Abstract

The concrete industry increasingly seeks sustainable alternatives to conventional materials to reduce the environmental impact while maintaining structural performance. This study evaluates the use of locally sourced rhyolite as a coarse aggregate combined with recycled supplementary cementitious materials (SCMs) to address the sustainability and durability. Due to its high silica content, rhyolite is prone to the alkali–silica reaction (ASR), which may affect concrete durability. Concrete mixtures incorporating rhyolite with silica fume (SF), Class F fly ash (FA), and slag cement (SC) were tested for compressive strength, porosity, density, absorption, mortar bar expansion, electrical resistivity, and rapid chloride permeability. All rhyolite-based mixtures—regardless of SCM incorporation—achieved higher 90-day compressive strengths than the conventional control mixture, with 10% SF reaching the highest value. Additionally, each recycled SCM effectively reduced ASR-induced expansion, with 20% FA showing the most significant reduction and superior durability, including the greatest decrease in chloride permeability and the highest electrical resistivity, indicating enhanced corrosion resistance. These results confirm that rhyolite aggregates, when combined with SCMs, can improve durability and reduce ASR. Therefore, rhyolite shows potential for use in structural concrete under standard exposure conditions. This strategy supports circular economy goals by incorporating regional and recycled materials to develop concrete with improved durability characteristics.

1. Introduction

Concrete remains the most widely utilized construction material globally, forming the backbone of infrastructure development worldwide. Research efforts primarily focus on enhancing its mechanical strength and durability properties, as these directly determine the service life and performance of reinforced concrete structures [1,2,3]. However, concrete structures face numerous deterioration mechanisms that challenge their durability, including carbonation [4], chloride ion penetration [5,6], surface detachment [7], and reinforcement corrosion [8]. Among these challenges, the alkali–silica reaction (ASR) stands out as particularly detrimental, as it generates an expansive gel that absorbs water and induces internal cracking, significantly compromising the concrete’s structural integrity and mechanical performance [9,10,11].

In response to growing environmental concerns and sustainability imperatives, the construction industry has increasingly embraced circular economy principles through the incorporation of locally available aggregates and recycled supplementary cementitious materials (SCMs). This approach not only reduces transportation-related carbon emissions and natural resource depletion but also maintains or enhances concrete performance characteristics.

In this context, the term “recycled SCMs” refers to industrial by-products that are recovered and reused in cementitious systems instead of being landfilled or discarded. These include Class F fly ash (FA), a by-product of coal combustion; ground granulated blast furnace slag (GGBS or SC), generated during steel manufacturing; and silica fume (SF), collected from silicon alloy production. Although these materials are not “recycled” in the post-consumer sense, they are widely recognized as recycled inputs under circular economy and sustainable construction frameworks.

These materials contribute substantially to reducing CO2 emissions associated with cement production while simultaneously enhancing mechanical properties, mitigating ASR susceptibility, and refining the concrete’s pore structure [12]. Studies have demonstrated that natural or recycled SCMs not only improve compressive strength and durability metrics but also decrease clinker consumption and enhance the concrete’s overall environmental profile [13], as confirmed in recent studies involving zeolite powder, which significantly reduced the carbon footprint in high-performance concrete [14].

The utilization of alternative aggregate sources becomes particularly significant in regions experiencing scarcity of conventional aggregates, positioning locally sourced materials as a key strategy for sustainable construction practices. Rhyolite, an extrusive volcanic rock abundant in various regions, including Mexico, has emerged as a promising coarse aggregate candidate due to its favorable mechanical properties and potential to substitute for virgin aggregates [15]. Its local availability substantially reduces the carbon footprint associated with aggregate transportation, making it a sustainable alternative. However, rhyolite’s inherent susceptibility to ASR necessitates a comprehensive evaluation, as its high amorphous SiO2 content and the presence of crypto-crystalline quartz potentially increase its reactivity under the alkaline conditions typical in concrete environments [16,17].

Several studies have confirmed rhyolite’s high reactivity, particularly through accelerated expansion testing methodologies such as the ASTM C1260 standard mortar-bar test [18,19]. This inherent susceptibility to ASR represents a major durability concern, as it can lead to internal cracking and compromise long-term concrete performance. However, this challenge can be addressed by incorporating appropriate SCMs, which mitigate ASR in reactive aggregate systems by modifying the pore solution chemistry and reducing alkali availability [20,21,22]. Despite its reactivity, rhyolite also presents notable advantages as a coarse aggregate.

Research examining concrete incorporating rhyolite as a coarse aggregate has revealed that, when properly proportioned, such mixtures can achieve competitive compressive strength values compared to conventional aggregates, with documented increases of up to 25%. Additionally, its angular texture enhances the mechanical bond within the cementitious matrix, improving the indirect tensile strength. The strategic combination of recycled SCMs with locally available rhyolite aggregates not only enhances the mechanical properties of concrete but also aligns perfectly with sustainable construction objectives [23]. For instance, FA and SF, as by-products of coal combustion and silicon manufacturing, respectively, provide environmentally responsible alternatives for reducing cement consumption [24,25]. Similarly, GGBS significantly refines the concrete microstructure, enhancing resistance to chloride ion penetration while mitigating ASR susceptibility through multiple mechanisms.

While rhyolite’s potential as an aggregate has been demonstrated in previous studies, research gaps remain regarding its long-term durability performance when used in combination with different SCMs. Specifically, the interactions between volcanic aggregates such as rhyolite and recycled SCMs under typical concrete exposure conditions have not been thoroughly characterized. In addition, the influence of rhyolite’s mineralogical variability on ASR susceptibility and durability performance has not been fully explored [26]. Based on this context, this study hypothesizes that a proper combination of rhyolite aggregates with recycled SCMs can produce concrete with improved mechanical strength and durability, making it viable for structural use in standard environments.

