Thermoacoustic, Physical, and Mechanical Properties of Bio-Bricks from Agricultural Waste

Abstract

1. Introduction

1.1. Related Research

1.2. Aim of This Work

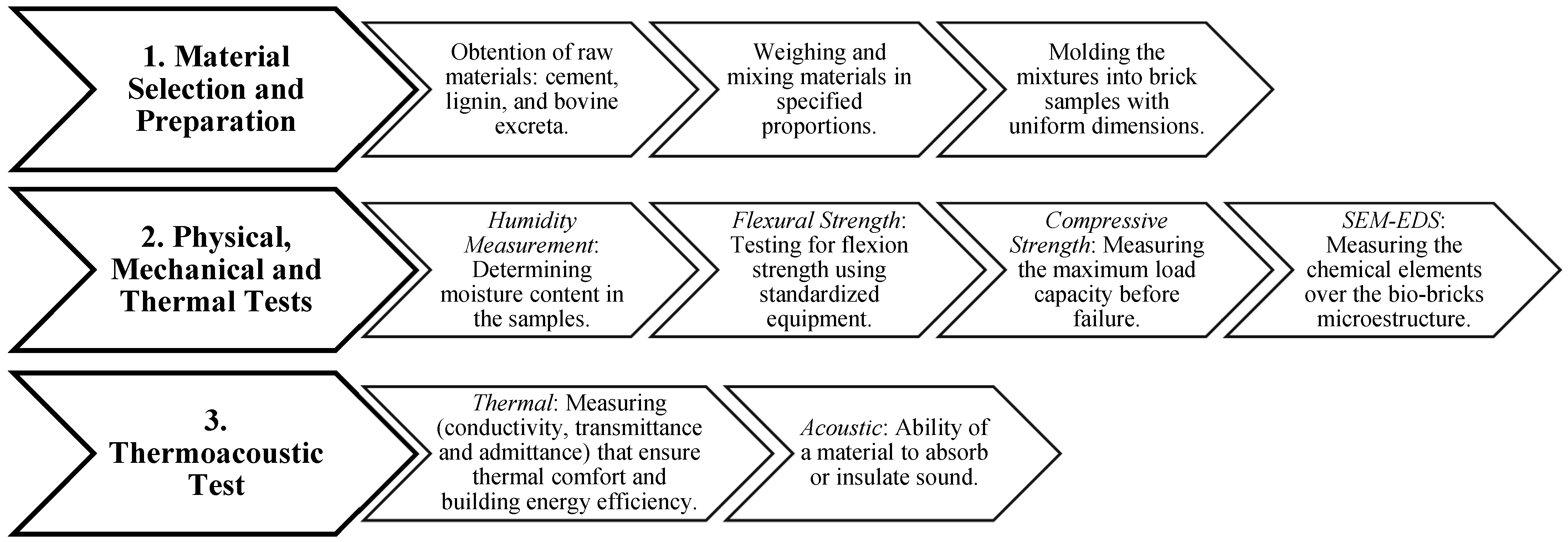

2. Materials and Methods

2.1. Selection and Preparation of Materials

2.2. Experimental Mix Design and Optimization

- Biomaterials preparation: All raw materials were pre-weighed according to the selected formulation.

- Mixing: Dry components (cement, ground coffee husks, and lime-treated bovine excreta) were first homogenized manually for 2 min. Then, water was added gradually, and the mixture was mechanically stirred using a concrete mixer for 8–10 min until a uniform and workable consistency was achieved.

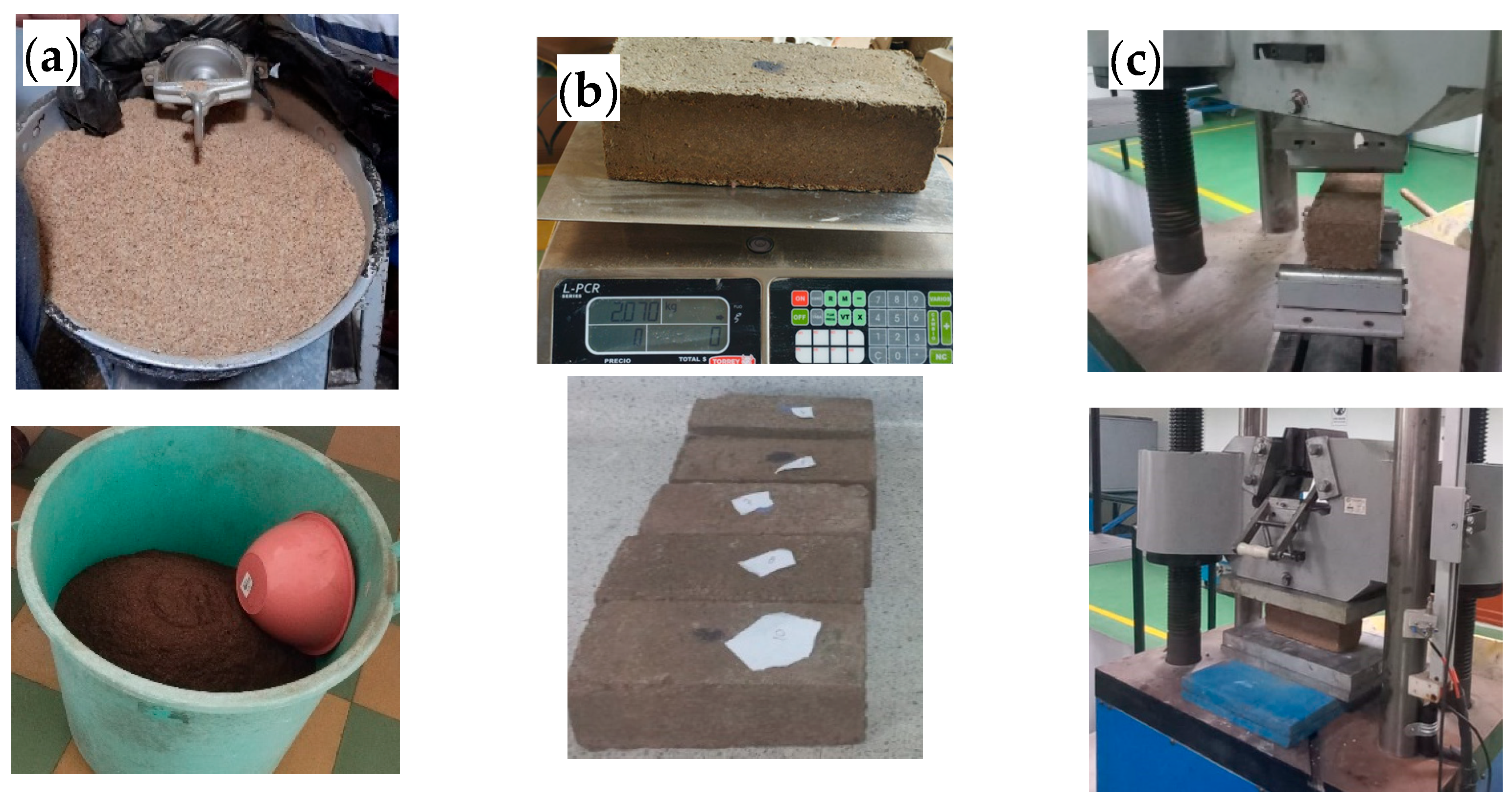

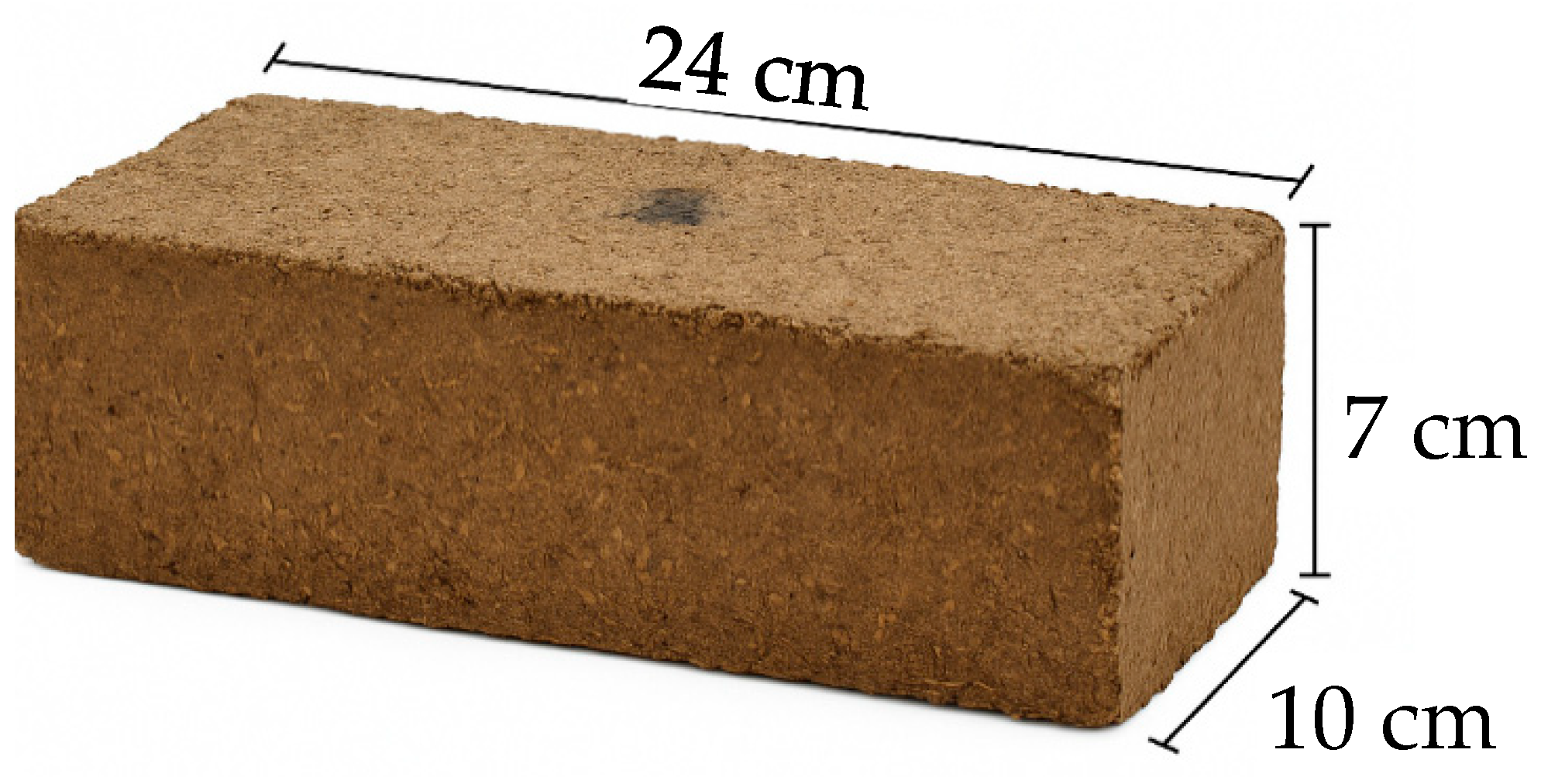

- Compaction: The fresh mixture was placed into metal molds (24 cm × 10 cm × 7 cm) in three successive layers, each compacted manually using a steel tamper to minimize porosity and ensure uniform density. No vibration table was used.

- Molding and demolding: Molds were left to rest for 24 h at room temperature before demolding to ensure adequate setting.

- Curing: After demolding, the samples were cured by natural air drying under shade for 28 days in a covered and ventilated space, avoiding direct sunlight and rain. Ambient curing conditions were approximately 25–30 °C and 60–70% relative humidity.

