Abstract

The enhancement of the thermal performance of transparent envelopes has been demonstrated to be an effective measure for reducing building energy consumption. To achieve enhanced performance in the domain of building windows, considerable economic investments are frequently necessary. The present study focuses on the 70 series of broken-bridge aluminum windows, which are widely used in China. The investigation explores the potential factors affecting the thermal performance of these windows, mainly considering their glass and profiles. The study also explores the influencing characteristics of various factors and their optimal combinations for their combined effect by comprehensively applying the single-variable method, orthogonal test method, and a numerical simulation. The findings of the study indicate a substantial reduction in the heat transfer coefficient of the 70 series of broken-bridge aluminum windows, achieving a decrease of 25.98%. Additionally, the heat transfer coefficient of the frame and edge is reduced by 29–35%, and the heat transfer coefficient of the entire window is reduced by 28.34%. These findings suggest that the energy-saving requirements for green and low-carbon buildings in most regions of China can be met. Furthermore, the product offers a significant economic advantage over similar market offerings with an equivalent performance. Concurrently, the performance enhancement measures derived from the study are applicable to other types of aluminum windows.

1. Introduction

A global consensus has emerged in support of reducing energy consumption. According to the U.S. Energy Information Administration (EIA), the world’s energy consumption is predicted to increase by approximately 50% by the year 2050 [1]. It is widely acknowledged that the construction, industry, and transportation sectors are of paramount importance in terms of global energy consumption. When the entire life cycle of buildings is taken into consideration, it is estimated that the building sector accounts for approximately 37% of global energy consumption [2]. Projections indicate that the global building area will expand by 75% by the year 2050 [3]. The imperative to curtail building energy consumption has garnered global attention, a pivotal strategy for which is the implementation of green and energy-efficient building technology [4]. Among these approaches, passive building design has emerged as a critical facet of green energy-saving building technology, leveraging the natural environment to ensure indoor environmental comfort and curtail energy consumption [5]. As indicated by the extant literature, envelope energy consumption is the most significant component of a building’s energy consumption, given its direct impact on safeguarding a building from external environmental influences [6]. It has been determined that, among the four major enclosure structures, external doors and windows, external walls, roofs, and floors, the energy consumption of door and window systems is approximately four times that of wall systems, five times that of roof systems, and twenty times that of floor systems. This accounts for approximately 40% to 50% of the total energy consumption of a building enclosure [6,7]. As the surface area share of windows and doors in an envelope system increases, their energy consumption will increase accordingly.

Presently, broken-bridge aluminum exterior windows constitute the primary products in energy-saving building envelopes. The China Windows and Doors Industry Report 2024 indicated a considerable surge in the demand for such windows and doors in recent years, which has exhibited a consistent annual growth rate of over 20% and currently holds the dominant market share. However, the industry is confronted with two significant challenges: First, the implementation of the Chinese regulation GB 55015-2021, also known as the “General Specification for Building Energy Saving and Renewable Energy Utilization”, has led to a significant upgrade to the country’s energy-saving requirements. This has created a challenge for the thermal performance of conventional broken-bridge aluminum exterior windows to meet these new and elevated standards, particularly with regard to energy savings. Additionally, there are issues related to condensation on the interior surfaces of these windows and their poor acoustic performance. Secondly, the economic burden associated with high-performance broken-bridge aluminum exterior windows and doors is often prohibitive. In general, the cost of high-performance aluminum window products is two to three times higher than that of conventional aluminum windows. Additionally, their scope of application is constrained by financial limitations. Consequently, the focal point of research endeavors concerning door and window systems should center on enhancing the thermal performance of conventional aluminum alloy doors and windows, with the objective of aligning them with emerging energy-saving requirements and ensuring their suitability for large-scale use.

Exterior window systems consist of glass and profiles. The surface area percentage of glass is significantly higher than that of profiles, a finding that has garnered attention in research circles. S. Grynning et al. highlighted that glass accounts for a substantial portion of a building’s energy consumption, underscoring the significance of glass optimization as a pivotal strategy for enhancing the thermal performance of exterior windows [7]. Presently, the field of research on glass is concentrated on the development of novel glass types, including vacuum glass, silica aerogel glass, thermochromic glass, and electrochromic glass. Vacuum glass has been demonstrated to exhibit minimal heat loss and high visible-light transmission in thin window products [8]; it can be combined with photovoltaic glass to form photovoltaic-combined vacuum glazing [9,10,11], and with water-flow windows to form vacuum-glazed insulated water-flow windows [12]. The incorporation of silicon dioxide aerogel glass into the interglazing results in the enhanced thermal performance of the glass due to the presence of the highly insulating aerogel [13,14]. Thermochromic/electrochromic glass is a material that has been developed to regulate light and heat. This is achieved by overlaying thermo-responsive and electrochromic materials between the glass layers [15]. Thermo-responsive materials rely on the thermal reaction of the material itself [16], while electrochromic materials undergo a color change through a redox reaction when an external alternating voltage is applied [17,18]. Moreover, experimental evidence has demonstrated that the incorporation of advanced spacers and edge seals can lead to substantial enhancements in the thermal performance of the entire window system [19]. In comparison with metal spacers, composite spacers have been shown to exhibit superior thermal performance and demonstrate a greater application potential [20]. Given that these new glasses have not yet reached production scale and that their application in practice is not common, this study will focus on the performance enhancement potential of double-insulating glass, which is the most widely used type.

Profiles have been identified as a critical weak link in the context of external window systems. Profiles, which encompass a wide range of materials—including wood, aluminum, and polymers—have undergone significant transformations in both their composition and their design [21]. Several studies have indicated the potential for future advancements in exterior window profiles, with particular emphasis on the development of glass fiber-reinforced polyurethane (GFRP) profiles and high-performance bridged aluminum profiles [22]. Presently, glass fiber-reinforced polyurethane (GFRP) profiles are utilized less frequently due to their structural performance, construction maturity, and other concerns [23]. Broken-bridge aluminum profiles have gained popularity due to their lightweight nature, ease of installation, and aesthetic appeal [24]. The present study is an investigation into the enhancement of the thermal performance of broken-bridge aluminum profiles. Previous investigations have identified that the implementation of materials with reduced thermal conductivity, in conjunction with altering the geometry of the profiles, has the potential to achieve a substantial reduction in the heat transfer coefficient [21,25,26]. The measures primarily consist of the following: the utilization of thermal break with reduced thermal conductivity [19], the application of insulation materials within the broken-bridge cavities [21,27], the augmentation of the sectional dimensions of the profiles [28], and the extension length of the thermal break [3]. Furthermore, it has been posited that the implementation of long-tailed rubber strips within the glazing channel [29], the integration of multiple seals between the window frame and the sash [30], and a linear isotherm design [31] could also contribute to the enhancement of the thermal performance of the profiles. The aforementioned conclusions were derived from the control variable method, which was employed to investigate the impact of a single factor on the experimental outcomes. This methodological approach does not encompass a comprehensive analysis from the standpoint of a multifactor implementation. Consequently, these previous studies were not able ascertain the relative influence of each factor on the performance of the profiles. Additionally, they were not able to determine whether the optimal solution was obtained following a comprehensive analysis.

In light of the aforementioned findings, this study aspires to investigate the thermal performance of external windows by focusing on conventional broken-bridge aluminum alloy profiles with double-layer insulating glass. The study aims to identify the various factors that influence the thermal performance and to determine the optimal combination of parameters through numerical simulation, single-variable and orthogonal test methods, and other research methods.

