Development and Performance Evaluation of a Novel Disc-Buckle Steel Scaffold Joint

Abstract

1. Introduction

2. An Innovative Disc-Buckle Scaffolding

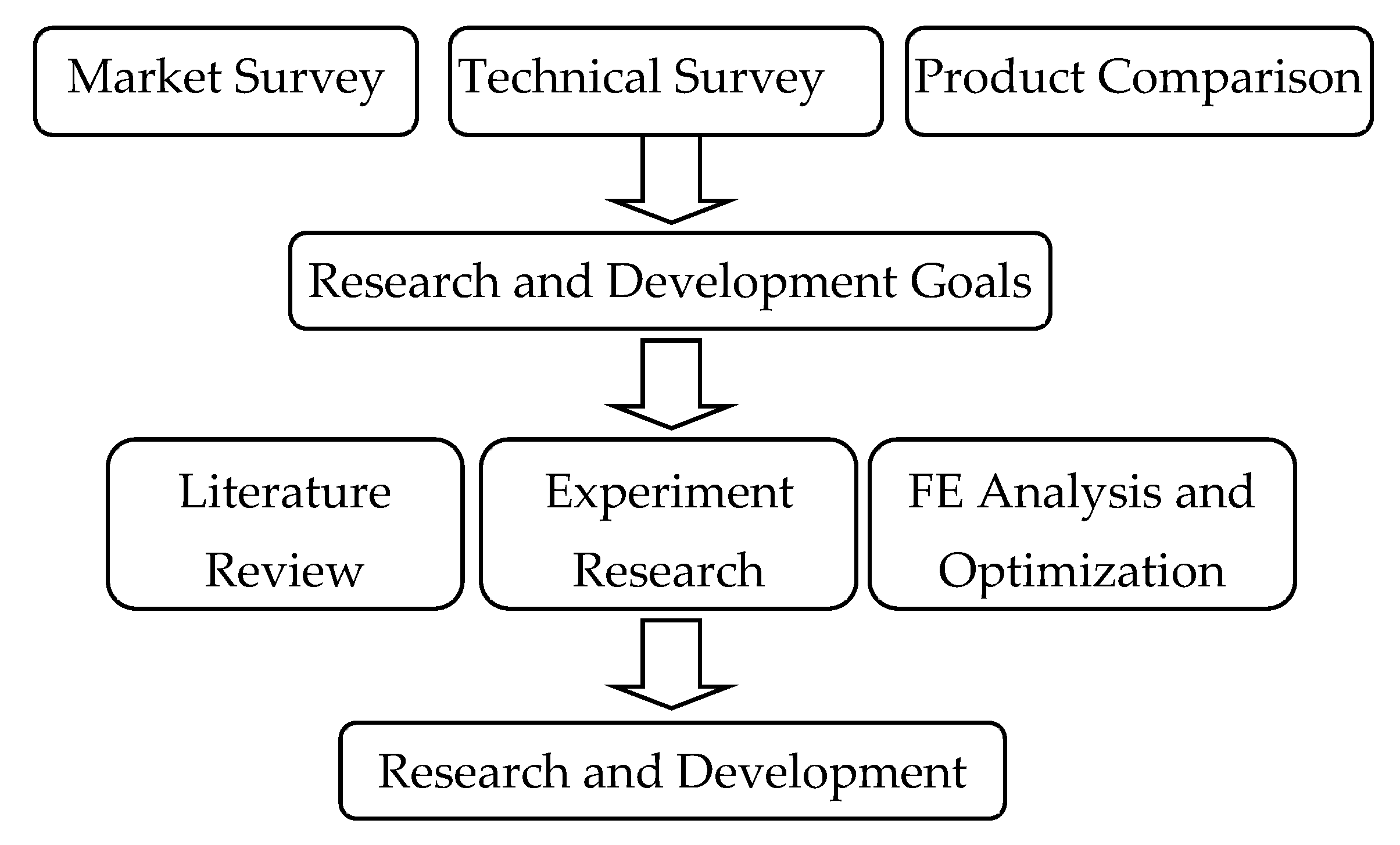

2.1. Research and Development Strategy

2.2. Research and Development Goals

2.3. The Configuration of the Novel Disc-Buckle Scaffolding

- Insertion and Compression: Initially, insert the horizontal pipe’s end connector into the fixed disc and let it attach tightly to the fixed disc by applying compressive force on it;

- Rotational Alignment: Subsequently, rotate the stopper disc to align the stopper spot by hammering the notches on the stopper disc, ensuring mechanical interlock through the stopper spot;

- Vertical Engagement: Third, engage the stopper disc with the fixed disc;

- Impact Fixation: Finally, secure the assembly by a hammer. The stopper disc is tightly attached to the fixed disc by hammering the striking mouth on the stopper disc.

