Abstract

As a highly active mineral admixture, metakaolin is often used as an efficient performance-enhancing material for concrete, but its performance in long-term complex service environments still needs to be verified. This article presents a composite green concrete with a substitution rate of 30% for recycled coarse aggregates (RCAs) and iron tailings (IOTs) and a waste polypropylene fiber (WPF) content of 0.6%. Concrete with different mixing conditions of metakaolin was prepared, and its carbonization resistance was studied with macro- and micro-experimental methods. The results indicated that when the content of metakaolin was less than 10%, its mechanical and deformation properties gradually improved, resulting in a maximum increase of 70% in its cubic compressive strength. Overall, carbonization improved the corresponding mechanical properties. For example, when carbonized for 14 days, the compressive strength growth rate increased by nearly 30%, and the elastic modulus did not change significantly. Through microscopic testing, it could be seen that when the content of metakaolin reached 10%, an appropriate amount of metakaolin (10%) promoted the hydration of cement, with the least number of pores and the best compaction performance, resulting in the best overall performance. But when added excessively, the coupling effect of secondary hydration and carbonization reactions could lead to the emergence of new harmful pores in the matrix structure. In future engineering applications of metakaolin, it is recommended that its mixing ratio be less than 10% to achieve better concrete performance.

1. Introduction

In order to reduce the impact of solidified waste on the environment, green concrete has emerged, which is also an effective way to reduce carbon sinks and improve resource utilization. With the acceleration of urbanization, the accumulation of iron ore tailings (IOTs) and recycled aggregate concrete (RAC) has increased rapidly, seriously occupying our valuable arable land resources, and there are also safety hazards that need to be addressed.

Levandoski [1] prepared a unique alkaline solution and evaluated the influence of an alkaline-activated binder on the physical and mechanical properties and microstructure of IOTs. The results showed that the special alkaline-activated binder could effectively reduce porosity and increase binder content, improving the overall mechanical properties. Mkikouri [2] conducted research on IOT-based recycled concrete to produce concrete, which proved that the carbon dioxide emission in Finland could be reduced from 1.9% to −1.3%, with the improvement being obvious. Using microscopic and physical examination techniques, Oritola [3] confirmed the structure and composition of five different tailings and also exhibited the feasibility of their application in the construction industry. Zhang [4] systematically studied the effects of ultrafine IOTs on the properties and hydration process of high-phosphogypsum-content supersulfate cement, which delayed early strength but improved later strength, and unreacted UIOT particles also played a physical filling role, helping to improve performance. Li [5] conducted research on the dynamic performance of iron tailings-based porous concrete at high strain rates, indicating that it had significant strain rate effects and density dependence. Li [6] explored the potential of combining iron tailings rich in iron oxide with metakaolin to synthesize high-strength geopolymers, providing a scalable approach for sustainable building materials. Li [7] studied the effects of different erosion environments and IOT contents on macro-mechanical properties and pore composition structure and then derived a multi-factor compressive strength model. Lu [8] reviewed and studied the progress of preparing new building materials from IOTs at home and abroad. They showed that adding coal gangue, fly ash, and other substances to IOT could make up for the shortage of raw materials for building products and produce high-value concrete products that could be applied in large quantities and have popularization value.

The above studies have proved that IOTs have a certain activity and filling effect, but they are relatively weak and need to be used in conjunction with other waste materials. However, at this stage, research has mostly focused on their mechanical properties, and that on its durability is weak. Amjad [9] reviewed the application of IOTs in cement-based composite materials, focusing on various methods for activating IOTs, and described the durability and mechanical properties of the cement mixtures. Shettima [10] studied the chloride ion permeation and carbonization effect of concrete with IOTs and showed that the values were better than those of natural aggregate concrete (NAC), suggesting that IOTs could be applied to traditional concrete. Lv [11] used IOTs to replace part of fine aggregates to make concrete and studied the resistance to chloride ion permeability and sulfate corrosion, indicating the durability of concrete with IOTs was better than that of NAC. Huang [12] proved through experiments that using IOTs to replace part of the fly ash could improve its freeze–thaw resistance and sulfate corrosion resistance. Wang [13] conducted macro- and micro-analyses on the freeze–thaw resistance and impermeability of IOTs-based concrete, suggested that the replacement rate should be 40–60%. Professor Wang S.L. conducted systematic research on the carbonization [14], salt spray erosion [15], sulfate erosion [16], freeze–thaw cycle [17] and other characteristics of TGC [18].

Based on the above analysis, tailings are helpful in improving the performance of concrete, but their impact is relatively limited. In order to improve the performance of tailings-based concrete, this article fully utilizes the strong activity and fine particle characteristics of metakaolin, modifies the performance of tailings-based recycled concrete (TRC), and studies the influence of different metakaolin concrete carbonization properties through macroscopic and microscopic means, providing a basis for its large-scale application and promoting sustainable economic development.

