Long-Term Stress Characteristics and Earth Pressure Calculation Method for High-Fill Box Culverts

Abstract

1. Introduction

2. Theoretical Analysis

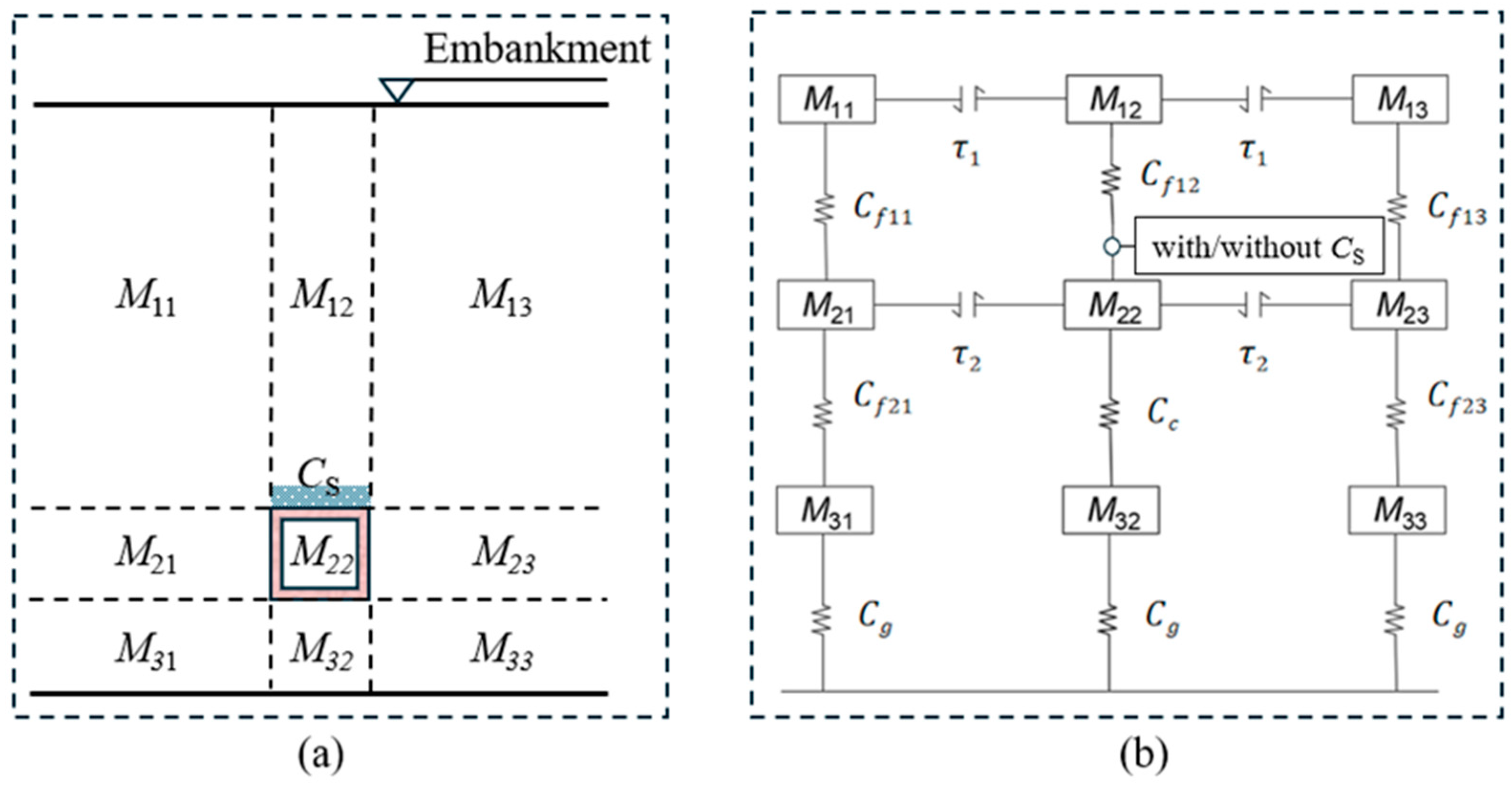

2.1. Load Transfer Mechanics

2.2. Theoretical Analysis of Long-Term Stress Characteristics

2.2.1. Stress Model of the Box Culvert with EPS Board

