Reconstruction of Old Pavements Based on Resonant Rubblization Technology: A Review of Technological Progress, Engineering Applications, and Intelligent Development

Abstract

1. Introduction

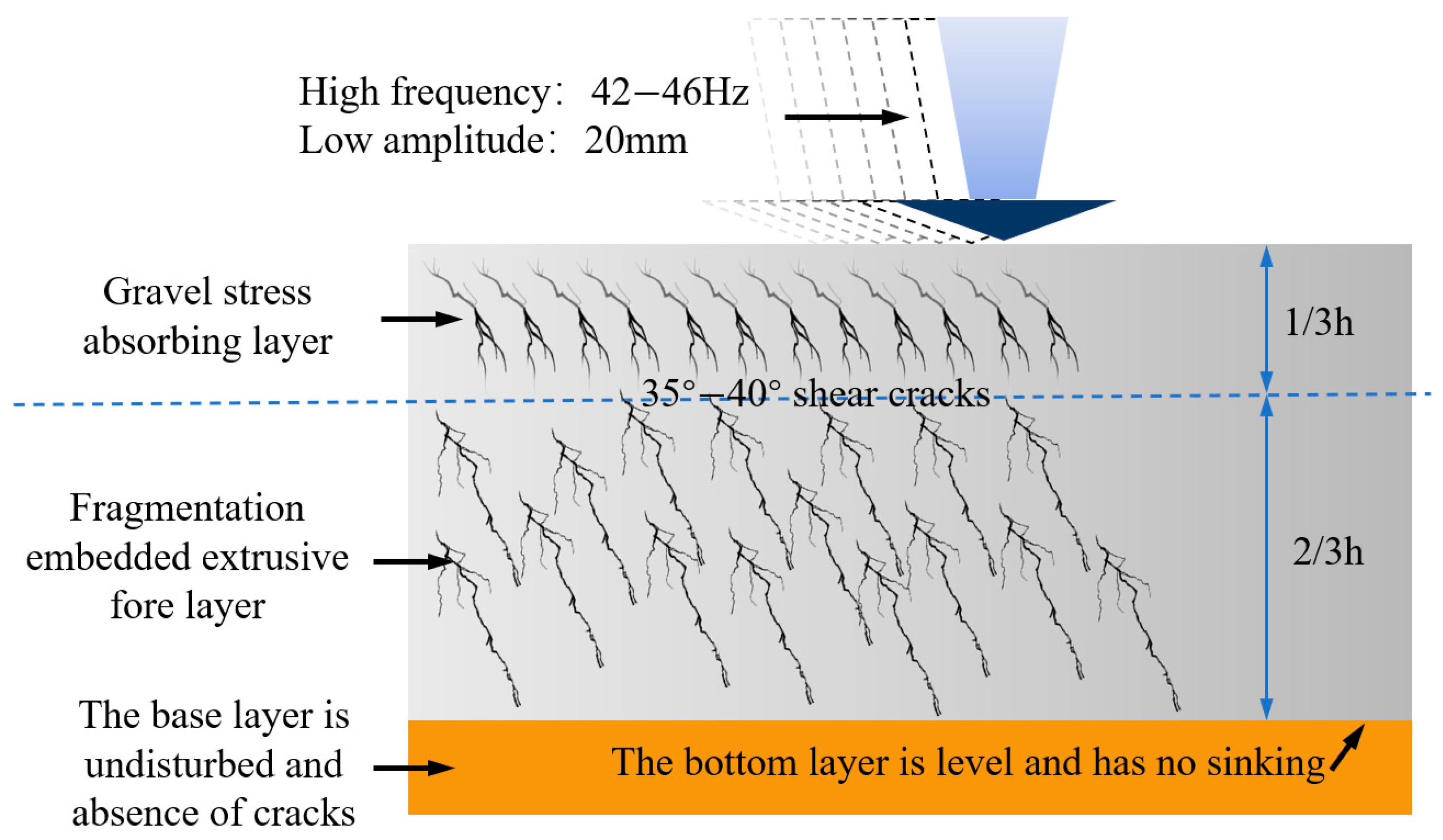

2. Basic Principles of Resonant Rubblization Technology

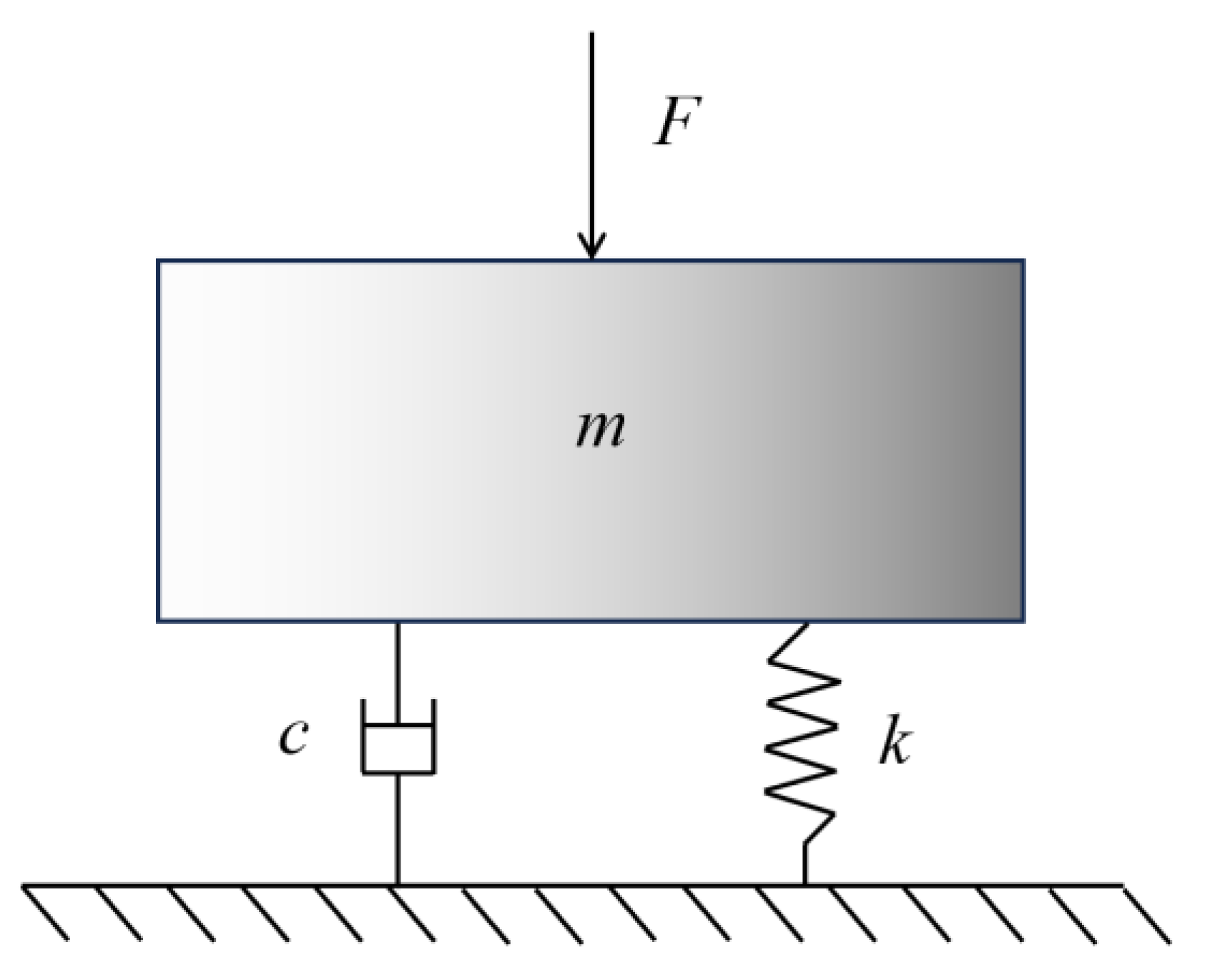

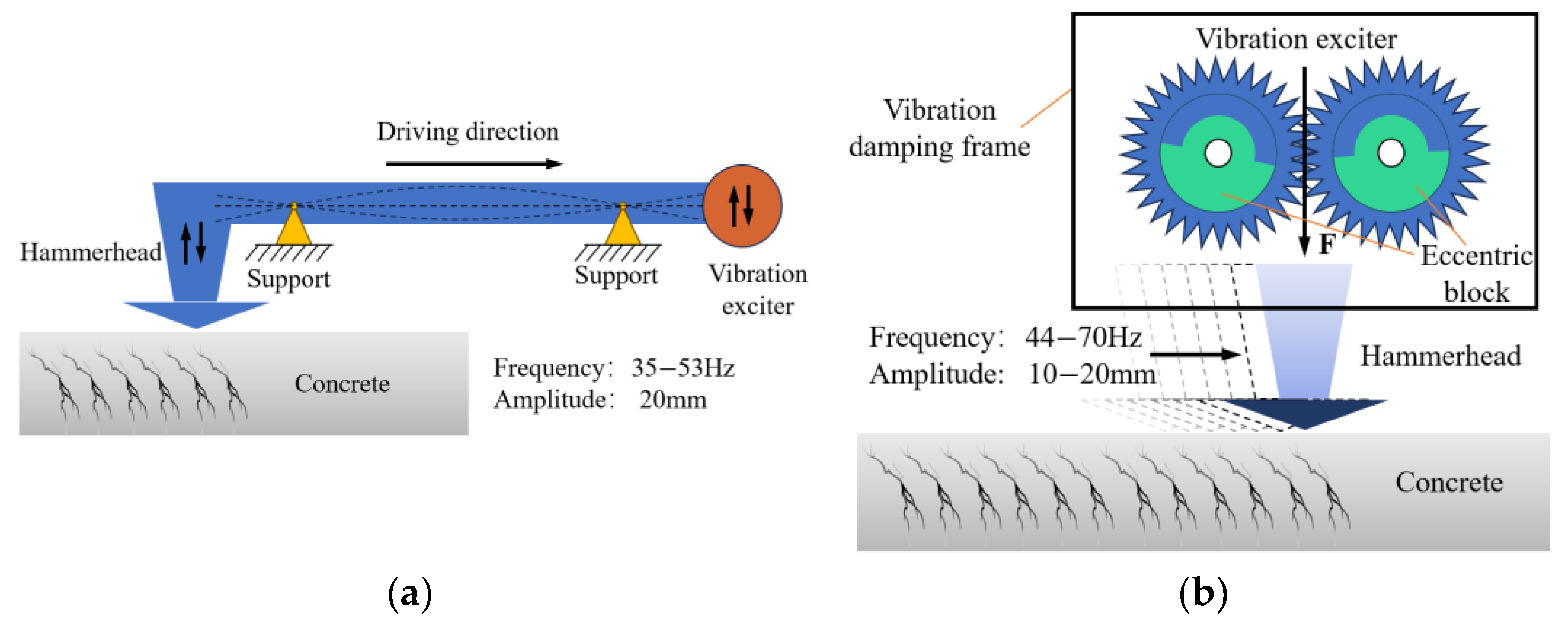

2.1. Forced Vibration of the Pavement Slab Under the Hammer’s Oscillation

2.2. The Onset of Resonance in the Slab

2.3. The Formation of the Rubblized Layer

3. Application of Resonant Rubblization Technology

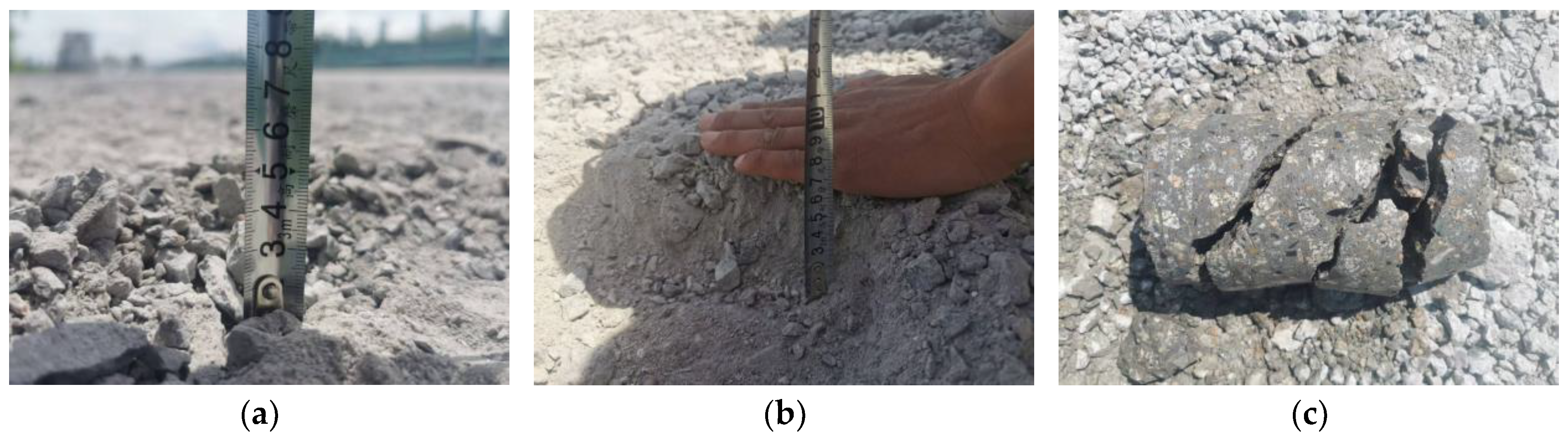

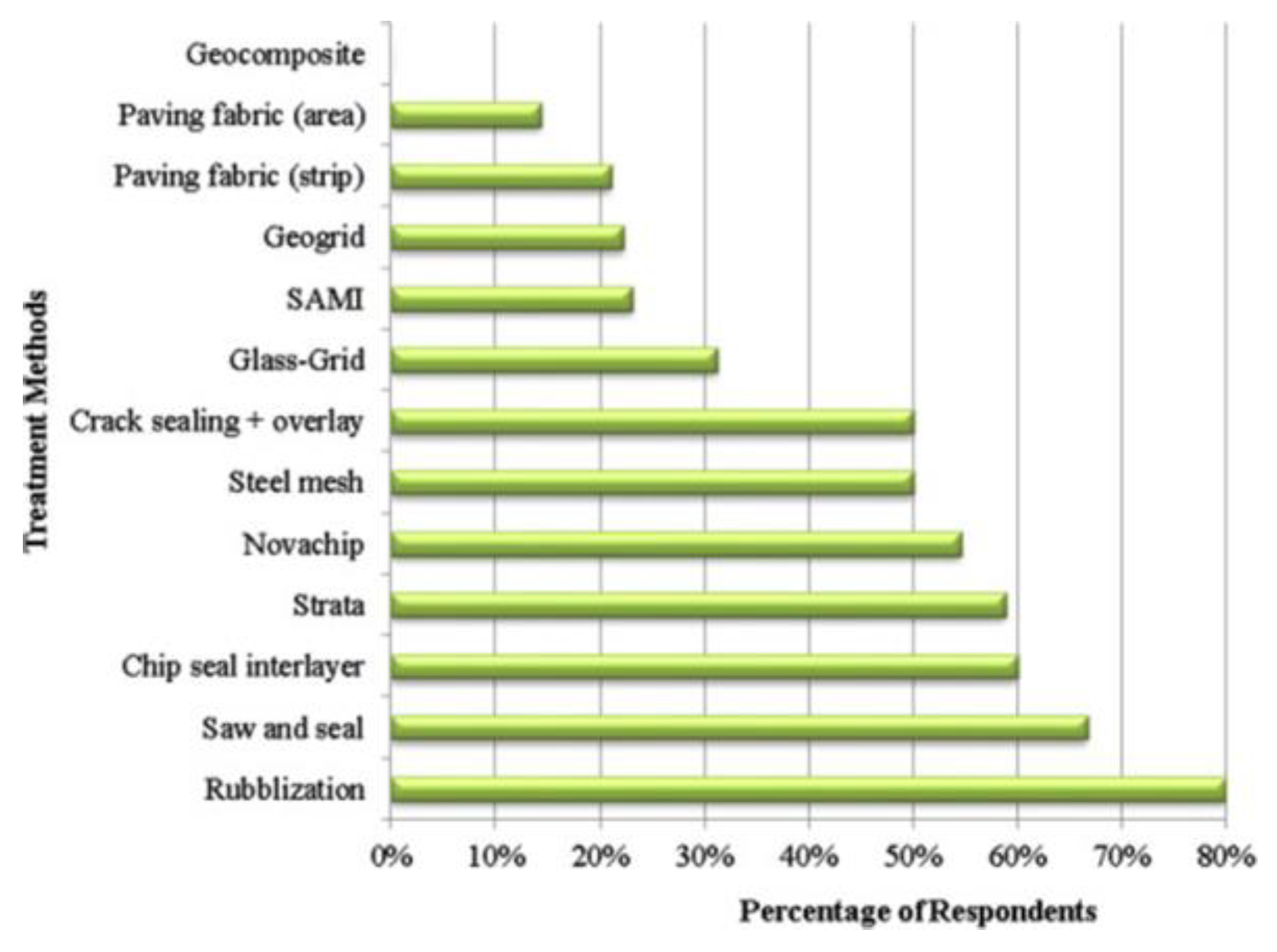

3.1. Research on Resonant Rubblization Technology

3.2. Resonant Rubblization Construction

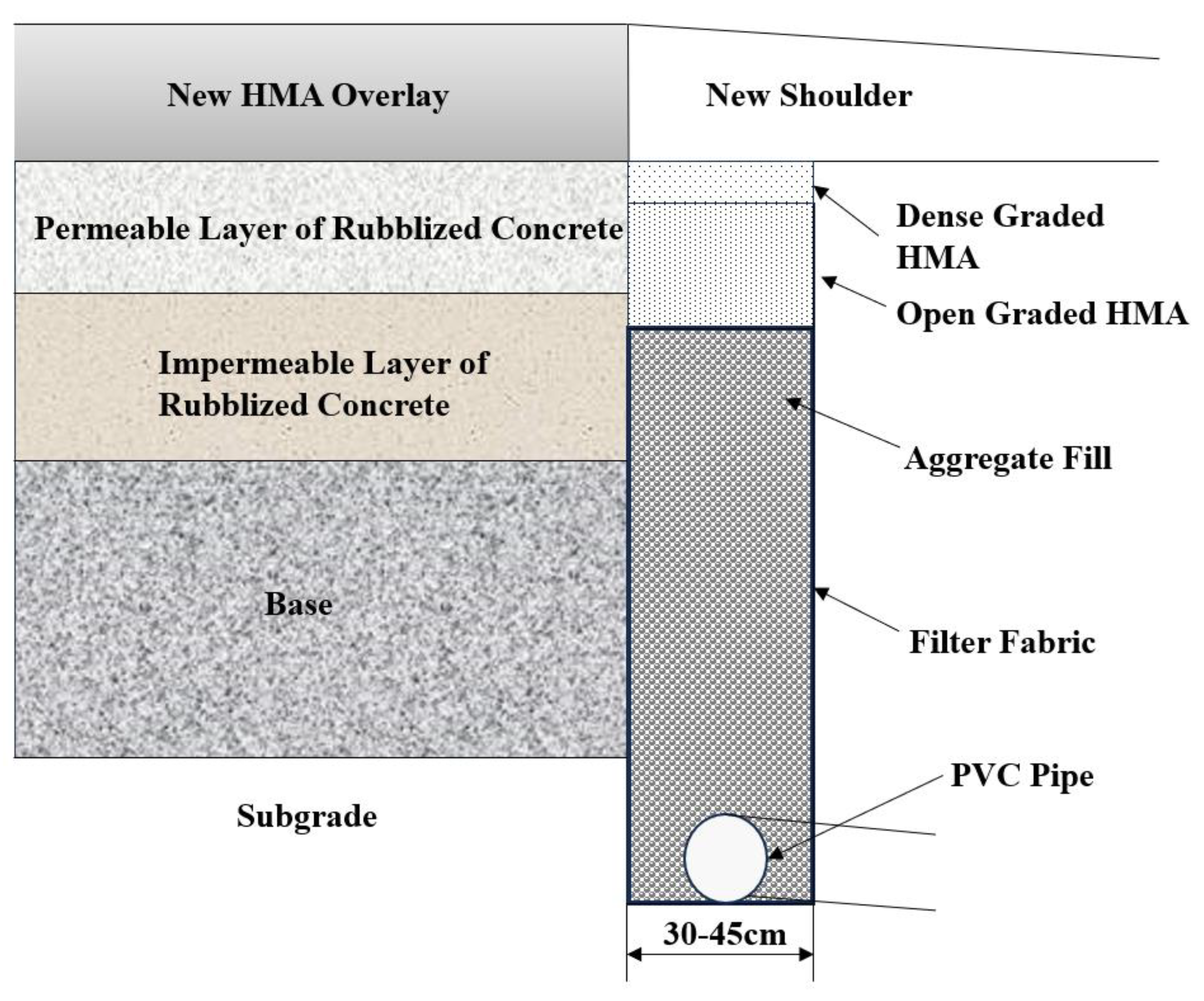

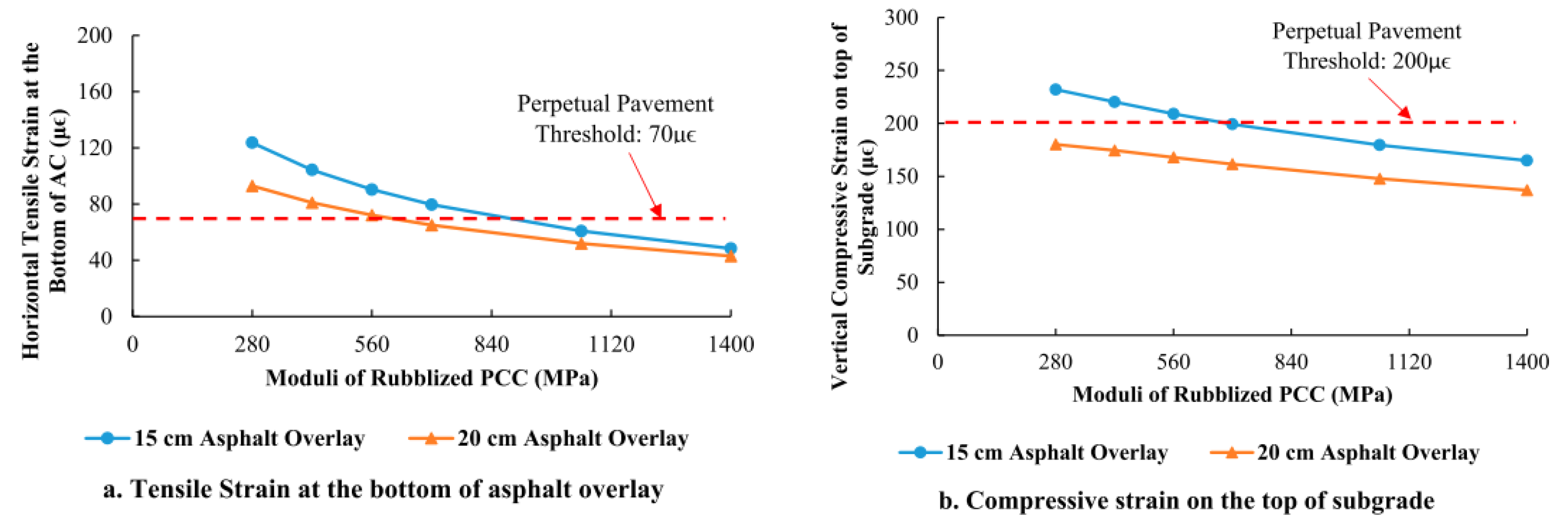

3.3. Study on Pavement Structure After Resonant Rubblization

4. Resonant Rubblization Equipment

5. Recommendations for Future Research

6. Conclusions

- The old concrete pavement slabs are fractured and transformed into an interlocking rubble structure by receiving impact excitation from the hammerhead at a frequency close to their natural frequency. When resonance occurs in the pavement slab, the excitation frequency of the vibrating hammer should be within the range of 0.7 to 1.3 times the natural frequency of the slab.

- The development of resonant rubblization technology represents an important trend in road rehabilitation engineering. Since its introduction, this technique has been widely applied and promoted globally in the field of road construction, with many countries establishing relevant industry standards. Compared to other concrete pavement breaking