2. Test Material Properties

Qinling 42.5 portland cement was used in the test (Table 1), and the natural coarse aggregate (NCA) with 5–20 mm continuous gradation was artificial gravel, while the recycled coarse aggregate (RCA) being in service for 30 years was produced by an environmental protection company in Xi’an, Shaanxi Province, China, all of which were continuously graded [19], as shown in Table 2. IOTs used in the test came from Heigou IOT pond, while the fiber was discarded waste polypropylene fiber (WPF) (Table 3), and the metakaolin (MK) with a 1250 mesh was produced by Jufeng New Material Technology Co., Ltd. in Xi’an, Shaanxi Province, China (Table 4) [20]. Urban drinking water was used in the experiment [21].

Table 1.

Basic parameters of the cement.

Table 2.

Basic parameters of aggregates.

Table 3.

Basic parameters of polypropylene fiber.

Table 4.

Basic parameters of metakaolin.

3. Design of Test Parameters

3.1. Mix Design

According to our previous research findings, the contents of RCAs [22], IOTs [14], and WPF [23] were set to 30% [24], 30%, and 0.6%, respectively. Abufarsakh et al. 2024 [25] studied the physical and mechanical properties of MK-based concrete. Tochahi et al. 2024 [26] researched the resistance of concrete mixed with MK to chloride ion erosion in seawater environment. Moradi et al. 2021 [27] used an artificial neural network model to calculate the concrete’s strength with MK. Referring to the above literature, we set the MK blending ratios to 0%, 5%, 10%, 15%, and 20%. Based on the concrete mix proportion design [28], the design standard for recycled concrete [29], the sand ratio and water binder ratio of each mix proportion were set to 0.35 and 0.4, respectively, and the mixing quality of the water-reducing agent was 0.3%. After on-site adjustment and trial mixing, the actual mix proportions are listed in Table 5.

Table 5.

Mix design for the experiment (kg/m3).

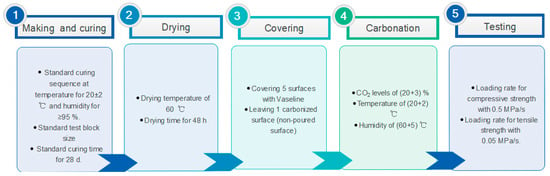

3.2. Rapid Carbonization Test Design

According to the specification requirements [30], a rapid carbonization test was conducted; the test process and main parameter settings are shown in Figure 1.

Figure 1.

Flow chart of the carbonization test.

3.3. Block Size and Test Method Design

In this paper, a cube block of 100 mm was used for the strength and carbonization depth of the TGC. The tests of axial compressive strength, stress–strain curve, and relative dynamic modulus of elasticity were carried out on a cube block of 100 mm × 100 mm × 300 mm. When the carbonization reached a certain age, the main mechanical properties were measured by a 1000 KN electro-hydraulic servo universal testing machine, and the constitutive curve was measured by a MTI-3d non-contact strain measurement system. Then, the dynamic elastic modulus with different carbonization ages were measured. The carbonization depth was quantitatively measured according to the specification GB/T50082-2009. In addition, the block carbonized to the specified age was split and sprayed with phenolphthale in an alcohol solution with a concentration of 1% on the section. Taking measuring points every 10 mm on the cross-section, the average value was used as the measured carbonization depth value.

4. Mechanical Property Test Results

4.1. Cube Compressive Strength

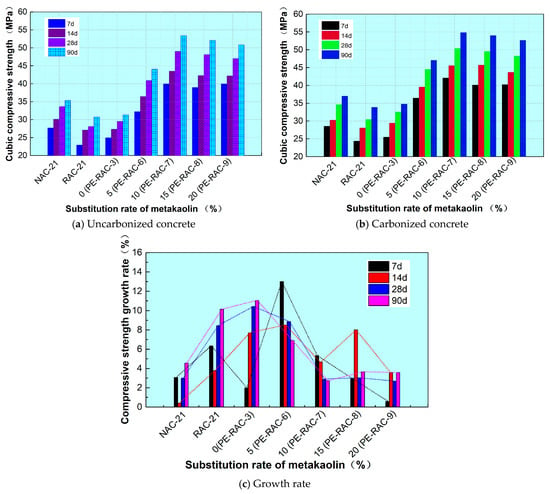

Figure 2 demonstrates the influence of the metakaolin content on the cube compressive strength. As can be observed, metakaolin had a considerable influence on its values. In Figure 2a,b, the strength values show a linear upward trend with a low metakaolin content (<10%), and the change range is large. For example, before carbonization, when the content varied from 0% to 10%, the strength values increased largely by 60.05%, 59.27%, 66.21%, and 70.45%. When the content of metakaolin was less than 10%, the strength value increased linearly with the amount added, and then the opposite trend appeared. It can be determined from Figure 2c that the strength value with a lower content was relatively more sensitive to carbonization and had a greater strength growth rate after carbonization. Based on the above analysis, as the amount of metakaolin increased, its strength value first slowly increased and then decreased, and the optimal content was 10%, which is similar to the optimal content of 15% [31,32] found in the literature.