2.3. Fabrication of Bio-Bricks

2.4. Mechanical and Physical Characterization

2.5. Thermal Characterization

Thermal Analysis

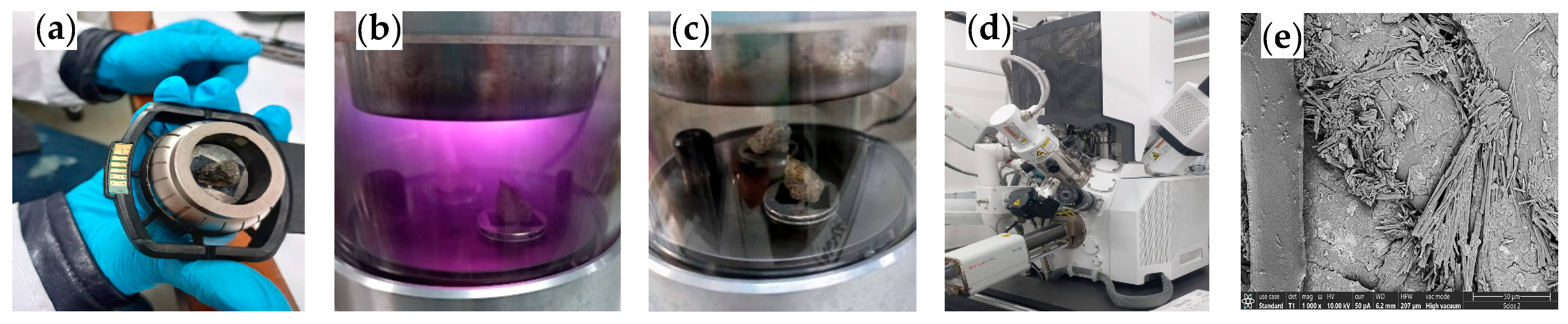

2.6. Chemical Characterization

2.6.1. Micrographs of the Mixture by SEM-EDS Technique

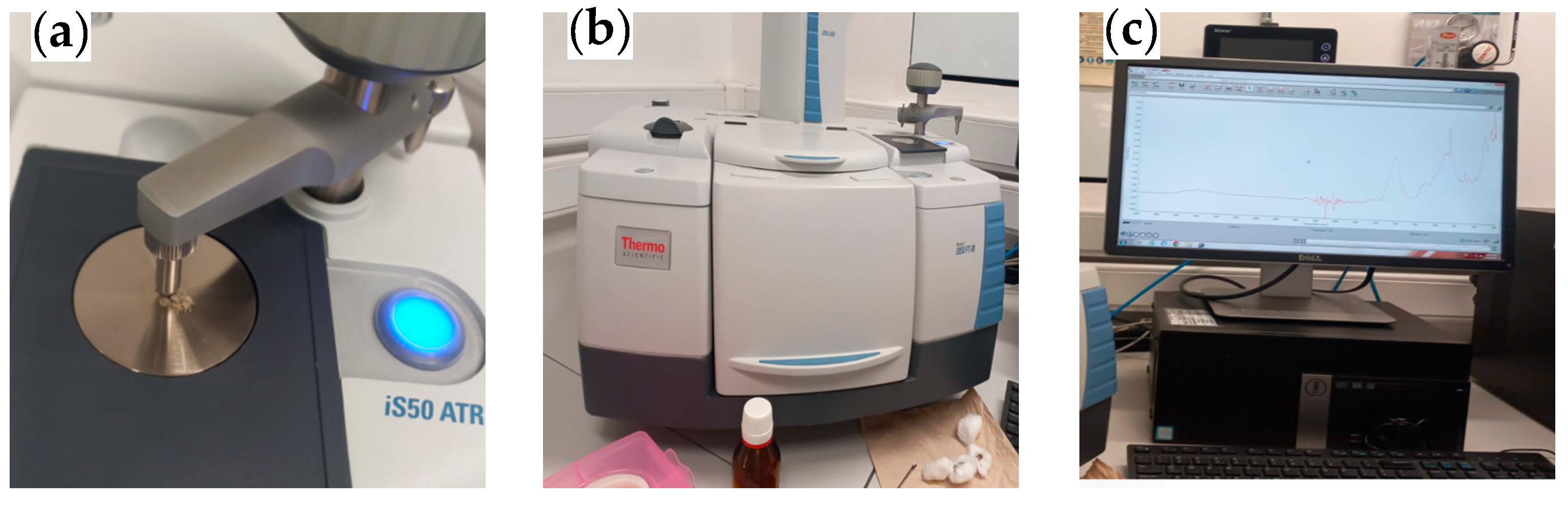

2.6.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.6.3. Thermogravimetric Analysis (TGA)

2.7. Thermal and Acoustic Results

2.7.1. Thermal Insulation Analysis

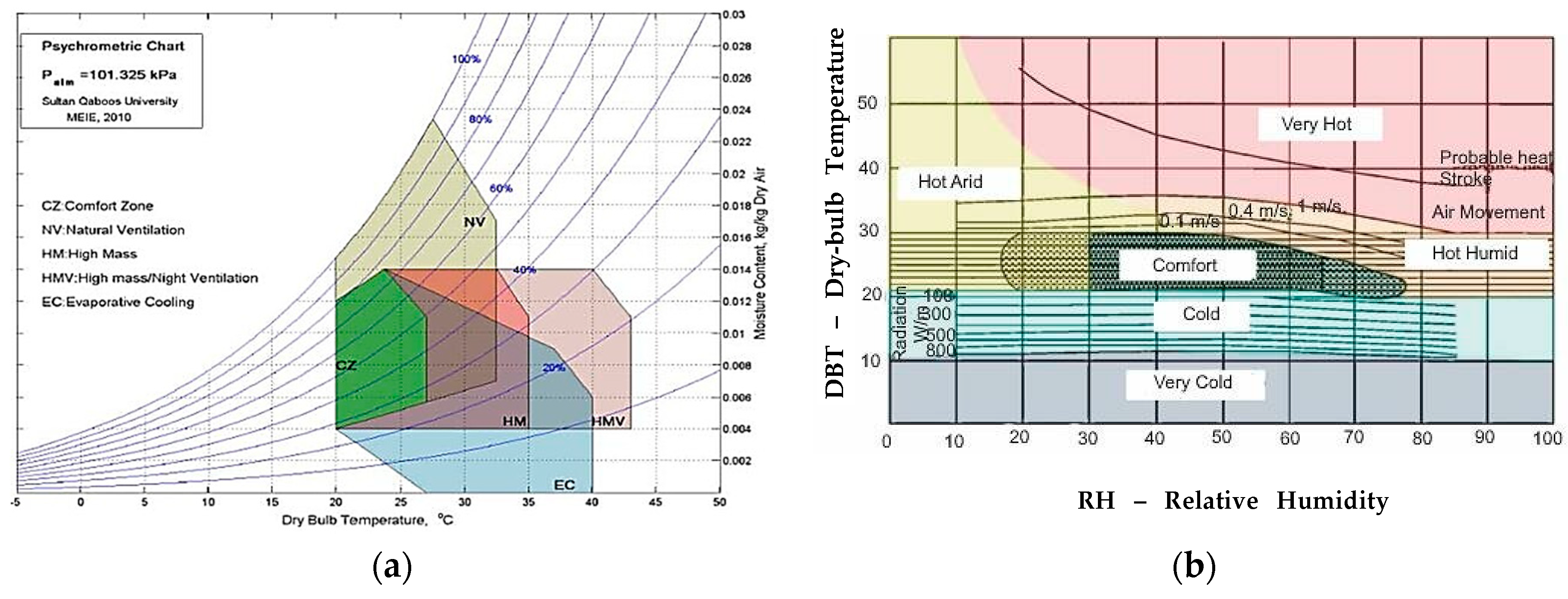

- Comfort zone: A shaded area in the center representing the optimal combination of temperature, humidity, and wind speed for moderate activity levels.

- Evaporation: Shows how increased evaporation facilitates body cooling in hot and humid climates.

- Radiation: Illustrates the impact of solar radiation on thermal perception, potentially intensifying heat or causing discomfort due to sun exposure.

- Wind: Indicates the role of wind in enhancing ventilation and dissipating body heat under warm conditions.

- Shadow line and freezing line: Mark the extremes of solar radiation and low temperatures that affect human comfort.

