1. Introduction

The increasing consumption of natural resources and the growing volumes of construction and demolition waste (CDW) have spurred a global push for sustainable practices within the construction industry. The literature reports extensive research on aggregate recycling from construction waste (RA, RAC), including various treatment methods [

1], and studies examining behavior over time [

2]. The research presented in this article focuses on recycled concrete aggregate (RCA), an aggregate type with the maximum treatment and of the highest quality (at least 90% concrete). This type of aggregate will be approved for use according to future standards in reinforced concrete structural elements with partial replacement percentages.

Recycled Concrete Aggregate (RCA), produced by processing CDW, offers a viable solution for reducing landfill loads and conserving natural aggregate resources. This aligns with circular economy principles, offering environmental benefits and potential cost savings. However, the widespread adoption of RCA in load-bearing structural elements requires a comprehensive understanding of its effects on the mechanical behavior of reinforced concrete. In particular, attention must be given to crack formation, serviceability limit state, and flexural performance in the ultimate limit state.

Due to adhered mortar, pre-existing microcracks, and variable composition, the inherent heterogeneity of RCA introduces additional complexity to its behavior in concrete mixtures [

1,

3,

4]. Previous research has highlighted that the interfacial transition zone (ITZ) between RCA particles and the surrounding cement paste tends to have a modified microstructure, which significantly affects crack initiation and propagation [

5,

6]. Numerous studies have investigated the influence of RCA on compressive strength [

4,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18], tensile strength [

4,

7,

10,

14,

18,

19,

20,

21,

22], mechanical behavior and fracture performance [

1,

3,

4,

8,

9], and the overall stress–strain characteristics of concrete [

1,

5,

6]. Moreover, limited research has focused on the interaction between steel reinforcement and concrete, particularly on the effect of aggregate type on the bond mechanism [

7,

11,

23,

24,

25]. Key factors influencing performance include the RCA replacement ratio and its physical properties, such as density and water absorption capacity [

10,

12,

13].

The studies reported in the literature are divided into two main groups: the replacement of natural aggregate with recycled aggregate without changing the mix components [

15,

26,

27] and the replacement of natural aggregate with recycled aggregate while changing the mix components [

14]. In the first group, replacement is often accompanied by a decrease in the compressive strength of the concrete and various properties of the hardened concrete [

5,

6]. The difference in concrete strength entails comparing results under different conditions.

Flexural behavior is a key consideration in structural design, and the incorporation of RCA can impact the bending capacity, crack patterns, and deflection behavior of reinforced concrete beams. Although some studies report that RCA-based beams can attain flexural strength similar to conventional concrete beams [

14,

27], others highlight increased deflections and more significant cracking patterns [

17,

26]. Long-term behaviors, including shrinkage and creep, warrant further evaluation of RCA-based concrete elements’ durability and structural performance [

17,

28,

29]. Additionally, performance may be influenced by factors such as RCA moisture content [

13], and the incorporation of chemical admixtures (e.g., silica fume [

18]) may also affect performance outcomes.

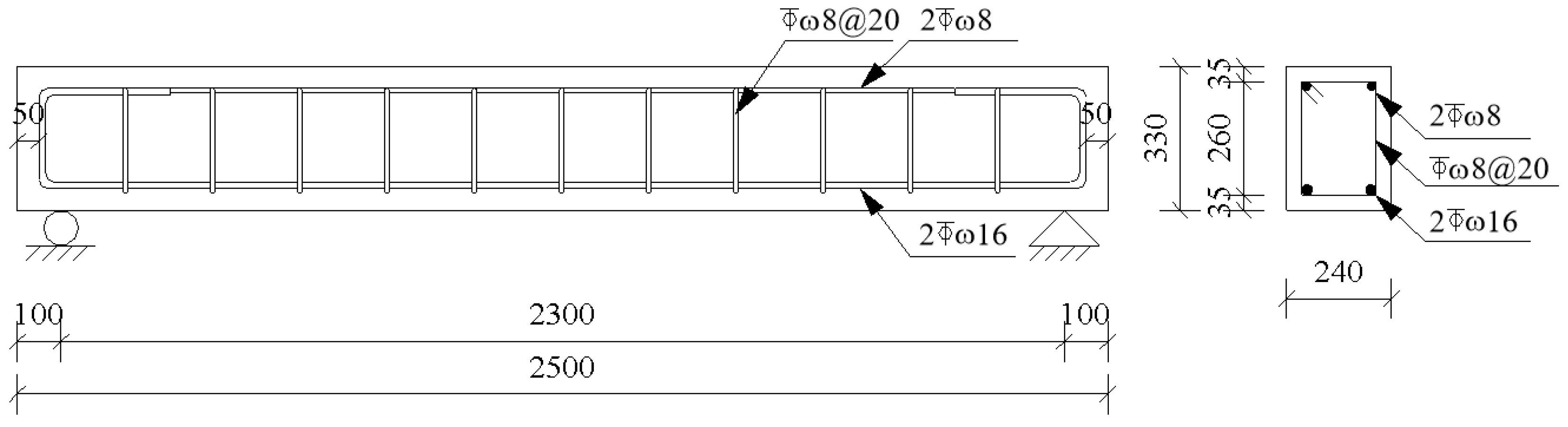

This study investigates the effect of locally produced RCA on the flexural behavior of reinforced concrete beams. Although international studies provide a foundation for understanding RCA behavior, the specific characteristics of concrete infrastructure demolished in Israel—produced with different standards and materials during the early to mid-20th century—necessitate targeted investigation. As such, this study aims to evaluate the flexural performance of beams made with RCA derived from Israeli demolition waste, focusing on flexural performance, serviceability behavior, and early cracking. Due to the differences in the properties of concrete made in Israel during the first half of the last century compared to that produced abroad, there is a need to establish a research infrastructure for recycled concrete aggregate (RCA) made in Israel. This infrastructure will support the integration of RCA into the local construction industry. This research focuses on crack development, bending moment capacity, and deformation of full-scale reinforced concrete beams made with RCA and natural aggregate (NA) concrete under serviceability and ultimate limit states.

