Improve Integrated Material Handling (IMH) Efficiency of Local High-Rise Building Projects by IMH Framework Optimization and Empirical Analysis

Abstract

1. Introduction

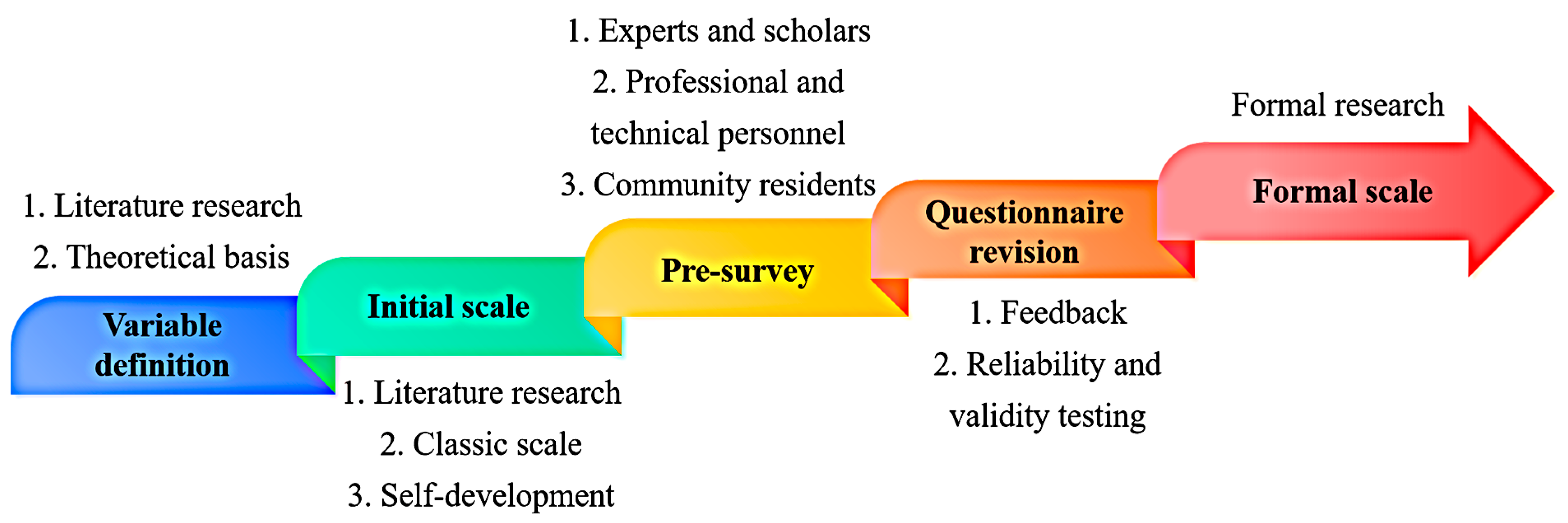

2. Data and Methods

2.1. Data Collection

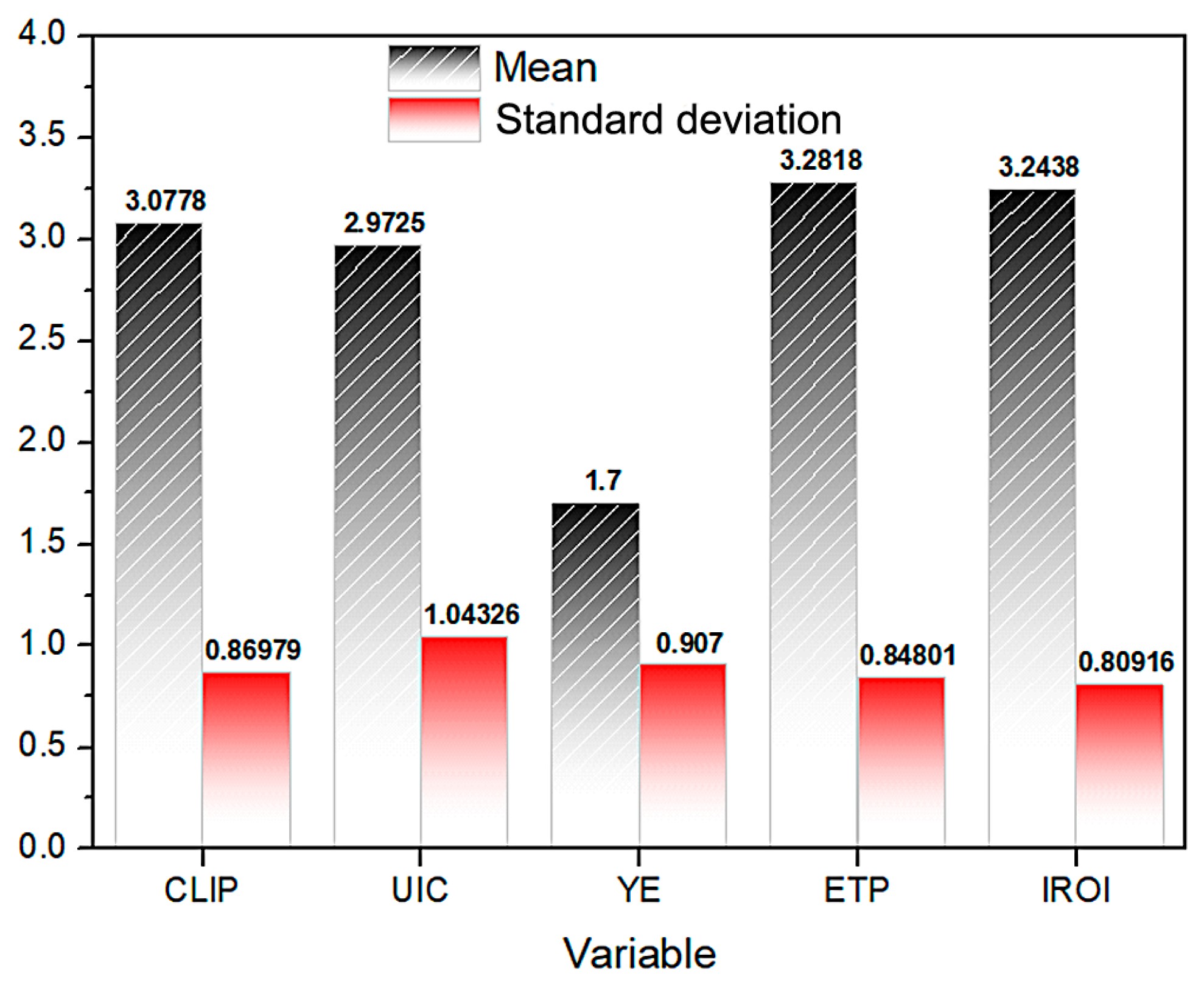

2.2. Data Description

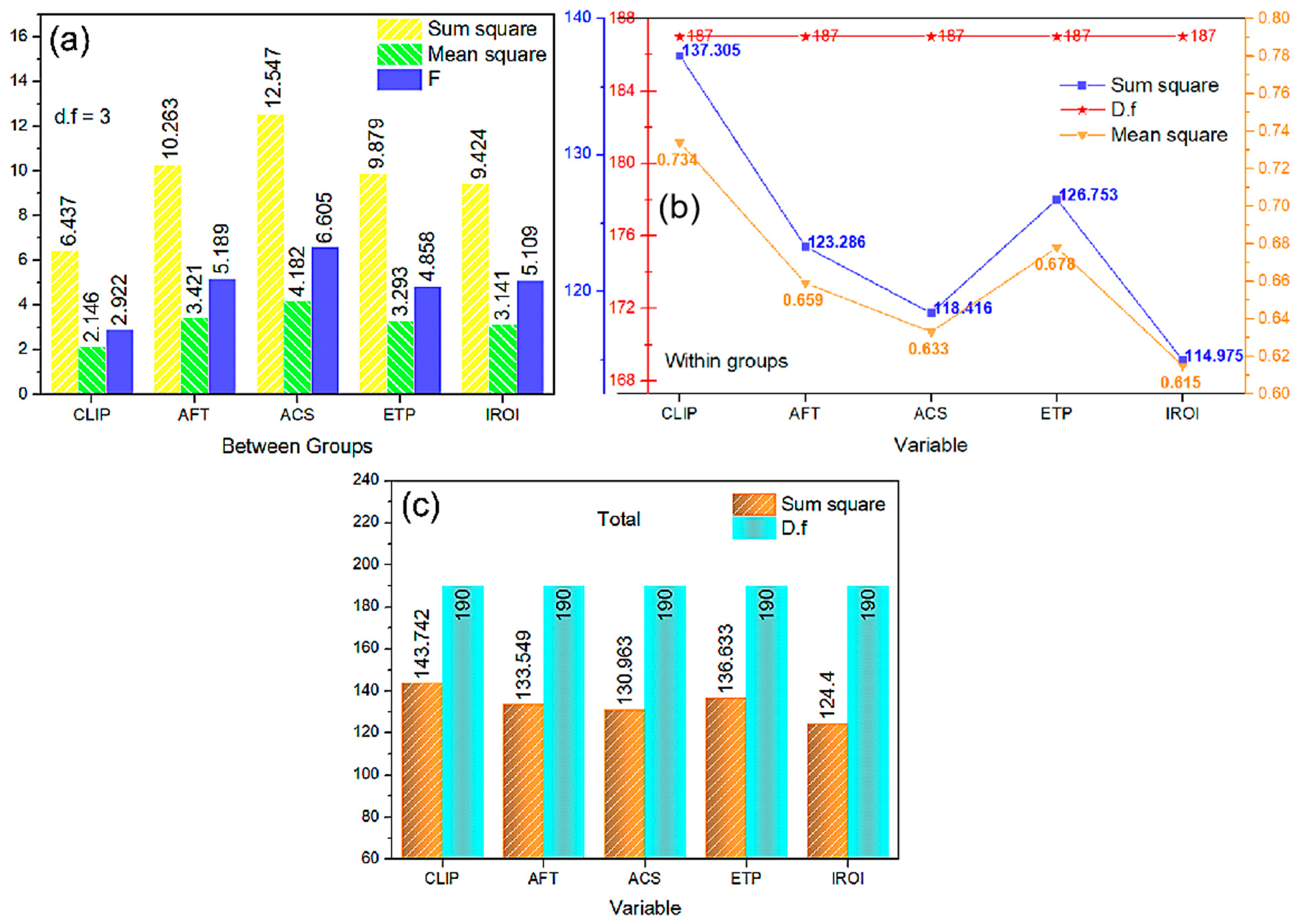

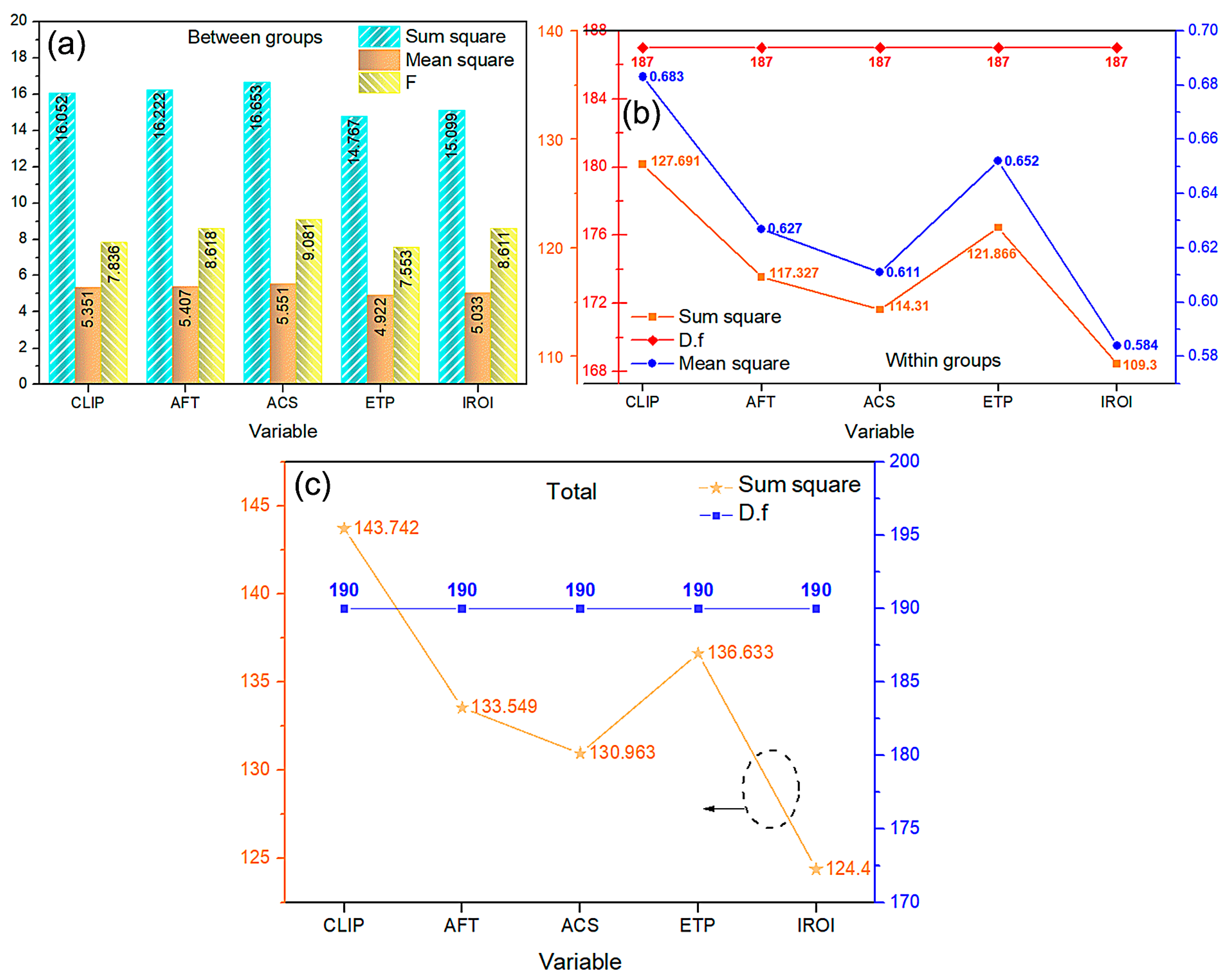

2.3. Reliability Analysis

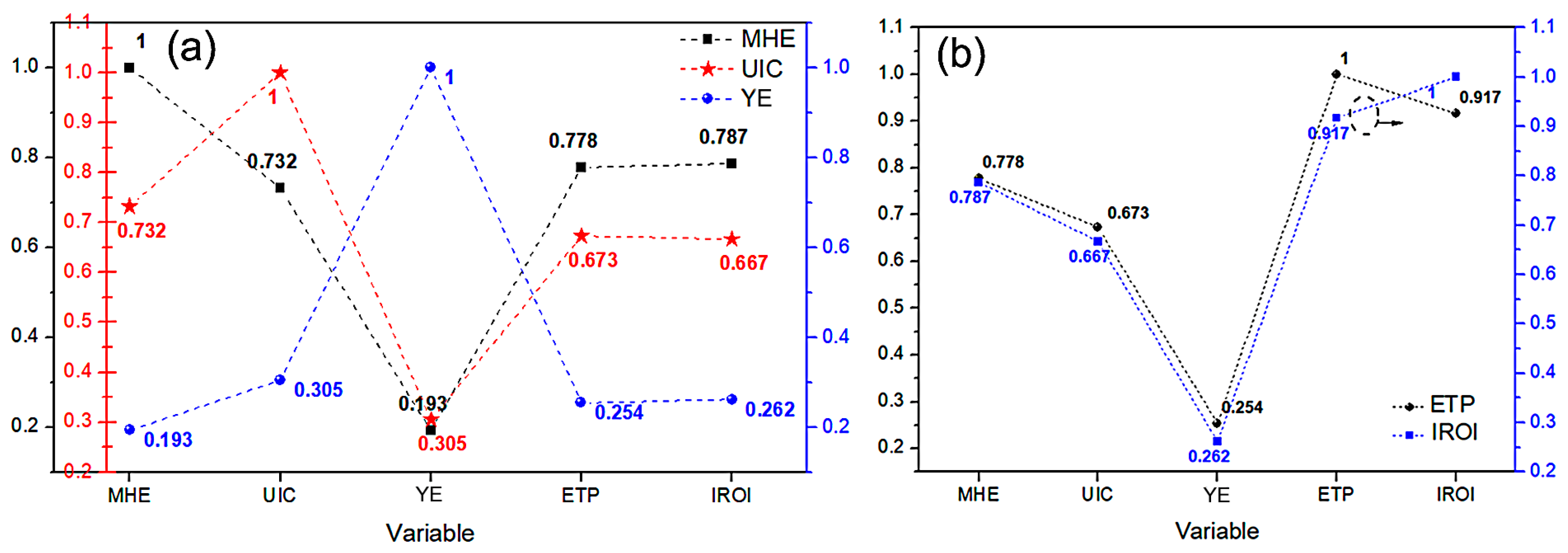

2.4. Correlation Analysis

2.5. Independent Sample t-Test

