Structural Vibration Analysis with Reference to Different Standards

Abstract

1. Introduction—Basic Issues Related to Vibration Control

1.1. Codes of Practice and Vibration Assessment Regulations and Recommendations

1.2. Experiences of Vibration Monitoring in the Case of Various Objects and Grounds

1.3. Analysis of Most Harmful Geotechnical Technologies

1.4. Attempts to Numerically Model Ground-Transmitted Vibrations of Various Sources

1.5. Monitoring, Technology Calibration, Vibration Control, and Possible Mitigation of Impact

1.6. Knowledge Gap and the Present Study’s Contribution

2. Vibration Classifications

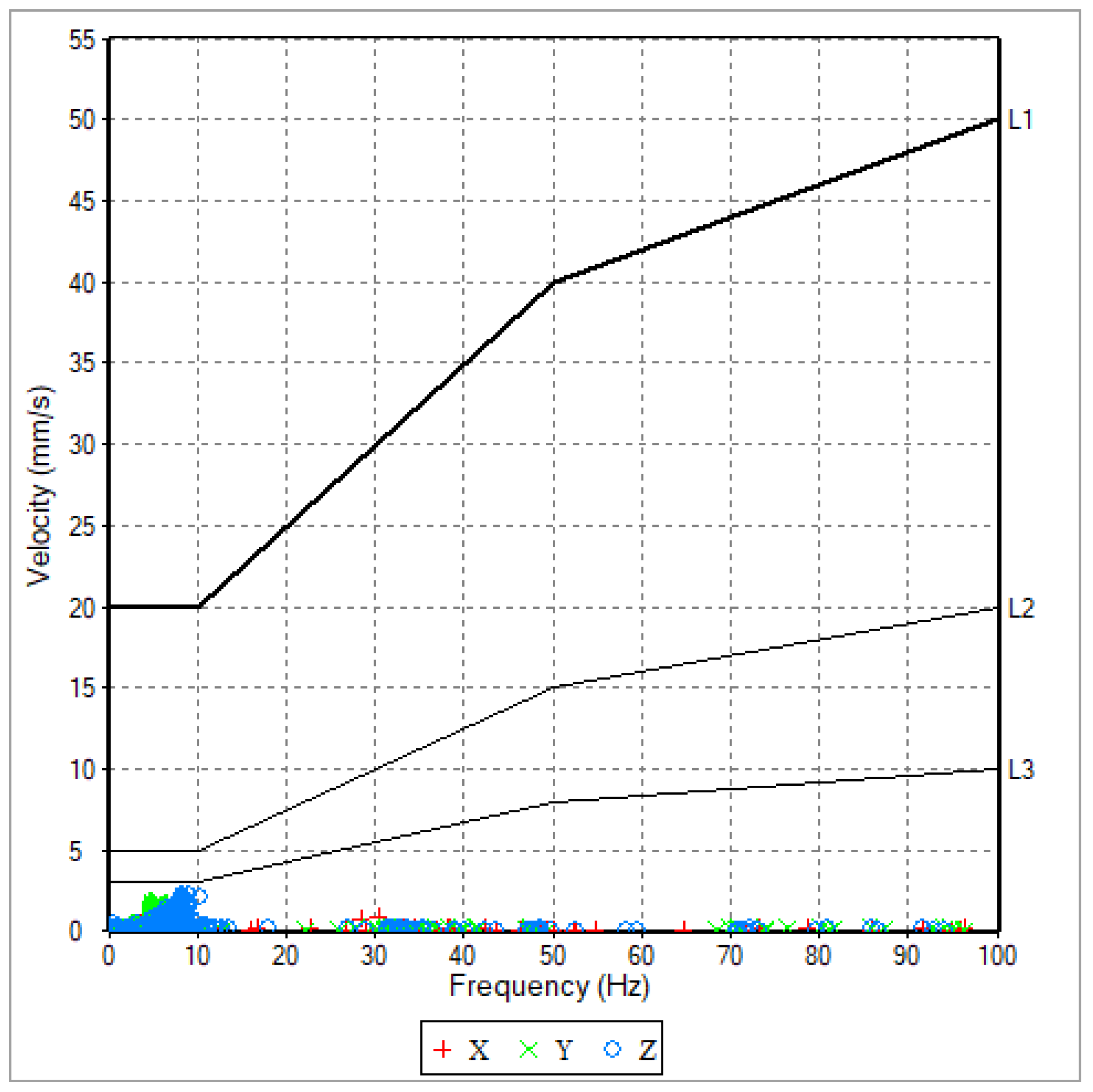

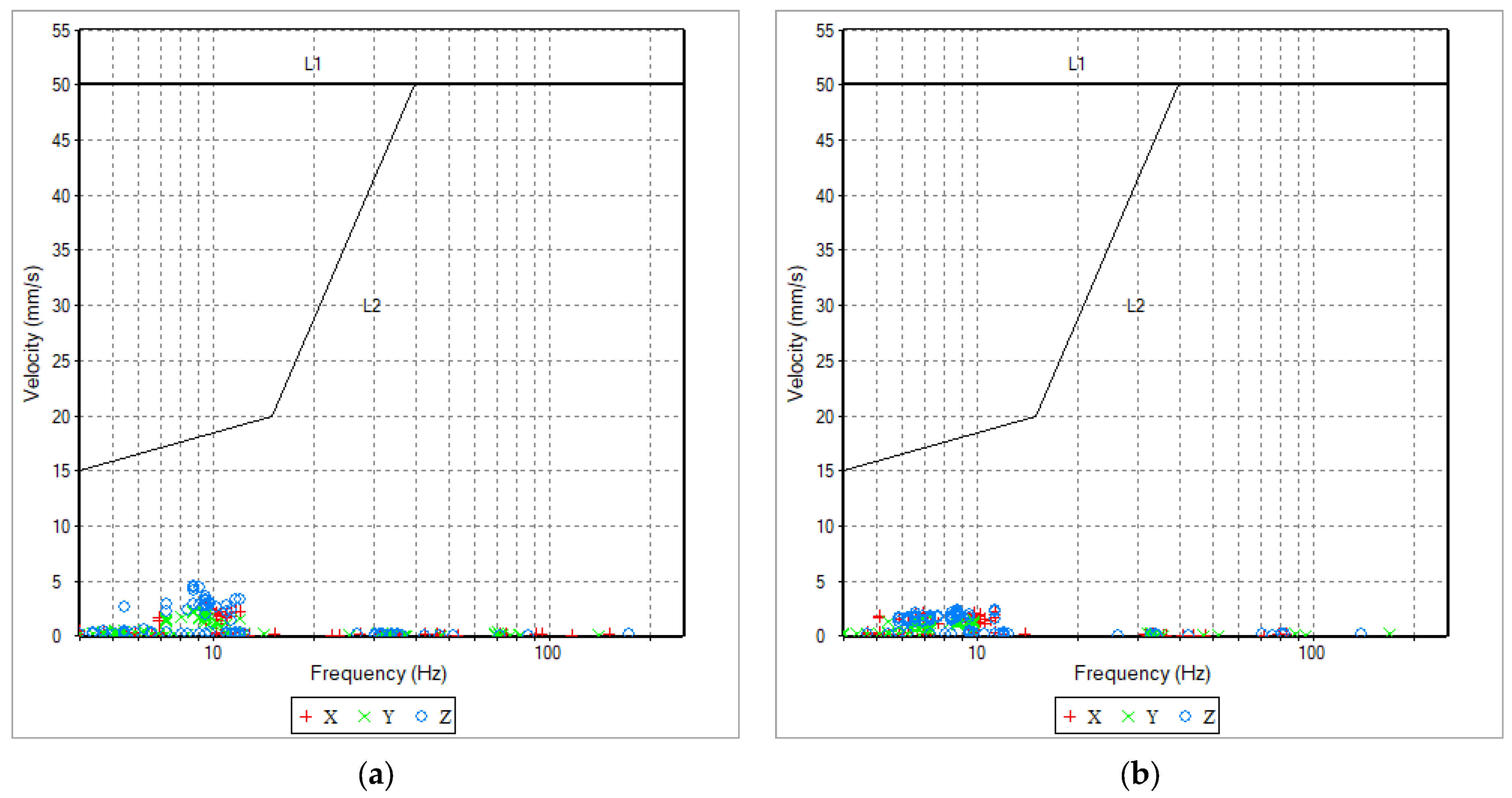

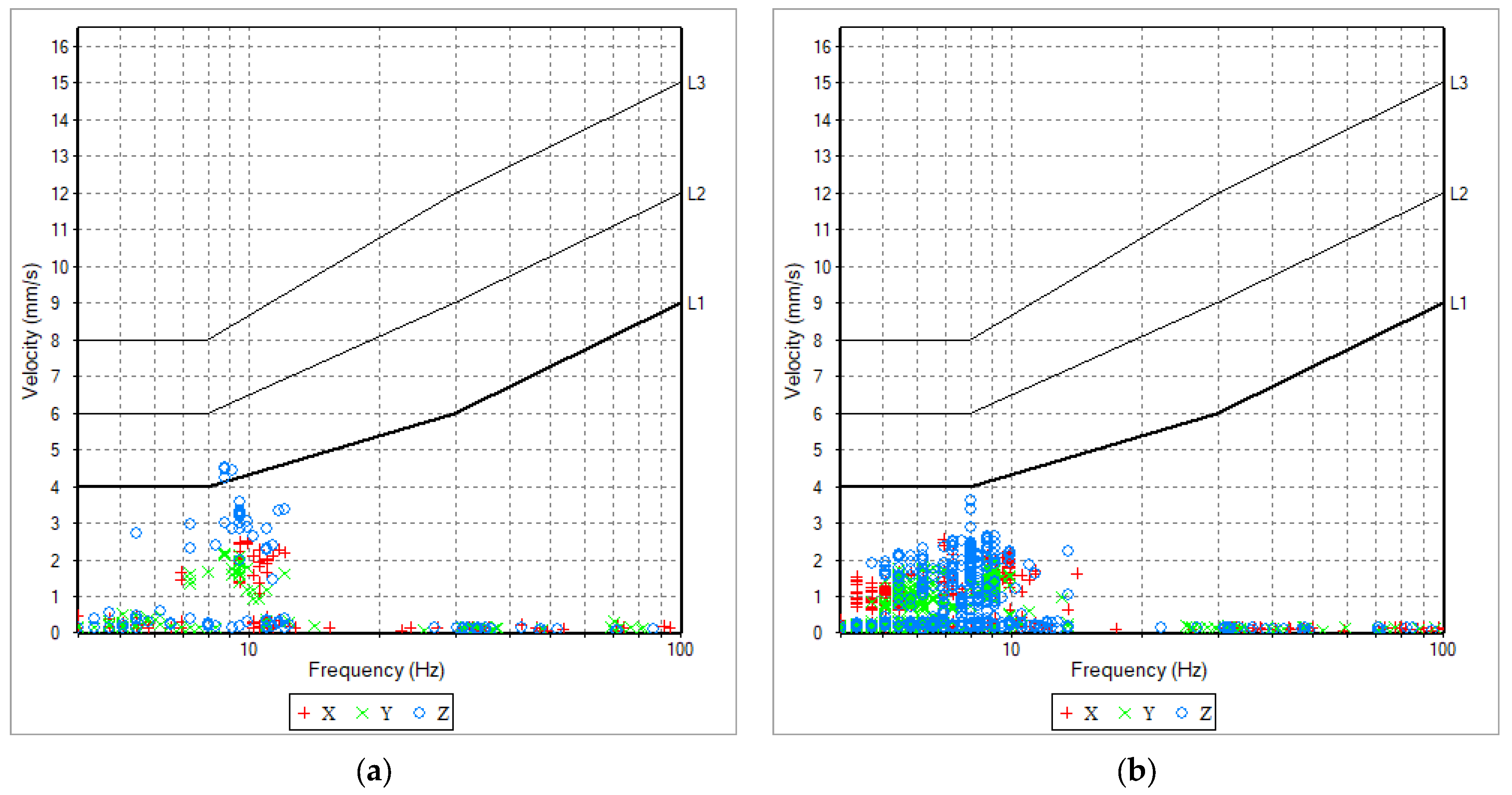