3. Finite Element Modeling of the Novel Scaffold Joint

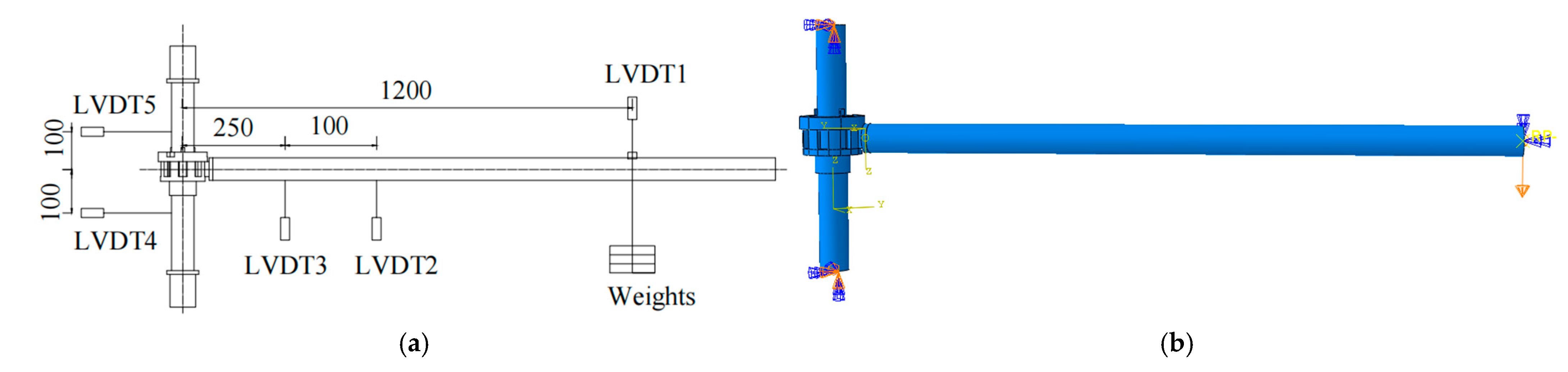

3.1. Finite Element Model

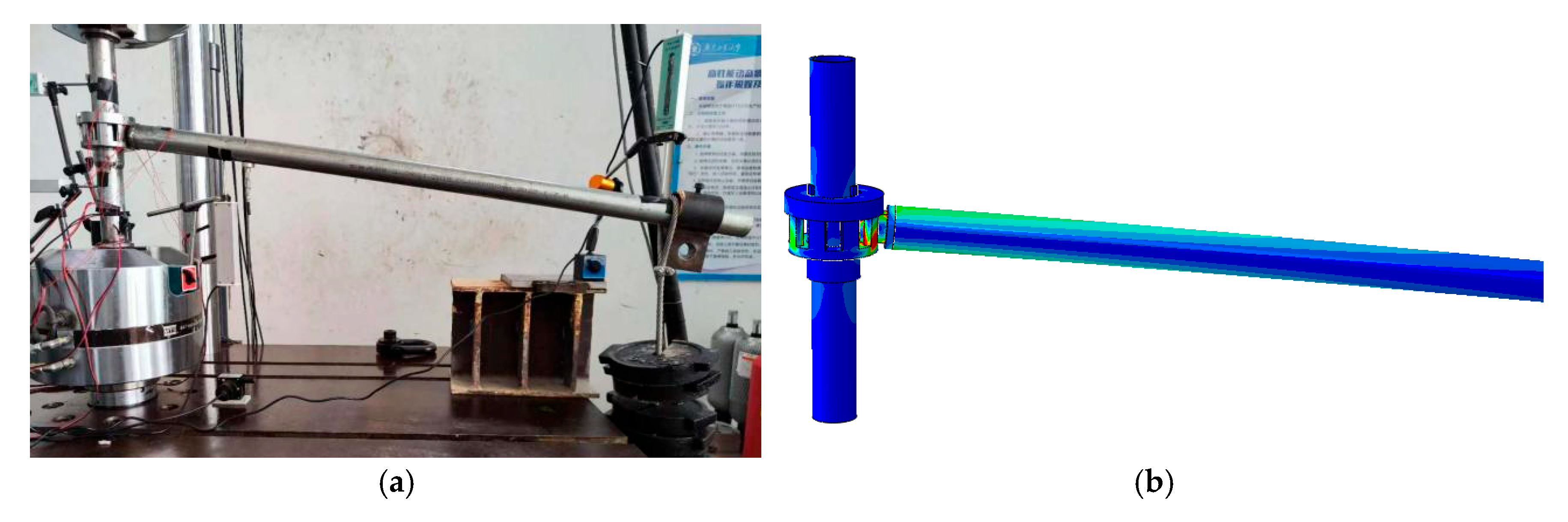

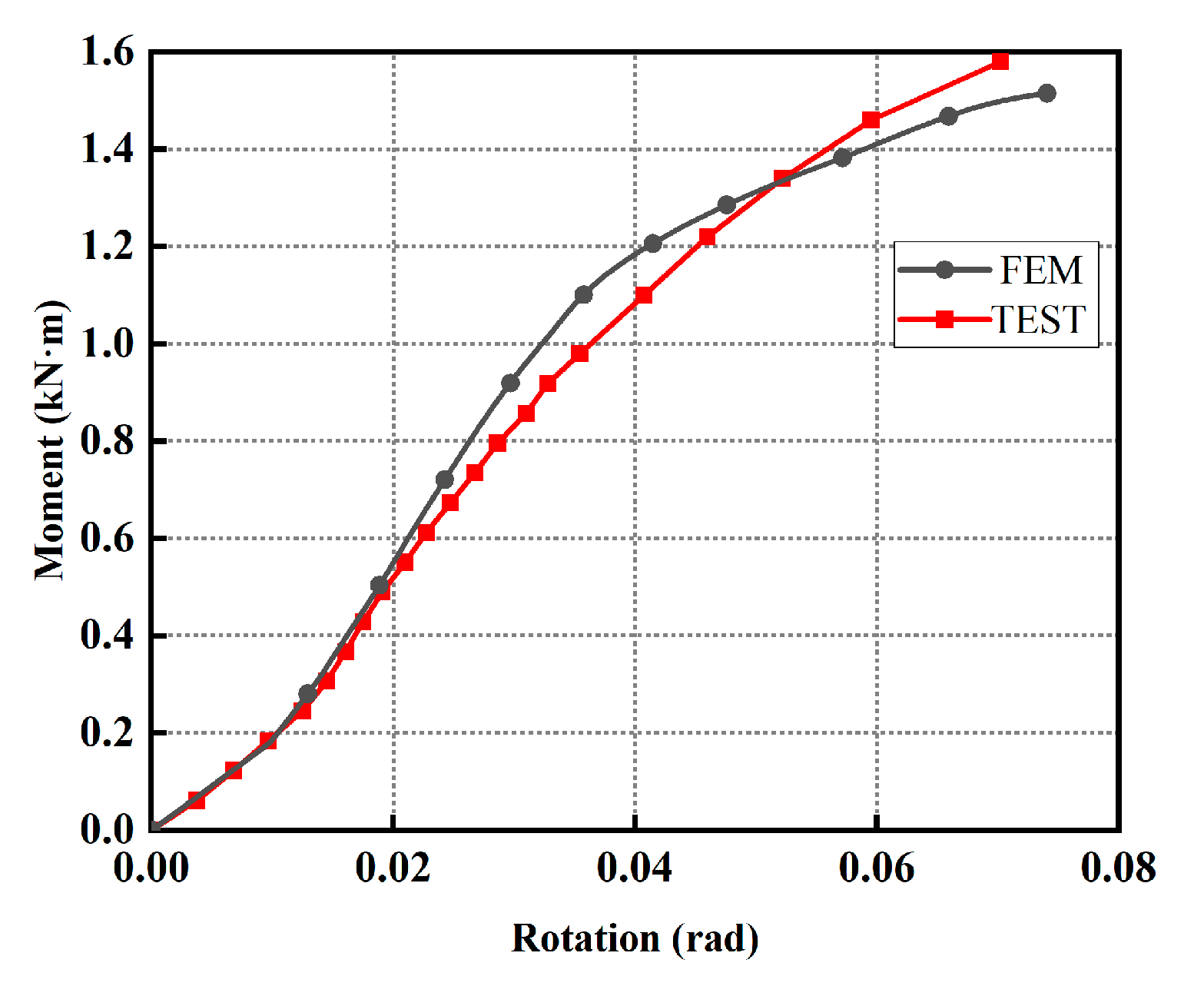

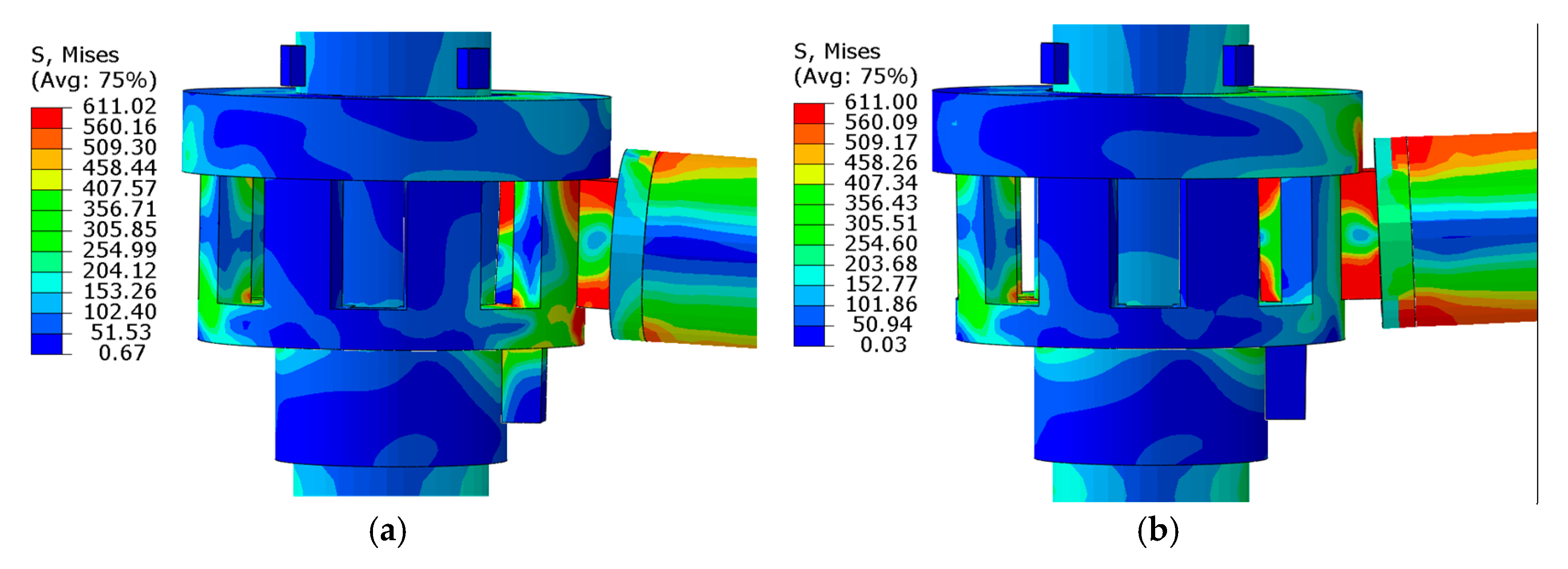

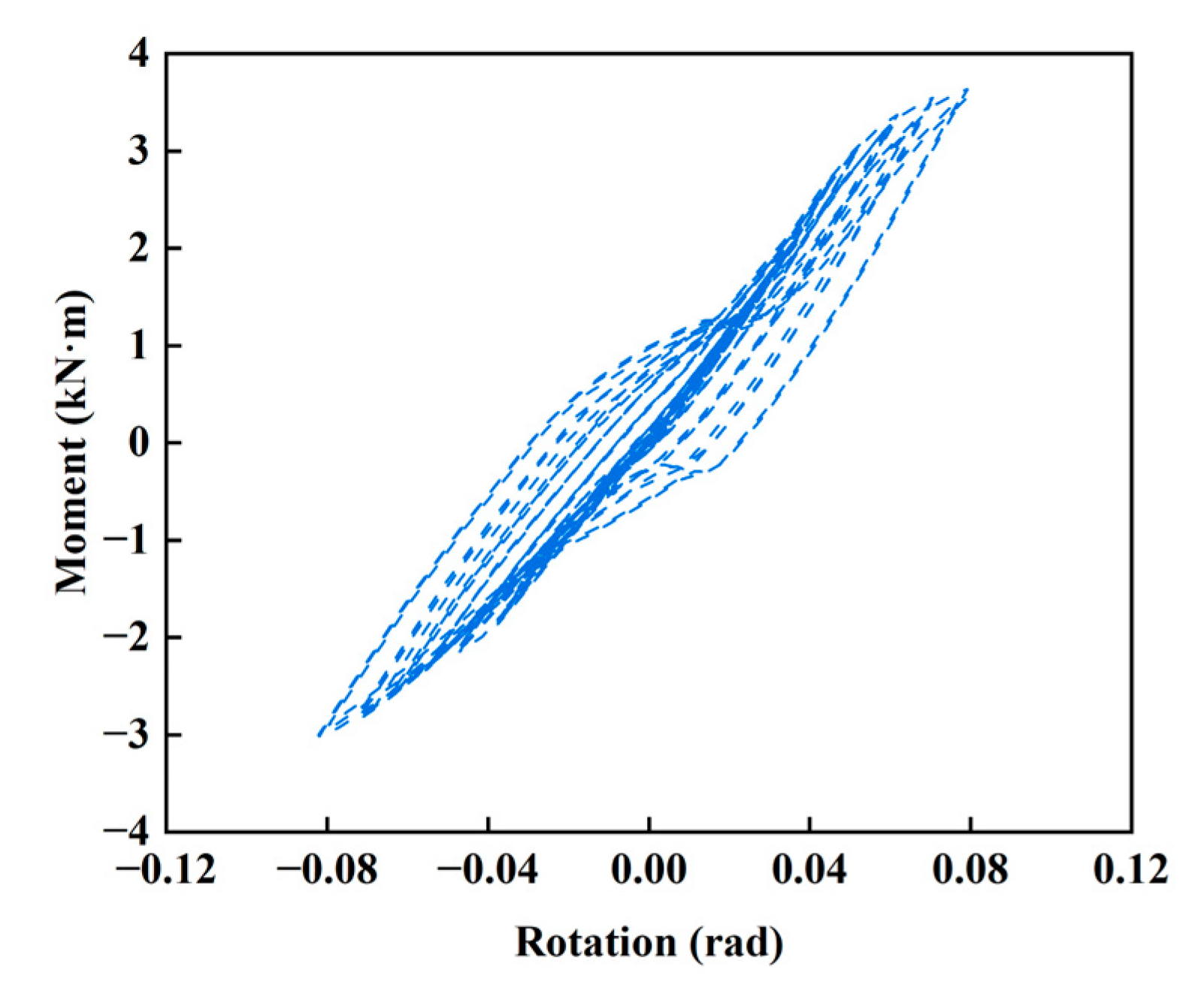

