Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation

Abstract

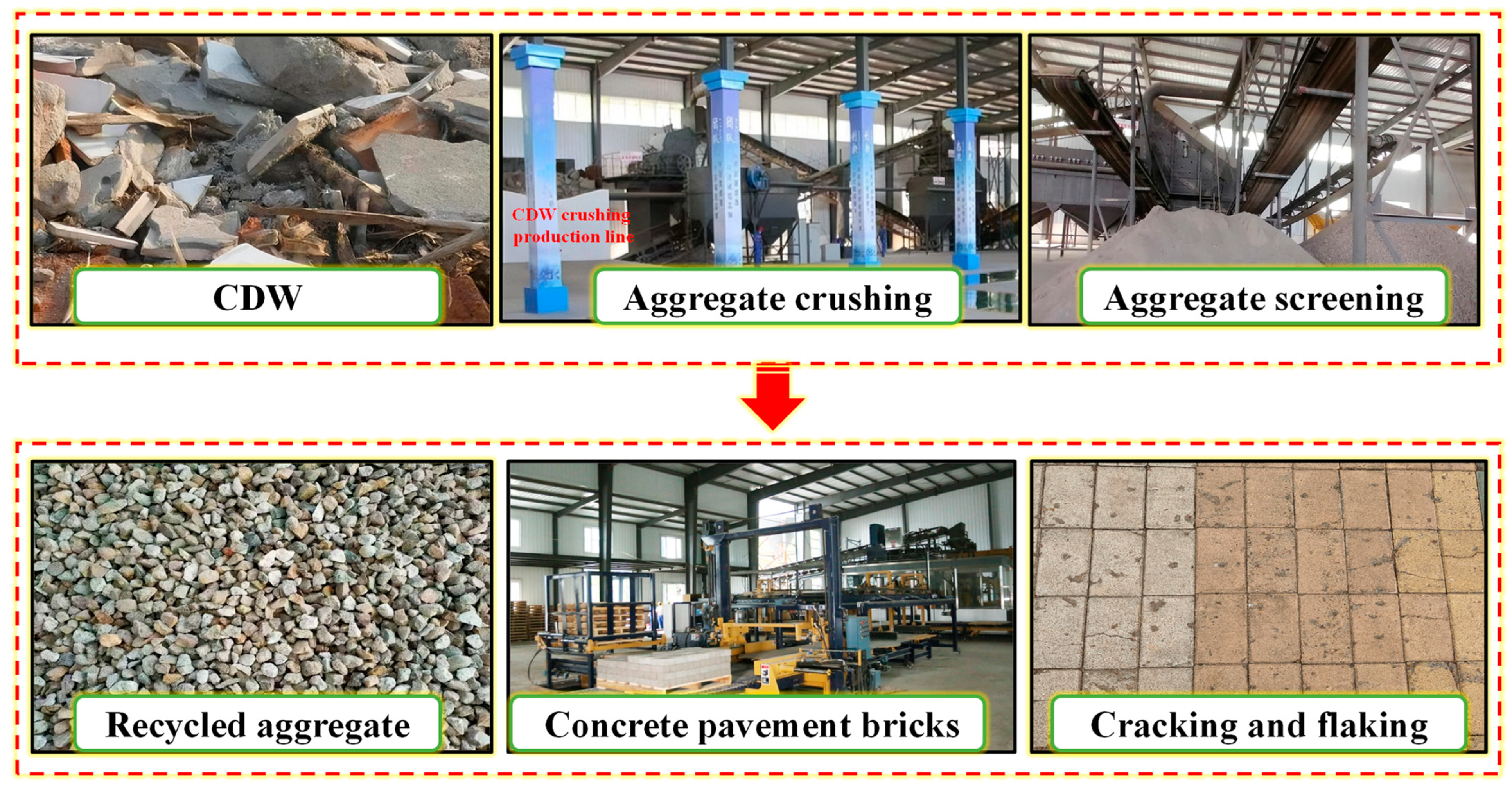

1. Introduction

2. Materials and Experimental Program

2.1. Materials

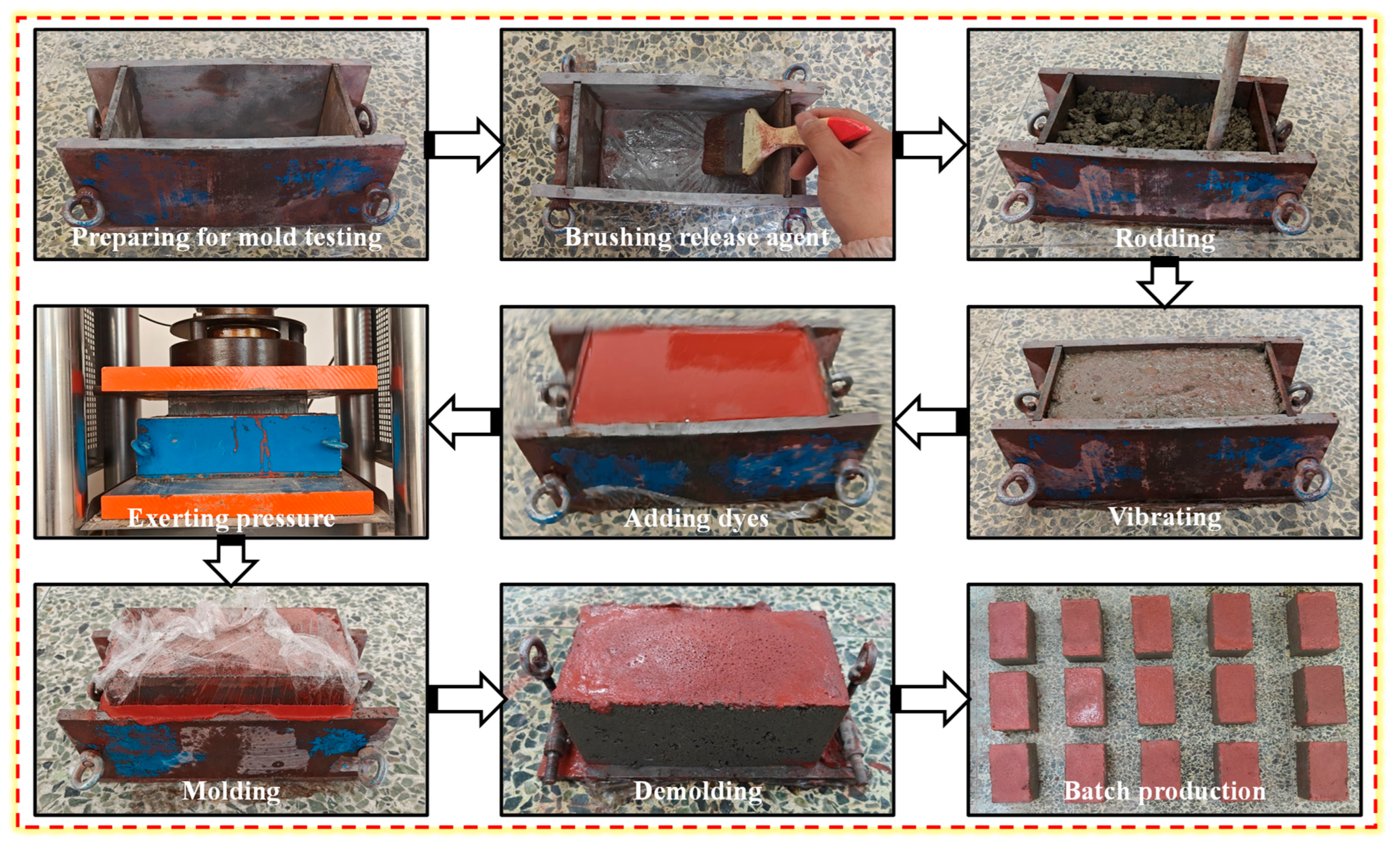

2.1.1. Cementitious Materials

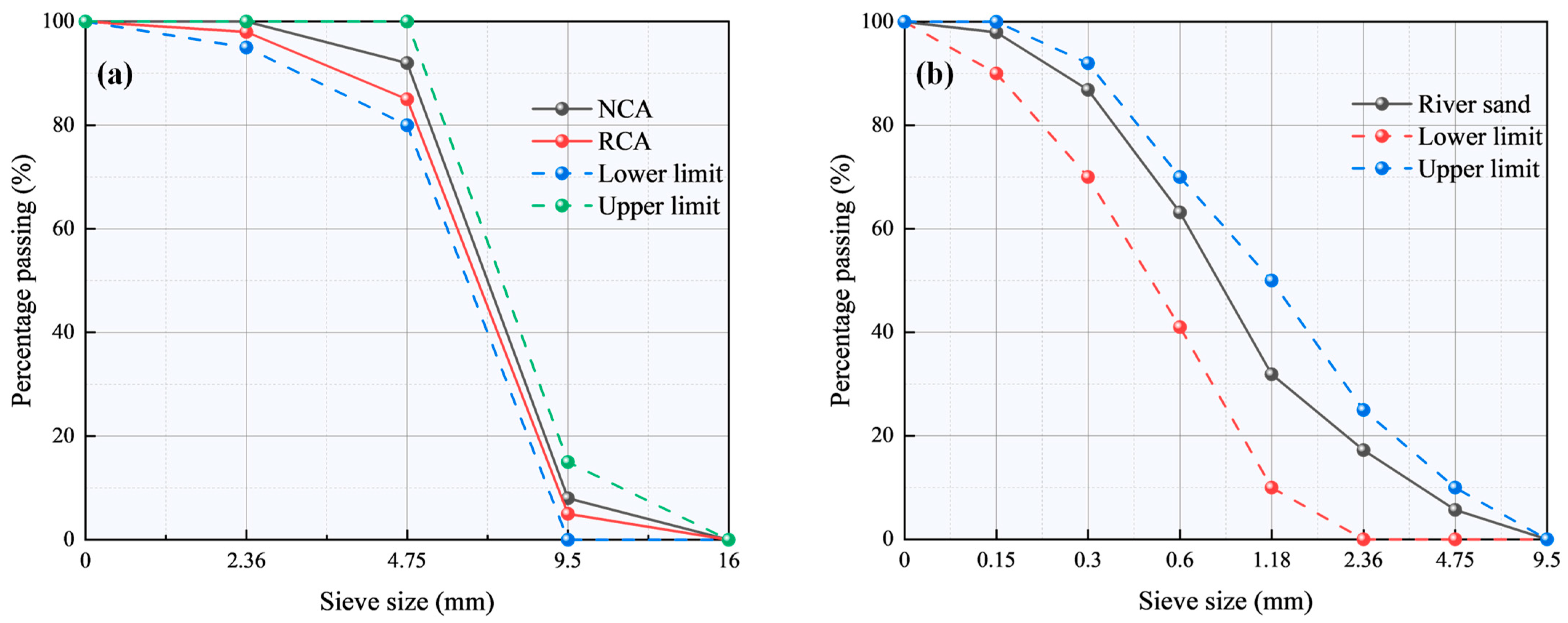

2.1.2. Aggregates

2.1.3. Other Materials

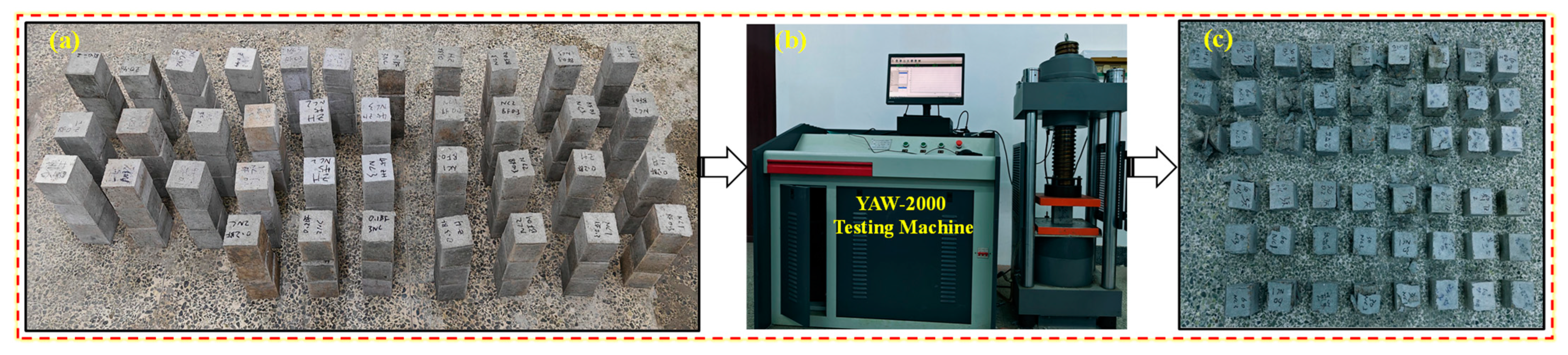

2.2. Experimental Program

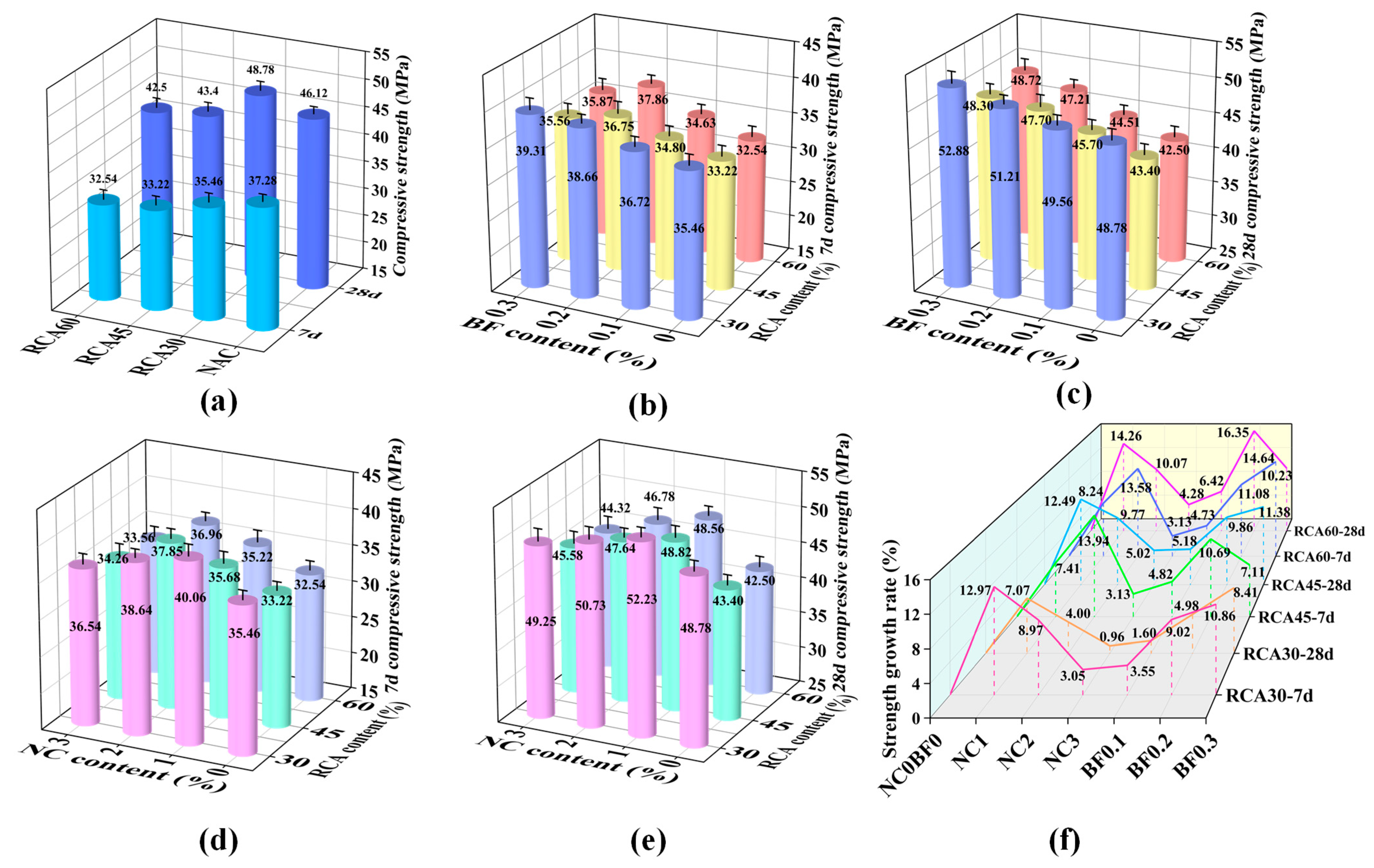

3. Compression Test Results and Analysis of RAC

3.1. Impact of Single Factors

3.1.1. Effect of RCA Substitution Rate on Compressive Strength

3.1.2. Effect of BF Substitution Rate on RAC Compressive Strength

3.1.3. Effect of NC Substitution Rate on RAC Compressive Strength

3.2. Influence of Multiple Factors

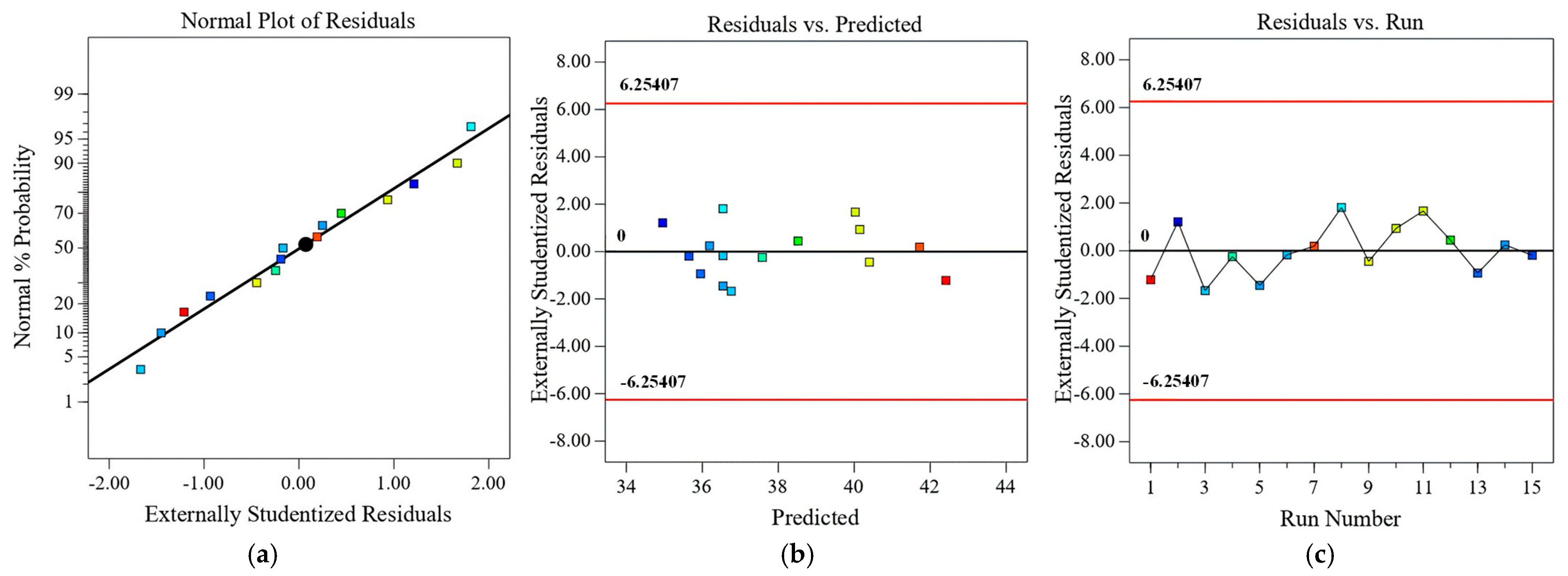

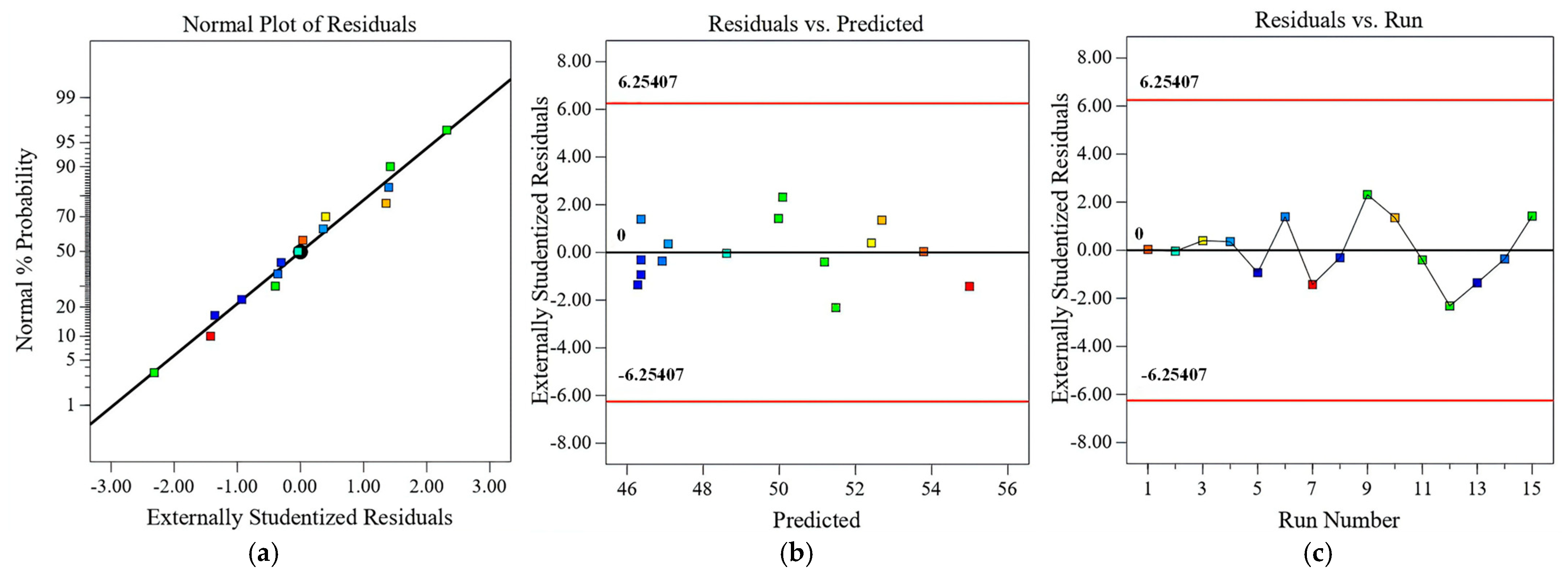

3.2.1. Test Results of the Compressive Strength of RAC Based on the RSM

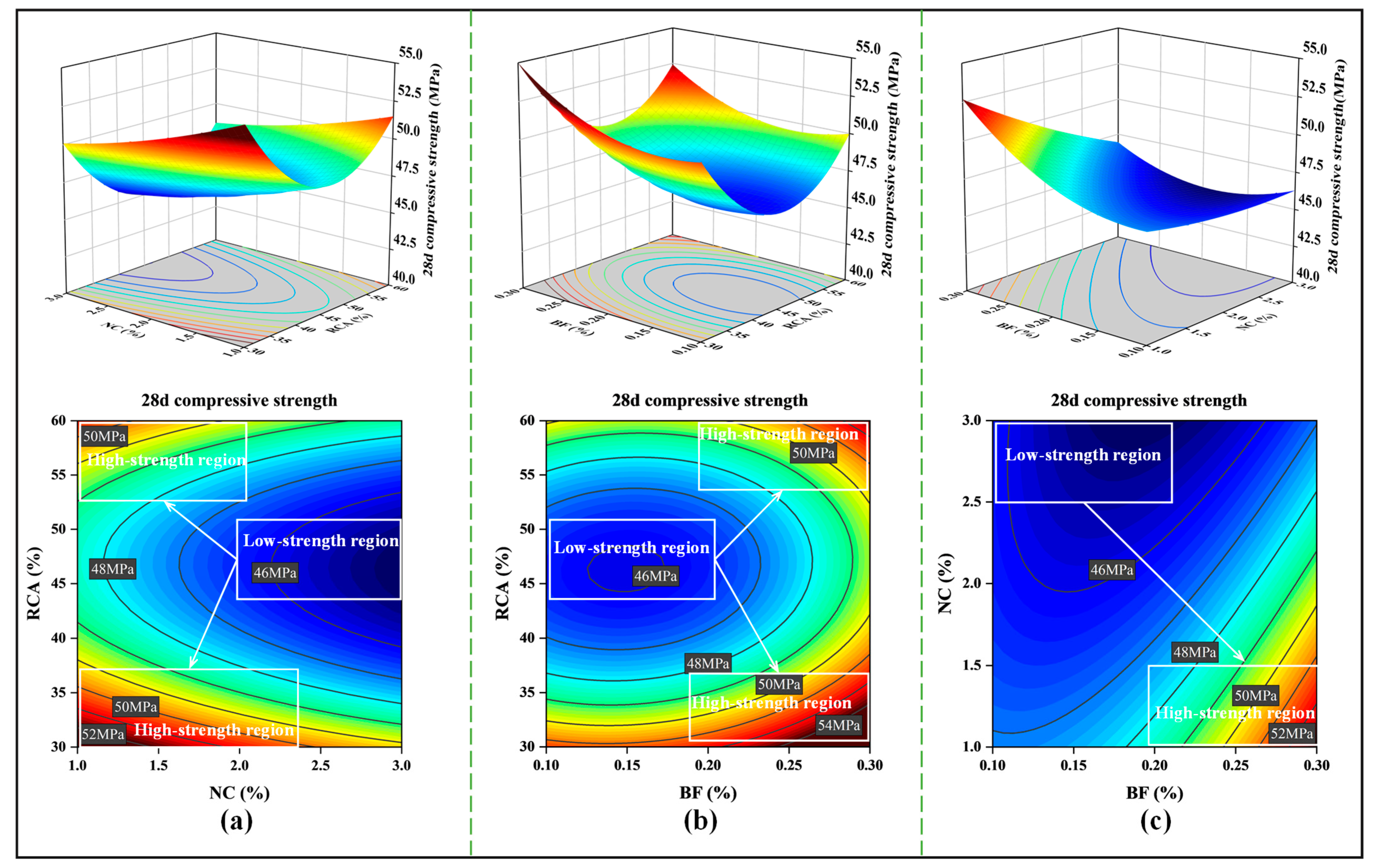

3.2.2. Response Surface Analysis

3.2.3. Multi-Objective Optimisation and Validation of the Model

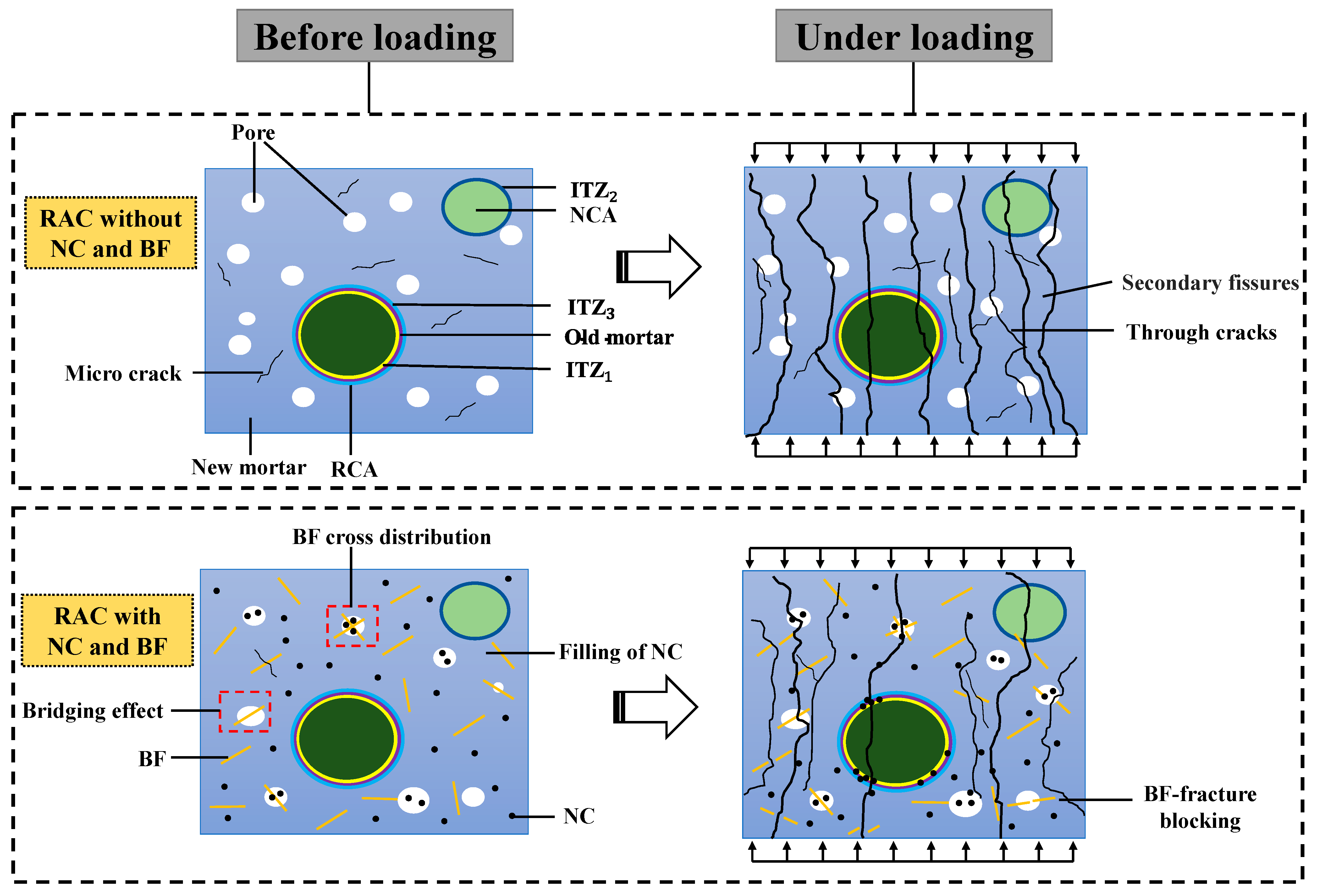

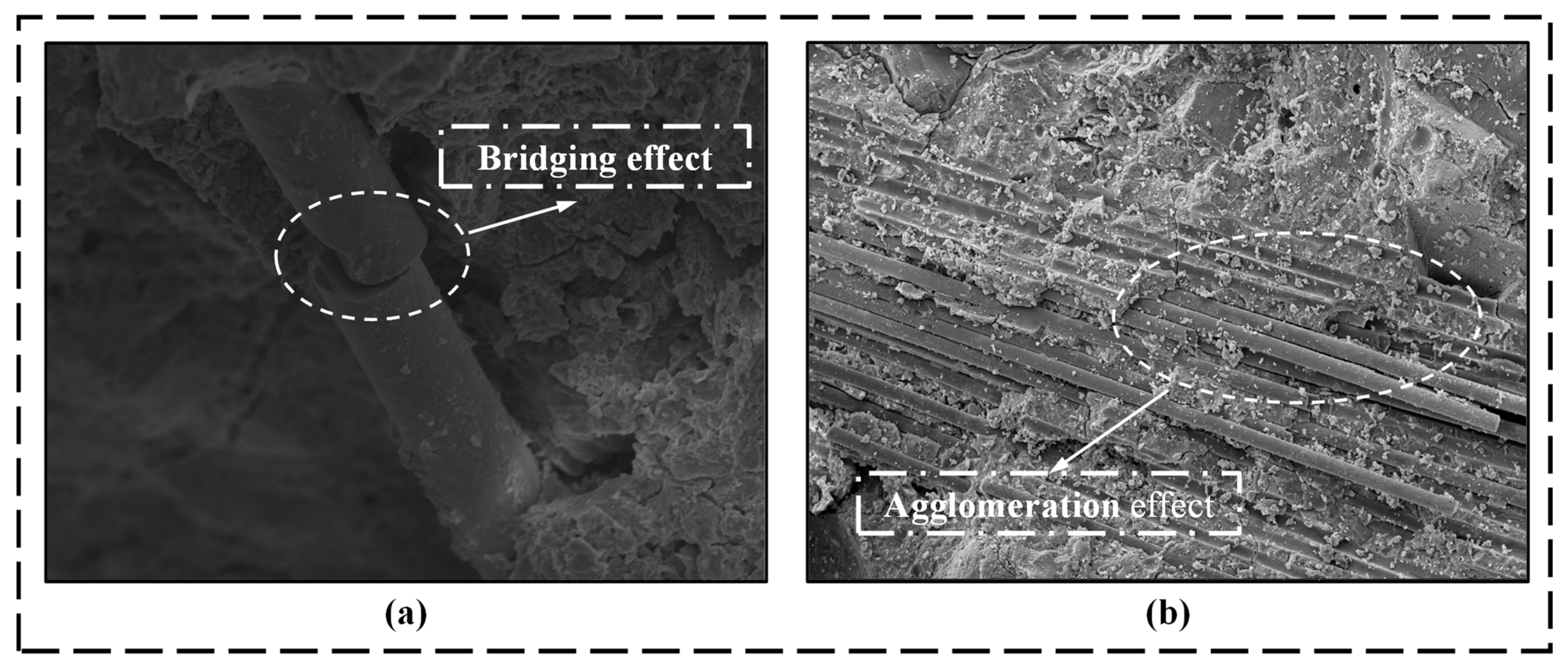

4. Microscopic Analysis

5. Model Test and Analysis of Concrete Pavement Bricks

