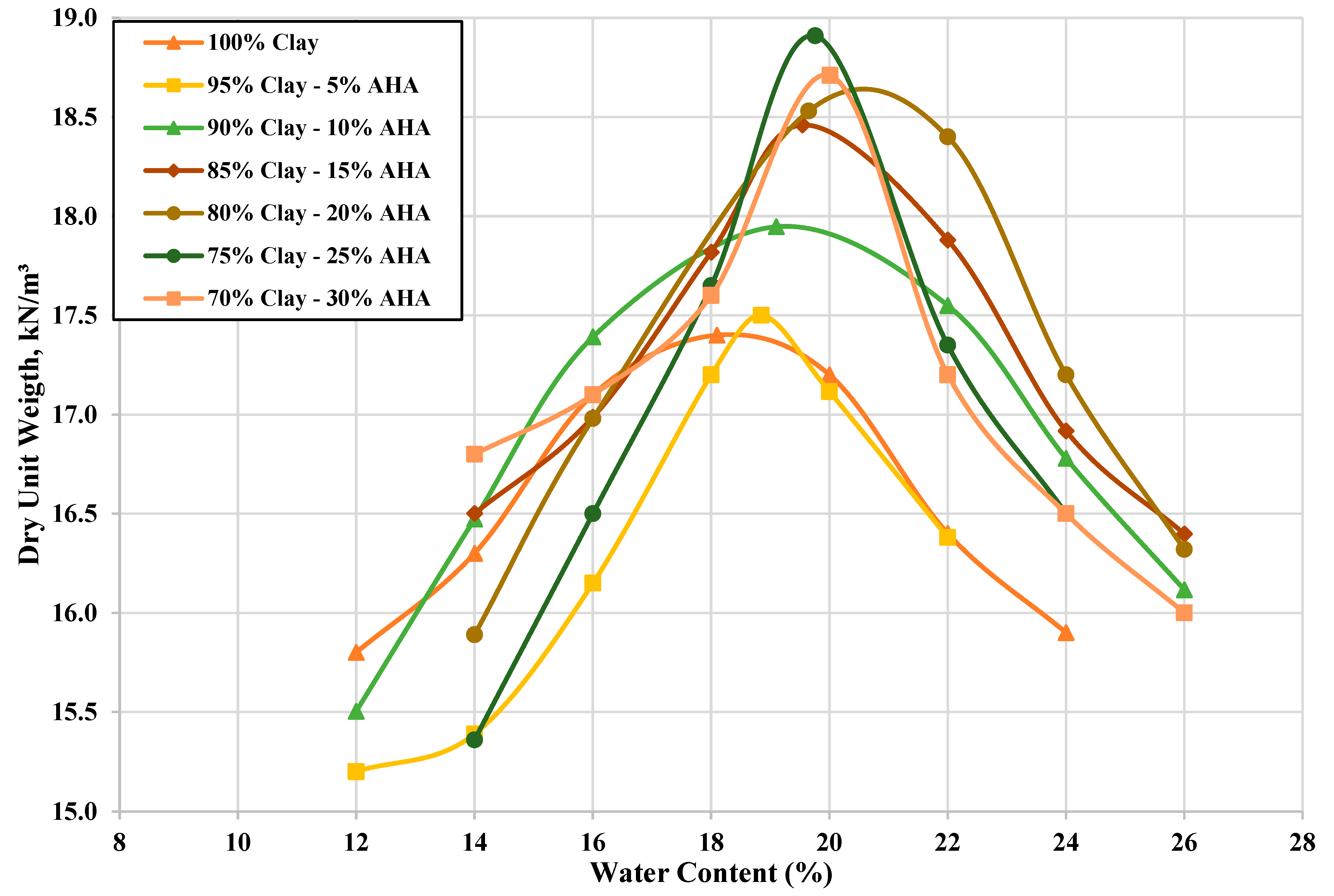

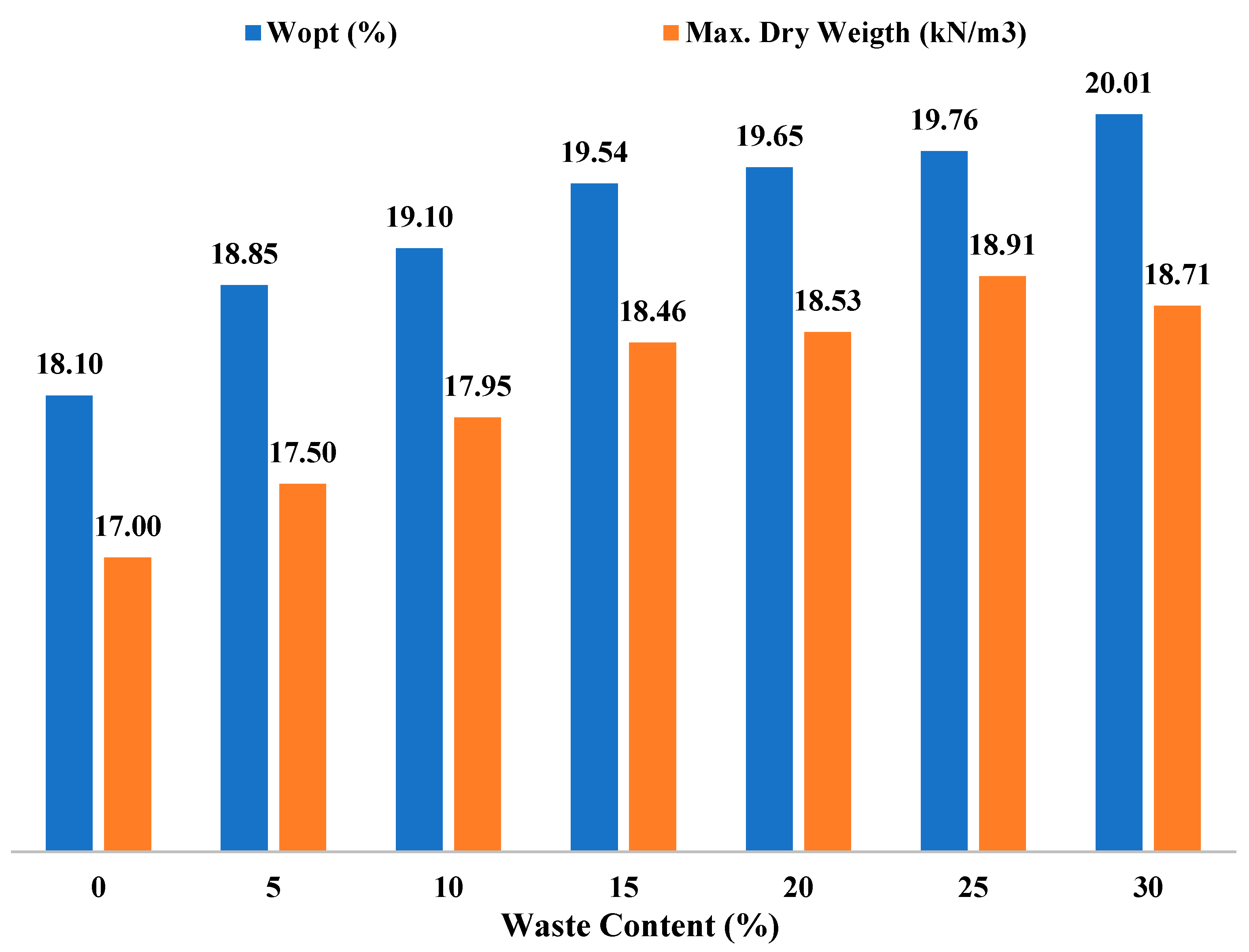

3.1. Effect of Water Content

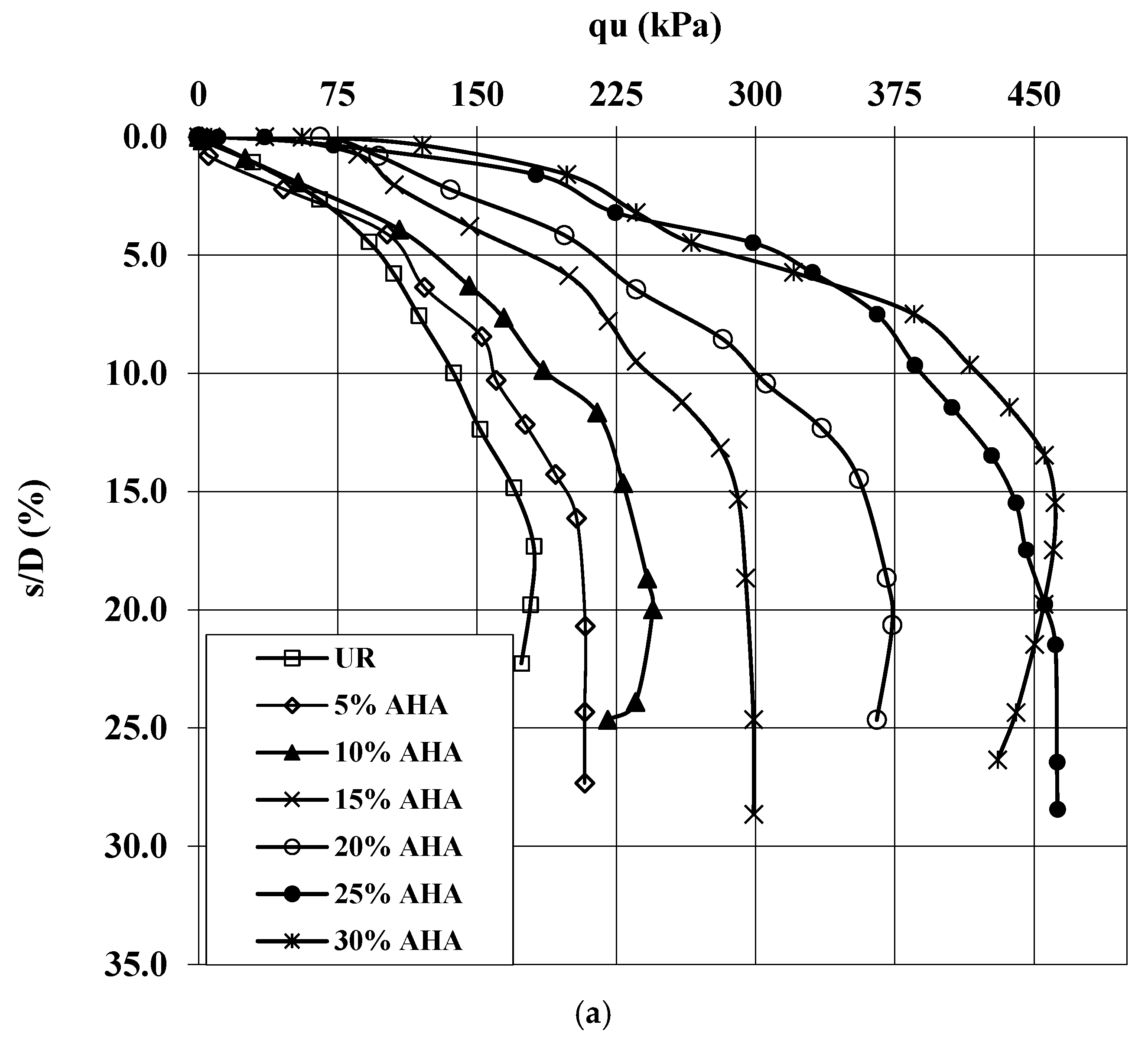

3.2. Effect of AHA on the BCR

3.3. Effect of the Depth of the AHA Zone

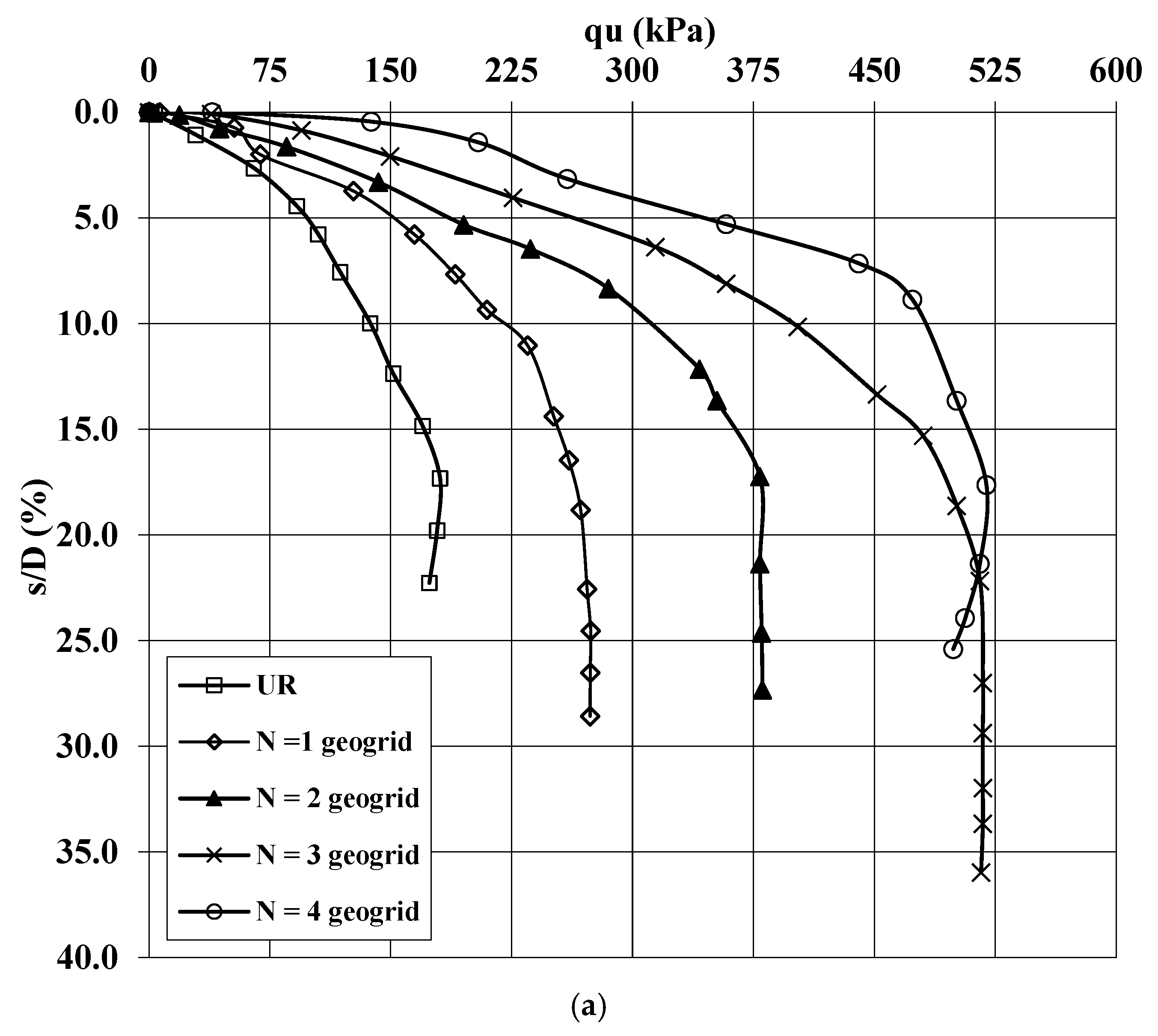

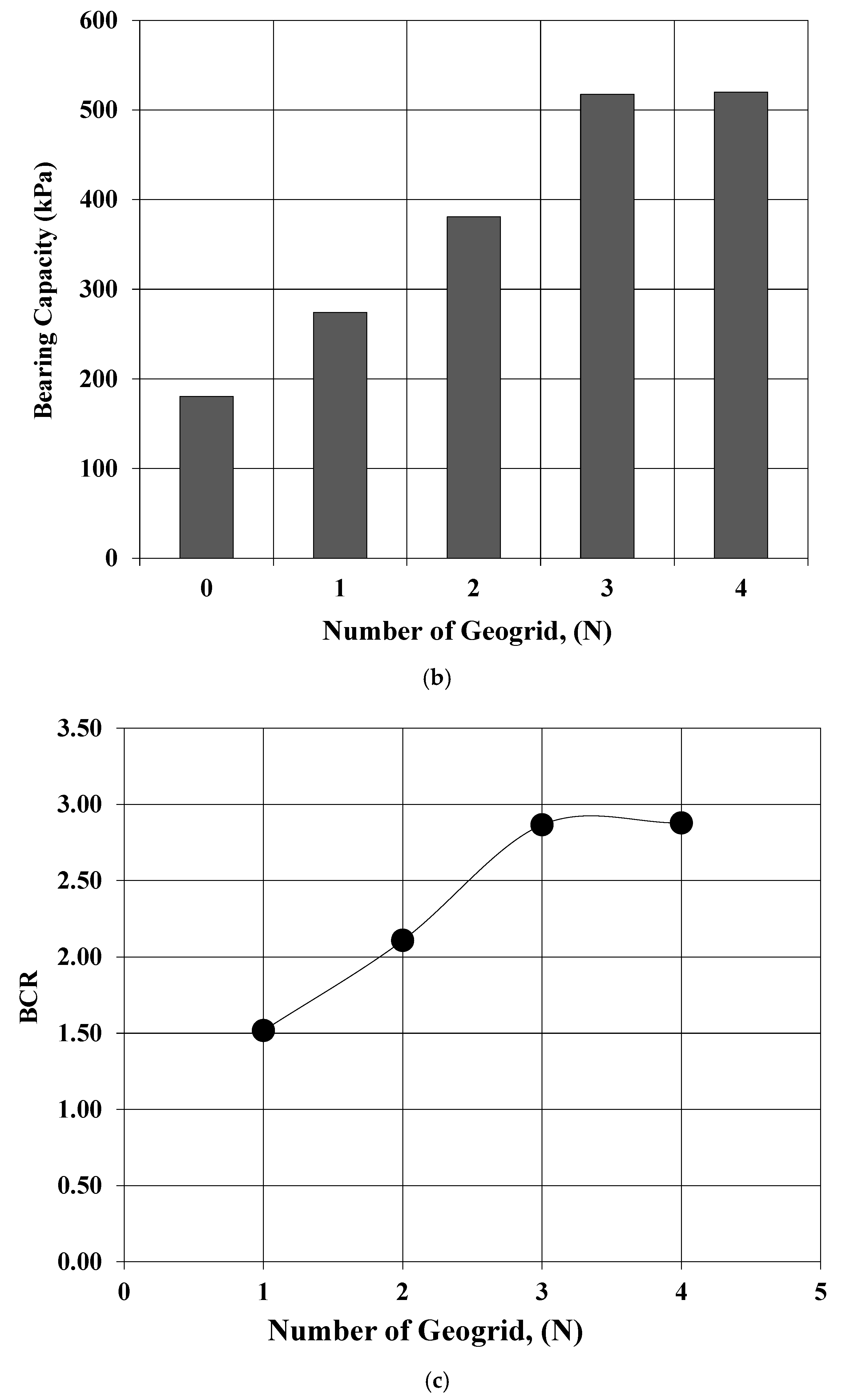

3.4. Effect of the Geogrid Layer