2.2.2. The Vertical Earth Pressure on the Culvert Roof

2.2.3. Horizontal Earth Pressure Along the Sidewall

2.2.4. Foundation Contact Pressure

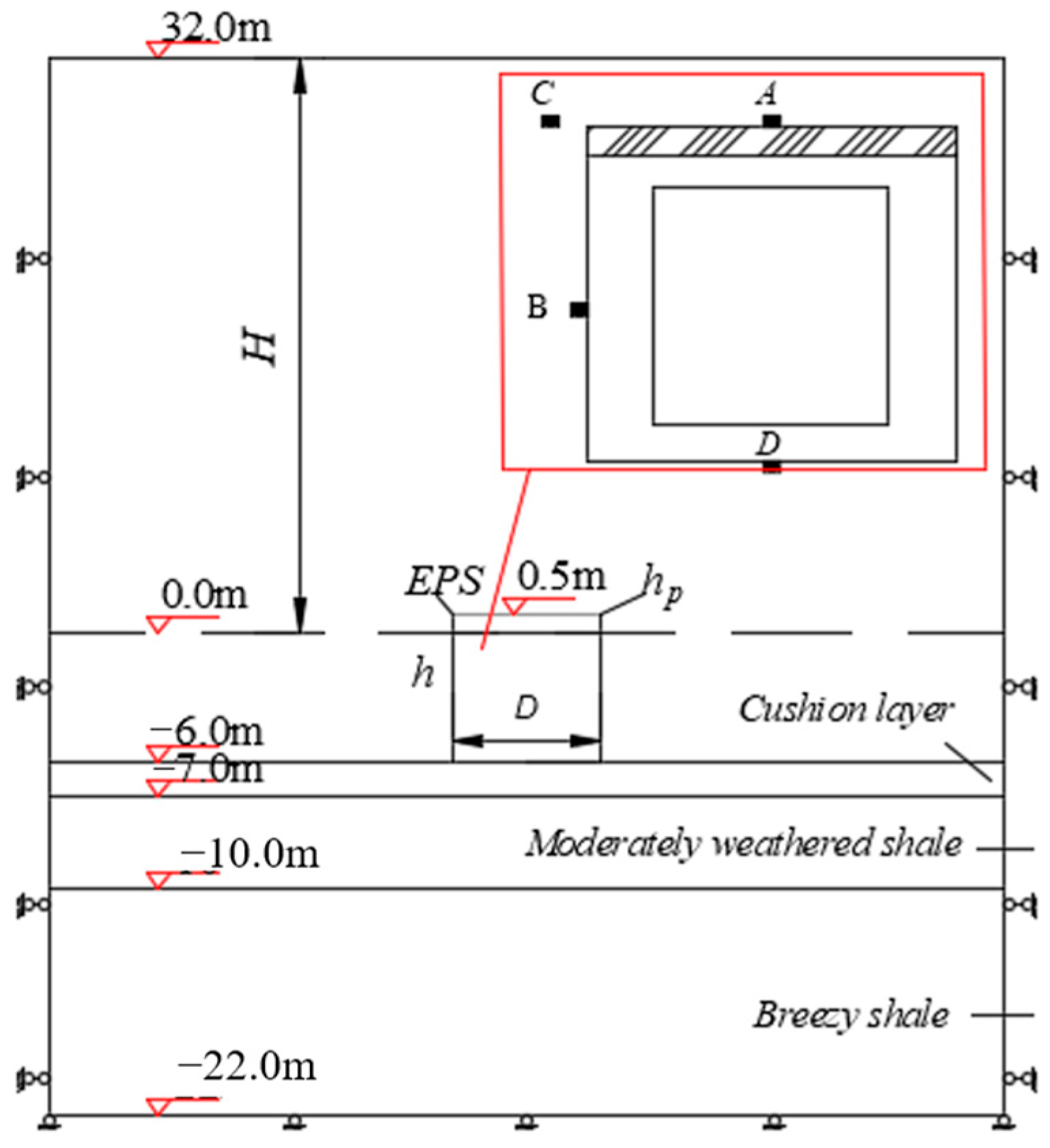

3. Numerical Modeling

3.1. Establishment of the Numerical Model

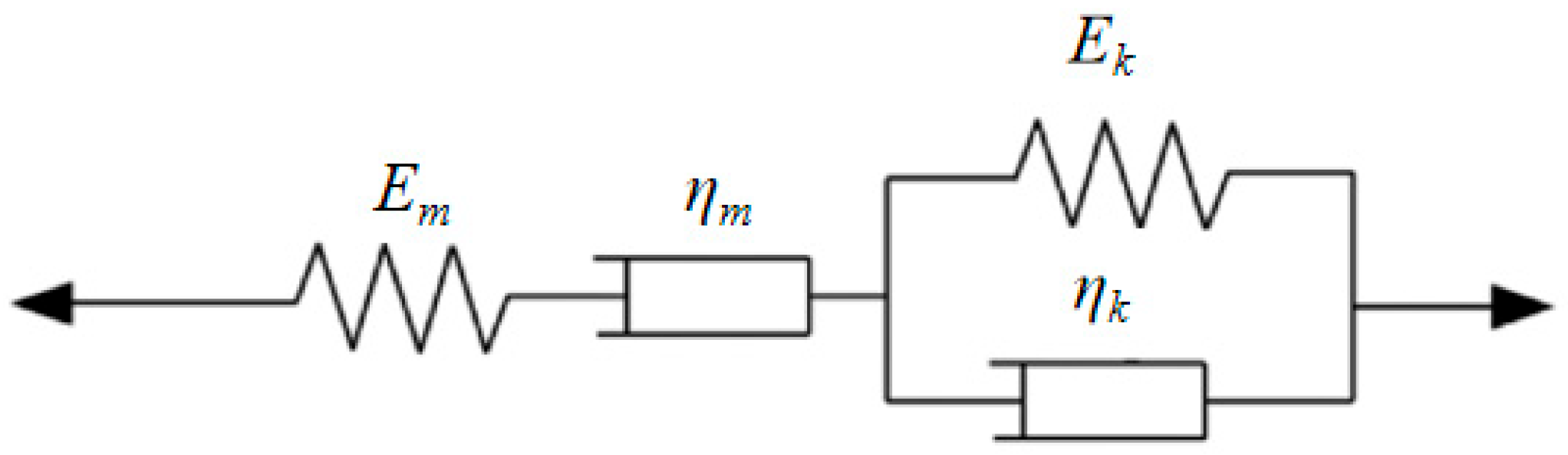

3.2. Material Parameters and Constitutive Model