Extensive rhyolitic formations are found across northwestern Mexico, particularly in the Sierra Madre Occidental and volcanic provinces, such as those in northern Chihuahua. These regions are characterized by massive rhyolites, ignimbrites, and pyroclastic flows derived from Oligocene anorogenic magmatic activity, resulting in silica-rich volcanic rocks. The widespread availability of these materials offers a strategic opportunity to incorporate rhyolite into sustainable construction. By leveraging local quarry resources, the use of rhyolite not only enhances the durability of concrete but also supports regional development and aligns with environmental goals related to material sourcing and circular economy strategies.

This comprehensive study evaluates the feasibility of utilizing rhyolite as a sustainable local aggregate combined with recycled SCMs (SF, FA, and GGBS) to enhance concrete’s mechanical strength and durability performance, effectively mitigating ASR potential. The experimental program includes a thorough assessment of compressive strength development, absorption, porosity measurements, electrical resistivity, chloride ion migration, and ASR expansion.

In contrast to previous studies, this research provides a more integrated analysis by simultaneously evaluating multiple durability indicators and linking them to ASR mitigation effectiveness across different SCMs. By incorporating local aggregates and industrial by-products, this research aims to promote circular economy principles, contributing to the sustainable utilization of rhyolite and recycled SCMs in developing durable and eco-efficient concrete solutions for modern construction challenges.

2. Materials and Methods

2.1. Materials

Cemex Centenario Portland cement (PC) was utilized as the primary binder for all concrete mixtures in this study. For recycled SCMs, commercial grade SF, Class F FA, and slag cement (SC) (DMI brand, Diversified Minerals Inc., Stockton, CA, USA) were incorporated into the experimental mixtures.

These SCMs are classified as recycled because they originate as industrial by-products from other manufacturing processes: SF from silicon alloy production, FA from coal combustion, and SC from blast furnace steelmaking. Their incorporation into concrete reduces waste and supports circular economy strategies by diverting them from landfills and repurposing them into value-added construction materials.

All materials comply with ASTM standards: C1240 for SF [27], C618 for FA [28], and C989 for SC [29]. According to product specifications, the silica fume exhibits high pozzolanic reactivity, the fly ash shows moderate pozzolanic reactivity, and the slag cement demonstrates latent hydraulic activity consistent with its classification.

The specific gravity ranges for SF, FA, and SC were 2.2–2.3, 2.3–2.7, and 2–3, respectively. The chemical composition of the cementitious materials was analyzed via energy-dispersive X-ray fluorescence (EDXRF) using a Panalytical Epsilon 3XLE spectrometer (Malvern Panalytical, Almelo, The Netherlands). The results are presented in Table 1.

Table 1.

Chemical composition of precursor materials.

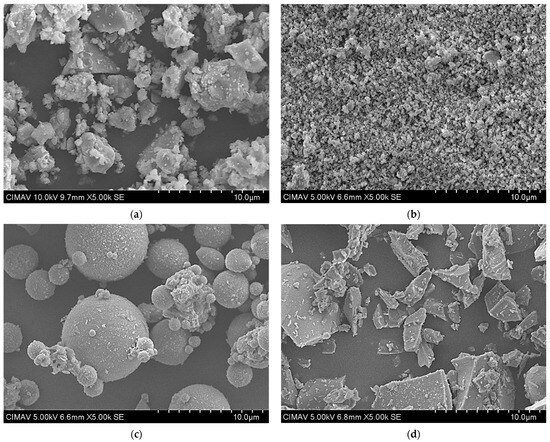

The morphology of the precursor materials was characterized using a HITACHI SU3500 scanning electron microscope (Hitachi High-Technologies Corporation, Tokyo, Japan), operating at 10 kV. As shown in Figure 1, each material exhibited distinct particle characteristics and surface textures. These SEM micrographs offer valuable insight into the physical characteristics of the precursors, which play a critical role in their performance within cementitious systems.

Figure 1.

Secondary electron SEM micrographs of precursor materials: (a) PC; (b) SF; (c) FA; (d) SC.

The Portland cement sample (Figure 1a) shows angular, dense particles with irregular edges and fractured surfaces, typical of clinker subjected to industrial grinding. The heterogeneous particle size and surface roughness increase the reactive surface area, promoting hydration and early strength development. The fractured morphology also enhances mechanical interlocking in cementitious systems.

The spherical and ultra-fine nature of the silica fume particles (Figure 1b), with diameters below 1 µm, contributes to a high specific surface area that enhances pozzolanic reactivity and promotes microstructure densification. This morphology also explains the reduced workability observed in fresh concrete mixtures containing SF.

The fly ash particles (Figure 1c) are predominantly smooth and spherical, promoting better flowability and improved particle packing in the fresh state, which supports the in-creased slump values reported. Additionally, these features facilitate long-term pozzolanic reactions that contribute to microstructural refinement.

In contrast, the angular and vitrified nature of slag cement particles (Figure 1d) favors the formation of a dense and cohesive cementitious matrix, enhancing early-age strength and reducing permeability. These morphological characteristics correlate with the im-proved durability performance seen in the SC-containing mixtures.

The SEM analysis thus not only confirms the physical properties of the SCMs but also supports the observed trends in workability, strength development, and durability metrics presented in later sections.

River sand and river gravel were used as the fine and coarse aggregates, respectively, in the control mixture, while rhyolite served as the coarse aggregate in all other mixtures. This volcanic rock, characteristic of the Sierra Madre Occidental, was obtained from a regional quarry. A petrographic examination of the coarse rhyolite aggregate was performed in accordance with ASTM C295 [30]. The analysis revealed compact, angular fragments with a porphyritic texture and a mineralogical composition rich in volcanic glass, quartz, plagioclase, and microcline—features associated with alkali–silica reactivity.

The relative density and water absorption of coarse and fine aggregates were determined according to ASTM C127 [31] and ASTM C128 [32] standards, respectively. Additionally, bulk density and void content measurements were performed as per the ASTM C29 standard [33].

The relative density and absorption test results for both coarse and fine aggregates are presented in Table 2.

Table 2.

Relative density and absorption of the coarse and fine aggregates.

