Experimental Study on the Force Mechanism of Internal Composite Connectors in Steel–Concrete Composite Sections of Bridge Towers

Abstract

1. Introduction

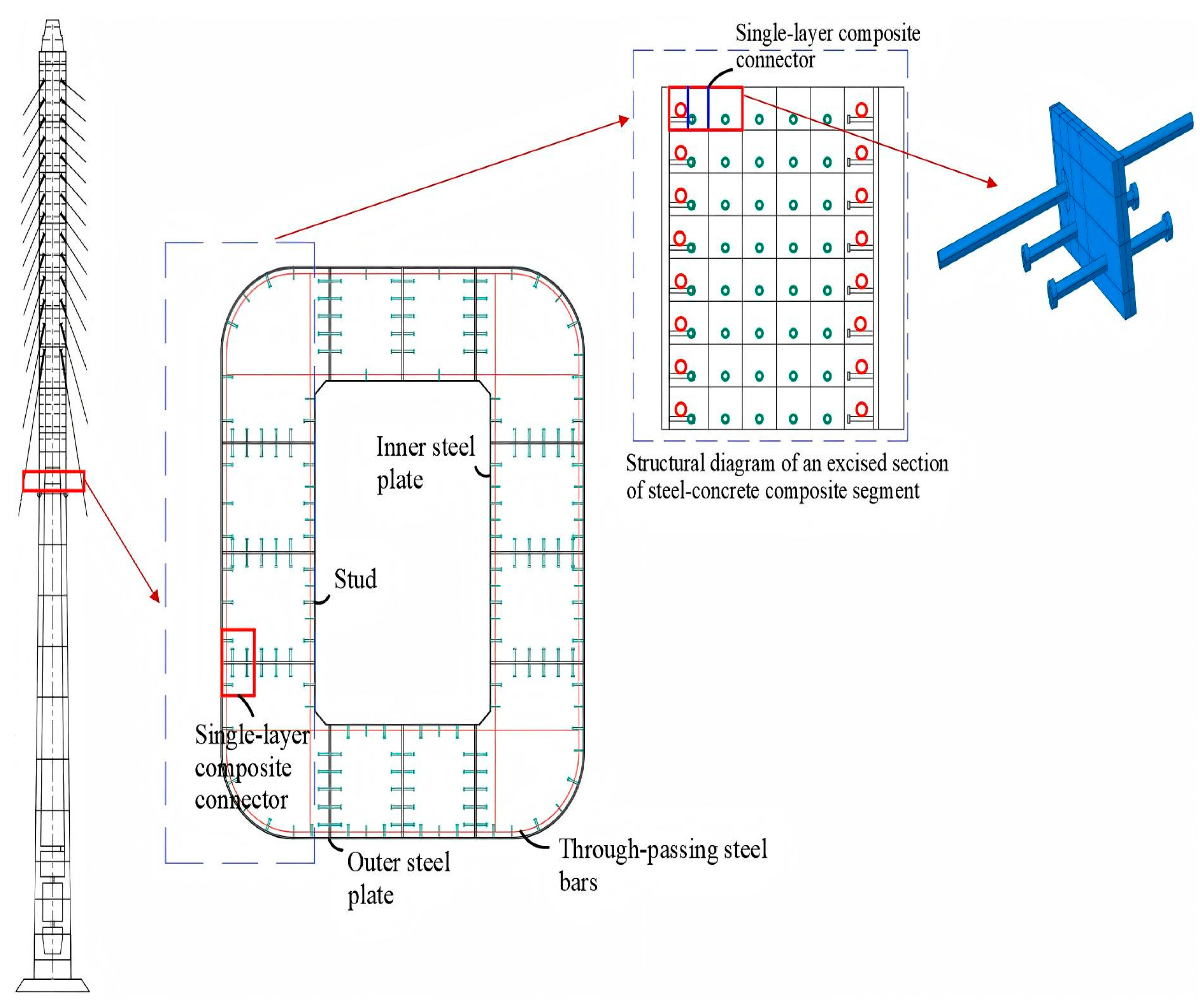

2. Engineering Background and Selection of Composite Connectors

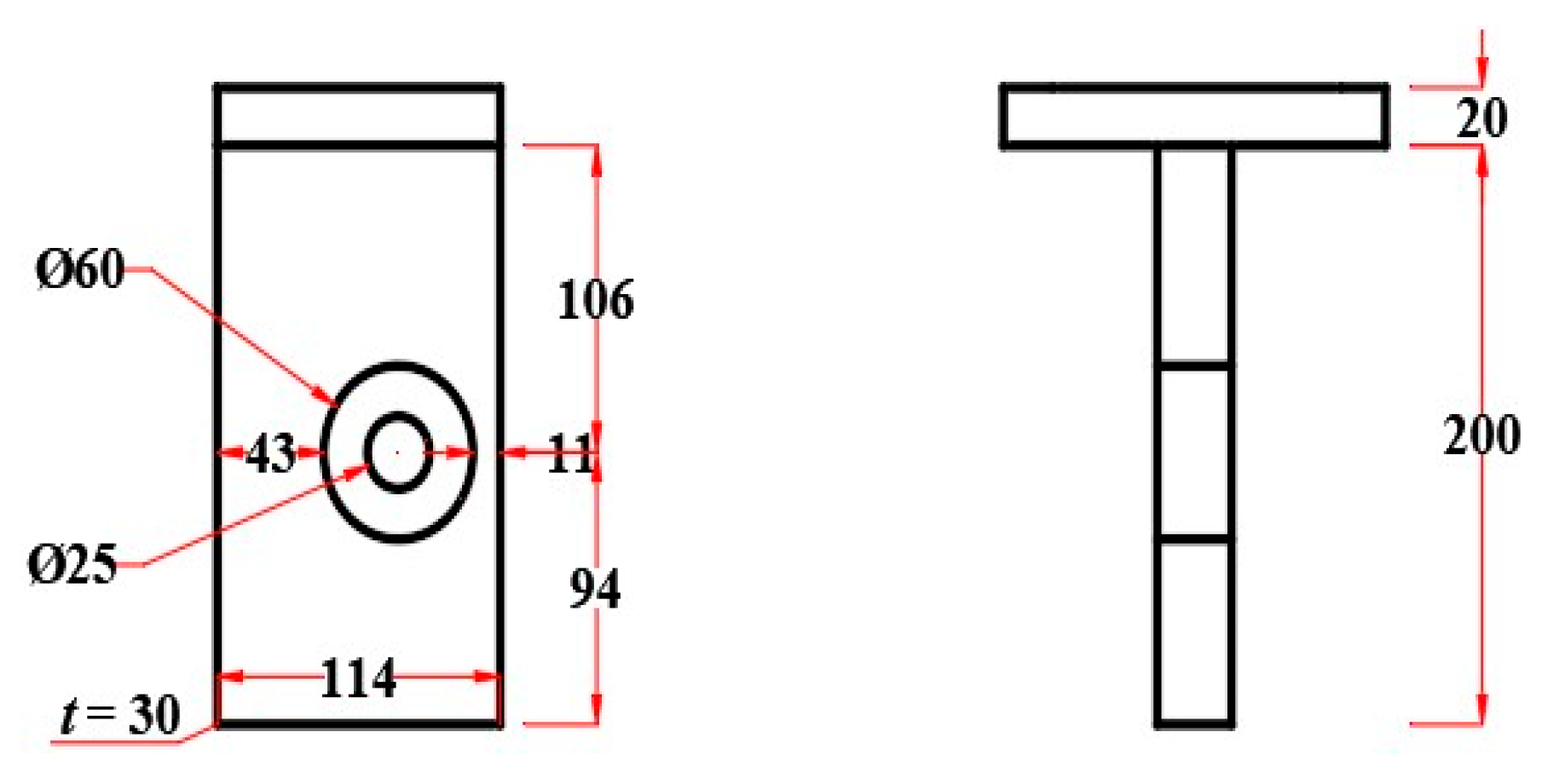