4. Long-Term Stress Characteristics of Box Culverts

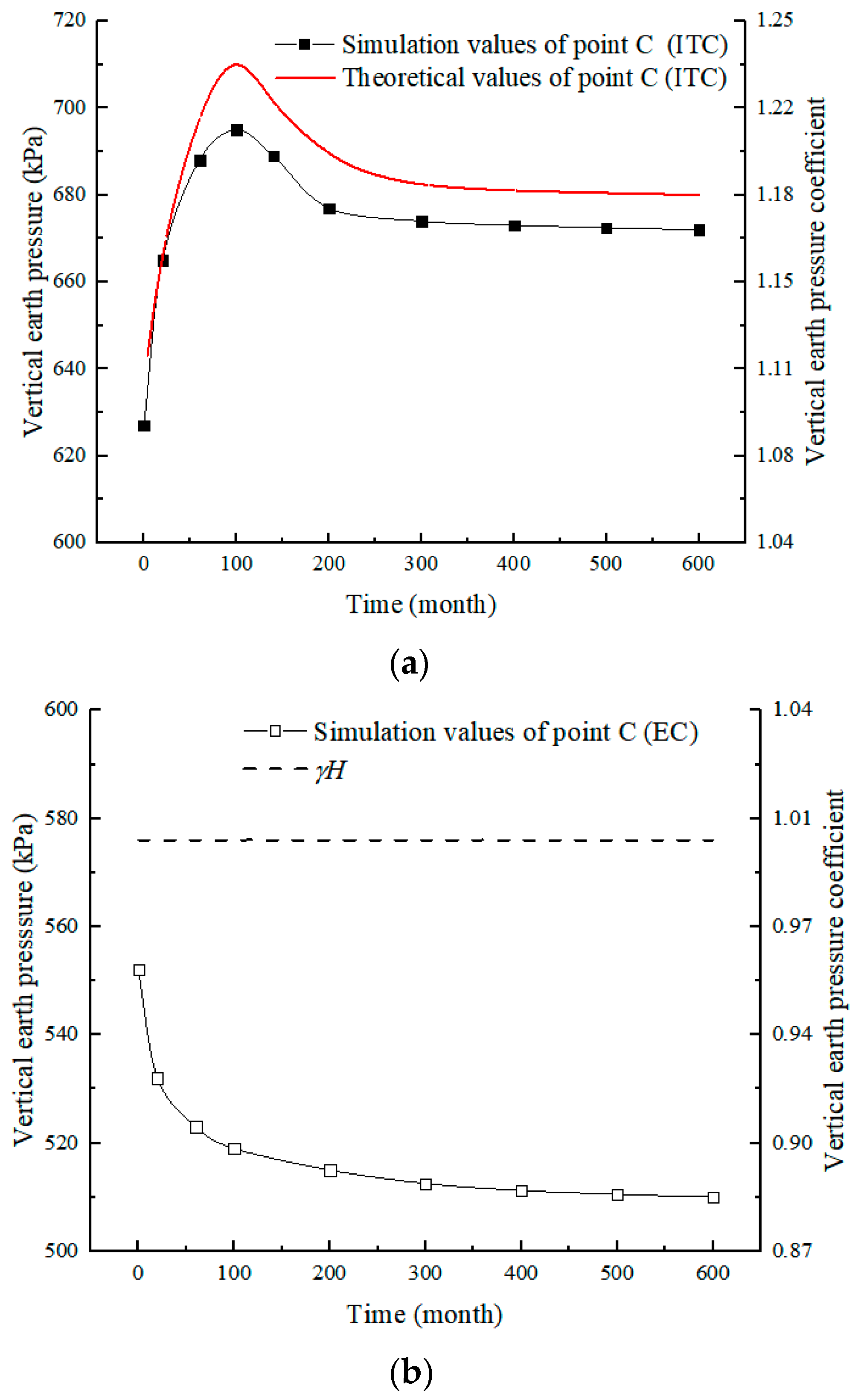

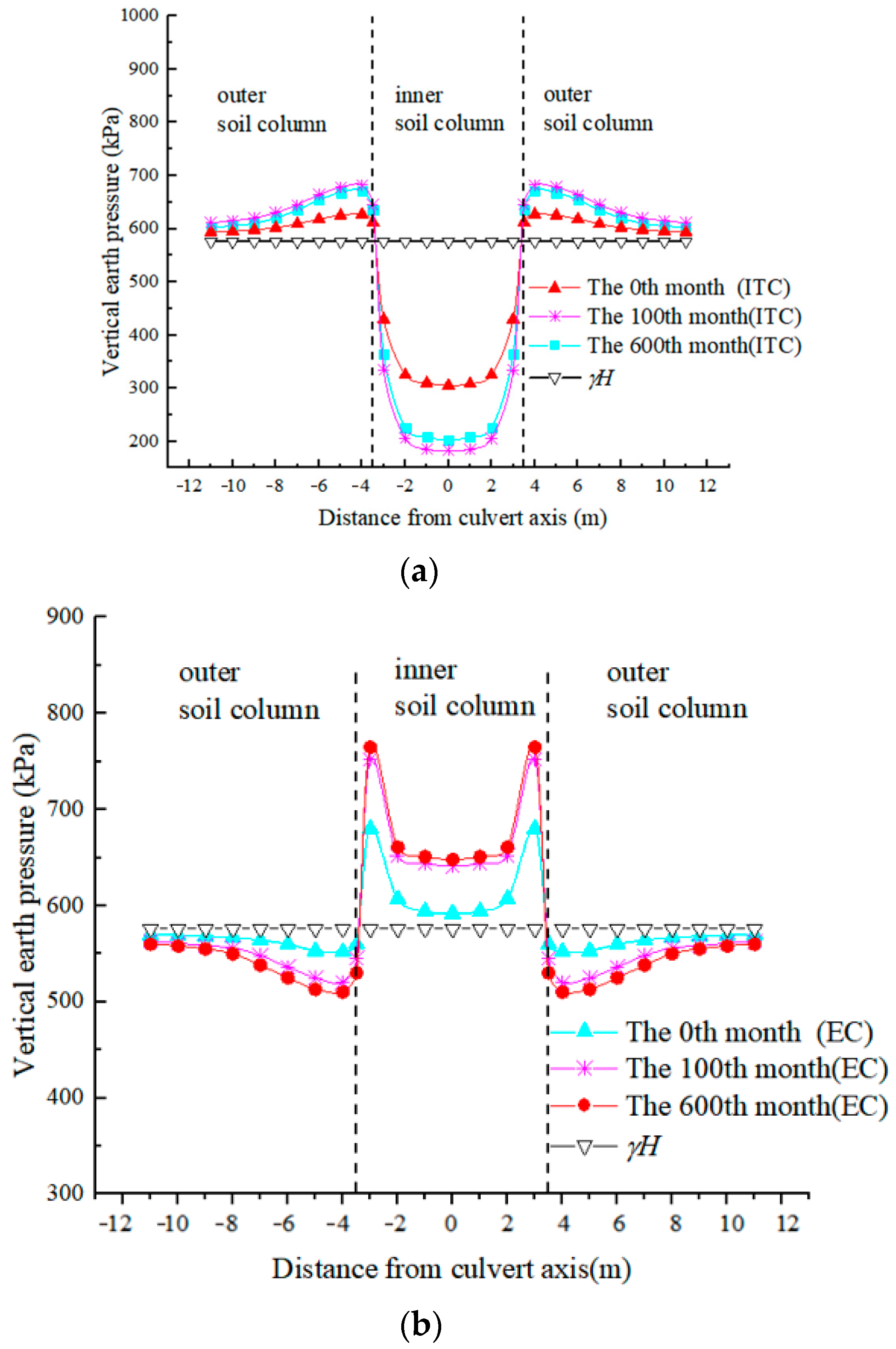

4.1. Vertical Earth Pressure on the Culvert Roof Plane

4.1.1. The Variation of VEP at the Midspan of the Top Slab with Time

4.1.2. The VEP on the Exterior of the Culvert Roof

4.1.3. Distribution of VEP on the Culvert Roof Plane

