Towards Selecting an Optimal Bonding Test Method for Rebar–Concrete: Comparison Between Pull-Out Test and Full-Beam Test

Abstract

1. Introduction

2. Test Methodologies

2.1. Materials

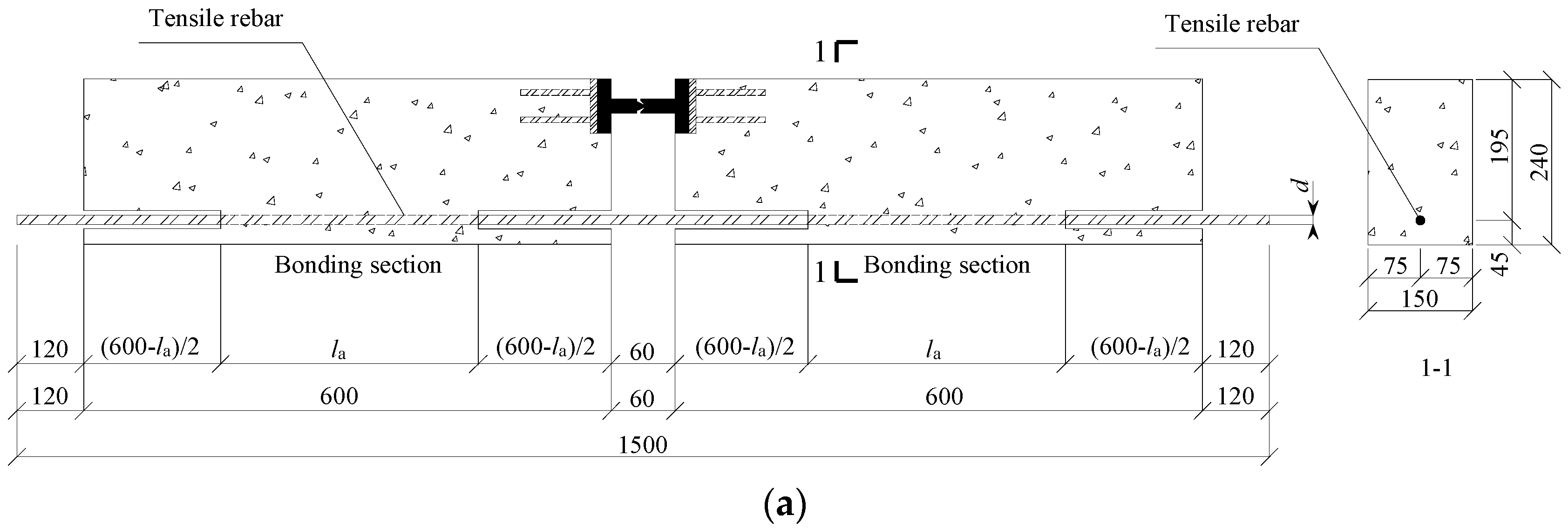

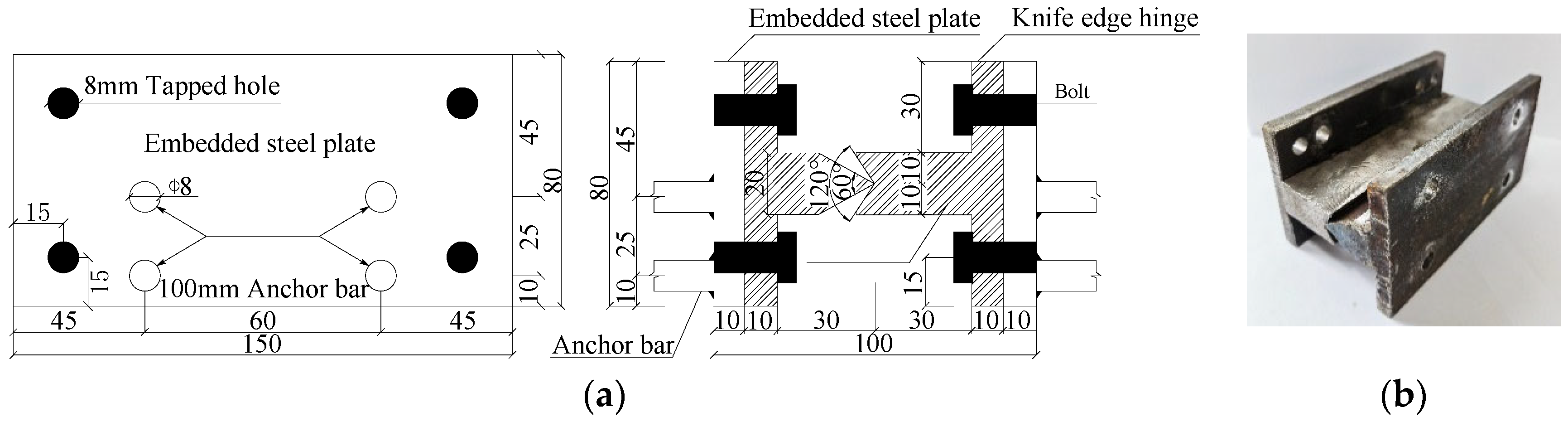

2.2. Bonding Specimen Preparation

2.2.1. Principal Rebars

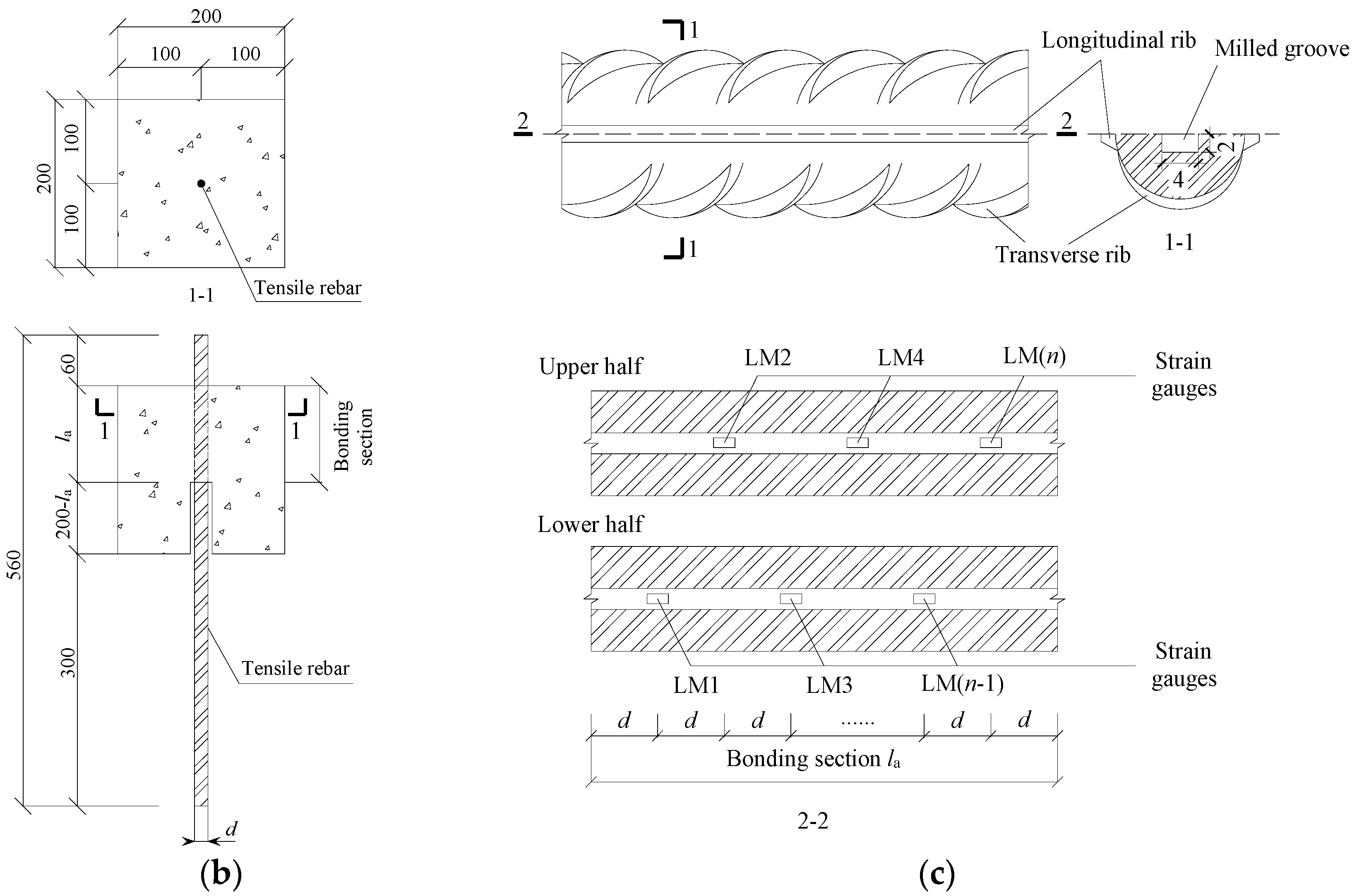

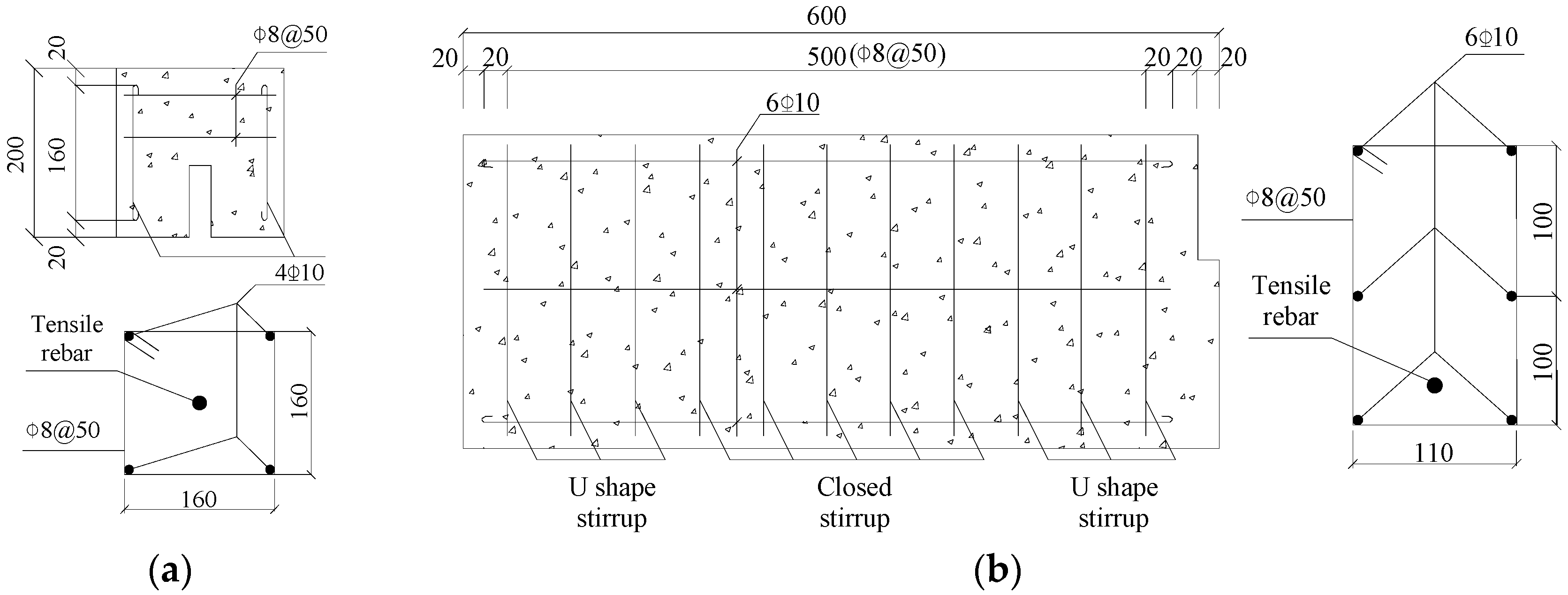

2.2.2. Stirrups and Steel Hinges

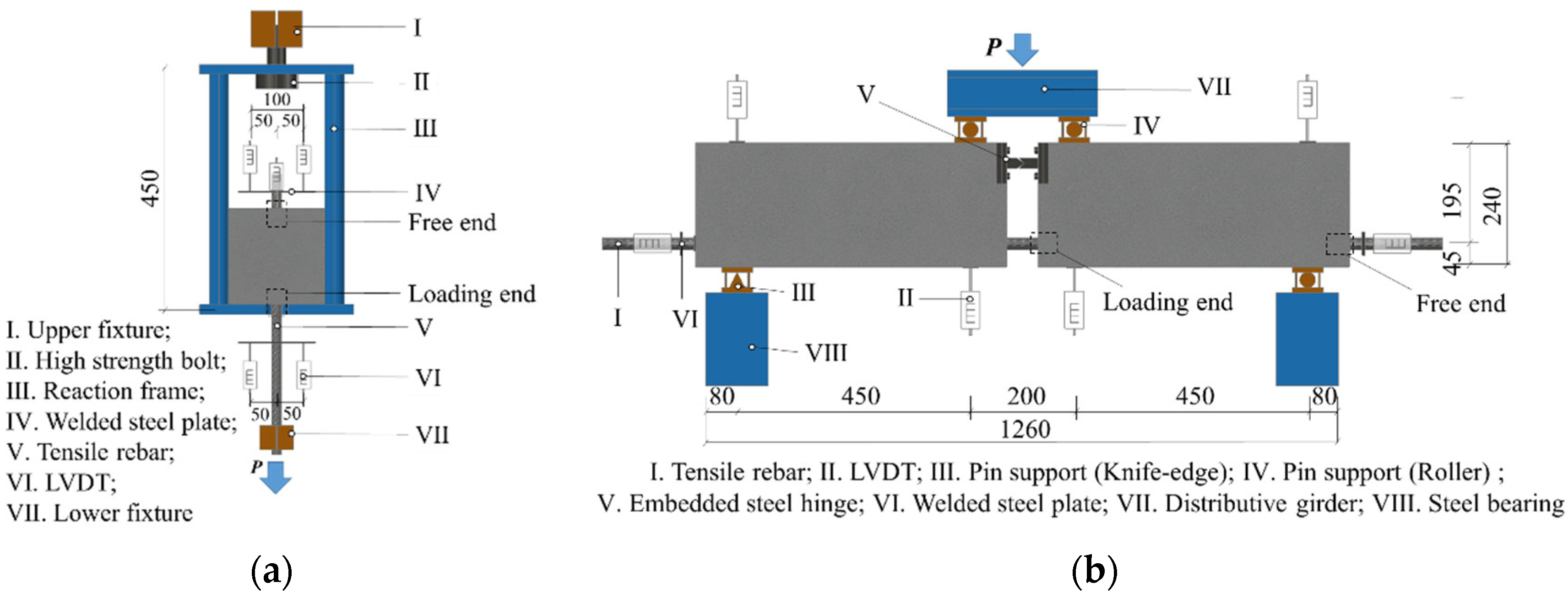

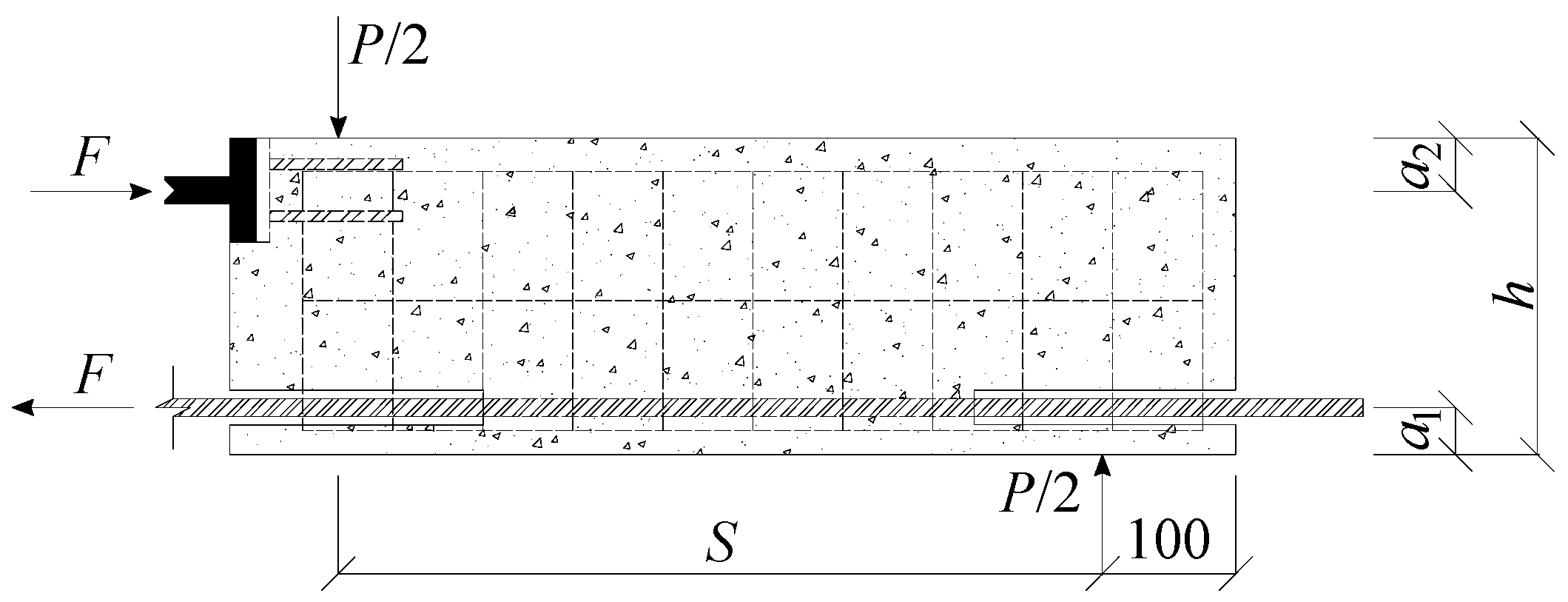

2.3. Loading System

3. Test Observations and Results

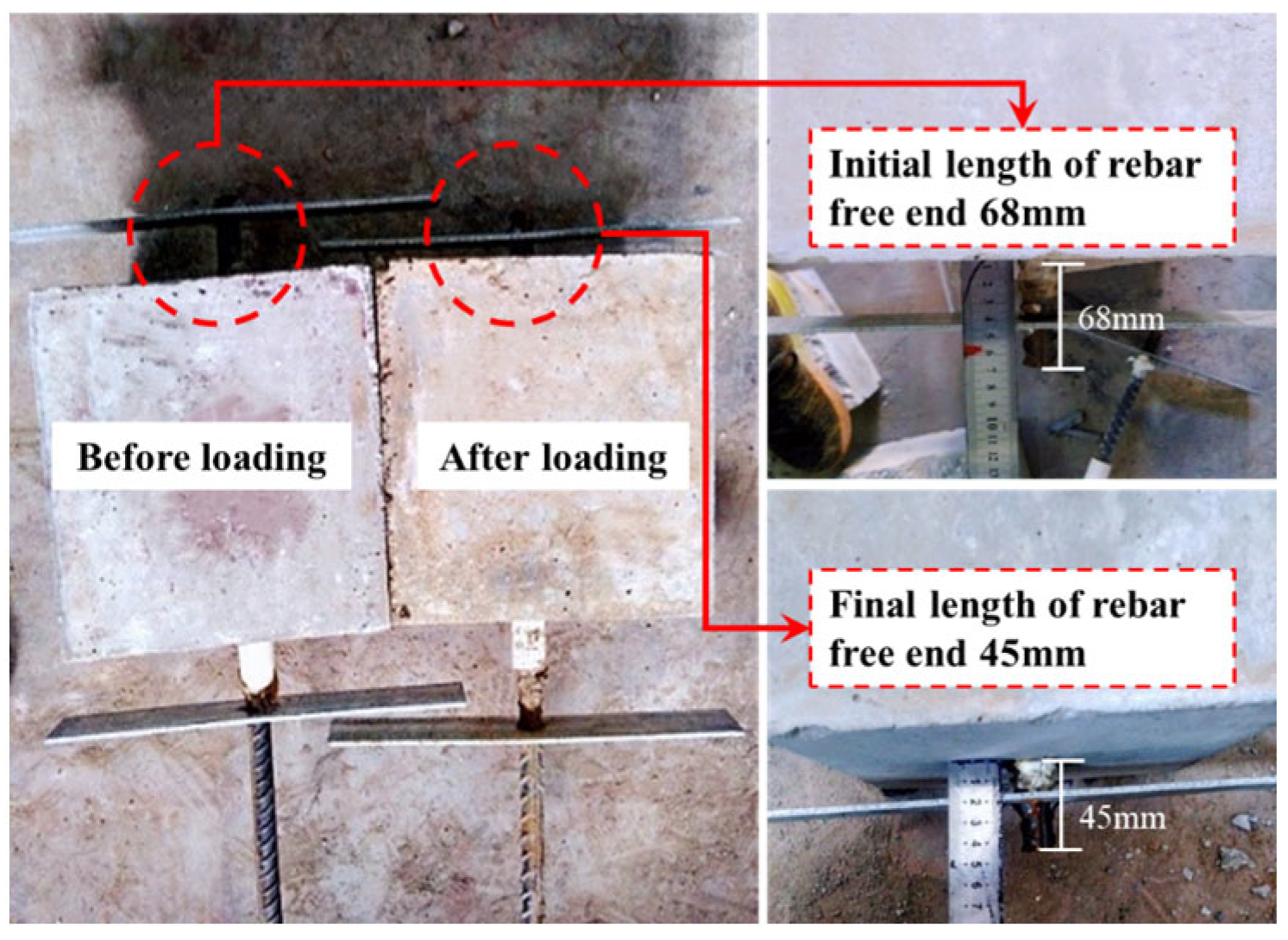

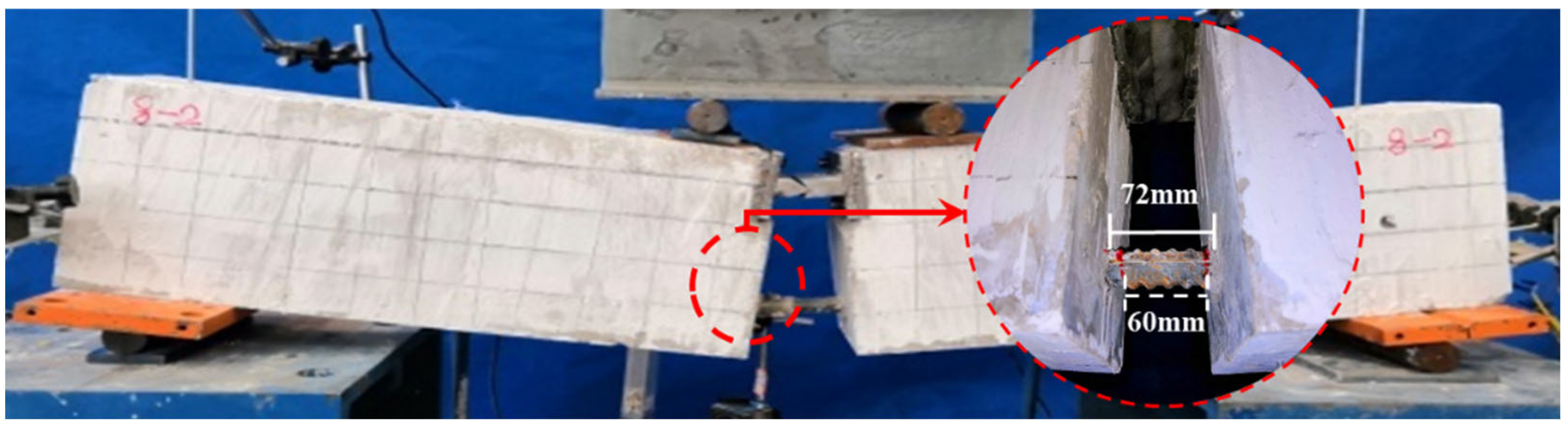

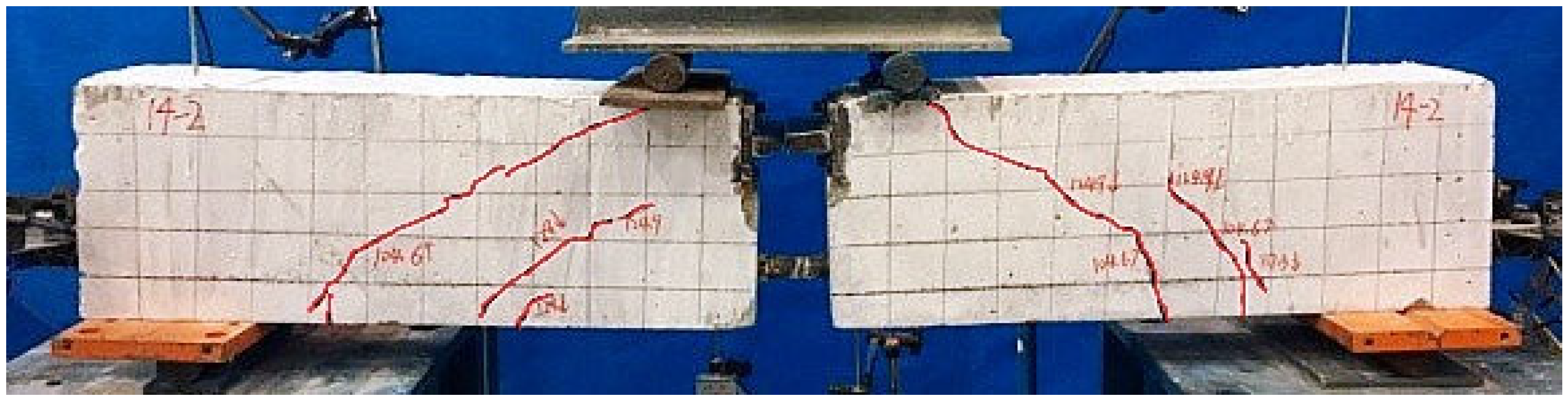

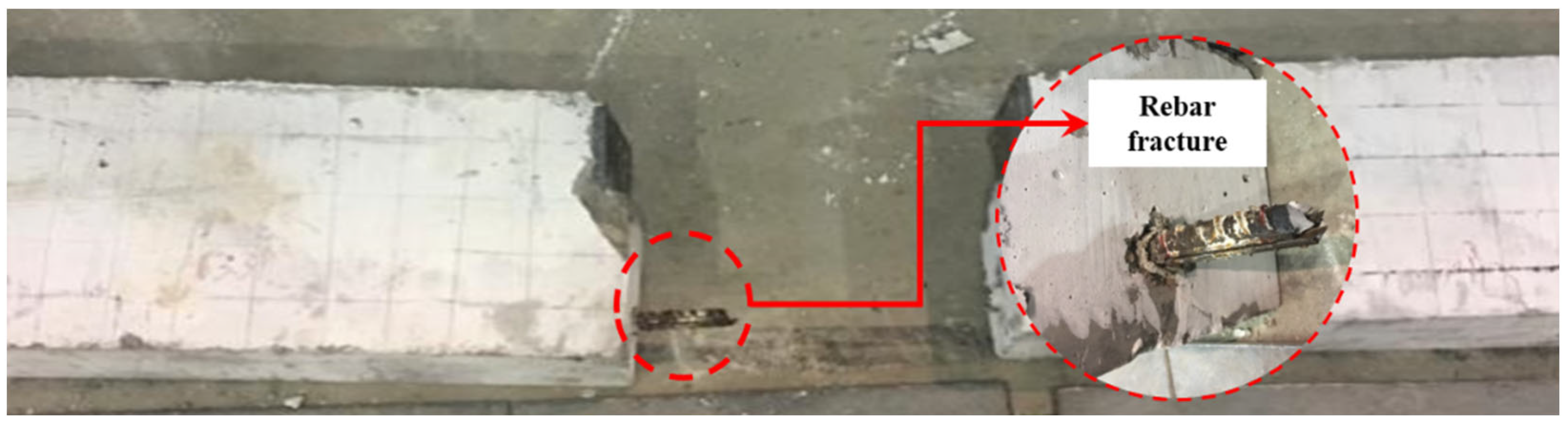

3.1. Failure Modes

3.2. Bond Strengths

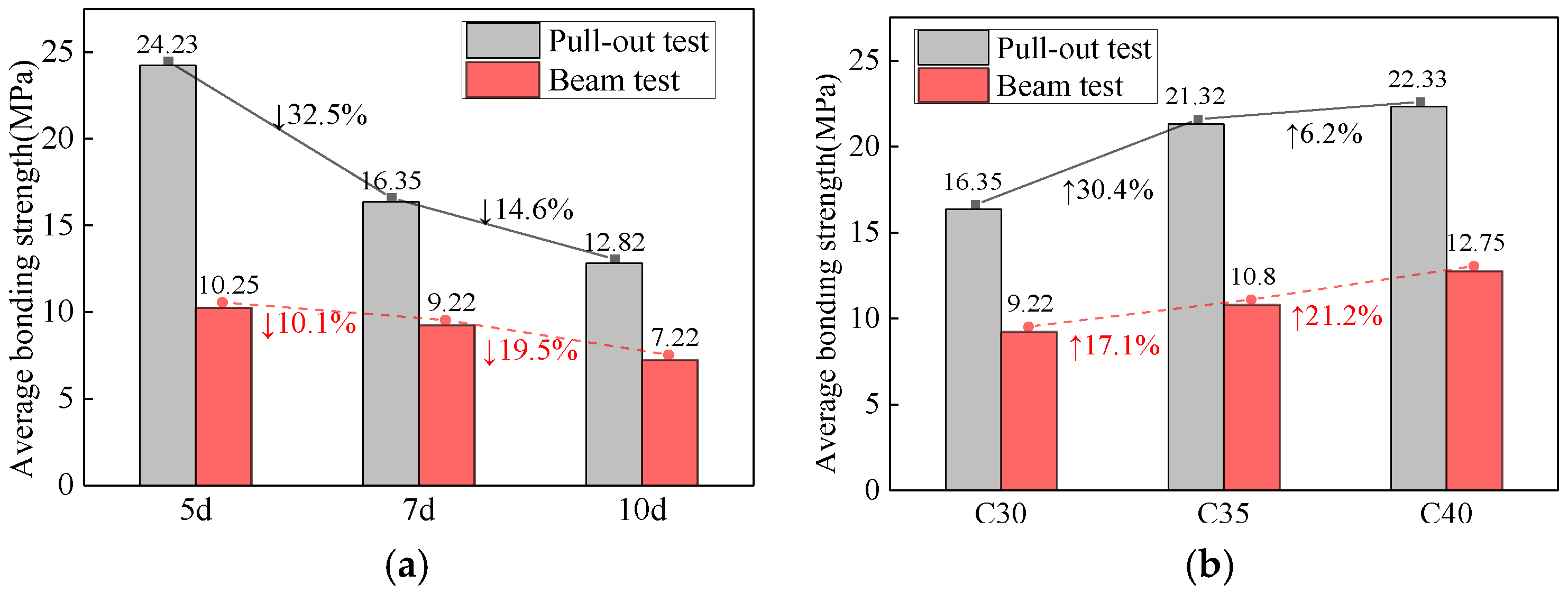

3.2.1. Average Bond Strength

3.2.2. Effect of Bonding Conditions

3.3. Bond–Slip Curves

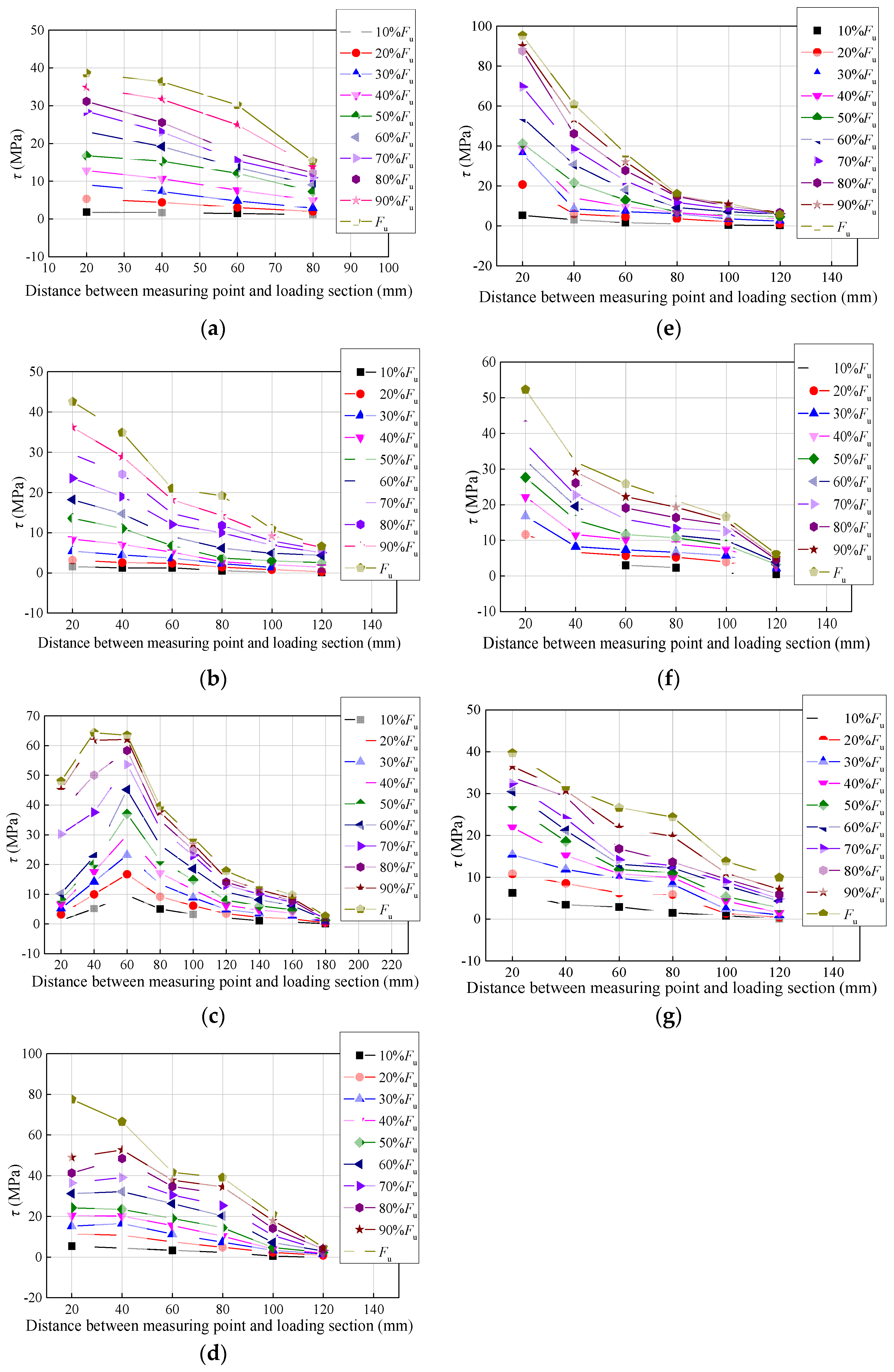

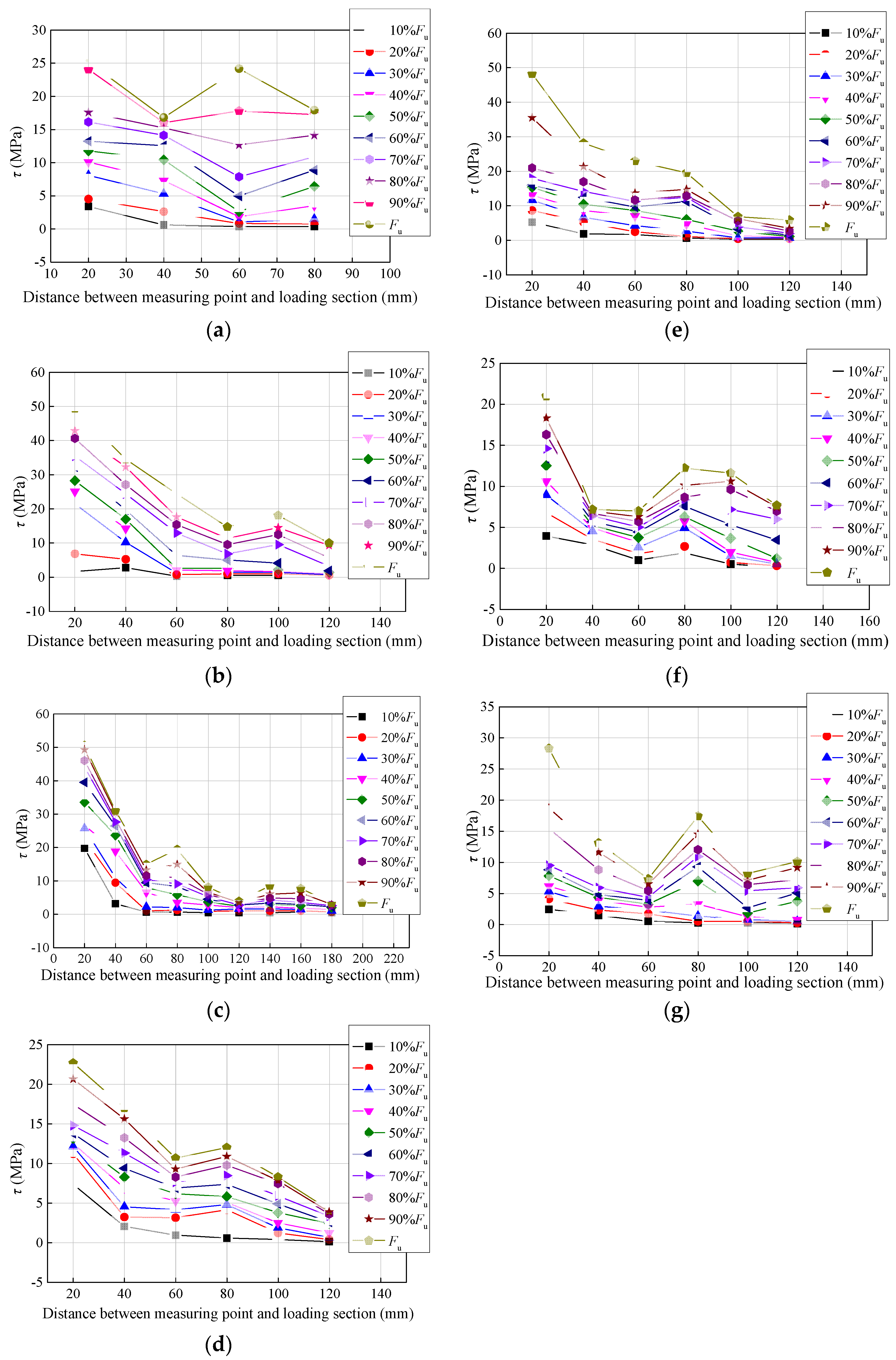

3.4. Distribution of Bonding Stress

4. Discussion

- (1)

- The bond strength measured in the pull-out tests described herein is generally higher than that determined by the beam test; specifically, the bond strength of the pull-out test is about 