Innovations and Applications in Lightweight Concrete: Review of Current Practices and Future Directions

Abstract

1. Introduction

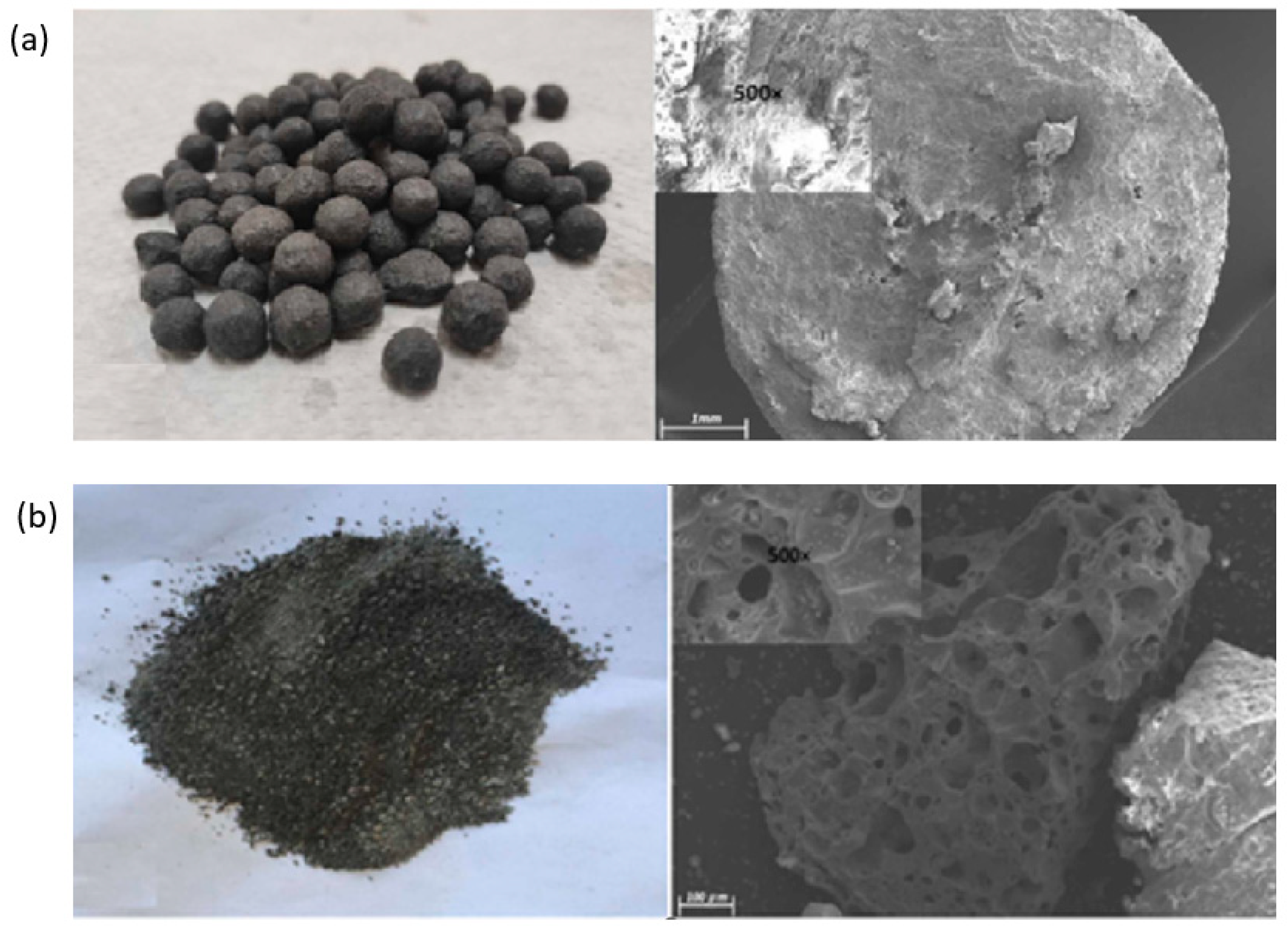

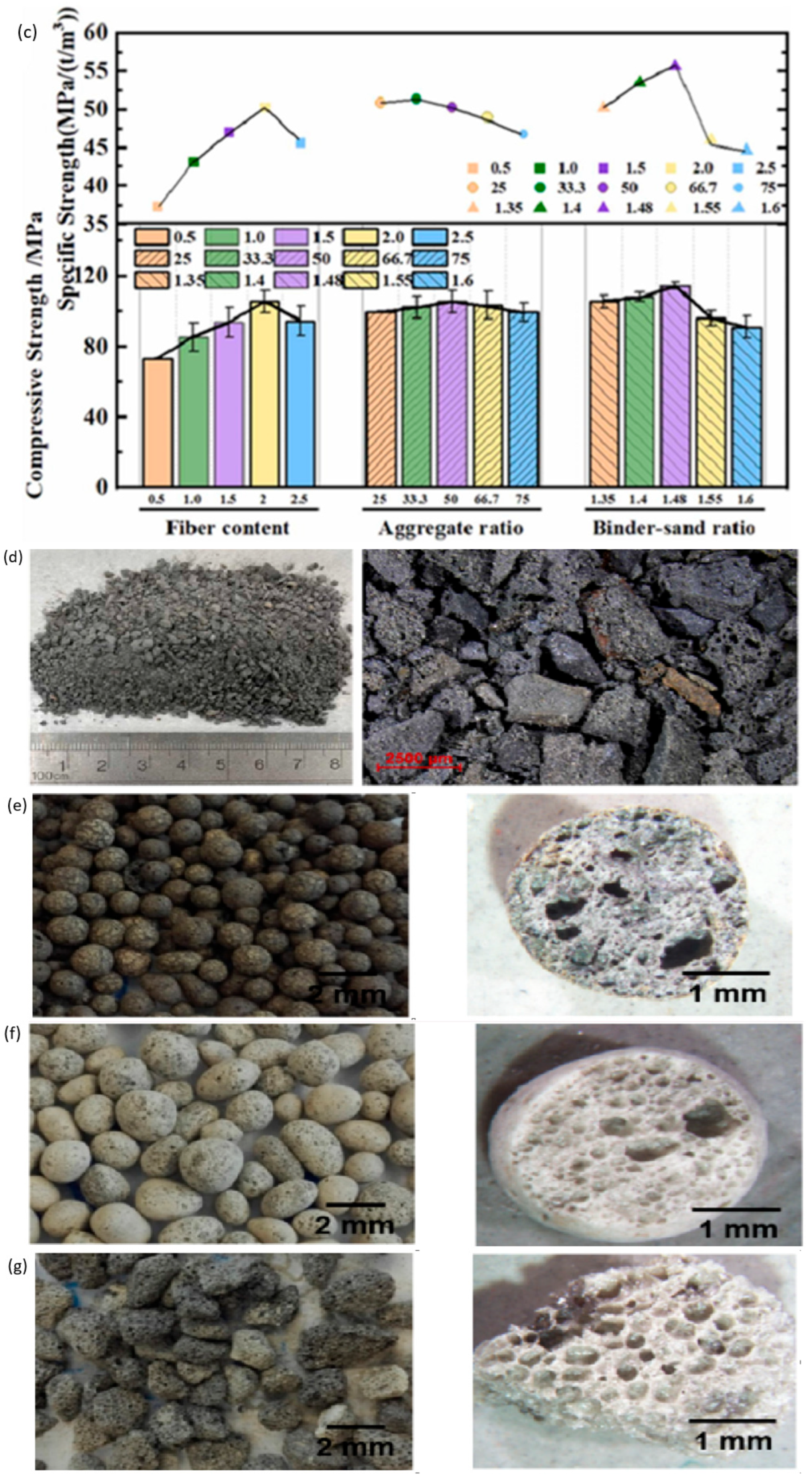

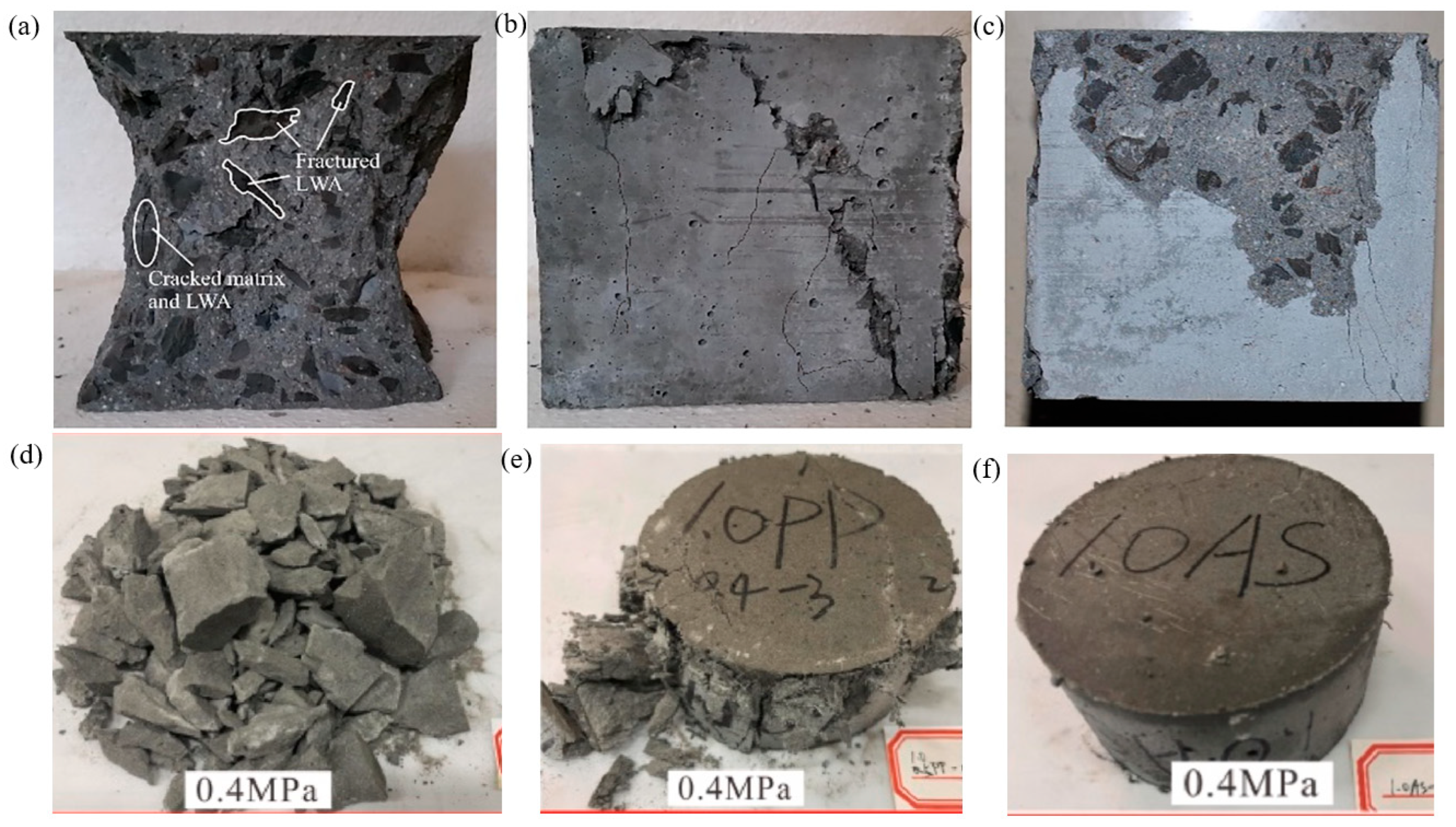

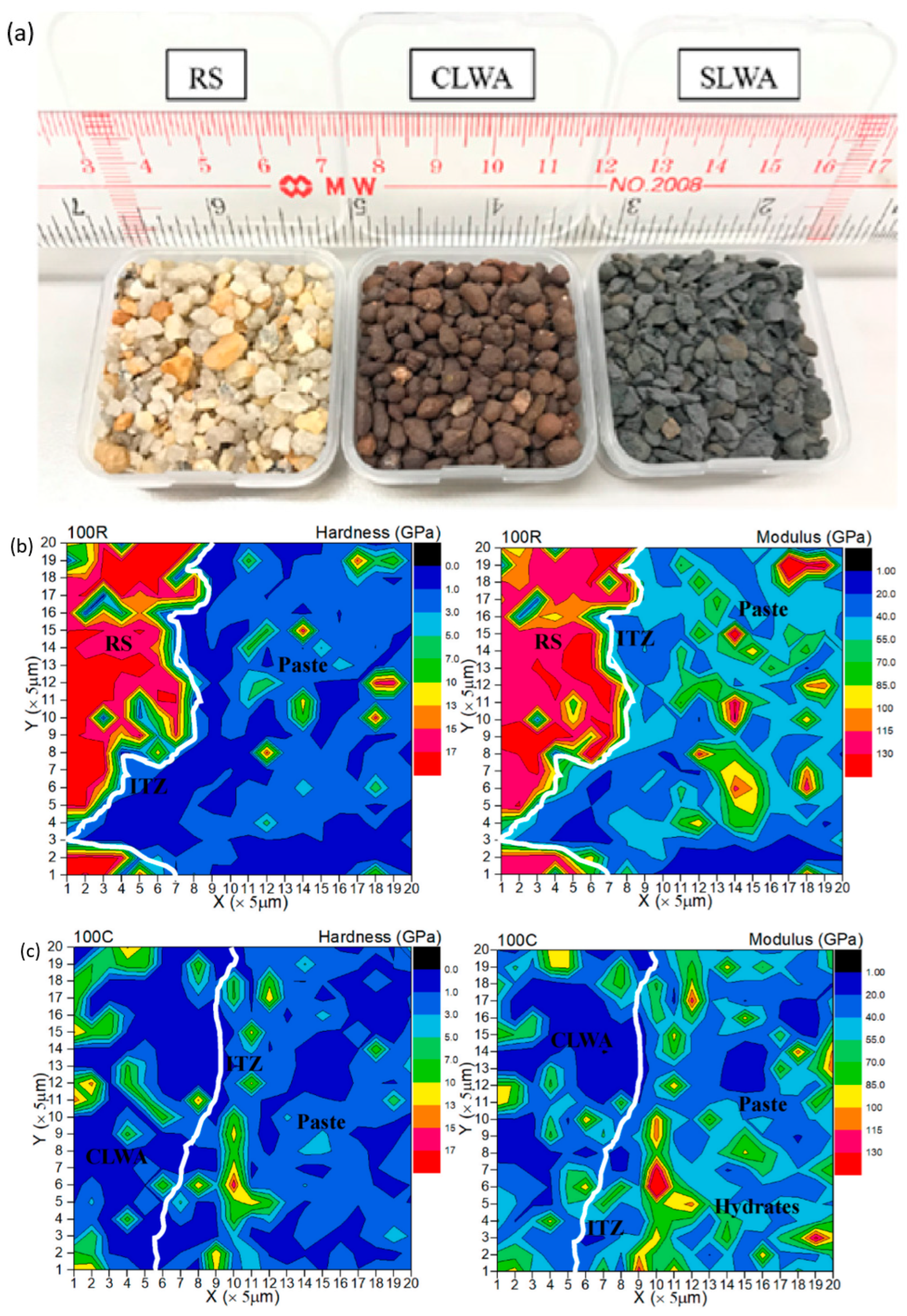

2. Materials and Fabrication Technologies

2.1. Materials and Methods

2.2. Aerated Concrete

| Material/Strategy | Density (kg/m3) | Compressive Strength (MPa) | Key Benefits | Notable Limitations | References |

|---|---|---|---|---|---|

| Natural LWA (pumice, scoria) | 1600–1800 | Moderate (~15–30) | Low cost, naturally available | Limited strength | [14,21,22] |

| Artificial LWA (FAC, SP) | 1995–2114 | 102.4–114.5 | High strength, microstructure control | Requires fiber for ductility | [4] |

| Recycled CDW aggregates | Varies (~1600–2000) | 15–30 | Sustainability, waste reuse | Variable quality | [14] |

| Engineered LWA (Liaver, Eco glass) | Lightweight (varies by type) | Low–High (depends on type) | Thermal/durability control | Porosity affects durability | [5,19,24] |

| Aerated Concrete (Al powder, foam) | 300–1200 | 2–10 (non-structural) | Thermal insulation, low weight | Low mechanical performance | [7,8,26] |

| SCMs (Fly ash, SF, GGBFS, MK) | Depends on mix | Enhanced (up to 90 MPa with blends) | Improved durability and strength | May reduce workability | [6,11,27,28,29] |

| Fibers (Steel, PVA, PP, Carbon) | 800–1800 | 10–87+ | Crack resistance, ductility | Mix design sensitivity | [10,12,13,30,31] |