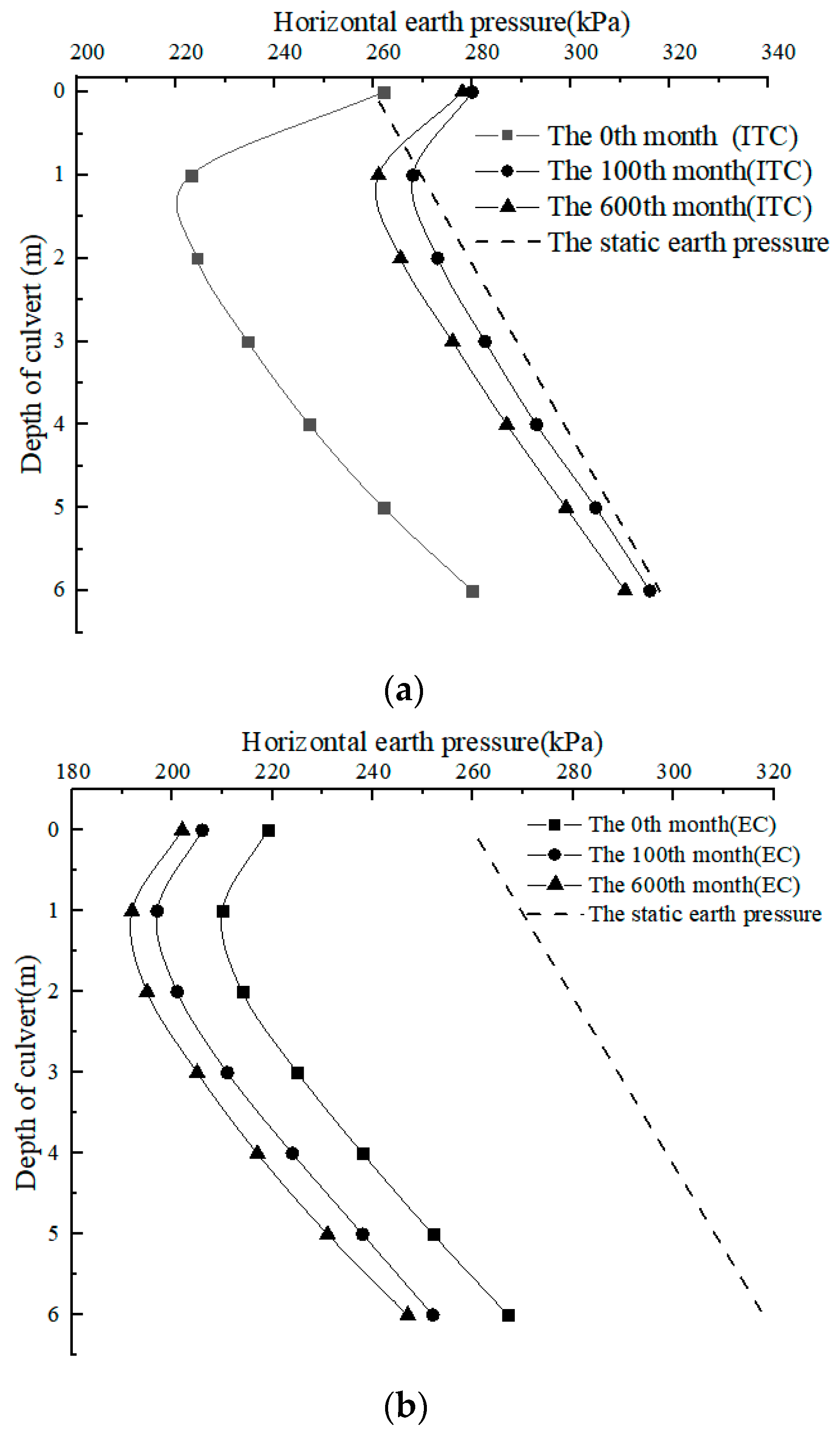

4.2. Horizontal Earth Pressure on the Culvert Sidewall

4.2.1. Variation of HEP at the Midpoint of the Sidewall with Time

4.2.2. Distribution of HEP Along the Culvert Sidewall

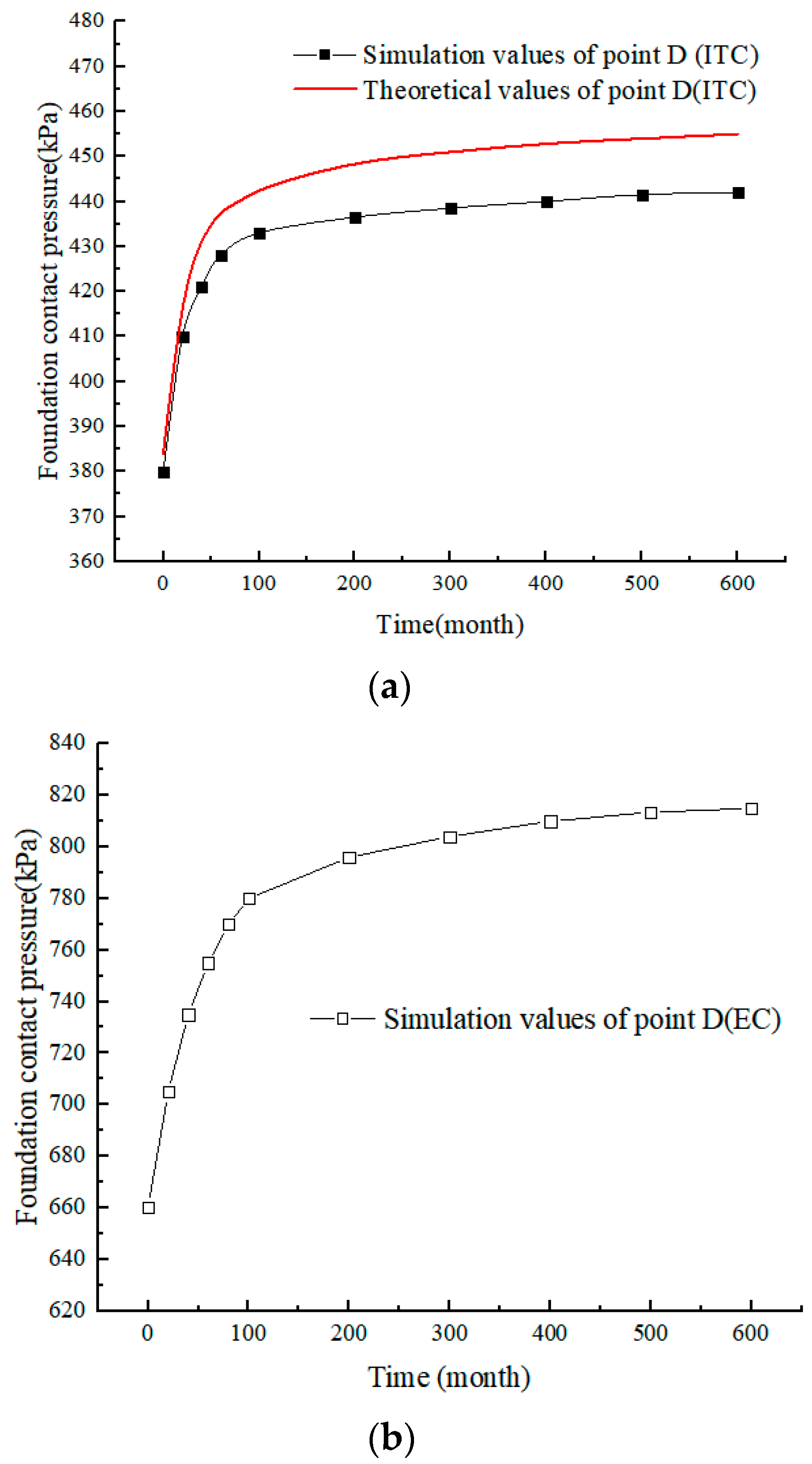

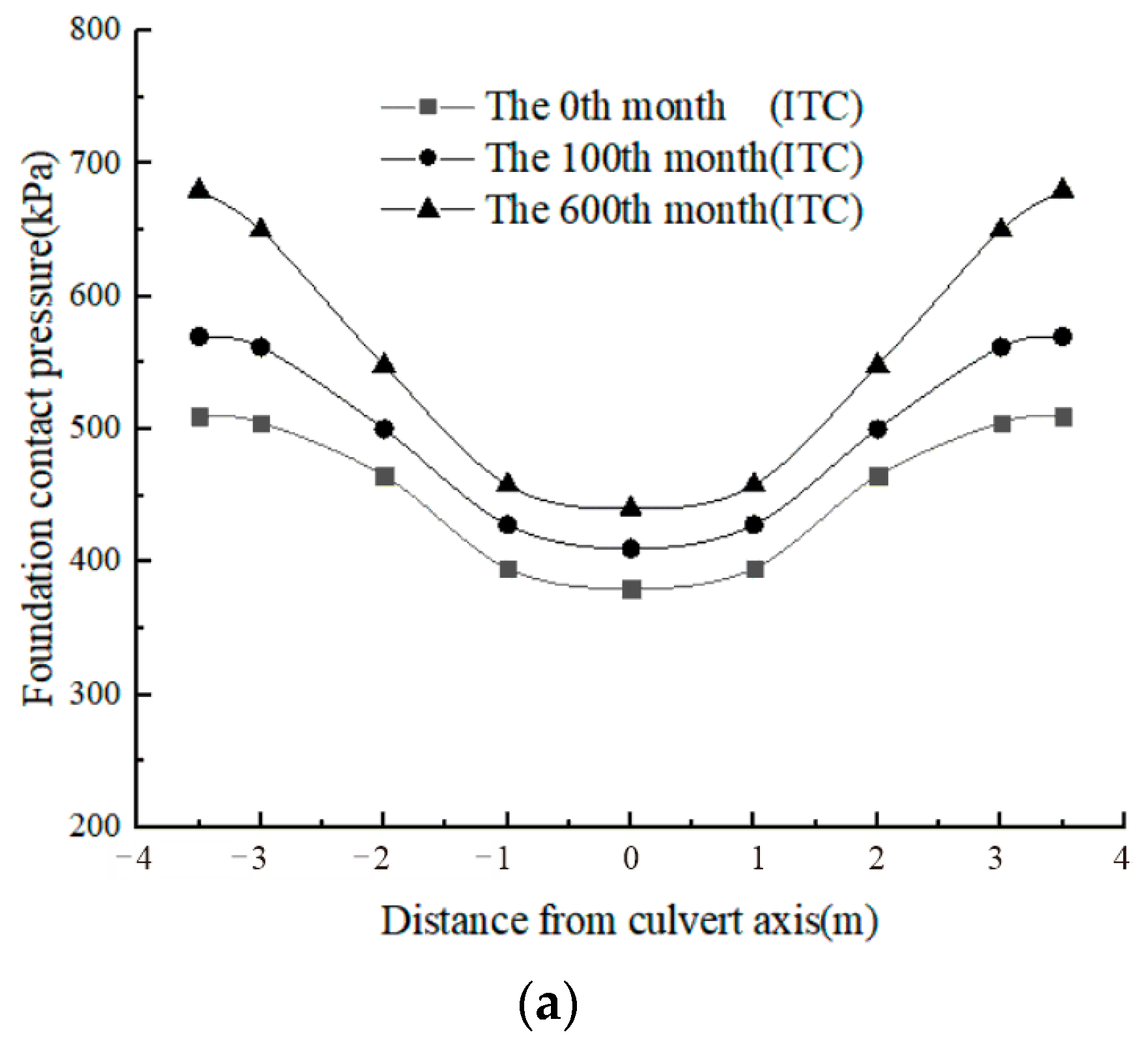

