Study on the Influence of Delay Time on the Propagation Law of Adjacent Blast Hole Cracks

Abstract

1. Introduction

2. Experimental Setup and Design

2.1. Experimental Device

2.2. Experimental Principle

2.2.1. Calculation of Crack Propagation Speed

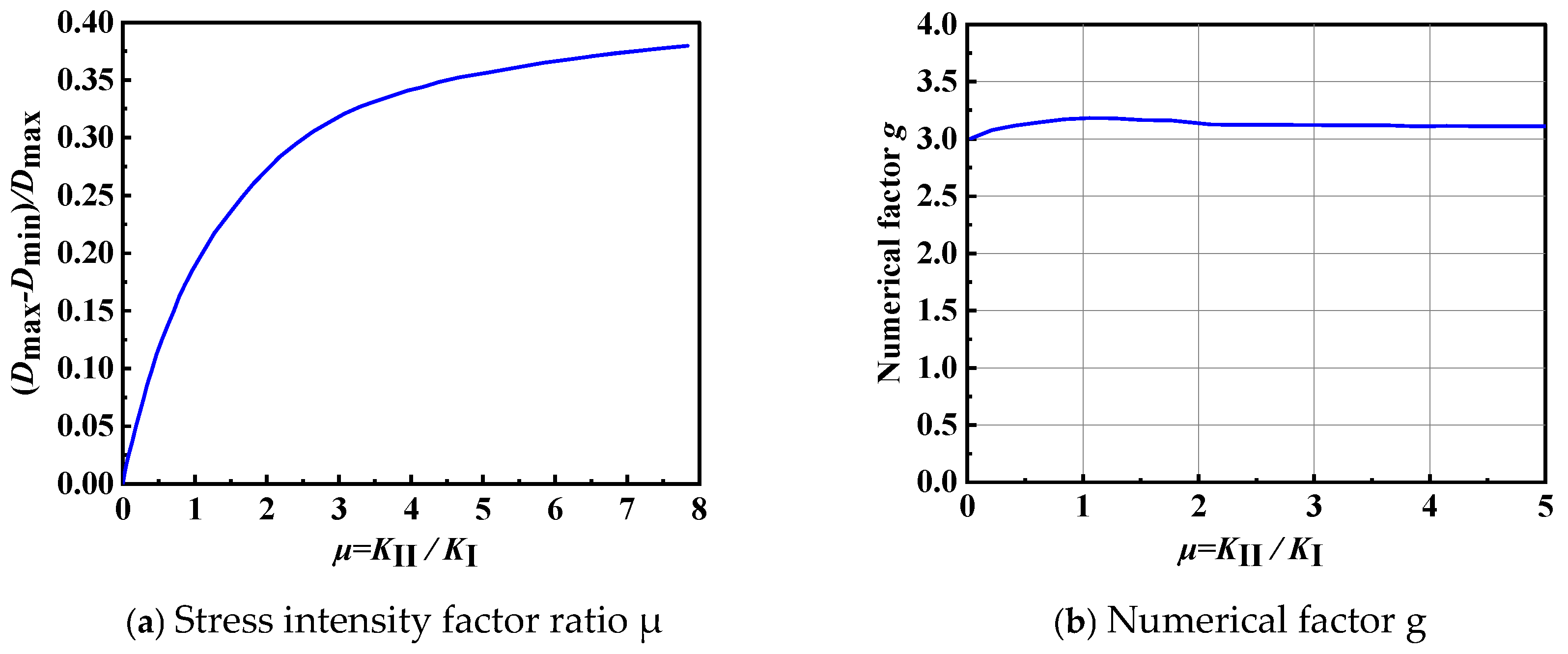

2.2.2. Dynamic Stress Intensity Factor

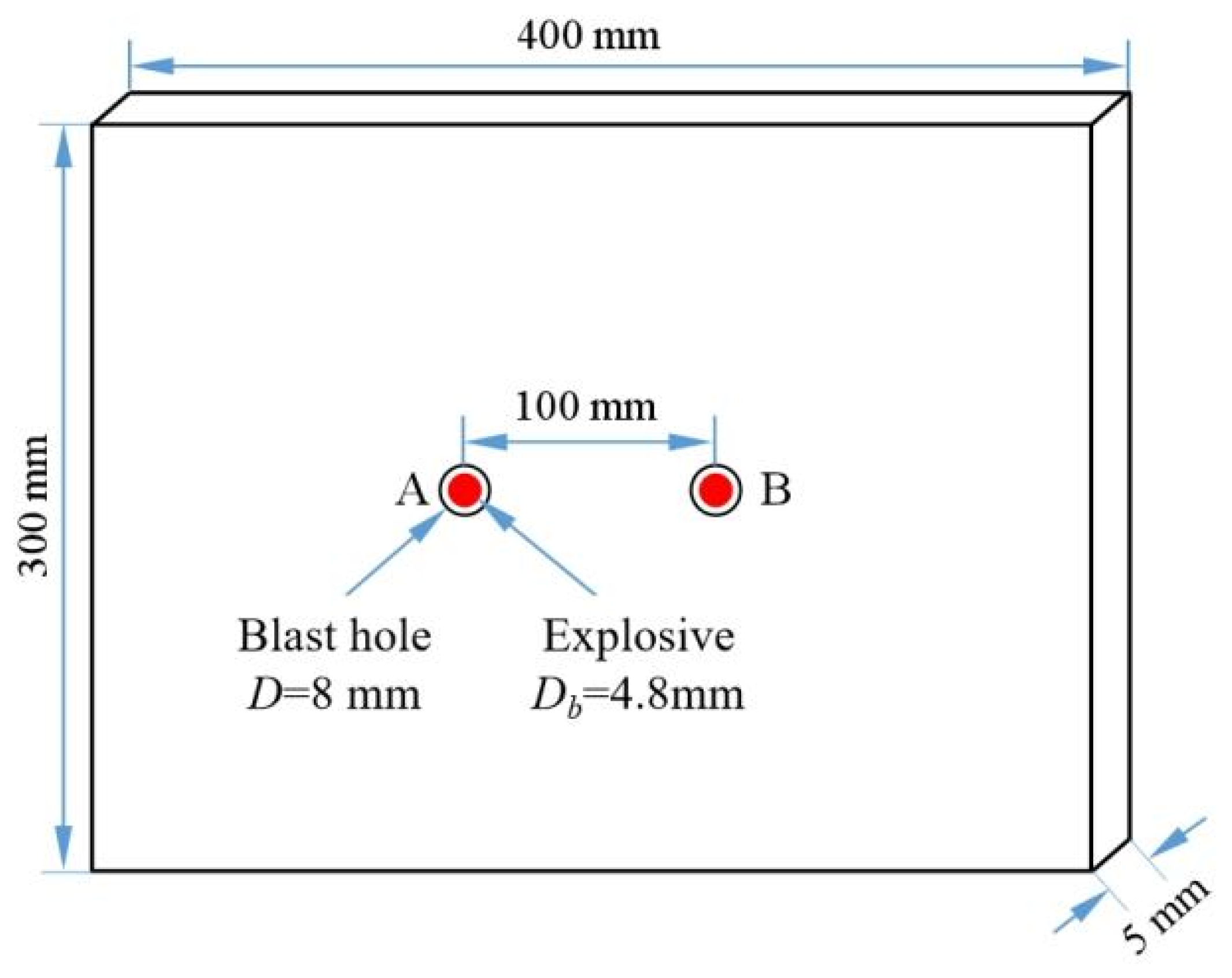

2.3. Experimental Plan Design

3. Experimental Results

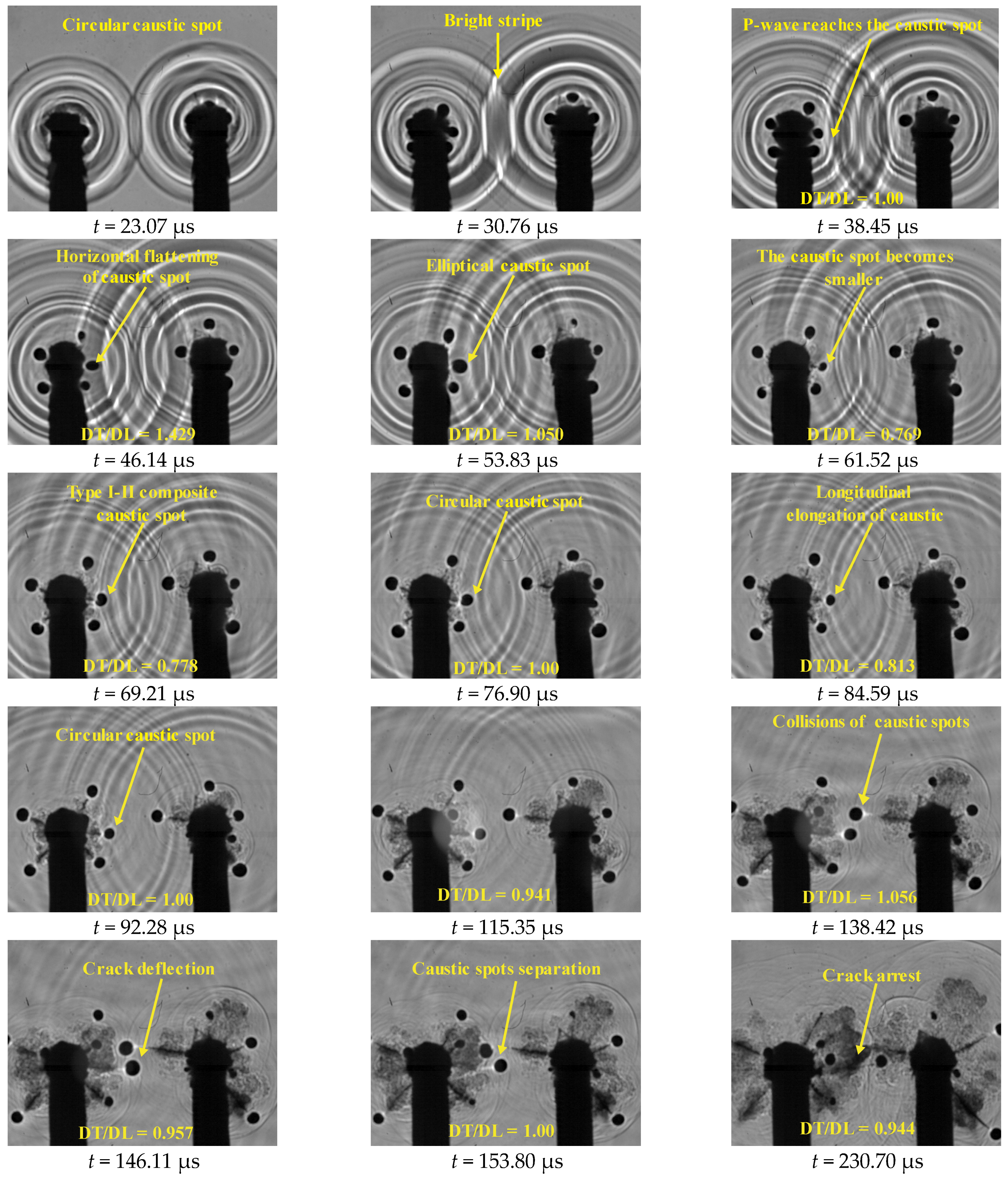

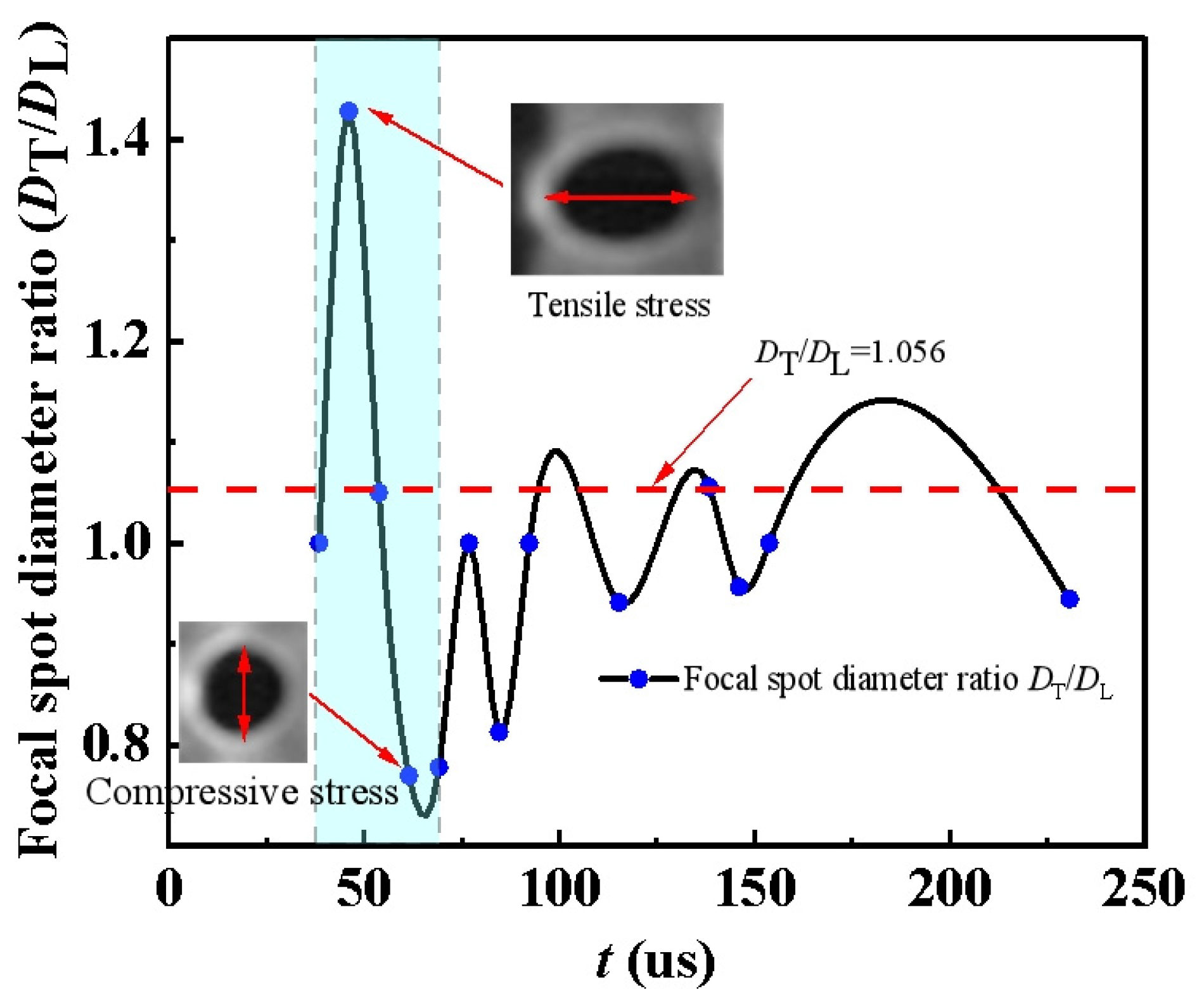

3.1. Analysis of Caustic Line Images

3.2. Main Crack Propagation Speed Between Holes

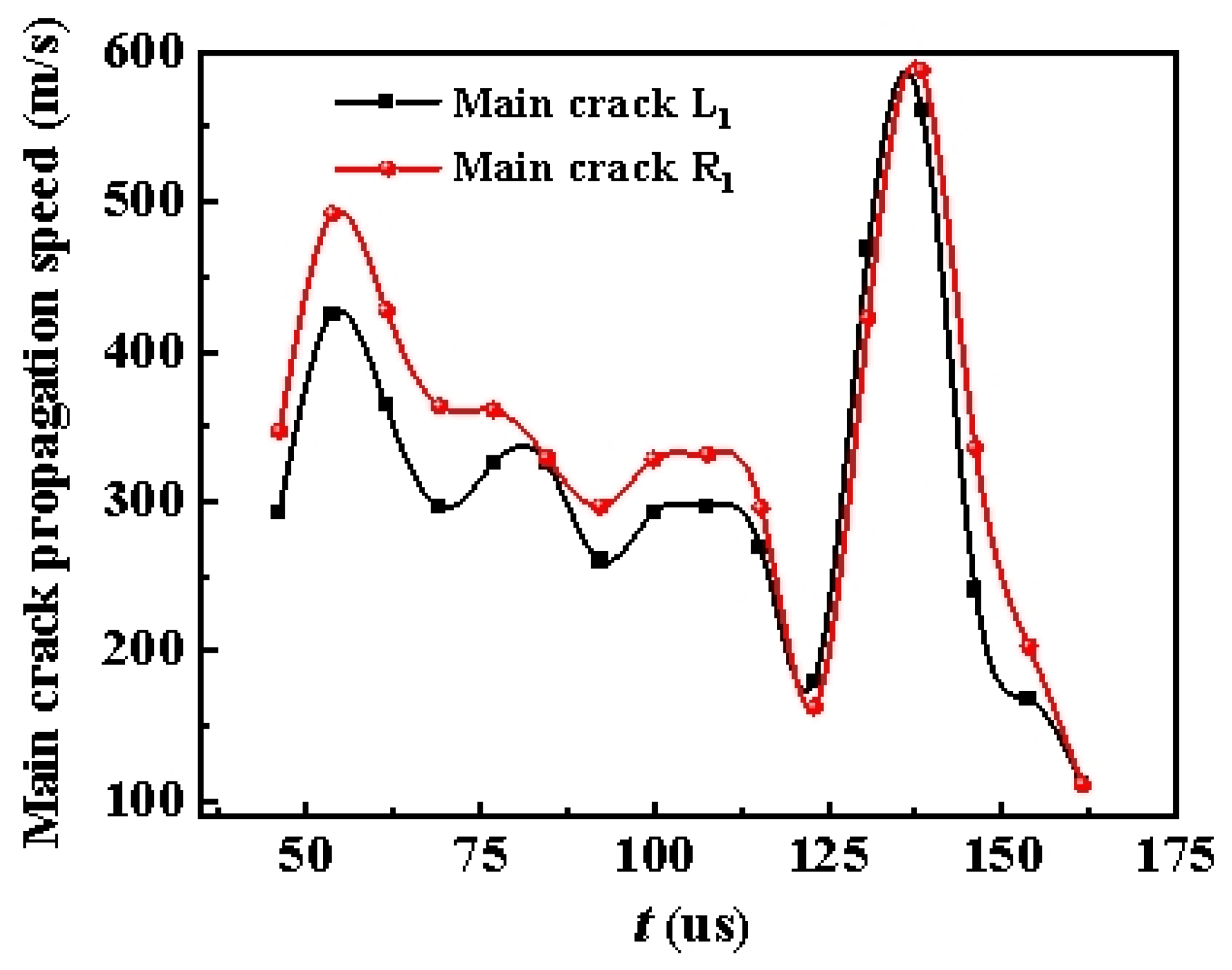

