Abstract

This study evaluates the effectiveness of rigid node connection prototypes for joining bamboo, in response to the growing need for sustainable construction solutions. Considering the superior mechanical properties of bamboo, including its flexibility and strength, the research focuses on the design and testing of nine connection prototypes subjected to compression, shear, and tensile tests in a laboratory. The results obtained demonstrate that the prototypes significantly exceed the established minimum strength criteria, with average maximum loads of 62.19 kN in compression tests, 10.16 kN in shear tests, and 25.41 kN in tensile adhesion tests. These findings not only confirm the viability of bamboo as a sustainable construction material but also highlight the need to develop efficient connection methods that integrate bamboo’s flexibility with the strength of other materials. Through these connections, bamboo presents itself as a solid alternative to address housing deficits and promote responsible construction practices. The research suggests continuing additional studies to strengthen knowledge about bamboo’s behavior in different construction contexts, thereby contributing to a more sustainable future in building.

1. Introduction

In the search for solutions for sustainable construction, interest in alternative materials has increased, with bamboo standing out for its exceptional mechanical properties, durability, adaptability, rapid growth, and low environmental impact, giving it a huge potential for use in sustainable structures; one of the main challenges for its effective application is the design of connection systems that ensure the structural stability and durability of the structural system [1]. Recent studies highlight various bamboo connection techniques, including metal connectors, lashing systems, and adhesive methods, each presenting specific advantages and limitations in terms of ease of installation, strength, and cost [2]. A solution to this scenario is the design of a dodecahedral experimental prototype, with the purpose of improving the stability and rigidity of bamboo connections.

The dodecahedron is a geometric figure formed by twelve organic faces, that is, it distributes the load resistance in its own way, and laterally, it optimizes the structural connections of bamboo. This design can be aligned with bioconstruction, as it maximizes structural efficiency and minimizes wasted material [3] but, on the other hand, it has forced us to innovate by challenging the recognized traditional construction systems, and the real-scale load conditions would be crucial to evaluate its mechanical behavior. This research also goes beyond technical needs: by studying a rigid bamboo connection, we address engineering challenges and delve into new possibilities for creative structural design, thus contributing to more sustainable architectural projects [4].

Bamboo has long been a fundamental construction material across Asia, particularly in tropical and subtropical regions, owing to its rapid growth rate and remarkable mechanical properties. However, its adoption in temperate climates remains limited, where steel and concrete continue to dominate construction markets [5]. Despite its established use in non-conventional structures, integrating bamboo into contemporary building methods requires standardized approaches [6]. Recent studies have quantified its structural performance under compressive, tensile, and shear stresses, demonstrating its suitability for multi-story buildings [7]. Notable examples include pilot projects in the Philippines that have successfully combined bamboo with modern construction systems in social housing programs [8]. Yet significant barriers persist: the persistent cultural perception of bamboo as a makeshift material, coupled with a lack of specialized technical training [9].

The fibrous-segmented morphology of bamboo substantially determines its mechanical properties. Specialized research has established direct correlations between its structural anisotropy—particularly cross-sectional variations and moisture content—and load-bearing capacity [10]. This phenomenon gains practical relevance in contexts like Peru, where high-strength species like Guadua angustifolia have been traditionally used in local building systems [11]. A significant advancement comes from laminated bamboo lumber (LBL), a composite material that has gained international recognition for its exceptional strength-to-weight ratio and low environmental impact [12]. These characteristics position bamboo as a viable alternative to conventional materials in structural engineering.

Various cultures, due to its availability, strength, and flexibility, face challenges in integrating bamboo into modern construction systems, especially in the connections and joints between components. They have traditionally used bamboo, and the joints it presents are fundamental to ensuring structural stability and durability, particularly in low-cost housing projects, where bamboo is presented as a viable alternative due to its accessibility and sustainability [13,14]. However, the lack of standardized joining techniques and the high maintenance requirements have limited its adoption in large-scale construction projects [15,16].

In this context, an experimental evaluation of a new rigid connection prototype for bamboo structures emerges as a promising technical alternative, aiming to optimize good structural performance while minimizing construction and maintenance costs, which is very necessary in areas with vulnerable populations; this is why our research focuses on the mechanical characterization of these prototypes through standardized tests of axial compression, shear resistance, and tensile capacity, thus generating scientific evidence for their implementation in real applications.

The study of bamboo as a structural material takes on strategic relevance in light of the urgent global sustainability challenges facing the construction industry. The sector grapples with critical issues, including: (1) dependence on non-renewable materials (aggregates, concrete, and steel), which account for 9% of global CO₂ emissions [6]; and (2) the growing scarcity of timber due to unsustainable forestry practices. In this context, bamboo emerges as an optimal technical–environmental solution, distinguished by its rapid growth cycle, negative carbon footprint, and competitive mechanical properties [7].

This study addresses a critical gap in materials engineering: the lack of standardized connection systems for bamboo structures that balance structural efficiency and sustainability. While conventional solutions exist (metal connectors, flexible systems), they exhibit fundamental deficiencies in nodal rigidity, accelerated weather-induced degradation, and suboptimal seismic performance [12]. The proposed innovation—a dodecahedral system—aims to overcome these limitations through: (1) geometric optimization of load distribution, (2) reduction of critical stress points, and (3) minimization of maintenance requirements. This advancement would enable the implementation of high-performance lightweight structures, particularly valuable in regions with limited access to industrial building materials [10].

Bamboo exhibits exceptional mechanical properties, particularly its strength-to-weight ratio and natural ductility under dynamic loads [17,18]. However, its mechanical behavior shows significant variability depending on: (i) bamboo species, (ii) physiological maturity (3–5 years), and (iii) post-harvest treatments [19,20]. Reinforcement strategies like cement mortar filling have demonstrated up to 300% increases in axial compression strength, expanding its applicability to load-bearing elements [14]. Complementarily, numerical models based on orthotropic beam theory can predict ultimate load capacity with ±15% accuracy, enabling safer designs [21].

Bamboo connection represents an active area of research due to its impact on structural integrity and the care of vulnerable populations in a variety of tropical countries. Traditional bamboo connection methods, such as rope ties or nailed joints, have proven insufficient under high-load scenarios, prompting the development of more robust solutions, such as rigid nodal connections [22,23]. These advanced connections incorporate reinforcing materials, such as steel or resins, to improve the strength and stiffness of the joints. However, their implementation requires analyzing mechanical properties, as the interaction between bamboo and reinforcing materials can significantly influence structural behavior [24].

