Abstract

The rapid growth of the global population and associated increases in resource consumption have accelerated environmental degradation, making sustainable design and construction processes increasingly essential. The construction sector holds significant potential for reducing environmental impacts, especially through sustainability-focused certification systems such as LEED. This study evaluates the projected energy efficiency and sustainability performance of the Surgical Sciences Building at Istanbul University’s Çapa Campus, which was designed with the goal of achieving LEED Gold certification. The assessment is based on design-phase data and conducted prior to construction. Energy performance analyses were carried out using DesignBuilder software, supported by the LEED Assessment Report and Energy Audit Report. According to simulation results, approximately 30% savings in energy consumption and water usage are expected. In addition, the process-oriented LEED approach is expected to result in a total CO2 emission savings of approximately 570 tonnes, while renewable energy systems are expected to meet approximately 13% of the building’s primary energy demand and reduce CO2 emissions by approximately 151 tonnes per year. Waste management strategies developed for both the construction and operational phases are aligned with LEED criteria and aim to achieve up to 80% recycling rates. The findings demonstrate that LEED certification, when employed as a process-oriented design and decision-making tool rather than a result-oriented label, can enable sustainable strategies to be integrated from the earliest stages of project development. Particularly for complex healthcare buildings, embedding LEED principles into the design process has strong potential to enhance environmental performance. Although based on a single case study, this research provides valuable insight into the broader applicability of LEED in diverse building types and geographic contexts.

1. Introduction

The rapidly growing world population is expected to reach 9.73 billion by 2064 [1]. The growing population is also increasing demand for societies’ needs, goals, and priorities. To meet these demands and ensure competitiveness, the rapid growth of technology and industry has led to a natural increase in CO2 emissions and waste, which recently has threatened humanity’s future in terms of sustainability. According to a report prepared by the International Solid Waste Association (ISWA), the amount of municipal solid waste worldwide is expected to reach 3.8 billion tonnes by 2050 [2]. The report also estimates that sustainable practices, primarily through waste avoidance and comprehensive waste management, could save 108.5 billion dollars annually. Construction and demolition waste accounts for 30–40% of solid waste (67% in America, 36% in Europe, and 30–40% in China), and only 20–30% of this waste can be recycled [3]. If equipped with sustainable design and construction processes, the construction sector has the potential to save approximately 44 billion dollars annually in the global economy, based on this information. Additionally, the construction sector is a sector where disputes frequently occur due to its multi-stakeholder structure and the risks it entails [4,5]. These disputes lead to the cancellation or delayed completion of public and private construction projects, as well as defective and flawed construction, resulting in financial and emotional losses [6]. By implementing sustainable design and construction processes, construction disputes can be prevented, thereby avoiding financial and non-financial losses. The construction sector has the potential to save approximately 44 billion dollars annually by adopting sustainable design and construction processes. Additionally, there is an opportunity to reduce energy consumption in the construction sector by 24% [7].

In order to ensure the design and construction of sustainable buildings, it is necessary to define buildings in detail, covering the design and construction processes. The world’s leading assessment system, Leadership in Energy and Environmental Design (LEED), stands out as the system used to evaluate a total of 105,712 buildings to date [8]. In addition to Türkiye not having its own assessment system, the LEED system has been in high demand in recent years. Currently, 1969 buildings based in Türkiye have been assessed, and 15 of these are healthcare buildings have been certified [8]. With the increasing interest in LEED certification in Türkiye, the number of Türkiye-based studies on energy efficiency and LEED certification applications has increased in recent years. In a preliminary study, the development levels of certification systems were examined from the perspective of developing countries (Türkiye, the United Arab Emirates, and India), and the levels of the three developing countries were compared [9]. Aktas and Ozorhon [10] examined the factors contributing to buildings obtaining LEED certification and the challenges faced in six LEED-certified projects in Türkiye. In addition, a performance comparison was made between LEED-NC 2009-certified construction projects in four different countries, including new construction projects in Türkiye, in an effort to understand the differences affecting the performance of projects in different regions [11]. It was observed that sustainable building designs and certification strategies may vary by country depending on the type of project [12]. An analysis of the applicability of LEED’s sustainability strategies in the material-selection preferences of 269 LEED-certified projects in Türkiye was conducted, focusing on many categories examined by LEED for sustainable buildings [13]. A study on which criteria should be prioritised for LEED certification of healthcare buildings in Türkiye also indicates that LEED certification is becoming increasingly important in the healthcare sector [14].

