Critical Review and Benchmark Proposal on FE Modeling for Patch Loading Resistance of Slender Steel Plate Girders in Launched Bridges

Abstract

1. Introduction

1.1. Background

1.2. Incremental Launching Method

1.3. Research Methodology

- -

- Selection of relevant experimental campaigns from the literature.

- -

- Development of a nonlinear Finite Element model capable of capturing key aspects of the structural response, including material and geometric nonlinearity, boundary conditions, and initial imperfections.

- -

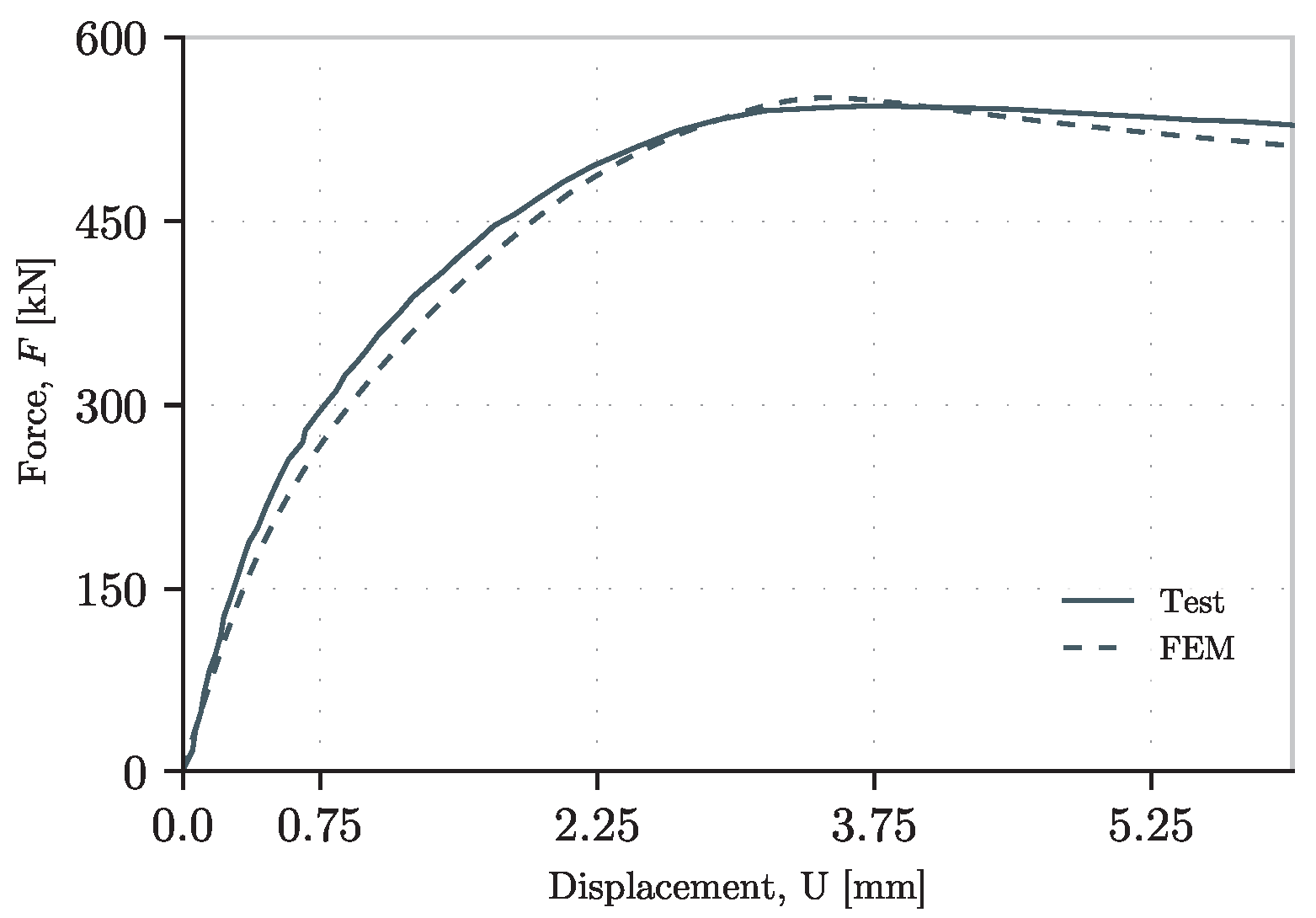

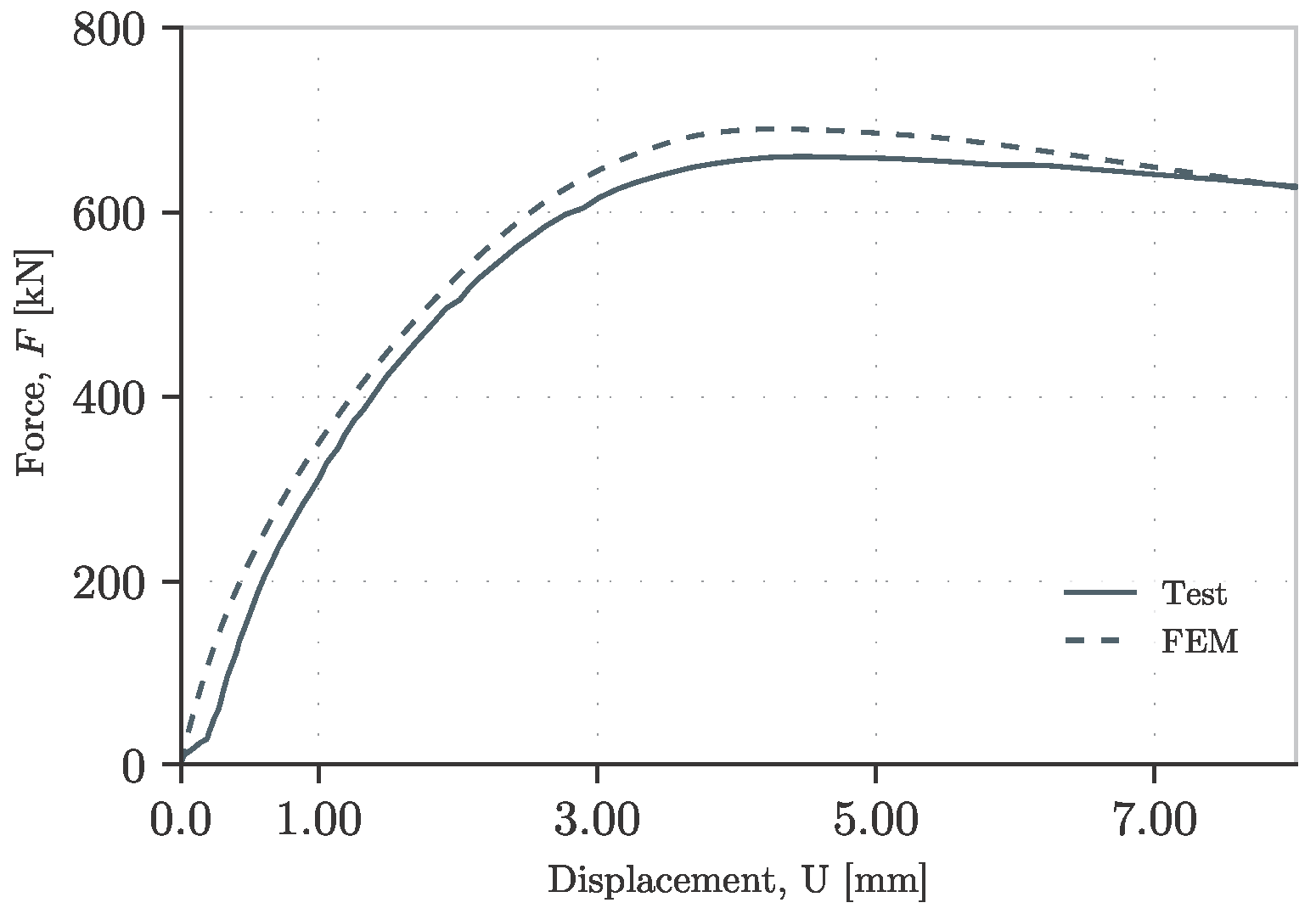

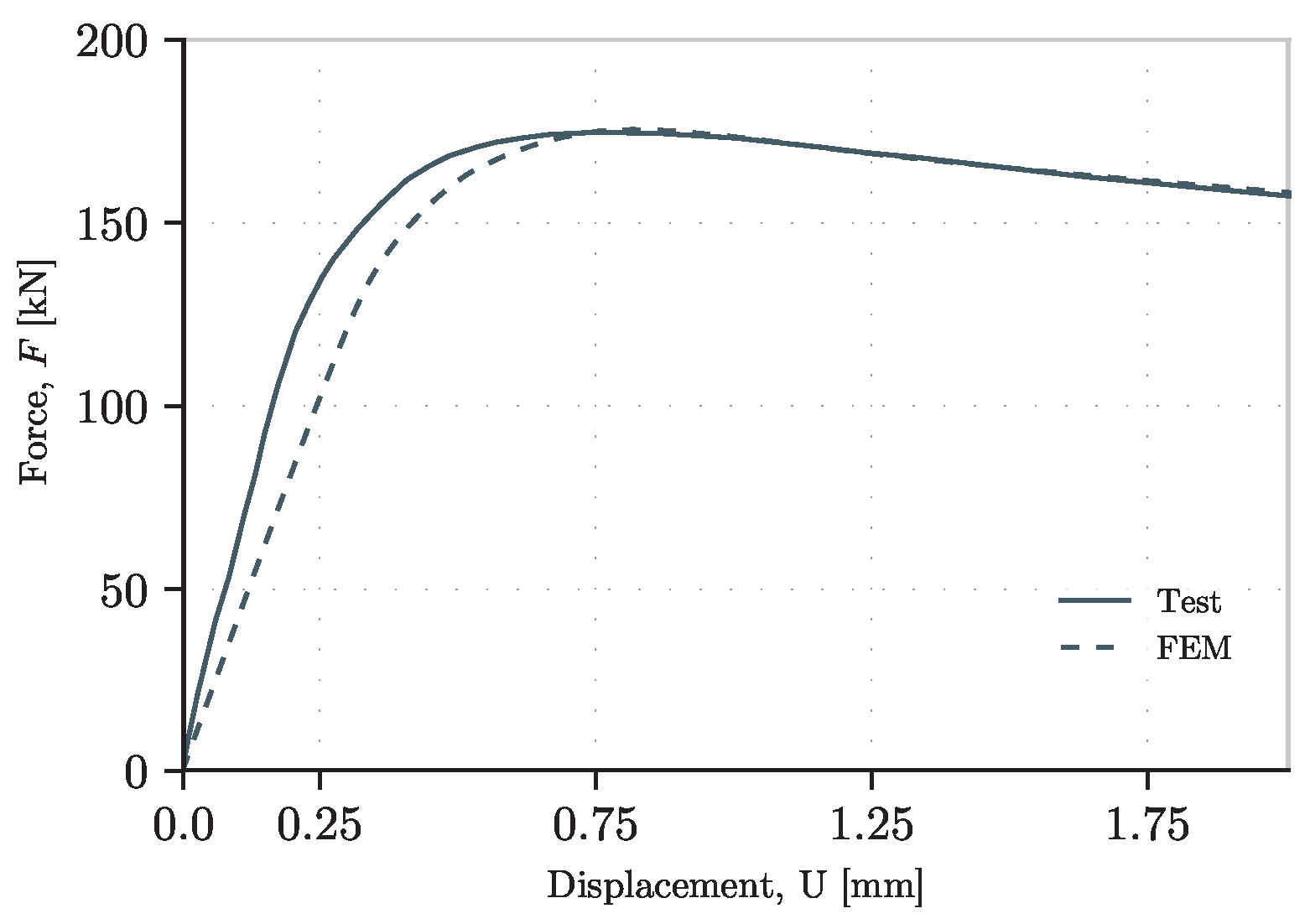

- Calibration and validation of the FE model against experimental results, based on force–displacement curves and ultimate load resistance.

- -

- Systematic parametric studies using the validated FE model to assess the influence of modeling choices on predicted behavior.