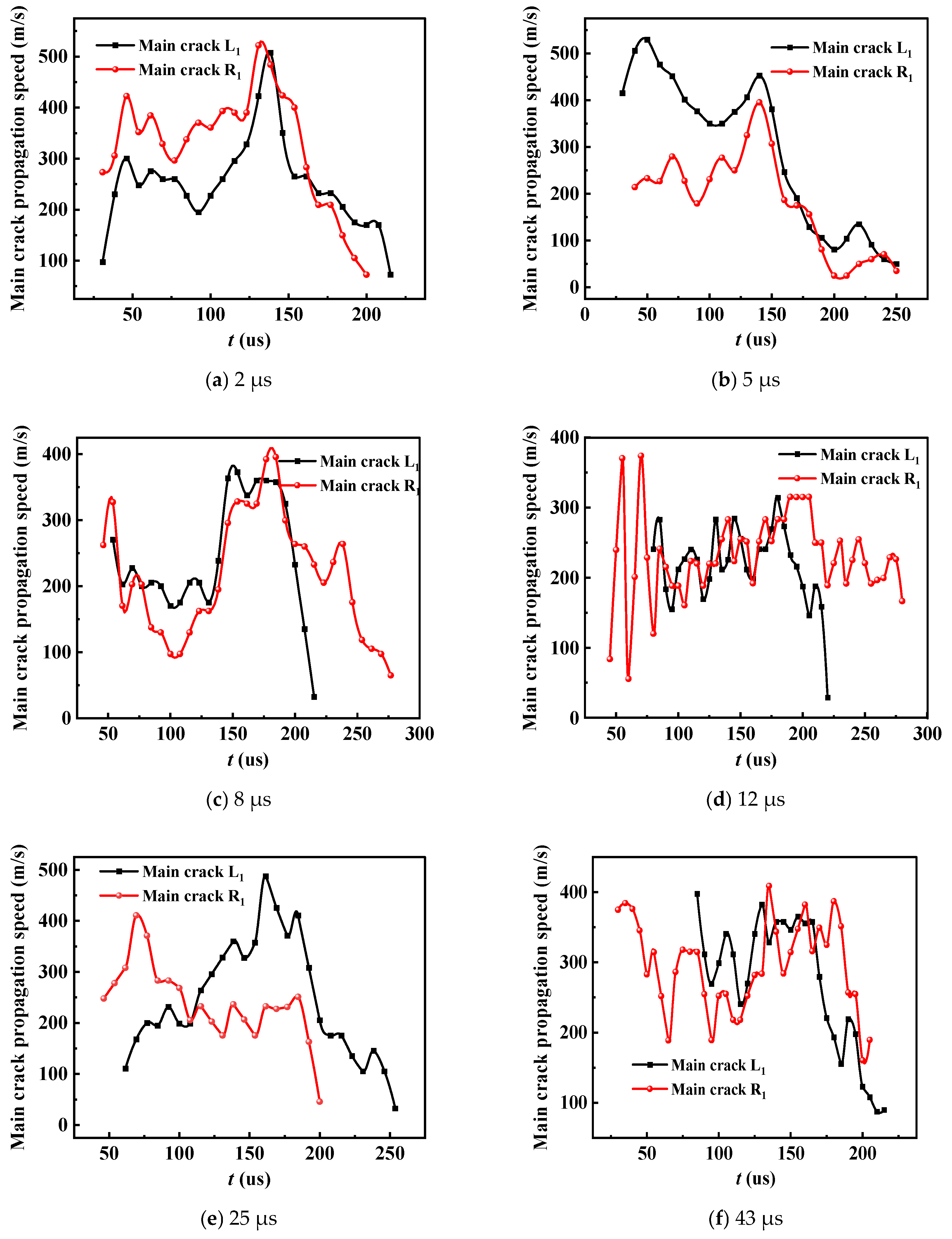

3.3. Stress Intensity Factor at the Tip of the Main Crack Between Holes

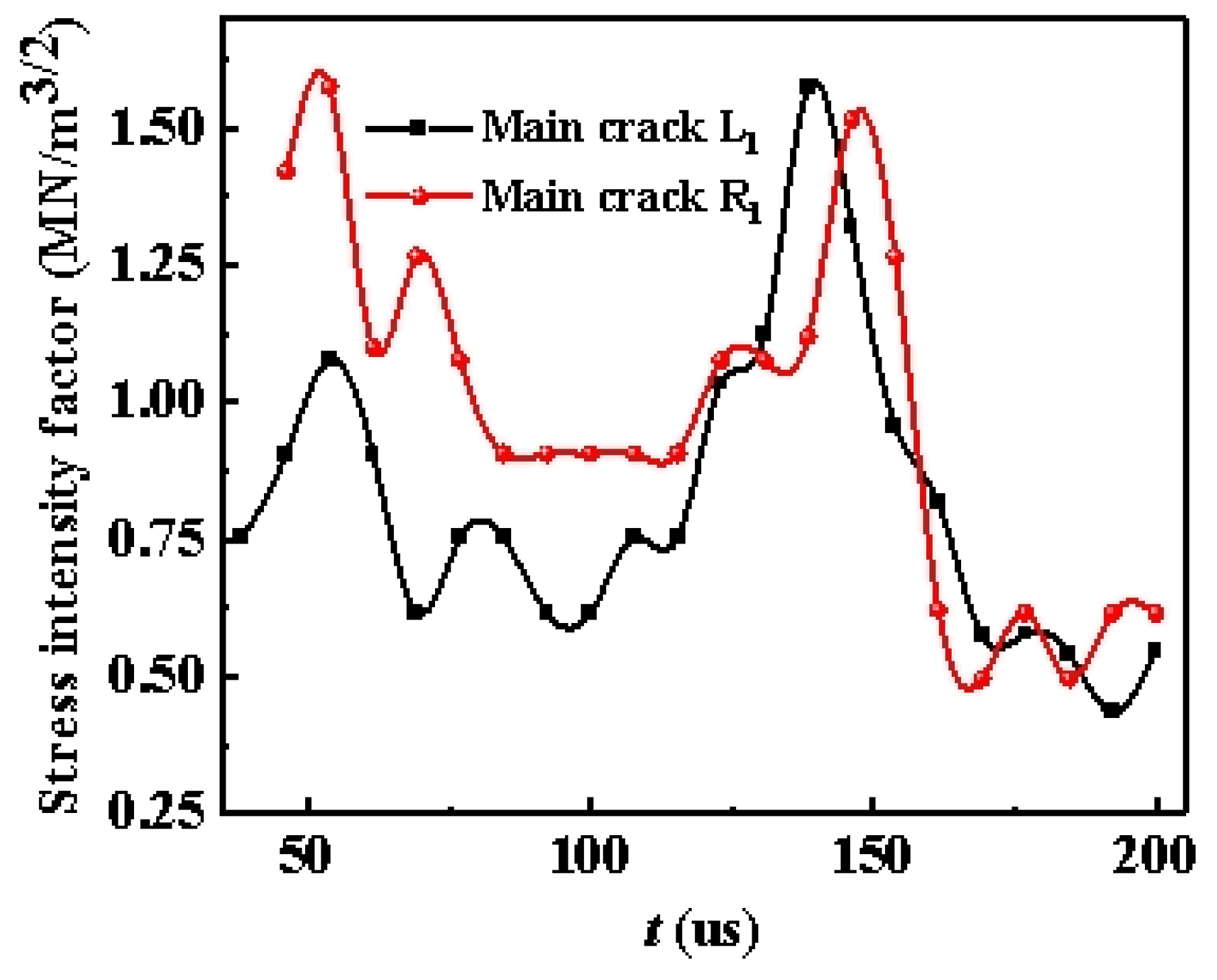

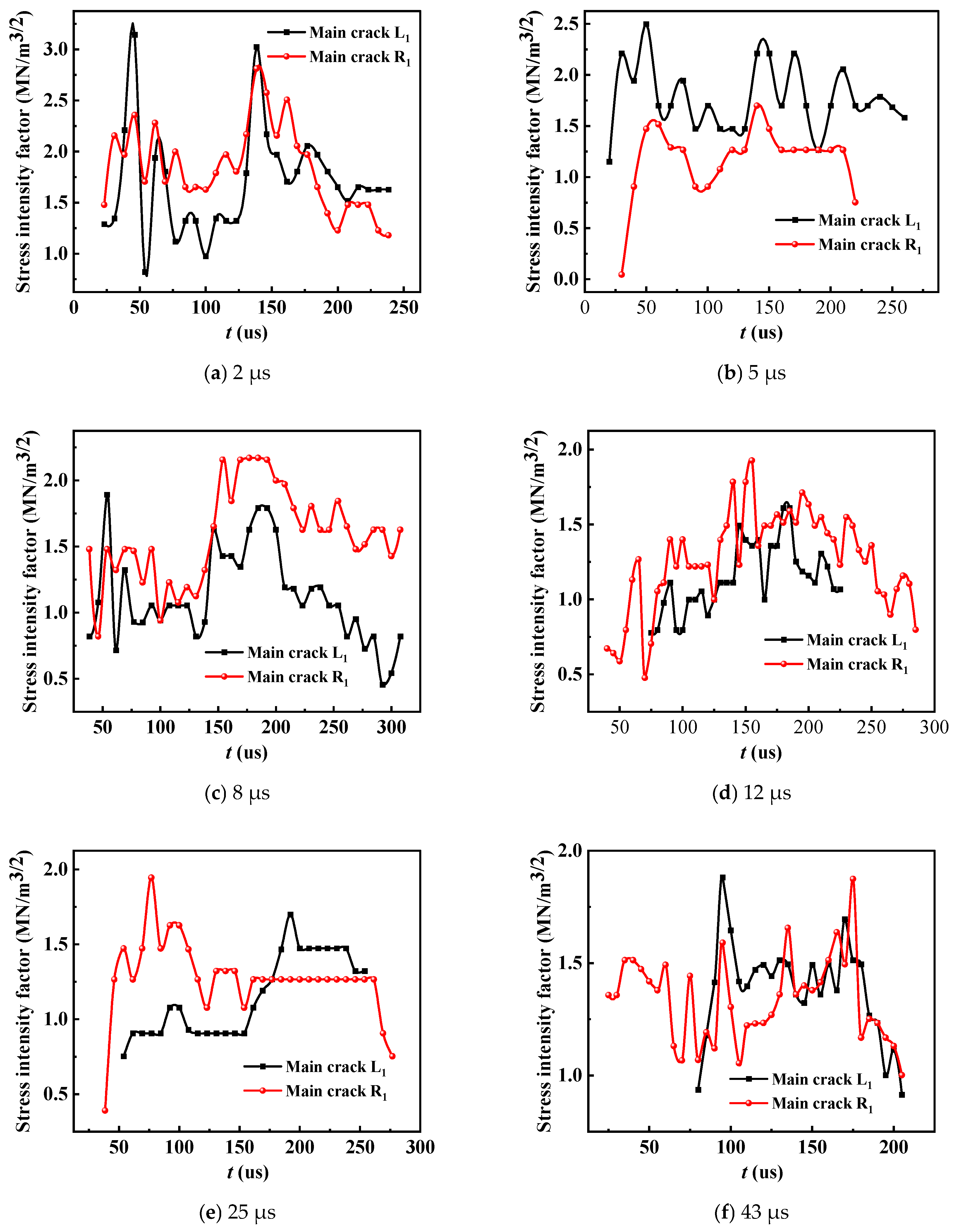

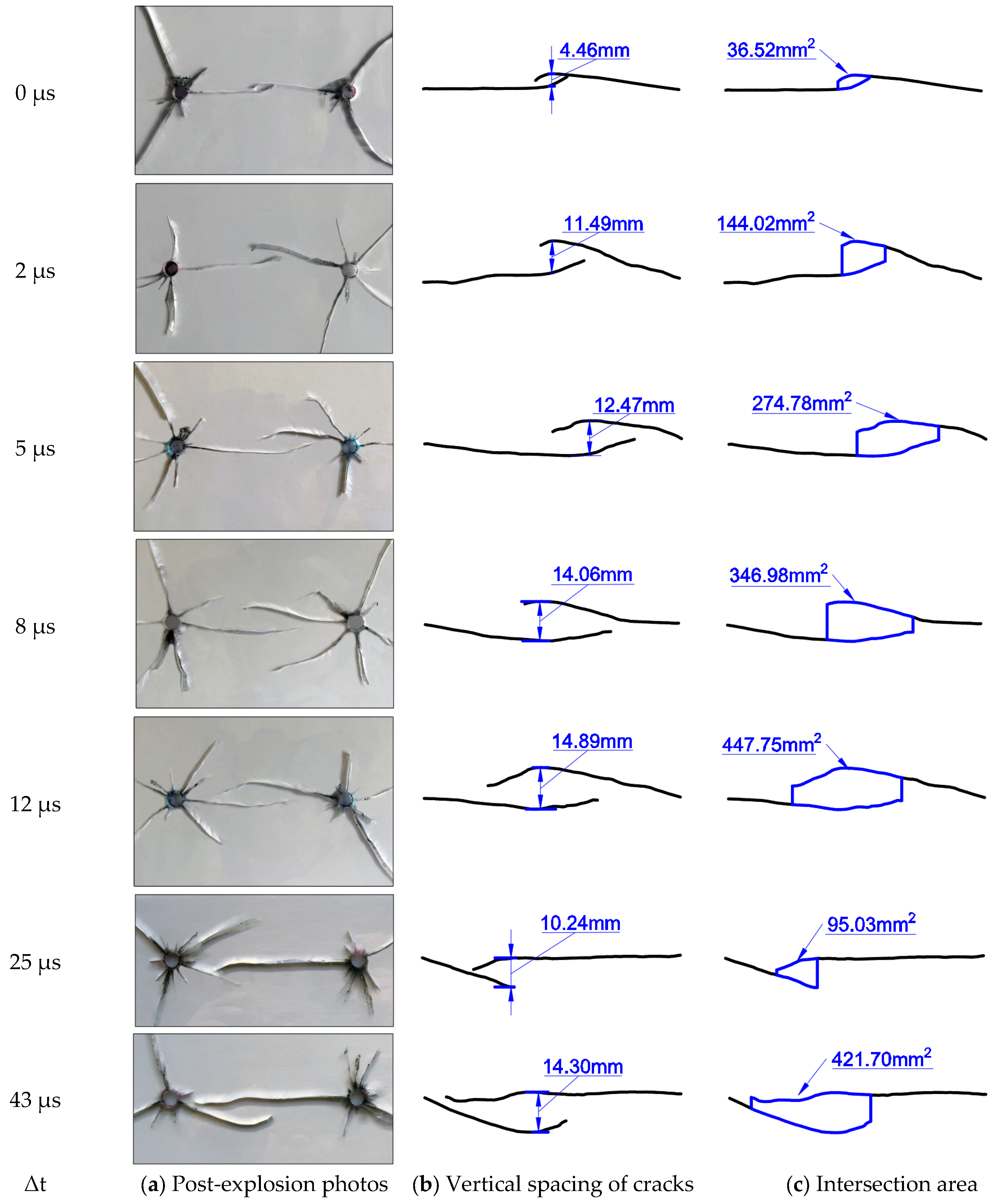

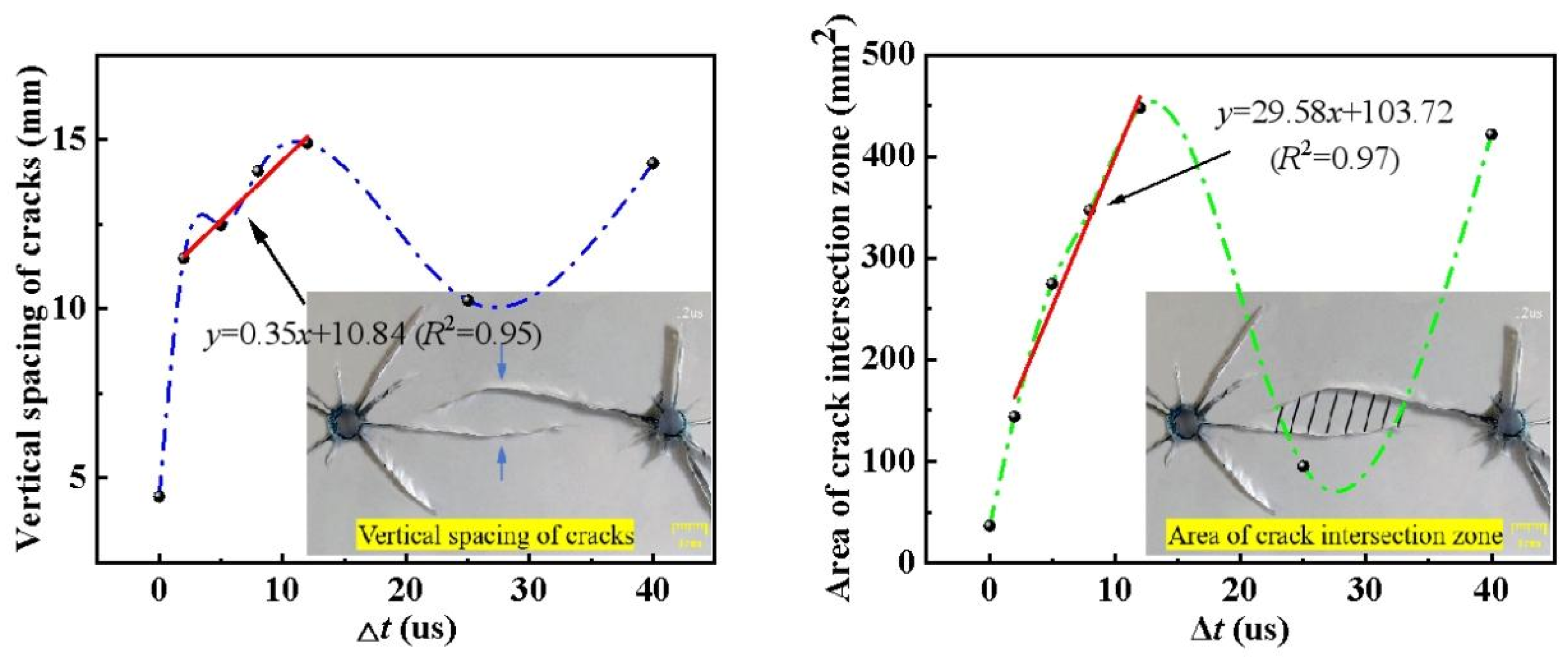

3.4. Inter-Hole Crack Morphology

4. Verification of Experimental Results

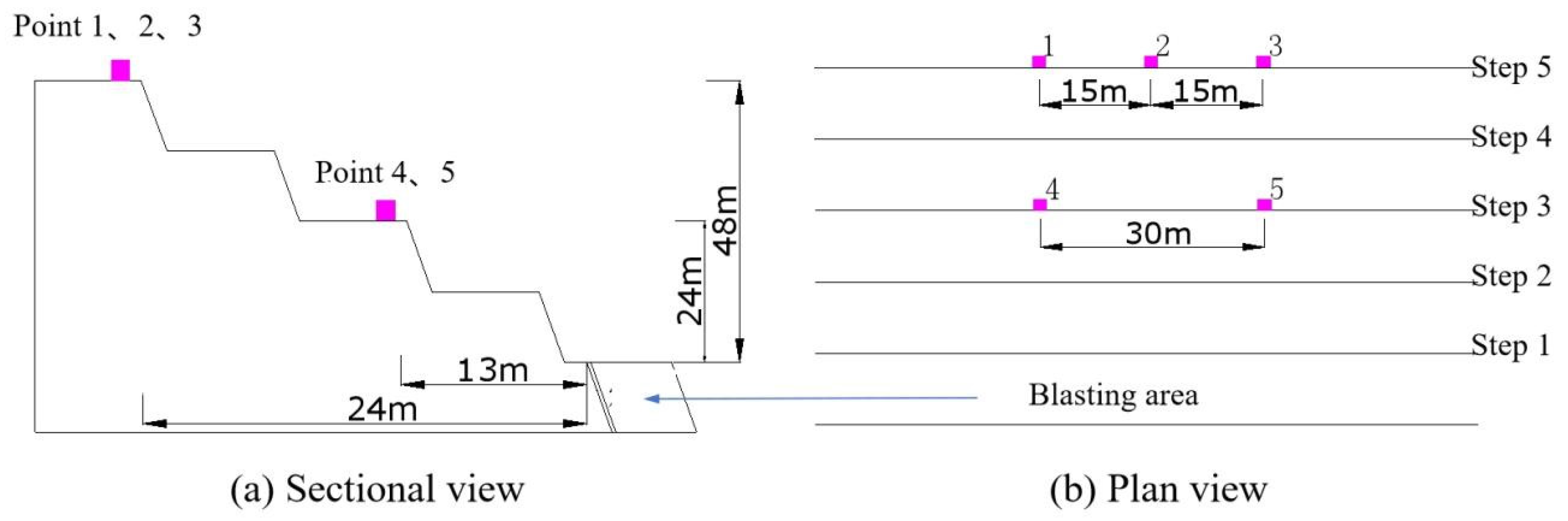

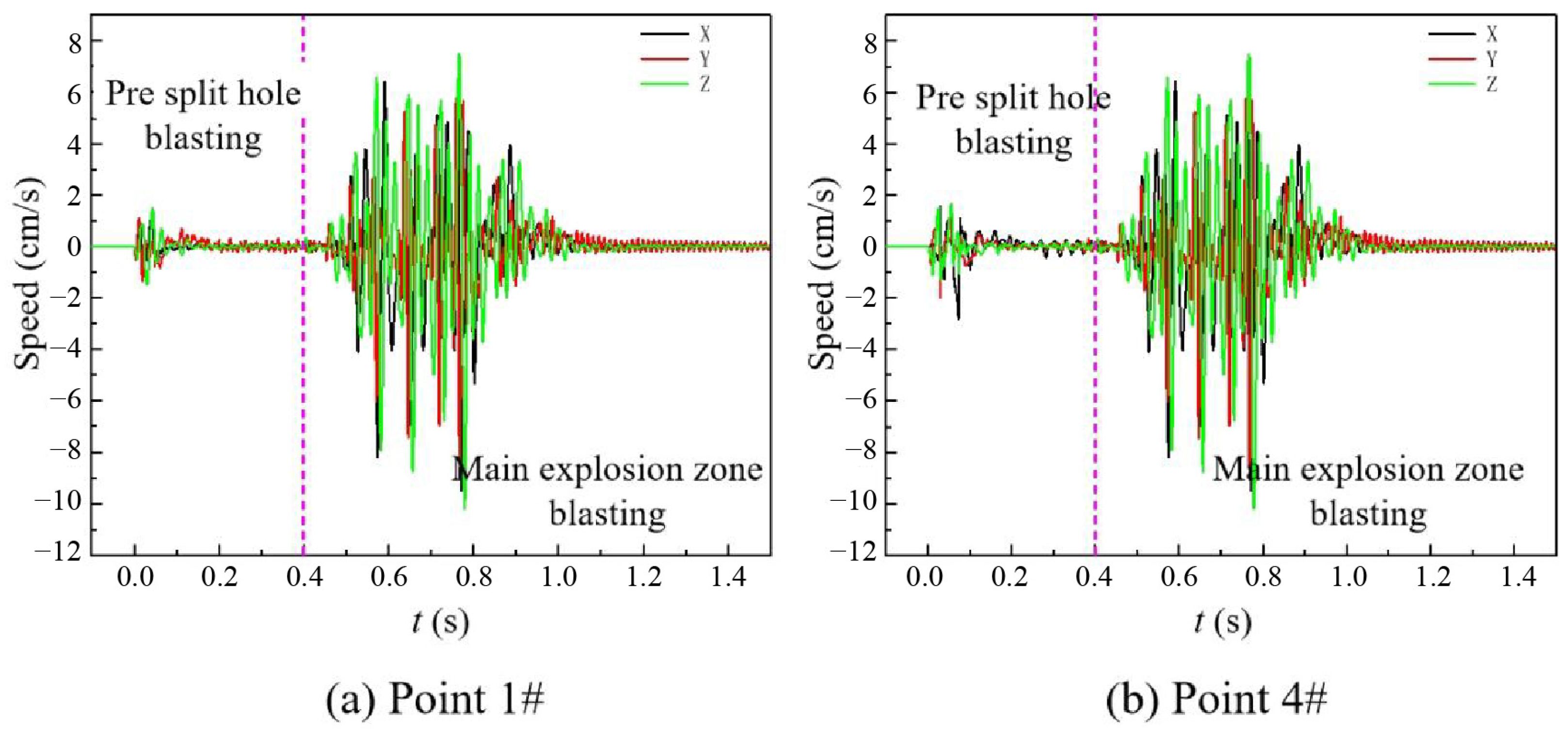

4.1. On-Site Experimental Situation

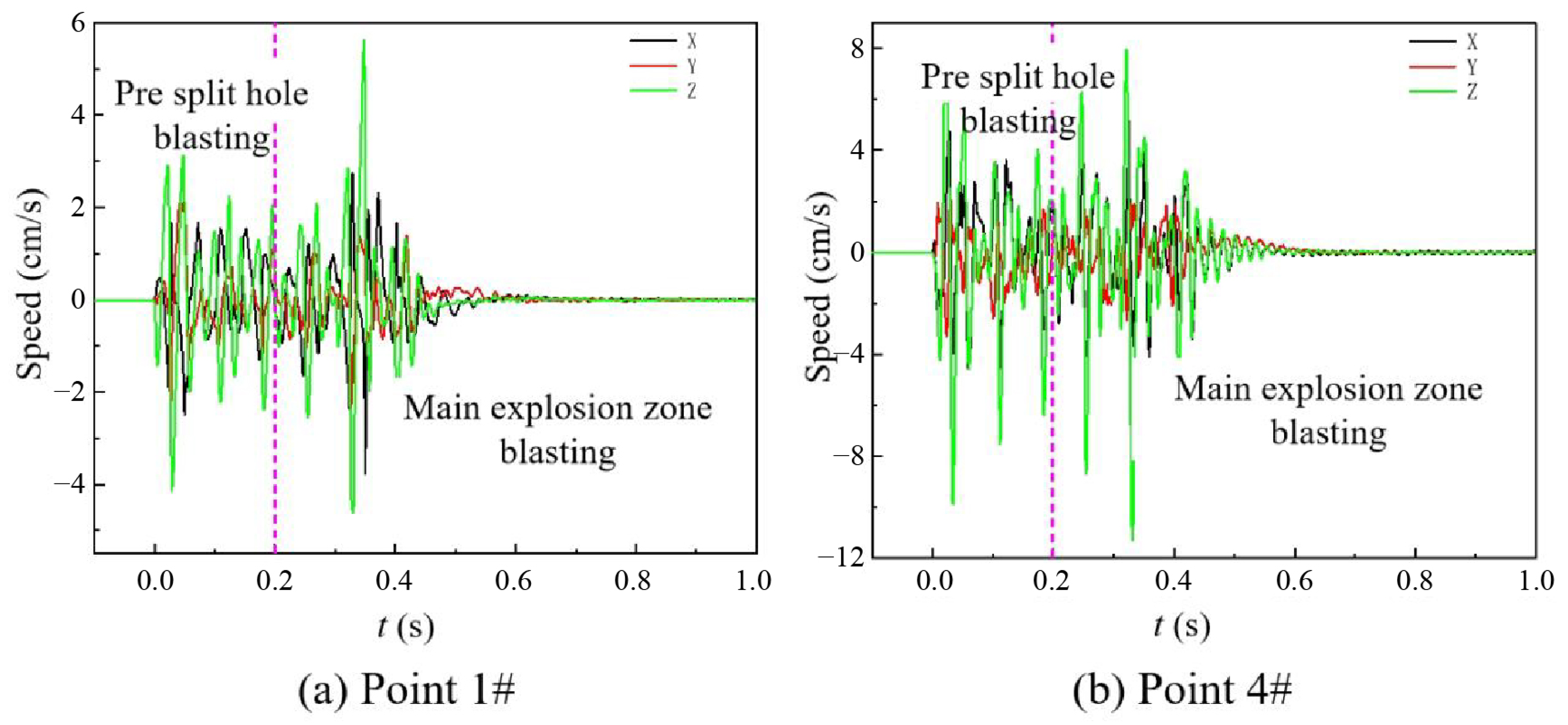

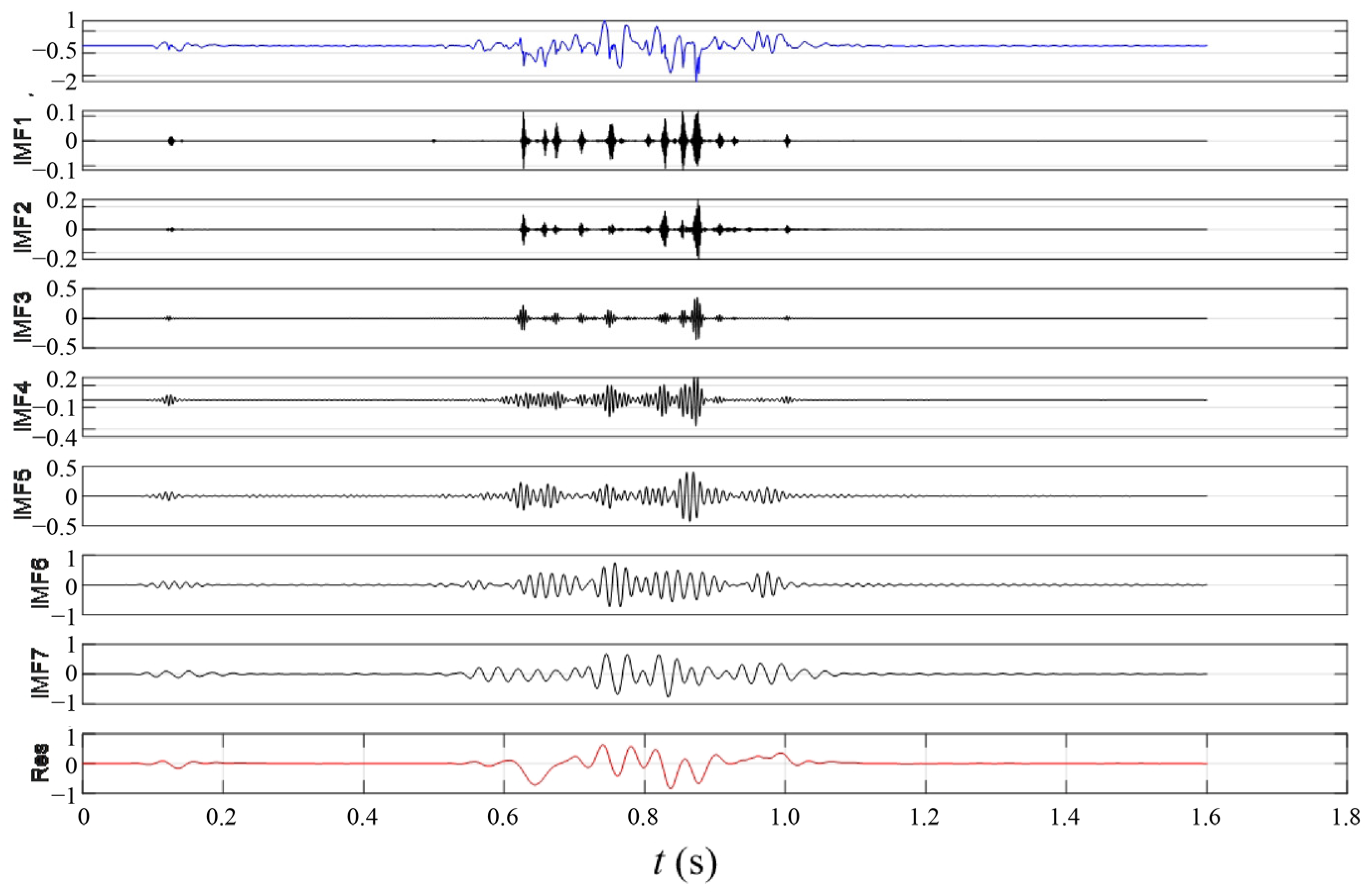

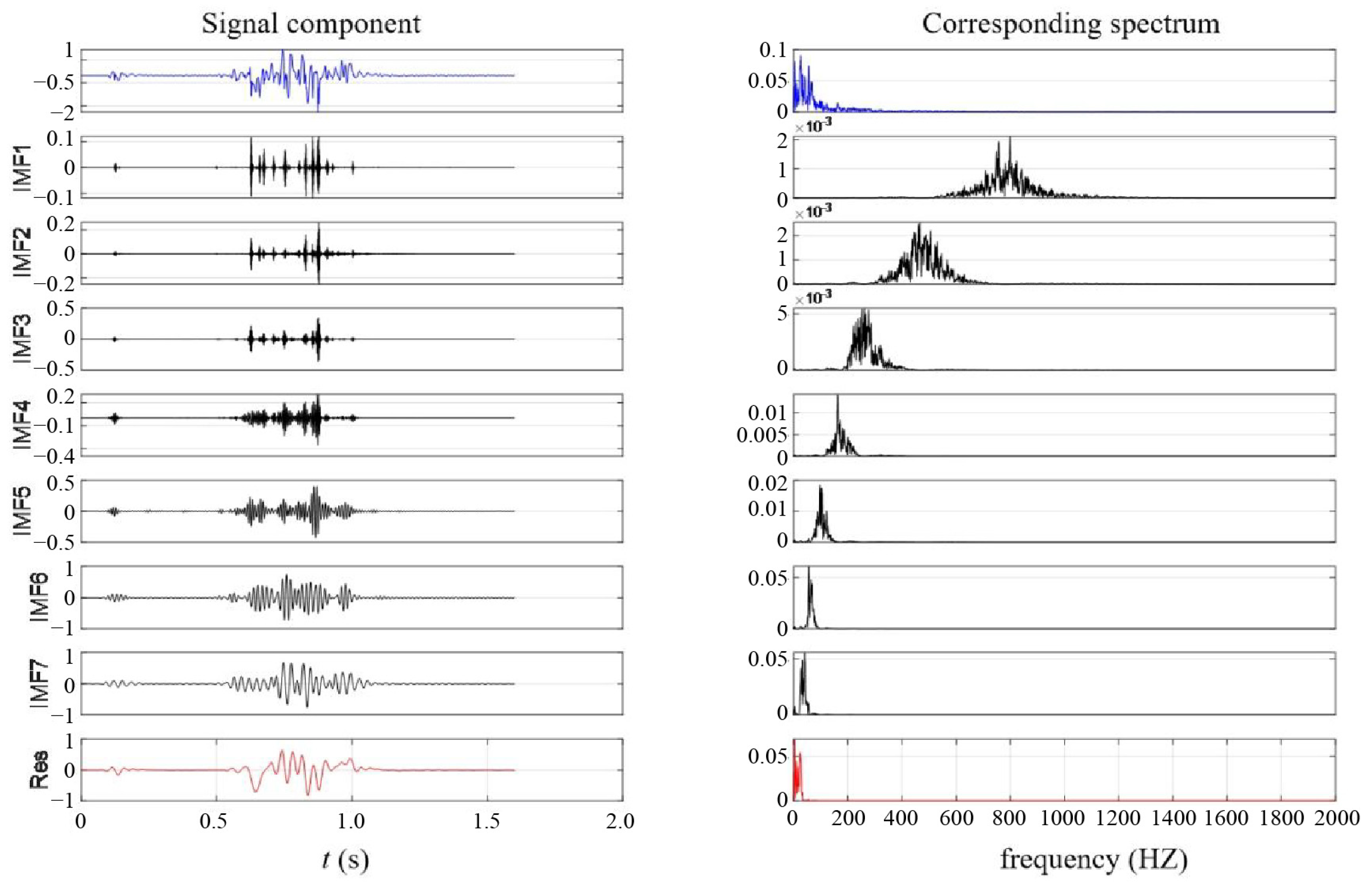

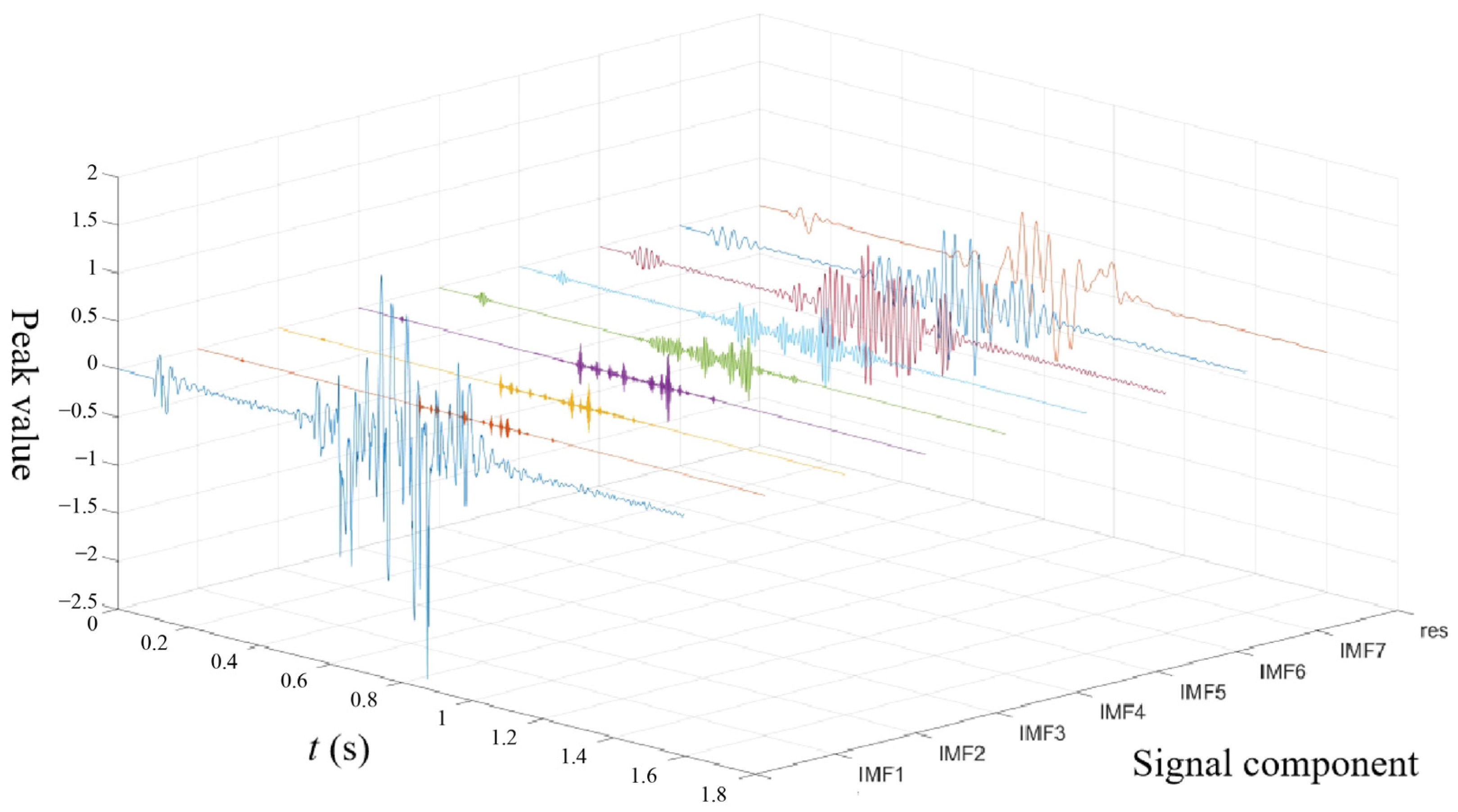