3. Results

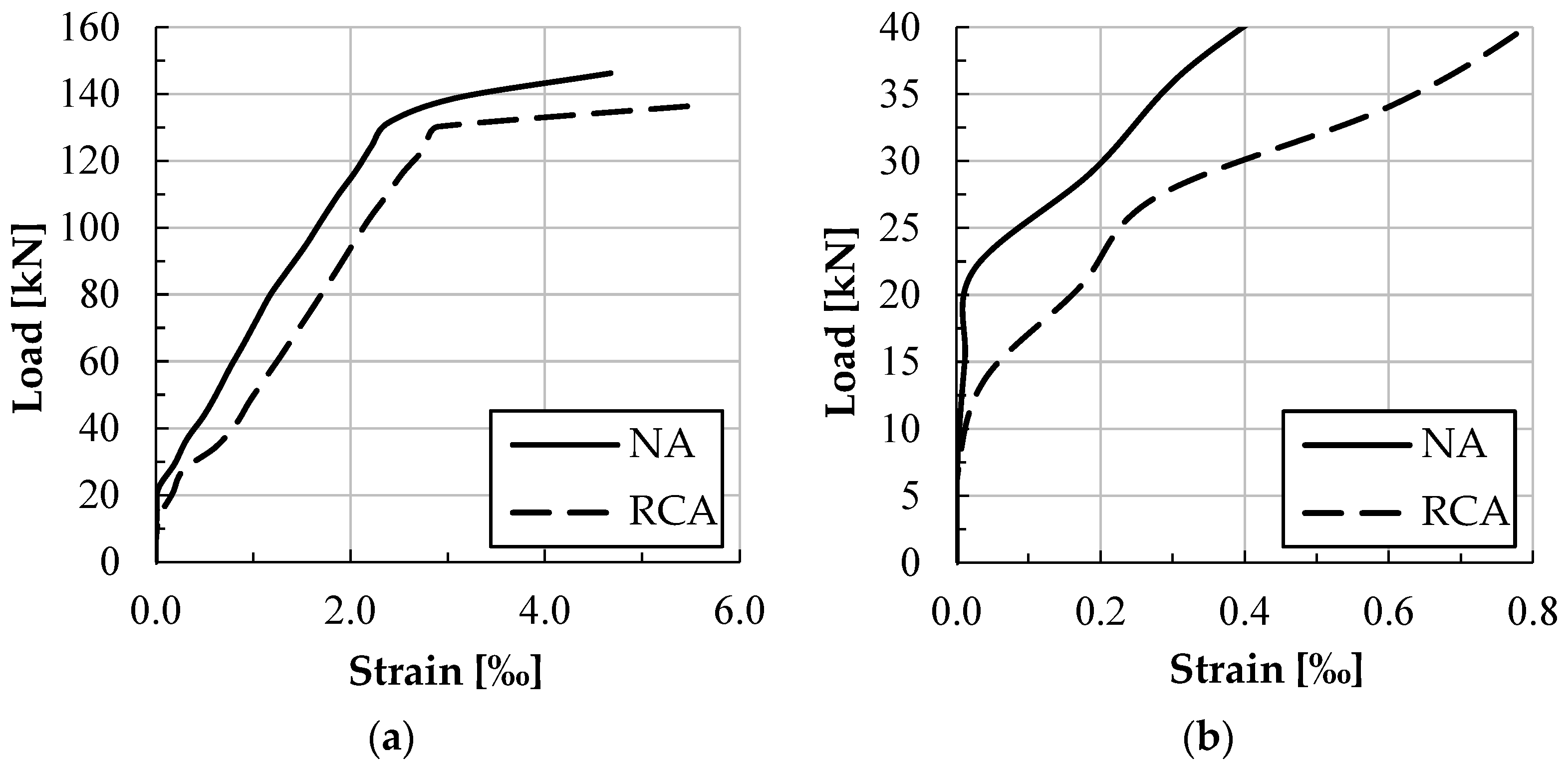

3.1. Load–Deflection and Moment–Deflection Curves

All beams in this study were designed and constructed to exhibit ductile failure, as required for structural design and execution. This ensured that tensile reinforcement yielded before any concrete crushing or failure occurred.

Figure 3 shows the load–deflection responses for each concrete type.

Figure 3a,b presents the results for NA and RCA beams, respectively.

Figure 3c presents the results for all beams, while

Figure 3d shows an enlarged view of the initial phase of the tests. Although the experimental results in the enlarged field do not overlap perfectly as expected, they exhibit similar behavior. Analysis of the initial loading phase reveals that both concrete types exhibited similar deflection behavior up to the onset of cracking. Numerical results for the different load and moment values are presented in

Table 4. However, a noticeable deflection behavior divergence emerges between the recycled concrete aggregate (RCA) beams and the natural aggregate (NA) beams after the cracking initiation. This difference becomes more pronounced following the onset of reinforcement yielding. RCA beams exhibited 14–25% greater deflection at peak load than NA beams, although they were subjected to a 3–10% lower maximum load. This behavior can be attributed to the lower tensile strength of RCA concrete, which leads to earlier crack formation and, consequently, larger deflections.

Several experimental studies [

14,

15,

17,

19,

27] have investigated the impact of replacing natural aggregate with recycled aggregate on the flexural performance of reinforced concrete beams. Data from the studies are summarized in

Table 5.

These studies vary in terms of the beams’ geometric dimensions, the concrete’s material properties, the support span lengths, and the locations of the applied concentrated forces.