2.2. Concrete Mixture Design

The concrete mixture designs were developed following the guidelines outlined in ACI PRC-211.1-22, as detailed in Table 3. A consistent water–cement ratio of 0.57 was maintained across all mixtures without the incorporation of chemical admixtures. The first mixture (M-C) represents the control mixture, made with conventional river gravel as the coarse aggregate. The second mixture (M-R) includes rhyolite as the coarse aggregate without any SCMs. In the third, fourth, and fifth mixtures, the PC was partially replaced by weight with 10% SF, 20% FA, and 20% SC, respectively.

Table 3.

Mixture proportion for 1 m3 of concrete in the study.

The replacement levels were selected according to standard practice and SCM-specific characteristics. The 20% dosage for fly ash and slag cement reflects the replacement levels typically used in pozzolanic and hydraulic activity evaluations and common in the literature. In contrast, silica fume was limited to 10% due to its very high fineness and water demand, which can reduce the mixture workability. This lower dosage is in line with industry recommendations and conventional applications in durable concrete formulations.

2.3. Testing Details

The concrete mixtures were prepared following the procedures outlined in ASTM C192 [34]. The consistency of fresh concrete was evaluated using the slump test method, under ASTM C143 [35]. Compressive strength testing was performed following the procedures established in ASTM C39 standard at curing ages of 7, 28, and 90 days [36]. For this evaluation, a properly calibrated and verified Controls brand testing apparatus was employed to apply an axial compressive load to three 10 × 20 cm molded cylindrical specimens per test age. The loading rate was maintained within the pre-scribed range of 0.25 ± 0.05 MPa/s until failure occurred. The compressive strength of each specimen was calculated by dividing the maximum load achieved during testing by the cross-sectional area of the specimen.

Additionally, the porosity, absorption, and bulk density were determined according to ASTM C642 standard at curing ages of 28 and 90 days, using two cylindrical specimens of the same dimensions (10 × 20 cm) as those used for the compressive strength tests [37].

The accelerated mortar bar test for alkali–silica was performed to assess expansion due to ASR according to ASTM C1260 and ASTM C1567 standards. Following the ASTM C1260 standard procedure, three mortar bars (2.5 × 2.5 × 4 cm) were prepared for each sample formulation and subsequently immersed in an alkaline solution maintained at 80 °C. This solution was prepared by dissolving 40 g of NaOH in 900 mL of water and then diluting it to a total volume of 1 L with distilled water. Expansion measurements were recorded at intervals of 3, 7, 10, and 14 days using a precision measuring device, with monitoring extended to 28 days to provide additional insights into the ASR potential of the aggregates and cement combinations. For each formulation, three specimens (n = 3) were tested. The ASTM C1567 standard method, like ASTM C1260, incorporates SCMs to evaluate their effectiveness in mitigating ASR-induced expansion. This procedure enabled a comprehensive assessment of the capacity of SCMs to reduce expansion and enhance durability, providing a more thorough understanding of their role in improving concrete performance [38].

Finally, after 100 days of curing, the electrical resistivity of concrete specimens was measured using a Proceq® Wenner Probe Resipod (38 mm) based on AASHTO T 358 standard [39]. Each saturated surface-dry specimen was divided into six longitudinal segments for measurement purposes; all measures were corrected for the curing conditions.

To evaluate the chloride ion penetration resistance, cylindrical specimens (100 mm diameter × 200 mm length) were precision-cut to a 50 ± 3 mm thickness and tested using the Germann Instruments® 8 channels PROOVE’it system according to AASHTO T 277 methodology [40]. Two specimens per mixture formulation were placed in a test cell containing NaCl and NaOH solutions, with a constant voltage of 60 V applied for 6 h. The recorded current values were utilized to calculate the total charge passed, with appropriate adjustments made for specimen dimensions to ensure an accurate comparative analysis.

3. Results and Discussion

3.1. Slump Tests

The results of the slump tests for the concrete mixtures are shown in Table 4. The highest slump was observed in the M-C mixture (19.0 cm), followed by M-FA (16.5 cm). The mixtures M-R and M-SC show intermediate results, while the mixture with SF (M-SF) displays the lowest slump value (7.5 cm).

Table 4.

Results of slump tests for the concrete mixtures.

The observed differences in slump values are mainly influenced by the type of coarse aggregate and SCM incorporated into each mixture. In addition, rhyolite is an aggregate characterized by a rough and irregular surface texture and presents angular particles after extraction, which can produce a reduction in consistency, potentially complicating the proper placement and compaction of concrete [41]. Although the reduced workability of concrete is often associated with increased void formation and porosity, negatively affecting its density, strength, and overall durability [42,43], this effect did not appear to be predominant in the present study, likely due to improved paste–aggregate bonding provided by the angularity of rhyolite and the densifying effect of the incorporated recycled SCMs.

By incorporating 10 wt.% SF in the concrete mixture with rhyolite as the coarse aggregate, the high specific surface area and fineness of SF decrease the workability of concrete, as it is a finer material than cement. The very fine particles of SF can absorb more water, as well as increase the cohesion of the mixture in the fresh state [44].

The addition of 20 wt.% FA in the concrete mixture with rhyolite as the coarse aggregate improved the consistency of the concrete mixture due to the spherical shape of the constituent particles, which helped reduce internal friction, facilitating better particle movement and improving the overall consistency of the mixture. This can reduce the friction between the particles, contributing to the improvement of workability. Because of its lower fine particle size compared to silica fume, FA helps maintain workability while still enhancing mixture cohesion and reducing segregation and bleeding in fresh concrete [45].

Finally, by incorporating 20 wt.% slag cement, the consistency of the concrete may be affected due to its capacity to absorb more water, forming a denser and more cohesive paste, which increases the internal friction of the mixture, thus decreasing the consistency of the concrete in its fresh state [46,47].