techniques, resonant rubblization offers broader applicability and superior performance in mitigating reflective cracking. It enhances the quality of road maintenance and reconstruction, ensures road safety, and supports the long-life development of pavements.

- The mechanism analysis of the resonant rubblization process is well developed but still has some limitations. When vehicular loads act on the edges or corners of finite-sized rectangular slabs, there are no corresponding analytical expressions for the resulting bending moments and deflections. Additionally, the existing theoretical foundation assumptions are inconsistent with actual sub-base structures, especially when slab structures are affected by thermal stresses or warping stresses, or when the subgrade is eroded by groundwater, leading to voids between the slab and the sub-base. These assumptions often fail to accurately reflect the complex working conditions of the foundation slab under such circumstances. There is further room for improvement in optimizing and enhancing the intelligence levels of resonant rubblization equipment. Implementing “Internet+” or intelligent unmanned operation models can allow for adaptation to complex and variable construction environments while reducing the impact of human factors on construction quality.

- The resonant rubblized layer behaves similarly to a flexible base, and its thickness is inversely proportional to the pavement deflection after overlay. Under load, the rubble layer is in a compressive state, while the bottom of the overlay layer is in tension. This structural behavior effectively distributes stress and strain, reducing tensile stress and strain at the bottom of the asphalt layer, thereby extending the remaining fatigue life of the resonantly rubblized pavement.