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Liu, Q.; Huang, T.; Peng, W. Mineralization and utilization of CO2 in construction and demolition wastes recycling for building materials: A systematic review of recycled concrete aggregate and recycled hardened cement powder. Sep. Purif. Technol. 2022, 298, 121512. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andra Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Ho, H.J.; Iizuka, A.; Shibata, E. Chemical recycling and use of various types of concrete waste: A review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Sun, C.; Chen, Q.; Xiao, J.; Liu, W. Utilization of waste concrete recycling materials in self-compacting concrete. Resour. Conserv. Recycl. 2020, 161, 104930. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, M. Strength enhancement of artificial aggregate prepared with waste concrete powder and its impact on concrete properties. J. Clean. Prod. 2020, 257, 120515. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Cao, D. Pore characteristics of recycled aggregate concrete and its relationship with durability under complex environmental factors. Constr. Build. Mater. 2021, 272, 121642. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Hu, H.; He, C.; Song, L.; Huang, W. Pore structure and durability of green concrete containing recycled powder and recycled coarse aggregate. J. Build. Eng. 2022, 53, 104584. [Google Scholar] [CrossRef]

- Le, H.B.; Bui, Q.B. Recycled aggregate concretes—A state-of-the-art from the microstructure to the structural performance. Constr. Build. Mater. 2020, 257, 119522. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Singh, R.; Nayak, D.; Pandey, A.; Kumar, R.; Kumar, V. Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: A comparative study. J. Build. Eng. 2022, 45, 103442. [Google Scholar] [CrossRef]

- Chang, J.N.; Wang, W.C.; Wang, H.Y.; Hu, C.Y. A study of the mechanical properties and appearance of efflorescence in paving bricks under different curing environments. Constr. Build. Mater. 2020, 265, 120148. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. The use of recycled demolition aggregate in precast concrete products—Phase III: Concrete pavement flags. Constr. Build. Mater. 2012, 36, 674–680. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