1.11–2.36 times the bond strength of the beam test under the same bonding conditions. This indicates that the test results measured by the pull-out test method, with a single stress state at the bonding interface (ignoring bending and shear stress in actual state), cannot be directly used in structural design. If the pull-out test results are used to guide the structural design, they should be converted. However, it is important to note that the beam and pull-out tests show different failure modes when the bonding length is large (≥10d) or when the diameter of the rebar is large (≥22 mm). For these cases exhibiting distinct failure modes, the use of conversion factors to relate the two test methods’ bond strength results is not applicable.

- (2)

- The pull-out test demonstrated higher sensitivity than the beam test in response to changes in bonding conditions (e.g., bonding length, concrete strength grade, rebar diameter). For example, when the rebar diameter increased from 16 to 25 mm, the change in bond strength measured by the pull-out test method was 48.9%, whereas the change in bond strength measured by the beam test method was only 18.1%. Therefore, if the purpose of the test is to accurately determine the effect of changes in bonding conditions on the bond strength of rebar and concrete, it is most appropriate to use the pull-out method for testing.

- (3)

- In terms of the bond–slip characteristics, the bond–slip curves obtained from the beam test are more stable than those obtained by the pull-out test. Specifically, the curves obtained by the pull-out test show more significant dispersion when concrete splitting failure occurred in the specimens. Therefore, to generalize the bond–slip behavior of rebar and concrete from the test curves more easily, it is recommended to employ the beam test method to obtain the bond–slip curves of rebar and concrete.

- (4)

- The bonding stress distribution in the bonding section decreases from the loaded end to the free end due to the “hoop effect” of the loaded plate in the pull-out test. During the early stage of loading, the bonding stress distribution of rebar in the beam test has the same distribution as that in the pull-out test. However, as the load increases, the bonding stress distribution in the beam test gradually develops a “double-peak” feature. Compared with the pull-out test, the bonding stress distribution of the rebar obtained by the beam test without the influence of the “hoop effect” of the loaded plate is closer to the actual stress state. Therefore, the beam test method is preferred to measure the distribution of bonding stresses in the bonding section.