A review of the existing literature reveals that studies have been conducted on certified buildings. The absence of studies demonstrating that LEED certification is not only a results-oriented but also a process-oriented tool is noteworthy. LEED’s main strength lies in the decisions made during the design phase and the impact of these decisions on construction projects. The originality of this study lies in addressing the gap in the literature by examining the LEED compliance of a public hospital project during the construction phase. The aim of the study is to demonstrate that LEED is not merely a certification awarded to completed buildings but can also serve as a process management tool capable of shaping project decisions in early stages. To this end, the energy efficiency and sustainability performance of the Surgical Sciences Building at Istanbul University’s Çapa Campus will be examined using LEED assessments and Energy Audit Reports. By doing so, the study aims to fill gaps in the existing literature, promote a process-oriented sustainability approach, and offer recommendations for improving green building practices in Türkiye.

2. Materials and Methods

The study examined the Istanbul University Çapa Campus Surgical Sciences Building using the case-study method. In this study, two reports were used: the ‘LEED Assessment Report’ and the ‘Energy Audit Report’ for the Surgical Sciences Building at Istanbul University Istanbul Faculty of Medicine Çapa Campus. All data related to the building were obtained from the LEED Assessment Report and the Energy Audit Report. The LEED Assessment Report details how the building was evaluated and scored according to LEED criteria, while the Energy Audit Report provides a detailed overview of the building’s current energy consumption and energy-saving potential.

The energy performance assessment was conducted using DesignBuilder v7. The simulation study was carried out using the TR_ATATURK-AIRPORT_TMY weather file, which represents the local climate conditions of the project site in Istanbul. The modelled building consists of 283 distinct thermal and HVAC zones; each defined according to the specific functional requirements of the hospital’s spatial programme. Heating and cooling setpoint temperatures were maintained at 21 °C and 25 °C, respectively, to reflect health standards and occupant comfort. Occupant density varies by room type, with an average of approximately 18 m2 per person. Operating schedules also vary depending on space usage. Critical areas such as inpatient rooms are assumed to be occupied 24 h a day, while examination rooms, operating rooms, and general shared areas are modelled with a typical daily occupancy rate of 15 h (06:00–23:00) in line with realistic hospital workflows.

The campus coordinates are approximately 41.015° N latitude and 28.940° E longitude, and it is located at an elevation of approximately 55–65 metres above sea level (Figure 1). The area is part of a gently sloping urban plateau facing south towards the Marmara Sea and is approximately 4 kilometres away in a straight line. Located on the historic peninsula of Istanbul, the Fatih district experiences a humid subtropical/temperate oceanic climate (classified as Cfa/Cfb under the Köppen–Geiger climate classification system), influenced by both Mediterranean and Black Sea climate zones. The district stretches along Istanbul’s southern coastline and is densely built-up with limited wind corridors and high urban-heat-island effects. Annual average temperatures range between 14 °C and 16 °C, with January being the coldest month (average ~6 °C) and July–August the hottest (average ~25 °C). Heating is typically required from mid-October to early April, while cooling demand peaks during the summer months, particularly in enclosed, high-occupancy areas such as hospitals.

Figure 1.

A Google Earth View of Cerrahi Bilimler Building at Istanbul University.

The energy performance assessment was carried out by DesignBuilder. Figure 2 shows a screenshot from the modelling process. The software is equipped with all the capabilities specified in the G2 Simulation General Requirements of the ASHRAE 90.1-2010 standard [15], which is widely used in Türkiye. In recent years, the ASHRAE 90.1-242 (2022) standard, which treats healthcare facilities as a separate category, has been published.

Figure 2.

DesignBuilder modelling screen.

The reason for using the ASHRAE 90.1-2010 standard instead of this updated standard is that the former is still in use in current applications in Türkiye and the relevant public institutions have not yet integrated the new standard. The use of a similar standard in recent studies [16,17] also indicates this. During the simulation, reference values obtained from ASHRAE for similar structures were used to determine the energy efficiency of the building when it meets the minimum criteria, and the extent to which the designed building meets these criteria was evaluated. ASHRAE’s reference values are provided in Table 1.

Table 1.

Reference values from ASHRAE 90.1.2010.