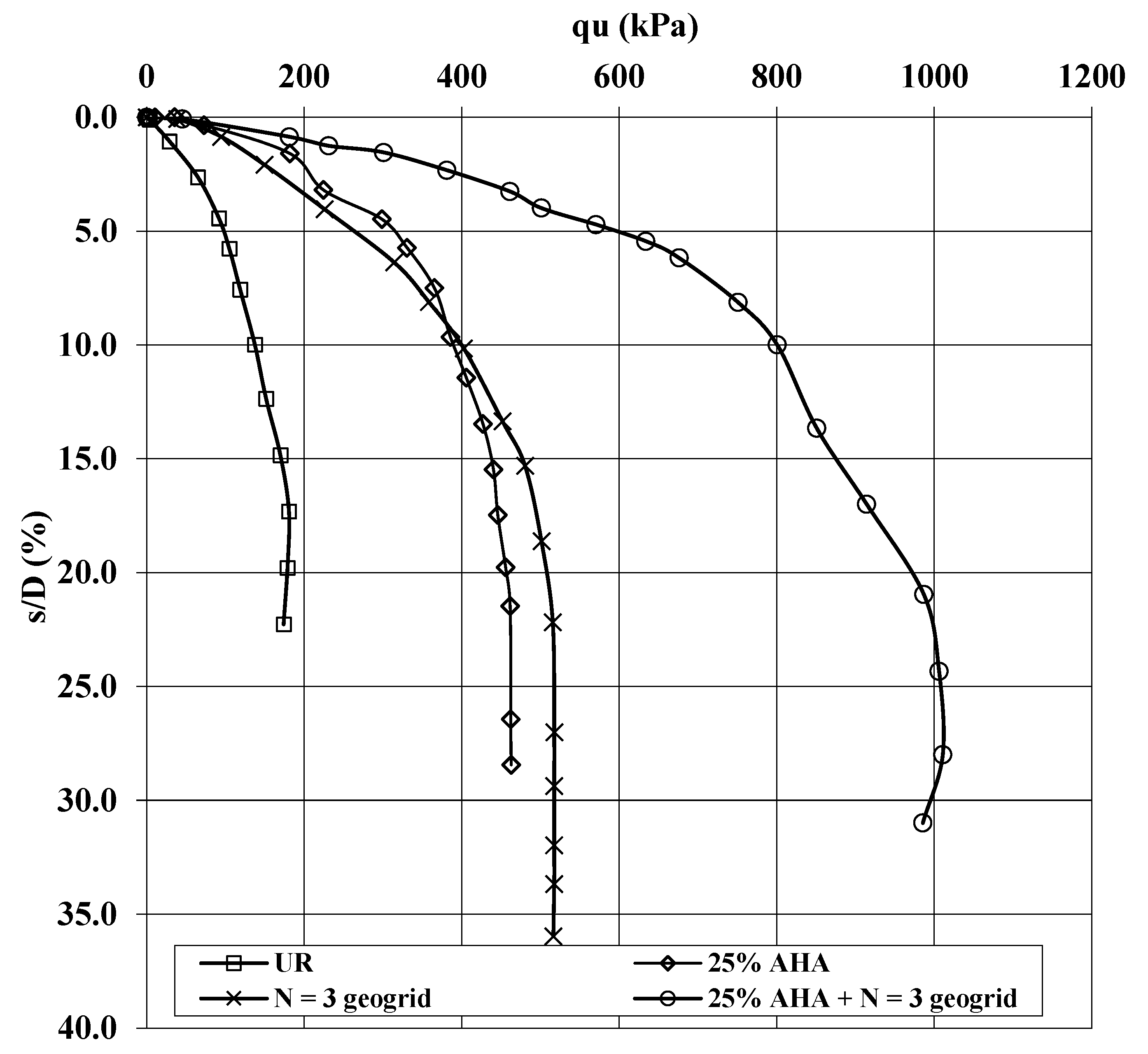

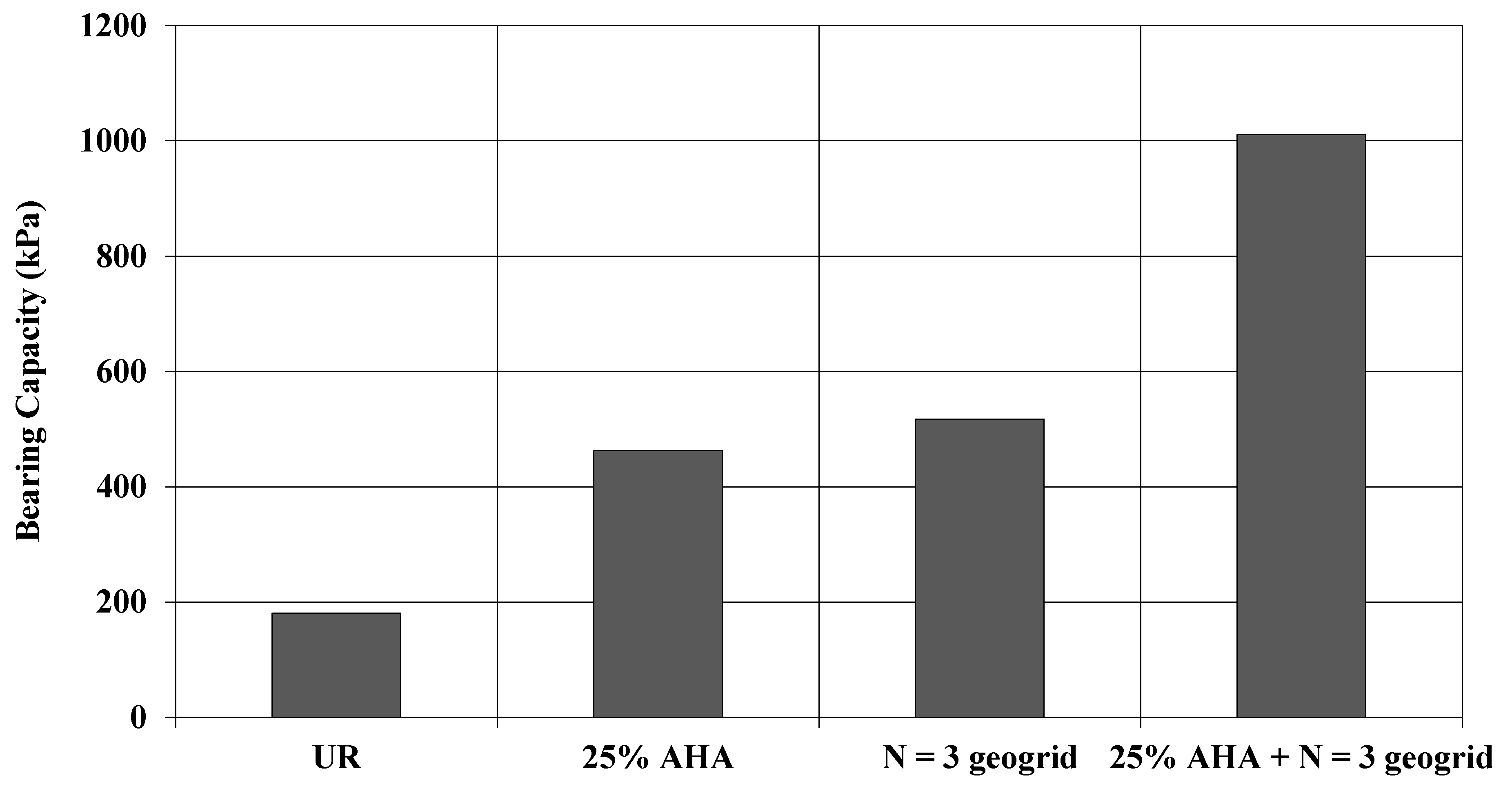

3.5. Effect of the Combination of Geogrids and AHA

4. Conclusions and Discussions

- The addition of AHA to the soil increased the optimum water content required for compaction, associated with an increase in the maximum dry density. As the AHA content rose, the water demand continuously increased, while the maximum dry density peaked at 25% AHA before declining at higher ratios. Therefore, 25% AHA was identified as the optimum content. The increased water requirement with higher AHA content is attributed to its fine-grained, porous structure and high moisture adsorption capacity.

