Experimental Study on Carbonization and Strengthening Performance of Recycled Aggregate

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Specimen Forming and Maintenance

2.2.1. Pretreatment of Recycled Aggregate

2.2.2. Regenerated Aggregate Carbonization Treatment

2.2.3. Regenerated Aggregate Concrete Specimen Forming and Curing

2.3. Experimental Scheme

2.3.1. Detection of Temperature, Humidity, and Carbon Dioxide Content During the Carbonization Process

2.3.2. Physical Properties Test of Regenerated Aggregate Before and After Carbonization

3. Results

3.1. Study on Physical Properties of Carbonized Reinforced Recycled Aggregate

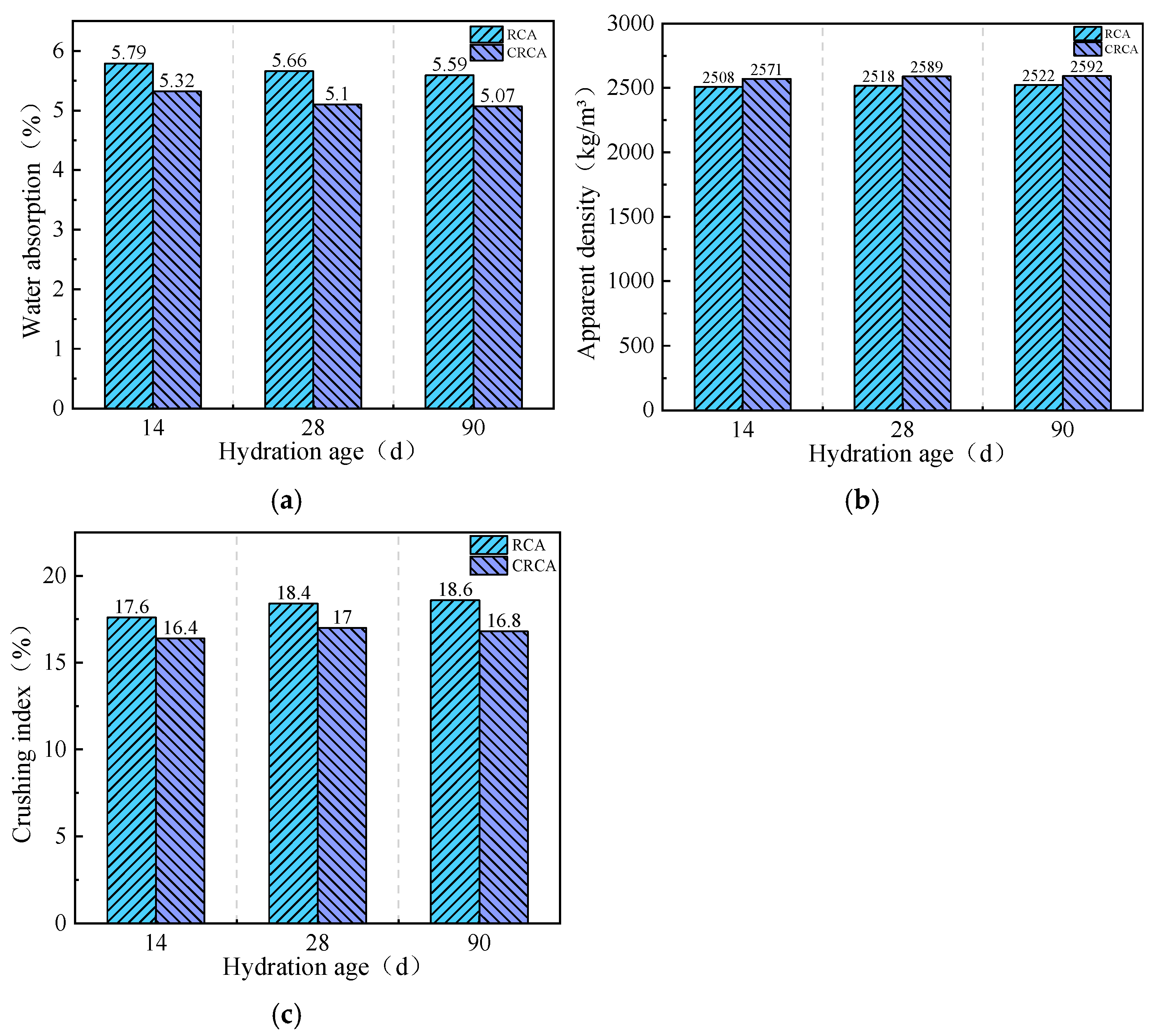

3.1.1. RCA Physical Performance