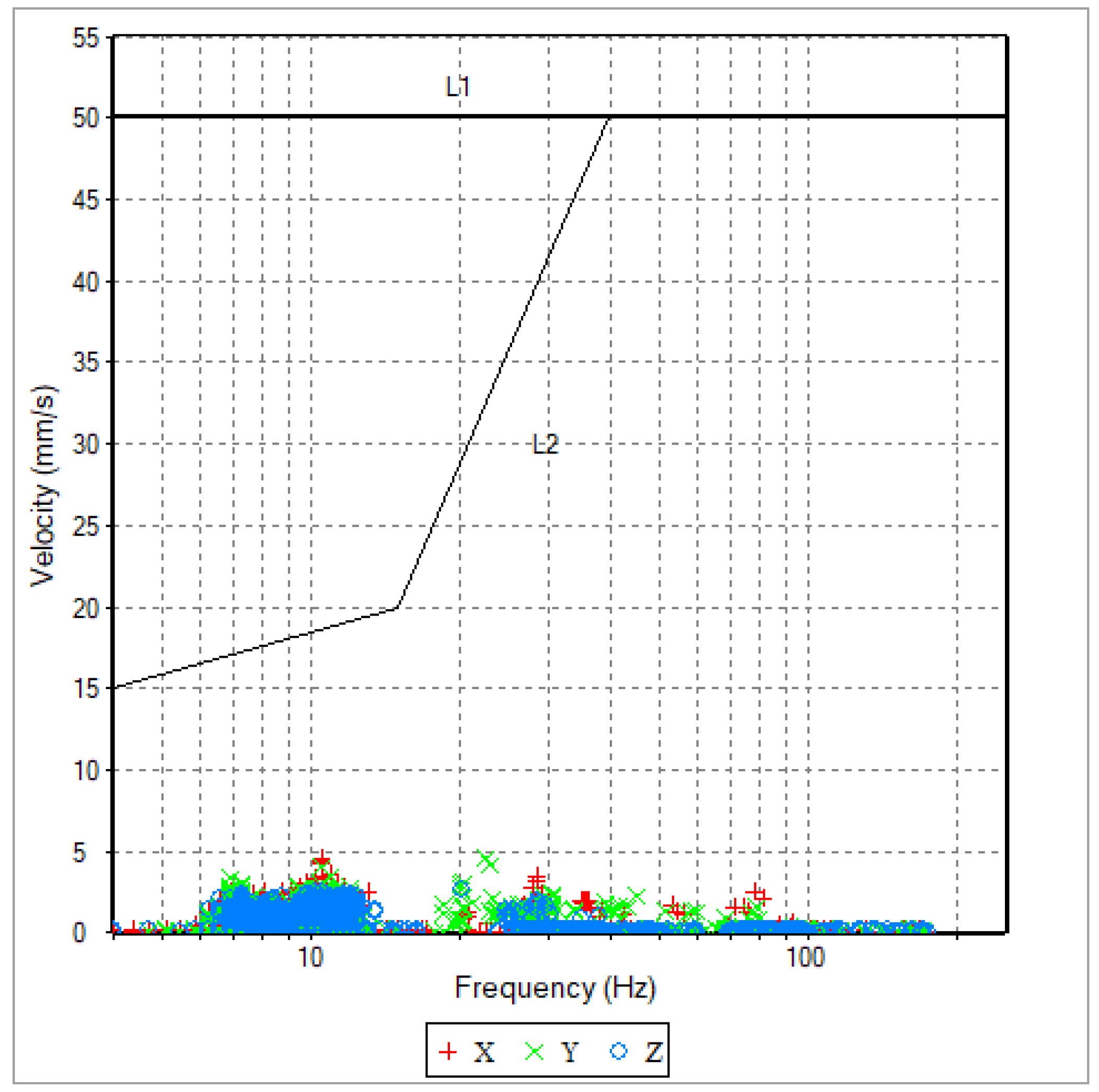

2.1. DIN 4150-3:1999-02 [11]

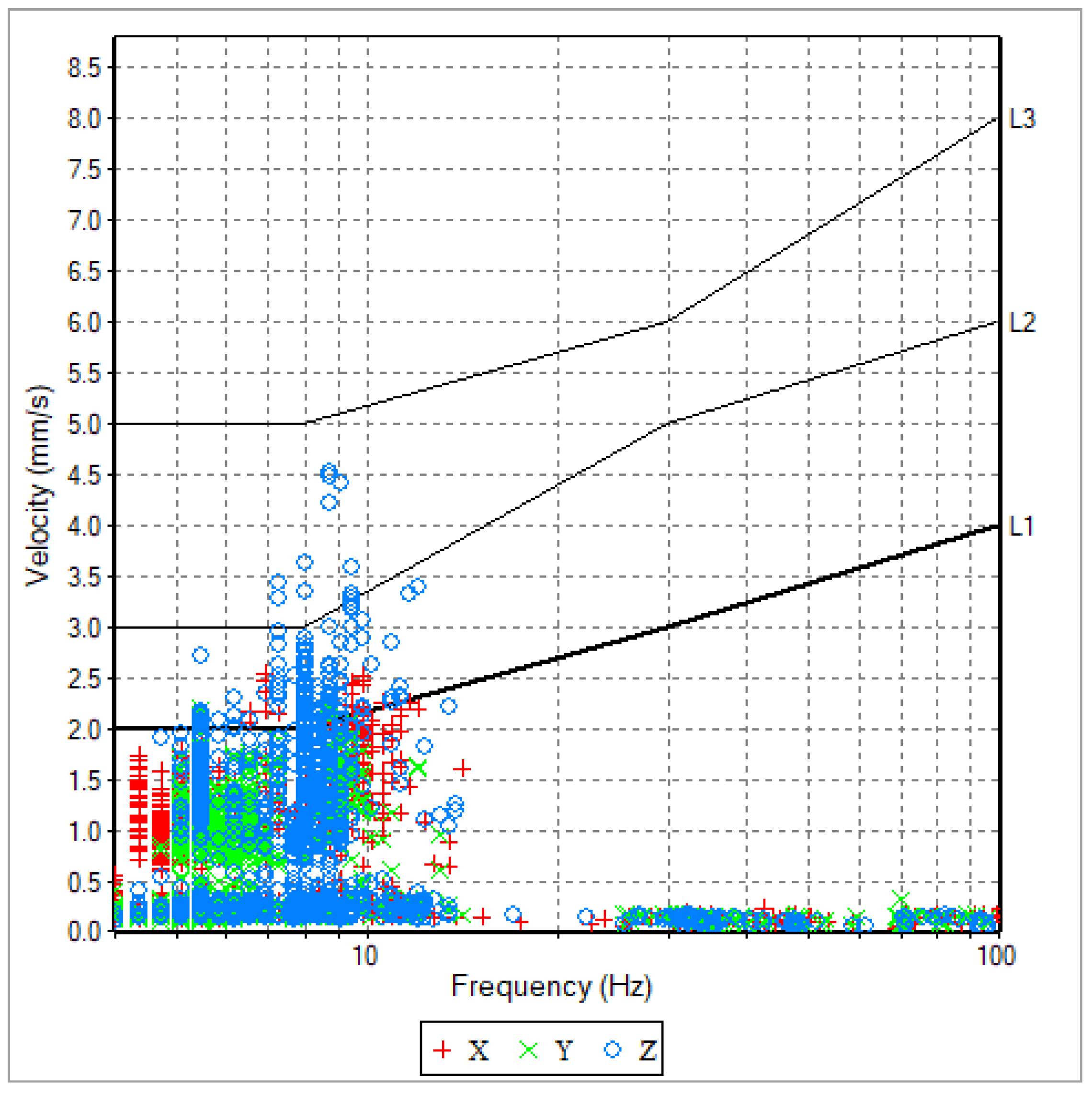

2.2. BS 5228-2 [12]

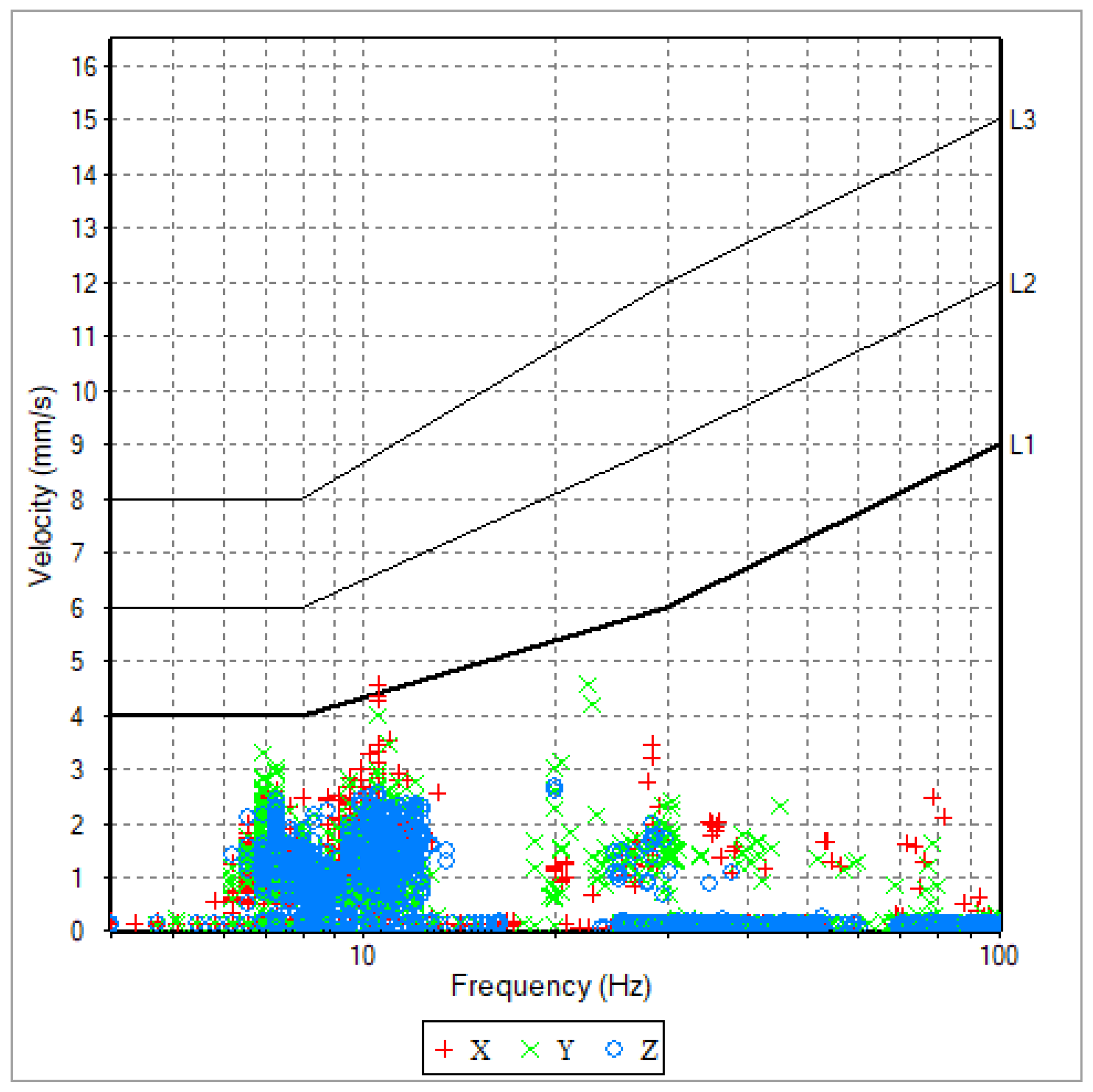

2.3. French Standard Circulaire 23/07/86 [13]

3. Rapid Impact Compaction Technology