Figure 2.

Influence of metakaolin on cube compressive strength.

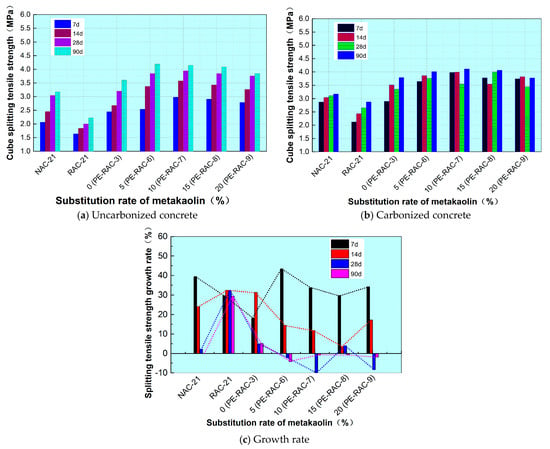

4.2. Splitting Tensile Strength

Figure 3 exhibits the variation in splitting tensile strength values of TGC with the addition of metakaolin. As can be seen from the figures, when the content was small (<5–10%), the intensity value showed a slow increase. When the content was large, it remained in a stable state and decreased slightly, which is in agreement with patterns found in the existing literature [32]. Compared with a content of 0%, when its content was 10%, the strength values before carbonization increased by 31.12%. After carbonization for 7 and 14 days, the strength values increased by 34.16% and 12.71%, respectively. In addition, the differences in strength caused by metakaolin in carbonized concrete became smaller under various working conditions. From Figure 3c, due to the influence of carbonization, the partial strength value tended to decrease with the high content. Therefore, in practical processes, the content of metakaolin should be strictly controlled with the recommended incorporation content observed in the literature [33] of 10%.

Figure 3.

Influence of metakaolin on splitting tensile strength.

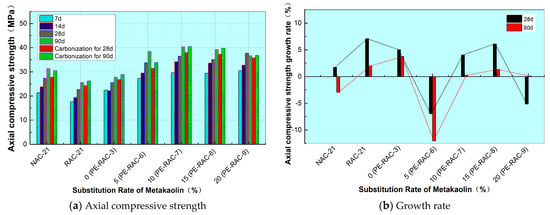

4.3. Axial Compressive Strength

Figure 4 reveals the change in axial compressive strength of TGC. The addition of metakaolin increased its degree of change, that is, metakaolin had a great impact on its axial compressive strength. Compared with recycled concrete (RAC-21), the strength value with the 10% content increased by 67.83%, 76.38%, 60.67%, and 57.12% before carbonization, and the corresponding value increased by 56.09% and 54.44% after carbonization. When the content of metakaolin was approximately 10%, TGC’s axial compressive strength reached its maximum under various working conditions. Above that, the addition of metakaolin made TGC’s strength relatively stable and even caused a decreasing trend, which was similar to results from the literature [34]. The reason was that the excessive addition of metakaolin replaced part of the cement and changed the composition of the cementitious material, resulting in the difference in its axial compressive strength.

Figure 4.

Effect of metakaolin.

4.4. Stress–Strain Constitutive Curve

The stress–strain constitutive curve of concrete is the basis for further theoretical research [35] and an important part of experimental formation theory [36]. A non-contact strain measurement system was adopted in the experiment.

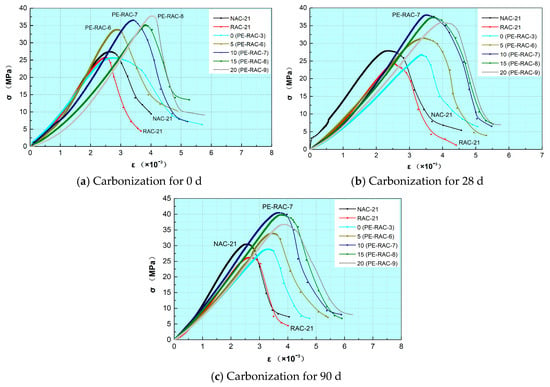

Figure 5 reflects the influence of carbonization on concrete mixed with metakaolin. As can be seen, compared with NAC, metakaolin significantly increased the peak stress of concrete, which was exactly opposite that of the elastic modulus. The inflection point of its falling section was more obvious than that obtained when adding RCAs alone (RAC-21), which is consistent with the results of the regeneration of modified recycled concrete [37] and RAC with MK [38]. The test block had better deformation performance, also indicating that when adding IOTs and WPF together with MK, its strength and deformation properties were greatly improved, which could meet the requirements for concrete performance in daily engineering practice.

Figure 5.

Influence of carbonization on the stress–strain curve.