2.3. Supplementary Cementitious Materials (SCMs)

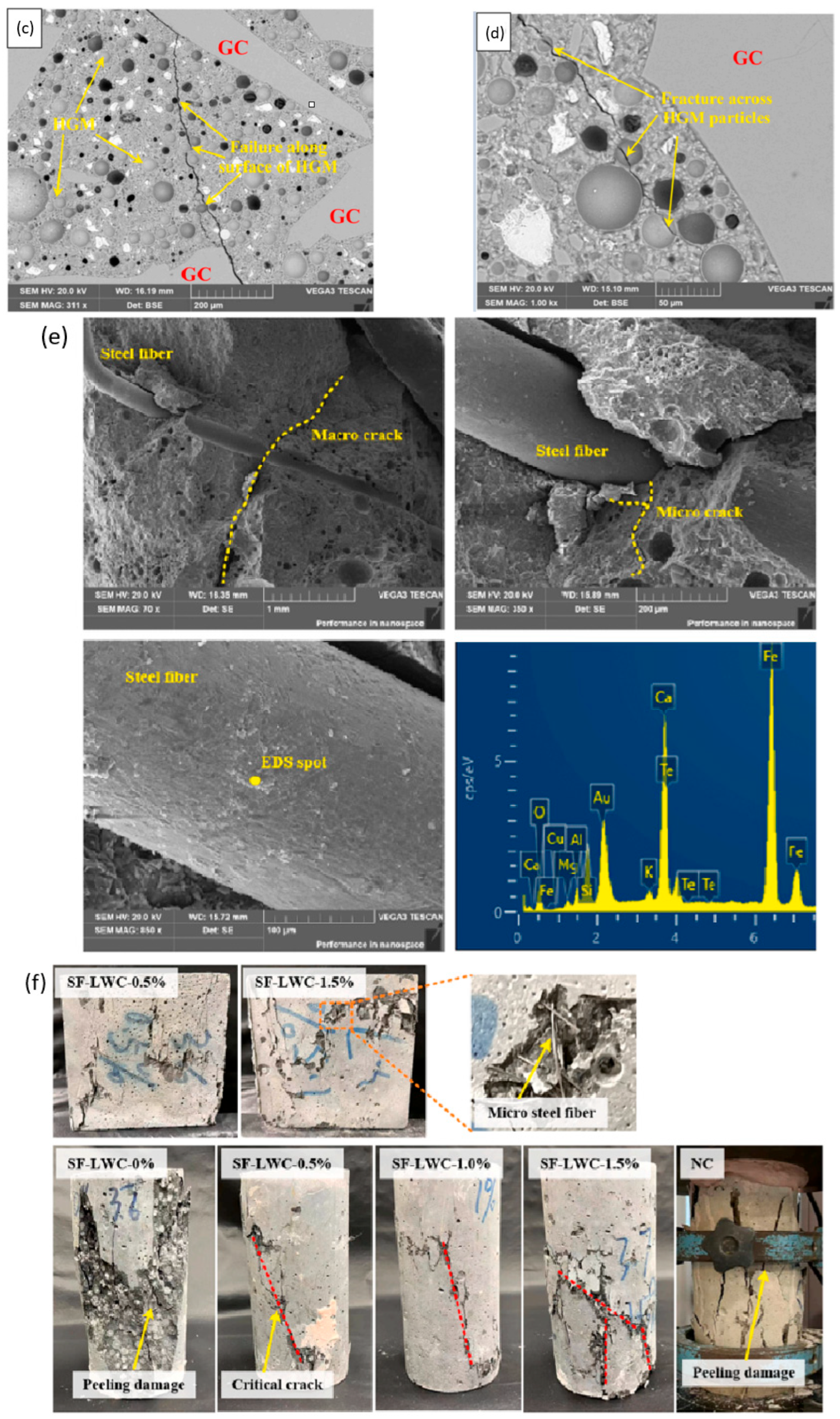

2.4. Fibers

2.5. Lightweight Fillers

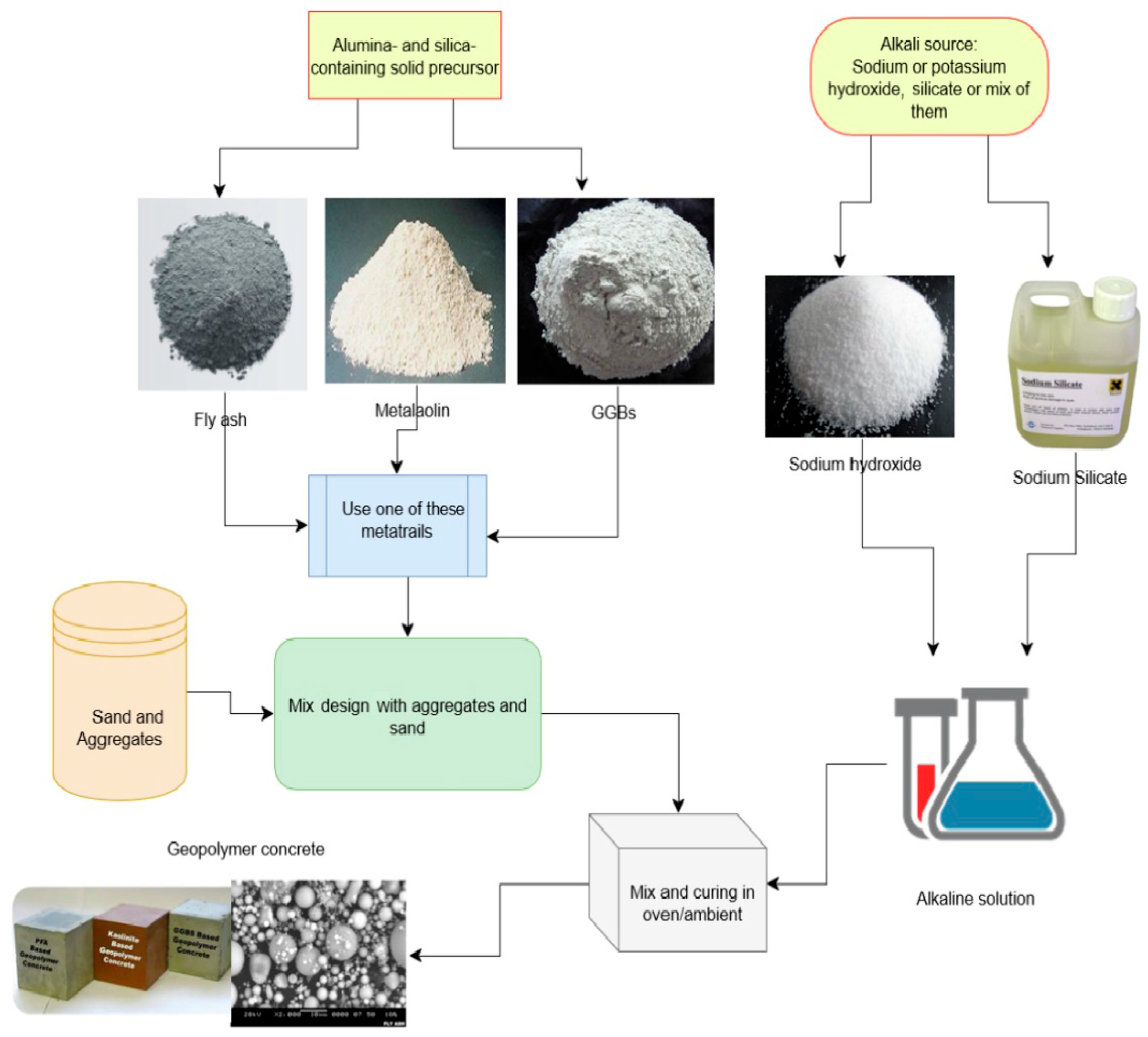

2.6. Geopolymers

2.7. Recycled Materials

2.8. Aerogels

2.9. Bio-Based Materials

3. Performance Characteristics of LWC

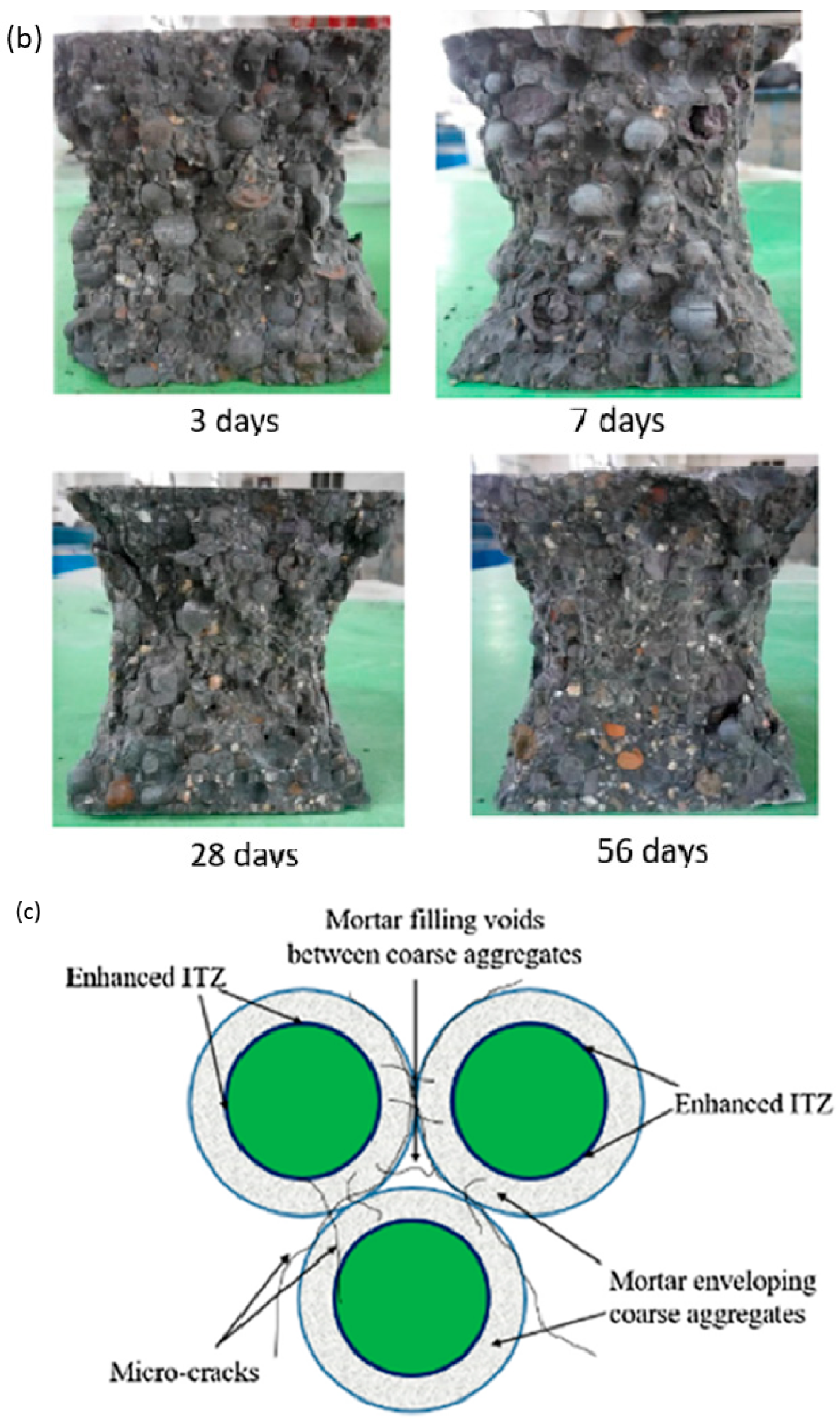

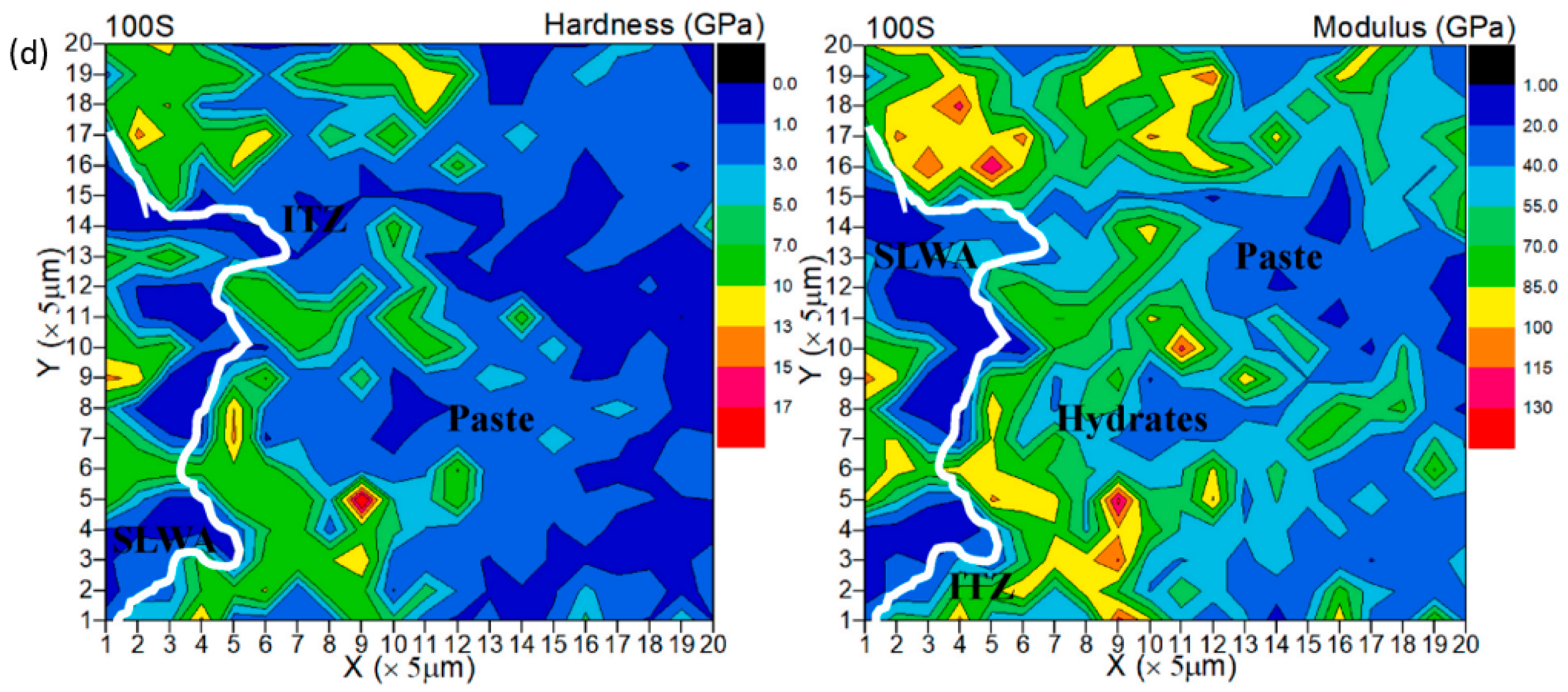

3.1. Strength and Elastic Modulus

| Ref. | Authors (Year) | Concrete Type | Relationship (E vs. f′c) | Comments |

|---|---|---|---|---|

| [68] | Kockal and Ozturan (2010) | SLWC with expanded clay/slate | E = 4730 × √f’c | Empirical model; E in MPa |

| [70] | Cui et al. (2012) | Structural lightweight aggregate concrete | E = 0.043 × (f’c)^1.5 | E in GPa; fits well for soaked aggregates |

| [69] | Kayali et al. (2003) | Fiber-reinforced LWC | E = 4400 × √f’c | LWC with fly ash-based LWA |

| [71] | Lu et al. (2020) | Foamed LWC with expanded clay | E = 0.053 × (f’c)^1.34 | Quasi-brittle modeling applied |

| [72] | Basha et al. (2020) | Recycled plastic aggregate LWC | E = 0.038 × (f’c)^1.48 | Low E due to plastic inclusions |

| [74] | Behera et al. (2022) | UHPC hybrid fiber LWC | E = 3900 × √f’c | With sintered fly ash and palm shell |

| [58] | Kazemi et al. (2025) | UHPC and advanced materials | ML-based; no fixed equation | GWO + ML ensemble model |

| [73] | Shafighfard et al. (2024) | High-performance alkali-activated concrete | ML-based estimation | ANN, RF, SVR, etc. |

Effects on Carbon Nanotubes for Improving Compressive Strength in LWC

- (a)