Bamboo-derived materials—including laminated and fiber-reinforced composites—are emerging as eco-friendly alternatives to traditional construction materials. These composites enhance bamboo’s natural advantages with synthetic improvements, such as greater moisture and fire resistance [25,26]. Recent studies show they can match the strength of steel and concrete, making them suitable for buildings and bridges [27]. However, widespread adoption still faces one major hurdle: the lack of specific design and usage standards [28].

Experimental research on rigid nodal connections in bamboo structures represents a particularly promising field. Laboratory testing allows analysis of their mechanical response under various loads—a crucial step for optimizing performance [13]. This is complemented by digital tools like numerical modeling and finite element simulations, which help predict behavior before practical implementation [19]. These advancements have overcome many limitations of traditional connections, paving the way for more durable and efficient solutions. Bamboo is emerging as a promising alternative to conventional materials, particularly reinforcement steel, due to its rapid renewability, low environmental impact, and excellent mechanical properties. However, despite its benefits, there is limited literature on bamboo as a structural reinforcement material. Its potential can even be explored in bamboo-reinforced concrete (BRC) beams, assessing how its implementation could significantly enhance load-bearing capacity and flexural strength [28].

The primary objective of this research was to evaluate the compressive strength, shear resistance, and tensile adhesion in rigid bamboo joints through the design and testing of experimental prototypes [29]. Computer-aided design (CAD) software version 2026 was employed to model the prototypes in compliance with technical standards including ASTM D143 [30], ASCE 7-16 [31], and E-100 [32]. Laboratory testing determined the joints’ mechanical properties, while statistical analysis compared results across different configurations [33]. The study also aimed to develop cost-effective, robust connection solutions for bamboo structures—particularly challenging due to the material’s anisotropic and hollow nature, which complicates efficient joint design [34].

The objectives of this research adhered to the SMART criteria: they were specific (optimizing rigid bamboo connections), measurable (through the quantification of mechanical properties), achievable (using available technologies), relevant (addressing the demand for sustainable construction solutions), and time-bound (executed within a defined period) [35]. These were further broken down into subobjectives, such as designing prototypes using CAD software, which allowed for the development of virtual models and analysis of the structural feasibility of the dodecahedral system. Additionally, experimental tests were conducted following ASTM D143 [30], ASCE 7-16 [31], and E-100 [32] standards to determine the mechanical properties of rigid bamboo joints with precision [9]. Statistical analyses were performed to compare prototypes, identifying the most efficient design in terms of strength and durability. Lastly, recommendations were proposed to standardize connection methods in bamboo structures, laying the foundation for predictive frameworks and technical regulations.

This research aimed to overcome the technical limitations hindering a broader use of bamboo in construction [36]. We started with the hypothesis that a dodecahedral design could significantly enhance the stiffness and stability of joints in bamboo structures, increasing their capacity to withstand both vertical and lateral loads. This proposal is based on the principle that symmetrical geometric shapes, such as the dodecahedron, distribute stresses evenly, reducing critical points of failure [37] and optimizing joint efficiency by minimizing material waste and improving energy dissipation during seismic events [38].

The central hypothesis posited that the dodecahedral prototype would outperform conventional methods in joint strength and stability by distributing loads uniformly and reducing critical stress points. It was further proposed that the system would surpass traditional approaches (metal connectors or lashing systems) in compressive, shear, and tensile strength [11], while minimizing brittle failure modes and enhancing both ductility and energy dissipation during seismic events [29]. These hypotheses, validated through empirical testing and statistical analysis, established a foundation for developing standardized connection systems—advancing bamboo’s adoption in sustainable construction [33].

To test the hypothesis, the mechanical properties of the dodecahedral prototypes were compared with other configurations through experimental tests and statistical analyses [39]. The results confirmed not only the feasibility of the design but also its potential for integrating bamboo into modern construction [40]. These developments could revolutionize housing design in vulnerable regions, offering more sustainable and accessible solutions.

The research addresses a specific need: to develop efficient rigid connections for bamboo structures, a sustainable and economical material whose use in construction is limited by the lack of reliable joint systems. To tackle this challenge, the study proposes an innovative solution combining metal polyhedrons with mortar, achieving better load distribution and greater structural strength. In addition to its technical contributions, this work fills a regulatory gap by suggesting standards for bamboo connections, promotes sustainable alternatives for safe and affordable housing, generates social impact by directly benefiting vulnerable communities, and reduces environmental impact compared to conventional materials.

2. Materials and Methods

2.1. Materials

Material selection is critical in bamboo construction. For this study, we used naturally harvested green bamboo of the Guadua angustifolia species [41], which was air-dried at ambient temperature before testing. Green bamboo is preferred for its flexibility and tensile strength [42]. In contrast, while drier bamboo offers greater rigidity, it tends to develop cracks that may compromise structural integrity [10]. For filling the bamboo internodes at the threaded bolt locations, we employed pre-mixed Rapimix mortar from Pacasmayo [43], and this mortar meets all specifications outlined in NTP 399.610 [44] and ASTM C270 [45]. The mortar uses Type I cement with aggregates conforming to ASTM C33 [46]/NTP 400.037 [47], with gradation and proportioning per ASTM C144 [48]/NTP 339.607 [49], and the mix demonstrates a minimum compressive strength of 125 kg/cm2 (NTP 400.011) [50] and minimum bond strength of 0.20 MPa (ASTM C952) [51].

2.2. Experimental Procedure

Three prototypes were fabricated, each containing three models of rigid bamboo nodal connections, totaling nine test specimens as shown in Table 1.

Table 1.

Rigid joint prototype types and models.