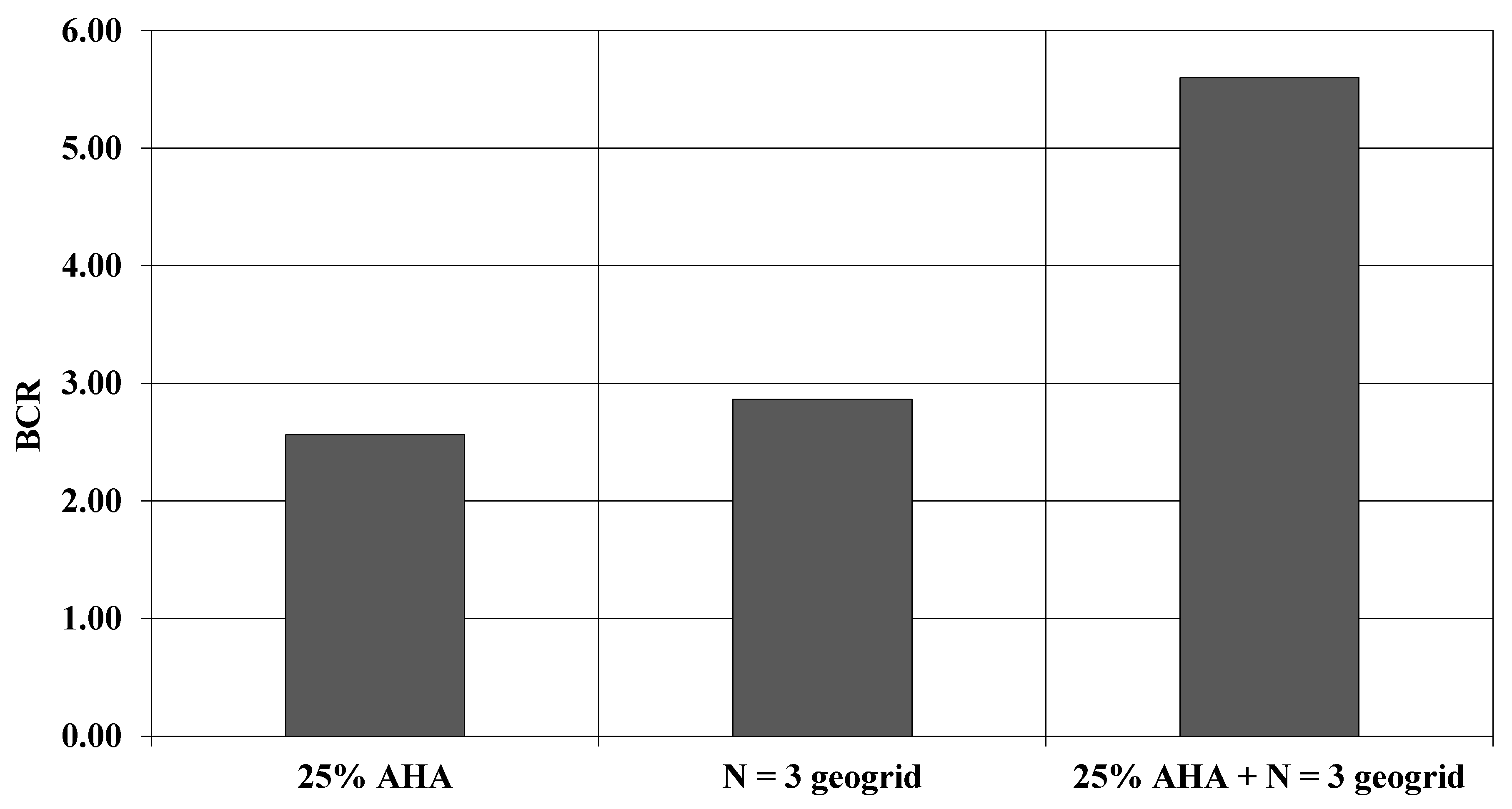

- Incorporating 25% AHA into the soil resulted in a 2.56-fold increase in the bearing capacity. This enhancement is primarily attributed to improved chemical bonding and a reduction in soil swelling.

- Increasing the reinforcement depth up to a relative depth (Rd) of 1.5 led to a 2.41-fold improvement in the bearing capacity; however, no significant gains were observed beyond Rd = 1.5, indicating this as the optimum improvement depth for AHA stabilization.

- The installation of up to four layers of geogrid reinforcement yielded bearing capacity increases of up to 2.87 times. No notable improvement was observed beyond three layers, suggesting that three geogrid layers represent the optimal configuration. Considering both performance and cost-effectiveness, three layers are recommended as the most efficient reinforcement strategy.

- The combined application of 25% AHA and three geogrid layers produced the maximum bearing capacity improvement of up to 5.60 times. AHA contributes to soil stabilization by chemically reducing swelling and enhancing bonding, while geogrids provide mechanical reinforcement and improved load distribution. The optimum AHA content aligns with previous studies on agricultural waste ashes in soil stabilization, which similarly identified 20–30% as effective for optimizing pozzolanic activity and soil-binding characteristics [18,49,50]. The enhancement in bearing capacity is supported by the high silica and alumina contents in AHA, confirmed through XRF analysis, which facilitates the formation of cementitious compounds upon hydration.