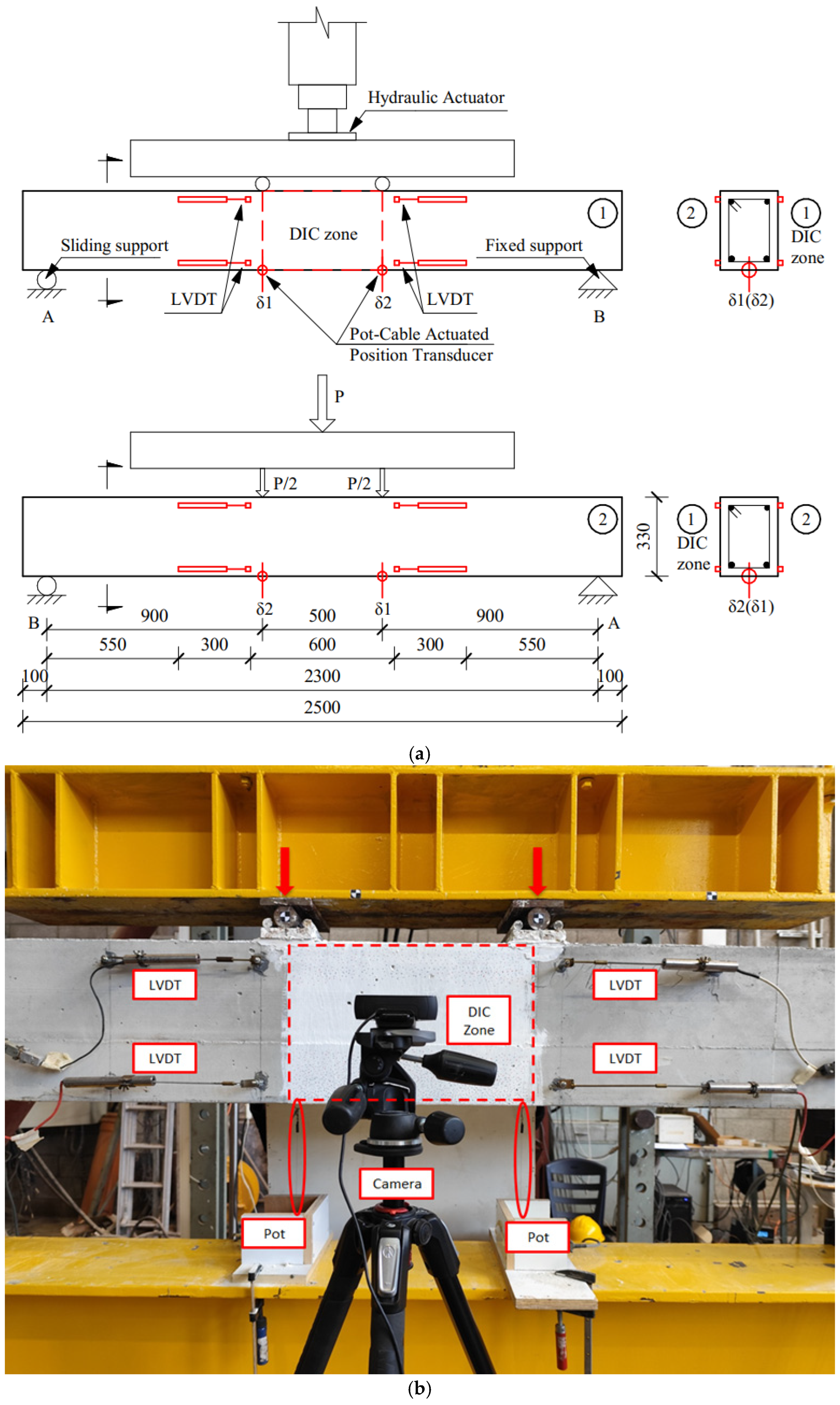

Figure 4 compares normalized force-deflection curves for RCA concrete beams to identify common behavioral trends. These curves are expressed as the ratio of applied force to maximum force versus the ratio of deflection to maximum deflection. The comparison includes data from both the present and previous studies. Only beams with full (100%) replacement of natural coarse aggregate by RCA, consistent with those tested in the present study, were considered.

A strong correlation was observed between the deflection curves reported in previous studies and those obtained for the RCA beams in this study. However, three models exhibited relatively significant deviations from the current and other studies’ results. These discrepancies are particularly notable in the experimental curves reported by Ignjatović et al. [

14], who used concrete mixtures with similar compressive strengths and varying tensile reinforcement configurations—3Ø18, 3Ø8, and 5Ø18 in beams RCA100-1, RCA100-2, and RCA100-3, respectively. In contrast, a strong agreement in deflection behavior was observed between the present study and the findings of Seara-Paz et al. [

26] (beams H50-100 and H65-100) and Arezoumandi et al. [

27] (beams RCA-F-6-1, RCA-F-6-2, RCA-F-7-1 RCA-F-7-2), all of which employed concrete mixtures with complete replacement of natural aggregate using recycled aggregate, without modifications to the original mix composition.