3.1.2. Physical Properties of CRCA

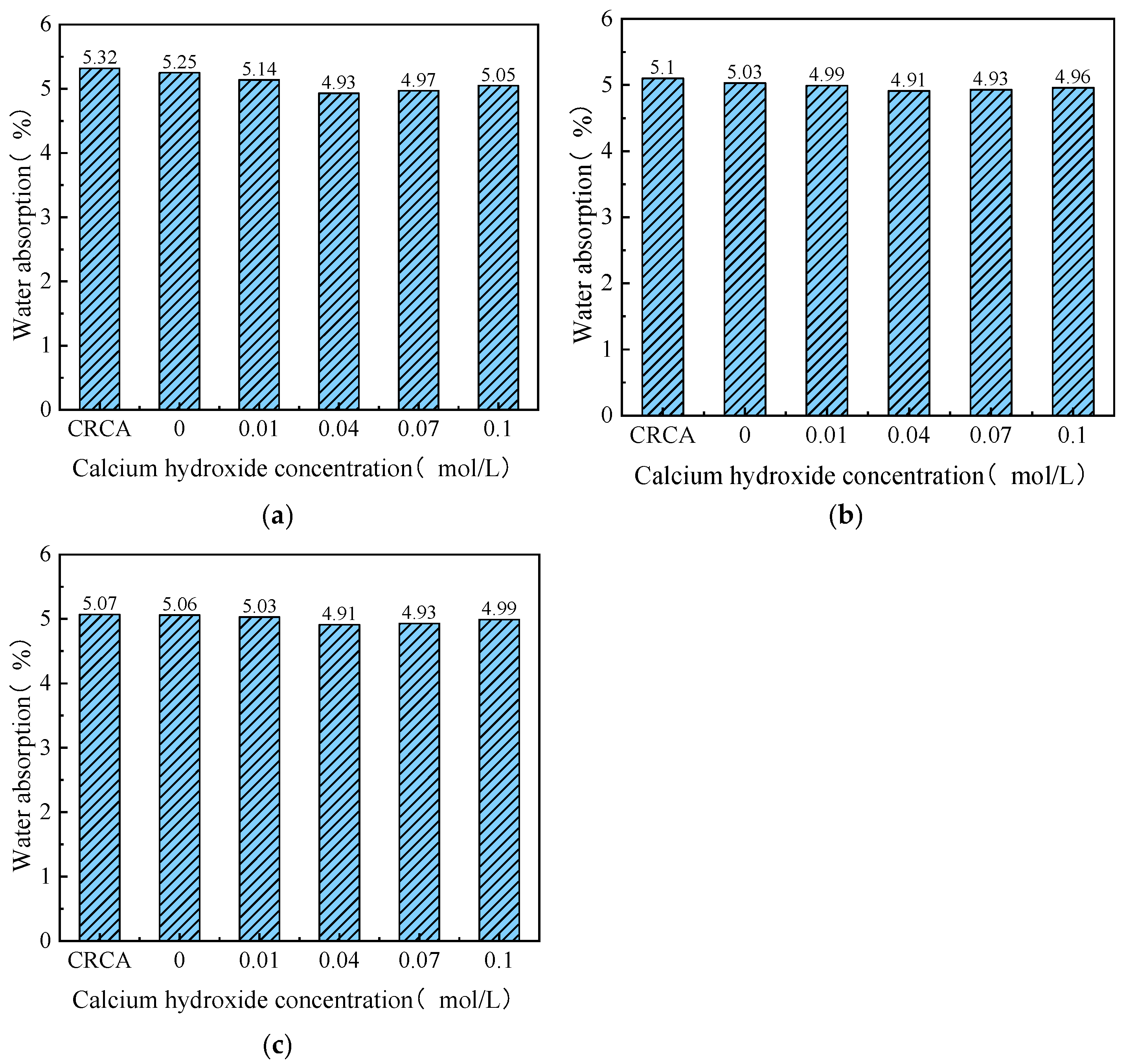

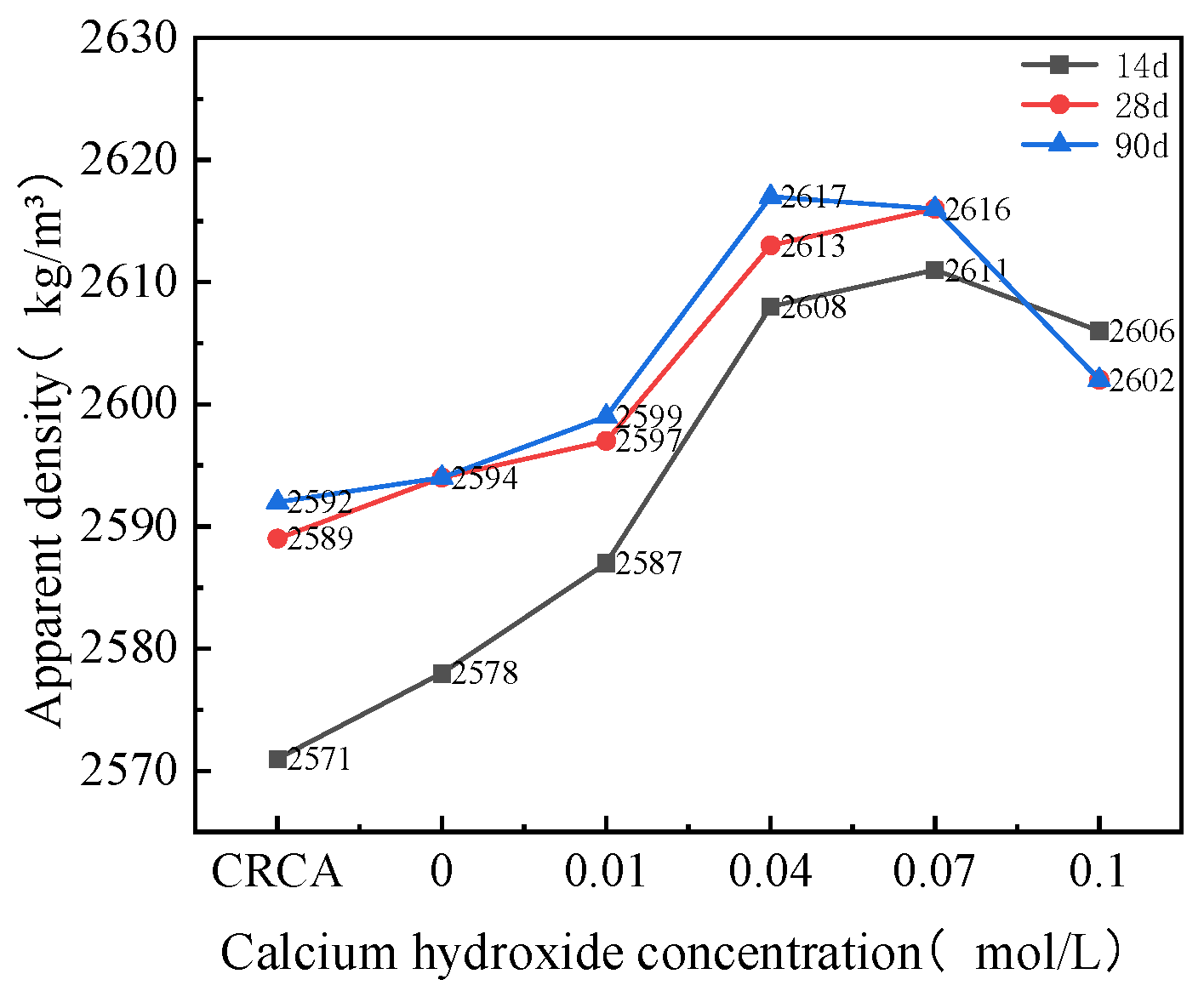

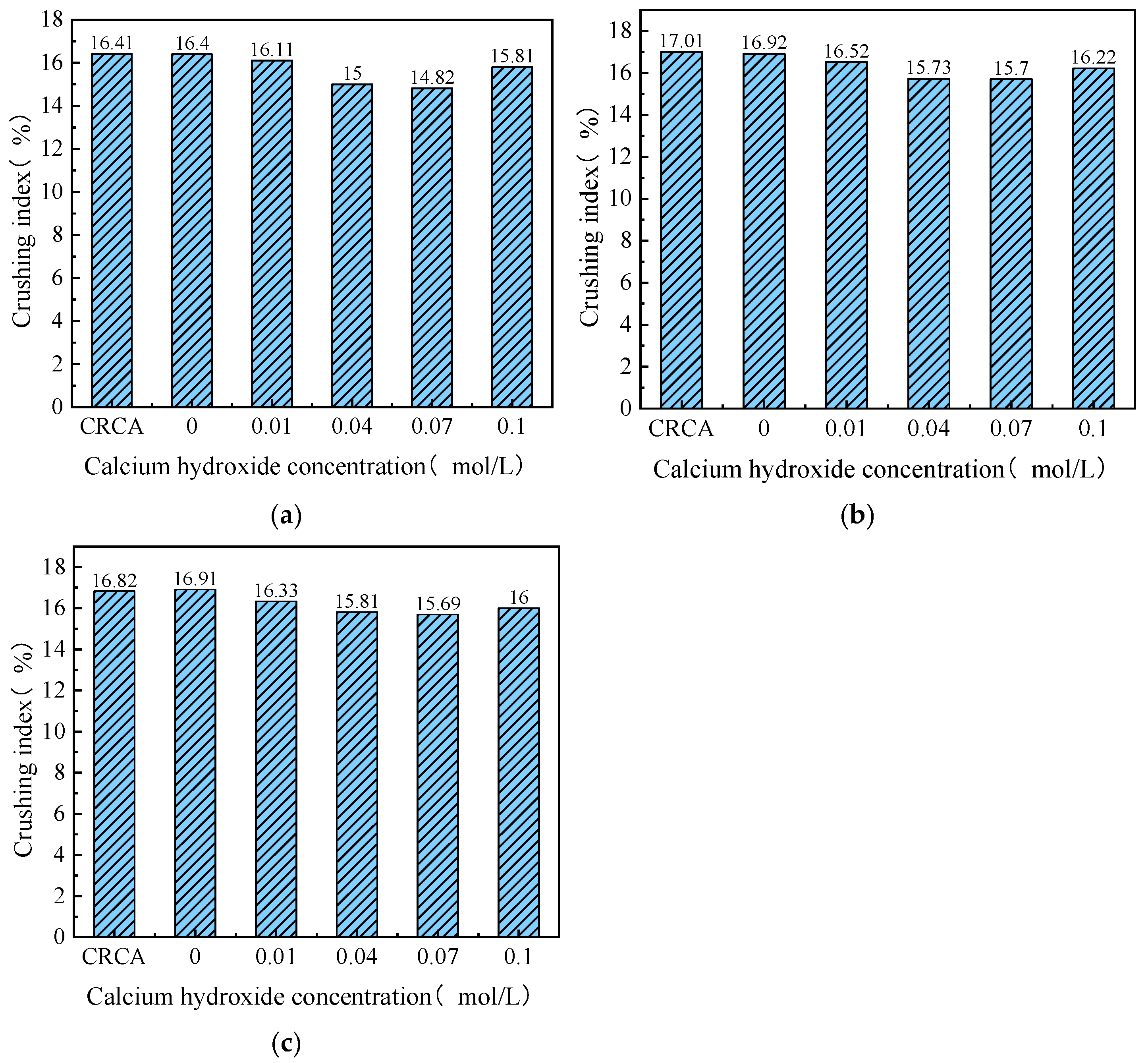

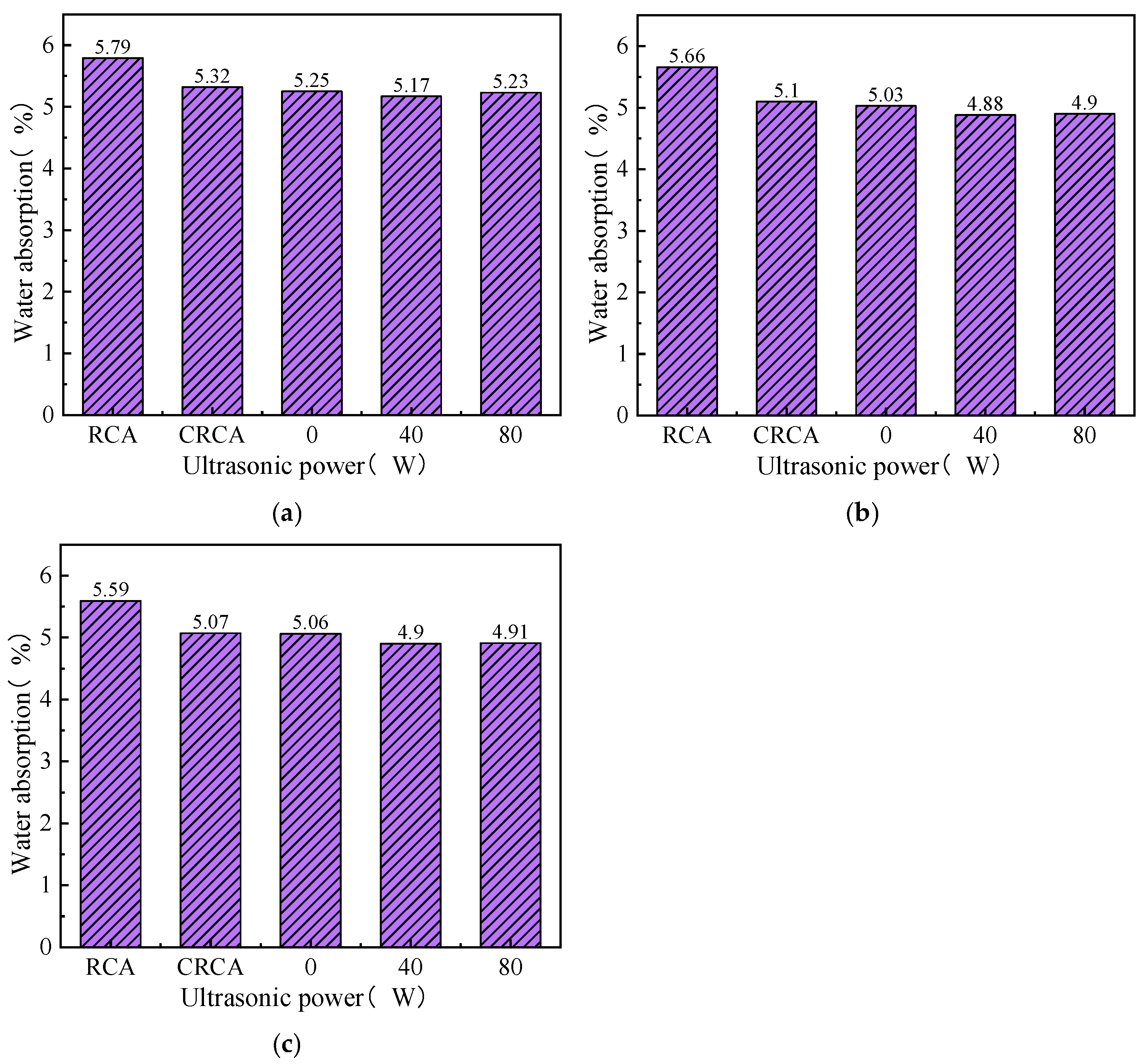

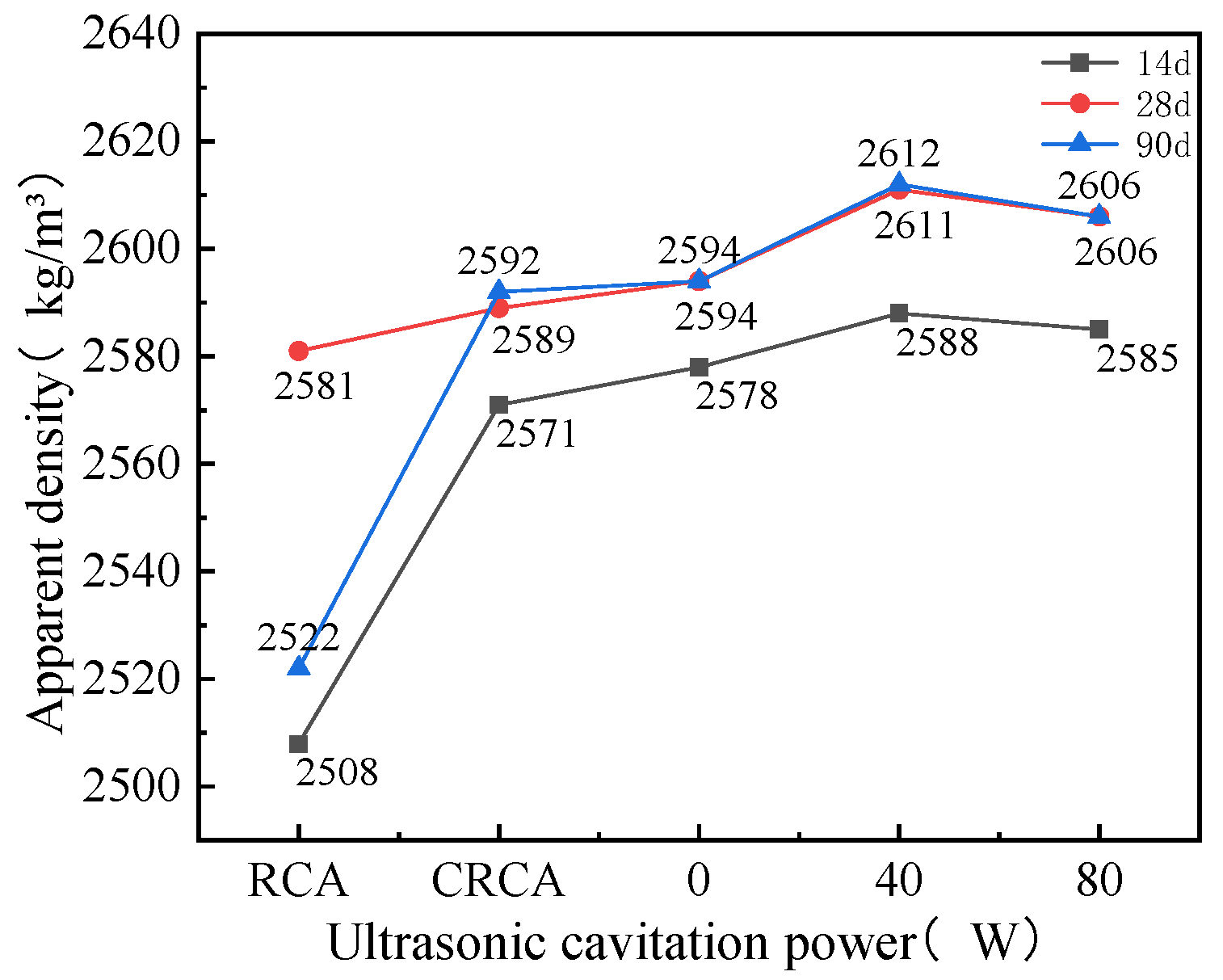

3.1.3. Physical Properties of L-RCA After Carbonization

3.1.4. Physical Properties of W-RCA After Carbonization

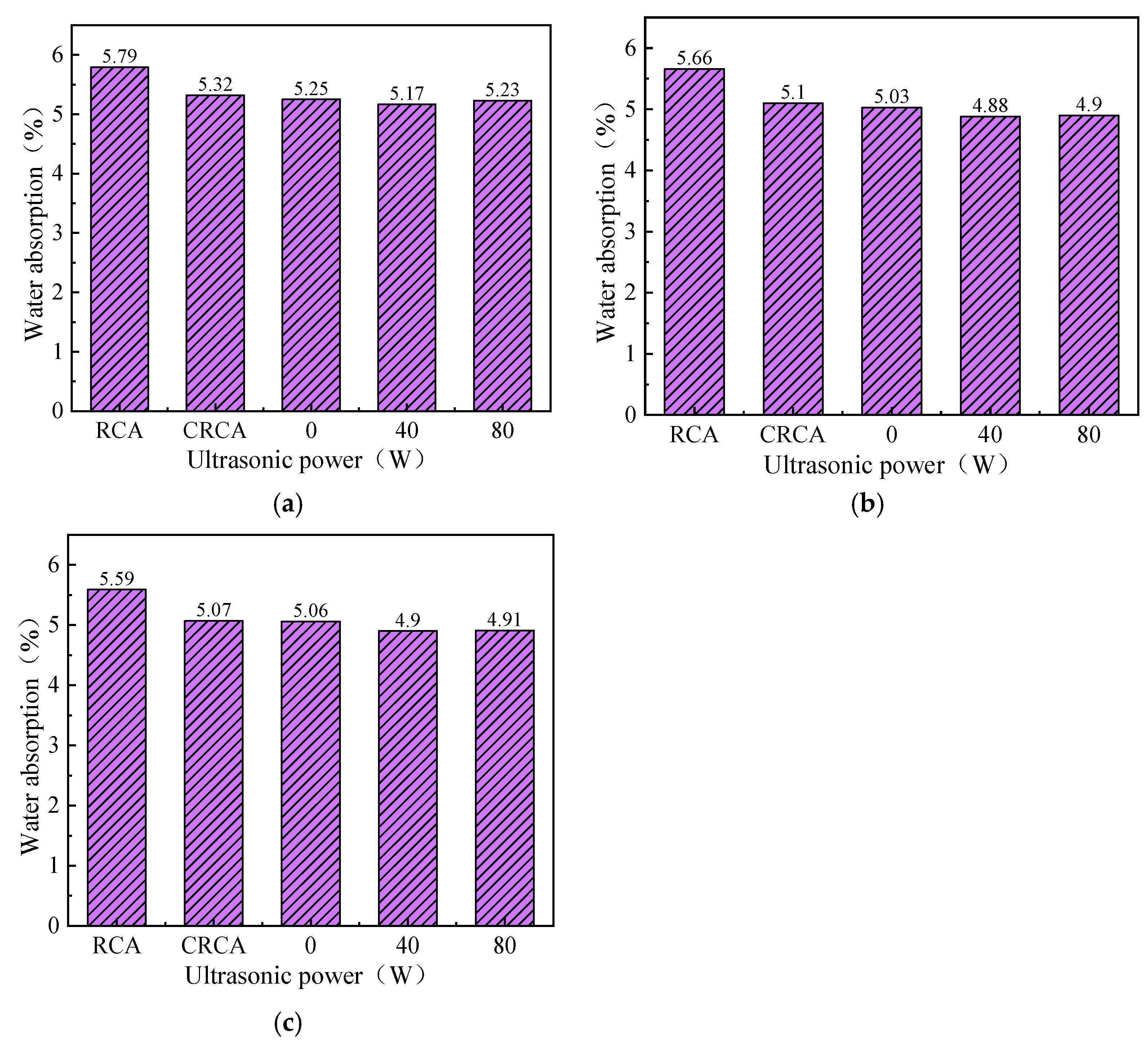