- The Effects of Carbon Nanotubes on the Compressive Strength of Cementitious Composites:

- (b)

- Mechanisms of Compressive Strength Enhancement:

- (c)

- Machine Learning Approaches to Predict CNT Influence:

- (d)

- CNTs in Lightweight and Foamed Concrete

- (e)

- Challenges and Optimization

- (f)

- Summary:

| Study | Cementitious Material | CNT Type | Key Findings | Modeling/Analysis Approach |

|---|---|---|---|---|

| [76] Özyüksel Çiftçioğlu et al. (2025) | Ultra-High-Performance Concrete (UHPC) | CNTs enhance compressive strength significantly; optimal dosage is critical | Grey Wolf Optimizer + Boosting algorithm | |

| [75] Li et al. (2022) | Cement-based composites | CNTs increase strength up to 30%; dispersion and dosage are key factors | Machine learning regression models | |

| [77] Bagherzadeh and Shafighfard (2022) | CNT-reinforced cementitious composites | Carbon nanotubes (general) | ML models show strength enhancement with optimal CNT content | Ensemble machine learning (EML) |

| [78] Sldozian et al. (2024) | Lightweight Foamed Concrete (LFC) | Multi-walled CNTs (MWCNTs) | Up to 25% improvement in compressive strength; water absorption reduced | Experimental analysis |

3.2. Impact Resistance and Fracture Behavior

3.3. Durability in Aggressive Environments

| LWC Type | CO2 Sequestration Potential | Sustainable Material Used | Cost Impact | Durability Trade-Offs | References |

|---|---|---|---|---|---|

| LWC with Recycled Aggregate | Moderate (~10–12% CO2 uptake) | Crushed concrete, C&D waste | Low to moderate (cost-saving in supply) | Variable quality, potential for increased shrinkage | [104,105] |

| CO2-Cured LWC (Carbonation Curing) | High (~15–20% CO2 uptake) | Accelerated carbonation of cement matrix | Higher (specialized curing needed) | Risk of carbonation-induced rebar corrosion if uncoated | [106,107] |

| Geopolymer LWC | Moderate (~8–12% CO2 reduction) | Fly ash, slag (no Portland cement) | Moderate (variable by material source) | Lower early strength, sensitive to curing conditions | [108,109] |

| GEGA-Cement-Grout Permeable LWC | Moderate (~8–12% CO2 reduction) | Granulated Expanded Glass Aggregate + cement (hydraulic binder) | Medium: energy for glass granulation and cement grout | High porosity & low bulk density (~1000 kg/m3) | [110] |

| Bio-based LWC (e.g., bacterial LWC) | Moderate (~10–15% uptake) | Bacteria-induced calcite precipitation | High (novel materials and systems) | Experimental; long-term durability under real conditions unknown | [111] |

3.4. Carbonation Performance

3.5. Sustainability and CO2 Absorption

3.6. Circular Economy and Low-Impact Design

4. Cost Analysis Report

4.1. Lightweight Concrete vs. Normal-Weight Concrete

4.2. Structural and Design Implications

4.3. Logistical Advantages

4.4. Summary

5. Applications and Future Directions

6. Conclusions

- (1)

- High Mechanical Strength:

- (2)

- Improved Durability:

- (3)

- Thermal and Acoustic Insulation:

- (4)

- Environmental Sustainability:

- (5)

- Microstructural Optimization:

- (6)

- Enhanced Fracture and Impact Resistance:

- (7)

- Adaptability to Advanced Construction:

- (8)

- Reduced Structural Loads:

- (9)

- Long-Term Performance in Aggressive Environments:

- (10)

- Challenges and Research Needs:

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LWC | Lightweight Concrete |

| LWA/LWAs | Lightweight Aggregate(s) |

| HSLWAC | High-Strength Lightweight Aggregate Concrete |

| LWASCC | Lightweight Aggregate Self-Compacting Concrete |

| L-UHSC | Lightweight Ultra-High-Strength Concrete |

| ULHSC | Ultra-Lightweight High-Strength Concrete |

| FAC | Fly Ash Ceramic |

| SP | Shale Pottery/Superplasticizer (context-dependent) |

| CDW/C&DW | Construction and Demolition Waste |

| SCM/SCMs | Supplementary Cementitious Material(s) |

| GGBFS | Ground Granulated Blast Furnace Slag |

| MK | Metakaolin |

| SF | Silica Fume |

| EG | Expanded Glass |

| EPS | Expanded Polystyrene |

| AAC | Autoclaved Aerated Concrete |

| RLA | Recycled Lightweight Aggregates |

| ITZ | Interfacial Transition Zone |

| CNT/CNTs | Carbon Nanotubes |

| MWCNTs | Multi-Walled Carbon Nanotubes |

| PVA | Polyvinyl Alcohol (fiber) |

| PP | Polypropylene (fiber) |

| UHPC | Ultra-High-Performance Concrete |

| HPLAC | High-Performance Lightweight Aggregate Concrete |

| LW-GPC | Lightweight Geopolymer Concrete |

| RHA | Rice Husk Ash |

| BA | Bottom Ash |

| WGP | Waste Glass Powder |

| TS | Tensile Strength |

| CS | Compressive Strength |

| FS | Flexural Strength |

| IS | Impact Strength |

| FT | Fracture Toughness |

| RCM | Rapid Chloride Migration |

| SEM | Scanning Electron Microscopy |

| XRD | X-ray Diffraction |

| TGA | Thermogravimetric Analysis |

| FTIR | Fourier Transform Infrared Spectroscopy |

| BSE | Backscattered Electron |

| ML | Machine Learning |

| SHCC | Strain-Hardening Cementitious Composites |

| HPC | High-Performance Concrete |

| TRC | Textile-Reinforced Concrete |

| UHDC | Ultra-High-Ductility Concrete |

| NDT | Non-Destructive Testing |

| CO2 | Carbon Dioxide |

| EC | Embodied Carbon |

| GEGA | Granulated Expanded Glass Aggregate |

| SCC | Self-Compacting Concrete |

| HPFRCC | High-Performance Fiber-Reinforced Cementitious Composite |

| APMT | Advanced Powder Materials (journal abbreviation) |

| wt. % | Weight Percentage |

| PC | Portland Cement |

| HRWR | High-Range Water Reducer |

| w/b | Water-to-Binder Ratio |

| w/c | Water-to-Cement Ratio |

References

- Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.L.; Siddique, S. A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Constr. Mater. 2021, 1, 39–62. [Google Scholar] [CrossRef]

- Lu, J.X. Recent advances in high strength lightweight concrete: From development strategies to practical applications. Constr. Build. Mater. 2023, 400, 132905. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Constr. Build. Mater. 2015, 82, 114–122. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Wei, J.; Li, L.; Liu, J.; Wang, S.; Ding, Y. Mechanical properties and microstructure of ultra-high strength concrete with lightweight aggregate. Case Stud. Constr. Mater. 2023, 18, e01745. [Google Scholar] [CrossRef]

- Chung, S.Y.; Sikora, P.; Kim, D.J.; El Madawy, M.E.; Elrahman, M.A. Effect of different expanded aggregates on durability-related characteristics of lightweight aggregate concrete. Mater. Charact. 2021, 173, 110907. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Sun, T.; Huang, Y.; Liu, K. Effects of seawater and supplementary cementitious materials on the durability and microstructure of lightweight aggregate concrete. Constr. Build. Mater. 2018, 190, 1081–1090. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Hamad, A.J. Materials, production, properties and application of aerated lightweight concrete. Int. J. Mater. Sci. Eng. 2014, 2, 152–157. [Google Scholar] [CrossRef]

- Lu, J.X.; Shen, P.; Ali, H.A.; Poon, C.S. Mix design and performance of lightweight ultra high-performance concrete. Mater. Des. 2022, 216, 110553. [Google Scholar] [CrossRef]

- Choi, J.; Zi, G.; Hino, S.; Yamaguchi, K.; Kim, S. Influence of fiber reinforcement on strength and toughness of all-lightweight concrete. Constr. Build. Mater. 2014, 69, 381–389. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Experimental application of mineral admixtures in lightweight concrete with high strength and workability. Constr. Build. Mater. 2008, 22, 1108–1113. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; He, J.; Zhang, Y.; Cai, C.; Huang, D.; Li, L. Effects of fibres on ultra-lightweight high strength concrete: Dynamic behaviour and microstructures. Cem. Concr. Compos. 2022, 128, 104417. [Google Scholar] [CrossRef]

- Schnell, A.; Rübner, K.; Seher, J.; Müller, C.; Müller, A.; Liebezeit, S.; Fenner, J.; Martin, F.; Pniok, N. Manufacturing and Application of Lightweight Aggregates from Construction and Demolition Waste. Chem. Ing. Tech. 2024, 96, 969–975. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853. [Google Scholar] [CrossRef]

- Haddadian, A.; Johnson Alengaram, U.; Ayough, P.; Mo, K.H.; Mahmoud Alnahhal, A. Inherent characteristics of agro and industrial By-Products based lightweight concrete—A comprehensive review. Constr. Build. Mater. 2023, 397, 132298. [Google Scholar] [CrossRef]

- Yew, M.K.; Beh, J.H.; Yew, M.C.; Lee, F.W.; Saw, L.H.; Lim, S.K. Performance of surface modification on bio-based aggregate for high strength lightweight concrete. Case Stud. Constr. Mater. 2022, 16, e00910. [Google Scholar] [CrossRef]

- Fořt, J.; Afolayan, A.; Medveď, I.; Scheinherrová, L.; Černý, R. A review of the role of lightweight aggregates in the development of mechanical strength of concrete. J. Build. Eng. 2024, 89, 109312. [Google Scholar] [CrossRef]

- Liao, Q.; Lu, S.Y.; Lu, J.X.; Poon, C.S. Improving mechanical and fracture properties of high-performance lightweight concrete by using steel fiber and sustainable high-strength core-shell lightweight aggregate. Constr. Build. Mater. 2025, 459, 139697. [Google Scholar] [CrossRef]

- Sahoo, S.; Selvaraju, A.K.; Suriya Prakash, S. Mechanical characterization of structural lightweight aggregate concrete made with sintered fly ash aggregates and synthetic fibres. Cem. Concr. Compos. 2020, 113, 103712. [Google Scholar] [CrossRef]

- Singh, N.; Raza, J.; Colangelo, F.; Farina, I. Advancements in Lightweight Artificial Aggregates: Typologies, Compositions, Applications, and Prospects for the Future. Sustainability 2024, 16, 9329. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; Bin Jumaat, M.Z. Utilization of oil palm kernel shell as lightweight aggregate in concrete—A review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Al Mohammad, A.; Çevik, A.; Jwaida, Z.; Shubbar, A. Effect of Expanded Glass Lightweight Aggregate on the Performance of Geopolymer Mortar at Elevated Temperatures. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2024, 49, 1479–1492. [Google Scholar] [CrossRef]

- Liu, Q.; Shen, X.; Wei, L.; Dong, R.; Xue, H. Grey Model Research Based on the Pore Structure Fractal and Strength of NMR Aeolian Sand Lightweight Aggregate Concrete. JOM 2020, 72, 536–543. [Google Scholar] [CrossRef]