- Meng, Y.; Ling, T.C.; Mo, K.H. Recycling of wastes for value-added applications in concrete blocks: An overview. Resour. Conserv. Recycl. 2018, 138, 298–312. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Use of recycled demolition aggregate in precast products, phase II: Concrete paving blocks. Constr. Build. Mater. 2011, 25, 3131–3143. [Google Scholar] [CrossRef]

- Huang, K.; Xie, J.; Wang, R.; Feng, Y.; Rao, R. Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete. Nanotechnol. Rev. 2021, 10, 304–317. [Google Scholar] [CrossRef]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, Y.; Zhang, P. Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol. Rev. 2022, 11, 2169–2189. [Google Scholar] [CrossRef]

- Wang, Z.H.; Bai, E.L.; Xu, J.Y.; Du, Y.H.; Zhu, J.S. Effect of nano-SiO2 and nano-CaCO3 on the static and dynamic properties of concrete. Sci. Rep. UK 2022, 12, 907. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Xiao, H.; Geng, J.; Du, J.; Liu, M. Effect of nano-CaCO3 and nano-SiO2 on improving the properties of carbon fibre-reinforced concrete and their pore-structure models. Constr. Build. Mater. 2020, 244, 118297. [Google Scholar] [CrossRef]

- Feng, J.; Yang, F.; Qian, S. Improving the bond between polypropylene fiber and cement matrix by nano calcium carbonate modification. Constr. Build. Mater. 2021, 269, 121249. [Google Scholar] [CrossRef]