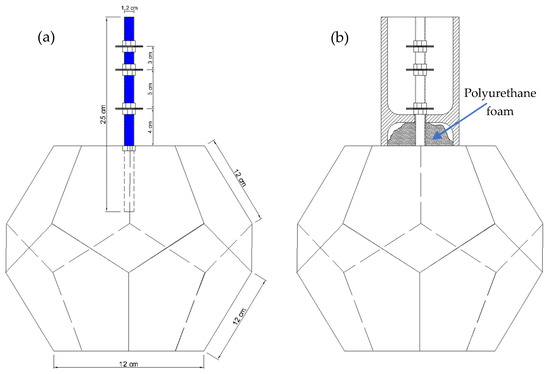

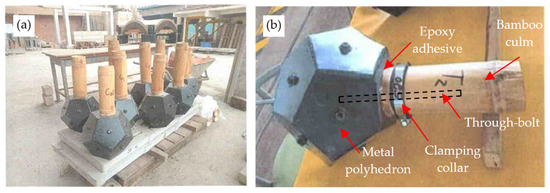

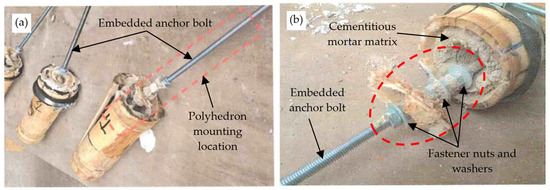

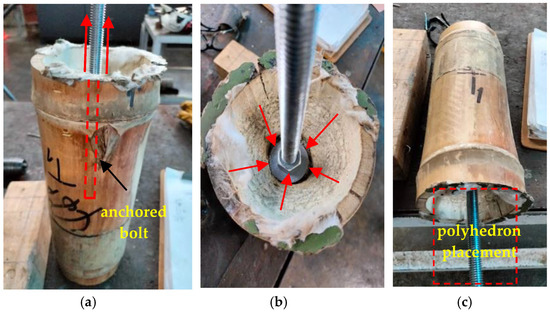

Each specimen was constructed by joining a rigid metal polyhedron (dodecahedron) with an overall diameter of 12 inches to a tubular bamboo segment measuring 4 inches in diameter and 12 inches in length. The connection was made using a threaded 1/2-inch diameter bolt, 60 cm long (Figure 1). This through-bolt was anchored to the polyhedron and secured 15 cm into the bamboo segment. The joint between materials is not fully rigid but rather semi-rigid, with the interface representing the structural weak point. To enhance bond strength and connection durability, Polyurethane foam was applied to the bamboo’s circular end crown. The bolt assembly was modified to include a 1½″ washer-and-nut system, using six nuts and three washers spaced approximately 3 cm apart along the bamboo-embedded section. Additionally, cement mortar was poured into the internodal space to reinforce the connection. Figure 2 and Figure 3 illustrate these construction details.

Figure 1.

(a) Polyhedron, bolt, washers, and nuts schematic with dimensions. (b) Polyurethane foam to prevent the runoff of cementitious material in the mortar.

Figure 2.

(a) Test specimens. (b) Polyhedron and bamboo segment connected by a bolt.

Figure 3.

(a) Mortar-filled bamboo with anchored bolt. The bolt’s free end corresponds to the polyhedron attachment section. (b) Fastener nut and washer placement detail.

Mechanical testing for compression, shear, and tensile bond strength was conducted in the Structures Laboratory at Pontificia Universidad Católica del Perú (PUCP). Table 2 provides the specimen coding system and corresponding test types.

Table 2.

Specimen coding and test types.

2.2.1. Axial Compression Testing

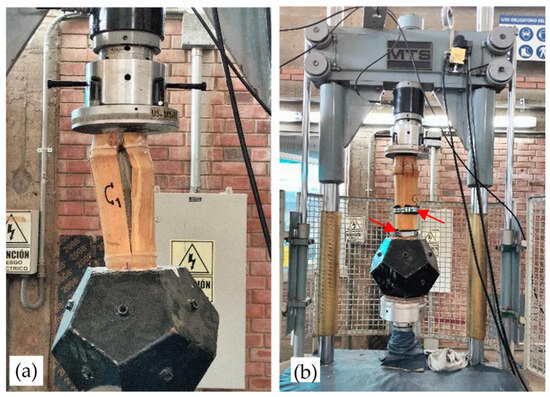

Three specimens were tested for compression. The first specimen (C1) lacked a clamp, while C2 and C3 incorporated clamps positioned near the polyhedron joint, serving as bamboo stem confinement mechanisms. Compression tests were performed using an MTS 312.31 universal testing machine (MTS Systems Corporation, Eden Prairie, MN, USA) with 250 kN capacity and ±100 mm displacement range.

2.2.2. Shear Testing

Shear testing employed precise measurements via an MTS 204.81 structural actuator (MTS Systems Corporation, Eden Prairie, MN, USA) featuring 500 kN capacity and ±150 mm displacement range.

2.2.3. Tensile Bond Testing

Tensile bond tests utilized 500 kN capacity load cells. Displacement measurements employed linear variable differential transformer (LVDT) sensors (MTS Systems Corporation, Eden Prairie, MN, USA) with ±1 mm accuracy. This test method was selected to evaluate the bolt–mortar–bamboo joint’s tensile resistance, addressing the complexity of direct tension testing between dodecahedron and bamboo components.

2.2.4. Mortar Compressive Strength

Concurrently with dodecahedral joint testing, hydraulic cement mortar underwent compressive strength evaluation using 50 mm cubic specimens [52]. These samples represented the binding matrix between anchor bolts and bamboo internodes. Testing employed a Cardinal 204-V compression device (Weaver, AR, USA).

3. Results

3.1. Axial Compression Testing

Three (3) specimens underwent axial compression testing under displacement control at 1 mm/min. Maximum loads and descriptive statistics are presented in Table 3. Results demonstrate that confined specimens (C2 and C3) exhibited superior load-bearing capacity.

Table 3.

Axial compression test results.

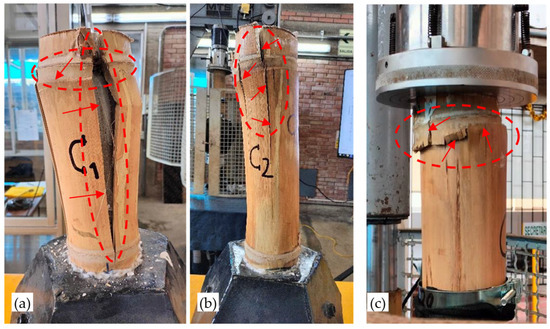

Specimens C2 and C3 incorporated a confinement clamp near the joint node (Figure 4b), unlike specimen C1 (Figure 4a), resulting in increased load capacity. This configuration caused the coefficient of variation to rise. Characteristic failure modes included bamboo circumferential cracking and warping (buckling) at the metal polyhedron’s pentagonal contact face (Figure 5).

Figure 4.

Axial compression testing setup: (a) Unconfined specimen C1, (b) Clamp-reinforced specimens C2 and C3.

Figure 5.

Failure modes showing circumferential cracking and bamboo warping for specimens: (a) C1, (b) C2, and (c) C3.