- The intelligence level of resonant rubblization equipment should be enhanced, with optimization in mechanical structure, signal processing, and algorithm design to prevent damage caused by hammer excitation. At the same time, further exploration should be conducted on the application of resonant rubblization technology in special engineering scenarios, such as road rehabilitation around airport runways and bridges. Research should also focus on minimizing environmental impacts during the rubblization process, including noise and dust control, as well as ensuring the safety of surrounding structures. The regeneration and utilization of waste materials from old cement concrete pavements should be promoted, and the advantages of resonant rubblization in energy conservation, environmental protection, and green efficiency should be highlighted.

Author Contributions

Funding

Conflicts of Interest

References

- Duranton, G.; Nagpal, M.A.G.; Turner, M. Transportation Infrastructure in the US. In Proceedings of the Economic Analysis and Infrastructure Investment, Cambridge, MA, USA, 15–16 November 2019; pp. 165–218. [Google Scholar]

- Dowd, Z.; Franz, A.Y.; Wasek, J.S. A Decision-Making Framework for Maintenance and Modernization of Transportation Infrastructure. IEEE Trans. Eng. Manag. 2020, 67, 42–53. [Google Scholar] [CrossRef]

- Wang, L.; Xue, X.; Zhao, Z.; Wang, Z. The Impacts of Transportation Infrastructure on Sustainable Development: Emerging Trends and Challenges. Int. J. Environ. Res. Public Health 2018, 15, 1172. [Google Scholar] [CrossRef]

