Construction of Structures with Thin-Section Ceramic Masonry

Abstract

1. Introduction

2. Object of Study: Constructions Using Thin Ceramic Elements

3. Methodology

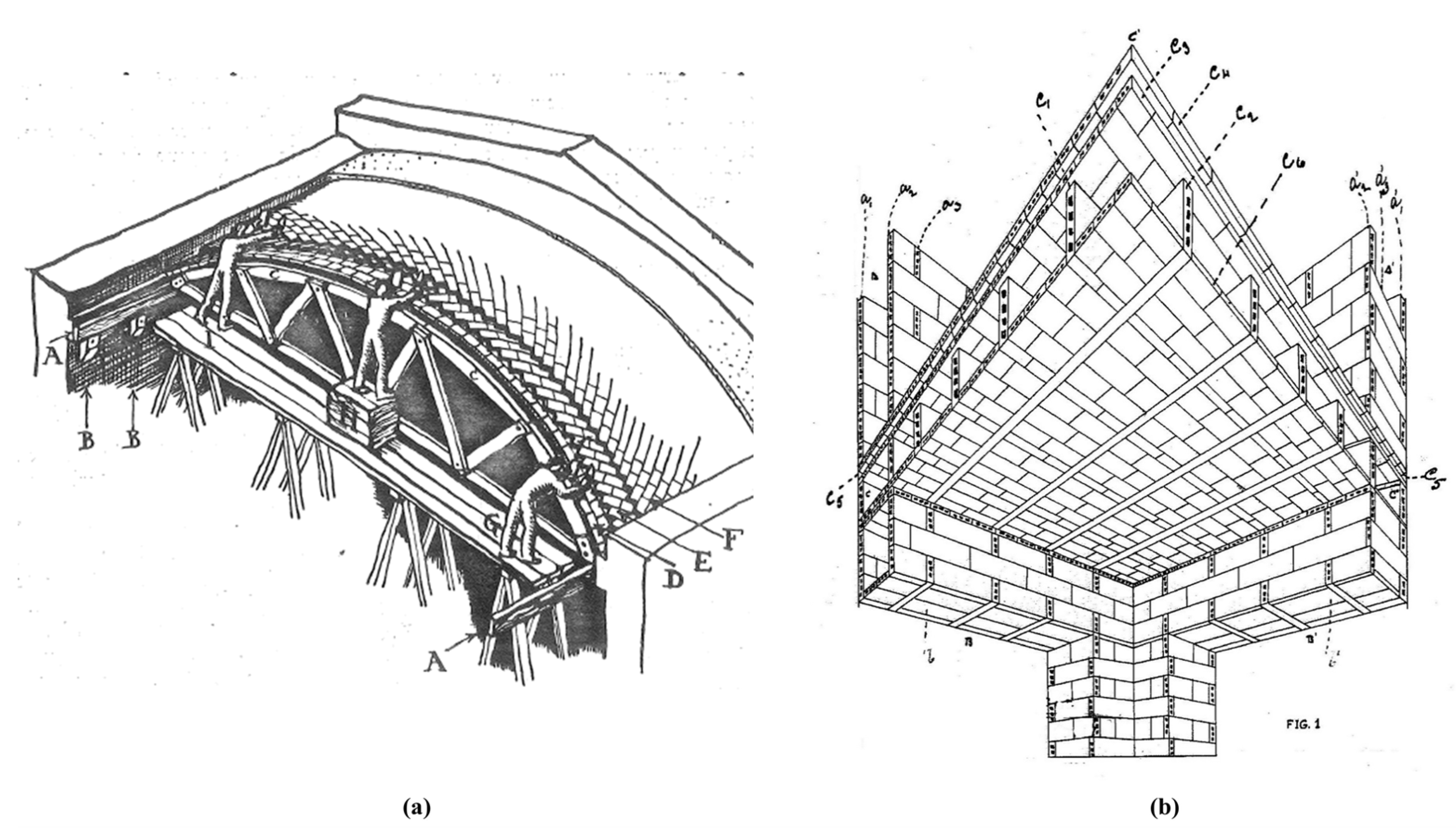

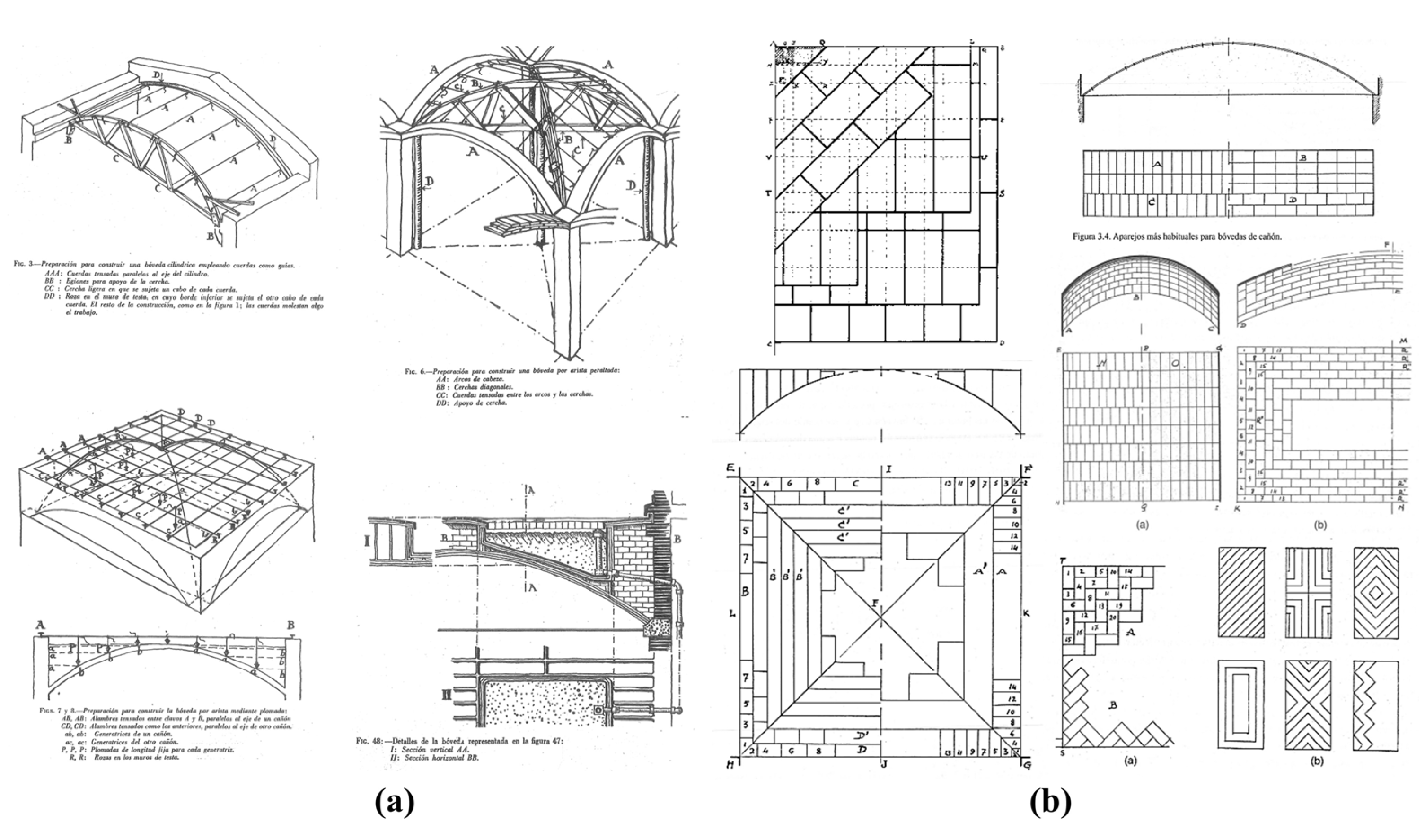

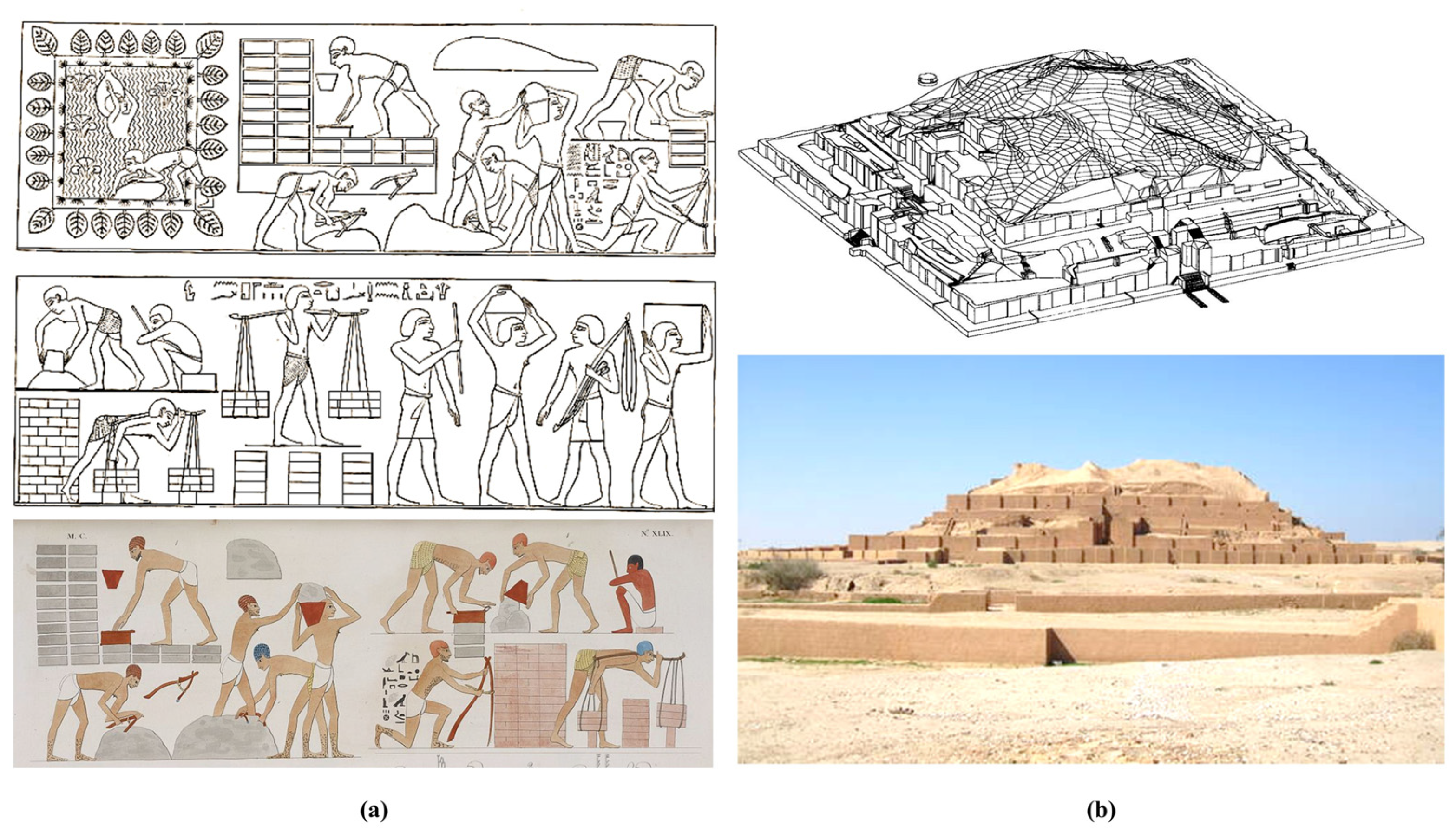

4. The Construction of Vaults Using Masonry Techniques

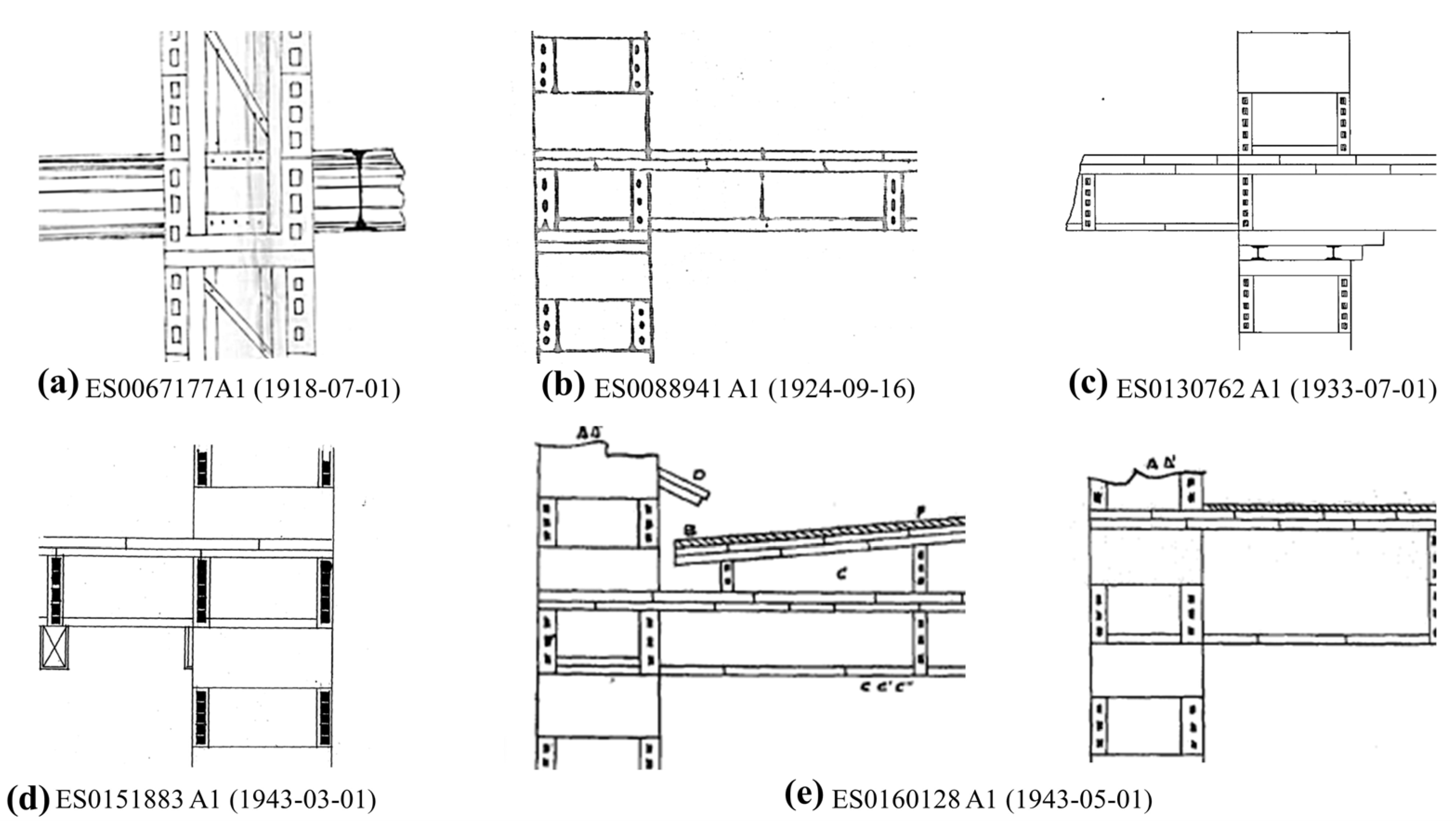