2. Methodology

2.1. Research Design

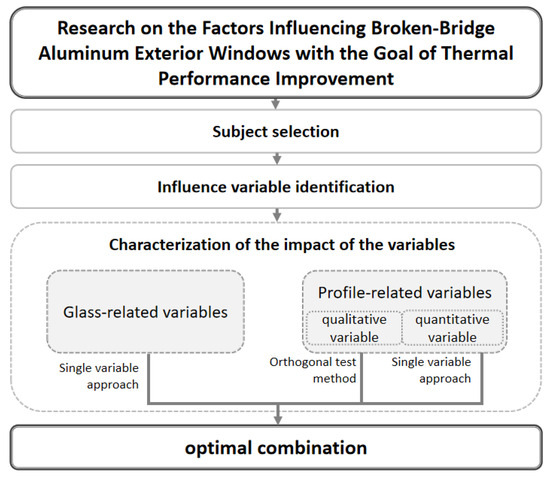

As demonstrated in Figure 1, the research focuses on broken-bridge aluminum exterior windows, which are currently the most prevalent type of window in China. Secondly, drawing upon the extant research and related practices, the potential factors affecting the thermal performance of external windows are identified and summarized. The influence of each factor on the thermal performance of external windows is then analyzed using the single-variable method and the orthogonal test method, according to the properties of each variable. Finally, a numerical simulation is employed to derive the optimal combination of the multiple variables for the typical thermal performance enhancement of external windows.

Figure 1.

Diagram showing the flow of this research study.

2.2. Subject Selection

At present, there are a considerable number of broken-bridge aluminum alloy window products available, but the node structure of each is similar. To enhance the generalizability of the research outcomes, this study selects the nodes from the China Standard Atlas 22J603-1 [32], entitled “Aluminium alloy windows and doors” (henceforth referred to as “atlas”).

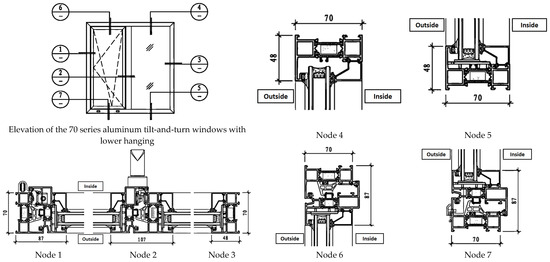

The Atlas range of aluminum exterior window models encompasses a spectrum from the 50 series to the 112 series, thereby offering a comprehensive selection that meets diverse architectural needs. According to the economic criteria, this study selects the 70 series of broken-bridge aluminum internal casement windows, with 5 mm (low-E) + 12 A + 5 mm insulating glass, as the typical object (Figure 2). The heat transfer coefficient of an external window is contingent upon the area ratio of the window frame and window opening. An increase in the area ratio of the window frame and window opening results in an increase in the heat transfer coefficient of the entire window (Table 1). According to GB 55015-2021, “General Specification for Energy Saving and Renewable Energy Utilization in Buildings”, it is evident that the performance requirements for external windows are exclusively applicable to residential buildings in climates characterized by hot summers and cold winters, hot summers and warm winters, and mild regions, as well as a limited number of public buildings with low window-to-wall ratios [33]. Presently, the architectural landscape is undergoing a transition, with a growing inclination toward buildings with elevated window-to-wall ratios [34,35,36]. This trend portends a diminution in the viability of these windows.

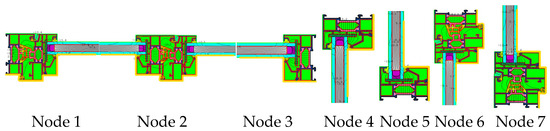

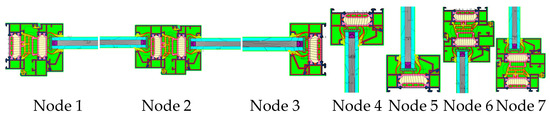

Figure 2.

The node details of the 70 series broken-bridge aluminum tilt-and-turn windows [32]. Note: ‘Node’ means the profile construction of the window frame and glazing.

Table 1.

Thermal performance of the 70 series aluminum tilt-and-turn windows [32].

2.3. Variable Identification

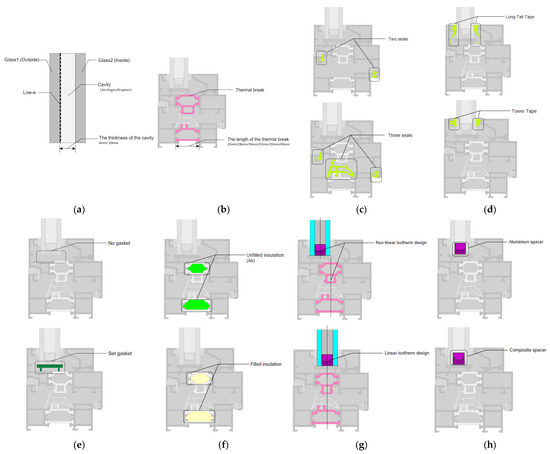

Combined with the existing research and practical experience, this study systematically analyzes the key factors affecting the thermal performance of broken-bridge aluminum exterior windows, focusing on the roles played by glass and aluminum alloy profiles. The primary research variables are elucidated in Table 2 and Figure 3.

Table 2.

Factors potentially influencing the thermal performance of broken-bridge aluminum exterior windows.

Figure 3.

Graphical representation of the potential influencing factors on the thermal performance of broken-bridge aluminum exterior windows. (a) Double glazing; (b) thermal break; (c) number of sealing channels between the window frame and window sash; (d) the shape of the sealing tape; (e) whether or not to set the gasket under the glass; (f) whether the cavity is filled with insulation material; (g) isothermal design; (h) spacer types.

In the context of glass, three factors must be considered: the configuration of the glass itself, and the type and thickness of the cavity. The thermal performance of glass is contingent upon its thickness, the number of sheets, the manufacturing process, the type of coating material, the number of layers, and the layers’ positions. These factors can even influence the performance of the glass, depending on the manufacturer [37]. In accordance with the principles of economy and control variables, the configuration of the glass itself is considered a fixed variable in this study, and only two factors are considered to change the type and thickness of the cavity. The gas within the cavity is typically air, and the thermal performance of the glass can be enhanced by filling it with inert gases, such as argon or krypton [38]. The thickness of the cavity is typically between 9 mm and 12 mm. To more accurately reflect the effects of different cavity thicknesses on the glass properties, the study will simulate and analyze the three gases, namely air, argon, and krypton, one by one, in varying cavities sized between 6 mm and 20 mm.

The profiles are regarded as the constraining element that hinders the enhancement of the thermal performance of an entire window. This is due to their elevated heat transfer coefficient in comparison to that of glass [19]. The present study will explore potential performance enhancement factors from the perspective of node construction, including the following eight factors: the number of profile cavities, the length of the thermal break, the number of sealing channels between the window frame and sash, the shape of the sealing strips, whether or not to set gaskets under the glass, whether or not to fill the insulation material in the broken-bridge cavities, the isothermal design, and the type of glazing spacer strips. The categorization of factors is predicated on their divergent characteristics, which are then classified as either quantitative or qualitative variables.

The correlation between the quantity of cavities in a given profile and its respective profile model is a matter of established significance. The higher the model, the greater the number of cavities, and thus the superior thermal performance and strength of the entire window. The 70 series of broken-bridge aluminum alloy profiles, selected for the present study, have three cavities, which are considered a fixed variable in accordance with the economic factors.

The material and length of the thermal break, as well as the composition of the broken-bridge aluminum alloy profile, are the primary factors that influence the outcome. Regarding the material, PA66 compounded with 25% glass fiber, which has been demonstrated to exhibit superior strength and performance, is selected as a fixed variable in the study. Concerning the variable of length, a total of six sizes are selected from the conventional range of 25 mm to 40 mm. These sizes, designated as 25 mm, 28 mm, 30 mm, 32 mm, 35 mm, and 40 mm, are employed as the quantitative variables in the subsequent analysis.