3.2. Mechanical Properties of Concrete

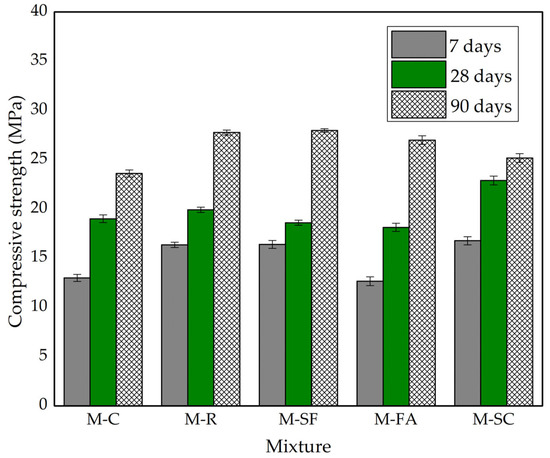

The compressive strength results are presented in Figure 2. The M-C mixture, made with river aggregates and without SCMs, shows the lowest compressive strength at 90 curing age. This may be attributed to the rounded morphology and smoother surface texture of the river aggregates, which reduce the mechanical interlocking and paste–aggregate bond, leading to lower strength development [24].

Figure 2.

Compressive strength test results.

In contrast, the M-R mixture, which does not contain SCMs and uses rhyolite as the coarse aggregate, shows an increase in strength from 7 to 28 days, followed by an even more pronounced gain between 28 and 90 days. This behavior deviates from the typical trend in conventional concrete, where strength development beyond 28 days is generally limited. The sustained increase suggests that the rhyolite aggregate may influence the long-term hydration process, either by enhancing aggregate–paste bonding due to its morphological characteristics or through potential late-stage interactions involving amorphous silica. These effects contribute to microstructural densification, improving the mechanical performance over time.

The strength results of the M-SF mixture with SF, being a highly reactive addition, provide an improvement in strength at 90 days of curing due to the formation of a denser microstructure and reduced porosity. However, its influence on strength at 7 and 28 days of curing is not as significant, suggesting that SF needs more time to fully react and develop its pozzolanic effect [48].

Meanwhile, the strength results of the M-FA mixed with FA, being a pozzolan of low initial reactivity, show lower strength at 7 days of curing, but gradually improve with age. At 90 days of curing, the strength approaches that of the M-R (without SCMs) and M-SF mixtures, which showed the highest values. FA contributes to long-term strength by filling the pores and reacting with calcium hydroxide to form additional cementitious compounds [49].

Finally, the compressive strength results of the M-SC mixture with slag cement show the highest values at 7 days and 28 days of curing. Although, the strength gains up to 90 days of curing are lower compared to other mineral additions, slag cement acts both as a pozzolan and as a hydraulic cementitious material, improving the microstructure of the concrete by reducing the porosity and increasing the density of the cementitious matrix, but its long-term effect is not as pronounced as in other mineral admixtures [50]. It also exceeded the strength of the control mixture (M-C) at all curing ages.

These findings underscore the importance of optimizing the content of supplementary cementitious materials, as excessive amounts may reduce the clinker availability and alter the hydration dynamics, ultimately limiting strength development. Although SCMs enhance durability and refine the microstructure, their overuse can lead to imbalances that compromise mechanical performance over time [51]. Additionally, the type of aggregate plays a relevant role, as the M-R mixture with rhyolite consistently outperformed the M-C mixture made with conventional river gravel, likely due to improved paste–aggregate bonding and microstructural densification.

3.3. Durability Tests

3.3.1. Absorption, Porosity, and Density

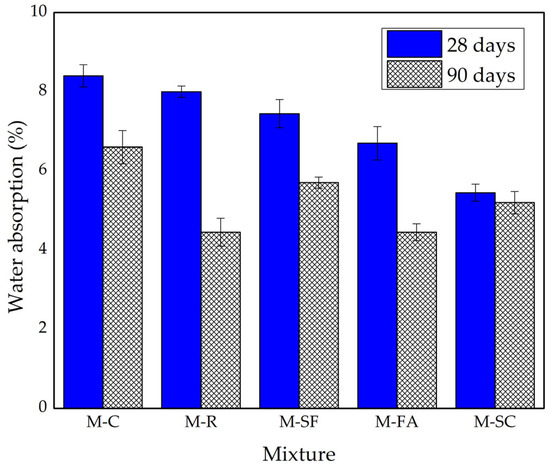

Figure 3 presents the results of absorption for all concrete mixtures at 28 and 90 days, respectively.

Figure 3.

Absorption after immersion and boiling samples.

A progressive reduction in absorption is observed for all mixtures over time. On 28 and 90 days, M-C exhibits the highest absorption. Among them, M-SC records the lowest absorption (5.5%) at 28 days and achieves the highest compressive strength, underscoring its effectiveness in refining the pore structure. At 90 days, M-R undergoes a substantial decrease in absorption, reaching a value comparable to that of M-FA, which ultimately attains the lowest absorption (4.3%). This result highlights the sustained pozzolanic reaction of fly ash, which contributes to continued microstructural densification over time. In summary, fly ash proves to be the most effective SCM in reducing water absorption at later ages, which is a key indicator of improved resistance to moisture ingress and enhanced long-term durability.

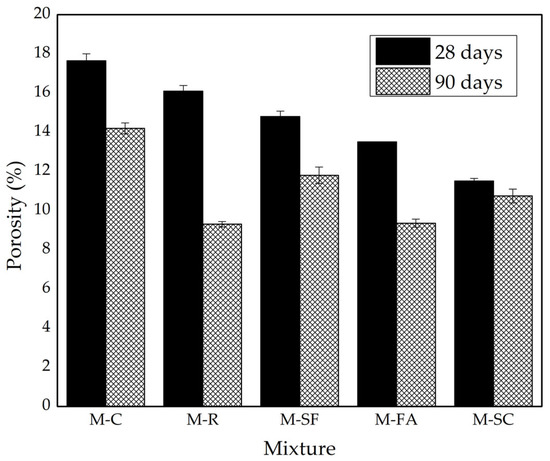

The porosity results (Figure 4) show a similar trend. The M-C mixture exhibited the highest porosity at all curing ages. In contrast, the M-R mixture showed the highest porosity among the SCM-containing mixtures at 28 days (16.1%), which significantly decreased to 9.3% by 90 days. The M-SF mixture also exhibited a substantial decrease from 14.8% to 11.8%, though it remains less effective in reducing permeability compared to other SCM-containing mixtures. The M-FA mixture notably reduced permeable pores from 13.5% at 28 days to 9.4% at 90 days, achieving the lowest permeability at later ages. Meanwhile, the M-SC mixture has the lowest porosity at 28 days (11.5%), but its reduction over time is less pronounced, reaching 10.8% at 90 days. These findings confirm the crucial role of FA in promoting microstructural densification over time, leading to reduced permeability and improved long-term durability [52]. Overall, the results highlight the effectiveness of SCMs and aggregate selection in refining the pore structure, as evidenced by the significantly lower porosity values compared to the conventional M-C mixture.