3. Results

The Surgical Sciences Building has a model area of 23,930 m2. The building consists of a total of 10 floors, including 3 floors above ground level and a service floor, and below ground level, a basement, floors 1-2-3, and an isolator floor (Figure 3 and Figure 4). The building has 125 patient beds, 23 intensive care units, and 14 operating rooms. The ground floor consists of a cafeteria, administrative units, endoscopy, urology endoscopy, and breast ultrasound departments. Floors 1-2-3 are planned as patient floors. Each floor has 24 rooms/34 beds, for a total of 72 rooms/102 beds. The utility floor includes a staff dining hall, administrative offices, and technical spaces. The mechanical floor includes a staff cafeteria, administrative offices, and technical areas. The basement floor, which is levelled at −5.00, is defined by an entrance area accessible from within the campus. It consists of an imaging unit and intensive care units. There are a total of 23 intensive care beds and support areas. The imaging unit consists of 1 MRI, 1 CT scan, 2 ultrasound, 2 X-ray, and 2 angiography rooms. The first basement floor has 13 operating rooms, 1 caesarean section operating room, and 2 delivery rooms. The second basement floor has technical areas and sterilisation facilities. Meals are prepared off-site and delivered to the campus. There is a meal distribution area. The third basement floor has a 30-car indoor car park and an archive.

Figure 3.

A 3D View of Cerrahi Bilimler Building at Istanbul University.

Figure 4.

The Çapa Campus of Cerrahi Bilimler Building at Istanbul University (DesignBuilder).

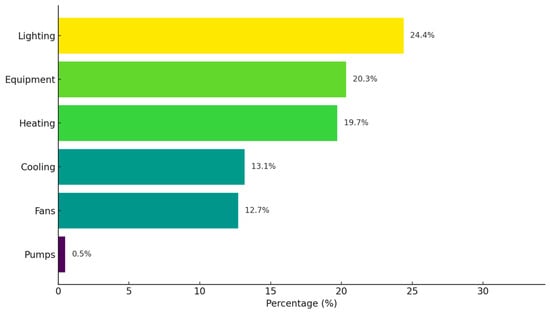

The highest energy consumption in the building is related to lighting, equipment, heating, cooling, fans, and pumps (Figure 5). As a result of the LEED assessment, there are four different certification levels (Table 2). These are 1. Certified (40–49 points), 2. Silver (50–59 points), 3. Gold (60–79 points), 4. Platinum (80–110 points). The LEED criteria for determining these levels are grouped under the following categories:

Figure 5.

The distribution of the building’s energy consumption.

Table 2.

LEED Certification Levels by Points.

The scoring for LEED certification, as shown in Table 3, reveals the results for the Cerrahi Bilimler Hospital. Based on these results, the LEED criteria are grouped under the following categories:

Table 3.

Distribution of energy consumption.

- Integrative Process:

- ○

- Includes an early analysis of inter-system relationships in order to achieve project results at the desired cost, time, and quality.

- 2.

- Location and Transportation:

- ○

- Includes an evaluation of criteria such as access to quality transportation and the presence of electric vehicles in the project’s location and transportation sections.

- 3.

- Sustainable Sites:

- ○

- Includes an assessment aimed at reducing the effects of deformations such as soil erosion caused by the implementation of the project, protecting natural and historical areas, and creating areas where social and cultural activities can be carried out.

- 4.

- Water Efficiency:

- ○

- Includes an assessment of reducing outdoor water consumption, protecting zero- and low-cost drinking water sources, and water conservation.

- 5.

- Energy and Atmosphere:

- ○

- Includes an assessment of ensuring minimum energy performance, designing an energy project that meets project requirements, and optimising energy performance.

- 6.

- Materials and Resources:

- ○

- Includes an assessment of the storage and collection of recycled waste, the provision of environmental product declarations, and the reduction in the impact of the building’s life cycle.

- 7.

- Indoor Environmental Quality:

- ○

- Includes an assessment aimed at ensuring minimum indoor air quality performance in the project, controlling tobacco smoke, and controlling the use of low-emission materials.

- 8.

- Innovation in Design:

- ○

- Includes an assessment aimed at encouraging innovative design strategies that provide high-level benefits to people and the environment in the project.

- ○

- No bolding necessary. Removed.Includes an assessment aimed at promoting projects targeting geographically prioritised areas.