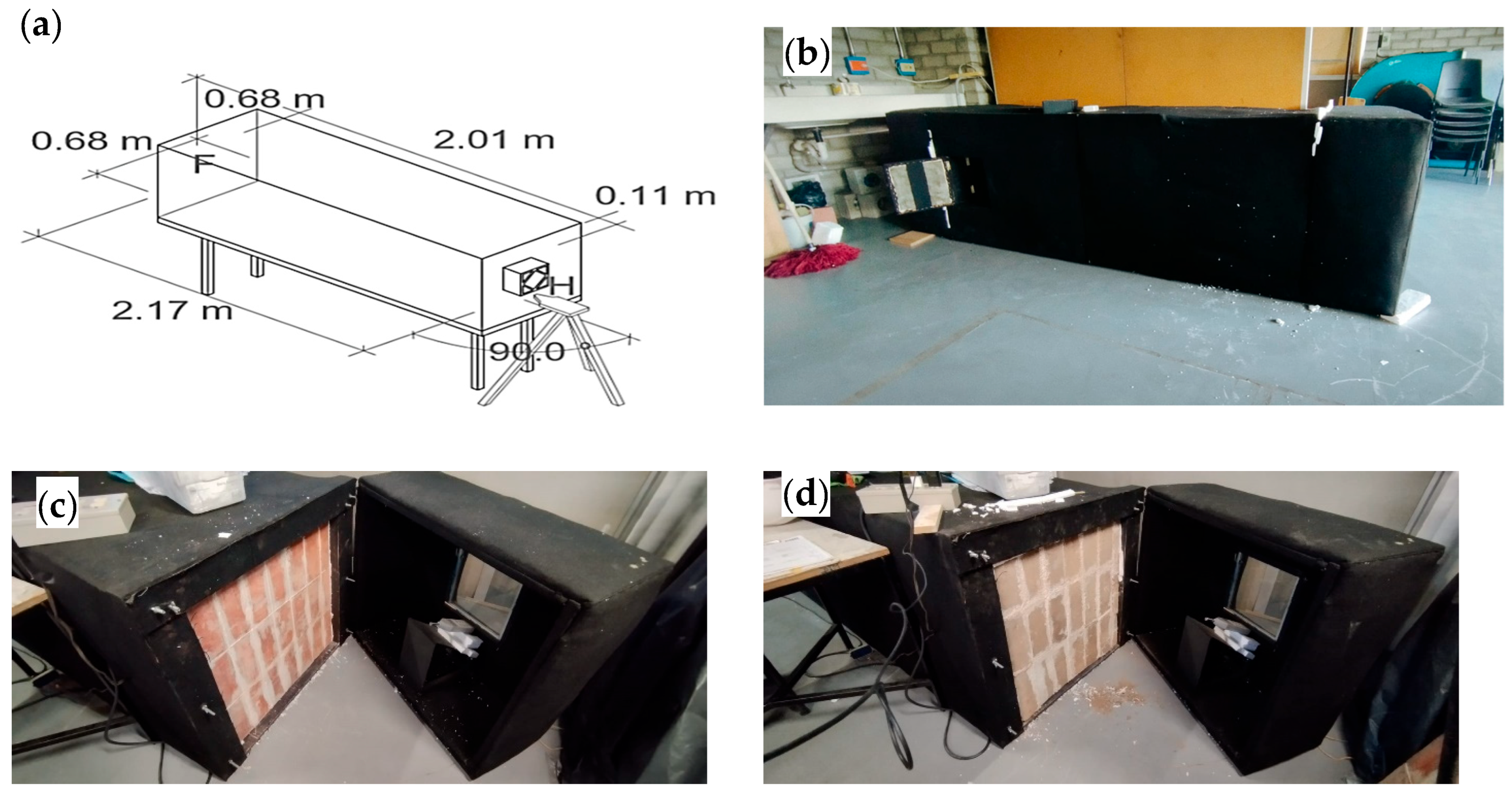

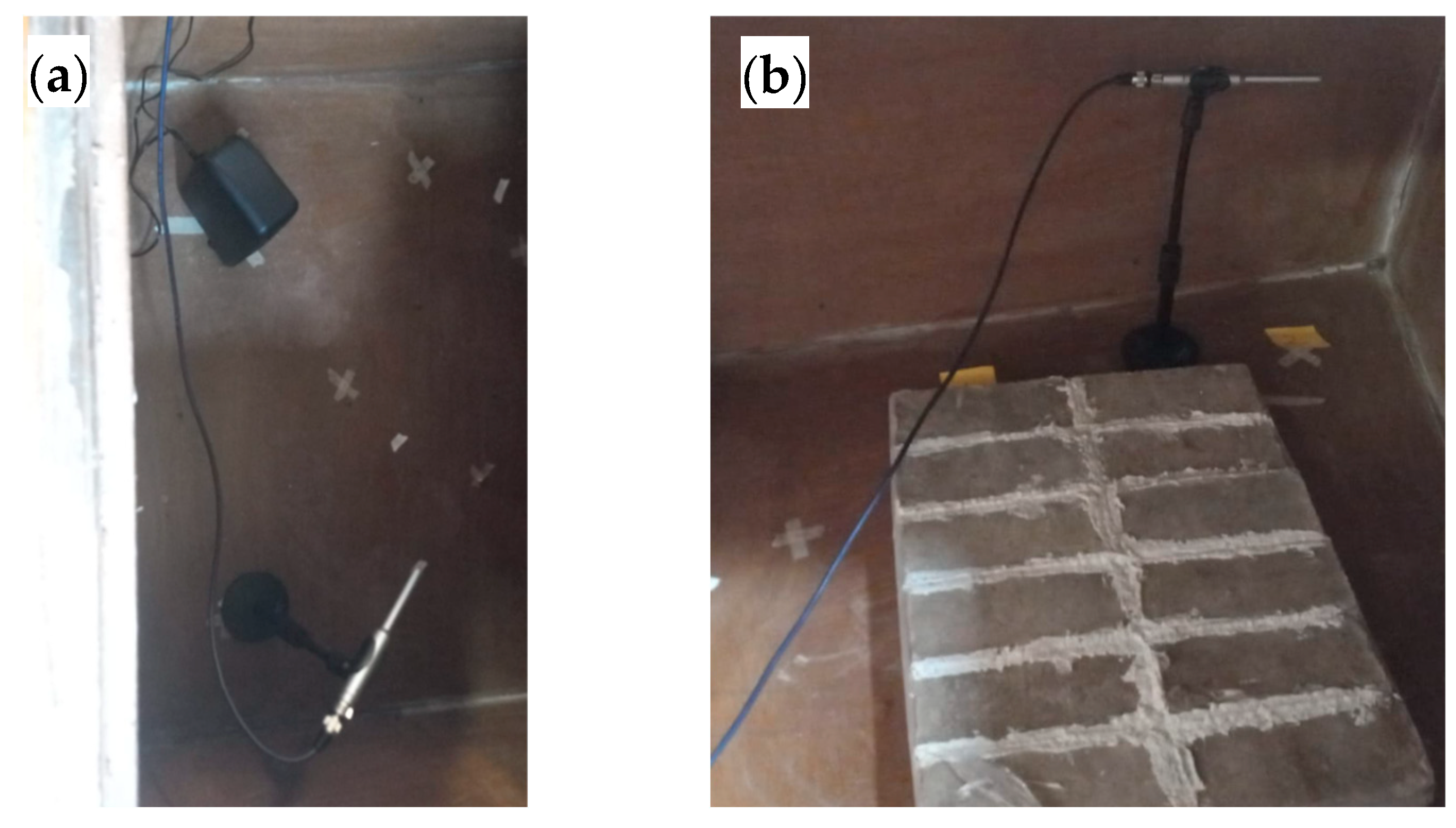

2.7.2. Thermoacoustic Analysis

- ⮚

- Step 1. Calibration: Perform baseline measurements with the empty chamber and each test sample. Per technical guidelines, the reverberation time (TR) should be approximately 1.0 s. The absorption coefficient (α), which ranges between 0 and 1, is calculated using the following Equation (7):where V is the room volume (m3) and A is the total absorption area, given by , where As is the surface area and Ca is the absorption coefficient.

- ⮚

- Step 2. Sine sweep: Apply the impulse response method using a sine sweep signal, as specified in UNE-EN ISO 354:2004. Use two sound source positions and six random microphone positions per source.

- ⮚

- Step 3. Data processing: Use Audacity-V3 software to generate the test signals and record reverberation times. Data was organized by one-third octave bands for enhanced accuracy and standardization. Using the T30 method, results are averaged to obtain the sound absorption coefficient for each sample.