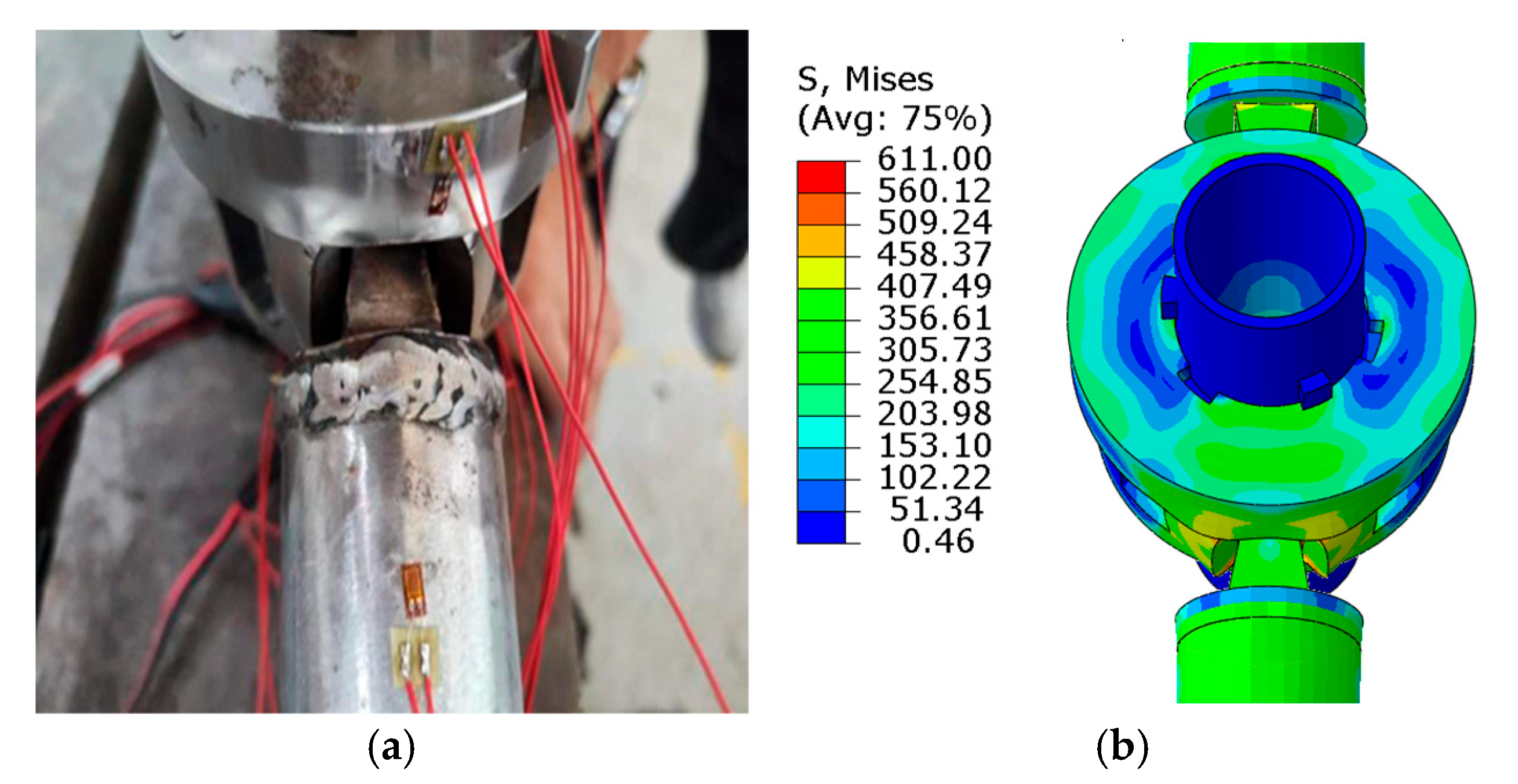

3.2. Semi-Rigid Behavior of Scaffold Joint

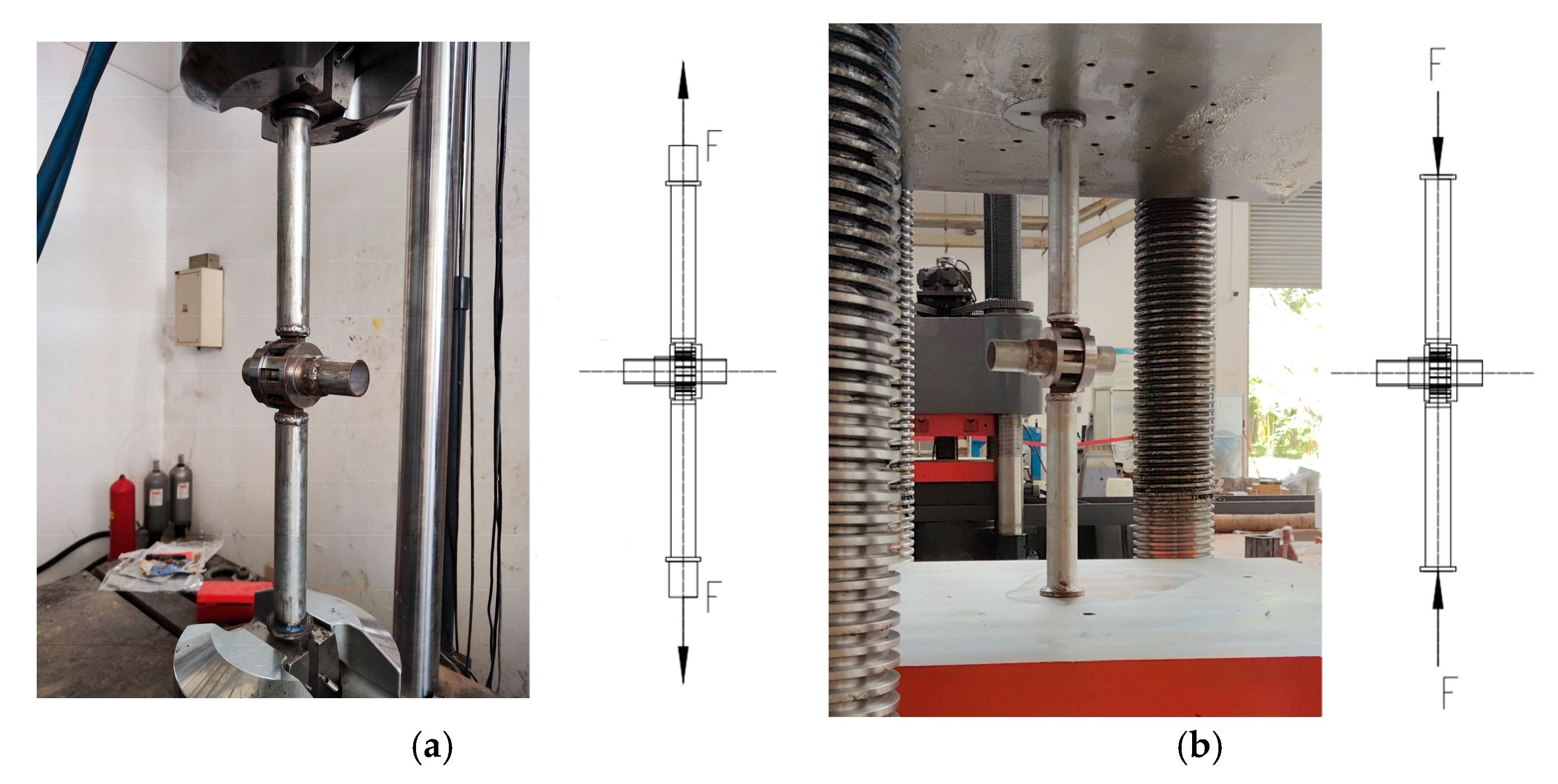

- Monotonic loading protocol: A displacement-controlled vertical load was applied at the distal end of the horizontal member following ASTM E2126 standards [13], with a constant loading rate of 2 mm/min until structural failure;

- Cyclic loading protocol: Quasi-static reversed cyclic loading was imposed, comprising three complete load–unload cycles at incremental displacement amplitudes of Δ = 20 mm, 40 mm, and 60 mm, respectively.