3. Experimental Design for Single-Layer Composite Connectors

3.1. Overview of the Experiment

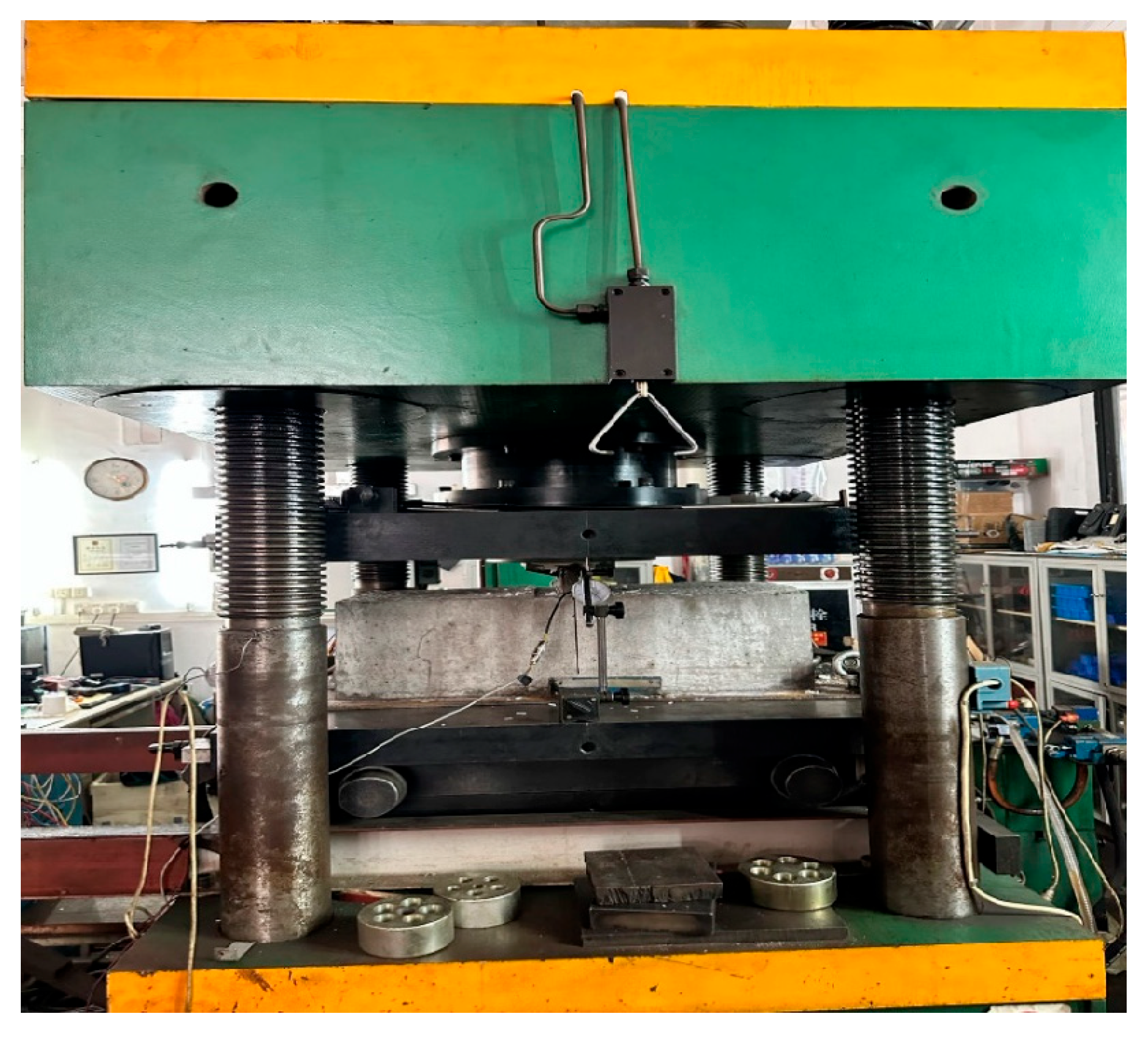

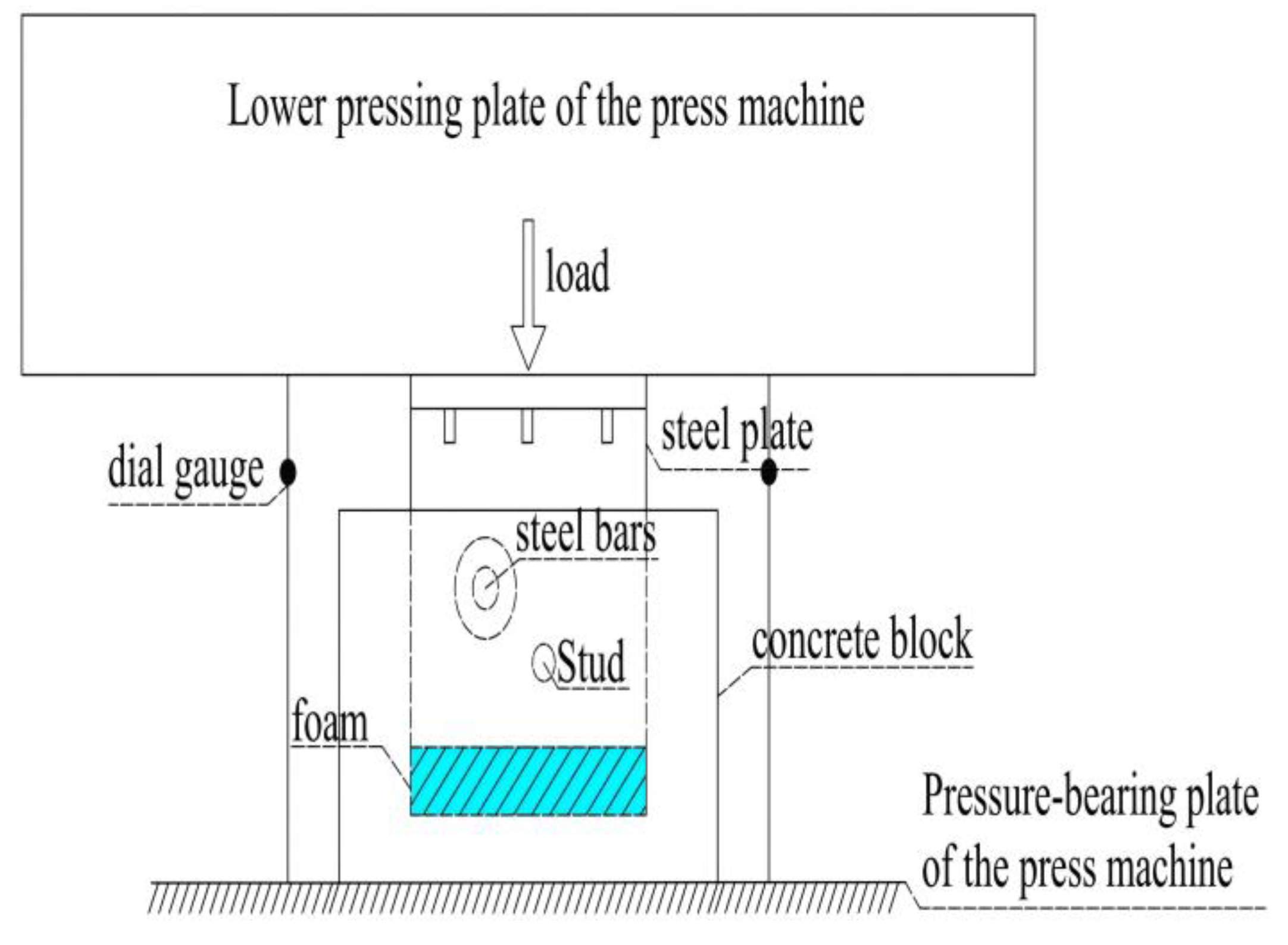

3.2. Loading and Measurement Scheme

4. Failure Modes and Results Analysis of Specimens

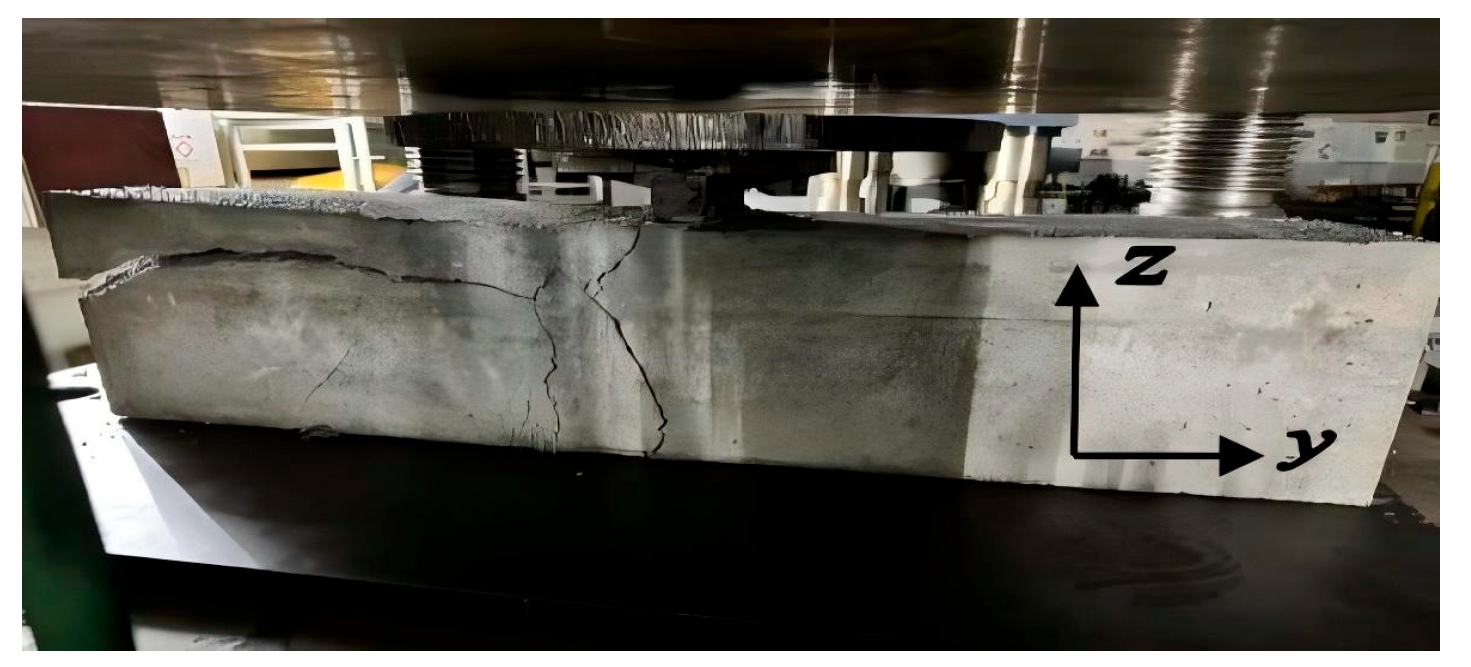

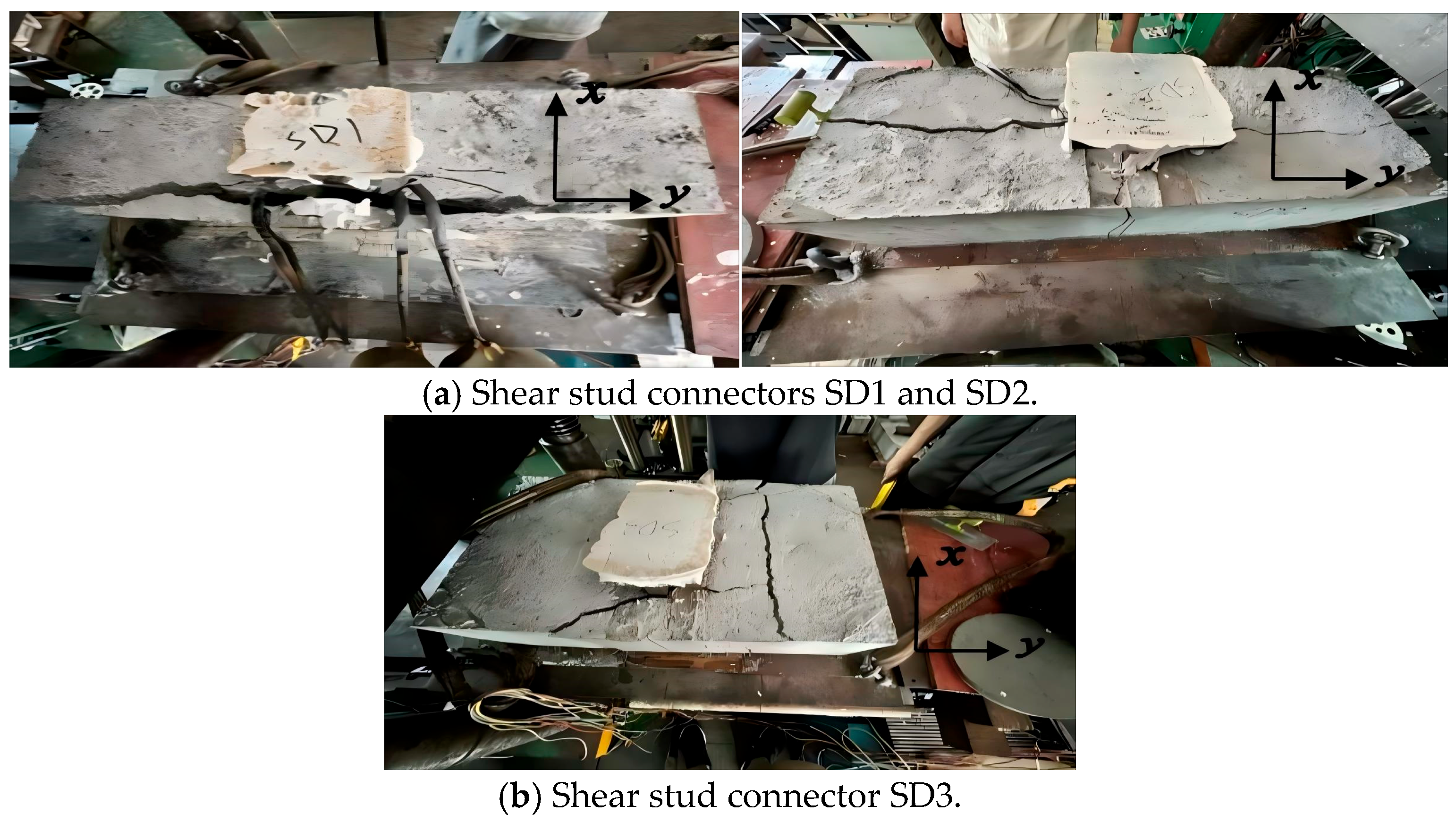