2.6. Analysis of Variance (ANOVA)

2.7. Regression Analysis

3. Results and Discussion

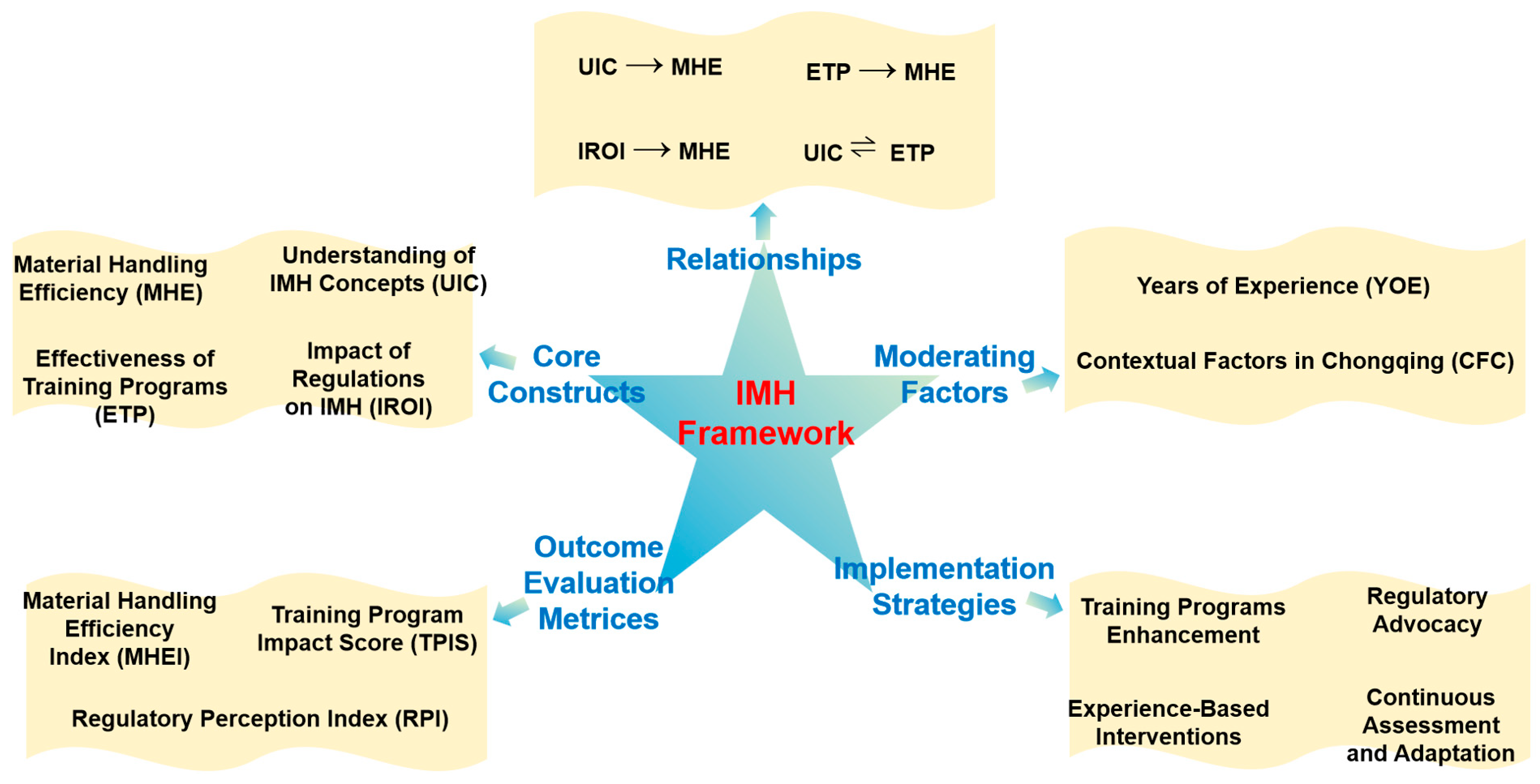

3.1. Construction of IMH Model Framework

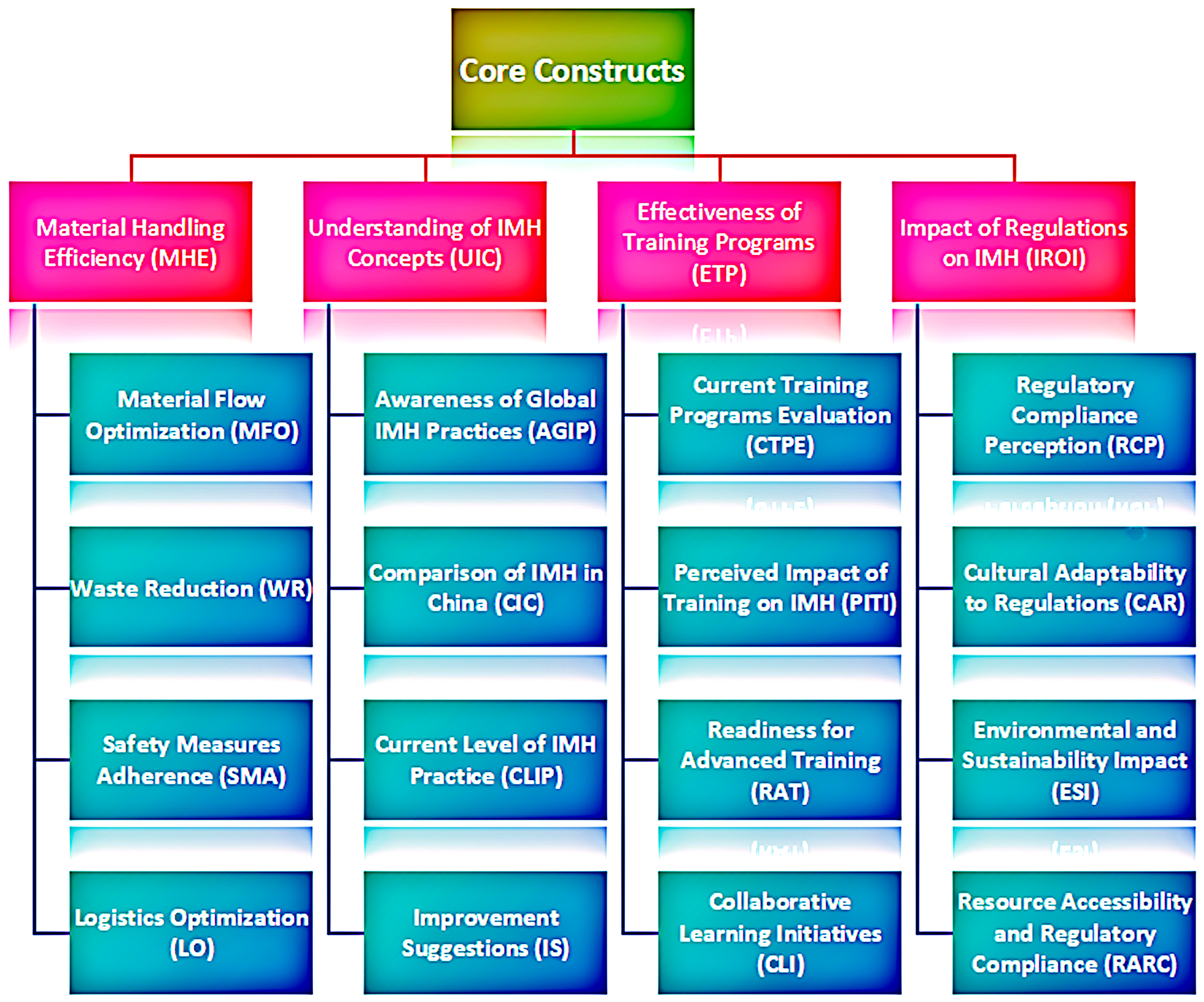

3.2. Components of the Model

3.3. Implementation Strategies

3.4. Effectiveness Assessment Indicators

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, J.; Broere, W.; Lin, D. Underground space utilisation for urban renewal. Tunn. Undergr. Space Technol. 2021, 108, 103726. [Google Scholar] [CrossRef]