Figure 4.

Permeable pore volume of samples.

Bulk density results at 28 and 90 days ranged from 2.14 to 2.29 Mg/m3 and from 2.17 to 2.30 Mg/m3, respectively. The highest values were recorded for the control mixture (M-C) made with conventional aggregates, which showed the greatest bulk density at both ages. The M-R mixture, made with rhyolite and without SCMs, showed higher density than the M-SF mixture but lower than all other mixtures, including those incorporating SCMs. Among the SCM-containing mixtures, the slag cement mixture (M-SC) presented the highest densities, while the lowest corresponded to the silica fume mixture (M-SF). Standard deviations were all below 0.06 Mg/m3, confirming good reproducibility. These variations are attributed to the intrinsic properties of SCMs, such as the particle size and morphology. The high specific surface area of silica fume may reduce the packing efficiency, whereas the particle structure of slag cement contributes to higher bulk density through denser matrix formation.

3.3.2. Accelerated Mortar Bar Expansion

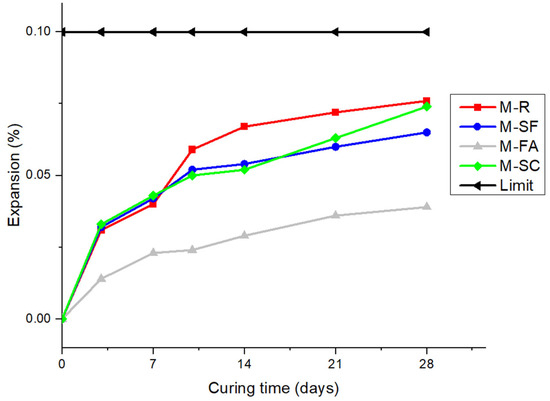

The results of accelerated method testing of mortar bars are presented in Figure 5. The expansion results of the mortar bars indicate that the mixture M-FA is the most effective in reducing the alkali–silica reactivity, showing the lowest expansions at 28 days, with 0.039%. SF also reduced expansion, although to a lesser extent (0.065% at 28 days). On the other hand, mixtures M-R and M-SC showed higher expansions at 28 days, with 0.076% and 0.074%, respectively, indicating a higher reactivity with cement alkalis.

Figure 5.

Mortar bar expansion results.

These results suggest that all mineral admixtures contribute to reducing the ARS, thereby enhancing concrete durability. For this case, the additions of FA proved to be the most effective. The physical microfilling effect of FA, together with the filling effect of the secondary pozzolanic reagents, reduces cement mortar porosity and densifies its structure. This prevents diffusion into the active aggregate and inhibits the ASR [53]. SF and SC also mitigate the ASR, but with limitations. SF is extremely fine and increases the water demand, which can complicate mixture workability and affect the mechanical performance and durability [54]. SC has a slower reactivity compared to other SCMs, potentially limiting its effectiveness in mitigating the alkali–silica reaction [55].

3.3.3. Electrical Resistivity of Concrete

The results of the electrical resistivity of concrete mixtures are presented in Table 5.

Table 5.

Results of electrical resistivity at 100 days of curing.

The electrical resistivity results of the concrete mixture show a positive behavior against corrosion risk [56]. The use of mineral admixtures produces highly dense and impermeable concrete. Moreover, the use of rhyolite as an aggregate provides better adhesion and a denser matrix compared to conventional aggregates, which improve the durability properties [57]. The relatively lower electrical resistivity of the concrete with both river (M-C) and rhyolite aggregates (M-R) leads to a greater conduction of ionic current during the RCPT, as shown in Table 5, due to the capillary network formed in the cement paste. The data clearly indicate that the type of coarse aggregate has no significant effect on the electrical resistivity of the concrete; in contrast, the incorporation of SCMs produced increases in electrical resistivity compared to the M-C and M-R control mixtures. Therefore, the comparative analysis of the electrical resistivity results shows that the incorporation of FA resulted in the highest value of ER. The incorporation of SCMs modifies the cement hydration process, leading to pozzolanic reactions that consume part of the calcium hydroxide generated during hydration and produce additional amounts of C-S-H gel [58].

From a microstructural point of view, SCMs act as microfillers due to their fine granulometry, which contributes to decreasing the connectivity between pores. By reducing the migration pathways for ions, the penetration of aggressive agents such as chlorides, which are responsible for initiating corrosion of the reinforcement, is limited [59,60]. This mechanism helps to increase the electrical resistivity of concrete, since a less interconnected pore system impedes the flow of electrical charges and consequently reduces the conductivity of the material [61,62].

3.3.4. Rapid Chloride Permeability Test

The results of rapid chloride permeability test are presented in Table 6. According to AASHTO T 277 classification, concrete made with river (M-C) and rhyolite (M-R) coarse aggregate would be classified as having high permeability. When compared to M-R, the M-SF mixture showed an approximate 88% improvement, M-FA achieved about 95%, and M-SC recorded a 74% improvement. These results demonstrate the effectiveness of SCMs in reducing chloride penetration.

Table 6.

Rapid chloride permeability test at 100 days of curing.

The M-SF mixture exhibits a marked decrease in passed charge. This result is due to the high fineness and pozzolanic reactivity of the SF, which favors the formation of an additional C-S-H gel and contributes to the closure of the interconnected pores, thus reducing their permeability to chloride ions [63,64,65].