- Zhang, R.; Sun, L.; Qiao, Y.; Sias, J.E.; Dave, E.V. Multidimensional comparative analysis of future climate change impacts on pavement infrastructure aging. Transp. Res. Part D Transp. Environ. 2025, 142, 104702. [Google Scholar] [CrossRef]

- Pais, J.C.; Amorim, S.I.R.; Minhoto, M.J.C. Impact of Traffic Overload on Road Pavement Performance. J. Transp. Eng. 2013, 139, 873–879. [Google Scholar] [CrossRef]

- Alkaissi, Z.A. Effect of high temperature and traffic loading on rutting performance of flexible pavement. J. King Saud Univ. Eng. Sci. 2020, 32, 1–4. [Google Scholar] [CrossRef]

- Selsal, Z.; Karakas, A.S.; Sayin, B. Effect of pavement thickness on stress distribution in asphalt pavements under traffic loads. Case Stud. Constr. Mater. 2022, 16, e01107. [Google Scholar] [CrossRef]

- Bhandari, S.; Luo, X.; Wang, F. Understanding the effects of structural factors and traffic loading on flexible pavement performance. Int. J. Transp. Sci. Technol. 2023, 12, 258–272. [Google Scholar] [CrossRef]

- Abu El-Maaty, A.E. Temperature Change Implications for Flexible Pavement Performance and Life. Int. J. Transp. Eng. Technol. 2017, 3, 1. [Google Scholar] [CrossRef]

- Gudipudi, P.P.; Underwood, B.S.; Zalghout, A. Impact of climate change on pavement structural performance in the United States. Transp. Res. Part D Transp. Environ. 2017, 57, 172–184. [Google Scholar] [CrossRef]

- Miao, Y.; Sheng, J.; Ye, J. An Assessment of the Impact of Temperature Rise Due to Climate Change on Asphalt Pavement in China. Sustainability 2022, 14, 9044. [Google Scholar] [CrossRef]

- Qiao, Y.; Dawson, A.R.; Parry, T.; Flintsch, G.; Wang, W. Flexible Pavements and Climate Change: A Comprehensive Review and Implications. Sustainability 2020, 12, 1057. [Google Scholar] [CrossRef]