The sealing treatment between the window frame and the window sash incorporates two or three seals. The sealing tape between the glass and the profile is either tower shaped or long-tail shaped. The junction between the glass and the profile features either a set gasket or no gasket treatment. The broken-bridge cavity is filled with a heat preservation material and has not undergone a filling treatment. The isothermal design incorporates both linear and non-linear isothermal elements. The type of glazing spacer strips features an aluminum spacer and composite spacer. The aforementioned six factors are used as the qualitative variables according to their characteristics.

2.4. Methods of Analysis

2.4.1. Numerical Simulation

- (1)

- Simulation Software Selection

At the present time, the widest range of applications and higher-maturity thermal performance calculation software have mainly been developed in the United States by the Lawrence Berkeley National Laboratory (LBNL) and their Window7, Therm7, and Optics7 series of software, and in Guangdong by the Guangdong Construction MQMC2010, with the title “building curtain wall, doors and windows thermal performance calculation software”.

It is evident that Therm and MQMC both utilize two-dimensional finite element analysis methods to calculate the thermal performance of a frame [39,40]. The distinction between the two approaches lies in the methodology employed for the heat transfer calculation within the glass inlay area. Specifically, MQMC makes use of the line heat transfer coefficient calculation theory [41], while Therm employs the glass edge region calculation theory [42]. For the calculation of the frame heat transfer based on the glass edge region calculation theory, the glass edge (within 63.5 mm) region is designated as a special region, and the three-dimensional heat transfer influence of the glass inlay site is taken into account [43]. In the context of this study on the thermal performance of exterior windows constructed with glass as the primary material, Therm demonstrates enhanced applicability. Furthermore, the series of software developed by LBNL is characterized by its open-source nature, which facilitates wider utilization within academic research communities. Consequently, Window and Therm are selected as the primary simulation software for this study. As Therm primarily simulates steady-state two-dimensional heat transfer effects, the potential impact of the temperature gradients in corner regions and the three-dimensional geometry on the simulation outcomes is not addressed in this study.

- (2)

- Calculation of environmental boundary conditions

JGJ/T151-2008 [44], entitled “Thermal Calculation Regulations for Building Doors, Windows and Glass Curtain Walls,” stipulates that, in the design or evaluation of the thermal performance of stereotyped products within the categories of building doors, windows, and curtain walls, the standard calculation conditions must be utilized. In the execution of the actual engineering design, the boundary conditions for a project’s calculation must be determined in accordance with the relevant design requirements. Moreover, the standard stipulates that the heat transfer coefficients of the windows, doors, and curtain wall products should be calculated using winter conditions, and that the shading coefficients of the windows, doors, and curtain wall products should be calculated using summer conditions [40,44]. The present study is principally concerned with the evaluation of exterior window products and a discussion of the influence of each factor on the heat transfer coefficient. For the purpose of this study, the following standard winter calculation conditions are selected:

Indoor air temperature (Tin) = 20 °C;

Outdoor air temperature (Tout) = −20 °C;

Indoor convective heat transfer coefficient (hc,in) = 3.6 W/(m2·K);

Outdoor convective heat transfer coefficient (hc,out) = 16 W/(m2·K);

Average indoor radiant temperature (Trm,in) = Tin;

Outdoor average radiation temperature (Trm,out) = Tout;

Solar irradiance (Is) = 300 W/m2;

Indoor and outdoor relative humidity (Relative Humidity) = 50%.

- (3)

- Analog Material Selection

The material parameters associated with the glass, gas, and profiles used in the study are enumerated in Table 3.

Table 3.

Parameter list for material selection.

- (4)

- Calculation of thermal performance of the whole window

The calculation of the thermal performance of the whole window is performed by utilizing the formula outlined within the NFRC standard system for determining the heat transfer coefficient for complete windows (Equation (1)) [45]:

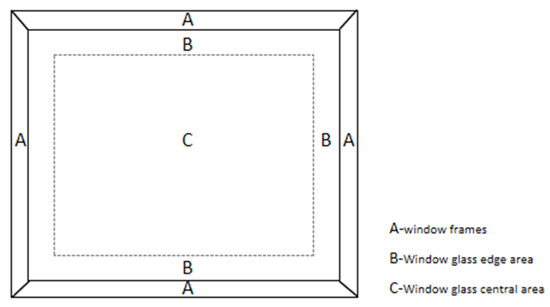

where Ut is the heat transfer coefficient of the whole window [W//(m2·K)]; Ag is the area of the central region of the window glass (m2); Ug is the heat transfer coefficient in the middle region of the window glass [W/(m2·K)]; Af is the window frame area (m2); Uf is the heat transfer coefficient of the window frame [W/(m2·K)]; Aeg is the area of the window glass edge area (m2); Ueg is the heat transfer coefficient in the edge region of the window glass [W/(m2·K)]; and At is the area of the whole window (m2).

Among these, the range of the central window glass area, the window glass edge area, and the window frame area are shown in Figure 4.

Figure 4.

Computational model of the statistical method for glass edges.

- (5)

- Validation of numerical simulation methods

The “Window” software is utilized to simulate the 5 mm (low-e) + 12 A + 5 mm insulating glass, with the glass manufacturer set as China South Glass. The simulation results indicate that the heat transfer coefficient of the glass is 1.6978 W/(m2·K), which is 0.0522 W/(m2·K) lower than the heat transfer coefficient of the glass shown in the atlas, at 1.75 W/(m2·K), with an error rate of 2.98%.

According to the atlas, Therm software is utilized to establish the node models of typical objects (i.e., the 70 series of broken-bridge aluminum internal casement down-hung windows). The simulation is executed subsequent to the importation of the 5 mm (low-e) + 12 A + 5 mm insulating glass (Figure 5), and the simulation results are exhibited in Table 4.

Figure 5.

Simulation of each node of a typical object.

Table 4.

Simulation of the thermal performance of each node of the 70 series broken-bridge aluminum tilt-and-turn window.

The following example will illustrate this calculation: For a 2.0 m × 2.0 m window, the area of the window frame that is covered by the hole in the frame is approximately 20%, according to Equation (1). The heat transfer coefficient of the entire window is thus calculated to be 2.050 W/(m2·K). A comparison of the aforementioned coefficient with the coefficient presented in the atlas, 1.96 W/(m2·K), reveals a discrepancy of 0.09 W/(m2·K), corresponding to an error rate of 4.5%.

In summary, the simulation results of the glass thermal performance and calculated whole window thermal performance, when compared with the atlas indices, exhibit an error rate of less than 5%. This is in alignment with the stipulation in the “Guidelines for Labeling the Energy-saving Performance of Doors and Windows in Buildings” that a maximum deviation of 5% is allowed between the test value and calculation value [46]. This demonstrates that the numerical simulation and calculation methods are both reasonable and feasible.

2.4.2. Statistical Analysis

In order to achieve a comprehensive understanding of the factors influencing the thermal performance of broken-bridge aluminum windows, a rigorous investigative approach is undertaken. This investigation involves the meticulous examination of nine distinct factors, encompassing both the glass and profile properties. Each factor is studied in various modes, ensuring that the multifaceted nature of the factors is thoroughly explored.

- (1)

- Single-variable approach

The univariate approach constitutes the examination of a single factor and the investigation of the impact of the independent variable on the dependent variable, whilst ensuring that only a single variable is altered at any given moment and that all other variables remain constant throughout the process; this enables the determination of the causal relationship between a single variable and the outcome [47].