Categories 4, 5, 6, and 7 (Figure 6) are directly related to energy efficiency, materials and resources, and waste management. The total score defined for these categories is 81, and a LEED Platinum certification can only be obtained with a full score from these categories. When examining the Energy and Atmosphere category, it alone accounts for a significant 35 points (32%) of the total scoring (Figure 6).

Figure 6.

LEED v4 for BD + C: Healthcare Project Checklist.

Due to this high proportion, analyses focused on energy efficiency are of great importance. Within this scope, the building achieves the following energy savings compared to the reference criteria by measuring usage based on operating hours and incorporating renewable energy sources (Table 3).

Based on the findings, the annual primary energy consumption for the Surgical Sciences Building was calculated to be 2,719,712.08 kWh/year, according to the preliminary energy performance certificate calculation. The primary energy contribution of the planned photovoltaic systems (PV) for the Surgical Sciences Building has been determined to be 340,938 kWh/year. The simulation of the PVs was carried out using PVsyst version 7.4, a widely recognised software tool for the examination, sizing, and analysis of PV systems. PVsyst provides detailed modelling capabilities, including hourly energy yield simulations based on location-specific meteorological data, shading analysis, module orientation, tilt angle, system losses, and inverter configurations. In our study, simulation parameters were carefully defined, considering the site’s exact geographical coordinates, local solar radiation data, system design characteristics (such as PV module type, string configuration, and inverter selection), and detailed loss factors (including temperature-related losses, soiling, mismatch, and cable losses). It is expected that the planned PVs will meet approximately 13% of the building’s primary energy needs from renewable sources (Figure 7). The rooftop PV system, consisting of 848 panels, has a total installed capacity of 254 kWp and is expected to produce 340,938 kWh of energy per year. The panels will be installed on the roof at a 30°/45° angle, and no shading is expected. Additionally, a 32.4 kWp solar collector system is planned for hot-water production, with 20 solar collectors expected to generate 46,620 kWh of energy annually. The collectors have a maximum hourly energy output of 32.4 kW, an average daily output of 259 kWh/day, and are expected to save 46,620 kWh of energy annually.

Figure 7.

PV Panel Feasibility Report.

Based on monthly rainfall data obtained from meteorological records at the Florya Meteorological Station, the nearest official measurement station to Istanbul University’s Çapa Campus [18], the amount of rainwater that can be collected from a 2302 m2 roof area has been calculated (1):

ER: Annual rainfall amount (lt);

AA: Rainwater collection area (m2);

e: Roof efficiency coefficient;

hN: Annual rainfall amount (lt/m2);

η: Filter efficiency coefficient (0.90).

The irrigation water requirement is met from water sources provided by the municipality. Rainwater harvesting will be carried out using a 20,000-litre rainwater tank to meet irrigation needs. The annual rainwater total is expected to be 1,144,462 litres, and 26.13% of the building’s water requirement is expected to be met through rainwater harvesting.

The Surgical Sciences Building scored 9 points in the water efficiency category, achieving a reduction in water consumption of approximately 30%. Waste management strategies have been considered for both the construction and operation phases of the Surgical Sciences Building. During construction, a Waste Management Plan was prepared to ensure the separation, tracking, and recycling of construction and demolition waste. The goal is to divert 75% of total construction waste from landfills. The building was designed with waste separation areas, including dedicated spaces for recyclable and medical waste, during the construction process. An Operational Waste Management Plan has also been developed, supported by staff training and regular monitoring, which achieves an estimated 80% recycling rate for non-hazardous waste. These strategies are consistent with LEED requirements and significantly contribute to the project’s sustainability goals. These findings demonstrate that the building has achieved its sustainability goals in terms of waste management. Although it has been found that some LEED-certified buildings consume more energy than non-certified buildings [19], the relationship between energy efficiency and LEED scores has also been examined. LEED-certified buildings generally show a 18–39% reduction in energy consumption compared to non-certified buildings, regardless of certification level [20]. The findings confirm that the high energy efficiency of the Surgical Sciences Building is consistent with its high LEED score potential. In this context, a positive relationship between energy efficiency and LEED certification has been observed.