- Deshpande, Y.S.; Hiller, J.E. Pore characterization of manufactured aggregates: Recycled concrete aggregates and lightweight aggregates. Mater. Struct. 2012, 45, 67–79. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Youm, K.S.; Moon, J.; Cho, J.Y.; Kim, J.J. Experimental study on strength and durability of lightweight aggregate concrete containing silica fume. Constr. Build. Mater. 2016, 114, 517–527. [Google Scholar] [CrossRef]

- Xiong, G.; Wang, C.; Zhou, S.; Jia, X.; Luo, W.; Liu, J.; Peng, X. Preparation of high strength lightweight aggregate concrete with the vibration mixing process. Constr. Build. Mater. 2019, 229, 116936. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Wan, C. A mix-design method for lightweight aggregate self-compacting concrete based on packing and mortar film thickness theories. Constr. Build. Mater. 2017, 157, 621–634. [Google Scholar] [CrossRef]

- Aldikheeli, M.R.; Shubber, M.S. The effects of fibre on the mechanical properties of aerated concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012076. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Properties of lightweight expanded polystyrene concrete reinforced with steel fiber. Cem. Concr. Res. 2004, 34, 1259–1263. [Google Scholar] [CrossRef]

- Silva, L.M.; Ribeiro, R.A.; Labrincha, J.A.; Ferreira, V.M. Role of lightweight fillers on the properties of a mixed-binder mortar. Cem. Concr. Compos. 2010, 32, 19–24. [Google Scholar] [CrossRef]

- Gencel, O.; Yavuz Bayraktar, O.; Kaplan, G.; Arslan, O.; Nodehi, M.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Constr. Build. Mater. 2022, 320, 126187. [Google Scholar] [CrossRef]

- Dixit, A.; Pang, S.D.; Kang, S.H.; Moon, J. Lightweight structural cement composites with expanded polystyrene (EPS) for enhanced thermal insulation. Cem. Concr. Compos. 2019, 102, 185–197. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Cheng, Y.; Diao, S.; Li, Z. Effects of Different Lightweight Functional Fillers for Use in Cementitious Composites. Int. J. Concr. Struct. Mater. 2017, 11, 99–113. [Google Scholar] [CrossRef]

- Tale Masoule, M.S.; Bahrami, N.; Karimzadeh, M.; Mohasanati, B.; Shoaei, P.; Ameri, F.; Ozbakkaloglu, T. Lightweight geopolymer concrete: A critical review on the feasibility, mixture design, durability properties, and microstructure. Ceram. Int. 2022, 48, 10347–10371. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Ismail, N.; El-Hassan, H. Development and Characterization of Fly Ash–Slag Blended Geopolymer Mortar and Lightweight Concrete. J. Mater. Civ. Eng. 2018, 30, 04018029. [Google Scholar] [CrossRef]

- Huiskes, D.M.A.; Keulen, A.; Yu, Q.L.; Brouwers, H.J.H. Design and performance evaluation of ultra-lightweight geopolymer concrete. Mater. Des. 2016, 89, 516–526. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Liu, M.Y.J.; Lim, J. Assessing some durability properties of sustainable lightweight oil palm shell concrete incorporating slag and manufactured sand. J. Clean. Prod. 2016, 112, 763–770. [Google Scholar] [CrossRef]

- Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrándiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C. Mechanical and thermal properties of lightweight geopolymer composites. Cem. Concr. Compos. 2018, 86, 266–272. [Google Scholar] [CrossRef]

- Wongsa, A.; Zaetang, Y.; Sata, V.; Chindaprasirt, P. Properties of lightweight fly ash geopolymer concrete containing bottom ash as aggregates. Constr. Build. Mater. 2016, 111, 637–643. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Zeyad, A.M.; Agwa, I.S.; Amin, M. Effect of elevated temperatures on mechanical properties of lightweight geopolymer concrete. Case Stud. Constr. Mater. 2021, 15, e00673. [Google Scholar] [CrossRef]

- Liu, X.; Wen, Y.; Chen, S.; Jiang, M. Geopolymer cold-bonded lightweight aggregate concrete: Mechanical properties and microstructure. Constr. Build. Mater. 2025, 465, 140261. [Google Scholar] [CrossRef]

- Gyurkó, Z.; Jankus, B.; Fenyvesi, O.; Nemes, R. Sustainable applications for utilization the construction waste of aerated concrete. J. Clean. Prod. 2019, 230, 430–444. [Google Scholar] [CrossRef]

- Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P. Structural Lightweight Concrete Containing Recycled Lightweight Concrete Aggregate. KSCE J. Civ. Eng. 2018, 22, 3077–3084. [Google Scholar] [CrossRef]

- Kalkan, Ş.O.; Gündüz, L. Silica aerogel added lightweight cement-based composite mortars for thermal insulation purposes in sustainable structures: A comprehensive study. Constr. Build. Mater. 2023, 409, 134066. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, Y.; Shi, S.; Yuan, N.; Ma, R.; Wu, X.; Shi, D.; Sun, K.; Zhao, Y.; Li, W.; et al. Compressive behavior of lightweight concrete using aerogel-reinforced expanded polystyrene foams. Case Stud. Constr. Mater. 2022, 17, e01557. [Google Scholar] [CrossRef]

- Tsioulou, O.; Lampropoulos, A.; Cacciola, P. Development of High-Strength Aerogel Concrete. Materials 2025, 18, 1040. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Kapoor, K.; Das, A.; Katare, V. Mechanical performance of bio-based materials in structural applications: A comprehensive review. Structures 2025, 75, 108726. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.S.; Pereira-de-Oliveira, L.A.; Pereira, S.F. Mix design of structural lightweight self-compacting concrete incorporating coarse lightweight expanded clay aggregates. Constr. Build. Mater. 2018, 166, 373–385. [Google Scholar] [CrossRef]

- Yew, M.K.; Yew, M.C.; Beh, J.H.; Saw, L.H.; Lim, S.K. Effects of pre-treated on dura shell and tenera shell for high strength lightweight concrete. J. Build. Eng. 2021, 42, 102493. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.; Bin Alengaram, U.J. A new method of producing high strength oil palm shell lightweight concrete. Mater. Des. 2011, 32, 4839–4843. [Google Scholar] [CrossRef]

- Bogas, J.A.; Carriço, A.; Pontes, J. Influence of cracking on the capillary absorption and carbonation of structural lightweight aggregate concrete. Cem. Concr. Compos. 2019, 104, 103382. [Google Scholar] [CrossRef]

- Iqbal, S.; Ali, A.; Holschemacher, K.; Bier, T.A. Mechanical properties of steel fiber reinforced high strength lightweight self-compacting concrete (SHLSCC). Constr. Build. Mater. 2015, 98, 325–333. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.H. Water absorption, permeability, and resistance to chloride-ion penetration of lightweight aggregate concrete. Constr. Build. Mater. 2011, 25, 335–343. [Google Scholar] [CrossRef]

- Liu, H.; Elchalakani, M.; Karrech, A.; Yehia, S.; Yang, B. High strength flowable lightweight concrete incorporating low C3A cement, silica fume, stalite and macro-polyfelin polymer fibres. Constr. Build. Mater. 2021, 281, 122410. [Google Scholar] [CrossRef]

- Kazemi, F.; Çiftçioğlu, A.Ö.; Shafighfard, T.; Asgarkhani, N.; Jankowski, R. RAGN-R: A multi-subject ensemble machine-learning method for estimating mechanical properties of advanced structural materials. Comput. Struct. 2025, 308, 107657. [Google Scholar] [CrossRef]

- Megat Johari, M.A.; Brooks, J.J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Yu, Q.L.; Spiesz, P.; Brouwers, H.J.H. Ultra-lightweight concrete: Conceptual design and performance evaluation. Cem. Concr. Compos. 2015, 61, 18–28. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yoon, Y.-S.; Banthia, N. Flexural response of steel-fiber-reinforced concrete beams: Effects of strength, fiber content, and strain-rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Committee, A.C.I. Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (ACI 318R-05); American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Guide for Structural Lightweight (Reapproved 1999) Aggregate Concrete, Reported by ACI Committee 213, 213R-87. Available online: https://www.vandidad-co.com/Uploadfiles/CkEditor/Files/%D9%85%D8%AD%D8%B5%D9%88%D9%84%D8%A7%D8%AA/213r_87.pdf (accessed on 28 May 2025).

- Eurocode 2: Design of Concrete Structures-Part 1–1: General Rules and Rules for Buildings; British Standard Institution: London, UK, 2005; Volume 668, pp. 659–668.

- Kockal, N.U.; Ozturan, T. Strength and elastic properties of structural lightweight concretes. Mater. Des. 2011, 32, 2396–2403. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.N.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Cui, H.Z.; Lo, T.Y.; Memon, S.A.; Xing, F.; Shi, X. Analytical model for compressive strength, elastic modulus and peak strain of structural lightweight aggregate concrete. Constr. Build. Mater. 2012, 36, 1036–1043. [Google Scholar] [CrossRef]

- Lu, Y.; Hu, X.; Yang, X.; Xiao, Y. Comprehensive tests and quasi-brittle fracture modeling of light-weight foam concrete with expanded clay aggregates. Cem. Concr. Compos. 2021, 115, 103822. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Shafighfard, T.; Kazemi, F.; Asgarkhani, N.; Yoo, D.-Y. Machine-learning methods for estimating compressive strength of high-performance alkali-activated concrete. Eng. Appl. Artif. Intell. 2024, 136, 109053. [Google Scholar] [CrossRef]

- Behera, D.; Liu, K.-Y.; Gopalakrishnan, D. Experimental Prognostication of Ultra-High-Performance Lightweight Hybrid Fiber-Reinforced Concrete by Using Sintered Fly Ash Aggregate, Palm Oil Shell Aggregate, and Supplementary Cementitious Materials. Materials 2022, 15, 5051. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, H.; Jin, C.; Shen, J. The study of effect of carbon nanotubes on the compressive strength of cement-based materials based on machine learning. Constr. Build. Mater. 2022, 358, 129435. [Google Scholar] [CrossRef]

- Çiftçioğlu, A.Ö.; Kazemi, F.; Shafighfard, T. Grey wolf optimizer integrated within boosting algorithm: Application in mechanical properties prediction of ultra high-performance concrete including carbon nanotubes. Appl. Mater. Today 2025, 42, 102601. [Google Scholar] [CrossRef]

- Bagherzadeh, F.; Shafighfard, T. Ensemble Machine Learning approach for evaluating the material characterization of carbon nanotube-reinforced cementitious composites. Case Stud. Constr. Mater. 2022, 17, e01537. [Google Scholar] [CrossRef]

- Sldozian, R.J.; Burakov, A.E.; Aljaboobi, D.Z.M.; Hamad, A.J.; Tkachev, A.G. The effect of multi-walled carbon nanotubes on mechanical properties and water adsorption of lightweight foamed concrete. Res. Eng. Struct. Mater. 2024, 10, 1139–1154. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.N.; Zhu, B. Drying shrinkage of fibre-reinforced lightweight aggregate concrete containing fly ash. Cem. Concr. Res. 1999, 29, 1835–1840. [Google Scholar] [CrossRef]