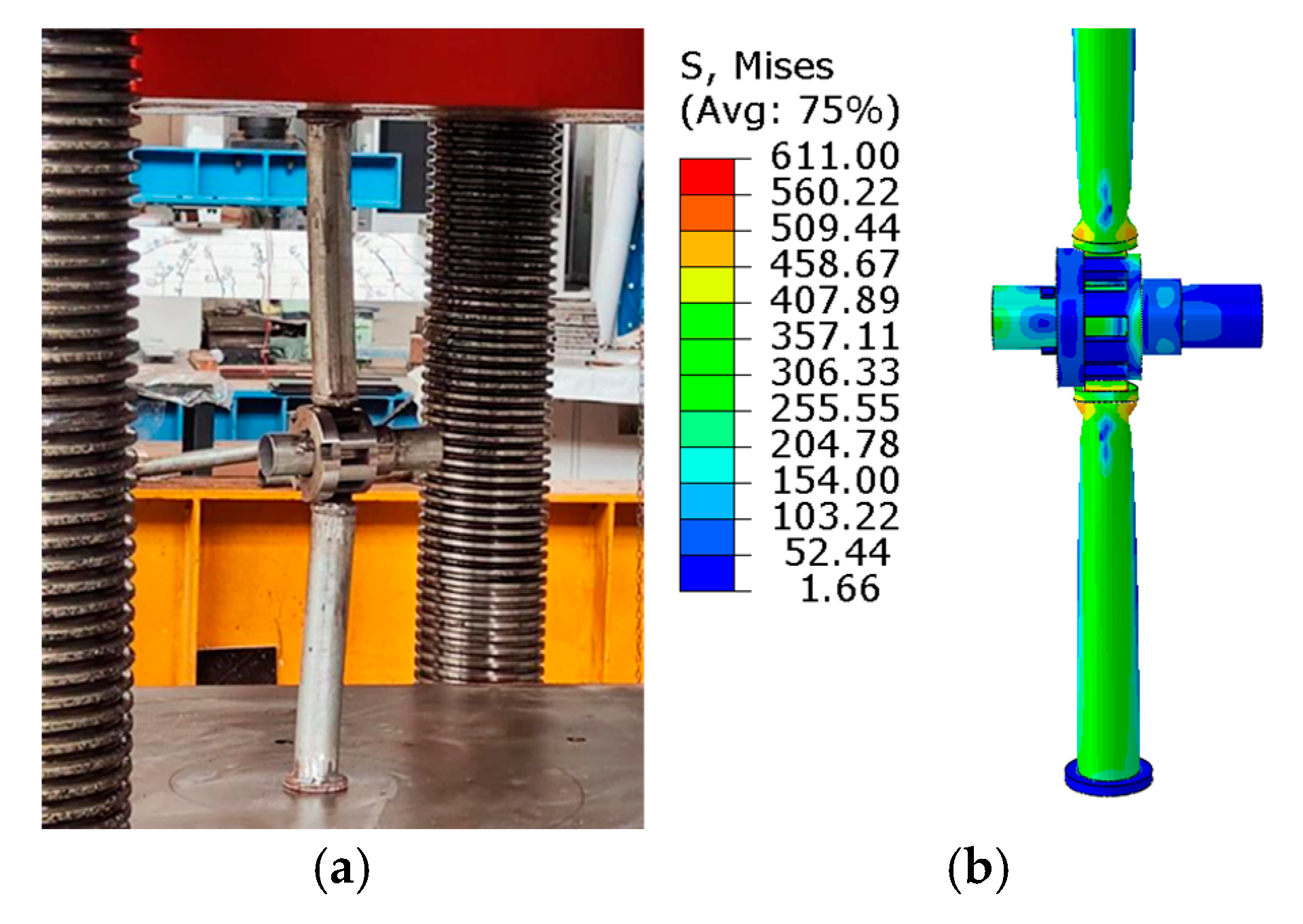

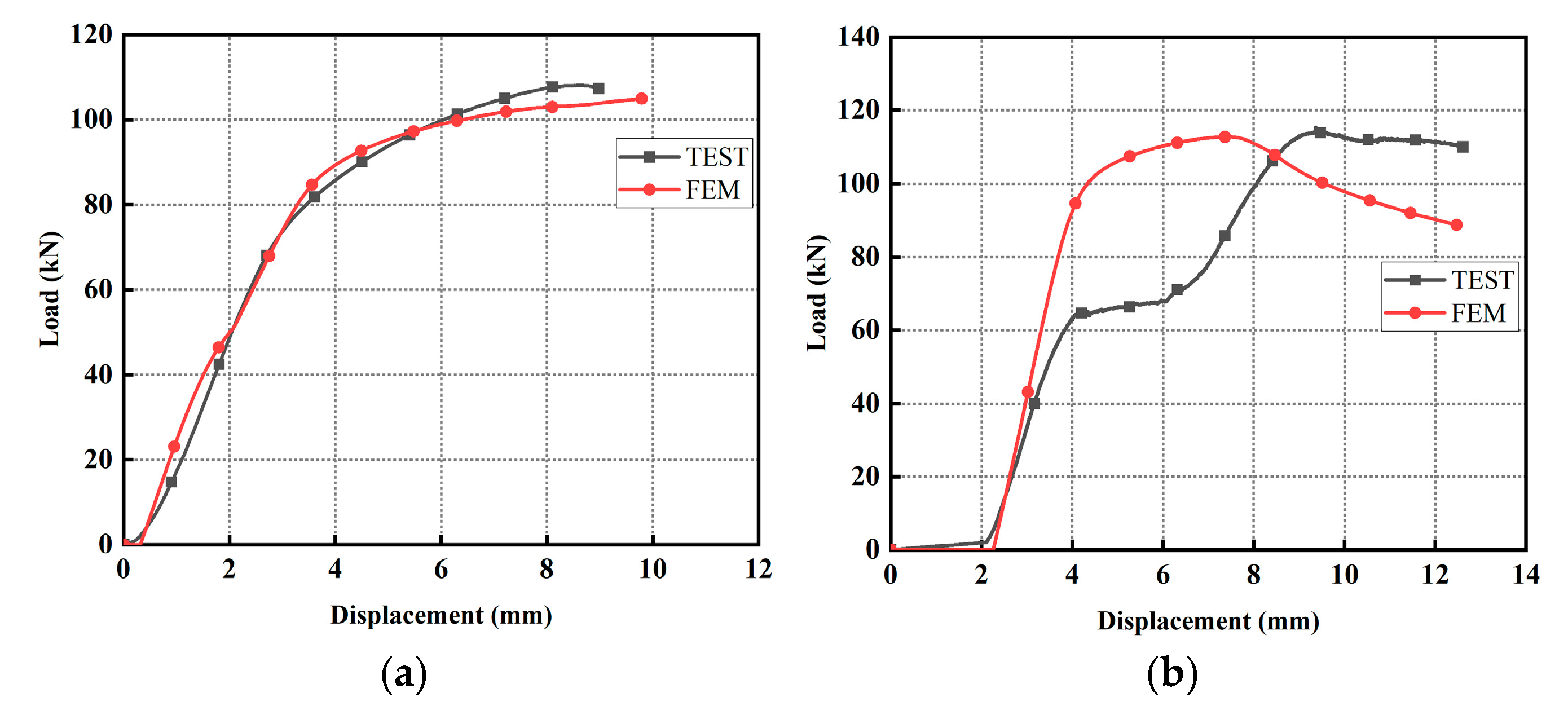

3.3. Analysis of Horizontal Tensile and Compressive Performance of the Joint

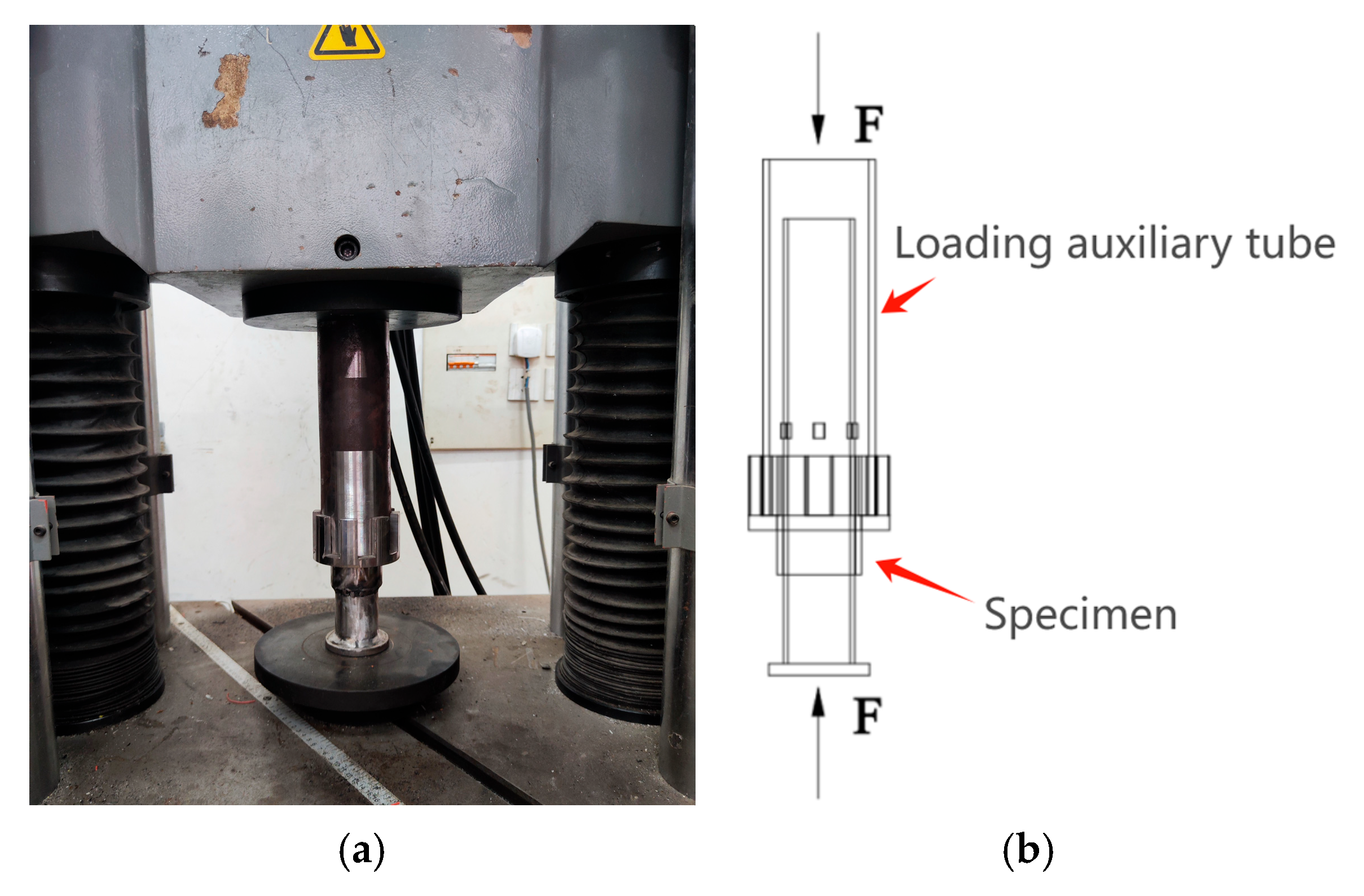

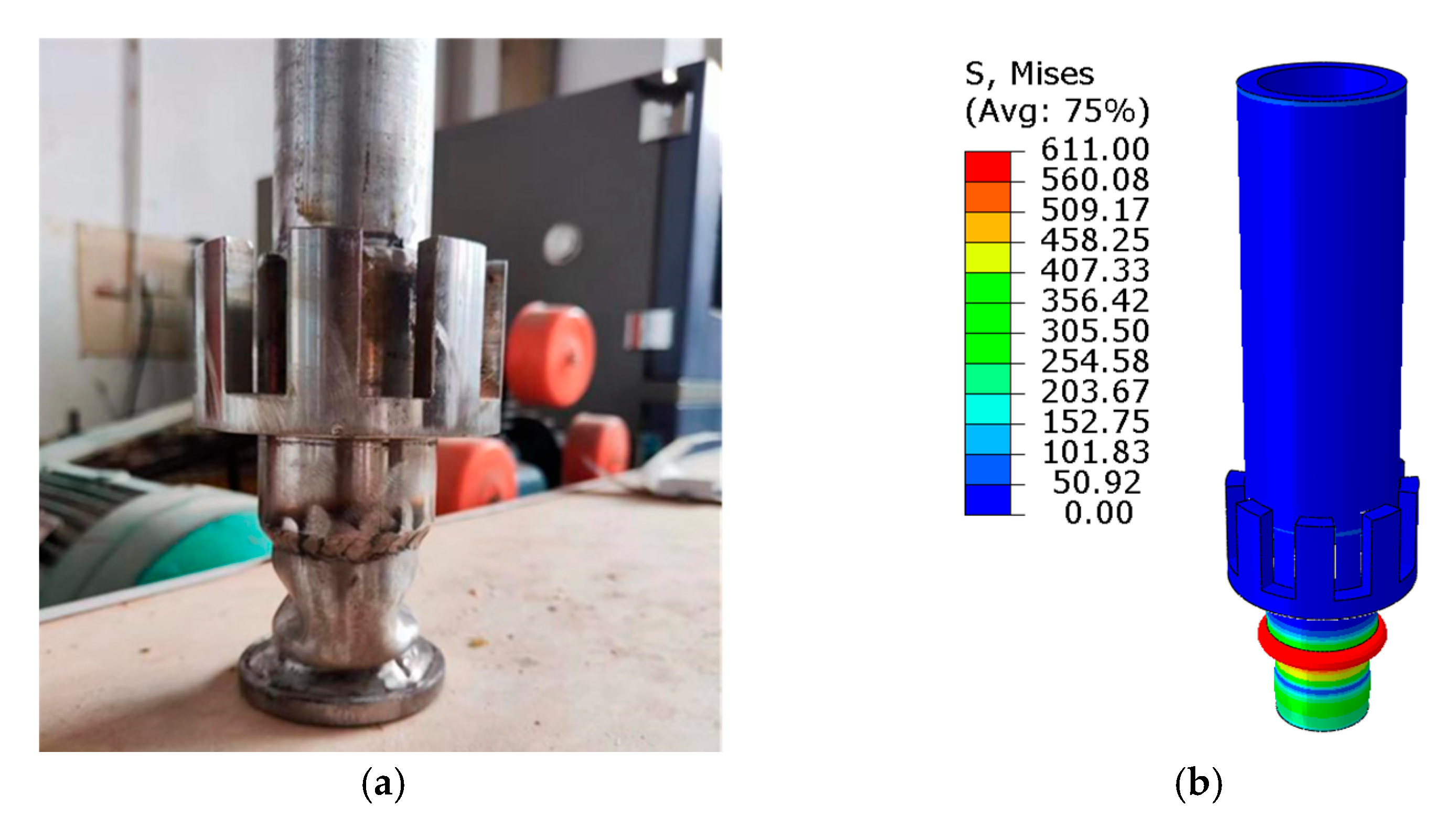

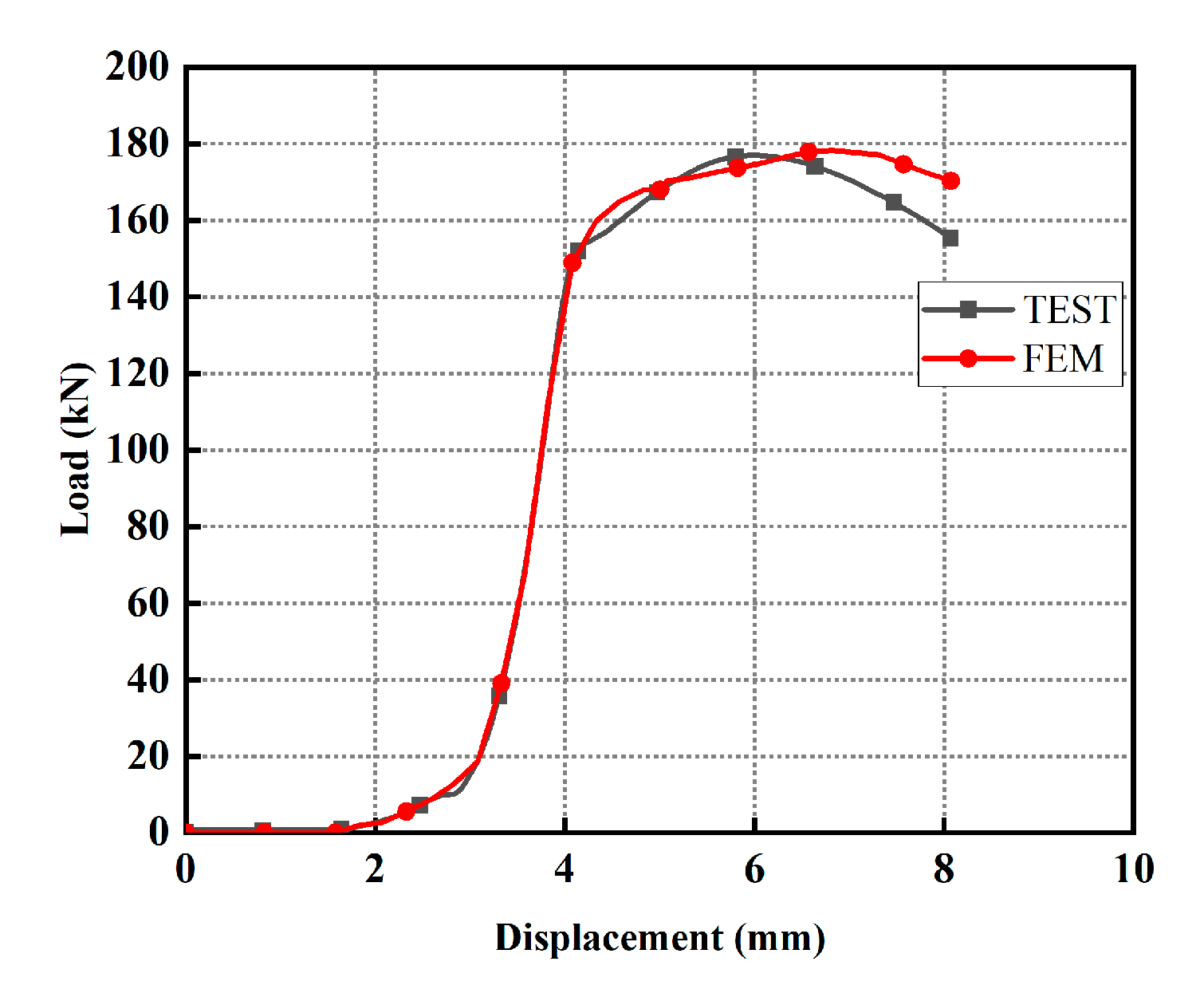

3.4. Shear Performance of Scaffold Joint

4. Conclusions

- Experimental moment–rotation relationships yield an average rotational stiffness of 34.5 kN·m/rad, satisfying the JGJ300-2013 specification threshold of 20 kN·m/rad for temporary support structures [14].

- The wedge-shaped plug-in structure maintains balanced load-transfer pathways. The novel scaffold joint also exhibits symmetric stiffness and bending moment under both positive and negative loading directions.

- The joint has a large tensile and compressive bearing capacity in the horizontal pipe direction. The maximum tensile bearing capacity of the joint in the horizontal direction is about 108 kN, and the maximum compressive bearing capacity is about 70 kN.

- The maximum shear bearing capacity of the joint exceeds 180 kN, and the shear resistance is greater than the buckling critical force of the vertical pipe, meeting the strength requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, G.; Peng, Z. Application and problems of steel scaffolding in China. Steel Constr. 2017, 32, 97–100. [Google Scholar]