2. Nonlinear Finite Element Model

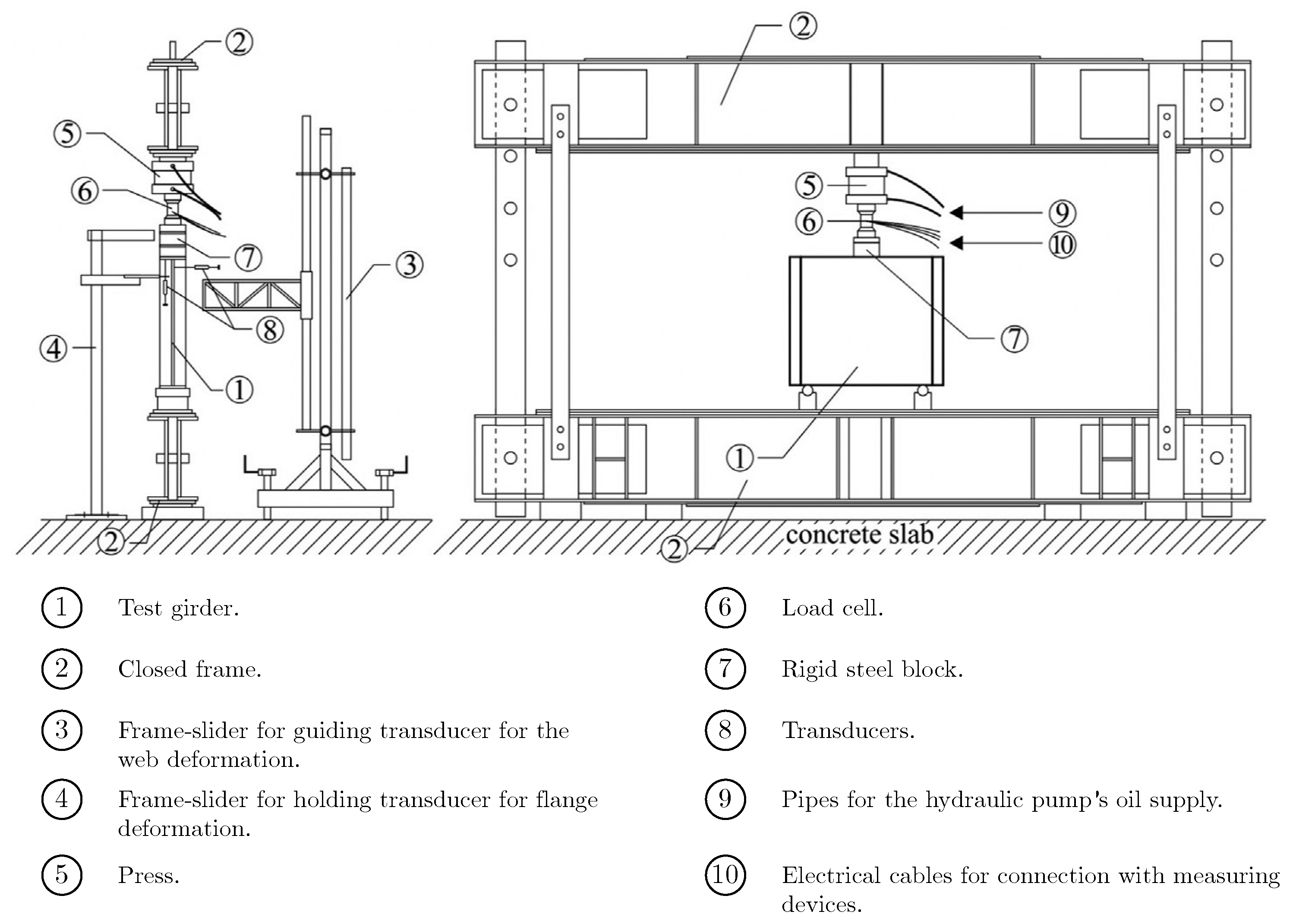

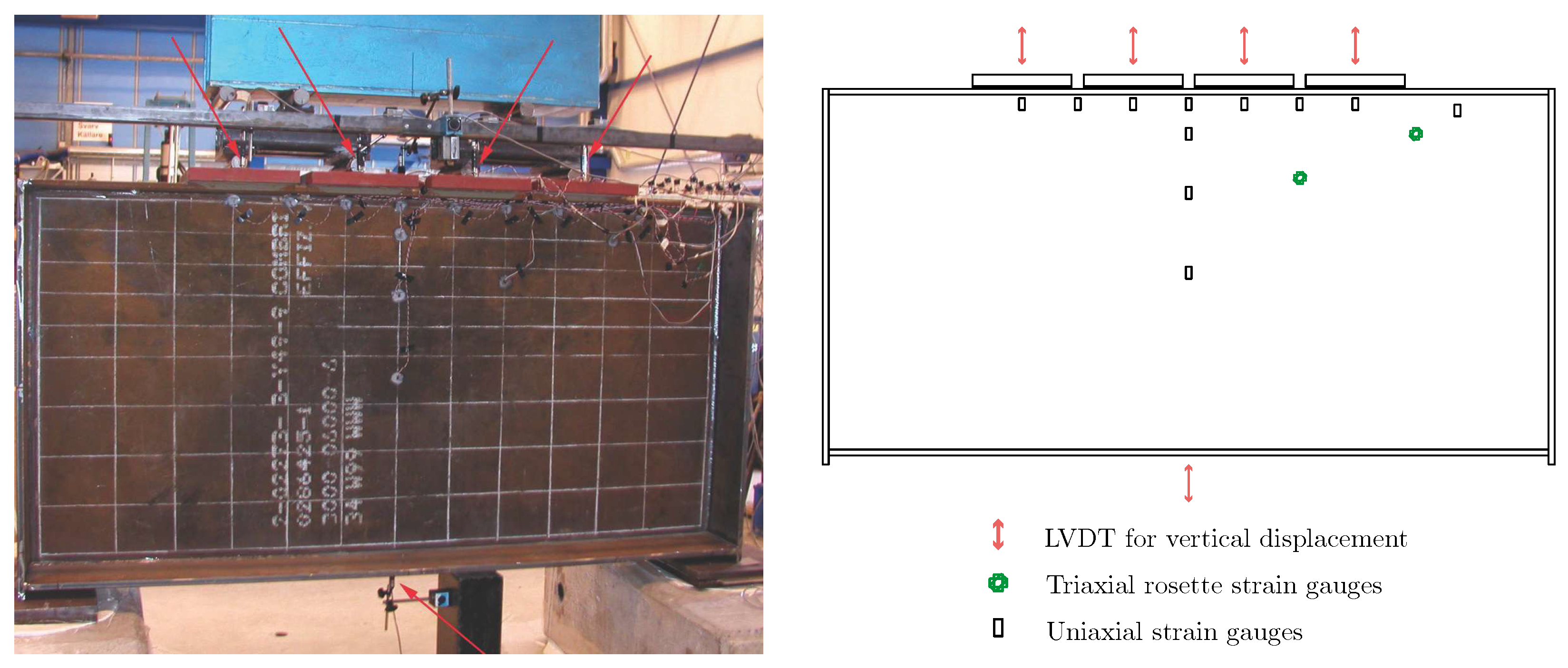

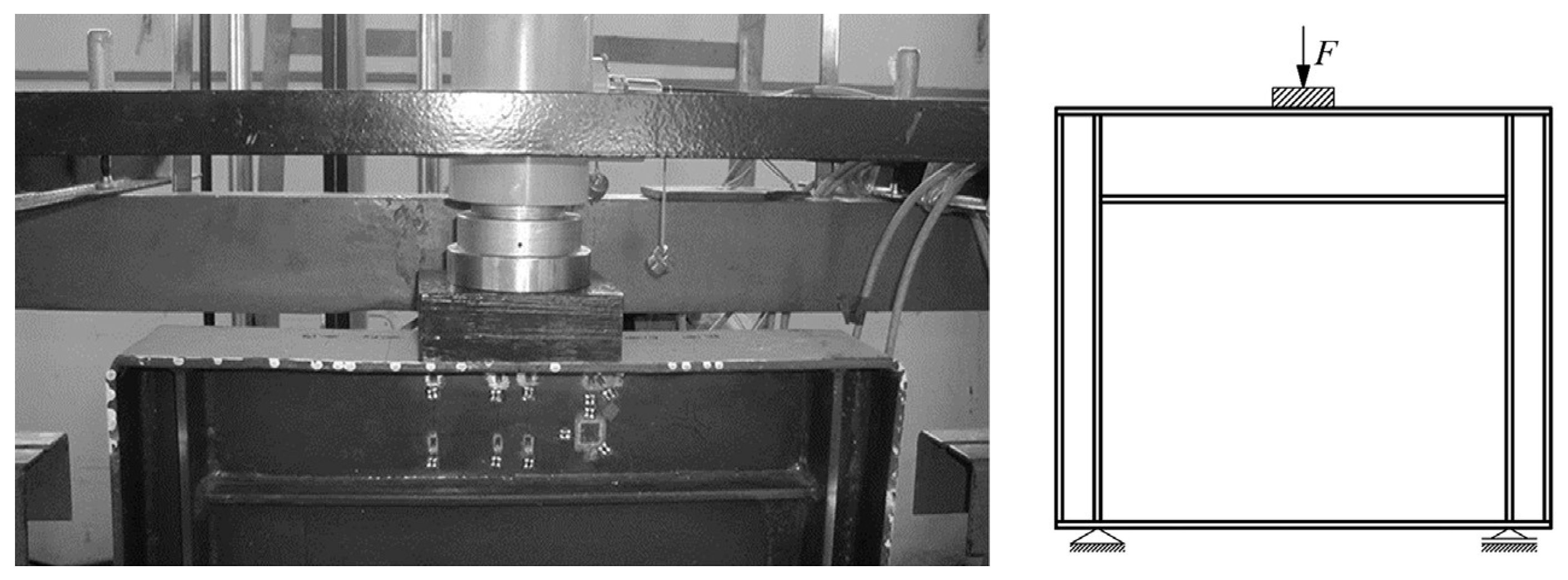

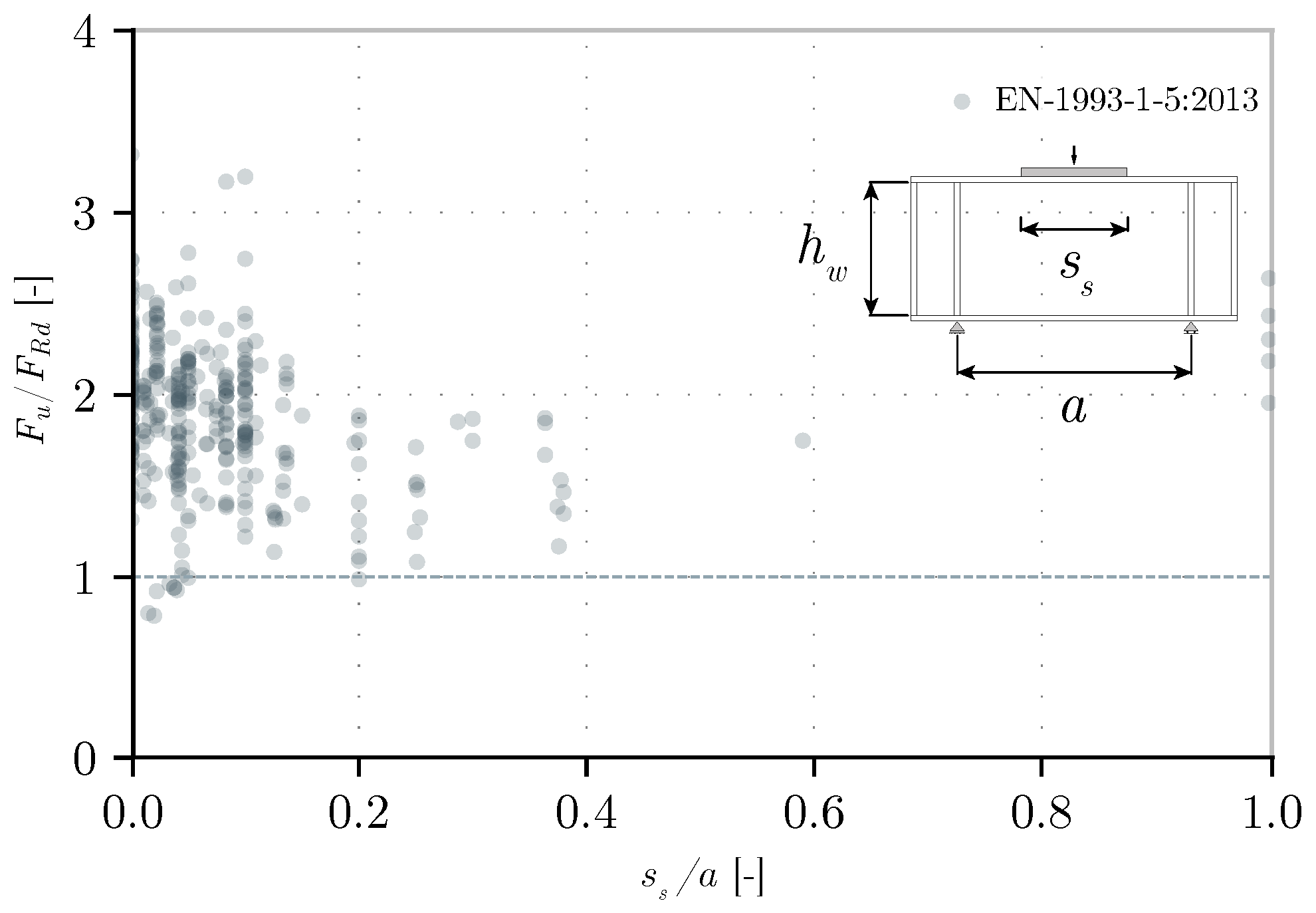

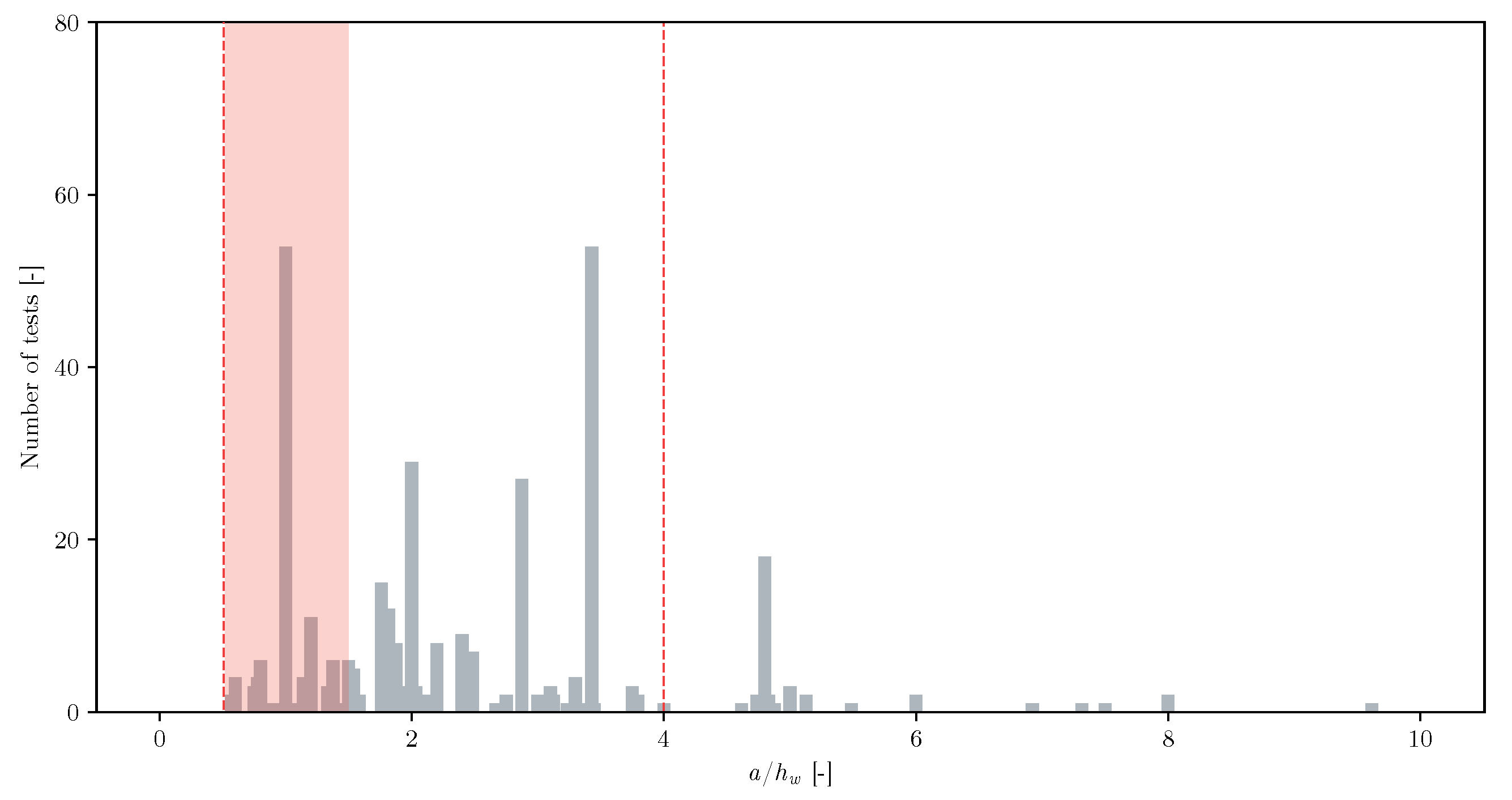

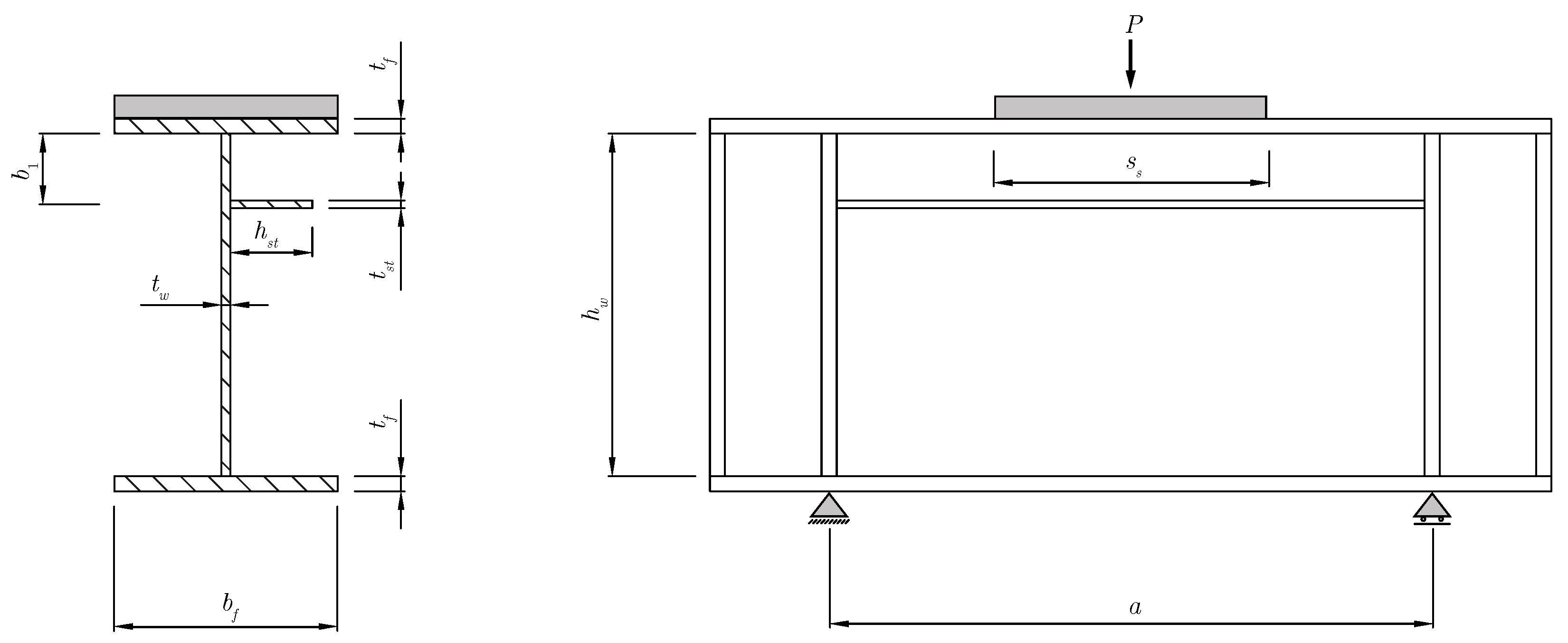

2.1. Reference Case Studies

2.2. Description

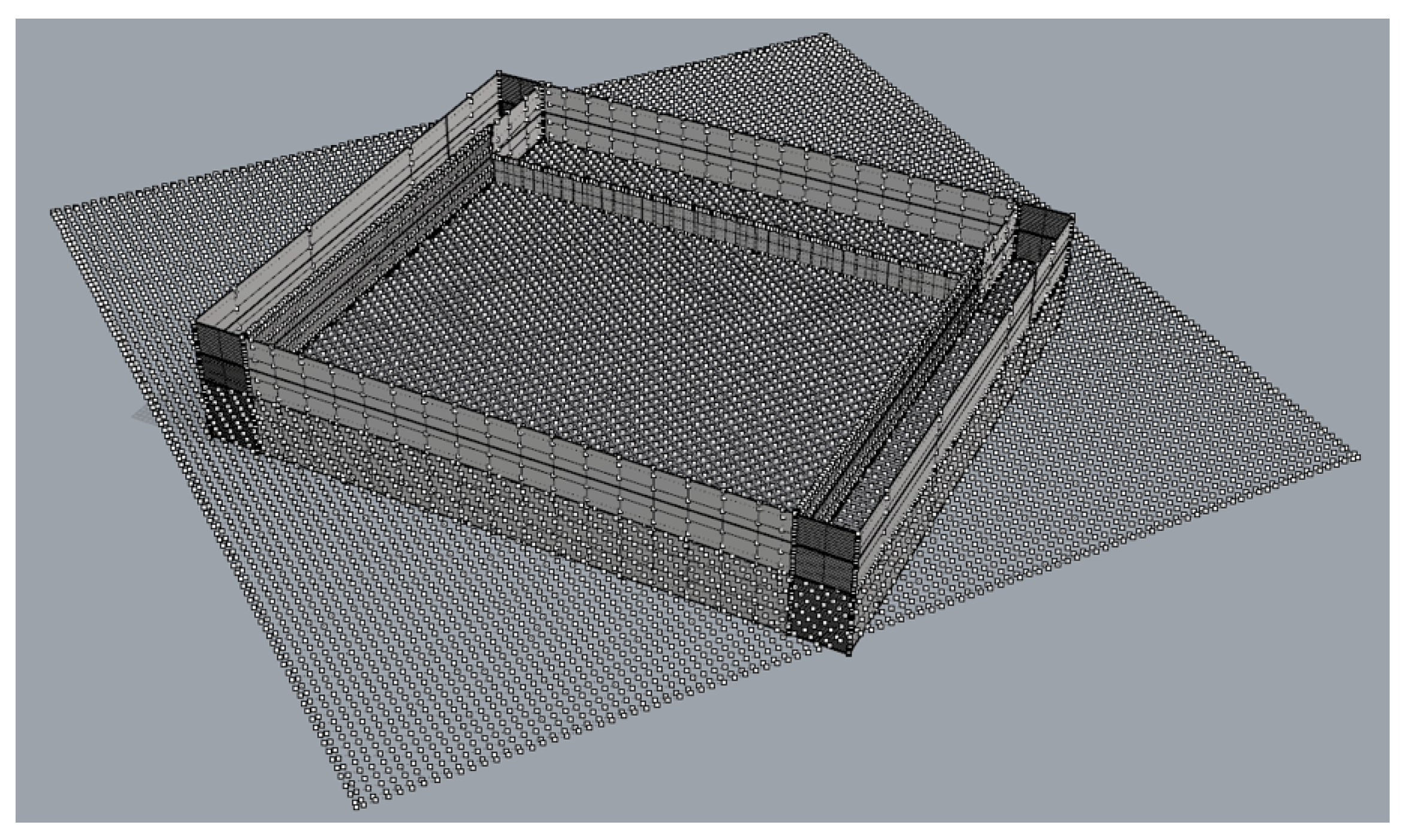

2.2.1. Geometry, Material Properties, and Meshing

2.2.2. Boundary Conditions, Load Application, and Analysis

2.2.3. Applied Imperfections

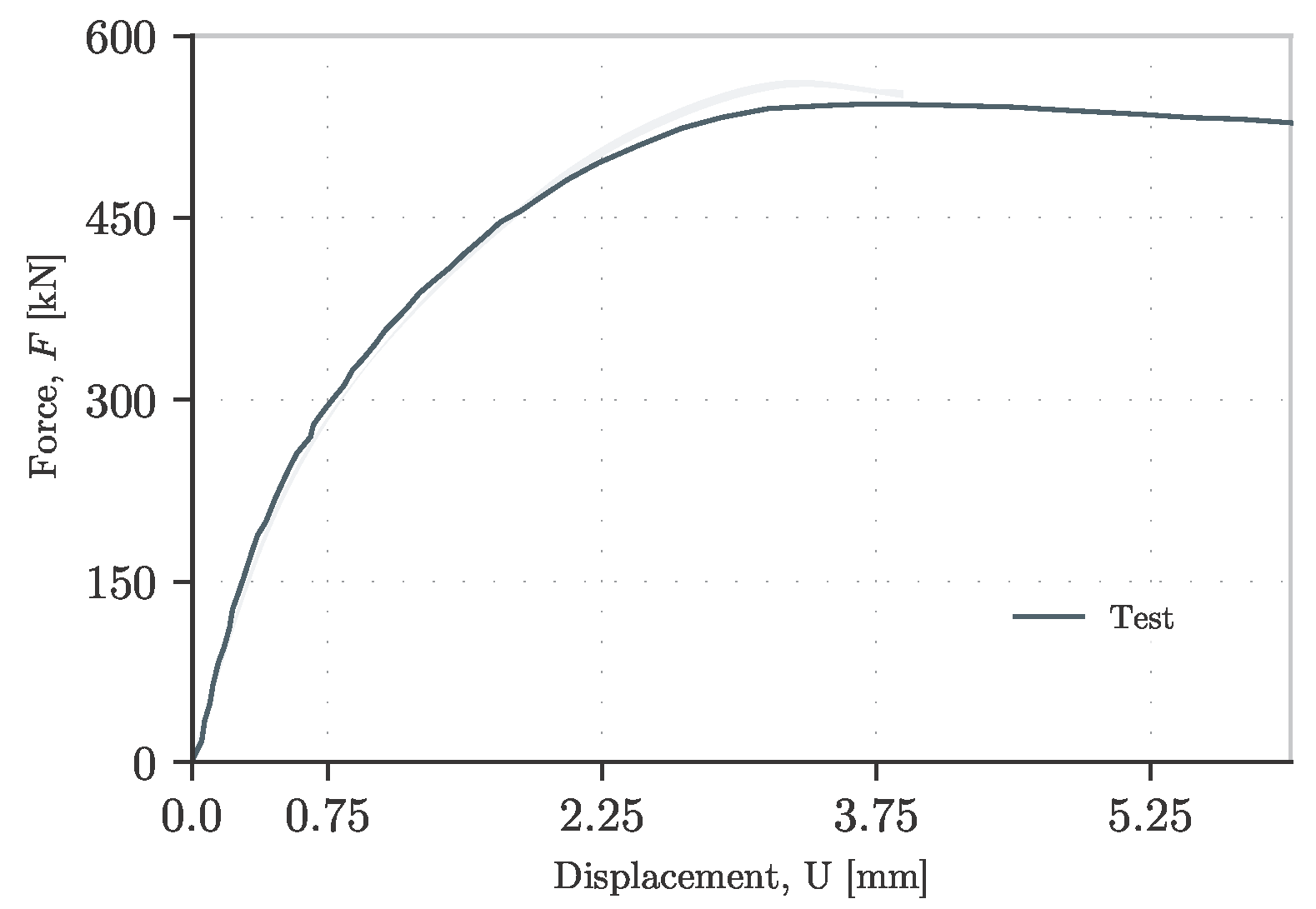

2.3. Validation

3. Modeling Strategies and Discussion

3.1. Introduction

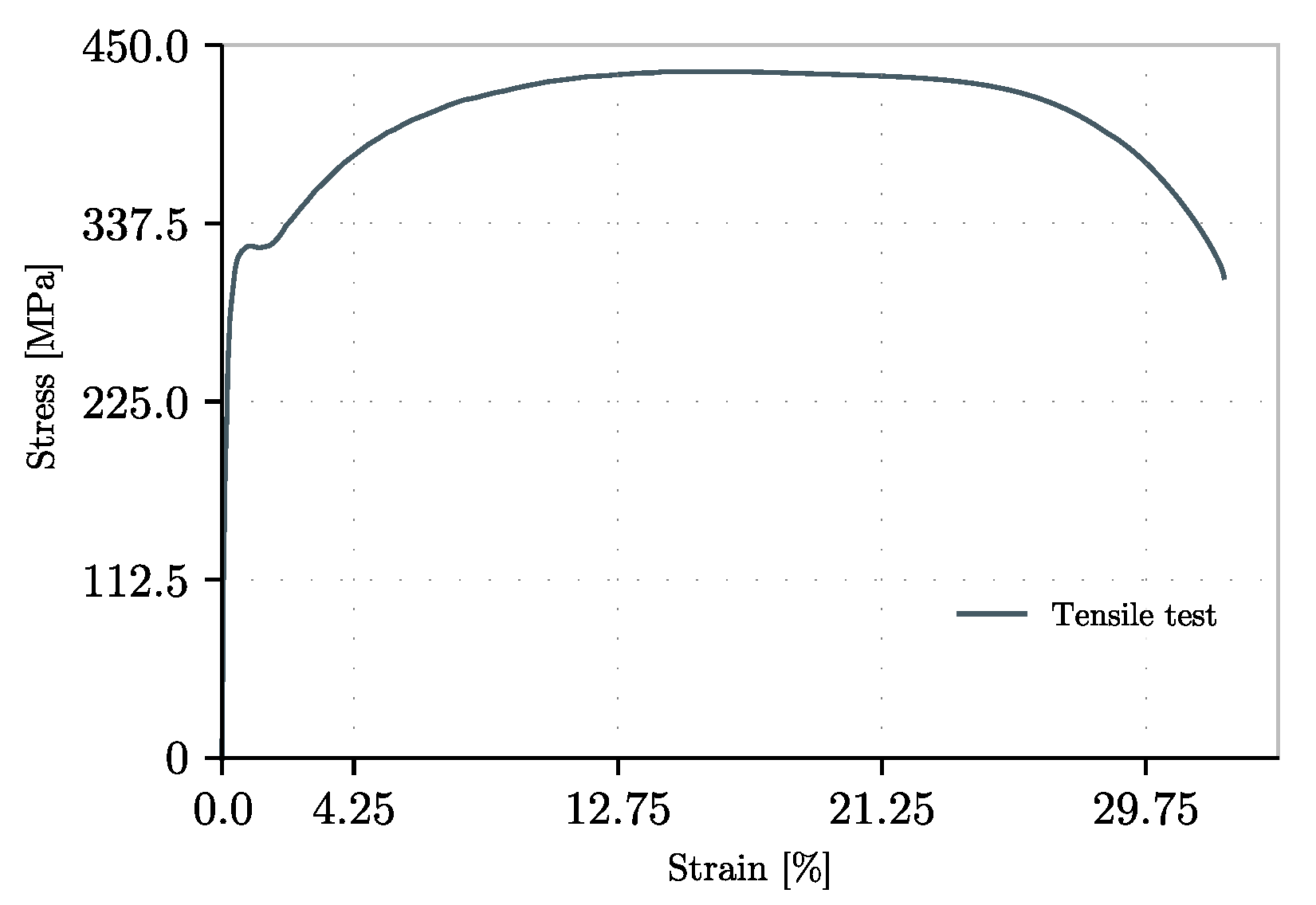

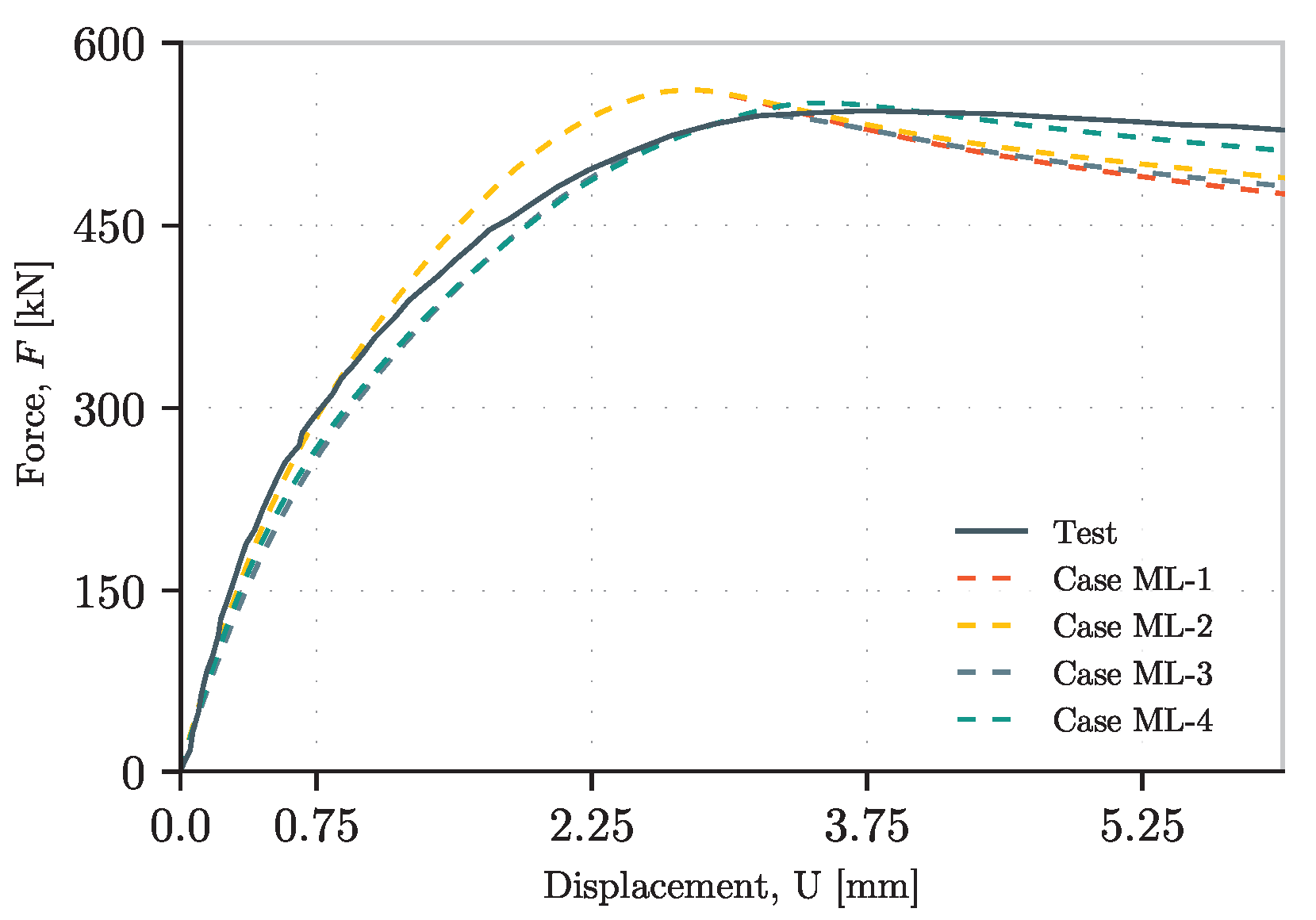

3.2. Material Stress–Strain Law

- -

- ML-1: Perfect elastoplastic stress–strain law (Tangent Elastic Moduli, Et = 0) with the same fy for all plates.

- -

- ML-2: Perfect elastoplastic stress–strain law (Tangent Elastic Moduli, Et = E/1000) with the same fy for all plates.

- -

- ML-3: Perfect elastoplastic stress–strain law (Tangent Elastic Moduli, Et = E/1000) with differing fy for each plate (flanges and web panel).

- -

- ML-4: Coupon tests.

- -