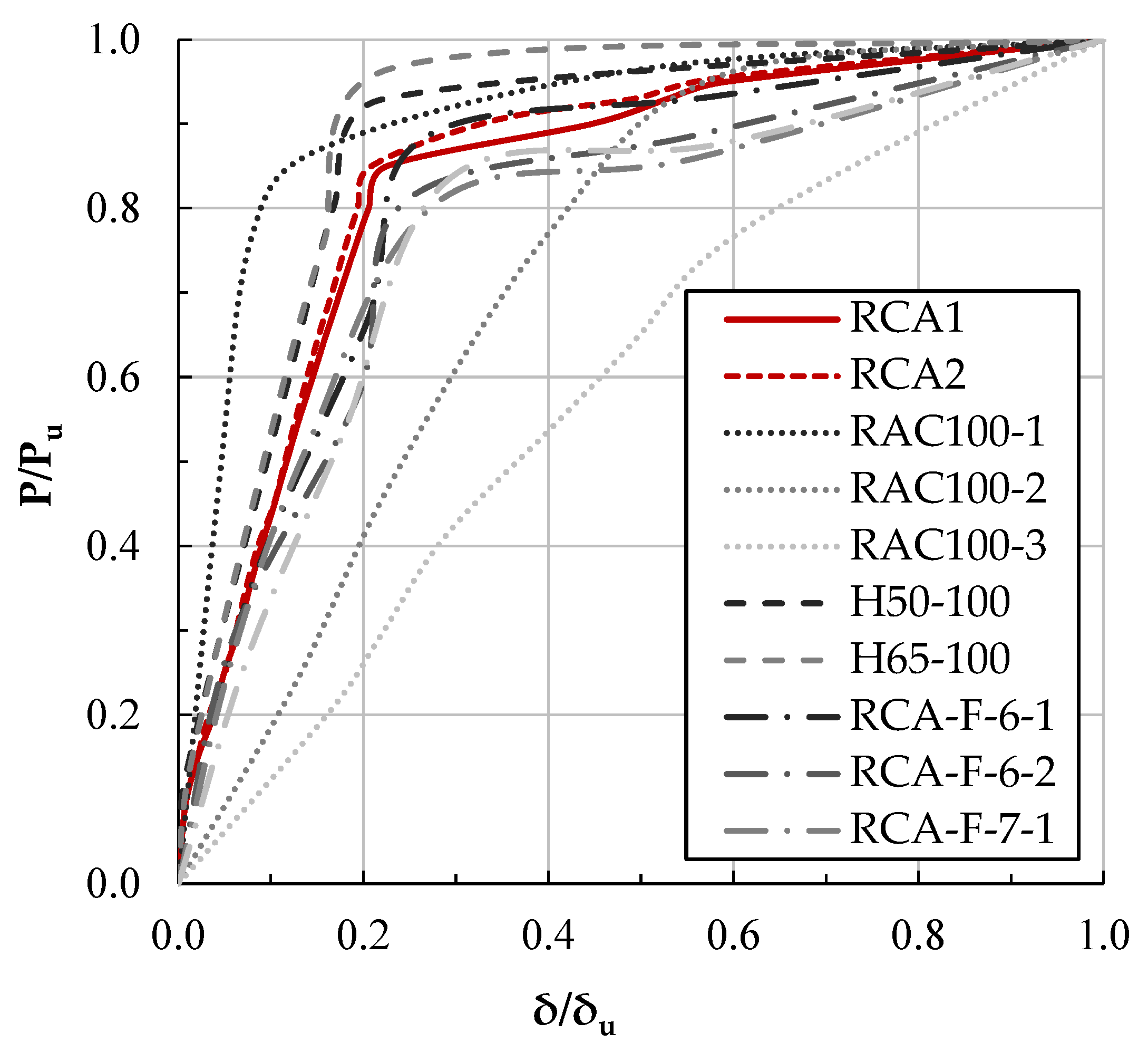

3.2. Strains

The LVDT gauges continuously recorded changes in specimen length throughout the loading process. Strain values were obtained by dividing the elongation measured by the LVDT by the original gauge length. Consistent results were observed within each series, and the comparison focuses on the variation in the average curve. The RCA beams exhibited substantially higher compressive strains across all stages of loading. Before cracking, both concrete types displayed similar strain levels. However, the cracking load in the RCA beams was approximately half that observed in the NA beams. Beyond the cracking point, the two concrete types observed a marked divergence in compressive strain. At both the yielding and ultimate load stages, the RCA beams exhibited strain values that were more than twice as high as those recorded in the NA beams.

Overall, RCA beams demonstrated greater compressive strains at lower load levels throughout the loading process (

Figure 5). These strain values reflect the concrete’s compressive behavior. The substantial differences observed indicate that RCA concrete exhibits mechanical behavior that differs from NA concrete under compressive loading. This behavior can be attributed to RCA concrete’s higher porosity and lower density, resulting from the adhered mortar and microcracks in the recycled aggregates [

5,

6,

16,

19]. These factors collectively lead to a reduction in compressive strength.

Regarding tensile strain, the overall structural response of the beams exhibited similar trends for both concrete types (

Figure 6). However, the RCA beams demonstrated higher tensile strain values following the onset of cracking (

Figure 6b). The divergence in strain began at the cracking load of the RCA concrete, approximately 13 kN, and continued to increase until around 35 kN. Both concrete types exhibited similar strain rates between the cracking and yielding stages, resulting in a relatively constant gap between their respective curves. Beyond the yielding point, the tensile strains in the RCA beams increased more sharply, resulting in the broader divergence in strain values as the beams approached the ultimate load.

While the yielding and ultimate load stages in the RCA beams occurred at lower applied loads, they were associated with higher tensile strain values. Following the cracking stage, the development of tensile strains was primarily governed by the behavior of the tension reinforcement. Since all beams were reinforced with identical steel bar types and quantities, the main difference in tensile strain behavior was observed in the post-cracking range. This behavior is attributed to the more extensive cracking observed in RCA beams. Despite these differences, the post-cracking tensile strain development exhibited qualitatively similar trends in both concrete types. It can be concluded that beyond the cracking stage, the influence of concrete type on tensile strain development is limited, as the reinforcing steel predominantly carries tensile stresses.

3.3. Crack Pattern

Vertical flexural cracks initiated at the bottom of the midspan during the initial loading stages and gradually propagated upward as the applied load increased. Once the steel reinforcement yielded, the central flexural cracks widened significantly, which was accompanied by a rapid increase in beam deflection. Final failure occurred due to concrete crushing in the compression zone.