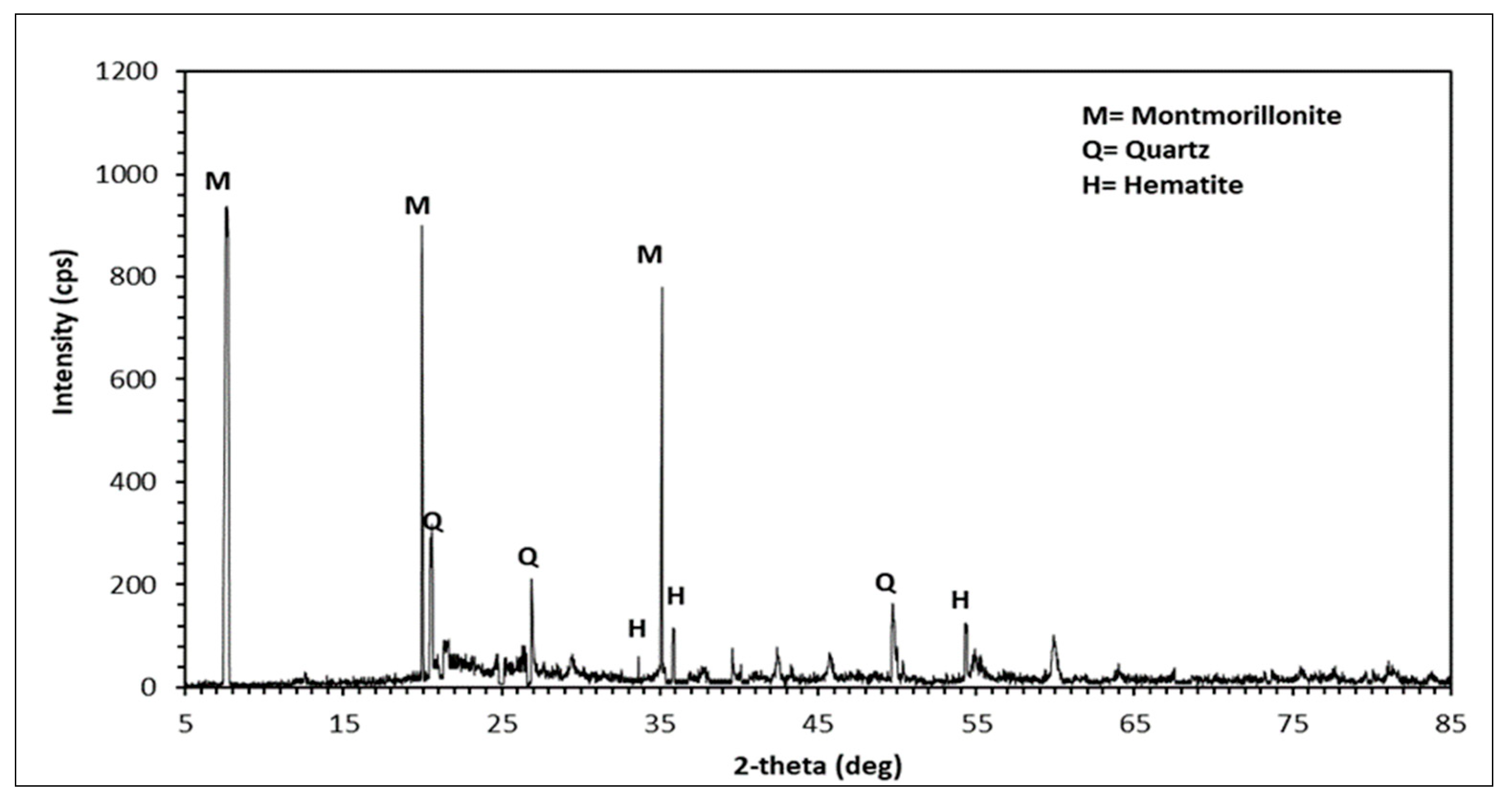

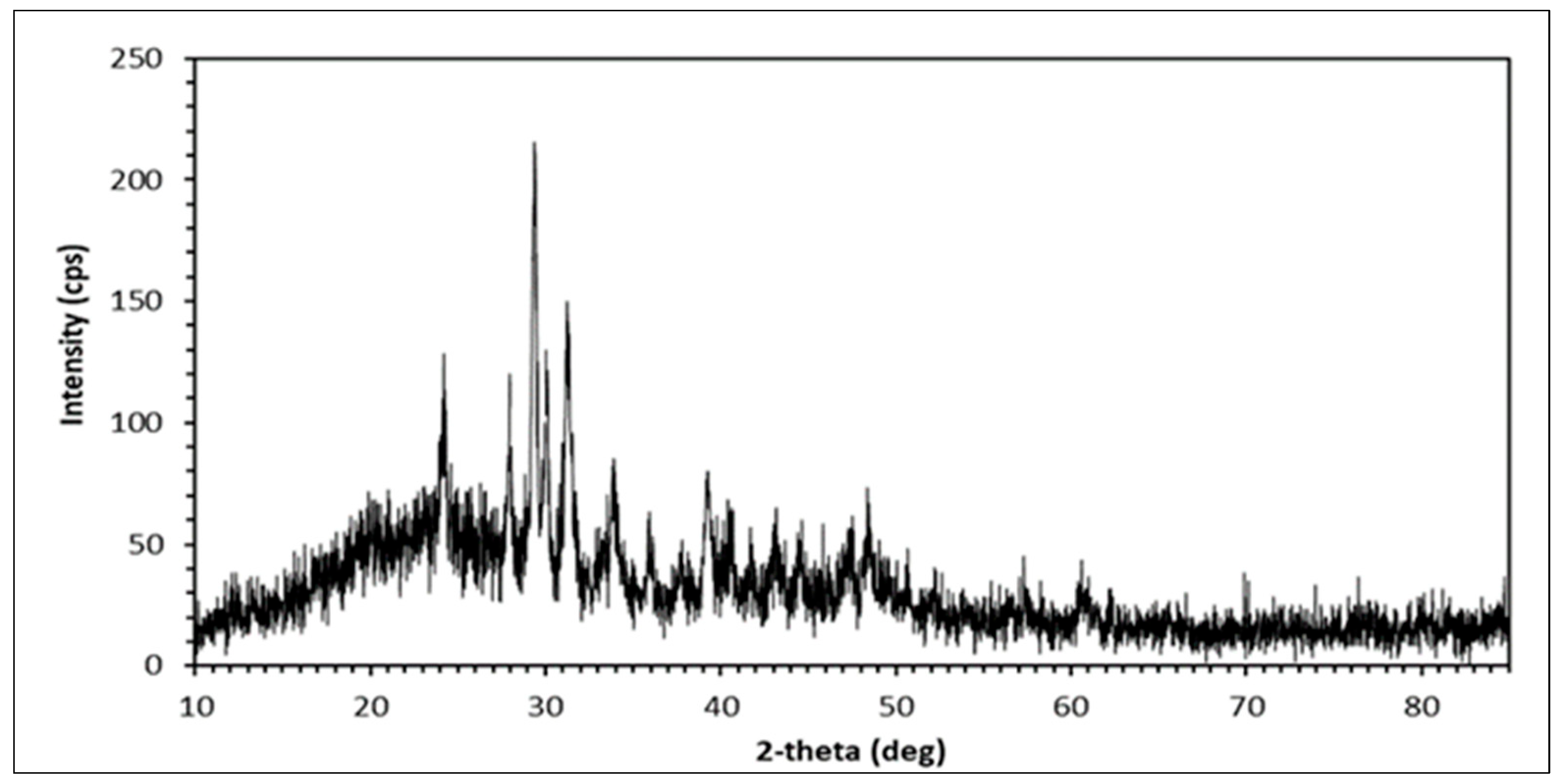

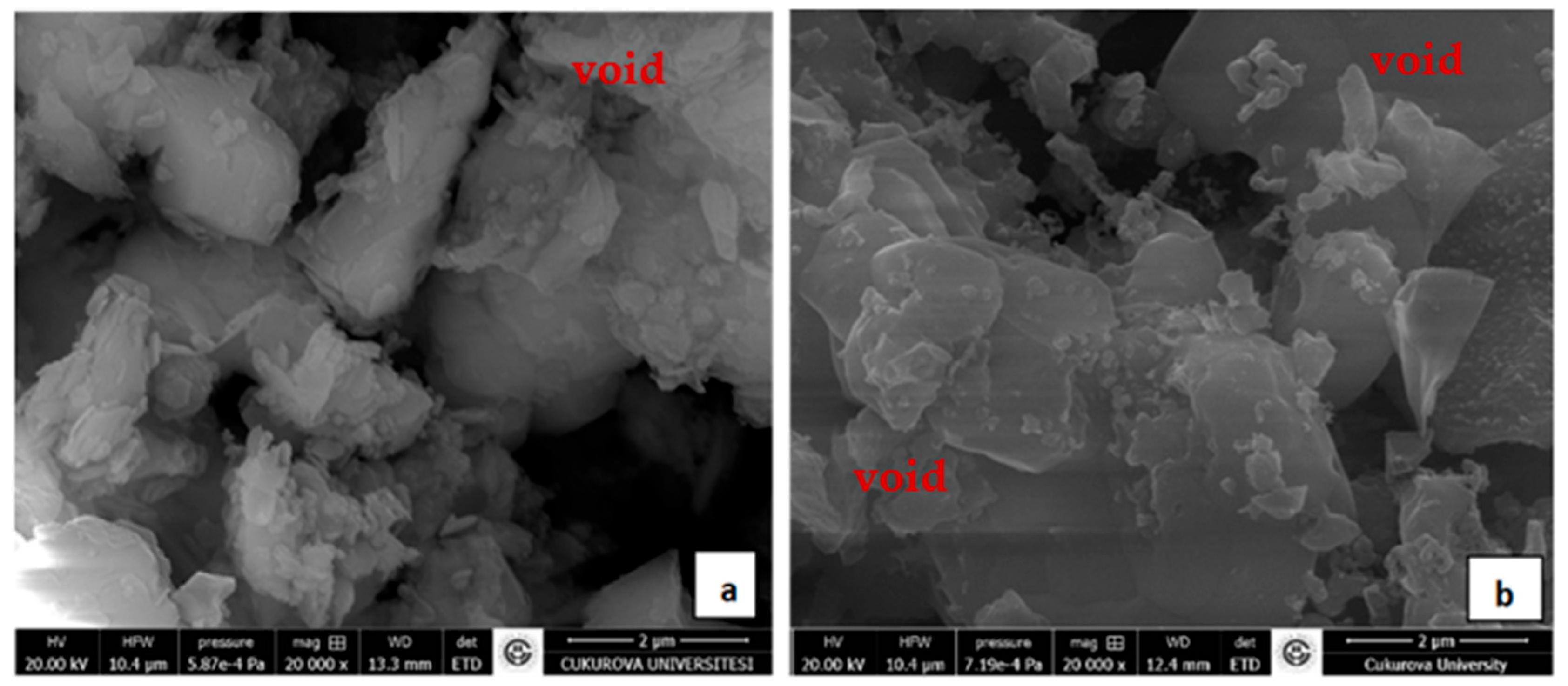

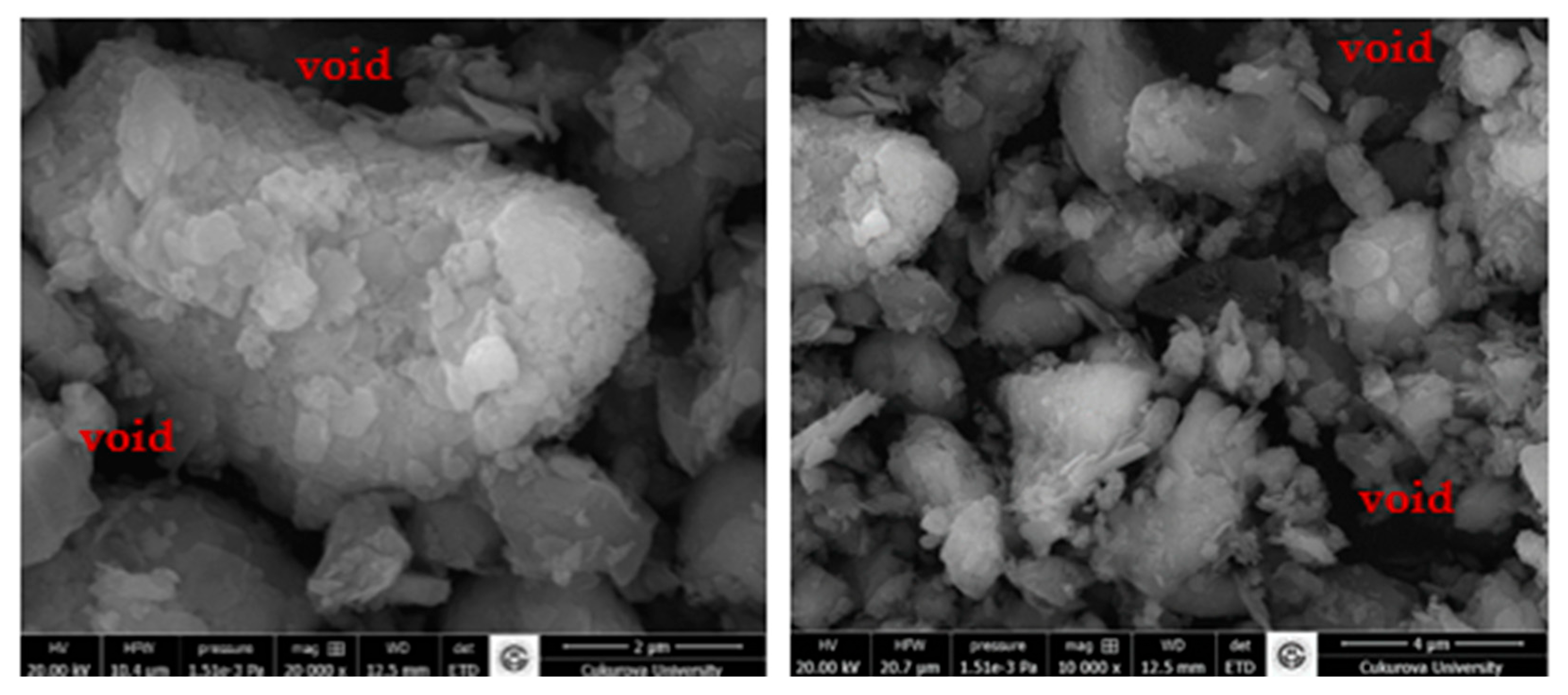

- Microstructural analyses via SEM, XRF, and XRD elucidated the mechanisms underpinning soil improvement. SEM images revealed enhanced particle bonding, reduced porosity, and increased density in AHA-treated soils. Potassium in AHA was found to reduce water absorption, while calcium promoted pozzolanic reactions forming cementitious phases that strengthen the soil matrix. XRD patterns confirmed the emergence of new crystalline phases indicative of pozzolanic activity, corroborating the macro-scale improvements in strength and stability.

- Overall, the findings demonstrate that AHA effectively stabilizes expansive soils and significantly enhances their load-bearing capacity. Additionally, the use of AHA supports sustainable construction practices by recycling agricultural waste. This aligns with environmental sustainability objectives and engineering performance demands. As a non-hazardous agricultural byproduct, AHA offers a sustainable alternative to conventional stabilizers, such as lime or cement. Its use not only valorizes waste but also mitigates the environmental impact by reducing landfill disposal [28]. This study contributes to the expanding knowledge base on agro-industrial waste application in geotechnical engineering. Future research should investigate the long-term durability, behavior under cyclic loading, and field-scale validation of the proposed stabilization method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Das, B.M. (Ed.) Geotechnical Engineering Handbook; J. Ross Publishing: Plantation, FL, USA, 2011. [Google Scholar]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; Foundation Failure; John Wiley &Sons. Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Karol, R.H. Chemical Grouting and Soil Stabilization, Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Chen, F.H. Foundations on Expansive Soils; Elsevier Publications: Maryland Heights, MO, USA, 1998. [Google Scholar]

- Cokca, E.; Yazici, V.; Ozaydin, V. Stabilization of expansive clays using granulated blast furnace slag (GBFS) and GBFS-cement. Geotech. Geol. Eng. 2009, 27, 489. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Industrial wastes as auxiliary additives to cement/lime stabilization of soils. Adv. Civ. Eng. 2016, 1, 1–17. [Google Scholar] [CrossRef]