- Zhang, M.H.; Gjvorv, O.E. Mechanical properties of high-strength lightweight concrete. Mater. J. 1991, 88, 240–247. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Tahmouresi, B.; Saradar, A. Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). Constr. Build. Mater. 2018, 162, 321–333. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z.; Li, Z.G. Influence of aggregate pre-wetting and fly ash on mechanical properties of lightweight concrete. Waste Manag. 2004, 24, 333–338. [Google Scholar] [CrossRef]

- Yap, S.P.; Bu, C.H.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater. Des. 2014, 57, 652–659. [Google Scholar] [CrossRef]

- Lu, J.-X.; Shen, P.; Ali, H.A.; Poon, C.S. Development of high performance lightweight concrete using ultra high performance cementitious composite and different lightweight aggregates. Cem. Concr. Compos. 2021, 124, 104277. [Google Scholar] [CrossRef]

- Feo, L.; Greco, F.; Leonetti, L.; Luciano, R. Mixed-mode fracture in lightweight aggregate concrete by using a moving mesh approach within a multiscale framework. Compos. Struct. 2015, 123, 88–97. [Google Scholar] [CrossRef]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Rossignolo, J.A.; Agnesini, M.V.C. Mechanical properties of polymer-modified lightweight aggregate concrete. Cem. Concr. Res. 2002, 32, 329–334. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, E.; Zhu, C.; Zhang, Z. Effect of microstructural characteristics of lightweight aggregate concrete on fracture parameters of three-point bending notched beams. Theor. Appl. Fract. Mech. 2022, 121, 103545. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z. Effect of porous lightweight aggregate on strength of concrete. Mater. Lett. 2004, 58, 916–919. [Google Scholar] [CrossRef]

- Hu, G.; Zhong, H.; Wang, W.; Huang, Y.; Gu, T.; Zhang, G.; Luo, X.; Liu, L.; Zhang, L. Finite Element Simulation of Fracture Behavior of Cordierite–Belite Core–Shell Lightweight Aggregate Concrete. Buildings 2024, 14, 3899. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, X.; Xiao, Y. Simulation and Experimental Study on Fracture Properties of Lightweight Aggregate Foam Concrete. IOP Conf. Ser. Earth Env. Sci. 2019, 371, 022093. [Google Scholar] [CrossRef]

- Musalamah, S.; Purnomo, H.; Handika, N. Method for Determining Fracture Energy of a Polypropylene Coarse Lightweight Aggregate Concrete Beam Using Digital Image Correlation. Eng. Proc. 2024, 63, 19. [Google Scholar] [CrossRef]

- Maglad, A.M.; Mansour, W.; Tayeh, B.A.; Elmasry, M.; Yosri, A.M.; Fayed, S. Experimental and Analytical Investigation of Fracture Characteristics of Steel Fiber-Reinforced Recycled Aggregate Concrete. Int. J. Concr. Struct. Mater. 2023, 17, 74. [Google Scholar] [CrossRef]

- Sahoo, S.; Lakavath, C.; Prakash, S.S. Experimental and Analytical Studies on Fracture Behavior of Fiber-Reinforced Structural Lightweight Aggregate Concrete. J. Mater. Civ. Eng. 2021, 33, 04021074. [Google Scholar] [CrossRef]

- Sim, J.-I.; Yang, K.-H.; Lee, E.-T.; Yi, S.-T. Effects of Aggregate and Specimen Sizes on Lightweight Concrete Fracture Energy. J. Mater. Civ. Eng. 2014, 26, 845–854. [Google Scholar] [CrossRef]

- Lu, J.X.; Ali, H.A.; Jiang, Y.; Guan, X.; Shen, P.; Chen, P.; Poon, C.S. A novel high-performance lightweight concrete prepared with glass-UHPC and lightweight microspheres: Towards energy conservation in buildings. Compos. B Eng. 2022, 247, 110295. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon-and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Ren, G.M.; Wu, H.; Fang, Q.; Liu, J.Z. Effects of steel fiber content and type on static mechanical properties of UHPCC. Constr. Build. Mater. 2018, 163, 826–839. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Zhang, H. Fracture properties of high-performance concrete containing fly ash. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2012, 226, 170–176. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Li, L.; Paramasivam, P. Shrinkage of high-strength lightweight aggregate concrete exposed to dry environment. ACI Mater. J. 2005, 102, 86–92. [Google Scholar]

- Mao, J.; Ayuta, K. Freeze–thaw resistance of lightweight concrete and aggregate at different freezing rates. J. Mater. Civ. Eng. 2008, 20, 78–84. [Google Scholar] [CrossRef]

- Libre, N.A.; Shekarchi, M.; Mahoutian, M.; Soroushian, P. Mechanical properties of hybrid fiber reinforced lightweight aggregate concrete made with natural pumice. Constr. Build. Mater. 2011, 25, 2458–2464. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Safiuddin, M.; Alengaram, U.J.; Rahman, M.; Salam, M.A.; Jumaat, Z. Use of Recycled Concrete Aggregate in Concrete: A Review. J. Civ. Eng. Manag. 2013, 19, 796–810. [Google Scholar] [CrossRef]

- Galan, I.; Andrade, C.; Mora, P.; Sanjuan, M.A. Sequestration of CO2 by Concrete Carbonation. Envion. Sci. Technol. 2010, 44, 3181–3186. [Google Scholar] [CrossRef]

- Al Fuhaid, A.F.; Niaz, A. Carbonation and Corrosion Problems in Reinforced Concrete Structures. Buildings 2022, 12, 586. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Kurpińska, M.; Grzyl, B.; Pszczola, M.; Kristowski, A. The application of granulated expanded glass aggregate with cement grout as an alternative solution for sub-grade and frost-protection sub-base layer in road construction. Materials 2019, 12, 3528. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Self-healing of cracks in bacterial concrete. In 2nd International Symposium on Service Life Design for Infrastructures; RILEM Publications SARL: Zagreb, Croatia, 2010; pp. 825–831. [Google Scholar]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. (1980–2015) 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Bentz, D.P.; Peltz, M.A. Reducing thermal and autogenous shrinkage contributions to early-age cracking. ACI Mater. J. 2008, 105, 414. [Google Scholar]

- Thomas, M.; Bremner, T. Performance of lightweight aggregate concrete containing slag after 25 years in a harsh marine environment. Cem. Concr. Res. 2012, 42, 358–364. [Google Scholar] [CrossRef]

- Zhang, M. Pore-scale modelling of relative permeability of cementitious materials using X-ray computed microtomography images. Cem. Concr. Res. 2017, 95, 18–29. [Google Scholar] [CrossRef]

- Al-Safy, R.; Al-Mahaidi, R.; Simon, G.P.; Habsuda, J. Experimental investigation on the thermal and mechanical properties of nanoclay-modified adhesives used for bonding CFRP to concrete substrates. Constr. Build. Mater. 2012, 28, 769–778. [Google Scholar] [CrossRef]

- Alexandre Bogas, J.; Gomes, M.G.; Real, S. Capillary absorption of structural lightweight aggregate concrete. Mater. Struct. 2015, 48, 2869–2883. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Lotfy, A.; Hossain, K.M.A.; Lachemi, M. Durability properties of lightweight self-consolidating concrete developed with three types of aggregates. Constr. Build. Mater. 2016, 106, 43–54. [Google Scholar] [CrossRef]

- Haque, N.; Al-Khaiat, H. Strength and durability of lightweight concrete in hot marine exposure conditions. Mater. Struct. 1999, 32, 533–538. [Google Scholar] [CrossRef]

- Jung, Y.B.; Yang, K.H.; Lee, Y.J.; Kim, H.K. Carbonation testing of lightweight concrete using expanded bottom ash and dredged soil aggregates. Constr. Build. Mater. 2024, 444, 137758. [Google Scholar] [CrossRef]

- Dinh, D.K.; Trenchev, G.; Lee, D.H.; Bogaerts, A. Arc plasma reactor modification for enhancing performance of dry reforming of methane. J. CO2 Util. 2020, 42, 101352. [Google Scholar] [CrossRef]

- Bogas, J.A.; Real, S. A review on the carbonation and chloride penetration resistance of structural lightweight aggregate concrete. Materials 2019, 12, 3456. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson: New York, NY, USA, 2011. [Google Scholar]

- Bentz, D.P.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Li, J.; Roychand, R.; Saberian, M. Microstructure, thermal conductivity and carbonation resistance properties of sustainable structural lightweight concrete incorporating 100% coarser rubber particles. Constr. Build. Mater. 2023, 408, 133658. [Google Scholar] [CrossRef]

- Zhao, X.; Zheng, X.; Zhong, W.; Jiang, W.; Hu, D. Experimental study on strength and carbonation performance of hybrid fibre lightweight aggregate concrete in precast structures. J. Phys. Conf. Ser. 2024, 2730, 012010. [Google Scholar] [CrossRef]

- Kuder, K.G.; Ozyurt, N.; Mu, E.B.; Shah, S.P. Rheology of fiber-reinforced cementitious materials. Cem. Concr. Res. 2007, 37, 191–199. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Shi, C.; He, F.; Wu, Y. Effect of pre-conditioning on CO2 curing of lightweight concrete blocks mixtures. Constr. Build. Mater. 2012, 26, 257–267. [Google Scholar] [CrossRef]

- Demirboga, R.; Kan, A. Thermal conductivity and shrinkage properties of modified waste polystyrene aggregate concretes. Constr. Build. Mater. 2012, 35, 730–734. [Google Scholar] [CrossRef]

- Xi, F.; Davis, S.J.; Ciais, P.; Crawford-Brown, D.; Guan, D.; Pade, C.; Shi, T.; Syddall, M.; Lv, J.; Ji, L.; et al. Substantial global carbon uptake by cement carbonation. Nat. Geosci. 2016, 9, 880–883. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Rumšys, D.; Bačinskas, D.; Spudulis, E. Mechanical properties of lightweight concrete produced with expanded glass aggregate. Moksl.-Liet. Ateitis-Sci.-Future Lith. 2017, 9, 500–506. [Google Scholar] [CrossRef][Green Version]

- Zhang, B.; Poon, C.S. Use of furnace bottom ash for producing lightweight aggregate concrete with thermal insulation properties. J. Clean. Prod. 2015, 99, 94–100. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z. Enhancement of mechanical properties in polypropylene–and nylon–fibre reinforced oil palm shell concrete. Mater. Des. 2013, 49, 1034–1041. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberized concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Tien, Y.M.; Wang, C.Y.; Juang, C.H.; Lee, D.H. Mechanical behavior of artificial anisotropic rock masses. In ARMA US Rock Mechanics/Geomechanics Symposium; ARMA: Vail, CO, USA, 1999; p. ARMA-99. [Google Scholar]

- de Jesus, A.M.P.; Pinto, J.M.T.; Morais, J.J.L. Analysis of solid wood beams strengthened with CFRP laminates of distinct lengths. Constr. Build. Mater. 2012, 35, 817–828. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Use of recycled demolition aggregate in precast products, phase II: Concrete paving blocks. Constr. Build. Mater. 2011, 25, 3131–3143. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Chaipanich, A. Compressive strength and drying shrinkage of fly ash-bottom ash-silica fume multi-blended cement mortars. Mater. Des. (1980–2015) 2012, 36, 655–662. [Google Scholar] [CrossRef]

- ESCSI. Cost Comparison of Lightweight Concrete. EscsiOrg 2022. Available online: https://www.escsi.org/e-newsletter/cost-comparison-of-lightweight-concrete (accessed on 28 May 2025).