- Alebooyeh, M.; Urbanic, J. Development of robotic automation solutions for limp flexible material handling leveraging a finite element modelling technique. Int. J. Adv. Manuf. Technol. 2024, 132, 781–800. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, B.; Chen, J. Low-carbon design path of building integrated photovoltaics: A comparative study based on green building rating systems. Buildings 2021, 11, 469. [Google Scholar] [CrossRef]

- Pence, I.W. A Perspective on Material Handling Engineering: History and New Challenges. J. Manuf. Sci. Eng. 1997, 119, 835–840. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Ferruzzi, G.; Palombo, A. Dynamic energy performance analysis: Case study for energy efficiency retrofits of hospital buildings. Energy 2014, 78, 555–572. [Google Scholar] [CrossRef]

- Jalali Yazdi, A.; Maghrebi, M.; Bolouri Bazaz, J. Mathematical model to optimally solve the lift planning problem in high-rise construction projects. Autom. Constr. 2018, 92, 120–132. [Google Scholar] [CrossRef]

- Jung, M.; Park, M.; Lee, H.-S.; Chi, S. Multimethod supply chain simulation model for high-rise building construction projects. J. Comput. Civ. Eng. 2018, 32, 04018007. [Google Scholar] [CrossRef]

- Cui, Z.; Wang, H.; Xu, J. Risk Assessment of Concentralized Distribution Logistics in Cruise-Building Imported Materials. Processes 2023, 11, 859. [Google Scholar] [CrossRef]

- Nolz, P.C. Optimizing construction schedules and material deliveries in city logistics: A case study from the building industry. Flexible Serv. Manuf. J. 2020, 33, 846–878. [Google Scholar] [CrossRef]

- Liu, T.; Chen, L.; Yang, M.; Sandanayake, M.; Miao, P.; Shi, Y.; Yap, P.-S. Sustainability considerations of green buildings: A detailed overview on current advancements and future considerations. Sustainability 2022, 14, 14393. [Google Scholar] [CrossRef]

- Rajeshkumar, V.; Anandaraj, S.; Kavinkumar, V.; Elango, K.S. Analysis of factors influencing formwork material selection in construction buildings. Mater. Today Proc. 2021, 37, 880–885. [Google Scholar] [CrossRef]