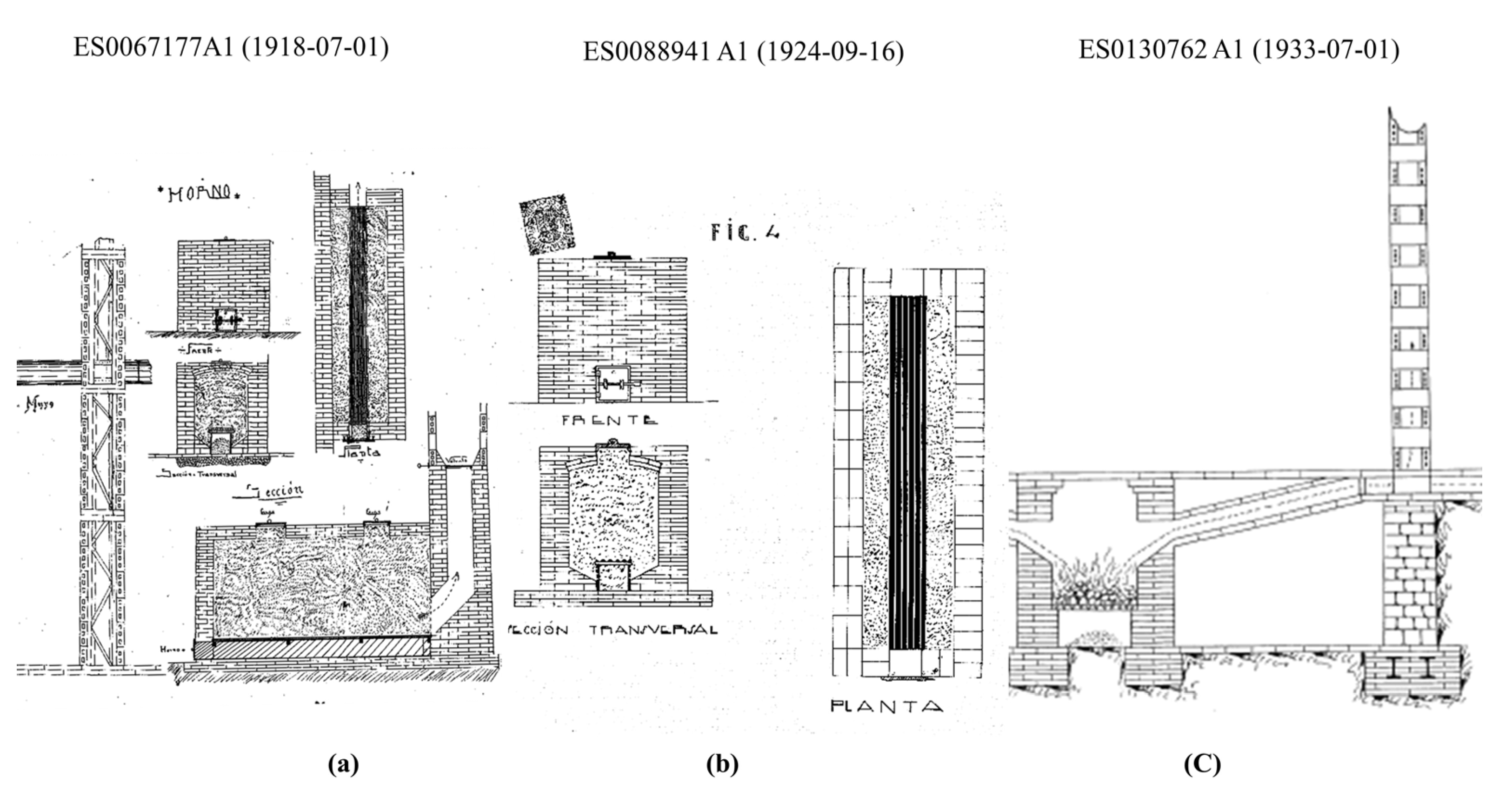

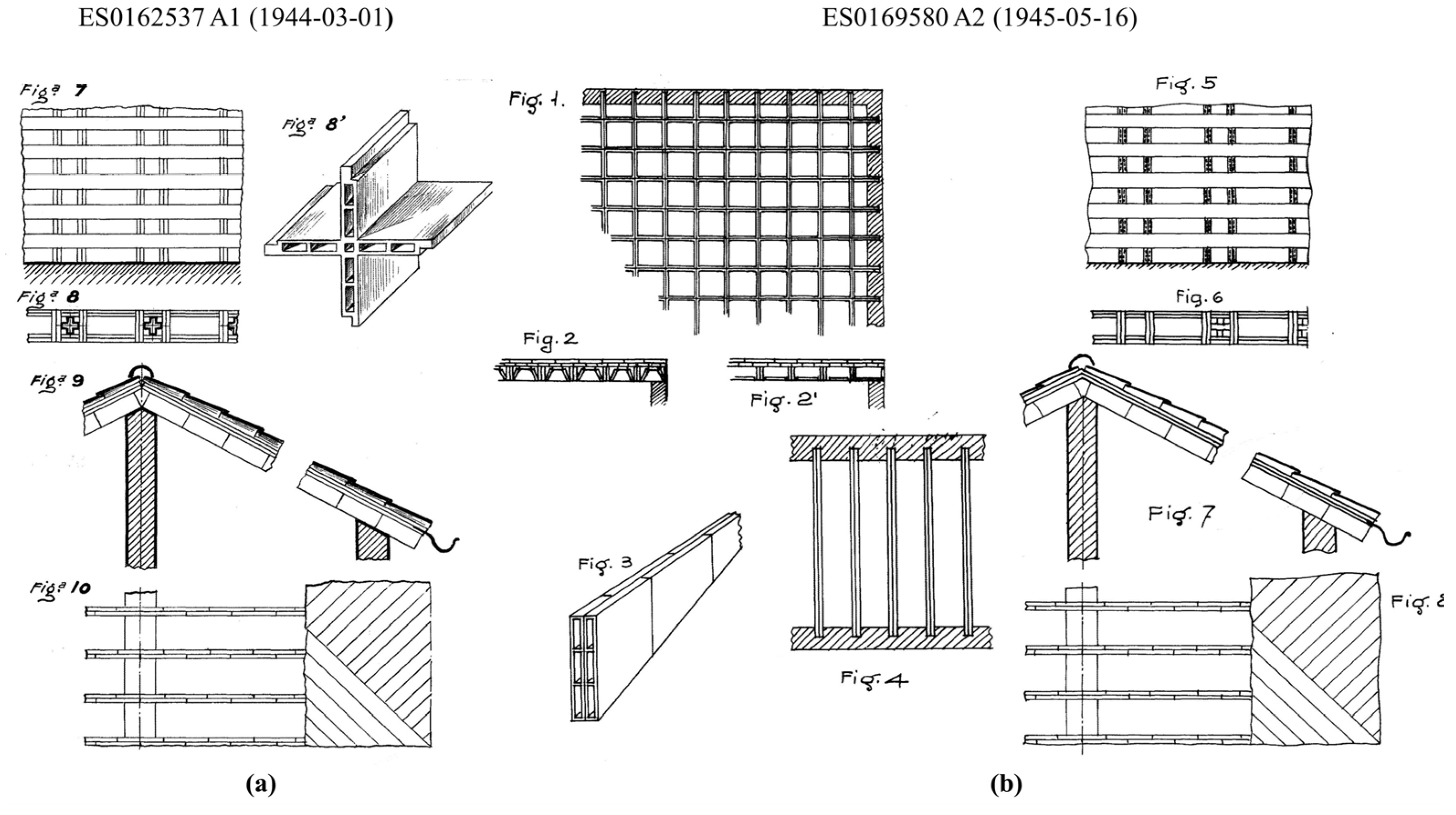

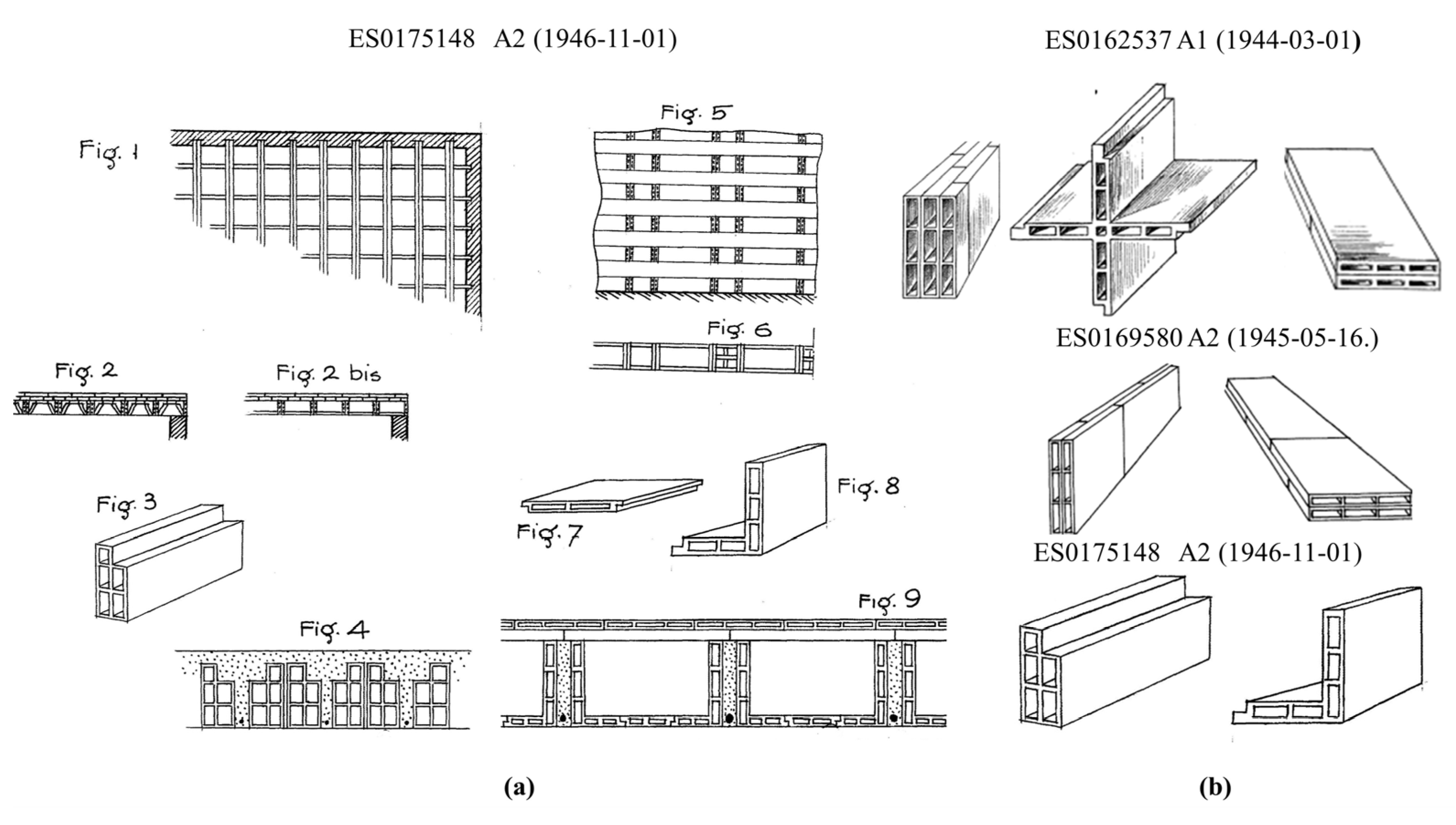

5. Constructions Using Fine Solid Bricks with a Thickness of 0.015 m

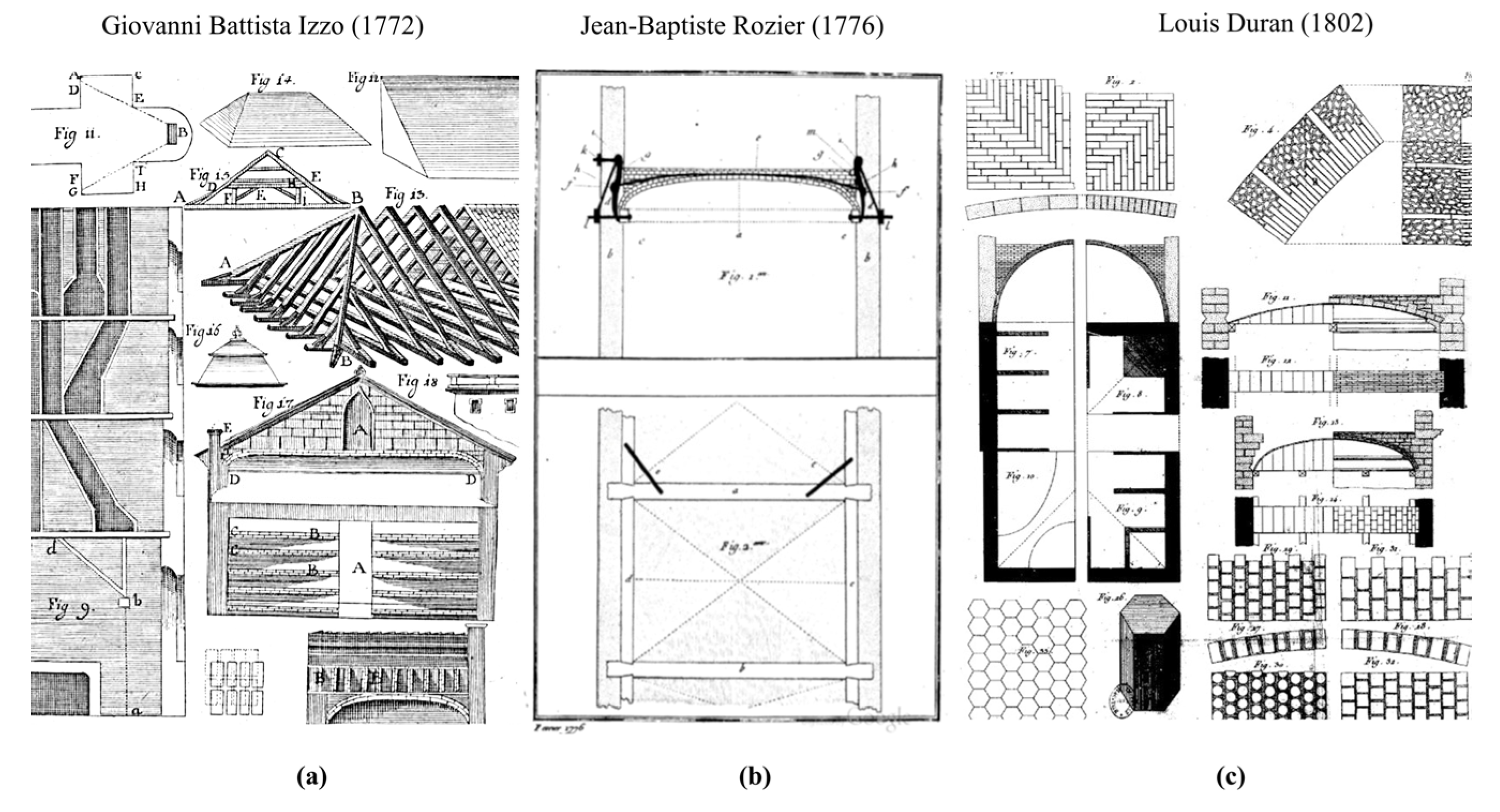

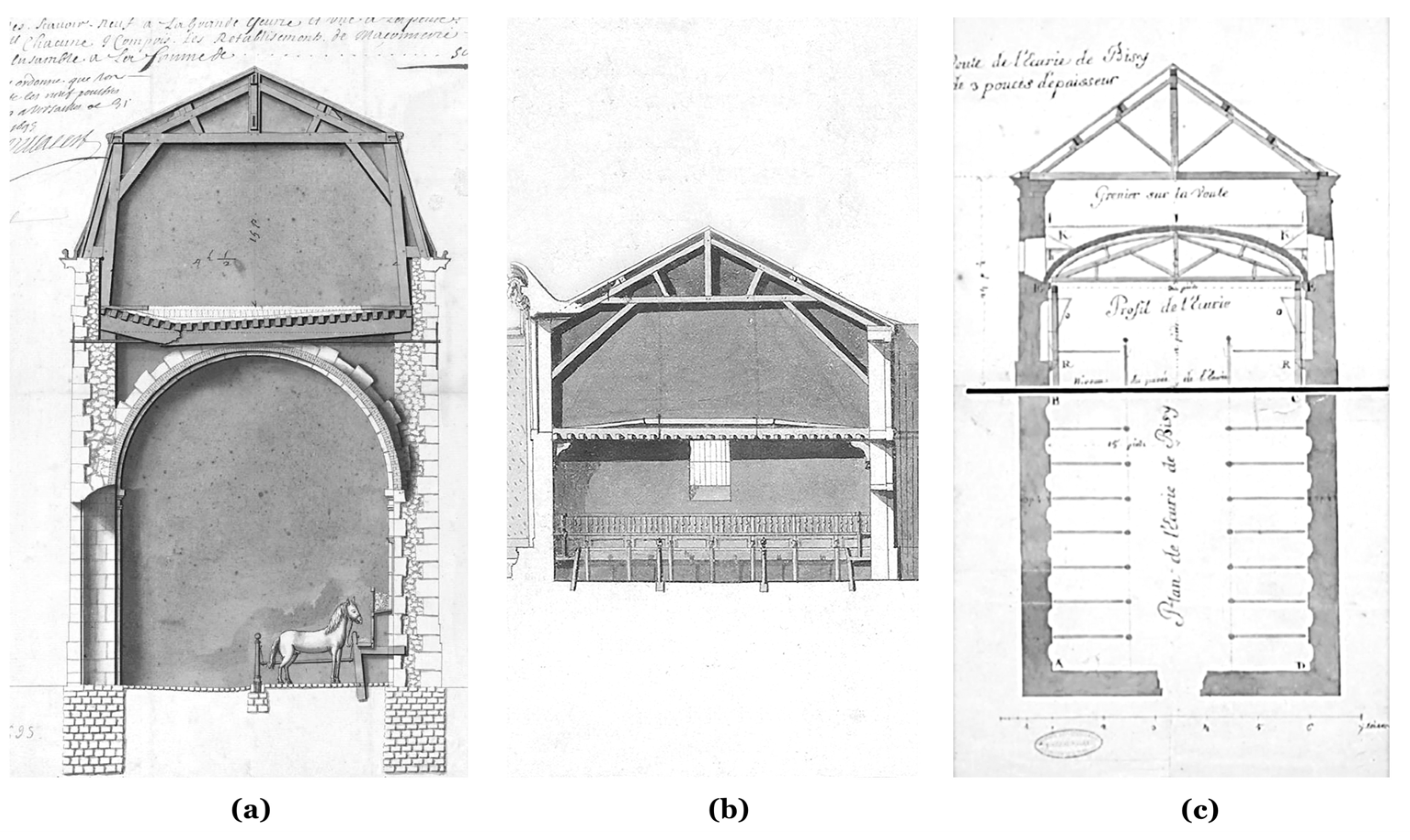

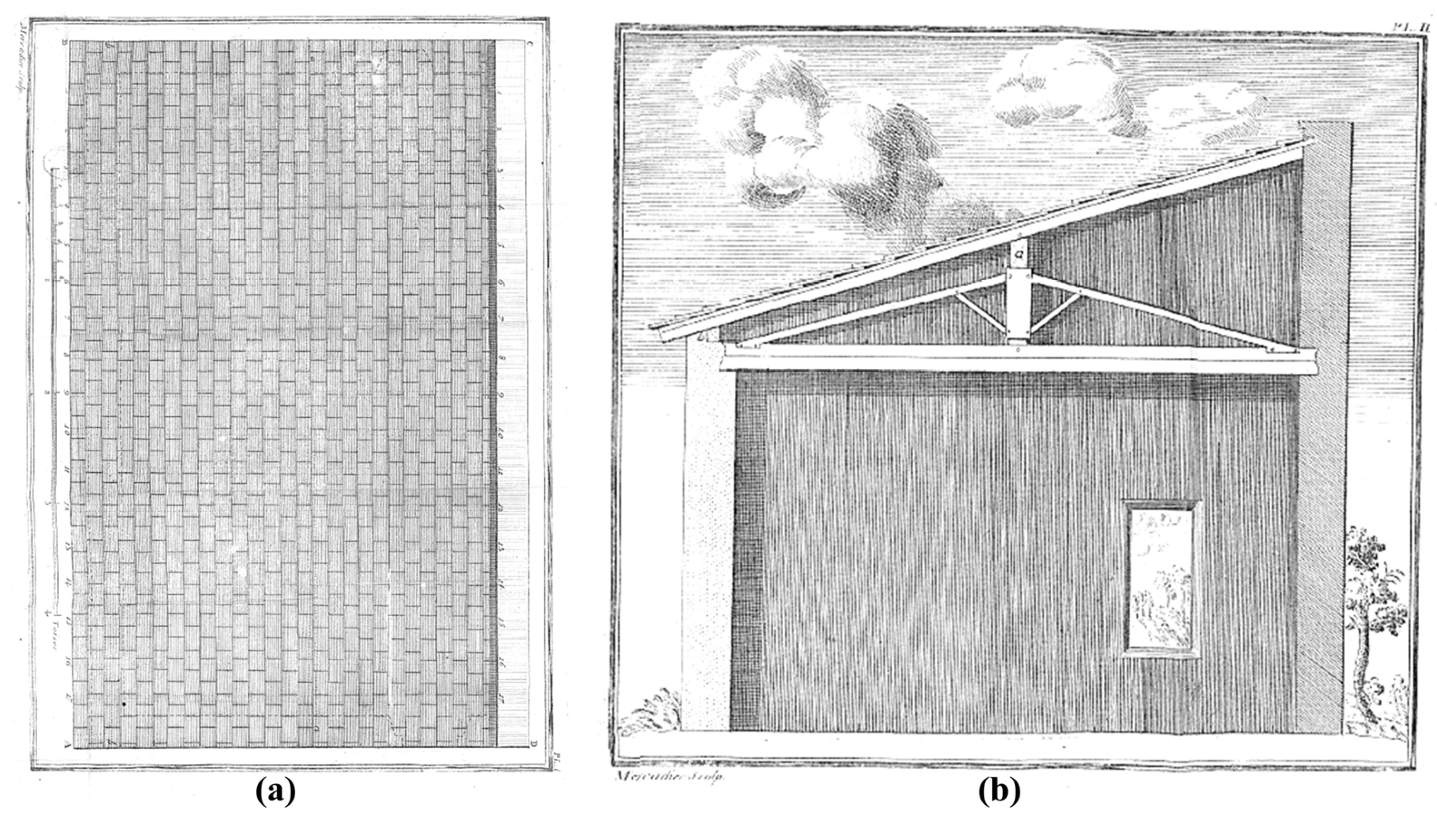