4.2. Spectral Characteristics of Vibration Signals

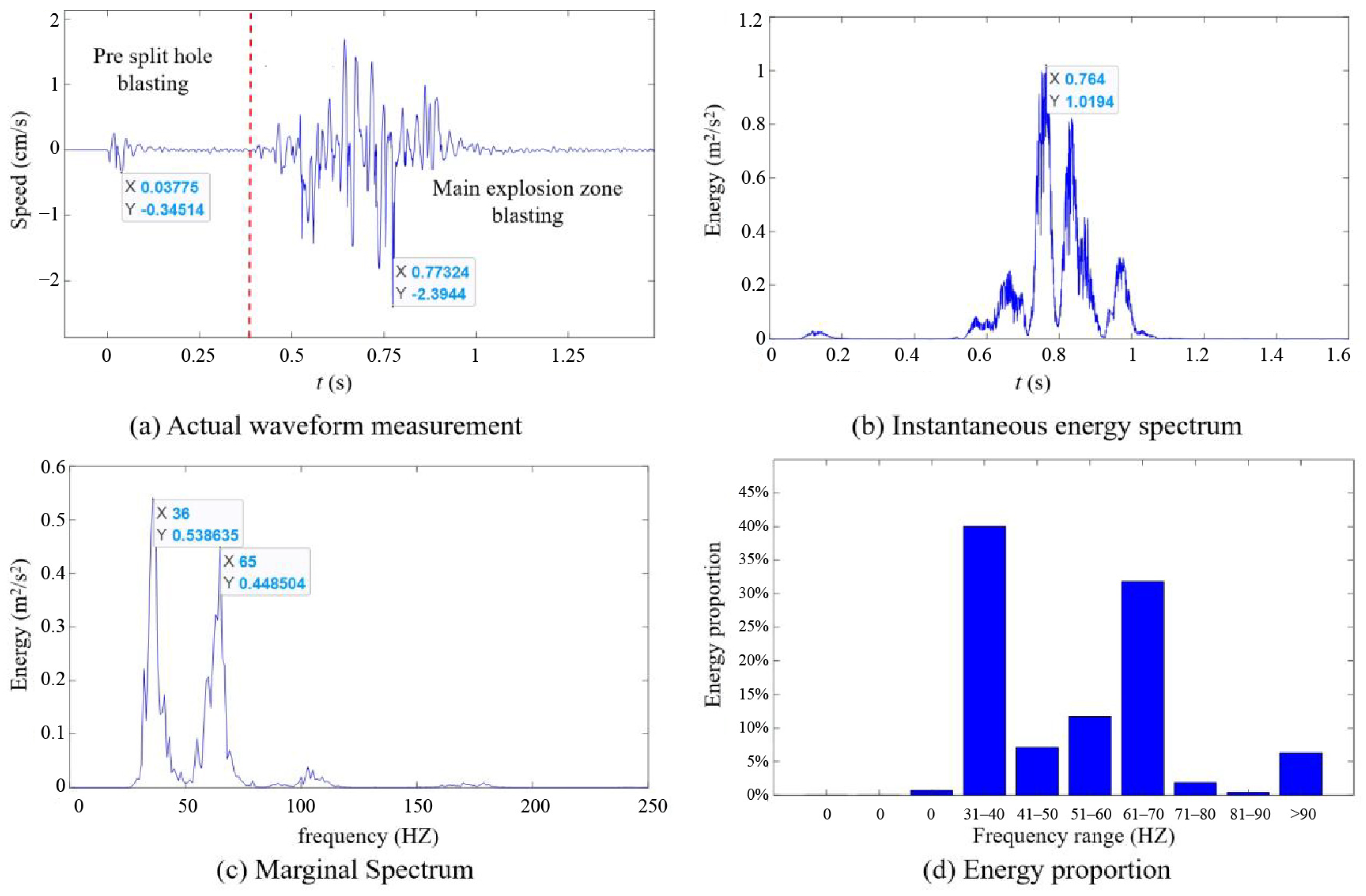

4.2.1. Spectral Analysis of Vibration Signals from Pre-Split Hole-by-Hole Blasting

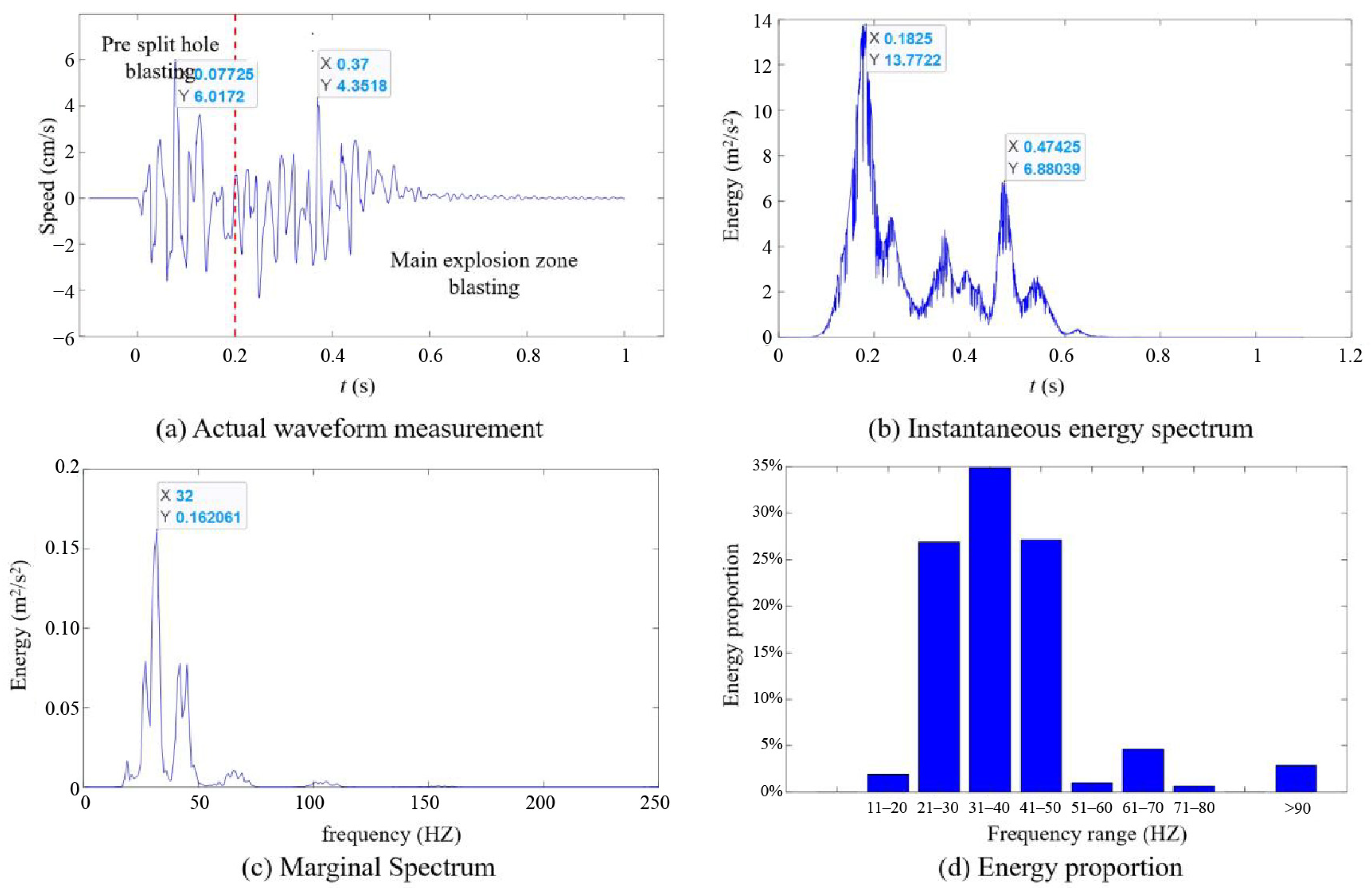

4.2.2. Spectral Analysis of Vibration Signals During Simultaneous Blasting of Pre-Split Holes

5. Conclusions

- Under the same conditions of charge quantity and borehole size, the delay time exhibits a more effective directional blasting impact on the desired cracking result.

- When the delay time between the holes is 0 to 12 μs, the caustics at the crack tip deflect upon meeting, causing the crack type to change from a type I