3. Results and Discussion

3.1. Mechanical, Physical, and Thermal Results

3.1.1. Compression Strength Results

3.1.2. Flexural Strength and Modulus of Rupture Test

3.1.3. Final Moisture Absorption Test

3.1.4. Physical Results

Density Test Result

Porosity Test Results

3.1.5. Thermal Analysis Results

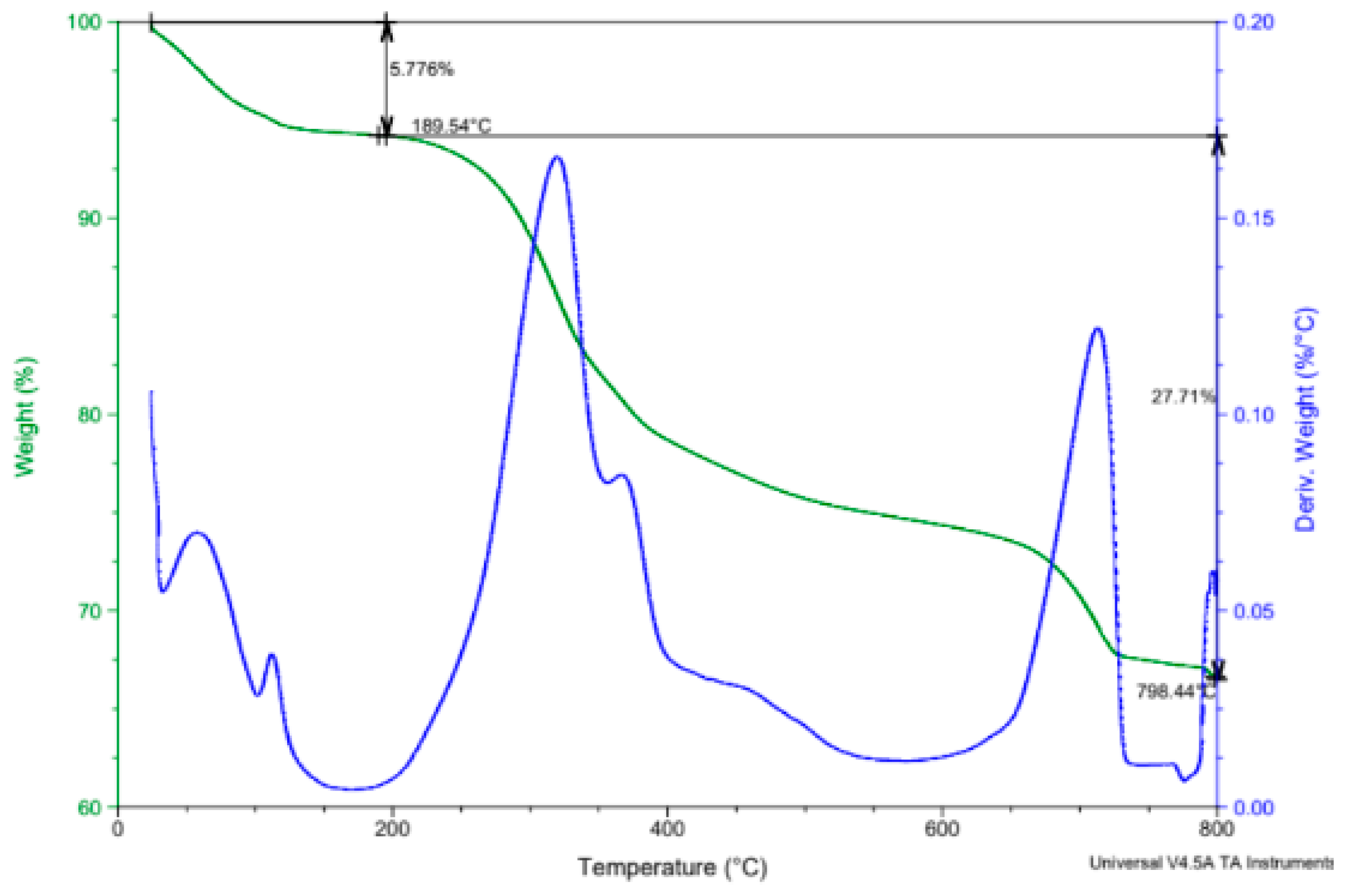

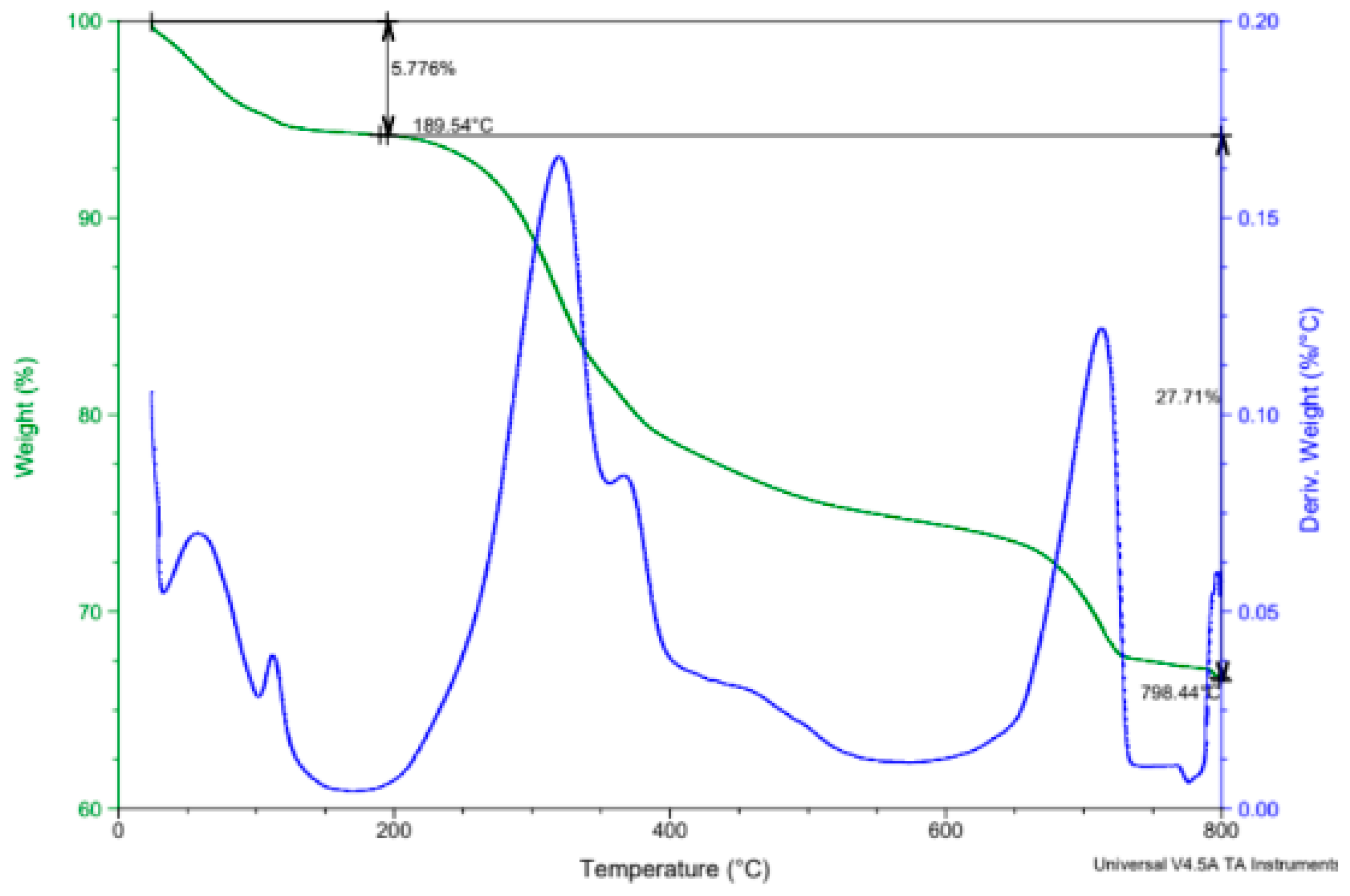

3.1.6. Thermogravimetric Analysis TGA Test

3.2. Biomaterial Chemical Characterization

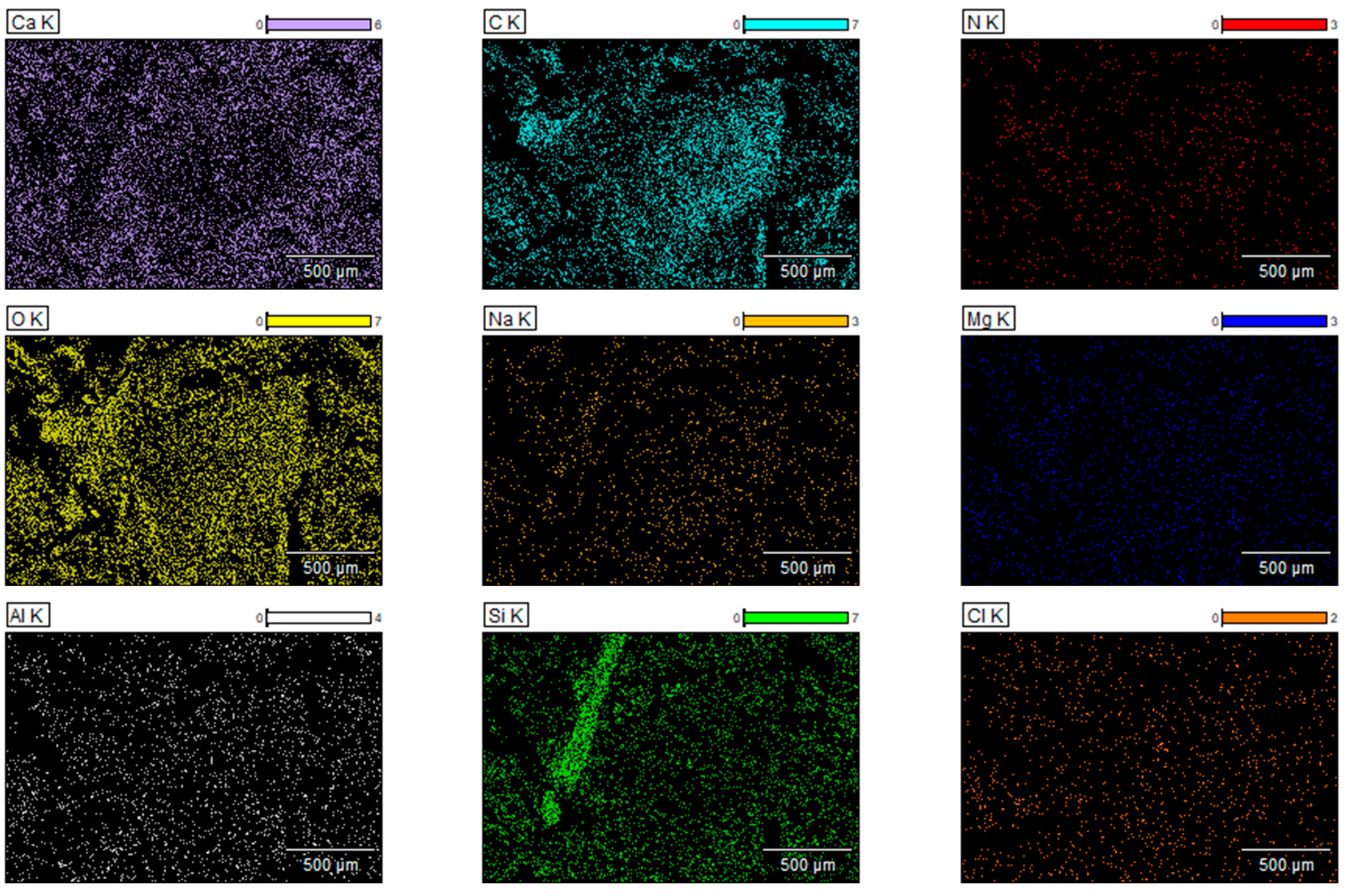

3.2.1. SEM-EDS Results

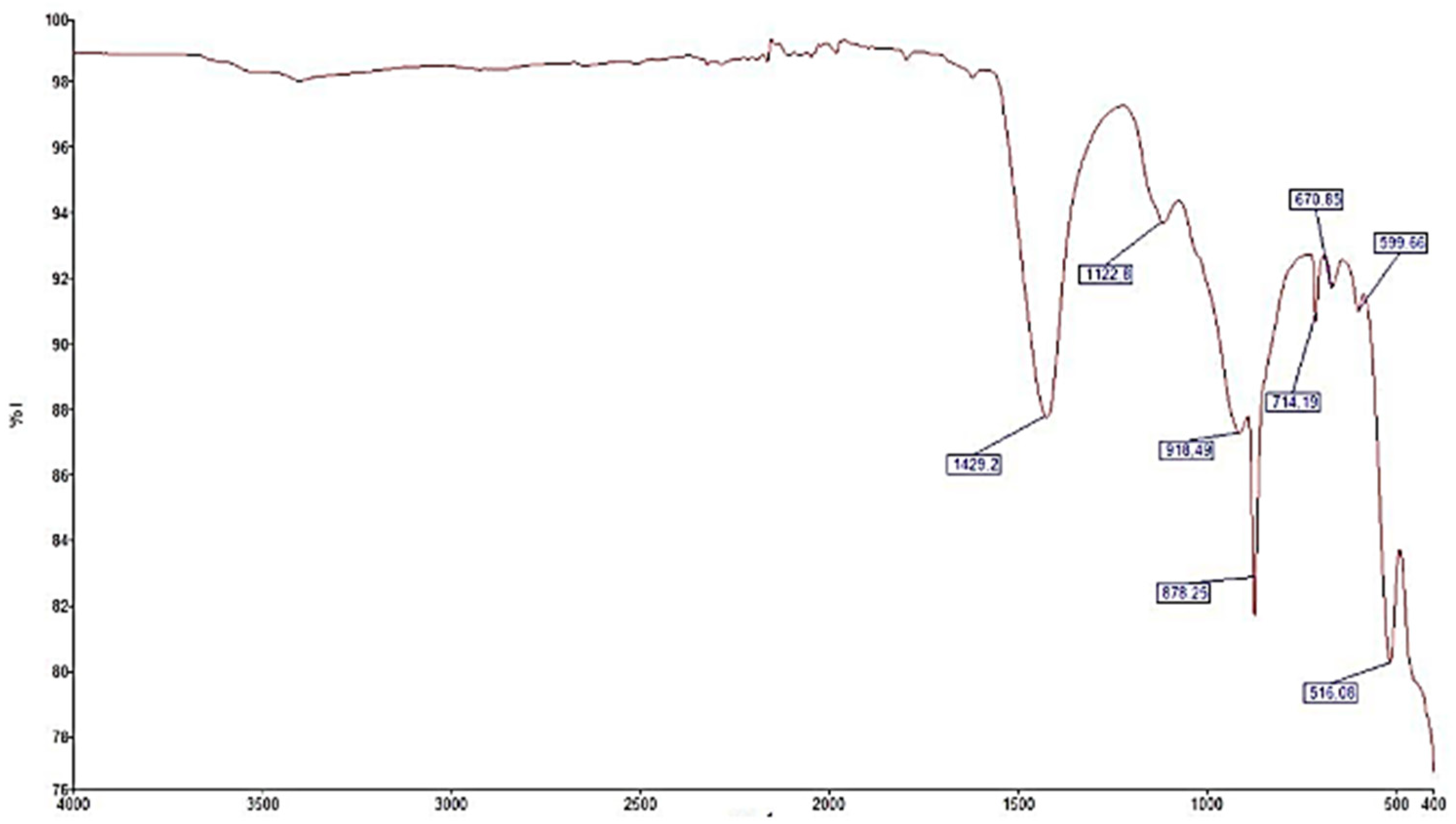

3.2.2. Fourier Transform Infrared (FTIR) Test

3.2.3. Thermogravimetric Results

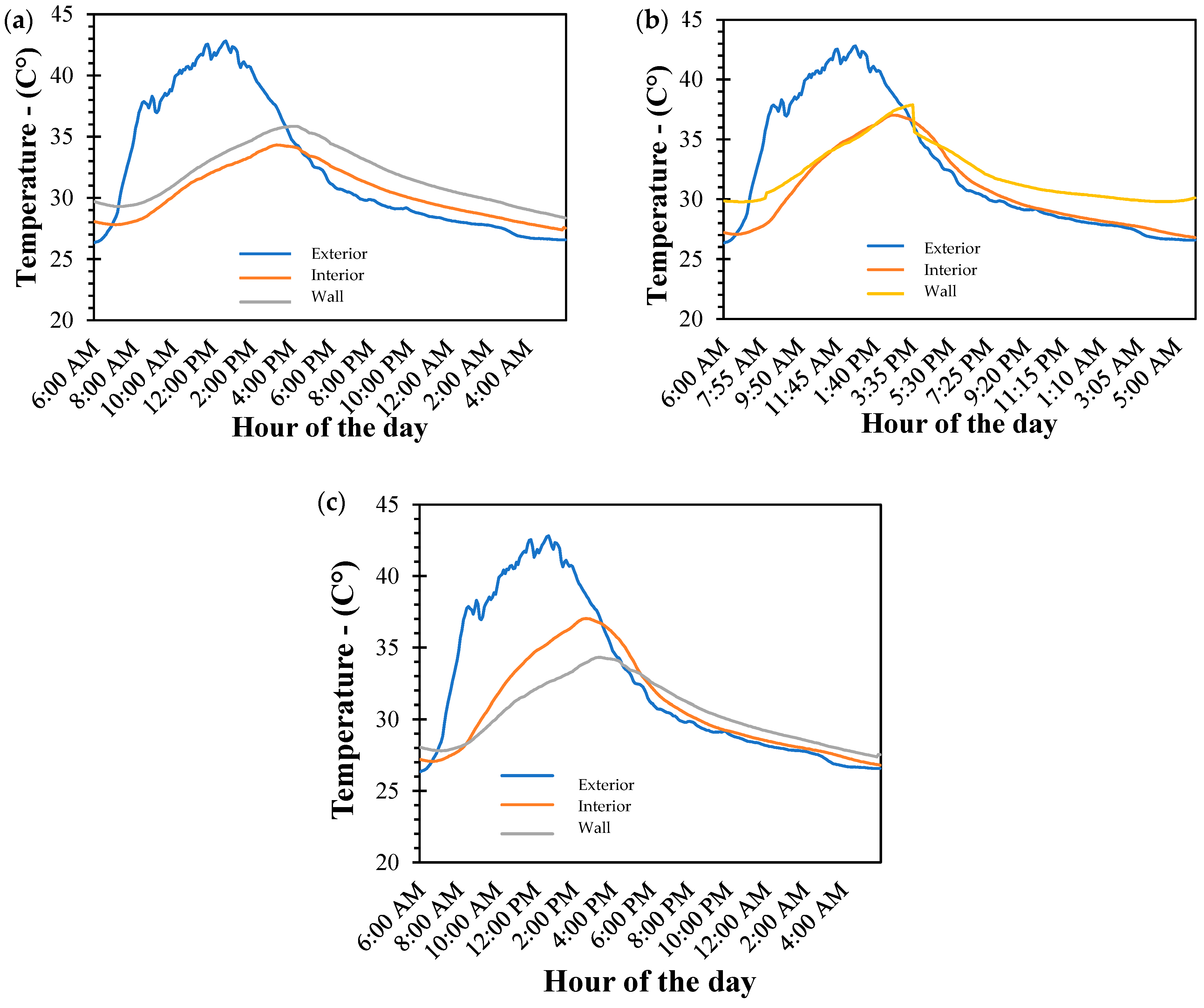

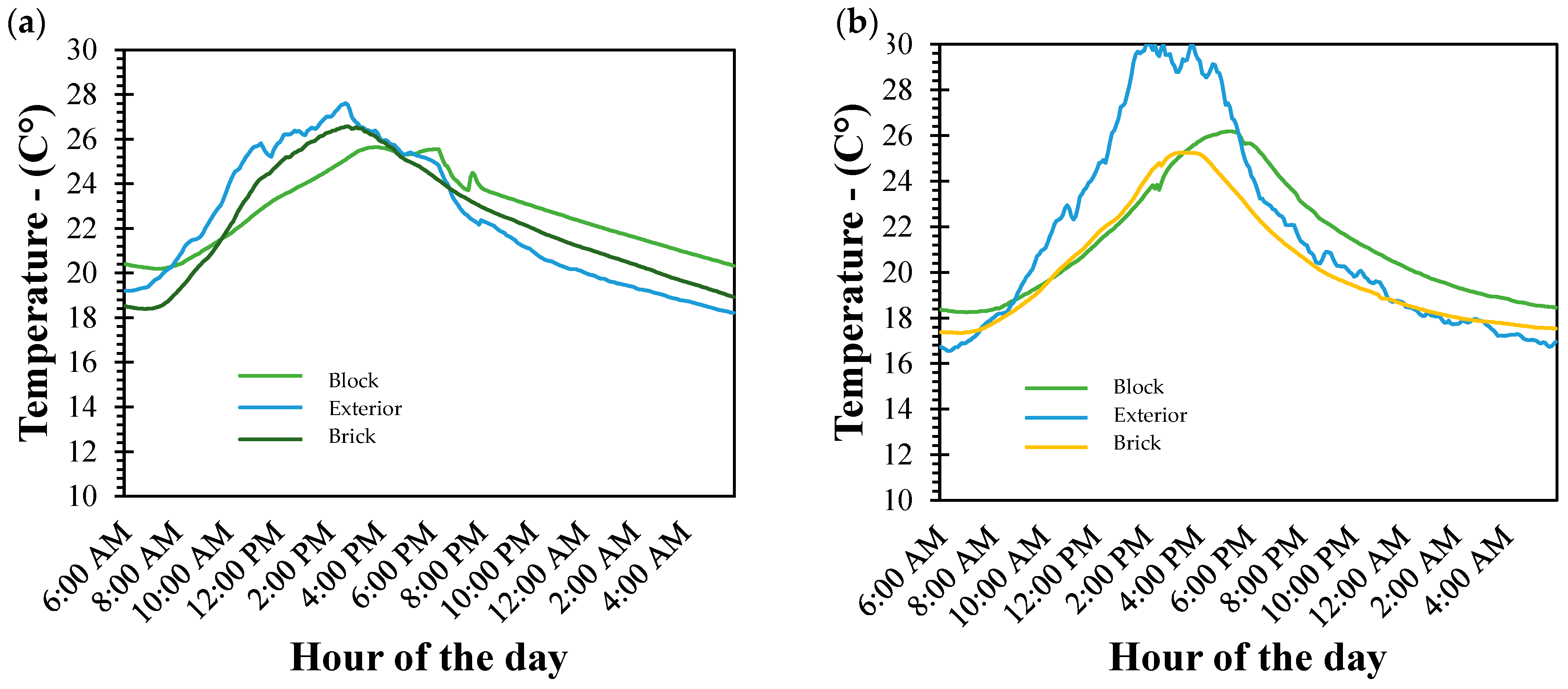

3.3. Thermal and Acoustic Characteristics

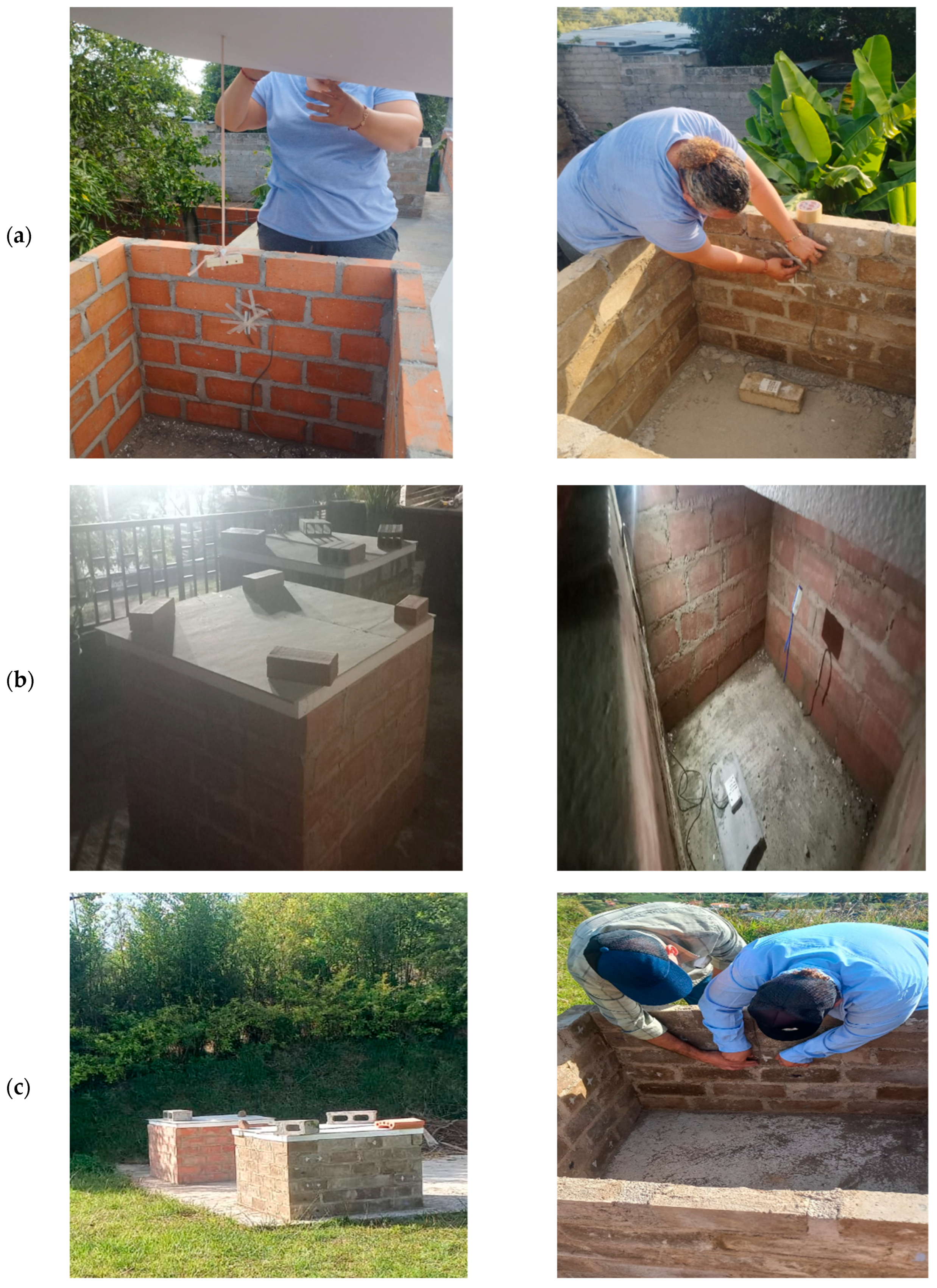

3.3.1. Thermal Tests Development

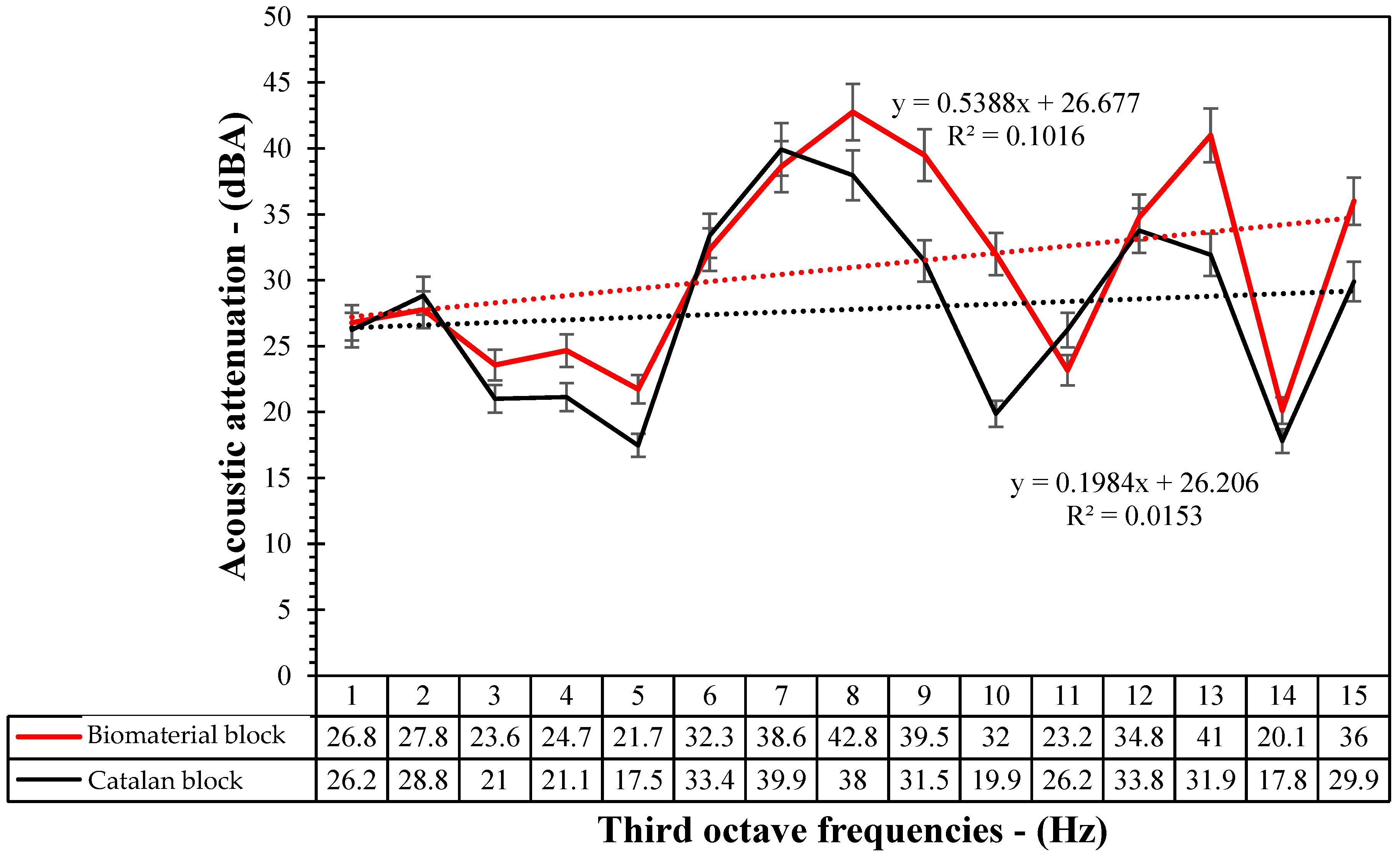

3.3.2. Acoustic Test Results

- Biomaterial block wall: This wall showed acoustic attenuation values of approximately 25 dBA for low and mid frequencies, with even better performance at high frequencies, reducing sound energy close to 30 dBA. These results suggest that biomaterial blocks offer a greater capacity to dissipate sound, primarily due to their porous microstructure and lower density, which increase internal friction and viscous losses when sound waves propagate through the material. The interconnected pores and heterogeneous internal composition act as sound absorbers by converting acoustic energy into heat, thus reducing transmitted sound. Additionally, the compliance (flexibility) of the biomaterial can lead to enhanced damping of vibrations, further contributing to sound attenuation. These mechanisms align with classical acoustic theory on porous absorbers and are consistent with findings reported by [23].