- Kodippily, S.; Yeaman, J.; Henning, T.; Tighe, S. Effects of extreme climatic conditions on pavement response. Road Mater. Pavement Des. 2020, 21, 1413–1425. [Google Scholar] [CrossRef]

- Papagiannakis, A.T.; Masad, E.A. Pavement Design and Materials; Wiley: Hoboken, NJ, USA, 2024. [Google Scholar]

- Yang, S.; Park, H.; Baek, C. Fatigue Cracking Characteristics of Asphalt Pavement Structure under Aging and Moisture Damage. Sustainability 2023, 15, 4815. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Y.; Zhang, W.; Shen, S.; Wu, S.; Mohammad, L.N.; She, X. Effects of Field Aging on Material Properties and Rutting Performance of Asphalt Pavement. Materials 2023, 16, 225. [Google Scholar] [CrossRef]

- Xu, S.; Huang, J.; Tighe, S.; Zhang, C.; Ma, H.; Jia, X.; Zhou, X. Aging evaluation of base and SBS modified bitumens under the coupling effect of multiple aging factors. Constr. Build. Mater. 2022, 348, 128670. [Google Scholar] [CrossRef]

- Wang, H.; Guo, Y.; Wu, M.; Xiang, K.; Sun, S. Review on structural damage rehabilitation and performance assessment of asphalt pavements. Rev. Adv. Mater. Sci. 2021, 60, 438–449. [Google Scholar] [CrossRef]

- Huang, W.; Hu, J.; Luo, S. The technological innovation pathway for green, low-carbon, and durable pavement construction and maintenance. Sci. China Technol. Sci. 2024, 67, 3959–3961. [Google Scholar] [CrossRef]

- Fitts, G.L. Rubblization of Portland Cement Concrete Pavements, Transportation Research Circular No. E-C087; Transportation Research Board: Washington, DC, USA, 2006; pp. 20–30. [Google Scholar]

- Ramoneda, J.; Gerbaudo, F.; Bucciarelli, J.M.; Yaryez, R. Rigid pavements rehabilitation through Rubblizing technology. In Bearing Capacity Evaluation in the National Route N° A-008 (Santa Fe Province, Argentina), from Fundamentals to Applications in Geotechnics; IOS Press: Amsterdam, The Netherlands, 2015; pp. 19–29. [Google Scholar]

- Chen, D.H.; Huang, Q.; Ling, J. Shanghai’s Experience on Utilizing the Rubblization for Jointed Concrete Pavement Rehabilitation. J. Perform. Constr. Facil. 2008, 22, 398–407. [Google Scholar] [CrossRef]

- Ma, H.; Chen, J.; Deng, J. Analysis of the dynamic response for Kirchhoff plates by the element-free Galerkin method. J. Comput. Appl. Math. 2024, 451, 116093. [Google Scholar] [CrossRef]

- Xu, X.; Deng, Z. Proposal and Application of Kirchhoff Plate Model Boundary Value Problem Based on Simplified Strain Gradient Theory. Appl. Math. Mech. 2022, 43, 363–373. [Google Scholar]

- Nguyen, D.T.A.; Li, L.; Ji, H. Stable and accurate numerical methods for generalized Kirchhoff–Love plates. J. Eng. Math. 2021, 130, 6. [Google Scholar] [CrossRef]

- Ozenda, O.; Virga, E.G. On the Kirchhoff-Love Hypothesis (Revised and Vindicated). J. Elast. 2021, 143, 359–384. [Google Scholar] [CrossRef]

- Mubaraki, A.M. Asymptotic Consideration of Rayleigh Waves on a Coated Orthorhombic Elastic Half-Space Reinforced Using an Elastic Winkler Foundation. Math. Comput. Appl. 2023, 28, 109. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, J.; Li, X. Bending Analysis of Stepped Rectangular Plates Resting on an Elastic Half-Space Foundation. Buildings 2023, 13, 1671. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Pan, E.; Wang, Q. Dynamic loading in a transversely isotropic and layered elastic half-space. Int. J. Mech. Sci. 2023, 260, 108626. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, L.; Shi, D.; Zhao, Z.; Lü, X.; Duan, X. Application of nonlinear soil resistance-pile lateral displacement curve based on Pasternak foundation model in foundation pit retaining piles. Yan Tu Li Xue 2022, 43, 2581–2591. [Google Scholar]

- Hadji, L.; Avcar, M.; Zouatnia, N. Natural frequency analysis of imperfect FG sandwich plates resting on Winkler-Pasternak foundation. Mater. Today Proc. 2022, 53, 153–160. [Google Scholar] [CrossRef]

- Alazwari, M.A.; Zenkour, A.M. A Quasi-3D Refined Theory for the Vibration of Functionally Graded Plates Resting on Visco-Winkler-Pasternak Foundations. Mathematics 2022, 10, 716. [Google Scholar] [CrossRef]

- Yang, C.; Huang, B.; Guo, Y.; Wang, J. Characterization of delamination effects on free vibration and impact response of composite plates resting on visco-Pasternak foundations. Int. J. Mech. Sci. 2021, 212, 106833. [Google Scholar] [CrossRef]

- Wang, Y.H.; Tham, L.G.; Tsui, Y.; Yue, Z.Q. Plate on layered foundation analyzed by a semi-analytical and semi-numerical method. Comput. Geotech. 2003, 30, 409–418. [Google Scholar] [CrossRef]

- Xiang, H.J.; Shi, Z.F.; Wang, S.J.; Mo, Y.L. Periodic materials-based vibration attenuation in layered foundations: Experimental validation. Smart Mater. Struct. 2012, 21, 112001–112003. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J. Delamination of layered structures on elastic foundation. Eng. Fract. Mech. 2011, 78, 1055–1066. [Google Scholar] [CrossRef]

- He, L.; Chen, X.; Wang, Z.; Han, Y.; Su, T.; Dai, G.; Zhang, E.; Long, Z. A case study on the bearing characteristics of a bottom uplift pile in a layered foundation. Sci. Rep. 2022, 12, 22457. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Tutumluer, E.; Kwon, J. Nonlinear Pavement Foundation Modeling for Three-Dimensional Finite-Element Analysis of Flexible Pavements. Int. J. Geomech. 2009, 9, 195–208. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, Y.; Guo, X.; Liu, Q.; Zhang, X.; Xie, X. Functional zoning optimization design of cemented sand and gravel dam based on modified Duncan-Chang nonlinear elastic model. Case Stud. Constr. Mater. 2022, 17, e01511. [Google Scholar] [CrossRef]

- Ouzizi, A.; Abdoun, F.; Azrar, L. Nonlinear dynamics of beams on nonlinear fractional viscoelastic foundation subjected to moving load with variable speed. J. Sound Vibr. 2022, 523, 116730. [Google Scholar] [CrossRef]

- Javadi, M.; Rahmanian, M. Nonlinear vibration of fractional Kelvin–Voigt viscoelastic beam on nonlinear elastic foundation, Commun. Nonlinear Sci. Numer. Simul. 2021, 98, 105784. [Google Scholar] [CrossRef]

- Boral, S.; Nath, S.; Sahoo, T.; Meylan, M.H. The role of viscoelastic foundation on flexural gravity wave blocking in shallow water. AIP Adv. 2021, 11, 65317. [Google Scholar] [CrossRef]

- Pham, Q.; Tran, V.K.; Tran, T.T.; Nguyen, V.C.; Zenkour, A.M. Nonlocal higher-order finite element modeling for vibration analysis of viscoelastic orthotropic nanoplates resting on variable viscoelastic foundation. Compos. Struct. 2023, 318, 117067. [Google Scholar] [CrossRef]