Energy modelling studies conducted for the Surgical Sciences Building located at Istanbul University’s Çapa Campus provide important information about the current state of the building and the strategies planned to reduce its carbon footprint. A detailed analysis of carbon emissions from electricity and natural gas consumption demonstrates LEED compliance during the design process. As a result of the design process, annual natural gas consumption was reduced from 1,575,562.06 kWh in the reference to 877,305.78 kWh in the design, achieving a 44.32% performance improvement. Based on the emission factor (0.234 kg CO2/kWh [21]), this resulted in a CO2 emission savings of 163,391.969 kg CO2/kWh CO2 emissions were saved. Similarly, the annual total energy consumption was 3,292,157.12 kWh, while in the design it was reduced to 2,719,712.08 kWh, achieving a 17.39% performance improvement. Based on the emission factor (0.442 kg CO2/kWh [22]), this resulted in a CO2 emission savings of 253,020.707 kg CO2/kWh. A total CO2 emission savings of 416,412.676 kg CO2/kWh was achieved through the design effect. Additionally, two energy simulation scenarios were developed using DesignBuilder software to assess the impact of the installed PV system: i. A baseline model without renewable systems; ii. The proposed model integrating rooftop PV panels. The annual energy production from PV was simulated to be approximately 340,938 kWh. This amount was subtracted from the building’s total electricity demand. Based on the emission factor for electricity (0.442 kg CO2/kWh), it is estimated that the PV system will reduce annual CO2 emissions by approximately 150,694.596 kg CO2/kWh compared to the baseline scenario. It is estimated that a total CO2 emission savings of 567,107.272 kg CO2/kWh will be achieved through the design-induced savings. These technologies not only reduce carbon emissions but also contribute to energy independence. The building’s energy performance, evaluated according to the ASHRAE 90.1 standard, shows a 26.10% improvement in energy consumption. This improvement highlights the project’s priority on energy efficiency and sustainability. Based on the findings, it is clear that LEED certification has positive effects on energy efficiency, water efficiency, and waste management, and makes significant contributions to improving the sustainability performance of buildings.

4. Discussion

In this study, the Surgical Sciences Building located at Istanbul University’s Çapa Campus was evaluated in terms of energy efficiency, materials and resources, water efficiency, and sustainability performance using LEED certification standards, and its LEED compliance was examined. The findings show that the design process was found to be in compliance with LEED criteria. This compliance also has the potential to achieve a high score. This demonstrates that LEED certification is an effective process-oriented tool for improving the environmental sustainability of buildings. The use of LEED certification as a process-oriented rather than results-oriented tool has revealed that important decisions in line with LEED criteria can be made prior to implementation. In particular, the approximately 30% reduction in the building’s energy and water consumption is consistent with the results of similar studies documented in the literature to date.

However, there appears to be no consensus in the literature on whether a results-oriented approach to LEED certification is effective in achieving energy efficiency. Amiri and Ottelin [23] found that LEED-certified buildings achieved energy savings ranging from 18% to 39%. In contrast, Scofield [19] claimed that some LEED-certified buildings did not meet the expected energy savings. A result-oriented approach revealed inconsistent results, as the effectiveness of LEED certification may vary on a project-by-project basis. Instead, this study suggests that using LEED certification with a process-oriented approach would eliminate this inconsistency. Similarly, in terms of energy and water efficiency, a significant reduction of approximately 30% in energy and water consumption in buildings demonstrates the positive impact of LEED certification on the efficient use of energy and water resources. This aligns with the findings of Gurgun and Polat [24], who demonstrated that Turkish construction projects with LEED certification excel in water efficiency. A 75% construction waste recycling rate and an 80% operational recycling rate in waste management demonstrate the positive impact of LEED certification on waste management practices. This observation is consistent with the existing literature. Ghisellini and Cialani [25] have highlighted the benefits of using a circular economy approach in waste management. This research demonstrates that LEED certification is necessary to achieve sustainability goals in waste management. Additionally, the presence of renewable energy sources was found to meet 12.54% of the building’s energy needs and facilitate a reduction of approximately 151 tonnes of CO2 emissions. Zuo and Zhao [26] align with the current study in highlighting the increasing integration of renewable energy systems into sustainable buildings. These alignments support the idea that the LEED certification can be considered a process-oriented tool applicable across various geographical regions and climates, enabling effective outcomes in energy efficiency, waste management, and water efficiency. The findings of this study reveal that the standards and technical specifications used in the design of the public hospital align with LEED criteria. This study has identified the potential for an implicit sustainability approach in the public hospital project through document-based analysis.