- (5)

- The treatment of strain gauges applied internally after slotting the rebar has no significant effect on the determination of the bond strength between the rebar and the concrete in the pull-out test. It should be noted, however, that for some special cases (e.g., high concrete strength grade or large bonding length), the slotted rebar may fracture under loads below their ultimate tensile strength. In pull-out tests, the configuration of the specimen with stirrups may change its mode of failure, thereby significantly increasing its average bond strength. For tests where a uniform failure mode (e.g., debonding failure) is expected, concrete splitting failure of the specimen can be avoided by configuring the specimen with stirrups.

- (6)

- The influence of bond length on failure mode transition is an important phenomenon worthy of in-depth discussion. As bond length increases, the failure mode may transition from interfacial pullout failure at short lengths to concrete splitting failure at longer lengths. This transition stems from the cumulative effect of bond stress; when the length exceeds a critical value, the accumulation of radial tensile stress may trigger splitting of the concrete cover. It is recommended to analyze in detail the failure characteristics at different bond lengths, including crack development patterns and load–displacement curve differences, to accurately identify the transition point. This analysis has important engineering significance because splitting failure typically exhibits brittle behavior while pullout failure is relatively ductile. This mode transition should be considered in anchorage length design to ensure structural safety and ductility performance.

- (7)

- This study is subject to limitations in specimen quantity and laboratory conditions, which may impose certain constraints on statistical reliability and engineering applicability. Future research should expand the specimen scale, consider size effects and actual service environment influences, establish a systematic theoretical framework for correction factors, and integrate experimental data with numerical simulations to enhance the practical engineering value of the research findings and provide a more reliable theoretical basis for the improvement of relevant testing method standards.

5. Conclusions

- (1)

- For specimens with large bonding lengths or high concrete strength grades, there are differences in the failure modes observed by the pull-out test versus the beam test. The bond strengths of rebar and concrete obtained by the pull-out test were greater than those determined by the beam test under the same bonding conditions (1.11–2.36 times). Compared with the beam test method, the pull-out test method was more sensitive to changes in bonding length, concrete strength grade, and rebar diameter.

- (2)

- For specimens exhibiting debonding failure, the bond–slip curves of rebar and concrete measured by the pull-out test and the beam test were similar. For the specimens experiencing concrete splitting failure, both test methods failed to measure the falling section of the bond–slip curve, and the bond–slip curve obtained from the pull-out test showed more significant dispersion.

- (3)

- The maximum bonding stresses in the bonding section of the rebar in both the pull-out and beam tests appeared near the loading end. However, as the load increased, the bonding stress distribution of the rebar obtained from the pull-out test decreased from the loaded end to the free end, while the bonding stress distribution of the rebar in the beam test showed a double-peak characteristic.