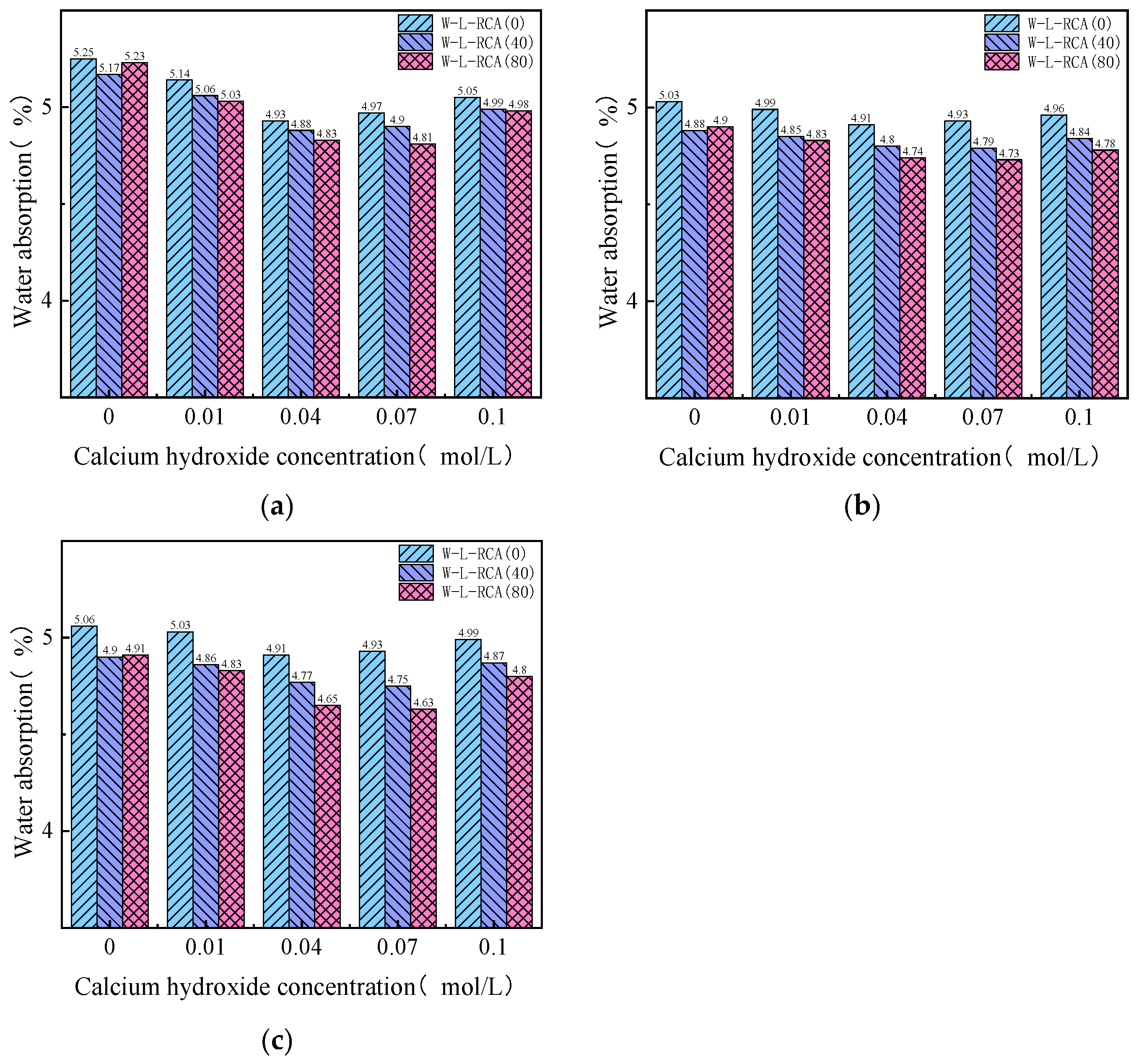

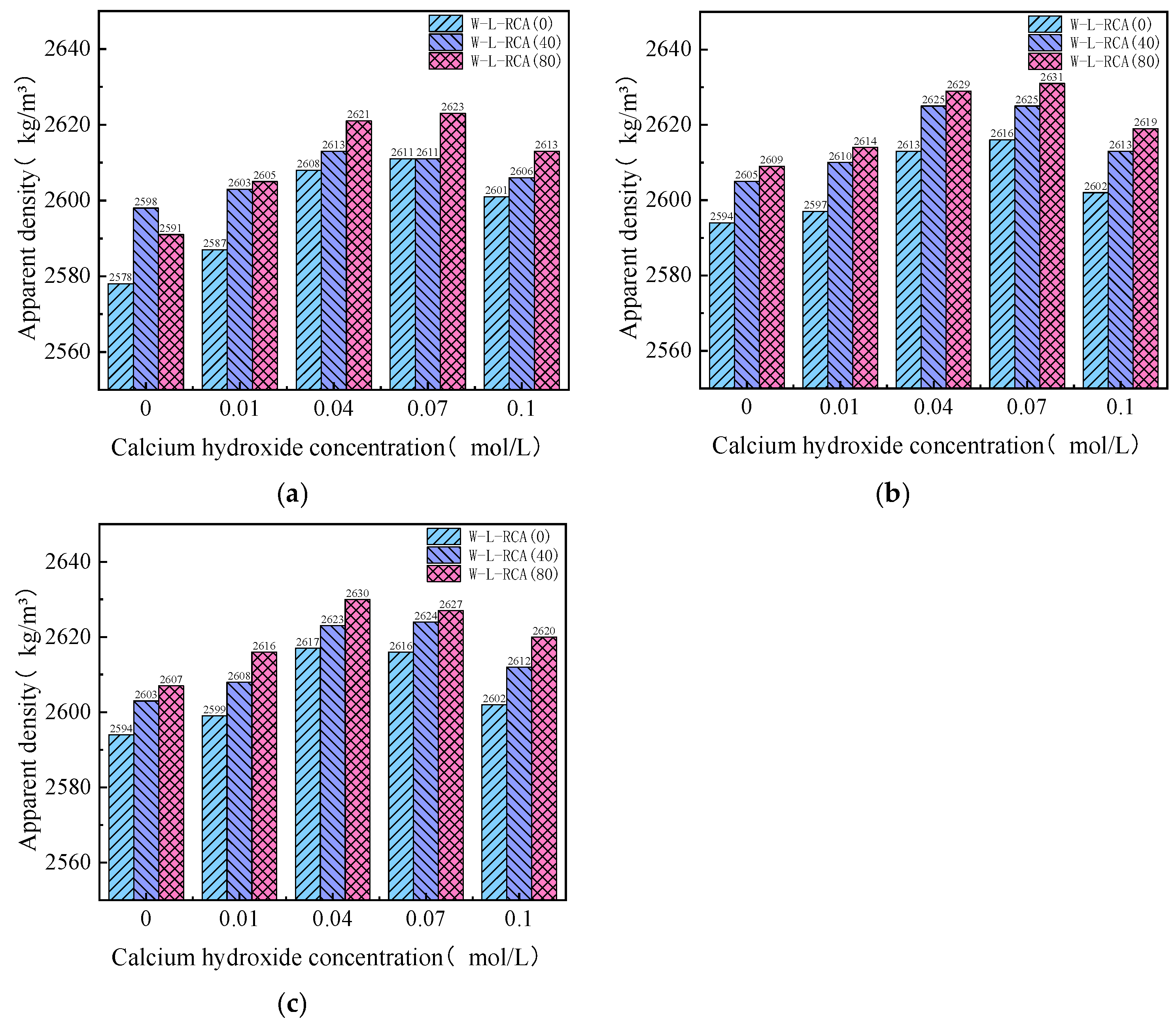

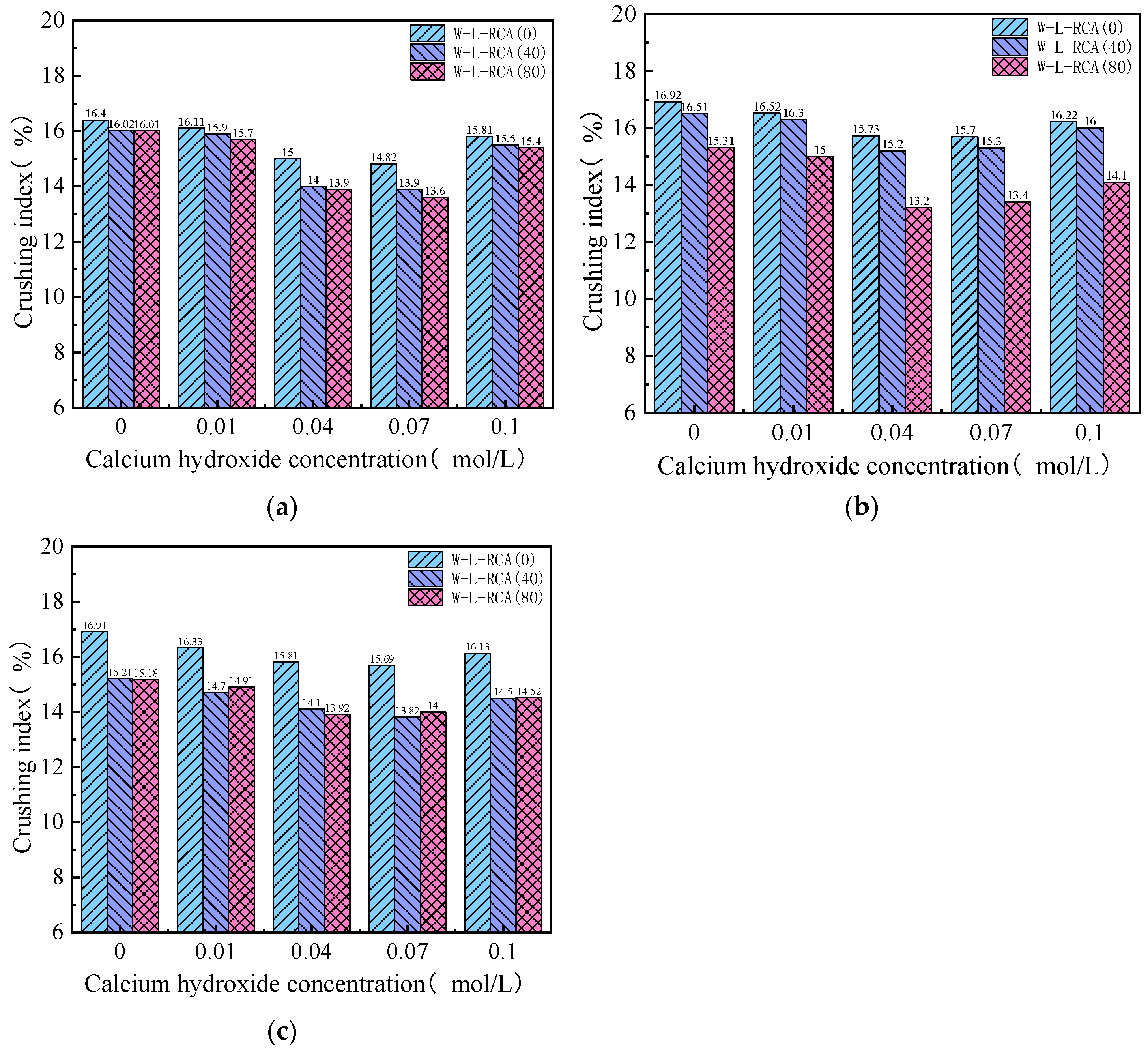

3.1.5. Physical Properties of W-L-RCA After Carbonization

3.2. Micromechanical Study of Carbonized Recycled Aggregates

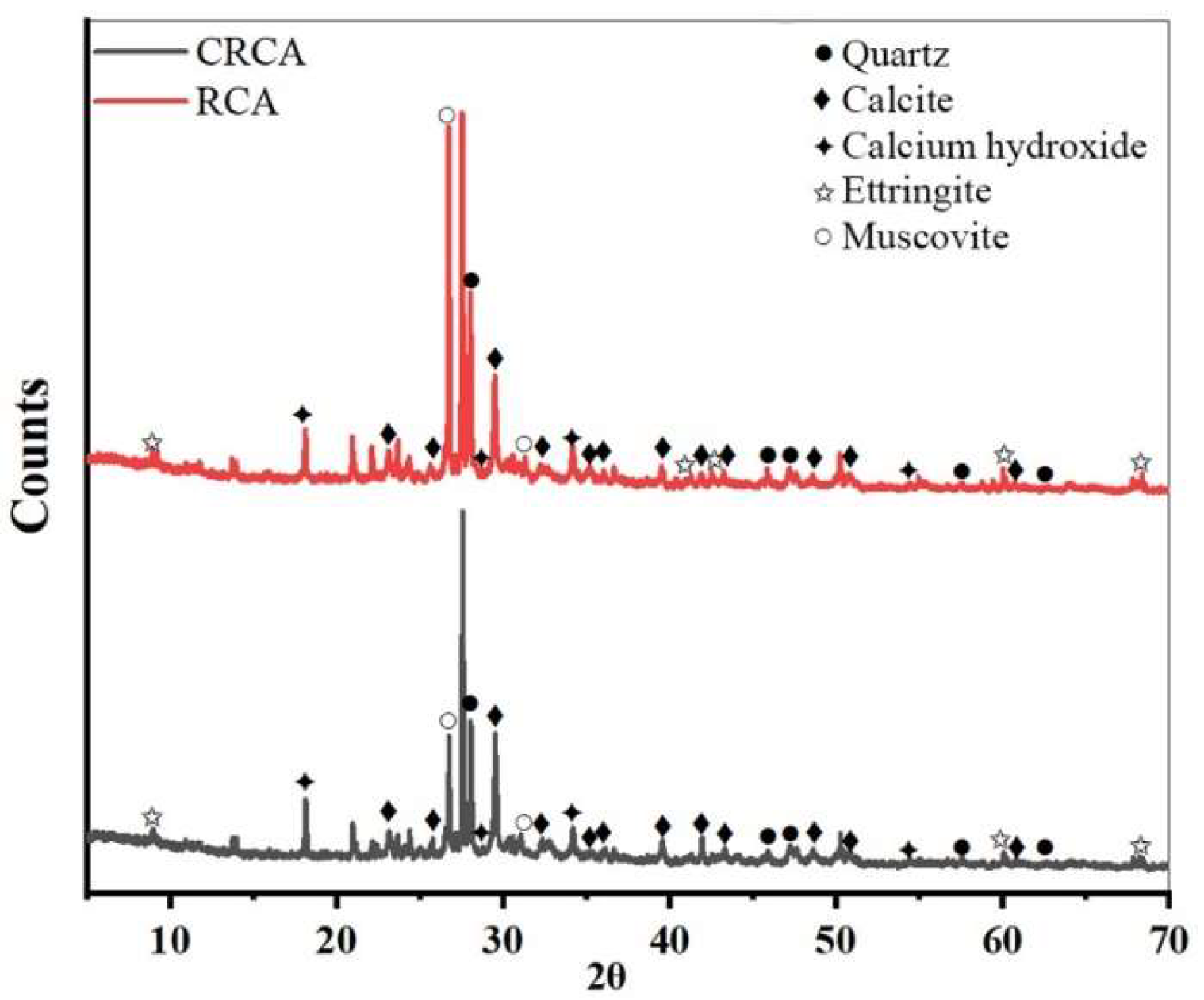

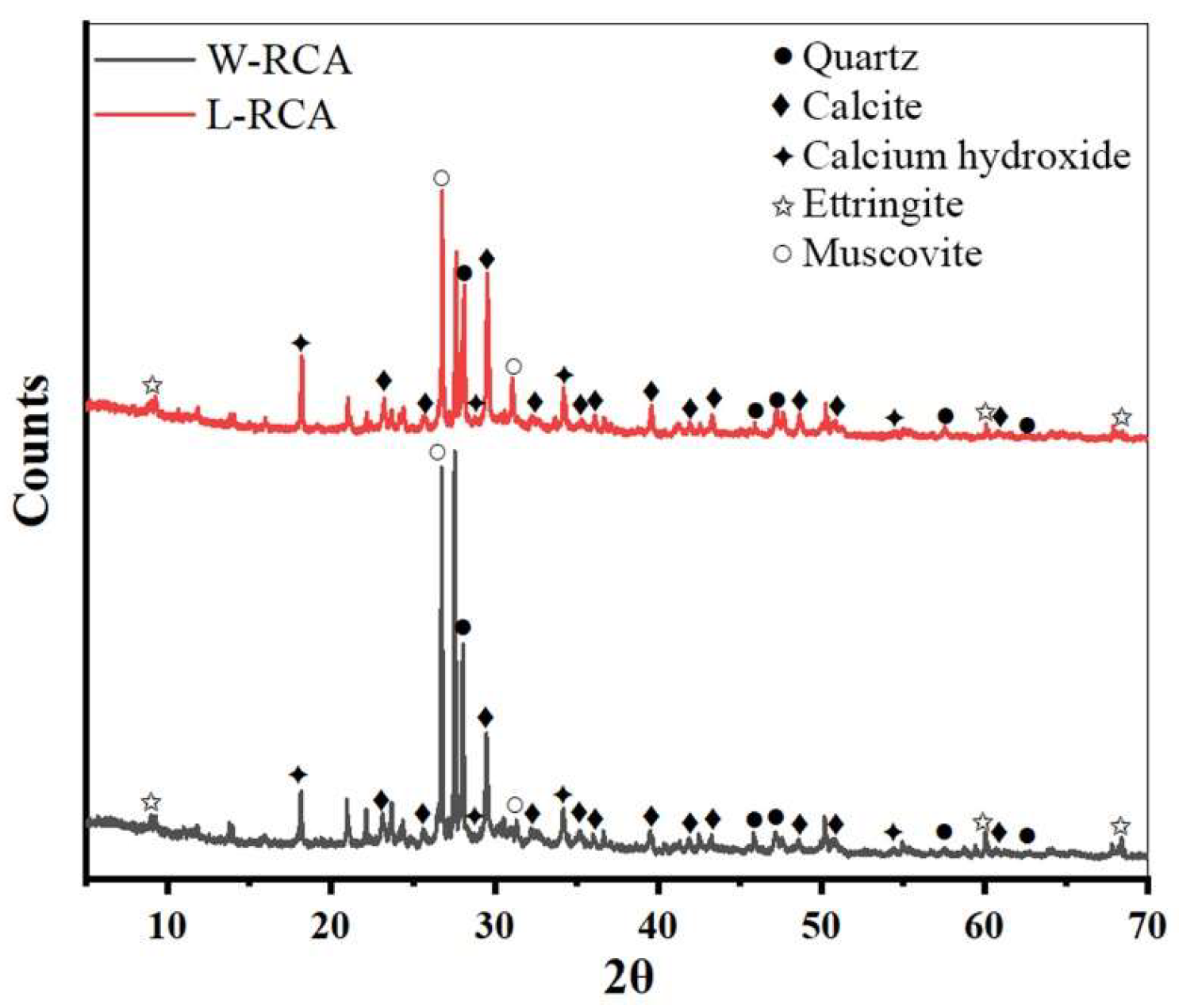