- Mistry, M.K.; Shukla, S.J.; Solanki, C.H. Reuse of waste tyre products as a soil reinforcing material: A critical review. Environ. Sci. Pollut. Res. 2021, 28, 24940–24971. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, P.; Li, L.; Zhao, M.; Yan, P.; Liu, Y.; Zhao, Q. Soil respiration and carbon sequestration response to short-term fertilization in wheat-maize cropping system in the North China Plain. Soil Tillage Res. 2025, 251, 106536. [Google Scholar] [CrossRef]

- Cokca, E. Use of class C fly ashes for the stabilisation of an expansive soil. J. Geotech. Geoenviron. Eng. 2001, 127, 568–573. [Google Scholar] [CrossRef]

- Lin, D.F.; Lin, K.L.; Luo, H.L. A comparison between sludge ash and fly ash on the improvement in soft soil. J. Air Waste Manag. Assoc. 2007, 57, 59–64. [Google Scholar] [CrossRef]

- Keerthi, Y.; Divya Kanthi, P.; Tejaswi, N.; Shyam Chamberlin, K.; Satyanarayana, B. Stabilization of clayey soil using cement kiln waste. Int. J. Adv. Struct. Geotech. Eng. 2013, 2, 77–81. [Google Scholar]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of expansive soils using agricultural waste bagasse ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef]

- Brooks, R.M. Soil stabilization with flyash and corn waste ash–improvements in engineering characteristics. Int. J. Appl. Eng. Res. 2019, 14, 1025–1030. [Google Scholar]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Ramakrishna, A.N.; Pradeepkumar, A.V. Stabilization of black cotton soil using rice husk ash and cement. In National Conference on Civil Engineering Meeting the Challenges of Tomorrow; GND Engineering College: Ludhiana, India, 2006; pp. 215–220. [Google Scholar]

- Sharma, R.S.; Phanikumar, B.R.; Rao, B.V. Engineering behaviour of a remolded expansive clay blended with lime, calcium chloride and rice- husk ash. J. Mater. Civ. Eng. 2008, 20, 509–515. [Google Scholar] [CrossRef]

- Bagriacik, B.; Kahraman, E.; Kılıç, A.M. Large-scale experimental model study: Soil improvement with olive mill solid residue ash. Int. J. Environ. Sci. Technol. 2022, 19, 12581–12592. [Google Scholar] [CrossRef]