- The use of different stress–strain laws of the material when parting from a completely idealized model, when no further information of the material is given (ML-1), has a sufficient approximation to the ultimate resistance of the girder with a maximum error of +3%.

- -

- Regarding the initial behavior of the plate in terms of stiffness, the difference between each model is not noticeable until 50% of the ultimate resistance. At this level, the nonlinear behavior governed by the initial stage of the buckling on the web plate behaves differently. For models ML-1 and ML-2, the girder behaves considerably stiffer than the other models. Therefore, the ultimate resistance is higher.

- -

- The effect of considering a hardening with a slope equivalent to the value of the Elastic Moduli divided by 1000 is only reflected in the post-ultimate load behavior. Moreover, this difference only makes this slope more positive but not in a considerable magnitude (see ML-1 and ML-2 in Figure 14).

- -

- In order to obtain a behavior closer to the validated model, the yield resistance should be known. This is mainly due to the influence of the yield strength between the flanges and the web on the patch loading resistance [56]. In this case, the force–displacement curve is close to the real behavior until the ultimate resistance. Even at this level, the descending branch cannot be obtained properly.

- -

- As can be concluded from the previous points, the behavior after passing the ultimate resistance cannot be obtained accurately enough unless the stress–strain law of the steel used is known.

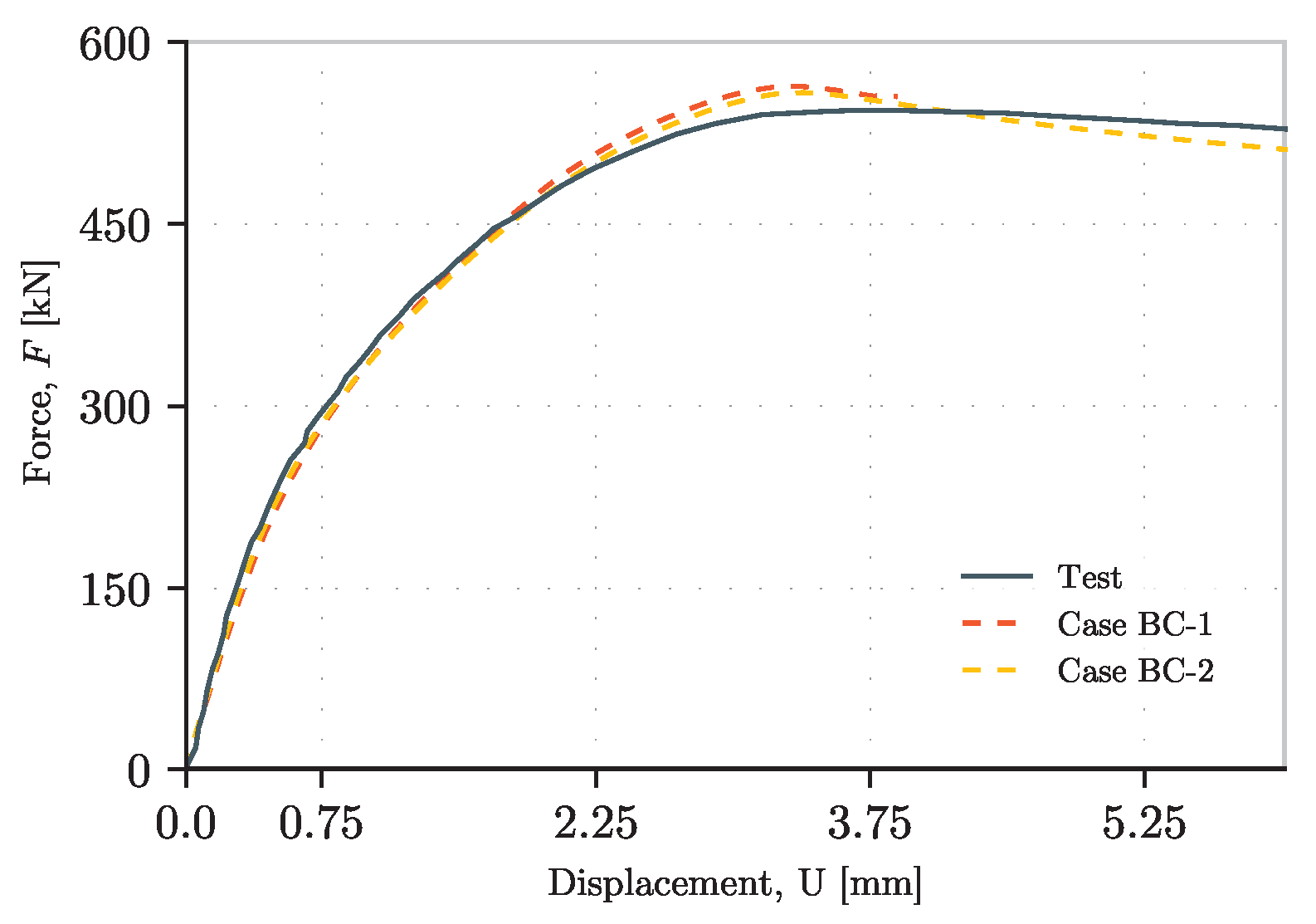

3.3. Boundary Conditions on the Extreme Side of Panels

- -

- BC-1: Using the transverse stiffeners;

- -

- BC-2: Using kinematic constraints.

- -

- In terms of stiffness, both models reproduce the same behavior. Therefore, the use of kinematic constraints is accurate enough to successfully replace the transverse stiffeners.

- -

- In terms of computing time, a considerable amount of time is saved when solving the problem with kinematics constraints instead of the stiffeners. Accordingly, when having more complex structures, this becomes advantageous.

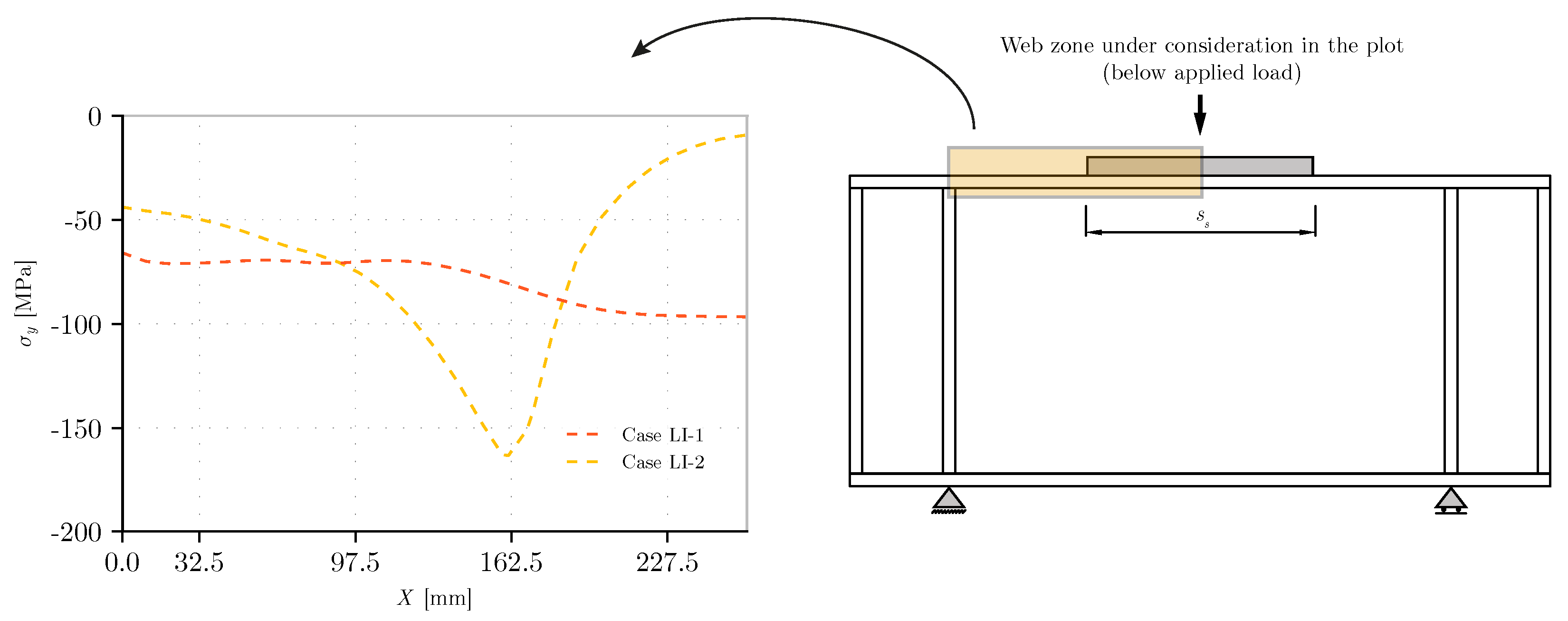

3.4. Introduction of the Concentrated Load

- -

- The normal tension on the edges of the load application is considerably higher.

- -

- The normal tension on the central part of the application load is drastically reduced.

- -

- In a stiff introduction of the load, one could interpret this as the case of patch loading happening separately on the two edges on a reduced length.

- -

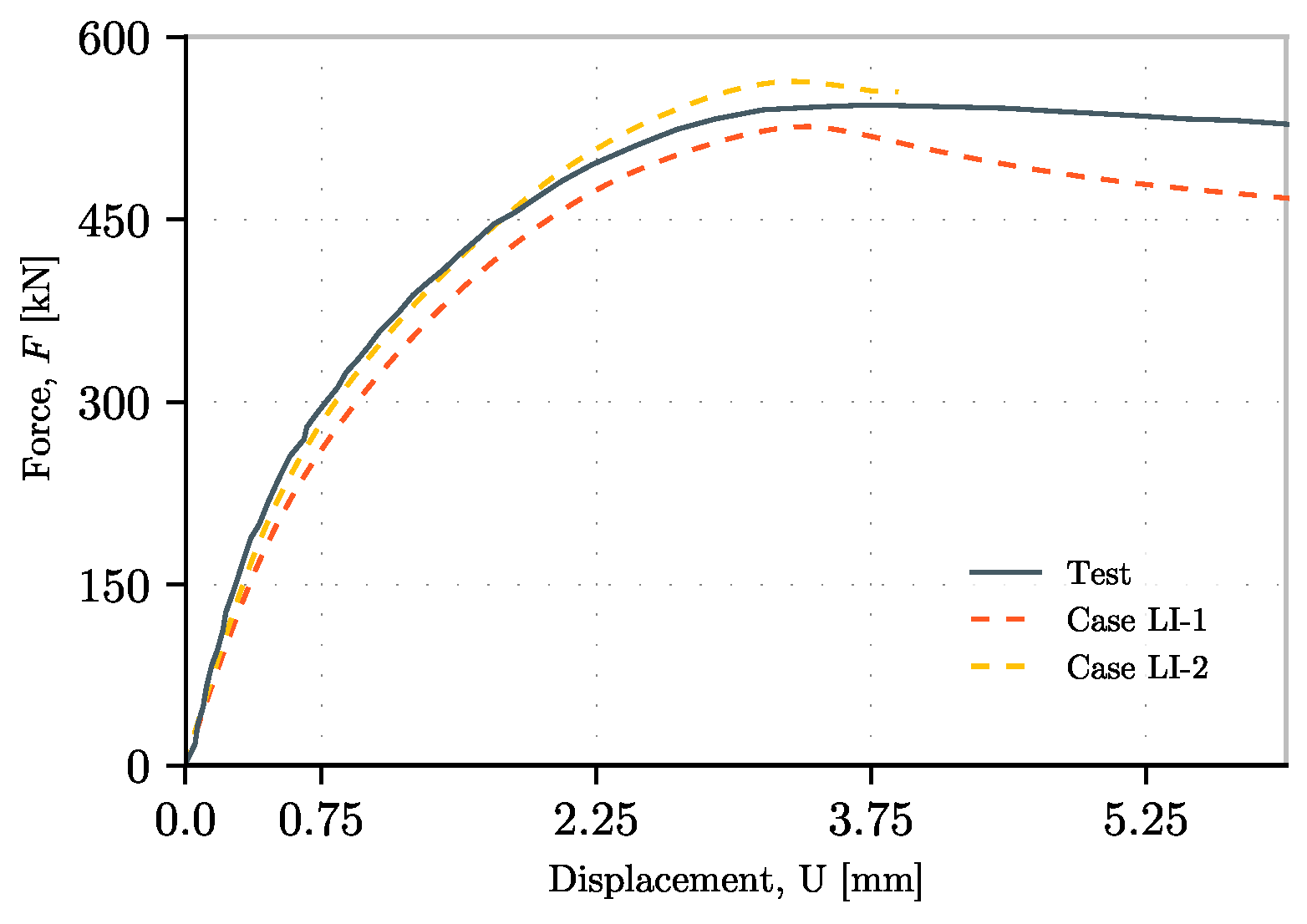

- LI-1: Flexible introduction of the concentrated load.