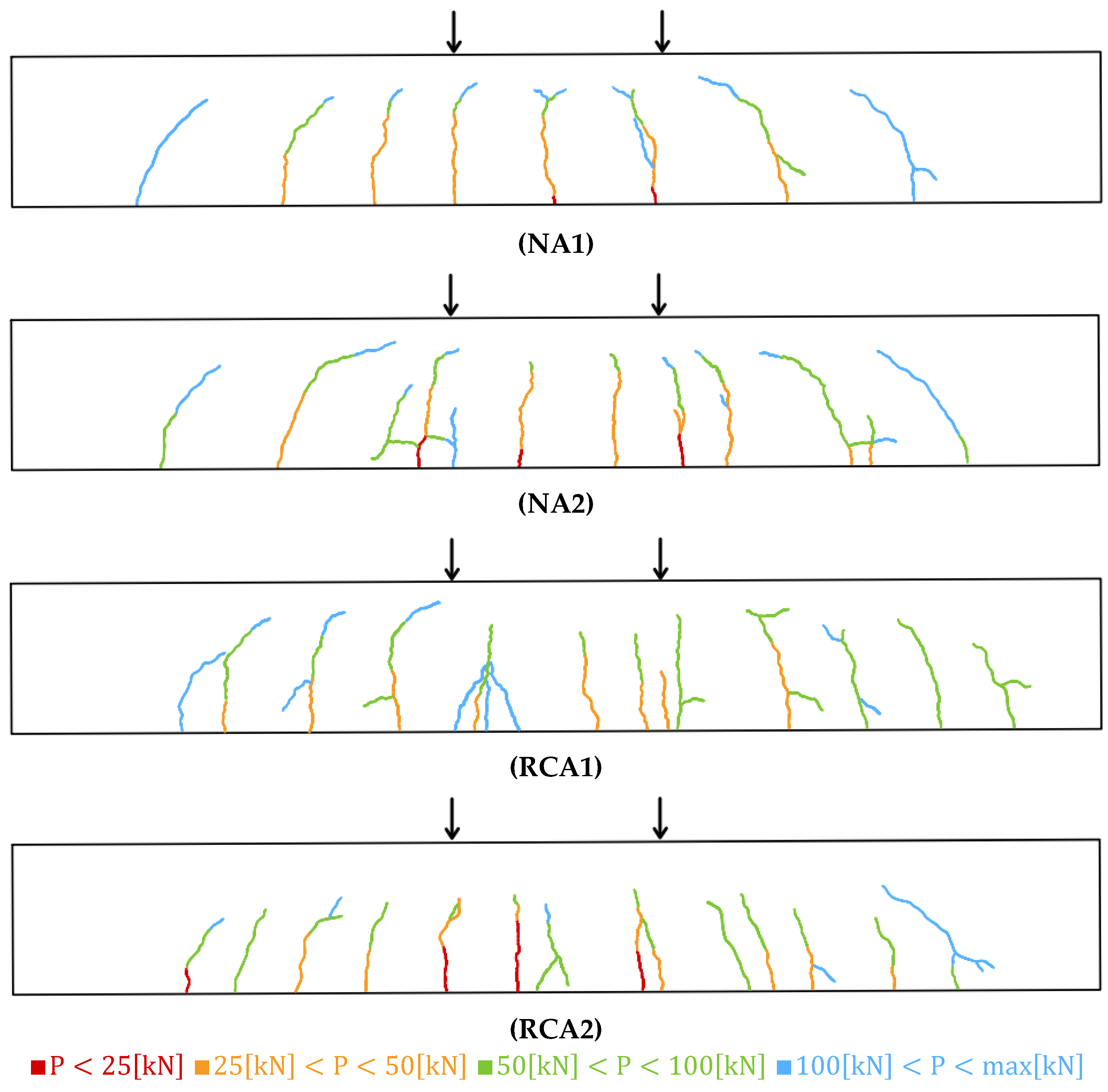

The crack distribution was analyzed using data recorded from both faces of the beams (

Figure 7). In the central region of the beam—where pure bending dominates—crack lengths and widths were extracted from image sequences, allowing evaluation of cracking patterns as the load increased. On the opposite face, manually recorded markings provided a full-span map of crack locations along with their corresponding load levels.

A comparison of crack distribution between the beams revealed that those prepared with natural aggregate concrete (NA) exhibited a smaller number of cracks (8 in specimen NA1 and 9 in specimen NA2). At the same time, the RCA beams developed approximately 13 primary cracks, accompanied by several secondary branches from them. Under a load of up to 25 kN, the NA beams showed moderate cracking, with only 2–3 initial cracks concentrated in the central region of the beam. In contrast, beam RCA2 had already developed three central flexural cracks reaching nearly half the beam’s height and an initial shear crack on its left side. Due to an execution error at the beginning of the RCA1 test, early-stage cracks were not recorded, and crack patterns were reported from 25 kN. Overall, it can be concluded that the RCA beams developed more cracks, initiated at earlier loading stages than the NA beams.

Notably, shear cracks due to diagonal tension (typically observed near the supports) were observed in the RCA beams at relatively lower load levels. This observation is significant and warrants further investigation, as shear failure is considered a brittle failure mode.

The flexural cracking at the beam midspan was also evaluated by measuring the crack width (

Table 6) and height (

Table 7) under load levels of 50 kN, 75 kN, 100 kN, and 125 kN. Up to 100 kN, crack widths remained comparable in both NA and RCA beams; however, at 125 kN, a notable divergence in crack widths emerged. The crack width in the RCA beam was nearly 50% greater than in the NA beam, indicating increased susceptibility to crack widening under higher loads. In contrast, the height of the central cracks remained relatively consistent across all load levels.

3.4. Strain Distribution over the Cross-Section

Based on LVDT displacement measurements, strain distribution profiles along the beam height were generated for each concrete type’s cracking, yielding, and ultimate load stages, using the Bernoulli–Euler assumption. As the measurements were taken near the loading points rather than at midspan, the calculated values do not represent the maximum strains observed in the beams.

Figure 8 shows the strain distribution across the beam cross-section. The results indicate that increasing load for both concrete types led to higher strains at the extreme fibers, with tensile strains rising faster than compressive strains. As a result, the height of the compression zone gradually decreased as the loading progressed.

The most notable difference between the two concrete types emerged during the cracking stage. In the RCA beams, initial cracking occurred at approximately half the load required for the NA beams. The disparity between the two concrete types decreased at the yielding and ultimate load stages. However, RCA concrete consistently exhibited higher strain values at the extreme fibers in tension and compression. It can be concluded that this difference primarily originates at the cracking stage and that beyond cracking, the concrete type has a limited effect on tensile strain development, as the steel reinforcement properties largely govern tensile behavior. In contrast, the differences in compressive strain mainly depend on the quality of the concrete, with RCA beams exhibiting higher compressive strains throughout the loading process.

The concrete’s tensile strength governs the strain development up to the cracking stage. The expected tensile strain at the bottom fiber at this stage can be estimated using the following equation:

where

εbot—tensile strain in the bottom fiber;

Mc—cracking moment;

y—distance from the neutral axis to the bottom fiber;

Ec—concrete modulus of elasticity;

I—moment of inertia of the cross-section.

Using the beam data, the calculated strain at midspan for NA concrete is 0.104%, which is in close agreement with the experimentally measured value of 0.107%. In contrast, for RCA concrete, the calculated strain is 0.113‰, which is significantly higher than the measured value of 0.048‰. These results suggest that the theoretical equation yields a reliable estimate for NA concrete but fails to accurately predict strains where cracking occurs earlier in RCA concrete. This discrepancy may be attributed to an overestimation of the elastic modulus, which is typically reduced in RCA concrete due to its heterogeneous composition and the presence of residual mortar [

32,

33].

The tensile strain expected to develop in the reinforcement at the yielding stage can be estimated based on Hooke’s Law:

where

σy—steel yield tensile stress;

εy—steel yield strain;

Es—steel modulus of elasticity.

The average strain measured at the tensile reinforcement level (60 mm from the bottom) was 2.200‰ in the NA beams and 2.518‰ in the RCA beams. The recorded tensile strain values align with the expected yield strain. These findings indicate that the tensile strains developing during the steel yielding stage are largely unaffected by the type of concrete.