4.1. Failure Modes of Specimens

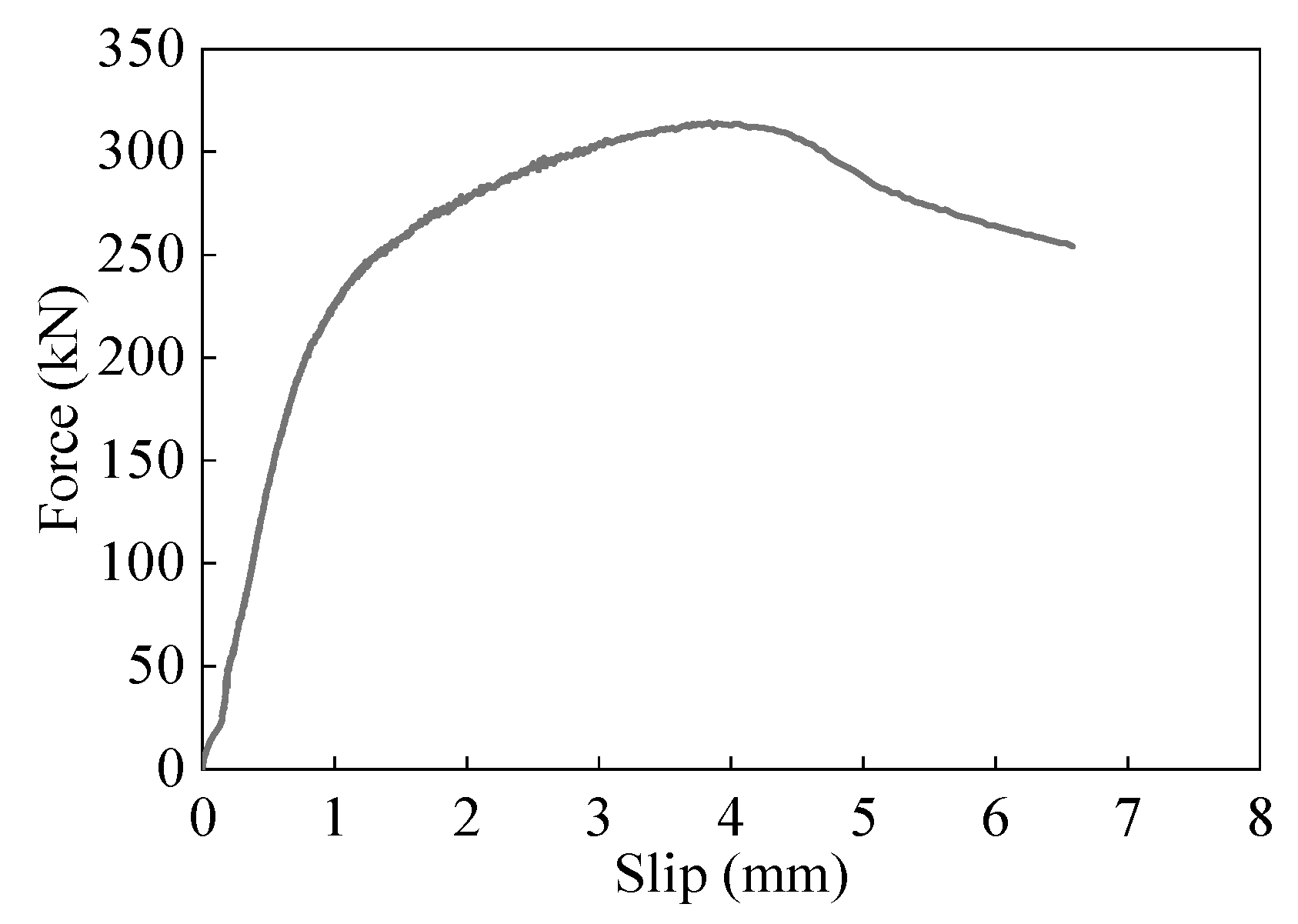

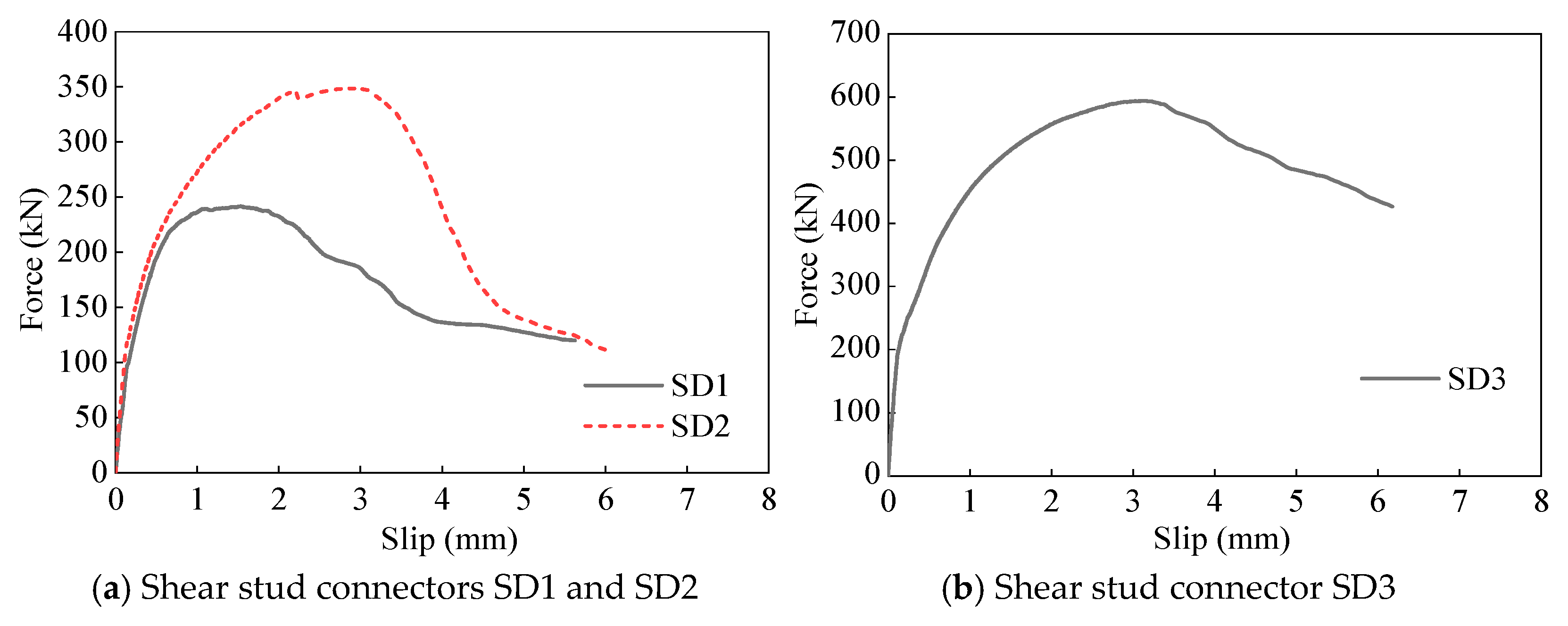

4.2. Experimental Results

4.3. Analysis of Experimental Results

5. Finite Element Numerical Analysis of Specimens

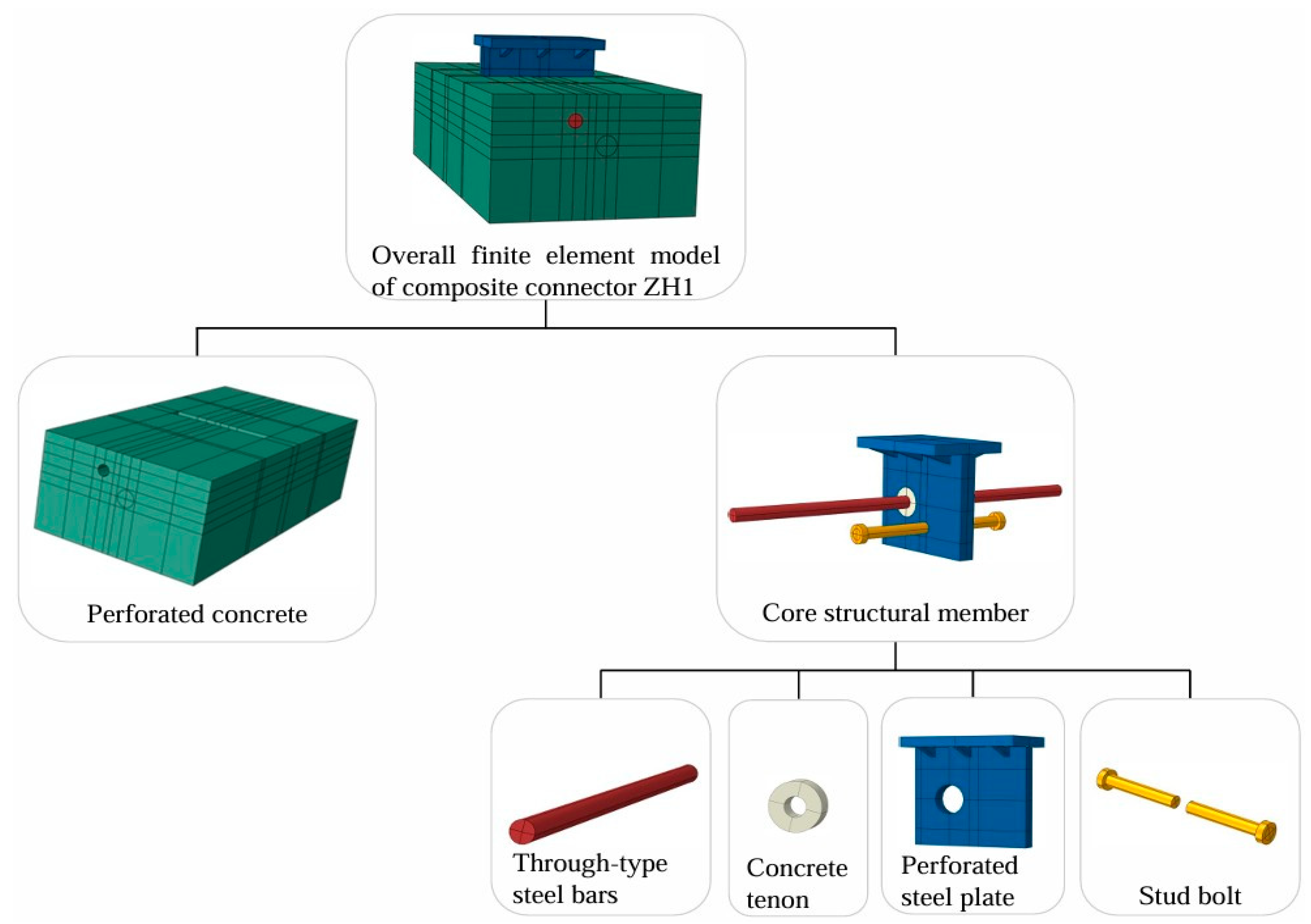

5.1. Finite Element Modeling Approach

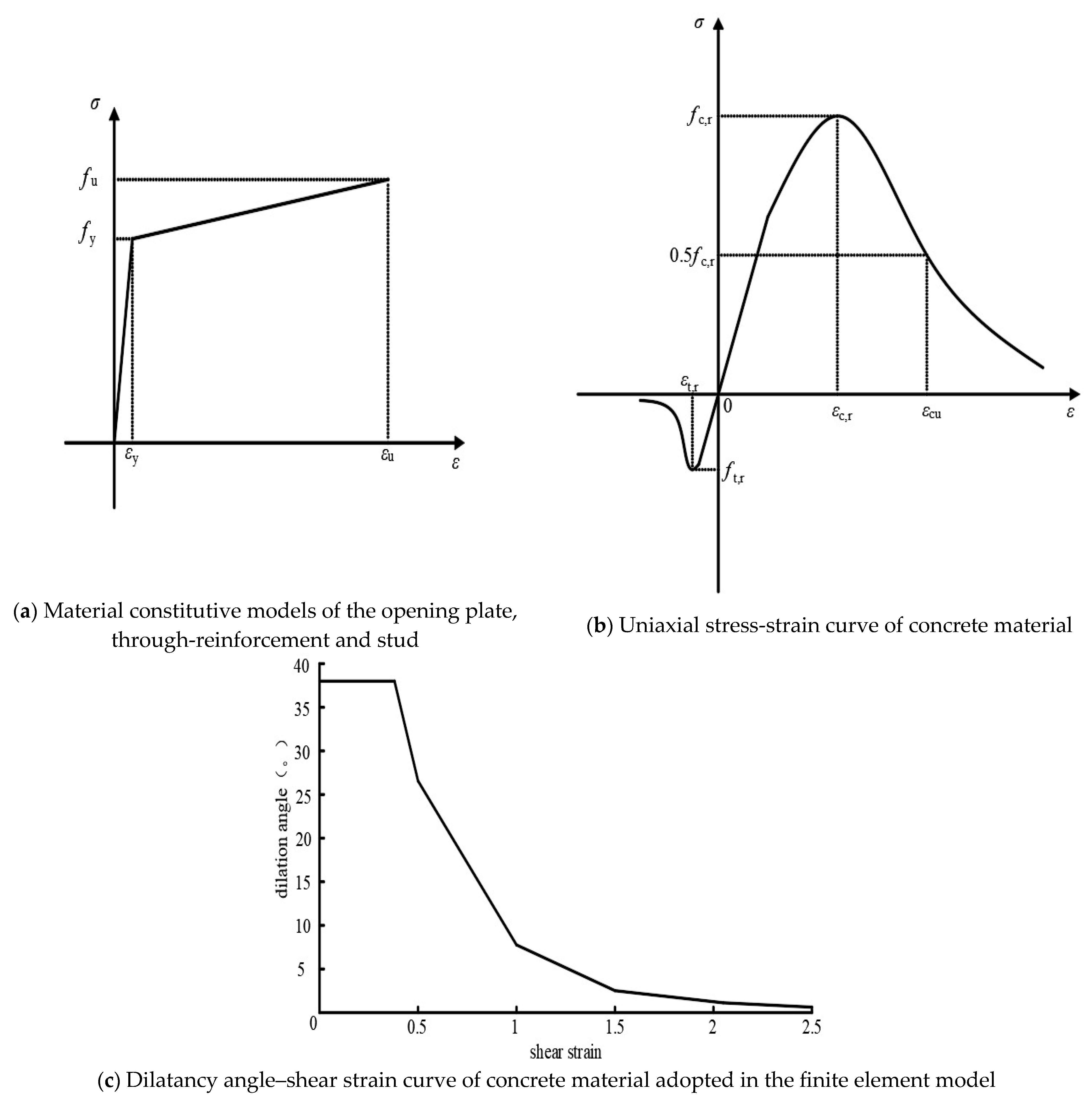