- -

- LI-2: Stiff introduction of the concentrated load.

- -

- As expected, due to the behavior change when the concentrated load is introduced flexibly, the ultimate resistance is lower. Moreover, its stiffness against the patch load decreases both before and after the ultimate resistance.

- -

- The introduction of the load with a stiff element can potentially bear a higher load mostly due to the acuteness of the concentrated load on two edges. If F is the patch load applied, F/2 works in a smaller loaded area on each of the edges. Here, three main facts coincide: first, a lower load acting on each of the borders of the loaded area; second, a combination of both loaded areas in further zones of the web; and third, a considerably smaller length of applied patch load. In this case, this results in a higher resistance. Nevertheless, the specific case of each girder must be assessed and analyzed to then be able to understand the results of such higher or lower resistance to patch loading.

- -

- In this case, the introduction of the load with a flexible element yields a lower resistance due to the reduced application length, ss, where the total load acts with a parabolic distribution.

- -

- Consequently, the area between the two force–displacement graphs is larger and considerable. In all cases, it is clear that the influence of the support device stiffness must be assessed with special care.

3.5. Influence of the Initial Imperfection

- -

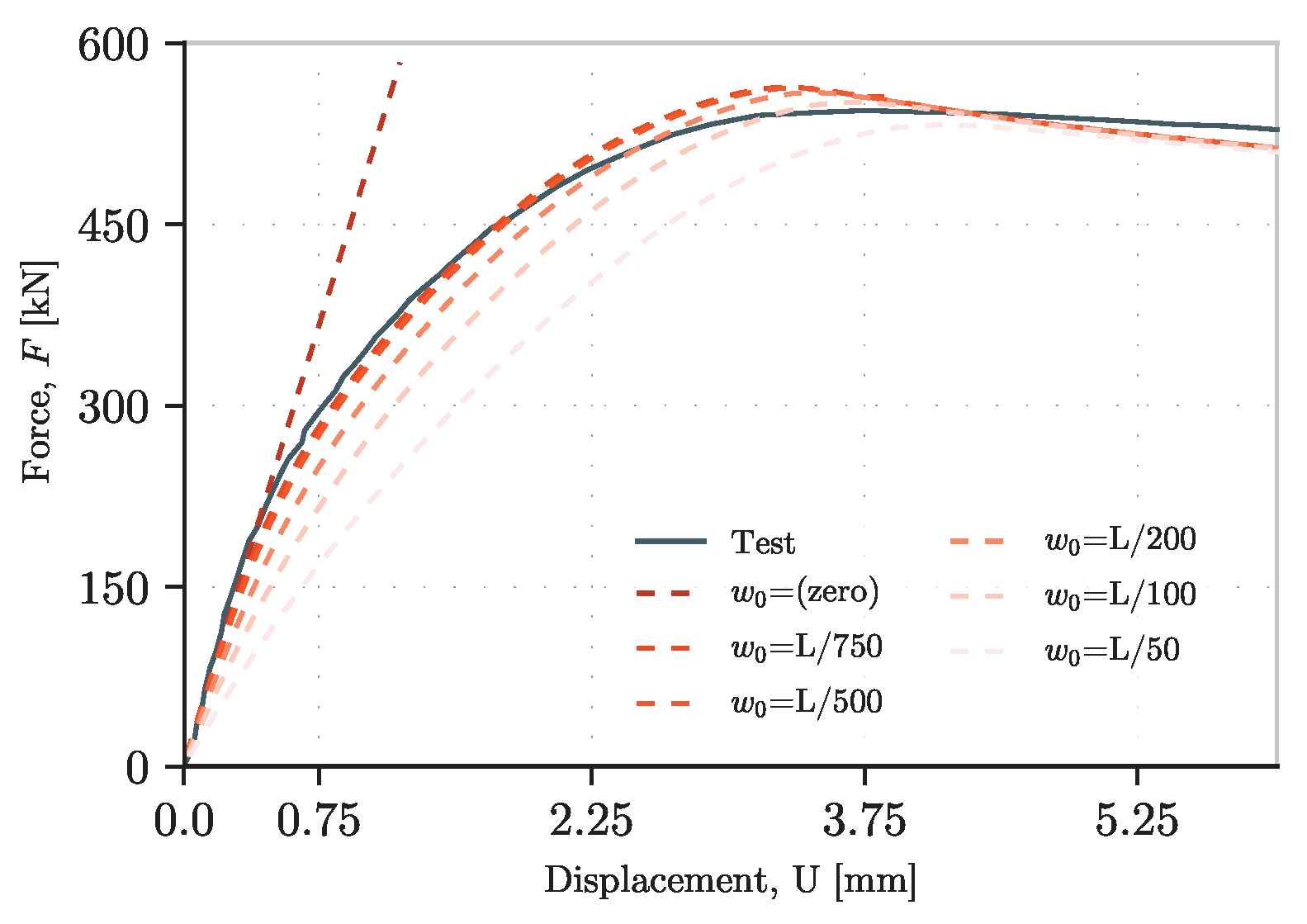

- w0 = zero.

- -

- w0 = L/750, L/500, L/200, L/100, L/50, and L/750, L being the web height of the girder.

- -

- In terms of analysis, the case of w0 equal to zero demonstrated what is mentioned at the beginning of this subsection. The problem becomes one of MNA in the absence of an initial imperfection.

- -

- In terms of the behavior of the girder, since the magnitude of w0 controls the geometric nonlinear behavior, the bigger the imperfection, the lower ultimate resistance it reaches.

- -

- In terms of stiffness, the stiffness logically decreases with the maximum load it can bear. Moreover, the ultimate resistance is lower because of the loss of the girder’s stiffness, mainly influenced by the buckling of the plate. The bigger this imperfection is, the faster the buckling of the web increases, provoking the quicker initiation of the plasticity of the web plate.

- -

- As stated in the previous points, the choice of the proper initial imperfection, despite the fact that it could be defined in different normatives with different values, directly affects the stiffness and resistance.

- -

3.6. Solving Algorithms

- -

- -

- -

- -

- When using Newton–Raphson with a load-driven analysis (SO-3), it is only possible to obtain the ultimate load depending on the refinement of time steps. Therefore, the final result depends on how small the step is, which, depending on the type of structure, can wind up in a considerably long analysis.

- -

- When Newton–Raphson is used with a load-driven analysis (SO-3), it is only possible to obtain the force–displacement curve up to the ultimate load. It is not possible to obtain the rest of the curve until the failure of the element (see red dot in Figure 22).

- -

- When Newton–Raphson is used with a displacement-driven analysis (SO-2), the curve is similar to the one obtained through the modified Riks method. Nevertheless, the refinement of the time steps in the analysis must also be considered in order to obtain the ultimate load accurately. Also, it is possible that nonconvergence of the problem takes place.

- -

- When using the modified Riks method (SO-1), despite it being a force–driven analysis, it is possible to obtain the whole force–displacement curve. This happens because the refinement is not controlled only by the force; the analysis also depends on a rule of displacement.

- -

- Regarding computational time, the total solution time for the GMNIA problem in models SO-1, SO-2, and SO-3 is 601, 584, and 603 s, respectively. Among these, models SO-1 and SO-2 exhibit the lowest computational cost, with only a marginal difference between SO-1 and SO-3. However, it is important to emphasize that when using load-driven analysis with the Newton–Raphson method (SO-3), the solution process terminates prematurely as higher load levels cannot be reached, resulting in errors in the solution. Consequently, if the magnitude of the results is entirely unknown, solving the problem would require multiple iterations, each with progressively smaller time steps. In a practical application, this would necessitate at least two iterations of the same problem, effectively doubling the computational cost.

- -

- In general, when aiming for sufficient accuracy in the force–displacement curve, the modified Riks method provides reliable results with reduced computational time. Moreover, this approach is particularly advantageous in buckling problems, where the web may be susceptible to snap-through behavior, as it helps maintain numerical stability [52].

3.7. Combination of Influencing Parameters: From Complex to Simple Models

- -

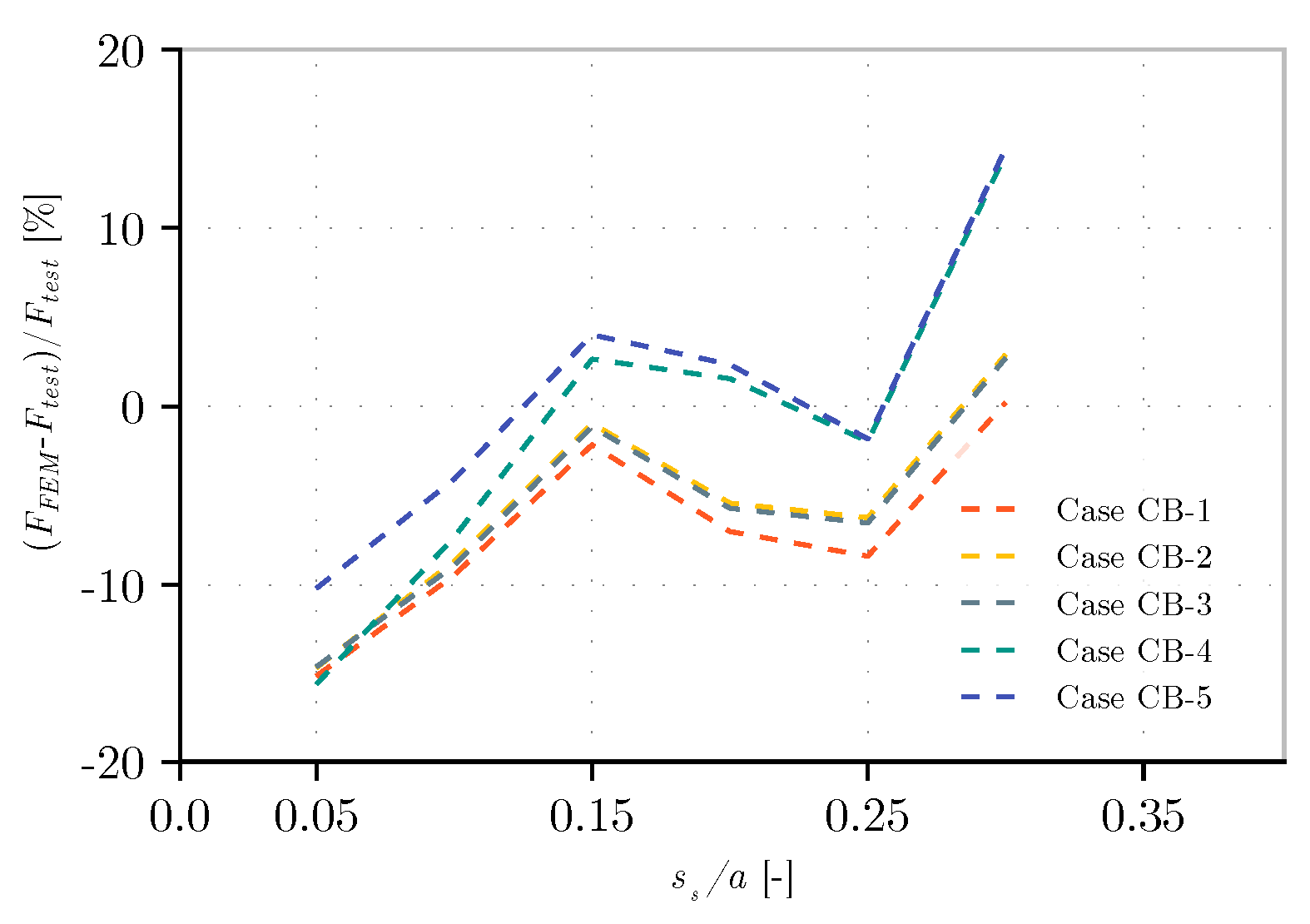

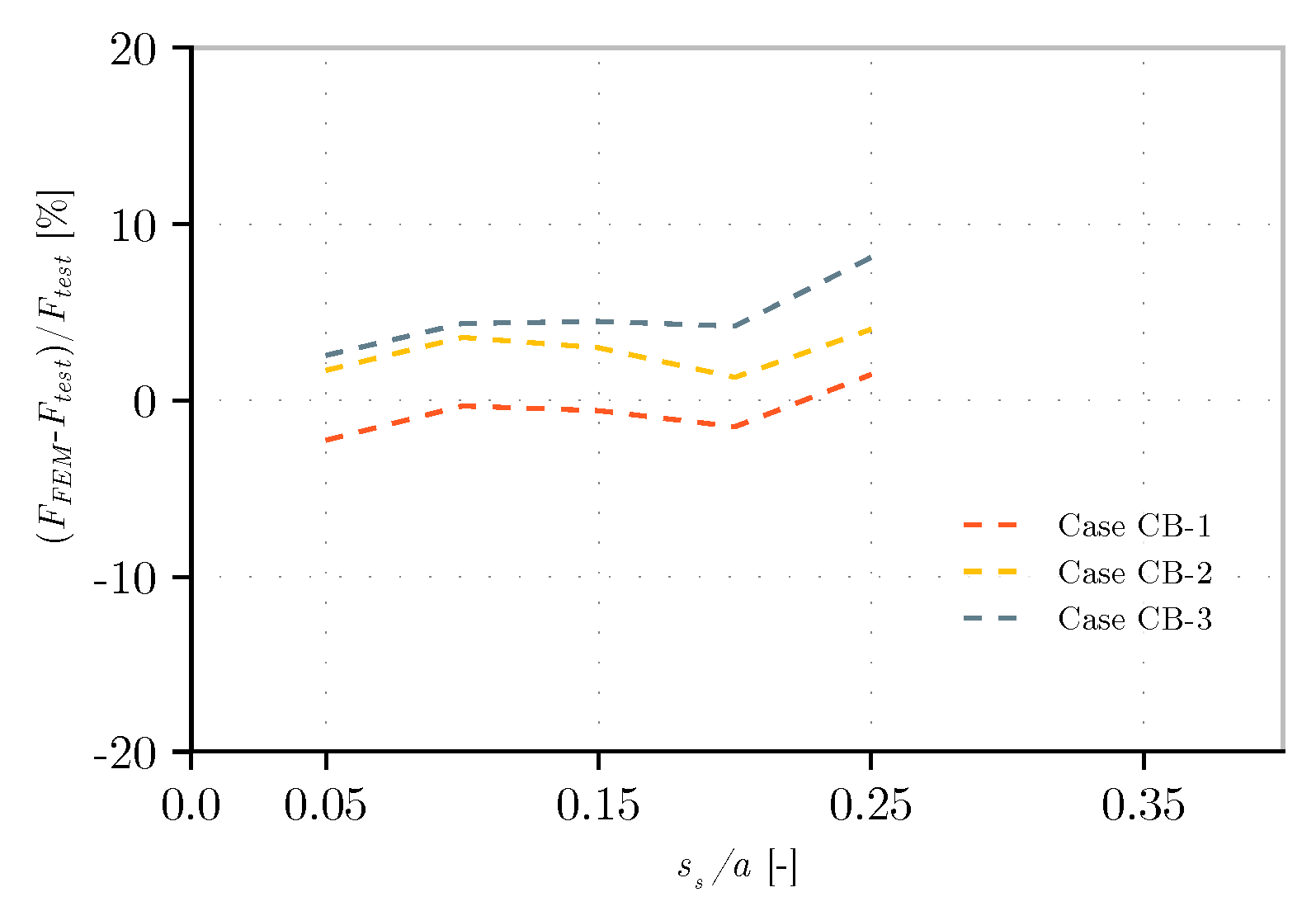

- In general, as expected, the results show no large variation. In percentage, they range in value from -16% to +14% of the test value.