To determine the corrected normative minimum load (Pmín), we applied the criteria specified in Standard E.100 [32], which establishes a minimum stress of 13 MPa. Using the experimentally determined average cross-sectional area of the bamboo specimens (23.71 cm2), we calculated: Pmín = σmín × A = 13 MPa × 23.71 cm2 × 0.1 = 30.82 kN. The 0.1 factor converts MPa·cm2 to kN, ensuring dimensional consistency. This 30.82 kN value represents the minimum load that must be exceeded to meet structural material requirements. The specimens have been treated as individual cases due to the absence of specific regulations for this type of experimental joint and considering the natural characteristics of bamboo. These initial results serve as a foundation for a second study under more controlled testing conditions. This precise calculation is crucial as it establishes the benchmark for evaluating the material’s true mechanical performance. Bamboo specimens exhibit natural variations in their dimensions due to factors such as species and growth conditions. These differences are reflected in the measured cross-sectional areas of each specimen, which were experimentally determined prior to testing. Although these areas vary slightly, they remain within the range established by standard E.100 (4” to 6”) [32]. To ensure a fair comparison between specimens, normalized stresses were calculated by dividing the measured maximum loads by their respective cross-sectional areas, as indicated in Table 4.

Table 4.

Summary of Normalized Stresses (MPa) by Test Type and Specimen.

Table 5 presents the significance level for each specimen per Equation (1), where represents the maximum load per specimen, is the corrected normative minimum load, and standard deviation (SD) indicates the data variability.

Table 5.

Summary of axial compression tests on bamboo specimens.

Evaluating the significance level for the load and according to standard normal distribution tables [53] and computational verification using tools like SciPy [54], Se siguió la ASTM E122-17 [55] para validación con pequeñas muestras, calculando SD y CV solo para configuraciones idénticas (C2 and -C3). The remaining 1.64% represents the minimal risk associated with natural data variability where the average might not meet the required limit. In this context, we have specifically calculated the SD (10.07 kN) and CV (14.46%) only for the identical configurations (C2 and C3), excluding C1 due to its fundamental structural differences (absence of a clamp). This approach helps minimize bias and ensures fair comparisons within the same experimental group. This high confidence level validates the results and confirms the material’s suitability for structural applications.

These results strongly support bamboo’s viability as a construction material, demonstrating not just compliance but performance exceeding minimum required standards.

3.2. Shear Testing Evaluation

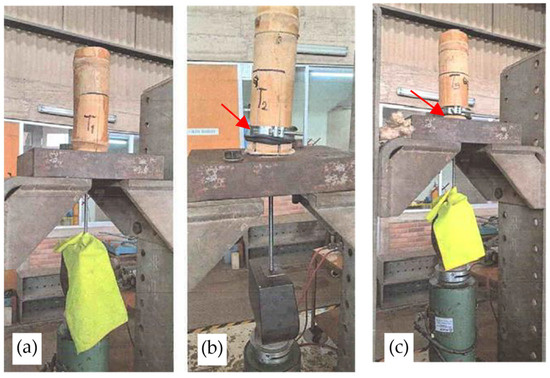

Shear tests were conducted on three (3) specimens using a specially configured testing apparatus designed to generate the required shear effect (Figure 6). The shear tests were load-controlled at a rate of 1 kN/min. Measured values and descriptive statistics are presented in Table 6.

Figure 6.

Shear testing. Machine setup and test configuration.

Table 6.

Shear test results.

The average maximum load reached 10.16 kN—significantly exceeding the established minimum threshold of 0.1016 kN (1 MPa) per the NTP E.100 standard [32].

For the minimum threshold analysis, we established a regulatory stress limit of 1 MPa. Using the actual average cross-sectional area of 10.16 cm2, we obtained a corrected minimum regulatory load of 1.016 kN. These results demonstrate remarkable reliability, significantly exceeding the minimum required load. The extreme statistical significance confirms that the materials meet regulatory standards and are suitable for structural applications. This high level of confidence validates both the material’s performance characteristics and its potential implementation in construction projects requiring minimum normative strength. Table 7 presents the detailed results of each specimen’s performance in these tests.

Table 7.

Summary of shear test results on bamboo specimens.

At peak shear load, failure occurred through slippage between the bamboo segment and the metal polyhedron’s pentagonal contact face. While Cor1 exhibited minor slippage, Cor2 showed more pronounced movement (Figure 7), suggesting the joint interface requires optimization for improved shear resistance. This behavior indicates the current interface design’s limitations in withstanding shear stress. Notably, the bamboo itself remained intact—displaying no cracking or shear failure.

Figure 7.

Shear testing. Specimens: (a,b) Cor1, (c) Cor2, and (d) Cor3.

3.3. Tensile Bond Evaluation

Tensile bond tests were conducted on three (3) specimens under displacement control at 1 kN/min. These tests specifically evaluated bolt adhesion within the bamboo. The controlled displacement rate yielded the results shown in Table 8, demonstrating exceptionally favorable connection performance. The data highlights both the adhesive system’s effectiveness and the bolt’s reliable performance under dynamic loading conditions. The effective stresses were evaluated by dividing the recorded maximum loads by the measured cross-sectional area of each specimen. The obtained values confirmed that, even with small differences in cross-sectional areas, all specimens far exceeded the minimum regulatory requirements.

Table 8.

Tensile bond test results.

Based on previous tests, we established a regulatory limit of 16.44 kN (16 MPa) according to standard E.100 [32], based on the anchoring strength of a washer with an outer diameter of 1½″ (12 mm inner diameter) and a net cross-sectional area of 10.273 cm2. The results meet the requirements and demonstrate exceptional structural performance, as indicated in Table 9.

Table 9.

Summary of Tensile bond test results on bamboo specimens.

Specimens AT2 and AT3 were tested with a confinement clamp (Figure 8).

Figure 8.

Tensile bond testing. Specimens: (a) AT1, (b) AT2, and (c) AT3.

The average strength of 25.41 kN exceeds the 20 kN minimum requirement by a significant margin. These results demonstrate outstanding bond performance, indicating both high-quality bolt characteristics and effective mortar adhesion within the bamboo internodes—fully compliant with the E.100 standard [32] requirements (Figure 9). Although current findings are highly satisfactory, we recommend additional verification under real-world service conditions to further validate performance.

Figure 9.

Bolt adhesion. (a) Bolt secured within bamboo, (b) Fixed washer and nut, (c) Undamaged bamboo.