The M-FA mixture also shows a considerable reduction in permeability to chloride ions. FA acts through a long-term pozzolanic reaction, consuming calcium hydroxide and generating additional hydrated products that refine the porous structure [66,67]. With prolonged curing, FA mixtures achieve greater durability, since this process allows for a more complete pozzolanic reaction, favoring the formation of additional hydrated products that densify the concrete microstructure and reduce its permeability [68].

Finally, the M-SC mixture shows a moderate improvement compared to the control. Although the slag reacts less strongly than SF or FA, its contribution to the formation of hydrated products and the gradual refinement of the microstructure results in an appreciable reduction in the permeability to chloride ions [69,70].

These results confirm that the incorporation of SCMs significantly enhances concrete durability by reducing chloride ion permeability. Among the evaluated materials, the FA mixture exhibited the highest improvement, achieving the lowest charge passed and the highest electrical resistivity. This indicates that FA is the most effective SCM for increasing concrete resistance to ionic penetration and corrosion risk mitigation. The correlation between electrical resistivity and the rapid chloride permeability results further validates the superior performance of FA in refining the pore structure, reducing interconnected pathways for aggressive agents, and enhancing long-term durability.

4. Conclusions

This study demonstrates that rhyolite is an effective coarse aggregate for concrete mixtures incorporating recycled SCMs, providing dual benefits in terms of sustainability and mechanical performance. Notably, all mixtures containing rhyolite—regardless of SCM incorporation—achieved higher 90-day compressive strength and exhibited lower bulk density, water absorption, and porosity compared to the conventional concrete made with river gravel.

Each supplementary cementitious material (SCM) imparted distinctive effects on the mechanical performance of concrete mixtures incorporating rhyolite as the coarse aggregate. The M-R and M-SF mixtures achieved comparable compressive strengths at 90 days. In contrast, the M-FA mixture, although it showed lower strength at early ages, demonstrated substantial improvements over time, ultimately reaching strength levels similar to the best-performing mixtures. The M-SC mixture exhibited the highest strengths at 7 and 28 days; however, its strength development stagnated by 90 days, exceeding only the control mixture with conventional aggregate. This behavior indicates that the contribution of slag cement is more pronounced at early ages, while other SCMs, particularly FA, promote continued strength gains over time.

These mechanical trends are consistent with the porosity and absorption results. The M-SC mixture exhibited the lowest values at 28 days but showed minimal further reductions by 90 days, whereas the M-FA and M-R mixtures experienced the most significant decreases in pore volume and water absorption. The M-FA mixture ultimately achieved the lowest absorption and porosity values, highlighting its sustained pozzolanic activity and capacity for long-term microstructural refinement. These findings underscore the importance of SCM selection not only for early strength but also for enhancing durability-related properties, such as permeability and pore connectivity, which directly influence long-term performance.

Additionally, all SCMs effectively mitigated ASR—a critical concern for rhyolite-based concrete—by reducing porosity, permeable pore volume, and expansion. FA emerged as particularly effective, further confirming that the strategic combination of rhyolite with the right SCMs not only counteracts its inherent ASR susceptibility but also enhances the overall durability.

The investigation of electrical resistivity and rapid chloride permeability test reveals that concretes with SF, FA, and SC had a higher value than those without SCMs due to reduced pore connectivity. FA provided superior performance, yielding the highest resistivity values and lowest chloride penetration. This indicates that FA most effectively reduced concrete permeability, thereby enhancing reinforcement corrosion resistance as a critical durability factor.

These results support the use of rhyolite as a sustainable coarse aggregate when combined with recycled SCMs. This approach improves resource efficiency, lowers the environmental impact, and enhances durability for long-lasting infrastructure.

The optimization of rhyolite–SCM concrete mixtures represents a significant advancement toward more sustainable construction practices that maintain or exceed conventional performance standards. Future research should focus on field implementation and long-term performance monitoring to further validate these promising laboratory findings under real-world environmental conditions. Assessing carbonation resistance is recommended, as it plays a critical role in the durability of cementitious systems, especially when exposed to atmospheric CO2 over extended periods.

Author Contributions

Conceptualization, C.K.V.-L., M.S.-F. and C.C.-G.; methodology, C.K.V.-L., M.S.-F., C.C.-G., O.F.O.-F. and J.R.G.-C.; software, C.K.V.-L. and O.F.O.-F.; validation, C.K.V.-L., M.S.-F., C.C.-G., J.R.G.-C., O.F.O.-F., J.M.H.-R. and J.R.G.-C.; formal analysis, C.K.V.-L., O.F.O.-F., M.S.-F., C.C.-G. and J.M.H.-R.; investigation, C.K.V.-L., C.C.-G. and M.S.-F.; resources, C.K.V.-L. and C.C.-G.; data curation, C.K.V.-L., O.F.O.-F. and M.S.-F.; writing—original draft preparation, C.K.V.-L. and M.S.-F.; writing—review and editing, M.S.-F., O.F.O.-F., J.M.H.-R. and C.C.-G.; visualization, C.K.V.-L., C.C.-G., J.R.G.-C., J.M.H.-R. and M.S.-F.; supervision, M.S.-F., C.K.V.-L., C.C.-G., J.R.G.-C. and J.M.H.-R.; project administration, C.K.V.-L., J.M.H.-R., C.C.-G. and M.S.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors express their appreciation to the R&D laboratories of GCC for their technical assistance throughout the experimental phase. Special thanks are extended to K. Campos Venegas and J.E. Ledezma Sillas for their valuable expertise and contributions to the technical development of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Beushausen, H.; Torrent, R.; Alexander, M.G. Performance-based approaches for concrete durability: State of the art and future research needs. Cem. Concr. Res. 2019, 119, 11–20. [Google Scholar] [CrossRef]

- Figueira, R.; Sousa, R.; Coelho, L.; Azenha, M.; de Almeida, J.; Jorge, P.; da Silva, C.J.R. Alkali-silica reaction in concrete: Mechanisms, mitigation and test methods. Constr. Build. Mater. 2019, 222, 903–931. [Google Scholar] [CrossRef]