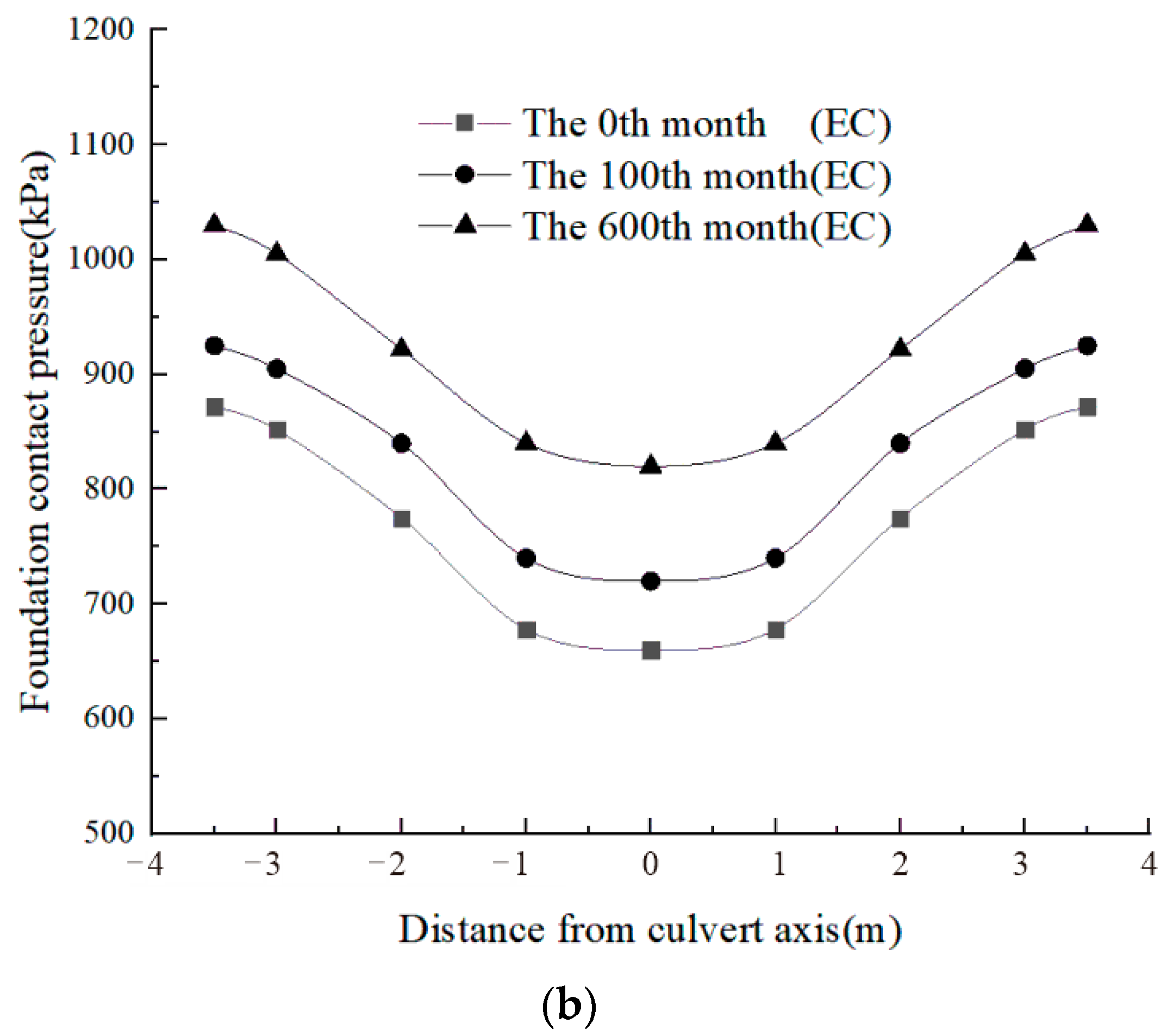

4.3. Foundation Contact Pressure on the Culvert Bottom

4.3.1. Variation of FCP at Midpoint of Bottom Slab with Time

4.3.2. Distribution of Foundation Contact Pressure

4.4. Discussion

5. Conclusions and Recommendations

- (1)

- The earth pressure acting on the top slab of the box culvert first decreases rapidly, then increases gradually with time; the stable value decreases by 33% compared to the end of the construction period. Concurrently, the VEP at the outer side of the culvert roof first increases rapidly, then decreases and gradually approaches an asymptotic value, which increases by 7% compared to that of the initial stage of post-construction.