tensile crack to a type I-II stretch mixed crack. As the delay time increases, the vertical distance of the crack between the holes and the area of the junction increase linearly with the delay time.

- When the delay time between holes exceeds 25 μs, the propagation of the main crack between the holes is only weakly influenced by the superposition of stress waves. The cracking occurs primarily due to a slight deflection near the after-burst blast hole, and there is no clear correlation when comparing the vertical distance of the main crack between the holes to the area of the intersection in relation to the short delay.

- The experimental results above indicate that the delay time between holes affects crack propagation, as a penetration crack can be formed by establishing a reasonable delay time. Furthermore, the results from field tests demonstrate that delayed detonation between holes can effectively mitigate the impact of blasting vibrations on the rear rock mass, offering a new approach to reducing slope damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, M.; Zhu, Z.; Liu, R.; Liu, B.; Zhou, L.; Dong, Y. Study of the effect of empty holes on propagating cracks under blasting loads. Int. J. Rock. Mech. Min. Sci. 2018, 103, 186–194. [Google Scholar] [CrossRef]

- Hao, X.; Du, W.; Zhao, Y.; Sun, Z.; Zhang, Q.; Wang, S.; Qiao, H. Dynamic tensile behaviour and crack propagation of coal under coupled static-dynamic loading. Int. J. Rock. Mech. Min. Sci. 2020, 30, 659–668. [Google Scholar] [CrossRef]

- Ding, C.; Yang, R.; Lei, Z.; Wang, M.; Zhao, Y.; Lin, H. Fractal damage and crack propagation in decoupled charge blasting. Soil Dyn. Earthquake Eng. 2021, 141, 106503. [Google Scholar] [CrossRef]

- Ocak, I.; Bilgin, N. Comparative studies on the performance of a roadheader, impact hammer and drilling and blasting method in the excavation of metro station tunnels in Istanbul. Tunn. Undergr. Space Technol. 2010, 25, 181–187. [Google Scholar] [CrossRef]

- Mazaira, A.; Konicek, P. Intense rockburst impacts in deep underground construction and their prevention. Can. Geotech. J. 2015, 52, 1426–1439. [Google Scholar] [CrossRef]

- Haibo, L.; Xiang, X.; Jianchun, L.; Jian, Z.; Bo, L.; Yaqun, L. Rock damage control in bedrock blasting excavation for a nuclear power plant. Int. J. Rock. Mech. Min. Sci. 2011, 48, 210–218. [Google Scholar] [CrossRef]

- Li, X.; Gong, F.; Tao, M.; Dong, L.; Du, K.; Ma, C.; Zhou, Z.; Yin, T. Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: A review. J. Rock. Mech. Geotech. Eng. 2017, 9, 767–782. [Google Scholar] [CrossRef]