- -

- The worst predictions are encountered in models CB-1 and CB-2, and the best values are found in the most complex model, CB-5. Generally, the most complex model is the one that best approximates the real experimental value but also presents the largest values. The minimum values are found in CB-1. This model, when compared to CB-2, shows lower values due to the magnitude of the initial imperfection which is higher than hw/200 (see Section 3.5).

- -

- The difference between models CB-2 and CB-3 is minor. This effect is also found in Section 3.3 when using kinematic constraints or modeling the transverse stiffeners.

- -

- When using real initial imperfections on the web, at low values of ss, the effect of the real shape compared to the one of the first eigenvalue is negligible, while at higher values it shows a more pronounced effect. In any of the cases, the last one logically approximates the real behavior of the test.

- -

- The effect of using the real stress–strain law material is that the results are closer to the real value of the ultimate resistance.

- -

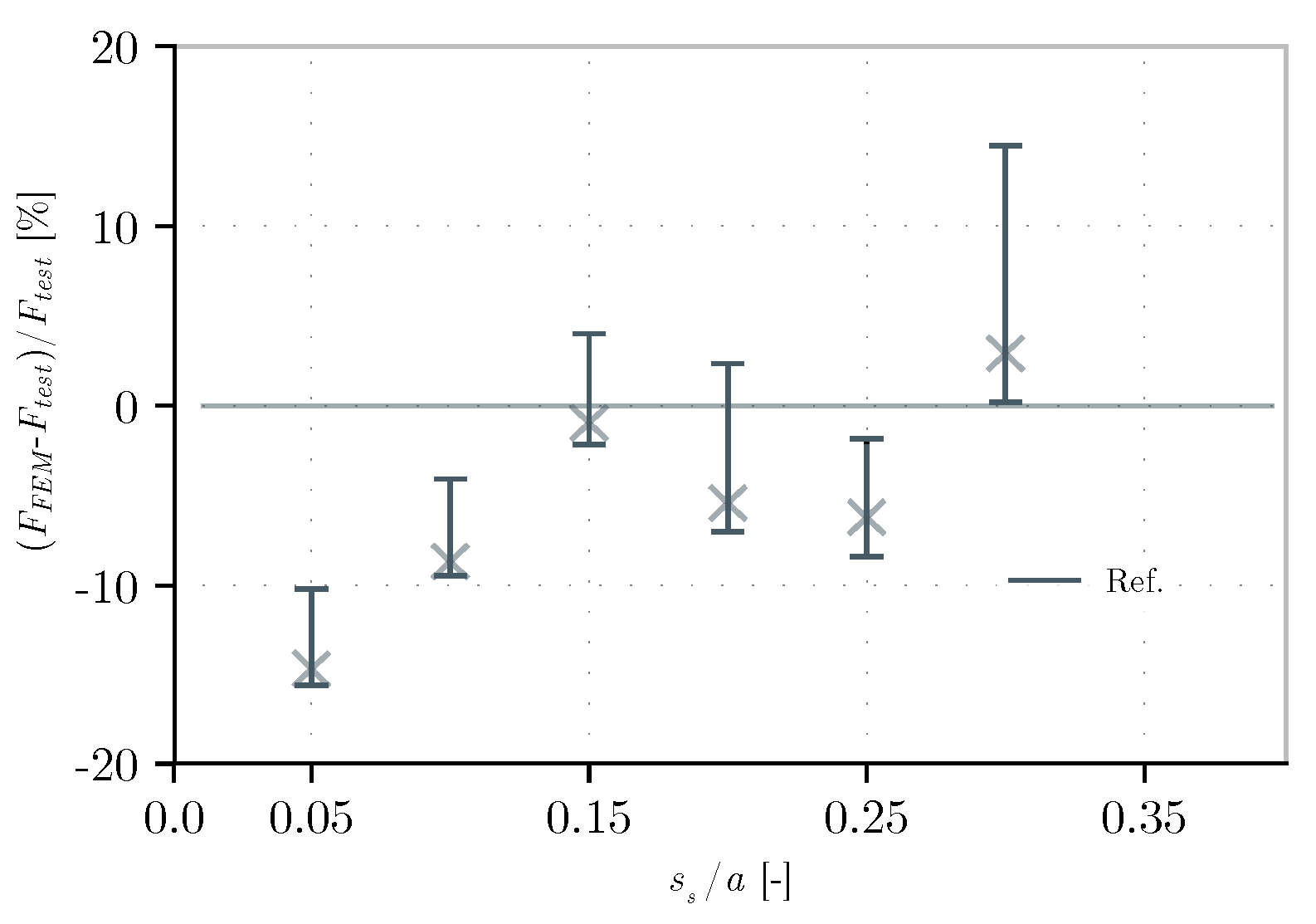

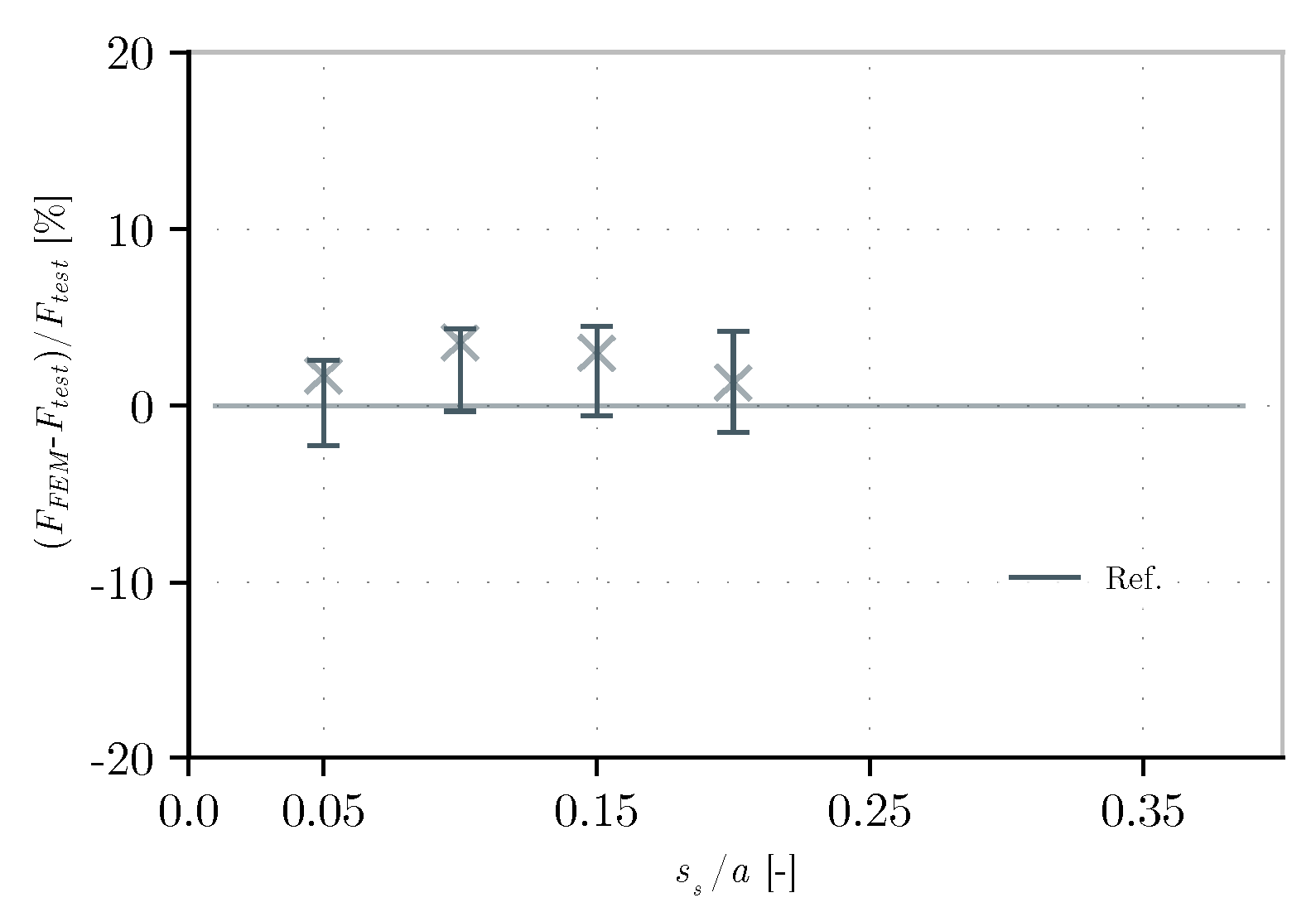

- As seen in Figure 24, the average of the values is below the real test resistance, except for the value of the longest patch load. Furthermore, the distance between the lowest and maximum values is similar for most of the tests.

- -

- For simple models, such as CB-1 or CB-2, it is possible to obtain a good approximation of the ultimate resistance. One of these cases represents the initial model that can be used as a first approximation (CB-2, also following the FEM guidelines according to [5,6]), while the other (CB-1) represents one in which the designer chooses to adopt a conservative assumption by considering a higher value of the initial imperfection.

- -

- The implementation of complex models such as CB-5 can give a closer approximation to what happens in reality and see other results, such as the force–displacement curve, and strains, among others. Nonetheless, much of this information is not always known in the first stage of design.

- -

- In general, as expected, the results show no large variation and are of a smaller dispersion than the ones with an aspect ratio of 1. In percentage, they range in value from −2% to +8% of the test value.

- -

- Similar results to the ones of an aspect ratio of 1 are obtained with regard to the initial imperfection and the modeling of transversal stiffeners. That is, the higher the value of w0, the lower the resistance and the more negligible the effect on the use of kinematics constraints or modeling the transverse stiffeners. In the latter case, not modeling the stiffeners yields conservative results by underestimating their contribution, offering a safety margin.

- -

- The results between the three types of models show the same hierarchy as the ones with an aspect ratio of 1.

- -

- Using simple models such as CB-1 to CB-3 can give a sufficient approximation with a small scatter of the ultimate resistance to patch loading.

4. Conclusions

- -

- FE modeling is capable of reproducing the force–displacement curve and ultimate resistance of experimentally tested specimens.

- -

- Simplifications in the material stress–strain law resulted in minimal variation. Therefore, adopting an idealized perfect elastoplastic bilinear model with a hardening branch is sufficient to estimate the ultimate load resistance.

- -

- The use of kinematic constraints as an alternative to transverse stiffeners, when the latter function as rigid boundary conditions, yields comparable behavior. The difference between these approaches is negligible, which enables the use of simplified boundary conditions in FE models.

- -

- The stiffness of the element where the concentrated load is applied significantly influences the structural response to patch loading. Thus, a detailed revision is necessary when dealing with flexible or stiff loading elements. In the context of launched bridges, this factor becomes particularly relevant. For cases where the load is applied through a rigid element which represents a large number of tests found in the literature, numerical models effectively replicate the observed behavior.

- -

- Initial imperfections have a considerable impact on stiffness and strength under patch loading conditions. Specifically, as the initial imperfection, w0, increases, both stiffness and strength decrease. In this regard, guidelines for defining initial imperfections, aligned with standard tolerances in steel structures, provide appropriate values that can be reliably used in numerical modeling.

- -

- In terms of solving algorithms, the modified Riks algorithm proves advantageous, not only by achieving sufficiently accurate results with reduced computational effort but also by effectively handling instability problems where snap-through behavior may occur.

- -

- An FE model incorporating all the proposed simplified modeling techniques has demonstrated sufficient accuracy and precision in predicting patch loading resistance, shedding light on the fact that it is possible to obtain accurate enough results with a simple modeling approach.

- -

- This study demonstrates that a simplified yet accurate FE model can reliably predict patch loading behavior across a broad range of conditions. Its validated performance enables the extension to cases beyond existing tests, particularly those underrepresented in current standards, supporting both design and further research.

- -

- To extend the applicability of the benchmark proposal, a validation process similar to that presented in Section 2.3 should be conducted using high-strength steels to verify that it remains effective and accurate for these material types.

- -

- Future research should investigate the interaction between specific subsets of the modeling techniques explored in this study. Although individual effects and the full combination were evaluated, intermediate combinations could offer deeper insight into the modeling behavior and enhance the robustness of the validation process.