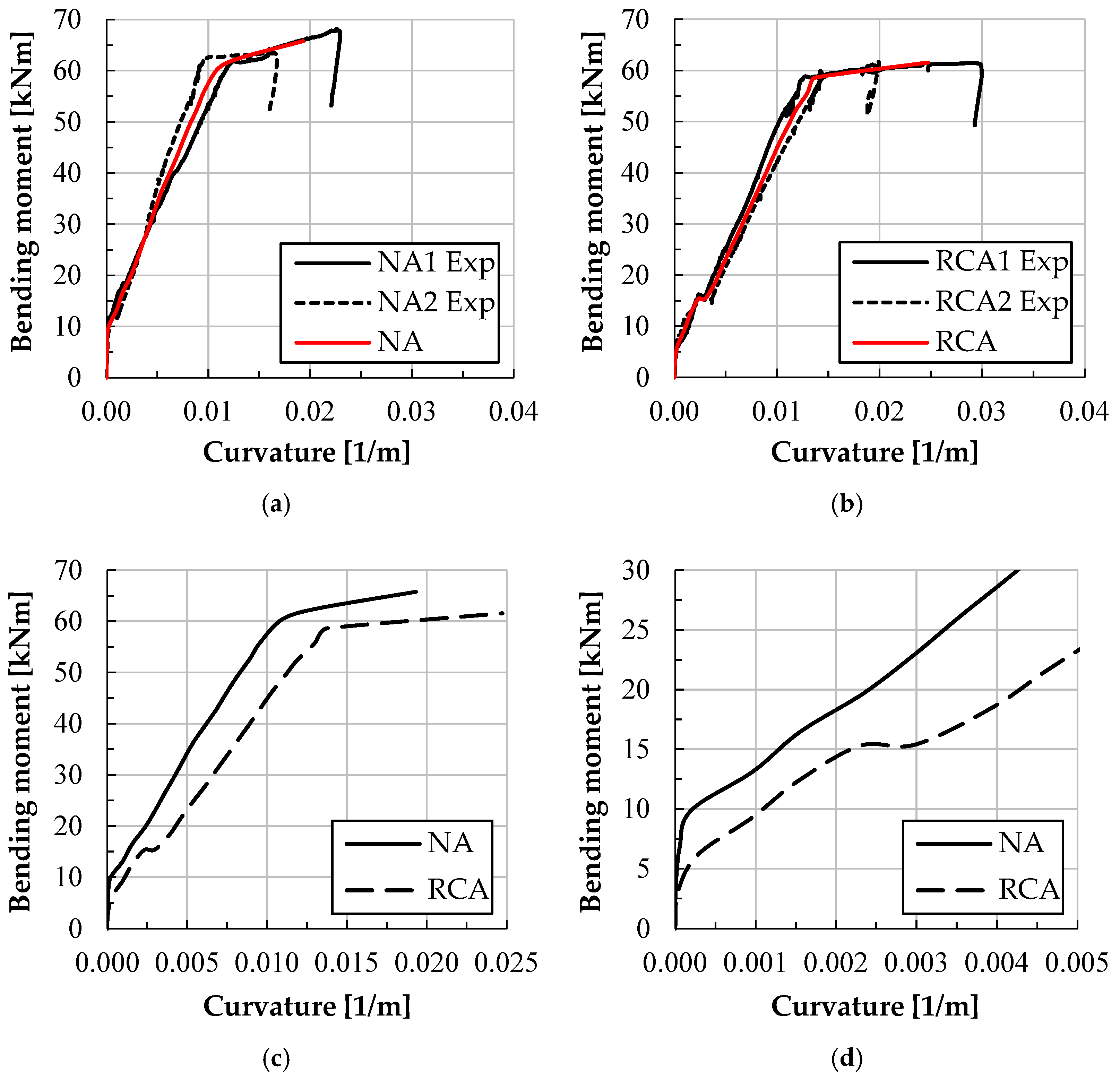

3.5. Moment–Curvature

The characteristic bending moments—Mc (cracking moment), My (yielding moment), and Mu (ultimate moment)—were calculated. These calculated values were compared with the experimental results obtained from the four-point bending tests.

Figure 9 compares moment–curvature responses for each concrete type. The results and the average curve of the NA and RCA beams are presented in

Figure 9a and

Figure 9b, respectively. The results obtained in all test series exhibited good consistency. Accordingly, the comparison between the series is based on the average response curve, shown in red.

Figure 9c shows a comparison of the average curves. The most significant difference between the two concrete types was observed at the cracking stage, where the RCA beams exhibited a cracking moment approximately 50% lower than that of the NA beams (

Figure 9d). Despite the lower moment, the curvature in the RCA beams was higher, reflecting more pronounced deformation at early loading stages. In contrast, the moment values were similar at the yielding and ultimate load stages, although the beams reached different curvature levels. However, the overall curvature values observed for both concrete types were comparable. This suggests that the kind of aggregate significantly affects curvature development in the beam, particularly during the cracking stage, thereby influencing the beam’s flexural capacity. This behavior is primarily attributed to the lower tensile strength of RCA concrete, which results in earlier and more extensive cracking.