- (4)

- The average bond strength of rebar and concrete measured by the pull-out test cannot be used directly in actual structural design; rather, it must be properly amended. The beam test method is more suitable than the pull-out test method for obtaining the bond–slip characteristics of the rebar and concrete, as well as the bonding stress distribution of the rebar in the bonding section.

- (5)

- The treatment of internal slotting of the rebar followed by the internal application of strain gauges has no appreciable effect on the bonding characteristics between the rebar and the concrete; however, for specimens with large bonding lengths and high concrete strength grades, the rebar may fracture at loads below their tensile limit.

- (6)

- In practical engineering applications, the beam test method should be prioritized for evaluating the bond performance between rebar and concrete, especially for important structures requiring precise understanding of rebar–concrete interface behavior. For high-strength concrete or large-diameter rebar components, special attention should be paid to the differences between test results and actual structural behavior, ensuring sufficient safety margins in design.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gkournelos, P.D.; Triantafillou, T.C.; Bournas, D.A. Seismic upgrading of existing reinforced concrete buildings: A state-of-the-art review. Eng. Struct. 2021, 240, 112273. [Google Scholar] [CrossRef]

- Phan, T.S.; Rossi, P.; Tailhan, J.L. Numerical modelling of the concrete/rebar bond. Cem. Concr. Comp. 2015, 59, 1–9. [Google Scholar] [CrossRef]

- Songpiriyakij, S.; Pulngern, T.; Pungpremtrakul, P.; Jaturapitakkul, C. Anchorage of steel bars in concrete by geopolymer paste. Mater. Design. 2011, 32, 3021–3028. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D.; Park, W.S.; Jang, Y.I. Bond strength prediction for deformed steel rebar embedded in recycled coarse aggregate concrete. Mater. Design. 2015, 83, 257–269. [Google Scholar] [CrossRef]

- Hu, X.; Peng, G.; Niu, D.; Wu, X.; Zhang, L. Bond behavior between deformed steel bars and cementitious grout. Constr. Build. Mater. 2020, 262, 120810. [Google Scholar] [CrossRef]

- Baktheer, A.; Spartali, H.; Hegger, J.; Chudoba, R. High-cycle fatigue of bond in reinforced high-strength concrete under push-in loading characterized using the modified beam-end test. Cem. Concr. Comp. 2021, 118, 103978. [Google Scholar] [CrossRef]

- Jin, L.; Li, X.; Zhang, R.; Du, X. Bond-slip behavior between concrete and deformed rebar at elevated temperature: Mesoscale simulation and formulation. Int. J. Mech. 2021, 205, 106622. [Google Scholar] [CrossRef]

- Natino, M.R.; Yang, Y.; Nakamura, H.; Miura, T. Experimental study on bond behavior of corroded rebars coated by anti-corrosive materials in polymer cement mortar. Constr. Build. Mater. 2021, 300, 124228. [Google Scholar] [CrossRef]

- Alharbi, Y.R.; Galal, M.; Abadel, A.A.; Kohail, M. Bond behavior between concrete and steel rebars for stressed elements. Ain Shams Eng. J. 2020, 12, 1231–1239. [Google Scholar] [CrossRef]

- Xu, Y.L.; Shen, W.D.; Wang, H. Experimental research on bonding and anchoring performance of reinforced concrete. J. Build. Struct. 1994, 3, 26–37. (In Chinese) [Google Scholar]

- Darwin, D.; Graham, E.K. Effect of deformation height and spacing on bond strength of reinforcing bars. ACI Struct. J. 1993, 90, 646–657. [Google Scholar]

- Haskett, M.; Oehlers, D.J.; Ali, M.S.M. Local and global bond characteristics of steel reinforcing bars. Eng. Struct. 2008, 30, 376–383. [Google Scholar] [CrossRef]

- Huang, L.; Ye, H.; Xu, L.; Chi, Y. A mechanistic model for the nonlinear bond behavior of rebar in concrete. Eng. Struct. 2021, 231, 111715. [Google Scholar] [CrossRef]

- RILEM. Tentative Recommendations: Recommendations for Reinforcing Steel, Bond Test for Reinforcing Steel: 1-Beam Test (RC5) 2-Pull Out Test (RC6); CEB-FIP: Paris, France, 1972. [Google Scholar]

- Windisch, A. A modified pull-out test and new evaluation methods for a more real local bond-slip relationship. Mater. Struct. 1985, 18, 181–184. [Google Scholar] [CrossRef]

- Filho, F.M.D.A.; Debs, M.K.E.; Debs, A.L.H.C.E. Bond-slip behavior of self-compacting concrete and vibrated concrete using pull-out and beam tests. Mater. Struct. 2008, 41, 1073–1089. [Google Scholar] [CrossRef]

- ASTM C234-91; Standard Test Method for Comparing Concretes on the Basis of the Bond Developed with Reinforcing Steel. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM A370-21; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2021.

- GB 50152-92; Standard for Test Methods of Concrete Structures. China Architecture & Building Press: Beijing, China, 1992. (In Chinese)

- GB/T 50152-2012; Standard for Test Methods of Concrete Structures. China Architecture & Building Press: Beijing, China, 2014. (In Chinese)

- ACI 408.2R-92; State-of-the-Art Report on Bond under Cyclic Loads. American Concrete Institute: Farmington Hills, MI, USA, 1992.

- Cabrera, J.G. Deterioration of concrete due to reinforcement steel corrosion. Cem. Concr. Comp. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Harajli, M.H.; Hamad, B.S.; Rteil, A.A. Effect of confinement on bond strength between steel bars and concrete. ACI Struct. J. 2004, 101, 595–603. [Google Scholar] [CrossRef]

- Harajli, M.H. Bond stress–slip model for steel bars in unconfined or steel, FRC, or FRP confined concrete under cyclic loading. J. Struct. Eng. 2009, 135, 509–518. [Google Scholar] [CrossRef]

- Chana, P.S. A test method to establish realistic bond stresses. Mag. Concrete Res. 1990, 42, 83–90. [Google Scholar] [CrossRef]

- Hanjari, K.Z.; Coronelli, D.; Lundgren, K. Bond capacity of severely corroded bars with corroded stirrups. Mag. Concrete Res. 2011, 63, 953–968. [Google Scholar] [CrossRef]

- Ožbolt, J.; Oršanić, F.; Balabanić, G. Modeling pull-out resistance of corroded rebar in concrete: Coupled three-dimensional finite element model. Cem. Concr. Comp. 2014, 46, 41–55. [Google Scholar] [CrossRef]

- Law, D.W.; Tang, D.; Molyneaux, T.K.; Gravina, R. Impact of crack width on bond: Confined and unconfined rebar. Mater. Struct. 2011, 44, 1287–1296. [Google Scholar] [CrossRef]

- Sharma, A.; Bošnjak, J.; Ožbolt, J.; Hofmann, J. Numerical modeling of rebar pull-out and cover splitting in fire-exposed beam-end specimens. Eng. Struct. 2016, 111, 217–232. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, H.; Gao, Y.; Wang, W.; Wang, Z. Influence of macadamia nutshell particles on the apparent density and mechanical behavior of cement-based mortars. Constr. Build. Mater. 2024, 411, 134600. [Google Scholar] [CrossRef]

- Wang, L.; Yi, J.; Xia, H.; Fan, L. Experimental study of a pull-out test of corroded steel and concrete using the acoustic emission monitoring method. Constr. Build. Mater. 2016, 163, 170. [Google Scholar] [CrossRef]