The present investigation adopts the single-variable method to analyze the gas types and thicknesses in the cavity of the insulating glass. The investigation encompasses the impact of diverse thicknesses, ranging from 6 mm to 20 mm, on the performance of the glass when the cavity is filled with air, argon, and krypton, respectively. The optimal performance gas type and thickness are determined through longitudinal and transversal comparative analyses of the simulation results.

- (2)

- Orthogonal test method

The orthogonal test method constitutes a design approach employed in the context of investigating multifactor and multilevel systems. Utilizing an orthogonal table to arrange the tests enables the systematic study of the effects that multiple factors and their interactions have on the experimental results. This can be achieved with a reduced number of tests [48]. A hallmark of this approach is the substitution of comprehensive tests with partial tests, a strategy that markedly reduces the number of tests required while concomitantly enhancing the efficiency of the process. The experimental results can be analyzed using variance and extreme variance analysis to clarify the trend of the influence of each factor on the indexes, the primary and secondary relationship between the factors, and the optimal combination [49].

It was hypothesized that there may be an interaction between the seven factors affecting the thermal performance of the profiles from the point of view of the nodal configuration. The length of the thermal break is known to affect the filling range of the insulation material in the bridging cavity. The other factors are weakly correlated, and the possibility of their interaction is small.

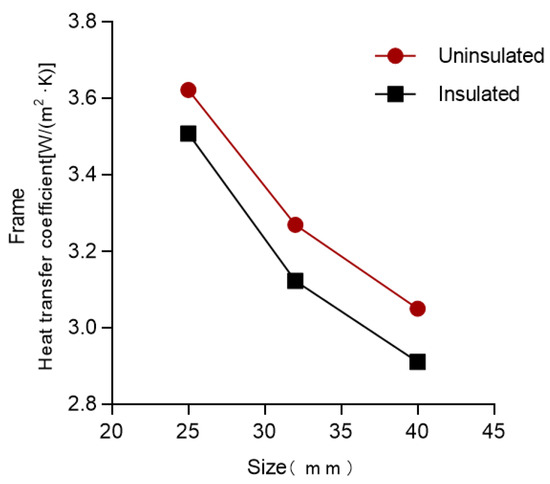

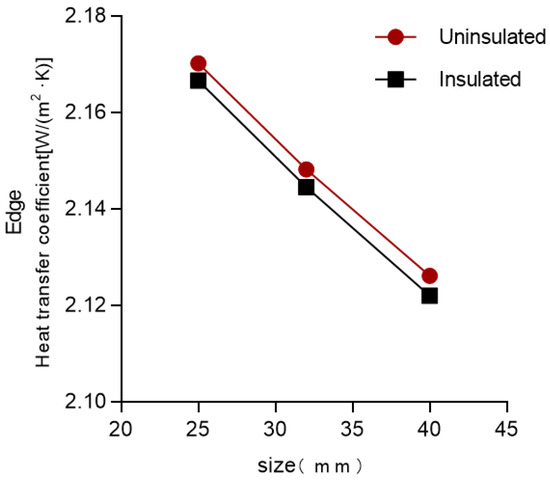

In the experimental investigation designed to ascertain the interaction between the length of the thermal break and the presence or absence of thermal insulation material within the bridging cavity, three sizes of cavity (25 mm, 32 mm, and 40 mm) were selected for the heat insulation strip; another variable was the presence or absence of thermal insulation material within the bridging cavity. The results of the experimental investigation are presented in Figure 6 and Figure 7.

Figure 6.

Simulation results of the thermal performance of frames with different lengths of thermal break (25 mm/32 mm/40 mm) and with or without the presence of filling insulation in the broken-bridge cavity.

Figure 7.

Simulation results of the thermal performance of edges with different insulating strip sizes (25 mm/32 mm/40 mm) and whether or not the bridging cavity was filled with insulation material.

The findings reveal a parallel linear relationship between the heat transfer coefficients of the frames and edges and the insulation material’s presence or absence in the broken-bridge cavity. This observation suggests that there is no interaction between the two factors.

Given the low probability of an interaction between the length of the thermal break and the other factors, and given the large number of thermal break length variables, a single-variable method was used in the study. Within the range of 25–40 mm, six values were selected for investigation. The objective of this investigation was to examine the influence of varying lengths of the thermal break on the thermal performance of the profiles. Additionally, an attempt was made to establish a mathematical model of the heat transfer coefficient of the profiles through a data analysis.

To investigate the effect of the combined effect of multiple factors on the heat transfer coefficient of the profiles, the orthogonal test method was used to examine the other six factors affecting the thermal performance of the profiles. The objective was to determine the optimal combination scheme. The six aforementioned factors included the number of sealing channels between the window frame and the window sash, the shape of the sealing tape, whether or not to set gaskets under the glass, whether or not to fill the insulation material in the broken-bridge cavity, the isothermal design, and the type of glazing spacer used.

3. Results and Analysis

3.1. Characterization of the Impact of Each Variable

3.1.1. Characterization of the Impact of the Glass-Related Variables

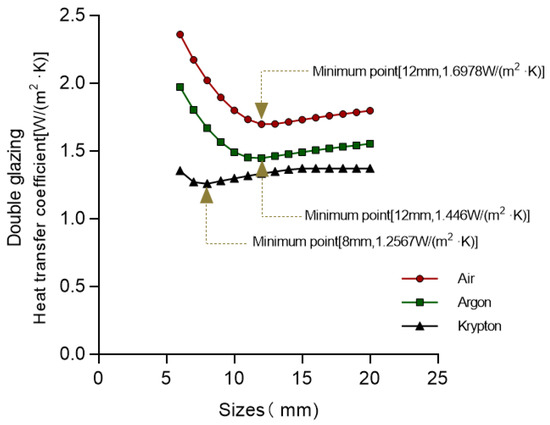

Utilizing 5 mm (low-e) + 5 mm insulating glass as the constant entity, Window7.8 software was employed to simulate the filling of the cavity with various gas types and thicknesses, as illustrated in Figure 8. As is apparent from the figure, the different gas types and thicknesses had significant impacts on the thermal performance of the glass, which predominantly manifested in three aspects: Firstly, for the configuration of double-glazed glass composed of 5 mm (low-e) + 5 mm layers, there was no consistent decline in the heat transfer coefficient of the glass with an increase in the width of the interlayer between the gases, regardless of the gas type, either air, argon, or krypton. The figure indicates an initial reduction, a subsequent rise, and eventual stabilization. Secondly, for a specific hollow glass cavity, the thermal performance of the glass varied according to the different gas fillings used; in this case, the order of the heat transfer coefficient was air > argon > krypton. Thirdly, within the range of 6–20 mm, the three gases were observed to demonstrate optimal performance values. The optimal thickness of the air filling was determined to be 12 mm, with a heat transfer coefficient of 1.6978 W/(m2·K); the optimal thickness of the argon filling was determined to be 12 mm, with a heat transfer coefficient of 1.446 W/(m2·K); and the optimal thickness of the krypton filling was determined to be 8 mm, with a heat transfer coefficient of 1.2567 W/(m2·K).

Figure 8.

Thermal performance simulation results for insulating glass using different gas types and thicknesses.

In the scenarios involving filling with distinct gases, the variations in the thermal performance of the insulating glass could be predominantly attributed to the differing thermal inertia exhibited by these gases. Concerning the radiative heat transfer within a cavity, the superior thermal inertia of a given gas results in reduced heat transfer. The thermal inertia of a material is determined by its thermal conductivity; therefore, materials with low thermal conductivity exhibit superior thermal inertia. This ranking indicates that, following the gas filling, the thermal performance of the entire window is ranked as krypton > argon > air.