- Lu, W.; Peng, Z.; Webster, C.; Wu, L. Developing a construction waste material ‘passport’ for cross-jurisdictional trading. J. Clean. Prod. 2023, 414, 137509. [Google Scholar] [CrossRef]

- Umar, U.A.; Shafiq, N.; Ahmad, F.A. A case study on the effective implementation of the reuse and recycling of construction & demolition waste management practices in Malaysia. Ain Shams Eng. J. 2021, 12, 283–291. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Yuan, H.; Zillante, G.; Wang, J. A review of performance assessment methods for construction and demolition waste management. Resour. Conserv. Recycl. 2019, 150, 104407. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Patil, M.; Boraste, S.; Minde, P. A comprehensive review on emerging trends in smart green building technologies and sustainable materials. Mater. Today Proc. 2022, 65, 1813–1822. [Google Scholar] [CrossRef]

- Teng, Y.; Pan, W. Estimating and minimizing embodied carbon of prefabricated high-rise residential buildings considering parameter, scenario and model uncertainties. Build. Environ. 2020, 180, 106951. [Google Scholar] [CrossRef]

- He, Q.; Hossain, M.U.; Ng, S.T.; Augenbroe, G. Identifying practical sustainable retrofit measures for existing high-rise residential buildings in various climate zones through an integrated energy-cost model. Renew. Sustain. Energy Rev. 2021, 151, 111578. [Google Scholar] [CrossRef]

- Xu, M.; Nie, X.; Li, H.; Cheng, J.C.P.; Mei, Z. Smart construction sites: A promising approach to improving on-site HSE management performance. J. Build. Eng. 2022, 49, 104007. [Google Scholar] [CrossRef]

- Foecke, T.; Banovic, S.W.; Gayle, F.W. Assessment of structural steel from the world trade center towers, part II: Analysis of images for forensic information. J. Fail. Anal. Prev. 2006, 6, 70–85. [Google Scholar] [CrossRef]

- Navaratnam, S. Selecting a suitable sustainable construction method for australian high-rise building: A multi-criteria analysis. Sustainability 2022, 14, 7435. [Google Scholar] [CrossRef]

- Yongqian, W.; Dejun, Z.; Liang, S.; Shiqi, Y.; Tang, S.; Yanghua, G.; Qinyu, Y.; Hao, Z. Evaluating FY3C-VIRR reconstructed land surface temperature in cloudy regions. Eur. J. Remote Sens. 2021, 54, 266–280. [Google Scholar] [CrossRef]

- Sepasgozar, S.; Khan, A.; Smith, K.; Romero, J.; Shen, X.; Shirowzhan, S.; Li, H.; Tahmasebinia, F. BIM and digital twin for developing convergence technologies as future of digital construction. Buildings 2023, 13, 441. [Google Scholar] [CrossRef]

- Guo, Y.; Tang, R. Research on the application of BIM technology in computer aided architectural design. J. Phys. Conf. Ser. 2020, 1574, 012074. [Google Scholar] [CrossRef]

- Xie, M.; Qiu, Y.; Liang, Y.; Zhou, Y.; Liu, Z.; Zhang, G. Policies, applications, barriers and future trends of building information modeling technology for building sustainability and informatization in China. Energy Rep. 2022, 8, 7107–7126. [Google Scholar] [CrossRef]

- Miljković, Z.; Vuković, N.; Mitić, M.; Babić, B. New hybrid vision-based control approach for automated guided vehicles. Int. J. Adv. Manuf. Technol. 2012, 66, 231–249. [Google Scholar] [CrossRef]

- Javanroodi, K.; Nik, V.M.; Mahdavinejad, M. A novel design-based optimization framework for enhancing the energy efficiency of high-rise office buildings in urban areas. Sustain. Cities Soc. 2019, 49, 101597. [Google Scholar] [CrossRef]

- Ali, S.B.M.; Mehdipoor, A.; Samsina Johari, N.; Hasanuzzaman, M.; Rahim, N.A. Modeling and performance analysis for high-rise building using ArchiCAD: Initiatives towards energy-efficient building. Sustainability 2022, 14, 9780. [Google Scholar] [CrossRef]

- Pakulski, J.D. The release of reducing sugars and dissolved organic carbon from Spartina alterniflora Loisel in a Georgia salt marsh. Estuar. Coast. Shelf Sci. 1986, 22, 385–394. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Li, Y.; Ning, Y.; Chen, W.T.; Chan, D.W.M. Critical success factors for safety management of high-rise building construction projects in China. Adv. Civ. Eng. 2018, 2018, 1516354. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S.; Wang, H. Construction automation and robotics for high-rise buildings: Development priorities and key challenges. J. Constr. Eng. Manag. 2020, 146, 04020096. [Google Scholar] [CrossRef]