- (2)

- The HEP on the sidewall of the box culvert first nonlinearly increases and then gradually decreases with time. The final value increases by 18.4% compared to that of the end of construction.

- (3)

- The FCP of the box culvert increases nonlinearly with time and approaches a stable value, which increases by 15.8% compared to that of the initial stage of the post-construction.

- (4)

- Although the EPS board reduces the earth pressure on the culvert roof, the frictional force on the culvert sidewall still leads to an increase in the FCP. Furthermore, the HEP and FCP of the box culvert show increments of about 37.3% and 46.0%, respectively, compared to the condition without the EPS board. The creep effect of EPS board and fill should be considered to avoid structural diseases in the design of box culverts with EPS board.

- (5)

- This analysis is only the preliminary theoretical basis for the long-term stress characteristics of high-fill culverts under load reduction conditions. Due to the lack of long-term field monitoring data, the theoretical results of this analysis were validated using numerical results. For future research, long-term field monitoring should be carried out to further verify the theoretical results, for example, by integrating field monitoring of actual culvert systems to verify that the predicted stress evolution matches reality.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, B.G.; Sun, L. Performance of a reinforced concrete box culvert installed in trapezoidal trenches. J. Bridge Eng. 2014, 19, 120–130. [Google Scholar] [CrossRef]

- Marston, A. The theory of external loads on closed conduits in the light of the latest experiments. Highw. Res. Board Proc. 1930, 9, 138–170. [Google Scholar]

- Brown, C.B. Forces on rigid culverts under high fills. J. Struct. Div. ASCE 1967, 93, 195–215. [Google Scholar] [CrossRef]

- Spangler, M.G. A theory of loads on negative projecting conduits. Highw. Res. Board Proc. 1950, 30, 153–161. [Google Scholar]

- Vaslestad, J. Load reduction on buried rigid pipes. In Proceedings of the Pipeline Crossings, Specialty Conference, Denver, CO, USA, 25—27 March 1991. [Google Scholar]

- McGuigan, B.L.; Valsangkar, A.J. Centrifuge testing and numerical analysis of box culverts installed in induced trenches. Can. Geotech. J. 2010, 47, 147–163. [Google Scholar] [CrossRef]

- Ahmed, M.R. Experimental Investigations into the Role of Geosynthetic Inclusions on the Earth Pressure Acting on Buried Structures. Ph.D. Thesis, McGill University, Montreal, QC, Canada, 2016. [Google Scholar]

- Meguid, M.A.; Youssef, T.A. Experimental investigation of the earth pressure distribution on buried pipes backfilled with tire-derived aggregate. Transp. Geotech. 2018, 14, 117–125. [Google Scholar] [CrossRef]

- Zhang, C.G.; Wu, K.; Kang, L.H.; Li, H.X. VEP against an induced trench installation culvert in unsaturated soils. J. Harbin Inst. Technol. 2023, 55, 80–87. (In Chinese) [Google Scholar]

- Qin, X.; Ni, P.; Zhou, M. Improved analytical solution of vertical pressure on top of induced trench rigid culverts. Geosynth. Int. 2017, 24, 615–624. [Google Scholar] [CrossRef]

- Beju, Y.Z.; Mandal, J.N. Compression creep test on expanded polystyrene (EPS) geofoam. Int. J. Geotech. Eng. 2016, 10, 401–408. [Google Scholar] [CrossRef]

- Sun, L.; Hopkins, T.C.; Beckham, T.L. Long-term monitoring of culvert load reduction using an imperfect ditch backfilled with geofoam. Transp. Res. Rec. 2018, 2212, 56–64. [Google Scholar] [CrossRef]

- Gnip, I.Y.; Vaitkus, S.; Keršulis, V.; Vėjelis, S. Long-term prediction of compressive creep development in expanded polystyrene. Polym. Test. 2008, 27, 378–391. [Google Scholar] [CrossRef]

- Gnip, I.Y.; Vaitkus, S.; Keršulis, V.; Vėjelis, S. Analytical description of the creep of expanded polystyrene (EPS) under long-term compressive loading. Polym. Test. 2011, 30, 493–500. [Google Scholar] [CrossRef]

- Vaslestad, J.; Johansen, T.H.; Holm, W. Load reduction on rigid culverts beneath high fills: Long-term behavior. In Transportation Research Record; National Academy Press: Washington, DC, USA, 1993; pp. 58–68. [Google Scholar]

- Hou, H.B.; Li, S.; You, Z.G.; He, Y.Z. Analysis of consolidation creep of backfill soil for unloaded high-filled cut-and-cover tunnel based on the, P.F.C.2.D. Sci. Technol. Eng. 2022, 22, 14360–14369. (In Chinese) [Google Scholar]

- Li, S.; Jianie, Y.C.; Ho, I.H.; Ma, L.; Yu, B.; Wang, C. Evolution of load reduction for high-filled cut-and-cover tunnels subjected to soil creep. Int. J. Geomech. 2021, 21, 04021172-1. [Google Scholar] [CrossRef]

- Chen, B.G.; Song, D.B.; Wang, C.; He, Y.H. Long-term behavior of load reduction culvert under high fills. J. Hydraul. Eng. 2015, 46, 117–123. (In Chinese) [Google Scholar]

- Gao, Q.; Chen, B.G.; Wu, S.; Yuan, S.; Sun, M.Y. Long-term stress characteristics and load reduction effect of high-fill box culverts with EPS slabs. Rock Soil Mech. 2023, 44, 2151–2160. (In Chinese) [Google Scholar]

- Birgul, R.; Al-shammari, F.M.W.; Yaman, I.O.; Aktan, M.H. Acoustic emission evaluation of concrete culverts. Res. Nondestruct. Eval. 2005, 15, 191–208. [Google Scholar] [CrossRef]

- Melchiorre, J.; D’Amato, L.; Agostini, F.; Rizzo, A.M. Acoustic emission onset time detection for structural monitoring with u-net neural network architecture. Dev. Built Environ. 2024, 18, 100449. [Google Scholar] [CrossRef]