- Chen, X.; Ai, Y.; Wu, Q.; Cheng, S.; Wei, Y.; Xu, X.; Fan, T. Potential use of nano calcium carbonate in polypropylene fiber reinforced recycled aggregate concrete: Microstructures and properties evaluation. Constr. Build. Mater. 2023, 400, 132871. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K.; Won, M. Mechanical and durability properties of portland limestone cement (PLC) incorporated with nano calcium carbonate (CaCO3). Materials 2021, 14, 905. [Google Scholar] [CrossRef]

- Wen, Y.; Wang, Z.; Yuan, X.; Yang, X. Optimization of Mechanical Properties and Durability of Steel Fiber-Reinforced Concrete by Nano CaCO3 and Nano TiC to Improve Material Sustainability. Sustainability 2025, 17, 641. [Google Scholar] [CrossRef]

- Salih, A.; Rafiq, S.; Mahmood, W.; Al-Darkazali, H.; Noaman, R.; Ghafor, K.; Qadir, W. Systemic multi-scale approaches to predict the flowability at various temperature and mechanical properties of cement paste modified with nano-calcium carbonate. Constr. Build. Mater. 2020, 262, 120777. [Google Scholar] [CrossRef]

- Li, L.; Wu, M. An overview of utilizing CO2 for accelerated carbonation treatment in the concrete industry. J. CO2 Util. 2022, 60, 102000. [Google Scholar] [CrossRef]