- Cai, W.; Chen, W.; Xu, W. Fractional modeling of Pasternak-type viscoelastic foundation. Mech. Time Depend. Mater. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Younesian, D.; Hosseinkhani, A.; Askari, H.; Esmailzadeh, E. Elastic and viscoelastic foundations: A review on linear and nonlinear vibration modeling and applications. Nonlinear Dyn. 2019, 97, 853–895. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, J.; Huang, M.; Yu, J. Winkler load-transfer analysis for pipelines subjected to surface load. Comput. Geotech. 2019, 111, 147–156. [Google Scholar] [CrossRef]

- Shitikova, M.; Krusser, A. Force driven vibrations of nonlinear plates on a viscoelastic winkler foundation under the harmonic moving load. Int. J. Comput. Civ. Struct. Eng. 2021, 17, 161–180. [Google Scholar]

- Zhou, Y.R.; Yan, X.B.; Wang, M.X.; Liu, Y.C.; Wen, P.H. Dynamic fundamental solution of dipole for Kirchhoff plate on Winkler-Pasternak foundation. Comput. Struct. 2024, 304, 107498. [Google Scholar] [CrossRef]

- He, D.; Li, P.; Zhang, Z. Analysis of a Simplified Model of a Rigid Rocking Block on Winkler Foundation. Sustainability 2023, 15, 5095. [Google Scholar] [CrossRef]

- Erbaş, B.; Kaplunov, J.; Kiliç, G. Asymptotic analysis of 3D dynamic equations in linear elasticity for a thin layer resting on a Winkler foundation. IMA J. Appl. Math. 2022, 87, 707–721. [Google Scholar] [CrossRef]

- Althobaiti, S.N.; Kaplunov, J.; Prikazchikov, D.A. An edge moving load on an orthotropic plate resting on a Winkler foundation. Procedia Eng. 2017, 199, 2579–2584. [Google Scholar] [CrossRef]

- Wang, M.X.; Yan, X.B.; Liu, Y.C.; Wen, P.H. Method of fundamental solution for thin plate resting on elastic foundation with in-plane forces. Eng. Anal. Bound. Elem. 2024, 164, 105767. [Google Scholar] [CrossRef]

- Ike, C. Flexural Analysis of Kirchhoff plates on Winkler foundations using finite Fourier sine integral transform method. Math. Model. Eng. Probl. 2017, 4, 145–154. [Google Scholar] [CrossRef]

- Gou, Z.L. Simulation and Engineering Application Study on Resonant Rubblization of Old Cement Concrete Pavement. Master’s Thesis, Guangxi University, Nanning, China, 2023; pp. 13–25. [Google Scholar]

- Hou, F.; Li, T.; Li, X.; Li, Y.; Guo, M. Research on the Anti-Reflective Cracking Performance of a Full-Depth Asphalt Pavement. Sustainability 2021, 13, 9499. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Yang, J.; Wang, H. Numerical Simulation on Reflective Cracking Behavior of Asphalt Pavement. Appl. Sci. 2021, 11, 7990. [Google Scholar] [CrossRef]

- Beskou, N.D.; Theodorakopoulos, D.D. Dynamic effects of moving loads on road pavements: A review. Soil Dyn. Earthq. Eng. 2011, 31, 547–567. [Google Scholar] [CrossRef]

- Sun, L. Analytical dynamic displacement response of rigid pavements to moving concentrated and line loads. Int. J. Solids Struct. 2006, 43, 4370–4383. [Google Scholar] [CrossRef]

- Vázquez, V.F.; Paje, S.E. Dynamic Stiffness Assessment of Construction Materials by the Resonant and Non-resonant Methods. J. Nondestruct. Eval. 2016, 35, 34. [Google Scholar] [CrossRef]

- Ma, X.; Quan, W.; Dong, Z.; Dong, Y.; Si, C. Dynamic response analysis of vehicle and asphalt pavement coupled system with the excitation of road surface unevenness. Appl. Math. Model. 2022, 104, 421–438. [Google Scholar] [CrossRef]

- Shi, R.C. Study on the Natural Frequency of Existing Cement Concrete Pavement Slabs and Its Application in Resonant Rubblization Technology. Master’s Thesis, Chang’an University, Xi’an, China, 2016; pp. 23–36. [Google Scholar]

- Andryanti, D.M.; Phan, T.M.; Lee, D.; Park, D. Impact of cement content in cement bound materials on the reflection cracking performance of asphalt pavements. Case Stud. Constr. Mater. 2024, 20, e03229. [Google Scholar] [CrossRef]

- Zeng, Z.; Underwood, B.S.; Kim, Y.R. A state-of-the-art review of asphalt mixture fracture models to address pavement reflective cracking. Constr. Build. Mater. 2024, 443, 137674. [Google Scholar] [CrossRef]

- Xu, Z. Application of Resonant Rubblization Technology in the Crushing of Cement Concrete Pavement. Sci. Technol. Innov. 2022, 20, 137–140. [Google Scholar]

- Li, S.; Ma, Y.B.; Liu, Z.H.; Xiang, Y.G. Study on Control Parameters and Structural Modulus of Resonant Rubblization. Inn. Mong. Highw. Transp. 2019, 1, 1–4. [Google Scholar]

- Zhang, H.; Ma, G.C.; Zhang, M.J. Analysis on the Mechanism of Reflective Crack Suppression in Asphalt Pavement by Graded Crushed Stone Base. J. Shenyang Jianzhu Univ. 2011, 27, 247–252. [Google Scholar]

- Yu, Q.D.; Xiao, M.W.Y.J.; Hua, W.J.; Wang, X.M.; Wang, W.D.; Chen, X.B. Experimental Study on Strength and Deformation Characteristics of Permeable Subgrade Graded Crushed Stone Fillers. Chin. J. Rock Mech. Eng. 2022, 41, 614–630. [Google Scholar]

- Gurries, R.A. Resonant system support. J. Acoust. Soc. Am. 1986, 80, 996. [Google Scholar] [CrossRef]

- LaForce, R. Performance of Colorado’s First Rubblization Project on I76 Near Sterling (No. CDOT-DTD-R-2005-20); Department of Transportation Research: Denver, CO, USA, 2006. [Google Scholar]

- Rada, G.R. Rehabilitation of PCC Pavements Using Fracture Techniques and HMA Overlays. 1992, pp. 37–55. Available online: https://docs.lib.purdue.edu/roadschool/1992/presentations/9 (accessed on 21 May 2025).