4. Methodology of Vibration Measurements

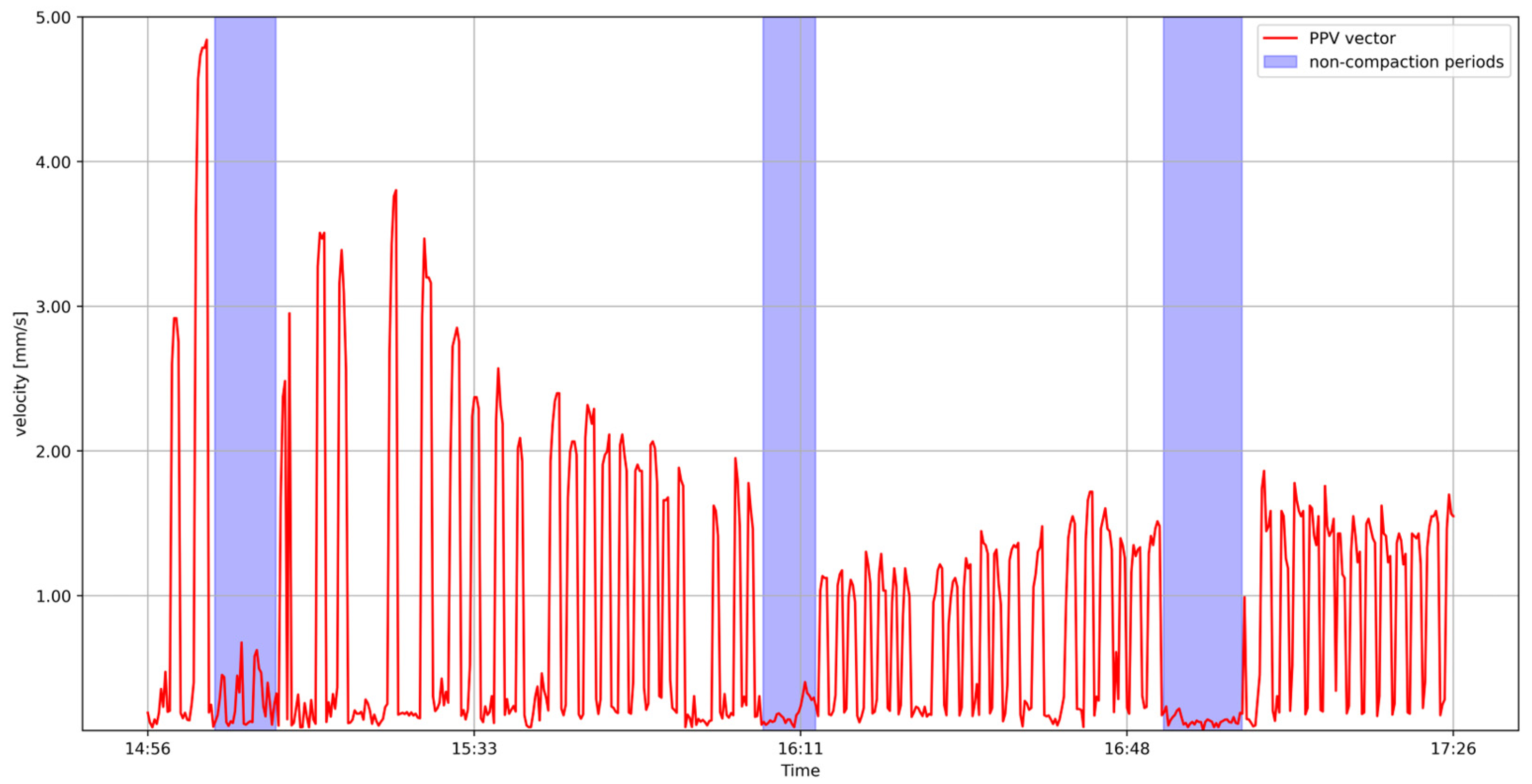

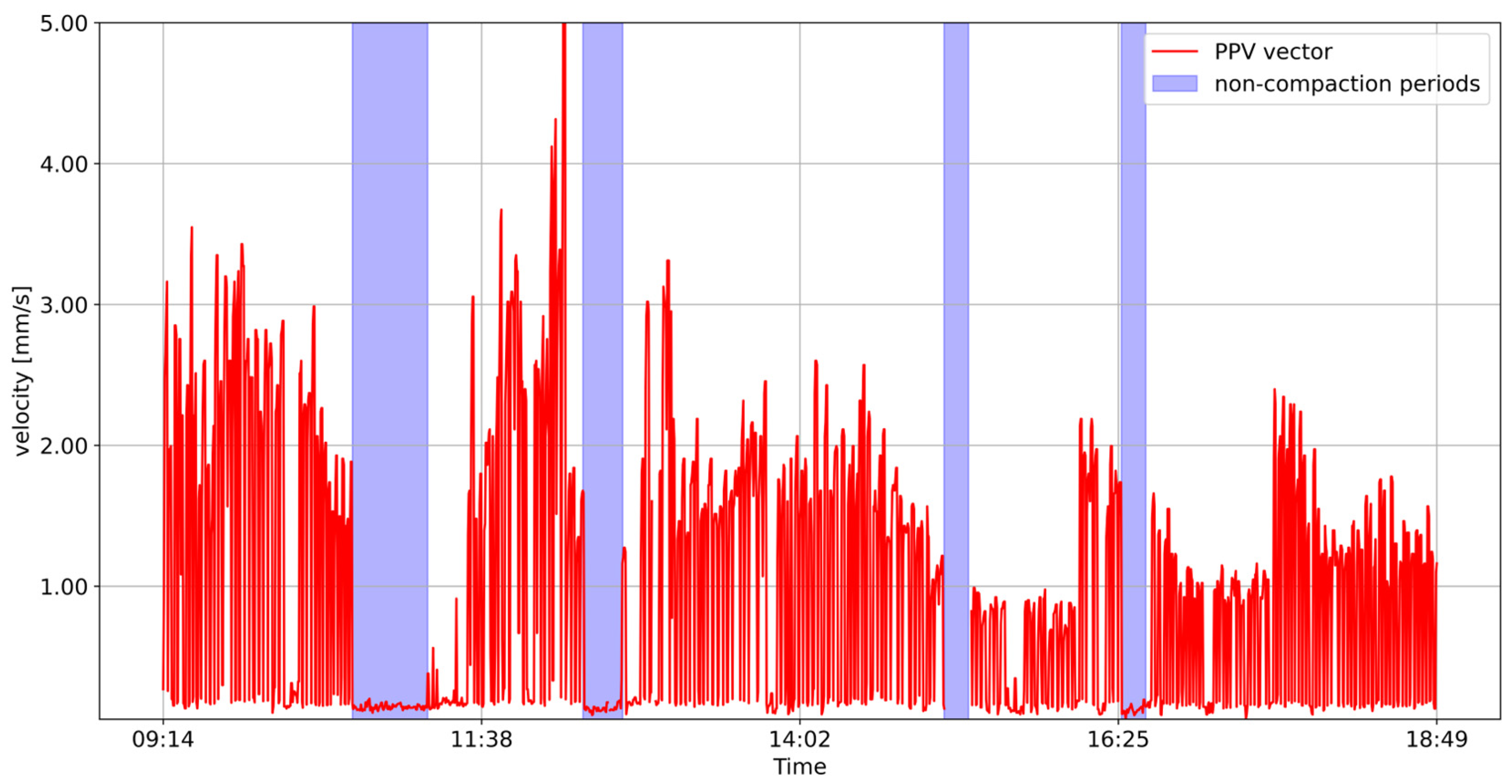

5. Application of Vibration Measurements to the Calibration of the RIC Method (Field Case Studies)

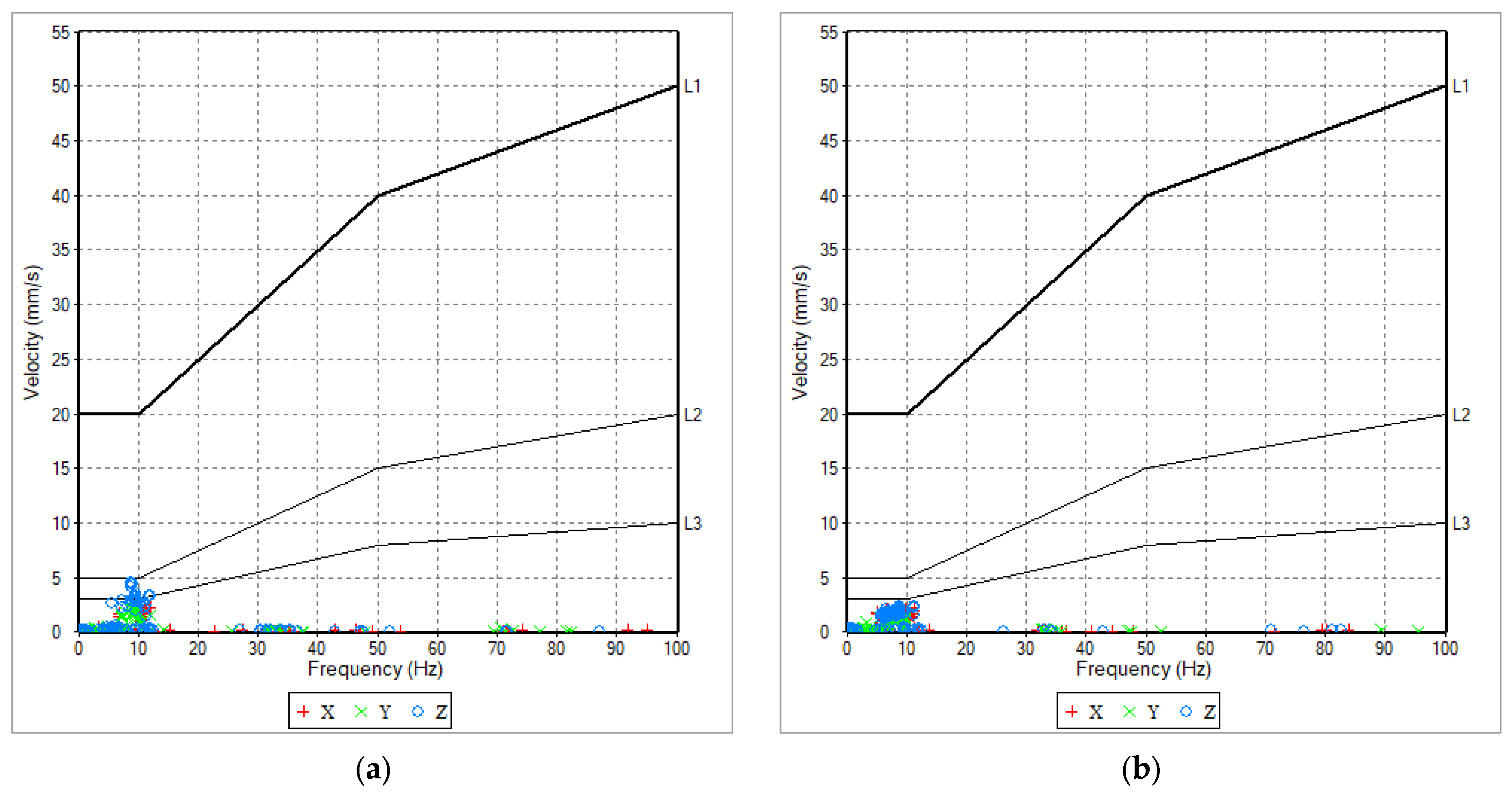

5.1. First Case

5.2. Second Case

6. Discussion of Presented Results

7. Conclusions

- The paper demonstrated the effectiveness of structural vibration monitoring in calibrating geotechnical technology, ensuring the safety of surrounding constructions.