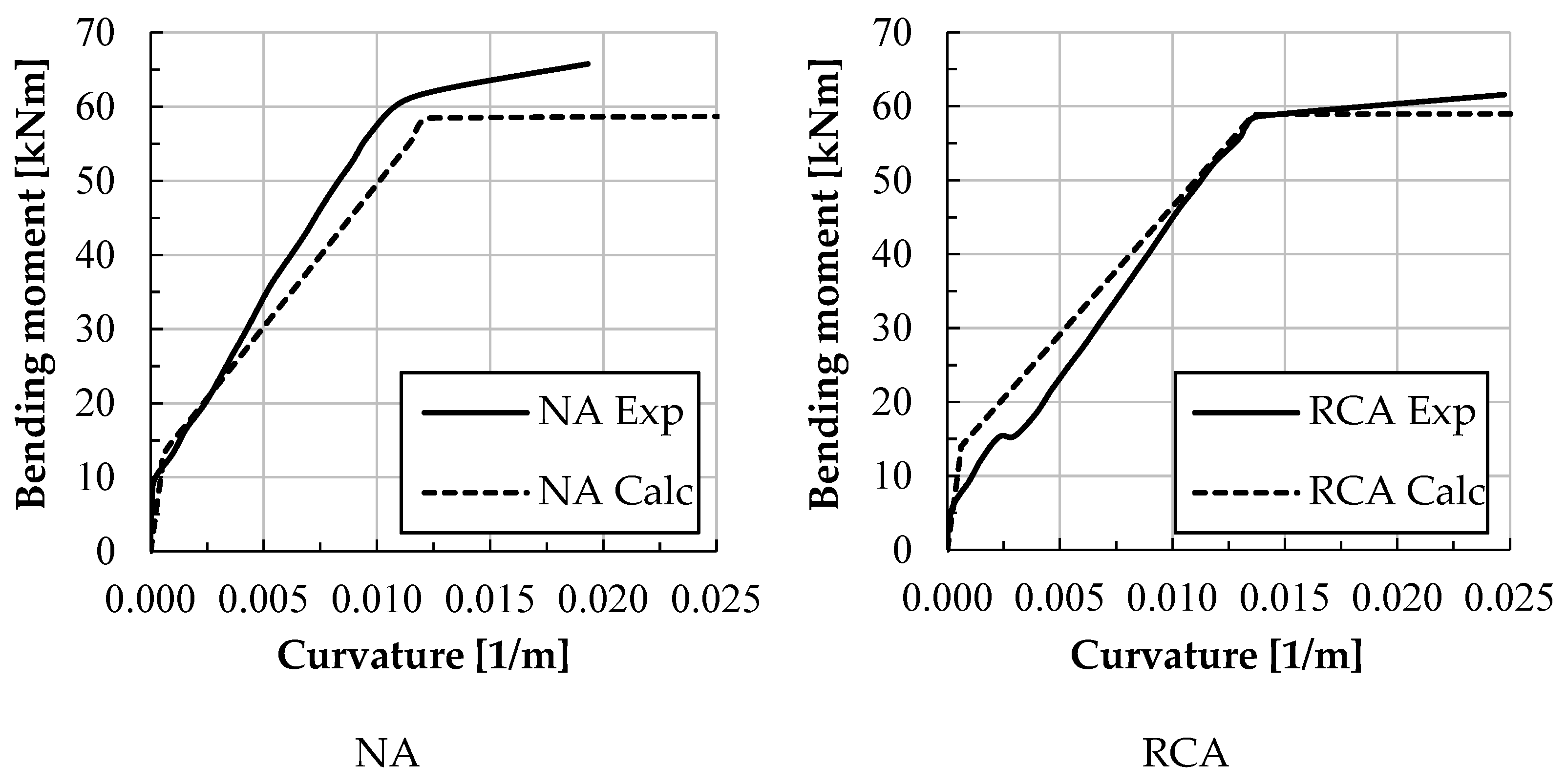

Theoretical values of Mc, My, and Mu curvatures were calculated and compared with the experimental results (

Figure 10). Overall, good agreement is observed between the experimental and calculated results across the entire curve for the NA specimens. However, a significant difference in the cracking moment value is observed for the RCA specimens compared to the theoretical calculation. This discrepancy can be attributed to the lower tensile strength of RCA concrete. The comparison between experimental and theoretical results for the yielding moment and corresponding curvature showed strong agreement for both concrete types. The curvature development from cracking to yielding followed a similar slope for both concrete types, suggesting that early cracking in recycled concrete aggregate (RCA) primarily influences the initial response. At the ultimate stage, experimental moments for RCA and NA beams exceeded those predicted by the theoretical models, with NA beams exhibiting a marginally larger deviation. These findings reinforce the applicability of theoretical models in estimating the yielding and ultimate behavior of reinforced concrete beams. However, the results also emphasize a critical limitation: the cracking moment in RCA concrete cannot be reliably predicted using standard theoretical formulations due to the reduced tensile strength of RCA concrete and the earlier initiation of cracking.

To further evaluate the applicability of classical design models, the experimental results were compared with theoretically predicted values of moment and curvature. This comparison is crucial for assessing whether standard design calculations can be applied to RCA concrete.

3.6. Concrete Crushing

Table 8 presents the average values of the load at the onset of crushing and the maximum load recorded for each concrete type. Concrete crushing in the upper central region of the beam occurred earlier in RCA beams than in NA beams. This behavior is attributed to the higher porosity of the RCA concrete, which adversely affects its compressive strength. The use of RCA led to earlier crushing initiation and consequently failed at a load of approximately 94% of that observed in NA beams.

4. Discussion

4.1. Deflection and Strain Behavior Under Loading

RCA beams showed increased deflections at every loading stage compared to their NA counterparts. At the ultimate load, deflections in RCA beams were approximately 14–25% higher, while the peak load was about 3–10% lower. Strain measurements revealed that RCA beams experienced significantly higher compressive strains throughout loading. Tensile strains also increased more rapidly in RCA beams following cracking; however, post-yield behavior was governed by the steel reinforcement, which was identical across all specimens. These findings confirm that RCA concrete deforms more extensively under load, particularly before yielding, and reinforce the role of aggregate quality in controlling flexural stiffness.

The normalized deflection curves obtained in this study align closely with those reported by Seara-Paz et al. [

26] and Arezoumandi et al. [

27], confirming the consistency of RCA behavior under full replacement conditions. However, deviations from the data by Ignjatović et al. [

14] suggest that reinforcement configuration may significantly influence the flexural response, warranting further parametric studies.

4.2. Influence of RCA on Crack Development and Tensile Behavior

The results demonstrate that using recycled concrete aggregate significantly impacts the tensile performance of concrete, particularly during the cracking stage. RCA beams exhibited earlier crack initiation and a greater number of cracks than NA beams. This behavior is primarily due to the lower tensile strength of RCA concrete, which results from its higher porosity and the presence of adhered mortar and microcracks within the recycled aggregate. The greater number and earlier onset of cracks contributed to wider crack openings under higher loads. These effects directly influence serviceability, requiring careful consideration in structural design.

Interestingly, despite wider cracks in RCA beams, the progression of crack height showed no consistent trend, indicating that while RCA accelerates crack opening, it does not significantly affect the depth of crack propagation within the tested range.

4.3. Strain Distribution and Neutral Axis Behavior

Strain profile analysis across the beam depth revealed that RCA beams exhibited higher extreme fiber strains in both tension and compression, particularly at the cracking stage. As loading increased, the neutral axis descended more rapidly in RCA beams due to faster tensile degradation. At the yielding and ultimate stages, the influence of concrete type on tensile strain diminished, while differences in compressive strain persisted. This suggests that the compressive behavior of RCA governs the deformation profile at higher loads, necessitating adjustments in design calculations involving compressive strain limits.