The change rule of the above constitutive curve is related to the degree of compactness, internal pore morphology, and crack development of materials [39]. The longer the carbonization time, the more perfect the hydration, and the stronger the filling effect of the carbonized products, which also leads to smaller internal porosity. There was little change in the rising section because micro-cracks were less likely to occur at that time. However, in the descending section, micro-cracks appeared with a strong randomness. Even under the same stress, the crack development was different, which made the descending section more dispersed. The development speed of random cracks slowed down with the increase in carbonization period. After its peak load, due to the large amount of strain energy stored in the testing device, the development of cracks made it difficult to accurately test the descending section. Therefore, in the future, additional experimental devices will be needed for the specialized measurement of its descending section.

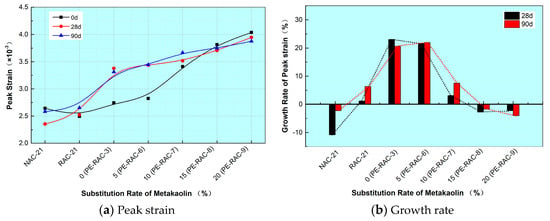

4.5. Deformation Properties

Figure 6 and Figure 7 exhibit the denaturation performance curves of concrete with metakaolin under different carbonization cycles, and the curves are fluctuating as a whole. According to Figure 6, with the addition of metakaolin, its peak strain increased steadily with a low growth rate. The higher the content, the smaller the influence of carbonization age, and the longer the carbonization period, the gentler the curve. When its dosage changed from 5% to 20%, the peak strain increased by 22.79%, 12.71%, and 6.27% with carbonization for 0 d, 28 d, and 90 d, respectively, which indicated a similar trend as that in the literature (Mukharjee et al., 2019) [32]. It can also be seen in Figure 7 that carbonization made its elastic modulus fluctuate in varying degrees, and the longer the carbonization cycle, the greater the fluctuation. When the content was large (>10%), the fluctuation tended to gradually become gentle. On the whole, metakaolin improved the concrete’s elastic modulus, but it was still lower than that of ordinary concrete (NAC-21).

Figure 6.

Influence of carbonization on the peak strain of concrete mixed with metakaolin.

Figure 7.

Influence of carbonization on the elasticity modulus of concrete mixed with metakaolin.

5. Durability

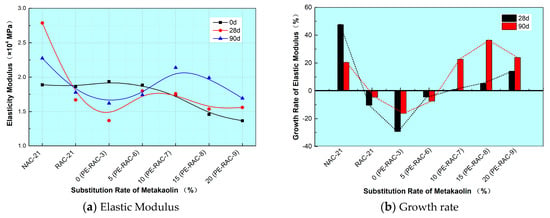

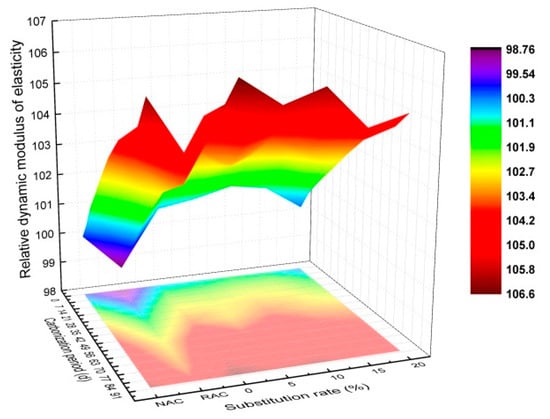

5.1. Relative Dynamic Elasticity Modulus

Based on the different propagation speeds of ultrasonic waves inside concrete, the microscopic changes in the structure can be reflected through the macroscopic value without damaging the structure, which is the so-called ultrasonic nondestructive testing. One probe is used to transmit ultrasonic waves, and the other probe receives ultrasonic waves, and the wave speed is determined by the propagation time, thereby indirectly reflecting the damage inside the concrete. We tested the concrete using the relevant method and calculation process as shown in the specification GB/T50082-2009 [30]. For a more convenient analysis, the relative dynamic elastic modulus (RDEM) was calculated, and the fundamental frequency value of the corresponding block with 0 d of carbonization was adopted for the initial value. The values of the RDEM after calculations are shown in Figure 8. From the figure, the values of the RDEM increased slightly with the carbonization period. When the carbonization period was 90 days, its maximum value occurred when the content of metakaolin was 5%. Compared with NAC-21 and RAC-21, the values increased by 6.14% and 4.85%, respectively. According to the corresponding equipotential curve, the RDEM of RAC was the smallest. Due to the presence of recycled mortar, the matrix structure of RAC was the most porous, which also led the RDEM value to be minimum.

Figure 8.

RDEM.

Meanwhile, the addition of metakaolin resulted in varying degrees of fluctuation in its values, and the position of the peak point was approximately between 0% and 10%. However, on the whole, the fluctuation remained small, and the change was not obvious at the same age. For example, when the dosage varied from 0% to 20%, the biggest fluctuation was with carbonization for 90 d, and its values reached 106.56, 105.71, 106.14, 104.88, and 105.21, respectively.