- Ural, N.; Karakurt, C.; Cömert, A.T. Influence of marble wastes on soil improvement and concrete production. J Mater. Cycles Waste Manag. 2014, 16, 500–508. [Google Scholar] [CrossRef]

- Gupta, C.; Sharma, R.K. Influence of marble dust, fly ash and beach sand on sub-grade characteristics of expansive soils. Int. Conf. Adv. Eng. Technol. 2014, 13–18. [Google Scholar]

- Bagriacik, B.; Güner, E.D. An experimental investigation of reinforcement thickness of improved clay soil with drinking water treatment sludge as an additive. KSCE J. Civ. Eng. 2020, 24, 3619–3627. [Google Scholar] [CrossRef]

- Mahmutluoglu, B.; Bagriacik, B. Sustainable implementation of glass manufacturing waste and geogrids in the improvement of fine-grained soils. KSCE J. Civ. Eng. 2021, 25, 1295–1307. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Latifi, N.; Vahedifard, F.; Ghazanfari, E.; Rashid, A.S.A. Sustainable usage of calcium carbide residue for stabilization of clays. J Mater. Civ. Eng. 2018, 30, 04018099. [Google Scholar] [CrossRef]

- Hu, M.; Wang, J.; Lu, L.; Gui, H.; Wan, S. Global recovery patterns of soil microbes after fire. Soil Biol. Biochem. 2023, 183, 109057. [Google Scholar] [CrossRef]

- Hu, M.; Feng, J.; Shi, Y.; Shao, P.; Chen, Z.; Zhou, Z.; Wang, J. Plant above-ground biomass drives the recovery of soil microbial communities in a subtropical-temperate transition zone following forest wildfire. Appl. Soil Ecol. 2025, 209, 106057. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Mustapha, F.; Mazlan, N.; Ishak, M.R. Rice-Husk-Ash-Based Geopolymer Coating: Fire-Retardant, Optimize Composition, Microstructural, Thermal and Element Characteristics Analysis. Polymers 2021, 13, 3747. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Das, B.M. Stabilization of expansive soil using agro-waste ash materials: A review. Constr. Build. Mater. 2021, 269, 121292. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Yilmaz, M.; Özaydın, K. Evaluation of the potential use of almond shell and husk as soil stabilizing materials. J. Clean. Prod. 2020, 258, 120685. [Google Scholar] [CrossRef]

- Wafa, B.; Bashir, A.; Nabi, S.Z. An experimental investigation of soil stabilized with almond shells: A tenable solution. Int. J. Adv. Eng. Res. Sci. 2018, 7, 528–543. [Google Scholar]

- ASTM Standard D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2007.