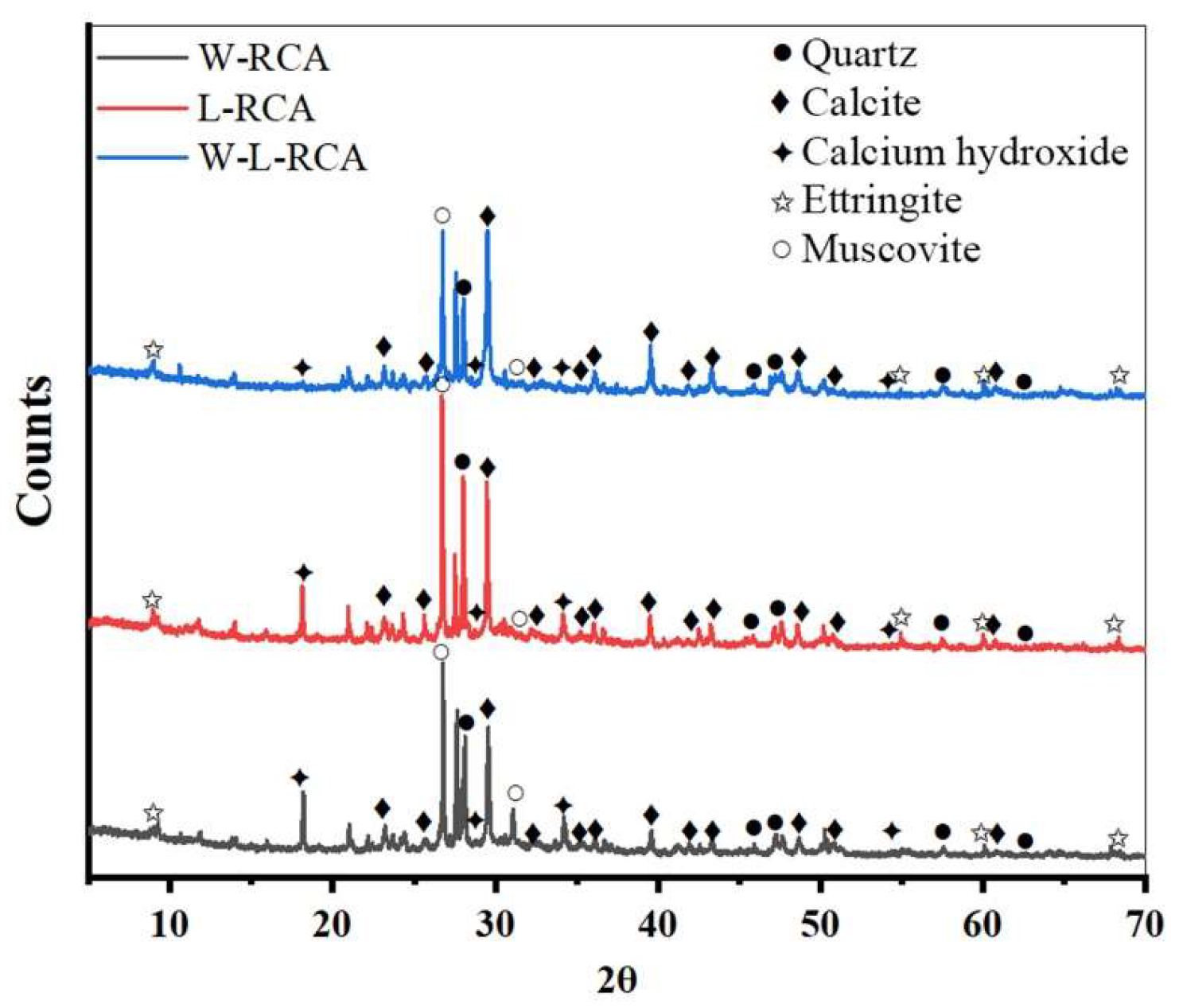

3.2.1. XRD Analysis of Recycled Aggregate Attached Mortar

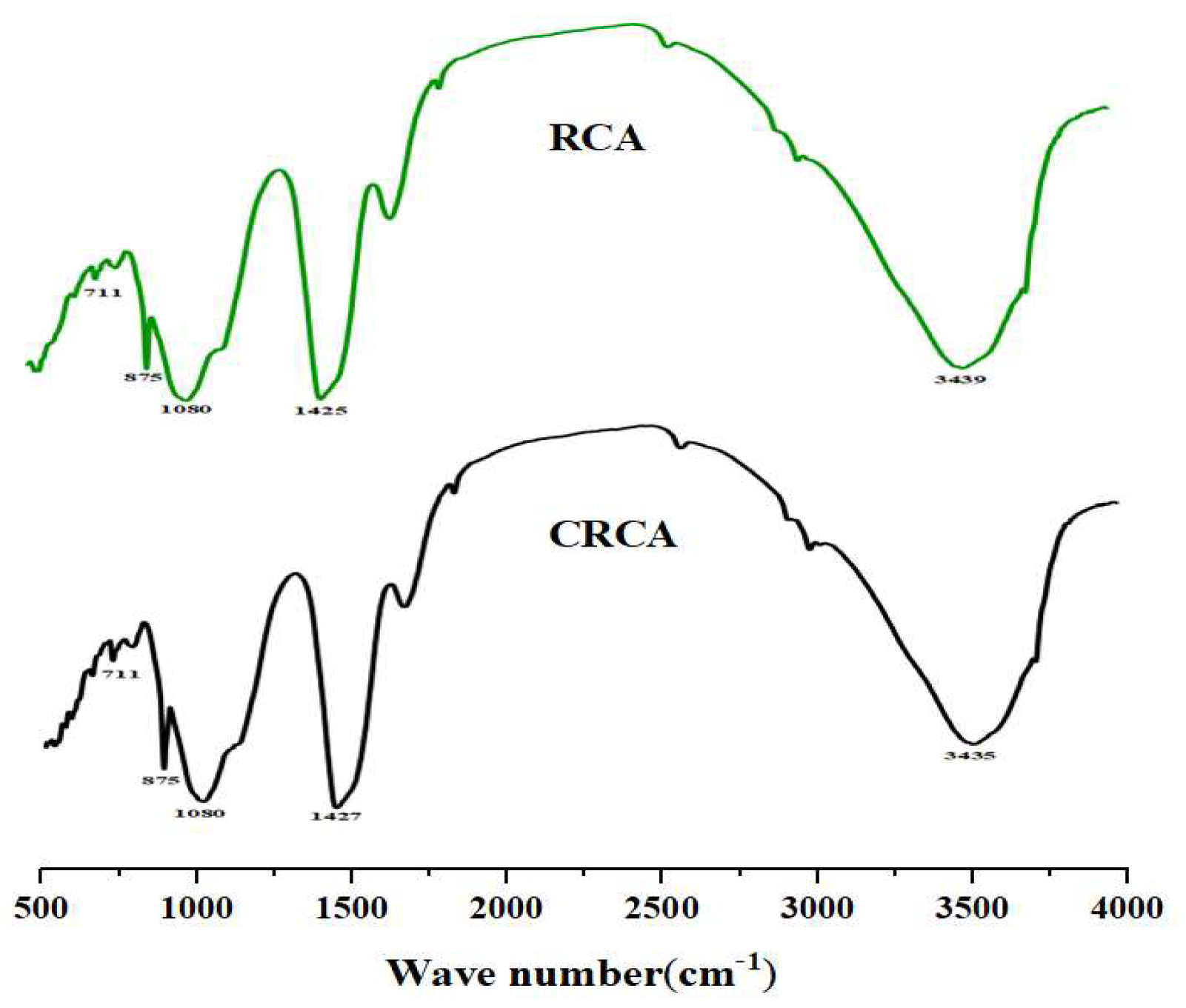

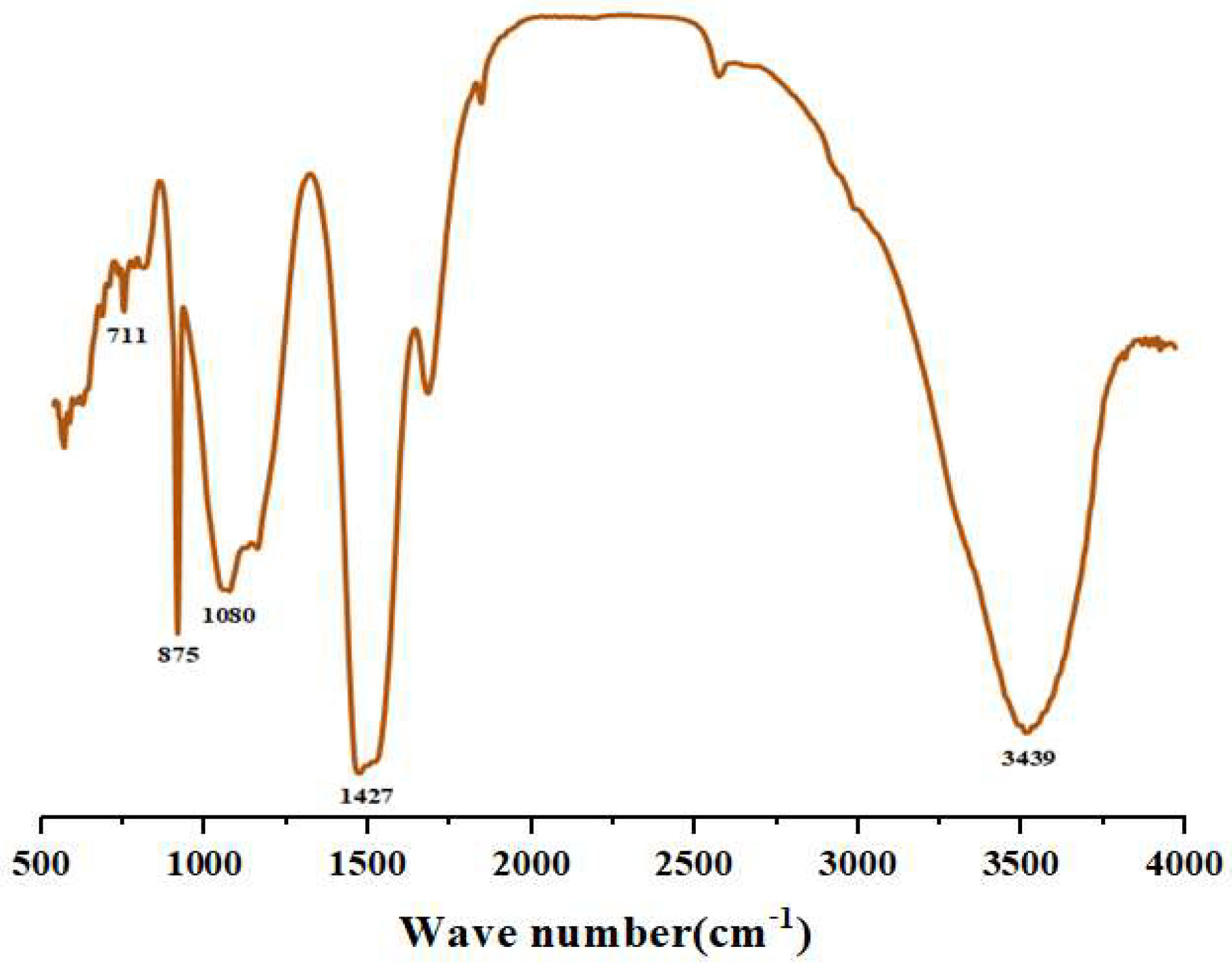

3.2.2. Infrared Spectral Analysis of Recycled Aggregates

3.2.3. Transition Zone Morphology of Recycled Aggregate Interface

4. Discussion

4.1. Effect of Carbonization Treatment on Physical Properties of RCA

4.2. Enhancement of RCA Carbonization Effect by Calcium Hydroxide Pretreatment

4.3. Effect of Ultrasonic Cavitation Pretreatment on the Carbonization Effect of RCA

4.4. Synergistic Effect of Ultrasonic Cavitation and Calcium Hydroxide Pretreatment

4.5. Microstructure Analysis

5. Future Research Directions

5.1. Study of Optimized Processing Conditions

5.2. Long-Term Performance and Durability Studies

5.3. Integration Studies with Other Technologies

5.4. Environmental Benefits and Economic Cost Analysis

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2006, 50, 71–81. [Google Scholar] [CrossRef]

- Annual report on the comprehensive utilization of resources in China. Recycl. Resour. Circ. Econ. 2014, 7, 3–8.