Funding

Data Availability Statement

Conflicts of Interest

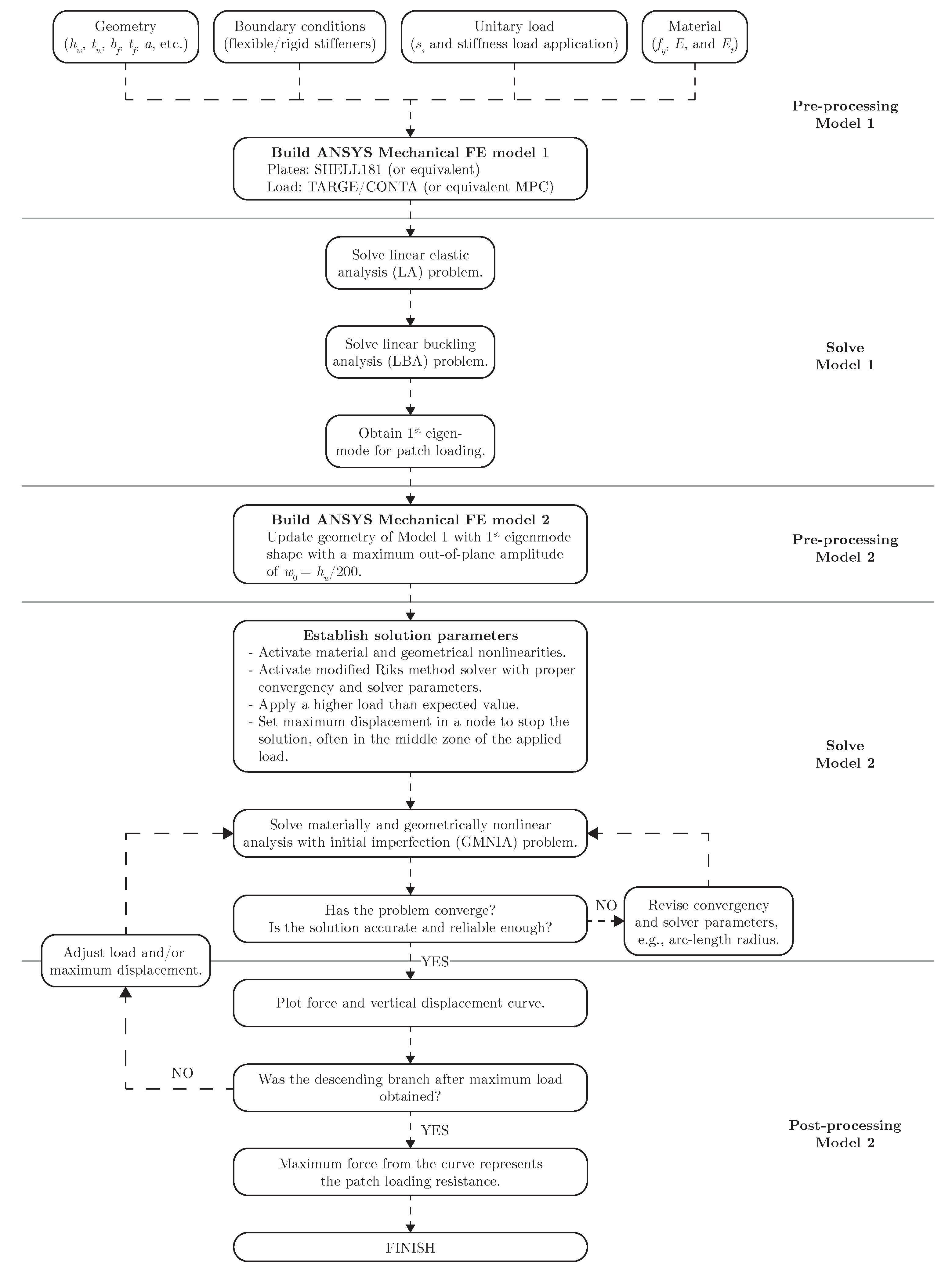

Appendix A. Step-by-Step FE Workflow

- -

- In the first row, with respect to the boundary conditions, when flexible transverse stiffeners are present, they must be modeled. The use of kinematic constraints is only valid when using rigid transverse stiffeners. Flexible transverse stiffeners remain outside the scope of this paper, and to provide a lower bound estimation, it is recommended to omit their modeling.

- -

- In the same row, with respect to the material, if different types of steel are used for different elements, then each type of steel for each plate must also be defined.

- -

- The flow chart can be used in any FEA program as long as the program has proven to work efficiently for GMNIA problems. In this case, ANSYS Mechanical was employed [47]. It is advisable to compare with one of the tests presented in Table 1, or others found in the literature, to validate the use of the software when its application to this type of analysis is not known.

- -

- The initial out-of-plane imperfection is in agreement with the European normative [5,6] but must be updated with the recommended values by the specific normative context. For example, in the United States, this value is defined as hw/100 [60]. It is worth noting that this value must be in agreement with the fabrication and execution tolerances of each specific country normative. In cases where the latter has higher values of initial imperfection, the last one must be used in the analysis.

| Aspect to Model | Proposal |

|---|---|

| Material | Bilinear stress–strain law with a Tangent Elastic Moduli, Et, of E/1000 after yielding. |

| Longitudinal elements | Four-node quadrilateral shell elements with 6-DOF well-suited for large strain and large-rotation nonlinear applications. |

| Transverse elements (stiffeners) | Flexible: Four-node quadrilateral shell elements with 6-DOF well-suited for large strain and large-rotation nonlinear applications. Rigid: kinematic constraints. |

| Mesh | A mesh sensitivity analysis must be carried out. The mesh size typically ranges around the web panel thickness value. |

| Applied force | CONTA and TARGE elements or MPC elements. The stiffness of the loading device must be studied and calibrated accordingly. A flexible load application introduces a safety margin, which is advisable in preliminary assessments. |

| Imperfection magnitude | European normative [5,6]: hw/200. |

| Solving algorithm | Modified Riks method. |

Appendix B. Test Summary of Reference Case Studies

Appendix B.1. Girders P200 and P700

Appendix B.2. Girder A3

Appendix C. Validation Tests

| Ref. | Year | Test | a | hw | tw | bf | tf | b1 | ss | hst | tst | w0 | fyw | fyf | Fu,test | Fu,FEM | Diff. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [-] | [-] | [-] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [MPa] | [MPa] | [kN] | [kN] | [%] |

| [38] | 2021 | A4 | 500 | 500 | 4 | 120 | 8 | 100 | 25 | 30 | 8 | 4 | 321 | 315 | 180 | 162 | −10 |

| A3 | 500 | 500 | 4 | 120 | 8 | 100 | 50 | 30 | 8 | 3 | 324 | 325 | 183 | 176 | −4 | ||

| A17 | 500 | 500 | 4 | 120 | 8 | 100 | 75 | 30 | 8 | 5.1 | 318 | 317 | 194 | 202 | +4 | ||

| A5 | 500 | 500 | 4 | 120 | 8 | 100 | 100 | 30 | 8 | 5.2 | 328 | 321 | 225 | 230 | +2 | ||

| A6 | 500 | 500 | 4 | 120 | 8 | 100 | 125 | 30 | 8 | 5.6 | 332 | 320 | 259 | 254 | −2 | ||

| A7 | 500 | 500 | 4 | 120 | 8 | 100 | 150 | 30 | 8 | 4 | 318 | 317 | 255 | 292 | +14 | ||

| B3 | 1000 | 500 | 4 | 120 | 8 | 100 | 50 | 30 | 8 | 11.5 | 315 | 313 | 165 | 169 | +3 | ||

| B5 | 1000 | 500 | 4 | 120 | 8 | 100 | 100 | 30 | 8 | 7.14 | 318 | 312 | 200 | 209 | +4 | ||

| B7 | 1000 | 500 | 4 | 120 | 8 | 100 | 150 | 30 | 8 | 19.2 | 327 | 339 | 240 | 251 | +4 | ||

| B17 | 1000 | 500 | 4 | 120 | 8 | 100 | 150 | 30 | 8 | 11 | 327 | 339 | 234 | 235 | +0 | ||

| B4 | 1000 | 500 | 4 | 120 | 8 | 100 | 200 | 30 | 8 | 25 | 318 | 323 | 275 | 287 | +4 | ||

| B6 | 1000 | 500 | 4 | 120 | 8 | 100 | 250 | 30 | 8 | 15.4 | 262 | 314 | 290 | 314 | +8 | ||

| [35] | 2018 | #1 | 1000 | 500 | 4 | 150 | 10 | - | 200 | - | - | - | 286 | 385 | 206 | 215 | +4 |

| [33] | 2007 | P200 | 2400 | 1200 | 6 | 450 | 20 | - | 200 | - | - | 1.6 | 371 | 354 | 544 | 556 | +2 |

| P700 | 2400 | 1200 | 6 | 450 | 20 | - | 700 | - | - | 6.4 | 371 | 354 | 660 | 690 | +5 | ||

| [27] | 1990 | VT07 | 1760 | 1000 | 3.8 | 150 | 8.35 | 200 | 40 | 90 | 2 | 5 | 375 | 281 | 167 | 165 | −1 |

| VT08 | 1760 | 1000 | 3.8 | 150 | 8.3 | 200 | 240 | 90 | 2 | 5 | 358 | 328 | 232 | 255 | +10 | ||

| VT09 | 1760 | 1000 | 3.8 | 150 | 12 | 150 | 40 | 90 | 2 | 5 | 371 | 283 | 182 | 186 | +2 | ||

| VT10 | 1760 | 1000 | 3.8 | 150 | 12 | 150 | 240 | 90 | 2 | 5 | 380 | 275 | 281 | 303 | +8 | ||

| [12] | 1978 | R1 | 800 | 800 | 2 | 300 | 15 | - | 40 | - | - | - | 266 | 295 | 60 | 63 | +5 |

| R3 | 799 | 800 | 2 | 120 | 5.07 | - | 40 | - | - | 5 | 266 | 285 | 38 | 41 | +9 |

References

- Kovacevic, S.; Markovic, N. Experimental study on the influence of patch load length on steel plate girders. Thin-Walled Struct. 2020, 151, 106733. [Google Scholar] [CrossRef]

- Markovic, N.; Kovacevic, S. Influence of patch load length on plate girders. Part I: Experimental research. J. Constr. Steel Res. 2019, 157, 207–228. [Google Scholar] [CrossRef]

- Lagerqvist, O. Patch Loading: Resistance of Steel Girders Subjected to Concentrated Forces. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 1995. [Google Scholar]

- Lagerqvist, O.; Johansson, B. Resistance of I-girders to concentrated loads. J. Constr. Steel Res. 1996, 39, 87–119. [Google Scholar] [CrossRef]

- EN 1993-1-5:2013; Eurocode 3: Design of Steel Structures—Part 1–5: Plated Structural Elements. The European Committee for Standardization: Bruxelles, Belgium, 2013.

- EN 1993-1-5:2024; Eurocode 3: Design of Steel Structures—Part 1–5: Plated Structural Elements. The European Committee for Standardization: Bruxelles, Belgium, 2024.

- COMBRI+. COMBRI Design Manual—Part I: Application of EurocodeRules; Institute for Structural Design: Stuttgart, Germany, 2008. [Google Scholar]

- COMBRI+. COMBRI Design Manual—Part II: State-of-the-Art and Conceptual Design of Steel and Composite Bridges; Institute for Structural Design: Stuttgart, Germany, 2008. [Google Scholar]

- Granholm, C. Provning av balkar med extremt tunt liv. Rapport 1961, 202, 1960–1961. (In Swedish) [Google Scholar]

- Drdacky, M.; Novotny, R. Partial edge load-carrying capacity tests of thick plate girder webs. Acta Tech. CSAV 1977, 222, 614–620. [Google Scholar]

- Bossert, T.W.; Ostapenko, A. Buckling and Ultimate Loads for Plate Girder Web Plates Under Edge Loading; Fritz Engineering Laboratory: Bethlehem, PA, USA, 1967. [Google Scholar]

- Rockey, K.C.; Bergfelt, A.; Larsson, L. Behaviour of Longitudinally Reinforced Plate Girders when Subjected to Inplane Patch Loading; Publication S78:19; Chalmers University of Technology, Division of Steel and Timbers Structures: Göterborg, Sweden, 1978. [Google Scholar]

- Bergfelt, A. Patch Loading on a Slender Web: Influence of Horizontal and Vertical Web Stiffeners on the Load Carrying Capacity; Institutionen för Konstruktionsteknik, Stål-och Träbyggnad: Göterborg, Sweden, 1979. [Google Scholar]

- Bagchi, D.; Rockey, K. A Note on the Buckling of a Plate Girder Web Due to Partial Edge Loadings; Final Report; International Association for Bridge and Structural Engineering: New York, NY, USA, 1968. [Google Scholar]

- Zoetemeijer, P. The Influence of Normal-, Bending-and Shear Stresses on the Ultimate Compression Force Exerted Laterally to European Rolled Sections; Stevin Rapport 6-80-5980; Facultiet der Civiele Techniek, Technische Universiteit Delft: Delft, The Netherlands, 1980. [Google Scholar]

- Roberts, T. Slender plate girders subjected to edge loading. Proc. Inst. Civ. Eng. 1981, 71, 805–819. [Google Scholar] [CrossRef]

- Skaloud, M.; Novak, P. Post-buckling behaviour and incremental collapse of webs subjected to concentrated loads. In Proceedings of the IABSE, 9th Congress, Amsterdam, The Netherlands, 8–13 May 1972; pp. 101–110. [Google Scholar]

- Roberts, T.; Markovic, N. Stocky plate girders subjected to edge loading. Proc. Inst. Civ. Eng. 1983, 75, 539–550. [Google Scholar] [CrossRef]

- Bamm, D.; Lindner, J.; Voss, R.P. Traglastversuche an ausgesteiften Trägerauflagern. Stahlbau 1983, 10, 296–300. (In German) [Google Scholar]

- Bergfelt, A. Girder Web Stiffening for Patch Loading; Publication S83:1; Chalmers University of Technology, Department of Structural Engineering: Goteborg, Sweden, 1983. [Google Scholar]

- Galea, Y.; Godart, B.; Radouant, I.; Raoul, J. Test of buckling of panels subject to in-plane patch loading. In Proceedings of the ECCS Colloquium on Stability of Plate and Shell Structures, Ghent, Belgium, 6–8 April 1987; pp. 65–71. [Google Scholar]

- Shimizu, S.; Yoshida, S.; Okuhara, H. An experimental study on patch loaded web plates. In Proceedings of the ECCS Colloquium on Stability of Plate and Shell Structures, Ghent, Belgium, 6-8 April 1987; pp. 85–94. [Google Scholar]

- Shimizu, S.; Yabana, H.; Yoshida, S. A new collapse model for patch-loaded web plates. J. Constr. Steel Res. 1989, 13, 61–73. [Google Scholar] [CrossRef]

- Scheer, J.; Liu, X.; Falke, J.; Peil, U. Traglastversuche zur Lasteinleitung an I-förmigen geschweißten Biegeträgern ohne Steifen. Der Stahlbau 1988, 57, 115–121. (In German) [Google Scholar]

- Oxfort, J.; Gauger, H.V. Beultraglast von Vollwandträgern unter Einzellasten. Der Stahlbau 1989, 58, 331–339. (In German) [Google Scholar]

- Elgaaly, M.; Nunan, W.L. Behavior of rolled section web under eccentric edge compressive loads. J. Struct. Eng. 1989, 115, 1561–1578. [Google Scholar] [CrossRef]

- Dubas, P.; Tschamper, H. Stabilité des âmes soumises à une charge concentrée et à une flexion globale. Constr. Met. 1990, 27, 25–39. (In French) [Google Scholar]

- Höglund, T. Local buckling of steel bridge girder webs during launching. In Contact Loading and Local Effects in Thin-walled Plated and Shell Structures; Springer: Berlin/Heidelberg, Germany, 1990; p. 135. [Google Scholar]