- Kahraman, E.; Bağrıaçık, B. Use of Wood Pellet Ash in Soil Improvement. In Proceedings of the 2nd Global Conference on Engineering Research (GLOBCER’22), Online, 7–10 September 2022; pp. 309–317. [Google Scholar]

- Dash, S.K.; Sireesh, S.; Sitharam, T.G. Model studies on circular footing supported on geocell reinforced sand underlain by soft clay. Geotext. Geomembr. 2003, 21, 197–219. [Google Scholar] [CrossRef]

- Bınquet, J.; Lee, K.L. Bearing capacity tests on reinforced earth slabs. J. Geotech. Eng. 1975, 101, 1241–1250. [Google Scholar] [CrossRef]

- Abdullah, W.S.; Al-Zou’bi, M.S.; Alshibli, K.A. On the physicochemical aspects of compacted clay compressibility. Can. Geotech. J. 1997, 34, 551–559. [Google Scholar] [CrossRef]

- ASTM Standard D698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2007.

- Abdullah, W.S.; Alshibli, K.A.; Al-Zou’bi, M.S. Influence of pore water chemistry on the swelling behavior of compacted clays. Appl. Clay. Sci. 1999, 15, 447–462. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Prasad, R.; Singh, A. Compressive load response of geogrid reinforced fine, medium and coarse sands. Geotext. Geomembr. 2009, 27, 183–186. [Google Scholar] [CrossRef]

- Latha, G.M.; Somwanshi, A.B. Bearing capacity of square footings on geosynthetic reinforced sand. Geotext. Geomembr. 2009, 27, 281–294. [Google Scholar] [CrossRef]

- Mittal, R.K.; Gill, G. Sustainable application of waste tire chips and geogrid for improving load carrying capacity of granular soils. J. Clean. Prod. 2018, 200, 542–551. [Google Scholar] [CrossRef]

- Gali, M.; Somwanshi, A. Effect of reinforcement form on the bearing capacity of square footings on sand. Geotext. Geomembr. 2009, 27, 409–422. [Google Scholar] [CrossRef]

- Akinmusuru, J.O.; Akinbolade, J.A. Stability of loaded footings on reinforced soil. J. Geotech. Eng. Div. 1981, 107, 819–827. [Google Scholar] [CrossRef]

- Guido, V.A.; Chang, D.K.; Sweeney, M.A. Comparison of geogrid and geotextile reinforced earth slabs. Can. Geotech. J. 1986, 23, 435–440. [Google Scholar] [CrossRef]

- Khing, K.H.; Das, B.M.; Puri, V.K.; Cook, E.E.; Yen, S.C. The bearing capacity of a strip foundation on geogrid reinforced sand. Geotext. Geomembr. 1993, 12, 351–361. [Google Scholar] [CrossRef]

- Khing, K.H.; Das, B.M.; Puri, V.K.; Yen, S.C.; Cook, E.E. Foundation on strong sand underlain by weak clay with geogrid at the interface. Geotext. Geomembr. 1994, 13, 199–206. [Google Scholar] [CrossRef]

- Shin, E.C.; Das, B.M.; Puri, V.K.; Yen, S.C.; Cook, E.E. Bearing capacity of strip foundation on geogrid-reinforced clay. Geotech. Test. J. 1993, 17, 535–541. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Inanir, M.; Inanir, O.E. A study on bearing capacity of randomly distributed fiber-reinforced sand fills overlying soft clay. Geotext. Geomembr. 2005, 23, 174–183. [Google Scholar] [CrossRef]

- Kolay, P.K.; Kumar, S.; Tiwasri, D. Improvement of bearing capacity of shallow foundation on geogrid reinforced silty clay and sand. J. Constr. Eng. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of Rice Husk Ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int. J. Geo-Eng. 2022, 13, 4. [Google Scholar] [CrossRef]

- Zlatanović, E.; Marinković, N.; Bonić, Z.; Romić, N.; Djorić-Veljković, S.; Cvetković, D.; Djordjević, D. Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique. Appl. Sci. 2024, 14, 6249. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Roselló, J.; Borrachero, M.V.; Font, A.; Soriano, L. Sustainable soil-compacted blocks containing blast furnace slag (BFS) activated with olive stone biomass ash (OBA). Sustainability 2020, 12, 9824. [Google Scholar] [CrossRef]

- Abhishek, A.; GuhaRay, A.; Hata, T.; Abuel-Naga, H. Microstructural Characterization of Expansive Soil Stabilized with Coconut Husk Ash: A Multi-Technique Investigation into Mineralogy, Pore Architecture, and Surface Interactions. Minerals 2025, 15, 516. [Google Scholar] [CrossRef]

- Fastelli, M.; Cambi, C.; Zucchini, A.; Sassi, P.; Pandolfi Balbi, E.; Pioppi, L.; Cotana, F.; Cavalaglio, G.; Comodi, P. Use of biomass ash in reinforced clayey soil: A multiscale analysis of solid-state reactions. Recycling 2023, 8, 5. [Google Scholar] [CrossRef]

| (%) | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | MnO | Fe2O3 | Na2O | TiO2 | SO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ES | 6.10 | 18.4 | 50.60 | 0.65 | 3.10 | 3.20 | 3.10 | 8.70 | 2.50 | 1.65 | - | 3.15 |

| AHA | 3.39 | 1.01 | 12.30 | 2.70 | 48.3 | 20.5 | 0.05 | 2.35 | 1.60 | 0.27 | 0.80 | 6.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ürünveren, A.; Bağrıaçık, B.; Kahraman, E. Investigation of the Effects of Almond Husk Ash on the Engineering Properties of Expansive Soil. Buildings 2025, 15, 2384. https://doi.org/10.3390/buildings15142384

Ürünveren A, Bağrıaçık B, Kahraman E. Investigation of the Effects of Almond Husk Ash on the Engineering Properties of Expansive Soil. Buildings. 2025; 15(14):2384. https://doi.org/10.3390/buildings15142384

Chicago/Turabian StyleÜrünveren, Abdulkadir, Baki Bağrıaçık, and Esma Kahraman. 2025. "Investigation of the Effects of Almond Husk Ash on the Engineering Properties of Expansive Soil" Buildings 15, no. 14: 2384. https://doi.org/10.3390/buildings15142384

APA StyleÜrünveren, A., Bağrıaçık, B., & Kahraman, E. (2025). Investigation of the Effects of Almond Husk Ash on the Engineering Properties of Expansive Soil. Buildings, 15(14), 2384. https://doi.org/10.3390/buildings15142384