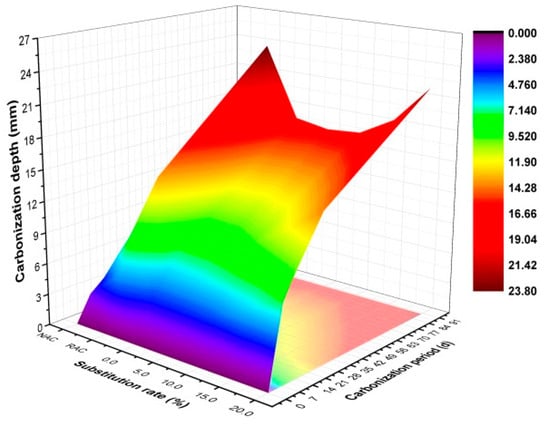

5.2. Carbonization Depth

Figure 9 represents the influence of metakaolin on the carbonization depth, and it shows a trend of first decreasing and then increasing. For 7 days of carbonization, when the dosage varied from 0% to 20%, the carbonization depth changed by 7.21%, 27.03%, 78.38%, and 124.92%, which also indicated that among the three functions of metakaolin, its chemical reactivity played a controlling role, and it was also the main reason why the strength value could be greatly improved. When the metakaolin content reached 20%, the carbonization depth at each carbonization age (7 d, 14 d, 28 d, and 90 d) increased by 124.92%, 77.71%, 69.19%, and 30.38%, respectively. The effect of carbonization resistance deterioration remained quite obvious, which also illustrated that with the carbonization age becoming longer, the concrete compactness gradually increased and then prevented CO2 gas from penetrating deeper into the interior and improved its carbonization resistance.

Figure 9.

Carbonization depth.

As shown in Figure 9, the carbonization depth showed the same trend with the increase in carbonization age. Under the same carbonization age, the carbonization depth of RAC was significantly greater than that of NAC, indicating its poor carbonization resistance. As a mineral admixture, metakaolin exhibits chemical reactivity, interface reinforcement, and micro-aggregate reaction [40]. The chemical reactivity is mainly due to its strong activity. By promoting the hydration reaction of cementitious materials, the alkali content in concrete is reduced to a great extent. Interface enhancement occurs because metakaolin can fill the pores at the interface, strengthen the weak area of its interface, then make this zone firmer. The micro-aggregate reaction is mainly due to its fine particles, which can fill the harmful pores inside concrete and effectively reduce its porosity. Generally, the first characteristic is not conducive to the improvement in carbonization resistance, while the latter two enhance carbonization resistance.

6. Micro-Morphology

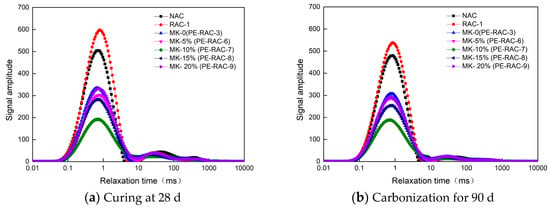

6.1. Nuclear Magnetic Resonance (NMR)

Figure 10 and Table 6 demonstrate T2 relaxation curves and relevant characteristic data points obtained by NMR technology. As can be seen, with the addition of metakaolin, the pore structure of concrete changed to a great extent. When its content increased from 0% to 20%, the amplitude decreased by 10.52%, 47.21%, 17.32%, and 6.61%, which was smaller than that of NAC-21 and RAC-21. When its content reached 10%, its amplitude decreased considerably, by 62.03% and 67.95%, respectively. A similar situation occurred after carbonization for 90 days. The porosity of concrete under various working conditions was reduced by different procedures due to carbonization. It also demonstrated that metakaolin could greatly reduce the number of pores in concrete, which is mainly due to its pozzolanic activity reaction, hydration promotion reaction, and filling effect. The layered aluminum silicate compound in metakaolin allows free water to enter the pores between the layers, forming a unique “internal curing” environment, continuously filling and dividing the internal pores, and reducing the diameter of the pores, so as to achieve the purpose of optimal structure. An appropriate amount can greatly lower its peak amplitude, but when its amount is large, the number of pores rises again. When its amount was increased to 20% (PE-RAC-9), compared with the 10% content, the amplitude increased by 73.51%, and the effect on the number of pores was quite serious.

Figure 10.

T2 relaxation curve.

Table 6.

Main eigenvalues of T2 relaxation curve (curing at 28 days).

On the abscissa, there were two peaks when the metakaolin content was less than 15%, but four peaks when the content was 20%. By comparing the occurrence time of the last peak value, the maximum diameter of pores in concrete can be determined. With the increase in metakaolin content, the relaxation time of the last peak was 178.347 ms, 286.601 ms, 22.219 ms, 174.587 ms, and 367.3 ms, which could explain why its effect on pore diameter approximately decreased first and then increased. Due to the finer particles, a larger specific surface area, and higher water demand, when its content was large, more cracks were produced, and the pore diameter became larger, which resulted in the aforementioned change in mechanical properties and durability.