3.1.2. Characterization of the Impact of the Profile-Related Variables

- (1)

- Influence of the length of the thermal break on the characteristics

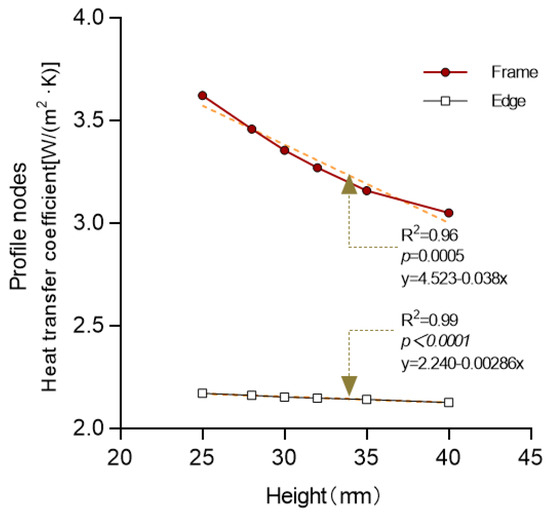

The research object selected for analysis was the 70 series of broken-bridge aluminum interior casement down-hung windows, which have a total of seven nodes (see Figure 2). Node 7 was selected as the base node. Therm7 was employed to simulate the thermal performance of the nodes with thermal break lengths of 25 mm, 28 mm, 30 mm, 32 mm, 35 mm, and 40 mm, respectively; the simulation results are shown in Figure 9.

Figure 9.

Thermal performance simulation results for different lengths of thermal break in broken-bridge aluminum alloy profiles.

As illustrated in Figure 9, the length of the thermal break exerts a more substantial influence on the thermal performance of the profile nodes, particularly in the following two respects: Firstly, within the range of 25 mm to 40 mm, the impact of the thermal break length on the heat transfer coefficient of the frame surpassed that on the edge of the heat transfer coefficient. Secondly, with an increase in the length of the thermal break, both the heat transfer coefficients of the frame and the edge underwent a reduction, exhibiting a linear relationship. The primary reason for this is the superior thermal performance of the thermal break material in comparison to that of aluminum alloy. A composite strip composed of a 25% glass fiber polyamide 66 (PA66) blend exhibited a thermal conductivity of 0.30 W/(m·K). This value is equivalent to 1/530 of that observed in aluminum alloys, thereby significantly diminishing the rate of heat conduction.

The linear fitting of the data using GraphPad Prism10.0 resulted in model equations (Equations (2) and (3)) for the insulating strip length for the frame and edge heat transfer coefficients. The p-values of the two equations were 0.005 and <0.001, respectively. Furthermore, the R2 values were 0.96 and 0.99, indicating a strong correlation between the dependent and independent variables in both cases. The two models under consideration were well constructed, and the equations explained the relationship between the independent and dependent variables satisfactorily.

y = 4.523 − 0.038x

y’ = 2.24 − 0.00286x

In the equations, y is the heat transfer coefficient of the frame, y’ is the heat transfer coefficient in the edge region, and x is the length of the thermal break.

In practice, the aforementioned two formulas can be used to swiftly ascertain the thermal performance of various lengths of thermal breaks of the 70 series of broken-bridge aluminum exterior window profiles under conventional construction.

- (2)

- Characterization of the impact of the other variables

The six factors other than the length of the thermal break, each of which contained two levels, were selected and appropriately altered in an orthogonal table of type L12(211), resulting in an orthogonal table of type L12(26), whose orthogonality was unaffected. Given that the interaction between the factors was not considered, the factors were only entered into the table in the position corresponding to the column number at the top of the chosen orthogonal table, and one factor occupies one column. The experiment thus yielded 12 groups of design schemes. The results of this experiment are displayed in Table 5, alongside the design scheme for each group and the simulation.

Table 5.

Orthogonal test data statistics.

The frame and edge heat transfer coefficients are pivotal parameters in the calculation of the heat transfer coefficient of the entire window. This study proposes an integrated heat transfer coefficient (Uz) of the profile based on the logic of calculating the heat transfer coefficient of the whole window. This process determines the significance of the influence of each factor on the heat transfer coefficient of the profile. The integrated heat transfer coefficient (Uz) is defined as the heat transferred per unit of time through a specific profile or edge area, given a unit area. In steady-state conditions, when the air on both sides of the profile or edge area is at a constant temperature difference, the coefficient can be calculated using Equation (4), as follows:

where Uz is the integrated heat transfer coefficient of the profile [W/(m2·K)]; Af is the window frame area (m2); Uf is the heat transfer coefficient of the window frame [W/(m2·K)]; Aeg is the area of the window glass edge area (m2); and Ueg is the heat transfer coefficient in the edge region of the window glass [W/(m2·K)].

In instances where Uf and Ueg can be derived from a Therm simulation, the calculation of Uz necessitates the solution of Af and Aeg. The dimensions of the node window frame are 87 mm, and the window glass edge area is 63.5 mm. In the absence of a specified window type, the lengths of the window frame and the window glass edge (h) are considered to be in approximate agreement. This results in the approximate Equation (5) for the integrated heat transfer coefficient of the node profile, as follows:

Utilizing the aforementioned equation, the integrated heat transfer coefficients of the profiles for the twelve groups of schemes of orthogonal tests can be calculated; the results are displayed in Table 5.

The level of each factor was characterized by the numbers “1” and “2” (Table 6). The orthogonal test data were subsequently subjected to an analysis of variance (ANOVA) using SPSS29.0 (Table 7). The results of the above analysis were used to determine the significance of each factor through the p-value. Furthermore, the F-value was used to provide additional insight into the relative importance of each factor. Table 7 demonstrates that, for the comprehensive heat transfer coefficient of the profiles, the type of spacer and the number of sealing channels are the significant factors; the presence or absence of insulation material in the cavity is a more significant factor; and the presence or absence of a gasket under the glass, the shape of the sealing tape, and the isothermal line design are the non-significant factors. The sequence of significance is as follows: the number of sealing channels > the type of spacer > the presence or absence of insulation material in the cavity.

Table 6.

Table of factor levels.

Table 7.

Analysis of variance.

3.2. Combination of Variables with the Goal of Thermal Performance Improvement

3.2.1. Optimal Combination Based on Mathematical Analysis

It is important to note that, although some of the factors were not significant according to the ANOVA, this does not necessarily indicate that they do not affect any of the combined heat transfer coefficients of the profiles; they may simply not reach the level of statistical significance. When determining the optimal combination, it is imperative to consider all factors within the research scope. Deriving the order of influence of each factor on the integrated heat transfer coefficient of the profiles and the optimal combination scheme is facilitated by a polar analysis, and this analysis is supported by the orthogonal test data, the results of which are shown in Table 8 below.

Table 8.

Extreme variance analysis.

The results of the extreme difference analysis indicate that the optimal level combination is a composite spacer strip + broken-bridge cavity with thermal insulation + three seals + gaskets under the glass + long-tailed tape + non-linear isotherms. This conclusion is supported by a comparison of the K1 avg value with the K2 avg value in the longitudinal direction. It is noteworthy that this combination does not appear in the orthogonal test program. According to the program developed for the establishment of the model and simulation, the node frame heat transfer coefficient is 2.9711 W/m2·K, the edge area heat transfer coefficient is 1.9035 W/m2·K, and the calculation of the profile comprehensive heat transfer coefficient is 2.5206 W/m2·K. A comparison of this combination with the smallest value for the orthogonal test on the nineth group of data (with a node frame heat transfer coefficient of 2.9984 W/m2·K, an edge area heat transfer coefficient of 1.8635 W/m2·K, and a profile comprehensive heat transfer coefficient of 2.5209 W/m2·K) reveals that the latter is almost identical, albeit smaller. This suggests that the combination is optimal.