5. Conclusions

In this study, the energy efficiency, materials and resources, water efficiency, and sustainability performance of the Istanbul University Çapa Campus Surgical Sciences Building were measured according to the LEED certification system. As a result of the measurements, the LEED certification compliance of the project was examined at the design stage. The results showed that LEED certification is a successful tool for improving the environmental performance of buildings as a process-oriented tool. The approximately 30% reduction in energy and water consumption in the building is consistent with studies in the literature. The current study contributes significant evidence to the effectiveness and efficiency of the LEED certification system. Additionally, the use of renewable energy sources, which account for 12.54% of the building’s total energy consumption and save approximately 151 tonnes of CO2, demonstrates the significant contribution of renewable energy systems to achieving sustainability goals. Consequently, it is anticipated that the process-oriented LEED procedure will reduce CO2 emissions by approximately 570 tonnes. The study offers a different approach to the effectiveness debates in the literature by using LEED certification as a process-oriented tool rather than a results-oriented one. The study provides realistic outputs through a special energy simulation for a hospital typology comprising 283 thermal and HVAC zones. A process-oriented LEED-based energy performance analysis offers decision-makers the opportunity for early intervention in a project during the construction phase. This study is unique in that it analyses and simulates PV systems not only from an energy perspective but also from a carbon footprint perspective in terms of carbon dioxide emissions. The simulation of the design phase of public hospitals in Türkiye for LEED-targeted facilities is a pioneering study.

However, the study has some limitations, such as the use of a single case study and dependence on certain assumptions (i. The assumption that energy systems will operate at constant efficiency; ii. The assumption that user behaviour is homogeneous; iii. The assumption that user behaviour is based on hospital building typologies and standard healthcare usage models; iv. The assumption that equipment power is calculated using values taken from standard guidelines and internal loads are used) have been incorporated into the simulation model. The validation of simulation results has not been conducted at this stage, as the building is still under construction. The project has recently progressed from the final design phase to the implementation phase, and therefore, there is currently no post-occupancy measured energy consumption data available to support a comparative evaluation or calibration of the simulation model. However, once the building is operational and sufficient monitoring data has been collected, a validation study will be conducted to ensure the accuracy and reliability of the simulation results. In future studies, the effects of using LEED certification as a process-oriented tool can be examined by investigating its effects on various building types (e.g., residential and industrial buildings) and various geographical locations.

Author Contributions

Conceptualization, C.A. and M.S.; methodology, C.A. and M.S.; validation, C.A. and M.S.; formal analysis, C.A. and M.S.; investigation, C.A. and M.S.; resources, C.A.; data curation, C.A.; writing—original draft preparation, M.S.; writing—review and editing, C.A. and M.S.; visualisation, C.A. and M.S.; supervision, C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be made available on reasonable request.

Acknowledgments

We would like to express our sincere gratitude to the Istanbul University Rectorate, Department of Construction and Technical Affairs, and Aymaz Architecture for their contributions in providing the project data used in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vollset, S.E.; Goren, E.; Yuan, C.-W.; Cao, J.; Smith, E.A.; Hsiao, T.; Bisignano, C.; Azhar, G.S.; Castro, E.; Chalek, J.; et al. Fertility, mortality, migration, and population scenarios for 195 countries and territories from 2017 to 2100: A forecasting analysis for the Global Burden of Disease Study. Lancet 2020, 396, 1285–1306. [Google Scholar] [CrossRef] [PubMed]

- ISWA. Global Waste Management Outlook 2024: Beyond an Age of Waste, Turning Rubbish into a Resource; ISWA: Rotterdam, The Netherlands, 2024. [Google Scholar]

- López Ruiz, L.A.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Sarı, M.; Sayın, B.; Akçay, C. Classification and resolution procedure for disputes in public construction projects. Revista de la Construcción. J. Constr. 2021, 20, 259–276. [Google Scholar]

- Sarı, M.; Bayram, S. İnşaat Anlaşmazlıklarının Önlenmesi ve Çözümünde Etkili Faktörler: Erken Aşamalarda ve Resmi Yargı Sürecindeki Rolü. Erciyes Üniversitesi Fen Bilimleri Enstitüsü Fen Bilimleri Dergisi 2025, 41, 133–142. [Google Scholar]