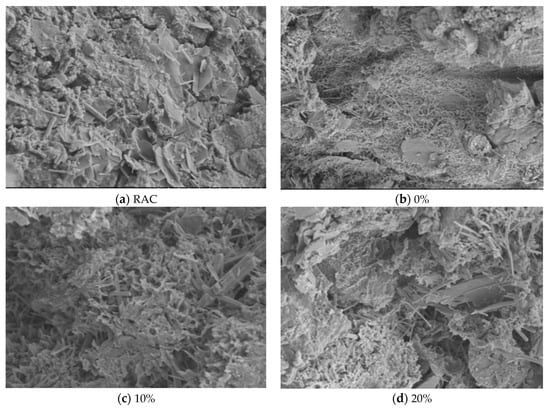

6.2. Scanning Electron Microscope (SEM)

Figure 11 shows its SEM microstructure after carbonization for 0 d under the action of RAC-21 and with 0%, 10%, and 20% of metakaolin.

Figure 11.

Micro-structure of RAC with metakaolin.

According to the comparative analysis in the above figure, the addition of metakaolin made the hydration reaction of concrete more complete, and a needle-like, fibrous, and honeycomb-like CSH gel structure could be clearly observed [16,17]. The hydrated products were stacked and overlapped, and some unhydrated cement particles were wrapped by the hydrated products, forming a staggered network structure, which could enhance the mechanical occlusion between the aggregates. The hydration products of the C-S-H gel were closely packed with unhydrated particles, which correspondingly made the matrix structure more compact, neat, and complete. Metakaolin had finer particles, and its fine powder filling effect was better than that of the IOT powder [23]. At the same time, its pozzolanic activity was strong, which could greatly promote the secondary hydration, reduce and fill the pores of its matrix structure, then improve compactness. As a large amount of alkali solution was consumed in the secondary hydration reaction, the ability to absorb CO2 was also reduced and degraded its anti-carbonization ability (Figure 9).

Similar to the case of adding IOTs, the appropriate amount of metakaolin could effectively improve the matrix structure and reduce its porosity, but an excessive amount of metakaolin adversely affected its matrix structure. The main difference between Figure 11c,d was that the latter matrix structure was relatively loose and had a lot of pores. The main reason was the accumulation of volcanic ash activity, which required a large amount of free water and free Ca(OH)2 in the hydration process. Once the free water or alkali solution in the pores of the unhydrated zone around metakaolin was consumed completely, those would be absorbed within the hydrated matrix structure area to continue hydration. When it exceeded a certain limit, tensile cracks would appear, which was also the main reason for the deterioration of the mechanical and durability properties.

7. Conclusions

This study investigated the feasibility of metakaolin as a performance-enhancing material for TGC. Setting the replacement rate of RCAs and IOTs to 30%, and the WPF content being 0.6%, we prepared concrete with metakaolin, then its mechanical properties, carbonization resistance, and micro-structural properties were obtained, and the main conclusions were as follows:

- (1)

- The compressive strength and splitting tensile strength presented a similar regular pattern, showing a trend of first increasing and then decreasing, with an optimal dosage of 5–10%.

- (2)

- The peak strain increased slightly, and the elastic modulus fluctuated with a low content of metakaolin (≤10%). With a high content (>10%), it gradually tended to decrease, and its brittleness was further strengthened. Carbonization could improve effects caused by differences in metakaolin content and made the correlation value become gentle and regular.

- (3)

- At the same carbonization age, the RDEM of RAC was the lowest, the metakaolin addition made the value fluctuate a little, and the peak point was approximately at a content ranging from 0% and 10%. As the content increased, its carbonization depth showed a trend of first decreasing and then increasing. When the content of metakaolin was 10%, the carbonization depth was minimal, indicating that its carbonization resistance was the strongest.

- (4)

- Through an NMR analysis, the peak amplitude could be reduced by adding the proper amount of metakaolin, but the number of pores rose again when the content was large, and the porosity reached its minimum when the content was 10%.

- (5)

- The SEM analysis indicated that a small MK amount could greatly promote the hydration of cement, improve its compactness, and greatly increase its mechanical properties. When the content was high (>10%), the secondary hydration promotion effect was large and increased the demand for free water and alkaline substances. With the progress of the carbonization reaction, harmful pores appeared in the matrix structure, resulting in a decline in relevant properties.

Through the above macro- and micro-analyses, it can be seen that when the content of metakaolin is 10%, its macro-mechanical and carbonization resistance properties can be approximately optimal. Meanwhile, the micro-pore diameter, pore number, and matrix structure also prove that 10% is the most appropriate content.