- Catalan brick wall: Although it presents similar behavior to the biomaterial block at low frequencies, its acoustic performance decreases from mid to high frequencies. Acoustic attenuation remains in the 25 dBA range, which, although acceptable, is lower than that achieved by the biomaterial block at high frequencies. This difference could be related to the higher density and rigidity of the Catalan brick, which limits internal friction and reduces the material’s ability to absorb sound energy, causing more sound waves to be reflected rather than absorbed. At higher frequencies, stiff and dense materials tend to transmit vibrations more effectively, resulting in lower attenuation.

3.4. Thermal Comfort Assessment Based on Bioclimatic Parameters

4. Conclusions

- ⮚

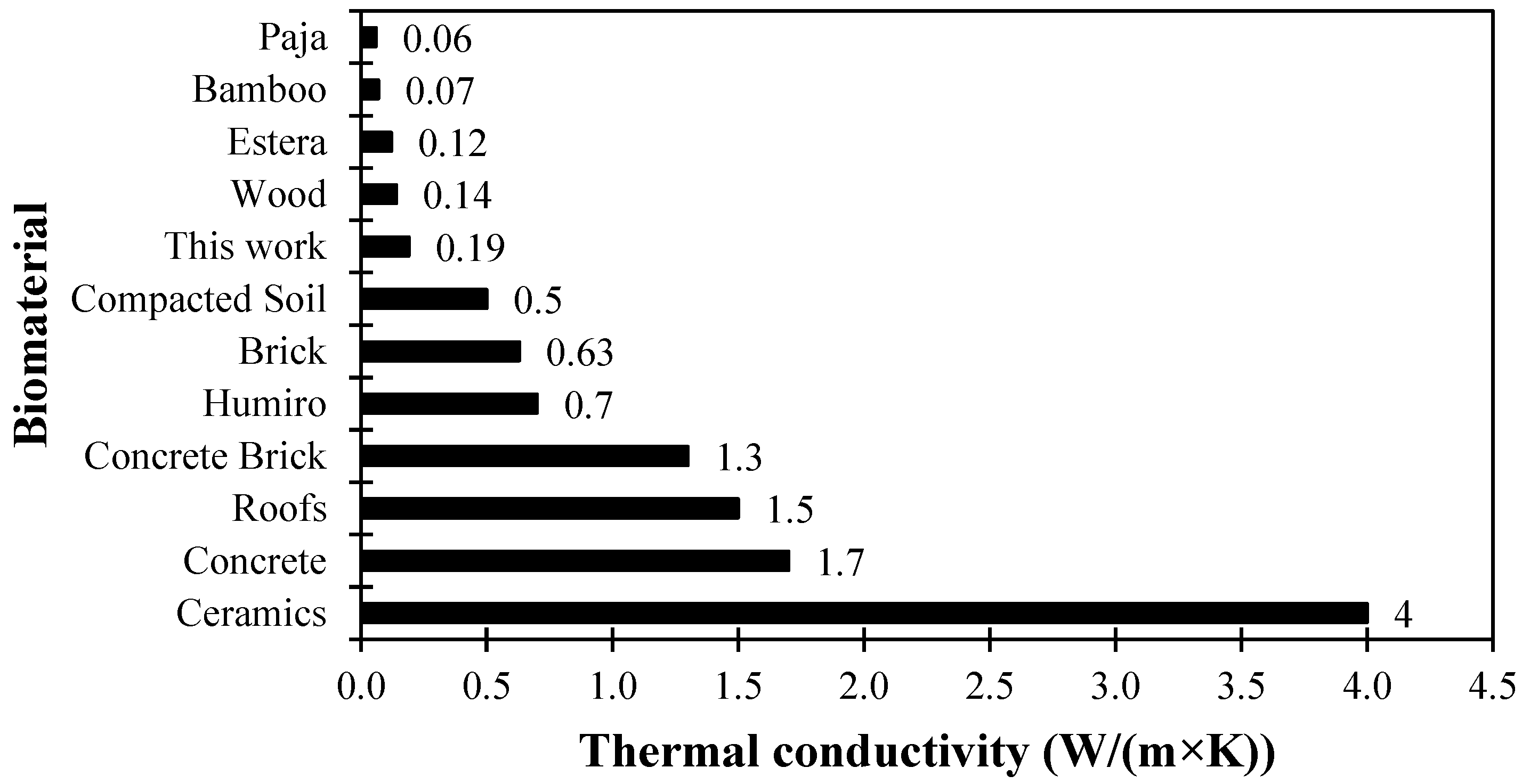

- This study demonstrates the technical and environmental viability of producing bio-bricks using agricultural waste—specifically coffee husks and bovine excreta—as partial substitutes for cement in masonry units. The optimized mixture (960 g of cement, 225 g of lignin, and 315 g of bovine excreta) achieved a compressive strength of 1.70 MPa and a flexural strength of 0.56 MPa, complying with the minimum standards for non-loadbearing walls established by Colombian regulations. Despite the increased water absorption (~22.5%), the thermal conductivity (0.19 W/(m×K)) and acoustic attenuation (~25 dBA) of the bio-bricks reveal superior insulation behavior compared to conventional clay bricks.

- ⮚

- Thermal and acoustic field evaluations conducted across three distinct Colombian climate zones confirmed the ability of the bio-bricks to reduce indoor temperature fluctuations and attenuate external noise more effectively than traditional masonry materials. The results also indicate a significant reduction in material density (~0.91 g/cm3), which may contribute to lighter structural loads and improved construction logistics.

- ⮚

- Morphological and chemical analyses (SEM-EDS, FTIR, and TGA) validated the integration and compatibility of organic and inorganic components within the composite matrix, contributing to the bio-brick’s overall thermal stability and performance. These findings support the potential for the large-scale application of bio-based masonry units in sustainable construction, particularly in tropical and rural regions where local resources and climate responsiveness are critical.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mori, D.; Uday, K.V. 12—Innovations toward bio-brick. In Woodhead Publishing Series in Civil and Structural Engineering; Choudhury, T., Raviteja, K.V.N.S., Singh, L., Bertolesi, E., Eds.; Woodhead Publishing: Sawston, UK, 2024; pp. 203–213. [Google Scholar] [CrossRef]

- Anitha, K.; Senthilselvan, S. Agricultural Waste Materials Applications in Building Industry—An Overview. ECS Trans. 2022, 107, 2371. [Google Scholar] [CrossRef]

- De Lucas, A.; Taranco, C.; Rodrígez, E.; Paniagua, P. Biomasa, Biocombustibles Y Sostenibilidad; Centro Tecnológico Agrario y Agroalimentario: Palencia, Spain, 2012; Volume 13. [Google Scholar]

- Jeguirim, M.; Salah, J.; Khiari, B. Sustainable Biomass Resources for Environmental, Agronomic, Biomaterials. C. R. Chim. 2020, 23, 583–587. [Google Scholar] [CrossRef]

- Dungani, R.; Karina, M.; Subyakto; Sulaeman, A.; Hermawan, D.; Hadiyane, A. Agricultural waste fibers towards sustainability and advanced utilization: A review. Asian J. Plant Sci. 2016, 15, 42–55. [Google Scholar] [CrossRef]

- Gbadeyan, O.J.; Sibiya, L.; Mpongwana, N.; Linganiso, L.Z.; Linganiso, E.C.; Deenadayalu, N. Manufacturing of building materials using agricultural waste (sugarcane bagasse ash) for sustainable construction: Towards a low carbon economy. A review. Int. J. Sustain. Eng. 2023, 16, 368–382. [Google Scholar] [CrossRef]

- Dungani, R.; Khalil, H.A.; Sumardi, I.; Suhaya, Y.; Sulistyawati, E.; Islam, M.N.; Suraya, N.L.M.; Aprilia, N.S. Non-wood Renewable Materials: Properties Improvement and Its Application. In Biomass and Bioenergy: Applications; No. April 2016; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–397. [Google Scholar] [CrossRef]

- Salleh, S.Z.; Kechik, A.A.; Yusoff, A.H.; Taib, M.A.A.; Nor, M.M.; Mohamad, M.; Tan, T.G.; Ali, A.; Masri, M.N.; Mohamed, J.J.; et al. Recycling food, agricultural, and industrial wastes as pore-forming agents for sustainable porous ceramic production: A review. J. Clean. Prod. 2021, 306, 127264. [Google Scholar] [CrossRef]

- Acchar, W.; Dultra, E.J.V.; Segadães, A.M. Untreated coffee husk ashes used as flux in ceramic tiles. Appl. Clay Sci. 2013, 75, 141–147. [Google Scholar] [CrossRef]

- Montoya, G. Hacia Una Construcción Sostenible en Colombia. Asobancaria. Available online: https://www.asobancaria.com/wp-content/uploads/2022/05/1329_BE.pdf (accessed on 11 May 2025).