- Sarı, M.; Bayram, S.; Aydemir, E. Construction-Related Disputes: A Comprehensive Bibliometric Investigation. In Proceedings of the 8th International Project and Construction Management Conference (IPCMC 2024), Istanbul, Turkiye, 6–8 June 2024; pp. 507–518. [Google Scholar]

- Turner, C.; Frankel, M.; U.S. Green Building Council. Energy performance of LEED for new construction buildings. New Build. Inst. 2008, 4, 1–42. [Google Scholar]

- USGBC. LEED Project Directory. 2025. Available online: https://www.usgbc.org/projects?check_logged_in=1&Country=%5B%22Turkiye%22%5D&SearchResult=1&SearchResultsortOption=%22Recently+certified%22 (accessed on 10 March 2025).

- Komurlu, R.; Arditi, D.; Gurgun, A.P. Applicability of LEED’s energy and atmosphere category in three developing countries. Energy Build. 2014, 84, 690–697. [Google Scholar] [CrossRef]

- Aktas, B.; Ozorhon, B. Green Building Certification Process of Existing Buildings in Developing Countries: Cases from Turkiye. J. Manag. Eng. 2015, 31, 05015002. [Google Scholar] [CrossRef]

- Pushkar, S. A Comparative Analysis of Gold Leadership in Energy and Environmental Design for New Construction 2009 Certified Projects in Finland, Sweden, Turkiye, and Spain. Appl. Sci. 2018, 8, 1496. [Google Scholar] [CrossRef]

- Pushkar, S. Leadership in Energy and Environmental Design Commercial Interior Version 4 (LEED-CI v4) Gold-Certified Office Space Projects: A Pairwise Comparative Analysis between Three Mediterranean Countries. Buildings 2024, 14, 815. [Google Scholar] [CrossRef]

- Aslan, M.; Pekdogan, T. Design for sustainability approach on material selection preferences of LEED certificated buildings. Revista de la Construcción 2025, 24, 152–171. [Google Scholar] [CrossRef]

- Cenani, S.; Can, G. Multi-criteria ranking of LEED healthcare criteria for designing green hospitals. J. Build. Eng. 2025, 105, 112443. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 90.1-2010; Energy Standard for Buildings Except Low-Rise Residential Buildings SI Edition. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2010.

- Kazaz, A.; Yetim, E. A Research on Improving the Energy Performance of Residential Buildings. J. Constr. Eng. Manag. Innov. 2024, 7, 310–335. [Google Scholar] [CrossRef]

- Yetim, E.; Kazaz, A. Investigation of Energy Efficiency in the Housing Sector Within the Framework of Sustainable Building Design. In Proceedings of the Creative Construction Conference 2024, Prague, Czech Republic, 29 June–2 July 2024. [Google Scholar]

- MGM. Official Climate Statistics. 2025. Available online: https://www.mgm.gov.tr/veridegerlendirme/il-ve-ilceler-istatistik.aspx?k=&m=ISTANBUL (accessed on 24 February 2025).

- Scofield, J.H. Do LEED-certified buildings save energy? Not really…. Energy Build. 2009, 41, 1386–1390. [Google Scholar] [CrossRef]

- Newsham, G.R.; Mancini, S.; Birt, B.J. Do LEED-certified buildings save energy? Yes, but…. Energy Build. 2009, 41, 897–905. [Google Scholar] [CrossRef]

- Çanka Kılıç, F. Endüstriyel Kazanlarda Enerji Verimliliği ve Emisyon Azalımı Fırsatları. Gazi Üniversitesi Fen Bilimleri Dergisi Part C Tasarım ve Teknoloji 2017, 5, 147–158. [Google Scholar]

- Ministry of Energy and Natural Resources (MENR). Turkey Electricity Production and Electricity Consumption Point Emission Factors; MENR: Ankara, Turkiye, 2024.

- Amiri, A.; Ottelin, J.; Sorvari, J. Are LEED-Certified Buildings Energy-Efficient in Practice? Sustainability 2019, 11, 1672. [Google Scholar] [CrossRef]

- Gurgun, A.P.; Polat, G.; Damci, A.; Bayhan, H.G. Performance of LEED Energy Credit Requirements in European Countries. Procedia Eng. 2016, 164, 432–438. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).