5.2. Material Properties

5.3. Validation of Finite Element Model

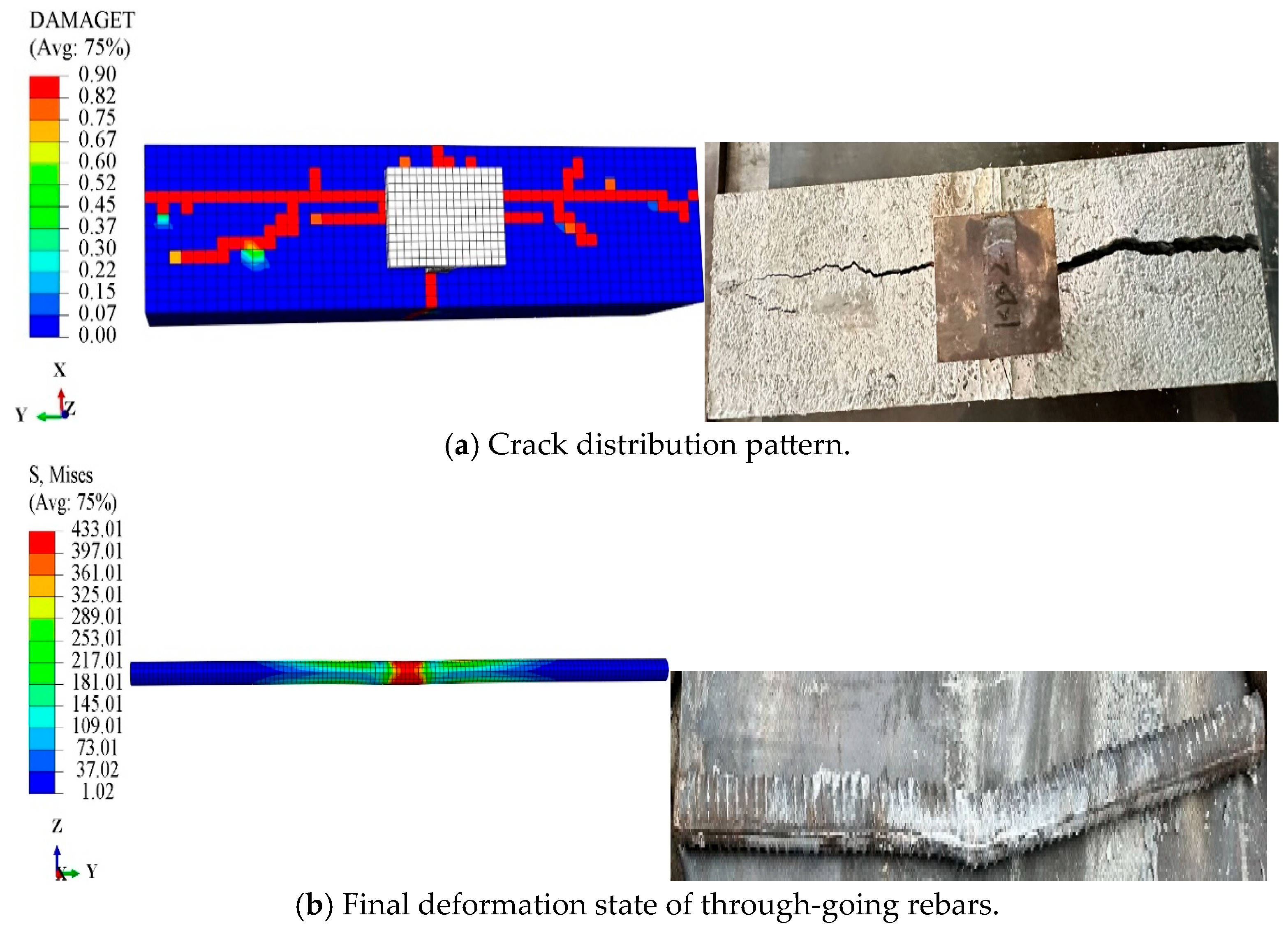

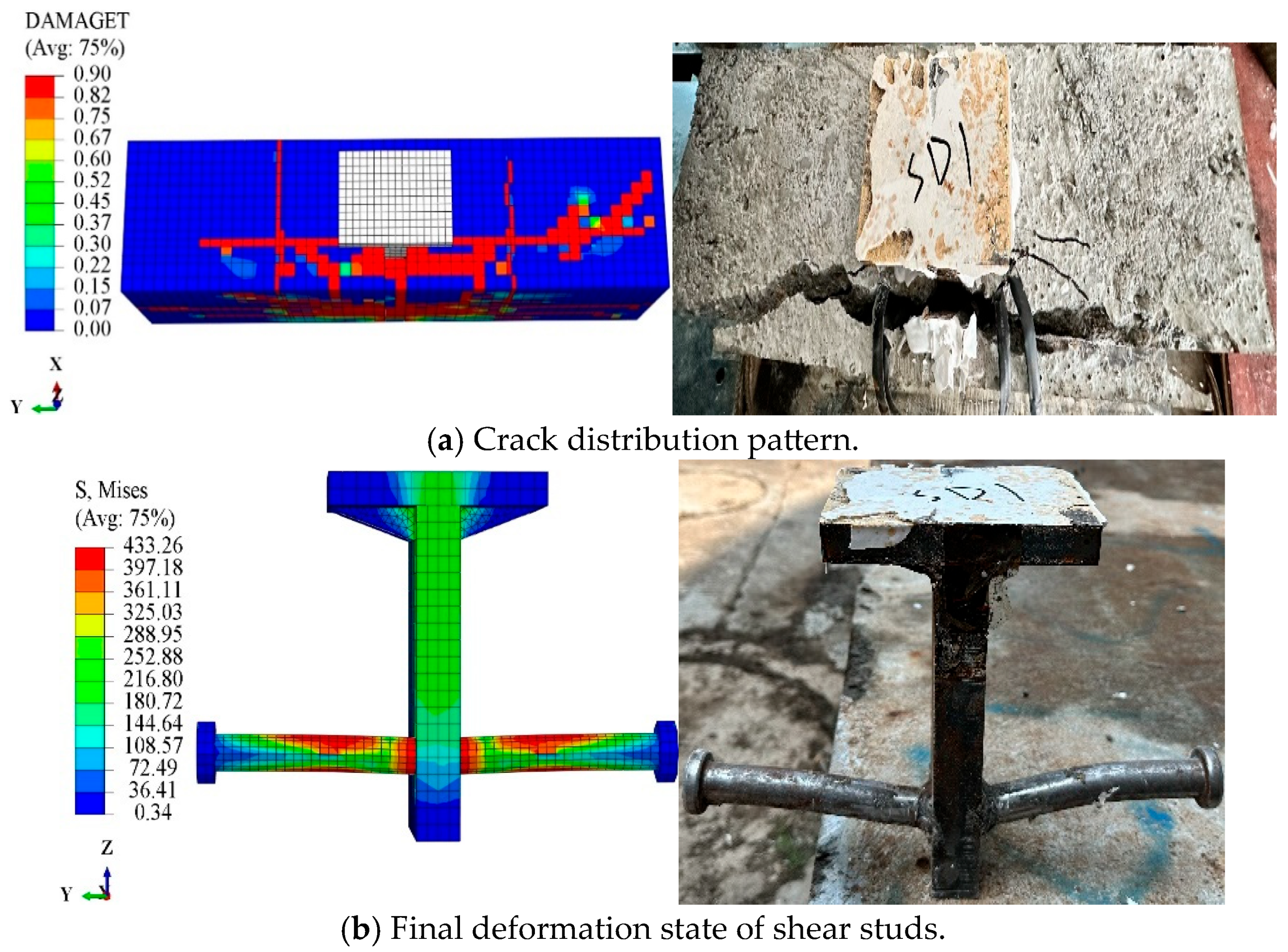

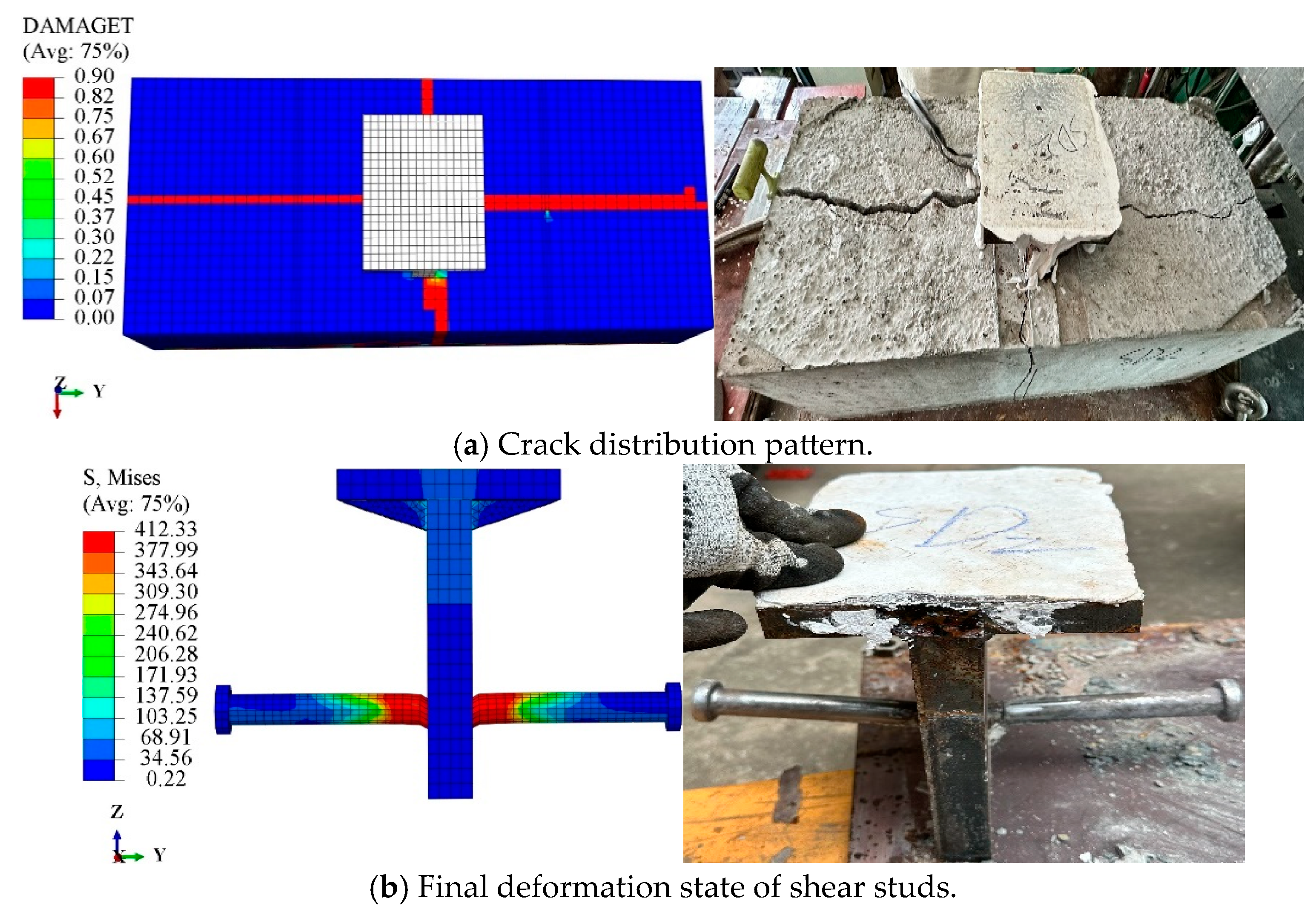

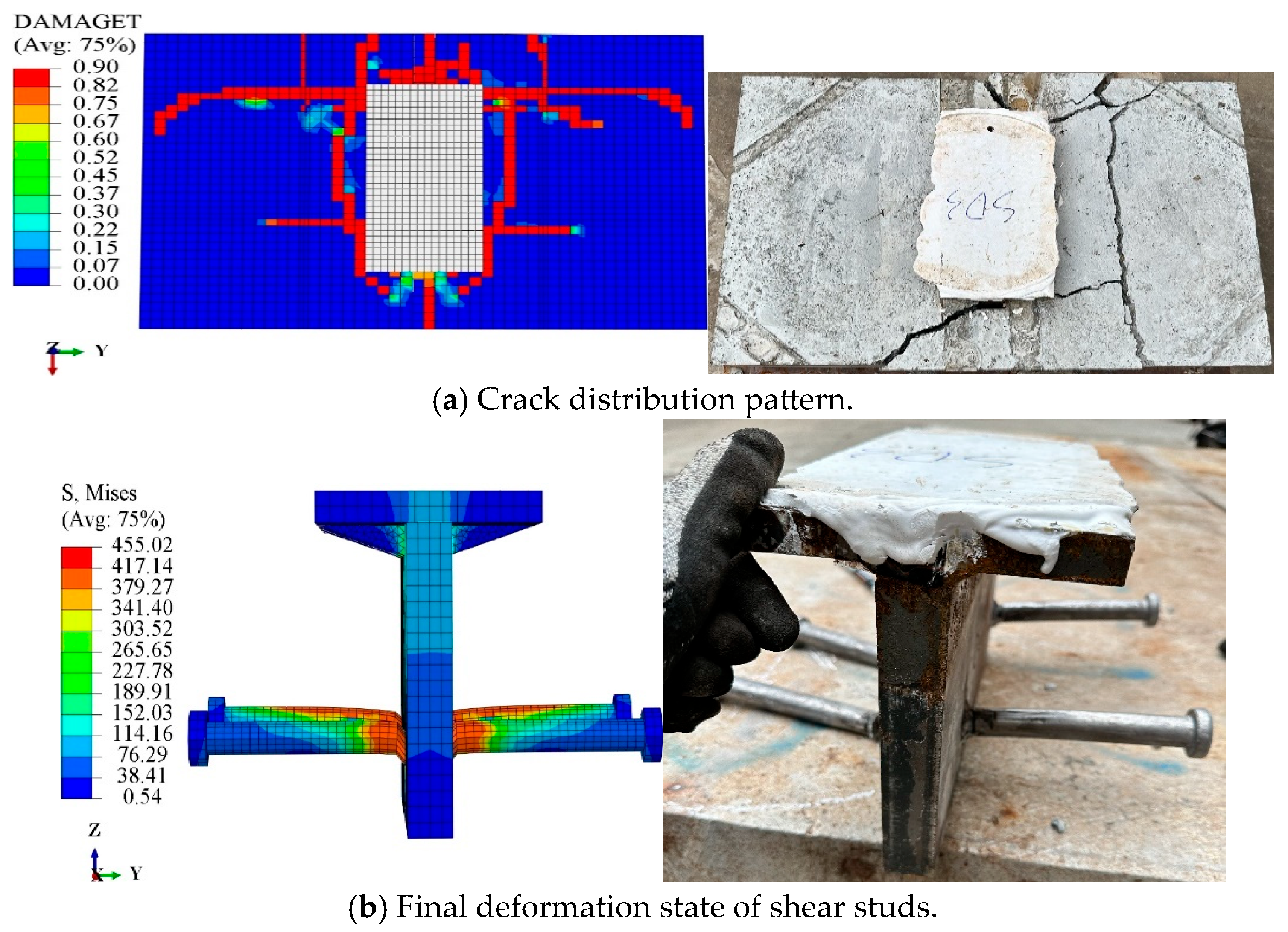

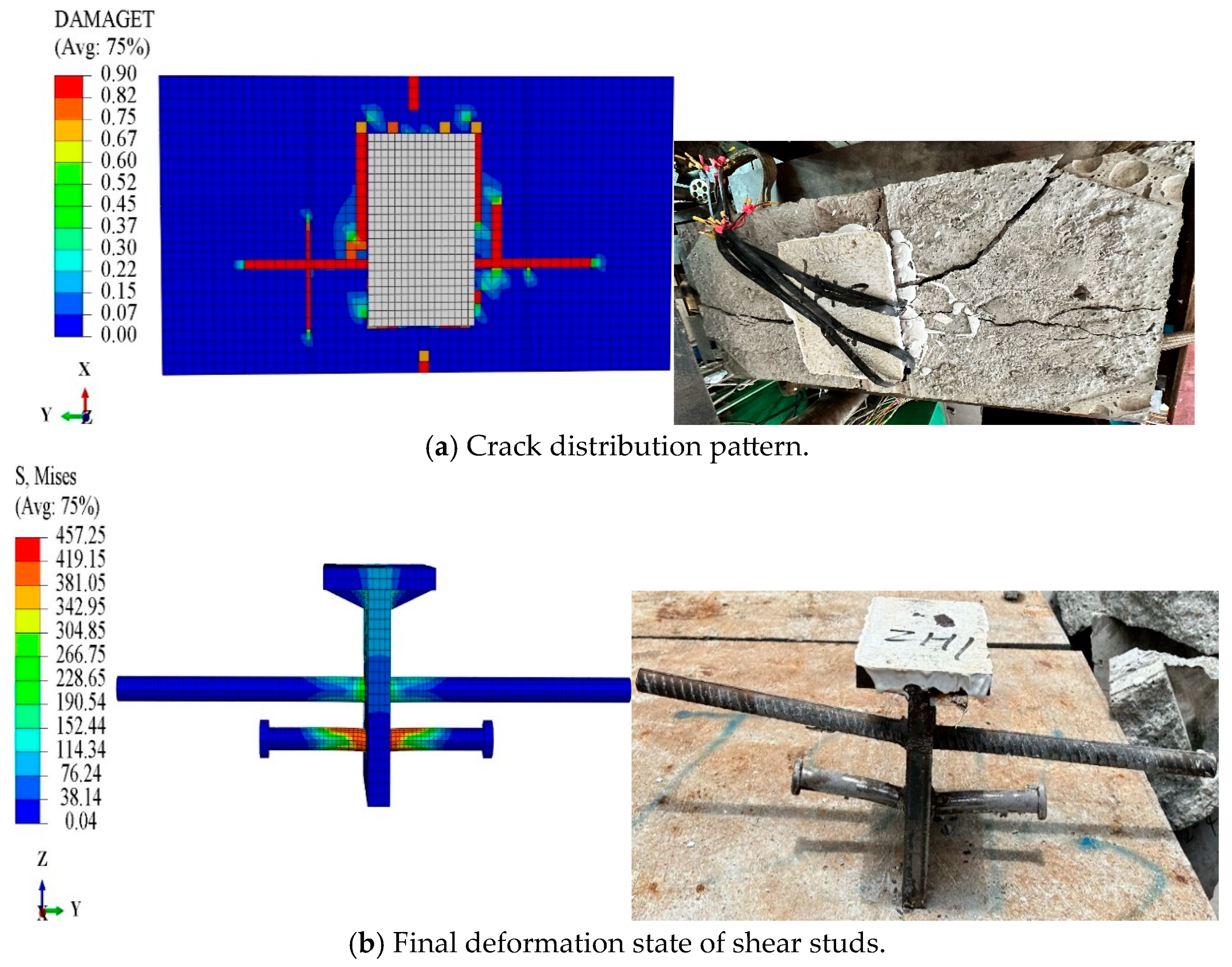

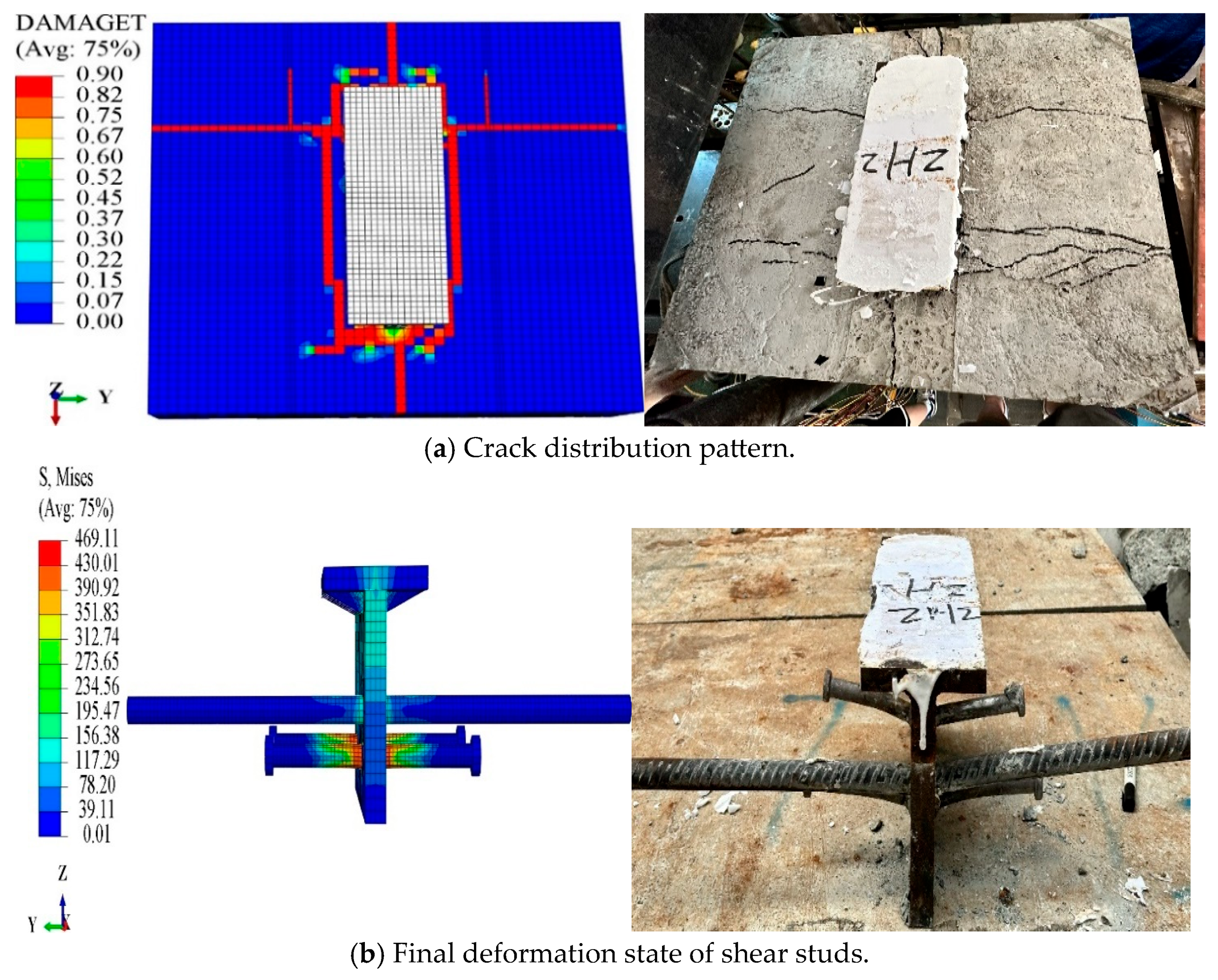