- ESCSI. Lightweight Concrete vs. Normalweight Concrete: Comparing Cost and Load Reduction. EscsiOrg 2024. Available online: https://www.escsi.org/lightweight-concrete-vs-normalweight-concrete-comparing-cost-and-load-reduction/ (accessed on 28 May 2025).

- Ramli, M.Z.; Mahayudin, H.M.; Hayder, G.; Hafiz, Z.M.; Daud, M.; Salleh, A.M. The importance of lightweight concrete technology development for IBS industry in Malaysia based on cost comparison between concrete slab and hollow core slab: A case study of LRT car park project. Appl. Mech. Mater. 2014, 567, 637–641. [Google Scholar] [CrossRef]

- Nunley, K. Evaluating Cost and Logistical Advantages of Working with Lightweight Concrete 2025. Available online: https://concreteproducts.com/index.php/2025/04/23/evaluating-cost-and-logistical-advantages-of-working-with-lightweight-concrete/ (accessed on 28 May 2025).

- ACI Committee 213. Guide for Structural Lightweight-Aggregate Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Cuevas, K.; Chougan, M.; Martin, F.; Ghaffar, S.H.; Stephan, D.; Sikora, P. 3D printable lightweight cementitious composites with incorporated waste glass aggregates and expanded microspheres–Rheological, thermal and mechanical properties. J. Build. Eng. 2021, 44, 102718. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. Porosity and permeability of foamed concrete. Cem. Concr. Res. 2001, 31, 805–812. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Resende, D.M.; de Carvalho, J.M.F.; Paiva, B.O.; Gonçalves Gdos, R.; Costa, L.C.B.; Peixoto, R.A.F. Sustainable Structural Lightweight Concrete with Recycled Polyethylene Terephthalate Waste Aggregate. Buildings 2024, 14, 609. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self-healing concrete–A review. Constr. Build. Mater. 2017, 152, 1008–1014. [Google Scholar] [CrossRef]

- Liu, B.; Wu, M.; Du, W.; Jiang, L.; Li, H.; Wang, L.; Li, J.; Zuo, D.; Ding, Q. The application of self-healing microcapsule technology in the field of cement-based materials: A review and prospect. Polymers 2023, 15, 2718. [Google Scholar] [CrossRef] [PubMed]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Ma, G.; Yuan, Y.; Nener, B. Automating the mixture design of lightweight foamed concrete using multi-objective firefly algorithm and support vector regression. Cem. Concr. Compos. 2021, 121, 104103. [Google Scholar] [CrossRef]

- Goertzen, T.; Neef, T.; Scheffler, P.; Macek, D.; Mechtcherine, V.; Niemeyer, A.C. 3D concrete printing of topological interlocking blocks. Mater. Des. 2025, 254, 114049. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Dehestani, M.; Hosseinzadeh, A. Prediction of mechanical properties of recycled aggregate fly ash concrete employing machine learning algorithms. J. Build. Eng. 2023, 76, 107006. [Google Scholar] [CrossRef]

- Hassan, M.; Misra, M.; Taylor, G.W.; Mohanty, A.K. A review of AI for optimization of 3D printing of sustainable polymers and composites. Compos. Part C Open Access 2024, 15, 100513. [Google Scholar] [CrossRef]

- Chen, Y.X.; Liu, G.; Schollbach, K.; Brouwers, H.J.H. Development of cement-free bio-based cold-bonded lightweight aggregates (BCBLWAs) using steel slag and miscanthus powder via CO2 curing. J. Clean. Prod. 2021, 322, 129105. [Google Scholar] [CrossRef]

- Wang, X.; Ding, S.; Ni, Y.-Q.; Zhang, L.; Dong, S.; Han, B. Intrinsic self-sensing concrete to energize infrastructure intelligence and resilience: A review. J. Infrastruct. Intell. Resil. 2024, 3, 100094. [Google Scholar] [CrossRef]

- Roopa, A.K.; Hunashyal, A.M.; Venkaraddiyavar, P.; Ganachari, S.V. Smart hybrid nano composite concrete embedded sensors for structural health monitoring. Mater. Today Proc. 2020, 27, 603–609. [Google Scholar] [CrossRef]

- Arisoy, B. Wall panel application of fibre-reinforced lightweight concrete. Aust. J. Civ. Eng. 2010, 6, 13–20. [Google Scholar] [CrossRef]

- Zhang, J. Application of ultra-high performance concrete in the marine environment. E3S Web Conf. 2025, 606, 04008. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Afolayan, A.; Ipindola, O.O.; Popoola, M.O.; Oginni, A.O. Effect of aggregate shapes on the properties of concrete. LAUTECH J. Civ. Envion. Stud. 2020. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.C.; Hansen, W. Internal Curing in High Performance Concrete: Effect of Lightweight Aggregate on Shrinkage and Salt Frost Durability. Key Eng. Mater. 2014, 629–630, 201–206. [Google Scholar] [CrossRef]

| Fiber Type | Key Benefits | Application Notes | References |

|---|---|---|---|

| Steel Fibers | Increases flexural and impact strength | Ideal for structural and dynamic load applications | [12,13,30,31] |

| Enhances energy dissipation | Best performance with longer fibers (e.g., 60 mm) | ||

| Improves compressive strength | |||

| Carbon Fibers | Improves splitting tensile and flexural strength (>60%) | Suitable for high-performance, crack-resistant concrete | [12] |

| Densifies microstructure | |||

| Enhances crack-bridging | |||

| Polypropylene (PP) Fibers | Boosts strain-rate sensitivity | Less effective in static strength due to weak bonding | [13] |

| Increases energy absorption under impact | Effective for impact resistance | ||

| Improves ductility | |||

| Natural Fibers (e.g., basalt, coconut, sisal) | Eco-friendly | Suitable for sustainable and non-structural applications | [12] |

| Enhances thermal and acoustic insulation | |||

| Vinylon Fibers | Enhances flexural strength and fracture toughness | Effective for improving mechanical performance of all-lightweight concrete | [10] |

| Steel + Silica Fume (Sand-Wrapping Method) | Increases split tensile strength (25%) | Suitable for structural and impact-resistant applications with lightweight concretes of 800–1800 kg/m3 | [31] |

| Reduces 90-day drying shrinkage by half |

| Type of LWA | SCM | Density (kg/m3) | Slump (mm) | Compressive Strength (MPa) | W/C | Keynote | Refs. |

|---|---|---|---|---|---|---|---|

| Crushed slate (Stalite) | 3.5% Silica Fume | 1893 | 210 | 71.0 | 0.259 | High compressive strength; good workability; superior chloride resistance and frost durability; and optimum silica fume dosage. | [27] |

| Artificial shale ceramsite (pre-soaked) | 10% Metakaolin + 10% GGBFS | 1881 | 210–220 | 52.6 | 0.3 | Best overall performance: seawater + 20% SCM (MK + GGBFS) led to high strength, low chloride permeability, and refined microstructure. | [6] |

| Expanded clay (5–15 mm, 6–10% absorption) | 30% Blast Furnace Slag (BS) | 1479 | 238 | 58.6 | 0.42 | Best single-admixture mix; BS improved strength and resisted bleeding; stable workability. | [11] |

| Lightweight expanded clay (30% Leca S + 70% Leca 4/12) | fly ash and limestone powder | 1834 | 687 | 56.4 | 0.29 | Highest compressive strength among tested LWSCCs; excellent flowability and aggregate distribution; adheres to SCC flow and passing criteria. | [51] |

| High-strength shale ceramic aggregates | 8% Silica Fume + 92% OPC | 1745 | NM | 36.2 | 0.28 | Prepared with vibration mixing process; improved hydration degree by 2.70%; formed dense ITZ with C–S–H gel; impregnation effect enhanced LWA-matrix bonding. | [28] |

| Spherical shale ceramsite (5–16 mm) | 21% Fly Ash + 9% Silica Fume | 1811 | 755 | 54.2 | 0.35 | Optimal performance among tested mixes; best balance between workability and mechanical strength; maximum specific strength and improved passing ability. | [29] |

| Coated Dura Shell (pre-treated oil palm shell) | fly ash, slag, silica fume | 1927 | 120 | 51.2 | 0.35 | Best-performing mix; 41% higher workability, 23% strength improvement over untreated; enhanced ITZ bonding from heat and grout coating; suitable for HSLWAC applications. | [52] |

| Pre-treated dura oil palm shell | 5% densified silica fume | 1981 | 145 | 56.5 | 0.3 | Best bio-based LWAC performance; 21% higher compressive strength, 31% increase in elastic modulus, improved ITZ and water absorption under 10%. | [17] |

| Old oil palm shell (OPS), max size 9.5 mm | 20% Limestone Powder (by weight of cement) | 1903 | 230 | 48.33 | 0.42 | The highest-strength mix uses bio-waste OPS and limestone powder; it has excellent early strength and low water absorption (3.12%) and is suitable for precast. | [15] |

| Crushed oil palm shell (OPS), max size 8 mm | NU | 1922 | 205 | 53.05 | 0.305 | Best-performing mix; 28% strength increase over CP1 due to reduced W/C ratio; crushed OPS improved ITZ bond and mechanical interlock. | [53] |

| Expanded shale ceramist | 12% Fly Ash + 8% Silica Fume | 1845 | Acceptable | 86 | 0.26 | Carbon fiber-reinforced LWAC; 0.9% fiber volume yielded the highest tensile (10.4 MPa) and flexural strength (5.15 MPa), dense microstructure, and excellent ITZ bonding. | [12] |

| Expanded clay (5–15 mm, 6–10% absorption) | 10% Fly Ash (FA) + 10% BS + 10% Silica Fume (SF) | 1532 | 178 | 60.5 | 0.42 | The combined use of FA, BS, and SF provides optimal workability and strength. | [11] |

| Fly ash cenospheres (hollow microspheres) | 45% Silica Fume + 15% Fly Ash | 1830 | NM | 105.8 | 0.25 | End-hooked steel fiber (1.0%) provided the highest specific strength (35.5 kPa/kg·m3), dynamic toughness, and densified microstructure, best for dynamic loading resistance. | [13] |

| Aerated concrete (air voids via aluminum powder) | NU | 1901 | NM | 36 | 0.5 | Best-performing mix; 37% increase in compressive and 64% in flexural strength; improved tensile ductility and lowest water absorption (8.1%). | [30] |

| All-lightweight aggregates (fine + coarse) made from expanded shale | NU | 1670 | 180 ± 20 | 46 | 0.45 | Vinylon fibers (1.5%) yielded the highest flexural strength (9.53 MPa) and improved splitting tensile and fracture toughness (>550%), optimal for ductility and toughness in ALC. | [10] |