- Al-Rousan, E.T.; Khalid, H.R.; Rahman, M.K. Fresh, mechanical, and durability properties of basalt fiber-reinforced concrete (BFRC): A review. Dev. Built. Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A review on durability of basalt fiber reinforced concrete. Compos. Sci Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- Dilbas, H.; Çakır, Ö. Influence of basalt fiber on physical and mechanical properties of treated recycled aggregate concrete. Constr. Build. Mater. 2020, 254, 119216. [Google Scholar] [CrossRef]

- Sohail, M.G.; Alnahhal, W.; Taha, A.; Abdelaal, K. Sustainable alternative aggregates: Characterization and influence on mechanical behavior of basalt fiber reinforced concrete. Constr. Build. Mater. 2020, 255, 119365. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Y.; Shen, Y.; Wang, J.; Fan, Y.; Gao, X.; Huang, Y. Compressive mechanical performance and microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete after elevated temperature exposure. J. Build. Eng. 2024, 96, 110647. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental study on basic mechanical properties of basalt fiber reinforced concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef] [PubMed]

- Sivanantham, P.; Pugazhlendi, D.; Gurupatham, B.G.A.; Roy, K. Influence of Steel Fiber and Carbon Fiber Mesh on Plastic Hinge Length of RCC Beams Under Monotonic Loading. J. Compos. Sci. 2022, 6, 374. [Google Scholar] [CrossRef]

- Sivanantham, P.; Gurupatham, B.G.A.; Roy, K.; Rajendiran, K.; Pugazhlendi, D. Plastic Hinge Length Mechanism of Steel-Fiber-Reinforced Concrete Slab Under Repeated Loading. J. Compos. Sci. 2022, 6, 164. [Google Scholar] [CrossRef]

- Deepak, M.S.; Surendar, M.; Aishwarya, B.; Ananthi, G.B.G. Bending Behaviour of Ferrocement Slab Including Basalt Fibre in High Strength Cement Matrix. Mater. Today Proc. 2021, 37, 2356–2359. [Google Scholar] [CrossRef]

- Alomayri, T. Performance evaluation of basalt fiber-reinforced geopolymer composites with various contents of nano-CaCO3. Ceram. Int. 2021, 47, 29949–29959. [Google Scholar] [CrossRef]

- Lian, H.; Sun, X.; Yu, Z.; Yang, T.; Zhang, J.; Li, G.; Guan, Z.; Diao, M. Research on the fracture mechanical performance of basalt fiber nano-CaCO3 concrete based on DIC technology. Constr. Build. Mater. 2022, 329, 127193. [Google Scholar] [CrossRef]

- GB/T 14685-2022; Pebble and Crushed Stone for Construction. Standards Press of China: Beijing, China, 2022. (In Chinese)

- Zhang, L.; Lin, G.; Qian, X.; Yan, D.; Qian, K.; Ruan, S. Unveil the role of nano-CaCO3 in early shrinkage and tensile properties of cement paste: From experimental work to modeling. Constr. Build. Mater. 2022, 243, 110185. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Kaze, C.R.; Jindal, B.B.; Subaer, S.; Shaikh, F.; Alrad-dadi, S. Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3. Constr. Build. Mater. 2020, 252, 119137. [Google Scholar] [CrossRef]

- Shi, W.; Guo, Y.; Liu, Y.; Wang, W.; Duan, P.; Bian, H.; Chen, J. Impact of basalt fiber on the fracture properties of recycled aggregate concrete. Constr. Build. Mater. 2024, 418, 135363. [Google Scholar] [CrossRef]

- Du, X.; Li, Y.; Si, Z.; Huang, L.; Chen, X. Effects of basalt fiber and poly-vinyl alcohol fiber on the properties of recycled aggregate concrete and optimization of fiber contents. Constr. Build. Mater. 2022, 340, 127646. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nano-silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Xie, L.; Sun, X.; Yu, Z.; Lian, H.; He, H.; Wang, L.; Zhang, Z.; Xu, X. Effects of nano-silica on fracture properties and mechanism analysis of basalt fiber reinforced concrete. Constr. Build. Mater. 2024, 439, 137375. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for the Testing of the Physical and Mechanical Properties of Concrete. Standards Press of China: Beijing, China, 2019. (In Chinese)

- Peng, Z.; Shi, C.; Shi, Z.; Lu, B.; Wan, S.; Zhang, Z.; Chang, J.; Zhang, T. Alkali-aggregate reaction in recycled aggregate concrete. J. Clean. Prod. 2020, 255, 120238. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, K.; Akbarnezhad, A. Variability of stress-strain relationship for recycled aggregate concrete under uniaxial compression loading. J. Clean. Prod. 2018, 181, 753–771. [Google Scholar] [CrossRef]

- Al Ajmani, H.; Suleiman, F.; Abuzayed, I.; Tamimi, A. Evaluation of concrete strength made with recycled aggregate. Buildings 2019, 9, 56. [Google Scholar] [CrossRef]

- Lv, J.; Han, W.; Zheng, J.; Lin, S.; Yuan, S. Effects of basalt fibre and rubber particles on the mechanical properties and impact resistance of concrete. Structures 2024, 65, 106677. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.; Tong, Y.; Chen, Y.; Li, Z.; Niu, D. Flexural toughness characteristics of basalt fiber reinforced shotcrete composites in high geothermal environment. Constr. Build. Mater. 2021, 298, 123893. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, A.H.; Wu, Z.G.; Xiao, P.; Gong, Y.F.; Sun, H.F. Investigation of the basalt fiber type and content on performances of cement mortar and concrete. Constr. Build. Mater. 2023, 408, 133720. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Xu, W.; Niu, D. Effect of nano-CaCO3 on hydration characteristics and microstructure of cement-based materials: A review. J. Build. Eng. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Mohammed, A.M.A.; Al Saadi, H.K.H.; Fahad, A.R.M.; Ali, A.N.N.; Salim, A.W.N.; Said, A.; Seku, K.R.; Bellum, R.R. Influence of nano-CaCO3 on pore structure and compressive strength in concrete bricks. J. Build. Eng. 2025, 105, 112520. [Google Scholar] [CrossRef]

- Aghajanzadeh, I.; Ramezanianpour, A.M.; Amani, A.; Habibi, A. Mixture optimization of alkali activated slag concrete containing recycled concrete aggregates and silica fume using response surface method. Constr. Build. Mater. 2024, 425, 135928. [Google Scholar] [CrossRef]

- Divya, S.; Praveenkumar, S. An integrated evaluation of graphene-based concrete mixture with copper slag and quarry dust using response surface methodology. J. Build. Eng. 2024, 86, 108876. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Liu, J.; Chu, F.; Tian, Y. Study on the Characteristics of Composite Recycled Aggregate Concrete Based on Box–Behnken Design Response Surface Model. Fractal. Fract. 2023, 7, 648. [Google Scholar] [CrossRef]

- Long, X.; Chang, C.; Ning, H.; Song, M.; Ma, Y.; Wang, X.; Kawkabi, K.W. Enhancing Mechanical Properties of High-Strength Recycled Concrete with Basalt Fiber and Nano-Calcium Carbonate: Experimental and Numerical Investigations. SSRN 5168853. Available online: https://ssrn.com/abstract=5168853 (accessed on 12 June 2025).