- Khaled, K.; Miley, W.; Armaghani, J. Rubblization of Concrete Pavements. Transp. Res. Rec. 1999, 166–170. [Google Scholar]

- Boyer, R.; Buncher, M. Rubblizing Concepts—Heavy Load Concrete Airfield Pavements. Adv. Airfield Pavements 2001, 1, 289–298. [Google Scholar]

- Liu, L.; Wu, S.; Xie, W.; Yao, G. Numerical analysis of rehabilitated concrete pavement using crack-and-seating technique. Int. J. Pavement Eng. 2021, 22, 1250–1262. [Google Scholar] [CrossRef]

- West, R.; Gu, F.; Bowers, B.F. Benefits of Rehabilitating Concrete Pavements with Slab Fracturing and Asphalt Overlays NCAT Report 20-03; NACT: Auburn, AL, USA, 2020. [Google Scholar]

- Lu, P.; Huang, Y. Assessing Condition of Rehabilitated Concrete Pavement with Slab Fracturing and Asphalt Overlay Using Distributed Fiber Optic Sensors; Transportation Research Board: Washington, DC, USA, 2024. [Google Scholar]

- Ramirez, L.; Morian, D. Structural Characterization of Fractured Portland Cement Concrete Pavements in Pennsylvania from Falling Weight Deflectometer Data. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 781–793. [Google Scholar] [CrossRef]

- Zhu, J.; Sargand, S.; Green, R.; Khoury, I. Forensic study of premature failures with unbonded concrete overlay on interstate 70 in Ohio. Int. J. Forensic Eng. 2018, 4, 1–19. [Google Scholar] [CrossRef]

- Gu, F.; West, R.C.; Bowers, B.F.; Willis, R. Influences of slab fracturing techniques on long-term performance of rehabilitated PCC pavements. Int. J. Pavement Eng. 2022, 23, 1422–1432. [Google Scholar] [CrossRef]

- Moses, A.; Chen, Q.; Zhang, Z. Performance Comparison of Break and Seat and Rubblization Rehabilitation Techniques for Reflection-Crack Mitigation: Case Study in Louisiana. Transp. Res. Rec. 2023, 2267, 837–851. [Google Scholar]

- Kim, S.; Gopalakrishnan, K.; Ceylan, H. Structural Characterization of Iowa’s Rubblized PCC Pavements. J. Transp. Eng. 2012, 138, 406–413. [Google Scholar] [CrossRef]

- Ozdemir, Z.; Coulier, P.; Lak, M.A.; François, S.; Lombaert, G.; Degrande, G. Numerical evaluation of the dynamic response of pipelines to vibrations induced by the operation of a pavement breaker. Soil Dyn. Earthq. Eng. 2013, 44, 153–167. [Google Scholar] [CrossRef]

- Li, N. Analysis and Performance Evaluation of Inverted Flexible Base Asphalt Pavement Structure on the Guanghe Expressway. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2022; pp. 35–41. [Google Scholar]

- Li, H. Research on Non-destructive Testing Technology for Thickness and Density of Asphalt Pavement Layers Based on 3D Ground Penetrating Radar. Master’s Thesis, Guangxi University, Nanning, China, 2020; pp. 19–24. [Google Scholar]

- Santos, A.G.; Ferrari, A.K. Influência do resíduo de PVC como agregado no concreto para peças de pavimentos intertravados. Ambiente Construído 2019, 19, 39–51. [Google Scholar] [CrossRef]

- Han, L.; Zhang, S.; Zhang, Z.; Gao, T. Mechanical Analysis of Preventing Reflection Cracks Based on Stress Absorbing Layer. Adv. Civ. Eng. 2022, 10, 1155. [Google Scholar] [CrossRef]

- Dhakal, N.; Elseifi, M.A.; Zhang, Z. Mitigation strategies for reflection cracking in rehabilitated pavements—A synthesis. Int. J. Pavement Res. Technol. 2016, 9, 228–239. [Google Scholar] [CrossRef]

- Martins, H.M.; Al-Aithan, H.I.; Al-Khalifah, N.H. Rubblization of Shaybah Airport Runway Pavement—A Sustainable Circular Economy Solution. Open J. Civ. Eng. 2022, 12, 231–246. [Google Scholar] [CrossRef]

- Lei, B.; Kong, L.; Guo, Y.; Sun, B.; Li, X.; Wu, K.; Tam, V.W.; Li, W. Optimizing decarbonation and sustainability of concrete pavement: A case study. Case Stud. Constr. Mater. 2024, 21, e03574. [Google Scholar] [CrossRef]

- Xia, H.Y. Research on the Application of Resonant Rubblization Technology and Asphalt Layer Overlay Techniques. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2013; pp. 26–31. [Google Scholar]

- Hu, W.F.; Li, G.L.; Zhang, L.; Wen, L.D.; Shen, Y.J. Study on Construction Technology of Asphalt Pavement Reconstruction Using Resonant Rubblization of Old Cement Pavement. China Highw. 2022, 11, 172–175. [Google Scholar]

- Zhao, Y.; Feng, S.; Peng, M.; Zhang, D.; Zhang, X. In-Situ Experimental Analysis of Acceleration Response of Mountain Tunnel Lining to Rubblization-Induced Vibrations; Zhang, D., Huang, X., Eds.; Springer: Singapore, 2018; pp. 319–328. [Google Scholar]

- Peng, M.; Zhang, D.; Zhao, Y.; Zhang, X.; Huang, Z. Dynamic Response of Tunnel Lining to Resonance Rubblization Induced Vibration in Pavement Renewal; Springer: Singapore, 2018; pp. 422–431. [Google Scholar]

- Nair, H.B.K.D. Evaluation of the Terminal Boulevard (SR 406) Concrete Rubblization Project; Virginia Transportation Research Council: Charlottesville, VA, USA, 2019. [Google Scholar]

- Yang, S.G. Coupled Analysis of Temperature and Load on Asphalt Overlay on Rubblized Old Cement Pavement. Master’s Thesis, Taiyuan University of Science and Technology, Taiyuan, China, 2021; pp. 33–38. [Google Scholar]

- Liu, Z.; Cui, B.; Yang, Q.; Gu, X. Sensor-Based Structural Health Monitoring of Asphalt Pavements with Semi-Rigid Bases Combining Accelerated Pavement Testing and a Falling Weight Deflectometer Test. Sensors 2024, 24, 994. [Google Scholar] [CrossRef] [PubMed]

- Shen, A.Q.; Jin, X.K.; Guo, Y.C.; He, Z.M.; Wang, S.N. Analysis of Mechanical Response of Semi-rigid Asphalt Pavement in Northern Shaanxi under Coupled Fields. J. Chang. Univ. 2022, 42, 1–11. [Google Scholar]

- Zhang, C.; He, H.; Xue, Y.; Luo, Z. Comparative Test and Analysis of Falling-Ball Instrument and FWD Deflection Detection Method, IOP Conference Series. Earth Environ. Sci. 2020, 514, 22065. [Google Scholar]

- Han, X.; Luo, Z.; Wang, M.; Xue, Y. Deflection detection of the cement stabilizing layer based on the falling ball test method, IOP Conference Series. Earth Environ. Sci. 2020, 580, 12088. [Google Scholar]

- Sanjay, R.; Tejeshwini, S.; Mamatha, K.H.; Dinesh, S.V. Comparative study on structural evaluation of flexible pavement using BBD and FWD. Mater. Today Proc. 2022, 60, 608–615. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; Gong, H.; Jia, X.; Xiao, R.; Huang, H.; Huang, B. Numerical investigation of pavement responses under TSD and FWD loading. Constr. Build. Mater. 2022, 318, 126014. [Google Scholar] [CrossRef]

- Zhang, Z.D. Deep Exploration on the Reconstruction of Urban Old Cement Concrete Pavement by Rubblization and Overlaying with Asphalt Concrete. Urban Constr. Theory Res. 2018, 16, 65. [Google Scholar]

- Yu, L.; Wang, L.; Pei, J.; Li, R.; Zhang, J.; Cheng, S. Structural optimization study based on crushing of semi-rigid base. Electron. Res. Arch. 2023, 31, 1769–1788. [Google Scholar] [CrossRef]

- Wang, X.; Zhong, Y. Reflective crack in semi-rigid base asphalt pavement under temperature-traffic coupled dynamics using XFEM. Constr. Build. Mater. 2019, 214, 280–289. [Google Scholar] [CrossRef]