5.3.1. Failure Patterns

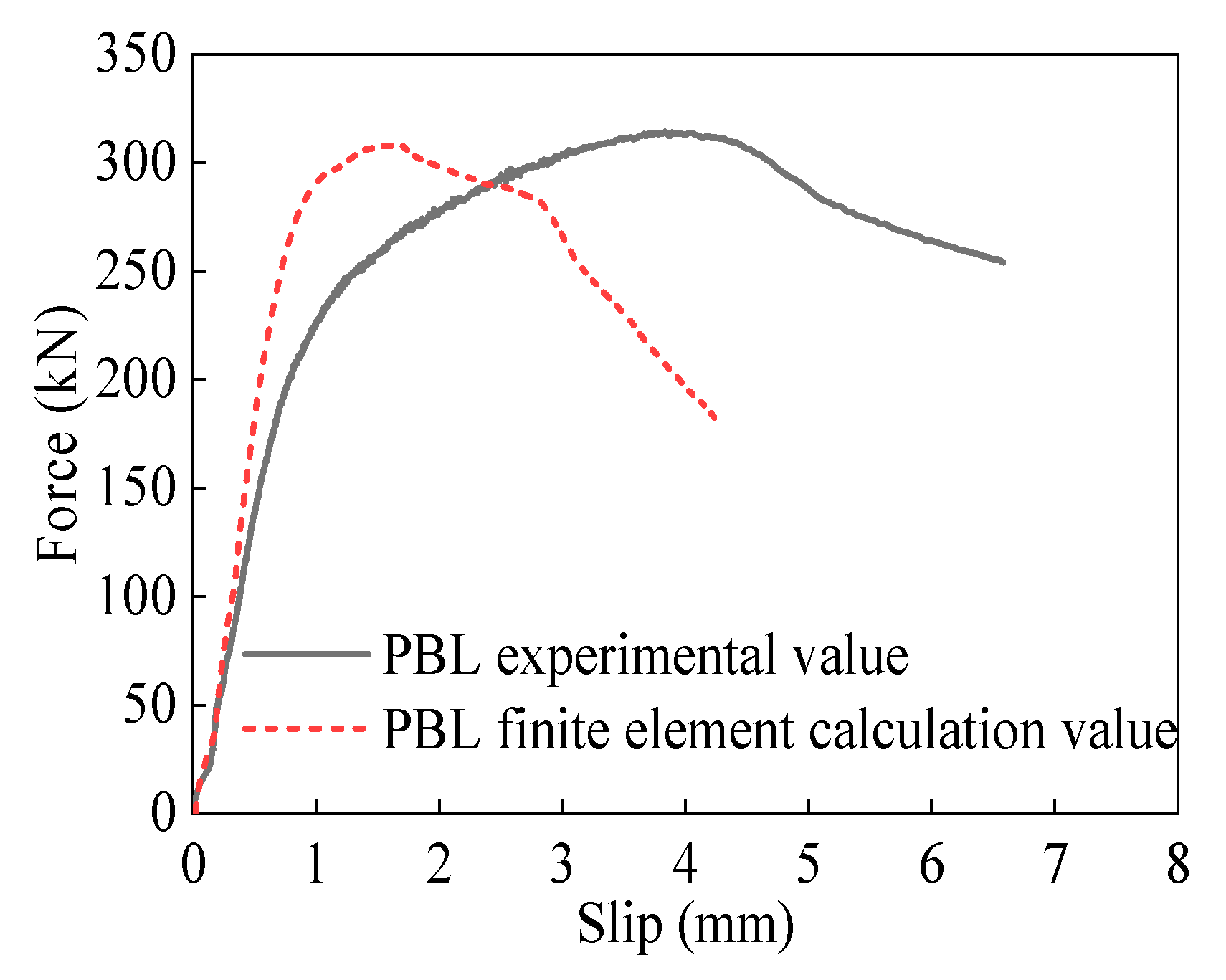

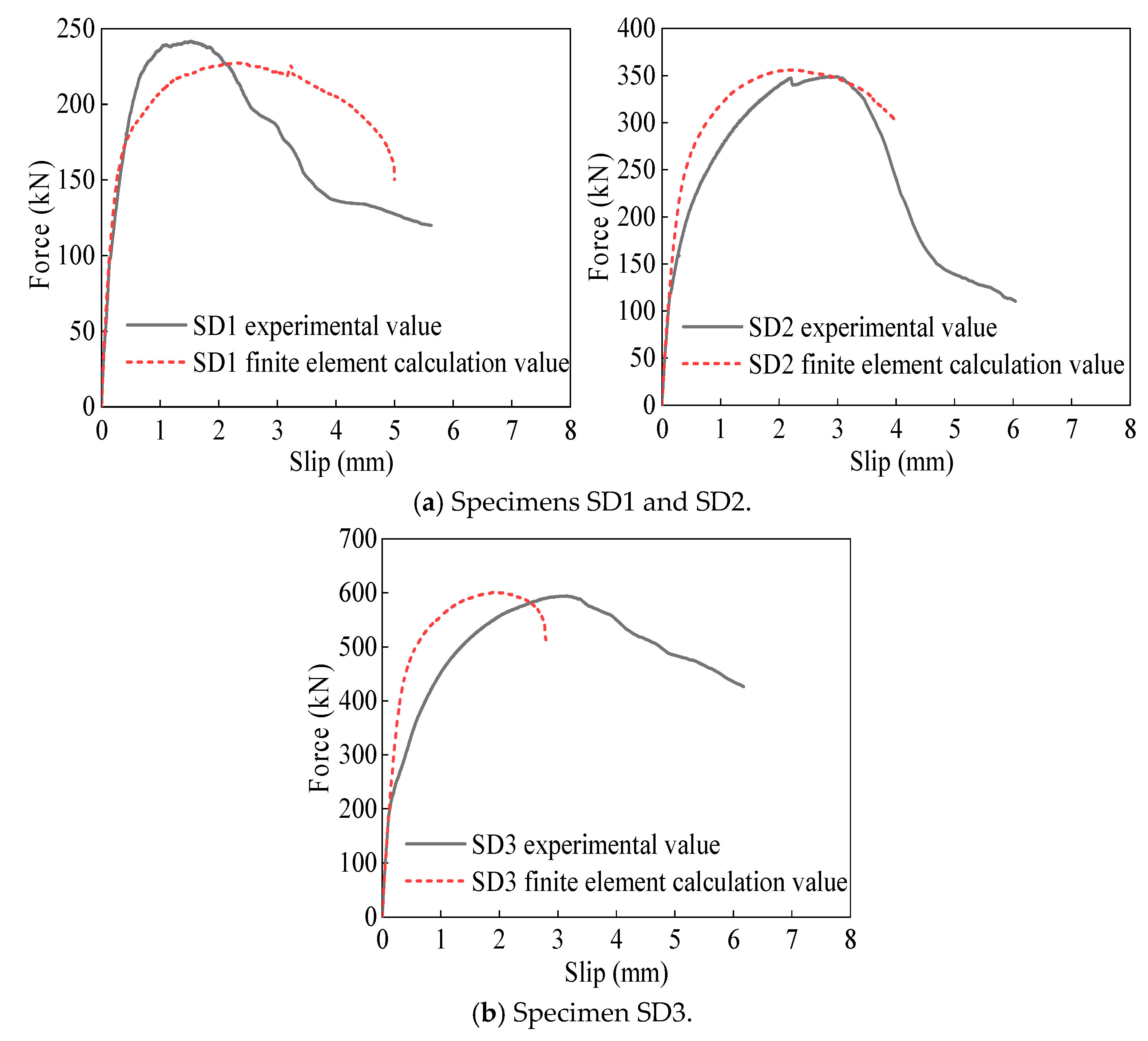

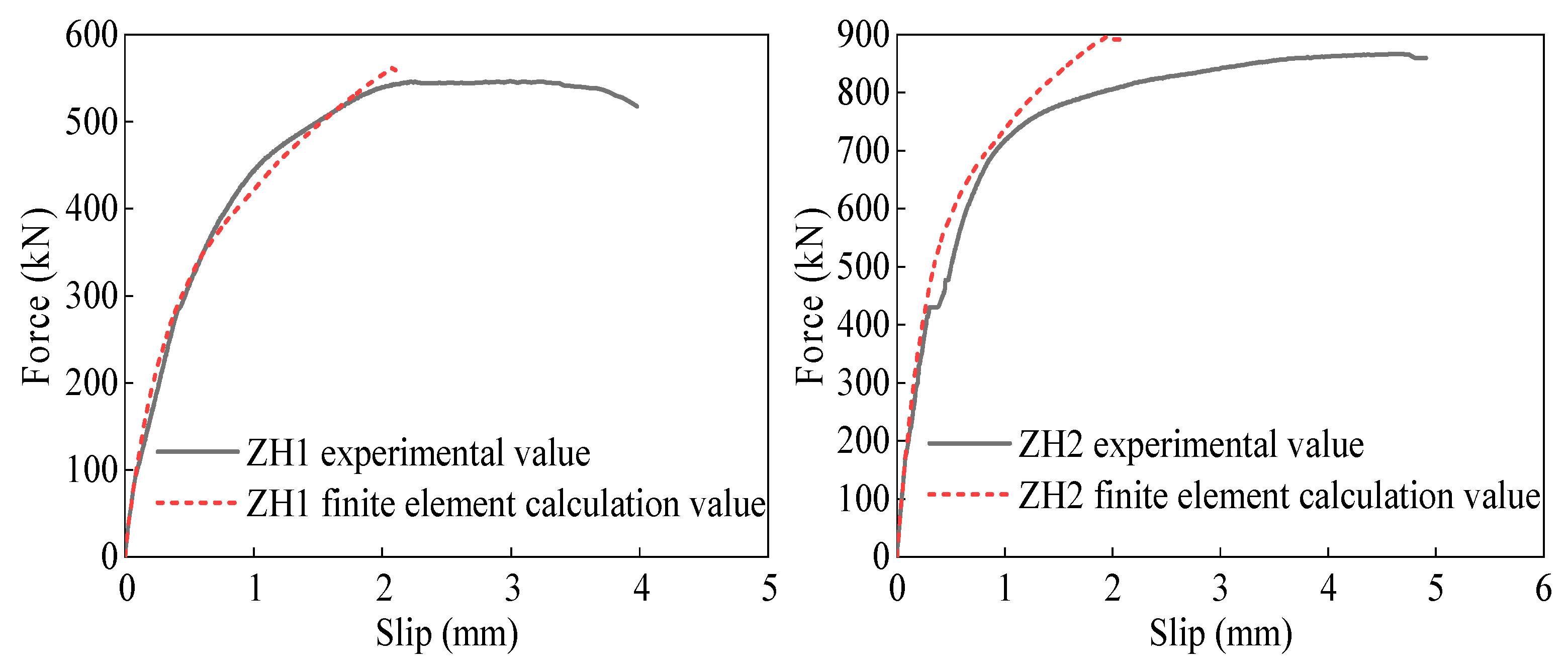

5.3.2. Comparison of Load–Slip Curves

6. Conclusions

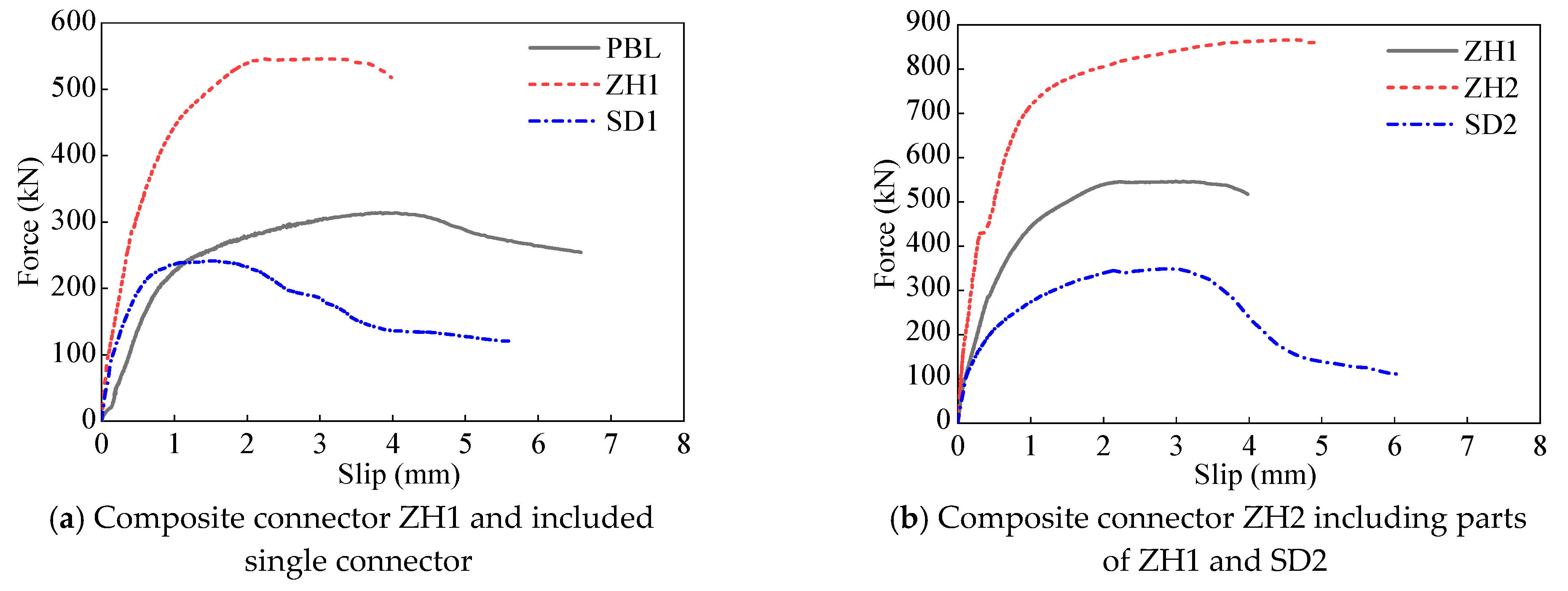

- The loading process of the composite connectors within the steel–concrete composite section of the bridge tower is divided into three stages: the elastic stage, the elastic-plastic stage, and the declining stage. Based on the comparison of the load–slip curves of the three types of specimens (Figure 23, Figure 24 and Figure 25) and the delineation of ductility as the deformation capacity of the specimen without a marked decrease in bearing capacity, it can be inferred that the combined connection constituted by parallel single connection components possesses better bearing capacity and ductility than the single connection component, and is capable of fulfilling the application requirements of steel shell concrete bridge towers.