5.1. The Tiled Vault in French Enlightenment Architecture: De La Voûte À La Roussillon a La Notre Maniere

5.2. The Diffusion of the Tiled Vault in Cultured Architecture

5.3. The Long Journey of Thin-Tile Vaults to America

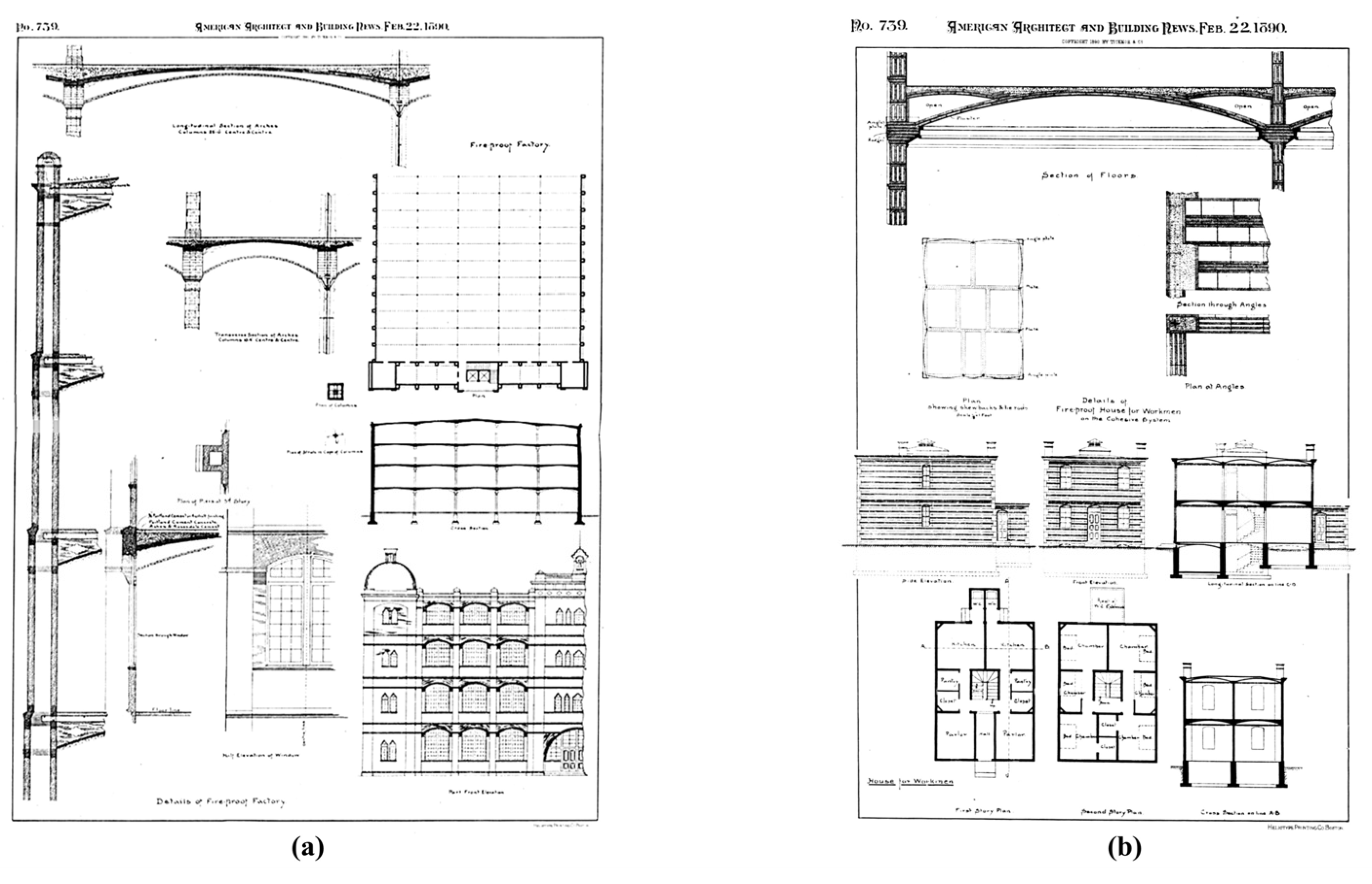

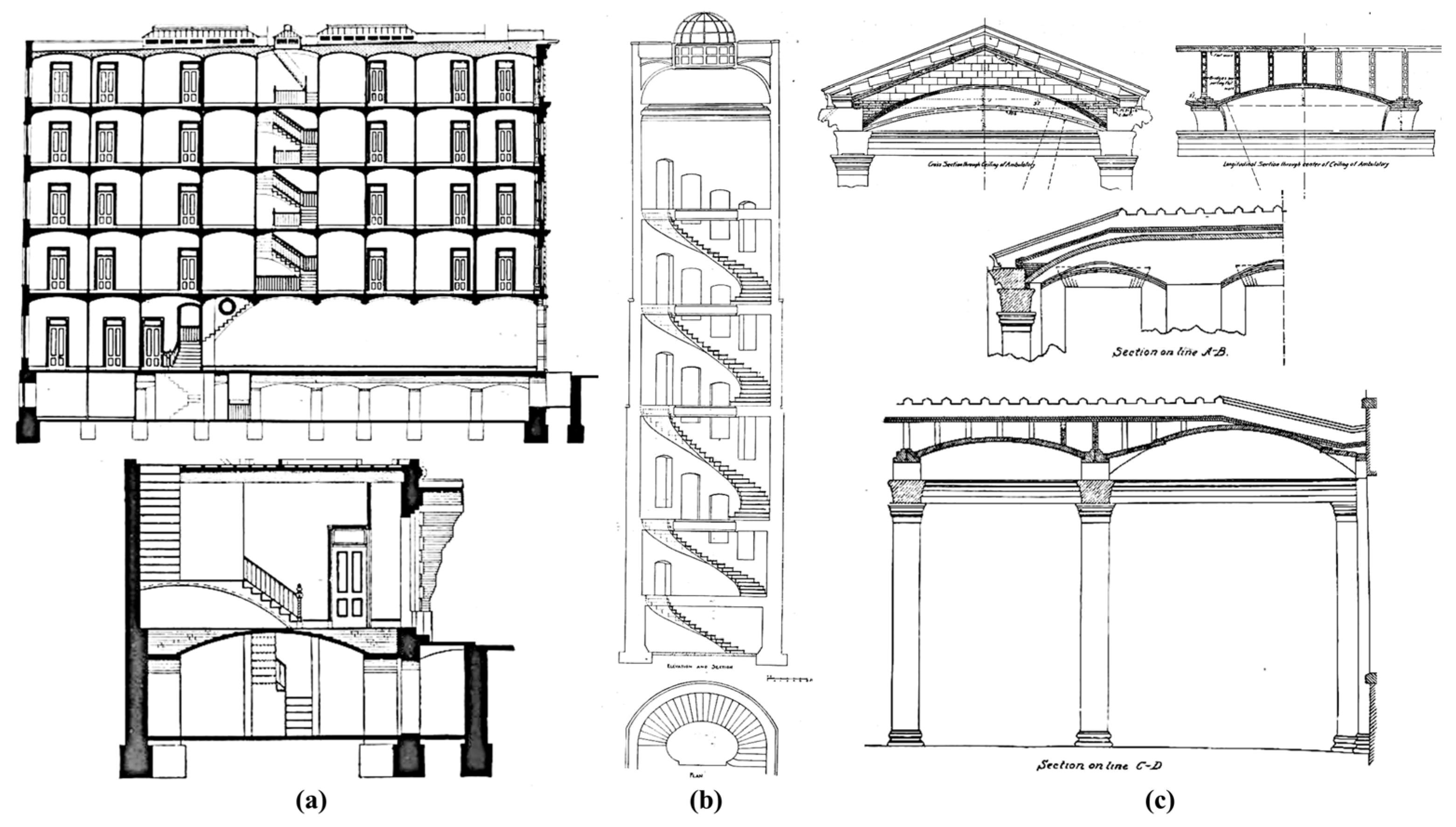

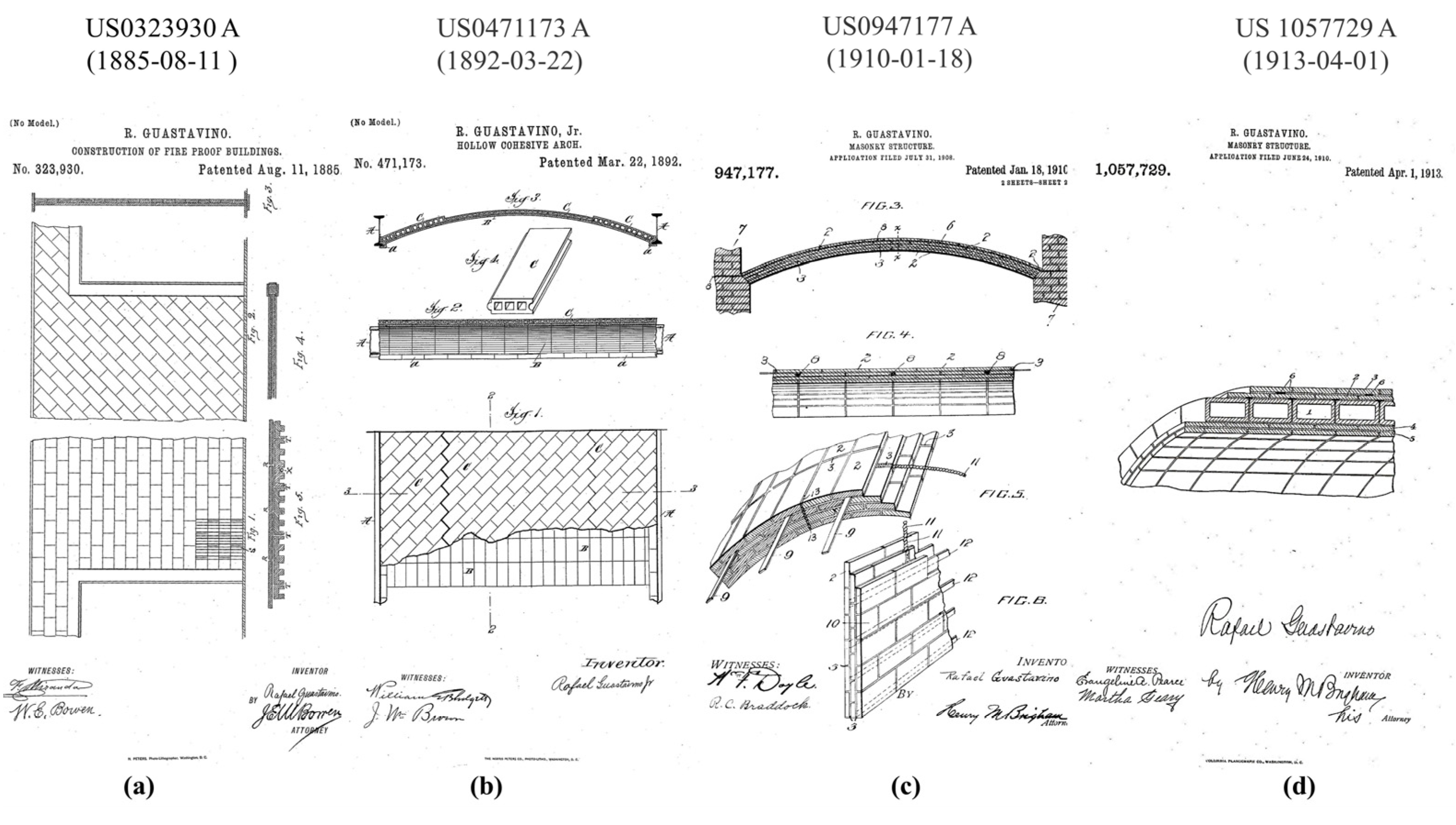

5.4. The American Influence on Cohesive Theory

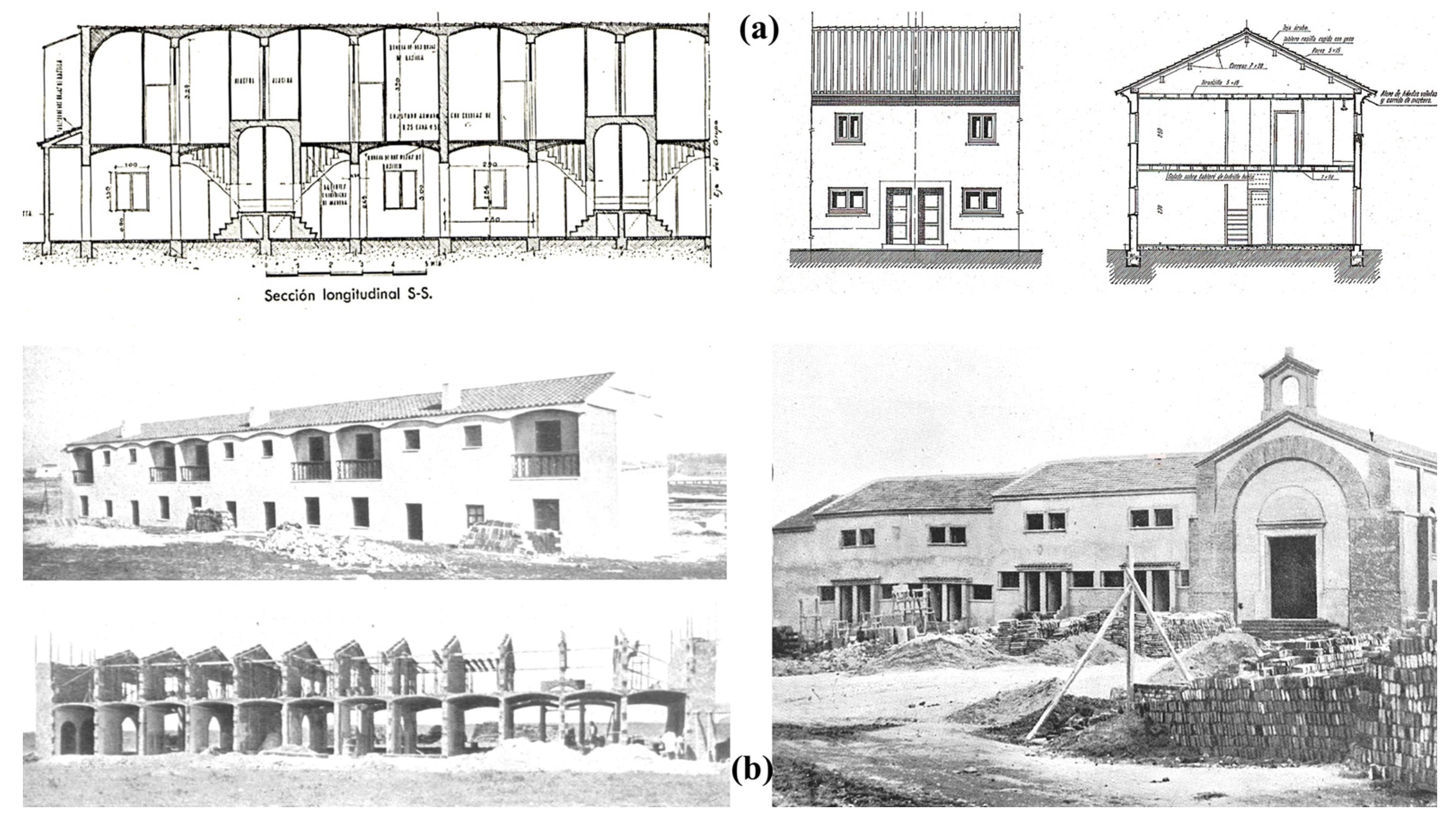