The adhesion observed between bamboo and mortar can be explained by the distribution of stresses at the interface, as illustrated in Figure 1b and Figure 9. These diagrams show how tensile forces generate an effective load transfer through the mortar, minimizing significant slippage and ensuring a robust connection.

3.4. Mortar Testing

The dodecahedral joint experimental testing required complementary mortar evaluation. The hydraulic cement mortar, poured between bamboo internodes, was tested for compressive strength using nine 50 mm cubic specimens [56]. These samples represented the binding matrix between anchor bolts and bamboo cell walls, with results detailed in Table 10. The mortar consistently met all normative parameters, demonstrating reliable performance as a reinforcement material for bamboo joints.

Table 10.

The 28-day mortar compressive strength test results.

To determine the significance level of the results being satisfactory for a minimum strength of 175 kg/cm2, the mean and standard deviation of the compressive strength were used in Equation (1). A value of 0.0006 (0.06%) was obtained. This means that approximately 0.06% of the compressive strength results fall below the minimum strength of 175 kg/cm2, indicating a 99.94% significance level that the results meet the required minimum strength. This suggests that nearly all compressive strength results are satisfactory and exceed the minimum requirement.

Finally, all calculated parameters from the three tests on the bamboo specimens are summarized in Table 11.

Table 11.

Summary of results from the three tests conducted.

The results indicate that the average maximum compressive load was 62.19 kN, well above the minimum required limit of 4.1879 kN (13 MPa), confirming compliance with the specifications outlined in NTP E.100 [32]. For the shear tests, the average peak load reached 10.16 kN, significantly exceeding the minimum threshold of 0.1016 kN (1 MPa), which also confirms adherence to the NTP E.100 [32] standards. This test yielded a coefficient of variation (CV) of 8%, indicating acceptable consistency in the results. Meanwhile, the tensile bond tests recorded an average maximum load of 25.41 kN, meeting the minimum requirement of 5.1091 kN (16 MPa) per NTP E.100 [32]. Additionally, this test showed a low CV of just 5%, reflecting high result reliability.

The results obtained in this study show significantly higher stress levels compared to previous research using simple joint configurations, such as those based solely on bolts or resins. For example, Malkowska et al. [4] reported maximum stresses of approximately 12–14 MPa in bolted connections, while Huang et al. [13] achieved values of 18–20 MPa using epoxy resins. Our rigid dodecahedral node design, combined with mortar as a filler material, achieved maximum stress levels of 24.72 MPa, 25.89 MPa, and 23.58 MPa, clearly exceeding minimum standards and offering a more cost-effective and sustainable solution.

This research represents an initial exploratory study on the bamboo–dodecahedral joint configuration, considering individual cases with specific variations due to structural and material differences. The three tested specimens have been treated as independent cases, acknowledging the limitations associated with bamboo’s natural heterogeneity and differences in specimen preparation and testing. These initial findings serve as a foundation for future more controlled studies that will establish repeatability and strengthen the conclusions.

4. Discussion

The interpretation of results from this study highlights the significance of sustainable construction solutions and emphasizes the importance of research to optimize bamboo’s use in contemporary architecture. The findings demonstrate the effectiveness of bamboo–metal connections, particularly how their composite system connectivity provides a new framework for structural analysis under seismic and load conditions [1,6]. By combining bamboo’s strength and adaptability with semi-complex joint designs, this approach opens new possibilities for sustainable engineering [36].

The results indicate that the rigid nodal bamboo connection prototypes meet established minimum strength criteria, confirming our initial hypothesis about this connection type’s effectiveness. During testing, compression specimens achieved an average peak load of 62.19 Kn—substantially exceeding the 4.1879 kN (13 MPa) minimum threshold [39]. The confined specimens (C2 and C3) demonstrated superior performance with an average load capacity of 62.19 kN compared to just 47.35 kN for the unconfined specimen (C1). This significantly surpasses the 4.1879 kN (13 MPa) minimum requirement per NTP E.100 standards. The strength increase confirms that confinement enhances structural capacity by restricting circumferential cracking and reducing localized buckling [57]. However, the 24% coefficient of variation suggests some specimen variability, potentially due to bamboo density differences or metal polyhedron contact quality. Shear testing specimens showed excellent performance with an average peak load of 10.16 kN, far exceeding the 1.016 kN (1 MPa) minimum. However, observed bamboo–polyhedron interface slippage indicates room for improvement in shear resistance through enhanced surface treatments or advanced adhesives to optimize joint performance [58]. Tensile bond tests proved particularly robust, with an average maximum load of 25.41 kN surpassing the 5.1091 kN (16 MPa) requirement [57,58]. These findings align with previous studies emphasizing the critical role of mechanical interaction between bamboo and metal components in creating durable, rigid connections [59,60]

The findings of this study align with previous research examining bamboo’s strength as a construction material, particularly in applications requiring flexibility and tensile resistance. Multiple studies have demonstrated that, despite certain limitations, bamboo possesses mechanical properties comparable to traditional materials like wood and steel [4,5,58]. However, our research reveals notable variations in joint effectiveness, contrasting with other studies that reported more consistent performance in bamboo–metal connections [3,9]. The observed variability in tensile bond strength suggests that, while theory supports these joints’ efficacy, practical implementation may face challenges affecting structural consistency [10,12]. These discrepancies could stem from prototype fabrication differences or variations in testing environments documented in the literature [5,6,7,8].

Tensile bond testing of three bamboo–metal nodal specimens yielded an average peak load of 25.41 kN with a 5% coefficient of variation (CV), demonstrating result consistency. These values significantly exceed established minimum thresholds for similar connections, validating our initial hypothesis about rigid bamboo–metal joints’ effectiveness [1]. Previous research confirms bamboo’s mechanical properties rival traditional materials, particularly in tensile strength and flexibility [2]. However, the variability observed in our study may relate to factors like bamboo density, moisture content, or fabrication methods [3].

Theoretically, these findings support developing more accurate predictive models for structural behavior under dynamic loads, such as those during seismic events [4]. They also highlight the need for research into surface treatments to enhance joint durability and adhesion [5]. Practically, the tested connections offer a cost-effective, sustainable solution for seismic regions where structural resilience and affordability are paramount [6].