- Kim, K.W.; Doh, Y.S.; Lim, S. Mode I reflection cracking resistance of strengthened asphalt concretes. Constr. Build. Mater. 1999, 13, 243–251. [Google Scholar] [CrossRef]

- Su, P.; Li, M. Review of Reflection Cracking Preventive Technologies on Asphalt Pavement with Semi-Rigid Base Course. J. Phys. Conf. Ser. 2020, 1549, 32108. [Google Scholar] [CrossRef]

- Xia, X.; Han, D.; Zhao, Y.; Xie, Y.; Zhou, Z.; Wang, J. Investigation of asphalt pavement crack propagation based on micromechanical finite element: A case study. Case Stud. Constr. Mater. 2023, 19, e02247. [Google Scholar] [CrossRef]

- Meng, K.; Zhong, M.; Jing, W.; Hu, X.; Lu, Z.; Lu, W. Study on the Concrete Pavement Performance of Crushed Stone Base Prepared with High Proportion of Recycled Construction Waste Aggregate. Eng. Res. Express. 2025, 10, 2631–8695. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, F.; Gou, C.; Chen, J.; Wei, L.; Yang, X. Simulation and application research of rubblization for aged cement concrete pavement. Constr. Build. Mater. 2024, 457, 139424. [Google Scholar] [CrossRef]

- Norouzi, A.; Kim, D.; Kim, Y.R. Numerical evaluation of pavement design parameters for the fatigue cracking and rutting performance of asphalt pavements. Mater. Struct. 2016, 49, 3619–3634. [Google Scholar] [CrossRef]

- AlKheder, S. Environment-friendly recycled asphalt pavement design for road maintenance applications. Environ. Dev. Sustain. 2022, 24, 14210–14234. [Google Scholar] [CrossRef]

- Luo, Z.; Xiao, F.; Sharma, R. Efficient reliability-based approach for mechanistic-empirical asphalt pavement design. Constr. Build. Mater. 2014, 64, 157–165. [Google Scholar] [CrossRef]

- Liu, Y. Research on the Application of Resonant Rubblization Pavement Structure. Master’s Thesis, Xinjiang University, Urumqi, China, 2020; pp. 26–33. [Google Scholar]

- Zhao, W.; Yang, Q.; Wu, W.; Liu, J. Research on cracking and mechanical responses of semi-rigid base under falling weight impact. Constr. Build. Mater. 2024, 411, 134718. [Google Scholar] [CrossRef]

- Wang, J.H.; Li, W.H.; Li, J.; Fu, P.; Xu, J. Development of a Resonant Fragmentation Machine. Constr. Mach. 2021, 9, 39–44. [Google Scholar]

- Mahdi, M.; Wu, Z. Potential Application of using Multi Head Pavement Breaker for Concrete Pavement Rubblization over Weak Subgrade. In Pavement Materials, Structures, and Performance; ASCE: Reston, VA, USA, 2014; pp. 262–272. [Google Scholar]

- Wang, X.B. Pre-resonance Synchronization Characteristics of an Inertial Vibrating Crusher System. China Min. 2020, 29, 185–192. [Google Scholar]

- Jiang, X.; Zhang, P.; Peng, J. Resonant frequency and resonant amplitude control of a RCPBV. J. Vib. Shock. 2011, 30, 249–253. [Google Scholar]

- Huang, W. Dynamic Study of the Vibration System of a Resonant Crusher. Master’s Thesis, Chang’an University, Xi’an, China, 2015; pp. 36–41. [Google Scholar]

- Zhu, S.H.; Yang, B.; Hou, X.X.; Lv, G.S.; He, M. Resonant Pavement Breaker Vibration System Design and Simulation. Adv. Mater. Res. 2014, 850–851, 266–269. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, G.; Yang, B.; Wang, C. The Finite Element Analysis and Optimization on a Special Vehicle. In SAE Technical Paper; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Guan, G. Optimization and Simulation of the Vibrating Hydraulic System of a Resonant Crusher. Master’s Thesis, Chang’an University, Xi’an, China, 2017; pp. 26–33. [Google Scholar]

- Chen, K.D. Study on the Dynamic Performance of the Vibrating System of a Fully Floating Resonant Crusher. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2019; pp. 36–45. [Google Scholar]

- Editorial Board of China Journal of Highway and Transport. Review of Academic Research on Road Construction Machinery in China—2018. China J. Highw. Transp. 2018, 31, 1–164. [Google Scholar]

- Li, J.X.; Fan, C.G.; Li, Y.D. Study on the Vibration Mechanism and Parameters of Resonant Stone Crushers. J. Highw. Transp. Res. Dev. 2020, 37, 15–21. [Google Scholar]

| Plan | Applicable Road Conditions | Effect on Reflective Crack Prevention | Construction Characteristics | Construction Cost |

|---|---|---|---|---|

| Full Slab Removal and Repaving | Pavement condition rating (PCR) is poor | Only delays reflective cracks, cannot prevent them completely | Long construction period, noisy and dusty | High cost, generates waste material |

| Milling and Removal | Pavement condition rating (PCR) is excellent | Poor effect on reflective crack prevention | Short construction period, noisy and dusty | Low cost |

| Resonant Rubblization | Pavement condition rating (PCR) is fair or better | Significantly reduces reflective cracks | Moderate construction period, relatively noisy and dusty | Moderate cost, reuses old pavements, no waste generated |

| Concrete Pavement Rubblization Technique | Fragment Size | Applicable Thickness | Risk of Reflective Cracking | Construction Speed |

|---|---|---|---|---|

| Crack and Seat [73,74,75] | 30–60 cm | <20 cm | High | Fast |

| Break and Seat [76,77] | 15–30 cm | 20–30 cm | Medium | Moderate |

| Rubblization | <15 cm | Unlimited (including severely damaged pavements) | Low | Slow |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, S.; Sun, D.; Hu, Y.; Lu, S.; Qiu, Z.; Zhang, S.; Wang, L.; Jiang, S.; Han, T.; Gao, Y. Reconstruction of Old Pavements Based on Resonant Rubblization Technology: A Review of Technological Progress, Engineering Applications, and Intelligent Development. Buildings 2025, 15, 2165. https://doi.org/10.3390/buildings15132165

Ding S, Sun D, Hu Y, Lu S, Qiu Z, Zhang S, Wang L, Jiang S, Han T, Gao Y. Reconstruction of Old Pavements Based on Resonant Rubblization Technology: A Review of Technological Progress, Engineering Applications, and Intelligent Development. Buildings. 2025; 15(13):2165. https://doi.org/10.3390/buildings15132165

Chicago/Turabian StyleDing, Sibo, Dehuan Sun, Yongtao Hu, Shuang Lu, Zedong Qiu, Shuo Zhang, Lei Wang, Shaowei Jiang, Tao Han, and Yingli Gao. 2025. "Reconstruction of Old Pavements Based on Resonant Rubblization Technology: A Review of Technological Progress, Engineering Applications, and Intelligent Development" Buildings 15, no. 13: 2165. https://doi.org/10.3390/buildings15132165

APA StyleDing, S., Sun, D., Hu, Y., Lu, S., Qiu, Z., Zhang, S., Wang, L., Jiang, S., Han, T., & Gao, Y. (2025). Reconstruction of Old Pavements Based on Resonant Rubblization Technology: A Review of Technological Progress, Engineering Applications, and Intelligent Development. Buildings, 15(13), 2165. https://doi.org/10.3390/buildings15132165