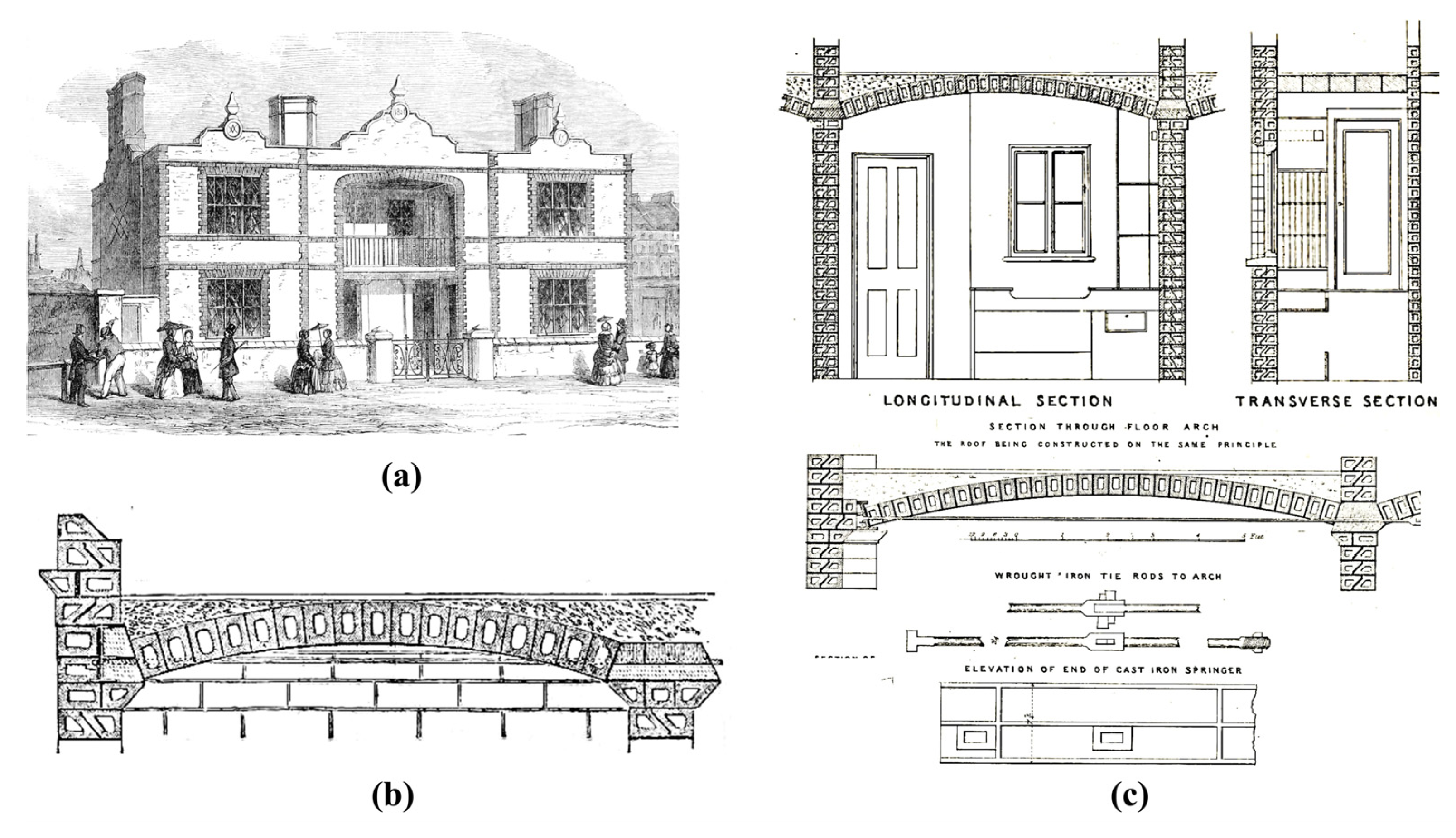

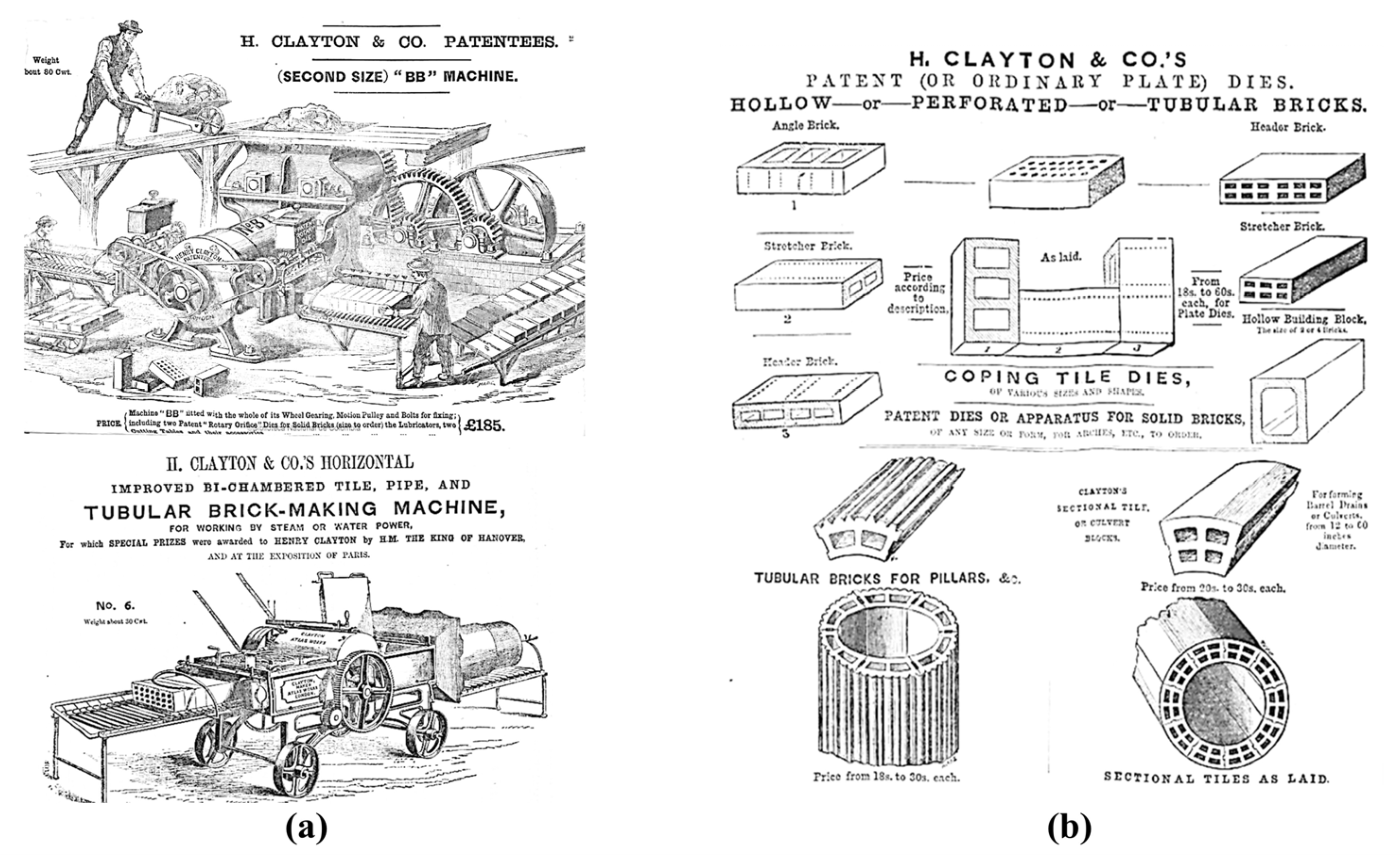

6. Structural Systems with Hollow Brick with a Thickness of Less than 0.050 m

6.1. Flat Ceramic Structures Without Iron or Wood

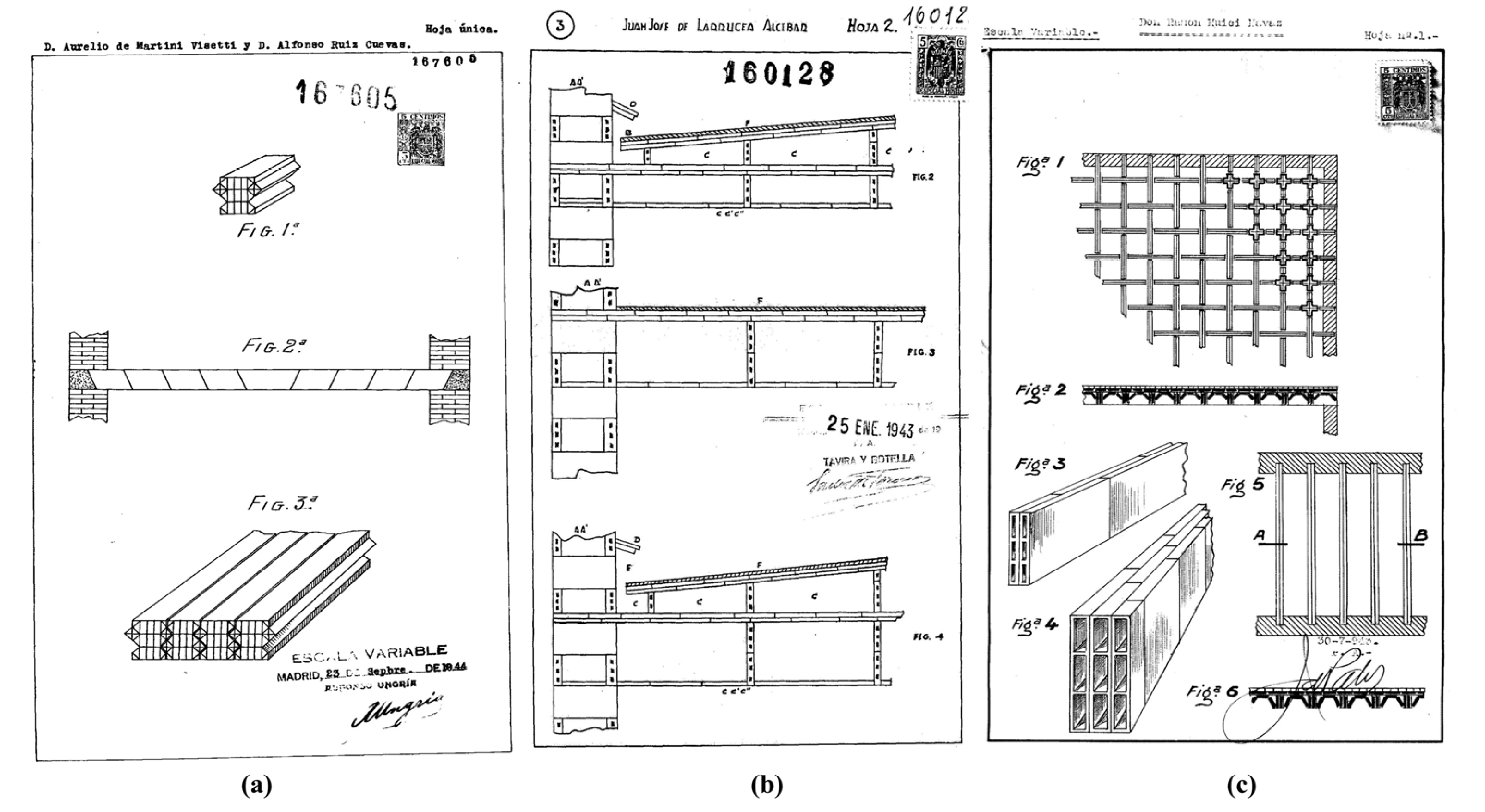

6.1.1. Patent of Aurelio De Martini ES0167605 A3

6.1.2. Patent Juan José Larrucea ES0160128 A1

6.2. Evolution of the Larrucea Patents

6.3. Patent Ramón Huici ES0162537 A1

7. Constructive Considerations of These Cohesive Systems

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ebers, G. Egypt, Descriptive, Historical, and Picturesque; Cassell & Company, Limited: New York, NY, USA, 1878; p. 104. [Google Scholar]

- Secundus, P. The Natural History of Pliny; Bostock, J.; Riley, H.T., Translators; Henry G. Bohn: London, UK, 1875; Volume VI, pp. 290–291. [Google Scholar]

- Jokilehto, J. Conservation of Chogha Zanbil: Mission Report by J. Jokilehto, 18 January 2000; Choga Zanbil 99.doc/JJ/09-Jun-00; UNESCO, World Heritage Convention: Paris, France, 2000. [Google Scholar]

- Heyman, J. The stone skeleton. Int. J. Solids Struct. 1966, 2, 249–279. [Google Scholar] [CrossRef]