- Prabhakar, C.G.; Babu, K.A.; Kataraki, P.S.; Reddy, S. A review on natural fibers and mechanical properties of banyan and banana fibers composites. Mater. Today Proc. 2022, 54, 348–358. [Google Scholar] [CrossRef]

- Kumar, P.; Gautam, P.; Kaur, S.; Chaudhary, M.; Afreen, A.; Mehta, T. Bamboo as reinforcement in structural concrete. Mater. Today Proc. 2021, 46, 6793–6799. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Yang, F.; Weng, Y.; Qian, S. Sustainable high strength, high ductility engineered cementitious composites (ECC) with substitution of cement by rice husk ash. J. Clean. Prod. 2021, 317, 128379. [Google Scholar] [CrossRef]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials 2014, 7, 3034–3048. [Google Scholar] [CrossRef]

- Uday Kiran, G.; Nakkeeran, G.; Roy, D. Thermal distribution of paver block with machine learning optimized design with alternative eco-friendly materials. Innov. Infrastruct. Solut. 2025, 10, 24. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Bustos, C.A.P.; Pumarejo, L.G.F.; Cotte, É.H.S.; Quintana, H.A.R. Construction demolition waste (CDW), a perspective of achievement for the city of Barranquilla since its management model. Ing. Y Desarrollo 2017, 35, 533–555. [Google Scholar] [CrossRef]

- Parece, S.; Rato, V.; Resende, R.; Pinto, P.; Stellacci, S. A Methodology to Qualitatively Select Upcycled Building Materials from Urban and Industrial Waste. Sustainability 2022, 14, 3430. [Google Scholar] [CrossRef]

- Ganasen, N.; Krishnaraj, L.; Onyelowe, K.C.; Alaneme, G.U.; Otu, O.N. Soft computing techniques for predicting the properties of raw rice husk concrete bricks using regression-based machine learning approaches. Sci. Rep. 2023, 13, 14503. [Google Scholar] [CrossRef]

- Nakkeeran, G.; Krishnaraj, L.; Shakor, P.; Alaneme, G.U.; Otu, O.N. Mechanical properties optimization and cost analysis of agricultural waste as an alternative in brick production. Sci. Rep. 2024, 14, 24075. [Google Scholar] [CrossRef]

- Ganasen, N.; Krishnaraj, L.; Onyelowe, K.C.; Stephen, L.U. Machine learning optimization of bio-sandcrete brick modelling using response surface methodology. Sci. Rep. 2024, 14, 3438. [Google Scholar] [CrossRef]

- Jonnala, S.N.; Gogoi, D.; Devi, S.; Kumar, M.; Kumar, C. A comprehensive study of building materials and bricks for residential construction. Constr. Build. Mater. 2024, 425, 135931. [Google Scholar] [CrossRef]

- Korjakins, A.; Sahmenko, G.; Lapkovskis, V. A Short Review of Recent Innovations in Acoustic Materials and Panel Design: Emphasizing Wood Composites for Enhanced Performance and Sustainability. Appl. Sci. 2025, 15, 4644. [Google Scholar] [CrossRef]

- Acuña-Portocarrero, G.; Soto-Chahua, J.; Otárola-Santiváñez, J. Evaluation of Building Materials and Proposal to Improve Thermal Comfort in Rural Housing. Civ. Eng. Archit. 2025, 13, 118–143. [Google Scholar] [CrossRef]

- Rautray, P.; Roy, A.; Eisenbart, B. Application of Bio-Bricks and its Benefits. Proc. Des. Soc. 2023, 3, 603–612. [Google Scholar] [CrossRef]

- Liu, S.; Du, K.; Huang, W.; Wen, K.; Amini, F.; Li, L. Improvement of erosion-resistance of bio-bricks through fiber and multiple MICP treatments. Constr. Build. Mater. 2021, 271, 121573. [Google Scholar] [CrossRef]

- Cruz, J.S. Estudio Comparativo de Materiales Sostenibles Aislantes en Arquitectura. 2019. Available online: https://riunet.upv.es:443/handle/10251/137334 (accessed on 14 September 2023).

- García-León, R.A.; Acevedo-Peñaloza, C.; Rojas-Suarez, J.P. Metodología Para la Fabricación del Bloque H-10 Para la Industria Cerámica de Norte de Santander; ECOE, Ed.; Universidad Francisco de Paula Santander: Bogota, Colombia, 2019. [Google Scholar]

- NTC-121; Performance Specification for Hydraulic Cement. Norma Técnica Colombiana. ICONTEC: Bogota, Colombia, 2021.

- Carvalho, V.R.; Costa, L.C.B.; Baeta, B.E.L.; Peixoto, R.A.F. Lignin-Based Admixtures: A Scientometric Analysis and Qualitative Discussion Applied to Cement-Based Composites. Polymers 2023, 15, 1254. [Google Scholar] [CrossRef]

- Jaramillo, H.Y.; Vasco-Echeverri, O.; López-Barrios, R.; García-León, R.A. Optimization of Bio-Brick Composition Using Agricultural Waste: Mechanical Properties and Sustainable Applications. Sustainability 2025, 17, 1914. [Google Scholar] [CrossRef]

- Goos, P.; Jones, B.; Antwerpen, U.; Syafitri, U. I-optimal design of mixture experiments. J. Am. Stat. Assoc. 2016, 111, 899–911. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S. An investigation on use of paper mill sludge in brick manufacturing. Constr. Build. Mater. 2017, 148, 334–343. [Google Scholar] [CrossRef]

- NTC-4017:2018; Métodos Para Muestreo y Ensayos de Unidades de Mampostería y Otros Productos de Arcilla. Norma Técnica Colombiana. ICONTEC: Bogota, Colombia, 2005; pp. 1–30.

- NTC 4205-1:2009; Unidades de Mamposteria de Arcilla Cocida. Ladrillos y Bloques Ceramicos. ICONTEC: Bogota, Colombia, 2000.

- García-León, R.A.; Trigos-Caceres, J.; Castilla-Quintero, N.; Afanador-García, N.; Gómez-Camperos, J. Experimental and Statistical Analysis of Concrete Eco-Cobble Using Organic and Synthetic Fibers. Processes 2024, 12, 1936. [Google Scholar] [CrossRef]

- Khalaf, F.M.; DeVenny, A.S. New Tests for Porosity and Water Absorption of Fired Clay Bricks. J. Mater. Civ. Eng. 2002, 14, 334–337. [Google Scholar] [CrossRef]

- García-León, R.A.; Flórez-Solano, E.; Espinel-Blanco, E. Conductividad térmica de polvos de arcillas utilizadas en la industria cerámica en Ocaña Norte de Santander y la región. Ingenio UFPSO 2017, 13, 29–37. [Google Scholar] [CrossRef]

- García-León, R.A.; Camperos, J.G.; Jaramillo, H.Y. Physical, chemical and thermal characterization of a Colombian clay. Int. J. Mech. Mechatron. Eng. 2020, 20, 225–234. [Google Scholar]

- Jaramillo, H.Y.; Vasco-Echeverri, O.H.; Moreno-Pacheco, L.A.; García-León, R.A. Biomaterials in Concrete for Engineering Applications: A Bibliometric Review. Infrastructures 2023, 8, 161. [Google Scholar] [CrossRef]

- García-León, R.A.; Solano, E.F.; Peñaloza, C.A. Caracterización térmica de mezclas de arcillas utilizadas en la fabricación de productos de mampostería para la construcción. In Revista Colombiana de Tecnologias de Avanzada (Rcta); Universidad de Pamplona: Pamplona, Colombia, 2018. [Google Scholar] [CrossRef]

- UNE-EN ISO-16283-3; Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements—Part 3. International Organization for Standardization: Geneva, Switzerland, 2016.

- Belén, A.; Romero, C.; Pérez, M.E.C.; Francisca, F.M. Evaluación del Comportamiento Térmico de Una Edificación Reemplazando el Material de la Envolvente Por SUELO-Cemento. 2016. Available online: https://www.researchgate.net/publication/315764135 (accessed on 11 May 2025).

- ISO-7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Van Hoof, J. Forty years of Fanger’s model of thermal comfort: Comfort for all? Indoor Air 2008, 18, 182–201. [Google Scholar] [CrossRef] [PubMed]

- Mohan, M.; Gupta, A.; Bhati, S. A Modified Approach to Analyze Thermal Comfort Classification. Atmos. Clim. Sci. 2014, 4, 7–19. [Google Scholar] [CrossRef][Green Version]

- Muñoz, N.; Marino, B.M.; Thomas, L.P. Caracterización Térmica De Edificios Aplicando El Modelo De Regresión Lineal Múltiple. Av. En Energías Renov. Y Medio Ambiente 2016, 20, 5–21. [Google Scholar]

- Basantes, A.C.N.; García, E.H. Altitude, climate variables and people’s length of stay in Ecuador squares. Urbe 2018, 10, 414–425. [Google Scholar] [CrossRef]

- Rincón-Martínez, J.C. Confort térmico en edificios educativos naturalmente ventilados: Un estudio en bioclima templado-seco. Rev. De Arquit. 2023, 25, 12–24. [Google Scholar] [CrossRef]

- De, J.P.O.; Aemet, G. Caracterización del Contenido de Vapor de Agua Atmosférico; Spanish Meteorological Association: Madrid, Spain, 2013. [Google Scholar]

- Guillén, B.L. Evaluación del Bienestar Térmico A Través de la Temperatura Operativa. Available online: https://www.carm.es/web/descarga?ARCHIVO=FT-4.pdf&ALIAS=ARCH&IDCONTENIDO=78385&IDTIPO=60&RASTRO=c721$m6645#:~:text=La%20temperatura%20operativa%20es%20una,de%20calor%20radiante%20y%20convectivo (accessed on 27 December 2024).

- Del Cisne Conforme-Zambrano, G.I.; Castro-Mero, J.I.L. Arquitectura bioclimática Bioclimatic architecture Arquitetura bioclimática. Polo del Conocimiento 2020, 5, 751–779. Available online: https://polodelconocimiento.com/ojs/index.php/es/article/view/1381 (accessed on 25 December 2024).

- Unión Europea. El Proyecto BIOURB. Available online: https://www.biourb.net/proyecto-biourb/ (accessed on 25 December 2024).

- Ariza, M.A.M. Construcción Sostenible en Colombia: Aproximaciones, Indicadores, y Aplicación al Caso de Estudio del Centro Cívico de la Universidad de Los Andes. 2020. Available online: https://repositorio.uniandes.edu.co/entities/publication/afcdafea-15d5-469b-9fc2-9e87603184c7 (accessed on 25 December 2024).

- Ochoa, J.A.G.; Rodríguez, J.C.Q.; Moreno, J.A.P. Análisis de la Huella de Carbono en la Construcción y su Impacto Sobre el Ambiente; Universidad Cooperativa de Colombia: Bogota, Colombia, 2021. [Google Scholar]

- Serrano, A.; Molina, F.Q.; Catalán, M.L.; Guillén-Mena, V.; Orellana, D.S. Sobre la Evaluación de la Sostenibilidad de Materiales de Construcción. 2015. Available online: https://www.researchgate.net/publication/316492577 (accessed on 11 May 2025).

- Chaudruc, K.V.D.; Arévalo, E.P.; Escorcia, R.S.; Pallares, R.R. Impacto De La Contaminación Auditiva Sobre El Ambiente Y La Salud Aguachica (Cesar). Mundo FESC 2023, 13, 7–20. [Google Scholar] [CrossRef]

- Vivienda y Desarrollo Territorial. Ministerio de Ambiente. Resolución 0627. April 2006. Available online: https://www.minambiente.gov.co/wp-content/uploads/2021/10/Resolucion-0627-de-2006.pdf (accessed on 11 May 2025).

- ISO-140-1; Acoustics—Measurement of Sound Insulation in Buildings and of Building Elements—Part 1. International Organization for Standardization: Geneva, Switzerland, 1997.

- Cálculo de la Pérdida de Transmisión Acústica y de Contrapresión en Silenciadores, Mediante el Método de Los Elementos Finitos. 2016. Available online: www.aenor.es (accessed on 11 May 2025).

- Toapanta, Á.R.I. Evaluación de la Fabricación de Bioladrillos Utilizando Materiales Alternativos Plástico Pet y Cascarilla de Arroz Para Disminuir el Impacto Ambiental en la Microempresa Pilicita en el Cantón Saquisili; Universidad Técnica de Cotopaxi: Latacunga, Ecuador, 2019. [Google Scholar]

- García-Léon, R.A.; Florez-Solano, E.; Guerrero-Gomez, G. Determinación de la Mezcla Óptima de Arcilla del Bloque H-10 Para la Industria Cerámica; ECOE, Ed.; Universidad Francisco de Paula Santander: Bogota, Colombia, 2020. [Google Scholar]

- Poornima, V.; Venkatasubramani, R.; Sreevidya, V.; Chandrasekar, P. Study on properties of bio-bricks. Mater. Today Proc. 2022, 49, 2103–2109. [Google Scholar] [CrossRef]

- Manoharan, A.; Raja, R.; Sharma, H.; Kumar, S. Recent Advances in Bio-Based Concrete Materials: A Critical In-Depth Review. World Sci. Annu. Rev. Funct. Mater. 2024, 2. [Google Scholar] [CrossRef]

- García-León, R.A.; Sanchez-Torrez, A.; Rincon-Cardenas, W.; Afanador-García, N.; Moreno-Pacheco, L.; Lanziano-Barrera, M. Experimental study about the improvement of the mechanical properties of a concrete cobble using recyclable additives. DYNA 2023, 90, 45–55. [Google Scholar] [CrossRef]

- ASTM-C90; Standard Specification for Loadbearing Concrete Masonry Units. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- EN-771-1; Specification for Masonry Units—Part 1: Clay Masonry Units. Asociación Española de Normalización: Madrid, Spain, 2016.