This study carries significant theoretical and practical implications for sustainable construction. Practically, the results suggest rigid connections could viably enhance structural integrity in bamboo buildings, particularly in cost-sensitive contexts [11,38]. Theoretically, they provide a foundation for developing precise predictive models of bamboo joint behavior under various conditions [40]. These advances could inform new design codes recognizing bamboo as a priority construction material in building standards [2,29].

Building on these findings and identified limitations, we recommend pursuing additional research with expanded sample sizes tested under both controlled and varied conditions. A longitudinal approach assessing joint performance over time across different environments would provide critical data to validate bamboo connection efficacy [34,37]. Further investigation should examine how surface treatments and bamboo moisture variations impact the mechanical properties of these joints. Finally, developing construction methods that integrate connection designs with enhanced durability and fire resistance could significantly advance bamboo’s acceptance as a viable structural material in modern building practices [61,62].

5. Conclusions

The confined specimens (C2 and C3) demonstrated significantly higher load-bearing capacity, averaging 62.19 kN, compared to the unconfined specimen (C1) which reached a maximum load of 47.35 kN. These values substantially exceed the 4.1879 kN (13 MPa) minimum threshold established by NTP E.100 standards, confirming confinement as an effective strategy for enhancing bamboo’s structural strength, particularly under high axial loads.

Observations revealed characteristic failure modes including circumferential cracking and warping at the bamboo–polyhedron interface, highlighting the need to optimize this critical region for maximum structural performance.

In shear testing, specimens achieved an average peak load of 10.16 kN—well above the 1.016 kN (1 MPa) regulatory minimum. Despite these positive results, interface slippage between bamboo and metal polyhedron was observed, suggesting the need for improved adhesion. Future research should explore surface treatments or alternative geometric designs to mitigate this issue and ensure optimal shear resistance.

Tensile bond tests produced an average maximum load of 25.41 kN, surpassing the 5.1091 kN (16 MPa) requirement. The low coefficient of variation (CV = 5%) indicates high specimen consistency, validating both the adhesion system’s effectiveness and the metal bolt’s strength. These results demonstrate the potential of bamboo–metal joints for structural applications where bond strength is critical.

Compressive strength tests of mortar yielded an average of 202.33 kg/cm2, exceeding the 175 kg/cm2 regulatory minimum. This finding supports mortar as a reliable material for reinforcing bamboo joints, contributing to their long-term stability and durability.

Collectively, results from all three test types (axial compression, shear, and tensile bond) satisfactorily met standards established by NTP E.100 and international regulations. This evidence confirms that bamboo, when properly combined with metal elements and confinement techniques, represents a viable and competitive structural material. However, optimizing joint interfaces through advanced surface treatments, mechanical design improvements, or enhanced adhesives remains crucial for ensuring optimal and sustainable structural performance.

6. Patents

Title of the Invention: Enhanced Joint for Rigid Metallic Nodes in Bamboo Elements Using a Dodecahedron. This invention introduces a novel joint system based on a dodecahedron, incorporating four stainless steel through-bolts with diameters ranging from 1/4″ to 5/8″. These bolts are strategically positioned through the lateral faces of the polyhedron, with their heads on the exterior and a nut inside to ensure a secure fit and robust anchoring. This configuration not only enhances the structural integrity of the dodecahedron but also streamlines the connection between bamboo components, optimizing the beam–column joint by minimizing the number of elements and overlaps required. The dodecahedron features rotational symmetry of 72 degrees and can be unfolded into a flat network, representing a significant advancement in bamboo construction systems and the efficient creation of physical models. A patent application for this invention is currently under review and has not yet been granted. The invention was developed by the principal author, with rights to be defined as per the terms agreed upon in the research contract. The information provided herein remains confidential and is subject to protection until the patent is officially granted.

Author Contributions

Conceptualization: G.D.-G.; methodology: M.F.-C.; writing (original): G.D.-G. and M.F.-C.; writing (review and editing): G.D.-G. and M.F.-C.; funding acquisition: G.D.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CESAR VALLEJO UNIVERSITY—OFFICE OF THE VICE RECTOR FOR RESEARCH—RESEARCH SUPPORT FUND, grant number RVI N° 186-2023-VI-UCV. The APC was funded by CESAR VALLEJO UNIVERSITY with funding code P-2023-116).

Data Availability Statement

Data available on request due to privacy restrictions. The data presented in this study are available on request from the corresponding author.

Acknowledgments

This research was funded by Universidad César Vallejo (UCV—Office of the Vice Rector for Research—Research Support Fund), RVI N° 186-2023-VI-UCV.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aniñon, M.J.C.; Garciano, L.E.O. Advances in Connection Techniques for Raw Bamboo Structures—A Review. Buildings 2024, 14, 1126. [Google Scholar] [CrossRef]

- Pradhan, N.P.N.; Paraskeva, T.S.; Dimitrakopoulos, E.G. Simulation and experimental verification of an original full-scale bamboo truss. Eng. Struct. 2022, 256, 113965. [Google Scholar] [CrossRef]

- Michiels, T.; Lu, L.; Archer, R.; Adriaenssens, S.; Tresserra, G. Design of Three Hypar Roofs Made of Guadua Bamboo. J. IASS 2017, 58, 95–104. [Google Scholar] [CrossRef]

- Malkowska, D.; Norman, J.; Trujillo, D. Theoretical and experimental study on laterally loaded nailed bamboo connection. Constr. Build. Mater. 2022, 342, 127971. [Google Scholar] [CrossRef]

- Dey, D. Bamboo as a Building Material. IJRASET 2024, 12, 17–24. [Google Scholar] [CrossRef]

- Jaramillo Hurtado, J.L. Uniones estructurales de bambú: Criterios de su desempeño a partir de ensayos. MQRInvestigar 2023, 7, 381–396. [Google Scholar] [CrossRef]

- Mercedes, J.R. Guía Técnica Cultivo del Bambú. 2006. Available online: https://www.academia.edu/9592074/Gu%C3%ADa_T%C3%A9cnica_Cultivo_del_Bamb%C3%BA (accessed on 1 February 2025).