- Moya, L. Bóvedas Tabicadas; Ministerio de Gobernación, Dirección General de Arquitectura: Madrid, Spain, 1947. [Google Scholar]

- Baitenov, E.; Tuyakayeva, A. Types of Space Arrangement of Memorial Buildings of Kazakhstan (I Millennium BC—The Early 20th Century). Civ. Eng. Archit. 2025, 13, 281–298. [Google Scholar] [CrossRef]

- Beltrame, M.; Rafanelli, S.; Quaratesi, C.; Mirão, J.; Coradeschi, G. Roof Tiles and Bricks of the Etruscan Domus dei Dolia (Vetulonia, Italy): An Archaeological and Archaeometric Study of Construction Materials. Open Archaeol. 2023, 9, 20220322. [Google Scholar] [CrossRef]

- Choisy, A. L’art de Bâtir Chez Les Romains; Ducher et Cie: Paris, France, 1873; pp. 31–101. [Google Scholar]

- Choisy, A. Note sur la construction des voûtes sans cintrage pendant la période byzantine. Ann. Ponts Chaussées 1876, 12, 439–449. [Google Scholar]

- Baitenov, E.; Tuyakayeva, A.; Abdrassilova, G. Medieval Mausoleums of Kazakhstan: Genesis, Architectural Features, Major Centres. Front. Archit. Res. 2018, 8, 80–93. [Google Scholar] [CrossRef]

- Calvigioni, S. Le volte in muratura nell’Architettura napoletana tra XII e XIV secolo. Archeol. Dell’architettura 2020, XXV, 27–48. [Google Scholar]

- Almagro, A. Un aspecto constructivo de las bóvedas en Al-Andalus. Al-Quantara 2001, XXII, 147–170. [Google Scholar] [CrossRef]

- Zaragozá, A. Hacia una Historia de las Bóvedas Tabicadas. In Construyendo Bóvedas Tabicadas. Actas del Simposio Internacional sobre Bóvedas Tabicadas Valencia 26, 27 y 28 de Mayo de 2011; Catalán, A.Z., Verdú, R.S., Sánchezal, R.M., Eds.; Universitat Politècnica de València: Valencia, Spain, 2012; pp. 11–45. [Google Scholar]

- Huerta, S. Tile Vaults in Post-War Germany. In Brick Vaults and Beyond. The Transformation of a Historical Structural System from 1750 to 1970; Fuentes, P., Wouters, I., Eds.; Instituto Juan de Herrera: Madrid, Spain, 2021; pp. 289–369. [Google Scholar]

- Martín-García, E. Las bóvedas tabicadas de las Maisons Jaoul: Autenticidad y tradición técnica. Rev. Arquit. 2023, 28, 9–31. [Google Scholar] [CrossRef]

- Cabeza, J.M.; Almodóvar, J.M. Las bóvedas de cerámica armada en la obra de Eladio Dieste. Análisis y posibilidades de adaptación a las condiciones constructivas españolas. In Actas del Primer Congreso Nacional de Historia de la Construcción, Madrid, 19–21 Septiembre 1996; De las Casas, A., Huerta, S., Rabasa, E., Eds.; I. Juan de Herrera, CEHOPU: Madrid, Spain, 1996; pp. 135–142. [Google Scholar]

- Pizarro, M.J.; Rueda, O. Una nueva expresividad de las bóvedas tabicadas. Las Escuelas Nacionales de Arte de La Habana. Arquit. Urban 2013, 34, 73–86. [Google Scholar]

- Sitz, M. Swooping In: A vaulted brick library in rural India becomes a public school’s new campus hub. Archit. Rec. 2019, 1, 30–31. [Google Scholar]

- Bannister, T.C. The Roussillon Vault: The Apotheosis of a “Folk” Construction. J. Soc. Archit. Hist. 1968, 27, 163–175. [Google Scholar] [CrossRef]

- Collins, G.R. The transfer of thin Masonry Vaulting from Spain to America. J. Soc. Archit. Hist. 1968, 2, 176–201. [Google Scholar] [CrossRef]

- Guastavino, R. Essay on the Theory and History of Cohesive Construction Applied Especially to the Timbrel Vault; Ticknor and Company: Boston, MA, USA, 1893; p. 45. [Google Scholar]

- Huerta, S. Guastavino Tile Vaults: The Long Migration of a Building Technique. In Migration und Baukultur: Transformation des Bauens Durch Individuelle und Kollektive Einwanderung; Kilper, H., Ed.; Birkhäuser Verlag GmbH: Basel, Switzerland, 2019; pp. 183–201. [Google Scholar]

- Boda, J.; Johnson, R. The Great Chicago Fire; Arcadia Publishing: Charleston, SC, USA, 2017; pp. 87–110. [Google Scholar]

- Chicago Board. Fire Ordinances of the City of Chicago, Published by Order of the Board of Public Works; Jameson & Morse, Printers: Chicago, IL, USA, 1872. [Google Scholar]

- Jacquelot, D. Incendie de la ville de Rennes en décembre 1720. Ann. Bret. Pays Ouest 1909, 25, 279–286. [Google Scholar] [CrossRef]

- Nortier, M. Le sort des archives dispersées de la Chambre des Comptes de Paris. Bibl. École Chartes 1965, 123, 460–537. [Google Scholar] [CrossRef]

- Levron, J. À l’ombre de la Cour: Les pompiers de Versailles. Rev. Deux Mondes 1967, 1er mai, 33–41. [Google Scholar]

- Bergeret, A. Le couvent des Franciscains de Perpignan: Données historiques et archéologiques. In Un Palais Dans la Ville: Actes du Colloque Tenu à Perpignan du 20 au 22 mai 2011; Éditions Trabucaire; Catafau, A., Passarrius, O., Eds.; Perpignan des rois de Majorque: Perpignan, France, 2014; Volume 2, pp. 301–314. [Google Scholar]

- Hautecoeur, L. Histoire de L’architecture Classique en France; Tome III; Première moitié du XVIIIe siècle le style Louis XV; Éditions A. et J. Picard et Cie: Paris, France, 1950; p. 183. [Google Scholar]

- Inzerra, M.S. San Lorenzo di Tigliole: Storia e Attualità di un Restauro; Stamperia Artistica Nazionale: Torino, Italy, 1994. [Google Scholar]

- Tomasoni, E. Le Volte in Murata Negli Edifici Storici: Tecniche Costruttive e Comportamento Strutturale. Ph.D. Thesis, Università degli Studi di Trento, Trento, Italy, 2008; pp. 69–80. [Google Scholar]

- Araguas, P. L’acte de naissance de la Boveda Tabicada ou le certificat de naturalisation de la «voûte catalane». Bull. Monum. 1998, 156, 129–136. [Google Scholar] [CrossRef]

- Araguas, P. Voûte à la Roussillon. Bull. R. Acad. Catalana Belles Arts St. Jordi 1999, XIII, 173–185. [Google Scholar]

- Lluis i Ginovart, J.; Lluis-Teruel, C.; Ugalde-Blázquez, I. Bóvedas tabicadas en la ingeniería militar española (s. XVIII). Inf. Constr. 2021, 73, e393. [Google Scholar] [CrossRef]

- Lluis i Ginovart, J.; Lluis-Teruel, C.; Gómez-Val, R. De la voûte à la Roussillon a la voûte à la notre manière. La fortuna de la bóveda tabicada en la Francia Ilustrada. Inf. Constr. 2023, 75, e496. [Google Scholar] [CrossRef]

- D’Espie, F.F. Manière de Rendre Toutes Sortes D’édifices Incombustibles; ou Traité Sur la Construction des Voutes Faites Avec des Briques & du Plâtre Dites Voutes Plates & D’un Toit de Brique Sans Charpente Appellé Comble Briqueté; Duchesne: Paris, France, 1754; pp. 2–12. [Google Scholar]

- D’Espie, F.F.; Dutens, L.; Wyche, P. The Manner of Securing All Sorts of Buildings from Fire, or, A Treatise upon the Construction of Arches Made with Bricks and Plaister, Called Flat-Arches, and of a Roof Without Timber Called a Bricked-Roof: With the Addition of Some Letters that Have Passed Between the Count of Espie and Peter Wyche; H. Piers and Partner; T. Payne and M. Cooper: London, UK, 1758. [Google Scholar]

- D’Espie, F.F. Abhandlung von Unverbrennlichen Gebäuden und der Art und Weise Wie Solche Vermittels Platter Gewölbe und Dächer zu Bauen Sind, aus dem Französischen des Erfinders Herrn Grafen D’espie; M. Macklot: Frankfurt/Leipzig, Germany, 1760. [Google Scholar]

- Sotomayor, J. Modo de Hacer Incombustibles Los Edificios, Sin Aumentar el Coste de su Construcción Extractado de el Que Escribió en Francés el Conde de Espie; Ilustrado y Añadido Por Joachin de Sotomayor Cisneros y Sarmiento; En la oficina de Pantaleón Aznar: Madrid, Spain, 1776. [Google Scholar]

- Laugier, M.A. Essai sur L’architecture, Nouvelle Édition Revue, Corrigée et Augmentée, avec un Dictionnaire des Termes; Duchesne: Paris, France, 1755; pp. 132–138. [Google Scholar]

- Laugier, M.A. An Essay on Architecture in Which Its True Principles Are Explained, and Invariable Rules Proponed, for Directing the Judgement and Forming the Taste of the Gentleman and the Architect, with Regard to the Different Kinds of Buildings, the Embellishment of Cities, and the Planning of Gardens, Adorned with a Frontispiece, Designed by Mr. Wale, and Curiously Engraven; Printed for T. Osborne & Shipton: London, UK, 1755. [Google Scholar]

- Laugier, M.A. Versuch Über die Bau-Kunst; Fischer: Leipzig Franckfurth, Germany, 1965. [Google Scholar]

- Rieger, C. Universae Architecturae Civilis Elementa. Brevis Recentiorum Observationibus Ilustrata Conscripta a Christiano Rieger; Soc. Iesy.; Pypis Ioannis Thomae Trattaner: Vindobonae, Austria; Pragae, Czech Republic; Triestae, Italy, 1756; pp. 250–251, Figure 10. [Google Scholar]

- Rieger, C. Elementos de Toda la Arquitectura Civil Con Las Más Singulares Observaciones de Los Modernos de Christian Rieger; Joaquín Ibarra: Madrid, Spain, 1763; pp. 250–251, Lam. XVII, Figures 12, 13, 14. [Google Scholar]

- Izzo, J.B. Éléments de L’architecture Civile: À L’usage des Cavaliers du Collège Royal Théresien; Chez Joseph Kurzböck: Vienne, France, 1772; pp. 172–175, Pla. 7. [Google Scholar]

- Patte, P. Monuments Érigés en France à la Gloire de Louis XV, Précédés D’un Tableau du Progrès des Arts & Des Sciences Sous ce Règne…Par M. Patte; Chez l’Auteur: Paris, France, 1765; pp. 7–8. [Google Scholar]

- Patte, P. Mémoires sur Les Objets Les Plus Importants de L’architecture; Chez Rozet: Paris, France, 1769; pp. 51–55. [Google Scholar]