- Dogaki, M.; Yonezawa, H.; Kishigami, N. Ultimate Strength Analysis of Plate Girder Webs Under Patch Loading; Elsevier Applied Science Publishers Ltd. (UK): Amsterdam, The Netherlands, 1991; pp. 192–201. [Google Scholar]

- Elgaaly, M.; Salkar, R. Web crippling under local compressive edge loading. In Proceedings of the 4th National Steel Construction Conference, Washington, DC, USA, 5–7 June 1991. [Google Scholar]

- Markovic, N.; Hajdin, N. A Contribution to the Analysis of the Behaviour of Plate Girders Subjected to Patch Loading. J. Construct. Steel Res. 1992, 21, 163–173. [Google Scholar] [CrossRef]

- Markovic, N. Buckling of the Plate Girders Under the Action of Patch Loading. Ph.D. Thesis, University of Belgrade Serbia, Belgrade, Serbia, 2003. [Google Scholar]

- Gozzi, J. Patch Loading Resistance of Plated Girders-Ultimate and Serviceability Limit State. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2007. [Google Scholar]

- Chacón, R.; Serrat, M.; Real, E. The influence of structural imperfections on the resistance of plate girders to patch loading. Thin-Walled Struct. 2012, 53, 15–25. [Google Scholar] [CrossRef]

- Kövesdi, B.; Mecséri, B.; Dunai, L. Imperfection analysis on the patch loading resistance of girders with open section longitudinal stiffeners. Thin-Walled Struct. 2018, 123, 195–205. [Google Scholar] [CrossRef]

- Kövesdi, B. Patch loading resistance of slender plate girders with longitudinal stiffeners. J. Constr. Steel Res. 2018, 140, 237–246. [Google Scholar] [CrossRef]

- Rogač, M.; Aleksić, S.; Lučić, D. Influence of patch load length on resistance of I-girders. Part-I: Experimental research. J. Constr. Steel Res. 2020, 175, 106369. [Google Scholar] [CrossRef]

- Kovačević, S.D. Stability and Ultimate Capacity of Thin-Walled Steel Plate Girders Subjected to Patch Loading. Ph.D. Thesis, Univerzitet u Beogradu-Građevinski fakultet, Belgrade, Serbia, 2021. [Google Scholar]

- Members of IABSE Working Group 6. Bridge Deck Erection Equipment; ICE Publishing: London, UK, 2018. [Google Scholar] [CrossRef]

- Grupo de trabajo 3/10 de la Asociación Española de Ingeniería Estructural. Tableros Empujados; Asociación Española de Ingeniería Estructural: Spain, 2021. (In Spanish) [Google Scholar]

- Mora Quispe, M.A.; Todisco, L.; Peiretti, H.C. Design Basis of Movable Scaffolding Systems Following American and European Code Provisions and Recommendations. Balt. J. Road Bridge Eng. 2021, 16, 151–177. [Google Scholar] [CrossRef]

- Virlogeux, M. The Millau cable-stayed bridge. In Recent Developments in Bridge Engineering; CRC Press: London, UK, 2003. [Google Scholar]

- Millanes Mato, F.; Pascual Santos, J. Viaducto Arroyo las Piedras. Primer viaducto mixto de las Líneas de Alta Velocidad Españolas. Hormigón Acero 2007, 58, 243. (In Spanish) [Google Scholar]

- Larsen, T.M. Plate Buckling in Movable Scaffolding Systems. Master’s Thesis, University of Oslo, Oslo, Norway, 2011. [Google Scholar]

- Ceranic, A.; Bendic, M.; Kovacevic, S.; Salatic, R.; Markovic, N. Influence of patch load length on strengthening effect in steel plate girders. J. Constr. Steel Res. 2022, 195, 107348. [Google Scholar] [CrossRef]

- Ministerio de Fomento. Instrucción de Acero Estructural (EAE); Boletín Oficial del Estado (BOE); Ministerio de Fomento: Madrid, Spain, 2012. (In Spanish) [Google Scholar]

- ANSYS Inc. Ansys Mechanical APDL, Version 2023R2. [Software]. Canonsburg, PA, USA, 2023.

- Chacón, R.; Mirambell, E.; Real, E. Influence of flange strength on transversally stiffened girders subjected to patch loading. J. Constr. Steel Res. 2014, 97, 39–47. [Google Scholar] [CrossRef]

- Graciano, C.; Casanova, E.; Martínez, J. Imperfection sensitivity of plate girder webs subjected to patch loading. J. Constr. Steel Res. 2011, 67, 1128–1133. [Google Scholar] [CrossRef]

- Chacón, R.; Mirambell, E.; Real, E. Hybrid steel plate girders subjected to patch loading, Part 1: Numerical study. J. Constr. Steel Res. 2010, 66, 695–708. [Google Scholar] [CrossRef]

- Demari, F.E.; Mezzomo, G.P.; Pravia, Z.M.C. Numerical study of slender I-girders with one longitudinal stiffener under patch loading. J. Constr. Steel Res. 2020, 167, 105964. [Google Scholar] [CrossRef]

- Riks, E. An incremental approach to the solution of snapping and buckling problems. Int. J. Solids Struct. 1979, 15, 529–551. [Google Scholar] [CrossRef]

- Robert McNeeel; Associates. Rhinoceros 3D, Version Rhino 6, [Software]; Seattle, WA, USA, 2018.

- Chacón, R.; Mirambell, E.; Real, E. Influence of designer-assumed initial conditions on the numerical modelling of steel plate girders subjected to patch loading. Thin-Walled Struct. 2009, 47, 391–402. [Google Scholar] [CrossRef]

- Schaper, L.; Tankova, T.; da Silva, L.S.; Knobloch, M. Effects of state-of-the-art residual stress models on the member and local stability behaviour. Steel Constr. 2022, 15, 244–254. [Google Scholar] [CrossRef]

- Chacón, R. Resistance of Transversally Stiffened Hybrid Steel Plate Girders to Concentrated Loads. Ph.D. Thesis, Universitat Politecnica de Catalunya Departament d’Enginyeria de la Construcció, Barcelona, Spain, 2009. [Google Scholar]

- Graciano, C.A.; Mendez, J.A.; Zapata Medina, D.G. Influence of the boundary conditions on FE-modeling of longitudinally stiffened I-girders subjected to concentrated loads. Rev. Fac. Ing. Univ. Antioquia 2014, 71, 221–229. [Google Scholar] [CrossRef]

- Loaiza, N.; Graciano, C.; Casanova, E. Design recommendations for patch loading resistance of longitudinally stiffened I-girders. Eng. Struct. 2018, 171, 747–758. [Google Scholar] [CrossRef]

- EN 1090-2; Execution of Steel Structures and Aluminium Structures. Part 2: Technical Requirements for Steel Structures. The European Committee for Standardization: Bruxelles, Belgium, 2013.

- ANSI/AISC 360-10; Specification for Structural Steel Buildings. American Institute of Steel Construction: Chicago, IL, USA, 2010.

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear Finite Elements for Continua and Structures, 2nd ed.; John Wiley & Sons: West Sussex, UK, 2013. [Google Scholar]

- Bathe, K.J. Finite Element Procedures; Prentice Hall, Pearson Education, Inc.: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

| Year | Author, Ref. | Number of Considered Tests |

|---|---|---|

| [-] | [-] | [-] |

| 1960 | Granholm [9] | 7 |

| 1977 | Drdacky & Novotny [10] | 16 |

| 1977 | Bossert & Ostapenko [11] | 10 |

| 1978 | Rockey [12] | 2 |

| 1979 | Bergfelt [13] | 136 |

| 1979 | Bagchi & Rockey [14] | 3 |

| 1980 | Zoetemeijer [15] | 11 |

| 1981 | Roberts [16] | 31 |

| 1981 | Skolaud & Novak [17] | 21 |

| 1983 | Roberts & Markovic [18] | 1 |

| 1983 | Bamm [19] | 4 |

| 1983 | Bergfelt [20] | 18 |

| 1987 | Galea [21] | 1 |

| 1987 | Shimizu [22,23] | 8 |

| 1988 | Scheer [24] | 30 |

| 1989 | Oxford & Lauger [25] | 5 |

| 1989 | Elgaaly & Nunan [26] | 4 |

| 1990 | Dubas & Tschamper [27] | 48 |

| 1991 | Höglund [28] | 2 |

| 1991 | Dogaki [29] | 2 |

| 1991 | Elgaaly & Sakar [30] | 15 |

| 1992 | Markovic & Hadjin [31] | 9 |

| 2003 | Markovic [32] | 6 |

| 2007 | Gozzi [33] | 3 |

| 2012 | Chacon [34] | 3 |

| 2018 | Kovesdi [35,36] | 2 |

| 2020 | Rogac, Aleksic, Lucic [37] | 8 |

| 2021 | Kovacevic [38] | 7 |

| Ref. | Test | tw | hw | fyw | tf | bf | fyf | a | ss | b1 | hst | tst | Fu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [-] | [-] | [mm] | [mm] | [MPa] | [mm] | [mm] | [MPa] | [mm] | [mm] | [mm] | [mm] | [mm] | [kN] |

| [33] | P200 | 6 | 1200 | 371 | 20 | 450 | 354 | 2440 | 200 | - | - | - | 544 |

| P700 | 6 | 1200 | 371 | 20 | 450 | 354 | 2440 | 700 | - | - | - | 660 | |

| [38] | A3 | 4 | 500 | 324 | 8 | 120 | 325 | 500 | 50 | 100 | 30 | 8 | 183 |

| Ref. | Year | Test | ss | ss/a | Fu,test | Fu,FEM | Difference |

|---|---|---|---|---|---|---|---|

| [-] | [-] | [-] | [mm] | [-] | [kN] | [kN] | [%] |

| [12] | 1978 | R1 | 40 | 0.05 | 60 | 63 | +5 |

| R3 | 40 | 0.05 | 38 | 41 | +9 | ||

| [27] | 1990 | VT07 | 40 | 0.02 | 167 | 165 | −1 |

| VT08 | 240 | 0.14 | 232 | 255 | +10 | ||

| VT09 | 40 | 0.02 | 182 | 186 | +2 | ||

| VT10 | 240 | 0.14 | 281 | 303 | +8 | ||

| [33] | 2007 | P200 | 200 | 0.20 | 544 | 556 | +2 |

| P700 | 700 | 0.70 | 660 | 690 | +5 | ||

| [35] | 2018 | #1 | 200 | 0.29 | 206 | 215 | +4 |

| [38] | 2021 | A4 | 25 | 0.05 | 180 | 162 | −10 |

| A3 | 50 | 0.10 | 183 | 176 | −4 | ||

| A17 | 75 | 0.15 | 194 | 202 | +4 | ||

| A5 | 100 | 0.20 | 225 | 230 | +2 | ||

| A6 | 125 | 0.25 | 259 | 254 | −2 | ||

| A7 | 150 | 0.30 | 255 | 292 | +14 | ||

| B3 | 50 | 0.05 | 165 | 169 | +3 | ||

| B5 | 100 | 0.10 | 200 | 209 | +4 | ||

| B7 | 150 | 0.15 | 240 | 251 | +4 | ||

| B17 | 150 | 0.15 | 234 | 235 | +0 | ||

| B4 | 200 | 0.20 | 275 | 287 | +4 | ||

| B6 | 250 | 0.25 | 290 | 314 | +8 |

| Model Aspect | CB-1 | CB-2 | CB-3 | CB-4 | CB-5 |

|---|---|---|---|---|---|

| Initial imperfection, w 0 | (max. value) a,b | hw/200 a | hw/200 a | Real shape c | Real shape c |

| Strain-stress law material | ML-2 | ML-2 | ML-2 | ML-2 | ML-4 |

| Boundary condition at extremes | BC-2 | BC-2 | BC-1 | BC-1 | BC-1 |

| Test | ss | ss/a | Fu,test | Fu,CB-1 | Diff. | Fu,CB-2 | Diff. | Fu,CB-3 | Diff. | Fu,CB-4 | Diff. | Fu,CB-5 | Diff. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [-] | [mm] | [-] | [kN] | [kN] | [%] | [kN] | [%] | [kN] | [%] | [kN] | [%] | [kN] | [%] |

| A4 | 25 | 0.05 | 180 | 153 | −15 | 154 | −15 | 154 | −15 | 152 | −16 | 162 | −10 |

| A3 | 50 | 0.10 | 183 | 166 | −9 | 167 | −9 | 167 | −9 | 170 | −7 | 176 | −4 |

| A17 | 75 | 0.15 | 194 | 190 | −2 | 192 | −1 | 192 | −1 | 199 | +3 | 202 | +4 |

| A5 | 100 | 0.20 | 225 | 209 | −7 | 213 | −5 | 212 | −6 | 229 | +2 | 230 | +2 |

| A6 | 125 | 0.25 | 259 | 237 | −8 | 243 | −6 | 242 | −7 | 254 | −2 | 254 | −2 |

| A7 | 150 | 0.30 | 255 | 256 | 0 | 262 | +3 | 262 | +3 | 291 | +14 | 292 | +14 |

| Test | ss | ss/a | Fu,test | Fu,CB-1 | Diff. | Fu,CB-2 | Diff. | Fu,CB-3 | Diff. |

|---|---|---|---|---|---|---|---|---|---|

| [-] | [mm] | [-] | [kN] | [kN] | [%] | [kN] | [%] | [kN] | [%] |

| B3 | 50 | 0.05 | 165 | 161 | −2 | 168 | +2 | 169 | +3 |

| B5 | 100 | 0.10 | 200 | 200 | 0 | 207 | +4 | 209 | +4 |

| B7 | 150 | 0.15 | 240 | 239 | −1 | 247 | +3 | 251 | +4 |

| B4 | 200 | 0.20 | 275 | 271 | −1 | 279 | +1 | 287 | +4 |

| B6 | 250 | 0.25 | 290 | 295 | +1 | 302 | +4 | 314 | +8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mora Quispe, M.A. Critical Review and Benchmark Proposal on FE Modeling for Patch Loading Resistance of Slender Steel Plate Girders in Launched Bridges. Buildings 2025, 15, 2153. https://doi.org/10.3390/buildings15132153

Mora Quispe MA. Critical Review and Benchmark Proposal on FE Modeling for Patch Loading Resistance of Slender Steel Plate Girders in Launched Bridges. Buildings. 2025; 15(13):2153. https://doi.org/10.3390/buildings15132153

Chicago/Turabian StyleMora Quispe, Marck Anthony. 2025. "Critical Review and Benchmark Proposal on FE Modeling for Patch Loading Resistance of Slender Steel Plate Girders in Launched Bridges" Buildings 15, no. 13: 2153. https://doi.org/10.3390/buildings15132153

APA StyleMora Quispe, M. A. (2025). Critical Review and Benchmark Proposal on FE Modeling for Patch Loading Resistance of Slender Steel Plate Girders in Launched Bridges. Buildings, 15(13), 2153. https://doi.org/10.3390/buildings15132153