- GB 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2002. (In Chinese)

- GB 175-2020; Common Portland Cement. China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- GB/T 228.1-2010; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2010. (In Chinese)

- GB 1499.2-2018; Steel for the Rebar of Concrete—Part 2: Hot Rolled Ribbed Bars. China Architecture & Building Press: Beijing, China, 2018. (In Chinese)

- Skorobogatov, S.M. Influence of the geometry of deformed rebars on their bond strength in concrete. Proc. Inst. Civ. Eng. 1979, 67, 327–339. [Google Scholar] [CrossRef]

- Zhao, J.H.; Wang, M.F. Elastic Mechanics and Finite Element Method; Wuhan University of Technology Press: Wuhan, China, 2008. (In Chinese) [Google Scholar]

- Hong, X.J.; Zhang, Y. The fitting method of the smooth bond stress in the bond-slip test. Struct. Eng. 2000, 3, 44–48. (In Chinese) [Google Scholar]

| Strength Grede | Mixture | Curing Duration (MPa) | ||

|---|---|---|---|---|

| Cement–Sand–Stone–Water | 7 Days | 14 Days | 28 Days | |

| C30 | 1:2.145:3.352:0.480 | 21.36 | 24.31 | 31.69 |

| C35 | 1:2.145:3.352:0.480 | 28.51 | 31.02 | 35.32 |

| C40 | 1:1.676:2.736:0.400 | 35.42 | 40.37 | 41.07 |

| Strength Grade | Diameter d (mm) | Yield Strength fy (N/mm2) | Ultimate Strength f (N/mm2) | Elasticity Modulus E (N/mm2) | Yield Ratio f/fy | Elongation After Fracture A |

|---|---|---|---|---|---|---|

| HPB335 | 8 | 341.8 | 464.9 | 2.0 × 105 | 1.36 | 27.4% |

| HRB400 | 10 | 416.6 | 562.8 | 2.0 × 105 | 1.35 | 26.7% |

| 16 | 418.3 | 573.5 | 1.37 | 27.3% | ||

| 22 | 427.9 | 582.7 | 1.36 | 25.9% | ||

| 25 | 433.6 | 603.4 | 1.39 | 26.1% |

| Specimen Grouping | Diameter of Rebar (mm) | Concrete Strength | Bonding Length (mm) | Stirrup | Rebar Grooving |

|---|---|---|---|---|---|

| P6-5d-C30 | 16 | C30 | 80 | None | Yes |

| P6-7d-C30 | 16 | C30 | 112 | None | Yes |

| P6-10d-C30 | 16 | C30 | 160 | None | Yes |

| P6-7d-C35 | 16 | C35 | 112 | None | Yes |

| P6-7d-C40 | 16 | C40 | 112 | None | Yes |

| P2-7d-C30 | 22 | C30 | 154 | None | Yes |

| P5-7d-C30 | 25 | C30 | 175 | None | Yes |

| P6-10d-C30-0 | 16 | C30 | 160 | None | No |

| P6-10d-C30-1 | 16 | C30 | 160 | φ8@50 | No |

| B6-5d-C30 | 16 | C30 | 80 | φ8@50 | Yes |

| B6-7d-C30 | 16 | C30 | 112 | φ8@50 | Yes |

| B6-10d-C30 | 16 | C30 | 160 | φ8@50 | Yes |

| R6-7d-C35 | 16 | C35 | 112 | φ8@50 | Yes |

| B6-7d-C40 | 16 | C40 | 112 | φ8@50 | Yes |

| B2-7d-C30 | 22 | C30 | 154 | φ8@50 | Yes |

| B5-7d-C30 | 25 | C30 | 175 | φ8@50 | Yes |

| Pull-Out Test | Beam Test | ||

|---|---|---|---|

| Specimen grouping | Failure mode | Specimen grouping | Failure mode |

| P6-5d-C30 | Debonding | B6-5d-C30 | Debonding |

| P6-7d-C30 | Debonding | B6-7d-C30 | Debonding |

| P6-10d-C30 | Concrete splitting | B6-10d-C30 | Rebar fracture |

| P6-10d-C30-0 | Concrete splitting | - | - |

| P6-10d-C30-1 | Debonding | - | - |

| P6-7d-C35 | Concrete splitting | B6-7d-C35 | Pull out after splitting |

| P6-7d-C40 | Concrete splitting | B6-7d-C40 | Pull out after splitting |

| P2-7d-C30 | Concrete splitting | B2-7d-C30 | Concrete splitting |

| P5-7d-C30 | Concrete splitting | B5-7d-C30 | Concrete splitting |

| Pull-Out Test | Beam Test | |||||||

|---|---|---|---|---|---|---|---|---|

| Grouping | F1 (kN) | τ1 (MPa) | SD1 (MPa) | Grouping | F2 (kN) | τ2 (MPa) | SD2 (MPa) | τ1/τ2 |

| P6-5d-C30 | 97.7 | 24.23 | 1.09 | B6-5d-C30 | 41.2 | 10.25 | 3.97 | 2.36 |

| P6-7d-C30 | 94.4 | 16.35 | 1.75 | B6-7d-C30 | 51.9 | 9.22 | 2.28 | 1.77 |

| P6-10d-C30 | 104.1 | 12.82 | 1.22 | B6-10d-C30 | 58.1 | 7.22 | 1.76 | 1.78 |

| P6-10d-C30-0 | 90.8 | 11.38 | 0.88 | - | - | - | - | - |

| P6-10d-C30-1 | 122.3 | 15.22 | 1.25 | - | - | - | - | - |

| P6-7d-C35 | 123.3 | 21.32 | 1.33 | B6-7d-C35 | 60.8 | 10.80 | 2.74 | 1.97 |

| P6-7d-C40 | 131.3 | 22.33 | 0.82 | B6-7d-C40 | 71.8 | 12.75 | 3.65 | 1.75 |

| P2-7d-C30 | 141.7 | 13.22 | 0.98 | B2-7d-C30 | 93.7 | 8.80 | 2.78 | 1.50 |

| P5-7d-C30 | 114.5 | 8.35 | 1.41 | B5-7d-C30 | 103.8 | 7.55 | 1.85 | 1.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, S.; Li, C.; Dong, J.; Lu, Z. Towards Selecting an Optimal Bonding Test Method for Rebar–Concrete: Comparison Between Pull-Out Test and Full-Beam Test. Buildings 2025, 15, 2375. https://doi.org/10.3390/buildings15132375

Chao S, Li C, Dong J, Lu Z. Towards Selecting an Optimal Bonding Test Method for Rebar–Concrete: Comparison Between Pull-Out Test and Full-Beam Test. Buildings. 2025; 15(13):2375. https://doi.org/10.3390/buildings15132375

Chicago/Turabian StyleChao, Sisi, Chenghua Li, Jiahong Dong, and Ziliang Lu. 2025. "Towards Selecting an Optimal Bonding Test Method for Rebar–Concrete: Comparison Between Pull-Out Test and Full-Beam Test" Buildings 15, no. 13: 2375. https://doi.org/10.3390/buildings15132375

APA StyleChao, S., Li, C., Dong, J., & Lu, Z. (2025). Towards Selecting an Optimal Bonding Test Method for Rebar–Concrete: Comparison Between Pull-Out Test and Full-Beam Test. Buildings, 15(13), 2375. https://doi.org/10.3390/buildings15132375