- Rozier, J.B. Manière de construire des voûtes de caves, sans pierres, briques, ni ceintres en charpente & qui coûtent les deux tiers moins que celles en pierres. In Observations Sur la Physique, sur L’histoire Naturelle et Sur Les Arts; Chez Rualt: Paris, France, 1774; Tome III; pp. 67–69. [Google Scholar]

- Rozier, J.B. Moyen d’empêcher que les murs de face soient poussés par les voûtes de briques & plâtres, dites Voûtes plates, substituées aux Planchers. In Observations sur la Physique, sur L’Histoire Naturelle et sur Les Arts; Chez Rualt: Paris, France, 1776; Tome VII, Pla. I; pp. 158–162. [Google Scholar]

- Blondel, J.F.; Patte, M. Cours D’architecture, Ou, Traité de la Décoration, Distribution & Construction des Bâtiments; Tome sixième; Chez la Veuve Desaint: Paris, France, 1777; pp. 84–125. [Google Scholar]

- Blondel, J.F.; Patte, M. Planches Pour le Sixième Volume du Cours D’architecture, Commencé Par Feu J. F. Blondel et Continué Par M. Patte; Chez la Veuve Desaint: Paris, France, 1777; pp. 54–59, Planches. [Google Scholar]

- Lemonnier, H. Procès-Verbaux de L’académie Royale D’architecture 1671–1793 Publiés Pour la Société de L’histoire de L’art Français; Tome VI, 1744–1758; Librairie Armand Colin: Paris, France, 1920; p. 235. [Google Scholar]

- D’Espie, F.F. Manière de Rendre Toutes Sortes D’édifices Incombustibles; ou Traité Sur la Construction des Voutes Faites Avec des Briques & Du Plâtre Dites Voutes Plates; & D’un Toit de Brique Sans Charpente Appellé Comble Briqueté; Chez la Veuve Duchesne: Paris, France, 1776. [Google Scholar]

- Bails, B. Elementos de Matemáticas. Tomo IX. Parte I. Que Trata de la Arquitectura Civil; Imprenta de la Viuda de Joachim Ibarra: Madrid, Spain, 1796; pp. 580–582, lámina p. 584. [Google Scholar]

- Durand, J.N.L. Précis des Leçons D’architecture Données à L’école Polytechnique; Premier Tome; Chez l’auteur, à l’Ecole Royale Polytechnique: Paris, France, 1802; pp. 55–65, Pla. 3. [Google Scholar]

- Rondelet, J. Traité Théorique et Pratique de L’Art de Bâtir; Tome Troisième; Chez l’Auteur, enclos du Panthéon: Paris, France, 1805; pp. 358–372, Pla. LXXXXII. [Google Scholar]

- Guastavino, R. Cohesive construction. Applications, Industrial sections. Am. Archit. Build. News 1890, 27, 123–129. [Google Scholar]

- Guastavino, R. The theory and history of cohesive construction. Am. Archit. Build. News 1889, 26, 218–220, 225. [Google Scholar]

- Guastavino, R. The Building of the Spanish Government at the World’s Fair. Am. Archit. Build. News 1893, 41, 44–45. [Google Scholar]

- Guastavino, R. Cohesive construction: Its past, present and future. Am. Archit. Build. News 1893, 41, 125–129. [Google Scholar]

- Guastavino, R. Prolegomenos on the Function of Masonry in Modern Architectural Structures; Record & Guide Press: New York, NY, USA, 1896; pp. 4–5. [Google Scholar]

- Guastavino, R. The Function of Masonry in Modern Architectural Structures; America Printing Co.: Boston, MA, USA, 1904. [Google Scholar]

- Wight, P.B. The practice of architecture and cohesive construction in America: The life and works of Rafael Guastavino. In The Brickbuilder; U.S. Magazine: New York, NY, USA, 1901; Volume 10, pp. 79–81, 100–102, 184–188, 211–214. [Google Scholar]

- Huerta, S. La mecánica de las bóvedas tabicadas en su contexto histórico: La aportación de los Guastavinos. In Las Bóvedas de Guastavino en América; Huerta, S., Ed.; Instituto Juan de Herrera: Madrid, Spain, 2001; pp. 87–112. [Google Scholar]

- Eddy, H.T. Researches in Graphical Statics; Illustrated by forty-one engravings in text and nine folding plates; D. Van Nostrand: New York, NY, USA, 1878. [Google Scholar]

- Goodyear, W.H. The Columbia University Chapel. In Brickbuilder; U.S. Magazine: New York, NY, USA, 1906; Volume 15, pp. 261–269, Pl. 162–168. [Google Scholar]

- Dunn, W. The Principles of Dome Construction. Archit. Rev. 1908, 23, 63–73, 108–112. [Google Scholar]

- Waite, D.; Gioia, P. United States Patents Held by the Rafael Guastavinos, Father and Son. APT Bull. 1999, 30, 59–156. [Google Scholar] [CrossRef]

- Domènech, J. La fábrica de ladrillo en la construcción catalana. In Anuario de la Asociación de Arquitectos de Cataluña; Tipografía La Academia de Serra Hermanos: Barcelona, Spain, 1900; pp. 37–48. [Google Scholar]

- Bayó, J. La bóveda tabicada. In Anuario de la Asociación de Arquitectos de Cataluña; Tipografía La Academia de Serra Hermanos: Barcelona, Spain, 1910; pp. 157–184. [Google Scholar]

- Martorell, J. Estructuras de ladrillo y hierro atirantado en la arquitectura catalana moderna. In Anuario de la Asociación de Arquitectos de Cataluña; Tipografía La Academia de Serra Hermanos: Barcelona, Spain, 1910; pp. 119–146. [Google Scholar]

- Cardellach, F. La filosofía de la Estructuras; Librería A. Bosch: Barcelona, Spain, 1911; pp. 84–99. [Google Scholar]

- Dirección General de Arquitectura. Sistemas Especiales de Forjados Para la Edificación. Tipos Aprobados y Revisados Por la Sección de Investigación y Normas; Ministerio de la Gobernación: Madrid, Spain, 1942. [Google Scholar]

- Moya, L. Casas abovedadas en el barrio de Usera construidas por la Dirección General de Arquitectura. Rev. Nac. Arquit. 1943, 14, 52–57. [Google Scholar]

- Navarro, J. Viviendas económicas en el barrio de Usera (Madrid). Rev. Nac. Arquit. 1944, 35, 392–394. [Google Scholar]

- Truñó, A. Construcción de Bóvedas Tabicadas; Instituto Juan de Herrera: Madrid, Spain, 2004. [Google Scholar]

- Bosch, I. La bóveda vaída tabicada. Rev. Nac. Arquit. 1949, 89, 185–199. [Google Scholar]

- Clark, W.M. The Crystal Palace, and Its Contents: Being an Illustrated Cyclopaedia of the Great Exhibition of the Industry of All Nations, 1851: Embellished with Upwards of Five Hundred Engravings, with a Copious Analytical Index; W. M. Clark: London, UK, 1852; pp. 81–82. [Google Scholar]

- Clayton, H. Descriptive Catalogue of Clayton’s Patent Tile, Pipe, and Brick Machines, Pugging Mills, Drainage Tools, Implements, and Other Agricultural Spade Tools; Henry Clayton, Patentee and Manufacturer, Atlas Works: London, UK, 1863; pp. 18–20. [Google Scholar]

- Barberot, E. Traité de Constructions Civiles; Libraire Polytechnique, Ch. Bèranger, éditeur: Paris, France, 1900; pp. 313–315. [Google Scholar]

- Sugrañes y Gras, D. Tratado Completo Teórico y Práctico de Arquitectura y Construcción Modernas; 3 Vol.; Marcelino Bordoy: Barcelona, Spain, 1916; Volume 2, pl. 100–101. [Google Scholar]

- Dirección General de Arquitectura. Normas Para el Cálculo y Ejecución de Estructuras Metálicas, Hormigón Armado y Forjados de Ladrillo Armado; Ministerio de la Gobernación: Madrid, Spain, 1941; p. 81. [Google Scholar]

- Lecci, F.; Mazzoli, C.; Bartolomei, C.; Gulli, R. Design of Flat Vaults with Topological Interlocking Solids. Nexus Netw. J. 2021, 23, 607–627. [Google Scholar] [CrossRef]

- D’Espie, F.F. Comble Carrelagé, ou Construction D’un Nouveau Comble Appelé Carrelagé, de L’invention de M. le Comte d’Espie…Avec des Plans Gravés en Taille-Douce; De l’Imprimerie de Me. de Jean-Florent Baour: Toulouse, France, 1788; pp. 21–28. [Google Scholar]

- Robertson, D. Seismic considerations for Guastavino ceiling, vault, and dome construction. APT Bull. 1999, 30, 51–58. [Google Scholar] [CrossRef]

- Atamturktur, S.; Sevim, B. Seismic performance assessment of masonry tile domes through nonlinear finite-element analysis. J. Perform. Constr. Facil. 2012, 26, 410–423. [Google Scholar] [CrossRef]

- Columbia University Archives. Finding Aids. Available online: https://findingaids.library.columbia.edu/archives/cul-9628774_aspace_fa66137b149828d3bf2a89a7086c4641 (accessed on 8 March 2025).

- Loren, M.M. La obra de la compañía Guastavino en Nueva York. Su actualidad y restauración. Loggia Arquit. Restauración 2007, 20, 28–45. [Google Scholar] [CrossRef]

- Lane, D.R. Putting Guastavino in Context: A Scientific and Historic Analysis of His Materials, Methods, and Technology. Master’s Thesis, Columbia University, New York, NY, USA, 2001. [Google Scholar]

- Ruíz, J.; Blanco, A. La Construcción Moderna; El método Larrucea Alcibar. Sin Hierro ni madera; Lib. Vda. Mauro Lázaro: Segovia, Spain, 1944. [Google Scholar]

- Ávila, J.M. Chabolismo urbano. Adeste Dinteles 2018, 6, 1–8. [Google Scholar]

- Fuentes, P.; Gil, I.J.; Huerta, S.; Martín, C.; Redondo, E. Bóvedas sin cimbra: La construcción tabicada. In Índice Memoria Académica del Taller Experimental de Historia de la Construcción del Curso 2013/2014; Instituto Juan de Herrera, ETSAM: Madrid, Spain, 2014; pp. 26–38. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lluis-Teruel, C.; Lluis i Ginovart, J. Construction of Structures with Thin-Section Ceramic Masonry. Buildings 2025, 15, 2042. https://doi.org/10.3390/buildings15122042

Lluis-Teruel C, Lluis i Ginovart J. Construction of Structures with Thin-Section Ceramic Masonry. Buildings. 2025; 15(12):2042. https://doi.org/10.3390/buildings15122042

Chicago/Turabian StyleLluis-Teruel, Cinta, and Josep Lluis i Ginovart. 2025. "Construction of Structures with Thin-Section Ceramic Masonry" Buildings 15, no. 12: 2042. https://doi.org/10.3390/buildings15122042

APA StyleLluis-Teruel, C., & Lluis i Ginovart, J. (2025). Construction of Structures with Thin-Section Ceramic Masonry. Buildings, 15(12), 2042. https://doi.org/10.3390/buildings15122042