- Diao, M.; Ren, Q.; Sun, X.; Zhao, Y.; Wei, C. Mechanical properties of nano-CaCO3 and basalt fiber reinforced concrete: Experiments and numerical simulations. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2022, 37, 922–932. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Hussain, A.; Chu, S.H. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 2021, 300, 124046. [Google Scholar] [CrossRef]

- Almohammed, F.; Thakur, M.S.; Lee, D.; Kumar, R.; Singh, T. Flexural and split tensile strength of concrete with basalt fiber: An experimental and computational analysis. Constr. Build. Mater. 2024, 414, 134936. [Google Scholar] [CrossRef]

- Yang, W.; Liu, L.; Wu, W.; Zhang, K.; Xiong, X.; Li, C.; Huang, Y.; Zhang, X.; Zhou, H. A review of the mechanical properties and durability of basalt fiber recycled concrete. Constr. Build. Mater. 2024, 412, 134882. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Constr. Build. Mater. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Muhammad, E.A.; Baharom, S.; Alrshoudi, F.; Syamsir, A.; Salah, H.A.; Anggraini, V. Optimizing polypropylene fiber and carbon nanotubes to reinforce concrete matrix: A response surface methodology. Constr. Build. Mater. 2024, 442, 137388. [Google Scholar] [CrossRef]

- Raveendran, N.; Vasugi, K. Synergistic effect of nano silica and metakaolin on mechanical and microstructural properties of concrete: An approach of response surface methodology. Case. Stud. Constr. Mat. 2024, 20, e03196. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Zhang, X.; Ding, Y.; Xu, P. Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. J. Clean. Prod. 2021, 278, 123252. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, M.; Zhang, D.; Zhang, B.; Wang, M. Experimental study on them mechanical properties of metallurgical slag aggregate concrete and artificial aggregate concrete. Buildings 2024, 14, 2548. [Google Scholar] [CrossRef]

- Taylor, H.F.W.; Newbury, D.E. An electron microprobe study of a mature cement paste. Cement. Concrete. Res. 1984, 14, 565–573. [Google Scholar] [CrossRef]

- GB/T 28635-2012; Concrete Pavement Bricks. Standards Press of China: Beijing, China, 2012. (In Chinese)

- Ahmad, M.; Hameed, R.; Shahzad, S.; Sohail, M.G. Performance evaluation of loadbearing compressed fully recycled aggregate concrete bricks. Structures 2023, 55, 1235–1249. [Google Scholar] [CrossRef]

| Chemical Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 44.23 | 31.60 | 10.95 | 3.85 | 2.63 | 1.19 | 0.72 | 0.61 | 3.67 |

| Coarse Aggregates | Packing Density/(kg·m−3) | Crushing Value/% | Moisture Content/% | 24 h Water Absorption/% | Clay Content (%) |

|---|---|---|---|---|---|

| RCA | 1295 | 23.4 | 2.48 | 6.18 | 1.85 |

| NCA | 1455 | 17.7 | 1.78 | 3.37 | 0.45 |

| Calibre/μm | Tensile Strength/MPa | Ultimate Elongation/% | Relative Density (g/cm3) | Elastic Modulus/MPa |

|---|---|---|---|---|

| 17 | 1550 | 3.6 | 2.62 | 35.8 |

| Mix Label | NCA (kg) | RCA (kg) | FA (kg) | Cement (kg) | BF (kg) | NC (kg) | Water (kg) | PCA (kg) | Additional Water (kg) |

|---|---|---|---|---|---|---|---|---|---|

| NAC | 730.24 | 0.00 | 1095.36 | 380.00 | 0.00 | 0.00 | 144.40 | 4.35 | 0.00 |

| RCA30 | 511.17 | 219.07 | 1095.36 | 380.00 | 0.00 | 0.00 | 144.40 | 4.35 | 13.53 |

| RCA45 | 401.63 | 328.61 | 1095.36 | 380.00 | 0.00 | 0.00 | 144.40 | 4.35 | 20.30 |

| RCA60 | 292.10 | 438.14 | 1095.36 | 380.00 | 0.00 | 0.00 | 144.40 | 4.35 | 27.07 |

| N1RAC30 | 511.17 | 219.07 | 1095.36 | 376.20 | 0.00 | 3.80 | 144.40 | 4.35 | 13.53 |

| N2RAC30 | 511.17 | 219.07 | 1095.36 | 372.40 | 0.00 | 7.60 | 144.40 | 4.35 | 13.53 |

| N3RAC30 | 511.17 | 219.07 | 1095.36 | 368.60 | 0.00 | 11.40 | 144.40 | 4.35 | 13.53 |

| B0.1RAC30 | 511.17 | 219.07 | 1095.36 | 380.00 | 2.62 | 0.00 | 144.40 | 4.35 | 13.53 |

| B0.2RAC30 | 511.17 | 219.07 | 1095.36 | 380.00 | 5.24 | 0.00 | 144.40 | 4.35 | 13.53 |

| B0.3RAC30 | 511.17 | 219.07 | 1095.36 | 380.00 | 7.86 | 0.00 | 144.40 | 4.35 | 13.53 |

| N1RAC45 | 401.63 | 328.61 | 1095.36 | 376.20 | 0.00 | 3.80 | 144.40 | 4.35 | 20.30 |

| N2RAC45 | 401.63 | 328.61 | 1095.36 | 372.40 | 0.00 | 7.60 | 144.40 | 4.35 | 20.30 |

| N3RAC45 | 401.63 | 328.61 | 1095.36 | 368.60 | 0.00 | 11.40 | 144.40 | 4.35 | 20.30 |

| B0.1RAC45 | 401.63 | 328.61 | 1095.36 | 380.00 | 2.62 | 0.00 | 144.40 | 4.35 | 20.30 |

| B0.2RAC45 | 401.63 | 328.61 | 1095.36 | 380.00 | 5.24 | 0.00 | 144.40 | 4.35 | 20.30 |

| B0.3RAC45 | 401.63 | 328.61 | 1095.36 | 380.00 | 7.86 | 0.00 | 144.40 | 4.35 | 20.30 |

| N1RAC60 | 292.10 | 438.14 | 1095.36 | 376.20 | 0.00 | 3.80 | 144.40 | 4.35 | 27.07 |

| N2RAC60 | 292.10 | 438.14 | 1095.36 | 372.40 | 0.00 | 7.60 | 144.40 | 4.35 | 27.07 |

| N3RAC60 | 292.10 | 438.14 | 1095.36 | 368.60 | 0.00 | 11.40 | 144.40 | 4.35 | 27.07 |

| B0.1RAC60 | 292.10 | 438.14 | 1095.36 | 380.00 | 2.62 | 0.00 | 144.40 | 4.35 | 27.07 |

| B0.2RAC60 | 292.10 | 438.14 | 1095.36 | 380.00 | 5.24 | 0.00 | 144.40 | 4.35 | 27.07 |

| B0.3RAC60 | 292.10 | 438.14 | 1095.36 | 380.00 | 7.86 | 0.00 | 144.40 | 4.35 | 27.07 |

| Mix Label | BF (%) | NC (%) | RCA (%) | NCA (kg) | RCA (kg) | FA (kg) | Cement (kg) | BF (kg) | NC (kg) | Water (kg) | PCA (kg) | Additional Water (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Z-1 | 0.1 | 1 | 45 | 401.63 | 328.61 | 1095.36 | 376.20 | 2.62 | 3.80 | 144.40 | 4.35 | 20.30 |