- The assessment of vibration impact can be conducted in accordance with the established standards systems, which delineate permissible vibration levels in consideration of the specific characteristics of the monitored structure.

- Nonetheless, standards are intended to serve as guidelines; the ultimate responsibility for the safety assessments rests with the individual interpreter and their ability to expert judgement.

- It is evident that this method of adapting technology in order to reduce the impact of vibration can also be applied to other technologies. For instance, in the context of the installation of sheet pile walls, the frequency of the vibration hammer can be modified.

- Furthermore, the calibration of numerical models can be enhanced through the utilisation of vibration measurements, thereby ensuring a more precise alignment with actual soil conditions.

- In addition to technological changes, alternative methods of vibration reduction (described in Section 1.5) could be employed. However, the implementation of any such solution would necessitate appropriate calibration to ensure the accuracy of the reduction in vibration measurements.

Funding

Data Availability Statement

Conflicts of Interest

References

- Rybak, J.; Pieczynska-Kozlowska, J. Vibration monitoring as a tool for a calibration of geotechnical technologies. In Proceedings of the 14th International Multidisciplinary Scientific Geoconference (SGEM), Albena, Bulgaria, 17–26 June 2014; pp. 1043–1050. [Google Scholar]

- Dobrzycki, P.; Kongar-Syuryun, C.; Khairutdinov, A. Vibration reduction techniques for Rapid Impulse Compaction (RIC). J. Phys. Conf. Ser. 2019, 1425, 012202. [Google Scholar] [CrossRef]

- Meng, L.; Cheng, Z.; Shi, Z. Vibration mitigation in saturated soil by periodic pile barriers. Comput. Geotech. 2020, 117, 103251. [Google Scholar] [CrossRef]

- Svinkin, M.R. Tolerable limits of construction vibrations. Pract. Per. Struct. D Constr. 2015, 20, 1–7. [Google Scholar] [CrossRef]

- Herbut, A.; Rybak, J. Guidelines and recommendations for vibration control in the case of rapid impulse compaction. In Advances and Trends in Engineering Sciences and Technologies II, Proceedings of the 2nd International Conference on Engineering Sciences and Technologies, ESaT 2016, Tatranské Matliare, Slovakia, 29 June–1 July 2016; CRC Press: Boca Raton, FL, USA, 2017; pp. 761–766. [Google Scholar]

- Herbut, A.; Jakubczyk-Galczynska, A.; Wyjadlowski, M. Vibration monitoring of structures in the light of the Polish and international requirements. Stud. Geotech. Mech. 2023, 45, 209–220. [Google Scholar] [CrossRef]

- Wyjadlowski, M. Methodology of dynamic monitoring of structures in the vicinity of hydrotechnical works-selected case studies. Stud. Geotech. Mech. 2017, 39, 121–129. [Google Scholar] [CrossRef]

- ISO 4866:2010; Technical Vibration and Shock Vibration of Fixed Structures—Guidelines for the Measurement of Vibrations and Evaluation of their Effects on Structures. International Organization for Standardization: Geneva, Switzerland, 2010.

- PN-B-02170:2016-12; Ocena Szkodliwości Drgań Przekazanych Przez Podłoże na Budynki. Polish Committee for Standardization: Warsaw, Poland, 2016. (In Polish)

- SS 02 52 11-1999; Vibration and Shock–Guidance Levels and Measuring of Vibrations in Buildings Originating from Piling, Sheet-Piling, Excavating and Packing to Estimate Permitted Vibration Levels. Swedish Institute for Standards: Stockholm, Sweden, 1999.

- DIN 4150-3:2016-12; Vibrations in Buildings–Part 3: Effects on Structures. German Institute for Standard: Berlin, Germany, 2016.

- BS 5228-2:2009; Code of Practice for Noise and Vibration Control on Construction and Open Sites—Part 2: Vibration. BSI: London, UK, 2009.

- Circulaire du 23/07/86 Relative Aux Vibrations Mécaniques Émises dans L’environnement par les Installations Classées pour la Protection de L’environnement. (In French). Available online: https://aida.ineris.fr/reglementation/circulaire-230786-relative-vibrations-mecaniques-emises-lenvironnement-installations (accessed on 4 May 2025).

- Herbut, A.; Rybak, J.; Brząkała, W. On a sensor placement methodology for monitoring the vibrations of horizontally excited ground. Sensors 2020, 20, 1938. [Google Scholar] [CrossRef]

- Wyjadlowski, M.; Zieba, Z. Impact of Dismantled Sheet Pile Vibration on Cohesive Soil Parameters. IOP Conf. Ser. Earth Environ. Sci. 2020, 609, 012062. [Google Scholar] [CrossRef]

- Dobrzycki, P.; Ivannikov, A.L.; Rybak, J.; Shkodkina, V.O.; Tyulyaeva, Y. The impact of Rapid Impulse Compaction (RIC) of large non-cohesive material deposits on the surrounding area. IOP Conf. Ser. Earth Environ. Sci. 2019, 362, 012132. [Google Scholar] [CrossRef]

- Wyjadłowski, M.; Sawicki, E. Study of impact sheet pile and Franki NG pile driving on weir construction. J. Phys. Conf. Ser. 2019, 1425, 012080. [Google Scholar] [CrossRef]

- Brząkała, W.; Baca, M. The measurement and control of building vibrations in course of sheet pile wall and Franki pile driving. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference, SGEM 2017, Albena, Bulgaria, 29 June–5 July 2017; Hydrogeology, Engineering Geology and Geotechnics, Issue 12, Science and Technologies in Geology, Exploration and Mining. STEF92 Technology: Sofia, Bulgaria, 2017; Volume 17, pp. 929–936. [Google Scholar]

- Wojtowicz, A.; Michałek, J.; Ubysz, A. Range of dynamic impact of geotechnical works on reinforced concrete structures. E3S Web Conf. 2019, 97, 03026. [Google Scholar] [CrossRef]