- Yuzhang, Z.; Ke, L. Safety accident of formwork engineering and its prevention in China. Archit. Technol. 2008, 07, 492–496. [Google Scholar]

- Jiaping, M. Achievement and development prospect of formwork and scaffold industry in China. Constr. Technol. 2009, 38, 16–18. [Google Scholar]

- Zhao, Z.; Liu, Q.; Kang, H.; Qian, J. A survey of bracing forms in braced frame structure. Ind. Constr. 2011, 41, 79–84. [Google Scholar]

- Zheng, Y.; Guo, Z. Investigation of joint behavior of disk-lock and cuplok steel tubular scaffold. J. Constr. Steel Res. 2021, 177, 106415. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

- JG/T 503-2016; Socket and Spigot Disc Lock Steel Tube Scaffolding Components. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2016.

- Chen, Z.; Lu, Z.; Wang, X.; Liu, H.; Liu, Q. Experimental and theoretical research on capacity of unbraced steel tubular formwork support based on sway frame with semi-rigid connection theory. J. Build. Struct. 2010, 31, 56–63. [Google Scholar]

- Lu, Z.; Chen, Z.; Wang, X.; Guo, C.; Liu, Q. Study of the bearing capacity of fastener steel tube full hall formwork support using the theory of stability of pressed pole with three-point rotation restraint. China Civ. Eng. J. 2012, 45, 104–113. [Google Scholar]