| Z-2 | 0.3 | 1 | 45 | 401.63 | 328.61 | 1095.36 | 376.20 | 7.86 | 3.80 | 144.40 | 4.35 | 20.30 |

| Z-3 | 0.1 | 3 | 45 | 401.63 | 328.61 | 1095.36 | 368.60 | 2.62 | 11.40 | 144.40 | 4.35 | 20.30 |

| Z-4 | 0.3 | 3 | 45 | 401.63 | 328.61 | 1095.36 | 368.60 | 7.86 | 11.40 | 144.40 | 4.35 | 20.30 |

| Z-5 | 0.1 | 2 | 30 | 511.17 | 219.07 | 1095.36 | 372.40 | 2.62 | 7.60 | 144.40 | 4.35 | 13.53 |

| Z-6 | 0.3 | 2 | 30 | 511.17 | 219.07 | 1095.36 | 372.40 | 7.86 | 7.60 | 144.40 | 4.35 | 13.53 |

| Z-7 | 0.1 | 2 | 60 | 292.10 | 438.14 | 1095.36 | 372.40 | 2.62 | 7.60 | 144.40 | 4.35 | 27.07 |

| Z-8 | 0.3 | 2 | 60 | 292.10 | 438.14 | 1095.36 | 372.40 | 7.86 | 7.60 | 144.40 | 4.35 | 27.07 |

| Z-9 | 0.2 | 1 | 30 | 511.17 | 219.07 | 1095.36 | 376.20 | 5.24 | 3.80 | 144.40 | 4.35 | 13.53 |

| Z-10 | 0.2 | 3 | 30 | 511.17 | 219.07 | 1095.36 | 368.60 | 5.24 | 11.40 | 144.40 | 4.35 | 13.53 |

| Z-11 | 0.2 | 1 | 60 | 292.10 | 438.14 | 1095.36 | 376.20 | 5.24 | 3.80 | 144.40 | 4.35 | 27.07 |

| Z-12 | 0.2 | 3 | 60 | 292.10 | 438.14 | 1095.36 | 368.60 | 5.24 | 11.40 | 144.40 | 4.35 | 27.07 |

| Z-13 | 0.2 | 2 | 45 | 401.63 | 328.61 | 1095.36 | 372.40 | 5.24 | 7.60 | 144.40 | 4.35 | 20.30 |

| Mix Label | FC7/MPa | FC28/MPa | ||

|---|---|---|---|---|

| Measured Value | Projected Value | Measured Value | Projected Value | |

| Z-1 | 37.54 | 37.58 | 47.2 | 47.08 |

| Z-2 | 40.28 | 40.15 | 53.07 | 52.69 |

| Z-3 | 35.82 | 35.95 | 45.9 | 46.28 |

| Z-4 | 36.23 | 36.19 | 46.8 | 46.92 |

| Z-5 | 40.23 | 40.03 | 51.05 | 51.18 |

| Z-6 | 41.75 | 41.72 | 54.6 | 54.98 |

| Z-7 | 35.62 | 36.65 | 50.37 | 49.98 |

| Z-8 | 36.56 | 36.76 | 52.55 | 52.42 |

| Z-9 | 42.25 | 42.41 | 53.8 | 53.79 |

| Z-10 | 40.33 | 40.40 | 50.6 | 50.09 |

| Z-11 | 38.59 | 38.52 | 50.97 | 51.48 |

| Z-12 | 35.12 | 34.96 | 48.6 | 48.61 |

| Z-13 | 36.5 | 36.54 | 47 | 46.37 |

| Z-13 | 36.24 | 36.54 | 45.9 | 46.37 |

| Z-13 | 36.89 | 36.54 | 46.2 | 46.37 |

| Response Surface Equation Model | (1) | |

| Compressive strength response surface equation (7d) | (2) | |

| Compressive strength response surface equation (28d) | (3) |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Y | 78.38|127.40 | 9|9 | 8.71|14.16 | 108.93|38.61 | <0.0001|0.0004 | Significant|Significant |

| A | 3.93|19.53 | 1/1 | 3.93|19.53 | 49.21|53.27 | 0.0009|0.0008 | Significant|Significant |

| B | 15.57|21.58 | 1/1 | 15.57|21.58 | 194.73|58.87 | <0.0001|0.0006 | Significant|Significant |

| C | 43.57|7.14 | 1/1 | 43.57|7.14 | 544.99|19.49 | <0.0001|0.0069 | Significant|Significant |

| AB | 1.36|6.18 | 1/1 | 1.36|6.18 | 16.98|16.84 | 0.0092|0.0093 | Significant|Significant |

| AC | 0.08|0.4692 | 1/1 | 0.08|0.4692 | 1.05|1.28 | 0.35|0.3092 | Not significant|Not significant |

| BC | 0.60|0.1722 | 1/1 | 0.60|0.1722 | 7.51|0.47 | 0.04|0.5236 | Significant|Not Significant |

| A² | 0.14|8.45 | 1|1 | 0.14|8.45 | 1.77|23.05 | 0.24|0.0049 | Not significant|Significant |

| B² | 1.96|0.4863 | 1|1 | 1.96|0.4863 | 24.50|1.33 | 0.004|0.3015 | Significant|Not Significant |

| C² | 11.97|67.10 | 1|1 | 11.97|67.10 | 149.77|183.02 | <0.0001|<0.0001 | Significant|Significant |

| Residual | 0.40|1.83 | 5|5 | 0.14|0.3666 | |||

| Lack of fit | 0.19|1.19 | 3|3 | 1.96|0.3955 | 0.58|1.22 | 0.24|0.4793 | Not significant|Not significant |

| Cor total | 78.78|129.23 | 14|14 |

| Std.Dev. | Mean Value | C.V./% | Adequate Precision | R2 | Adjusted | Predicted R2 |

|---|---|---|---|---|---|---|

| 0.28|0.61 | 38.00|49.64 | 0.74|1.22 | 32.30|17.62 | 0.995|0.986 | 0.986|0.960 | 0.956|0.842 |

| Literature | BF(%) | NC(%) | RCA(%) | Test Value (MPa) | Predicted Value (MPa) | Difference Ratio (%) |

|---|---|---|---|---|---|---|

| Lian et al. [39] | 0.2 | 1 | 0 | 54.53 | 52.59 | 3.6 |

| Long et al. [59] | 0.3 | 2.5 | 50 | 44.62 | 45.83 | 2.7 |

| Diao et al. [60] | 0.2 | 2 | 0 | 53.06 | 51.57 | 2.8 |

| Khan et al. [61] | 0.1 | 2.5 | 0 | 49.88 | 50.95 | 2.1 |

| Zheng et al. [20] | 0.2 | 0 | 30 | 52.15 | 53.79 | 3.1 |

| Parameters to Be Optimised | Range of Values | Target Value | |

|---|---|---|---|

| Minimum Value | Maximum Value | ||

| A/% | 0.1 | 0.3 | 0.1~0.3 |

| B/% | 1 | 3 | 1~3 |

| C/% | 30 | 60 | 30, 45, 60 |

| Y/MPa | 45.9 | 54.6 | Maximum value |

| Serial Number | BF/% | NC/% | RCA/% | Projected Value/MPa | Experimental Value/MPa | E/% | Thirsty Function Values |

|---|---|---|---|---|---|---|---|

| I | 0.3 | 1 | 30 | 58.45 | 56.81 | 2.8 | 1 |

| II | 0.3 | 1 | 45 | 52.69 | 51.16 | 2.9 | 0.780 |

| III | 0.3 | 1 | 60 | 55.46 | 53.57 | 3.4 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Zhang, X.; Wang, M.; Zhang, D.; Wang, D.; Ma, X. Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation. Buildings 2025, 15, 2070. https://doi.org/10.3390/buildings15122070

Zhang B, Zhang X, Wang M, Zhang D, Wang D, Ma X. Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation. Buildings. 2025; 15(12):2070. https://doi.org/10.3390/buildings15122070

Chicago/Turabian StyleZhang, Biao, Xueyuan Zhang, Mengyao Wang, Daoming Zhang, Dandan Wang, and Xinwu Ma. 2025. "Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation" Buildings 15, no. 12: 2070. https://doi.org/10.3390/buildings15122070

APA StyleZhang, B., Zhang, X., Wang, M., Zhang, D., Wang, D., & Ma, X. (2025). Improvement in the Recycled Aggregate Replacement Ratio in Concrete Pavement Bricks by Incorporating Nano-Calcium Carbonate and Basalt Fibre: Model Experiment Investigation. Buildings, 15(12), 2070. https://doi.org/10.3390/buildings15122070