- Grizi, A.; Athanasopoulos-Zekkos, A.; Woods, R.D. Ground vibration measurements near impact pile driving. J. Geotech. Geoenviron. Eng. 2016, 142, 1–11. [Google Scholar] [CrossRef]

- Hwang, J.-H.; Tu, T.Y. Ground vibration due to dynamic compaction. Soil Dyn. Earthq. Eng. 2006, 26, 337–346. [Google Scholar] [CrossRef]

- Vlček, J.; Gago, F.; Mihálik, J.; Malík, F.; Bahleda, F.; Prokop, J.; Štefánik, M. Investigation of dynamic effect of rapid impact compaction. Sci. Rep. 2024, 14, 21364. [Google Scholar] [CrossRef] [PubMed]

- White, D.; Finlay, T.; Bolton, M.; Bearss, G. Press-in piling: Ground vibration and noise during pile installation. Geotech. Spec. Publ. 2002, 116I, 363–371. [Google Scholar] [CrossRef]

- Athanasopoulos, G.; Pelekis, P. Ground vibrations from sheetpile driving in urban environment: Measurements, analysis and effects on buildings and occupants. Soil Dyn. Earthq. Eng. 2000, 19, 371–387. [Google Scholar] [CrossRef]

- Golik, V.I.; Kongar-Syuryun, C.B.; Michałek, A.; Pires, P.; Rybak, A. Ground transmitted vibrations in course of innovative vinyl sheet piles driving. J. Phys. Conf. Ser. 2021, 1921, 012083. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, L.; Han, Y.; Cai, D.; Wei, S. Study on the transmission and evolution Characteristics of vibration wave from vibratory roller to filling materials based on the field test. Appl. Sci. 2020, 10, 2008. [Google Scholar] [CrossRef]

- Yao, J.; Yue, M.; Ma, H.; Yang, C. Wave propagation characteristics and compaction status of subgrade during vibratory compaction. Sensors 2023, 23, 2183. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.; Zhou, J.; Chen, X.; Qiu, X. Effective Assessment of Blast-Induced Ground Vibration Using an Optimized Random Forest Model Based on a Harris Hawks Optimization Algorithm. Appl. Sci. 2020, 10, 1403. [Google Scholar] [CrossRef]

- Rodríguez, R.; Bascompta, M.; Fernández, P.; Fernández, P.R. Representative-Area Approach to Define Blast-Induced Ground Vibrations—Damage Prevention Criterion Abacus. Minerals 2022, 12, 691. [Google Scholar] [CrossRef]

- Łupieżowiec, M. Modeling the Phenomenon of Propagation of Technological Impulses in Subsoil. Int. J. Geomech. 2022, 22, 04022175. [Google Scholar] [CrossRef]

- Papán, D.; Valašková, V.; Drusa, M. Numerical and Experimental Case Study of Blasting Works Effect. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 052052. [Google Scholar] [CrossRef]

- Nguyen, N.L.; Nguyen, C.L.; Bui, T.T.; Dang, H.L. 3D Finite Element Model and Measurement Comparison for Roller Compaction Ιnduced Vibration: The Case Study of a Ring Road in Hanoi, Vietnam. Eng. Technol. Appl. Sci. Res. 2023, 13, 11338–11343. [Google Scholar] [CrossRef]

- Papán, D.; Brozová, E.; Papánová, Z. Experimental Measurements of Explosion Effects Propagating in the Real Geological Environment—Correlation with Small-Scale Model. Buildings 2024, 14, 3603. [Google Scholar] [CrossRef]

- Majumder, M.; Venkatraman, S. A state-of-the-art review paper on the vibration screening techniques using open and in-filled trenches. Asian J. Civ. Eng. 2023, 24, 2693–2708. [Google Scholar] [CrossRef]

- Mach, A.; Wałach, D. Implementation of Integrated Life Cycle Design Principles in Ground Improvement and Piling Methods—A Review. Sustainability 2024, 16, 659. [Google Scholar] [CrossRef]

- Zhao, C.; Zeng, C.; Wang, Y.; Bai, W.; Dai, J. Theoretical and Numerical Study on the Pile Barrier in Attenuating Seismic Surface Waves. Buildings 2022, 12, 1488. [Google Scholar] [CrossRef]

- Pu, X.; Shi, Z. Periodic pile barriers for Rayleigh wave isolation in a poroelastic half-space. Soil Dyn. Earthq. Eng. 2019, 121, 75–86. [Google Scholar] [CrossRef]

- Toygar, O.; Ulgen, D. A full-scale field study on mitigation of environmental ground vibrations by using open trenches. Build Environ. 2021, 203, 108070. [Google Scholar] [CrossRef]

- Esmaeili-Moghadam, A.; Rafiee-Dehkharghani, R. Ground-borne vibration screening in layered dry and saturated grounds using optimal inclined wave barriers. Soil Dyn. Earthq. Eng. 2022, 162, 107448. [Google Scholar] [CrossRef]

- Toygar, O.; Ulgen, D.; Fidan, N.B. Experimental Study on Reutilization of Waste Rubber Chips with Sheetpiles as a Coupled-Wave Barrier to Reduce Ground-Borne Vibrations. J. Vib. Eng. Technol. 2024, 12, 8451–8463. [Google Scholar] [CrossRef]

- Sound and Vibration. Available online: https://svantek.com/ (accessed on 17 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baca, M. Structural Vibration Analysis with Reference to Different Standards. Buildings 2025, 15, 1951. https://doi.org/10.3390/buildings15111951

Baca M. Structural Vibration Analysis with Reference to Different Standards. Buildings. 2025; 15(11):1951. https://doi.org/10.3390/buildings15111951

Chicago/Turabian StyleBaca, Michal. 2025. "Structural Vibration Analysis with Reference to Different Standards" Buildings 15, no. 11: 1951. https://doi.org/10.3390/buildings15111951

APA StyleBaca, M. (2025). Structural Vibration Analysis with Reference to Different Standards. Buildings, 15(11), 1951. https://doi.org/10.3390/buildings15111951