- Gong, Y.; Lin, S.; He, F.; He, Y.; Song, J. Damage identification of prefabricated reinforced concrete box culvert based on improved fuzzy clustering algorithm and acoustic emission parameters. Adv. Mater. Sci. Eng. 2021, 2021, 6660915. [Google Scholar] [CrossRef]

- Melchiorre, J.; Bertetto, A.M.; Rosso, M.M.; Marano, G.C. Acoustic emission and artificial intelligence procedure for crack source localization. Sensors 2023, 23, 693. [Google Scholar] [CrossRef]

- Xu, Z.L. A Concise Course in Elasticity; Higher Education Press: Beijing, China, 2018. [Google Scholar]

- Wang, F.; Miao, L.C.; Zhang, Y.J. A simplified method to predict creep behavior of the Yangtze River sand. Bull. Eng. Geol. Environ. 2012, 71, 317–324. [Google Scholar] [CrossRef]

- Wang, Y.H.; Lau, Y.M.; Gao, Y. Examining the mechanisms of sand creep using DEM simulations. Granul. Matter 2014, 16, 733–750. [Google Scholar] [CrossRef]

- Taylor, S.B.; Manbeck, H.B.; Janowiak, J.J. Modeling structural insulated panel (SIP) flexural creep deflection. J. Struct. Eng. 1997, 123, 1555–1697. [Google Scholar] [CrossRef]

- Yong, Z.; Chin, J.L.; Henry, W. Time dependent viscoelastic behaviour of EPS geofoam. Appl. Mech. Mater. 2013, 330, 1095–1099. [Google Scholar]

- Wu, Y.; Li, N.; Wang, X.; Cui, J.; Chen, Y.; Wu, Y.; Yamamoto, H. Experimental investigation on mechanical behavior and particle crushing of calcareous sand retrieved from South China Sea. Eng. Geol. 2021, 280, 105932. [Google Scholar] [CrossRef]

- Wu, Y.; Yamamoto, H.; Cui, J.; Cheng, H. Influence of Load Mode on Particle Crushing Characteristics of Silica Sand at High Stresses. Int. J. Geomech. 2020, 20, 04019194. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, J.; Huang, J.; Zhang, W.; Yoshimoto, N.; Wen, L. Correlation of critical state strength properties with particle shape and surface fractal dimension of clinker ash. Int. J. Geomech. 2021, 21, 04021071. [Google Scholar] [CrossRef]

- Chrysikos, D.; Atmatzidis, D.; Missirlis, E. EPS geofoam surface shear resistance. In Proceedings of the 8th IGS (International Geotechnical Symposium on Disaster Mitigation), Yokohama, Japan, 26–28 May 2006; Millpress: Rotterdam, The Netherlands, 2006; pp. 1647–1650. [Google Scholar]

- Shi, X.Q.; Xue, Y.Q.; Wu, J.C.; Zhang, Y.; Ye, S.; Yu, J. Uniaxial compression tests for creep model of saturated sand in Changzhou. J. Eng. Geol. 2007, 15, 212–216. (In Chinese) [Google Scholar]

- Cai, G.J.; Chen, S.H.; Zhao, D.; Zhou, Y. Experimental study on creep characteristics of saturated sand and its influencing factors. J. Eng. Geol. 2019, 27, 1048–1055. [Google Scholar]

- Kang, Y.; Li, X.; Tan, J. Uniaxial tension and tensile creep behaviors of EPS. J. Cent. South Univ. Technol. 2010, 15, 202–205. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Chen, B.G.; Meng, Q.D.; Xu, X. Stress mechanism and foundation contact pressure of high fill culvert under load reduction condition. Rock Soil Mech. 2019, 40, 4813–4818+4847. [Google Scholar]

| Material | Elastic Modulus /MPa | Density /kg∙m−3 | Poisson’s Ratio | Porosity | Friction Angle /° | Cohesion /kPa |

|---|---|---|---|---|---|---|

| Sandy soil | 32 | 1800 | 0.26 | 40% | 33 | 0 |

| Culvert | 30,000 | 2500 | 0.20 | - | - | - |

| EPS board | 3 | 20 | 0.20 | 94% | - | - |

| Cushion layer | 300 | 2150 | 0.25 | - | 34 | 5 |

| Mid-weathered rock strata | 15,000 | 2650 | 0.23 | - | 29 | 600 |

| Slight-weathered rock strata | 26,000 | 2720 | 0.20 | - | 35 | 2000 |

| Material | Em/MPa | Ek/MPa | /MPa∙h | /MPa∙h |

|---|---|---|---|---|

| EPS board | 0.5 | 3.14 | 3.642 × 104 | 6.727 |

| Sandy soil | 30 | 75.65 | 1.264 × 104 | 3.315 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Chen, B.; Ren, G.; Luo, R.; Ding, L. Long-Term Stress Characteristics and Earth Pressure Calculation Method for High-Fill Box Culverts. Buildings 2025, 15, 1954. https://doi.org/10.3390/buildings15111954

Jia Z, Chen B, Ren G, Luo R, Ding L. Long-Term Stress Characteristics and Earth Pressure Calculation Method for High-Fill Box Culverts. Buildings. 2025; 15(11):1954. https://doi.org/10.3390/buildings15111954

Chicago/Turabian StyleJia, Zengpan, Baoguo Chen, Guoqing Ren, Ruiping Luo, and Lan Ding. 2025. "Long-Term Stress Characteristics and Earth Pressure Calculation Method for High-Fill Box Culverts" Buildings 15, no. 11: 1954. https://doi.org/10.3390/buildings15111954

APA StyleJia, Z., Chen, B., Ren, G., Luo, R., & Ding, L. (2025). Long-Term Stress Characteristics and Earth Pressure Calculation Method for High-Fill Box Culverts. Buildings, 15(11), 1954. https://doi.org/10.3390/buildings15111954