- Katsabanis, P.D. Analysis of the effects of blasting on comminution using experimental results and numerical modelling. Rock. Mech. Rock. Eng. 2020, 53, 3093–3109. [Google Scholar] [CrossRef]

- Li, X.; Liu, K.; Yang, J.; Song, R. Numerical study on blast-induced fragmentation in deep rock mass. Int. J. Impact Eng. 2022, 170, 104367. [Google Scholar] [CrossRef]

- Zhu, X.; Ding, C.; Sui, Z.; Su, H.; Guo, X. Rock fracture mechanism of buffer blasting with cushion layer at the borehole bottom. Int. J. Miner. Metall. Mater. 2025, 32, 325–334. [Google Scholar] [CrossRef]

- Rossmanith, H.P. The use of Lagrange diagrams in precise initiation blasting. Part I: Two interacting blastholes. Fragblast 2002, 6, 104–136. [Google Scholar] [CrossRef]

- Rossmanith, H.P.; Kouzniak, N. Supersonic detonation in rock mass-part 2: Particle displacements and velocity fields for single and multiple non-delayed and delayed detonating blastholes. Fragblast 2004, 8, 95–117. [Google Scholar] [CrossRef]

- McKinstry, R.; Floyd, J.; Bartley, D. Electronic detonator performance evaluation. In Proceedings of the 28th Annual Conference on Explosives and Blasting Technique, Las Vegas, NV, USA, 10–13 February 2002; pp. 1–20. [Google Scholar]

- Lewis, N.; Pereira, P. Operating improvements at Vuloan Materials McCook quarry using electronic detonators. In Proceedings of the 29th Annual Conference on Explosives and Blasting Technique. Nashville, Nashville, TN, USA, 2–5 February 2003; pp. 1–14. [Google Scholar]

- Khandelwal, M.; Singh, T.N. Prediction of blast-induced ground vibration using artificial network. Int. J. Rock. Mech. Min. Sci. 2009, 46, 1214–1222. [Google Scholar] [CrossRef]

- Liu, K.; Zhao, X.; Li, X.; Sha, Y.; Hong, Z.; Yang, J.; Ma, S. Effects of delay time on crack coalescence between two boreholes. Theor. Appl. Fract. Mech. 2024, 129, 104210. [Google Scholar] [CrossRef]

- Yi, C.; Johansson, D.; Nyberg, U.; Beyglou, A. Stress wave interaction between two adjacent blast holes. Rock. Mech. Rock. Eng. 2016, 49, 1803–1812. [Google Scholar] [CrossRef]

- Tang, H.L.; Liu, X.; Yang, J.; Yu, Q. Experimental study on the influence of delay time on rock fragmentation in bench blasting. Appl. Sci. 2022, 13, 85. [Google Scholar] [CrossRef]

- Huang, D.; Cui, S.; Li, X. Wavelet packet analysis of blasting vibration signal of mountain tunnel. Soil. Dyn. Earthq. Eng. 2019, 117, 72–80. [Google Scholar] [CrossRef]

- Chen, G.; Li, Q.Y.; Li, D.Q.; Wu, Z.Y.; Liu, Y. Main frequency band of blast vibration signal based on wavelet packet transform. Appl. Math. Model. 2019, 74, 569–585. [Google Scholar] [CrossRef]

- Wang, Z.-W.; Li, X.-B.; Peng, K.; Xie, J.-F. Impact of blasting parameters on vibration signal spectrum: Determination and statistical evidence. Tunn. Undergr. Space Technol. 2015, 48, 94–100. [Google Scholar] [CrossRef]

- Li, B.; Wang, E.; Li, Z.; Cao, X.; Liu, X.; Zhang, M. Automatic recognition of effective and interference signals based on machine learning: A case study of acoustic emission and electromagnetic radiation. Int. J. Rock. Mech. Min. Sci. 2023, 170, 105505. [Google Scholar] [CrossRef]

- Aldaş, G.G.U.; Bilgin, H.A.; Esen, S. Timing simulation for the selection of optimum delay time. In Proceedings of the 17th International Mining Congress and Exhibition of Turkey, Ankara, Turkey, 19–22 June 2001. [Google Scholar]

- Zhang, X.; Yan, P.; Lu, W.; Cheng, Y.; Sun, C.; Zhu, J.; Guo, W.; Cheng, X. Frequency spectrum characteristics of blast-induced vibration with electronic detonators in ground blasting. J. Build. Eng. 2023, 74, 106892. [Google Scholar] [CrossRef]

- Wang, C.; Du, X.; Wang, K.; Wang, K.; Sun, Y.; Hu, Z.; Wang, L.; Sun, D. Research on the vibration reduction characteristics of digital electronic detonators in the blasting of flood discharge and sand removal tunnels. Blasting 2023, 40, 205–212. [Google Scholar]

- Bai, X.; Li, M.; Di, Z.; Dong, W.; Liang, J.; Zhang, J.; Sun, H. Open circuit fault diagnosis of wind power converter based on VMD energy entropy and time domain feature analysis. Energy Sci. Eng. 2024, 12, 577–595. [Google Scholar] [CrossRef]

- Ambrożkiewicz, B.; Syta, A.; Georgiadis, A.; Gassner, A.; Litak, G.; Meier, N. Intelligent Diagnostics of Radial Internal Clearance in Ball Bearings with Machine Learning Methods. Sensors 2023, 23, 5875. [Google Scholar] [CrossRef]

- Konieczny, J.; Łata, W.; Stojek, J. Application of analysis of variance to determine important features of signals for diagnostic classifiers of displacement pumps. Sci. Rep. 2024, 14, 6098. [Google Scholar] [CrossRef]

- Li, J.; Guo, J.; Zhu, X.; Yu, Y. Nonlinear characteristics of damaged bridges under moving loads using parameter optimization variational mode decomposition. J. Civ. Civil. Struct. Health Monit. 2022, 12, 1009–1026. [Google Scholar] [CrossRef]

- Washabaugh, P.D.; Knauss, W.G. The effect of aligned defects on the propagation speed of a dynamic crack in PMMA. Int. J. Solids Struct. 1995, 32, 2481–2496. [Google Scholar] [CrossRef]

- Liu, W.; Yao, X.; Yang, R.; Yue, Z. Multi-crack propagation in PMMA plates under dynamic out-of-plane impact. Opt. Lasers Eng. 2020, 124, 105849. [Google Scholar] [CrossRef]

- Xiao, C.; Yang, R.; Zuo, J.; Chen, J.; Zhao, J.; Yang, Y. Influence of open joints on blasting damage and crack propagation of PMMA. Mech. Adv. Mater. Struct. 2024, 31, 3204–3215. [Google Scholar] [CrossRef]

- Faye, A.; Parameswaran, V.; Basu, S. Dynamic fracture initiation toughness of PMMA: A critical evaluation. Mech. Mater. 2016, 94, 156–169. [Google Scholar] [CrossRef]

- Yang, R.; Zhao, Y.; Fang, S.; Zhao, J.; Wang, Y.; Liu, Z. Effect of the detonation method on the stress field distribution and crack propagation of spacer charge blasting. Chin. J. Eng. 2023, 45, 714–737. [Google Scholar]

| Number | Charge (mg) | Delay Time (μs) | Proportion of Delay Time (%) | |

|---|---|---|---|---|

| Left (A) | Right (B) | |||

| 1 | 120 | 120 | 0 | 0% |

| 2 | 120 | 120 | 2 | 5% |

| 3 | 120 | 120 | 5 | 12% |

| 4 | 120 | 120 | 8 | 19% |

| 5 | 120 | 120 | 12 | 28% |

| 6 | 120 | 120 | 25 | 58% |

| 7 | 120 | 120 | 43 | 100% |

| NO. | Name | D/mm | H/m | L /m | Charge /mm | Single-Pore Dosage /kg | Maximum Segment Dosage /kg | Total Dosage /kg |

|---|---|---|---|---|---|---|---|---|

| 1 | Presplit hole | 120 | 10.5~14.8 | 1.3 | 32 | 12 | 672 | 9792 |

| 2 | Buffer hole | 120 | 5.0~8.2 | 2.5 | 90 | 15~33 | 550 | |

| 3 | Main explosion hole | 120 | 5~12.8 | 5 | 90 | 51~66 | 756 |

| NO. | Name | D/mm | H/m | L /m | Charge /mm | Single-Pore Dosage /kg | Maximum Segment Dosage /kg | Total Dosage /kg |

|---|---|---|---|---|---|---|---|---|

| 1 | Presplit hole | 120 | 10.8~14.6 | 1.3 | 32 | 12 | 12 | 9792 |

| 2 | Buffer hole | 120 | 4.7~7.8 | 2.5 | 90 | 16~32 | 586 | |

| 3 | Main explosion hole | 120 | 3.2~15.5 | 5 | 90 | 52~68 | 858 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, Y.; Zhang, X.; Fan, Z.; Hu, F.; He, J.; Zhao, J. Study on the Influence of Delay Time on the Propagation Law of Adjacent Blast Hole Cracks. Buildings 2025, 15, 2030. https://doi.org/10.3390/buildings15122030

Wang Y, Yang Y, Zhang X, Fan Z, Hu F, He J, Zhao J. Study on the Influence of Delay Time on the Propagation Law of Adjacent Blast Hole Cracks. Buildings. 2025; 15(12):2030. https://doi.org/10.3390/buildings15122030

Chicago/Turabian StyleWang, Yu, Yang Yang, Xiang Zhang, Ziyi Fan, Fangqiang Hu, Jianqiang He, and Jianbin Zhao. 2025. "Study on the Influence of Delay Time on the Propagation Law of Adjacent Blast Hole Cracks" Buildings 15, no. 12: 2030. https://doi.org/10.3390/buildings15122030

APA StyleWang, Y., Yang, Y., Zhang, X., Fan, Z., Hu, F., He, J., & Zhao, J. (2025). Study on the Influence of Delay Time on the Propagation Law of Adjacent Blast Hole Cracks. Buildings, 15(12), 2030. https://doi.org/10.3390/buildings15122030