- Zou, A.; Li, Q.; He, M.; Zhang, H. FEA on bearing behavior of cuplok scaffold based on tri-linear semi-rigid joint model. J. Build. Struct. 2016, 37, 151–157. [Google Scholar]

- Xiangyang, X.; Guo, C.; Lei, Y. Multi-parameter simulation method of semi-rigid node of steel tubular scaffold with coupler. J. Civ. Environ. Eng. 2019, 41, 92–103. [Google Scholar]

- He, Z.; Chen, H.; Zhong, G.; Zhou, Y. Seismic performance of end-reinforced steel pipe dampers: Laboratory test and numerical investigation. J. Constr. Steel Res. 2023, 208, 107994. [Google Scholar]

- ASTM E2126-21; Standard Test Methods for Cyclic (Reversed) Load Testing for Shear Resistance of Vertical Elements of the Lateral Force Resisting Systems for Buildings. ASTM International: West Conshohocken, PA, USA, 2021.

- JGJ 300-2013; Technical Code for Temporary Support Structures in Construction. China Architecture & Building Press: Beijing, China, 2013.

- Cheng, X.; Li, Y.; Wu, B.; Zhang, Y. Research on the compressive performance of plug-pin scaffold joints in low-temperature. J. Constr. Steel Res. 2024, 216, 108497. [Google Scholar]

- Li, Y.; Zhang, Y.; Zhang, Y.; Wu, B.; Cheng, X. Research on the tensile performance of plug-pin scaffold joints in low-temperature. J. Constr. Steel Res. 2024, 216, 108589. [Google Scholar] [CrossRef]