- Zea Escamilla, E.; Habert, G.; Wohlmuth, E. When CO2 Counts: Sustainability Assessment of Industrialized Bamboo as an Alternative for Social Housing Programs in the Philippines. Build. Environ. 2016, 103, 44–53. [Google Scholar] [CrossRef]

- Jain, M.K.; Rizwani, M.F. A Review on Medicinal Bamboo: An Ancient Source Towards Healthy Lifestyle. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 569–572. [Google Scholar] [CrossRef]

- Mayor, G.T.; Gutiérrez, G.O.; Arellano, J.F.N.; Enríquez, J.J.S.; Peña, J.R.M. Análisis de la normatividad de construcción con bambú en Latinoamérica. Rev. Arquit. Y Urban. Taypi 2024, 3, 10–18. [Google Scholar]

- Sánchez, M.T.; Espuna, J.A.; Roux, R.S. El bambú como elemento estructural: La especie Guadua amplexifolia. Nova Sci. 2016, 8, 657–677. [Google Scholar] [CrossRef]

- Jacobs, J.M.; von May, R.; Kavanaugh, D.H.; Connor, E.F. Beetles in bamboo forests: Community structure in a heterogeneous landscape of southwestern Amazonia. PeerJ 2018, 6, e5153. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Liu, X.; Long, Y.; Li, W.; Wu, R. An Investigation into the Variables Influencing the Structural Bamboo Architecture Using Filled Concrete and Cement Mortar. Buildings 2024, 14, 2029. [Google Scholar] [CrossRef]

- Rashid, Z.; Chinnasamy, G. Numerical Modelling of Structural Bamboo Under Compression. Proc. Int. Struct. Eng. Constr. 2024, 11, SUS-06. [Google Scholar] [CrossRef]

- Bala, A.; Gupta, S. Engineered bamboo and bamboo-reinforced concrete elements as sustainable building materials: A review. Constr. Build. Mater. 2023, 394, 132116. [Google Scholar] [CrossRef]

- Himasree, P.R.; Korde, C.; West, R.P.; Ganesan, N. State of the art review of bamboo-reinforced concrete structural elements. Mag. Concr. Res. 2024, 76, 55–68. [Google Scholar] [CrossRef]

- Ba, Z.; Luo, H.; Cui, J.; Guo, Z. Mechanically robust and environmentally stable Al2O3/KH550 densified bamboo structural materials. Ind. Crops Prod. 2024, 211, 118201. [Google Scholar] [CrossRef]

- Dai, F.; Chen, Y.; Zhang, W.; Zhong, T.; Tian, G.; Wang, H. Analyzing the structure of bamboo culms using computer vision and mechanical simulation. Holzforschung 2024, 78, 62–71. [Google Scholar] [CrossRef]

- Sharma, B.; Bauer, H.; Schickhofer, G.; Ramage, M.H. Mechanical characterisation of structural laminated bamboo. Proc. Inst. Civ. Eng. Struct. Build. 2017, 170, 250–264. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Shang, L.; Ma, X.; Fang, C.; Fei, B.; Liu, H.; Zhang, S. Three-dimensional structural characterization and mechanical properties of bamboo parenchyma tissue. Ind. Crops Prod. 2024, 208, 117833. [Google Scholar] [CrossRef]

- Altieri, D.; Molari, L. Bamboo Scaffolding as a European Promising Opportunity: A Structural Feasibility Study. Sustainability 2024, 16, 915. [Google Scholar] [CrossRef]

- Rittironk, S. Design-built bamboo structure using multiple-member pre-fabricated connectors. Proc. Int. Struct. Eng. Constr. 2023, 10, AAE-01. [Google Scholar] [CrossRef]

- Carbonari, G.; Carbonari, L.T. Bamboo Structural Systems. In Bamboo and Sustainable Construction; Palombini, F.L., Nogueira, F.M., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer Nature: Singapore, 2023; pp. 61–97. [Google Scholar] [CrossRef]

- Han, S.; Chen, F.; Ye, H.; Zheng, Z.; Chen, L.; Wang, G. Bamboo-Inspired Renewable, High-Strength, Vibration-Damping Composites for Structural Applications. ACS Sustain. Chem. Eng. 2023, 11, 1146–1156. [Google Scholar] [CrossRef]

- Kelkar, B.U.; Shukla, S.R.; Nagraik, P.; Paul, B.N. Structural bamboo composites: A review of processing, factors affecting properties and recent advances. Adv. Bamboo Sci. 2023, 3, 100026. [Google Scholar] [CrossRef]

- Amede, E.A.; Hailemariama, E.K.; Hailemariam, L.M.; Nuramo, D.A. A Review of Codes and Standards for Bamboo Structural Design. Adv. Mater. Sci. Eng. 2021, 2021, 4788381. [Google Scholar] [CrossRef]

- Kaminski, S.; Lawrence, A.; Trujillo, D.; López, L.F. Structural use of bamboo. Part 4: Element design equations. Struct. Eng. 2017, 95, 24–27. [Google Scholar] [CrossRef]

- Waqas, H.A.; Bahrami, A.; Sahil, M.; Poshad Khan, A.; Ejaz, A.; Shafique, T.; Tariq, Z.; Ahmad, S.; Özkılıç, Y.O. Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction. Materials 2023, 16, 6788. [Google Scholar] [CrossRef]

- Modiano, J.Y.; Wijaya, P.A.D.; Putra, H.A. The Impact of Bamboo Cavities on Thermal Comfort in Building Construction. J. Archit. Hum. Exp. 2024, 2, 39–50. [Google Scholar] [CrossRef]

- ASTM International ASTM D143-22; Standard Test Methods for Small Clear Specimens of Timber. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021. Available online: https://store.astm.org/d0143-22.html (accessed on 8 April 2025).

- ASCE/SEI 7-16; Minimum Design Loads and Associated Criteria for Buildings and Other Structures (7-16). American Society of Civil Engineers: Reston, VA, USA, 2017. Available online: https://sp360.asce.org/personifyebusiness/Merchandise/Product-Details/productId/233133882 (accessed on 8 April 2025).

- E.100 Bambú E.100 Bambú DS N° 011-2012. Available online: https://www.gob.pe/institucion/munisantamariadelmar/informes-publicaciones/2619715-e-100-bambu-ds-n-011-2012 (accessed on 8 April 2025).