- China Building Materials Industry Carbon Emission Report. China Build. Mater. 2021, 64, 59–62. [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Tian, J. Comprehensive Benefit Analysis of Recycled Aggregate Produced by Construction Waste. Master’s Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Gluzhge, P. The work of scientific research institute. Gidrotekhnicheskoye Stroit. 1946, 4, 27–28. [Google Scholar]

- ABE Michihiko. Efficient use of construction by-products. Civ. Constr. 1995, 36, 7–9. [Google Scholar]

- Juan MS, D.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2008, 23, 872–877. [Google Scholar] [CrossRef]

- Li, J.; Xiao, J.; Sun, Z. Properties of Recycled Coarse Aggregate and Its Influence on Recycled Concrete. J. Build. Mater. 2004, 7, 390–395. [Google Scholar]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Quan, H.; Ding, J.; Zhu, Y.; Yang, X.; Li, Q. Experimently Study on Effects of Different Properties of Recycled Coarse Aggregates on Strengths and Durability of Concrete. In Proceedings of the 1st Symposium on Research and Application of Recycled Concrete in P.R. China, Shanghai, China, 18–19 July 2008. [Google Scholar]

- Zhang, J. The Characteristics of Mechanical Properties of Recycled Aggregate Concrete and Influencing Factor. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2010. [Google Scholar]

- Lei, B.; Xiao, J. Research on Carbonation Resistance of Recycled Aggregate Concrete. J. Build. Mater. 2008, 11, 605–611. [Google Scholar]

- Ding, Y.; Wu, J.; Xu, P.; Zhang, X.; Fan, Y. Treatment Methods for the Quality Improvement of Recycled Concrete Aggregate (RCA)—A Review. J. Wuhan Univ. Technol. -Mater. Sci. Ed. 2021, 36, 77–92. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, Q.; Li, W.; Vivian, T. On the Micro-and Meso-Structure and Failure Mechanism of Recycled Concrete. J. Qingdao Technol. Univ. 2009, 30, 24–30. [Google Scholar]

- Leite, M.B.; Monteiro, P.J.M. Microstructural analysis of recycled concrete using X-ray microtomography. Cem. Concr. Res. 2016, 81, 38–48. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhu, P.; Feng, J.; Hu, K. Mechanical Properties and ITZ Microstructure of Recycled Aggregate Concrete Using Carbonated Recycled Coarse Aggregate. J. Wuhan Univ. Technol. -Mater. Sci. Ed. 2018, 33, 648–653. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.G.; Sun, Z.H.; Lange, D.A.; Shah, S.P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem. Concr. Compos. 2013, 37, 276–292. [Google Scholar] [CrossRef]

- Cheng, X.; Lin, Z.; Ren, P. Review of CO2 curing for concrete and recycled concrete. Concrete 2020, 42, 156–160. [Google Scholar]

- Yuan, C.; Niu, D.; Chen, N.; Duan, F. Effect of carbonation on the microstructure of concrete. Bull. Chin. Ceram. Soc. 2013, 32, 687–691+707. [Google Scholar] [CrossRef]

- Kuang, T. Effect of Carbonization on Microstructure of Recycled Concrete. Master’s Thesis, Southeast University, Nanjing, China, 2018. [Google Scholar]

- Tang, W. Research on Key Technology of Utilization of Recycled Concrete Aggregate to Sequestrate CO2. Master’s Thesis, Shenzhen University, Shenzhen, China, 2019. [Google Scholar]

- Kou, S.-C.; Zhan, B.-J.; Poon, C.-S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S. Enhancement of recycled aggregate properties by accelerated CO2 curing coupled with limewater soaking process. Cem. Concr. Compos. 2018, 89, 230–237. [Google Scholar] [CrossRef]

- Fang, X.; Zhan, B.; Poon, C.S. Enhancement of recycled aggregates and concrete by combined treatment of spraying Ca2+ rich wastewater and flow-through carbonation. Constr. Build. Mater. 2021, 277, 122202. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Cao, Z.; Ling, T.C.; Zheng, J. Performance of mortar prepared with recycled concrete aggregate enhanced by CO2 and pozzolan slurry. Cem. Concr. Compos. 2018, 86, 130–138. [Google Scholar] [CrossRef]

- Li, Y.; Fu, T.; Wang, R.; Li, Y. An assessment of microcracks in the interfacial transition zone of recycled concrete aggregates cured by CO2. Constr. Build. Mater. 2020, 236, 117543. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Cao, D.; Dang, H.; Ding, B. Comparison of recycled aggregate treatment methods on the performance for recycled concrete. Constr. Build. Mater. 2020, 234, 117366. [Google Scholar] [CrossRef]

- Li, L.; Poon, C.S.; Xiao, J.; Xuan, D. Effect of carbonated recycled coarse aggregate on the dynamic compressive behavior of recycled aggregate concrete. Constr. Build. Mater. 2017, 151, 52–62. [Google Scholar] [CrossRef]

- Ying, J.; Meng, Q.; Xiao, J. CO2 strengthening of recycled aggregate and its influence on compressive strength of concrete. J. Build. Mater. 2017, 20, 277–282. [Google Scholar]

- Luo, S.; Ye, S.; Xiao, J.Z.; Zheng, J.; Zhu, Y. Carbonated recycled coarse aggregate and uniaxial compressive stress-strain relation of recycled aggregate concrete. Constr. Build. Mater. 2018, 188, 956–965. [Google Scholar] [CrossRef]

- Ding, J. Effects of the replacement ratio of carbonized recycled fine aggregate on the compressive strength of recycled concrete. J. Fujian Univ. Technol. 2019, 17, 13–16. [Google Scholar]

- Medina, C.; Zhu, W.; Howind, T.; de Rojas, M.I.S.; Frías, M. Influence of mixed recycled aggregate on the physical—Mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Tam VW, Y.; Butera, A.; Le, K.N. Carbon-conditioned recycled aggregate in concrete production. J. Clean. Prod. 2016, 133, 672–680. [Google Scholar] [CrossRef]

- Kazmi, S.M.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Xuan, D.X.; Zhan, B.J.; Poon, C.S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cem. Concr. Compos. 2016, 65, 67–74. [Google Scholar] [CrossRef]

- GB175-2007; Universal Silicate Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2007.

- GB/T14684-2001; Construction Sand. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2001.

- JGJ52-2006; Standard for Quality and Test Method of Sand and Stone for Ordinary Concrete. Ministry of Construction of the People’s Republic of China: Beijing, China, 2006.

| Chemical Composition | Cao | Al2O3 | TiO2 | Fe2O3 | SiO2 | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| content | 57.28 | 6.23 | 1.07 | 6.79 | 21.74 | 3.48 | 0.62 | 0.56 |

| Water/Cement Ratio | Age (Days) | Water Absorption (%) | Apparent Density (kg/m3) | Crush Indicator (%) |

|---|---|---|---|---|

| 14 | 5.79% | 2508 | 17.60 | |

| 0.4 | 28 | 5.66% | 2518 | 18.40 |

| 90 | 5.59% | 2522 | 18.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, M.; Li, X.; Wei, M.; Xie, Q. Experimental Study on Carbonization and Strengthening Performance of Recycled Aggregate. Buildings 2025, 15, 2309. https://doi.org/10.3390/buildings15132309

Lin M, Li X, Wei M, Xie Q. Experimental Study on Carbonization and Strengthening Performance of Recycled Aggregate. Buildings. 2025; 15(13):2309. https://doi.org/10.3390/buildings15132309

Chicago/Turabian StyleLin, Mingqiang, Xiang Li, Maozhi Wei, and Qun Xie. 2025. "Experimental Study on Carbonization and Strengthening Performance of Recycled Aggregate" Buildings 15, no. 13: 2309. https://doi.org/10.3390/buildings15132309

APA StyleLin, M., Li, X., Wei, M., & Xie, Q. (2025). Experimental Study on Carbonization and Strengthening Performance of Recycled Aggregate. Buildings, 15(13), 2309. https://doi.org/10.3390/buildings15132309