4.4. Moment–Curvature Relationship and Theoretical Implications

The moment–curvature analysis reinforced the experimental findings, particularly the pronounced divergence at the cracking stage. RCA beams exhibited approximately 50% lower cracking moments and higher curvature, highlighting increased deformability at low stress levels. Despite these early differences, both concrete types showed similar yielding and ultimate moments, suggesting that the reinforcement controls the response beyond cracking. However, the initial stiffness and cracking moment of RCA concrete are not accurately captured by standard theoretical models, pointing to the need for revised tensile strength parameters in design standards when using RCA.

The discrepancy between theoretical and measured tensile strain at the cracking stage in RCA concrete suggests that commonly used elastic modulus values overestimate the stiffness of RCA mixes. This highlights the need to revise constitutive models to account for the reduced elastic performance resulting from residual mortar and heterogeneity.

4.5. Concrete Crushing and Failure Modes

Concrete crushing occurred earlier in RCA beams, with failure observed at roughly 94% of the load carried by NA beams. This is consistent with the higher compressive strains of RCA concrete. Although both concrete types failed in flexure rather than shear, RCA beams displayed signs of premature shear crack formation under lower loads, which may require further examination in future studies. These early crushing phenomena stress the importance of accounting for RCA’s lower compressive ductility in structural limit-state design.

The observation of premature shear cracking in RCA beams, even under a set-up designed for pure flexural failure, suggests that RCA may compromise shear resistance. Although the ultimate failure mode remained flexural, this behavior warrants future study under different shear span-to-depth ratios and with varying stirrup configurations.

4.6. Mechanistic Influence of Aggregate Type on Flexural Behavior

The experimental observations across all response metrics—cracking, deflection, strain distribution, and moment–curvature behavior—underscore the aggregate type’s central role in governing reinforced concrete’s mechanical performance. The use of RCA, in contrast to NA, introduces several interrelated material deficiencies that directly affect structural response.

RCA possesses higher porosity and lower bulk density due to the presence of adhered mortar from previous concrete applications. This residual mortar increases water absorption and reduces the overall elastic stiffness of the aggregate-matrix system. As a result, RCA concrete exhibits a lower modulus of elasticity, which contributes to higher deflections and more pronounced curvature under loading.

The interfacial transition zone (ITZ) in RCA concrete tends to be weaker and more porous, with pre-existing microcracks that facilitate early crack initiation and crack coalescence under tensile stress. This directly explains the lower observed cracking moment and earlier onset of cracking in the RCA beams.

The bond strength between RCA particles and the new cement paste may be inferior due to surface contamination or irregular aggregate texture, which affects stress transfer and further promotes strain localization. These combined effects result in a compound reduction in both tensile and compressive performance, particularly in the serviceability limit state.

5. Conclusions

The experimental study revealed distinct behavioral differences between reinforced concrete beams manufactured with 100% recycled concrete aggregate (RCA) and those made with natural aggregate (NA).

This study is our country’s first and primary study examining the replacement of natural aggregate with recycled aggregate in concrete. The results of the experiments at the qualitative level correspond to the behavior reported in the literature. More extensive follow-up research will determine whether relying quantitatively on studies worldwide is possible.

This study did not find any significant differences in the values of yield force or yield moment and maximum force or maximum moment, meaning that the type of aggregate has little effect on the design limit state. On the other hand, the cracking strength or moment and the shape of the cracks are greatly influenced by the type of aggregate. Therefore, future research that quantitatively examines the effect of the aggregate type should focus mainly on the service limit state.

The main findings of this study are as follows:

The cracking moment in RCA beams was about 46% lower than in NA beams (6.11 kNm versus 11.39 kNm). RCA beams experienced more cracks and wider crack widths by up to 30%, although crack heights generally stayed similar;

RCA beams had about 19% higher deflection at maximum load and a 6% decrease in load capacity;

Strain measurements showed higher compressive strain development in RCA beams, especially after cracking. The neutral axis dropped more quickly in RCA beams, and moment–curvature analysis confirmed significantly greater curvature at the same moment levels, especially during the serviceability phase.

The experimental results indicate that the mechanical behavior of RCA beams deviates substantially from that of NA beams, particularly in the serviceability domain. The significantly lower cracking moment and earlier onset of tensile cracking in RCA beams reflect the reduced tensile capacity and elastic modulus of RCA concrete as reported in the literature, which are consequences of its high porosity, weak interfacial transition zone, and the presence of adhered mortar [

5,

6]. These material deficiencies result in more rapid crack propagation and increased deformation under service loads. Notably, the higher compressive strains and increased deflections observed in RCA beams under identical reinforcement and loading conditions demonstrate that RCA concrete elements are more deformable and less stiff in pre- and post-cracking phases. As a result, existing theoretical models, which typically assume idealized tensile behavior calibrated to natural aggregate concrete, tend to overestimate the cracking resistance, underpredict the crack width, and misrepresent the curvature and strain distribution in RCA-based members. Without correction, the use of such models in RCA applications may lead to unsafe serviceability performance, even if ultimate limit states are satisfied.

To translate these findings into practical structural applications, future research should focus on developing revised analytical models for moment–curvature behavior and crack prediction in RCA concrete, particularly for serviceability limit state design. These models must incorporate adjusted tensile strength parameters and reduced elastic modulus values that reflect the microstructural characteristics of RCA, such as high porosity, weaker interfacial transition zones, and residual mortar content. In parallel, experimental studies should be expanded to assess the flexural behavior of beams with partial RCA replacement ratios (e.g., 25%, 50%, 75%) and identify the optimal balance points between sustainability benefits and structural performance. The pronounced shear crack development observed at relatively low loads in RCA beams also necessitates targeted testing on shear capacity, stirrup effectiveness, and potential revisions to minimum shear reinforcement provisions. Moreover, the observed higher strains and deflections underscore the importance of investigating RCA behavior under long-term loading, including creep, shrinkage, and fatigue, which were not addressed in the current study. Finally, region-specific material databases and design recommendations should be formulated to support safe implementation in engineering practice, particularly for RCA sourced from legacy concrete typical of Israeli demolition waste.