- Wang, W.; Noguchi, T. Alkali-silica reaction (ASR) in the alkali-activated cement (AAC) system: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119105. [Google Scholar] [CrossRef]

- CM, I.; Adeniji, A.A.; Obisesan, A.A.; Odeyemi, O.; Ajayi, J.A. Effects of Carbonation on the Properties of Concrete. Sci. Rev. 2019, 5, 205–214. [Google Scholar]

- Angst, U.M.; Geiker, M.R.; Alonso, M.C.; Polder, R.; Isgor, O.B.; Elsener, B.; Wong, H.; Michel, A.; Hornbostel, K.; Gehlen, C.; et al. The effect of the steel–concrete interface on chloride-induced corrosion initiation in concrete: A critical review by RILEM TC 262-SCI. Mater. Struct. 2019, 52, 1–25. [Google Scholar] [CrossRef]

- Fan, L.; Zhong, W.; Zhang, X. Chloride-induced corrosion of reinforcement in simulated pore solution of geopolymer. Constr. Build. Mater. 2021, 291, 123385. [Google Scholar] [CrossRef]

- Böhni, H. Corrosion in Reinforced Concrete Structures; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Broomfield, J.P. Corrosion of Steel in Concrete: Understanding, Investigation and Repair, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Lindgård, J.; Andiç-Çakır, Ö.; Fernandes, I.; Rønning, T.F.; Thomas, M.D.A. Alkali–silica reactions (ASR): Literature review on parameters influencing laboratory performance testing. Cem. Concr. Res. 2012, 42, 223–243. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Almakrab, A. Alkali-silica reaction (ASR) in concrete structures: Mechanisms, effects and evaluation test methods adopted in the United States. Case Stud. Constr. Mater. 2021, 15, e00563. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ghiasvand, E.; Nili, M. Relation between mechanical properties of concrete and alkali-silica reaction (ASR); a review. Constr. Build. Mater. 2020, 258, 119567. [Google Scholar] [CrossRef]

- Li, C.; Thomas, M.D.; Ideker, J.H. A mechanistic study on mitigation of alkali-silica reaction by fine lightweight aggregates. Cem. Concr. Res. 2018, 104, 13–24. [Google Scholar]

- Imam, A.; Kumar, V.; Srivastava, V. Review study towards effect of Silica Fume on the fresh and hardened properties of concrete. Adv. Concr. Constr. 2018, 6, 145. [Google Scholar]

- Mostafaei, H.; Bahmani, H. Sustainable High-Performance Concrete Using Zeolite Powder: Mechanical and Carbon Footprint Analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- Cai, G.; Noguchi, T.; Degée, H.; Zhao, J.; Kitagaki, R. Volcano-related materials in concretes: A comprehensive review. Environ. Sci. Pollut. Res. 2016, 23, 7220–7243. [Google Scholar] [CrossRef] [PubMed]

- Seidlová, Z.; Prikryl, R.; Pertold, Z.; Sachlova, S. Alkali-Silica Reaction of Volcanic Rocks. In Proceedings of the International Conference on Alkali-Aggregate Reaction (Concrete), Austin, Texas, USA, 20–25 May 2012. [Google Scholar]

- Tiecher, F.; Gomes, M.E.; Molin, D.C.D. Alkali-Aggregate Reaction: A study of the influence of the petrographic characteristics of volcanic rocks. Eng. Technol. Appl. Sci. Res. 2018, 8, 2399–2404. [Google Scholar] [CrossRef]

- ASTM C1260-23; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2014.

- Sims, I.; Hassan, K.; Reid, M.; Al-Kuwari, M.B.; Attia, M.; Sidiq, A.; Al Naemi, A. Wadi gravel—A new concrete aggregate in Qatar: Part 2–Alkali aggregate reactivity. Q. J. Eng. Geol. Hydrogeol. 2020, 53, 400–412. [Google Scholar] [CrossRef]

- Zapała-Sławeta, J. Alkali Silica Reaction In The Presence Of Metakaolin—The Significant Role of Calcium Hydroxide. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022020. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B.; Jain, A.; Hanifehzadeh, M. Mitigating alkali-silica reaction induced concrete degradation through cement substitution by metakaolin and bentonite. Appl. Clay Sci. 2019, 182, 105257. [Google Scholar] [CrossRef]

- Luo, D.; Sinha, A.; Adhikari, M.; Wei, J. Mitigating alkali-silica reaction through metakaolin-based internal conditioning: New insights into property evolution and mitigation mechanism. Cem. Concr. Res. 2022, 159, 106888. [Google Scholar] [CrossRef]

- Elsheikh, M.Y.; Elshami, A.A.; Mohsen, I.A. Green Concrete Utilizing Andesite and Rhyolite Aggregate. Int. J. Civ. Eng. Technol. 2020, 11, 1–15. [Google Scholar] [CrossRef]

- Mehta, and Monteiro, Concreto: Microestrutura, Propriedades e Materiais, 2nd ed.; IBRACON: Sao Paulo, Brazil, 2014.

- Scrivener, K.L. Juilland, and P.J. Monteiro, Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Angulo-Ramírez, D.E.; de Gutiérrez, R.M.; Medeiros, M. Alkali-activated Portland blast furnace slag cement mortars: Performance to alkali-aggregate reaction. Constr. Build. Mater. 2018, 179, 49–56. [Google Scholar] [CrossRef]

- ASTM C1240-20; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C618-25a; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C989/C989M-18; Standard Specification for Slag Cement for Use in Concrete and Mortars. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C295-08; Standard Guide for Petrographic Examination of Aggregates for Concrete. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C127-24; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C192/C192M-22; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1567-25; Standard Test Method for Determining the Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2023.