- Salazar, J. Dosificación de hormigones ligeros con cascarilla de café. In Ingeniería E Investigación; Fundación Dialnet: Logroño, Spain, 1984. [Google Scholar]

- Zapata, C.P.S. Impacto del Uso de Cascarilla de Arroz en Propiedades Mecánicas y Microestructurales de Morteros de Mampostería. 2023. Available online: https://orcid.org/0000-0003-1344-1895 (accessed on 11 May 2025).

- Clayton, T.; Pearce, R.B. Rapid chemical analysis of the <2 μm clay fraction using an SEM/EDS technique. Clay Miner. 2007, 42, 549–562. [Google Scholar] [CrossRef]

- McManis, A.; Ferrell, K.; Arman, R.E.Y. Interpretación de las propiedades físicas de una arcilla mediante técnicas de microanálisis. Rev. Pruebas Geotécnicas 1983, 87–92. [Google Scholar]

- Nayak, P.S.; Singh, B.K. Instrumental characterization of clay by FTIR, XRF, BET and, TPD-NH3. Bull. Mater. Sci. 2007, 30, 235–238. [Google Scholar] [CrossRef]

- París, J.M.F. Influencia del medio ambiente en los materiales de construcción II. La Humedad. Mater. De Constr. 1976, 26, 49–58. [Google Scholar] [CrossRef][Green Version]

- Al-Azri, N.; Zurigat, Y.; Al-Rawahi, N. Development of bioclimatic chart for passive building design in Muscat-Oman. Int. J. Sustain. Energy 2012, 32, 713–723. [Google Scholar] [CrossRef]

- Gupta, J.; Dhobekar, N. Using Appropriate Technology in Designing Climate Responsible Architecture: A study in hot-dry climate of Aurangabad. Compr. Adv. Spec. Summ. Stud. 2022, 5, 1–26. [Google Scholar]

| % | Experimental Variables | ||

|---|---|---|---|

| Cement (g) | Lignin (g) | Bovine Excreta (g) | |

| 5 | 960 | 75 | 465 |

| 10 | 150 | 390 | |

| 15 | 225 | 315 | |

| 20 | 300 | 240 | |

| % Coffee Husk | Weight (kg) | Length (cm) | Height (cm) | Width (cm) | Maximum Applied Load (KN) | Area (cm2) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 5 | 2.90 ± 0.07 | 24.00 | 7.00 | 10.00 | 54.40 ± 1.85 | 240.00 | 1.56 ± 0.07 |

| 10 | 3.18 ± 0.05 | 55.60 ± 2.01 | 1.62 ± 0.06 | ||||

| 15 | 2.76 ± 0.30 | 59.43 ± 2.78 | 1.70 ± 0.11 | ||||

| 20 | 2.23 ± 0.01 | 44.50 ± 0.20 | 1.84 ± 0.01 | ||||

| Ceramic brick | 3.34 ± 0.58 | 23.00 | 7.00 | 11.00 | 153.80 ± 18.53 | 260.00 | 5.91 ± 0.36 |

| % Coffee Husk | Weight (Kg) | Length (cm) | Maximum Applied Load (KN) | L (cm) | b (cm) | d (cm) | x | Flexural Strength—Modulus of Rupture (MPa) |

|---|---|---|---|---|---|---|---|---|

| 5 | 2.89 ± 0.05 | 24.00 | 1.40 ± 0.17 | 20.00 | 10.00 | 7.00 | 1.91 ± 0.10 | 0.50 ± 0.06 |

| 10 | 3.26 ± 0.11 | 1.60 ± 0.10 | 2.05 ± 0.23 | 0.55 ± 0.12 | ||||

| 15 | 2.79 ± 0.50 | 1.73 ± 0.15 | 2.05 ± 0.32 | 0.56 ± 0.10 | ||||

| 20 | 2.23 ± 0.01 | 6.10 ± 0.87 | 1.72 ± 0.11 | 0.63 ± 0.01 | ||||

| Ceramic brick | 3.30 ± 0.55 | 23.50 | 6.10 ± 0.87 | 19.00 | 11.00 | 7.00 | 6.07 ± 0.21 | 1.08 ± 0.23 |

| % Coffee Husk | Dry Weight (kg) | Wet Weight (kg) | Moisture Absorption (%) |

|---|---|---|---|

| 5 | 2.854 ± 0.296 | 3.472 ± 0.321 | 21.94 |

| 10 | 2.755 ± 0.113 | 3.324 ± 0.191 | 20.61 |

| 15 | 2.339 ± 0.348 | 2.851 ± 0.277 | 22.47 |

| 20 | 2.002 ± 0.064 | 2.747 ± 0.065 | 37.26 |

| Ceramic brick | 2.645 ± 0.077 | 3.032 ± 0.089 | 14.63 |

| % Coffee Husk | Biomaterial—(g) | V (cm3) | D (g/cm3) |

|---|---|---|---|

| 5 | 2317.266 ± 653.769 | 1680 | 1.3792 |

| 10 | 2707.983 ± 748.375 | 1.6120 | |

| 15 | 1535.116 ± 273.079 | 0.9137 | |

| 20 | 2228.000 ± 0.001 | 1.326 | |

| Ceramic brick | 2.645 ± 0.077 | 1.574 |

| Composite Material | Compressive Strength (MPa) | Flexural Strength (MPa) | Density (kg/m3) | Water Absorption (%) | Analysis |

|---|---|---|---|---|---|

| Wood–cement composite | 30–50 | 10–25 | 600–1200 | 5–15 | High mechanical performance and moderate density; suitable for structural applications. |

| Bioblocks | 25–35 | 12–20 | 700–1300 | 6–12 | Balanced properties with good insulation and loadbearing capabilities. |

| Lignocellulosic composite | 20–30 | 8–15 | 500–900 | 10–20 | Lightweight and sustainable; moderate strength limits use to non-structural elements. |

| Lightweight cement composite | 30–40 | 10–18 | 300–800 | 4–10 | Excellent weight reduction; ideal for prefabricated or modular construction. |

| Plant waste composite | 15–25 | 5–12 | 400–850 | 15–25 | Good eco-efficiency, though water absorption is high; needs treatment for durability. |

| Modified wood–cement composite | 35–55 | 15–28 | 750–1400 | 8–18 | Superior performance; suitable for high-end sustainable construction. |

| Extruded wood fiber composite | 25–30 | 10–18 | 400–1000 | 5–15 | Good strength-to-weight ratio; promising for cladding or partition walls. |

| Conventional ceramic bricks (Ocaña) | 5.91 ± 0.36 | 1.08 ± 0.23 | 1574 | 14.63 | Widely used but with lower mechanical performance; high density increases dead load. |

| Coffee husk + bovine excreta (15%) (This work) | 1.70 ± 0.11 | 0.56 ± 0.10 | 913.7 | 22.47 | Lower mechanical strength but lighter weight; high absorption requires improvement for exterior use. |

| Coffee Husk % | Wet Weight—Ph (g) | Pore Volume—Vp (cm3) | Solid Volume—Vs (cm3) | Total Volume—Vt (cm3) | Porosity Value (%) |

|---|---|---|---|---|---|

| 5 | 2320.737 ± 648.886 | 9.803 ± 3.178 | 1680 | 1689.803 ± 3.178 | 0.578 ± 0.186 |

| 10 | 2719.690 ± 751.318 | 11.707 ± 3.078 | 1691.707 ± 3.078 | 0.692 ± 0.179 | |

| 15 | 1541.678 ± 273.394 | 6.562 ± 0.814 | 1686.562 ± 0.814 | 0.390 ± 0.048 | |

| 20 | 2237.805 ± 1.252 | 9.805 ± 1.252 | 1689.805 ± 1.252 | 0.582 ± 0.075 |

| Material | Thermal Conductivity (λ—W/((m×K)) | Thermal Transmittance (U—W/(m2×K)) | Thermal Admittance (Y—W/(m2×K)) | Technical Comment |

|---|---|---|---|---|

| Calamine (corrugated metal) | 50.00 | 5.70 | 10.00 | Highest heat conduction; extremely poor insulator, prone to overheating. |

| Concrete | 1.70 | 1.50 | 6.00 | High thermal mass slowly releases heat, potentially causing thermal lag. |

| Concrete brick | 1.30 (literature) | 2.08 | 6.00 (estimated) | Moderately insulating; suitable for structural use but not optimal for comfort. |

| Fired clay brick | 0.63 | 1.93 | 5.00 | Traditional material: better insulator than concrete but still heat-retaining. |

| Wood | 0.14 | 0.30 (estimated) | 2.00 | Natural insulator; balances thermal resistance and responsiveness. |

| Bamboo | 0.07 | 1.00 | 2.00 | Low conductivity; light and responsive, ideal for tropical zones. |

| Straw (Paja) | 0.06 | 0.08 | 0.80 (estimated) | Excellent thermal insulator; biodegradable and low cost. |

| Humiro (traditional soil block) | 0.70 (literature) | 0.08 | 1.00 (estimated) | Low transmittance; traditional and climatically adapted. |

| Estera (woven palm mat) | 0.12 | 0.25 (estimated) | 1.50 (estimated) | Flexible and breathable; good for wall coverings. |

| Coffee husk + bovine excreta (This work) | 0.19 ± 0.02 | 0.20 ± 0.02 | 2.10 ± 0.05 | Eco-composite with balanced thermal resistance and fast responsiveness; sustainable and affordable. |

| Element | Weight % | Atomic % |

|---|---|---|

| C | 9.44 ± 0.06 | 15.84 ± 0.32 |

| N | 5.24 ± 0.31 | 7.55 ± 1.36 |

| O | 42.13 ± 0.29 | 53.09 ± 1.09 |

| Na | 0.14 ± 0.03 | 0.12 ± 0.07 |

| Mg | 0.35 ± 0.03 | 0.29 ± 0.06 |

| Al | 1.08 ± 0.05 | 0.81 ± 0.11 |

| Si | 6.29 ± 0.06 | 4.52 ± 0.14 |

| Cl | 0.18 ± 0.04 | 0.10 ± 0.06 |

| Ca | 35.14 ± 0.25 | 17.68 ± 0.38 |

| Total | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaramillo, H.Y.; Zuluaga-Gallego, R.; Arango-Correa, A.; García-León, R.A. Thermoacoustic, Physical, and Mechanical Properties of Bio-Bricks from Agricultural Waste. Buildings 2025, 15, 2183. https://doi.org/10.3390/buildings15132183

Jaramillo HY, Zuluaga-Gallego R, Arango-Correa A, García-León RA. Thermoacoustic, Physical, and Mechanical Properties of Bio-Bricks from Agricultural Waste. Buildings. 2025; 15(13):2183. https://doi.org/10.3390/buildings15132183

Chicago/Turabian StyleJaramillo, Haidee Yulady, Robin Zuluaga-Gallego, Alejandro Arango-Correa, and Ricardo Andrés García-León. 2025. "Thermoacoustic, Physical, and Mechanical Properties of Bio-Bricks from Agricultural Waste" Buildings 15, no. 13: 2183. https://doi.org/10.3390/buildings15132183

APA StyleJaramillo, H. Y., Zuluaga-Gallego, R., Arango-Correa, A., & García-León, R. A. (2025). Thermoacoustic, Physical, and Mechanical Properties of Bio-Bricks from Agricultural Waste. Buildings, 15(13), 2183. https://doi.org/10.3390/buildings15132183