Author Contributions

T.L.: Conceptualization, Methodology, Formal analysis, Writing—Original Draft; X.C.: Methodology, Formal analysis, Data Curation, Writing—Review and Editing; W.Y.: Data Curation, Software, Validation, M.Z.: Conceptualization, Editing; L.H.: Writing—Review, Writing—Review and Editing; L.Z.: Software, Validation, Writing—Review; Y.Y.: Resources, Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by Henan Province Key Projects of Science and Technology (242102320002, 242102320004, 242102321031); Youth Backbone Teacher Training Program of Henan Province (2019GGJS232); Henan Province Graduate Education Reform and Quality Improvement Project (YJS2023JD52); Support Program for Young Backbone Teachers at Huanghuai University; National Fund Cultivation Project of Huanghuai University.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Levandoski, W.M.K.; Ferrazzo Suéllen Tonatto Bruschi, G.J.; Consoli, N.C.; Korf, E.P. Mechanical and microstructural properties of iron mining tailings stabilized with alkali-activated binder produced from agro-industrial wastes. Sci. Rep. 2023, 13, 15754. [Google Scholar] [CrossRef] [PubMed]

- Mkikouri, S.; Vares, S.; Korpijrvi, K.; Papakonstantinou, N. The Carbon Dioxide Emissions Reduction Potential of Carbon-Dioxide-Cured Alternative Binder Concrete. Rec. Prog. Mater. 2021, 3, 2689–5846. [Google Scholar] [CrossRef]

- Oritola, S.F.; Saleh, A.L.; Sam, A. Characterization of iron ore tailings as fine aggregate. Aci Mater. J. 2020, 117, 51720305. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Chen, B.; Zhu, W.S. Performance and hydration mechanisms of ultrafine iron ore tailings enhanced supersulfated cement with high phosphogypsum content. Cem. Compos. Comp. 2025, 157, 105891. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.; Liu, P.; Li, H.-N.; Tian, Y.; Chen, W.; Lin, S.; Hao, H. Influences of strain rate and density on the dynamic material properties and energy dissipation characteristics of iron tailing porous concrete. J Mater Civ. Eng. 2024, 36, 18456. [Google Scholar] [CrossRef]

- Li, P.; Luo, S.; Wang, Y.; Zhang, L.; Wang, H.; Teng, F. Mix design and mechanical properties of geopolymer building material using iron ore mine tailings. Renew. Sustain. Energy Rev. 2025, 211, 115274. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J. Relationship between compressive strength and pore structure of tailings ball concrete. Mag. Concr. Res. 2023, 75, 506–517. [Google Scholar] [CrossRef]

- Lu, C.; Chen, H.Y.; Fu, L.J.; Tian, G.Y.; Zhang, H.; Liang, J.S.; Yang, H.M. Research Progress on the Preparation of New Building Materials Using Iron Tailings. Mater. Rep. 2021, 35, 5011–5026. [Google Scholar] [CrossRef]

- Amjad, H.; Abd-Elaal, E.-S.; Ma, X.; Benn, T.; Fisher, M. A critical review of iron ore tailings as cement and aggregate substitutes for robust infrastructure: Mechanical, durability, eco-economic, and social impacts. J. Clean. Prod. 2025, 492, 144853. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Carbonation and electrical resistance of self-compacting concrete made with recycled concrete aggregates and metakaolin-sciencedirect. Construct. Build. Mater. 2016, 121, 400–409. [Google Scholar] [CrossRef]

- Lv, X.D.; Lin, Y.Q.; Xia, C.; Yan, S.; Liang, R.Q.; Wang, R.K.; Peng, Z.L. Environmental impact, durability performance, and interfacial transition zone of iron ore tailings utilized as dam concrete aggregates. J. Clean. Prod. 2021, 292, 126068. [Google Scholar] [CrossRef]

- Huang, Z.X.; Hou, Y.H.; Song, S.M. Effect of iron tailings power on shrinkage and durability of concrete. Concrete 2020, 5, 56–59. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.F.; Bao, W.B.; Qi, H.J. Experimental study on durability of tailings concrete. Concrete 2020, 4, 93–97. [Google Scholar] [CrossRef]

- Li, T.; Zhan, M.; Chen, X.Y.; Xu, F.; Wang, S.L.; Liu, X.X. Study on Carbonization Characteristics and Deterioration Mechanism of Recycled Concrete with Tailings and Polypropylene Fiber. Polymers 2022, 14, 2758. [Google Scholar] [CrossRef]

- Li, T.; Yang, W.; Zhan, M.; Chen, X.; Zhang, L.; Wang, C.; Yang, Y.; Lyv, H. Study on the Microscopic Transmission Characteristics and Coupled Erosion Depth of Tailings Recycled Concrete under the Coupling Effect of Carbonization and Salt-fog. J. Build. Eng. 2024, 95, 110051. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.L.; Li, T.; Liu, B.; Li, B.B.; Zhou, Y. The mechanical properties of tailing recycled aggregate concrete and its resistance to the coupled deterioration of sulfate attack and wetting–drying cycles. Structures 2020, 7, 2208–2216. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.L.; Li, T.; Liu, B.; Zhao, N.; Liu, K.N. The mechanical properties and resistance against the coupled deterioration of sulfate attack and freeze-thaw cycles of tailing recycled aggregate concrete. Construct. Build. Mater. 2021, 269, 121273. [Google Scholar] [CrossRef]

- Liu, K.N.; Wang, S.L.; Quan, X.Y.; Duan, W.; Zhao, N.; Wei, T.; Xu, F.; Li, B.B. Study on the mechanical properties and microstructure of fiber reinforced metakaolin-based recycled aggregate concrete. Construct. Build. Mater. 2021, 294, 123554. [Google Scholar] [CrossRef]

- JGJ52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2006.