- AASHTO T 358-19; Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T 227-03 (2020); Standard Method of Test for Potential Volume Change of Cementitious Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- Dehghan, A.; Maher, M.; Navarra, M. The Effects of Aggregate Properties on Concrete Mix Design and Behaviour. In Proceedings of the Canadian Society of Civil Engineering Annual Conference 2021; Walbridge, S., Ed.; Lecture Notes in Civil Engineering, Vol. 248; Springer: Singapore, 2023; pp. 457–468. [Google Scholar]

- Kewalramani, M.; Khartabil, A. Porosity evaluation of concrete containing supplementary cementitious materials for durability assessment through volume of permeable voids and water immersion conditions. Buildings 2021, 11, 378. [Google Scholar] [CrossRef]

- Liu, H.B.; Luo, G.B.; Wei, H.B.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef]

- Chishi, A.K.; Gautam, L. Sustainable use of silica fume in green cement concrete production: A review. Innov. Infrastruct. Solut. 2023, 8, 195. [Google Scholar] [CrossRef]

- Pramanik, S.; Pradhan, S.S.; Mishra, U. Effect of fly ash inclusion on fresh and hardened properties of concrete: A Review. In Recent Advances in Civil Engineering, Proceedings of the 2nd International Conference on Sustainable Construction Technologies and Advancements in Civil Engineering (ScTACE 2021), Bhubaneswar, India, 22–24 December 2021; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Suresh, D.; Nagaraju, K. Ground granulated blast slag (GGBS) in concrete—A review. IOSR J. Mech. Civ. Eng. 2015, 12, 76–82. [Google Scholar]

- Panjehpour, M.; Ali, A.A.A.; Demirboga, R. A review for characterization of silica fume and its effects on concrete properties. Int. J. Sustain. Constr. Eng. Technol. 2011, 2, 1–7. [Google Scholar]

- Alaj, A.; Krelani, V.; Numao, T. Effect of class F fly ash on strength properties of concrete. Civ. Eng. J. 2023, 9, 2249–2258. [Google Scholar] [CrossRef]

- Divsholi, B.S.; Lim, T.Y.D.; Teng, S. Durability properties and microstructure of ground granulated blast furnace slag cement concrete. Int. J. Concr. Struct. Mater. 2014, 8, 157–164. [Google Scholar] [CrossRef]

- Park, S.; Wu, S.; Liu, Z.; Pyo, S. The role of supplementary cementitious materials (SCMs) in ultra high performance concrete (UHPC): A review. Materials 2021, 14, 1472. [Google Scholar] [CrossRef]

- Malhotra, V. Fly ash, slag, silica fume, and rice husk ash in concrete: A review. Concr. Int. 1993, 15, 23–28. [Google Scholar]

- Cao, H.; Mao, Z.; Huang, X.; Deng, M. Inhibition of Alkali-Carbonate Reaction by Fly Ash and Metakaolin on Dolomitic Limestones. Materials 2022, 15, 3538. [Google Scholar] [CrossRef] [PubMed]

- Boakye, K.; Khorami, M. Hydration, Reactivity and Durability Performance of Low-Grade Calcined Clay-Silica Fume Hybrid Mortar. Appl. Sci. 2023, 13, 11906. [Google Scholar] [CrossRef]

- Cassiani, J.; Dugarte, M.; Martinez-Arguelles, G. Evaluation of the chemical index model for predicting supplementary cementitious material dosage to prevent the alkali-silica reaction in concrete. Constr. Build. Mater. 2021, 275, 122158. [Google Scholar] [CrossRef]

- Roberge, P. Corrosion Basics: An Introduction, 3rd ed.; National Association of Corrosion Engineers: Houston, TX, USA, 2018. [Google Scholar]

- Mohamed, O. Durability and compressive strength of high cement replacement ratio self-consolidating concrete. Buildings 2018, 8, 153. [Google Scholar] [CrossRef]

- El-Diadamony, H.; Amer, A.A.; Sokkary, T.M.; El-Hoseny, S. Hydration and characteristics of metakaolin pozzolanic cement pastes. HBRC J. 2018, 14, 150–158. [Google Scholar] [CrossRef]

- Ahmed, A. Assessing the effects of supplementary cementitious materials on concrete properties: A review. Discov. Civ. Eng. 2024, 1, 1–47. [Google Scholar] [CrossRef]

- Huang, X.; Hu, S.; Wang, F.; Yang, L.; Rao, M.; Mu, Y.; Wang, C. The effect of supplementary cementitious materials on the permeability of chloride in steam cured high-ferrite Portland cement concrete. Constr. Build. Mater. 2019, 197, 99–106. [Google Scholar] [CrossRef]

- Layssi, H.; Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical resistivity of concrete. Concr. Int. 2015, 37, 41–46. [Google Scholar]

- Cleven, S.; Raupach, M.; Matschei, T. Electrical resistivity of steel fibre-reinforced concrete—Influencing parameters. Materials 2021, 14, 3408. [Google Scholar] [CrossRef]

- Chaudhary, S.K.; Sinha, A.K. Effect of silica fume on permeability and microstructure of high strength concrete. Civ. Eng. J. 2020, 6, 1697–1703. [Google Scholar] [CrossRef]

- Bentz, D.; Jensen, O.; Coats, A.; Glasser, F. Influence of silica fume on diffusivity in cement-based materials: I. Experimental and computer modeling studies on cement pastes. Cem. Concr. Res. 2000, 30, 953–962. [Google Scholar] [CrossRef]

- Zhang, W.-M.; Ba, H.-J. Effect of silica fume addition and repeated loading on chloride diffusion coefficient of concrete. Mater. Struct. 2013, 46, 1183–1191. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Rao, M.K.; Kumar, D. Durability assessment of concrete with class-F fly ash by chloride ion permeability. Int. J. Recent Technol. Eng. 2019, 8, 8831–8836. [Google Scholar] [CrossRef]

- Yu, Z.; Ma, J.; Ye, G.; van Breugel, K.; Shen, X. Effect of fly ash on the pore structure of cement paste under a curing period of 3 years. Constr. Build. Mater. 2017, 144, 493–501. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Effect of chemical composition of slag on chloride penetration resistance of concrete. Cem. Concr. Compos. 2014, 46, 56–64. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Meng, Z. Resistance to Chloride Ion Permeability of Concrete Mixed with Fly Ash, Slag Powder, and Silica Fume. Ann. Chim. Sci. Des Matériaux 2020, 44, 67–72. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).