In addition, a horizontal comparison of the R-values indicates that the order of influence of each factor on the integrated heat transfer coefficient of the profile is as follows: number of sealing channels > spacer types > whether or not there is insulation in the broken-bridge cavities > under-glass gaskets > shape of sealing tape > isothermal design. This ordering result is consistent with the ordering of the significant factors in the ANOVA, and it is evident from these analyses that the latter three factors, which are non-significant, exert a lesser influence on the comprehensive heat transfer coefficient of profiles.

3.2.2. Performance Simulation of the Optimal Combination of Whole Windows

In order to achieve the best possible performance from a window, it is necessary to consider the factors that influence the performance of the glass and the profile in conjunction. In order to explore the extreme value of the optimal combination on the performance of the whole window within the scope of this study, 5 mm (low-e) + 8 Kr + 5 mm insulating glass, as well as a 40 mm long thermal break, were selected in combination with the six factors mentioned above, specifically 5 mm (low-e) + 8 Kr + 5 mm insulating glass + 40 mm long thermal break + composite spacer strips + broken-bridge cavities with insulation + 3 seals + gaskets + long-tailed tape + non-linear isothermal design.

The nodes of the object under study were optimized according to the optimal combination scheme of the whole window performance (Figure 10). The optimized simulation results were then compared with the simulation results of a typical object (Table 9 and Table 10). The findings indicate a 25.98% reduction in the heat transfer coefficient of the glass, with the average reduction rate for the heat transfer coefficient of the frame and the edge of each node of the profile ranging from 29% to 35%.

Figure 10.

Simulation of each node after optimizing a typical object by the optimal combination.

Table 9.

Comparison of glass heat transfer coefficients.

Table 10.

Comparison of heat transfer coefficients at each node of profile.

To illustrate this point, consider a whole window measuring 2.0 m × 2.0 m. Utilizing Equation (1), the optimal combination of the whole window heat transfer coefficient is calculated to be 1.469 W/(m2·K). Compare this to the typical simulation of the object, which has a calculated value of 2.05 W/(m2·K). The reduction rate is therefore 0.581 W/(m2·K), which is equivalent to a reduction of 28.34%.

The enhancement of the performance of the traditional 70 series aluminum alloy windows not only ensures adherence to elevated standards of energy-saving requirements but also extends the range of its applications. Concurrently, in comparison with the typical target construction node, the optimal combination of the node inside the window frame, the window, and the glass edges does not appear to result in condensation. Furthermore, the sound insulation performance is enhanced by the bridging cavity, which is filled with thermal insulation materials.

3.2.3. Cost-Effectiveness of the Optimal Combination of Whole Windows

Cost-effectiveness is frequently analyzed from the perspective of the whole life cycle, as illustrated by the following examples. The initial cost, payback time, energy cost savings, and total life cycle savings are the primary factors to be considered [50,51]. The present study focused on the improvement of the thermal performance of aluminum with broken-bridge windows. A cost–benefit analysis was carried out from the perspectives of the incremental cost and a price comparison of products with the same performance.

The enhancement of the optimal combination scheme of the entire window over the typical object was achieved through the following adjustments:

- -

- The glass selection was adjusted from 5 mm (low-e) + 12 A + 5 mm to 5 mm (low-e) + 8 Kr + 5.

- -

- The length of the thermal break was adjusted from 25 mm to 40 mm.

- -

- The spacer tape between the glass was adjusted from an aluminum spacer to an composite spacer.

- -

- The broken-bridge cavity was filled with insulation material.

- -

- The shape of the sealing tape between the glass and the profile was adjusted from tower-shaped tape to a long-tailed tape shape.

The financial implications of each factor are delineated in Table 11 below.

Table 11.

Typical objects’ difference factor market costs from optimal portfolio.

The calculation of the incremental cost of the optimal combination scheme for the more typical object is determined by the cost–price difference of each factor. The result indicates that the incremental cost is approximately 80 RMB/m2. In this estimation scheme, the relevant cost is ignored due to the uncertainty surrounding labor and production line upgrading. According to the quotes from the relevant manufacturers in China, the market price of the typical object is approximately 500 RMB/m2. This can serve as the basis for estimating the market price of the optimal combination scheme to be approximately 580 RMB/m2.

The prevailing value of the common heat transfer coefficient is 1.4 W/(m2·K) for external window products in the 100 series of aluminum broken-bridge windows with three-glass and two-cavity hollow low-E glass. The market price of these products is approximately 850 RMB/m2. The optimal combination proposed in this study exhibits a price difference of approximately 270 RMB/m2. This finding indicates that the study demonstrates superior economic benefits and market application value.

4. Summary and Discussion

The present study investigated the factors influencing the thermal performance of aluminum windows, specifically focusing on their glass and profiles. With regard to the glass, the primary investigation focused on the impact of the insulating glass cavity gas type and the thickness of the glass on the performance, with krypton gas demonstrating superior performance, followed by argon, and air proving to be the least effective. Additionally, the optimal thickness of the different gases was identified to be 12 mm for air and argon, and 8 mm for krypton. The study established that regardless of the type of gas used, the heat transfer coefficient of the glass exhibited an initial decrease, followed by an increase, and subsequently stabilized with an increasing thickness of the cavity.

In terms of the profiles, first, the effect of heat-insulating strips on the performance of the profiles was explored. The study demonstrated that the heat transfer coefficients of both the frames and edges decreased linearly with an increase in the length of the thermal break. Concurrently, a linear relationship was identified and a linear equation was constructed, which enabled the rapid deduction of the thermal performance of conventionally constructed broken-bridge aluminum under different thermal break lengths. Second, the other factors affecting the thermal performance of the profiles were studied using the orthogonal test method. Through an analysis of variance (ANOVA), the type of spacer strip, whether the broken-bridge cavity was filled with insulation material, and the number of sealing channels were found to be the most significant factors. The significance order of these factors was determined to be the number of sealing channels > the type of spacer strip > whether the broken-bridge cavity was filled with insulation material. Whether or not to set the gasket under the glass, the shape of the sealing tape, and the isothermal design were found to be non-significant factors. Finally, the optimal combination of factors was found to be, according to a polar analysis, a composite spacer + broken-bridge cavity with thermal insulation + three seals + under-glass gaskets + long-tailed tape + a non-linear isothermal line.

The optimal combination of factors for the entire window, including the glass and profile, is hereby proposed as follows: 5 mm (low-e) + 8 Kr + 5 mm insulating glass + 40 mm thermal break + composite spacer + broken-bridge cavity with thermal insulation + three seals + under-glass gaskets + long-tailed tape + a non-linear isothermal line. The heat transfer coefficient of the entire window is calculated to be up to 1.469 W/m2·K, representing a 28.34% reduction compared to that of a typical object. Concurrently, the cost–benefit analysis indicates that this window exhibits superior performance enhancement with a minimal incremental cost, thereby expanding its application scope. Regarding China specifically, the GB 55015-2021 “General Specification for Energy Efficiency and Renewable Energy Utilization in Buildings” stipulates that these standards apply to all buildings, except those with a high window-to-wall ratio in cold regions. This is particularly evident in the context of numerous low-cost projects, where this product’s popularity and application value are amplified; thus, it will play a pivotal role in reducing building energy consumption.