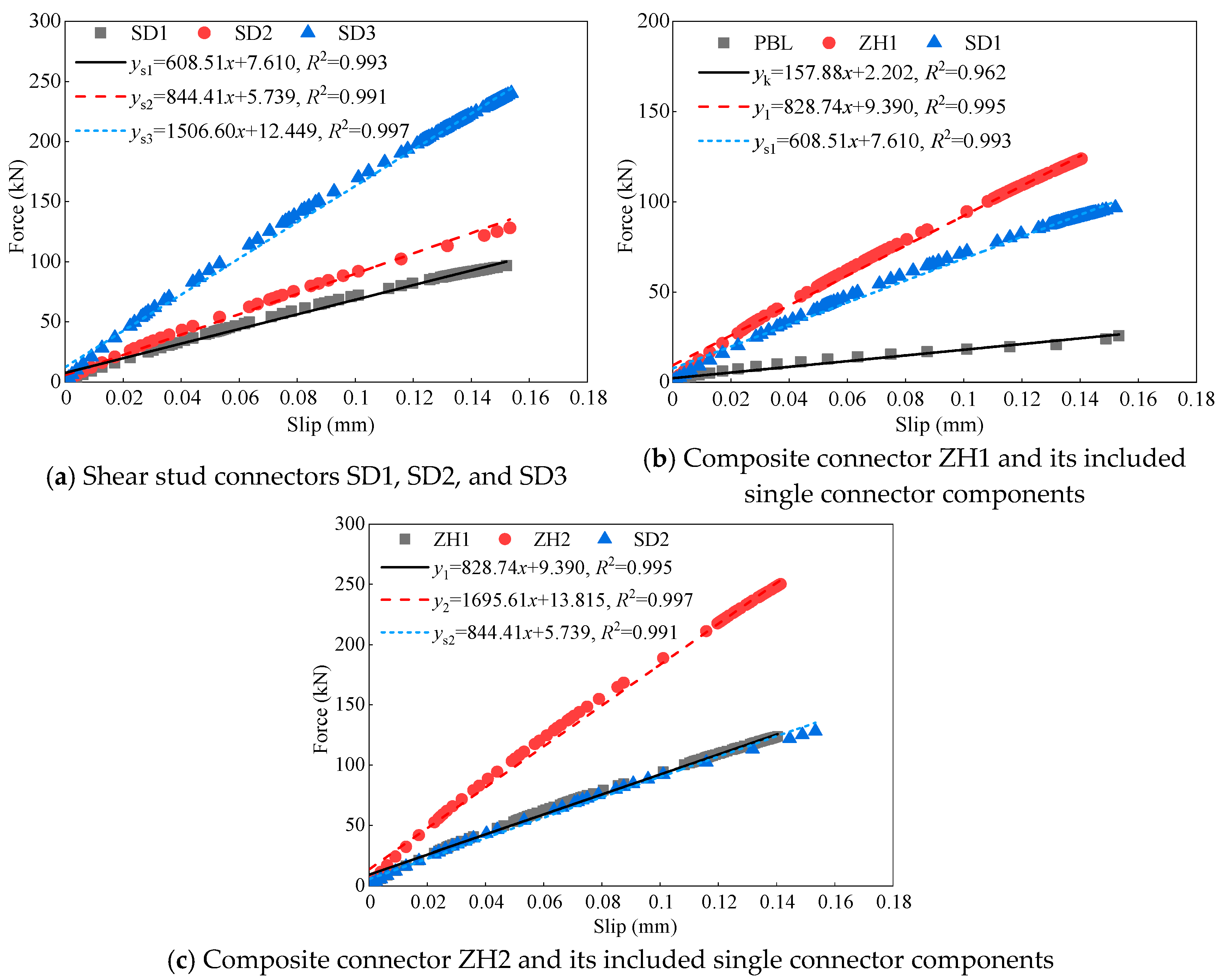

- The study identified a superposition relationship between the ultimate load-bearing capacity and elastic stiffness of individual connectors and their failure modes in the composite connectors. It was determined that deconstructing the composite connectors into parallel individual connectors for studying their mechanical properties and stress mechanisms is feasible. This further supports that the mechanical performance of the composite connectors in the steel–concrete section of the bridge tower is approximately the additive sum of the mechanical performances of the individual connectors comprising them.

- The finite element models of the specimens accurately predicted the distribution of concrete cracks and the deformation locations of the reinforcing bars and shear studs, aligning well with the experimental findings. This validates the modeling approach of the finite element model and the material parameters established through material characteristic tests and literature review.

- By comparing the experimentally measured load–slip curves with those calculated from the finite element models, it was found that the load–slip curves during the elastic loading phase of the specimens were almost identical, with a generally consistent pattern throughout the entire curve.

- Based on the combined connection components used in the steel–concrete composite sections of bridge towers in actual engineering, a testing method is proposed for studying their force mechanism, providing a powerful tool for subsequent optimization design at the structural level for this type of bridge tower composite sections.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H. Study on the Stress Characteristics of Railway Tall and Low Tower Cable-Stayed Bridges. China Railw. Sci. 2019, 40, 54–59. [Google Scholar] [CrossRef]

- Nie, J.G.; Tao, M.X.; Wu, L.L.; Nie, X.; Li, F.X.; Lei, F.L. Advances of Research on Steel-Concrete Composite Bridges. China Civ. Eng. J. 2012, 45, 110–122. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, L.P.; Zhou, H.X.; Xian, J.P.; Zhang, N.; Li, H. Progress in the Application of Research on Concrete-filled Steel Tubular Bridge Towers. China J. Highw. Transp. 2022, 35, 1–21. [Google Scholar] [CrossRef]

- Sham, S.H.R.; Wyatt, T.A. Construction aerodynamics of cable-stayed bridges for record spans: Stonecutters bridge. Structures. 2016, 8, 94–110. [Google Scholar] [CrossRef]

- Wang, Q. Experimental Study on the Force Performance of Steel Bridge Tower and Combined Bridge Tower. Ph.D. Thesis, Chang’an University, Xi’an, China, 2008. [Google Scholar]

- Varma, A.H.; Ricles, J.M.; Sause, R.; Lu, L.W. Experimental behavior of High Strength Square Concrete-Filled Steel Tube Beam-Columns. J. Struct. Eng. 2002, 128, 309–318. [Google Scholar] [CrossRef]

- Varma, A.H.; Ricles, J.M.; Sause, R.; Lu, L.W. Seismic behavior and modeling of high-strength composite concrete-filled steel tube (CFT) beam-columns. J. Constr. Steel Res. 2002, 58, 725–758. [Google Scholar] [CrossRef]

- Nie, J.G.; Tan, Y.; Wang, H.Q. Strength of stud shear connectors in composite steel HC beams. J. Tsinghua Univ. (Nat. Sci. Ed.) 1999, 39, 94–97. [Google Scholar] [CrossRef]

- Nie, J.G. Steel-Concrete Composite Structure Bridges; China Communication Press: Beijing, China, 2011. [Google Scholar]

- Vianna, J.D.C.; Costa-Neves, L.F.; Vellasco, P.D.S.; De Andrade, S.A.L. Experimental assessment of Perfobond and T-Perfobond shear connectors’ structural response. J. Constr. Steel Res. 2009, 65, 408–421. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kang, J.Y.; Kim, S.H.; Kim, D.J. Structural Performance of Steel Pile Caps Strengthened with Perfobond Shear Connectors under Lateral Loading. Appl. Sci. 2016, 6, 317. [Google Scholar] [CrossRef]

- Cândido-Martins, J.P.S.; Costa-Neves, L.F.; Vellasco, P.D.S. Experimental evaluation of the structural response of Perfobond shear connectors. Eng. Struc. 2010, 32, 1976–1985. [Google Scholar] [CrossRef]

- Mia, M.M.; Bhowmick, A.K. A finite element based approach for fatigue life prediction of headed shear studs. Structures 2019, 19, 161–172. [Google Scholar] [CrossRef]

- Bielak, J. On the role of dowel action in shear transfer of CFRP textile-reinforced concrete slabs. Compos. Struct. 2023, 311, 116812. [Google Scholar] [CrossRef]

- Pardeshi, R.T.; Patil, Y.D. Review of various shear connectors in composite structures. Adv. Steel Constr. 2021, 17, 394–402. [Google Scholar] [CrossRef]

- Luo, Y.B.; Yan, J.B. Developments of prefabricated steel-concrete composite beams with novel steel-yielding demountable bolt connectors. J. Constr. Steel Res. 2022, 190, 107123. [Google Scholar] [CrossRef]

- Chen, B.C.; Chen, J.K. Experimental Studies on Shear-Bearing Capacity of Headed Stud in Concrete-Filled Steel Tube. Eng. Mech. 2016, 33, 66–73. [Google Scholar]

- Yosri, A.M.; Farouk, A.I.B.; Haruna, S.I.; Deifalla, A.F.; Shaaban, W.M. Sensitivity and robustness analysis of adaptive neuro-fuzzy inference system (ANFIS) for shear strength prediction of stud connectors in concrete. Case Stud. Constr. Mater. 2023, 18, e02096. [Google Scholar] [CrossRef]

- Maliji, E.; Yousefpour, H. Postfire strength of channel-type shear connectors. J. Struct. Eng. 2023, 149, 04023141. [Google Scholar] [CrossRef]

- Qi, J.; Hu, Y.; Wang, J.; Li, W. Behavior and strength of headed stud shear connectors in ultra-high performance concrete of composite bridges. Front. Struct. Civ. Eng. 2019, 13, 1138–1149. [Google Scholar] [CrossRef]

- Xiao, L. Study of static and fatigue properties of PBL shear keys in steel-mixed composite structures. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2012. [Google Scholar]

- Xiao, L.; Qiang, S.Z.; Li, X.Z.; Wei, X. Research on Mechanical Performance of PBL Shear Connectors Considering the Perforated Plate’s Thickness. Eng. Mech. 2012, 29, 282–288. [Google Scholar]

- Wang, Q.; Liu, Y.Q. Experimental Study of Shear Capacity of Stud Connector. J. Tongji Univ. (Nat. Sci. Ed.) 2013, 41, 659–663. [Google Scholar] [CrossRef]

- Shim, C.S.; Lee, P.G.; Yoon, T.Y. Static behavior of large stud shear connectors. Eng. Struct. 2004, 26, 1853–1860. [Google Scholar] [CrossRef]

- Prates Aguiar, O.; Barreto Caldas, R. Circular openings with transverse rebar as steel-concrete shear connection (part 1/2): Analytical model for strength and slip capacity. Eng. Fail. Anal. 2022, 133, 106007. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, N.; Guo, W. Dynamic Interaction of Train-Bridge Systems in High-Speed Railways; Advances in High-Speed Rail Technology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Li, S.Z.; Li, H.; Zhou, X.H.; Wang, Y.H.; Li, X.H.; Gan, D.; Zhu, R.H. Damage detection of flange bolts in wind turbine towers using dynamic strain responses. J. Civ. Struct. Health Monit. 2023, 13, 67–81. [Google Scholar] [CrossRef]

- Chen, E.L.; Zhang, X.; Wang, G.L. Rigid-flexible coupled dynamic response of steel-concrete bridges on expressways considering vehicle-road-bridge interaction. Adv. Struct. Eng. 2020, 23, 160–173. [Google Scholar] [CrossRef]

- EN 1994-1-1; Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1-1: General Rules and Rules for Buildings. CEN: Brussels, Belgium, 1994.

- Su, Q.T.; Wang, W. Influence of Transverse Bar Position in Hole on Mechanical Behavior of Petfood Rib Connectors. J. Tongji Univ. (Nat. Sci. Ed.) 2011, 39, 1746–1752. [Google Scholar] [CrossRef]

- Zhu, Y.Y. Research on Force mechanism and design method of bridge tower of steel plate-concrete combination structure. Ph.D. Thesis, Tsinghua University, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Zou, Y. Study on Mechanical Properties and Calculation Method of Confined Perfobond Connectors. Ph.D. Thesis, Chongqing University, Chongqing, China, 2018. [Google Scholar]

- GB 50010-2010; Code for the Design of Concrete Structures. Architecture & Building Press: Beijing, China, 2015.

| Material Name | fy (MPa) | fu (MPa) | Eg (GPa) |

|---|---|---|---|

| Q420qD | 455 | 572 | 206 |

| HRB400E | 433 | 598 | 200 |

| ML15AL | 402 | 479 | 206 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Yu, Z.; Chen, Y.; Ma, N.; Wang, R. Experimental Study on the Force Mechanism of Internal Composite Connectors in Steel–Concrete Composite Sections of Bridge Towers. Buildings 2025, 15, 2284. https://doi.org/10.3390/buildings15132284

Du Y, Yu Z, Chen Y, Ma N, Wang R. Experimental Study on the Force Mechanism of Internal Composite Connectors in Steel–Concrete Composite Sections of Bridge Towers. Buildings. 2025; 15(13):2284. https://doi.org/10.3390/buildings15132284

Chicago/Turabian StyleDu, Yunwei, Zhenqing Yu, Yuyang Chen, Niujing Ma, and Ronghui Wang. 2025. "Experimental Study on the Force Mechanism of Internal Composite Connectors in Steel–Concrete Composite Sections of Bridge Towers" Buildings 15, no. 13: 2284. https://doi.org/10.3390/buildings15132284

APA StyleDu, Y., Yu, Z., Chen, Y., Ma, N., & Wang, R. (2025). Experimental Study on the Force Mechanism of Internal Composite Connectors in Steel–Concrete Composite Sections of Bridge Towers. Buildings, 15(13), 2284. https://doi.org/10.3390/buildings15132284