- GB/T51003-2014; Technical Code for Application of Mineral Admixture. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2014.

- JGJ63-2006; Standard of Water for Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing., China, 2014.

- Wang, S.L.; Li, T.; Yang, T.; Zhang, B.; Ju, J. Experimental study on seismic behavior of RAC columns with silica fume and hybrid fiber. J. Build. Struct. 2013, 34, 122–129. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.L.; Li, T.; Liu, B.; Zhou, Y. Mechanical properties and pore structure of recycled aggregate concrete made with iron ore tailings and polypropylene fibers. J. Build. Eng. 2021, 33, 101572. [Google Scholar] [CrossRef]

- Zhang, B.Z.; Wang, S.L.; Zhang, B.; Jing, L.P.; Luo, S.C. Experimental analysis of the basic mechanical properties of recycled concrete. Concrete 2011, 7, 4–6. [Google Scholar]

- AbuFarsakh, R.; Amador, G.A.; Noorvand, H.; Subedi, S.; Hassan, M. Influence of sand and fiber type on the fiber-bridging properties of metakaolin-based engineered geopolymer composites. Transp. Res Rec. 2024, 2678, 1639–1658. [Google Scholar] [CrossRef]

- Tochahi, P.M.; Asadollahfardi, G.A.; Saghravani, S.F.; Mohammadzadeh, N. Curing of concrete specimens containing metakaolin, zeolite, and micro-/nanobubble water in seawater. ACI Mater. J. 2024, 121, 10. [Google Scholar] [CrossRef]

- Moradi, M.J.; Khaleghi, M.; Salimi, J.; Farhangi, V.; Ramezanianpour, A.M. Predicting the compressive strength of concrete containing metakaolin with different properties using ann. Measurement 2021, 183, 109709. [Google Scholar] [CrossRef]

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2011.

- GB/T50010-2015; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2015.

- GB/T50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2009.

- Mukharjee, B.B.; Muduli, R. Effect of incorporation of metakaolin and recycled coarse aggregate on properties of concrete. J. Clean. Prod. 2018, 209, 398–414. [Google Scholar] [CrossRef]

- Mukharjee, B.B.; Muduli, R. Performance assessment of concrete incorporating recycled coarse aggregates and metakaolin: A systematic approach. Construct. Build. Mater. 2019, 233, 117223. [Google Scholar] [CrossRef]

- Singh, M.; Saini, B.; Chalak, H.D. Smart Technologies for Sustainable Development: Select Proceedings of SMTS 2019; Springer: Singapore, 2021; pp. 213–222. [Google Scholar]

- Jiang, C.Y.; Yu, R.; Ma, D.H.; Shui, Z.H.; Song, Q.L.; Sun, M.J.; Rao, S.D.; Chen, H.; Xiao, X.G. Physical and Chemical Influences of Compounded Pozzolanic Material on the Properties and Microstructure Development of Ultra-High Performance Concrete (UHRC). Bull. Chin. Ceram. Soc. 2019, 38, 1102–1107. [Google Scholar]

- Li, B.; Li, Y.P.; Wang, C.X.; Cao, F.B. Experimental study on stress-strain curve of granulated steel slag concrete. J. Build. Struct. 2019, 40, 163–169. [Google Scholar]

- Xu, L.H.; Huang, B.; Li, B.; Chi, Y.; Li, C.N.; Shi, Y.C. Study on the stress-strain relation of polypropylene fiber reinforced concrete under cyclic compression. China Civ. Eng. J. 2019, 52, 1–12. [Google Scholar] [CrossRef]

- Zhang, B.X. Experimental Study on Axial Compressive Properties of SF/KS-GRAC. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Xie, J.H.; Chen, W.; Wang, J.J.; Tang, C.; Zhang, B.X.; Liu, F. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete. Construct. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Cimentada, A.; Sainz-Aja, J.A. Macro- and micro- properties of multi-recycled aggregate concrete. J. Clean. Prod. 2019, 245, 118843. [Google Scholar] [CrossRef]

- Fang, Z.J.; Yan, C.; Li, J.P.; Zhai, X.S. Effects of metakaolin on the anti-carbonization property of concrete. J. Guangxi Univ. Sci. Technol. 2015, 26. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).