While the present study focused on the 70 series, its findings are also applicable to other models due to the shared structural characteristics of broken-bridge aluminum exterior windows. To illustrate this point, consider the 60 series of aluminum windows. According to the optimal structure, the heat transfer coefficient of the entire window is reduced from 2.12 W/m2·K to 1.568 W/m2·K, representing a 26.0% decrease. Moreover, despite the study’s proposal of the optimal combination of parameters, the following points must be considered during actual engineering applications: Firstly, the process for extracting krypton gas is intricate and technically challenging. The requirements for the production and operation procedures are exceedingly stringent, and the cost is three times that of argon. However, the application of argon can be reasonably selected according to the budget [52,53]. Secondly, if the sealing performance of the hollow glass cavity is inadequate, krypton and argon gases may escape too quickly, thereby affecting the thermal performance of the entire window [54]. The sealing performance of the cavity is a critical index in the selection process. Thirdly, it is essential to ensure that the length of the thermal break is not increased, particularly for low-series profiles. Additionally, the thermal performance and material strength should be evaluated comprehensively. It has been demonstrated that, particularly at the stress concentration, these elements have the potential to become the weakest link in the structural loading, affecting the overall stability and integrity [53]. Fourthly, it is important to note that the simulation results are subject to variation due to shifts in the environmental boundary conditions or window orientation [55,56]. The results of this study are based on the standard calculation conditions specific to Chinese winters. However, if the simulation is based on the ISO (EN) standard system or the NFRC standard system (NFRC100/NFRC200), the results may vary. Conversely, the conclusions may vary if the window orientation is changed.

In subsequent research, we will collaborate with manufacturers to sample and experimentally test the identified optimal combination. We will then compare and analyze the test data with the simulation results. This will allow us to verify the practical application effect and manufacturing feasibility of the identified optimal combination.

Author Contributions

Conceptualization, F.Y. and L.L. (Lin Liu); methodology, Y.S. and D.W.; validation, F.Y.; formal analysis, L.L. (Lei Li); investigation, Y.Z. and L.S.; resources, F.S. and Y.S.; data curation, Y.Z.; writing—original draft preparation, L.L. (Lei Li); writing—review and editing, F.Y. and Y.S.; visualization, L.L. (Lei Li) and L.S.; supervision, L.L. (Lin Liu); project administration, F.S.; funding acquisition, D.W. All authors have read and agreed to the published version of the manuscript.

Funding

China MCC5 Group Corp. Ltd., China: WY2023B010.

Data Availability Statement

The data presented in this study are available in [Research on the Factors Influencing Broken-Bridge Aluminum Exterior Windows with the Goal of Thermal Performance Improvement]. Your prompt attention to this matter is greatly appreciated, as it helps us maintain the highest standards of research integrity and ensures the reproducibility of your work. If you have any questions or need further clarification, please do not hesitate to contact us.

Conflicts of Interest

Author Feining Yang, Yu Sun, Lei Li, Yu Zhang, Lingyun Sun, Dong Wang and Fengjun Sun are employed by the China MCC5 Group Corp. Ltd. The remaining author declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- U.S. Energy Information Admnistration. Internaltional Energy Outlook 2019; U.S. Energy Information Admnistration: Washington, DC, USA, 2019; pp. 25–150. [Google Scholar]

- IEA. Roadmap for Energy-Efficient Buildings and Construction in ASEAN; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/roadmap-for-energy-efficient-buildings-and-construction-in-the-association-of-southeast-asian-nations (accessed on 15 May 2025).

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021; p. 224. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 15 May 2025).

- Qiu, C.; Yang, H.; Zhang, W. Investigation on the energy performance of a novel semi-transparent BIPV system integrated with vacuum glazing. Build. Simul. 2019, 12, 29–39. [Google Scholar] [CrossRef]

- Chel, A.; Kaushik, G. Renewable energy technologies for sustainable development of energy efficient building. Alex. Eng. J. 2018, 57, 655–669. [Google Scholar] [CrossRef]

- Kim, H.; Yeo, M. Thermal Bridge Modeling and a Dynamic Analysis Method Using the Analogy of a Steady-State Thermal Bridge Analysis and System Identification Process for Building Energy Simulation: Methodology and Validation. Energies 2020, 13, 4422. [Google Scholar] [CrossRef]

- Grynning, S.; Gustavsen, A.; Time, B.; Jelle, B.P. Windows in the buildings of tomorrow: Energy losers or energy gainers? Energy Build. 2013, 61, 185–192. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Vacuum glazing for highly insulating windows: Recent developments and future prospects. Renew. Sustain. Energy Rev. 2016, 54, 1345–1357. [Google Scholar] [CrossRef]

- Uddin, M.M.; Jie, J.; Wang, C.; Zhang, C.; Ke, W. A review on photovoltaic combined vacuum glazing: Recent advancement and prospects. Energy Build. 2023, 286, 112939. [Google Scholar] [CrossRef]

- Huang, J.; Chen, X.; Peng, J.; Yang, H. Modelling analyses of the thermal property and heat transfer performance of a novel compositive PV vacuum glazing. Renew. Energy 2021, 163, 1238–1252. [Google Scholar] [CrossRef]

- Pont, U.; Wölzl, M.; Schober, P.; Khosravi, S.N.; Schuss, M.; Mahdavi, A. Recent progress in the development of windows with vacuum glass. MATEC Web Conf. 2019, 282, 02020. [Google Scholar] [CrossRef]

- Lyu, Y.; Zheng, S.; Zhuo, K.; Su, H.; Li, J.; Liu, C. Experimental and numerical performance investigation of a water-flow window with vacuum-glazing insulation. Sol. Energy 2022, 233, 259–270. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- Schultz, J.M.; Jensen, K.I.; Kristiansen, F.H. Super insulating aerogel glazing. Sol. Energy Mater. Sol. Cells 2005, 89, 275–285. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Duan, M.; Mao, H.; Wu, Y.; Zhao, H.; Lin, B. Applications of thermochromic and electrochromic smart windows: Materials to buildings. Cell Rep. Phys. Sci. 2023, 4, 101370. [Google Scholar] [CrossRef]

- Liang, R.; Sun, Y.; Aburas, M.; Wilson, R.; Wu, Y. Evaluation of the thermal and optical performance of thermochromic windows for office buildings in China. Energy Build. 2018, 176, 216–231. [Google Scholar] [CrossRef]

- Piccolo, A. Thermal performance of an electrochromic smart window tested in an environmental test cell. Energy Build. 2010, 42, 1409–1417. [Google Scholar] [CrossRef]

- Bai, T.; Li, W.; Fu, G.; Zhang, Q.; Zhou, K.; Wang, H. Dual-band electrochromic smart windows towards building energy conservation. Sol. Energy Mater. Sol. Cells 2023, 256, 112320. [Google Scholar] [CrossRef]

- Gustavsen, A.; Grynning, S.; Arasteh, D.; Jelle, B.P.; Goudey, H. Key elements of and material performance targets for highly insulating window frames. Energy Build. 2011, 43, 2583–2594. [Google Scholar] [CrossRef]

- Van Den Bergh, S.; Hart, R.; Jelle, B.P.; Gustavsen, A. Window spacers and edge seals in insulating glass units: A state-of-the-art review and future perspectives. Energy Build. 2013, 58, 263–280. [Google Scholar] [CrossRef]

- Paulos, J.; Berardi, U. Optimizing the thermal performance of window frames through aerogel-enhancements. Appl. Energy 2020, 266, 114776. [Google Scholar] [CrossRef]

- Xiaoyan, Y. Analysis of the influence of building exterior window profiles on heat transfer coefficient. Green Build. 2022, 14, 72–76. [Google Scholar]