| Expanded slate (Stalite) | NU | 1881 | 160 | 61.6 | 0.35 | Crack widths >0.1 mm increased carbonation rate by over 80% and capillary absorption, with porous aggregates further amplifying durability loss in cracked structural lightweight aggregate concrete. | [54] |

| Expanded clay aggregates | Fly Ash (125 kg/m3) | 1746 | 630 | 59.74 | 0.58 | Highest flexural strength (7.62 MPa) and toughness (23 J); splitting tensile strength improved by 37%; concrete exhibited strain-hardening behavior at 1.25% steel fiber content. | [55] |

| Sintered fly ash aggregates (SFA) | 10% Fly Ash + 0.6% Macro + 0.02% Micro Synthetic Fibers | 1800 | NM | 40 | 0.3 | Best combination of strength, fracture energy (1.78 × 10−3 kN/mm), and post-cracking resistance; flexural toughness index I50 = 21.04; suitable for precast structural use. | [20] |

| Only coarse lightweight aggregate (F6.5, 4.75–9.5 mm) | NU | 1900 | 125 | 50.0 | 0.38 | Best-performing LWAC mix; uses only coarse lightweight aggregate; good workability and strength with high durability. | [56] |

| Stalite (crushed slate aggregate) | Fly Ash (FA) + Undensified Silica Fume (SF) + 0.5% MPP fibers | 1911.9 | 660 | 90.08 | 0.22 | High-flowable lightweight concrete with 0.5% macro-polyresin fiber; improved ductility without compromising workability; strong ITZ and low water absorption. | [57] |

| Expanded shale + Hollow Glass Microspheres (HGM) | Silica Fume + HGM (Pozzolanic filler) | 1929 | 210 | 123 | 0.22 | Ultra-high-strength (123 MPa), low density (1929 kg/m3); excellent durability, acoustic absorption, low permeability, and minimal shrinkage; designed using CCD optimization. | [9] |

| Reference | LWA Type/Feature | Morphological Characteristics | Observed Influence on Pore Structure | Impact on Bonding Behavior |

|---|---|---|---|---|

| [88] Wang et al. (2022) | Expanded shale and clay | Rough, porous surface, irregular shape | Increased interfacial transition zone (ITZ) porosity; visible microcracking | Weak ITZ bonding due to poor paste penetration in deep pores |

| [89] Lo and Cui (2003) | Porous lightweight aggregate | Highly porous internal structure | High overall porosity; larger total pore volume | Reduced mechanical interlock and paste adhesion at ITZ |

| [71] Lu et al. (2020) | Expanded clay | Spherical, porous granules | Induced foam-like pore distribution in matrix | Weaker paste–aggregate adhesion; stress concentration zones |

| [90] Hu et al. (2024) | Core-shell (cordierite–belite) | Smooth outer shell over porous core | Reduced open porosity in ITZ | Improved ITZ bonding due to shell barrier limiting water ingress |

| [92] Musalamah et al. (2024) | Polypropylene LWA | Coarse, irregular, with rough texture | Reduced pore continuity; heterogeneous distribution | Enhanced mechanical interlock but localized stress intensification |

| [91] Lu et al. (2019) | Foam concrete with LWA | Highly porous with cellular structure | High internal porosity; weak matrix continuity | Poor bonding due to mismatch in stiffness and microstructure |

| [93] Maglad et al. (2023) | Recycled aggregates with steel fibers | Irregular, cracked surfaces | Increased ITZ porosity; more voids around fibers | Disrupted bonding continuity, but fiber bridging compensates partially |

| [94] Sahoo et al. (2023) | Structural LWA with fiber reinforcement | Angular, fibrous LWA | Micro-porous zones; entrapped air at interfaces | Mixed behavior: weak paste bond, but fiber enhances crack bridging |

| [95] Sim et al. (2013) | Varying LWA sizes | Smooth vs. rough textures | Larger LWA led to higher porosity; smoother types reduced ITZ interaction | Smaller aggregates showed better bonding through finer particle interaction |

| Ref. No. | Authors | Focus Area | Model Type/Approach | Identified Limitations in Models |

|---|---|---|---|---|

| [88] | Wang et al. (2022) | Fracture parameters via three-point bending | Experimental + Linear Elastic Fracture Mechanics (LEFM) | Microstructure-fracture links are hard to generalize; limited to notched beams and lab conditions. |

| [89] | Lo and Cui (2003) | Strength of porous LWA concrete | Analytical | Oversimplifies porosity effects; lacks fracture zone modeling. |

| [71] | Lu et al. (2020) | Quasi-brittle fracture modeling of foam concrete | Cohesive Zone Model (CZM) + Experimental | Scale-sensitive; assumes uniform aggregate distribution and idealized bonding. |

| [90] | Hu et al. (2023) | Simulation of core–shell LWA concrete | Finite Element Modeling (FEM) | High computational cost; complex crack path difficult to model precisely. |

| [58] | Kazemi et al. (2025) | Machine learning prediction of mechanical properties | Ensemble ML (RAGN-R) | Non-physical predictions; lacks transparency and validation against fracture mechanics. |

| [92] | Musalamah et al. (2024) | DIC-based fracture energy estimation | Digital Image Correlation (DIC) | Resolution-sensitive; limited to surface cracks; integration with numerical models is lacking. |

| [91] | Lu et al. (2019) | Simulation of foam concrete fracture | FEM + Experimental | Fails to model interfacial transition zones (ITZ); geometric simplifications limit accuracy. |

| [93] | Maglad et al. (2023) | SF-reinforced RAC fracture | Experimental + Analytical | Incomplete fiber bridging models; insufficient parameter calibration for hybrid aggregates. |

| [94] | Sahoo et al. (2023) | Fracture of fiber-reinforced LWC | Experimental + LEFM | Does not fully capture energy dissipation from fiber pull-out; lacks multi-scale modeling. |

| [95] | Sim et al. (2014) | Size effects in LWC fracture energy | Fracture Mechanics (Size Effect Law) | Scaling laws are not tuned for lightweight systems; they need larger datasets for validation. |

| Aspect | Description | Implication | References |

|---|---|---|---|

| Workability | Fibers (steel, PP, natural) hinder flow and dispersion | Requires superplasticizers or special mixing techniques | [62] |

| Material Cost | Specialty additives (carbon fibers, nano-silica, etc.) increase unit cost | Higher initial investment despite long-term structural savings | [59] |

| Aerogels | High thermal performance but cost-prohibitive | Suitable only for high-end or niche applications | [60] |

| Brittleness | Aerated LWC has low mechanical strength | Requires reinforcement or altered design strategy | [61] |

| Lifecycle Trade-offs | Material selection impacts overall cost-efficiency and durability | Informed trade-off decisions needed for real-world application | [59,60,61] |

| Component | Lightweight Concrete (LWC) | Normal-Weight Concrete (NWC) |

|---|---|---|

| Cement (per m3) | Similar (~$100) | Similar (~$100) |

| Fine Aggregate (sand) | ~$15 | ~$10 |

| Coarse Aggregate | ~$50 (expanded clay) | ~$25 (crushed stone) |

| Water | ~$2 | ~$2 |

| Admixtures | ~$10 | ~$5 |

| Total Material Cost | ~$177/m3 | ~$142/m3 |

| C-1 100%Normal Concrete in NTD | ||||

|---|---|---|---|---|

| Material | Unit Volume (m3) | Quantity (kg/m3) | Price/Ton | Total Cost (NTD) |

| Cement | 0.19 | 600.00 | 5500.00 | 3300.00 |

| Sand (FA) | 0.25 | 651.96 | 450.00 | 293.38 |

| NCA | 0.38 | 1053.17 | 450.00 | 473.92 |

| SFA | 0.00 | 0.00 | 0.00 | 0.00 |

| POS | 0.00 | 0.00 | 0.00 | 0.00 |

| Silica Fume | 0.00 | 0.00 | 0.00 | 0.00 |

| GGBS | 0.00 | 0.00 | 0.00 | 0.00 |

| Fly Ash | 0.00 | 0.00 | 0.00 | 0.00 |

| SP | 0.01 | 6.00 | 0.00 | 0.00 |

| Water | 0.18 | 176.64 | 100.00 | 17.66 |

| Total Quantity | 2487.76 | 4084.97 | ||

| E-3 Light Weight High Strength Concrete (80% SFA + 20% POS in NTD) | ||||

|---|---|---|---|---|

| Material | Unit Volume (m3) | Quantity(kg/m3) | Price/Ton | Total Cost (NTD) |

| Cement | 0.10 | 330.00 | 5500.00 | 1815.00 |

| Sand (FA) | 0.23 | 613.47 | 450.00 | 276.06 |

| NCA | 0.00 | 0.00 | 450.00 | 0.00 |

| SFA | 0.28 | 345.43 | 350.00 | 120.90 |

| POS | 0.07 | 82.82 | 5600.00 | 463.79 |

| Silica Fume | 0.02 | 60.00 | 30,000.00 | 1800.00 |

| GGBS | 0.09 | 210.00 | 1200.00 | 252.00 |

| Fly Ash | 0.00 | 0.00 | 800.00 | 0.00 |

| SP | 0.01 | 6.00 | 2000.00 | 12.00 |

| Water | 0.18 | 176.64 | 100.00 | 17.66 |

| Total Quantity | 1824.36 | 4757.42 | ||

| Cost Comparison Results—NTD (New Taiwan Dollar) | ||||||

|---|---|---|---|---|---|---|

| Mix | Unit Weight (kg/m3) | Cost (NTD) | fc’ (MPa) | Increment Cost | Increment Strength | Decrease Unit Weight |

| C1 (NC) | 2487.76 | 4084.97 | 35.55 | 16.46% | 55.98% | 26.67% |

| E3 (LWC) | 1824.36 | 4757.42 | 55.45 | |||

| Item | Lightweight Concrete (LWC) | Normal-Weight Concrete (NWC) |

|---|---|---|

| Labor | Slightly lower (easier handling) | Standard |

| Equipment | Standard | Standard |

| Transportation | Fewer trips due to lighter weight | More trips required |

| Total Labor and Equipment Cost | Potentially lower overall | Standard |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behera, D.; Liu, K.-Y.; Rachman, F.; Worku, A.M. Innovations and Applications in Lightweight Concrete: Review of Current Practices and Future Directions. Buildings 2025, 15, 2113. https://doi.org/10.3390/buildings15122113

Behera D, Liu K-Y, Rachman F, Worku AM. Innovations and Applications in Lightweight Concrete: Review of Current Practices and Future Directions. Buildings. 2025; 15(12):2113. https://doi.org/10.3390/buildings15122113

Chicago/Turabian StyleBehera, Diptikar, Kuang-Yen Liu, Firmansyah Rachman, and Aman Mola Worku. 2025. "Innovations and Applications in Lightweight Concrete: Review of Current Practices and Future Directions" Buildings 15, no. 12: 2113. https://doi.org/10.3390/buildings15122113

APA StyleBehera, D., Liu, K.-Y., Rachman, F., & Worku, A. M. (2025). Innovations and Applications in Lightweight Concrete: Review of Current Practices and Future Directions. Buildings, 15(12), 2113. https://doi.org/10.3390/buildings15122113