- JGJ 130-2011; Safety Technical Code for Steel Pipe Scaffolding with Fasteners in Construction. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

| Item | Detail (mm) | Length (mm) | Elastic Modulus (MPa) | Yield Strength (MPa) |

|---|---|---|---|---|

| Vertical pipe | φ48.3 × 3.2 | 1500 | 2.09 × 105 | 345 |

| Horizontal pipe | φ48.3 × 3.2 | 1500 | 2.09 × 105 | 235 |

| Other | - | - | 2.09 × 105 | 345 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, S.; Xu, Y.; Yuan, B.; Chen, H.; Zhong, G.; Zhang, G. Development and Performance Evaluation of a Novel Disc-Buckle Steel Scaffold Joint. Buildings 2025, 15, 2034. https://doi.org/10.3390/buildings15122034

Wei S, Xu Y, Yuan B, Chen H, Zhong G, Zhang G. Development and Performance Evaluation of a Novel Disc-Buckle Steel Scaffold Joint. Buildings. 2025; 15(12):2034. https://doi.org/10.3390/buildings15122034

Chicago/Turabian StyleWei, Si, Yu Xu, Bing Yuan, Haofan Chen, Genquan Zhong, and Guoyan Zhang. 2025. "Development and Performance Evaluation of a Novel Disc-Buckle Steel Scaffold Joint" Buildings 15, no. 12: 2034. https://doi.org/10.3390/buildings15122034

APA StyleWei, S., Xu, Y., Yuan, B., Chen, H., Zhong, G., & Zhang, G. (2025). Development and Performance Evaluation of a Novel Disc-Buckle Steel Scaffold Joint. Buildings, 15(12), 2034. https://doi.org/10.3390/buildings15122034