- Yonemoto, R.; Suwa, H. Task Scheduling of Material-Handling Manipulator for Enhancing Energy Efficiency in Flow-Type FMS. Int. J. Autom. Technol. 2020, 14, 943–950. [Google Scholar] [CrossRef]

- Wang, K.; Xue, Y.; Guo, Q.; Shahidehpour, M.; Zhou, Q.; Wang, B.; Sun, H. A Coordinated Reconfiguration Strategy for Multi-Stage Resilience Enhancement in Integrated Power Distribution and Heating Networks. IEEE Trans. Smart Grid 2023, 14, 2709–2722. [Google Scholar] [CrossRef]

- Wang, K.; Xue, Y.; Shahidehpour, M.; Chang, X.; Li, Z.; Zhou, Y.; Sun, H. Resilience-Oriented Two-Stage Restoration Considering Coordinated Maintenance and Reconfiguration in Integrated Power Distribution and Heating Systems. IEEE Trans. Sustain. Energy 2025, 16, 124–137. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Jin, X.; Wang, P.; Sun, H. Risk-averse energy management for integrated electricity and heat systems considering building heating vertical imbalance: An asynchronous decentralized approach. Appl. Energy 2025, 383, 125271. [Google Scholar] [CrossRef]

- Ding, B.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Sun, H. Cooperative Operation for Multiagent Energy Systems Integrated with Wind, Hydrogen, and Buildings: An Asymmetric Nash Bargaining Approach. IEEE Trans. Ind. Inform. 2025, 1–12. [Google Scholar] [CrossRef]

- Zinbarg, R.E.; Revelle, W.; Yovel, I.; Li, W. Cronbach’s α, revelle’s β, and mcdonald’s ωh: Their relations with each other and two alternative conceptualizations of reliability. Psychometrika 2025, 70, 123–133. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, X.; Wang, L. A Pearson’s correlation coefficient based decision tree and its parallel implementation. Inf. Sci. 2018, 435, 40–58. [Google Scholar] [CrossRef]

- Castro, R.; Pasanen, P. How to design buildings with Life Cycle Assessment by accounting for the material flows in refurbishment. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012019. [Google Scholar] [CrossRef]

- Guo, Z.; Tao, H.; Yang, Y.; Lin, W. Evaluating the Effectiveness and Efficiency of a Training Program for Tunnel Construction Workers. Buildings 2024, 14, 3733. [Google Scholar] [CrossRef]

- Fischer, J.; Guy, S. Re-interpreting Regulations: Architects as Intermediaries for Low-carbon Buildings. Urban Stud. 2009, 46, 2577–2594. [Google Scholar] [CrossRef]

| Model | Sum of Squares | D.f | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Regression | 101.873 | 4 | 25.468 | 113.140 | 0.000 |

| Residual | 41.869 | 186 | 0.225 | - | - |

| Total | 143.742 | 190 | - | - | - |

| Model | R | R2 | R2 Adjusted | Standard Error | ΔR2 | ΔF | D.f1 | D.f2 | Sig. |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.842 | 0.709 | 0.702 | 0.47445 | 0.709 | 113.14 | 4 | 186 | 0.000 |

| Predictor Variable | Beta Coefficient | p Value | R-Squared |

|---|---|---|---|

| UIC | 0.42 | <0.05 | 0.29 |

| YE | 0.18 | 0.07 | 0.13 |

| ETP | 0.35 | <0.01 | 0.24 |

| IROI | 0.29 | <0.01 | 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, P.; Mohamed, G.F.E.; Lee, Y.S. Improve Integrated Material Handling (IMH) Efficiency of Local High-Rise Building Projects by IMH Framework Optimization and Empirical Analysis. Buildings 2025, 15, 2286. https://doi.org/10.3390/buildings15132286

Xiong P, Mohamed GFE, Lee YS. Improve Integrated Material Handling (IMH) Efficiency of Local High-Rise Building Projects by IMH Framework Optimization and Empirical Analysis. Buildings. 2025; 15(13):2286. https://doi.org/10.3390/buildings15132286

Chicago/Turabian StyleXiong, Ping, Ghazali F. E. Mohamed, and Yong Siang Lee. 2025. "Improve Integrated Material Handling (IMH) Efficiency of Local High-Rise Building Projects by IMH Framework Optimization and Empirical Analysis" Buildings 15, no. 13: 2286. https://doi.org/10.3390/buildings15132286

APA StyleXiong, P., Mohamed, G. F. E., & Lee, Y. S. (2025). Improve Integrated Material Handling (IMH) Efficiency of Local High-Rise Building Projects by IMH Framework Optimization and Empirical Analysis. Buildings, 15(13), 2286. https://doi.org/10.3390/buildings15132286