- Zhang, J.; Tong, K.; Wu, P.; Li, Y. Research Status on Steel-bamboo Composite Structure. MATEC Web Conf. 2019, 275, 01018. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. Development of Laminated Bamboo Lumber: Review of Processing, Performance, and Economical Considerations. J. Mater. Civ. Eng. 2011, 23, 1036–1042. [Google Scholar] [CrossRef]

- Bundi, T.; Lopez, L.F.; Habert, G.; Zea Escamilla, E. Bridging Housing and Climate Needs: Bamboo Construction in the Philippines. Sustainability 2024, 16, 498. [Google Scholar] [CrossRef]

- Torres, B.; Segarra, M.; Bragança, L. El bambú como alternativa de construcción sostenible. Extensionismo Innovación Transf. Tecnológica 2019, 5, 389. [Google Scholar] [CrossRef]

- Umar, M.Z.; Arsyad, M.; Santi, S.; Faslih, A. Principles of sustainable architecture in the production of bamboo woven wall materials (dendrocalamus asper). Sinergi 2020, 24, 57–64. [Google Scholar] [CrossRef]

- Ega, I.J.; Job, O.F. Comparative Study of Materials used for Props and Scaffoldings in Southern Nigeria. Laujoces 2023, 10, 52–61. [Google Scholar] [CrossRef]

- Manandhar, R.; Kim, J.-H.; Kim, J.-T. Environmental, social and economic sustainability of bamboo and bamboo-based construction materials in buildings. J. Asian Archit. Build. Eng. 2019, 18, 49–59. [Google Scholar] [CrossRef]

- Eleftheriou, E.; Lopez Muñoz, L.F.; Habert, G.; Zea Escamilla, E. Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects. Sustainability 2022, 14, 7409. [Google Scholar] [CrossRef]

- Gutiérrez-Collao, J.E.; Acosta-Román, M.; Abanto-Rodríguez, C.; Palomino-Santos, E.R.; Chavarría Márquez, E.Y.; Massa-Palacios, L.A. Propiedades mecánicas de la Guadua angustifolia para uso y preservación medioambiental de la Amazonia peruana. Prod. + Limpia 2025, 19, 66–83. [Google Scholar] [CrossRef]

- Latifah, K.; Siswanto, J.; Supriyadi, B. The Relation Tensile Strength And Flexibility Of Bamboo For Soil Stabilization. JACEE J. Adv. Civ. Environ. Eng. 2021, 4, 11. [Google Scholar] [CrossRef]

- Mortero Rapimix para Asentado de Muros Estructurales. Pacasmayo Profesional. Available online: https://pacasmayoprofesional.com/ (accessed on 8 April 2025).

- INACAL NTP 399.610. Unidades de Albañilería. Especificación Normalizada Para Morteros. 2a Edición. Available online: https://es.scribd.com/document/674751069/NTP-399-610 (accessed on 2 June 2025).

- ASTM Internacional ASTM C270-25; Standard Specification for Mortar for Unit Masonry. American Society of Testing Materials: West Conshohocken, PA, USA, 2025. Available online: https://store.astm.org/c0270-25.html (accessed on 2 June 2025).

- ASTM Internacional ASTM C33 C33M-18; Standard Specification for Concrete Aggregates. American Society of Testing Materials: West Conshohocken, PA, USA, 2023. Available online: https://store.astm.org/c0033_c0033m-18.html (accessed on 17 October 2024).

- INACAL NTP 400.037. AGREGADOS. Agregados Para Concreto. Especificaciones. 5a Edición. Available online: https://es.scribd.com/document/713215674/33406-NTP-400-037-1 (accessed on 3 June 2025).

- ASTM Internacional ASTM C144-24; Standard Specification for Aggregate for Masonry Mortar. ASTM International: West Conshohocken, PA, USA, 2024. Available online: https://store.astm.org/c0144-24.html (accessed on 3 June 2025).

- NACAL NTP 399.607:2018. Unidades de Albañilería. Agregados Para Mortero de Albañilería. Requisitos. 2a Edición. Available online: https://es.slideshare.net/slideshow/ntp-399607-2018/242540241 (accessed on 8 April 2025).

- INACAL NTP 400.011:2020. AGREGADOS. Definición y Clasificación de Agregados Para uso en Morteros y Concretos. Available online: https://www.collegesidekick.com/study-docs/19238144 (accessed on 8 April 2025).

- ASTM Internacional ASTM C952-12; Standard Test Method for Bond Strength of Mortar to Masonry Units (Withdrawn 2018). ASTM International: West Conshohocken, PA, USA, 2018. Available online: https://store.astm.org/c0952-12.html (accessed on 8 April 2025).

- INACAL NTP 334.051:2022. Método de Ensayo—Resistencia a La Compresión. Available online: https://www.scribd.com/document/654388524/NTP-334-051-2022-Metodo-de-ensayo-Resistencia-a-la-compresion (accessed on 17 October 2024).

- Hogg, R.V.; Tanis, E.A.; Zimmerman, D.L. Probability and Statistical Inference; Pearson Education, Inc.: London, UK, 2015. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef]

- ASTM E122-17; Practice for Calculating Sample Size to Estimate, With Specified Precision, The Average for a Characteristic of a Lot or Process. E11 Committee ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- 334.051:2022 INACAL CEMENTOS. Determinación de la Resistencia a la Compresión de Morteros de Cemento Hidráulico usando es-Pecímenes Cúbicos de 50 mm de Lado. Método de Ensayo. 7a Edición. Available online: http://www.inacal.gob.pe/cid/categoria/normas-tecnicas-peruanas (accessed on 8 April 2025).

- Janssen, J.J.A. Designing and Building with Bamboo; en INBAR Technical Report, No. 20; International Network for Bamboo and Rattan: Beijing, China, 2000. [Google Scholar]

- Xiao, Y., Inoue, M., Eds.; Modern bamboo structures. In Proceedings of the First International Conference on Modern Bamboo Structures (ICBS-2007), Changsha, China, 28–30 October 2007; CRC Press/Balkema: Boca Raton, FL, USA, 2008. [Google Scholar]

- Zea, E.; Habert, G.; Correal, J.F.; Archilla, H.F.; Echeverry, J.S.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Bredenoord, J. Bamboo as a Sustainable Building Material for Innovative, Low-Cost Housing Construction. Sustainability 2024, 16, 2347. [Google Scholar] [CrossRef]

- Seixas, M.; Moreira, L.E.; Stoffel, P.; Bina, J.; Ripper, J.L.M.; Ferreira, J.L.; Ghavami, K. Analysis of a self-supporting bamboo structure with flexible joints. Int. J. Space Struct. 2021, 36, 137–151. [Google Scholar] [CrossRef]

- Seixas, M.; Eustáquio Moreira, L.; Bina, J.; Ripper, J. Design and Analysis of a Self-Supporting Bamboo Roof Structure with Flexible Connections. J. Int. Assoc. Shell Spat. Struct. 2019, 60, 221. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).