- Appelfeld, D.; Hansen, C.S.; Svendsen, S. Development of a slim window frame made of glass fibre reinforced polyester. Energy Build. 2010, 42, 1918–1925. [Google Scholar] [CrossRef]

- Pittie, T.; Ahmad, S.; Singh, H.; Rashid, M.M.; Adhikari, S.; Shetty, S.; Krishnan, N.M.A. A combined experimental and numerical analysis framework for the design of aluminum windows. J. Build. Eng. 2024, 82, 108259. [Google Scholar] [CrossRef]

- Simko, T.; Moore, T. Optimal window designs for Australian houses. Energy Build. 2021, 250, 111300. [Google Scholar] [CrossRef]

- Van Den Bossche, N.; Buffel, L.; Janssens, A. Thermal Optimization of Window Frames. Energy Procedia 2015, 78, 2500–2505. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Zhang, L.; Li, W.; Li, C.; Huang, L.; Jiang, S.; Luo, T. Research on new heat-insulating aluminum alloy profiles for building exterior windows. Build. Sci. 2021, 37, 170–174+210. [Google Scholar] [CrossRef]

- Wan, C.; Wang, H.; Sun, S.; Wang, L. Simulation study on factors affecting thermal performance of aluminum alloy windows. Constr. Sci. Technol. 2014, 1, 62–65. [Google Scholar] [CrossRef]

- Jin, J.; Yu, H. Analysis of key technology of thermal performance of heat-insulating aluminum alloy profiles. Sichuan Build. Sci. Res. 2017, 43, 132–135. [Google Scholar]

- Xi, Y.; Liu, W. Research on heat transfer coefficient of building exterior windows based on different measures. New Build. Mater. 2020, 47, 20–24+34. [Google Scholar]

- Chen, J.; Shen, R. Research on isothermal distribution and heat transfer coefficient of thermal insulation profiles. Doors Windows 2011, 5, 46–51. [Google Scholar]

- 22J603-1; Aluminum Alloy Windows and Doors. China Institute of Building Standard Design & Research: Beijing, China, 2022.

- GB55015-2021; General Specification for Building Energy Efficiency and Renewable Energy Utilization. International Energy Agency: Paris, France, 2021.

- Amaral, A.R.; Rodrigues, E.; Gaspar, A.R.; Gomes, Á. A thermal performance parametric study of window type, orientation, size and shadowing effect. Sustain. Cities Soc. 2016, 26, 456–465. [Google Scholar] [CrossRef]

- Troup, L.; Phillips, R.; Eckelman, M.J.; Fannon, D. Effect of window-to-wall ratio on measured energy consumption in US office buildings. Energy Build. 2019, 203, 109434. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Does window-to-wall ratio have a significant effect on the energy consumption of buildings? a parametric analysis in Italian climate conditions. J. Build. Eng. 2017, 13, 169–183. [Google Scholar] [CrossRef]

- Teich, M.; Scherer, C.; Schuster, M.; Brandenstein, M.; Elstner, M. Reuse and remanufacturing of insulated glass units. Glass Struct. Eng. 2024, 9, 339–356. [Google Scholar] [CrossRef]

- Mert Cüce, A.P.; Cüce, E.; Şen, H. Numerical analysis of thermal insulation performance of double glazing products using air, argon and krypton. In Proceedings of the II-International Conference on Global Practice of Multidisciplinary Scientific Studies, Batumi, Georgia, 26–28 July 2022; pp. 1480–1486. [Google Scholar]

- Mo, Y.; Wang, C.; Kassem, M.A.; Wang, D.; Chen, Z. Optimizing Window Configurations for Energy-Efficient Buildings with Aluminum Alloy Frames and Helium-Filled Insulating Glazing. Sustainability 2024, 16, 6522. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Q.; Zhang, L.; Meng, Q. Thermal properties of Aluminum & PVC co-extrusion sliding window. In Proceedings of the 2011 International Conference on Multimedia Technology, Hangzhou, China, 26–28 July 2011; pp. 5660–5663. [Google Scholar] [CrossRef]

- 2006BAJ02B06; Research on Thermal Calculation Standard System of Chinese and Foreign Building Doors, Windows and Curtain Walls: One of the Special Research Contents of National Eleventh Five-Year Plan “Research and Development of Typical Building Window Systems for Regional Use”. China Building Metal Structure: Beijing, China, 2011; Volume 2, pp. 33–38.

- Curcija, D.C.; Hart, R.G. Modeling Thermal Performance of VIG: WINDOW and THERM Software Tools; Proc. Presented at the 1st China (Qingdao) International Glass & Equipment Technology Seminar; Lawrence Berkeley National Laboratory: Alameda County, CA, USA, 2018. [Google Scholar]

- Mitchell, R.; Kohler, C.; Curcija, D.; Zhu, L.; Vidanovic, S.; Czarnecki, S.; Arasteh, D.; Carmody, J.; Huizenga, C. THERM 7/WINDOW 7 NFRC Simulation Manual; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2017. [Google Scholar]

- JGJ/T151-2008; Thermal Calculation Regulations for Building Doors, Windows and Glass Curtain Walls. China Construction Industry Press: Beijing, China, 2009.

- NFRC 100:2004; Procedure for Determining Fenestration Product U-Factors. NFRC: Greenbelt, MD, USA, 2004.

- RISN-TG013-2012; Guidelines for Labeling Energy-Saving Performance of Building Windows and Doors. NFRC: Greenbelt, MD, USA, 2012.

- Mead, R. The Design of Experiments; Wikimedia: San Francisco, CA, USA, 1990. [Google Scholar]

- Zhu, J.; Chew, D.A.S.; Lv, S.; Wu, W. Optimization method for building envelope design to minimize carbon emissions of building operational energy consumption using orthogonal experimental design (OED). Habitat Int. 2013, 37, 148–154. [Google Scholar] [CrossRef]

- Li, Q.; Hu, H.; Ma, L.; Wang, Z.; Arıcı, M.; Li, D.; Luo, D.; Jia, J.; Jiang, W.; Qi, H. Evaluation of energy-saving retrofits for sunspace of rural residential buildings based on orthogonal experiment and entropy weight method. Energy Sustain. Dev. 2022, 70, 569–580. [Google Scholar] [CrossRef]

- Omle, I.; Kovács, E.; Bolló, B. Applying recent efficient numerical methods for long-term simulations of heat transfer in walls to optimize thermal insulation. Results Eng. 2023, 20, 101476. [Google Scholar] [CrossRef]

- Marwan, M.; Jamal, J.; Hamid, A.; Nasir, N.; La Nafie, N.A.; Gunawan, A.; Syamsuddin, S.; Razak, B.A.; Musaruddin, M. Optimize electrical energy cost of air conditioning considering to different wall characteristics. Results Eng. 2023, 17, 100990. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Wakili, K.G.; Raedle, W.; Krammer, A.; Uehlinger, A.; Schüler, A.; Stöckli, T. Ug-value and edge heat loss of triple glazed insulating glass units: A comparison between measured and declared values. J. Build. Eng. 2021, 44, 103031. [Google Scholar] [CrossRef]

- Wolf, A.T. Studies into the life-expectancy of insulating glass units. Build. Environ. 1992, 27, 305–319. [Google Scholar] [CrossRef]

- Altun, A.F. Determination of Optimum Building Envelope Parameters of a Room concerning Window-to-Wall Ratio, Orientation, Insulation Thickness. Buildings 2022, 12, 383. [Google Scholar] [CrossRef]

- Alghoul, S.K.; Rijabo, H.G.; Mashena, M.E. Energy consumption in buildings: A correlation for the influence of window to wall ratio and window orientation in Tripoli, Libya. J. Build. Eng. 2017, 11, 82–86. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).